Preparation method of ether viscosity reduction type polycarboxylate superplasticizer

A technology of viscous polycarboxylate and water reducing agent, which is applied in the field of building materials, can solve the problems of adverse effects on the strength of high-strength concrete, reduce the frictional resistance between aggregate particles, and the limited effect of air-entraining agents on reducing viscosity, so as to increase the space position Resistance effect, short synthesis time, improved dispersion and slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

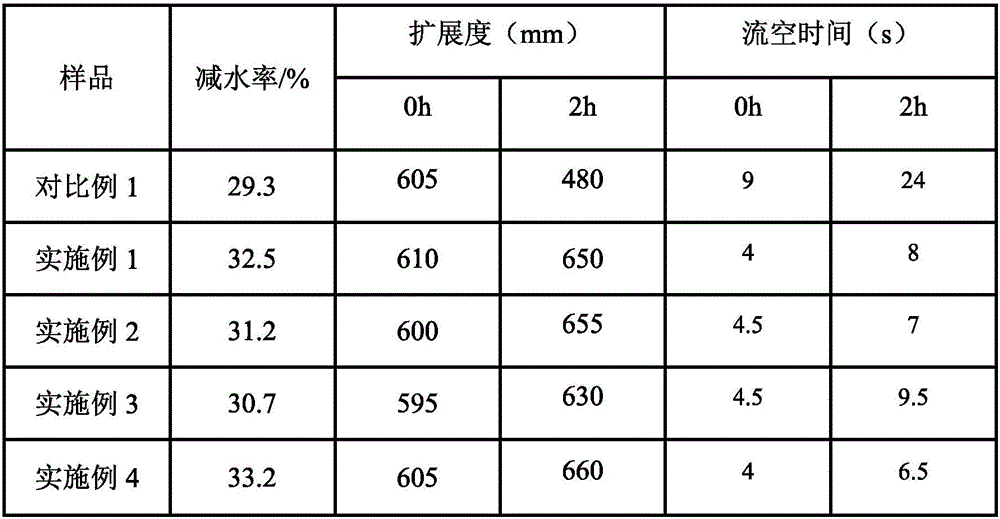

Examples

Embodiment 1

[0025] (1) Copolymerization: by weight, first place 200 parts of isopentenyl polyoxyethylene ether and 142 parts of water in the first reaction device; 10 parts of isoacryloyl polyoxypropylene ether amine, 25 parts Parts of acrylic acid, 3 parts of 3-allyloxy-2-hydroxy-1-propanesulfonate sodium, 4 parts of ethylene glycol dimethacrylate, 0.8 parts of mixed emulsifier and 40 parts of water are mixed evenly In the first dropping device; 3 parts of ammonium persulfate and 30 parts of water are mixed uniformly in the second dropping device; 0.6 parts of sodium bisulfite, 0.3 parts of sodium formaldehyde sulfoxylate and 1.5 parts of normal Butanethiol and 30 parts of water are mixed uniformly in the third dropping device; then the material in the first dropping device of 1 / 4, the material in the second dropping device of 1 / 4, the material of 1 / 4 The material in the third dropping device and 1.5 parts of sodium bicarbonate are added to the first reaction device, and when the tempera...

Embodiment 2

[0028] (1) Copolymerization reaction: by weight, first place 200 parts of isopentenyl polyoxyethylene ether and 156 parts of water in the first reaction device; 15 parts of isoacryloyl polyoxypropylene ether amine, 32 parts Parts of acrylic acid, 4 parts of 3-prop-2-enoyloxypropane-1-potassium sulfonate, 2.5 parts of ethylene glycol dimethacrylate, 1.5 parts of mixed emulsifier and 40 parts of water are mixed evenly In the first dropping device; 3.8 parts of sodium persulfate and 30 parts of water are mixed uniformly in the second dropping device; 0.9 parts of ferrous sulfate, 0.38 parts of sodium formaldehyde sulfoxylate and 2.5 parts of n-butyl Mercaptan and 30 parts of water are mixed evenly in the third dropping device; then 1 / 4 of the material in the first dropping device, 1 / 4 of the material in the second dropping device, 1 / 4 of the The materials in the three dropping devices and 1.2 parts of sodium dihydrogen phosphate are added to the first reaction device, and when th...

Embodiment 3

[0031] (1) Copolymerization: by weight, first 200 parts of methallyl polyoxyethylene ether and 146 parts of water are placed in the first reaction device; 12 parts of isoacryl polyoxypropylene ether amine, 28 parts of acrylic acid, 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.5 parts of 1,4-butylene glycol dimethacrylate, 1.2 parts of mixed emulsifier and 40 parts of water are mixed evenly In the first dropping device; 4 parts of sodium persulfate and 30 parts of water are mixed uniformly in the second dropping device; 0.9 parts of sodium bisulfite, 0.35 parts of sodium formaldehyde sulfoxylate and 3 parts of ten Dithiol and 30 parts of water are mixed uniformly in the third dropping device; then the material in the first dropping device of 1 / 4, the material in the second dropping device of 1 / 4, the The material in the third dropping device and 0.8 parts of sodium dihydrogen phosphate are added to the first reaction device, and when the temperature rises to 55°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com