Ultra-long sustained release polycarboxylic acid slump inhibitor and preparation method thereof

A slow-release polycarboxylic acid and slump-retaining agent technology, applied in the field of concrete, can solve problems such as scarcity, poor encapsulation, and segregation, and achieve the effects of high operability, easy control of conditions, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

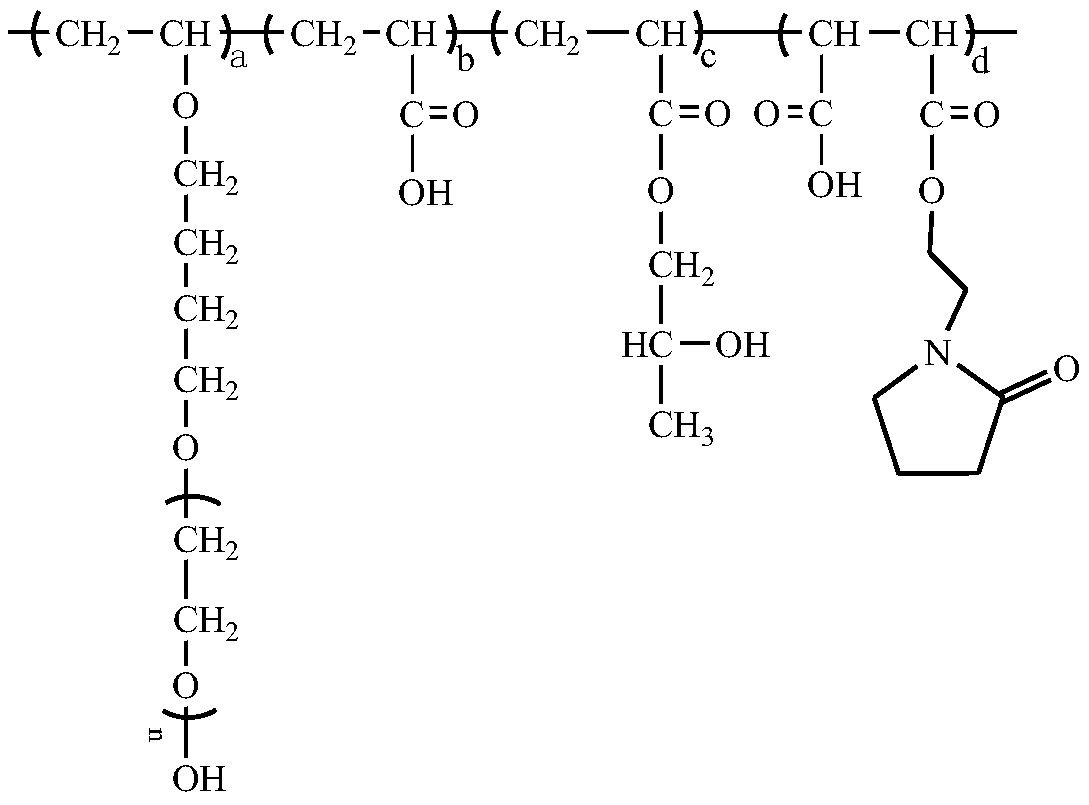

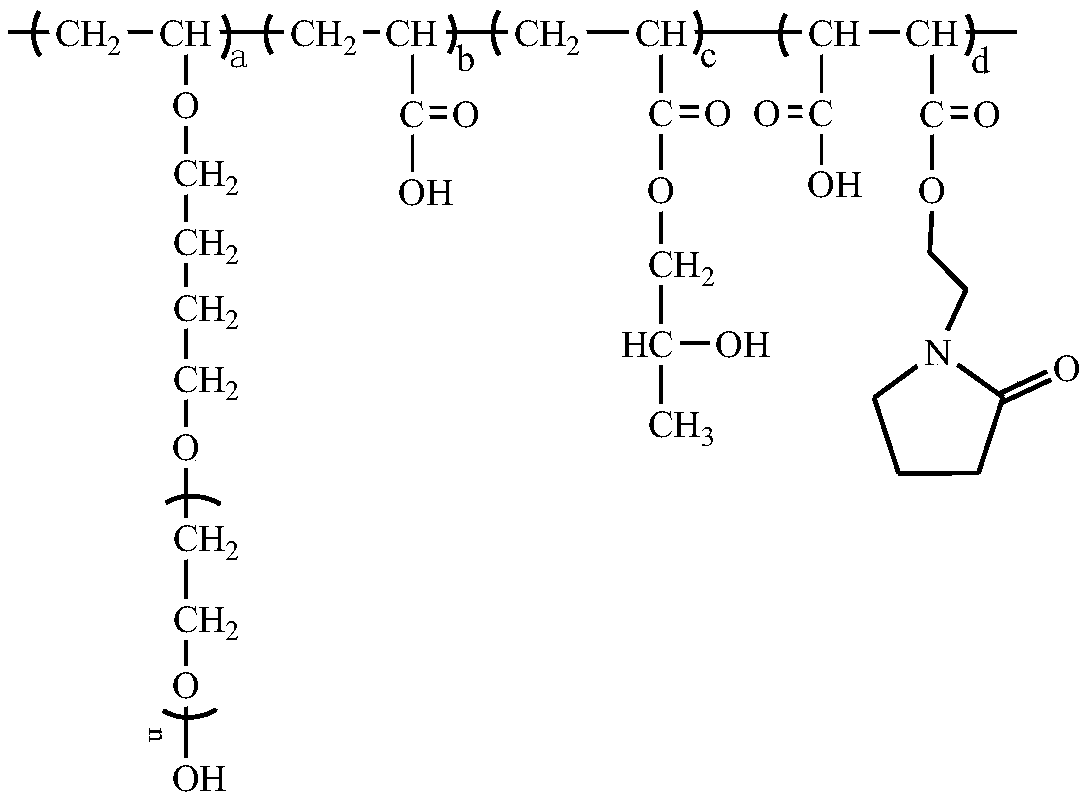

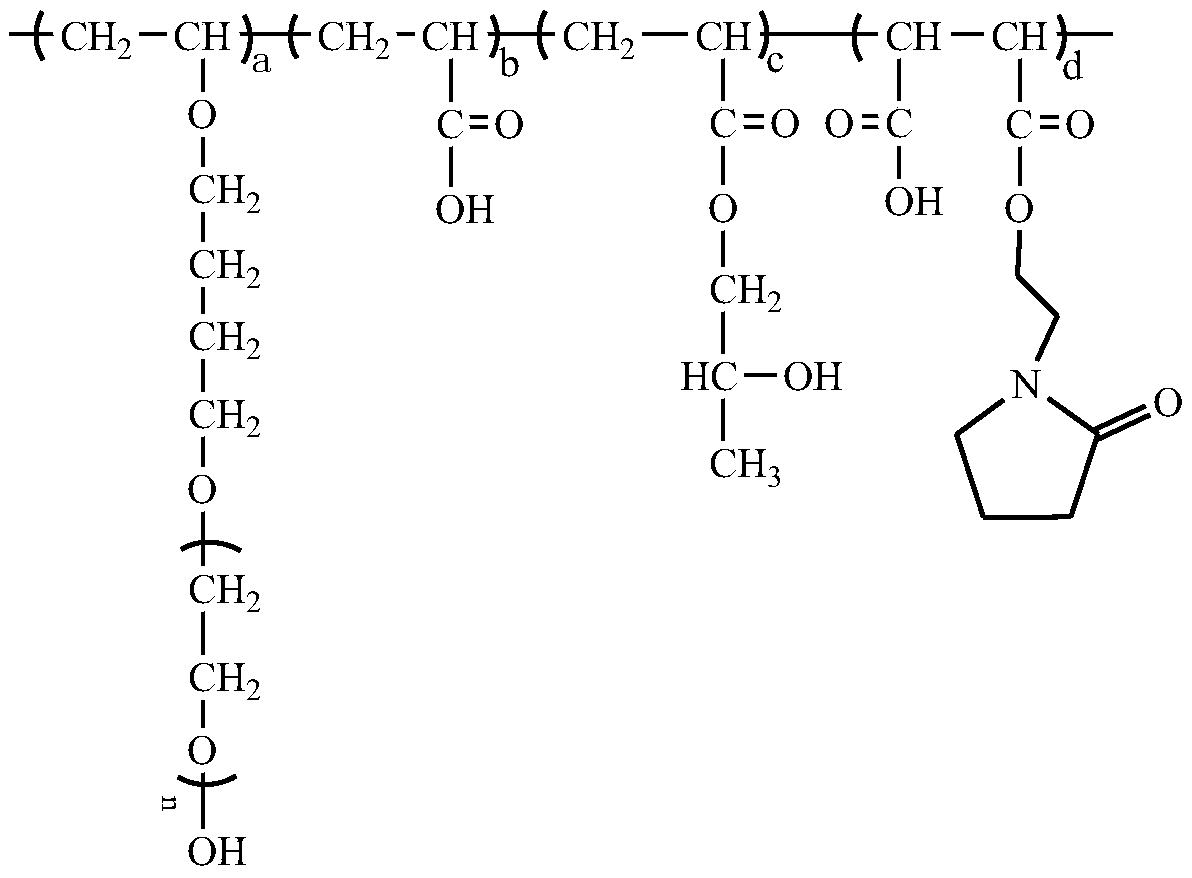

[0031] The preparation method of the ultra-long slow-release polycarboxylate slump-retaining agent of the present invention comprises the following steps:

[0032] 1) Add 4-hydroxybutyl vinyl polyoxyethylene ether and deionized water into the reaction kettle, stir and dissolve to obtain A solution;

[0033] 2) Heat solution A to the initial reaction temperature, add hydrogen peroxide to solution A, and simultaneously dropwise add deionized water mixed solution of acrylic acid, hydroxypropyl acrylate and maleyloxyethylpyrrolidone, mercaptopropionic acid and The deionized water mixed solution of ascorbic acid, after the dropwise addition, continues the insulation reaction, and finally cools to room temperature to obtain the B solution;

[0034] 3) Add a 30% mass fraction of sodium hydroxide solution to the B solution, adjust the pH value to 6-7, and obtain a 40% mass fraction of ultra-long slow-release polycarboxylic acid slump-retaining agent; 4-hydroxybutyl vinyl The molar ra...

Embodiment 1

[0036] (1) Synthesis of maleoyloxyethylpyrrolidone: at room temperature, pass nitrogen gas into the reaction kettle for 10 minutes, then add hydroxyethylpyrrolidone and maleic anhydride in sequence, continue to pass nitrogen gas, stir, heat up to 50°C and start to keep warm, control The reaction temperature is between 55°C and 70°C, and the reaction time is 1.0h. After the reaction is completed, the temperature is lowered to below 45°C with cooling water, and the nitrogen gas is stopped to obtain a liquid maleoyloxyethylpyrrolidone monomer; hydroxyethylpyrrolidone , The molar ratio of maleic anhydride is 1.0:1.0.

[0037] (2) Polymerization reaction: Add 4-hydroxybutyl vinyl polyoxyethylene ether with a molecular weight of 2400 and deionized water into the reaction kettle, stir and dissolve to obtain A solution; heat A solution to 25°C, and pour into A solution Add hydrogen peroxide, and drop the deionized water mixed solution of acrylic acid and maleyloxyethylpyrrolidone and ...

Embodiment 2

[0039] (1) Synthesis of maleoyloxyethylpyrrolidone: same as Example 1.

[0040](2) Polymerization reaction: Add 4-hydroxybutyl vinyl polyoxyethylene ether with a molecular weight of 2400 and deionized water into the reaction kettle, stir and dissolve to obtain A solution; heat A solution to 30°C, and pour into A solution Add hydrogen peroxide, and drop the deionized water mixed solution of acrylic acid and maleyloxyethylpyrrolidone and the deionized water mixed solution of mercaptopropionic acid and ascorbic acid respectively at the same time. The dropping time is 2.0h. After the dropping is completed, the Continue the heat preservation reaction at 35°C for 1.0h, and finally cool to room temperature to obtain solution B; add 30% sodium hydroxide solution to solution B, adjust the pH value to 6-7, and obtain a super-long buffer with a mass fraction of 40%. Release-type polycarboxylic acid slump-retaining agent, denoted as B2, with a measured molecular weight of 43728; 4-hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com