Patents

Literature

1741results about How to "Conditions are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

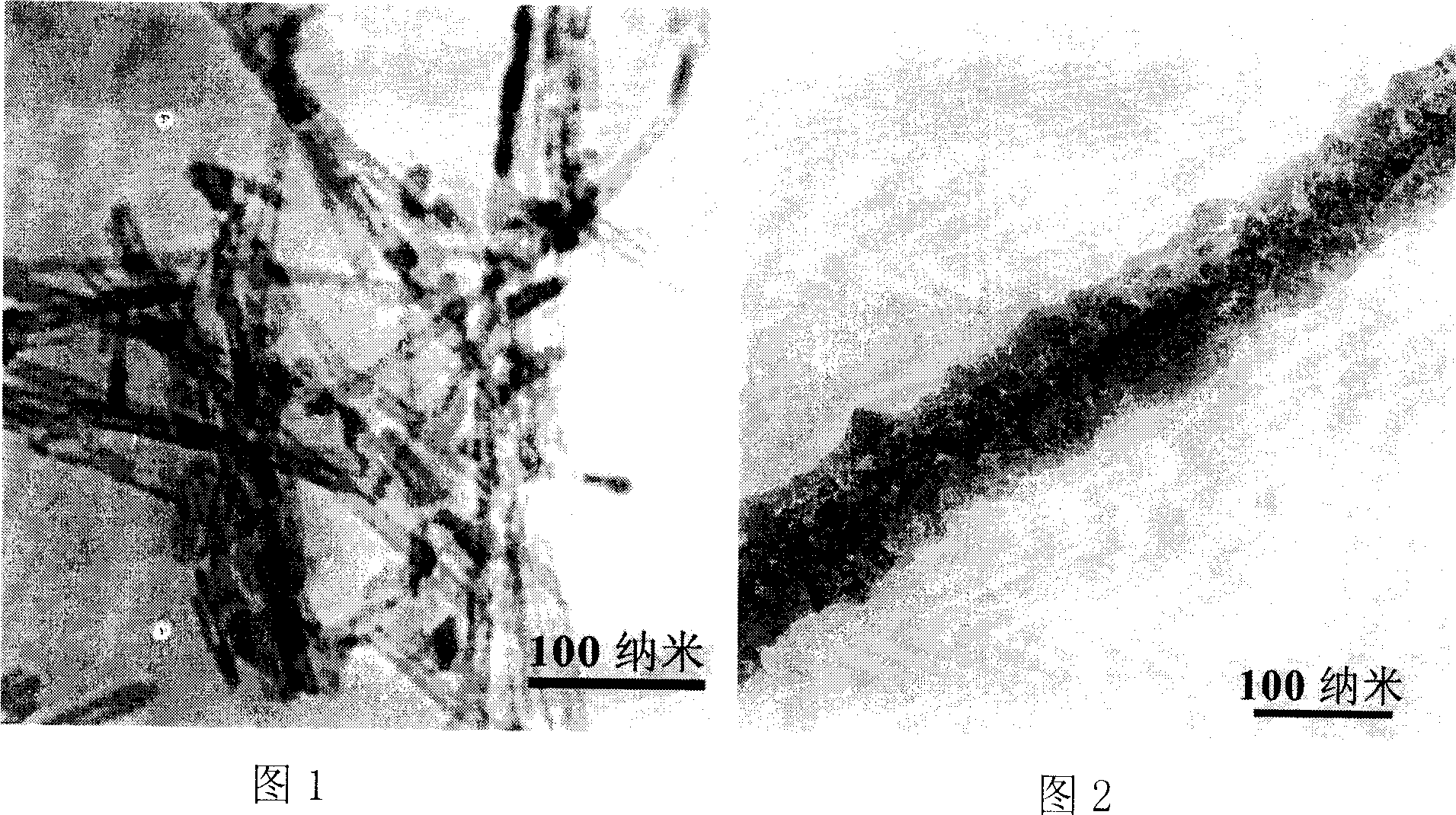

Preparation method of zinc oxide nano-rod film on fibre product

InactiveCN101012621ASmall granularityHigh purityFibre treatmentLiquid/gas/vapor textile treatmentFiberChemical solution

The invention relates to a manufacturing method for nanometer rod film of zinc oxide on fiber product, comprising (1) by sol-gel method ZnO nano-crystal grain is prepared and a great deal of ZnO seed crystal is deposited on the surface of fiber product, molar concentrations of zinc salt and alkaline agent are all 0.001M-0.75M; (2) by hydrothermal method or precipitation of chemical solution pool, nanometer rod film of zinc oxide grows on fiber product, molar concentrations of zinc salt solution and complexing agent solution are all 0.001M-0.05M; ZnO nanometer rod film with equal surface and good directivity is obtained. The manufacturing method is provided with simple method and low cost. It is suitable for industrial production.

Owner:DONGHUA UNIV

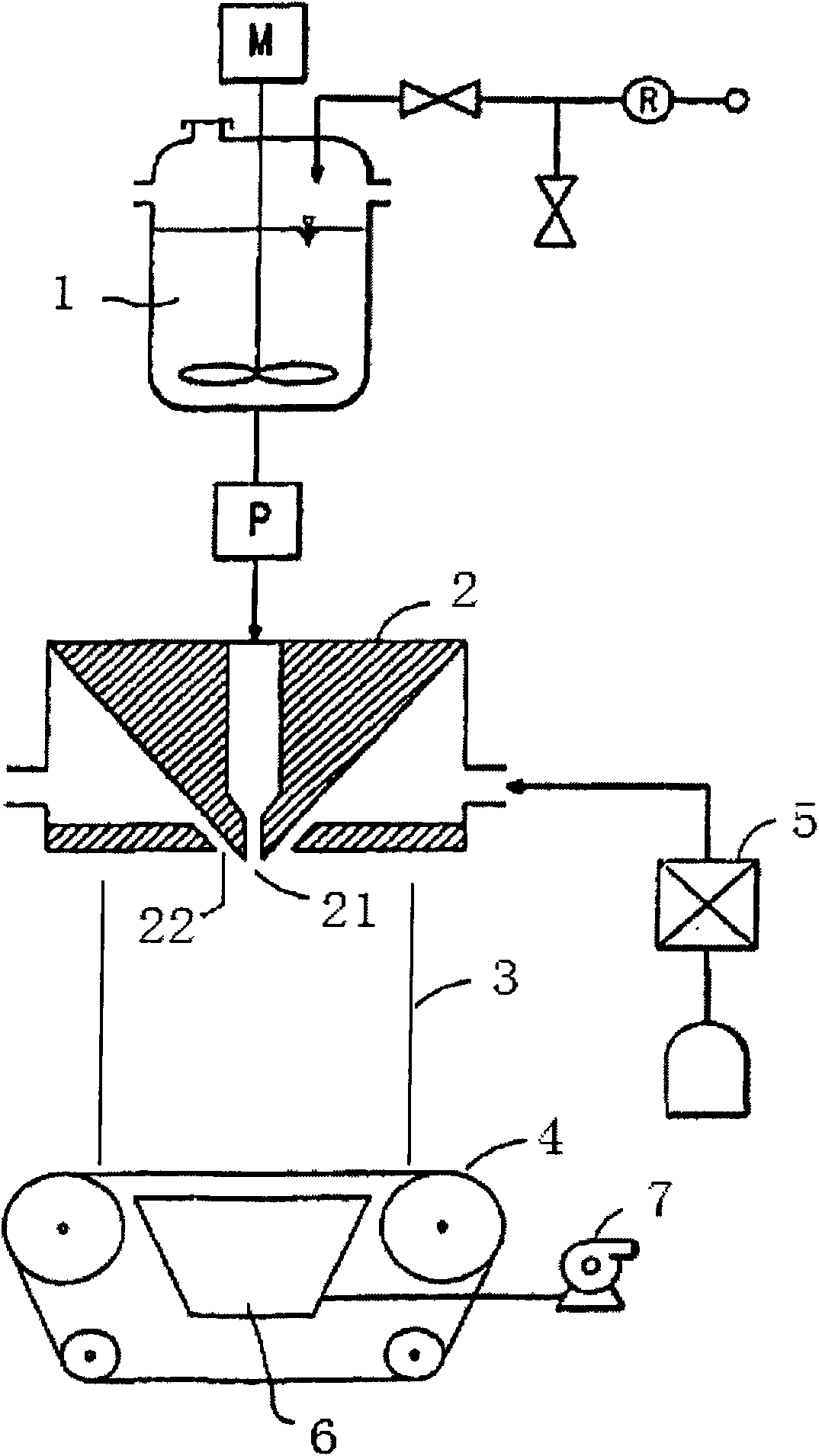

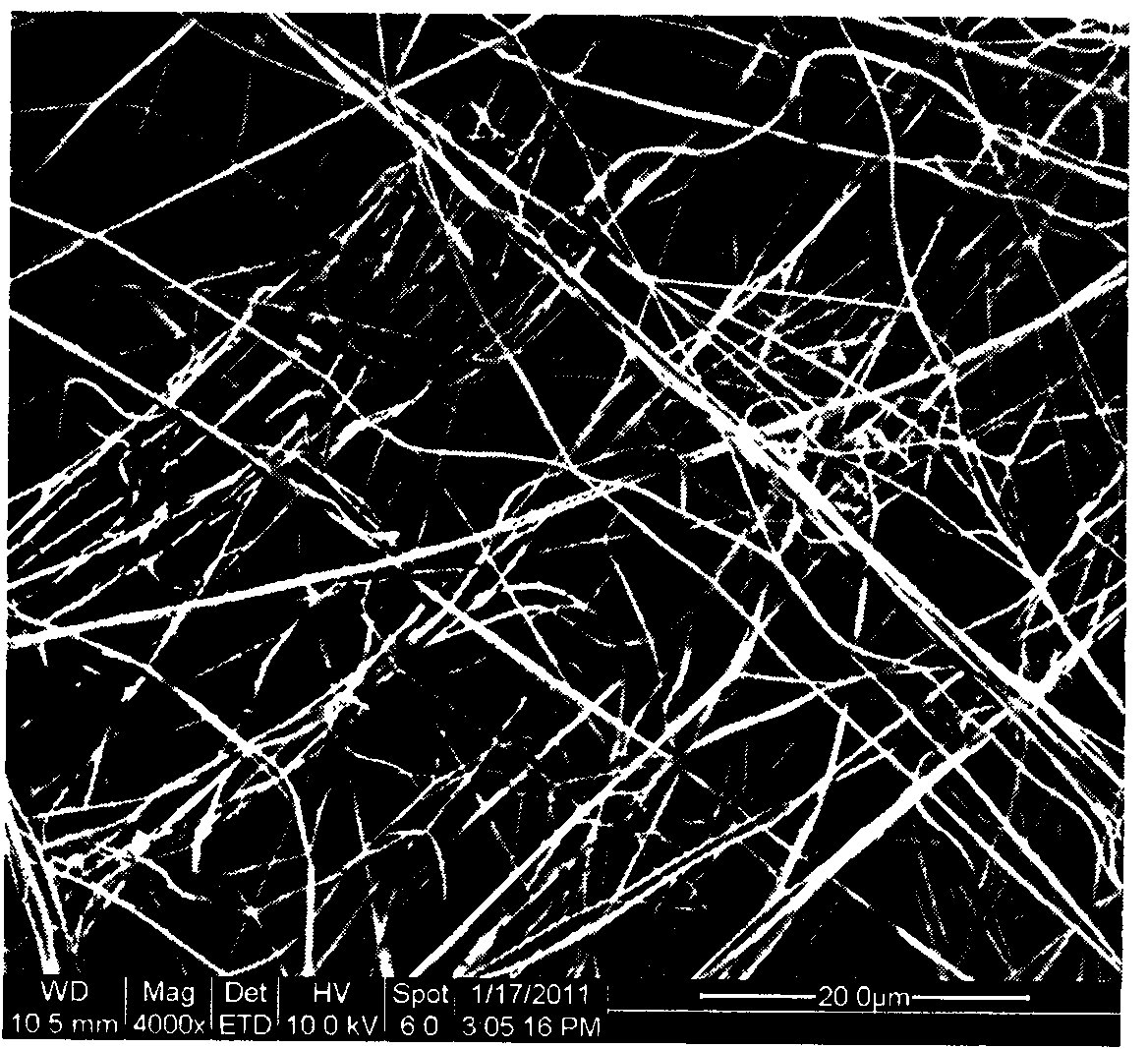

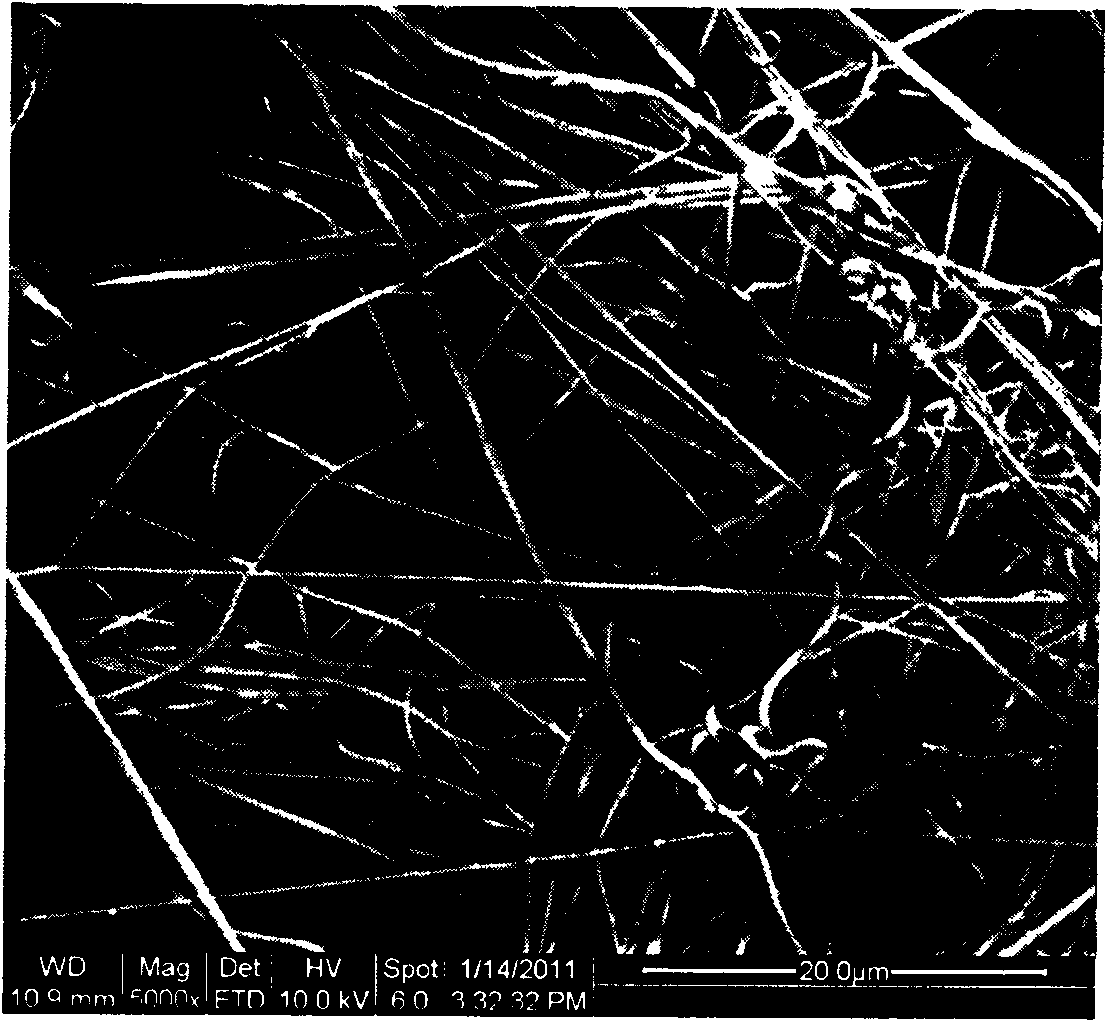

Method for preparing polymeric nano-micro fiber non-woven fabric

ActiveCN102071542AOvercoming demandsUniversally applicableNon-woven fabricsDry spinning methodsFiberPolymer dissolution

The invention discloses a method for preparing a polymeric nano-micro fiber non-woven fabric. The method comprises the following steps of: firstly, dissolving at least one polymer in at least one solvent to prepare spinning solution; then supplying the spinning solution to a spinneret plate with a series of spinneret orifices so as to make the spinning solution extruded from the spinneret orifices of the spinneret plate to form a trickle of the spinning solution; secondly, stretching and refining the trickle of the spinning solution by utilizing at least one high-speed jet airflow, and accelerating the volatilization of the solvent to form nano-micro fiber; and finally, collecting the nano-micro fiber on a web curtain by utilizing high-speed airflow and suction airflow. The polymer is a fiber-forming polymer; the solvent can dissolve the fiber-forming polymer and has the volatility; a jet angle of the high-speed airflow is between 15 and 60 degrees, and the jet velocity is at least 50 times higher than extrusion speed of the trickle of the spinning solution; the mass concentration of the polymer in the spinning solution is between 2 and 50 percent; and the viscosity of the spinning solution at a spinning temperature is between 10 and 100, 000mP.s.

Owner:上海榕融新材料技术有限公司

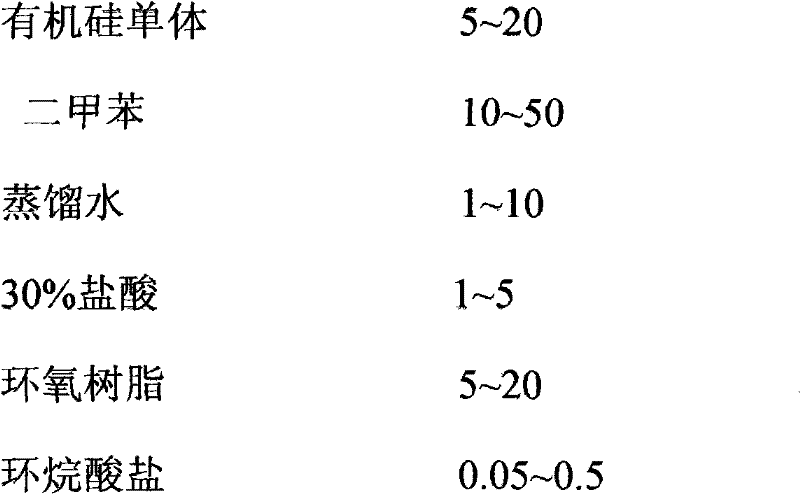

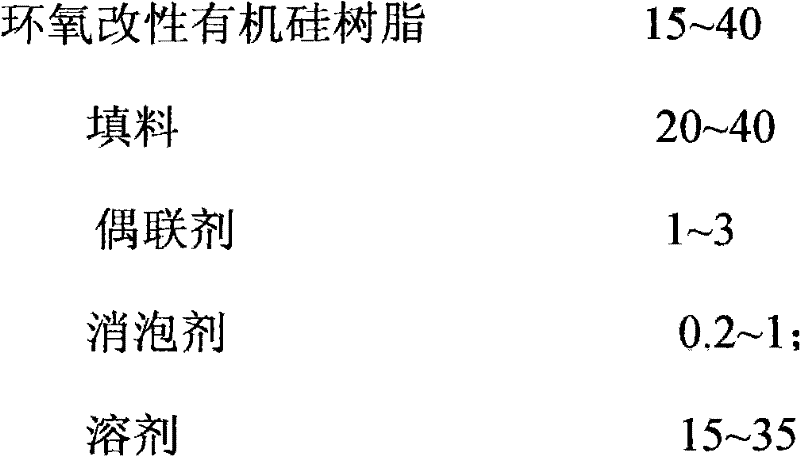

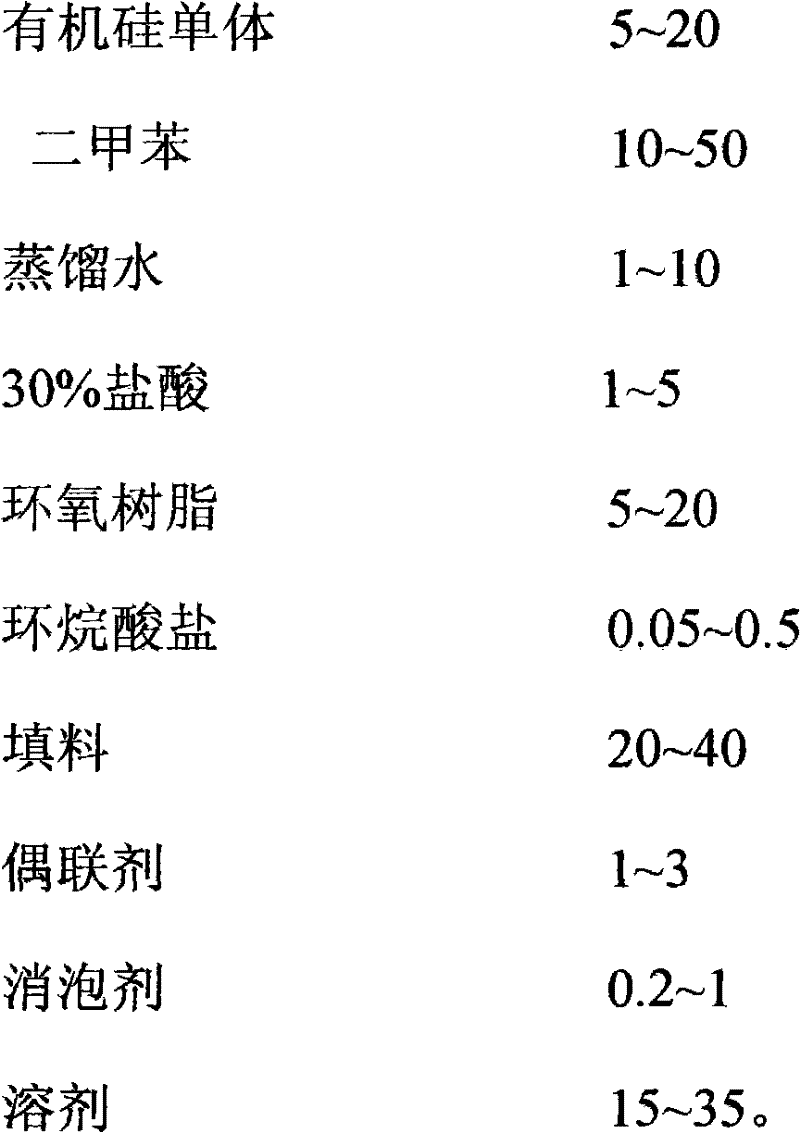

Preparation method of epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating and its products

The invention provides a preparation method of an epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating, comprising the following steps: preparing raw materials; synthesizing an organosilicon pre-polymer; synthesizing an epoxy-modified organosilicon resin; and preparing the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating. The invention also provided the epoxy-modified insulated thermal-conductive high-temperature resistant organosilicon coating prepared by the method. The coating is composed by the epoxy modified organosilicon resin, fillers, a coupling agent and solvents. The coating prepared by the method in the invention takes account of insulation, thermal-conductivity, and high-temperature resistance at the same time, has coating adhesion of first level, hardness of 5H, a breakdown voltage of 1800V / 0.5mA, 2 seconds, a heat transfer coefficient of larger than 100W / (m<2>.K), and no obviously changed coating at a temperature of 250 DEG C for 24 hours, therefore the coating can be widely used in various industrial equipment and household appliances.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN +2

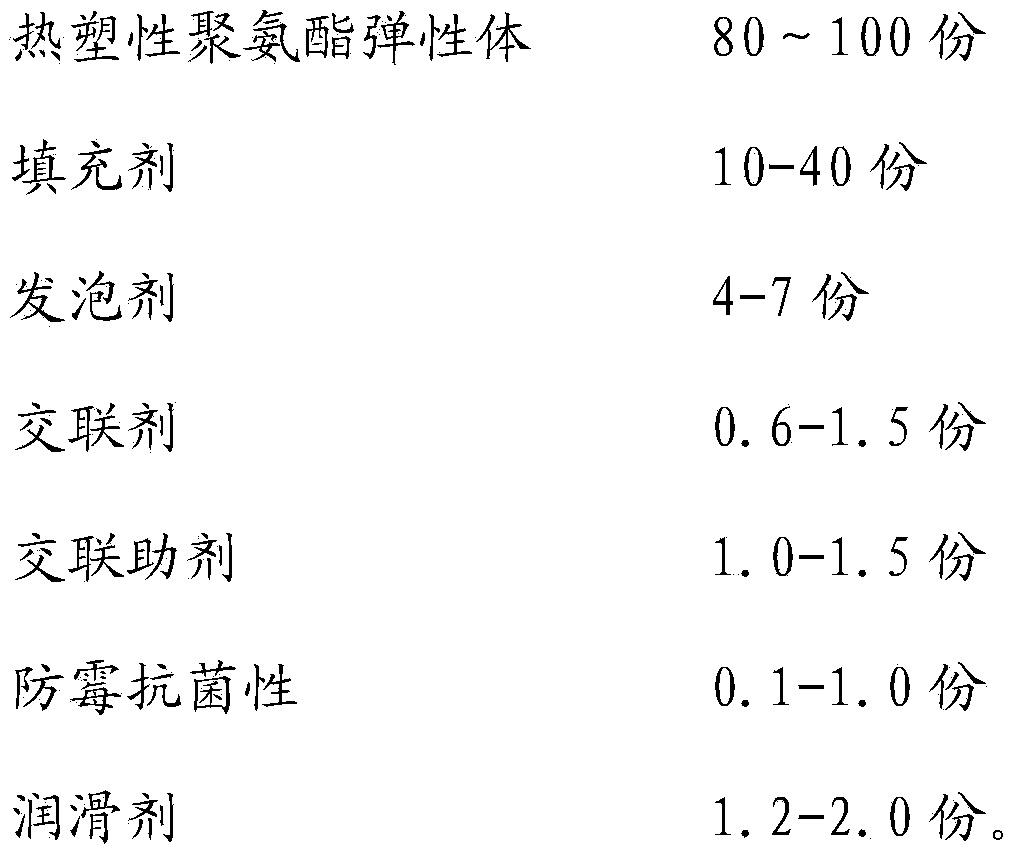

Thermoplastic polyurethane elastomer foam material and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam material, which is prepared from the following raw materials by weight: 80-100 parts of a thermoplastic polyurethane elastomer, 10-40 parts of a filler, 4-7 parts of a foaming agent, 0.6-1.5 parts of a cross-linking agent, 1.0-1.5 parts of a cross-linking assistant, 0.1-1.0 part of a mildew proof antibacterial agent and 1.2-2.0 parts of a lubricant. Adopting the above technical scheme, the invention has the beneficial effects of improving the foam expansion of the thermoplastic polyurethane foam material, expanding the scope of usage of the polyurethane foam material, and realizing compression deformation of a finished product produced from the thermoplastic polyurethane foam at no more than 35%, which is unmatched by an EVA foam material with equivalent foam expansion and similar elasticity. In addition, the foam material improves the performance of existing traditional foam materials, and solves the defects that polyester-type thermoplastic polyurethane elastomer has short service life, easily goes moldy on the product surface and generates mechanical performance loss in the field and damp and hot environment.

Owner:泉州三盛橡塑发泡鞋材有限公司

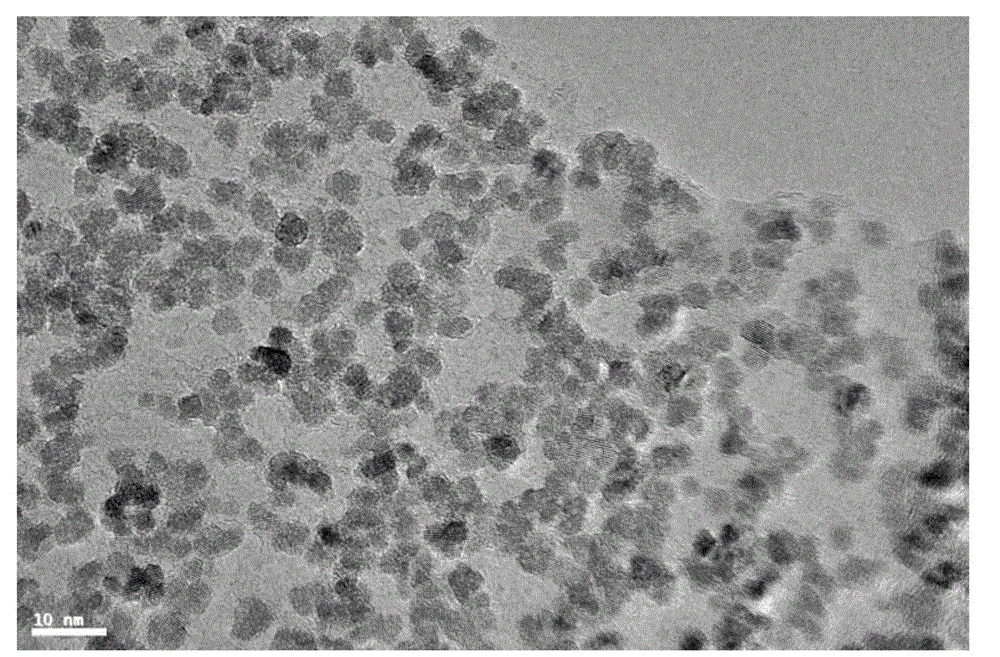

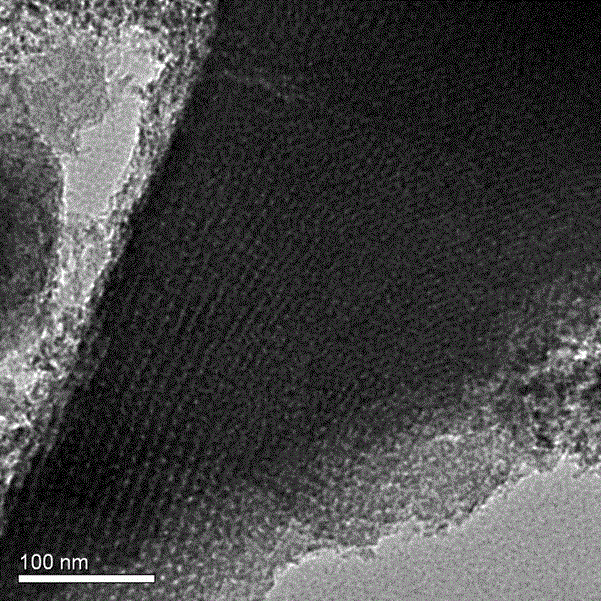

Preparation method of spinel lithium titanate nano tube/wire for lithium battery and capacitor

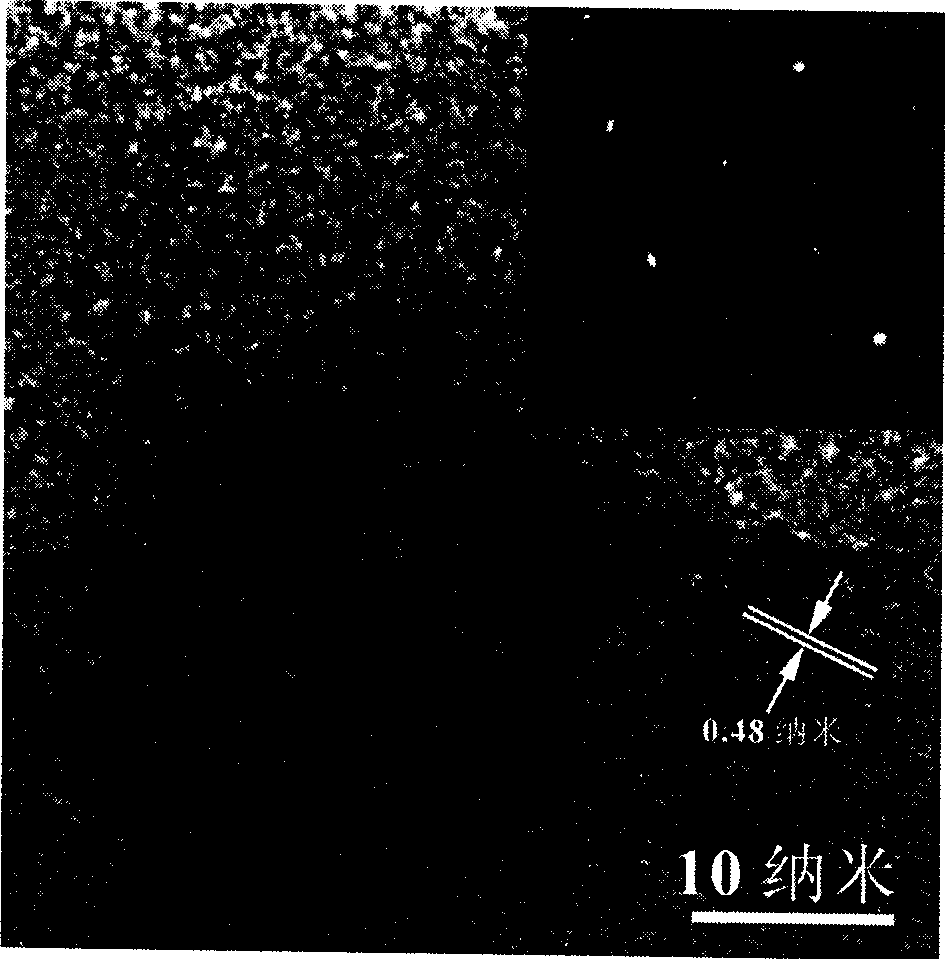

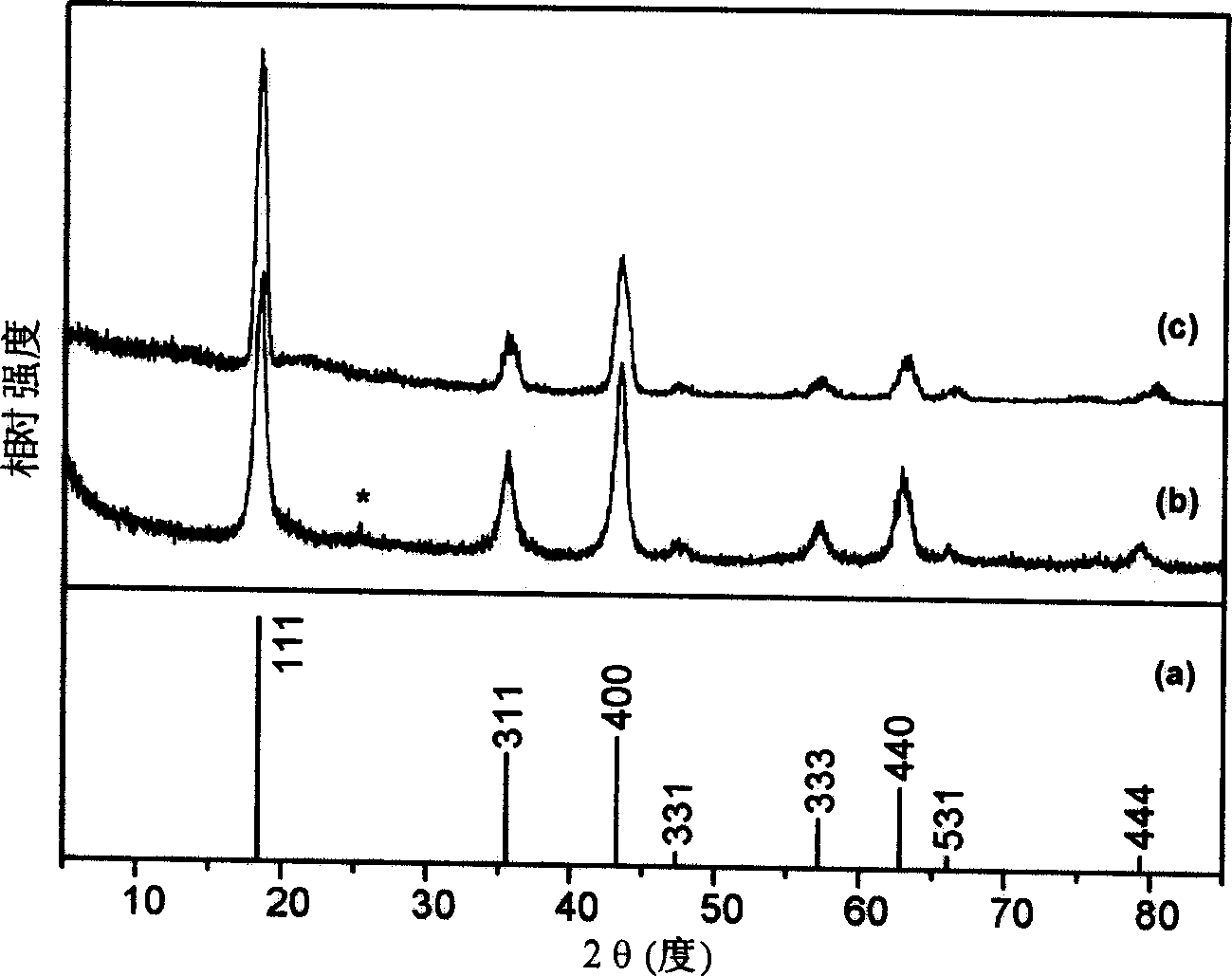

InactiveCN1725530AReduce energy consumptionUniform shapeNanostructure manufactureElectrode manufacturing processesNanowireIon exchange

This invention discloses a preparation method for spinel lithium titanate nm pipes / nm lines used in Li batteries and capacitors, which applies cheap industrial TiO2 as the raw material and supersonic chemical method to prepare said nm pipes / lines then takes them as the raw materials to be mixed with a certain quantity of soluble Li salt solution to be baked in air and by low-temperature hydrothermal ion exchange method to manufacture spinel lithium titanate nm pipes / lines with uniform shape, uniform diameter and even larger major diameter ratio and big ratio surface area.

Owner:TSINGHUA UNIV

Preparation method of 3D printing inorganic powder molding material

InactiveCN103936392ASmall median diameterStable in natureClaywaresMaterials preparationPolyvinyl alcohol

The invention discloses a preparation method of a 3D printing inorganic powder molding material. The method is characterized in that the method comprises the following steps: 1, powder material pretreatment: mixing 10-30% of acetone with 62-85% of a powdery material and 2-10% of gamma-(2,3-epoxypropoxy)propyltrimethoxysilicane, and grinding the obtained mixture at a rotating speed of 500-1000rpm for 1-2h to obtain a pretreated powdery material; and 2, molding material preparation: adding 40-65% by mass of acetone, adding 2-8% of polyvinyl formal, stirring for dissolving, adding 30-55% of the pretreated powdery material, stirring for uniform mixing, putting the obtained solution in a grinder, carrying out normal temperature mixing grinding at a rotating speed of 500-1000rpm for 6-9h, and carrying out spray drying to obtain the 3D printing inorganic powder molding material. The 3D printing inorganic powder molding material can be directly molded at a temperature of 190-210DEG C under a pressure of 1-10MPa without sprinkling a binder, and has the advantages of simple preparation technology, easy condition control, low production cost and easy industrialized production.

Owner:UNIV OF JINAN

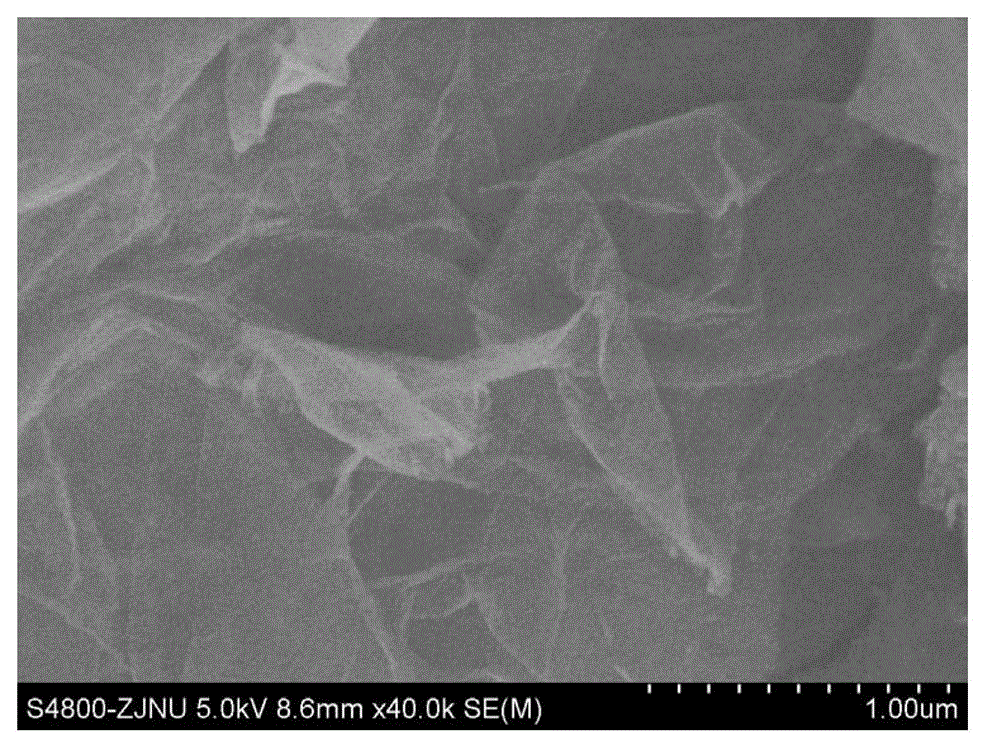

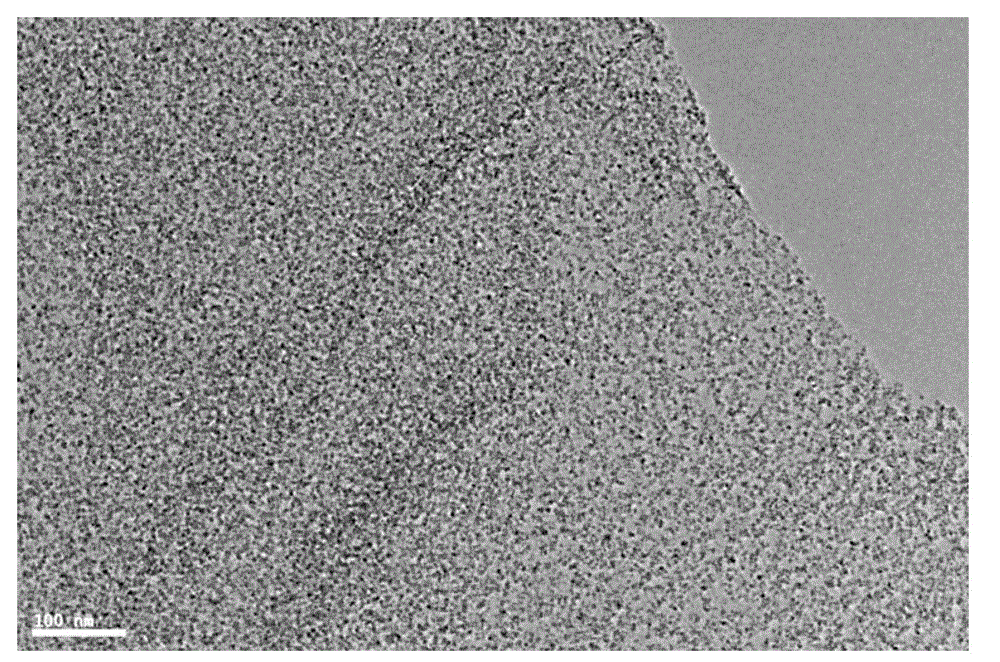

Preparation method for cerium oxide/graphene oxide nanocomposite

InactiveCN102716734AShort reaction timeReduce energy consumptionMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsSodium acetateNano composites

The invention relates to a preparation method for cerium oxide / graphene oxide nanocomposite. The invention aims at providing a preparation method of cerium oxide / graphene oxide nanocomposite, and the preparation method is low in equipment requirement, simple to operate and fast in reaction speed, and is capable of saving energy consumption and uniformly dispersing metal nanoparticles on the surface of graphene. The method comprises the steps of: based on cerate, sodium acetate, urea and graphite oxide as raw materials, placing graphite oxide and water into a container, and carrying out ultrasonic treatment so that graphite oxide form a suspension in the water; placing cerate, sodium acetate and urea into the container for dissolving cerate, sodium acetate and urea into the water; and placing the container into a reactor with a backflow device for reaction until the reaction is finished, so as to obtain a black precipitate namely cerium oxide / graphene oxide nanocomposite.

Owner:ZHEJIANG NORMAL UNIVERSITY

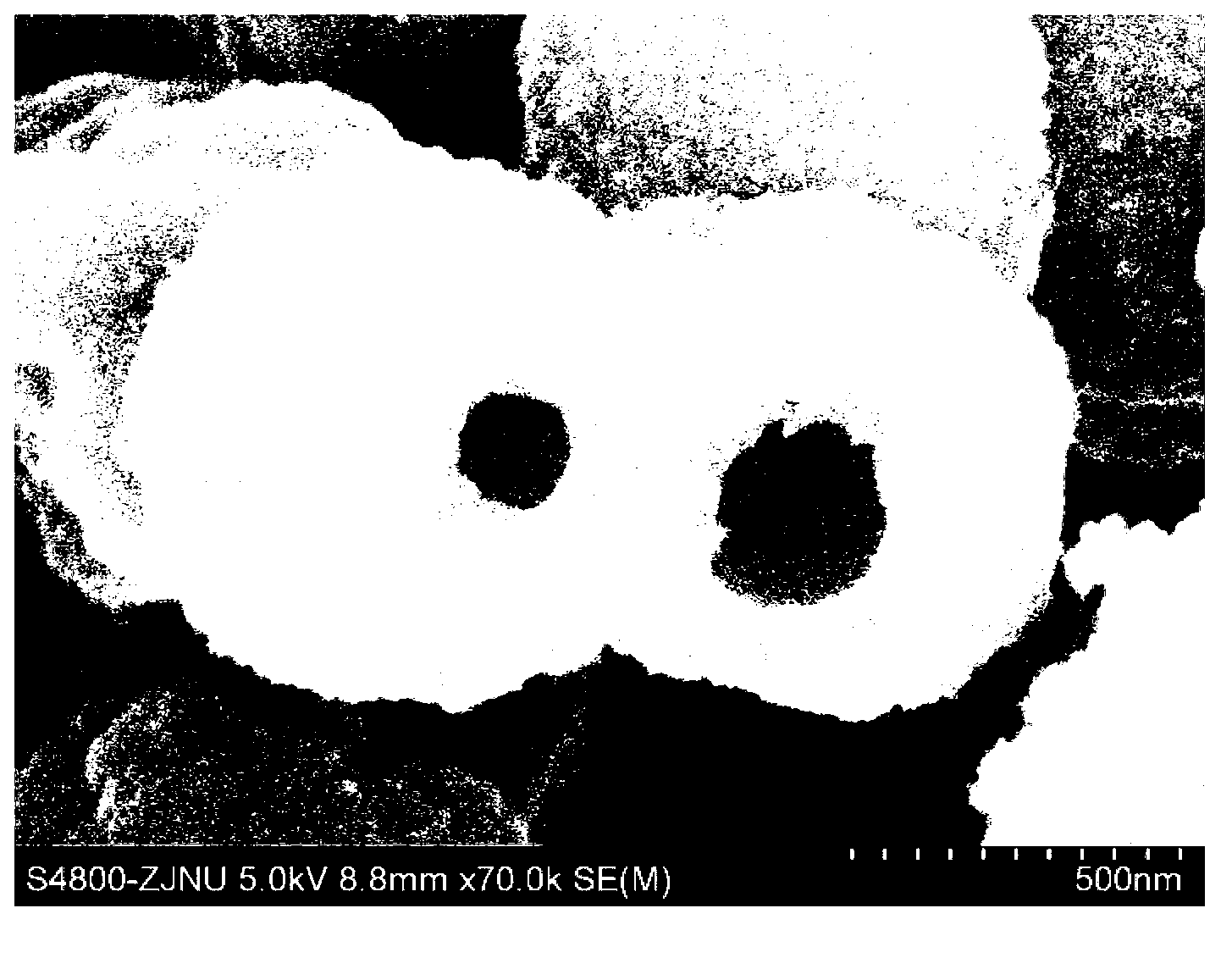

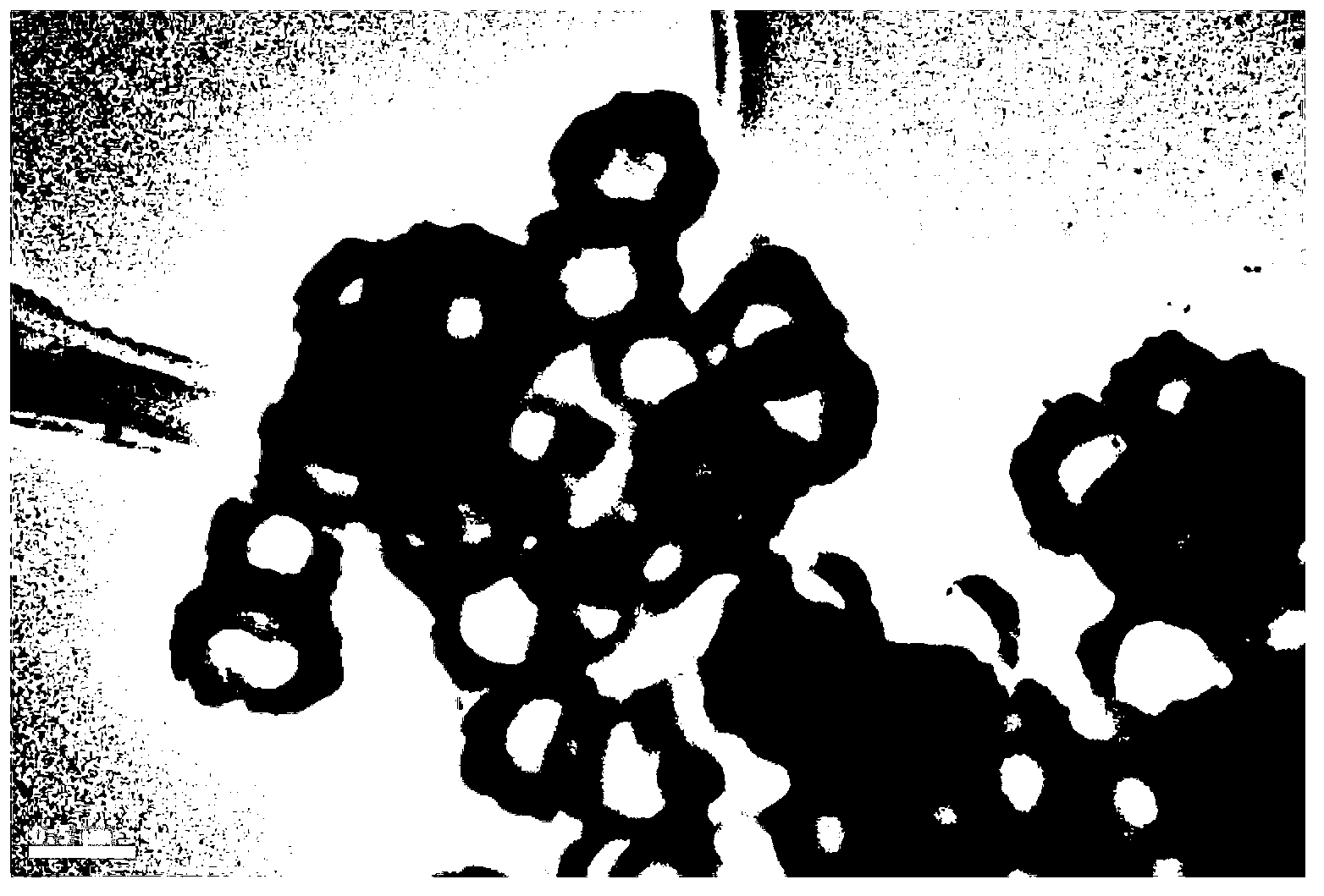

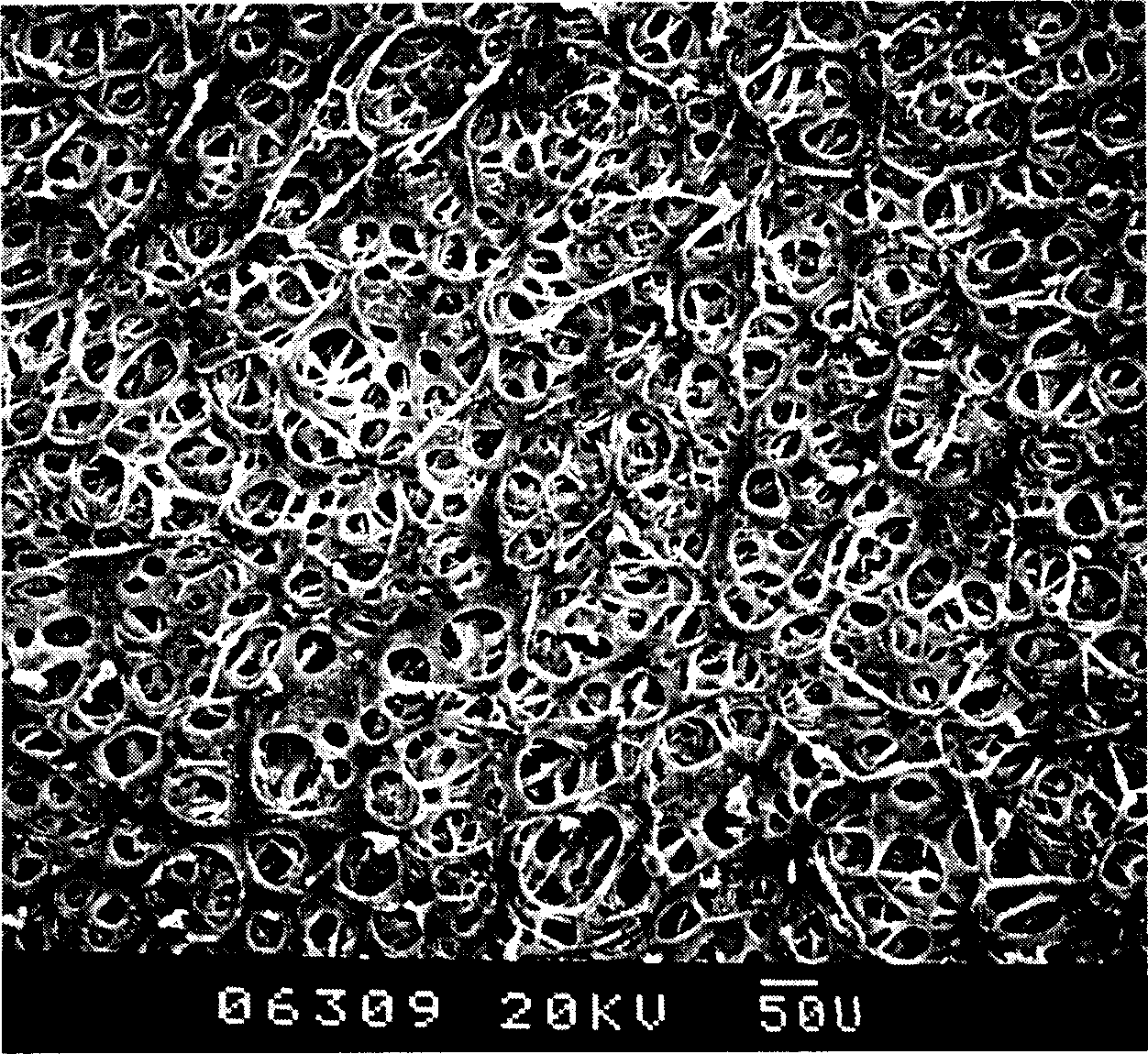

Polypyrrole hollow microsphere/ sulfur composite material as well as preparation method and application thereof

InactiveCN103259000AEnvironmentally friendlyReduce energy consumptionCell electrodesMicrospherePolypyrrole

The invention discloses a polypyrrole hollow microsphere / sulfur composite material which comprises a polypyrrole hollow microsphere and powdered sulfur, wherein the powdered sulfur is dispersed and absorbed on the polypyrrole hollow microsphere, so that a uniform compound can be formed. The invention also discloses a preparation method of the polypyrrole hollow microsphere / sulfur composite material. The method comprises the following steps of: firstly, initiating the polymerization reaction of pyrrole under the action of an oxidizing agent, and covering the surface of a silicon dioxide microsphere by the product; then washing, drying and then dissolving the silicon dioxide microsphere by hydrofluoric acid to obtain the polypyrrole hollow microsphere; and then, fully grinding the powdered sulfur with certain mass and the polypyrrole hollow microsphere, evenly mixing, and carrying out heat treatment at a certain temperature to obtain the polypyrrole hollow microsphere / sulfur composite material. The method is low in energy consumption, simple in operation, good in controllability, high in yield and suitable for large-scale production. The invention also discloses the application of the polypyrrole hollow microsphere / sulfur composite material. The polypyrrole hollow microsphere / sulfur composite material is used for a cathode material of a lithium sulfur battery and has the characteristics of high capacity and stable cycle performance.

Owner:ZHEJIANG NORMAL UNIVERSITY

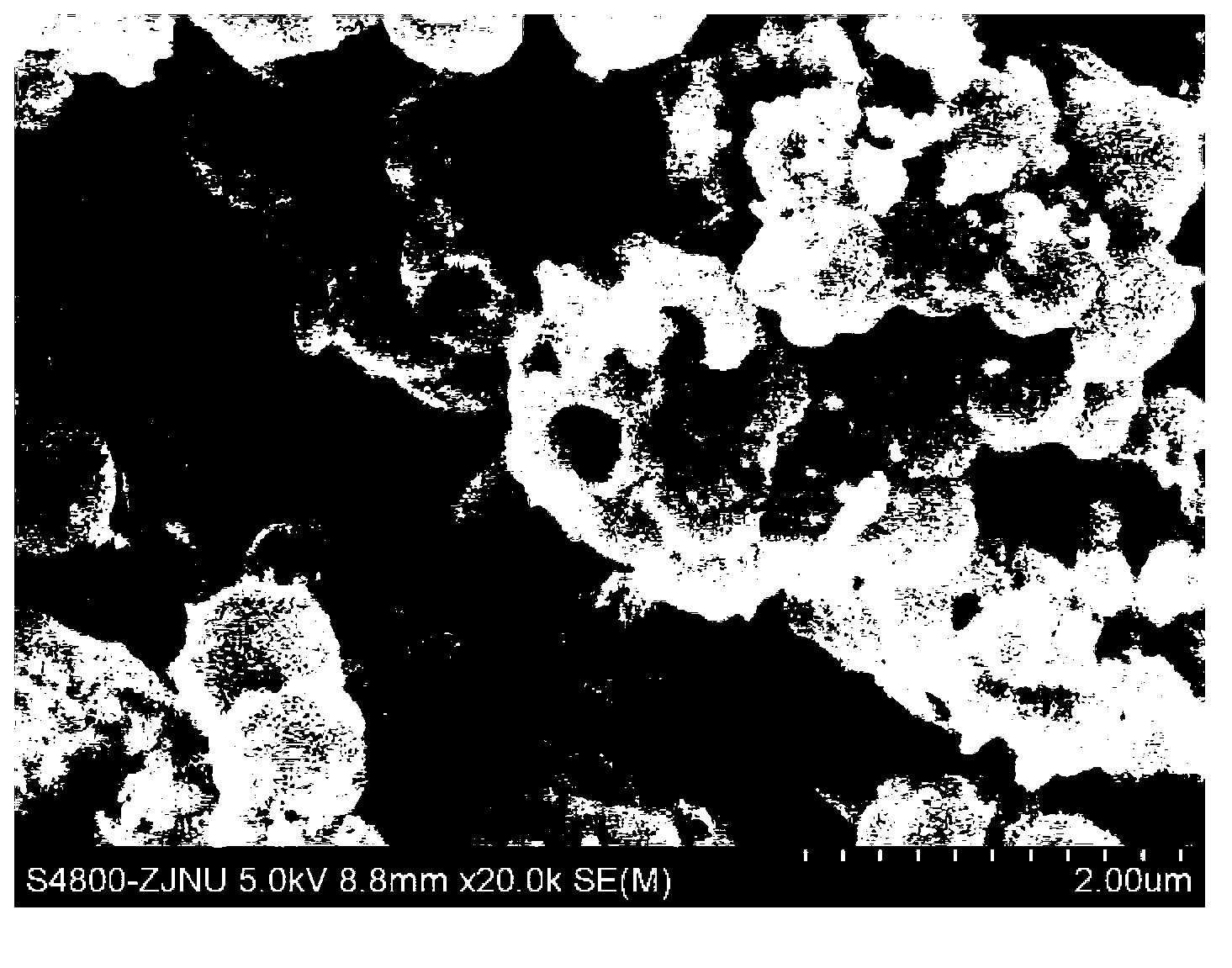

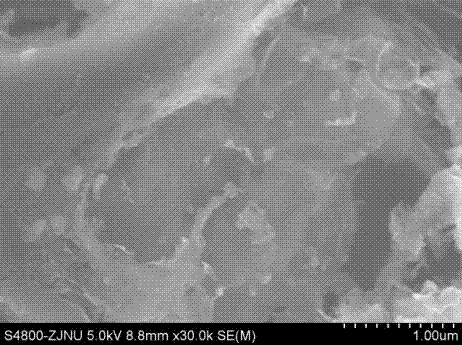

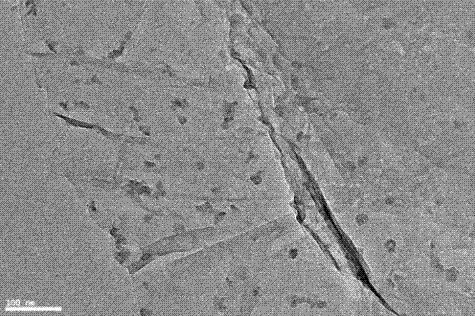

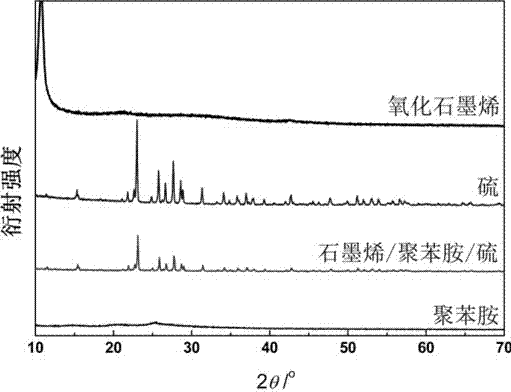

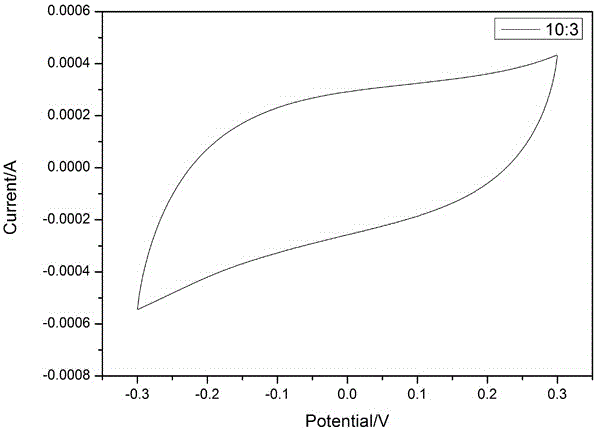

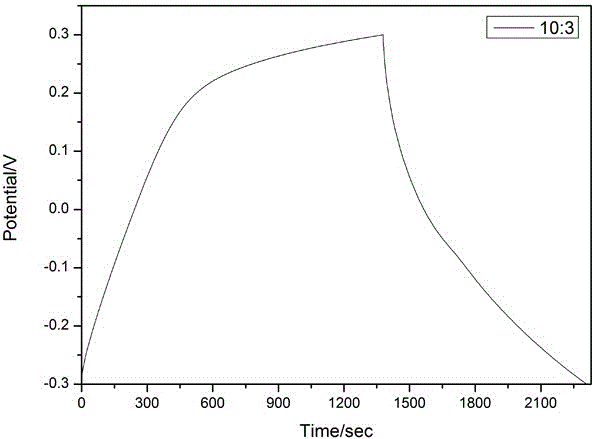

Graphene/polyaniline/sulfur composite material and preparation method thereof

InactiveCN103682274AEasy to operateConditions are easy to controlCell electrodesSecondary cellsGraphite oxideSodium thiosulfate

The invention discloses a graphene / polyaniline / sulfur composite material characterized in that graphene oxide is reduced to graphene by aniline, meanwhile, the aniline is oxidized and polymerized to polyaniline, and sulfur particles produced by sodium thiosulfate and hydrochloric acid are evenly distributed on a graphene polyaniline conducting layer in a reaction process. The invention further discloses a preparation method of the graphene / polyaniline / sulfur composite material. The method comprises the steps as follows: firstly, dispersing the graphene oxide in water to form a uniform graphene oxide solution, then dissolving an aniline solution into the hydrochloric acid to form an aniline salt solution, and adding the aniline salt solution into the graphene oxide solution; dissolving a sodium thiosulfate solid into the water to form a sodium thiosulfate solution, dropwise adding the odium thiosulfate solution into a graphene oxide and aniline mixed solution, stirring the mixture at a certain temperature for a moment, and separating, washing and drying produced deep green precipitation to obtain the graphene / polyaniline / sulfur composite material. The method is low in energy consumption, simple to operate, good in controllability, high in yield and suitable for mass production.

Owner:ZHEJIANG NORMAL UNIVERSITY

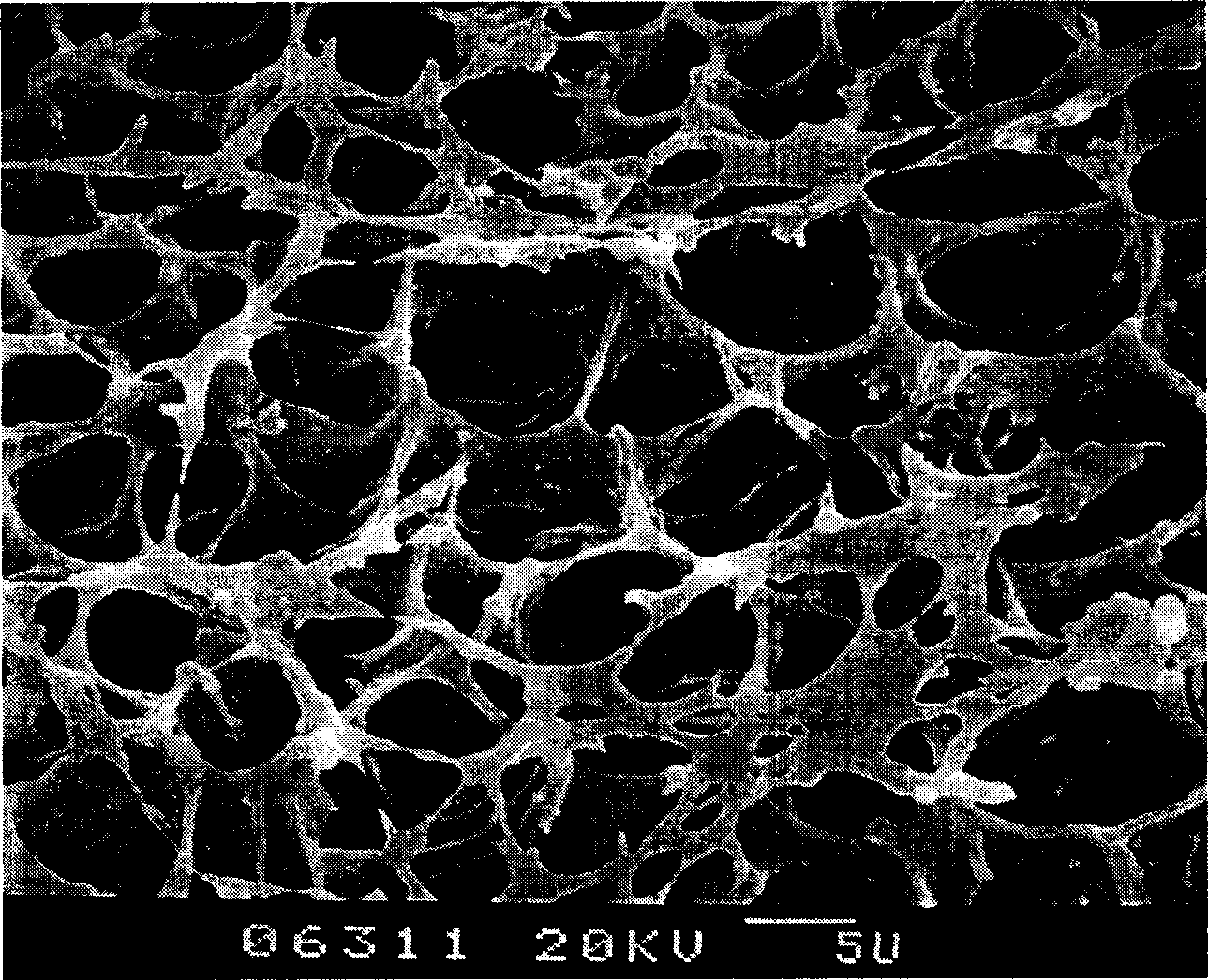

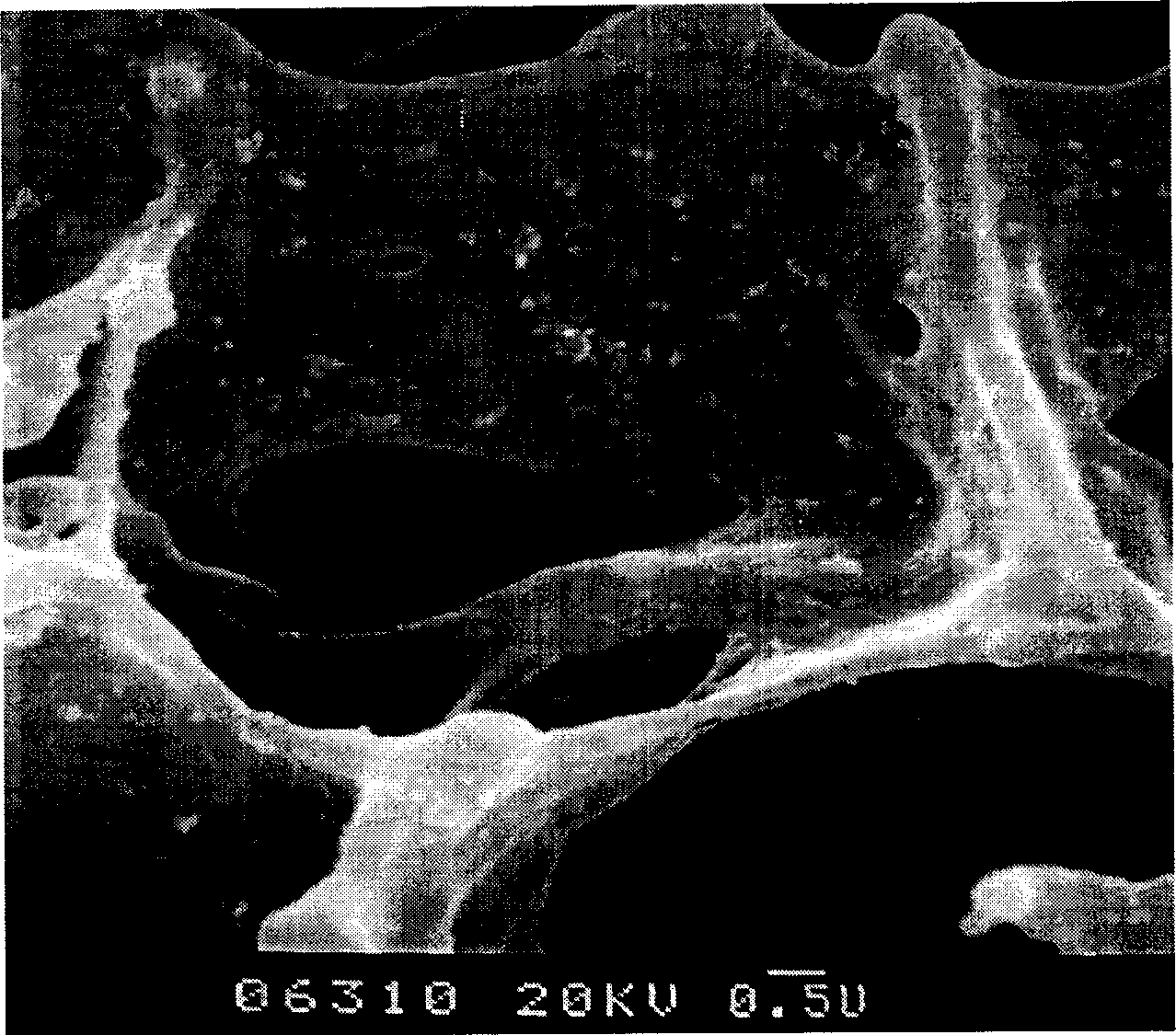

Biological material film with porous structure and its prepn

The biological material film with porous structure is medical film of polyamide or composite polyamide / nanometer osteolith material with through pores in gradually changed sizes, and has one compact side with fine pores in diameters of 0.01-30 microns and the opposite loose side with large pores in diameters of 30-300 microns. During its preparation, solvent with high volatility is used as the dispersant, medical polyamide or composite polyamide / nanometer osteolith material is heated and stirred to form the filming liquid, and film is formed and washed with deionized water to obtain the biological film. The porous biological film has controllable porous structure, and excellent mechanical performance and biological performance, and may be used widely as medial separating film, medicine slow releasing film, tissue regeneration inducing film, etc.

Owner:SICHUAN UNIV

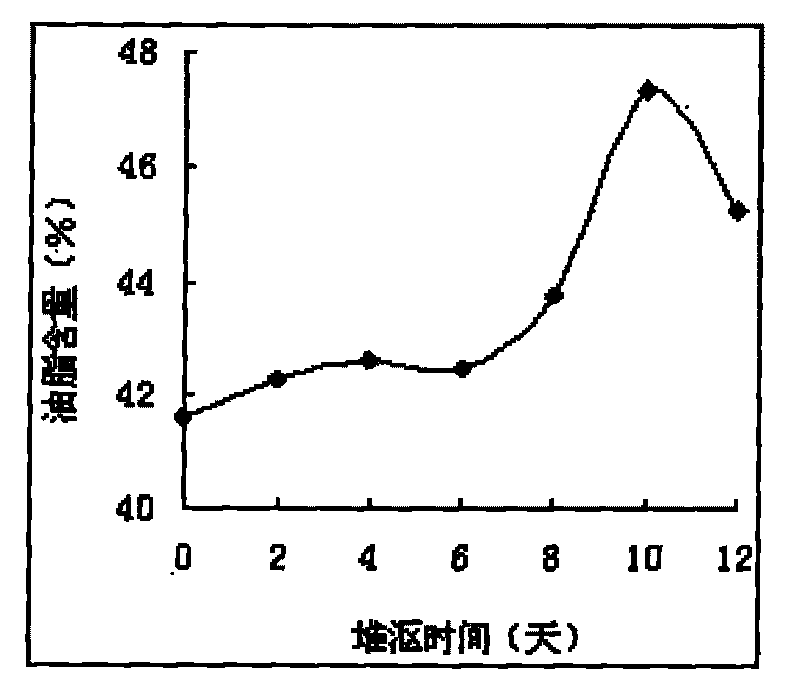

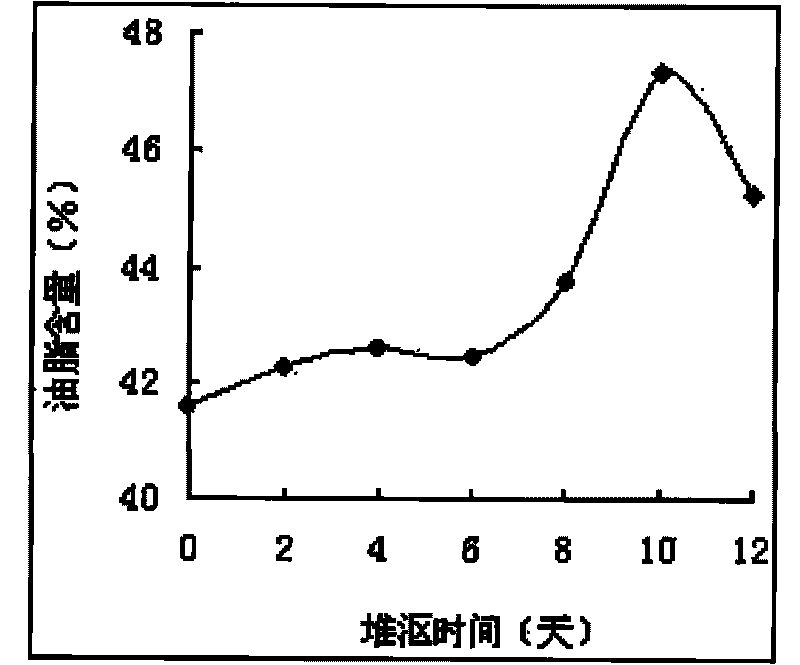

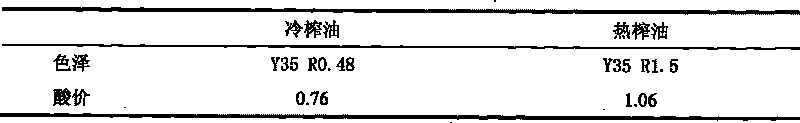

Method for preparing edible safflower tea oil

InactiveCN101692854AHigh oil contentQuality improvementEdible oils/fats production/working-upFlavorLoss rate

The invention discloses a method for preparing edible safflower tea oil, comprising the following steps: taking safflower tea seeds as raw materials; conducting stackretting, removal of the oil tea fruit shells, and taking-off of the tea seeds for low-temperature drying below safe moisture content on the harvested mature safflower oil tea fruits, and then cleaning stone, removing shells, separating kernels and shells, and crushing till the particle size is 20 to 60 meshes and adding water for tempering; adopting a cold pressing method for extracting the tea oil; and finally conducting simple refining processes such as filtration, wintering and the like so that the quality index can achieve national first-class edible tea oil standards. The method for preparing edible safflower tea oil hassimple and feasible process, easily-controlled production conditions, less refining processes, low refining loss rate, can keep various nutritional components in the safflower tea seeds from being destroyed, leads the finished tea oil to have light, clear and transparent color, aromatic natural flavor of the tea seeds, and is a nutritional and healthy tea oil.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing iron/nitrogen-codoped ordered mesoporous carbon material

ActiveCN106517136AImprove wettabilityImprove electrochemical performanceCarbon preparation/purificationEtchingReaction temperature

The invention provides a method for preparing an iron / nitrogen-codoped ordered mesoporous carbon material. The method comprises the following steps: taking a triblock copolymer F127 as a template, under acidic condition, a silicon source-tetraethoxysilane, a carbon source-phenolic resin, a nitrogen source 1-urea, a nitrogen source 2-pyrroles monomer and an iron source-ferric trichloride are added, the micelle having a three-dimensional porous structure is synthesized with one step by a solvent volatilization induction self-assembly method, and the ordered mesoporous carbon material is obtained through high temperature carbonization and hydrofluoric acid etching. The method of the ordered mesoporous carbon material has the advantages of simple operation, low reaction temperature, and controllable condition, the prepared ordered mesoporous carbon material has the ordered three-dimensional tunnel structure, high specific surface area and excellent electrochemistry performance, and has good application prospect in the field of electrochemistry.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Oxidization coagulant for treating coking wastewater

InactiveCN101734780AWide pH rangeGood removal effectWater/sewage treatment by flocculation/precipitationWater/sewage treatment by oxidationChemical oxygen demandAqueous solution

The invention discloses an oxidization coagulant for treating coking wastewater, which consists of two parts of an oxidization flocculant and a coagulant aid. The oxidization flocculant comprises the following components according to proportion by weight: 8-20% of flocculant polyferric sulfate, 0.1-2.0% of oxidant ferrate and the balance of water; and the coagulant aid is polyacrylamide aqueous solution. In the invention, the double functions of oxidization and flocculation are available, the removal rate of the coking wastewater CODcr (Chemical Oxygen Demand) can reach more than 70%, the draining water is clear, the colority is less than 80 times, the adding amount is little, and the cost is low, wherein the medicament cost of advanced treatment is only 0.5 RMB / ton; the condition is easy to control and the operation is convenient. The invention provides an economical and efficient method and powerful assurances for the draining standard of advanced treatment of the coking wastewater.

Owner:娄底市裕德科技有限公司

Citric acid loofah sponge preparation method and application

InactiveCN102430393AImprove adsorption efficiencyGood physical and chemical stabilityOther chemical processesAlkali metal oxides/hydroxidesFiltrationOrganic dye

The invention discloses a citric acid loofah sponge preparation method and an application technology. The preparation method provided by the invention is characterized by comprising the following steps of: adding 18-25 wt% of citric acid, 18-25 wt% of saponified loofah sponge and 50-60 wt% of water into a plugged Erlenmeyer flask, putting on a plug, carrying out refluxing at the temperature of 60-70 DEG C for 2-3h with stirring, heating up to the temperature of 110-120 DEG C, reacting for 2-3h, cooling, washing by using deionized water, carrying out pumping filtration until a filtrate is neutral, washing by using a few ethanol, and drying in a baking oven of 75 DEG C to obtain the citric acid loofah sponge. The citric acid loofah sponge has strong adsorption capability, can directly used for the adsorption and elution of various metal ions and organic dyes in a water body, is characterized by high adsorption efficiency, fast adsorption speed, good physical and chemical stability and excellent mechanical stability, and can be used within a wide soda acid range. Simultaneously, the citric acid loofah sponge has regeneration capability and is a natural green adsorbent.

Owner:UNIV OF JINAN

Carboxylation graphene oxide/polyvinylidene fluoride compiste ultrafiltration membrane and preparation method thereof

InactiveCN104028115AThe film surface contact angle decreasesImprove hydrophilicitySemi-permeable membranesPhosphoric acidGraphite oxide

The invention discloses a carboxylation graphene oxide / polyvinylidene fluoride compiste ultrafiltration membrane and a preparation method thereof. The carboxylation graphene oxide / polyvinylidene fluoride compiste ultrafiltration membrane is prepared by firstly, ultrasonically dispersing carboxylation graphene oxide in double solvents consisting of dimethylacetamide and triethyl phosphate, subsequently mixing with polyvinylidene fluoride, regulating the temperature to be 50-60 DEG C, mechanically stirring for dissolving, cooling to the room temperature, scraping a glass plate to form a membrane, soaking in deionized water for 3-5 days, and naturally drying in air, so as to obtain the carboxylation graphene oxide / polyvinylidene fluoride compiste ultrafiltration membrane. The carboxylation graphene oxide / polyvinylidene fluoride compiste ultrafiltration membrane disclosed by the invention is relatively good in hydrophilia and mechanical strength. The preparation method has the characteristics of simplicity, environment friendliness, easiness in condition control, short preparation period and the like.

Owner:SHANGHAI INST OF TECH

Preparation method of 3D printing rapid-prototyping precoated sand

InactiveCN105195667AStable in natureHigh surface glossFoundry mouldsFoundry coresStearic acidAmmonium bromide

The invention discloses a preparation method of 3D printing rapid-prototyping precoated sand. The method is characterized by comprising the steps that 1, fused ceramite is washed with water, soaked in a water solution with hexadecyl trimethyl ammonium bromide mass percentage concentration being 1-2%, filtered, washed with water to be neutral and dried to obtain pretreated fused ceramite; 2, by mass, 89-94% of pretreated fused ceramite, 2-5% of thermoplastic polyimide, 2-5% of phenolic resin, 0.4-1.0% of bisphenol A type dianhydride, 0.4-1.0% of glyceryl monostearate and acetone are added into a stirring machine, a grinding machine is started to rotate by 120 turns per minute, the mixture is ground for 30 min and then dried, and therefore the 3D printing rapid-prototyping precoated sand is obtained. The precoated sand can be directly molded under laser sintering, and has the advantages that the preparation process is simple, the conditions are easy to control, the production cost is low, and industrial production is easy to achieve.

Owner:UNIV OF JINAN

Tackifier and preparation thereof as well as adhesion addition type liquid silicone rubber and preparation thereof

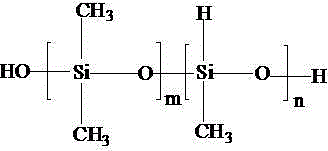

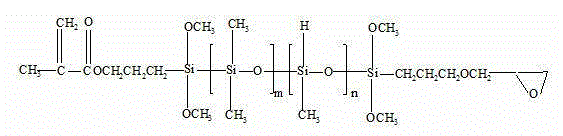

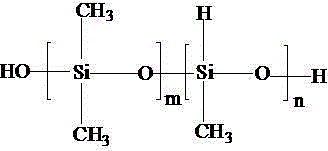

The invention belongs to the technical field of electronic element encapsulating materials, and specifically relates to a tackifier for addition type liquid silicone rubber and a preparation method thereof as well as adhesion addition type liquid silicone rubber containing the tackifier and a preparation method thereof. In a general structural formula of the tackifier, which is shown in the specification, m+n is equal to 15 to 20. The adhesion addition type liquid silicone rubber containing the tackifier has the advantages of good flowing property, high curing speed at room temperature, excellent heat-conducting property after curing and good adhesion property to aluminum products, glass, stainless steel, PA, PVC and ABS materials.

Owner:广东皓明有机硅材料有限公司

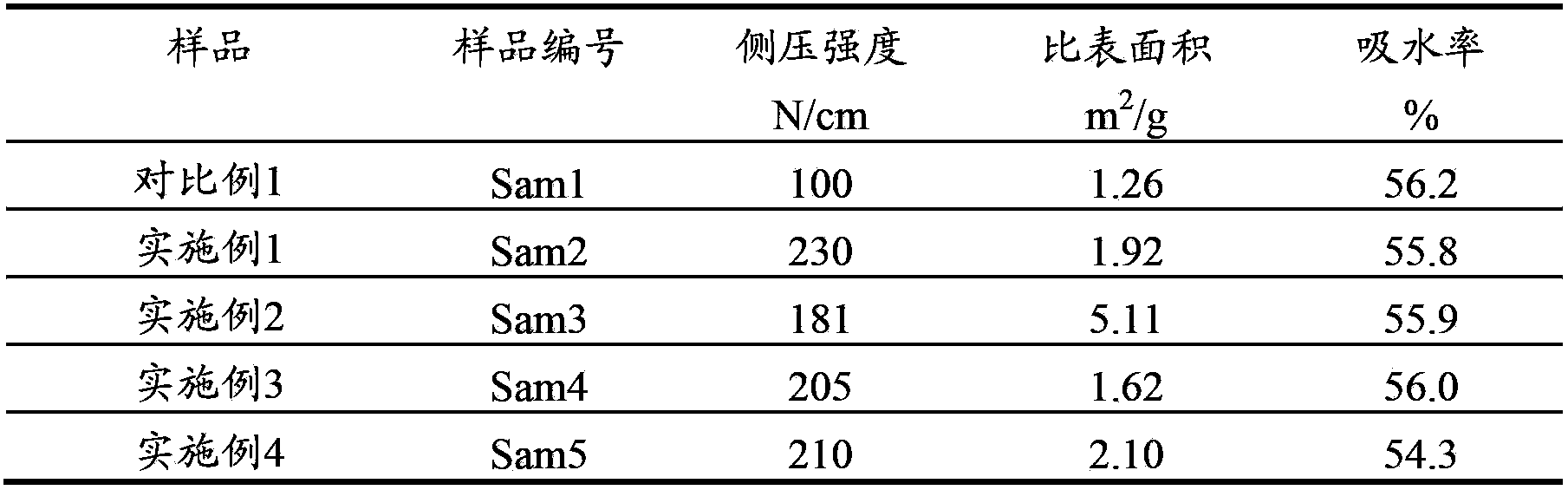

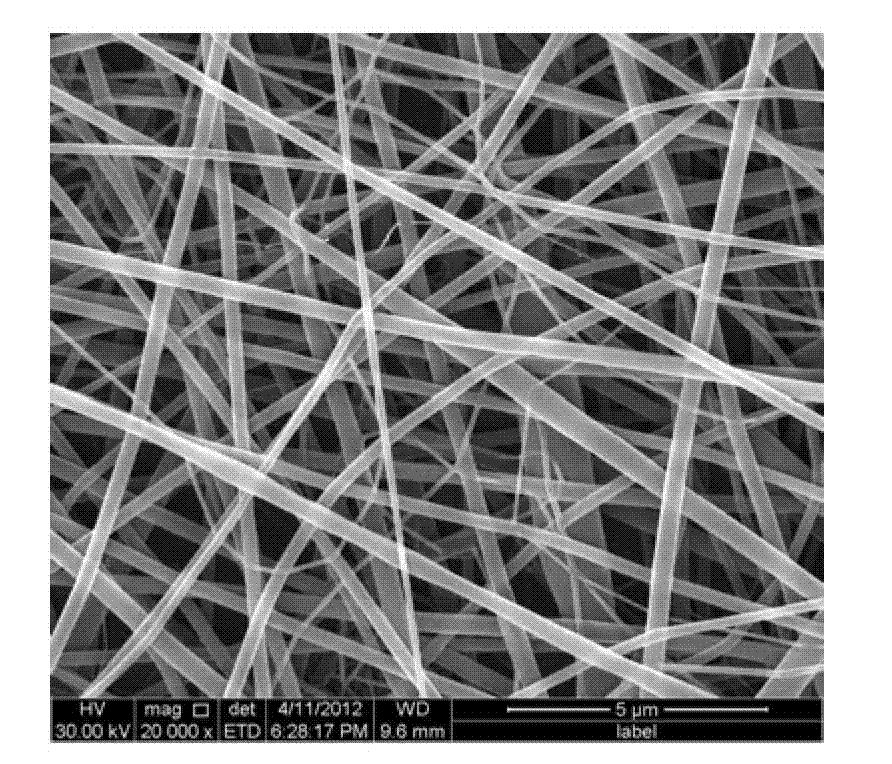

Aluminum oxide carrier and preparation method thereof

ActiveCN103816940AHigh strengthReduce manufacturing costCatalyst carriersOther chemical processesChemical industryWater vapor

The invention provides an aluminum oxide carrier which is higher in intensity and larger in specific surface area and is suitable for chemical industries such as olefin epoxidation reaction, alkyne and alkadiene selective hydrogenation or methane-steam conversion. The invention also provides an aluminum oxide carrier preparation method which is simple in technology and operation and has easily controlled conditions. Alpha-tri-hydro-aluminum oxide and / or surge aluminum stones and a proper amount of pseudo-boehmite and / or alumina sol which are low in cost and readily available are used as main raw materials, so that the production cost of the aluminum oxide carrier is lowered; meanwhile, due to the doping of a proper amount of a silicon source and other auxiliary ingredients, the strength of the carrier is obviously improved, and the specific surface area is properly enlarged; particularly, the strength of the carrier is further improved by controlling the temperature rise rate in a preparation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

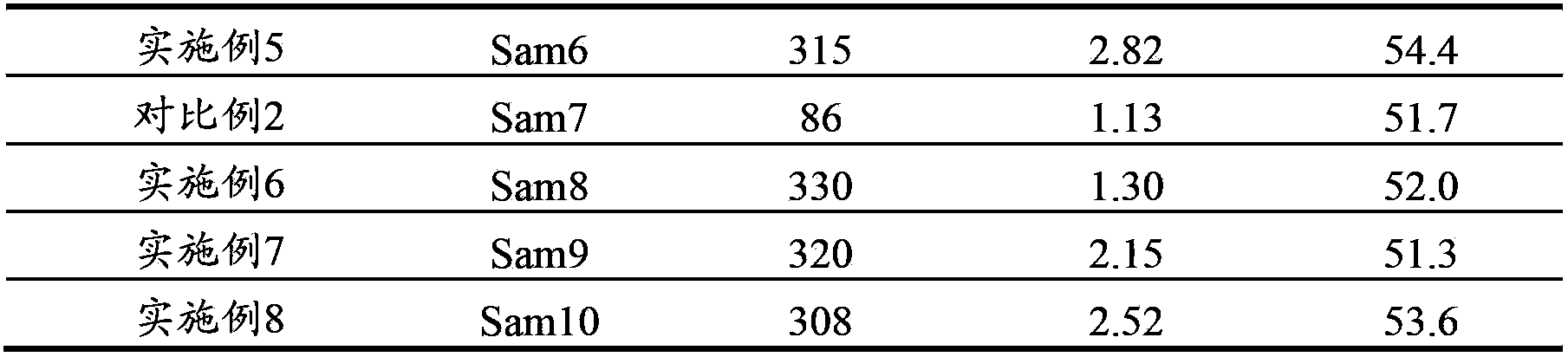

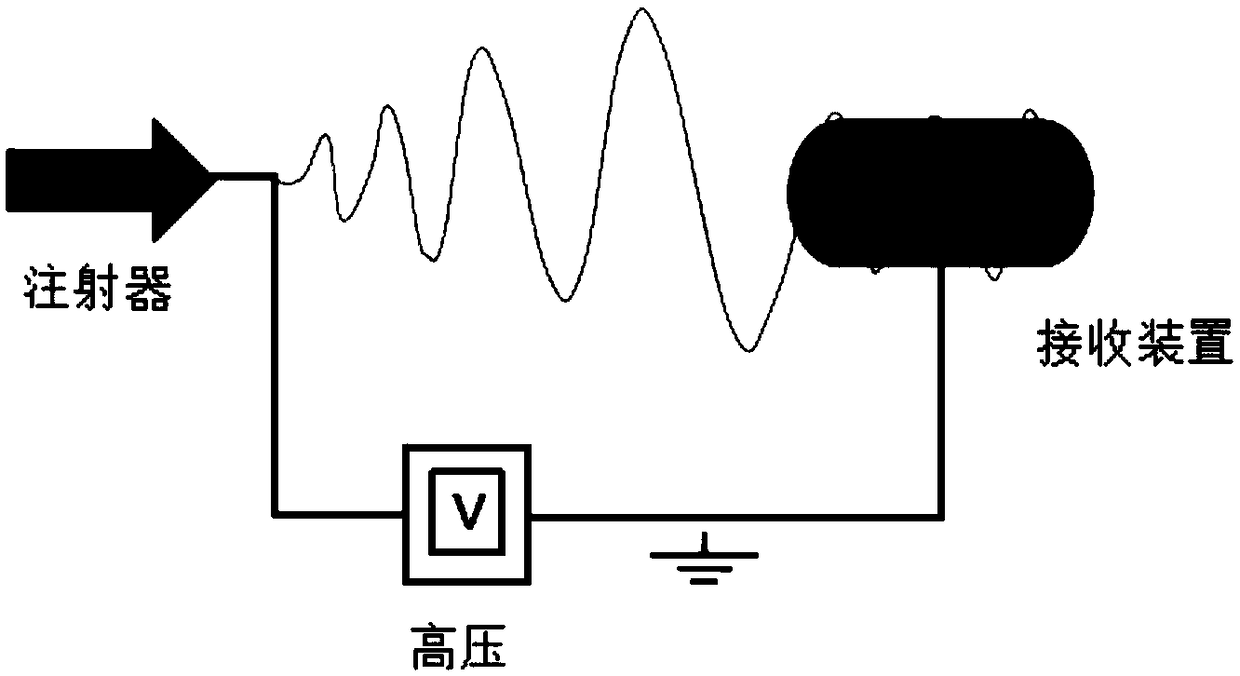

Thermo-sensitive poly N-isopropylacrylamide/polyurethane medicine-loading electro-spun fibrous membrane and preparation method thereof

ActiveCN102733088ALarge specific surface areaHigh drug loadingOrganic active ingredientsFilament/thread formingN dimethylformamideElectrospinning

The invention relates to a thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane and a preparation method thereof, relating to a medicine-loading electro-spun fibrous membrane and a preparation method thereof and aiming to solve problems of poor mechanical property of existing poly N-isopropylacrylamide medicine-loading electro-spun fibrous membrane and no temperature sensitivity of a polyurethane medicine-loading electro-spun fibrous membrane. The thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane is prepared by poly N-isopropylacrylamide, polyurethane, N,N-dimethylformamide and a medicine; the preparation method comprises the following steps: 1, preparing static spinning solution; 2, dissolving the medicine so as to obtain the static spinning solution containing the medicine; 3, carrying out electrospinning; and 4, carrying out dry treatment to obtain the thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane. According to the invention, the preparation method is mainly used for preparing the thermo-sensitive poly N-isopropylacrylamide / polyurethane medicine-loading electro-spun fibrous membrane.

Owner:HARBIN INST OF TECH

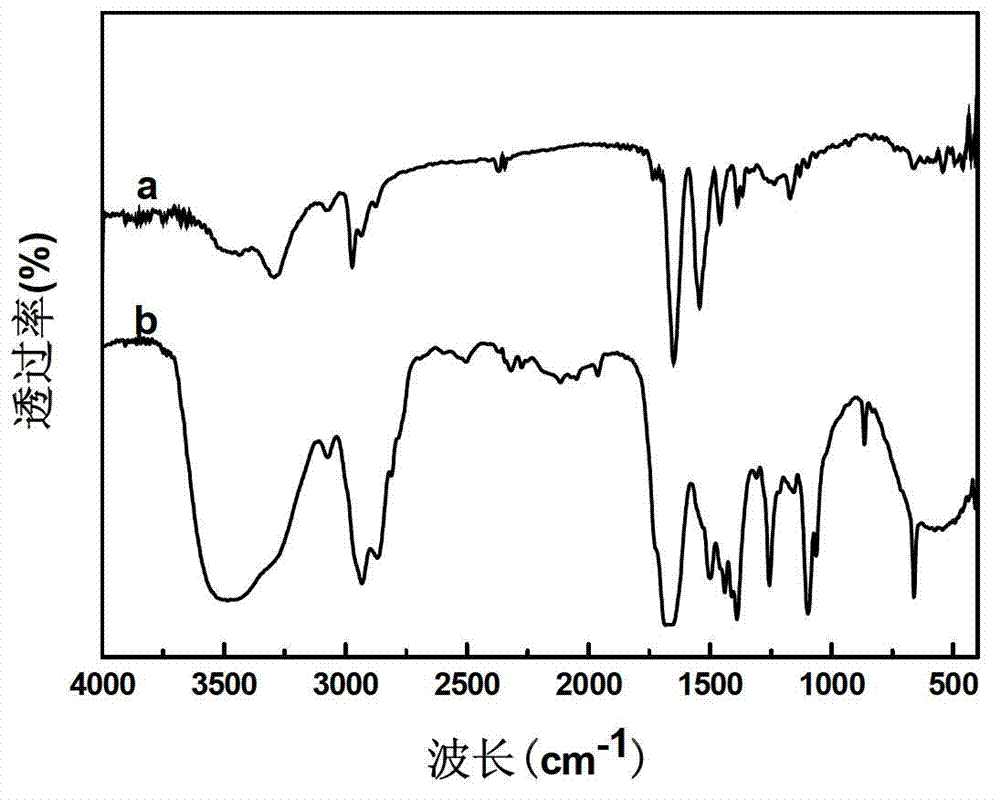

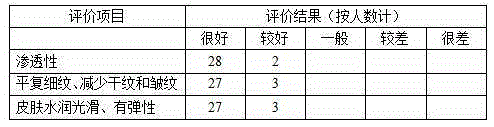

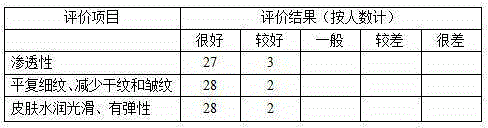

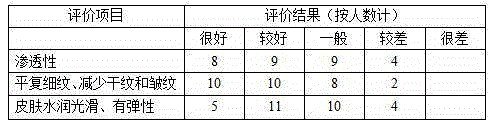

Anti-wrinkle face cream and preparation method thereof

ActiveCN105147591AAnti agingImprove youthCosmetic preparationsToilet preparationsEthylhexyl palmitateApple extract

The invention belongs to the technical field of cosmetics, and in particular relates to an anti-wrinkle face cream and a preparation method thereof. The anti-wrinkle face cream comprises butanediol, ethylhexyl palmitate, caprylic / capric triglyceride, glycerol, polyglycerol-10, ethylhexyl isononanoate, polymethyl methacrylate, polydimethylsiloxane, ceteareth-21, cetostearyl alcohol, ceteareth-2, acrylic acid (ester) type / acrylamide copolymer, betaine, avocado fruit butter, a lactic acid bacillus / balausta fermentation product extract, an arctic rock chlamydomonas essence, a starfish essence, a ginseng extract, a lucid ganoderma extract, an apple extract, tocopheryl acetate and the like. The anti-wrinkle face cream provided by the invention is good in penetrability and easy to absorb, can effectively replenish water and preserve moisture, and can repair skin wrinkles and inhibit generation of the winkles, thereby delaying skin aging.

Owner:广州科玛生物科技股份有限公司

Crosslinked alginate-bacterial cellulose sponge and preparation method thereof

ActiveCN103536954AImprove mechanical propertiesSimple structureAbsorbent padsBandagesPolymer scienceFreeze-drying

The invention relates to the field of a biomedical material, and particularly discloses a crosslinked alginate-bacterial cellulose sponge and a preparation method thereof. The crosslinked alginate-bacterial cellulose sponge takes an alginate biomaterial and bacterial cellulose as raw materials. The crosslinked alginate-bacterial cellulose sponge is characterized in that a sponge product is prepared from the alginate biomaterial and the bacterial cellulose in manners of crosslinking and freeze-drying after being compounded, wherein the alginate biomaterial accounts for 80-95% of the sponge product in mass fraction; the bacterial cellulose accounts for 5-20% of the sponge product in mass fraction. The crosslinked alginate-bacterial cellulose sponge is abundant in used material sources, low in cost, controllable to process, and simple in production technology; the prepared crosslinked alginate-bacterial cellulose sponge has good mechanical property, liquid absorption property, water retention capacity and air permeability, and is applicable to bleeding healing of large seepage or a bleeding wound.

Owner:山东颐诺生物科技有限公司

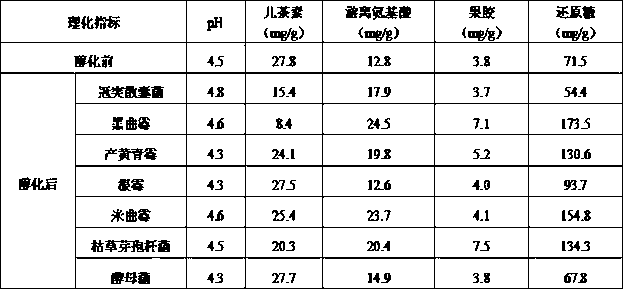

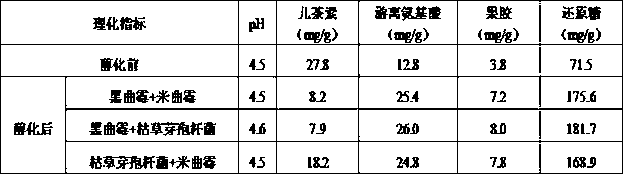

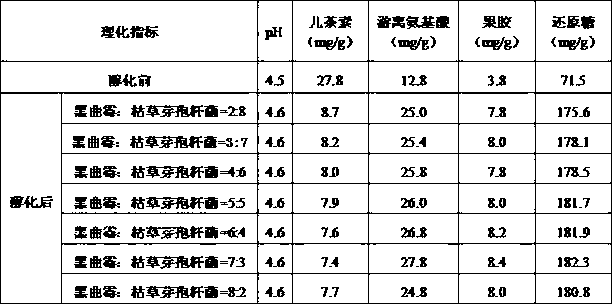

Fast alcoholized dark green tea and preparation method thereof

The invention discloses fast alcoholized dark green tea and a preparation method of the dark green tea. The preparation method comprises the following steps of: converting catechin with bitter taste in the raw dark green tea into theaflavin, thearubigin and theabrownin, degrading cellulose into glucose with sweet taste, converting insoluble pectin into soluble pectin (to increase the thickness of a tea soup), and degrading protein into amino acids with umami taste by adding microorganisms and an enzyme solution into the raw dark green tea under the condition with certain temperature and humidity, and applying chemical action to the resulting product in supplementation, and at last neutralizing partial acidic components with baking soda. The technical problems of long fermentation time and the generation of nauseating and sour smells in dark green tea pile fermentation are solved; the tea made from the dark green tea obtained by the preparation method disclosed by the invention is delicate and mellow in taste, orange red and transparent in tea soup, and rich in stale flavor; and the dark green tea is pretty high in contents such as soluble sugar, theaflavin, thearubigin and amino acid, and can reach the taste effect of old tea more than 5 years in about 4 days.

Owner:湖南省怡清源茶业有限公司

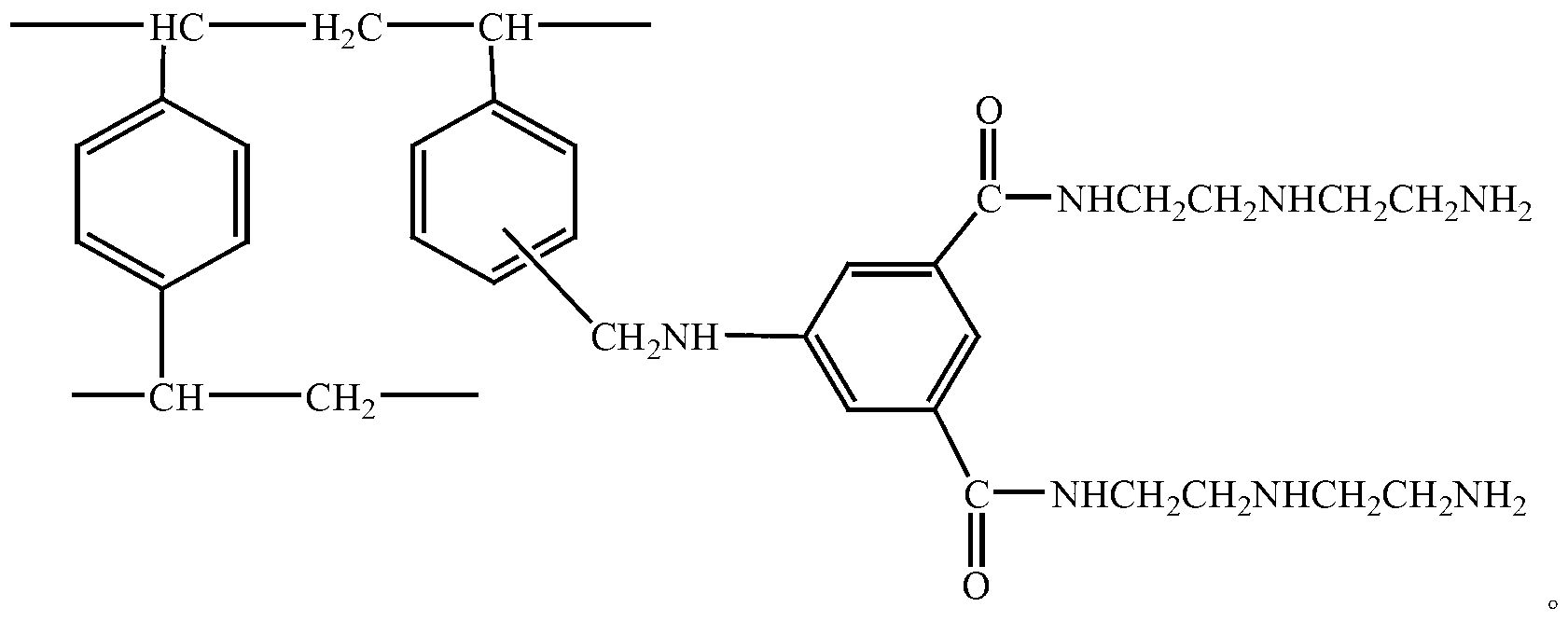

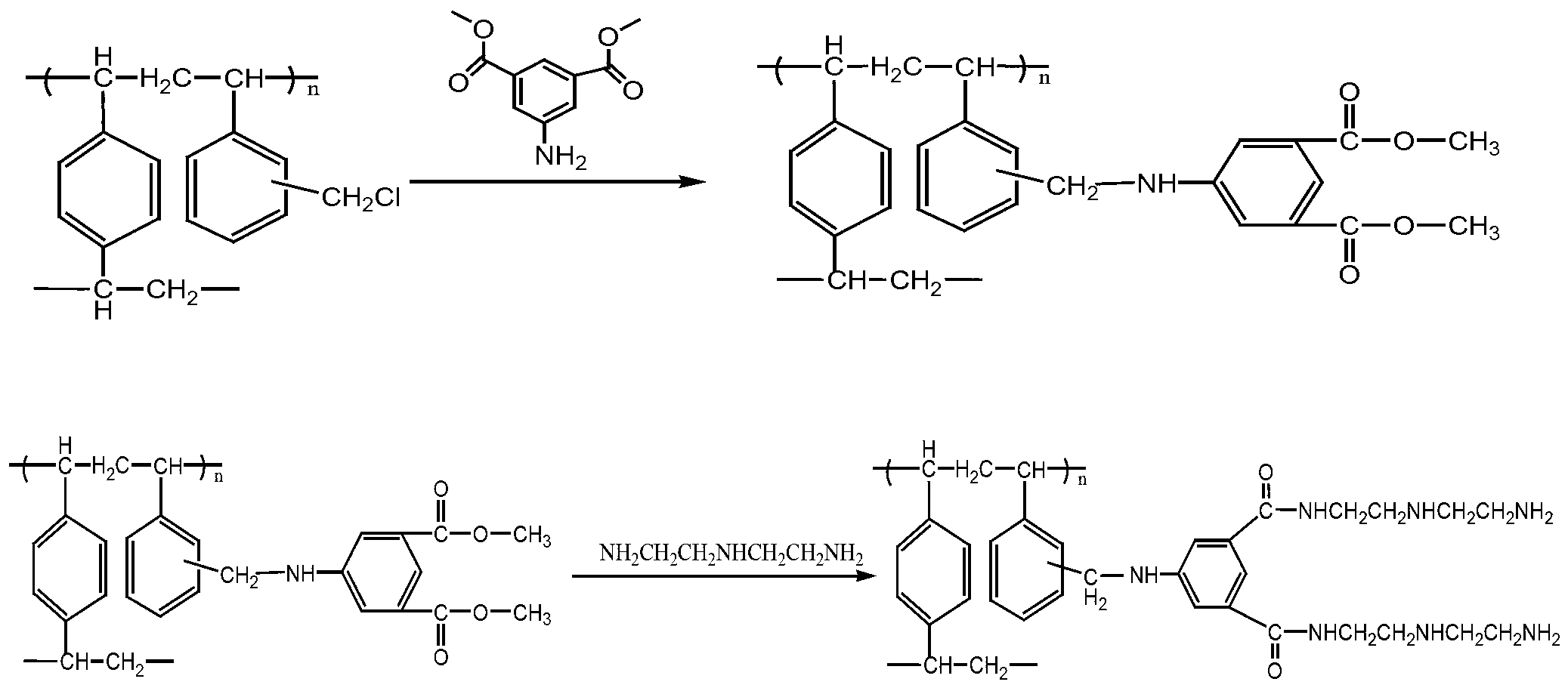

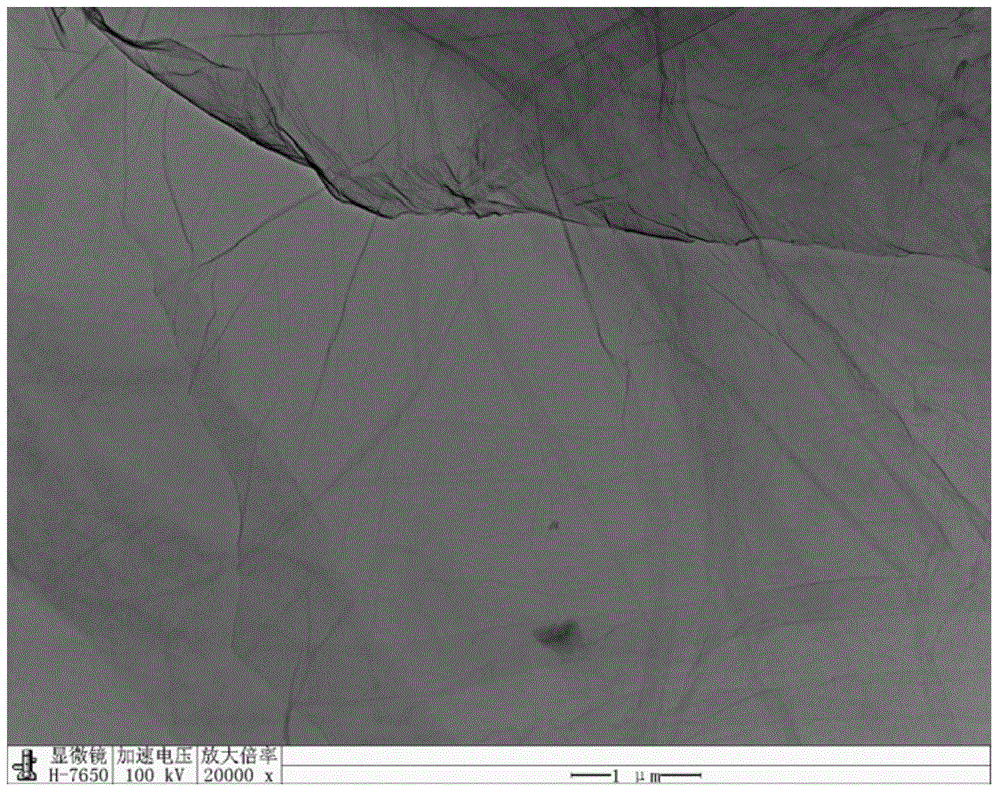

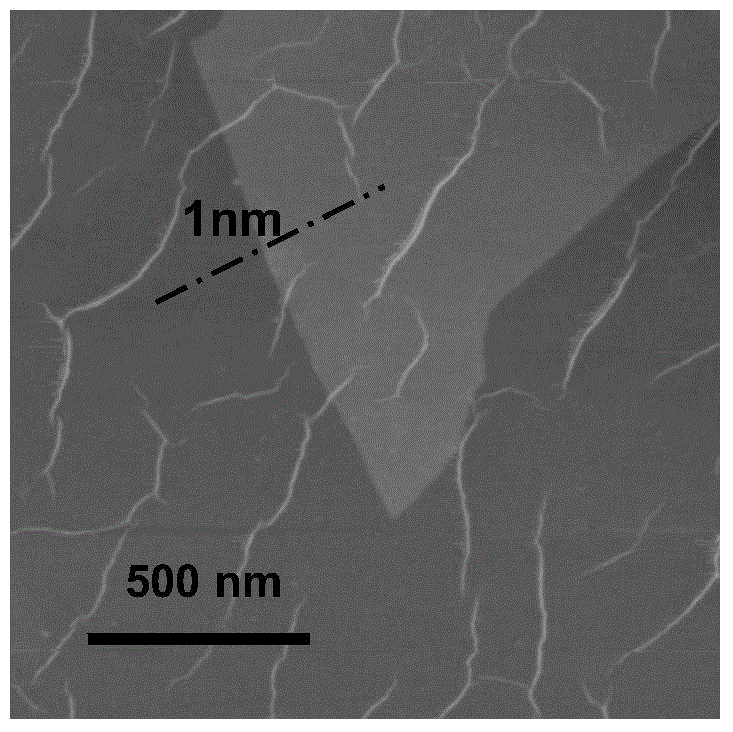

Primary diamido chelating resin and preparation method thereof

ActiveCN103073667AHigh adsorption selectivityWide range of usesOther chemical processesWater/sewage treatment by sorptionWastewaterCopper

The invention discloses primary diamido chelating resin and a preparation method thereof and belongs to the field of chelating resin waste water treatment. A constitutional unit of the primary diamido chelating resin is as follows as shown in the specification. The chelating resin has a certain space structure, and primary diamido groups of the resin has special adsorptive selectivity to copper ions.

Owner:NANJING UNIV

Graphene oxide solution for wet spinning and preparation method thereof, graphene fiber and preparation method of graphene fiber

ActiveCN105088415AEasy qualityQuality improvementInorganic material artificial filamentsWet spinning methodsFiberPre expansion

The invention provides a preparation method of a graphene oxide solution for wet spinning; the preparation method includes the following steps: carrying out centrifugal concentration on a graphene oxide solution, to obtain the graphene oxide solution for wet spinning. The graphene oxide solution is subjected to centrifugal concentration so as to obtain the graphene oxide solution for wet spinning finally. The preparation method of the graphene oxide solution for wet spinning simplifies operation processes, and omits ultrasound, dialysis and pre-expansion processes and the like; the experimental preparation process is simple, the conditions are easy to control, and large-scale production can be realized. In addition, the graphene oxide solution used for wet spinning and prepared by the preparation method provided by the invention has the advantages of stable quality, good water solubility, controllable concentration, and easy adjustment of the size of obtained graphene fiber.

Owner:UNIV OF SCI & TECH OF CHINA

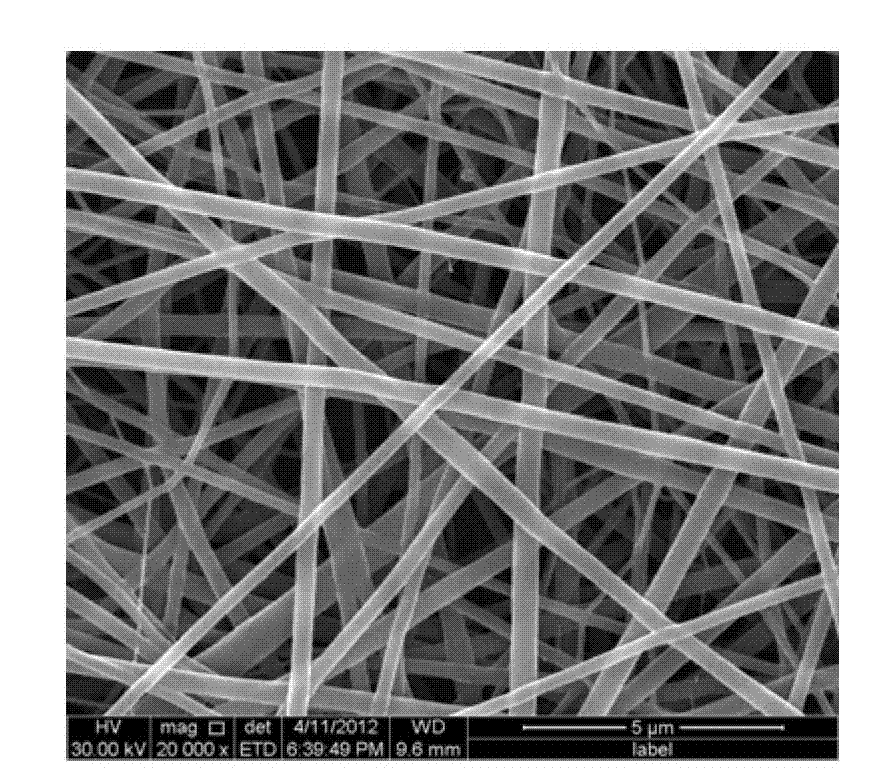

Preparation method and application of composite antibacterial electrostatic spinning nanofiber membrane

ActiveCN108993167ASimple manufacturing methodConditions are easy to controlMembranesSemi-permeable membranesFiberNanofiber

The invention discloses a preparation method and application of a composite antibacterial electrostatic spinning nanofiber membrane. The preparation method is used for an antibacterial air filtering material for masks. The material is prepared by taking polyvinyl alcohol, chitosan, vinyl amine-copolymerized-3-allyl-5,5-dimethyl hydantoin as raw materials. The preparation method comprises the following steps: uniform blend spinning is carried out on the polyvinyl alcohol and the chitosan to obtain a material as an innermost-layer nanofiber membrane and an outermost-layer nanofiber membrane, andan auxiliary antibacterial effect and a mechanical supporting effect are achieved; an intermediate layer is prepared by carrying out blend spinning on the polyvinyl alcohol and the vinyl amine-copolymerized-3-allyl-5,5-dimethyl hydantoin, and a main antibacterial effect is achieved; and a three-layer nanofiber membrane obtained by spinning is placed in glutaraldehyde steam for cross-linking treatment. The preparation method disclosed by the invention is simple and feasible and is controllable in condition, and the composite antibacterial electrostatic spinning nanofiber membrane is excellentin interception effect and sterilization effect and has important value and significance in the field of antibacterial filtering materials for masks.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Preparation method for biomass activated carbon

InactiveCN110255559AExpand sourceEasy to operateCarbon compoundsGaseous fuelsCarbonizationClean energy

The invention relates to the field of preparation of activated carbon, specifically to a preparation method for biomass activated carbon. The preparation method comprises the following concrete steps: S1, pulverizing of raw materials; S2, preparation of a solution; S3, carbonization treatment; S4, activation treatment; and S5, drying treatment. All the raw materials used in the invention are biomass waste; the biomass waste that is usually discarded at ordinary times is subjected to a series of physical and chemical changes to turn the biomass waste into activated carbon which can be used by people; carbon monoxide and methane syngas are produced during experiments, and the methane syngas can be collected through exhaust gas collection and used as clean energy; the preparation of the biomass activated carbon broadens the sources of raw materials for preparation of the activated carbon, provides a basis for the subsequent research of biomass raw materials, and is of great significance to multi-directional and high value-added utilization of biomass waste; and the preparation method is simple to operate, and conditions are easy to control.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Probe based on double-signal amplification triggered by target and application of probe

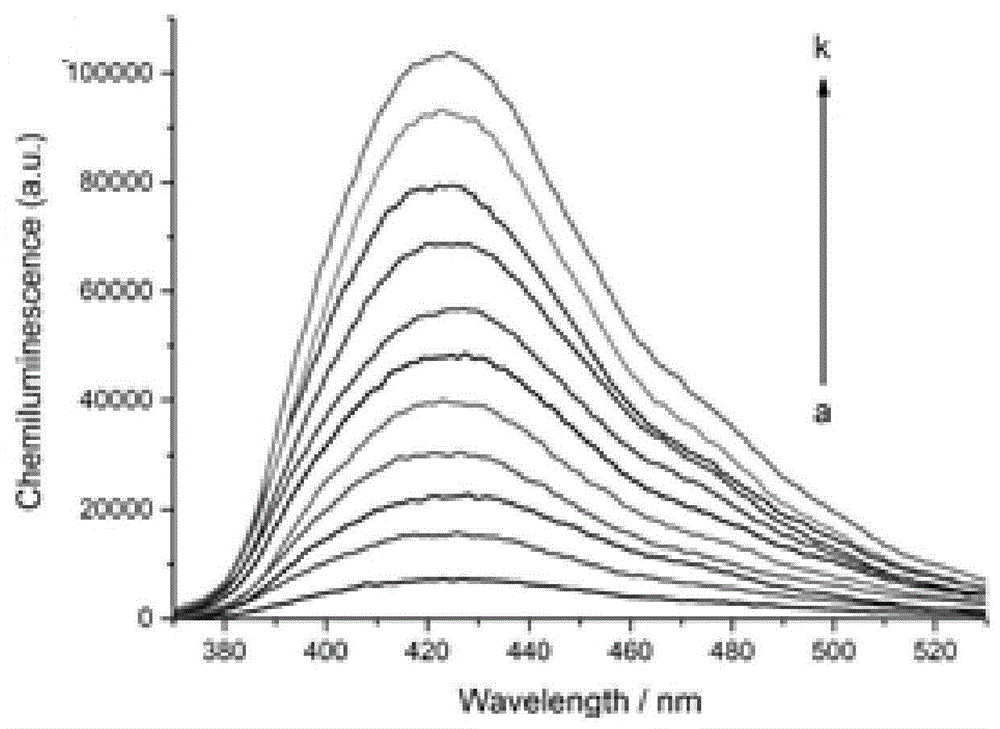

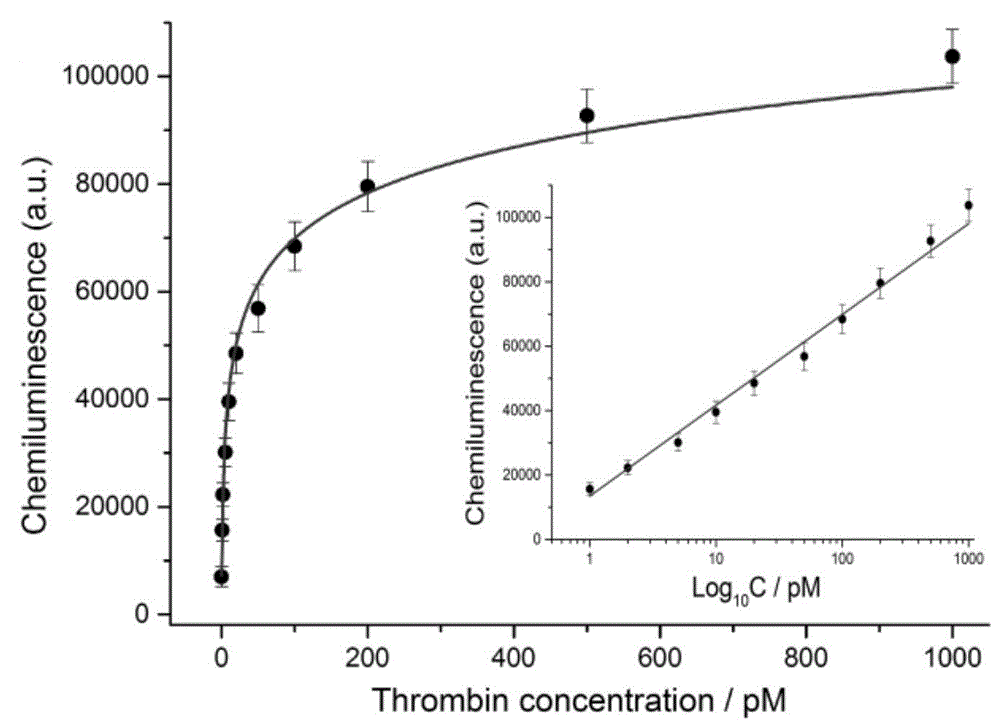

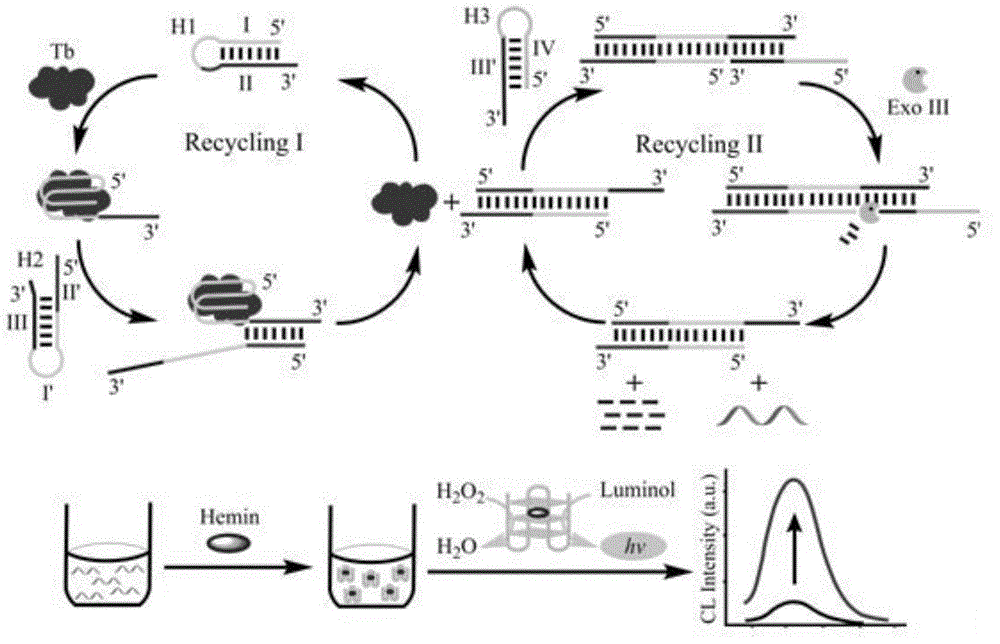

ActiveCN104789674AKeep the hairpin structureGuaranteed steady stateMicrobiological testing/measurementDNA/RNA fragmentationProtein targetDouble strand

The invention provides a probe based on double-signal amplification triggered by a target and application of the probe. The probe comprises a first hairpin, a second hairpin and a third hairpin, wherein the first hairpin, the second hairpin and the third hairpin are formed by pairing hybridization of complementary bases in folding areas after single-chain linear molecules are folded back; the parts, forming double-chain structures in the partial areas, of the hairpins are stem areas, and the parts, not forming the double-chain structures and folded back, are ring-shaped areas. According to the probe provided by the invention, the self-assembly of hairpins is realized through target protein catalysis, signal amplification is achieved under the assistance of an excision enzyme III, obvious amplification of a detection signal is realized, and the detection sensitivity is greatly improved further; since the probe does not depend on template replication in the detection process, the problem that false positive occurs due to cross contamination in the detection process is avoided, generation of a false positive signal is effectively prevented and background noise is reduced greatly.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

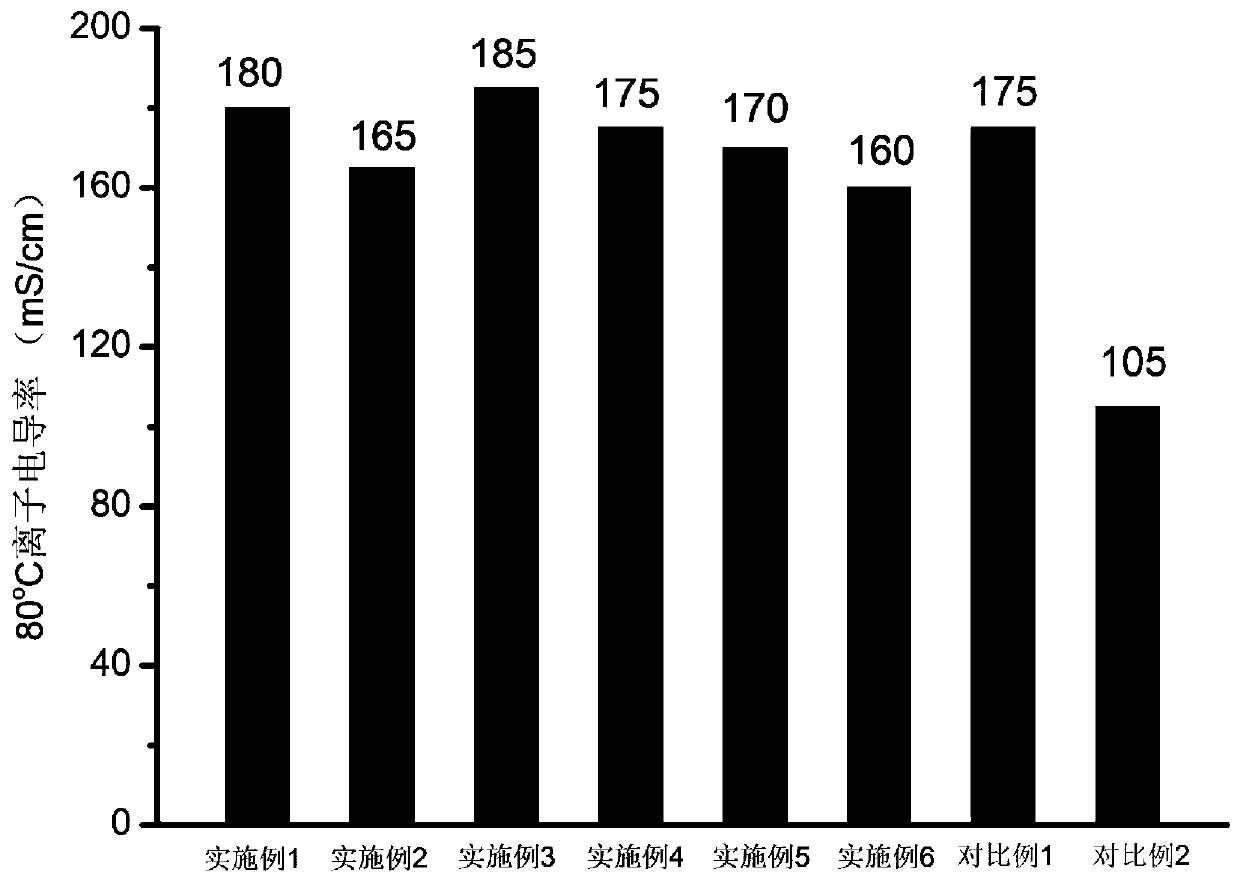

Piperidine tertiary amine group-containing polymer, anion exchange polymer and preparation method and application thereof

The invention relates to a polymer containing a piperidine tertiary amine group, an anion exchange polymer, and preparation methods and applications thereof. The polymer containing the piperidine tertiary amine group comprises fluorene structural units represented by a formula (1A) and / or a formula (2A), and piperidine tertiary amine structural units represented by a formula (3'A), wherein the anion exchange polymer comprises a fluorene structural unit represented by a formula (1A) and / or a formula (2A), and a piperidine quaternary ammonium structural unit represented by a formula (3A). The polymer containing the piperidine tertiary amine group and the anion exchange polymer provided by the invention contain fluorene groups in the main chain chemical structure, so that the material has excellent mechanical strength; in addition, the distortion and rotation of a benzene ring on the main chain are weak, and the microstructure regularity of the polymer after film formation is relatively high, so that the polymer has good main chain stability.

Owner:惠州市亿纬新能源研究院

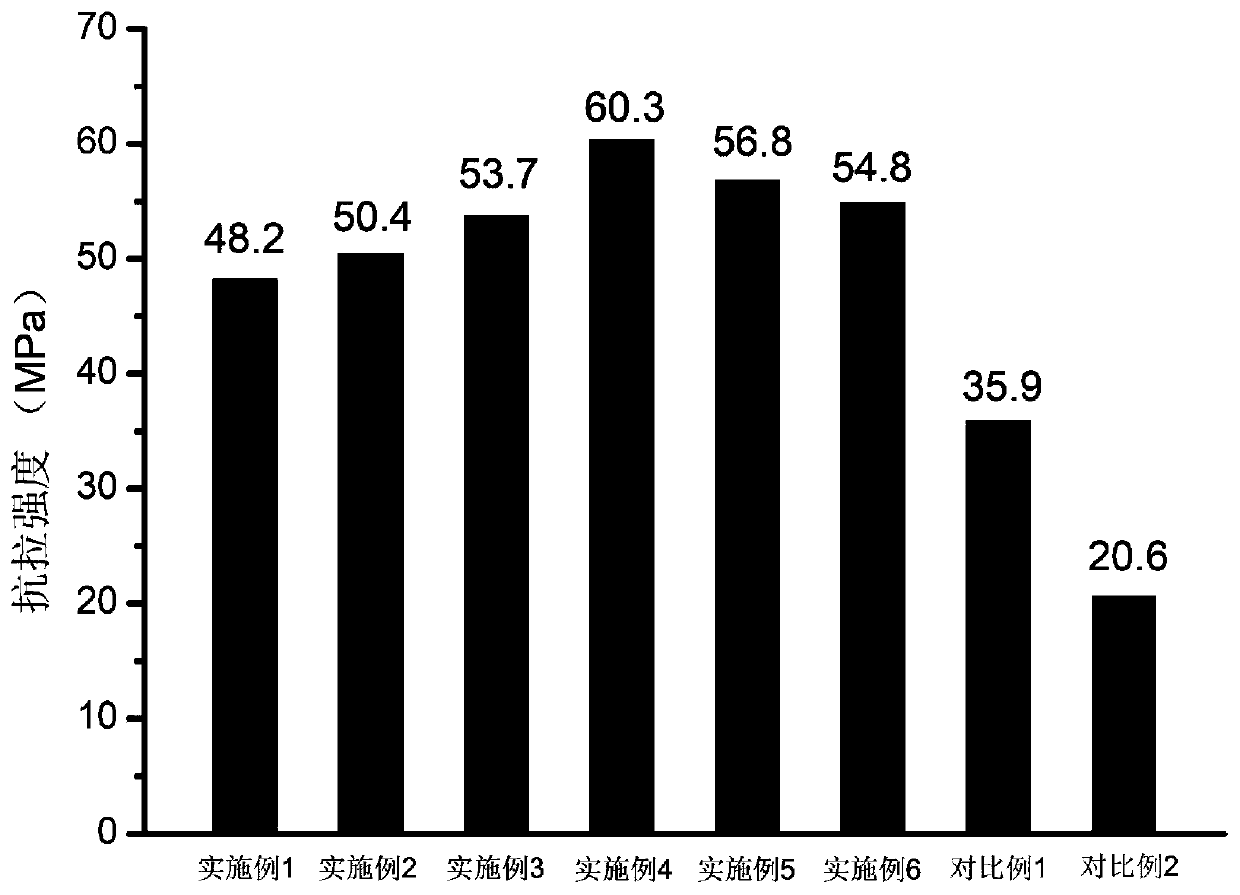

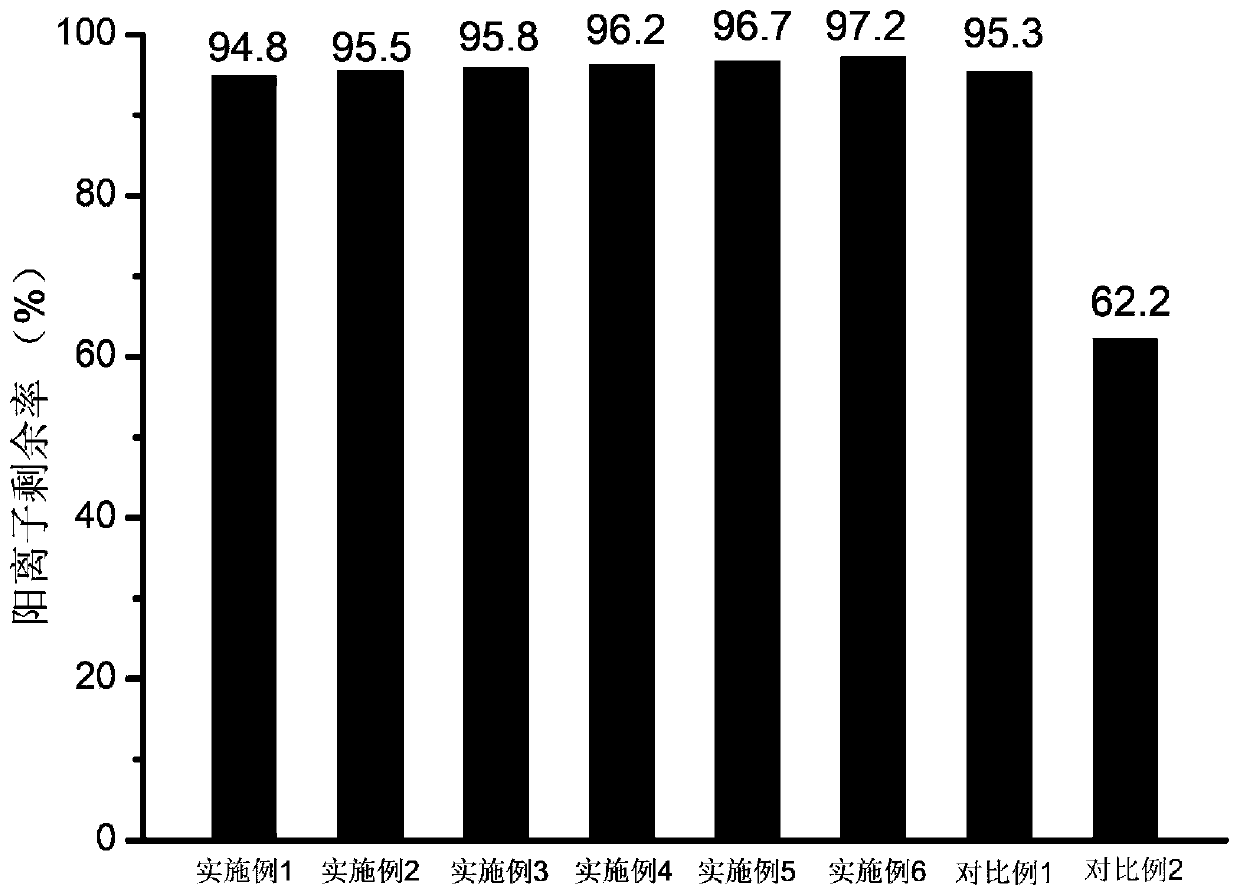

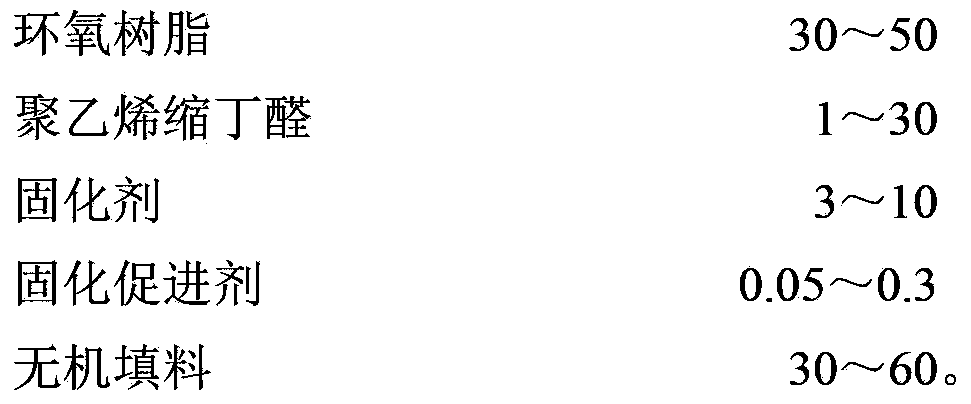

High flexibility epoxy resin composition

ActiveCN103467912AGood flexibilityImprove thermal shock resistancePowdery paintsEpoxy resin coatingsEpoxyNetwork structure

The present invention provides a high flexibility epoxy resin composition, which can be used in the fields of electronic packaging materials and powder coating materials, and comprises, by mass, 30-50 parts of an epoxy resin, 1-30 parts of polyvinyl butyral (PVB), 3-10 parts of a curing agent, 0.05-0.3 part of a curing accelerator, and 30-60 parts of an inorganic filler. The epoxy resin has characteristics of excellent interpenetrating network structure and excellent flexibility, and can be used in the fields of electronic packaging materials and powder coating materials.

Owner:天津凯华绝缘材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com