Preparation method and application of composite antibacterial electrostatic spinning nanofiber membrane

An air filter material and nanofiber technology, which can be used in applications, dispersed particle filtration, clothing, etc., can solve the problems of antibacterial masks and poor filtering effects, and achieve the effects of simple and easy preparation, good air permeability, and avoidance of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

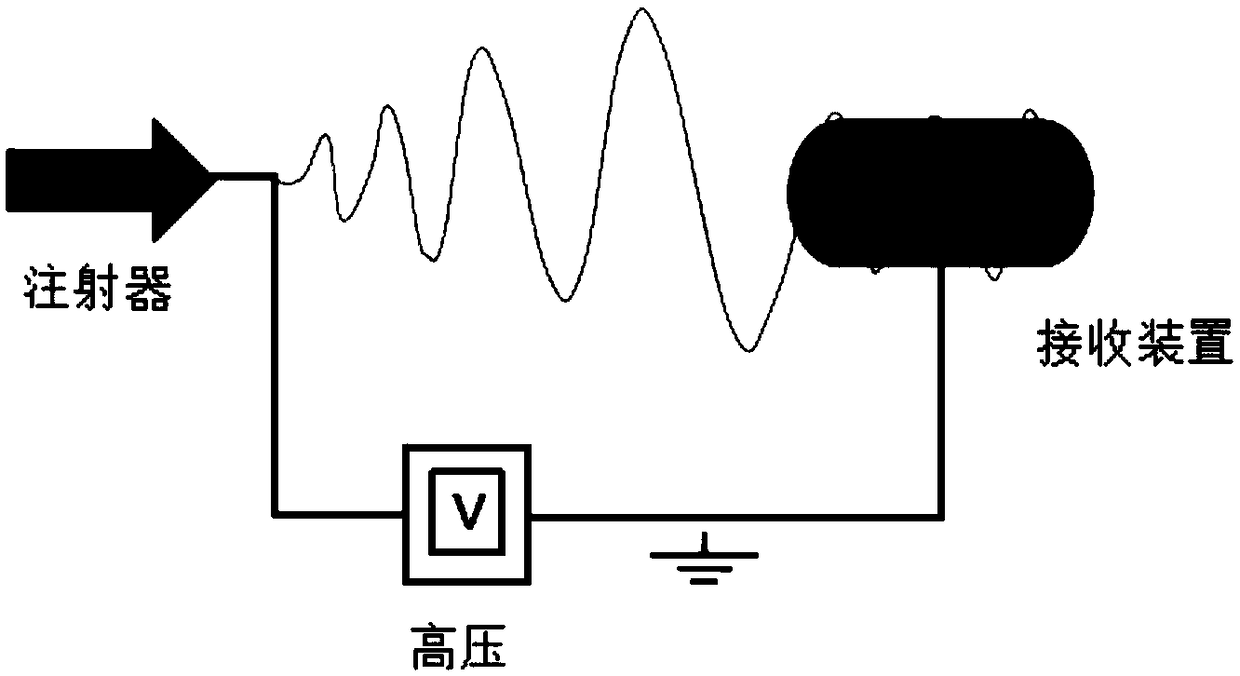

[0030] Prepare 8% polyvinyl alcohol aqueous solution and 1% chitosan acetic acid solution, stir and mix them evenly at a mass fraction ratio of 1:1, and then add them to the syringe. The output voltage of the high-voltage power supply is 20KV, the needle and the receiver Under the conditions of a device distance of 10 cm and a flow rate of 0.3 mL / h, the electrospinning machine is used for spinning to obtain the first nanofiber membrane.

[0031] The copolymer sample is dissolved in an 8% polyvinyl alcohol aqueous solution at a ratio of 1:1, and the fiber membrane obtained in the above steps is used as the collecting matrix to perform electrostatic spinning to obtain two-layer fiber membrane.

[0032] The same method for preparing the spinning solution for the first layer of spinning membrane, using the two-layer fiber membrane obtained in the above steps as the collection matrix, spinning to obtain a three-layer fiber membrane.

[0033] The three-layer nanofiber membrane obtained by ...

Embodiment 2

[0035] Prepare 9% polyvinyl alcohol aqueous solution and 2% chitosan acetic acid solution, stir and mix them evenly at a mass fraction ratio of 2:1, and then add them to the syringe. The output voltage of the high-voltage power supply is 25KV, the needle and the receiver The first nanofiber membrane was obtained by spinning using an electrospinning machine under the conditions of a device distance of 15 cm and a flow rate of 0.4 mL / h.

[0036] The copolymer sample was dissolved in a 9% polyvinyl alcohol aqueous solution at a ratio of 2:1, and the fiber membrane obtained in the above step was used as the collecting matrix to perform electrostatic spinning to obtain two-layer fiber membrane.

[0037] The same method for preparing the spinning solution for the first layer of spinning membrane, using the two-layer fiber membrane obtained above as the collecting matrix, spinning to obtain a three-layer fiber membrane.

[0038] The three-layer nanofiber membrane obtained by spinning in the...

Embodiment 3

[0040] Prepare 10% polyvinyl alcohol aqueous solution and 3% chitosan acetic acid solution, stir and mix them at a mass fraction ratio of 3:1, and then add them to the syringe. The output voltage of the high-voltage power supply is 15KV, the needle and the receiver The first nanofiber membrane was obtained by spinning using an electrospinning machine under the conditions of a device distance of 5 cm and a flow rate of 0.5 mL / h.

[0041] The copolymer sample is dissolved in a 10% polyvinyl alcohol aqueous solution at a ratio of 3:1, and the fiber membrane obtained in the above steps is used as the collecting matrix to perform electrostatic spinning to obtain two-layer fiber membrane.

[0042] The same method for preparing the spinning solution for the first layer of spinning membrane, using the two-layer fiber membrane obtained above as the collecting matrix, spinning to obtain a three-layer fiber membrane.

[0043] The three-layer nanofiber membrane obtained by spinning in the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com