Patents

Literature

47results about How to "Small median diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of 3D printing inorganic powder molding material

InactiveCN103936392ASmall median diameterStable in natureClaywaresMaterials preparationPolyvinyl alcohol

The invention discloses a preparation method of a 3D printing inorganic powder molding material. The method is characterized in that the method comprises the following steps: 1, powder material pretreatment: mixing 10-30% of acetone with 62-85% of a powdery material and 2-10% of gamma-(2,3-epoxypropoxy)propyltrimethoxysilicane, and grinding the obtained mixture at a rotating speed of 500-1000rpm for 1-2h to obtain a pretreated powdery material; and 2, molding material preparation: adding 40-65% by mass of acetone, adding 2-8% of polyvinyl formal, stirring for dissolving, adding 30-55% of the pretreated powdery material, stirring for uniform mixing, putting the obtained solution in a grinder, carrying out normal temperature mixing grinding at a rotating speed of 500-1000rpm for 6-9h, and carrying out spray drying to obtain the 3D printing inorganic powder molding material. The 3D printing inorganic powder molding material can be directly molded at a temperature of 190-210DEG C under a pressure of 1-10MPa without sprinkling a binder, and has the advantages of simple preparation technology, easy condition control, low production cost and easy industrialized production.

Owner:UNIV OF JINAN

High precision rare earth polishing powder and preparation thereof

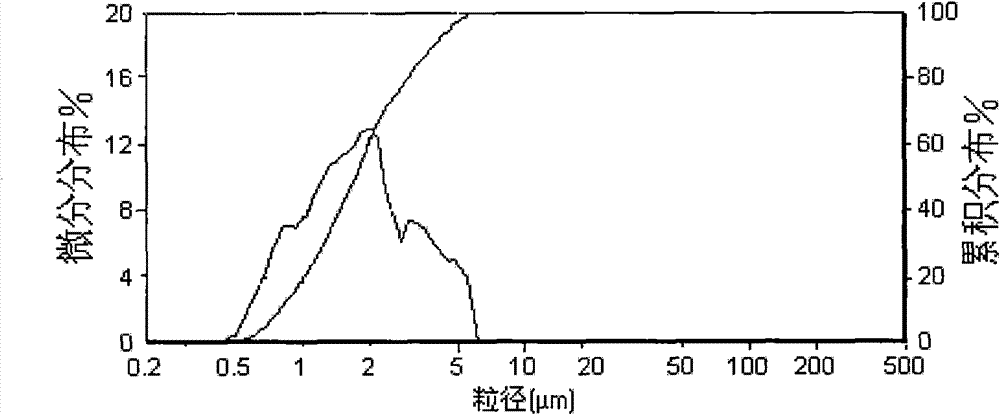

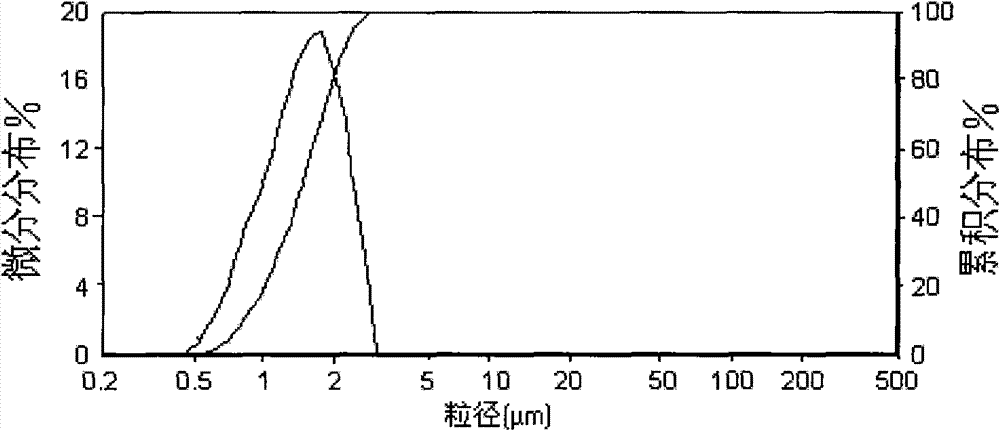

ActiveCN101475777AEasy to control abrasion resistanceImprove control stabilityOther chemical processesPolishing compositions with abrasivesCerium oxalateGranularity

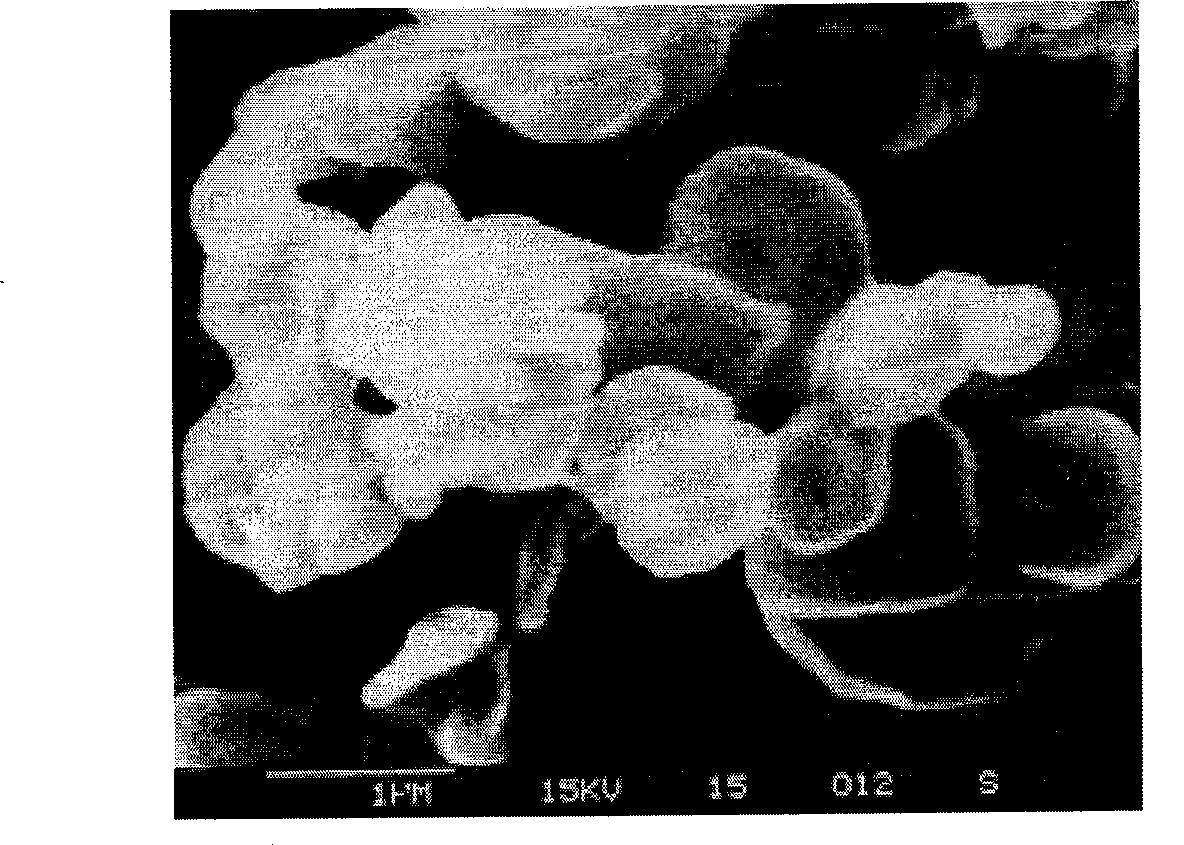

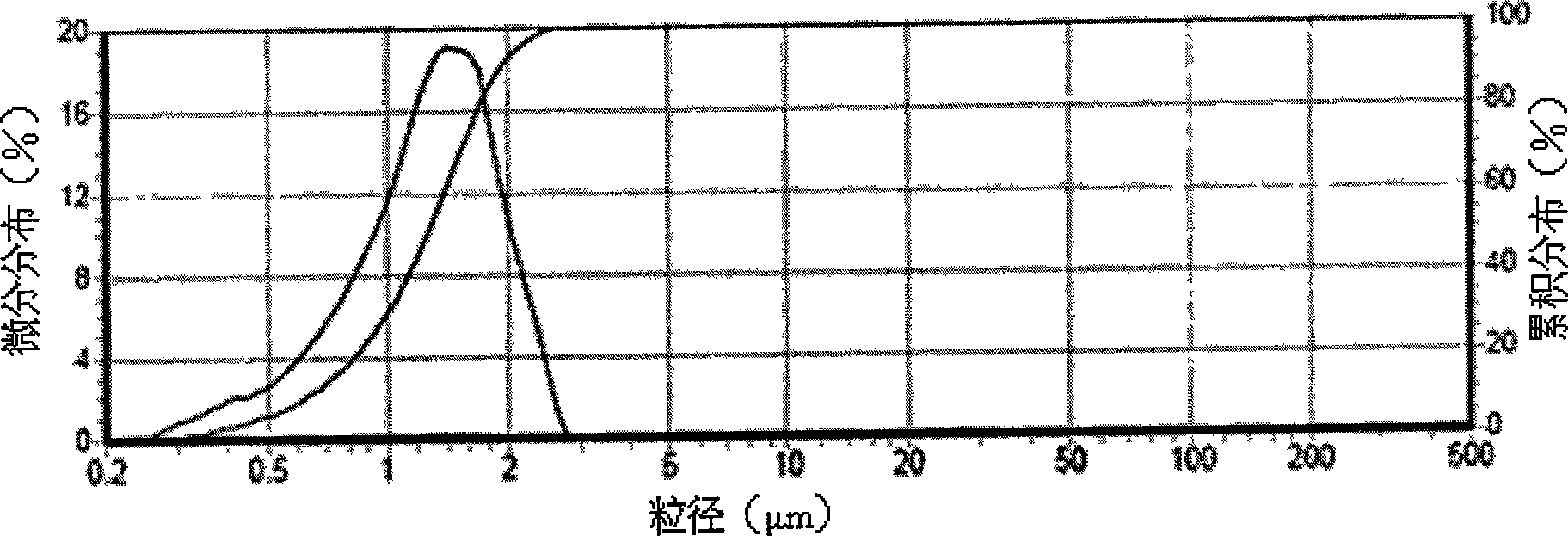

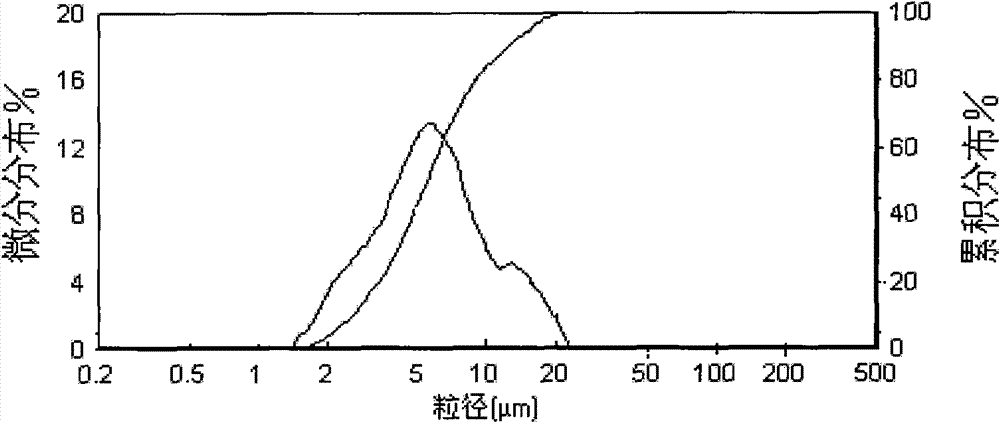

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

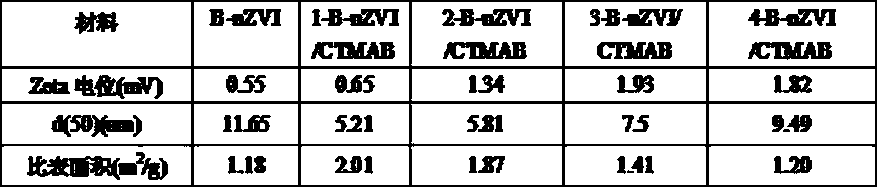

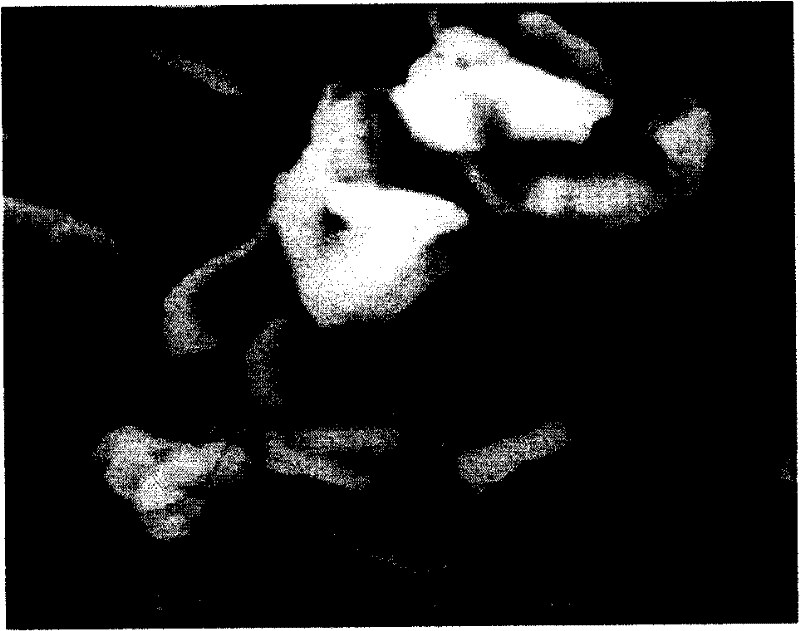

Modified bentonite load nanometer iron material and preparation method thereof

InactiveCN103464091AImprove adsorption capacityStrong positiveOther chemical processesWater/sewage treatment by sorptionIron saltsFiltration

The invention relates to a modified bentonite load nanometer iron material and a preparation method thereof. According to the technical scheme, the preparation method includes the steps of stirring bentonite and bivalent iron salt solutions to prepare the mixed liquor of the bentonite and the bivalent iron salt solutions, wherein the mass ratio between an iron element and the bentonite is 1: (1-2), then dropwise adding reducing agent solutions to the mixed liquor of the bentonite and the bivalent iron salt solutions and stirring to prepare mixed liquor containing bentonite load nanometer iron, and adding alkyl quaternary ammonium salt solutions into the mixed liquor containing the bentonite load nanometer iron and stirring, wherein the volume ratio between the mixed liquor containing the bentonite load nanometer iron and modifying agent solutions is 1: (0.15-0.20), and the steps are all carried out in a nitrogen environment; then carrying out suction filtration, drying and grinding the obtained solid in a vacuum environment to obtain the modified bentonite load nanometer iron material. The modified bentonite load nanometer iron material prepared by the preparation method has strong reducing capacity and adsorption capacity, and is suitable for removing heavy metal chromium (VI) and heavy metal arsenic (V), wherein the heavy metal chromium (VI) and the heavy metal arsenic (V) exist in water in an anionic form.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of laser sintering 3D printing rapid prototyping silicon nitride powder material

InactiveCN104744049ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusMetallurgyStearic acid

The invention discloses a preparation method of a laser sintering 3D printing rapid prototyping silicon nitride powder material. The preparation method is characterized by comprising the following steps: firstly, pretreating silicon nitride ceramic powder with gamma-methacryloxypropyltrimethoxysilane in an ethyl alcohol solvent to obtain pretreated silicon nitride ceramic powder; then, in percentage by mass, adding 75-88% of the pretreated silicon nitride ceramic powder, 5-15% of phenolic resin, 0.5-1.5% of melamine and 0.2-1.5% of glyceryl tristearate into a grinding miller, starting the grinding miller, grinding for 10min at 200r / min, and adding acetone, wherein the sum of all the components is 100%; starting the grinding miller, grinding for 30min at 200r / min, and drying, thus obtaining the laser sintering 3D printing rapid prototyping silicon nitride powder material. The material can be directly prototyped under the condition of laser sintering; the preparation process is simple, the preparation conditions are easy to control, and the production cost is low; therefore the preparation method of the laser sintering 3D printing rapid prototyping silicon nitride powder material can be easily put into industrial production.

Owner:UNIV OF JINAN

Preparation method of jade polishing powder

InactiveCN103923569APolishing friction hardness increasedSmall median diameterOther chemical processesPolishing compositions with abrasivesCeriumSlurry

The invention discloses a preparation method of jade polishing powder. The method is characterized by comprising the steps of feeding 12-26% of cerium chloride and 20-32% of zirconium oxychloride into a reactor according to the mass percent concentration, and dissolving the mixture in water; then, feeding 15-30% of aluminium oxide, 8-15% of silicon nitride, 2-6% of chromic oxide and 0.5-3% of dispersing agent into the water solution, and stirring to obtain slurry; dissolving 15-30% of ammonium oxalate into water, and then feeding the product into the slurry, wherein the sum of the content of all the components except water of the slurry is 100%; stirring under the normal pressure, heating up to 85 DEG C, and carrying out a reaction for 30-36h; then, heating up to 120 DEG C, and carrying out the reaction for 2-4h; carrying out calcination for 2-4h at the temperature of 950-1000 DEG C, cooling and crushing by airflow to obtain the jade polishing powder. The preparation technology is simple, easy in control of conditions, low in production cost and easy in industrial production. When being used for the polishing process, the polishing powder is good in powder polishing effect, high in glossiness, free from scratch, high in flatness and less in power dosage.

Owner:UNIV OF JINAN

High precision rare earth polishing powder and preparation thereof

ActiveCN101475777BImprove control stabilitySmall median diameterOther chemical processesPolishing compositions with abrasivesCerium oxalateRare earth

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

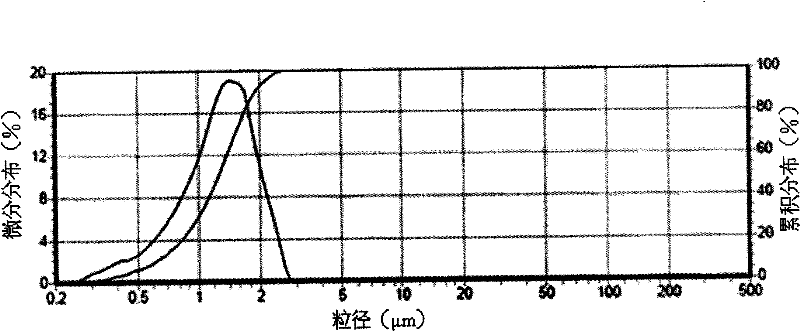

High accuracy aluminum oxide polishing powder and production method thereof

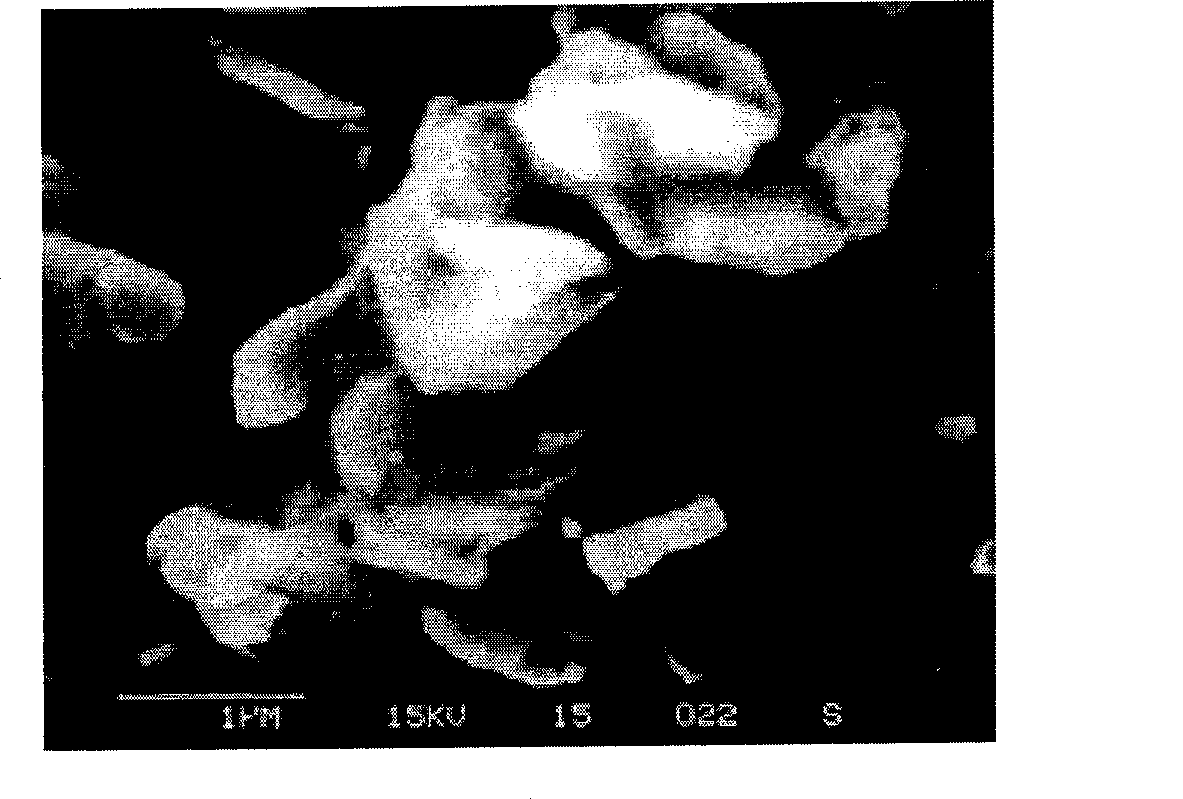

InactiveCN101824279AHigh polishing precisionSmall median diameterPolishing compositions with abrasivesAluminium oxides/hydroxidesLiquid-crystal displayGranularity

The invention discloses an aluminum oxide polishing powder and a production method thereof. The aluminum oxide polishing powder is characterized in that a D50 particle size is smaller than 2.0 microns and satisfies that D10 is no less than 0.5 times of D50, D90 is no more than 2 times of D50 and D100 is no less than 3 times of D50. The preparation method comprises the following steps of pulping raw materials of alpha-aluminum oxide with water, carrying out classification and obtaining a product. The aluminum oxide polishing powder has the advantages of small median particle diameter, narrow granularity distribution range, easy control of the polishing accuracy stability and small fluctuation of the product quality, can be used for accurate polishing processing of electronic product components including glasses for liquid crystal display screens, flat plane displays, optical elements, ultrathin glass substrates and glass magnetic discs and can also be used for preparing aluminum oxide polishing solution for polishing chemical machinery.

Owner:SHANGHAI GONA POWDER TECH

Preparation method for nano-silicon nitride powder for laser sintering 3D printing technology

InactiveCN104788102ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusSolventSilicon nitride

The invention discloses a preparation method for a nano-silicon nitride powder for the laser sintering 3D printing technology. The preparation method is characterized by comprising the following steps: firstly, using gamma-glycidoxypropyl trimethoxysilane for the pretreatment of nano-silicon nitride powder in an ethanol solvent to obtain pretreated nano-silicon nitride powder; then, adding the following components by mass percentage into a grinding machine to obtain a mixture I: 84%-90% of pretreated nano-silicon nitride powder, 3%-8% of epoxy resin and 0.4%-1.0% of pyromellitic dianhydride, starting the grinding machine, grinding the mixture I at a revolution speed of 300 rpm for 5 min, and then adding 5%-10% of acetone to obtain a mixture II, turning on the grinding machine, grinding the mixture II at a revolution speed of 300 rpm for 30-40 min, and drying the grinded mixture II to obtain the nano-silicon nitride powder for laser sintering 3D printing technology. The nano-silicon nitride powder for the laser sintering 3D printing technology can be molded directly under laser sintering, is simple in preparation process, low in production cost, and easy to realize industrial production, and the condition is easy to control.

Owner:UNIV OF JINAN

Preparation method of rare earth-doped silicon carbide composite polishing powder

InactiveCN103923570APolishing friction hardness increasedSmall median diameterPolishing compositions with abrasivesNitrateRare earth

The invention discloses a preparation method of rare earth-doped silicon carbide composite polishing powder. The method is characterized by comprising the steps of feeding 45-70% of cerous nitrate according to the mass percent concentration, and dissolving into water, then respectively feeding 8-20% of aluminium oxide, 5-15% of silicon carbide and 0.5-1% of dispersing agent, and stirring to obtain slurry; then feeding 14-25% of oxalic acid into the slurry, stirring and dissolving, wherein the sum of the content of all the components except water of the slurry is 100%; stirring under the normal pressure, heating up to 80-90 DEG C, and carrying out a reaction for 2-6h at the temperature of 800-1000 DEG C; cooling and crushing by airflow to obtain the rare earth-doped silicon carbide composite polishing powder. The preparation technology is simple, easy in control of conditions, low in production cost and easy in industrial production. When being used for stone polishing process, the polishing powder is good in powder polishing effect, high in glossiness, less scratch, high in flatness and less in power dosage.

Owner:UNIV OF JINAN

Preparing method for polishing powder used for polishing of zirconium dioxide ceramic

InactiveCN104694018APolishing friction hardness increasedSmall median diameterPolishing compositions with abrasivesNitrateMicrometer

The invention discloses a preparing method for polishing powder used for polishing of zirconium dioxide ceramic. The preparing method is characterized by comprising the following technological steps: 6%-12% by mass of ceros nitrate is added in a reactor, 22%-32% by mass of stannic chloride is dissolved into water, 6%-13% by mass of calcium carbonate, 3%-7% by mass of silicon dioxide, 38%-48% by mass of silicon nitride are further added, stirring is carried out, seriflux is formed, 3%-10% by mass of ammonium hydroxide is further added during the stirring process, and the sum of the percents, except water, is 100%. Under the normal pressure and temperature, stirring reaction is carried out for 2-4 h, solid-liquid separation is carried out, washing is carried out, calcinations is carried out for 10-12h at the temperature ranging from 1000 DEG C to 1100 DEG C, after cooling is carried out, smashing is carried out through airflow, the polishing powder of the zirconium dioxide ceramic is obtained, and the particle size of the obtained polishing powder of the zirconium dioxide ceramic ranges from 0.2 to 2.0 micrometers. The polishing powder has the advantages of being high in grinding rigidity, good in powder polishing effect, high in glossiness, free of scratch, high in flatness, and low in powdery usage amount.

Owner:UNIV OF JINAN

Preparation method of granite polishing powder

InactiveCN103937412ASmall median diameterNarrow particle size distributionPolishing compositions with abrasivesPlane surface grinding machinesAmmonium carbonateSlurry

The invention discloses a preparation method of granite polishing powder. The method is characterized in that the method comprises the following steps: dissolving 3-12% by mass of ammonium dichromate and 6-18% of zirconium oxychloride in water, adding 50-70% of alumina, adding 2-10% of titanium dioxide, adding 0.5-1% of a surfactant, stirring to form a slurry, adding 10-20% of ammonium carbonate, stirring for dissolving, stirring under normal pressure, heating to 70-75DEG C, reacting for 20-30h, evaporate to dryness, heating to 190-195DEG C, reacting for 2-4h, roasting at 1000-1100DEG C for 1-2h, cooling, and carrying out air flow crushing to obtain the granite polishing powder. The preparation method has the advantages of simplicity, easy condition control, low production cost, and easy industrialized production. The granite polishing powder is used for the granite polishing process, and has the advantages of good polishing effect, glossiness, small scratch quantity, high flatness, and small amount.

Owner:UNIV OF JINAN

Preparation method of jade polishing powder

InactiveCN103923569BPolishing friction hardness increasedSmall median diameterOther chemical processesPolishing compositions with abrasivesCeriumSlurry

The invention discloses a preparation method of jade polishing powder. The method is characterized by comprising the steps of feeding 12-26% of cerium chloride and 20-32% of zirconium oxychloride into a reactor according to the mass percent concentration, and dissolving the mixture in water; then, feeding 15-30% of aluminium oxide, 8-15% of silicon nitride, 2-6% of chromic oxide and 0.5-3% of dispersing agent into the water solution, and stirring to obtain slurry; dissolving 15-30% of ammonium oxalate into water, and then feeding the product into the slurry, wherein the sum of the content of all the components except water of the slurry is 100%; stirring under the normal pressure, heating up to 85 DEG C, and carrying out a reaction for 30-36h; then, heating up to 120 DEG C, and carrying out the reaction for 2-4h; carrying out calcination for 2-4h at the temperature of 950-1000 DEG C, cooling and crushing by airflow to obtain the jade polishing powder. The preparation technology is simple, easy in control of conditions, low in production cost and easy in industrial production. When being used for the polishing process, the polishing powder is good in powder polishing effect, high in glossiness, free from scratch, high in flatness and less in power dosage.

Owner:UNIV OF JINAN

Preparation of silicon nitride ceramic powder through laser sintering and rapid moulding

InactiveCN104944962ASmall median diameterNarrow particle size distributionPolyvinyl alcoholTriethylenetetramine

The invention discloses a preparation method of silicon nitride ceramic powder through laser sintering and rapid moulding. The method comprises the following steps: pretreating silicon nitride ceramic powder by using polyvinyl alcohol to obtain the pretreated silicon nitride ceramic powder; then in a grinder, adding the following components by mass percentage: 80-85% of pretreated silicon nitride ceramic powder, 4-8% of phenolic resin, 2-5% of polyvinyl butyral and 0.8-3% of triethylenetetramine, turning on the grinder with rotating speed being 250 rotation / min, grinding for 5 minutes, adding 7-12% of acetone, wherein sum of the components is 100%, and rotating speed of the grinder is 250 rotation / min, grinding for 40-60 minutes, and drying to obtain the silicon nitride ceramic powder. The material can be directly moulded under laser sintering, moulding precision is high, and the method has the advantages of simple preparation technology, easy control of condition, low production cost, and easy industrial production.

Owner:UNIV OF JINAN

Preparation method of polishing powder for polishing of emeralds

InactiveCN105754489APolishing friction hardness increasedSmall median diameterPolishing compositions with abrasivesChromium sesquioxideEmerald

The invention discloses a preparation method of polishing powder for polishing of emeralds. The preparation method is characterized by comprising the following process steps: adding the following components in a reactor in mass percentage concentration: 2-8% of beryllium oxide, 86-92% of a compound and 5-10% of talcum powder, wherein the sum of the components is 100%; starting a grinder to grind the components at a revolving speed of 500 revolutions per minute for 60-100 minutes so as to obtain agate polishing powder, wherein the particle size of the polishing powder is 1.0-5.0 microns, and the compound contains boron nitride, chromium sesquioxide, cerium oxide and iron oxide. The preparation method is simple in process, easy for control of conditions, low in production cost and easy for industrial production. The polishing process is good in powder polishing effect and glossiness, free of scratches, high in flatness and low in powder dosage.

Owner:UNIV OF JINAN

Preparation method of 3D printing zirconium dioxide powder moulding material

InactiveCN104725039ASmall median diameterNarrow particle size distributionAdditive manufacturing apparatusRoom temperatureSolvent

The invention discloses a preparation method of a 3D printing zirconium dioxide powder moulding material. The preparation method of the 3D printing zirconium dioxide powder moulding material is characterized by comprising the following steps: carrying out pre-treatment on zirconium dioxide powder in an ethanol solvent by adopting allyl trimethoxy silicane, so that pretreated zirconium dioxide powder is obtained; then adding 60-72% by mass of petroleum ether and 3-8% by mass of polyethylene into a reactor, heating, stirring, dissolving, and then adding 20-30% by mass of pretreated zirconium dioxide powder and 1-4% by mass of azodiisobutyronitrile, wherein the sum of the percents by mass of all the components is one hundred percent; heating while stirring until the temperature is increased to 80+ / -5 DEG C, carrying out constant temperature refluxing reaction for 6-8 hours, cooling to room temperature, and then carrying out spray drying, so that the 3D printing zirconium dioxide powder moulding material is obtained. The 3D printing zirconium dioxide powder moulding material can be directly moulded without spraying a binding agent in a range that the temperature is increased to 125-137 DEG C by heating and has the advantages that a preparation technology is simple, conditions are easy to control, production cost is low, and industrial production can be easily realized.

Owner:UNIV OF JINAN

Preparation method of marble composite polishing powder

InactiveCN102925060BFine and uniform particlesSmall median diameterOther chemical processesPolishing compositions with abrasivesSlurryZirconium oxychloride

The invention discloses a preparation method of marble composite polishing powder and application of the preparation method in a polishing process of marble production and refurbishment. The method comprises dissolving 5%-18% of zirconium oxychloride in water, adding 50%-65% of aluminum oxide, adding 10%-22% of stannic oxide, adding 2%-8% of silicon dioxide, stirring to be slurry, adding 10%-25% of urea, conducting heating reaction, solid-liquid separation, drying and roasting, mixing with lead powder according to the proportion of 10-25:1, and then obtaining the marble composite polishing powder. The preparation process is simple, preparation methods are easy to control, production cost is low, and industrial production is easy to achieve. The preparation method is used for a marble polishing procedure, the marble composite polishing powder has good polishing effects, glossiness can achieve more than 98 degrees, scratches are fewer, evenness is high, and using amount of the powder is less.

Owner:UNIV OF JINAN

High accuracy aluminum oxide polishing powder and production method thereof

InactiveCN101824279BHigh polishing precisionSmall median diameterPolishing compositions with abrasivesAluminium oxides/hydroxidesLiquid-crystal displayGranularity

The invention discloses an aluminum oxide polishing powder and a production method thereof. The aluminum oxide polishing powder is characterized in that a D50 particle size is smaller than 2.0 microns and satisfies that D10 is no less than 0.5 times of D50, D90 is no more than 2 times of D50 and D100 is no less than 3 times of D50. The preparation method comprises the following steps of pulping raw materials of alpha-aluminum oxide with water, carrying out classification and obtaining a product. The aluminum oxide polishing powder has the advantages of small median particle diameter, narrow granularity distribution range, easy control of the polishing accuracy stability and small fluctuation of the product quality, can be used for accurate polishing processing of electronic product components including glasses for liquid crystal display screens, flat plane displays, optical elements, ultrathin glass substrates and glass magnetic discs and can also be used for preparing aluminum oxide polishing solution for polishing chemical machinery.

Owner:SHANGHAI GONA POWDER TECH

A preparation method of 3D printing rapid prototyping inorganic powder material

InactiveCN104310948BEasy to operateSmall median diameterClaywaresVinyltriethoxysilaneRoom temperature

The invention discloses a preparation method of 3D printing rapid prototyping inorganic powder material, which is characterized in that the method comprises: adding vinyltriethoxysilane: 8% to 22% in a grinding machine according to the mass percentage concentration, Add inorganic powder materials: 78%~92%, turn on the grinder at 200 rpm, grind at room temperature for 4~6? h, to obtain the pretreated inorganic powder material; then in the grinder, add the pretreated inorganic powder material according to the mass percentage concentration: 85%~96%, add EVA hot melt adhesive powder: 4%~15%, and turn on the grinder speed At 200 rpm, grind 4~6 at room temperature? h, The obtained 3D printing rapid prototyping inorganic powder material. The preparation process is simple, the conditions are easy to control, the production cost is low, and the industrial production is easy. The material does not need to be sprayed with adhesive, and can be directly formed by heating at 140-180°C and pressure within the range of 2MPa-6MPa, and the forming operation is simple.

Owner:UNIV OF JINAN

Preparation method for regenerating rear-earth polishing powder

InactiveCN103215012BReduce dosageReduce pollutionOther chemical processesPolishing compositions with abrasivesAqueous solutionAmmonium

The invention discloses a preparation method for regenerating rear-earth polishing powder. The preparation method comprises the following processes: (1) mixing the waste rear-earth polishing powder and adopting a shaker reselecting device for reselecting and separating to obtain heavy constituents; (2) treating the reselected rear-earth polishing powder by 2%-25% (in percentage by weight) of ammonium fluozirconate aqueous solution; heating up to 50 DEG C to 75 DEG C; stirring and reacting for 6-12 hours; and settling, cleaning and filtering to recycle solid; and (3) preparing regenerated rear-earth polishing powder, wherein the primarily generated rear-earth polishing powder is primarily dried, roasted for 3-10 hours at 1000 DEG C to 1100 DEG C, cooled, crushed by gas flow to obtain the regenerated rear-earth polishing powder which can reach a grain size range for being reused as the polishing powder. The preparation method for regenerating rear-earth polishing powder has the advantages of being less in using amount of chemical substances, simple in process, easy to control conditions, low in production cost, easy to realize industrial production, high in recovery rate, good in powder polishing effect and the like.

Owner:UNIV OF JINAN

Preparation method of marble polishing powder

InactiveCN107446506AComplementary soft and hard, good fluidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOxalateChemical reaction

The invention discloses a preparation method of marble polishing powder. The method is characterized by comprising the following process steps of adding the following ingredients in percentage concentration by mass into a grinding machine: 47 to 53 percent of oxalate dihydrate, 12 to 15 percent of aluminum oxide and 5 to 10 percent of stannic oxide; performing grinding and uniform mixing; adding 6 to 10 percent of sodium binoxalate and 15 to 21 percent of stearic acid; performing grinding and uniform mixing; then adding 2 to 4 percent of paraffin powder and 0.3 to 1.0 percent of fatty alcohol polyoxy ether, wherein the sum of all ingredients is hundred percent; performing grinding and uniform mixing; obtaining the marble polishing powder with the particle diameter being 2.0 to 10 mu m. The polishing powder has the advantages that chemical reaction is taken between the polishing powder and marble in the polishing process; the chemical polishing characteristics are realized, so that the polishing effect of the polishing powder is good; the luster degree is high; scratch marks are few; the flatness and smoothness degree is high; the consumption is low; the corrosion of oxalic acid can be buffered through the addition of the sodium binoxalate.

Owner:UNIV OF JINAN

Method for preparing blue marble polishing powder

InactiveCN107474745AImprove liquidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOxalateRoom temperature

The invention discloses a method for preparing blue marble polishing powder. The method is characterized by comprising the following steps: (1) preparing an AlN-ZrO2 complex, namely adding the following components: 40-60% of water, 20-26% of zirconium oxychloride, 30-36% of nano aluminum nitride and 1-5% of sodium hydroxide, stirring and reacting at a room temperature for 30 minutes, performing solid-liquid separation, drying at the temperature of 105+ / -2 DEG C, roasting at the temperature of 550+ / -10 DEG C for 2 hours, cooling, and performing air jet milling so as to prepare the AlN-ZrO2 complex; and (2) adding the following components into a grinder: 40-45% of oxalate dehydrate, 18-22% of the AlN-ZrO2 complex and 4-8% of cupric oxalate, grinding, uniformly mixing, adding 8-12% of ammonium binoxalate and 18-24% of stearic acid, grinding, uniformly mixing, adding 0.3-1.0%of a nonionic surfactant, uniformly mixing, thereby obtaining the blue marble polishing powder. The polishing powder has the chemical polishing characteristic. Therefore, the polishing powder is excellent in polishing effect, high in glossiness, less in scratch, high in flatness and small in usage amount.

Owner:UNIV OF JINAN

A kind of preparation method of polishing powder for onyx polishing

InactiveCN105754490BPolishing friction hardness increasedSmall median diameterPolishing compositions with abrasivesIron oxideNitride

The invention discloses a method for preparing polishing powder for onyx polishing, which is characterized in that the method has the following process steps: in the reactor, add according to the following composition mass percentage concentration, lead powder: 5-8% , compound: 80~88%, tin oxide: 5~13%, the sum of each component is 100%, turn on the grinder, grind at a speed of 500 rpm for 30~60min, and obtain agate polishing powder, in which the compound Contains nano aluminum nitride, aluminum oxide, zirconium oxide, iron oxide, cobalt oxide. The preparation process is simple, the conditions are easy to control, the production cost is low, and the industrial production is easy. In the polishing process, it has good powder polishing effect, high gloss, no scratches, high flatness, and less powder consumption.

Owner:UNIV OF JINAN

Preparation method of polishing powder for polishing water grindstone

InactiveCN107446508ASmall median diameterNarrow particle size distributionPolishing compositions with abrasivesROSIN POWDEROxalate

The invention discloses a preparation method of polishing powder for polishing a water grindstone. The preparation method is characterized in that a Cr2O3-Fe2O3-SnO2 compound is used as a grinding material, oxalic acid is used as an acidic polishing agent, and additives including a dispersant, a surfactant and the like are added to prepare the polishing powder. The specific preparation method comprises the following steps: in a grinding machine, adding the following components according to the following mass percent concentration: 10 percent to 15 percent of the Cr2O3-Fe2O3-SnO2 compound, 50 percent to 55 percent of oxalic acid dihydrate and 15 percent to 20 percent of ammonium bioxalate; grinding the materials and uniformly mixing; adding 4 percent to 8 percent of rosin powder and 6 percent to 12 percent of stearic acid, and grinding and uniformly mixing; adding 1.0 percent to 3.0 percent of a non-ionic surfactant, wherein the sum of all the components is 100 percent; grinding and uniformly mixing to prepare the water grindstone polishing powder. The polishing powder disclosed by the invention has a good polishing effect, high glossiness, fewer scratches, high flatness and a small dosage; the ammonium bioxalate is added so that the corrosion performance of the oxalic acid can be buffered.

Owner:UNIV OF JINAN

Preparation of a laser sintering 3D printing rapid prototyping alumina powder

InactiveCN104908143BImprove absorption efficiencyNo splashAdditive manufacturing apparatusCeramic shaping apparatusMetallurgyEthyl acetate

Owner:UNIV OF JINAN

A kind of preparation method of aluminum oxide powder 3D printing material

InactiveCN104788081BPrevent splashSmall median diameterAdditive manufacturing apparatusEpoxyAdhesive cement

The invention discloses a preparation method of an aluminum oxide powder 3D printing material. The preparation method is characterized by comprising the following steps: adopting a sodium hexametaphosphate aqueous solution to pretreat the aluminum oxide powder, and obtaining the pretreated aluminum oxide powder; adding the following constituents into a grinding miller according to mass percent: 80-87% of aluminum oxide powder, 2-6% of photosensitive epoxy resin, 1-3% of petroleum resin and 0.5-3% of hydroxylamine hydrochloride; starting the grinding miller, keeping the revolving speed to be 400 rpm, grinding for 5 minutes, and then adding 8-15% of acetone, wherein the sum of the constituents in mass percent is 100%; keeping the revolving speed of the grinding miller to be 400 rpm, then grinding for 20-30 minutes, drying, and at last obtaining the aluminum oxide powder 3D printing material. The material can be directly molded instead of being sprayed with an adhesive substance under a laser sintering condition, is high in molding precision, simple in preparation process, easy to control conditions, low in production cost, and easy for industrial production.

Owner:UNIV OF JINAN

Preparation of nano silicon nitride powder for laser sintering 3D printing technology

InactiveCN104788102BSmall median diameterNarrow particle size distributionAdditive manufacturing apparatusNano siliconEpoxy

The invention discloses a preparation method of nano-silicon nitride powder for laser sintering 3D printing technology. Pretreatment to obtain pretreated nano-silicon nitride powder; then, in the grinder, add according to the mass percentage, pre-treated nano-silicon nitride powder: 84%~90%, epoxy resin: 3%~8%, all benzene Tetraformic anhydride: 0.4%~1.0%, turn on the grinder at 300 rpm, grind for 5 minutes, then add acetone: 5%~10%, the sum of each component is 100%, turn on the grinder at 300 rpm , grind for 30-40 minutes, and dry to obtain nano-silicon nitride powder for laser sintering 3D printing technology. The material can be directly formed under laser sintering, has the advantages of simple preparation process, easy control of conditions, low production cost and easy industrial production.

Owner:UNIV OF JINAN

A kind of preparation method of 3D printing zirconia powder molding material

InactiveCN104725039BSmall median diameterNarrow particle size distributionAdditive manufacturing apparatusRoom temperaturePre treatment

The invention discloses a preparation method of a 3D printing zirconium dioxide powder moulding material. The preparation method of the 3D printing zirconium dioxide powder moulding material is characterized by comprising the following steps: carrying out pre-treatment on zirconium dioxide powder in an ethanol solvent by adopting allyl trimethoxy silicane, so that pretreated zirconium dioxide powder is obtained; then adding 60-72% by mass of petroleum ether and 3-8% by mass of polyethylene into a reactor, heating, stirring, dissolving, and then adding 20-30% by mass of pretreated zirconium dioxide powder and 1-4% by mass of azodiisobutyronitrile, wherein the sum of the percents by mass of all the components is one hundred percent; heating while stirring until the temperature is increased to 80+ / -5 DEG C, carrying out constant temperature refluxing reaction for 6-8 hours, cooling to room temperature, and then carrying out spray drying, so that the 3D printing zirconium dioxide powder moulding material is obtained. The 3D printing zirconium dioxide powder moulding material can be directly moulded without spraying a binding agent in a range that the temperature is increased to 125-137 DEG C by heating and has the advantages that a preparation technology is simple, conditions are easy to control, production cost is low, and industrial production can be easily realized.

Owner:UNIV OF JINAN

Preparation method of boron nitride composite polishing solution

InactiveCN105860855ASmall median diameterNarrow particle size distributionPolishing compositions with abrasivesAmmonium dichromateLignosulfonates

The invention discloses a preparation method of a boron nitride composite polishing solution. The preparation method is characterized in that by mass, 28-38% of water, 18-26% of ammonium dichromate, 12-20% of zirconium oxychloride and 24-32% of nano boron nitride are added to a grinding machine, the grinding machine is started, and a BN-Cr2O3-ZrO2 compound is prepared through grinding, drying and calcining; by mass, 70-78% of water, 2.0-4.0% of lignosulfonate, 3.0-5.0% of isopropyl alcohol, 1.0-5.0% of potassium bromate and 14-22% of BN-Cr2O3-ZrO2 compound are added to a reactor, a stirring reaction is conducted for 4-6 h at the rotating speed of 300 r / min, and the boron nitride composite polishing solution is obtained. The preparation process is simple, conditions are easy to control, the production cost is low, and industrial production is easy. In the polishing process, the advantages of being good in liquid polishing effect, free of scratches, high in flatness, small in dosage, resistant to abrasion and easy to wash are achieved.

Owner:UNIV OF JINAN

A preparation method of 3D printing rapid prototyping nano zirconia material

InactiveCN104291832BSmall median diameterNarrow particle size distributionCeramic shaping apparatusPolymer sciencePolymer adhesive

The invention discloses a preparation method of a rapid-prototyping nano-zirconium dioxide material for 3D printing. The invention is characterized in that the method contains the following steps: 1, nano-zirconium dioxide is pretreated by the use of 3-aminopropyltriethoxysilane; 2, tetrahydrofuran, dodecyl mercaptan methacrylate and azodiisobutyronitrile are used to synthesize a polymer adhesive; and 3, 56-72wt% of acetone is added, 21-35% of the pretreated nano-zirconium dioxide is added, 2-10% of the polymer adhesive is added, the total weight of the three components is 100%, intense agitation is carried out at room temperature, a reaction is carried out for 2-4 h, and spray drying is conducted to obtain the rapid-prototyping nano-zirconium dioxide material. The material is directly prototyped at the temperature of 120-150 DEG C and at the pressure of 2-8 MPa. The preparation method provided by the invention has advantages of simple preparation technology, easily-controlled condition and low production cost, and is easy for industrial production. Various shapes of components, thin-wall minimal parts, porcelain teeth and the like can be molded through a 3D printer.

Owner:UNIV OF JINAN

A kind of preparation method of blue marble polishing powder

InactiveCN107474745BImprove liquidityGood mechanical grinding abilityOther chemical processesPolishing compositions with abrasivesOxalateActive agent

The invention discloses a method for preparing blue marble polishing powder. The method is characterized by comprising the following steps: (1) preparing an AlN-ZrO2 complex, namely adding the following components: 40-60% of water, 20-26% of zirconium oxychloride, 30-36% of nano aluminum nitride and 1-5% of sodium hydroxide, stirring and reacting at a room temperature for 30 minutes, performing solid-liquid separation, drying at the temperature of 105+ / -2 DEG C, roasting at the temperature of 550+ / -10 DEG C for 2 hours, cooling, and performing air jet milling so as to prepare the AlN-ZrO2 complex; and (2) adding the following components into a grinder: 40-45% of oxalate dehydrate, 18-22% of the AlN-ZrO2 complex and 4-8% of cupric oxalate, grinding, uniformly mixing, adding 8-12% of ammonium binoxalate and 18-24% of stearic acid, grinding, uniformly mixing, adding 0.3-1.0%of a nonionic surfactant, uniformly mixing, thereby obtaining the blue marble polishing powder. The polishing powder has the chemical polishing characteristic. Therefore, the polishing powder is excellent in polishing effect, high in glossiness, less in scratch, high in flatness and small in usage amount.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com