High accuracy aluminum oxide polishing powder and production method thereof

An alumina polishing powder, high-precision technology, applied in alumina/aluminum hydroxide, polishing compositions containing abrasives, etc., can solve the problem of rapid separation and controlled separation results in industrialized large-scale production, gravity sedimentation separation time Long and other problems, to achieve the effect of easy control of stability, narrow particle size distribution, and small fluctuation of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

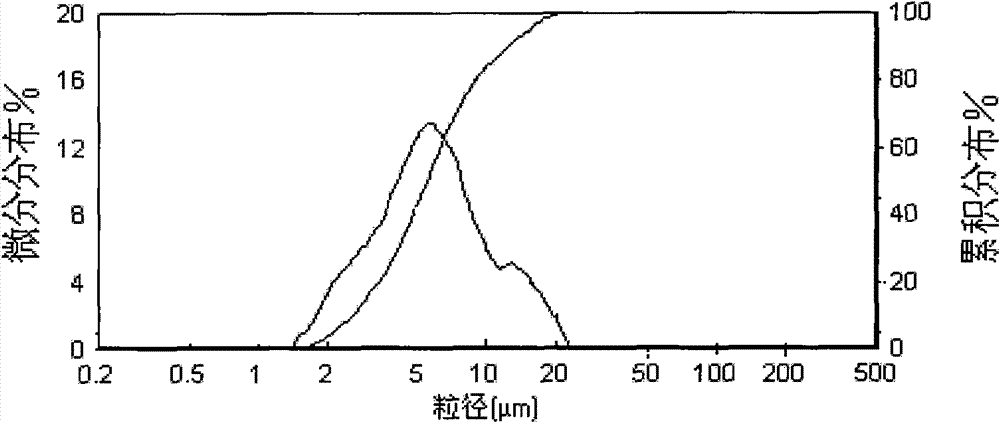

[0038] (1) Preparation of α-alumina: commercially available α-alumina A (characteristic parameters of particle size are as follows: D 10 : 2.50 μm, D 25 : 3.65 μm, D 50 : 5.42 μm, D 75 : 8.07 μm, D 90: 12.43 μm, D (3,2) : 4.64 μm, D (4,3) : 6.48μm), see figure 1 .

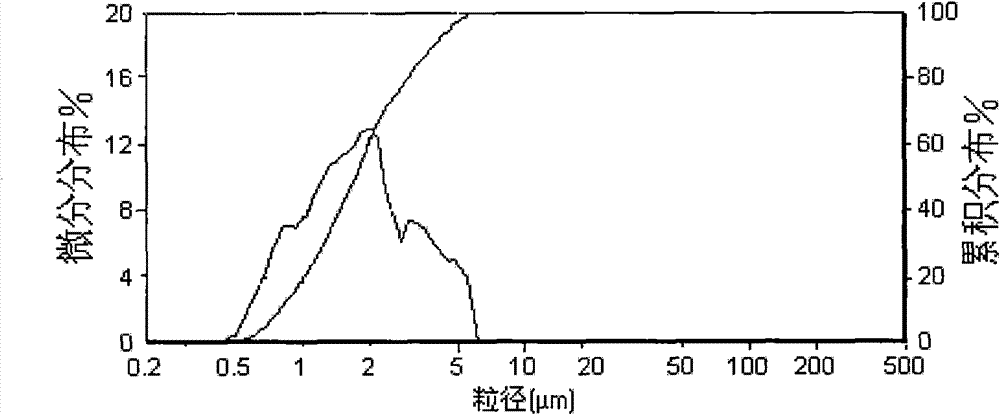

[0039] Through the OYF-400 jet mill of Shanmiyou Industrial Co., Ltd., the alumina product B suitable for grading was obtained.

[0040] The characteristic parameters of B granularity are as follows: D 10 : 0.79 μm, D 25 : 1.13 μm, D 50 : 1.71 μm, D 75 : 2.61 μm, D 90 : 3.88 μm, D (3,2) : 1.46 μm, D (4,3) : 2.02 μm. See figure 2 .

[0041] (2) Hydraulic centrifugal classification: Mix B and water to form a slurry with a weight solid content of 40%. After centrifugal classification by a DBS500 butterfly separator, slurry with different particle size distributions is obtained, and α with different particle size distributions are collected respectively. - slurries C' and slurries D' of alumina;

[0...

Embodiment 2

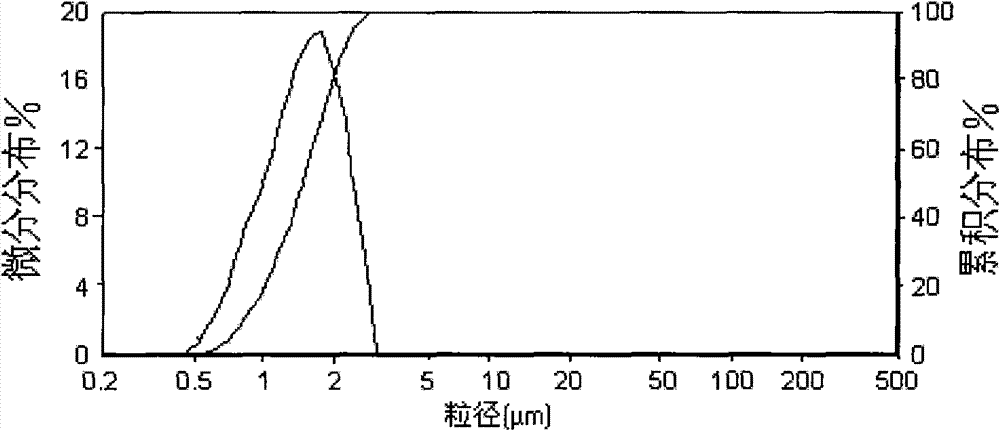

[0049] (1) Preparation of α-alumina: select commercially available α-alumina A, (characteristic parameters of particle size are as follows: D 10 : 0.70 μm, D 25 : 0.89 μm, D 50 : 1.28 μm, D 75 : 1.85 μm, D 90 : 2.55 μm, D 100 : 13.31 μm, D (3,2) : 1.17 μm, D (4,3) : 1.56 μm). Particle size distribution see Figure 5 .

[0050] (2) Hydraulic centrifugal classification: A and water are mixed and beaten to form a slurry with a weight solid content of 5%, which is repeatedly centrifugally classified by a DBS500 butterfly separator, and the slurry C containing α-alumina with different particle size distributions is collected separately ' and Serum D';

[0051] The particle size distribution of slurry C' is as follows: D 50 =1.5±0.2μm, D 10 ≥0.5D 50 , D90≤2D 50 ,D 100 ≤3D 50

[0052] The particle size distribution of the slurry D' is as follows: D 50 =0.5±0.2μm, D 10 ≥0.5D 50 , D90≤2D 50 ,D 100 ≤3D 50

[0053] (3) Drying: respectively dry the slurry C' and the...

Embodiment 3

[0056] 74.2 parts by weight of C in Example 1, 25 parts of aluminum chloride, and 0.8 parts by weight of sodium lauryl sulfate were formulated with water into a slurry with a weight solid content of 0.5%, and were sheared and dispersed for 2 hours by a shearing machine. Taking laser disc master glass CD-ROM as the polishing object, the polishing test was carried out by Unipol polishing tester (equipment pressure: 26Mpa, rotation speed 650r / min). The roughness of the polished product is No scratches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com