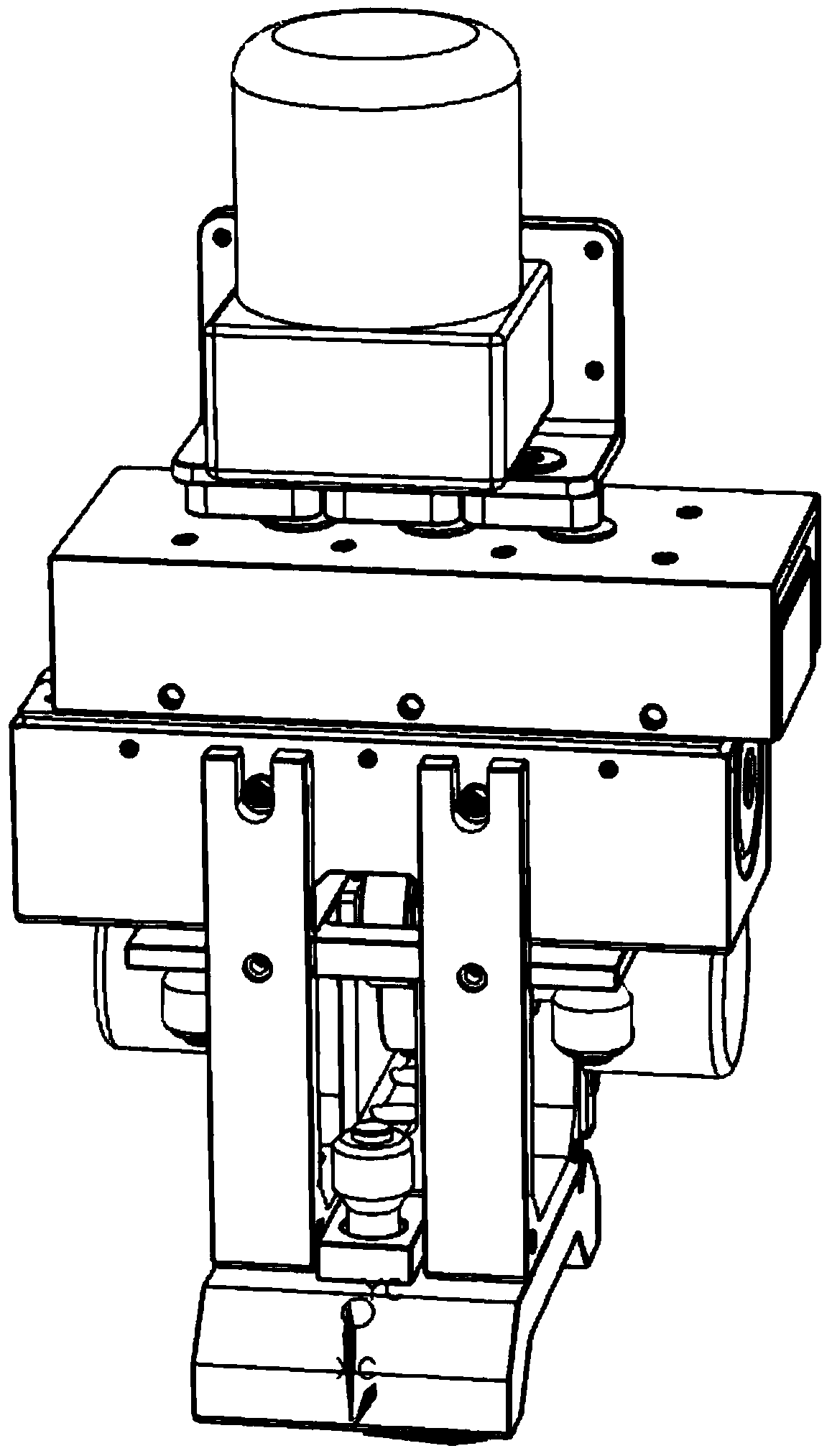

High-precision automatic polishing device

A high-precision, polishing technology, which is applied in the direction of grinding/polishing equipment, workpiece feed movement control, honing machine tools, etc., to achieve the effects of reducing full runout error and surface roughness, convenient adjustment, and high polishing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

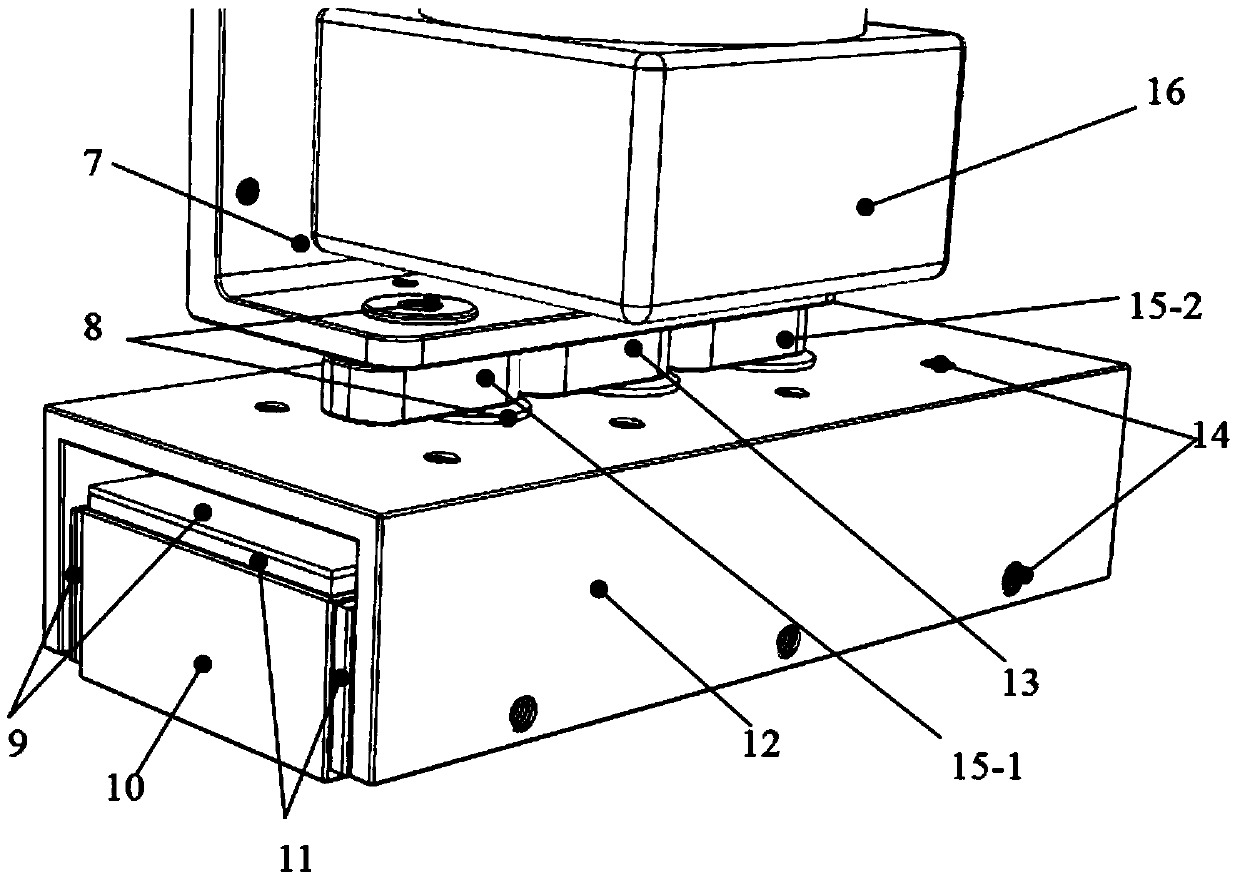

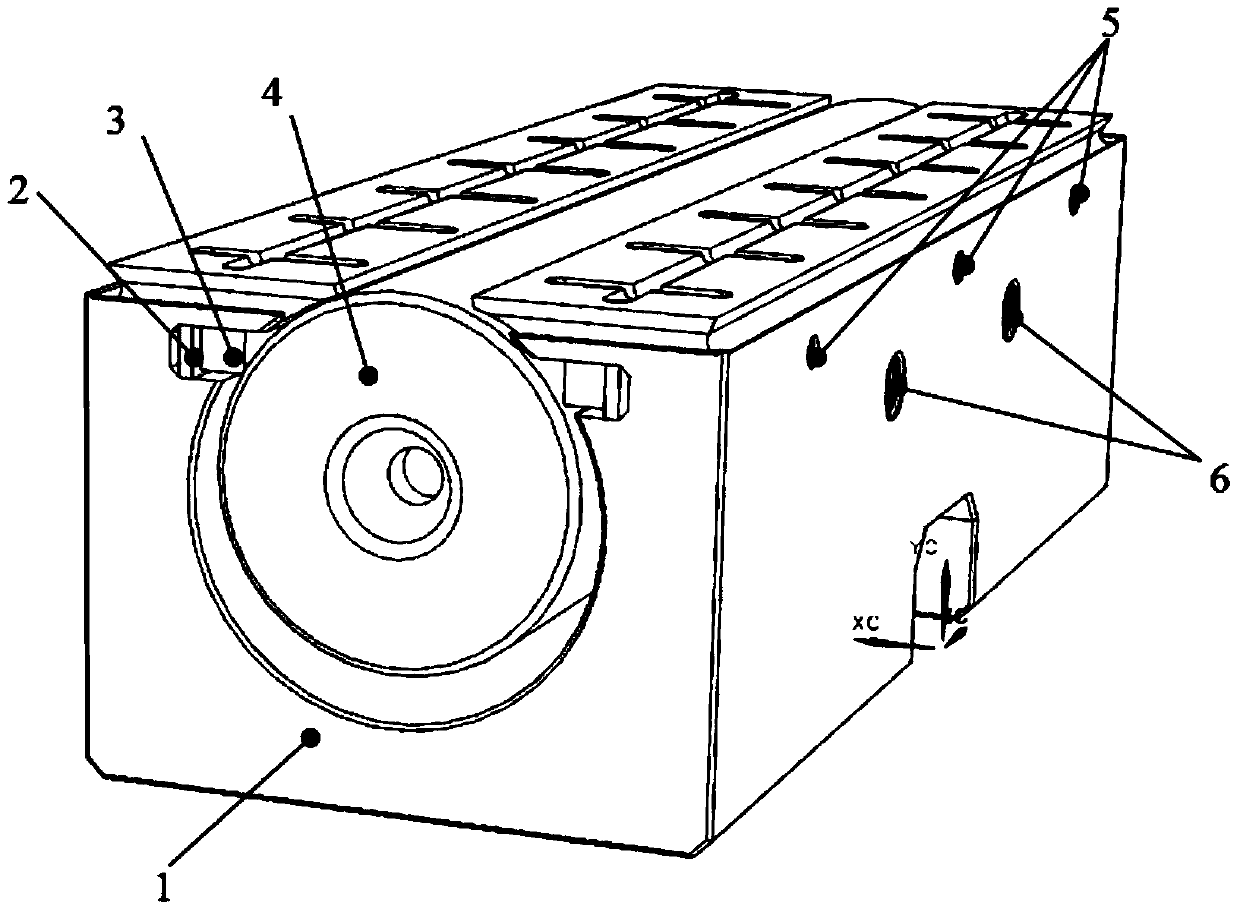

[0018] Taking the grinding and polishing of measuring cone mandrel taper 1:15000 as an example, the specific implementation of the invention is described.

[0019] The oil stone guide rail 1 and the precision oil stone for grinding are ground through three planes to obtain higher plane precision. Check the flatness of the oilstone guide rail with a long flat crystal. The direction Moiré fringes on the length of the guide rail should be close to parallel and symmetrically distributed in the width direction. Regardless of the sag area, the coverage area of two moiré fringes is not less than 50% of the total area of the guide rail and one moiré fringe is about 0.29 μm.

[0020] Firstly, the center hole of the taper mandrel 4 to be processed is repaired to improve the precision of the rotary reference. Then pass the cone mandrel into the hole of the oilstone guide rail 1, and support the cone mandrel with a 60°elastic tip. Adjust the screw A21 on the bearing seat to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com