Multi-angle automatic polishing system and polishing method

An automatic polishing, multi-angle technology, applied in the field of polishing, can solve the problems of poor polishing environment, poor polishing cleanliness, low labor intensity, etc., and achieve the effect of good polishing effect, accurate polishing and reduction of manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

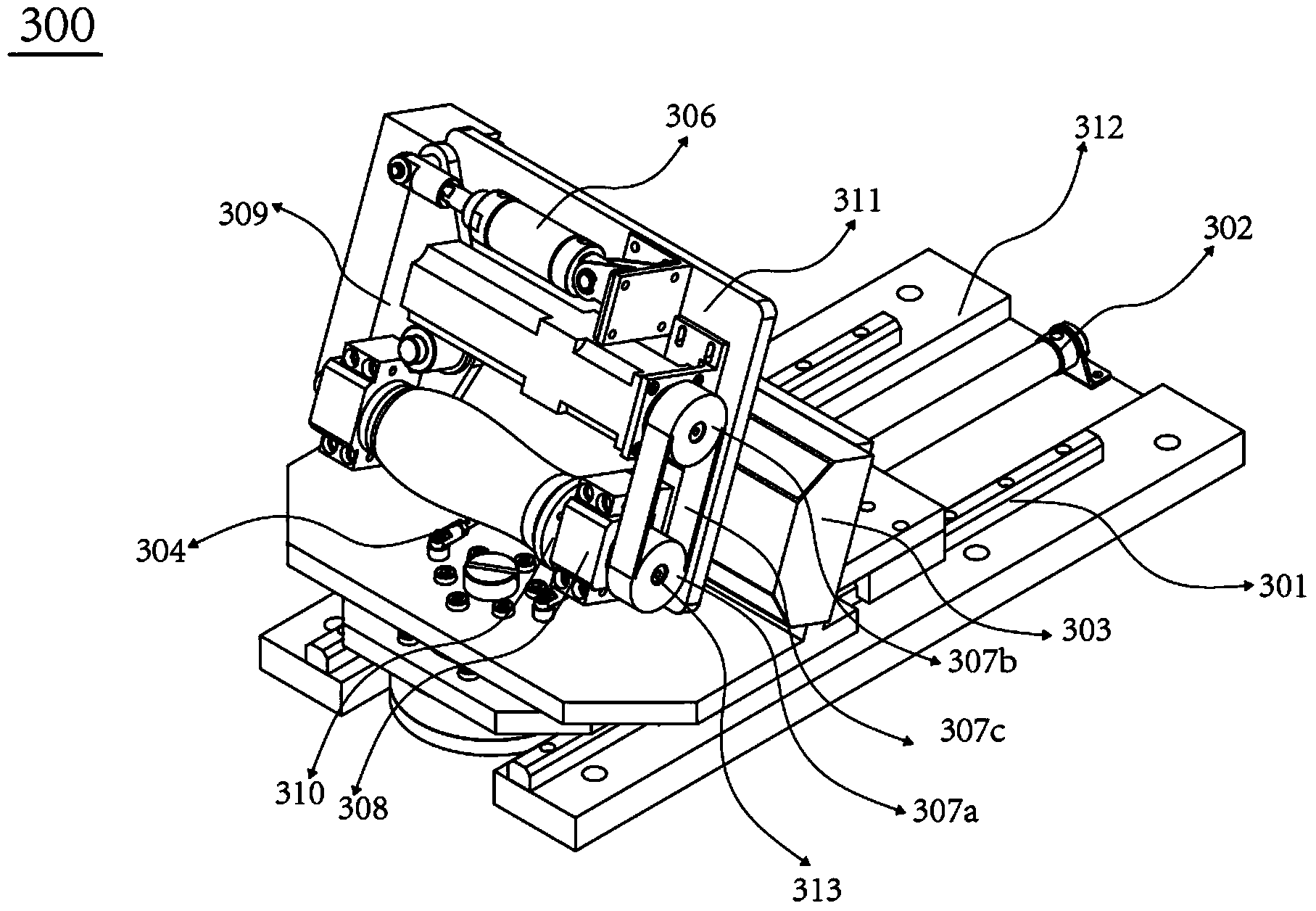

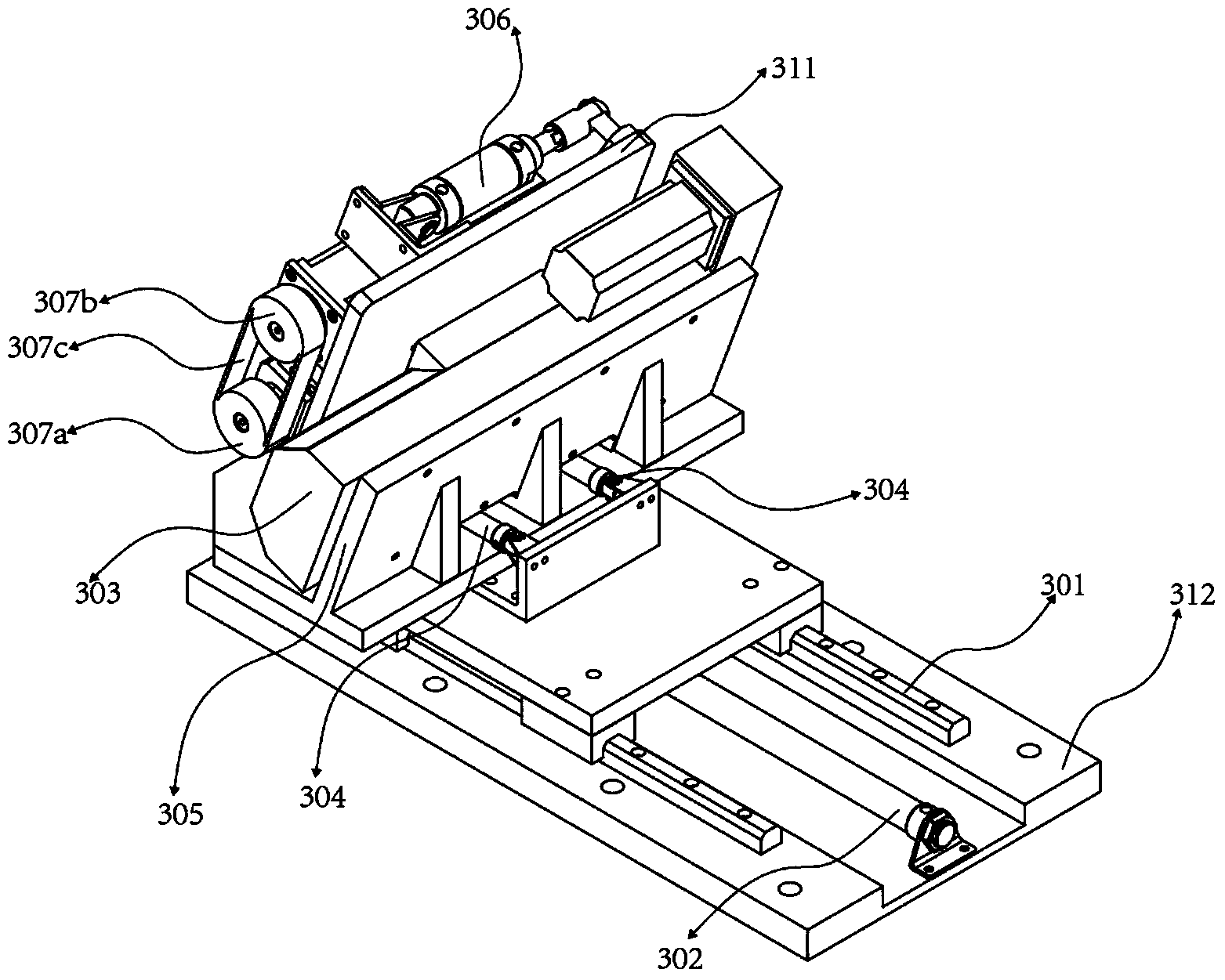

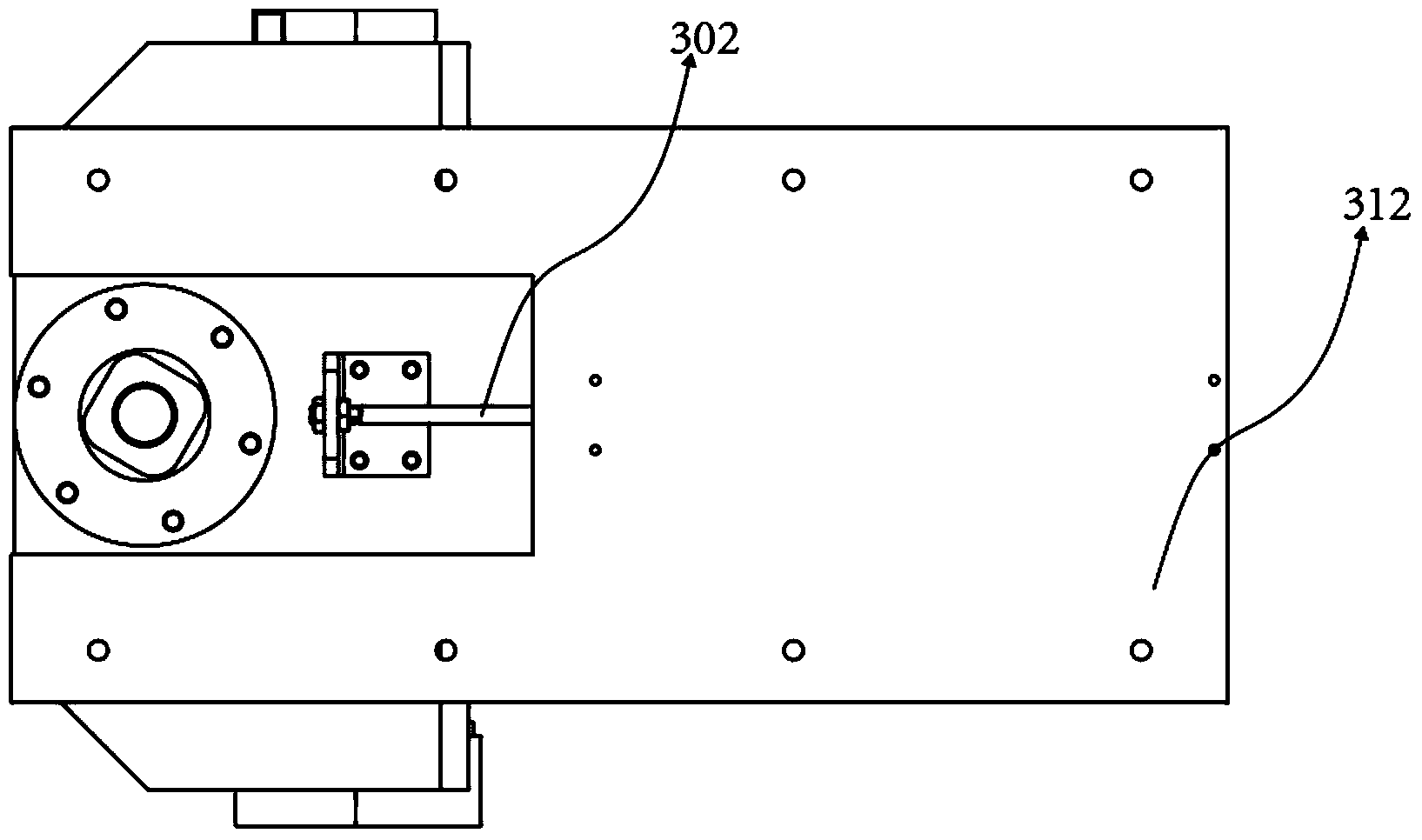

[0057] A multi-angle automatic polishing system includes a workbench 201, a clamping device 300, a polishing device, an automatic feeding system, an automatic receiving system and a control device; the plane on which the upper surface of the workbench 201 is located is in a horizontal state.

[0058] see Figure 1-Figure 4 , the clamping device has 300 hinged plates 305, a clamping part for clamping materials, a lateral drive device 302 for driving the clamping part to move laterally (horizontal plane) along the plane where the workbench 201 is located, driving the clamping A translational drive device 303 for translational movement of the holding part along the plane where the workbench 201 is located, and a rotation drive device for driving the clamping part to rotate laterally along the plane where the workbench 201 is located (horizontal plane direction);

[0059] In this embodiment, preferably, the clamping component has a bottom plate 311 , a first locking portion 308 an...

Embodiment 2

[0091] This embodiment relates to a rotary multi-angle automatic polishing system. On the basis of Embodiment 1, the clamping device 300 of this embodiment is different from that of Embodiment 1.

[0092] see Figure 11-Figure 19 , the clamping device 300 has a clamping part hinged to the workbench 201 through a rotating shaft 700, and a propulsion driving device 701 that drives the clamping part to rotate toward the polishing part along a plane perpendicular to the rotating shaft 700 . A translation drive device 303 that drives the clamping component to reciprocate along the axial direction of the rotating shaft 700 ; the control device is connected to the propulsion drive device 701 .

[0093]The clamping part has a bottom plate 311, a first clamping part 308 and a clamping plate 309; the clamping plate 309 is hinged to the bottom plate 311, and the clamping device 300 also has the function of driving the clamping plate 309 along the The second clamping driving device that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com