Three-stage hydrator for preparing hydrated lime

The technology of digester and slaked lime is applied in the field of slaked lime production and manufacturing equipment to achieve the effects of stable product quality, high output and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

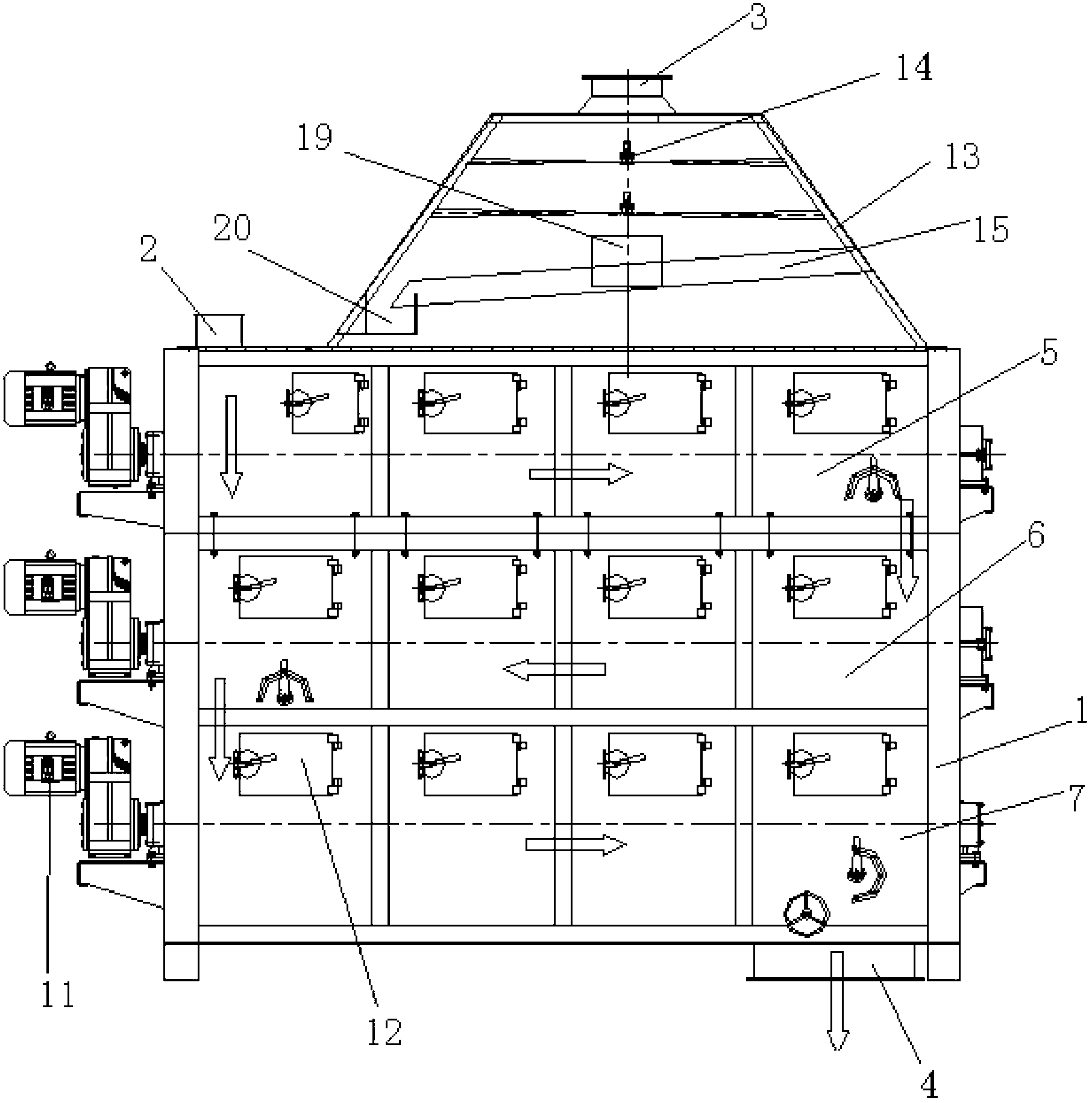

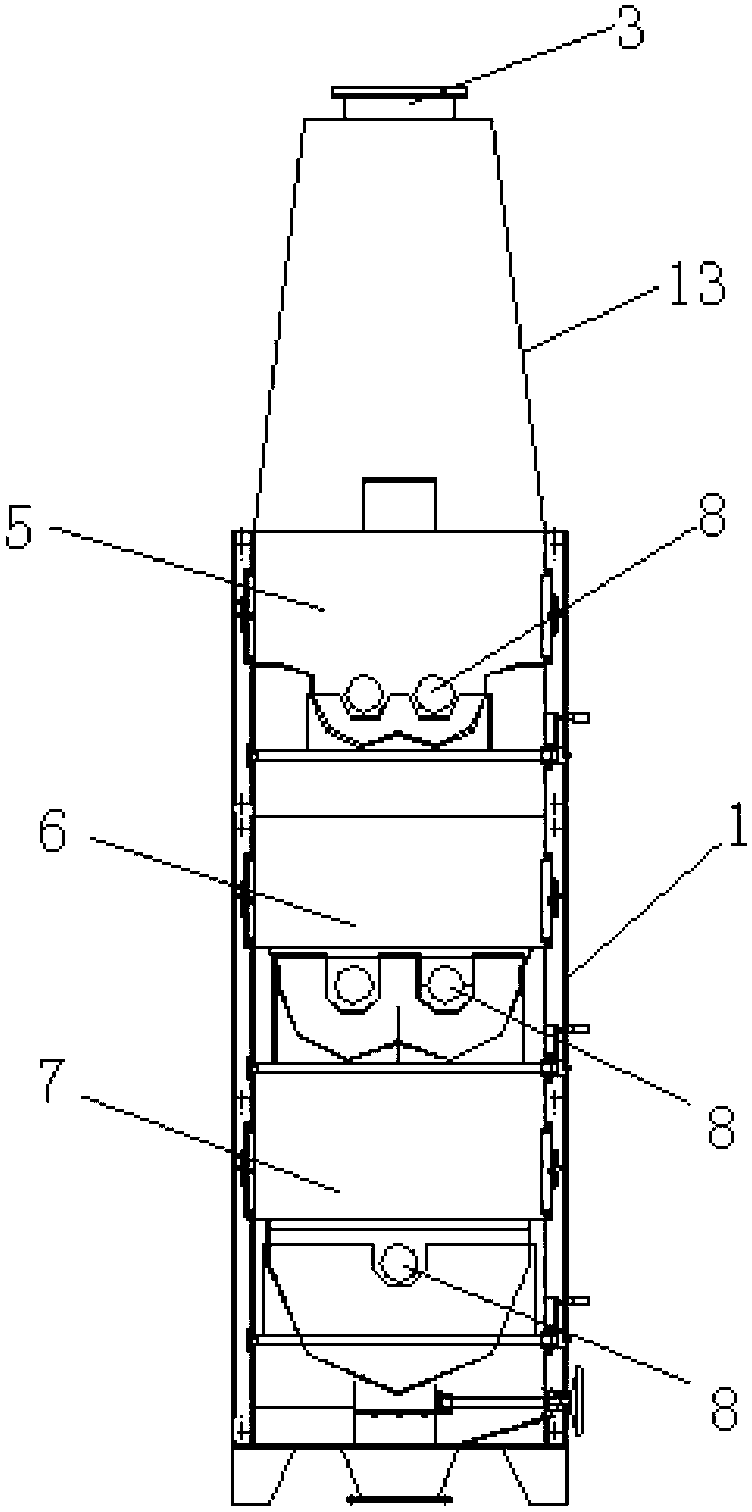

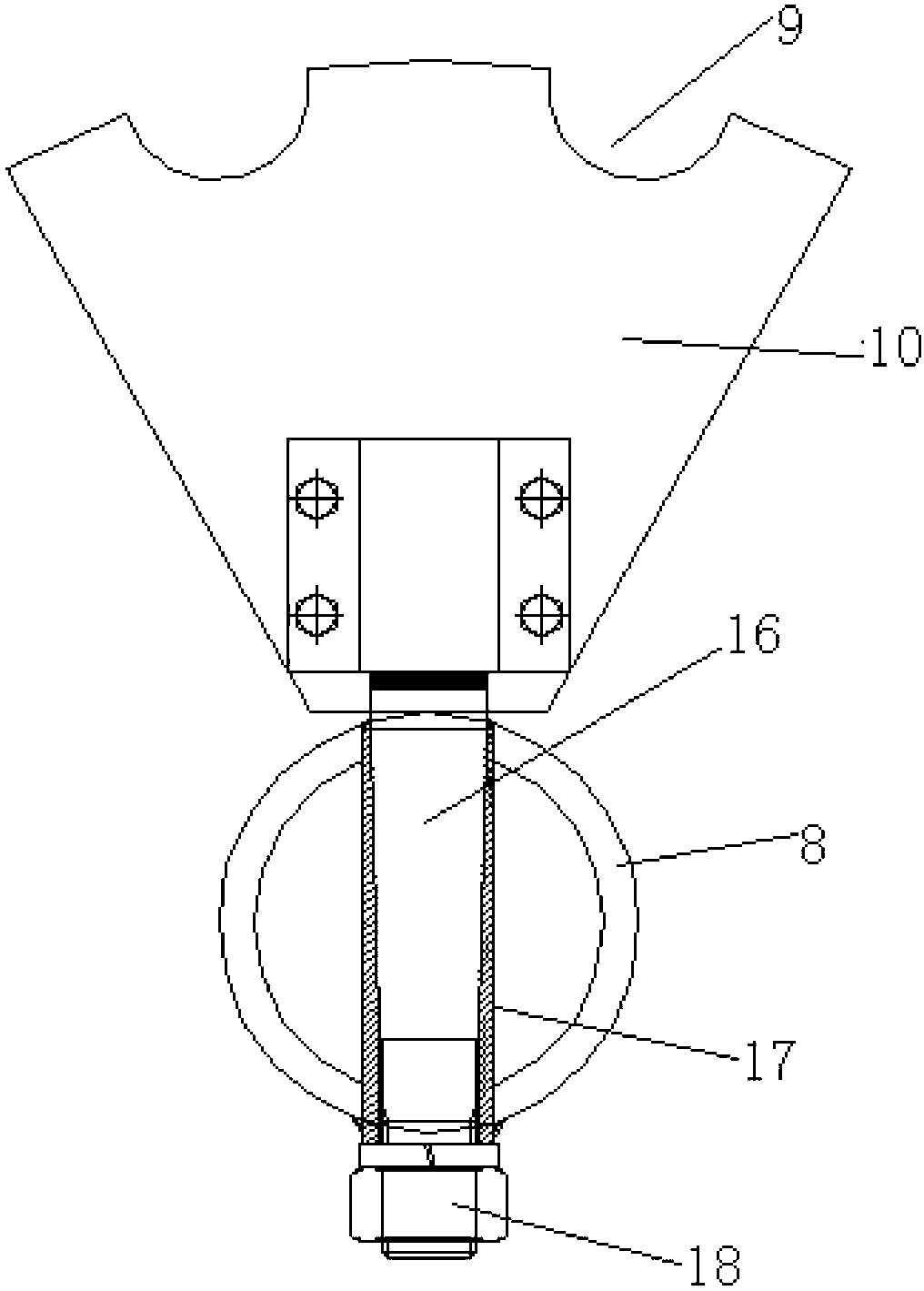

[0025] Referring to the accompanying drawings, a three-stage digester for preparing slaked lime includes a tank body 1, the top of the tank body 1 is provided with a feed port 2 and an exhaust port 3, and the bottom end of the tank body 1 is provided with a discharge port 4, There are three layers of partitions distributed from top to bottom inside the tank body 1. There is a channel between one end of the partition and the side wall of the tank body 1, and the channels of adjacent partitions are misaligned with each other. The partition divides the tank body into The first-level digestion chamber 5, the second-level digestion chamber 6 and the third-level digestion chamber 7, the first-level digestion chamber 5, the second-level digestion chamber 6 and the third-level digestion chamber 7 are respectively equipped with a stirring shaft 8, and a stirring shaft 8 is distributed on the stirring shaft 8. The axial direction of the blade 10 and the stirring shaft 8 is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com