Patents

Literature

62results about How to "Effective destination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

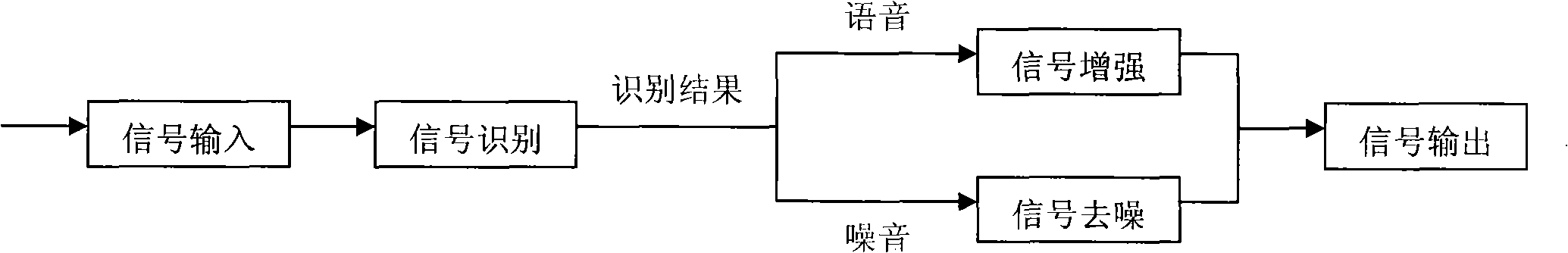

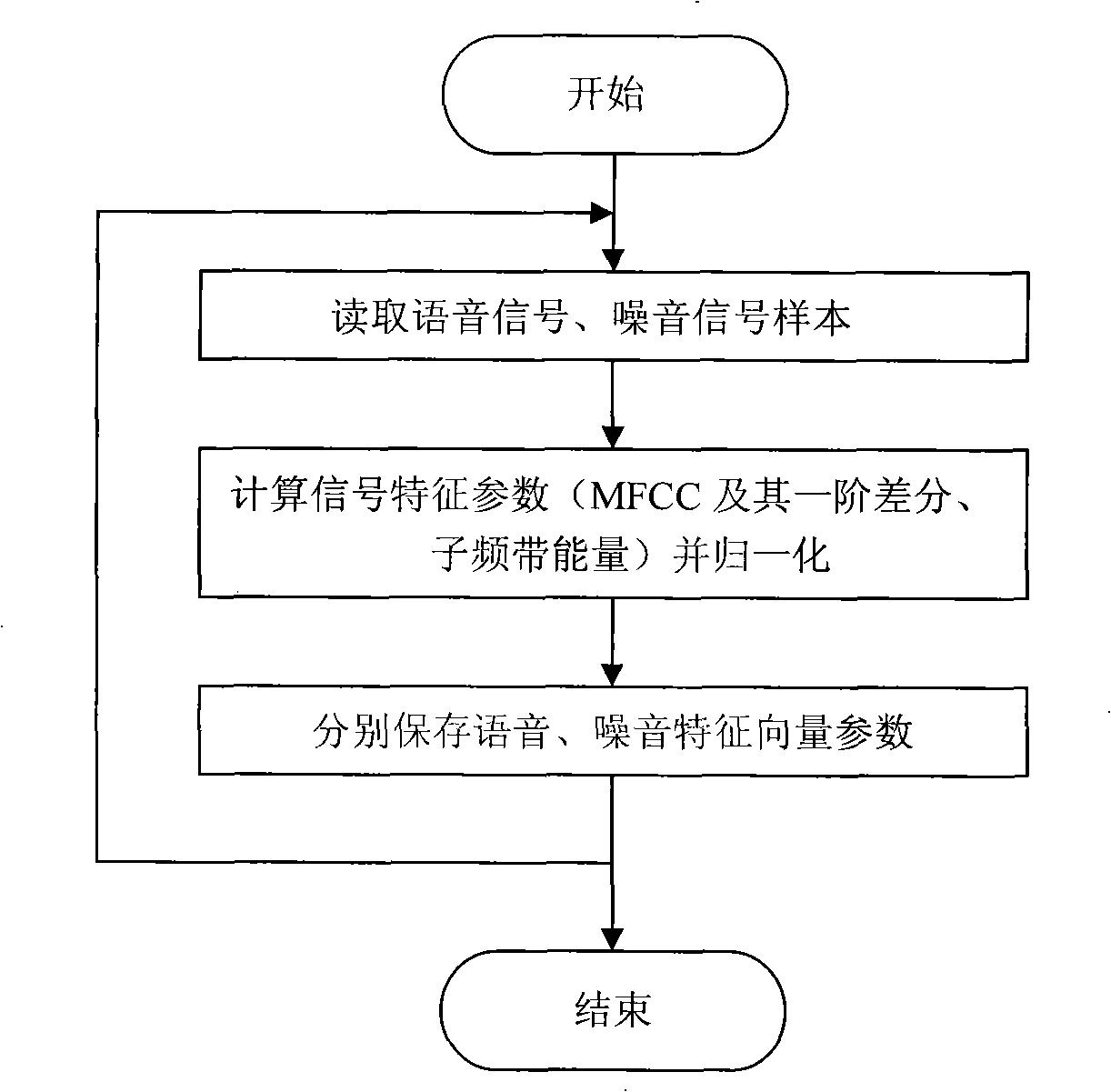

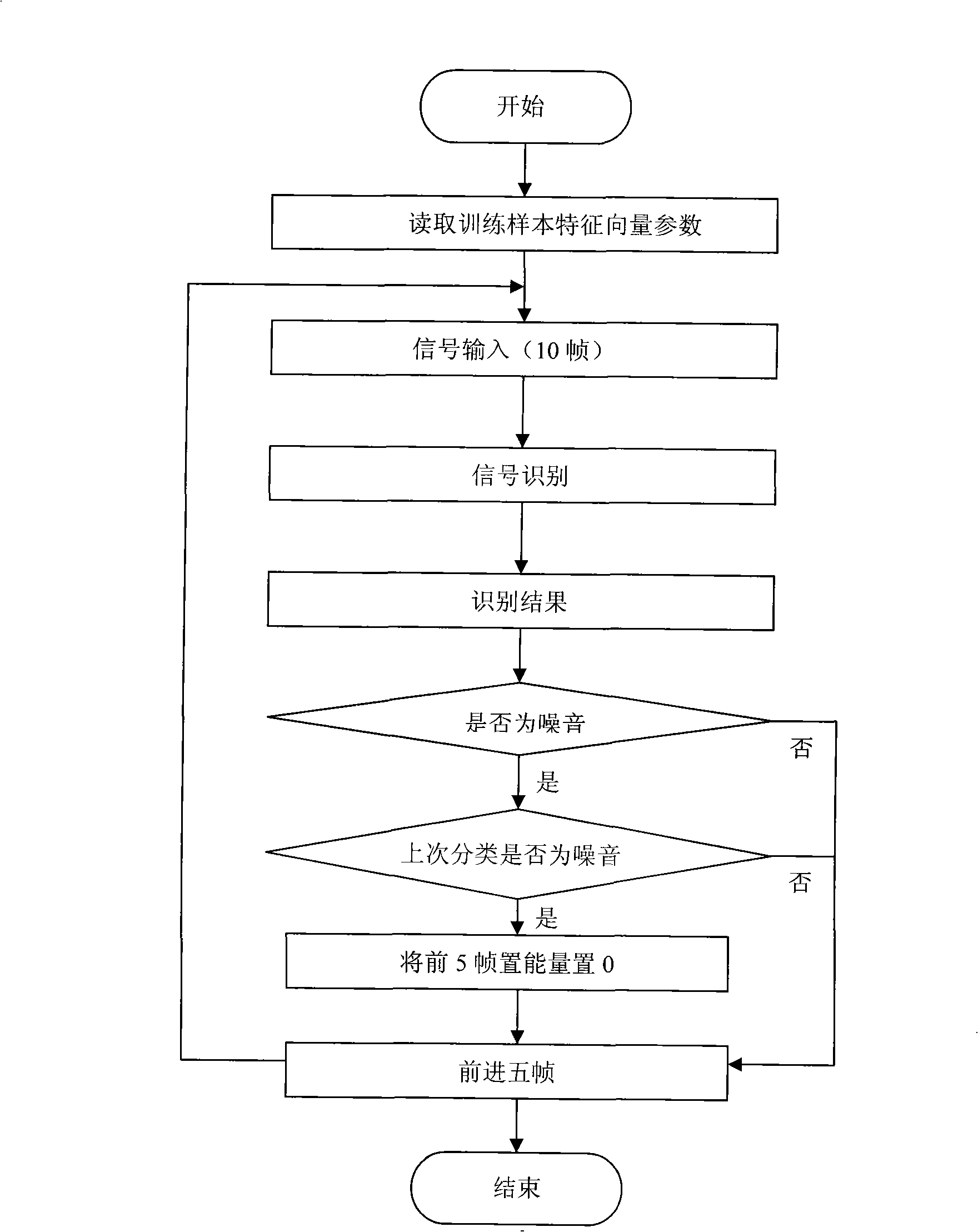

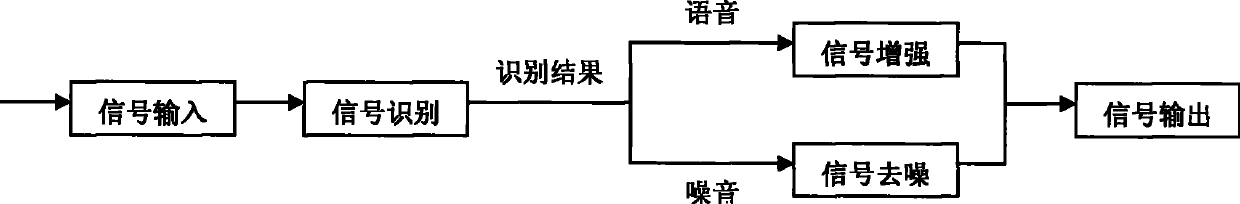

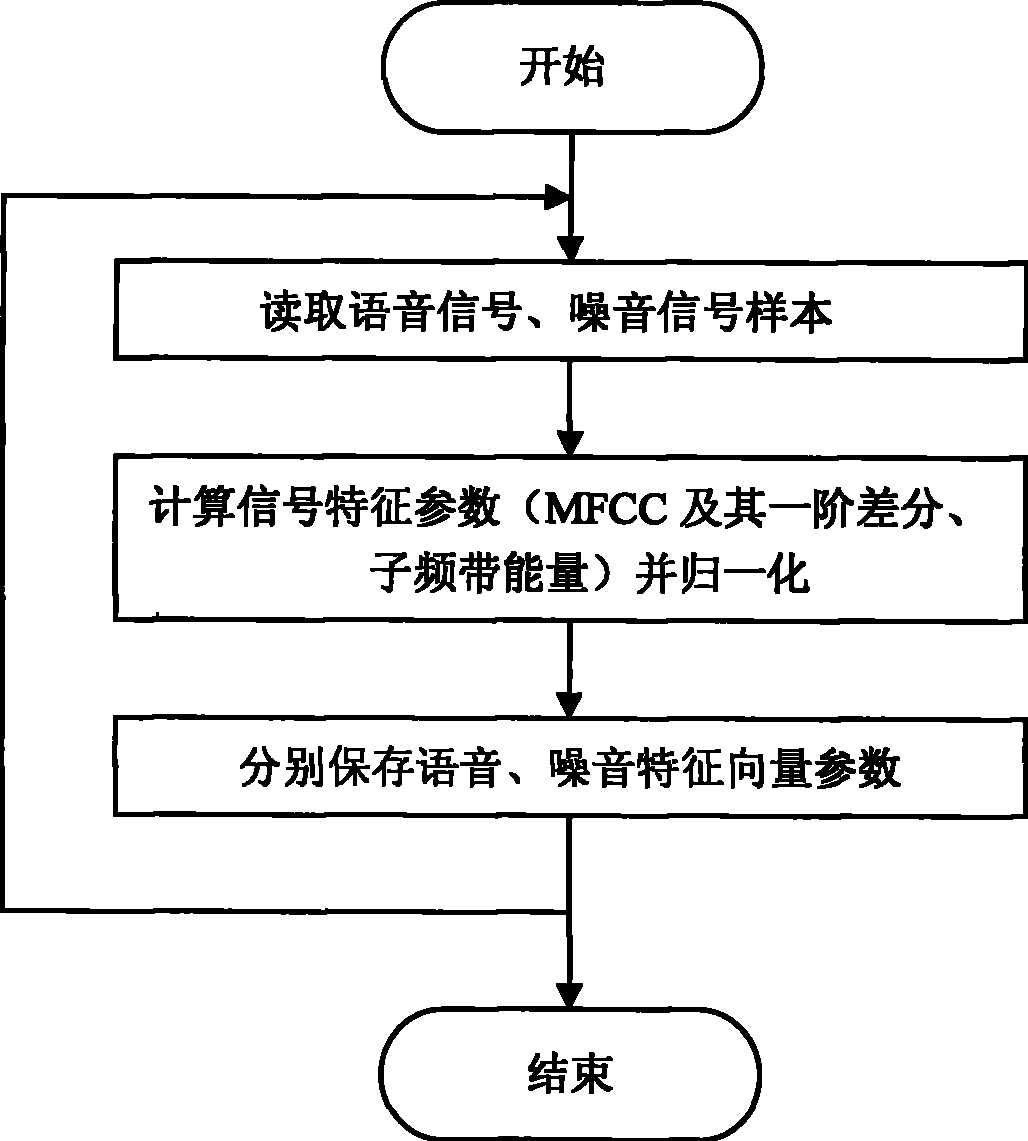

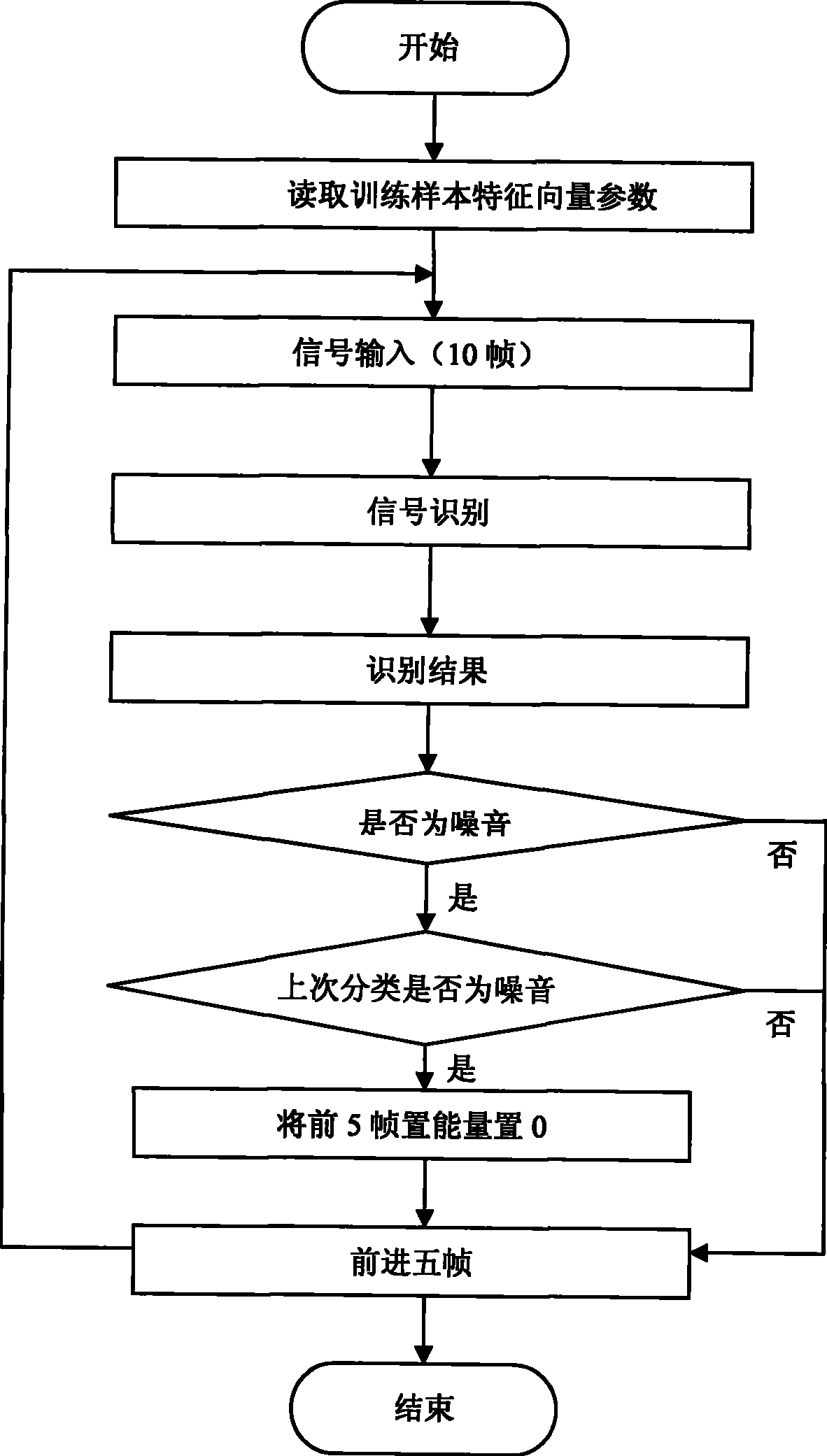

Voice denoising method based on audio recognition

The invention provides a speech noise reduction method based on audio recognition, which reduces the noise of a receiving end by aiming at the speech communication under complex noise environment, belonging to the field of computer science and technology. Most of the existing noise reduction methods are only suitable for stable noise environment and can not remove the noise under the situations of complex noise environment, especially the situation of frequent mutagenicity noise and the like. The method leads a mode recognition idea in the communication speech noise reduction, divides an audio signal into a speech signal and a non-speech signal, automatically identifies the input signal by extracting the speech characteristic and designing a sorter model, and judges the audio type; if the audio type is noise, the audio signal is removed; if the audio type is speech, the audio signal is remained and processed further. The method meets the real-time requirement and has better reduction noise effect at the same time, can be suitable for the situations with complex communication environments such as manned spaceflight speech communication, construction sites, battlefields and the like, and provides an idea and a method for the noise reduction of signals.

Owner:UNIV OF SCI & TECH BEIJING

Fried rabbit meet crisps and the manufacture method thereof

InactiveCN101731639AEffective destinationUnique tasteFood preparationMonosodium glutamateTissue protein

The invention discloses a fried rabbit meet crisps and the manufacture method thereof. The ingredients and the weight proportion thereof are: rabbit meet grain 1000 parts, salt 5-60 parts, white sugar 10-150 parts, chili 10-50 parts, cooking wine 5-50 parts, pericarpium zanthoxyli 2-20 parts, sodium nitrite 0.05-0.3 part, five-spice powder 3-20 parts, MSG 5-20 parts, soybean sauce 20-80 parts, starch 0-500 parts, tissue protein 0-500 parts, phosphate 2-5 parts, beta-cyclodextrin 2-20 parts.The combination of beta-cyclodextrin and phosphate can effectively remove the fishy smell and maintain the water to preserve the rabbit flesh at its best taste. After the sousing, spreading slice, parching and high-temperature curing, the taste of the rabbit flesh has a spicy and delicious flavour. The flesh tastes chewy and the nutrients of the rabbit flash are preserved to the maximum degree by the special technology of parching and high-temperature curing. The flesh has a bright red look and is convenient for food. The invention creates a completely new way of utilizing the rabbit flesh scraps and enjoys a broad market prospect.

Owner:SICHUAN BAI JIA FOOD CO LTD

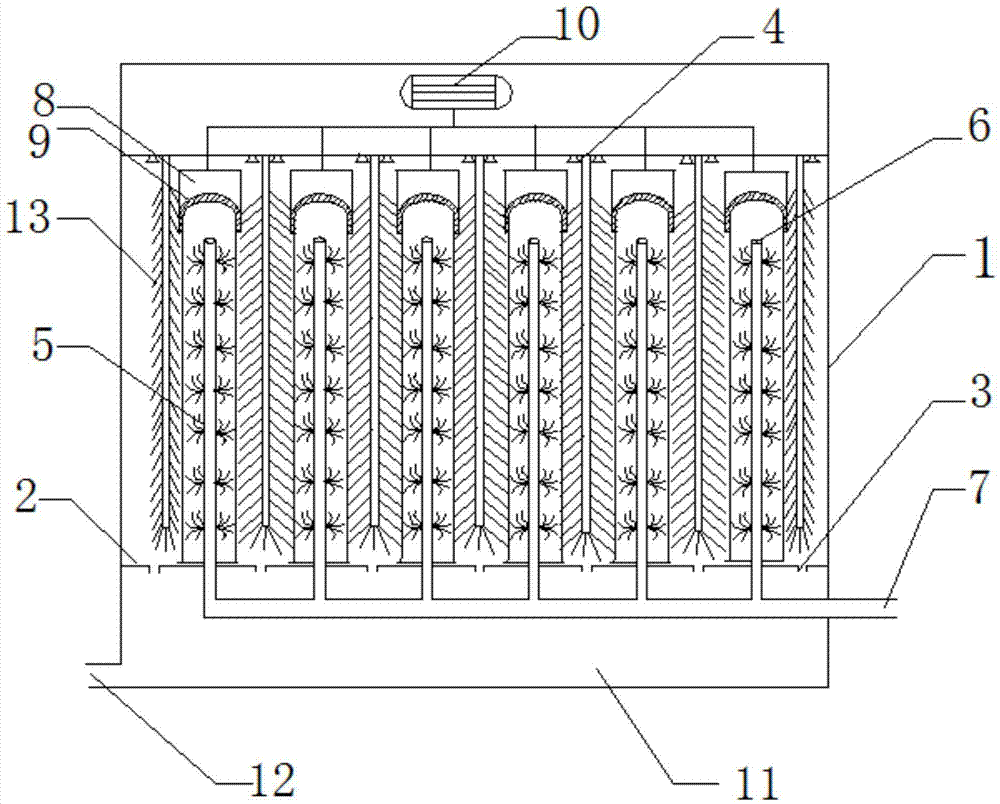

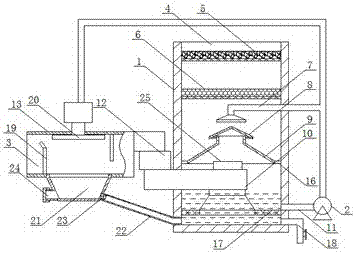

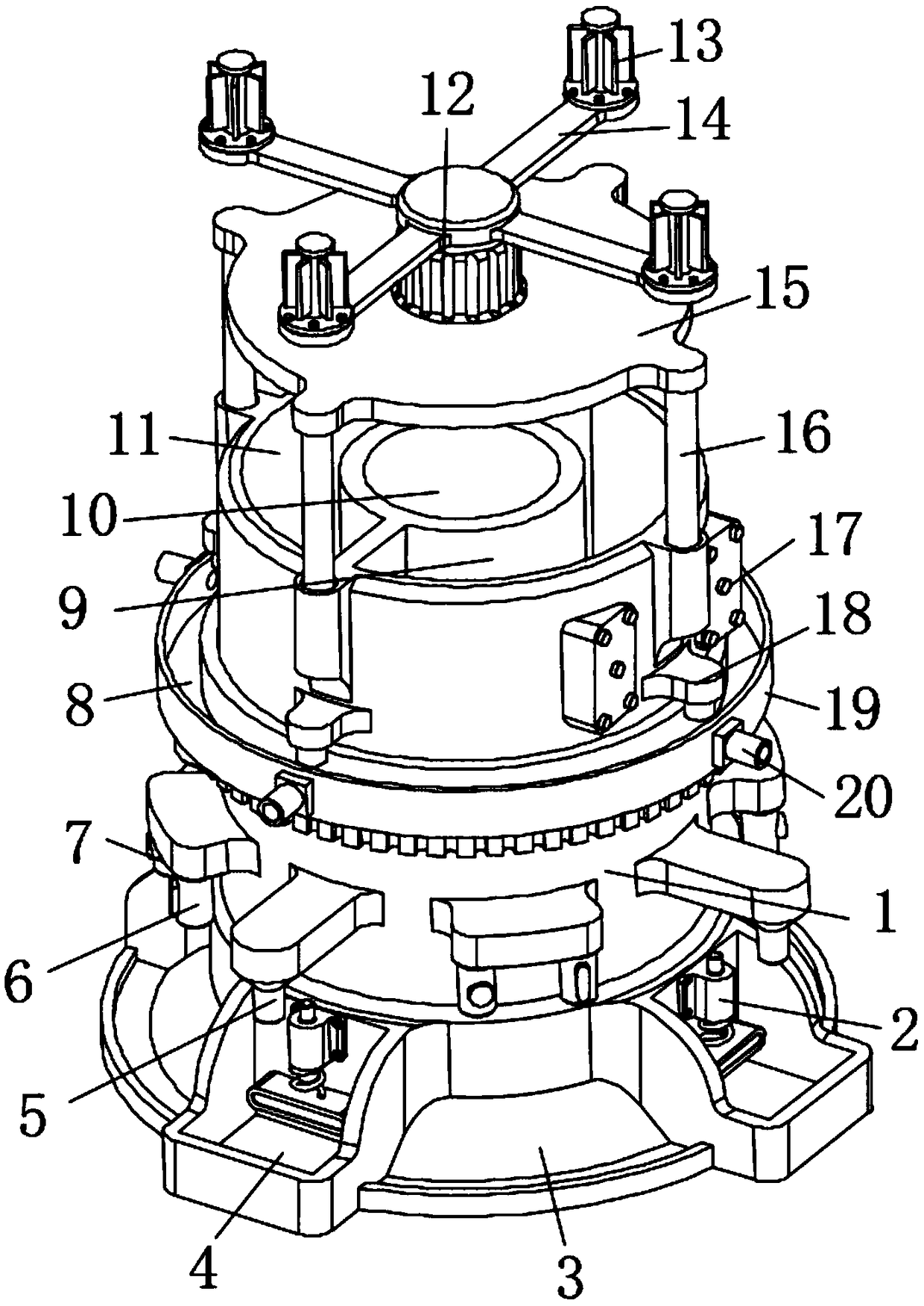

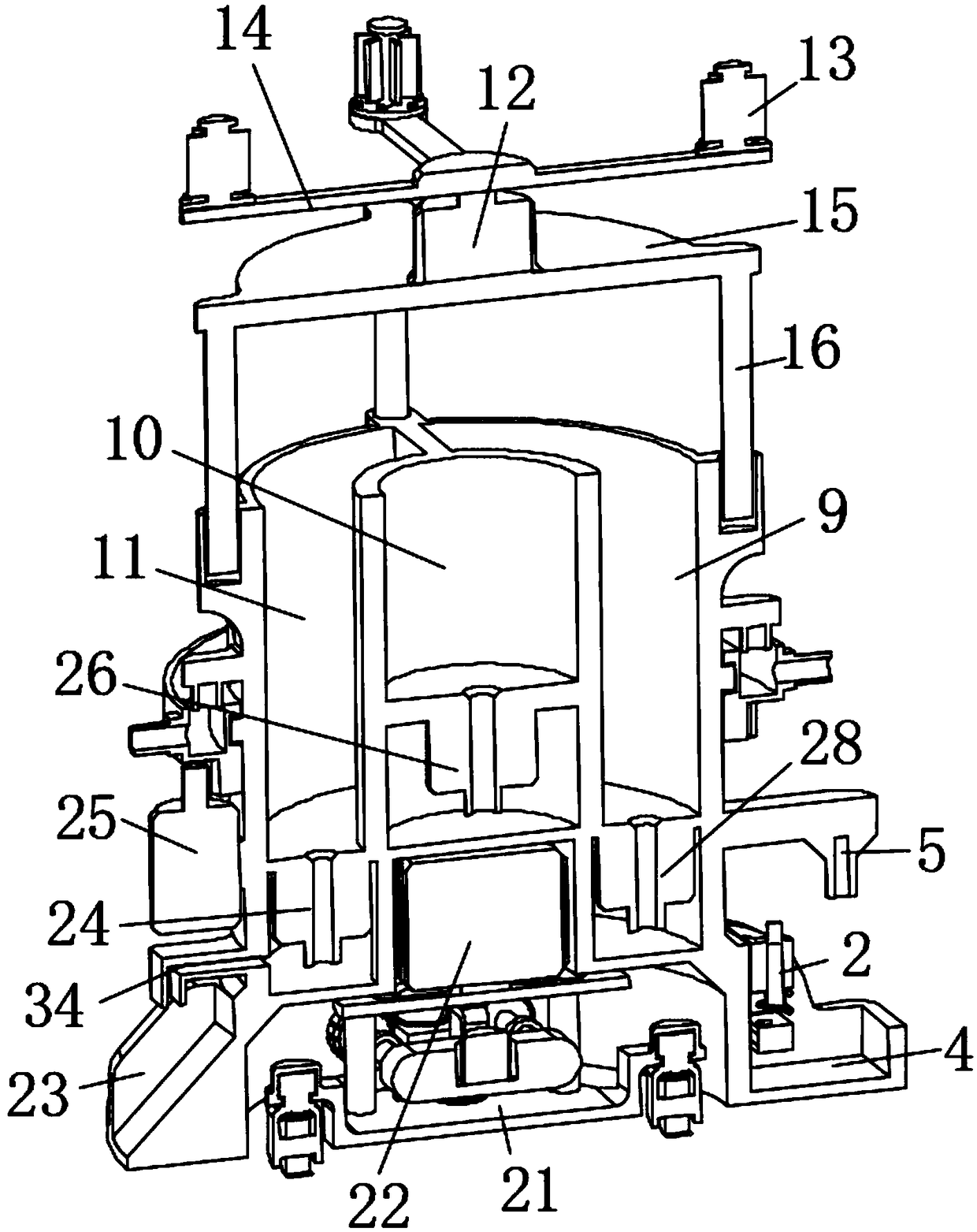

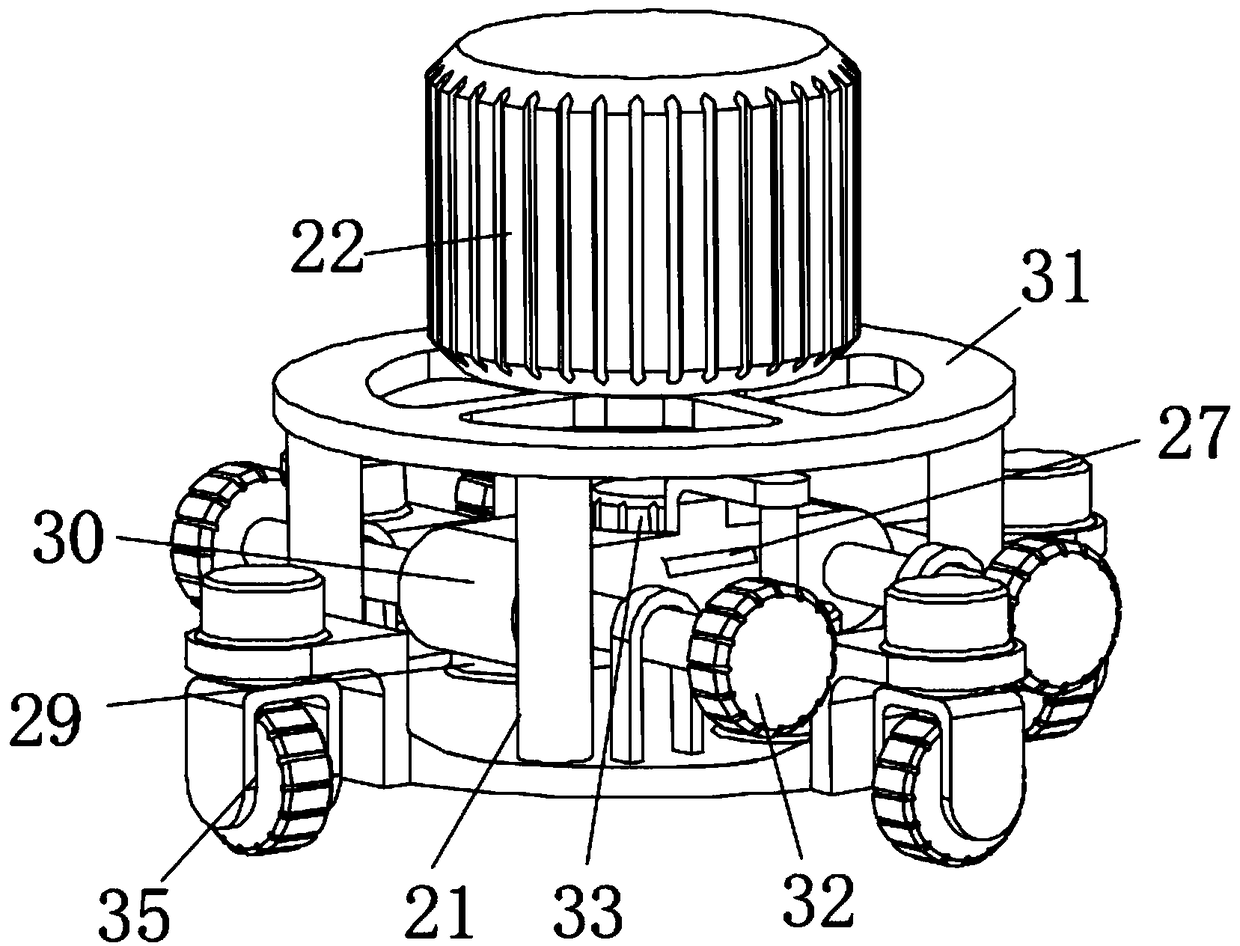

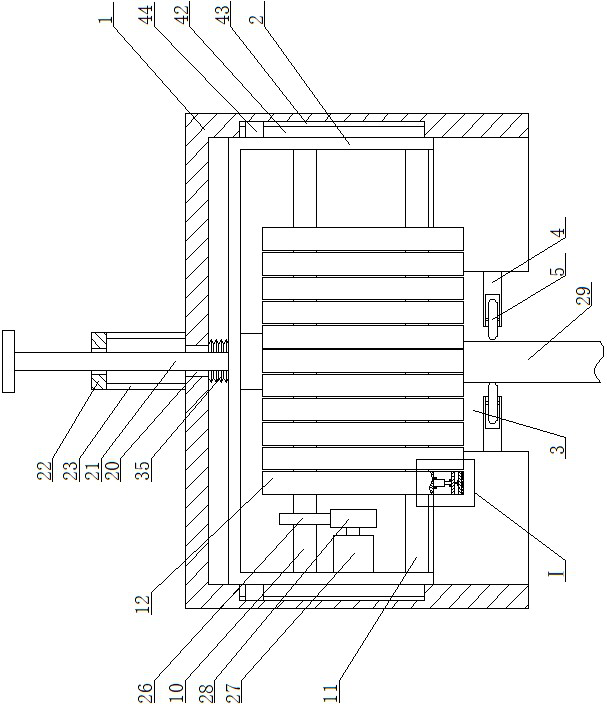

Efficient test tube cleaning device

InactiveCN105436165AImprove accuracyEffective destinationHollow article cleaningElectricityWater flow

The invention provides an efficient test tube cleaning device. The efficient test tube cleaning device comprises a cleaning box, wherein a partition board is arranged at the lower part of the cleaning box; a plurality of water leaking holes are formed in the partition board; a plurality of atomizers are arranged at the top inside the cleaning box; a plurality of lower brushes are arranged on the partition board; water outlets are formed in the tops of the lower brushes and communicated with a water inlet; rotatable test tube fixing devices electrically connected with a driving motor are further arranged at the top, corresponding to the lower brushes, of the cleaning box. The efficient test tube cleaning device adopts a batch cleaning mode, so that the cleaning efficiency is improved, the manual cost is saved, the test time is shortened, when the efficient test tube cleaning device is connected with high-pressure water flow, the test tube fixing devices drive test tubes to rotate, the water flow can powerfully wash the bottoms and the inner walls of the test tubes, substances attached to the side walls of the test tubes can be effectively removed, and the accuracy of an experimental result is improved.

Owner:TIANJIN INGENOCHEM TECH CO LTD

Method for separating red cells from blood sample and application

ActiveCN101750244AExtended use timeExtended service lifePreparing sample for investigationBiological testingAmount of substanceFibrin

The invention relates to a device and a method for separating red cells from a blood sample and a device and a method for detecting analyzed substances in the blood sample. The method for separating red cells from the blood sample comprises the following steps: making the blood sample contact receptors of fibrin in a combined blood sample; and separating out the receptors of the fibrin from the blood sample. The device for detecting the analyzed substances in the blood sample comprises a carrier which comprises a detection area, and the device is characterized in that the upstream of the detection area comprises the receptors of the fibrin in the combined blood sample. The red cells in the blood sample can be effectively separated by using the devices and the methods so as to reduce the obstruction effect of the red cells on liquid flow and the interference of the red cells on a response background. The methods and the devices do not cause adverse effects on the detection results.

Owner:ABON BIOPHARM HANGZHOU

Surface treating method for metal workpieces

InactiveCN101205617AImprove surface propertiesGood colorAnodisationMetallic material coating processesAcetic acidMetal

The invention provides a surface treatment method for a metal workpiece, which includes the following steps: the metal workpiece is provided; the surface of the metal workpiece is conducted with anodic oxidation treatment to form an anode oxidation film on the surface of the metal workpiece; the surface of the metal workpiece is washed by water; the metal workpiece is dipped in dyeing liquor for dyeing treatment; the surface of the workpiece is washed by water; the surface of the workpiece is dipped in hole sealing solution for hole sealing treatment; the metal workpiece is washed with acetic acid.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Method for producing ultra-high-purity magnesium from industrial pure magnesium

InactiveCN107841638APrecise temperature controlHigh purityProcess efficiency improvementVacuum chamberElectron

The invention belongs to the field of metal material preparation, and specifically relates to a method for producing ultra-high-purity metallic magnesium from industrial pure magnesium. According to the method, vacuum distillation is directly carried out on an industrial magnesium ingot; the vacuum degree of a vacuum chamber is controlled to be 1.0-10Pa; the temperature of a raw material area is controlled to be 700-850 DEG C; and the temperature of a condensation area is controlled in three sections: the temperature in the first section is 500-600 DEG C, the temperature in the second sectionis 350-500 DEG C, and the temperature in the third section is 250-350 DEG C. Relative to metal metallic magnesium, impurities with high boiling points and low saturated vapor pressures are condensed in the first section of the condensation area, impurities with low boiling points and high saturated vapor pressures are condensed in the third section of the condensation area, and the main metallic magnesium is condensed in the middle area, so that the ultra-high-purity metallic magnesium is directly generated. According to the method disclosed by the invention, the ultra-high-purity metallic magnesium with a purity of greater than or equal to 99.996wt% is obtained, and the needs of the high-end science and technology fields such as national defense, aerospace, high-end electronic industry and nuclear industry can be completely met.

Owner:WENXI COUNTY REGAL MAGNESIUM

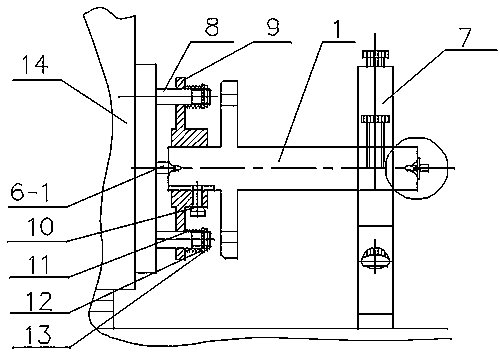

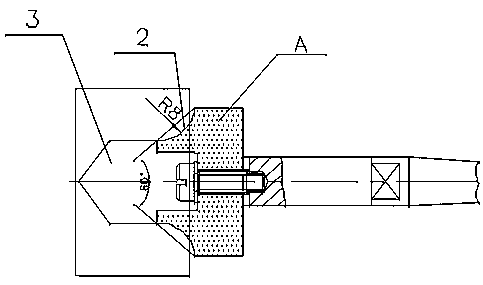

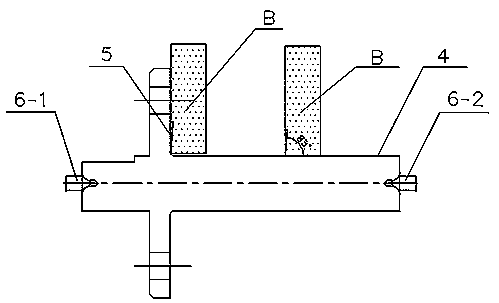

Grinding method for thin wall guide tube with tungsten carbide coating

InactiveCN109277885AEliminate the effects of processingCorrection of concentricity errorGrinding work supportsProcess systemsThin walled

The invention discloses a grinding method for a thin wall guide tube with a tungsten carbide coating and particularly relates to the grinding method for the thin wall guide tube with the tungsten carbide coating and a fixture. According to the grinding method for the fixture, the fixture is ground by operating a grinding machine, and the positioning accuracy of workpieces is improved; according tothe grinding method for the thin wall guide tube with the tungsten carbide coating, grinding machining process parameters are confirmed on base of the grinding technical requirements for the outer outline (an outer circle, a transition circle angle, an end face and an end face chamfer) of the thin wall guide tube with the tungsten carbide coating, and grinding process control is performed on theouter outline of the thin wall guide tube with the tungsten carbide coating; by means of the grinding method for the thin wall guide tube with the tungsten carbide coating and the fixture, the fact that the grinding machine, the fixture, a grinding wheel and the workpieces form a complete process system in grinding is realized, in this way, occurrence of the coating grinding quality problem of aluminum alloy sleeve type thin-wall parts of some type is completely eradicated, and the long-term practice test is performed, the qualified rate of the parts is increased, and the grinding method for the thin wall guide tube with the tungsten carbide coating and the fixture has reference significance in guiding production.

Owner:HARBIN UNIV OF SCI & TECH

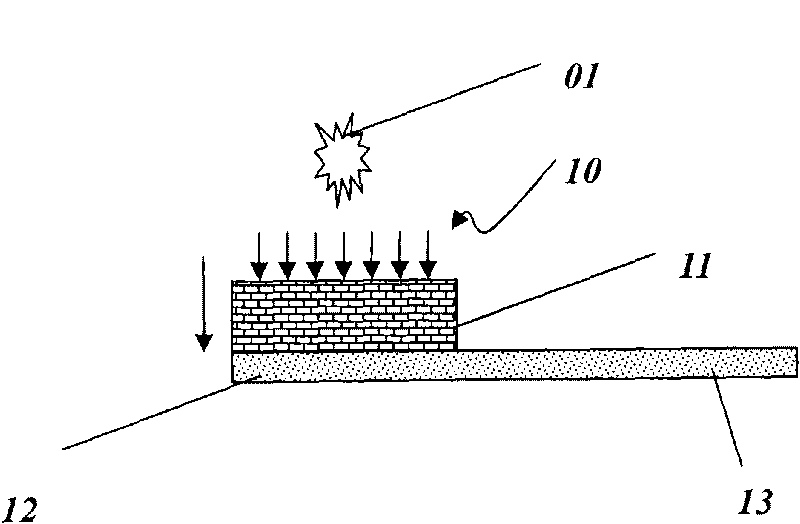

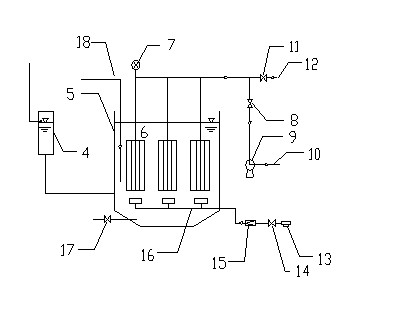

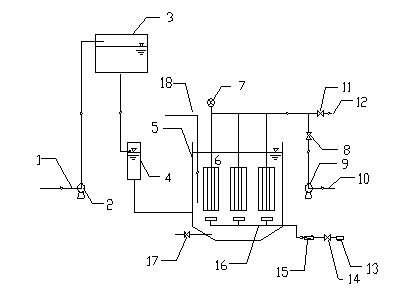

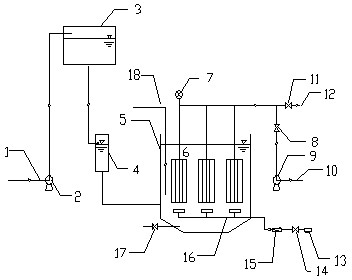

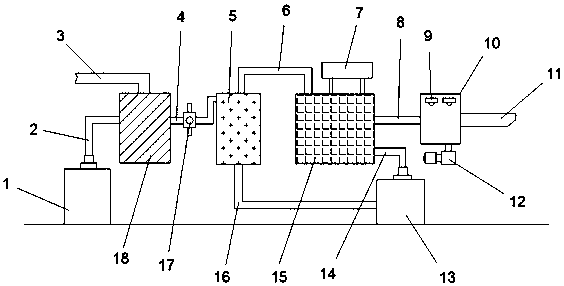

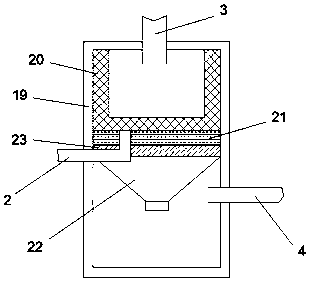

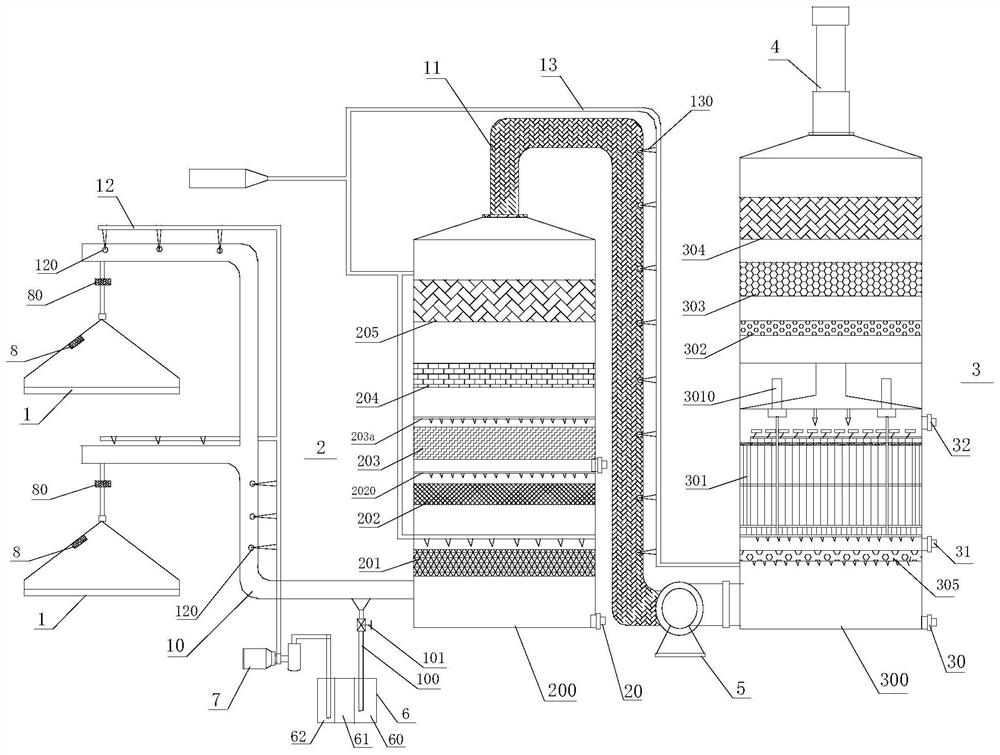

Oxidation-adsorption integral arsenic removal device and method for drinking water

InactiveCN102583698ALow costLow running costWater/sewage treatment by sorptionWater/sewage treatment by oxidationUltrafiltrationSludge

The invention discloses an oxidation-adsorption integral arsenic removal device and method for drinking water, which belong to the field of deep arsenic removal of the drinking water. The device comprises a water inlet control system, a reactor, an ultrafiltration membrane filtration system, an aeration oxidation system, a sludge discharge system and a water outlet control system, wherein the ultrafiltration membrane filtration system is arranged on the middle lower part of the reactor and is connected with the water outlet control system; the sludge discharge system comprises a sludge discharge valve and a sludge discharge pipe; the aeration oxidation system comprises an aeration pipe, an air inlet valve and an air pump; and the water outlet control system is formed by sequentially connecting a water outlet valve, a sucking pump and a water outlet pipe, and is connected with the ultrafiltration membrane filtration system. According to the oxidation-adsorption integral arsenic removal device and method for drinking water, oxidation, adsorption and membrane separation are organically combined to be completed in a same reaction pool, and the advantages that: the engineering application is convenient, the fixed investment is low, the operation cost is low, and deep arsenic removal with the safety of water quality of the drinking water can be ensured, are realized.

Owner:JIANGSU YONGTAI ENVIRONMENTAL PROTECTION TECH

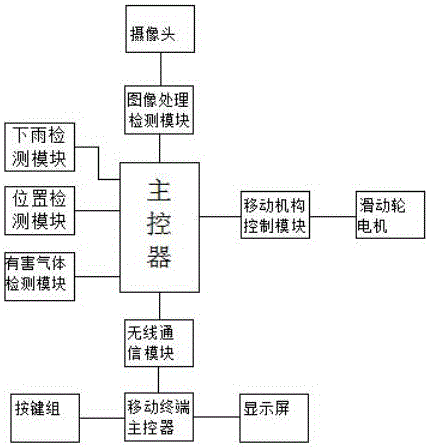

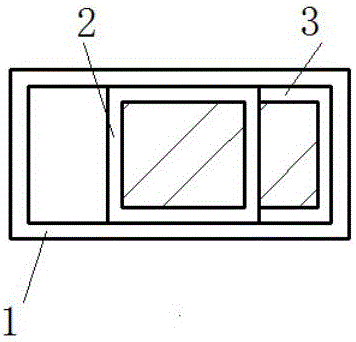

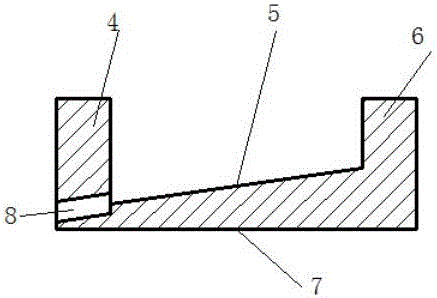

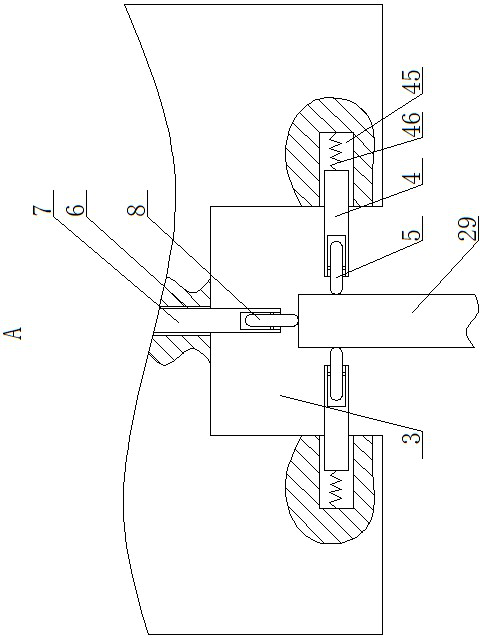

Multi-functional window and control system and control method thereof

InactiveCN106437430AEffective destinationEffective isolationCondensed water drain-offPower-operated mechanismControl systemEngineering

The invention discloses a multi-functional window and a control system and control method thereof. The multi-functional window comprises an inner glass frame and an outer glass frame which are installed on a window frame in a sliding mode, soundproof glasses are installed both in the inner glass frame and the outer glass frame, the bottom of the window frame is provided with a groove-type base, and two side surfaces of the groove of the groove-type base are an inner side sliding rail for installing the inner glass frame as well as an outer side sliding rail for installing the outer glass frame respectively; the bottom surface of the inside of the groove is an inclined surface, the high end position of the inclined surface is located at one side of the inner side sliding rail, and the low end position is located at one side of the outer side sliding rail; the lower part of the outer side sliding rail is provided with a plurality of water drain holes located at a same horizontal plane, wherein the water drain holes are communicated with the bottom surface of the inside of the groove; moving mechanisms are arranged both on the inner glass frame and the outer glass frame, and installed at the inner side sliding rail and the outer side sliding rail through the moving mechanisms; the moving mechanisms are sliding wheels. The multi-functional window and the control system can solve the problem that the window frame is waterlogged and has a poor soundproof effect.

Owner:成都创慧科达科技有限公司

Separating and culturing method for olfactory ensheathing cells of rats

InactiveCN107603952AEffective destinationAchieve purificationNervous system cellsTissue ProcessorDigestion

The invention provides a separating and culturing method for olfactory ensheathing cells of rats. The separating and culturing method comprises the following steps: (1) disinfecting a tissue processing instrument; (2) selecting male SD rats of 2-3 months old, killing the male SD rats after anesthesia, separating the olfactory mucosa tissue by adopting surgical scissors, placing the tissue in PBSsolution which is precooled, is sterile and contains double antibodies, and washing the tissue for a plurality of times, so that blood stains and outer membranes are removed; (3) cutting up the tissue, and carrying out digestion by adopting preheated neutral enzyme and trypsin respectively; (4) terminating the digestion, carrying out centrifugation, and discarding the supernatant; (5) inoculatingthe obtained product into an enveloped culture flask by adopting an artificial wall sticking method; (6) carrying out incubation for 1-2 h, and carrying out culturing in the environment being at 37 DEG C containing 5% CO2; (7) carrying out cell purification; (8) carrying out cell morphological observation; (9) carrying out cell subculturing; (10) carrying out cell counting and survival rate testing; and (11) carrying out immunological identification. For the separating and culturing method for olfactory ensheathing cells of rats, the operation is simple, a large number of cells are obtained, the survival rate is high, the method belong to an ideal primary separating and culturing method for the olfactory ensheathing cells of rats, and a reliable cell resource is provided for the experiment.

Owner:JIANGYIN CHI SCI

Flue gas dust collector

PendingCN107149837ASimple structureEasy to operateUsing liquid separation agentSeparation devicesActivated carbonFlue gas

The invention discloses a flue gas dust collector and belongs to the field of chemical equipment. The flue gas dust collector comprises a spraying tower, a pump body, an air inlet and an air outlet; the top of the spraying tower is the air outlet; an inner cavity of the spraying tower is sequentially provided with a first activated carbon layer, a second activated carbon layer, a spraying pipe, a liquid cap, a diversion cover and an air inlet pipeline from top to bottom; the lower part of the spraying tower is provided with a liquid outlet pipe to be communicated with an inlet of the pump body; the inlet end of the air inlet pipeline is sequentially communicated with a fan and a primary spraying box; the other end of the primary spraying box is the air inlet; one path of an outlet pipeline of the pump body is communicated with the spraying pipe; a fog distributor is installed at the end part of the spraying pipe; and the other path of the outlet pipeline of the pump body is communicated with the primary spraying box. The flue gas dust collector has a simple structure and is convenient to operate and high in dust collection efficiency. By adopting the flue gas dust collector, corresponding substances are moved from flue gas after the flue gas passes through a primary dust collection box and dust collection liquid in a tower body, so that the dust collection effect is greatly improved, wherein water in the whole device is recycled, so that the effects of water conservation and cost reduction are facilitated.

Owner:湖州博通节能环保设备有限公司

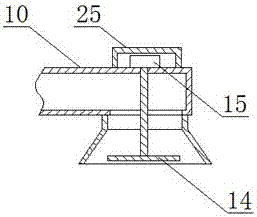

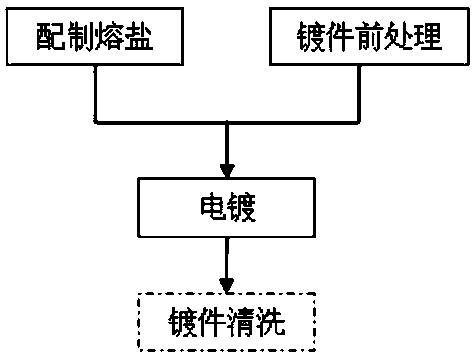

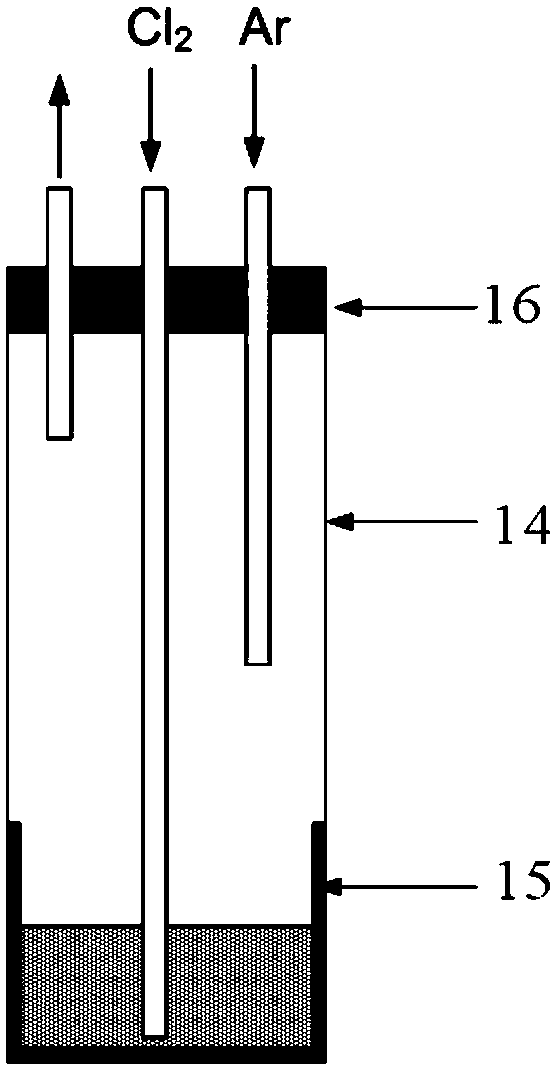

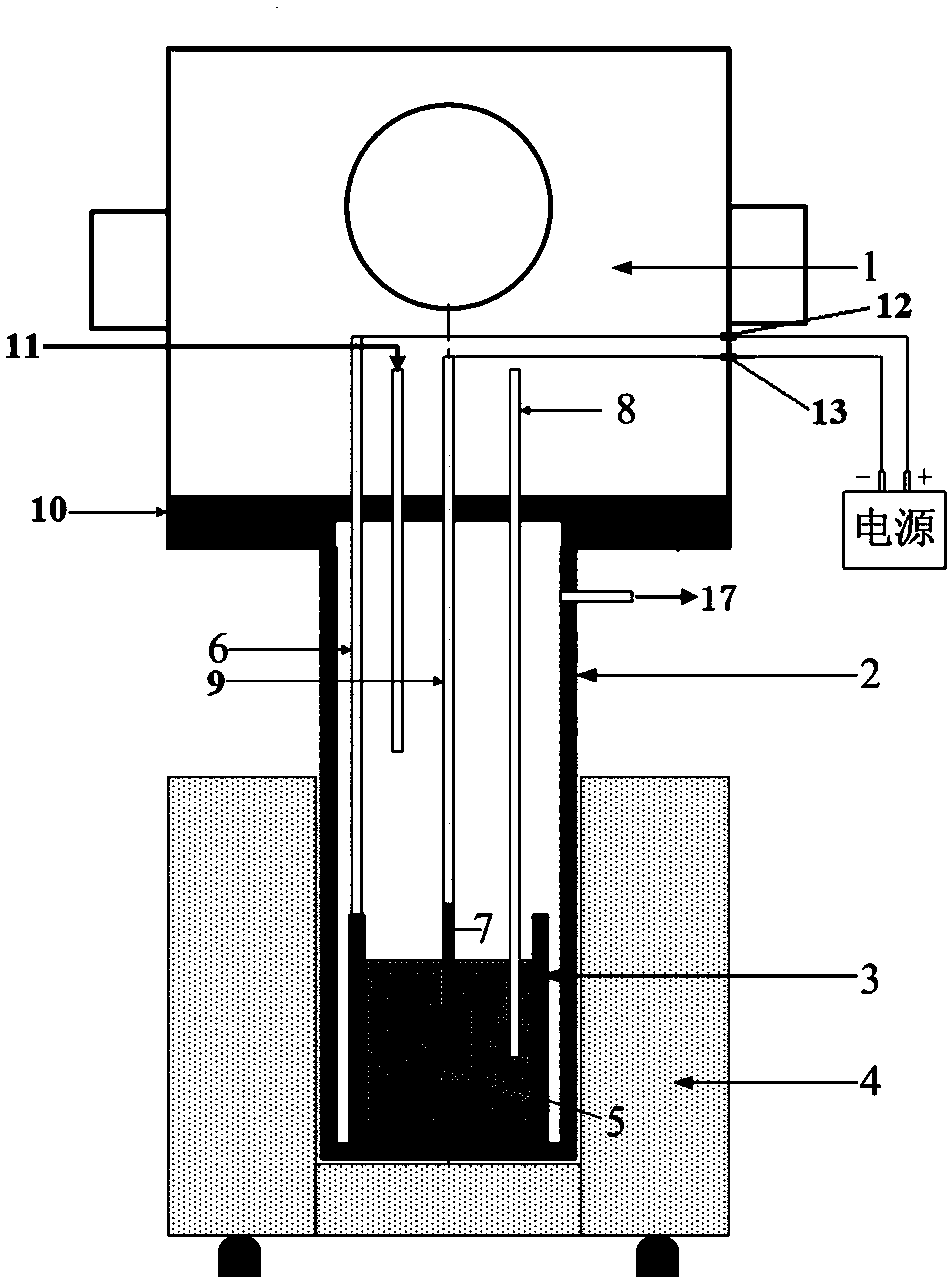

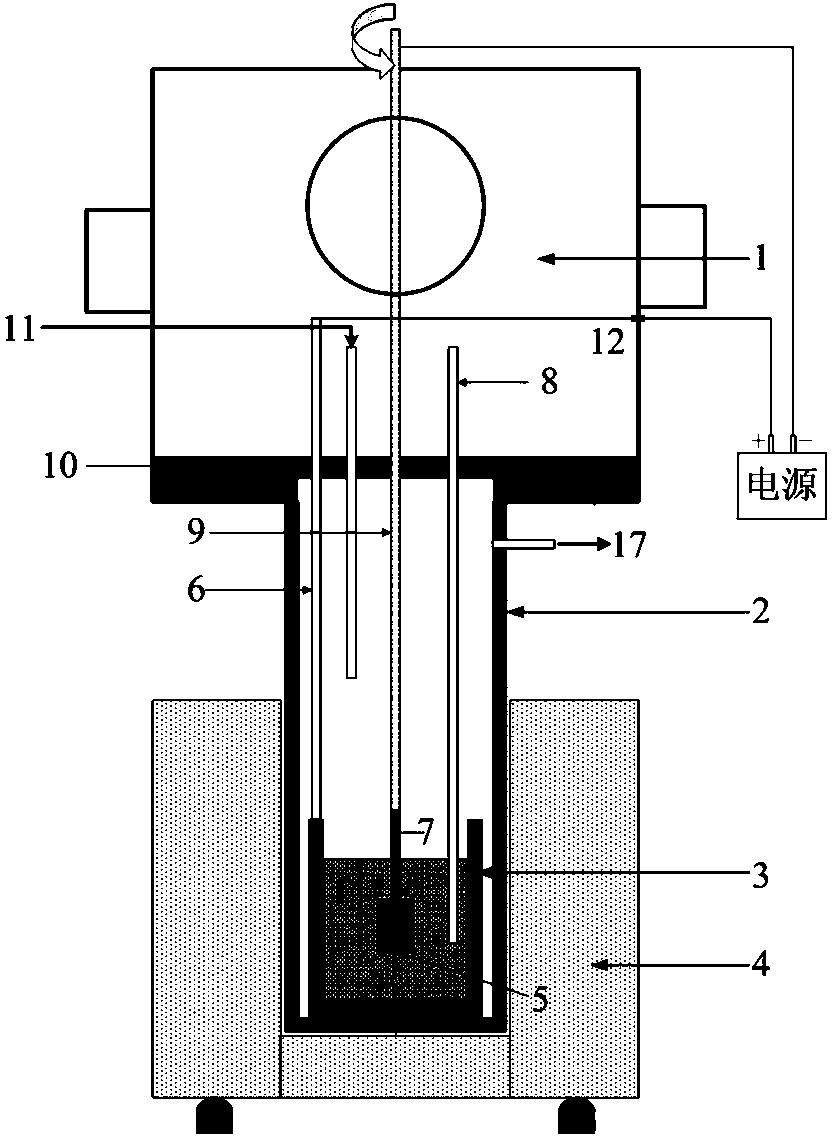

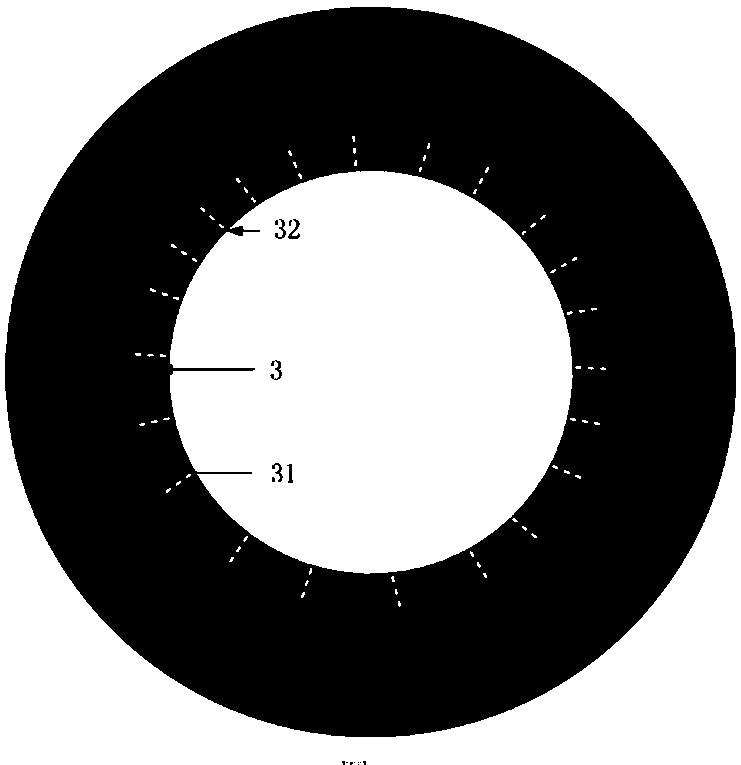

Preparation method for black rhenium coating

ActiveCN107699928AConcentration is easy to controlStable dissolutionSealing devicesRheniumMolten state

The invention discloses a preparation method for a black rhenium coating. The preparation method comprises the following steps that S1, molten salt chlorination is performed, wherein under inert gas protection, after CsCl is heated to a molten state, K2ReCl6 is added, the molten salt containing K2ReCl6 is obtained, chlorine is introduced into the molten salt containing K2ReCl6, chlorinating is performed, and after cooling, the chlorinated molten salt is obtained; and S2, electroplating is performed, wherein the chlorinated molten salt obtained in the step S1 is heated to the molten state underinert gas protection, a plating piece base body is immersed into the chlorinated molten salt in the molten state, the chlorinated molten salt in the molten state is a plating solution, the plating piece base body is used as a negative electrode, an inert electrode is used as a positive electrode, electroplating is performed after electrification, and the black rhenium coating is obtained on the plating piece base body. The preparation method is low in cost and high in deposition rate, and the prepared black rhenium coating is good in uniformity.

Owner:NAT UNIV OF DEFENSE TECH

Internet public welfare system based on blockchain

InactiveCN110826084AEffective destinationImprove trustData processing applicationsDigital data protectionInternet privacyDatabase server

The invention relates to the technical field of application of a blockchain technology in Internet public welfare. The Internet public welfare system based on the blockchain comprises a block databaseserver which is provided with and runs Internet public welfare account management software and belongs to a public welfare participant, and the block database server is connected to form a blockchainnetwork based on an Internet public welfare account; the internet public welfare system further comprises an account encryption module used for encrypting account information of an Internet public welfare account, and the account encryption module adopts an interactive zero knowledge proof method to encrypt data written and / or read in the blockchain network. According to the system, the technicalproblem that the privacy information in each fund cannot be protected on the basis of realizing effective supervision of each fund in the existing Internet public welfare system based on the blockchain is solved.

Owner:李纳

Processing method of salty crabs

InactiveCN104068422ATender meatAvoid embrittlementFood thermal treatmentFood ingredientsDistillationSeawater

The invention provides a novel processing method of salty crabs, and the processing method is low in requirements for material selection, meets the demands of long-time storage and transportation and enables the meat of the salty crabs to be delicious; the processing method is characterized by mainly comprises the steps of (1) washing: cleaning the freshly caught crabs or frozen crabs by clear water; (2) pre-soaking: presoaking the cleaned crabs by concentrated seawater mixed solution mainly containing tea essence, glycine and glycinate; (3) heating: after the crabs are presoaked, removing the mixed solution for pre-soaking, putting into hot clear water and heating; (4) crushing: crushing the heated crabs in a crushing device until the crabs become mushy state fluid; (5) mixing and soaking: fully mixing the crushed mushy state fluid and sauce for pickling, and then soaking; and (6) packaging and sterilizing: packaging the soaked salty crabs, and carrying out distillation sterilization to obtain the final product.

Owner:FENGHUA XINGDA SEAFOOD

Method for sealing ultra-thin shadow mask plasma display

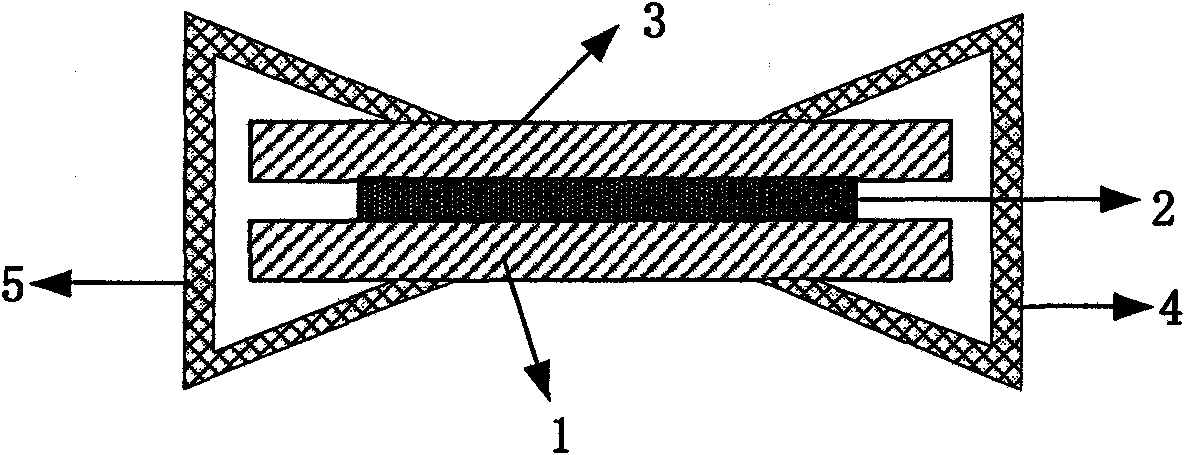

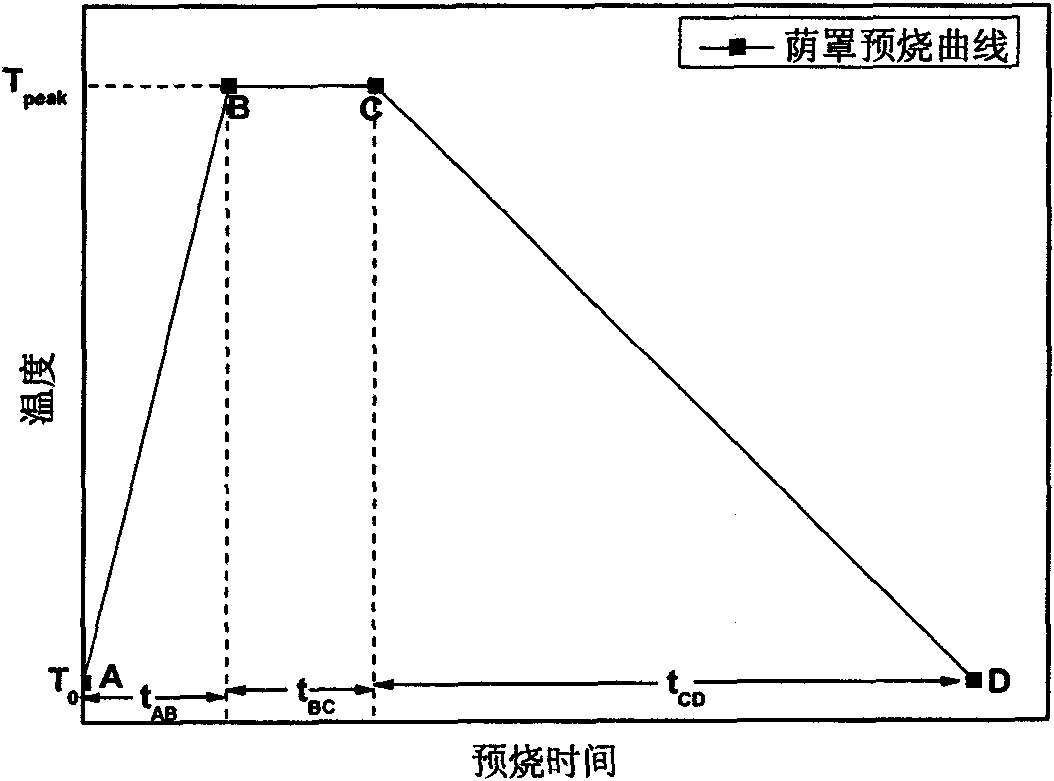

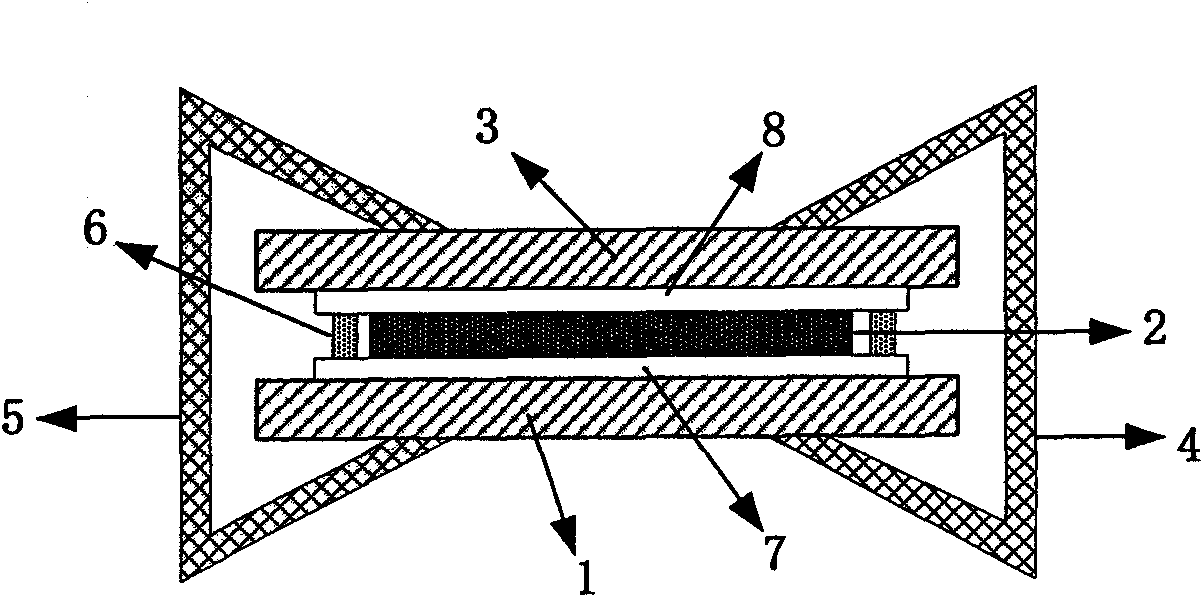

InactiveCN101800141AEven by forceGuaranteed smoothCold cathode manufactureMaterials sciencePlasma display

The invention discloses a method for sealing an ultra-thin shadow mask plasma display. The method comprises the following steps of: cleaning and drying a shadow mask, first thick glass and second thick glass; positioning the shadow mask between the first and second thick glass and fixing the two sides of the shadow mask by using a first sealing clamp and a second sealing clamp; putting the shadow mask in a vacuum sealing furnace for pre-burning after fixing the shadow mask, wherein the pre-burning comprises an AB phase of raising the temperature, a BC phase of keeping temperature and a CD phase of lowering the temperature; cleaning the shadow mask after the pre-burning; aligning and attaching the front glass substrate of the display, the back glass substrate coated with a sealing frame, and the upper and lower surfaces of the shadow mask, placing the product obtained between the first thick glass and the second thick glass to form a sealing combination and fixing the sealing combination by using the first sealing clamp and the second sealing clamp; putting the sealing composition in the sealing furnace; setting the sintering temperature and the time; sealing the ultra-thin shadow mask plasma display; and filling working gas.

Owner:SOUTHEAST UNIV

Voice denoising method based on audio recognition

The invention provides a speech noise reduction method based on audio recognition, which reduces the noise of a receiving end by aiming at the speech communication under complex noise environment, belonging to the field of computer science and technology. Most of the existing noise reduction methods are only suitable for stable noise environment and can not remove the noise under the situations of complex noise environment, especially the situation of frequent mutagenicity noise and the like. The method leads a mode recognition idea in the communication speech noise reduction, divides an audio signal into a speech signal and a non-speech signal, automatically identifies the input signal by extracting the speech characteristic and designing a sorter model, and judges the audio type; if theaudio type is noise, the audio signal is removed; if the audio type is speech, the audio signal is remained and processed further. The method meets the real-time requirement and has better reduction noise effect at the same time, can be suitable for the situations with complex communication environments such as manned spaceflight speech communication, construction sites, battlefields and the like, and provides an idea and a method for the noise reduction of signals.

Owner:UNIV OF SCI & TECH BEIJING

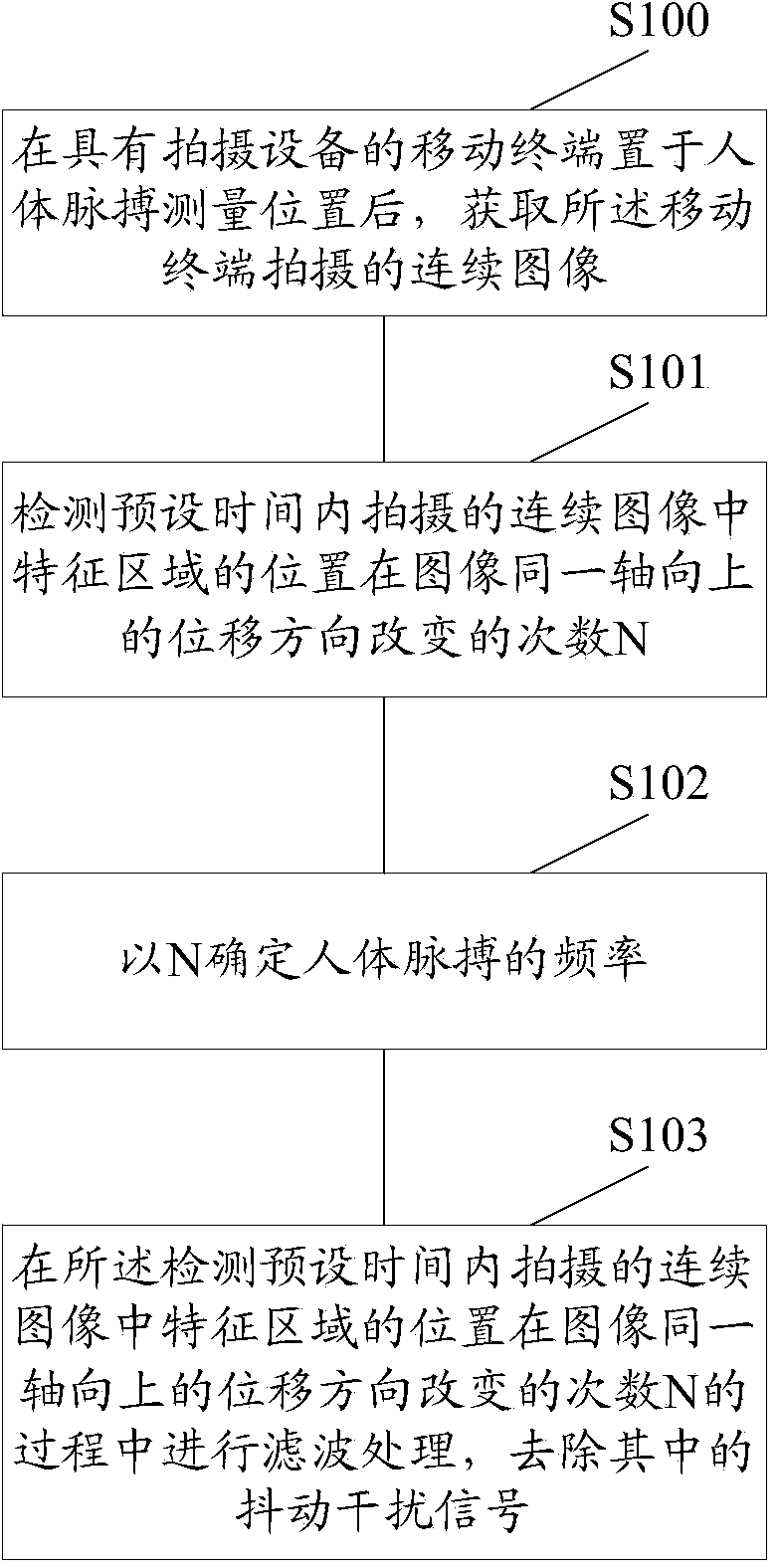

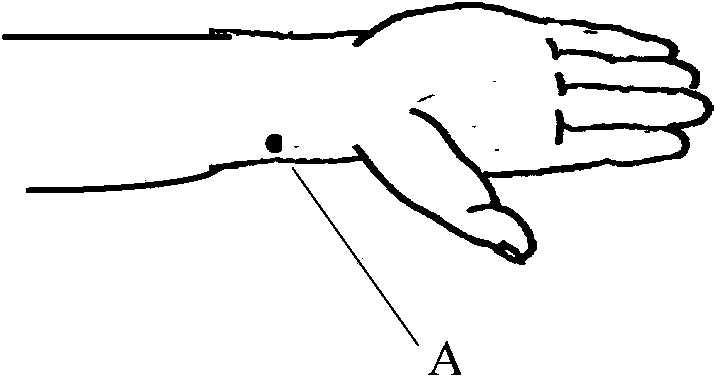

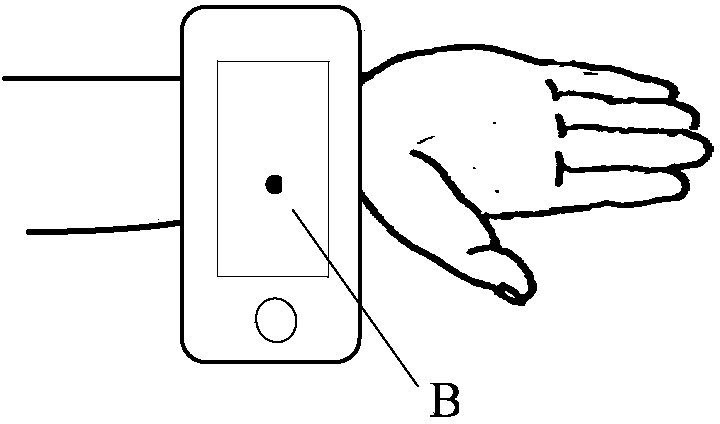

Method and device for measuring human body pulse and mobile terminal

ActiveCN103505196ARealize measurementImprove compatibilityMeasuring/recording heart/pulse rateComputer scienceMobile device

The invention discloses a method and device for measuring a human body pulse and a mobile device. The method comprises the steps that after the mobile terminal provided with a camera is located at the human body pulse measuring position, continuous images shot by the mobile terminal are obtained; the times N of changes of displacement directions of the positions of characteristic areas of the continuous images shot in preset time in the same axial direction of the images are detected; the frequency of the human body pulse is determined according to N. According to the technical scheme, the method for measuring the human body pulse has the advantages of being low in achieving cost, convenient to achieve and good in compatibility.

Owner:芯鑫融资租赁(厦门)有限责任公司

Environment-friendly decoration pollution deodorant and preparation method thereof

InactiveCN105771606AImprove removal efficiencyLong durationDispersed particle separationFlavoring essencesPolyethylene glycol

The invention relates to an environment-friendly decoration pollution deodorant and a preparation method thereof. The environment-friendly decoration pollution deodorant is prepared from main reactants, solvents, a surfactant, flavoring essences and water, wherein the main reactants are pyrone and adipic dihydrazide; the solvents are deionized water and an alcoholic solvent; the surfactant is dipolidocanol; the flavoring essences are at least one of carene, terpineol, citionella oil and alpha-ionone. The environment-friendly decoration pollution deodorant prepared by the preparation method is high in formaldehyde removal efficiency and long in effect duration and does not cause secondary pollution.

Owner:山东惠净居环保科技有限公司

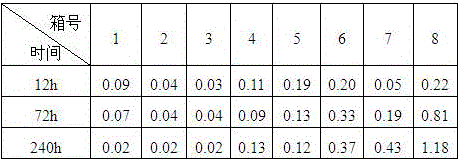

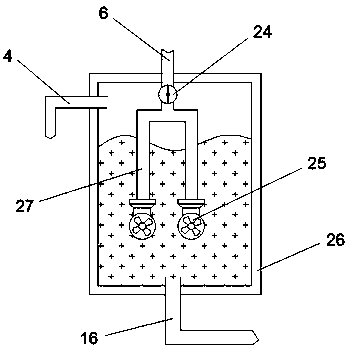

Biodegradable sewage treatment equipment

InactiveCN109179868AReduce harmful ingredientsImprove work efficiencyWater/sewage treatment by irradiationSpecific water treatment objectivesFiltrationSludge

The invention relates to biodegradable sewage treatment equipment. The biodegradable sewage treatment equipment comprises a glove box, a first conduit is installed by penetrating the glove box, one end of the first conduit is movably connected to the glove box, the other end of the first conduit is provided with a filtering device, an inlet pipe is installed by penetrating the upper part of the filtering device, a second conduit is installed by penetrating one side of the filtering device, and one end of the second conduit penetrates and extends into the filtering device. The biodegradable sewage treatment equipment has the beneficial effect that through connection by the conduits, the working efficiency of the biodegradable sewage treatment equipment is improved, and the sealing performance of the biodegradable sewage treatment equipment is improved; collection is carried out through a sludge tank and the glove box, impurities in the sewage can be effectively removed, and the occurrence of clogging phenomenon is prevented; adjusting is carried out through an adjustment tank device, and the circulation of the sewage filtration is realized; the disinfection is carried out through asterilization box, the exposure of the toxic liquid is reduced, and the environment and human safety can be increased.

Owner:金紫媚

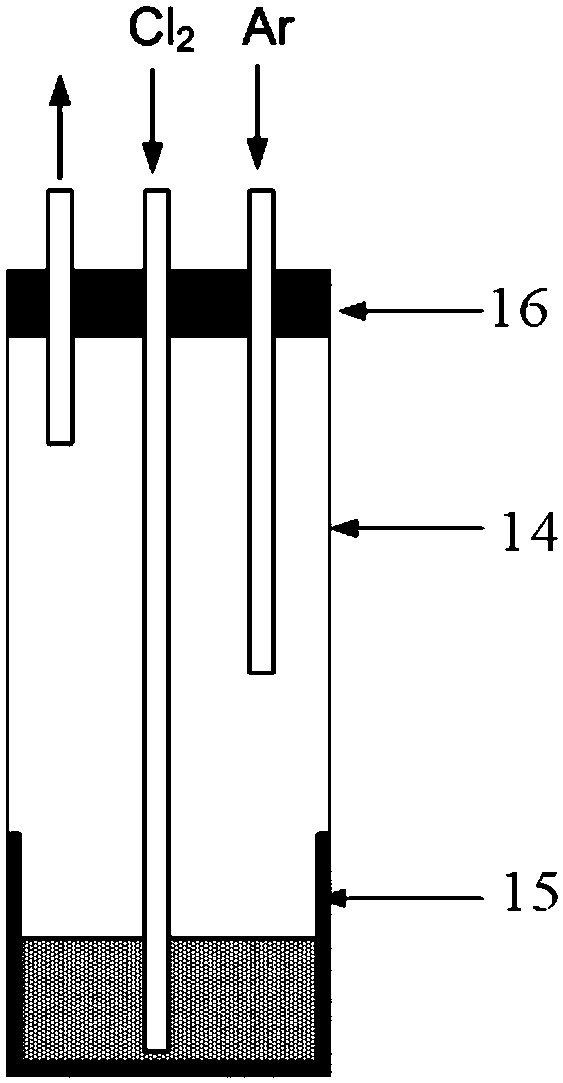

Molten salt electroforming preparation method of rhenium

ActiveCN107699925AConcentration is easy to controlEffective destinationElectroforming processesRheniumMolten state

The invention discloses a molten salt electroforming preparation method of rhenium. The method comprises the following steps: S1, molten salt chlorination: under protection of inert gas, heating a molten salt medium to a molten state, adding K2ReCl6 to obtain molten salt containing K2ReCl6, introducing chlorine into the molten salt containing K2ReCl6 for chlorination, and cooling the molten salt to obtain the chloridized molten salt; and S2, electroforming: under protection of inert gas, heating the chloridized molten salt in S1 to the molten state, immersing a core mold into the chloridized molten salt in the molten state, and performing electrifying to carry out electroforming to obtain a rhenium metal casting on the surface of the core mold by taking the chloridized molten salt in the molten state as an electrolyte, the core mold as a cathode and an inert electrode carrying rhenium as an anode. The preparation method disclosed by the invention is low in cost and high in efficiency and can prepare the rhenium casting which is good in uniformity and compactness, and the casting is easy to demold.

Owner:NAT UNIV OF DEFENSE TECH

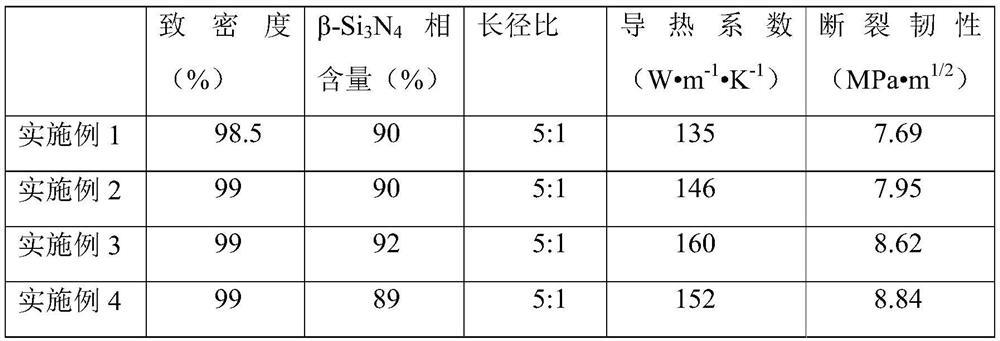

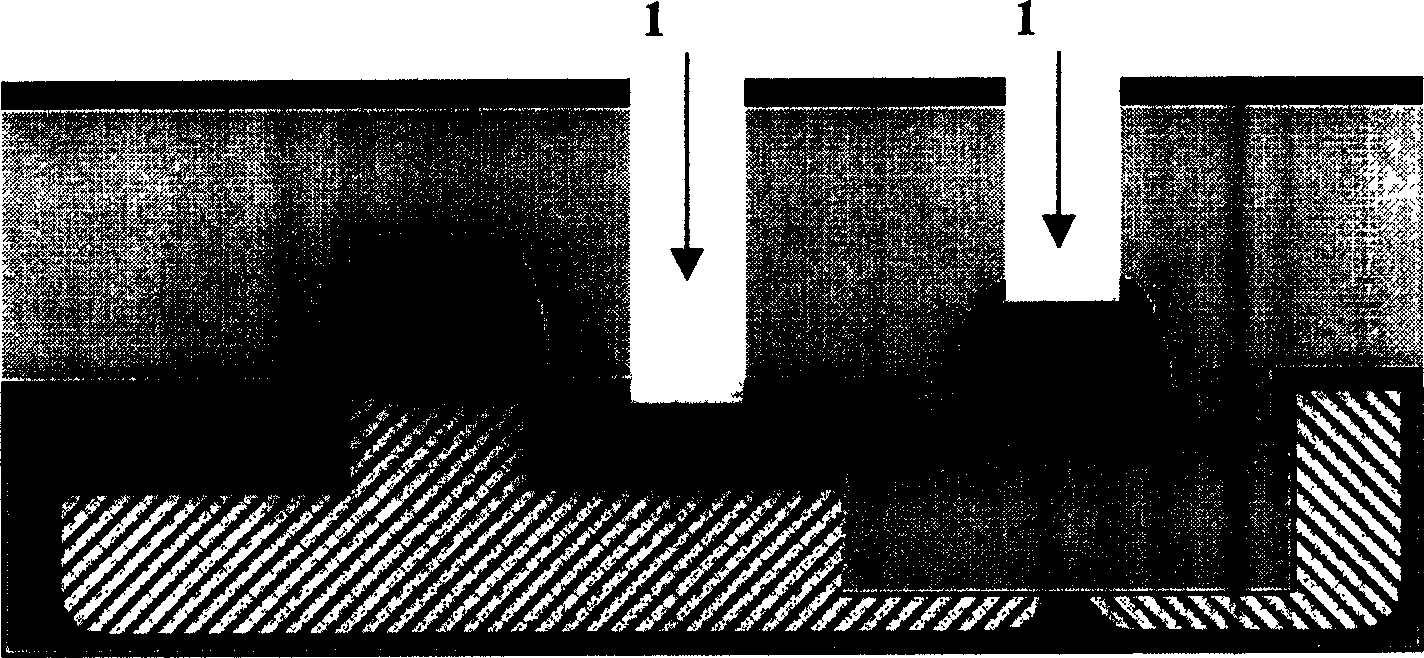

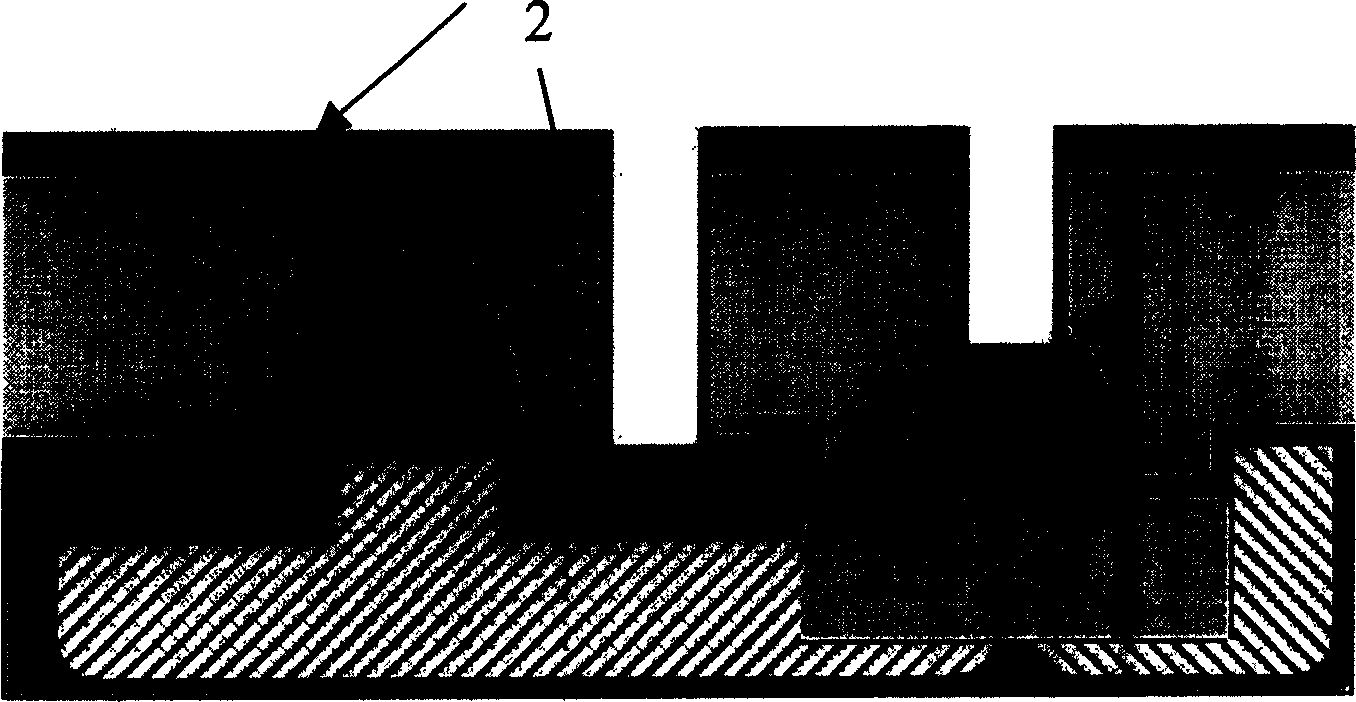

Trace in-situ carbon-induced Si3N4 heat-conducting ceramic material and preparation method thereof

The invention discloses a preparation method of a trace in-situ carbon-induced Si3N4 heat-conducting ceramic material. The ceramic material is prepared by taking Si3N4 powder, a sintering aid and an organic matter as raw materials through modification, molding, primary sintering and secondary sintering. High-activity, high-uniformity and controllable trace carbon is generated in situ through the organic matter at a certain temperature to realize in-situ distribution in a silicon nitride substrate, so that oxygen at a grain boundary is removed, a glass phase is reduced, the alpha-to-beta phase transformation rate is increased, the problems of deformation and cracking of a green body, limited lattice oxygen removal effect, non-uniform structure and the like caused by non-uniform distribution when carbon is directly added are solved, and the heat-conducting property and the strength of the Si3N4 heat-conducting ceramic material are improved.

Owner:HUNAN UNIV OF TECH

Plasma processing technique for reducing MOCVD TiN film thickness on through-hole side wall

InactiveCN1632930AFacilitated DiffusionReduce processing timeSemiconductor/solid-state device manufacturingSemiconductor devicesPlasma GasesImpurity

This invention belongs to integration circuit process technique field, which in detail is a plasm process to decrease the MOCVD TiN film thickness of the hole sidewall. The current process, the Tin film on the inner sidewall of holes cannot be processed with its thickness of ten percent only to make the resistance increase when in plasm gas process.

Owner:SHANGHAI HUA HONG GROUP +1

Purifier for shower

InactiveCN101311124AEasy to installEffective destinationBathsDouchesHazardous substanceEnvironmental engineering

The invention relates to a water purifying device used for shower, which is characterized in that the device of the invention comprises a shell with a water inlet end and a water outlet end; the shell is provided with hanging components with the function of hanging or fixing; KDF filtering material and granular activated carbon are filled from the water inlet end to the water outlet end in the shell. The purifying device for shower has the advantages of simple installation and being capable of effectively removing residual chlorine and other harmful substances in water, thereby bringing people healthy and happy showering experience.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD

New method for removing volatile phenol from wastewater of pulping and papermaking with boiler fly ashes

InactiveCN102225815AReduce processing operating costsGood removal effectUsing liquid separation agentMultistage water/sewage treatmentVolatile phenolsPapermaking

Belonging to a treatment method for volatile phenol in wastewater of pulping and papermaking, the invention relates to a new method for removing volatile phenol from the wastewater of pulping and papermaking with boiler fly ashes. In the invention, condensed sewage from pulping and papermaking is introduced as dedusting water into a spray tower where the condensed sewage and boiler fuel gas undergo a counter-current mass transfer. The dedusted flue gas is released into the air, and the generated ash sluicing water is introduced in order into an ash settling basin, a turbid water basin and a high turbidity water purifier for treatment and then delivered into a clean water basin which finally sends the ash sluicing water into a sewage treatment system for advanced treatment. The method of the invention can improve the removal rate of volatile phenol in the wastewater of pulping and papermaking, and simultaneously reduce the amount of acid for adjusting the pH value of the wastewater during wastewater treatment as well as reduce the amount of alkali for desulphurization while treating the boiler fuel gas. Therefore, the treatment cost of wastewater and exhaust gas generated in papermaking can be reduced.

Owner:四川省环保科技工程有限责任公司 +1

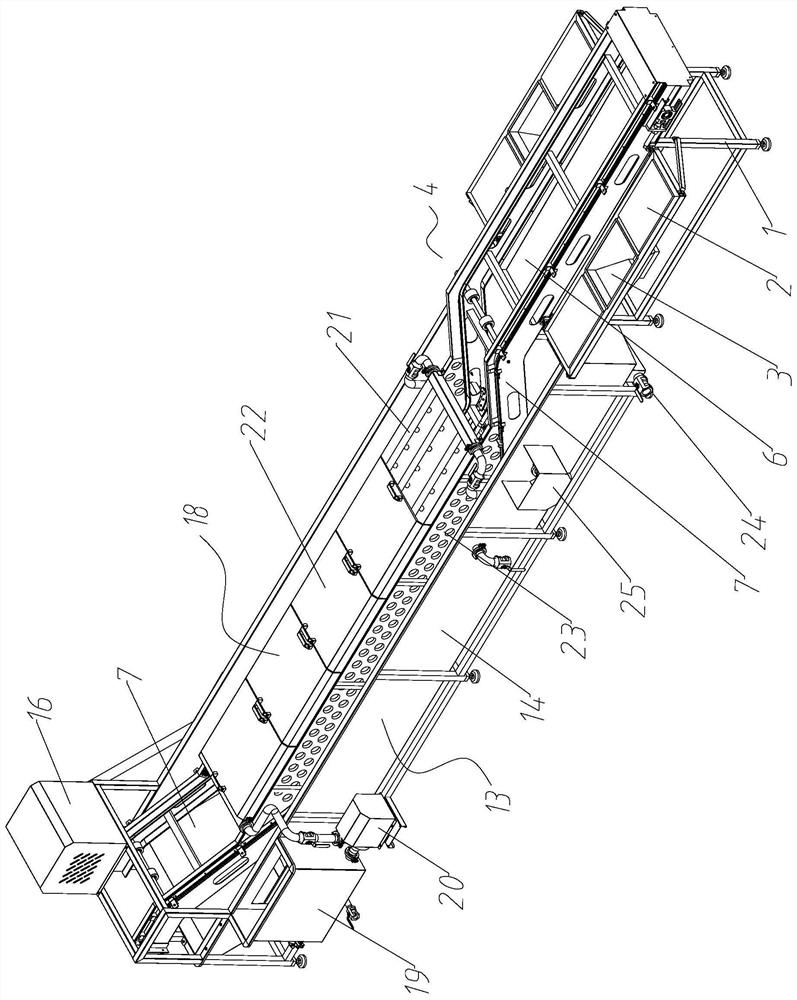

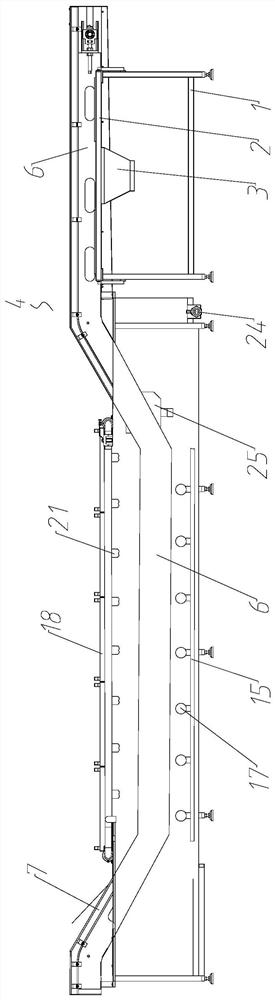

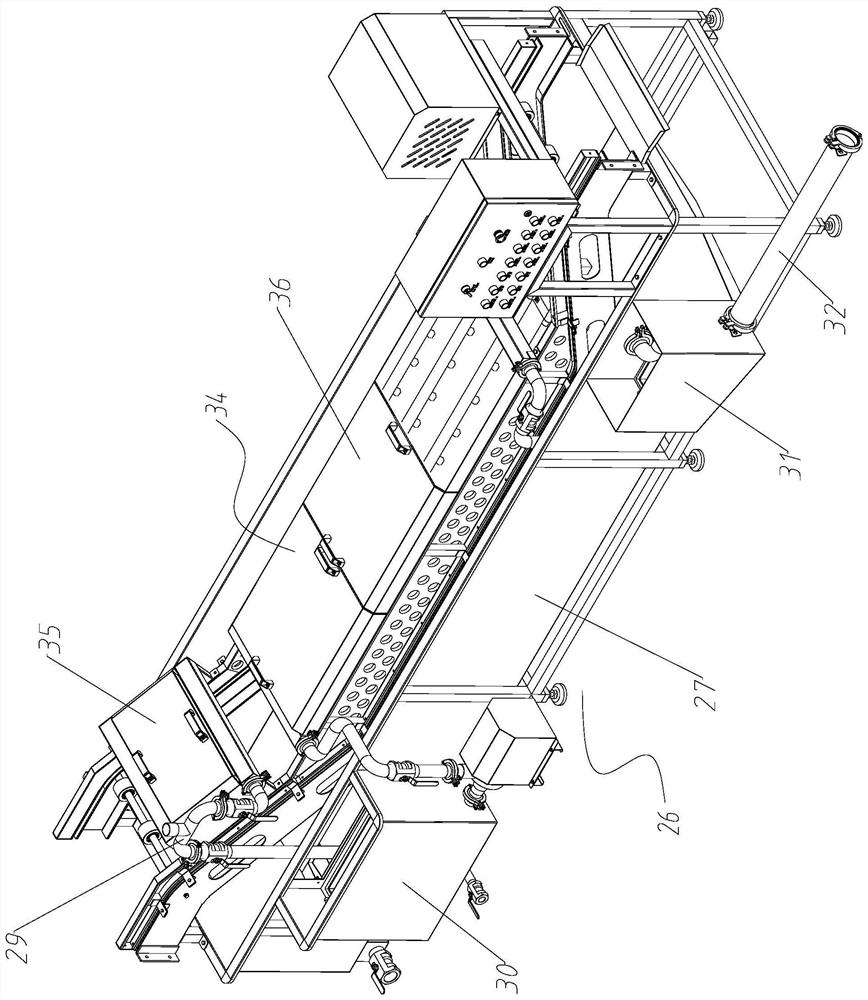

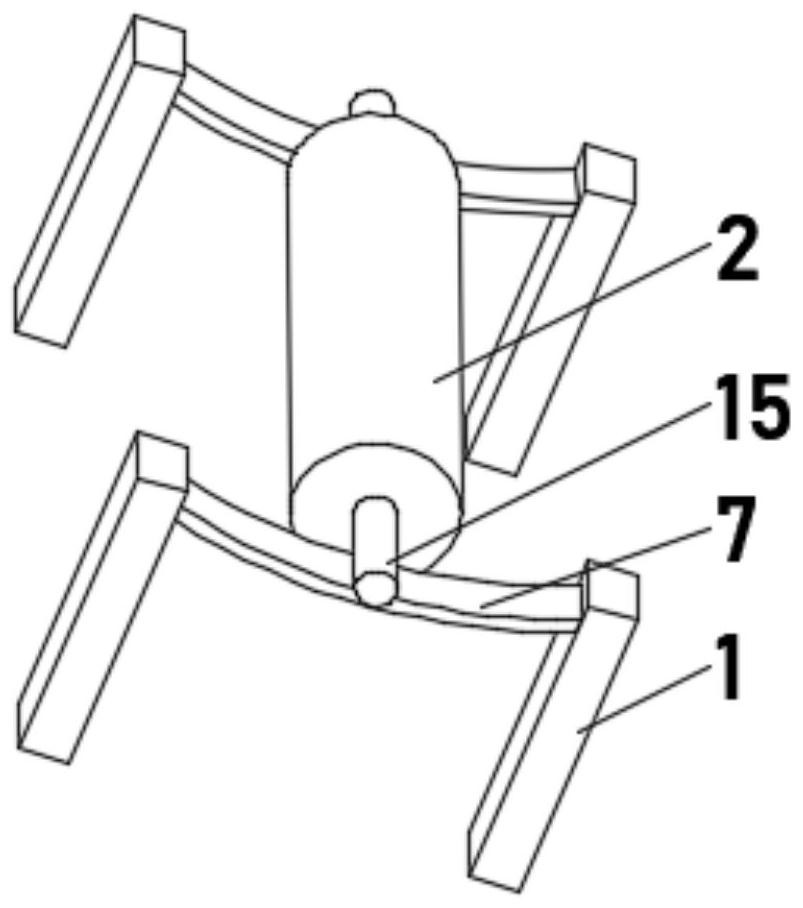

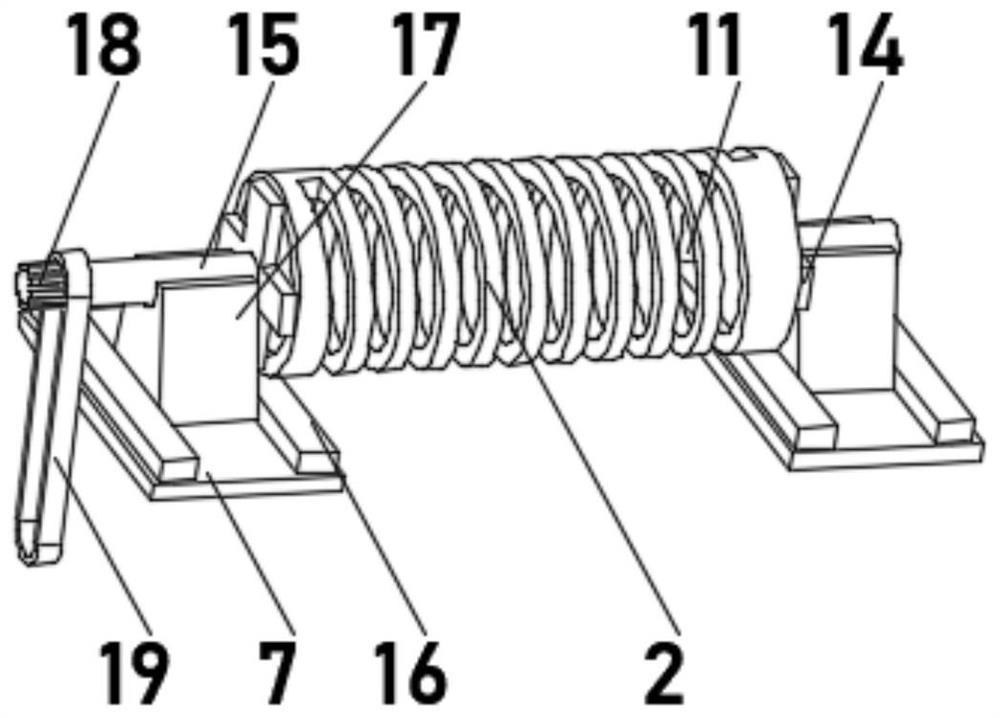

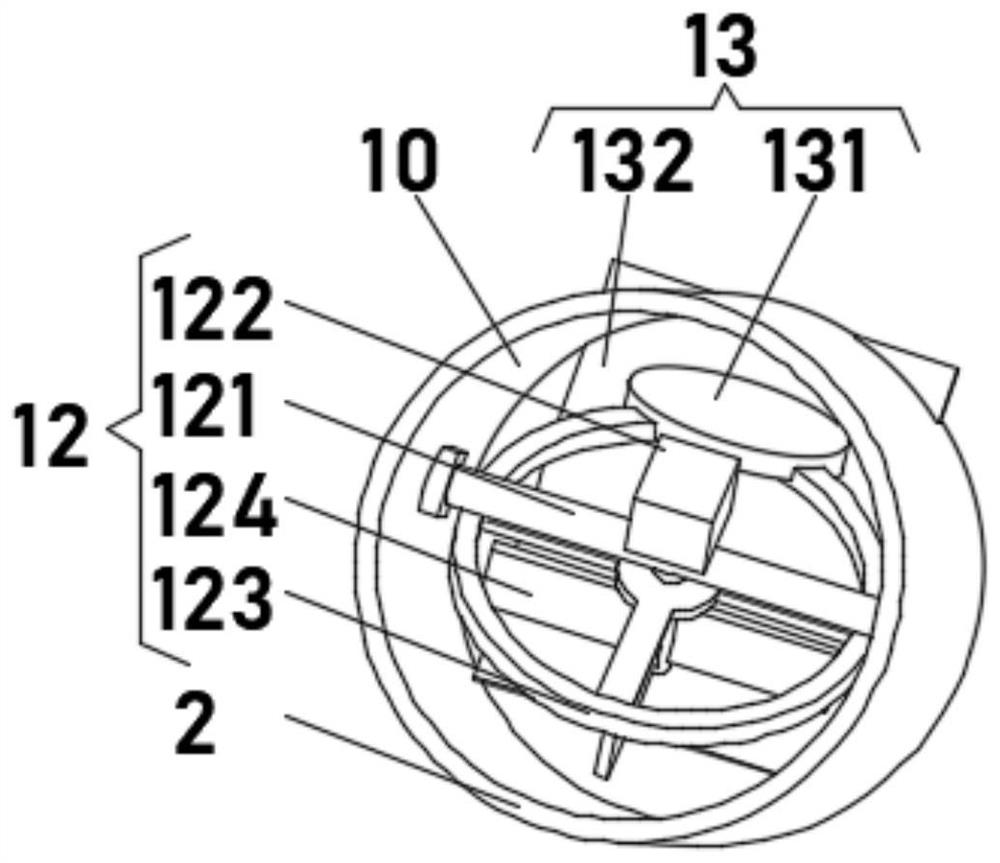

Bubbling cleaning device for whole vegetables

InactiveCN112293764AOscillation does not affectGuaranteed shaking effectFood treatmentAir dryingMechanical engineering

The invention relates to the technical field of vegetable cleaning, and provides a bubbling cleaning device for whole vegetables. The bubbling cleaning device comprises a frame, a sorting table, a conveying belt, a first bubbling cleaning device, a first spraying device, a second bubbling cleaning device, a second spraying device, a clear water spraying device and a vegetable air-drying device, wherein the conveying belt is arranged on the frame, and the conveying belt is provided with bubbling holes; the clear water spraying device is arranged right above a slope section belt behind the second bubbling cleaning device, the clear water spraying device is provided with a spraying protective cover, and the clear water spraying device communicates with a water inlet of a water inlet pipe; andthe conveying belt further includes elastic pieces, shaking water filtering plates and connecting pieces. According to the technical scheme, the problems of continuous cleaning and cleaning and air drying integration of the whole vegetable in the prior art are solved.

Owner:河北领创机械制造有限公司

Printing and dyeing airing device

PendingCN112411085AReduce labor costsProgram to reduce dyeingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsStructural engineeringMechanical engineering

The invention discloses a printing and dyeing airing device, and relates to the technical field of printing and dyeing equipment. The printing and dyeing airing device comprises mounting frames, the mounting frames are symmetrically mounted, and an airing rod is mounted between the mounting frames. Each mounting frame comprises a fixing rod and an A-shaped rod, guide grooves are formed in the topsof the A-shaped rods, guide rollers are rotatably connected between the two sides of the inner walls of the guide grooves, supporting strips are fixedly connected to the sides, close to the A-shapedrods, of the fixing rods, and the supporting strips are slidably connected with the guide rollers. According to the printing and dyeing airing device, shaking generated when the airing rod ascends anddescends can be avoided, the stability of the airing rod is improved, the airing environment is purified, flocculent floating objects in air are removed, the situation that the flocculent floating objects in the air are prone to adhering to aired cloth again to cause pollution is avoided, the quality of the printed and dyed cloth is improved, the floating objects adsorbed on the airing rod can beremoved, the situation that the floating objects block the airing rod and affect the purification function is avoided, and cloth on an airing frame can be conveniently taken down.

Owner:懂效岩

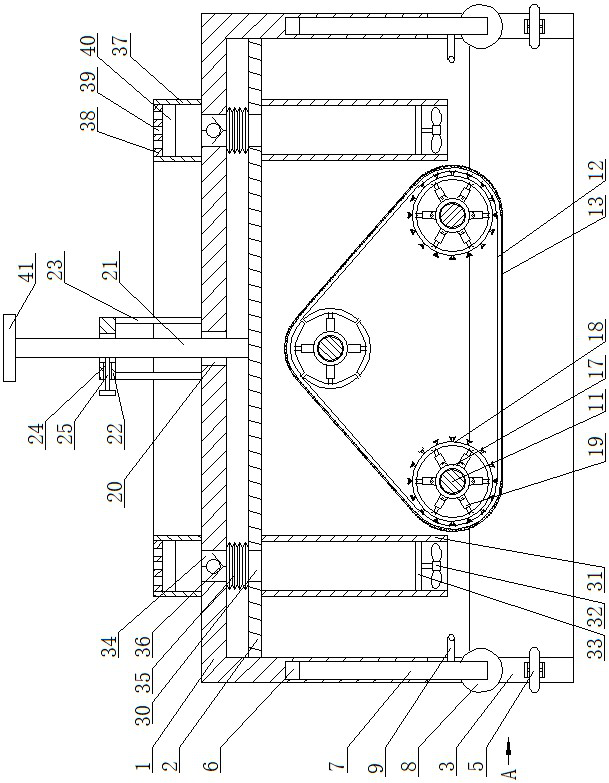

Movable feeding device for livestock raising

ActiveCN109430086AConvenient quantitative feedingEffective destinationAnimal watering devicesAnimal feeding devicesWater storage tankEngineering

The invention relates to the technical field of livestock raising, and discloses a movable feeding device for livestock raising. The movable feeding device comprises a base. Feeding troughs and watertroughs are alternately installed at the bottom of the base. A paste-shaped feed conveying pipe and a grain-shaped feed conveying pipe are fixedly installed at the position, corresponding to each feeding trough, of the upper side of the base. A paste-shaped feed storage tank, a water storage tank and a grain-shaped feed storage tank are arranged in the base. Livestock in a large area of livestockstocking area can be effectively raised through the livestock raising device instead of manpower, grain-shaped feed capable of being scattered on the ground and paste-shaped feed not capable of beingconveniently scattered on the ground can be distinguished, and the cleanliness in the stocking area is ensured; by means of the feeding device, birds can be effectively repelled, feed waste is avoided, feed can be regularly and quantitatively supplied, and the quantitative feeding of livestock is convenient.

Owner:杨青

Handheld furniture plate edge end burr treatment device

ActiveCN111941228AEfficient removalEffective destinationEdge grinding machinesPortable grinding machinesHand heldStructural engineering

The invention discloses a handheld furniture plate edge end burr treatment device. The handheld furniture plate edge end burr treatment device comprises a box body with a downward opening, a U-shapedplate with a downward opening is installed in the box body, the length direction of the U-shaped plate is in the left-right direction, the inner side face of the box body is in sliding connection withthe front side face and the rear side face of the U-shaped plate, first through holes with through bottom faces are formed in the left side face and the right side face of the box body, first transverse rods are correspondingly installed on the front side surfaces and the rear side surfaces of the first through holes, first rolling wheels are installed at the ends, away from the side faces of thefirst through holes, of the first transverse rods, blind holes are formed in the top faces of the first through holes, first vertical rods are inserted into the blind holes in a matching mode, secondrolling wheels are installed at the bottom ends of the first vertical rods, first supports have deformability, and a first rotating shaft in the front-back direction is arranged in the U-shaped plate. According to the handheld furniture plate edge end burr treatment device, the device is held by hand to polish the edge end of a furniture plate by using a friction layer, burrs at the edge end canbe effectively removed, small areas of the side faces of some plates can be further polished, use is convenient, automation is higher, use is convenient and rapid, the working efficiency is greatly improved, and the device is convenient to store and carry.

Owner:HUNAN INSTITUTE OF ENGINEERING

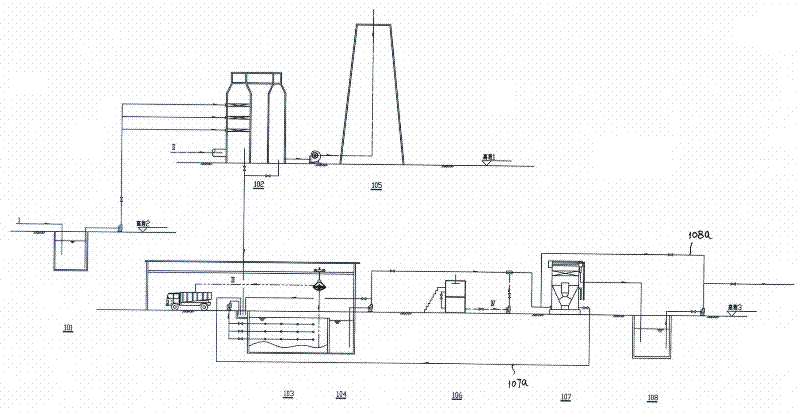

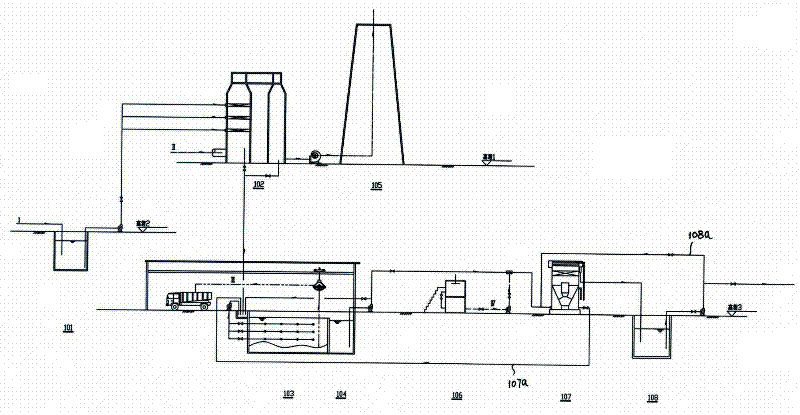

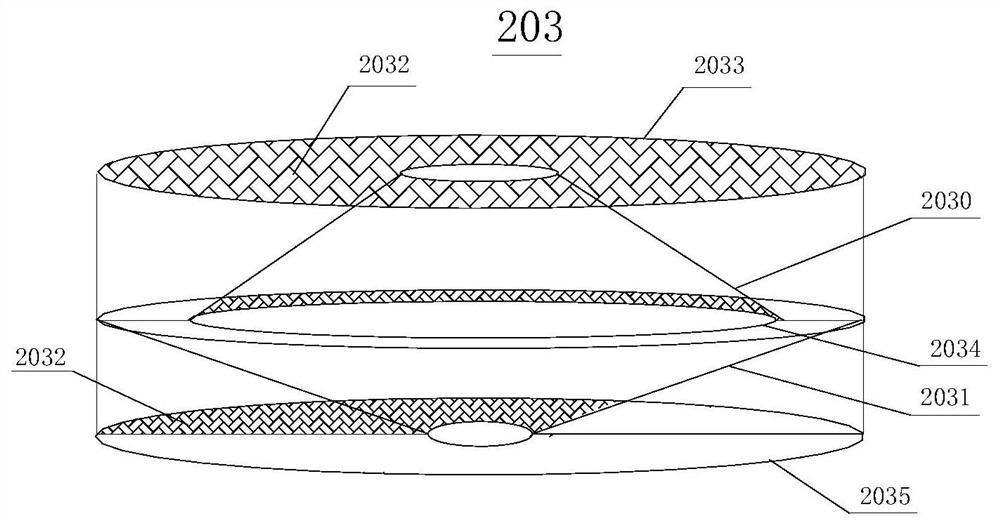

A flue gas treatment system and treatment process of a polymer waterproof coiled material production line

ActiveCN109647114BLow boiling pointEliminate spontaneous combustionCombination devicesGas treatmentThermodynamicsFlue gas

Owner:广西神宇新材料有限公司

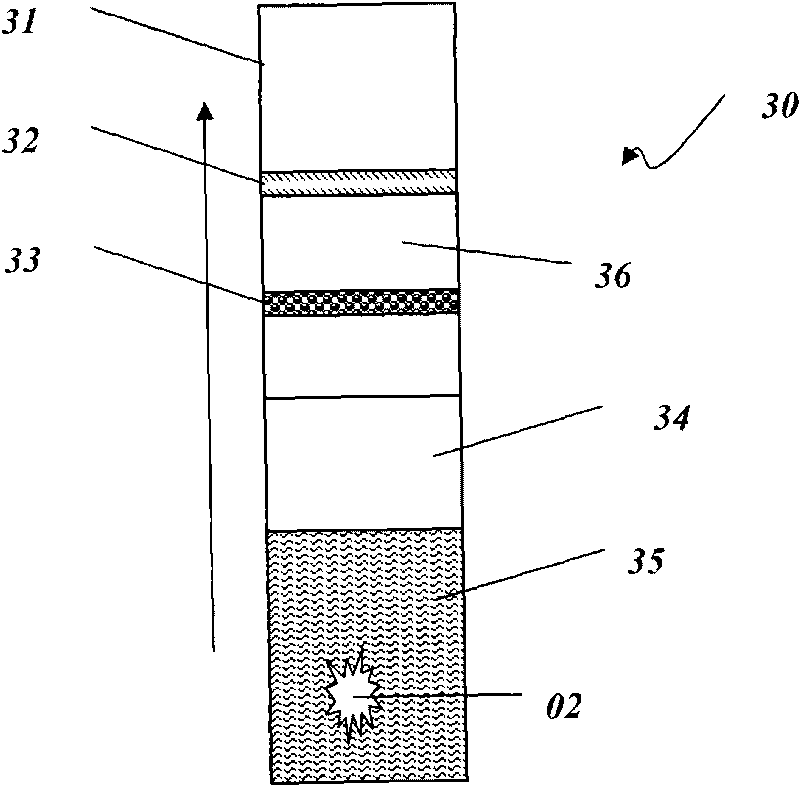

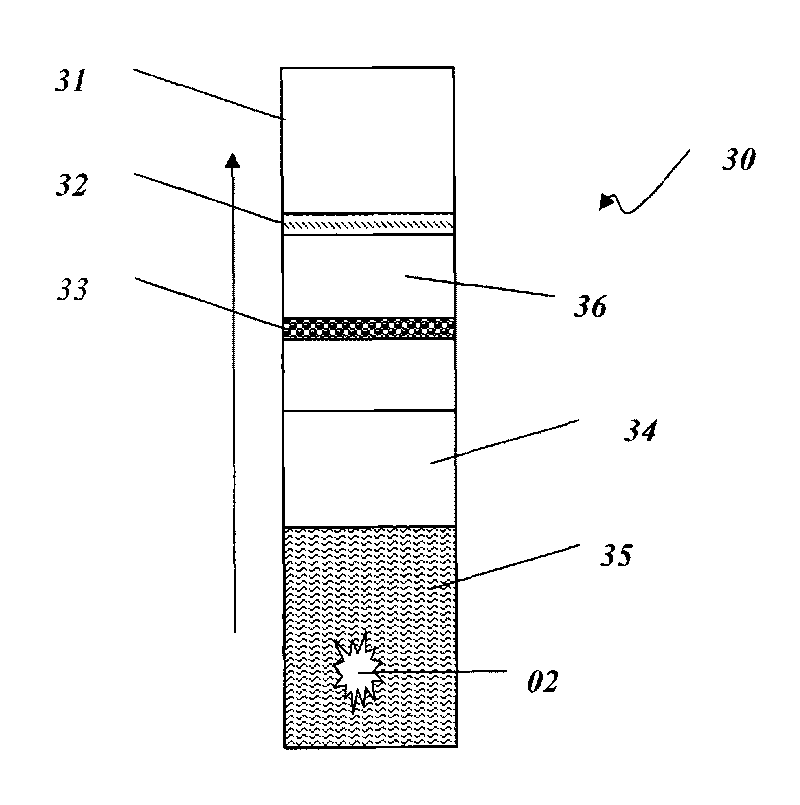

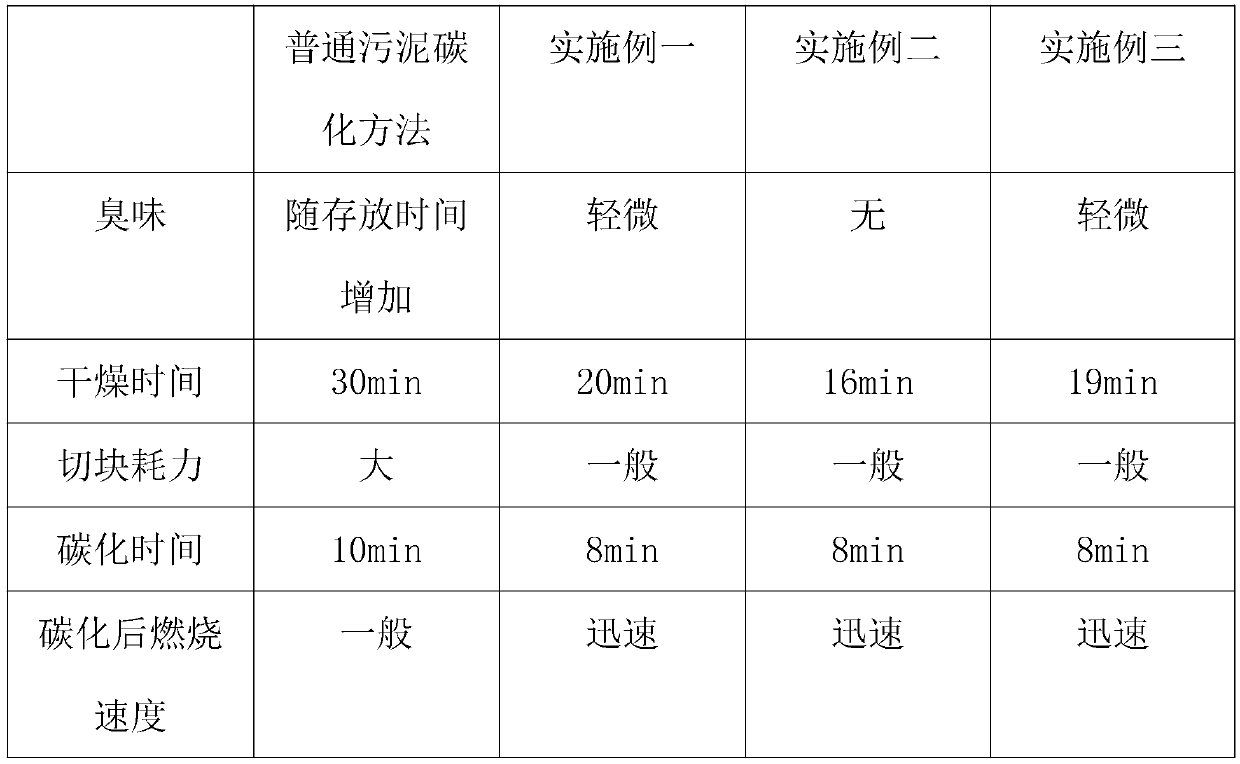

Sludge carbonizing method

InactiveCN109650688AEffective destinationHarmful to healthSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionSludge

The invention discloses a sludge carbonizing method, and relates to the technical field of sludge treatment. The method comprises the following steps of sludge deodorization, wherein deodorization bacteria are prepared according to a formula, sludge is heated, deodorization bacteria are added, and after stirring is performed, standing is performed for 2-10 h; drying, wherein sludge is supplied into a drying machine to be dried till the water content is 85-90%, then, a pressing machine is used for pressing to form a honeycomb shape, and the pressed sludge is placed into the drying machine to continuous drying till the water content is 70-80%; carbonizing; recycling, wherein the carbonized sludge is pressed into meshes, 3-5 carbonized sludge meshes are stacked to form a simple filter device,and the sludge in step 1 penetrates through the filter device for the deodorization link; sludge carbonizing, wherein the filtered carbonized sludge meshes are dried for combustion. According to thesludge carbonizing method, odor caused after sludge is stored for a long time is effectively removed, damage to health of workers is avoided, meanwhile, the carbonizing efficiency of the dried sludgeis improved, and more labor is saved in the process when sludge is cut into small pieces after drying.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com