New method for removing volatile phenol from wastewater of pulping and papermaking with boiler fly ashes

A technology for pulping and papermaking and wastewater production, which is applied in separation methods, chemical instruments and methods, and wastewater treatment during processing, etc., can solve the problems of effective treatment of hardly volatile phenolic substances, low removal of volatile phenolic substances, and high treatment costs, Achieve the effect of reducing flue gas desulfurization cost, treatment cost and CODcr concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

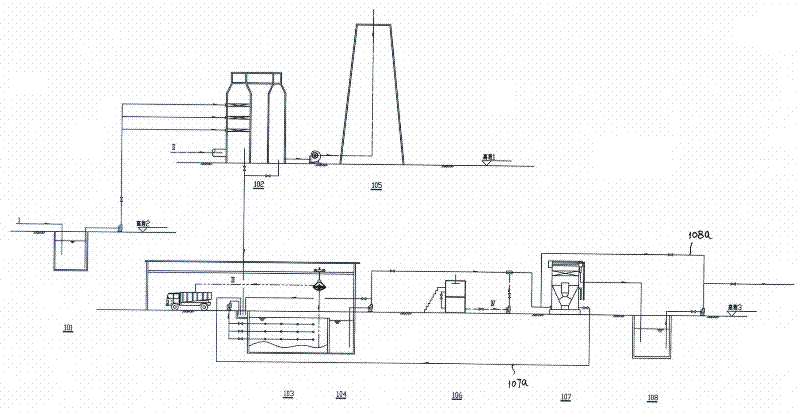

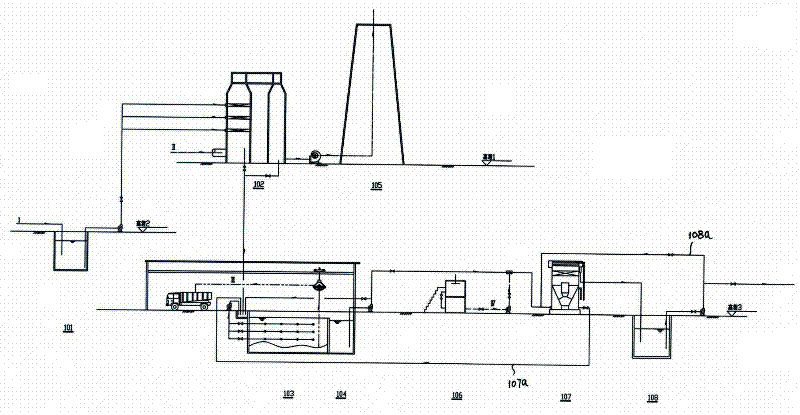

[0023] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0024] figure 1 Middle: Ⅰ, waste water pipeline; Ⅱ, flue gas pipeline; Ⅲ, ash pipeline; Ⅳ, dosing pipeline (pipeline from the medicine storage tank); 101, water storage tank; 102, water film dust removal system; 103, ash 104, turbid water pool; 105, chimney; 106, dosing system (drug storage tank); 107, high turbidity water purifier; 107a, sludge return pipeline; 108, clear water pool; 108a, circulation pipeline.

[0025] A kind of method utilizing boiler fly ash to remove volatile phenol in pulping and papermaking waste water, carry out according to the following steps:

[0026] a) According to the dedusting time and water volume requirements of the water film dedusting system, the condensed sewage produced by the pulp and paper mill with a pH value of 10-11.5 is imported into the water storage tank 101 through the pipeline, and then pumped to the water film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com