Patents

Literature

230results about How to "Reduce processing operating costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

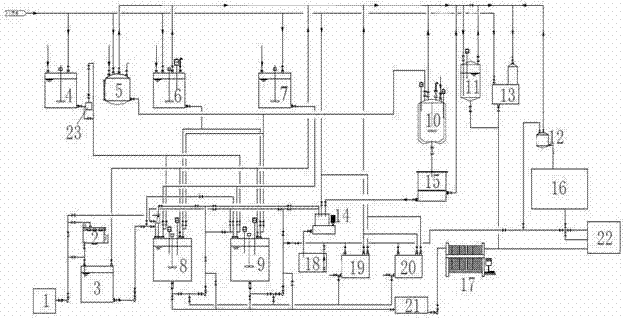

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

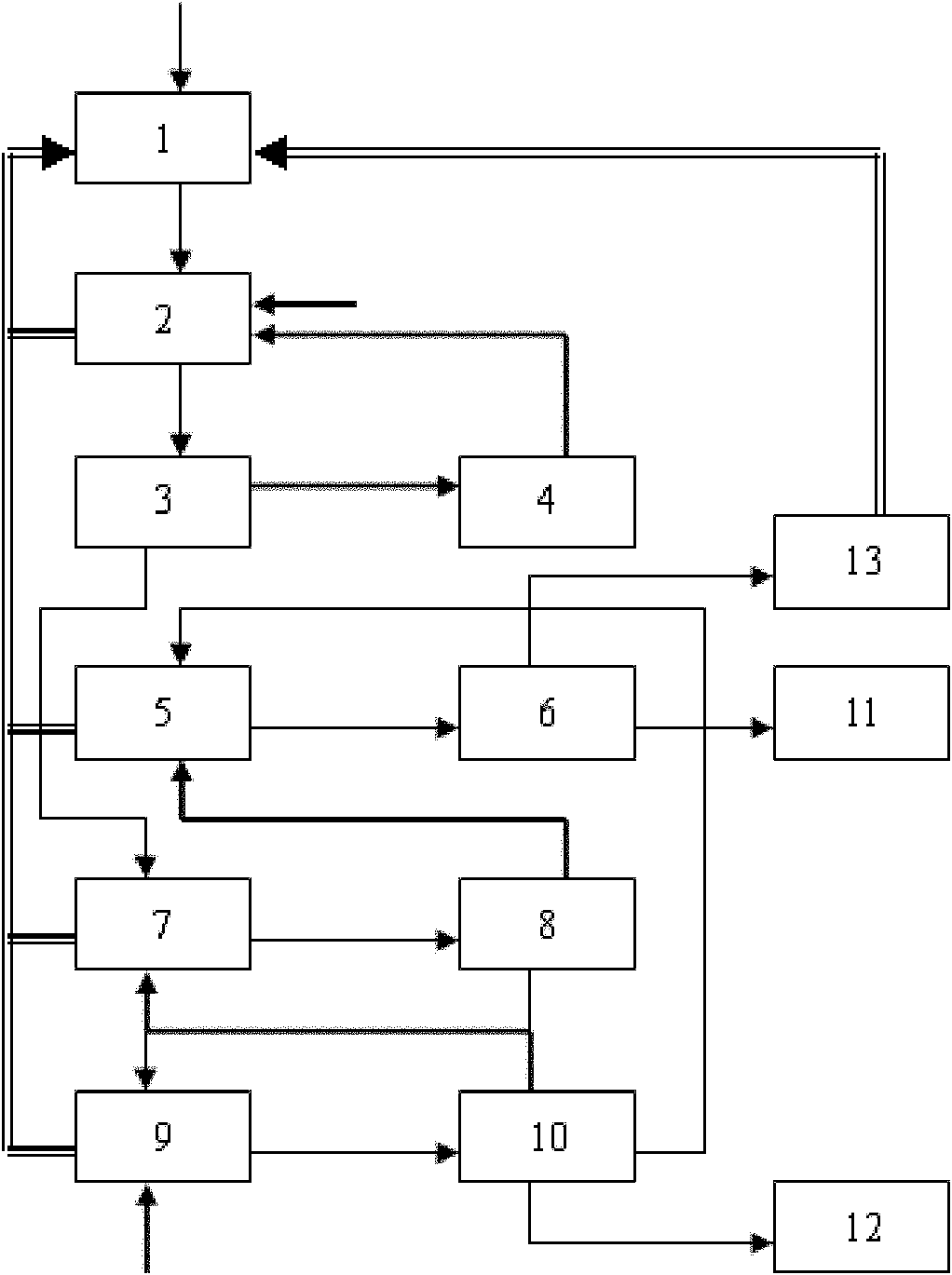

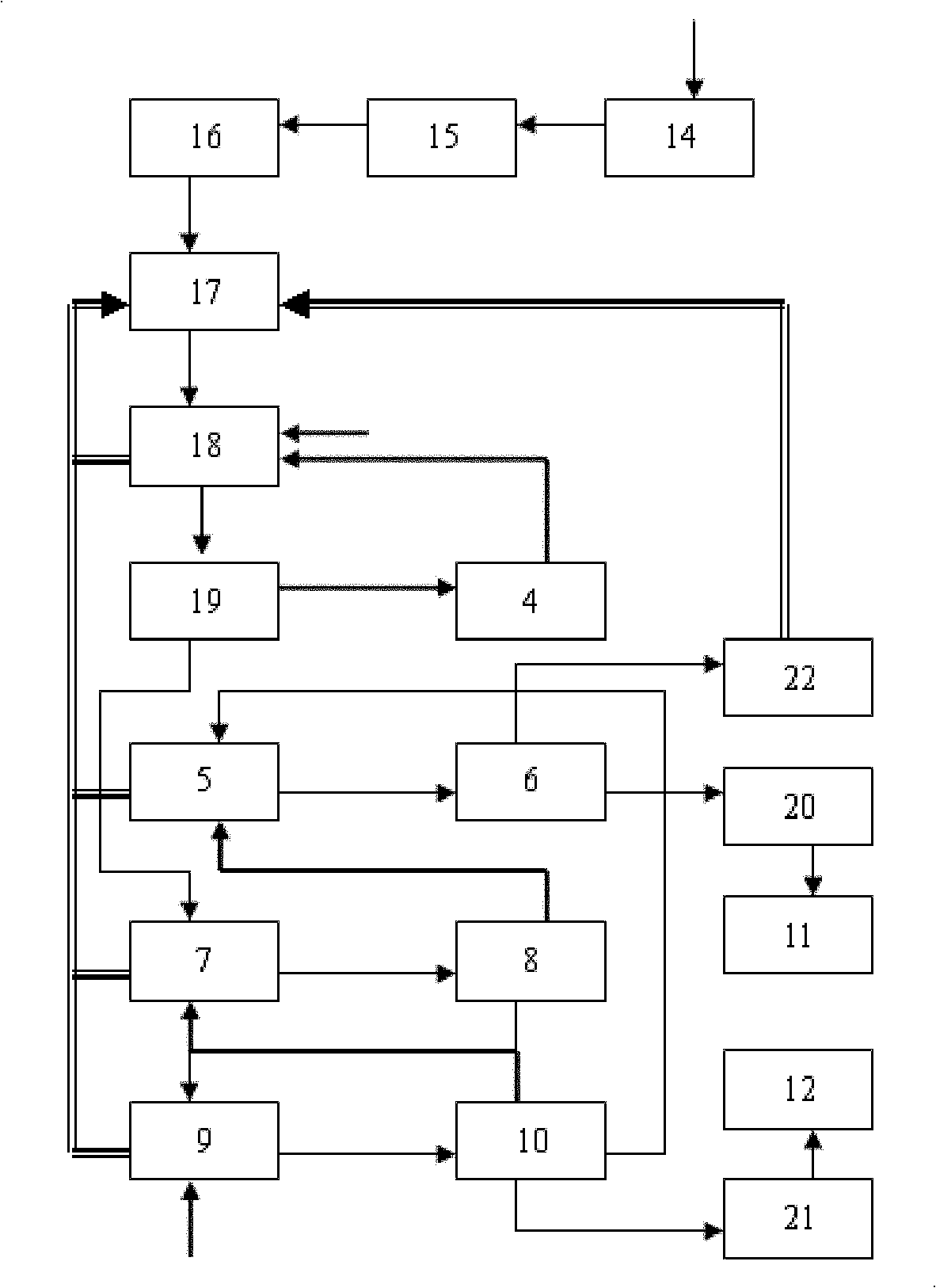

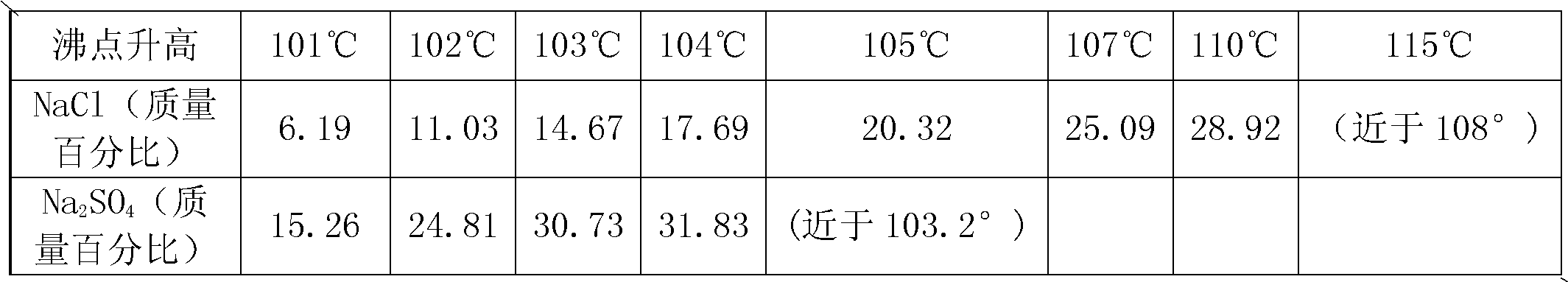

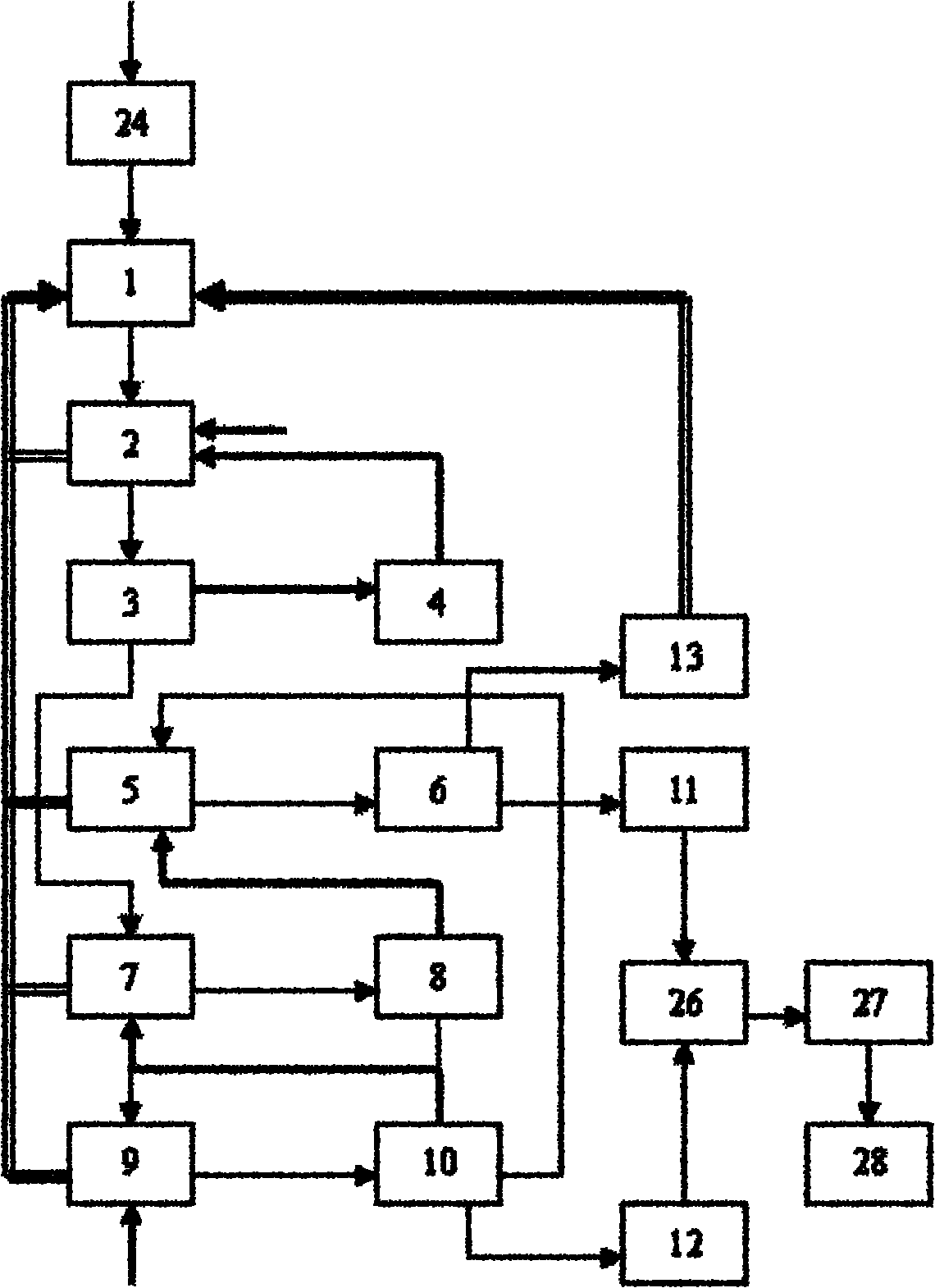

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

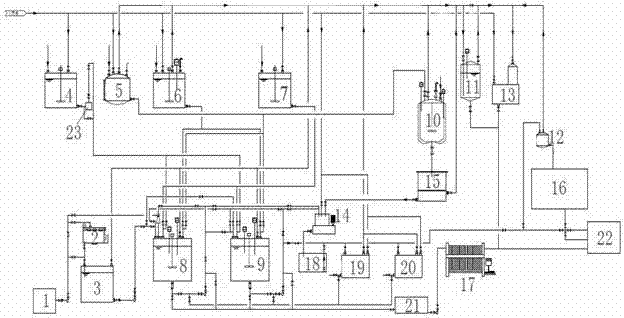

Wastewater evaporating process and device system

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

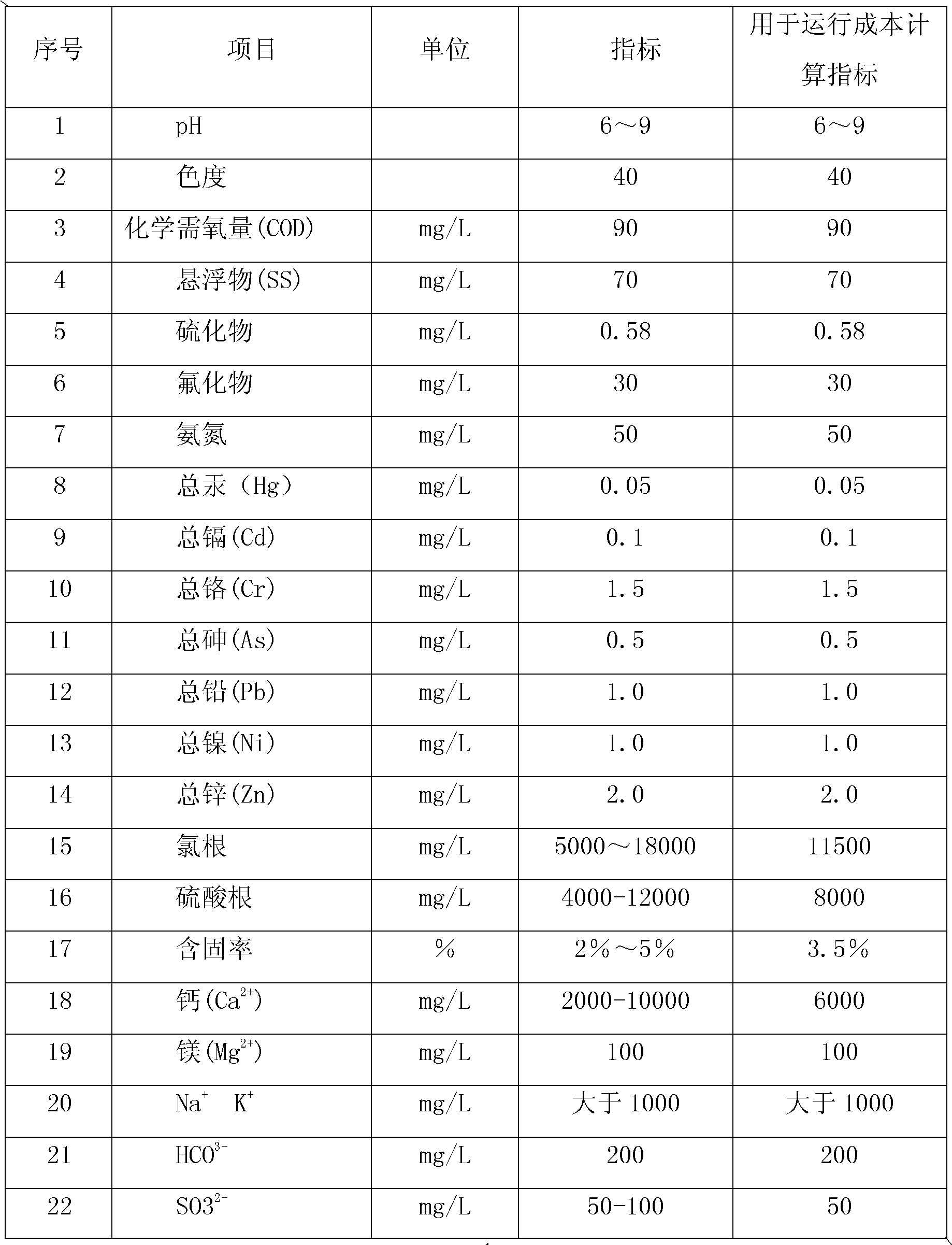

Technology for recovering production of electrolytic copper and zinc from smelting ash

ActiveCN102851693AWide adaptabilityFlexiblePhotography auxillary processesProcess efficiency improvementElectrolysisCopper oxide

The invention discloses a technology for recovering production of electrolytic copper and zinc from smelting ash. The technology comprises a step of smelting ash leaching, a step of copper extraction and purification through copper electrodeposition, a step of iron removal through neutralization, a step of cadmium removal, and a step of zinc extraction and purification through zinc electrodeposition. The method is characterized in that chemical components in the smelting ash are analyzed, and the smelting ash is leached by a sulfuric acid solution leaching agent; the leachate obtained after the above leaching reaction undergoes a separation operation of copper extraction and purification through the copper electrodeposition; the resultant copper extraction liquor is neutralized by high-zinc dust which is a neutralizer to remove iron; cadmium is displaced and deposited by zinc powder having a mass same with cadmium after the iron removal through the neutralization; and the zinc extraction is carried out through the zinc electrodeposition by casting zinc ingot products. The technology has a wide adaptability, adopts two steps to complete the exchange reaction of zinc oxide and copper oxide in the raw material with an acid, and adopts the high-zinc dust as the neutralizer, so the massive zinc loss caused by entrainment of routine neutralizers comprising calcium oxide and sodium hydroxide is avoided. A zinc extraction liquor obtained in the above step is purified by N235, so economy and effectiveness are realized.

Owner:江西自立环保科技有限公司

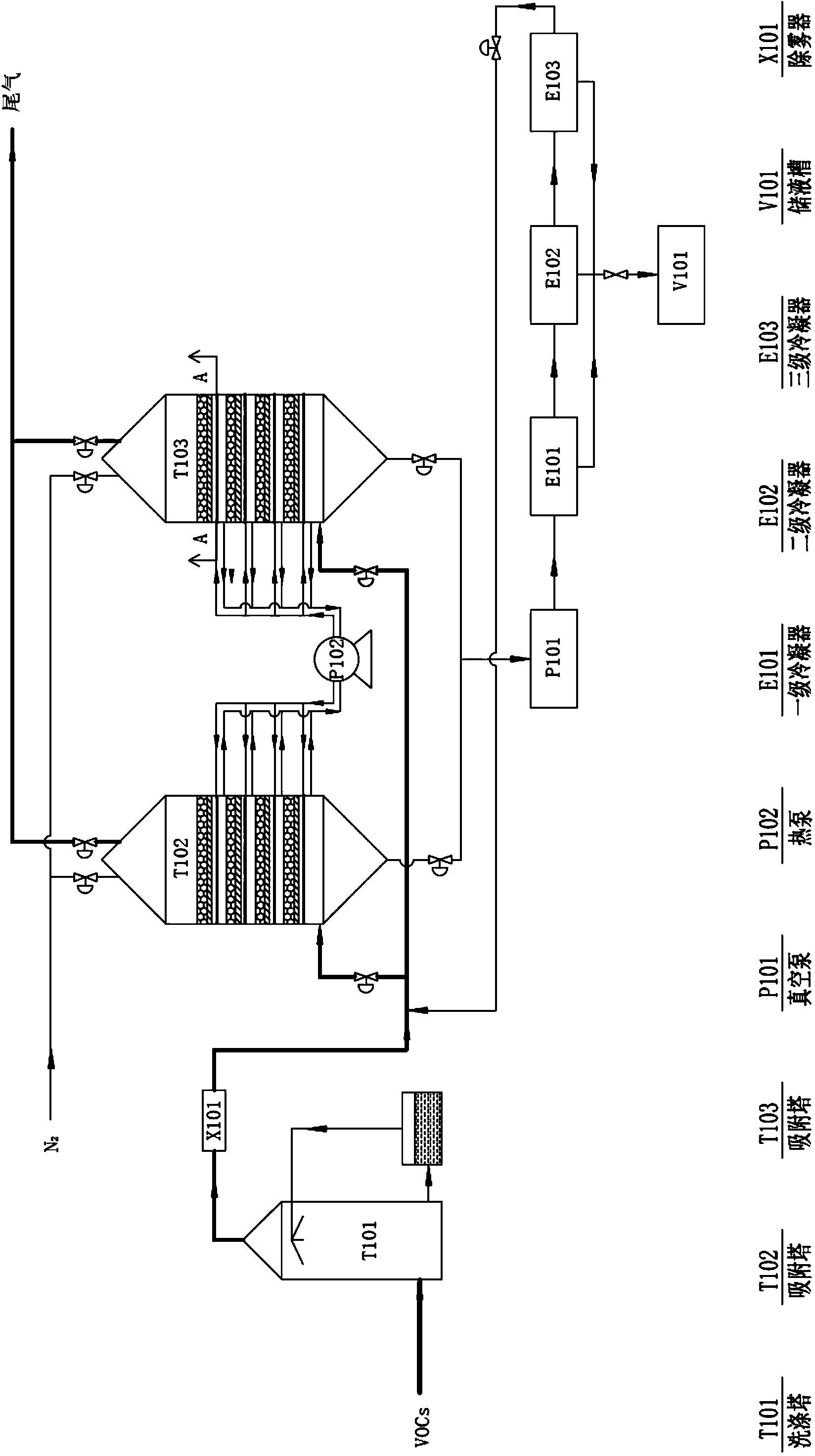

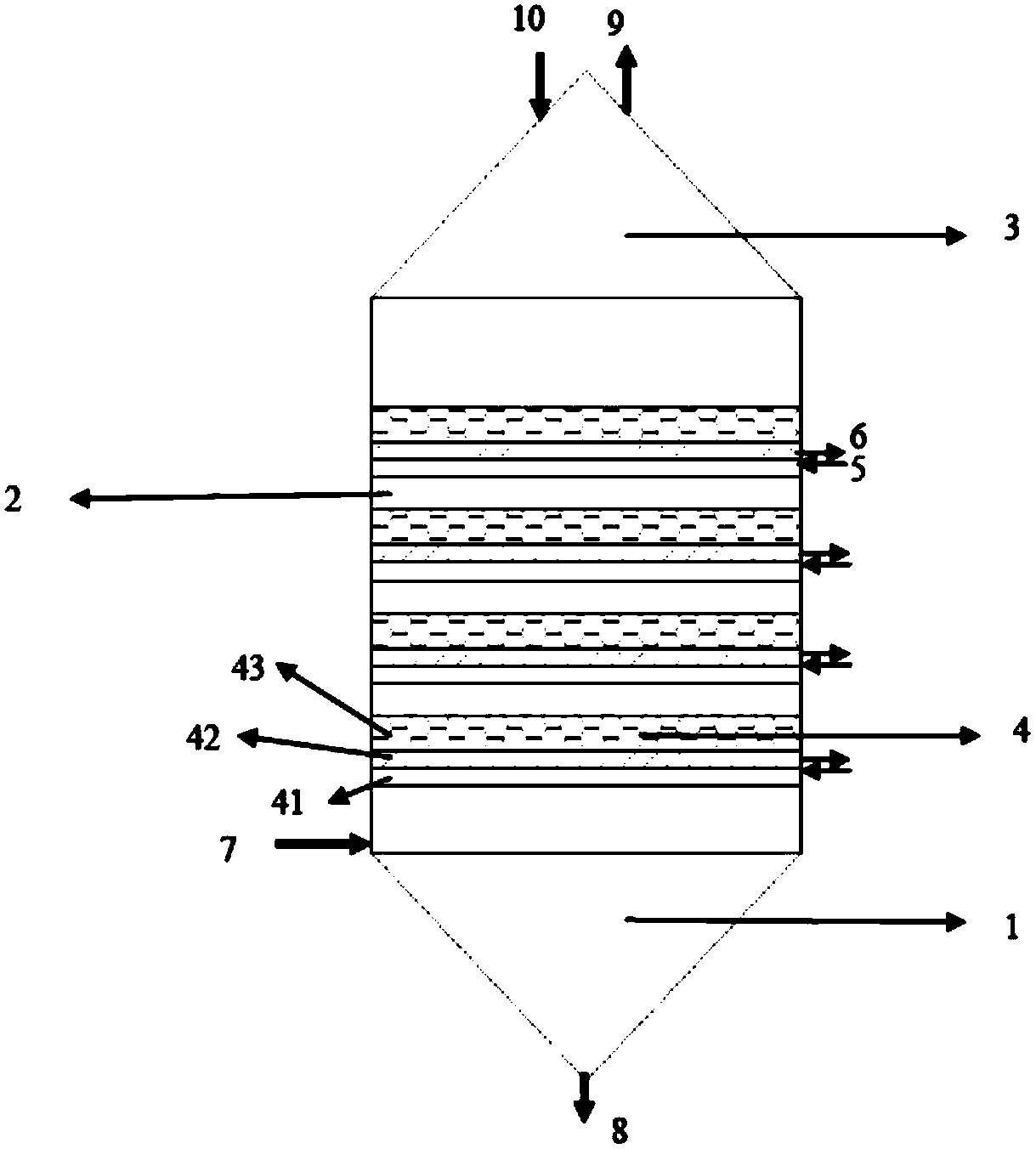

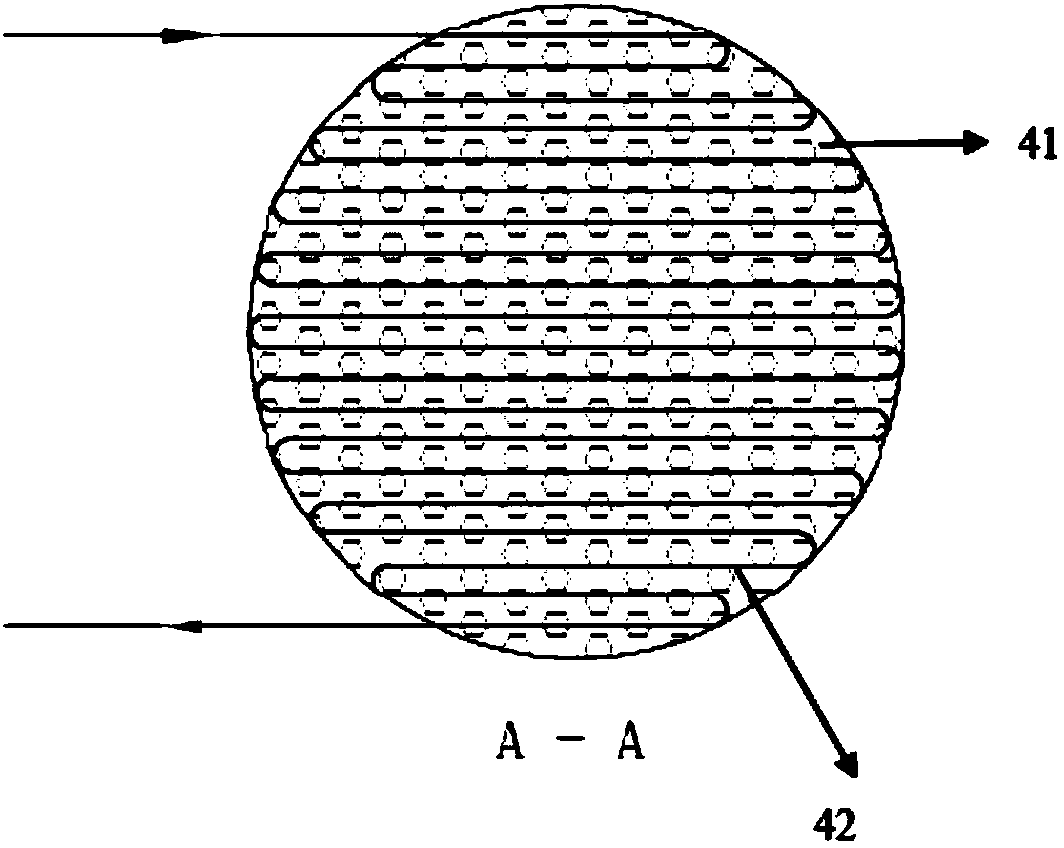

Organic waste gas adsorbing recovery device and process

ActiveCN103877827AHigh recovery rateAvoid cokingDispersed particle separationProduct gasHigh concentration

The invention discloses an organic waste gas adsorbing recovery device and a process. The device comprises at least two macromolecule resin adsorbing towers, a heat pump, a vacuum pump, a condenser, a liquid storing tank and the like, wherein the macromolecule resin adsorbing towers are internally provided with waste gas inlet regions, purifying regions for adsorbing and purifying gas and a purifying gas discharging region; the purifying regions are provided with adsorbing layers which are horizontally paved, the adsorbing layers are composed of multi-hole supporting plates fixed on the adsorbing towers, heat exchanging coils paved above the multi-hole supporting plates and macromolecule resin layers which are fully paved on the cross sections of the adsorbing towers above the heat exchanging coils successively in a overlaying manner, and the heat exchanging coils are provided with inlets and outlets communicated with the heat pump arranged outside the adsorbing towers. The organic waste gas adsorbing recovery device and the process provided by the invention have the advantages that a non-flammable macromolecule resin is adopted as an adsorbing material, the removing rate of middle-high concentration organic waste gas is more than 98%, the organic waste gas recovery rate is more than 95%, the resin is fully regenerated, and the organic waste gas can reach the discharge standard.

Owner:杭州润信科技有限公司

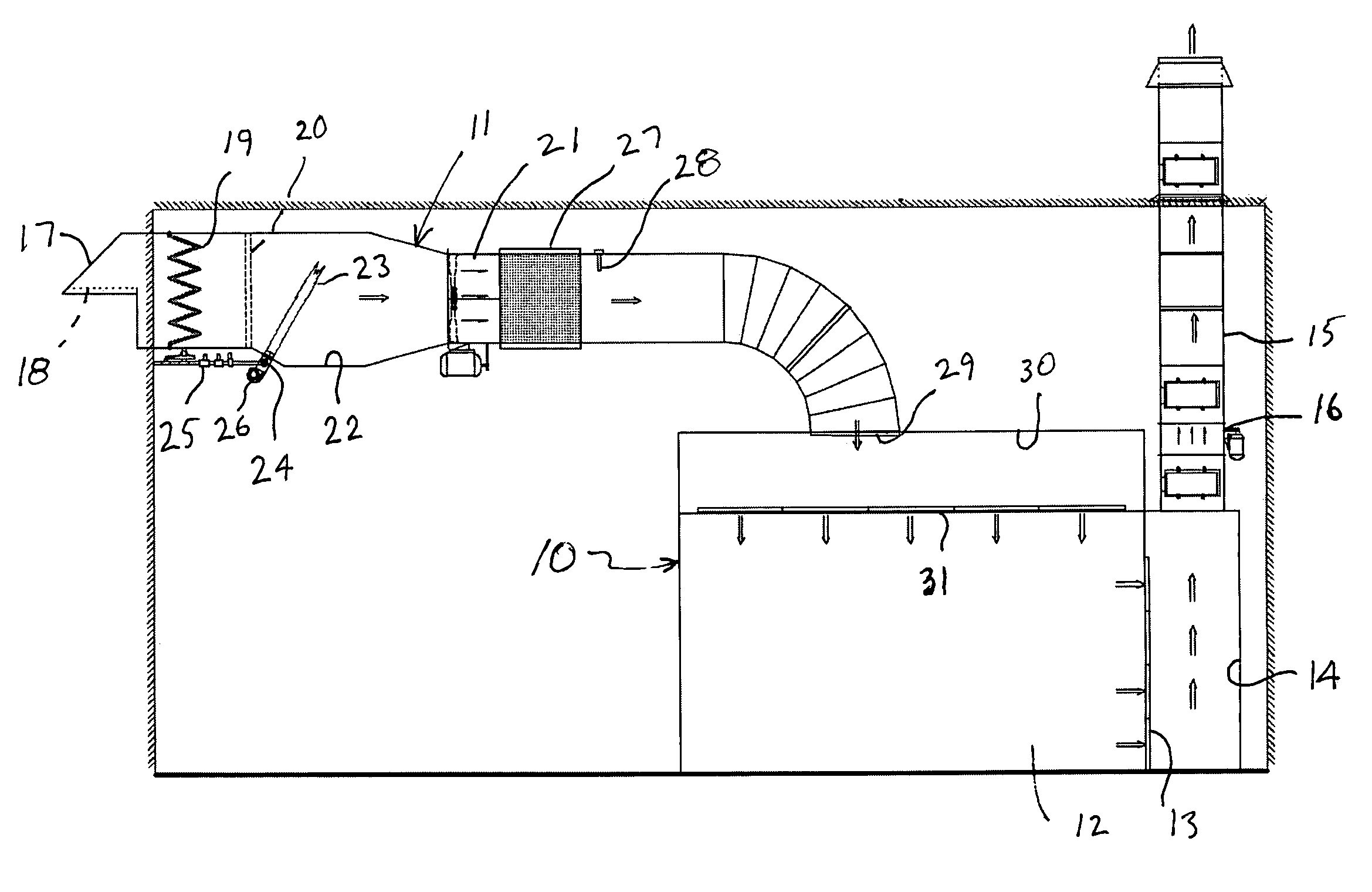

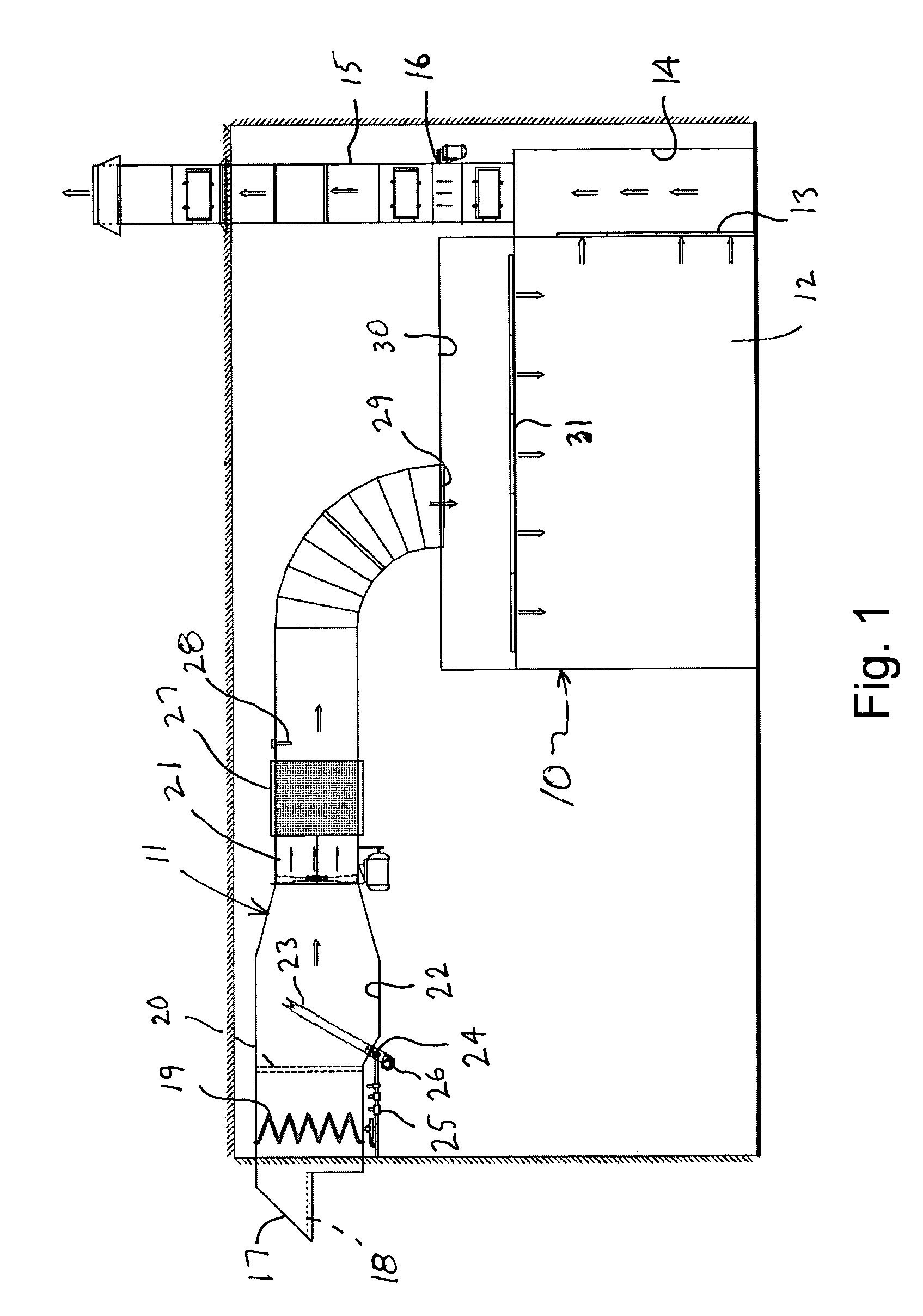

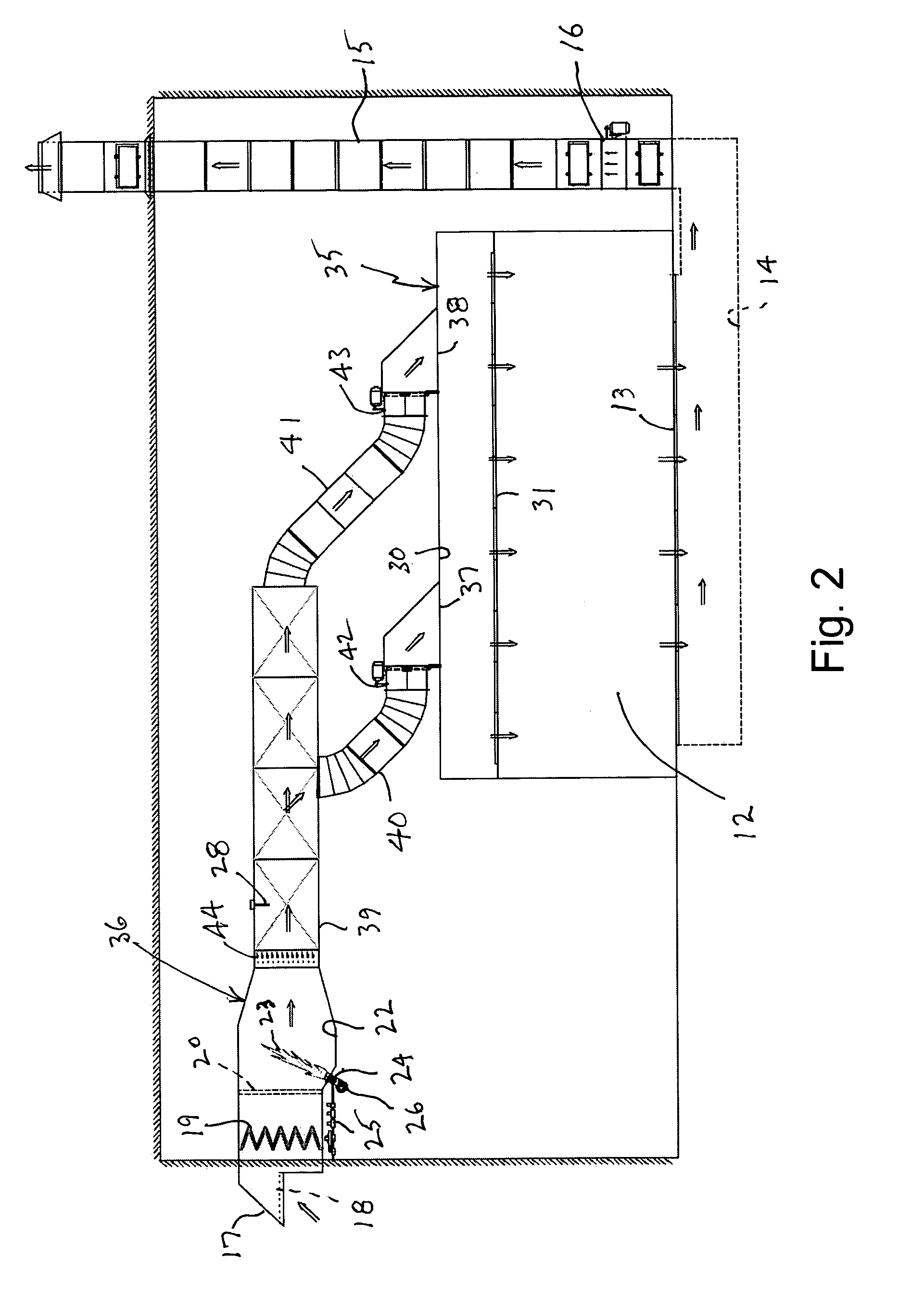

Heated replacement air system for commercial applications

ActiveUS7360534B2Improve transmission efficiencyEmission reductionLiquid surface applicatorsDomestic stoves or rangesCombustorEngineering

Apparatus and a method for providing heated replacement air to a paint spray booth or other commercial process which requires heated make-up air to replace exhausted air. A blower draws outside air through a filter and an injection chamber prior to delivering the air to the process. Hot gases from a burner are injected into the injection chamber and mixed with the replacement air to adjust the temperature of the replacement air. The burner uses combustion air which is separate from the replacement air. The flow rate of the exhaust air and the replacement air can be adjusted to meet changing needs of the process. The BTU output from the burner is adjusted to maintain a desired replacement air temperature.

Owner:SUPPLIER SUPPORT INT

Preparation method of nickel foam supported bimetal MOF base ozone catalyst, production thereof and application

ActiveCN110302841ASolve separation and recyclingSimple and fast operationWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsDecomposition

The invention relates to a preparation method of nickel foam supported bimetal MOF base ozone catalyst, a production thereof and application. The preparation method comprises the steps that a metal organic framework ZIF-67 is taken as a template, nickel foam serves as a carrier, an in-situ hydrothermal-impregnation synthesis method is adopted to prepare a supported porous Mn / Co bimetal MOF base ozone catalyst, bimetal Mn / Co oxide in situ grows on a nickel foam base through a hydrothermal method, the supported bimetal oxide is modified by ZIF-67 through a impregnation method, and thus the nickel foam supported bimetal MOF base ozone catalyst is prepared. According to the preparation method, the crystal size and morphology of the catalyst are regulated effectively and accurately, evenly-distributing of active sites is facilitated, the decomposition rate on ozone and the mineralization rate on organic matter of the nickel foam supported bimetal MOF base ozone catalyst are greatly improved, the problems of separating and recycling of suspended catalysts can be effectively solved, the operation cost of water treatment is lowered, and large application prospects are achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

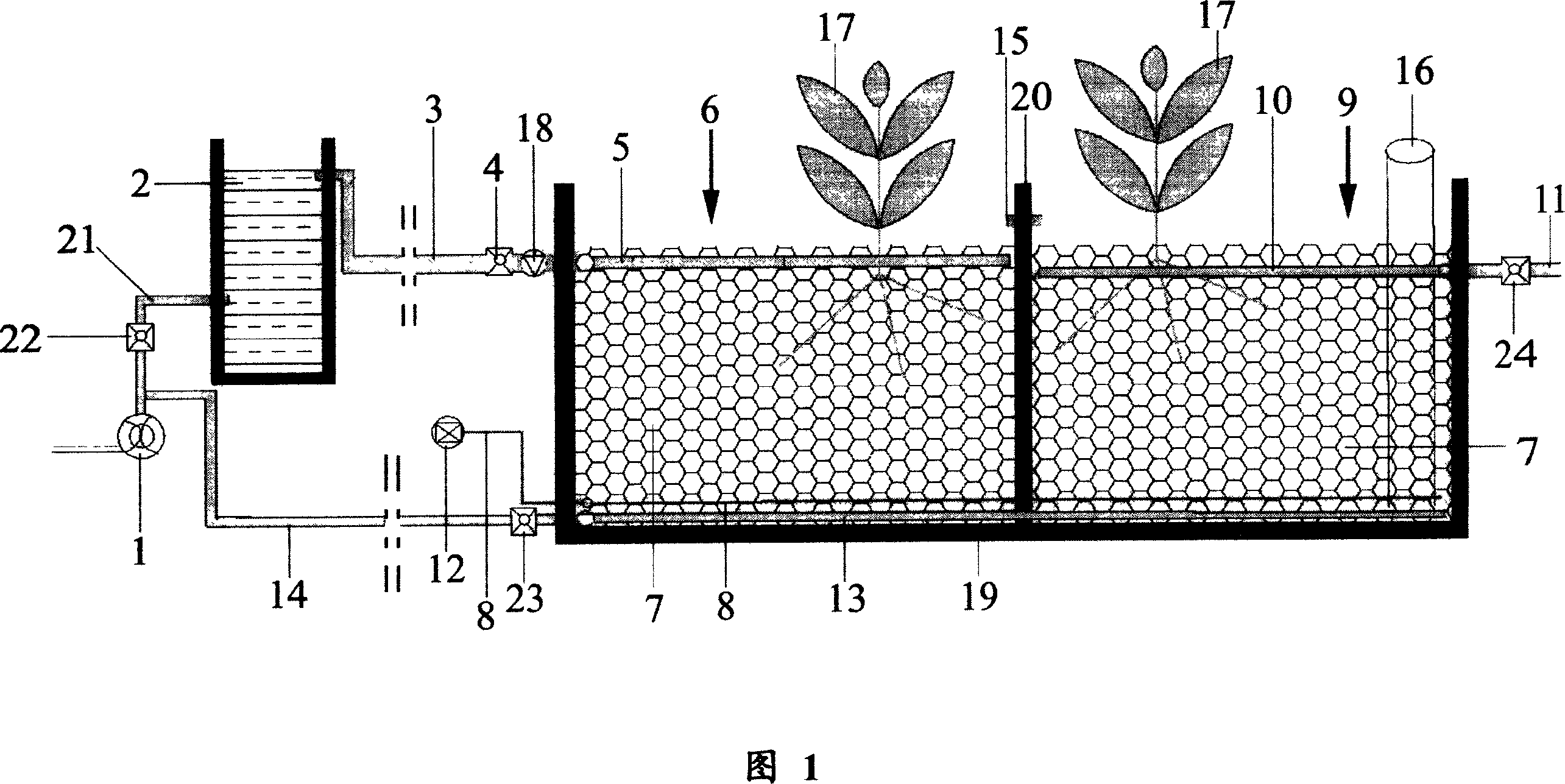

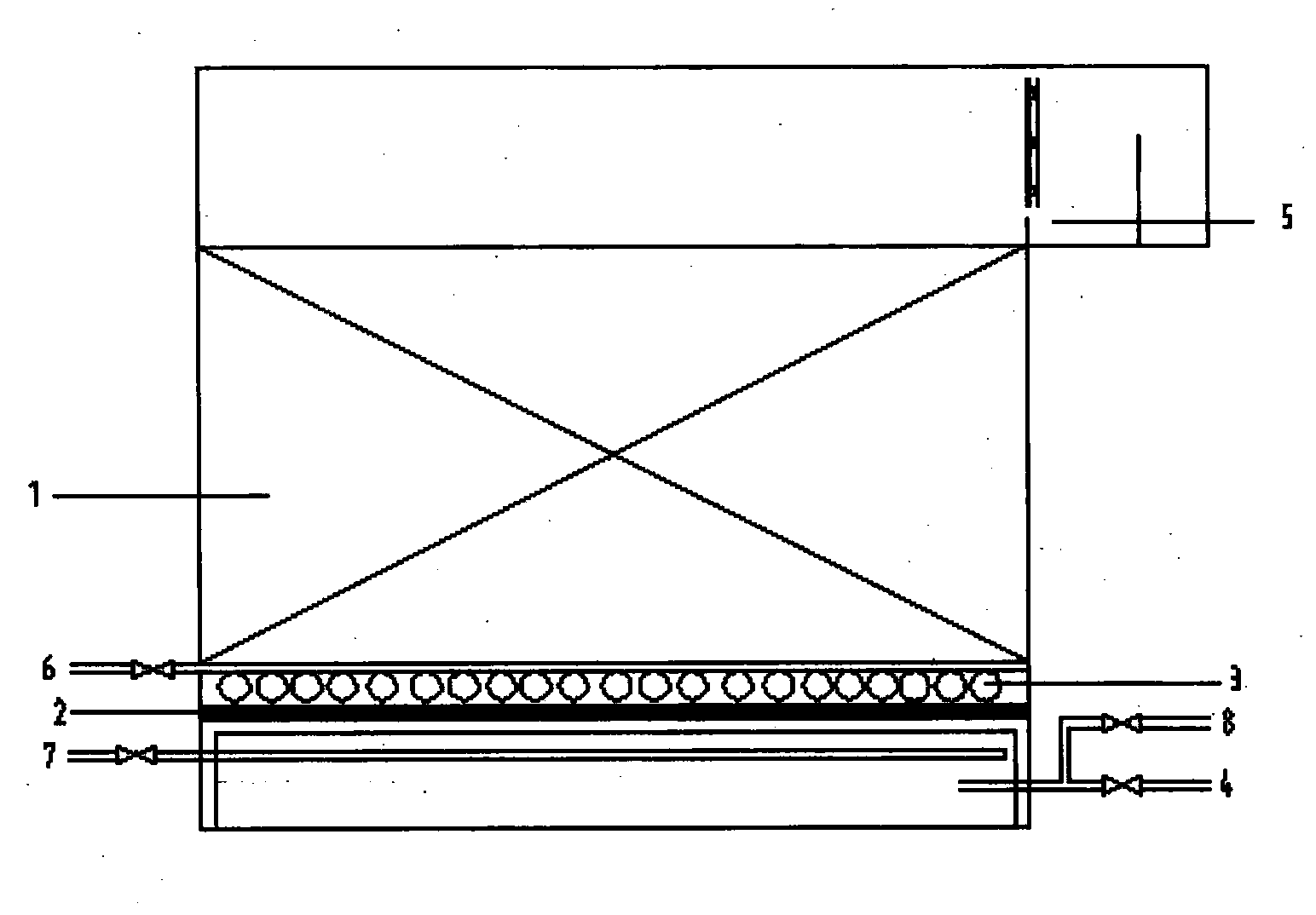

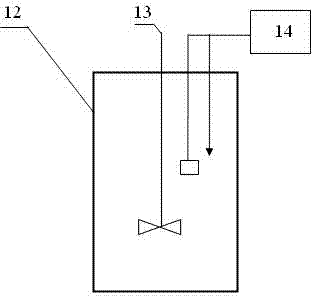

Backwash, aeration type undercurrent wetland water body purification apparatus and water body purification method

InactiveCN101007687AImprove water purification abilityAvoid cloggingTreatment using aerobic processesTreatment with aerobic and anaerobic processesWater pipeSmall footprint

The invention discloses a purifying device of backwash, aeration type hidden flow marshland water body and a method of purifying water body, wherein the whole purified pool display cube box; the separating pool separate the pool as downward pool and upper pool; the filling base material pack evenly in the pool; planting amphibious plant on the upper; setting cloth water pipe on the upper of the upper pool; making the upper of adjusting pool higher than purifying pool; setting inlet pipe and water-feed pump on the one side of the adjusting pool; setting admitting pipe and admitting pipe on the upper of the upper pool; setting aeration machine on one side of the purifying pool. The invention possesses high load factor, small plot area and good treatment effect, which can improve treatment effect.

Owner:TIANJIN WATER CONSERVANCY INST

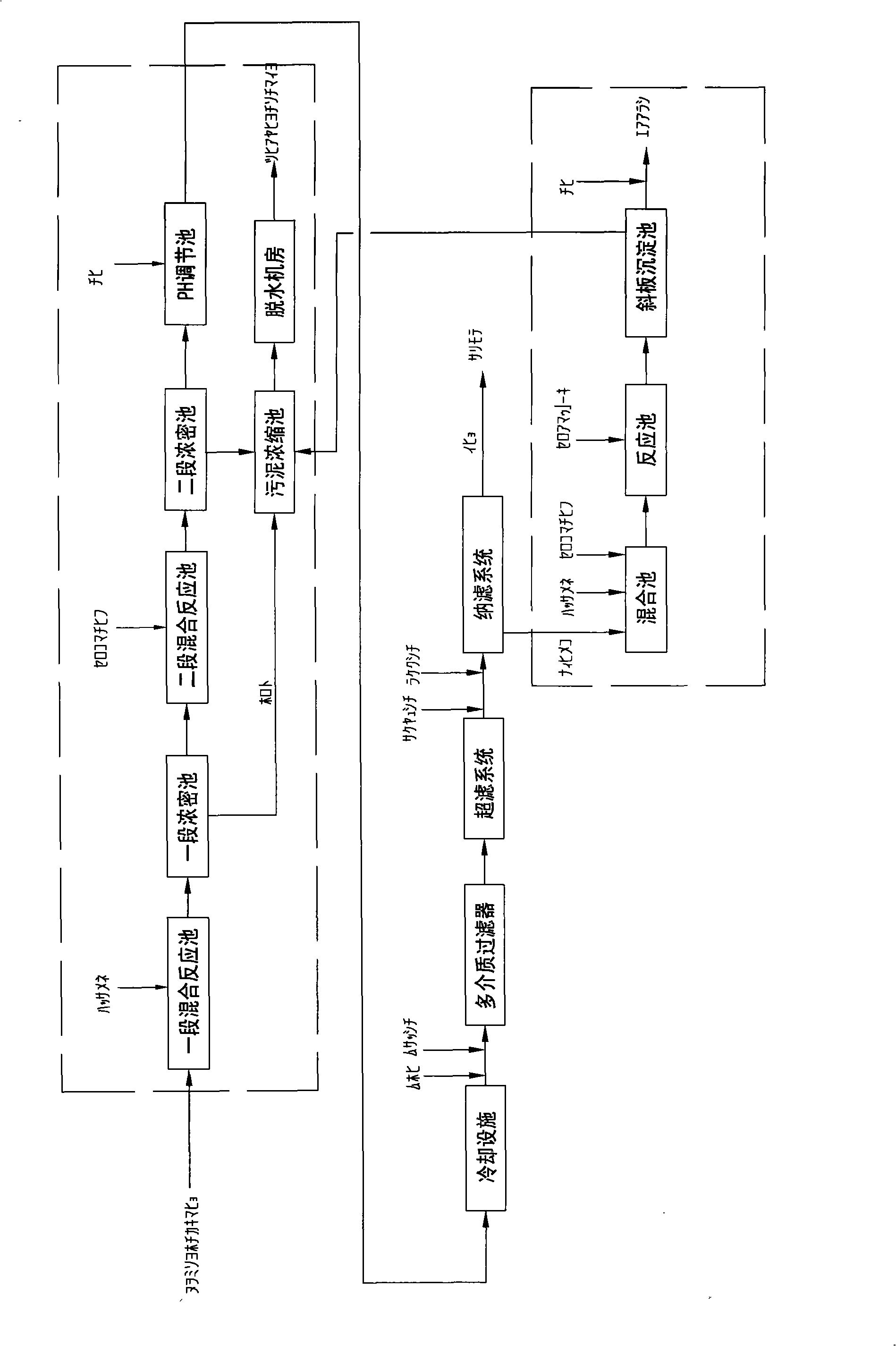

Metal salt-converting method for treating high concentration phosphor-containing wastewater

InactiveCN101439901AGood removal effectReduce processing operating costsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationHigh concentrationSludge

The invention relates to a treatment method for chemical gold high concentration P-contained wastewater. The method is characterized in that the method comprises the following steps: lifting the wastewater from a collecting tank to an oxidation precipitation tank, opening the oxidation precipitation tank for aeration, adding steam, calcium hydroxide, ferrous sulfate and hydrogen peroxide solution into the wastewater for reaction, leading the supernatant into a subsequent physiochemical system for treatment, and pumping the precipitant into a sludge concentration tank for treatment through a sludge pump; after the catalytic oxidation reaction is completed, leading the supernatant into a physiochemical treatment neutralization tank, adding calcium hydroxide into the neutralization tank, leading the supernatant into a flocculating tank after a polyaluminium chloride reaction, adding polyacrylamide into the flocculating tank for intensive agitation, mixing and reaction, then leading the supernatant into a precipitation tank for solid-liquid separation, discharging the supernatant into the next flow, and pumping the sludge to the sludge concentration tank for treatment. A catalytic oxidation method is used to oxidize the stable hypophosphorous acid radical into the phosphate radical capable of easily reacting with metallic salts and producing precipitant; and then a physiochemical method is used to precipitate and remove the phosphate radical, thereby enabling the P content in the outputted water to reach the state emission standard.

Owner:TRIPOD WUXI ELECTRONICS

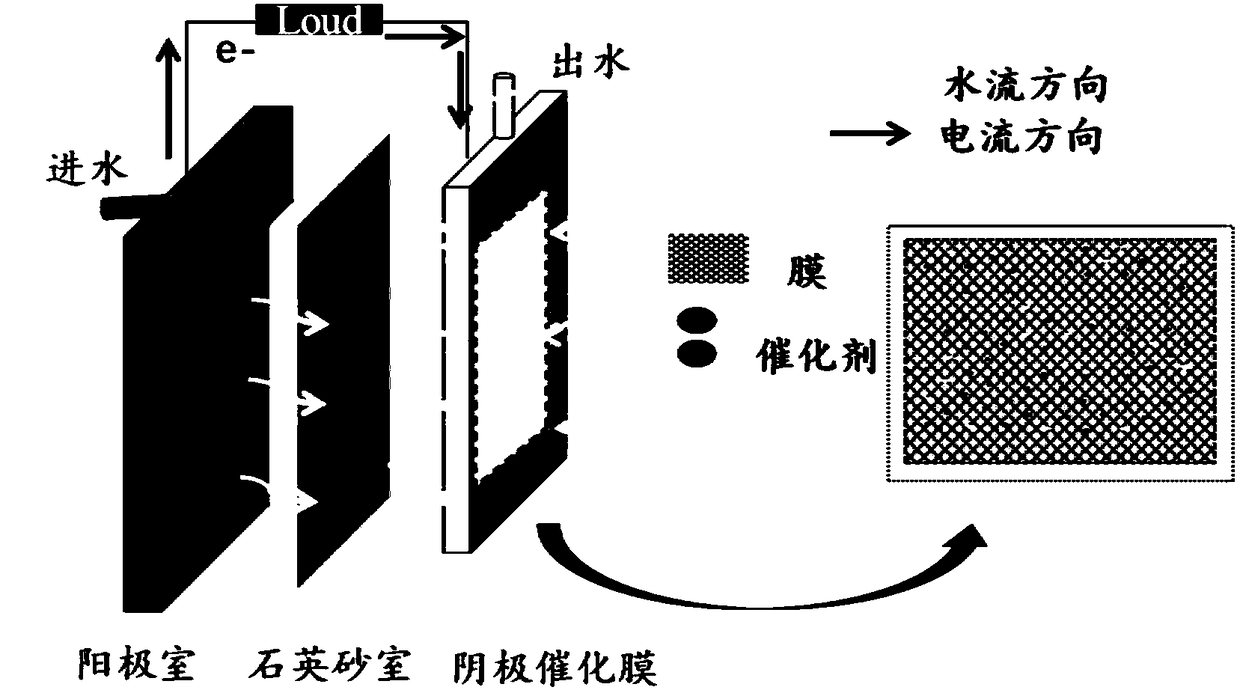

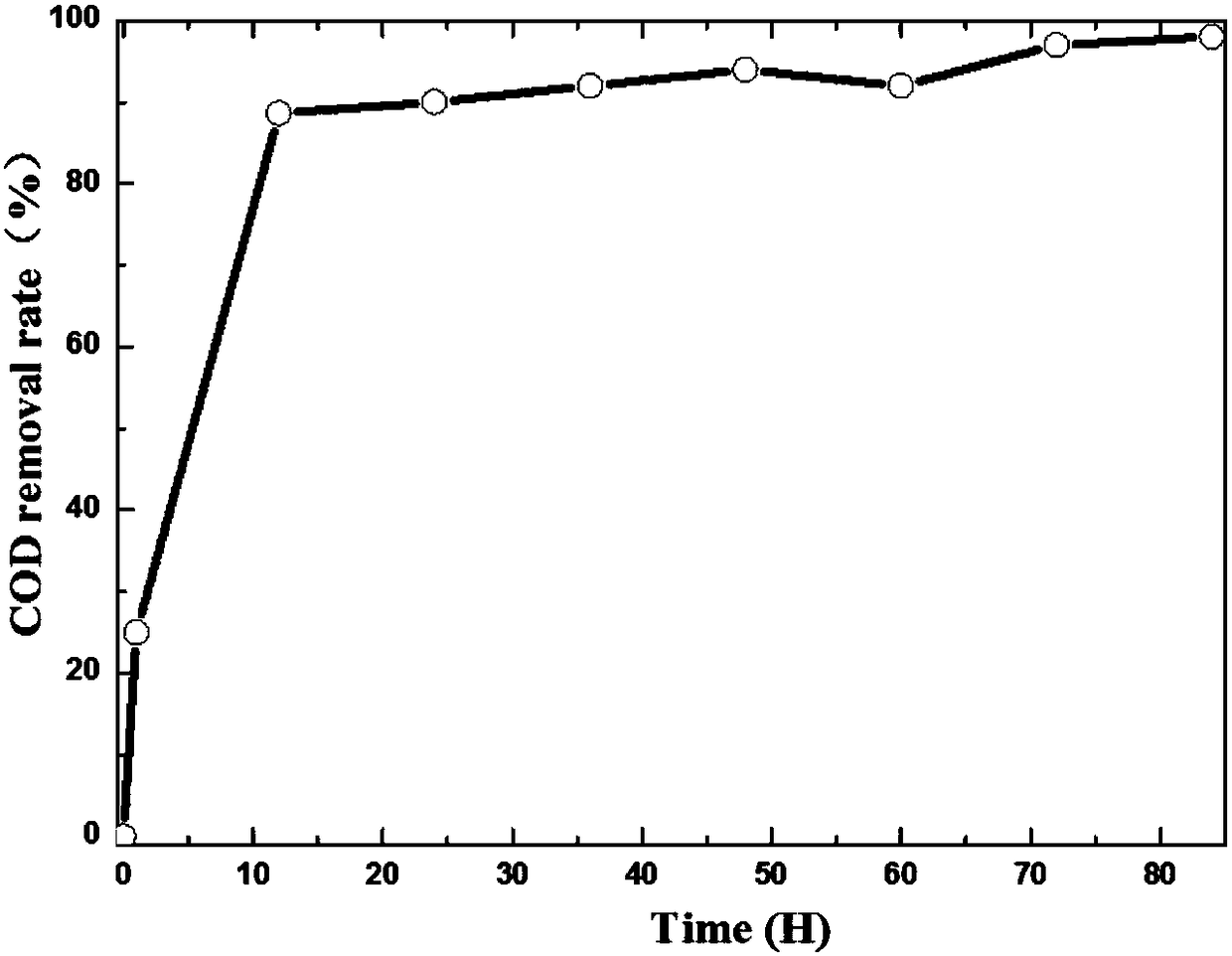

Cathode catalysis membrane coupled membrane-free microbial fuel cell for coking wastewater treatment system

InactiveCN108275777AImprove effluent qualityReduce process operating costsWater/sewage treatment by irradiationTreatment by combined electrochemical biological processesChemistryCoupling system

The invention belongs to the technical field of sewage purification and wastewater recycling, discloses a cathode catalysis membrane coupled membrane-free microbial fuel cell for a coking wastewater treatment system, and in particular relates to a method that pollutants are degraded through an anode chamber power generation microorganism anaerobic oxidation function, together with a cathode catalysis membrane photonic / electric catalysis degradation function and a membrane filtering function, both intermittent and continuous operation modes have relatively high degradation rates, and the designpurposes of sewage treatment and biological power generation can be achieved. The battery has the effects and benefits that the effluent quality of a conventional MFC (Microbial Fuel Cell) can be improved; as a middle layer is filled with quartz sand, a proton exchange membrane can be replaced, and the cost can be lowered; due to adoption of a coupling system micro electric field, the service life of a filtering membrane can be prolonged, and degradation refractory material can be subjected to catalytic oxidation treatment; a reaction system is small in floor space, short in procedure, good in treatment effect and energy-saving and environmental-friendly, and large-scale experiments and industrialization can be well carried out.

Owner:DALIAN UNIV OF TECH

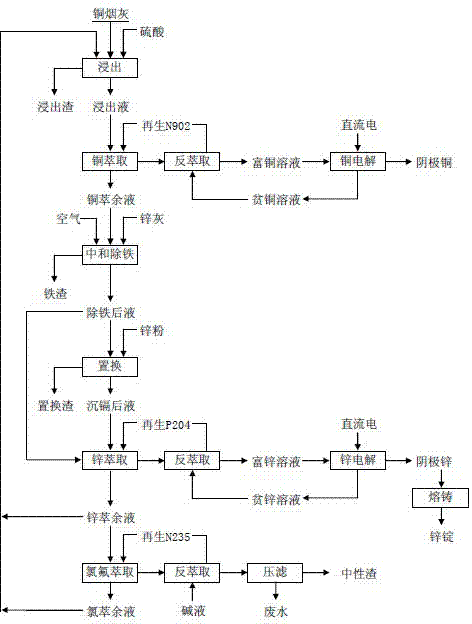

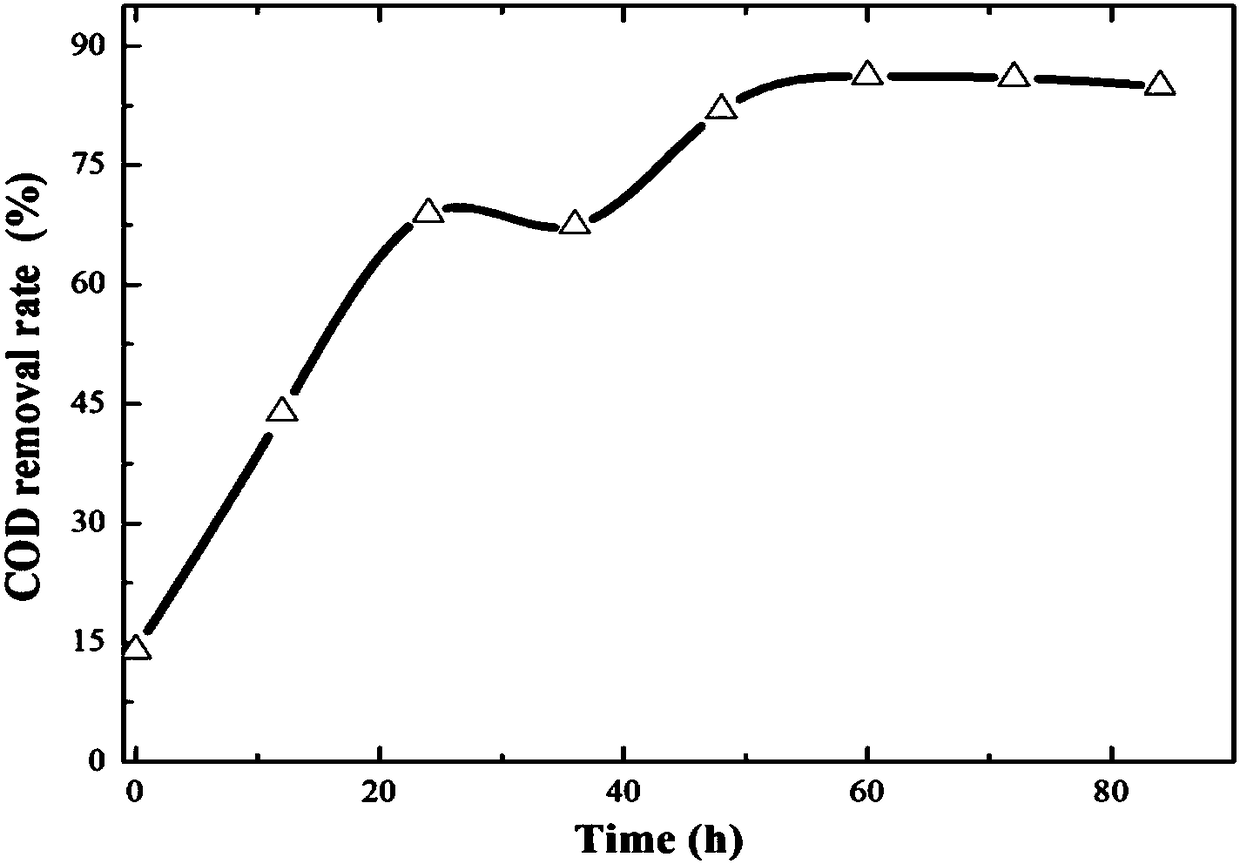

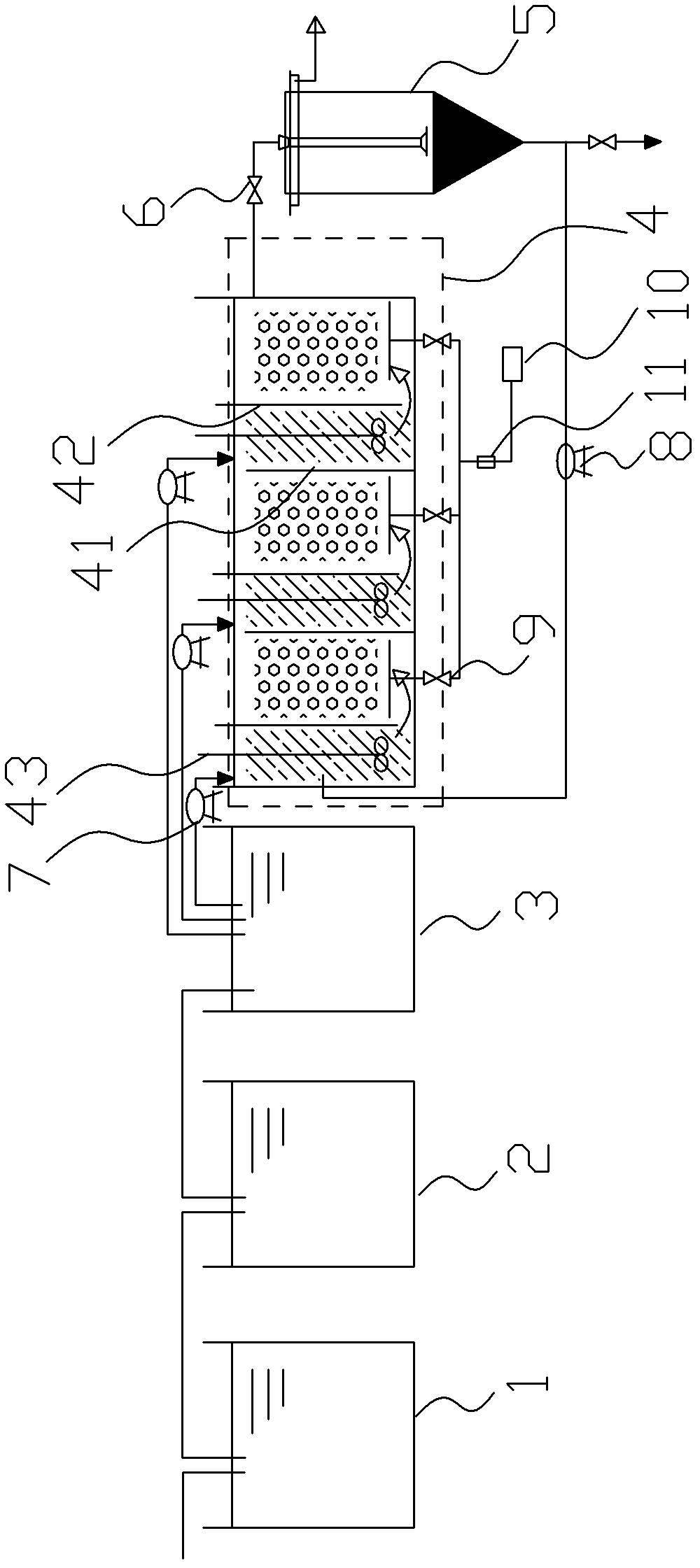

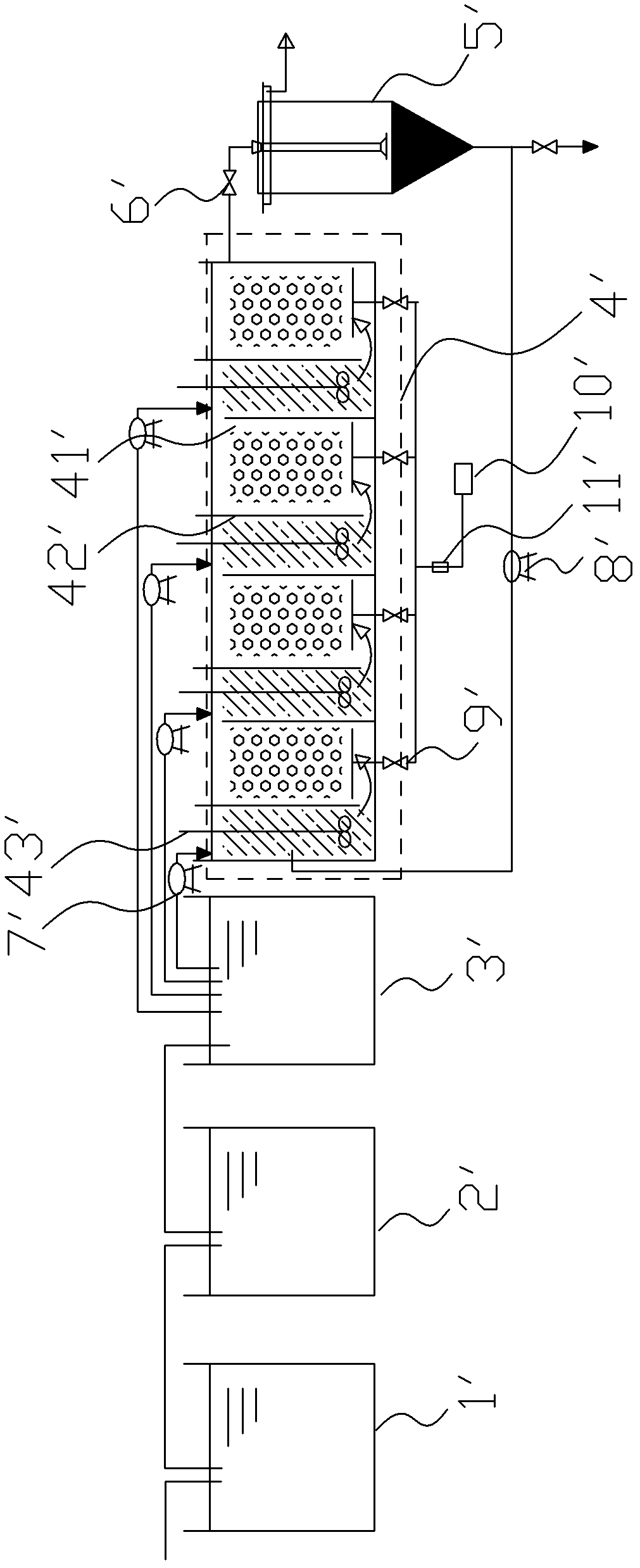

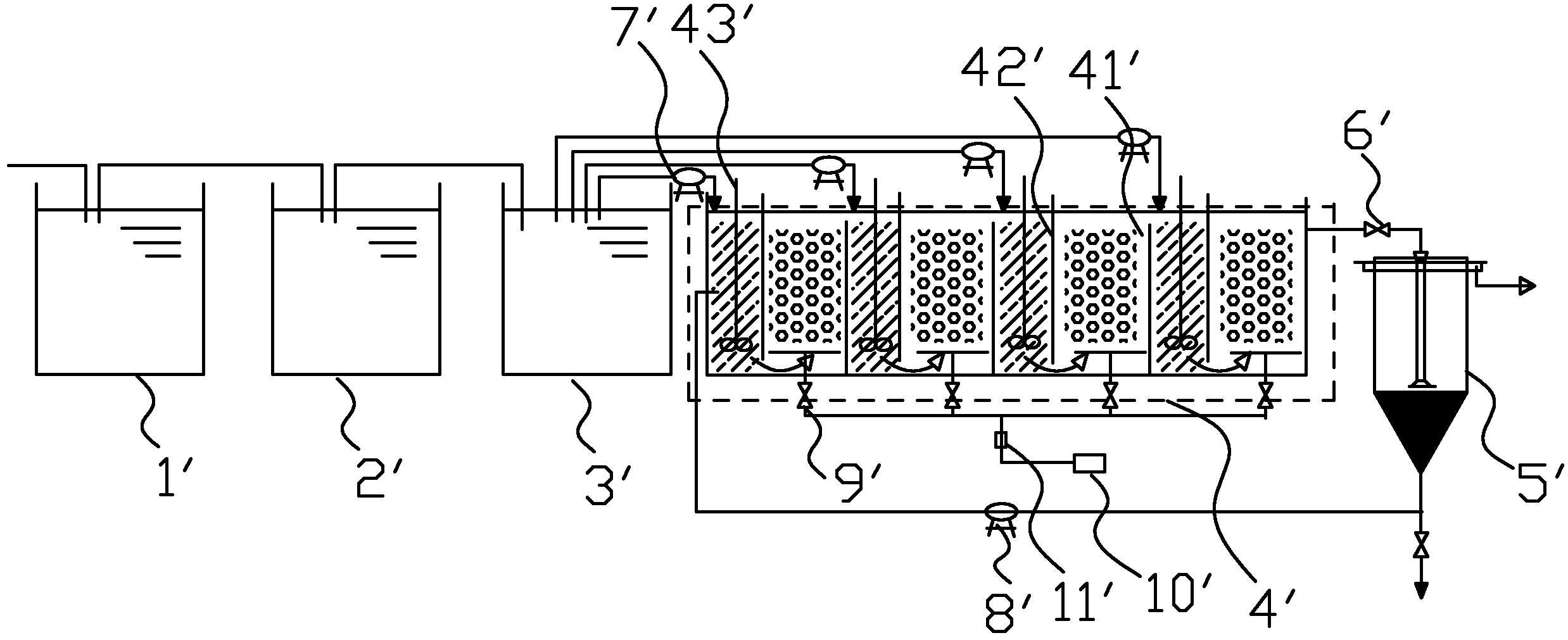

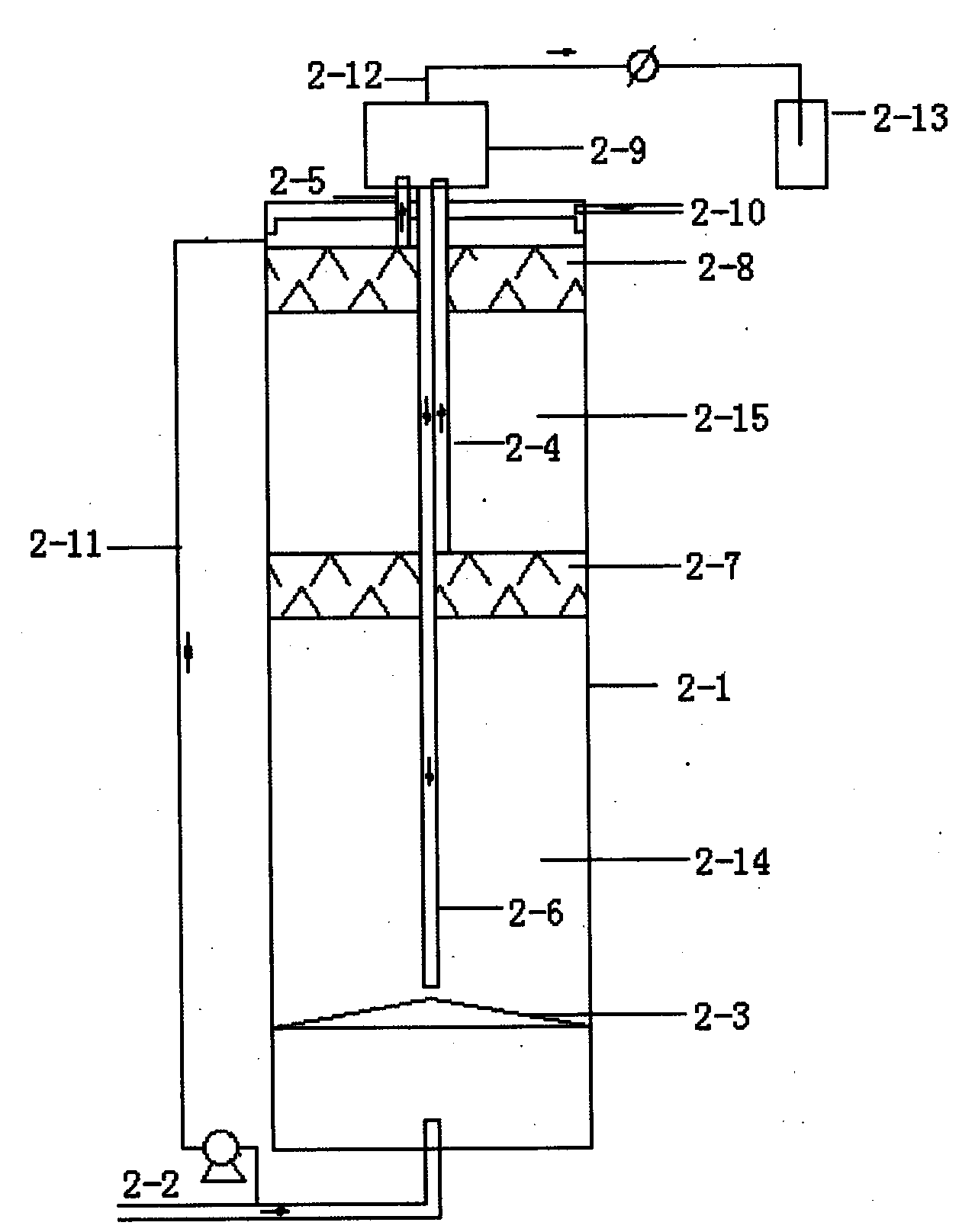

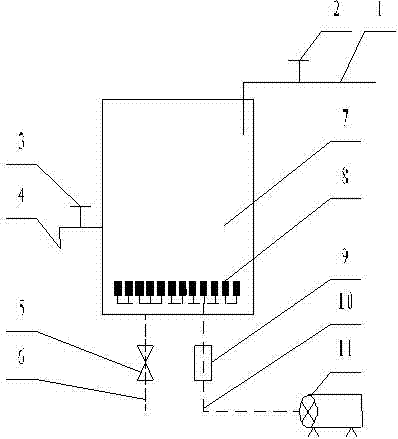

Device and process for biochemically denitrifying high-ammonia nitrogen tanning wastewater

InactiveCN102583747AImprove nitrogen removal efficiencyReduce processing operating costsTreatment with aerobic and anaerobic processesChemical oxygen demandSludge

The invention relates to the technical field of industrial wastewater treatment and provides a device and a process for biochemically denitrifying high-ammonia nitrogen tanning wastewater. The device and the process can effectively and synchronously remove chemical oxygen demand (COD), ammonia nitrogen and total nitrogen from the tanning wastewater. The device mainly comprises a materializing pre-treatment unit, a biochemical pre-treatment unit, an adjusting water pool, a multi-grade anaerobic / aerobic treatment unit and a sludge and water separating unit. The treatment process mainly relates to a tanning wastewater treatment process in which anaerobic biological treatment and aerobic biological treatment are mutually alternated and in multistage series operation.

Owner:HARBIN INST OF TECH +1

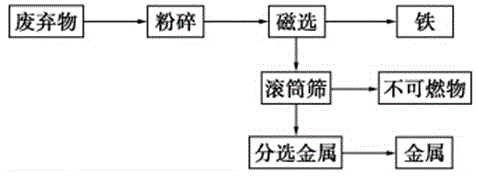

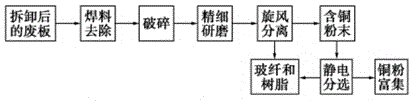

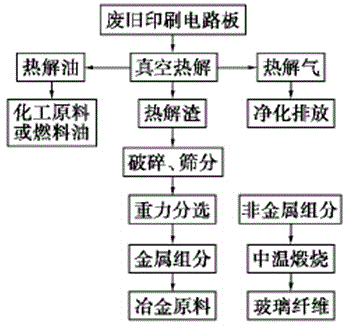

Energy-regeneration pollution-free disposal method for waste electrical appliance circuit board

ActiveCN104624611ASimple waste recycling processLess investmentWaste processingSolid waste disposalCatalytic oxidationDust control

The invention discloses an energy-regeneration pollution-free disposal method for a waste electrical appliance circuit board. The energy-regeneration pollution-free disposal method comprises the following steps: coarsely crushing the waste electrical appliance circuit board, performing alkalization and incineration at a temperature of 870-1400 DEG C to enrich multiple metals; cooling the incineration smoke in a hierarchical manner to coarsely separate the enriched metal oxides; collecting dust through a pipeline membrane process, removing dust through a dust collector, discharging after performing catalytic oxidative purifying, heating boiler stream through incineration heat energy to drive a steam turbine to generate power. The energy-regeneration pollution-free disposal method is simple and reliable, free of emission of harmful residues, waste gas and wastewater and free of secondary pollution; moreover, multiple metals in the waste circuit board can be completely enriched and recycled.

Owner:长沙紫宸科技开发有限公司 +1

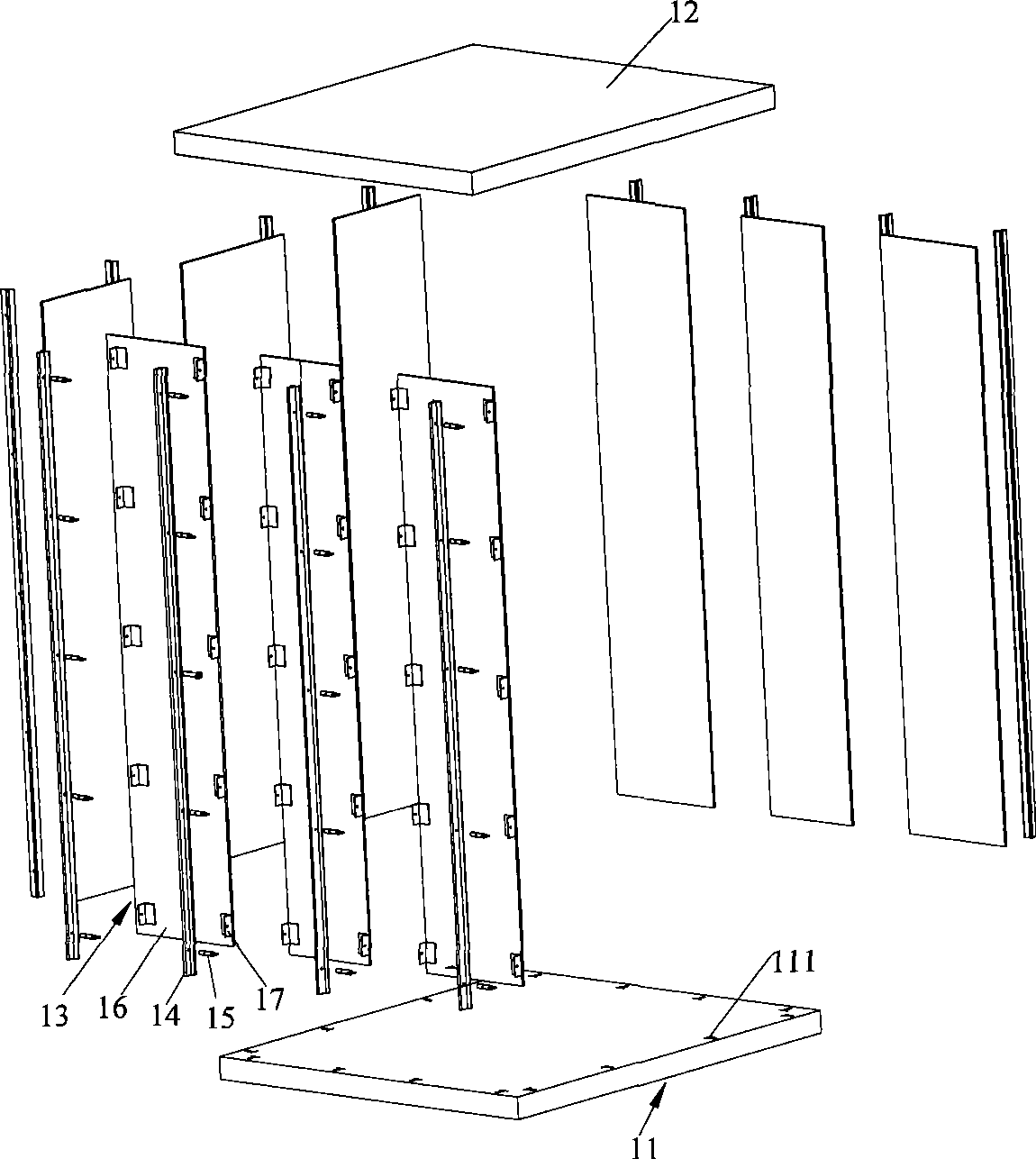

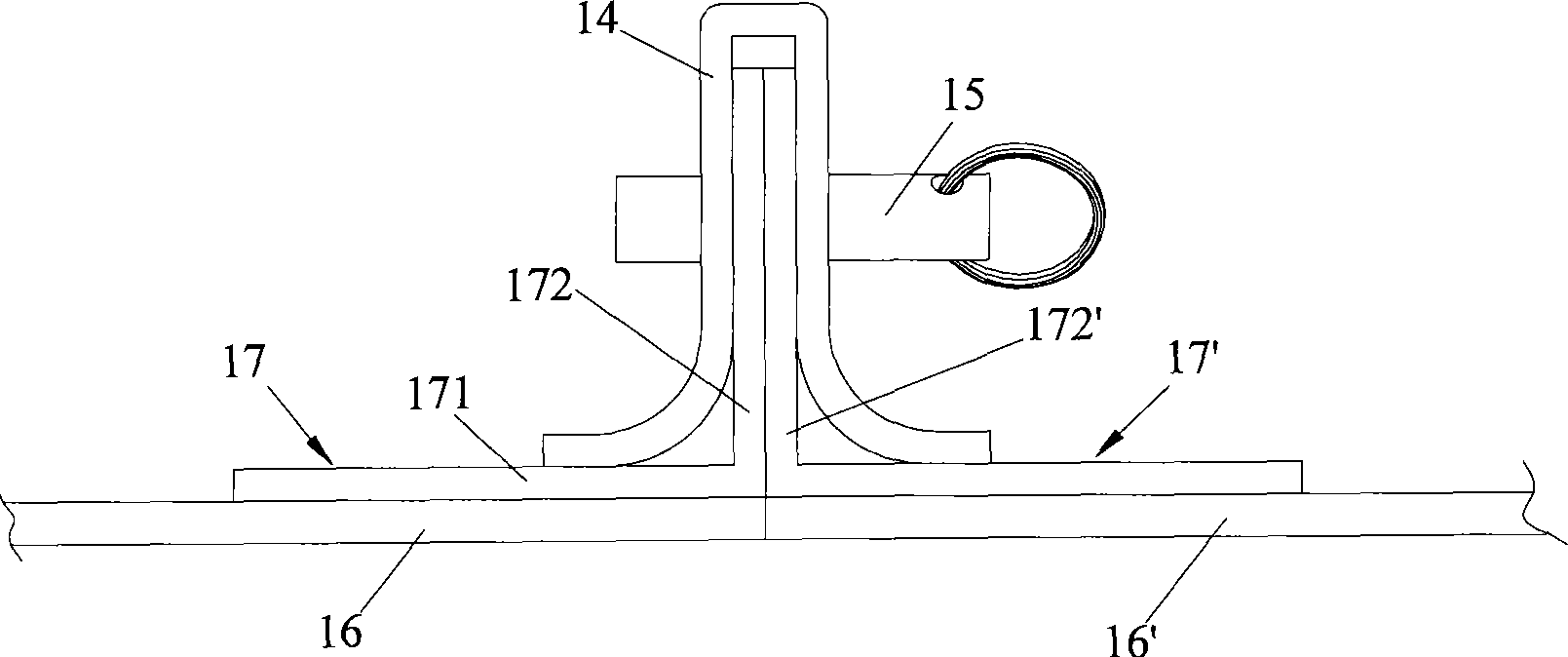

Elevator cage

The invention discloses an elevator car, comprising a bottom platform of the car, a car top and a car wall; the car wall consists of a plurality of independent car wall decoration plates; furthermore, the elevator car also comprises a supporting connection part, the bottom of which is fixed on the bottom platform of the car and the top of which supports the car top and sequentially connects the plurality of independent car wall decoration plates one by one, thus enclosing a cage-shaped structure; and the elevator car also comprises a fastening part which fastens the supporting connection part and the plurality of independent car wall decoration plates. The elevator car is convenient for replacing the interior trimming of the car, reinforces the impact endurance in the horizontal direction of the car wall, and ensures the fastness of the car.

Owner:XIZI OTIS ELEVATOR

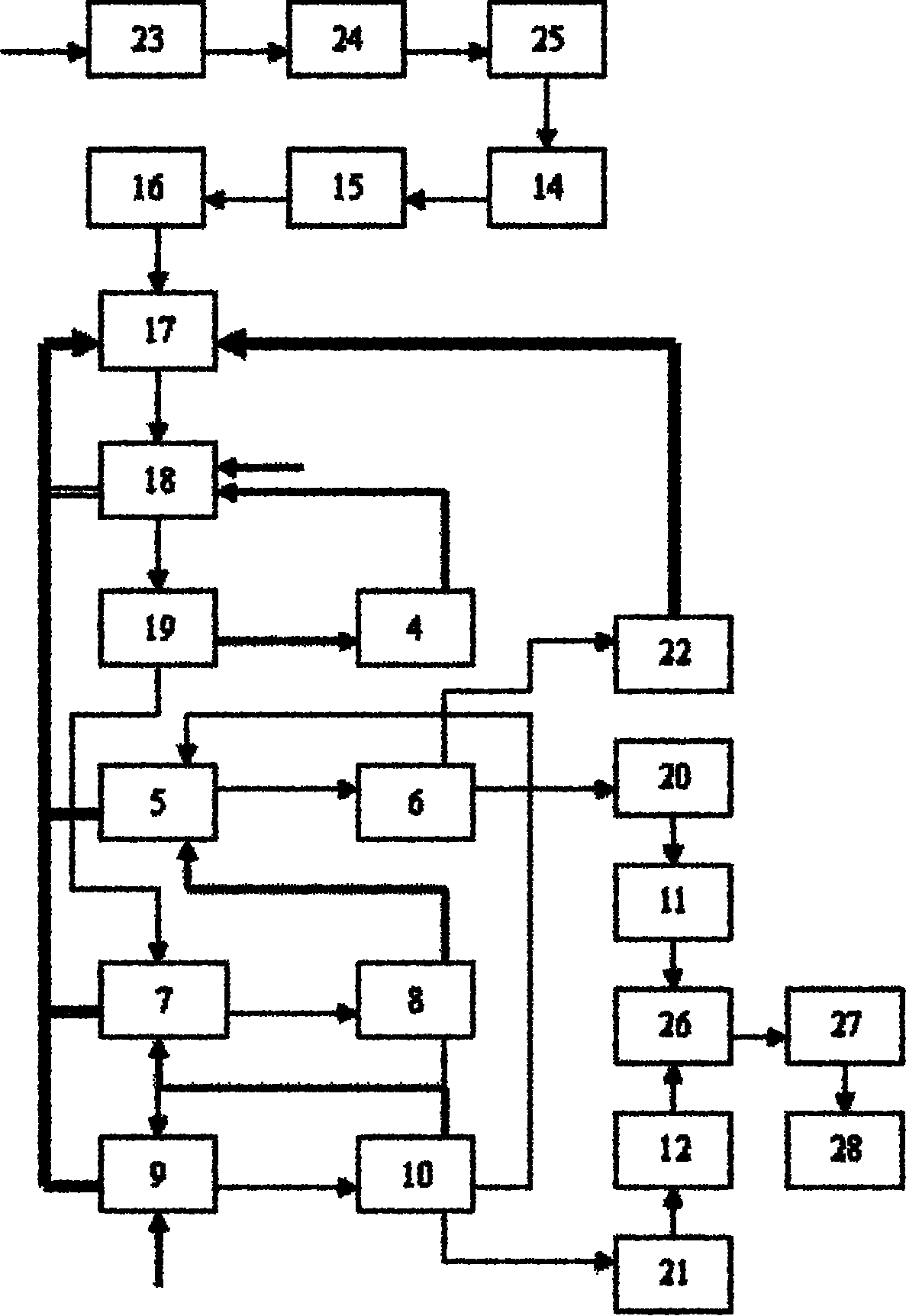

Physicochemical comprehensive treatment system for dangerous waste liquid

InactiveCN102344214AAvoid running, dripping and leakingReduce processing operating costsMultistage water/sewage treatmentLiquid wastePaper tape

The invention discloses a physicochemical comprehensive treatment system for a dangerous waste liquid. The system comprises a waste liquid storage tank, a paper tape filter, a quenching and tempering groove, four reagent grooves, three reaction vessels with stirrers, a tail gas absorption groove, a buffer tank, a water injection vacuum set, a centrifuge, a suction filtration groove, a membrane processor, a filter press, a filtrate collection pool, two waste liquid intermediate grooves, a sludge collection pool and a wastewater regulating pool. Each processing unit of the invention can be switched and combined flexibly so as to be adapted to various physicochemical comprehensive treatments of a dangerous waste liquid, such as acid-base neutralization, coagulation sedimentation, redox, desalination, solid-liquid separating and tail gas purifying treatment etc. Under the condition of satisfying the technical requirements of waste liquid treatment, the system of the invention can reduce repeated treatment facility construction and investment. Under the premise of ensuring a good treatment effect, the system provided in the invention reduces human consumption, material consumption and energy consumption, and reduces the treatment operation cost of per unit of waste amount. The escaping and leaking phenomena common in present waste liquid treatment processes can be avoided, and secondary pollution to the environment as well as damage to people can be eradicated.

Owner:ZHEJIANG UNIV

Process method for separating and purifying cresol mixed isomers

PendingCN107879900AHigh purityReduce processing operating costsOrganic chemistryOrganic compound preparationChromatographic separationSimulated moving bed

The invention discloses a process method for separating and purifying cresol mixed isomers. The process method is characterized by comprising the following steps: inputting a mixture primarily comprising m-cresol and p-cresol isomers into a sequential simulated moving bed as a feed to be adsorbed and separated, obtaining a high purity p-cresol solution from a displacing liquid port, and then rectifying, separating and removing a desorption solvent to obtain a m-cresol product; and obtaining a mixed solution primarily comprising m-cresol from a raffinate port, then rectifying, separating and removing the desorption solvent to obtain a mixture rich in m-cresol, and then carrying out crystallization and separation to obtain the m-cresol product. The sequential simulated moving bed disclosed by the invention at least contains four chromatographic columns, a raw material feed inlet, a strippant feed inlet, a strippant discharge port and a raffinate discharge port. The process method can obtain high purity m-cresol and p-cresol products continuously and efficiently at the same time, and has a very good industrial application prospect.

Owner:CHINA CATALYST HLDG CO LTD

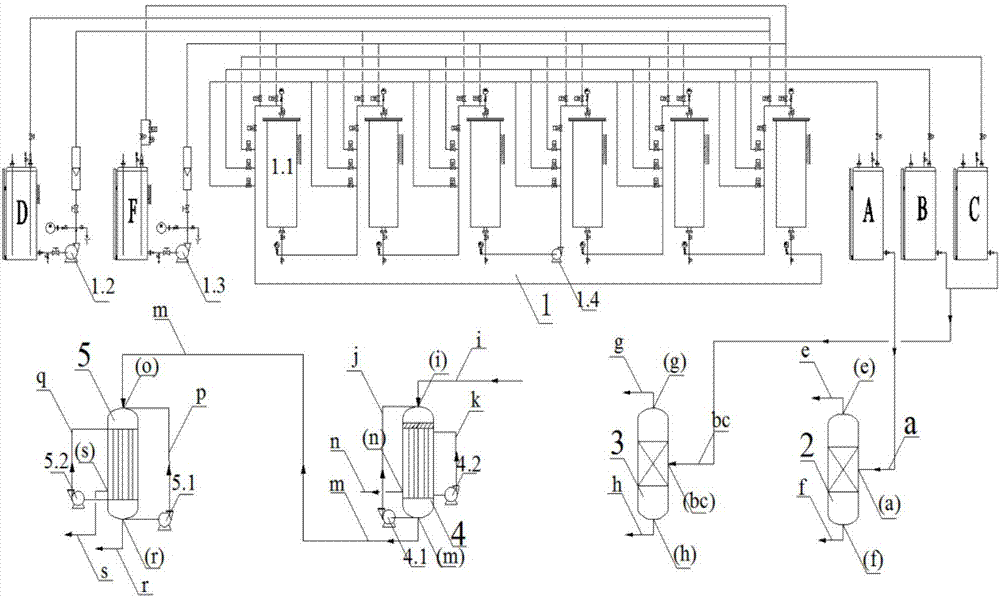

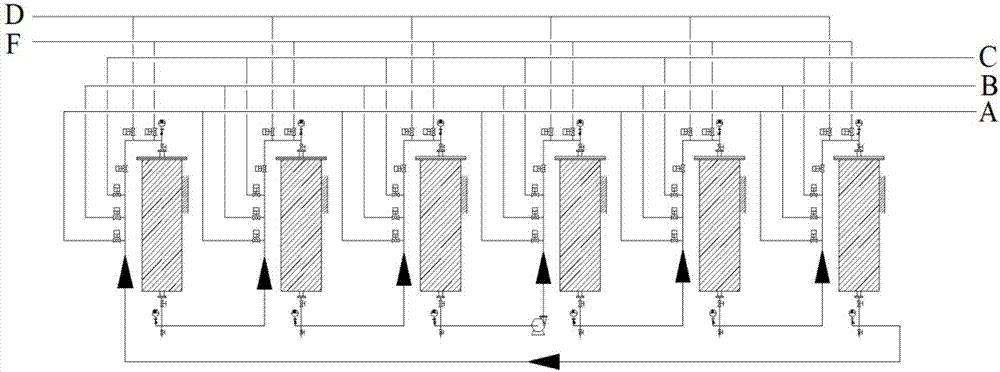

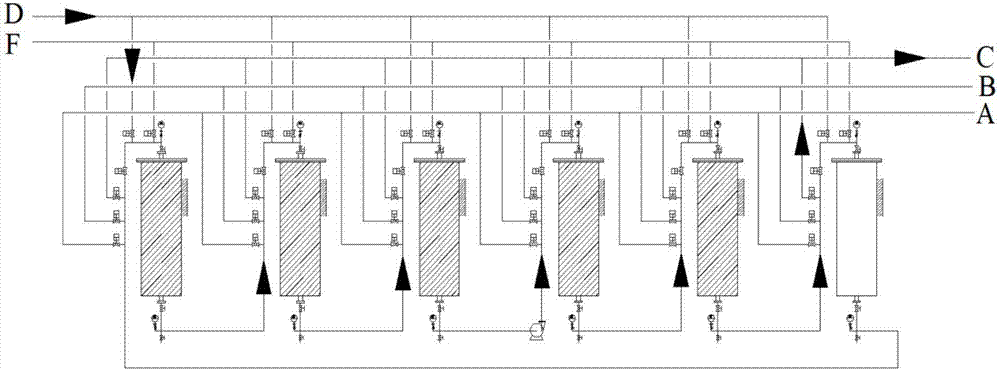

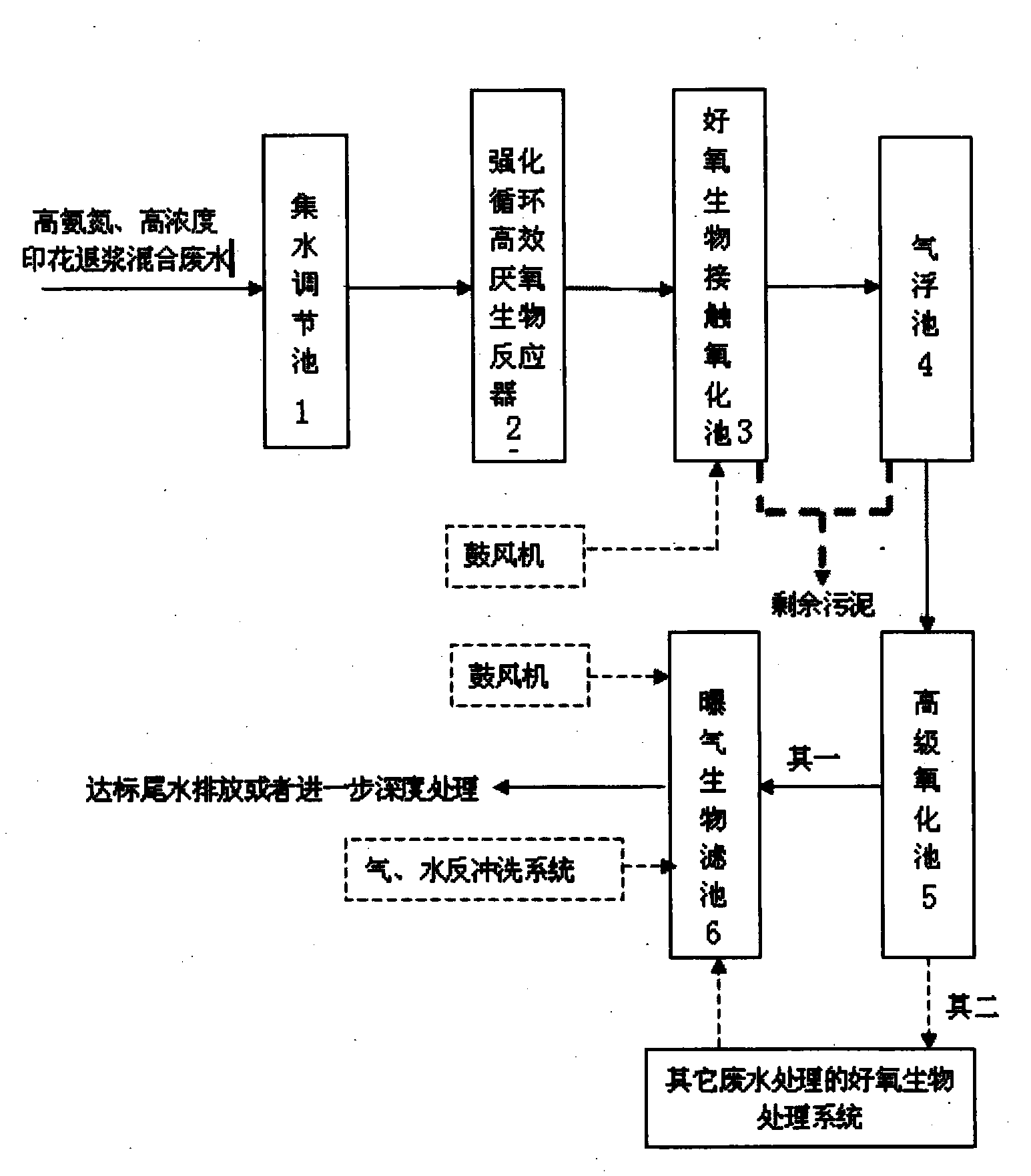

Treatment device and method of printing and desizing mixed wastewater

InactiveCN103523996AImprove interception effectImproved resistance to shock loadsMultistage water/sewage treatmentWaste water treatment from textile industryHigh concentrationProcess systems

The invention provides a treatment device and method of printing and desizing mixed wastewater. The treatment device of the printing and desizing mixed wastewater is characterized by comprising a water collecting regulating tank, a reinforced circulating type efficient anaerobic bioreactor, an aerobic biological contact oxidation tank, a gas-flotation tank, a high-level oxidization tank and an aeration biological filter tank. The treatment device and method disclosed by the invention are especially suitable for treating the high-ammonia-nitrogen high-concentration printing and desizing mixed wastewater generated in printing and desizing processes, a process system disclosed by the invention is adopted to effectively treat the high-concentration high-ammonia-nitrogen wastewater generated by the printing process and high-concentration high-alkaline wastewater generated by the desizing process in printing and dyeing enterprises after the two kinds of wastewater are subjected to flow-dividing and mixing, and also can be combined with a wastewater treatment process for other relatively-low-concentration pollutants in a printing and dying plant to form a complete wastewater treatment system of the enterprise, thereby realizing modifying and upgrading an existing wastewater system.

Owner:DONGHUA UNIV

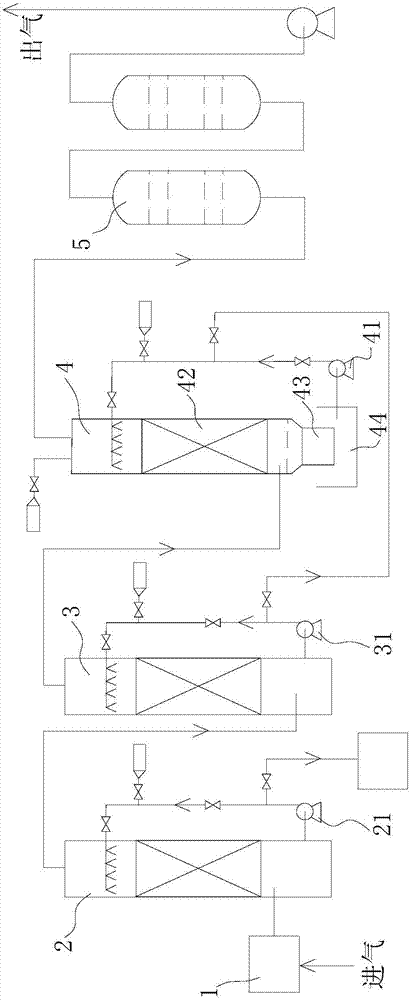

Treatment method and system for organic exhaust gas generated from chlorination reaction

PendingCN107321123AStrong oxidation abilityAchieve synchronous removalGas treatmentWater contaminantsPtru catalystCatalytic oxidation

The invention discloses a treatment method and system for an organic exhaust gas generated from a chlorination reaction. The treatment method includes: cooling the organic exhaust gas generated from a chlorination reaction through a condenser; leading the cooled exhaust gas in from the top of a washing tower and spraying and washing the exhaust gas to obtain washed discharged water and washed exhaust gas; leading the washed exhaust gas in from the bottom of an alkaline washing tower for spraying and alkaline washing to obtain alkaline-washed discharged water and alkaline-washed exhaust gas; leading the alkaline-washed exhaust gas in from the middle part of a catalytic oxidation tower, performing spraying and washing, spraying the alkaline-washed discharged water from the top of the catalytic oxidation tower to obtain washed discharged water and treated gas; and allowing the washed discharged water to fall on a catalyst bed layer for oxidation degradation. According to the treatment method, organic matters in an organic exhaust gas generated from a chlorination reaction can be well removed, useful substances in the exhaust gas can be fully used, the object of treating waste with other waste is achieved, and no secondary pollution is caused.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

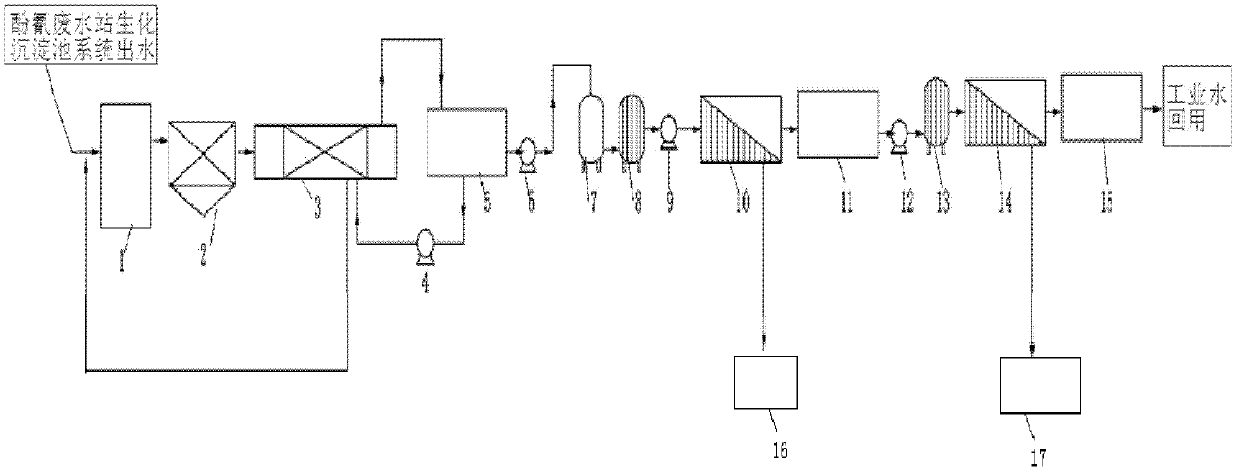

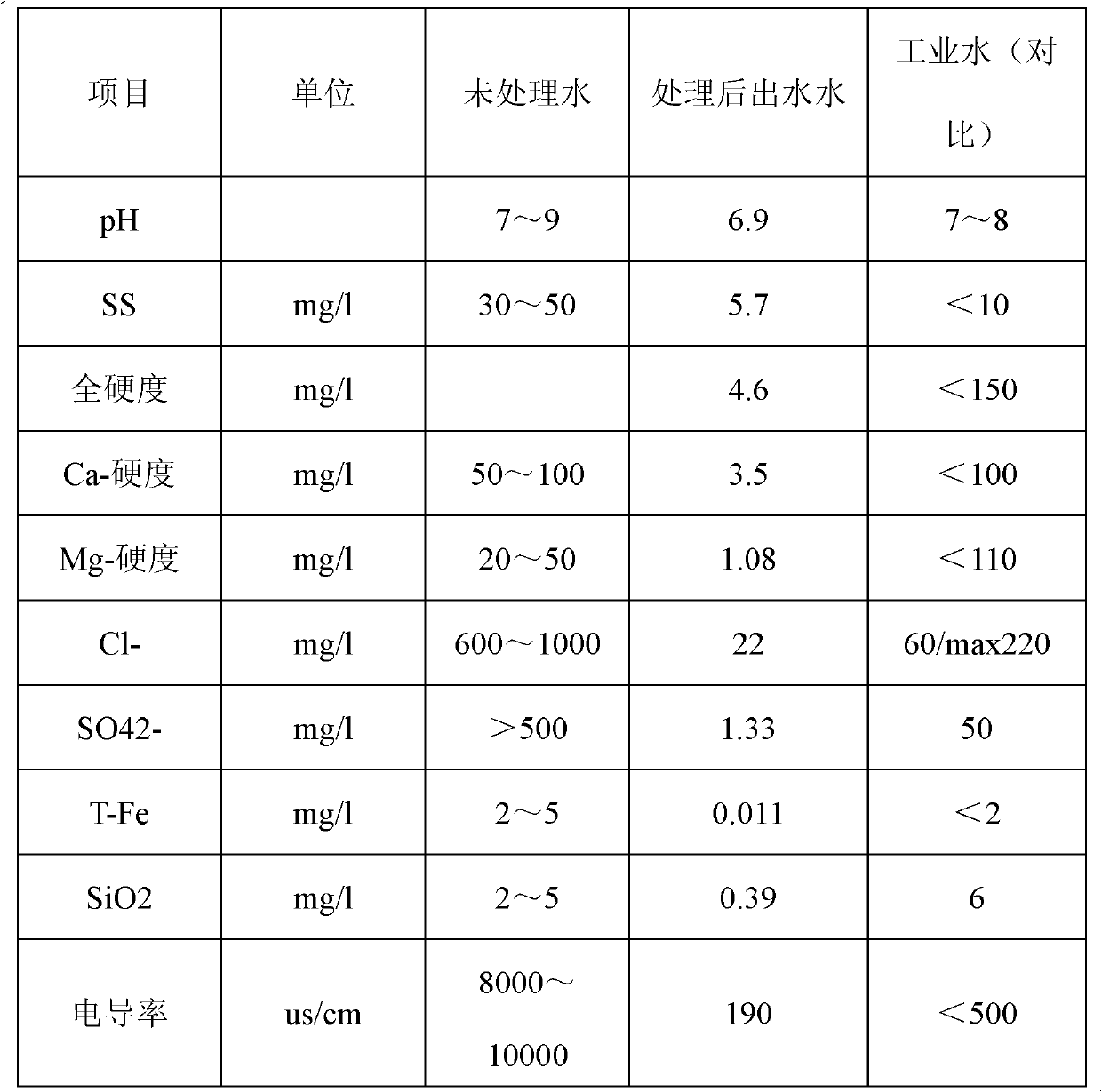

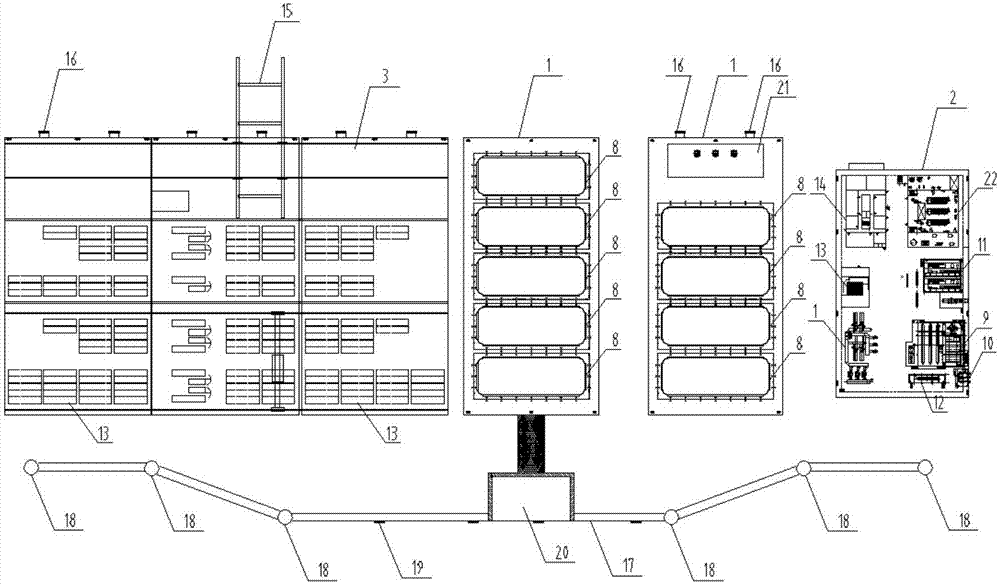

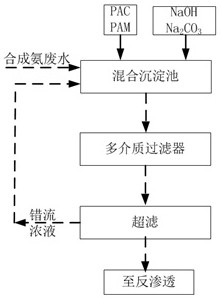

Coking wastewater reuse treatment system and method thereof

ActiveCN103304049AReduce processingReduce processing operating costsGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisUltrafiltrationSludge

The invention relates to a coking wastewater reuse treatment system. The system is characterized in that the system comprises a coagulation pool (1), and the coagulation pool (1) is sequentially connected with an inclined plate sedimentation pool (2), an ultrafiltration device (3), an ultrafiltration water production pool (5), a first pump (6), a first filter (7), a second filter (8), a second pump (9), a nanofiltration device (10), a nanofiltration water production pool (11), a third pump (12), a third filter (13), a reverse osmosis device (14) and a reverse osmosis water production pool (15) through a pipeline. The invention also provides a coking wastewater reuse treatment method. The system has the advantages of stable treatment effect, low production running cost, simple operation running, realization of the water discharge through adopting a biochemical sedimentation pool, avoiding of the physical-chemical treatment segment after routine biochemical treatment, avoiding of the massive application of agents, reduction of the sludge throughout of the system, and reduction of the wastewater treatment running cost.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

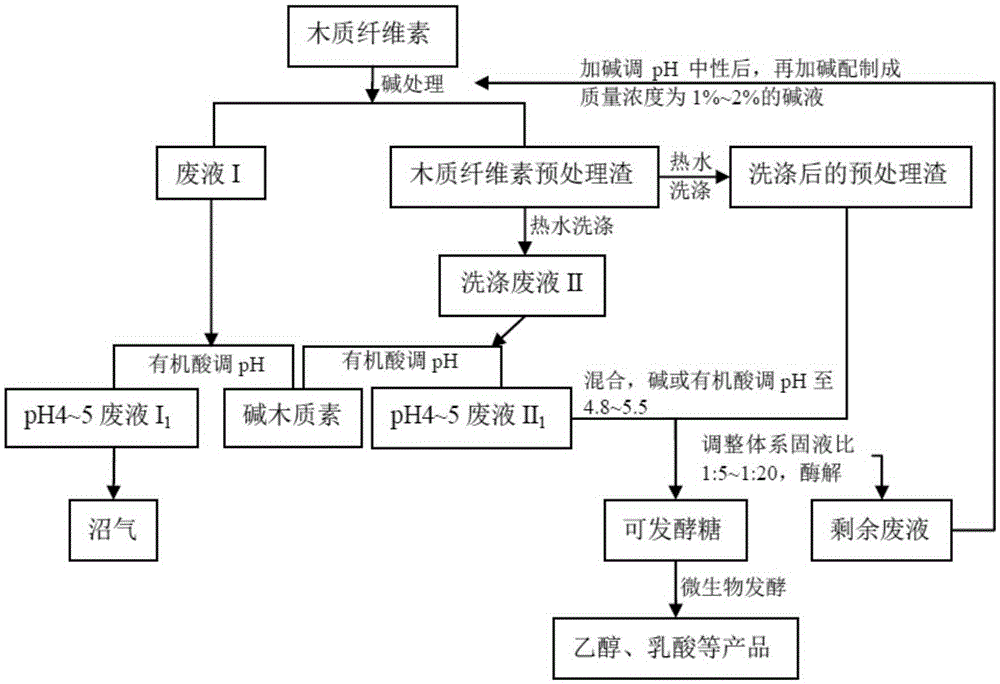

Method for recycling alkali treatment lignocellulose waste fluid

ActiveCN105296568AReduce water consumptionAchieve reuseWaste based fuelFermentationLiquid wasteHydrolysate

The invention relates to a method for recycling alkali treatment lignocellulose waste fluid. The method comprises the following steps: 1) adopting alkali liquor treatment lignocellulose to perform solid-liquid separation, and obtaining lignocellulose treatment residue and waste fluid I; 2) washing the lignocellulose treatment residue in the step 1), and collecting washing waste fluid II; 3) adjusting the pH of the waste fluid I and the waste fluid II, precipitating lignin, performing centrifugal separation to obtain alkali lignin, supernatant II 1 and supernatant I 1 for biogas fermentation, and mixing the supernatant II 1 with the lignocellulose treatment residue washed in the step 2); 4) adjusting the pH of the mixed system of the supernatant II 1 and the lignocellulose treatment residue in step 2), adding cellulase for enzymolysis, and obtaining hydrolysate obtaining fermentable sugars. According to the method for recycling alkali treatment lignocellulose waste fluid, the recycling of the waste fluid in the lignocellulose alkali pretreatment process is achieved, no environmental pollution is caused, and the process operating cost is reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

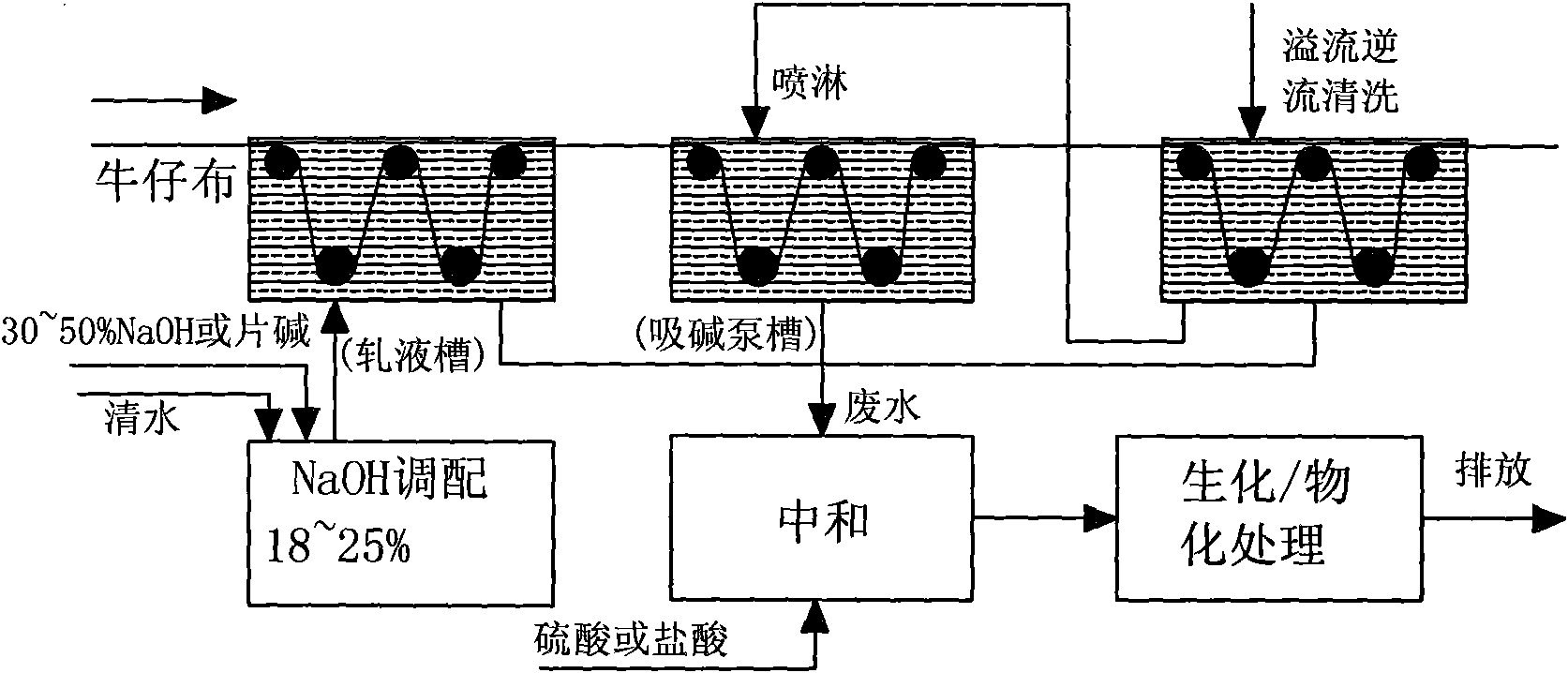

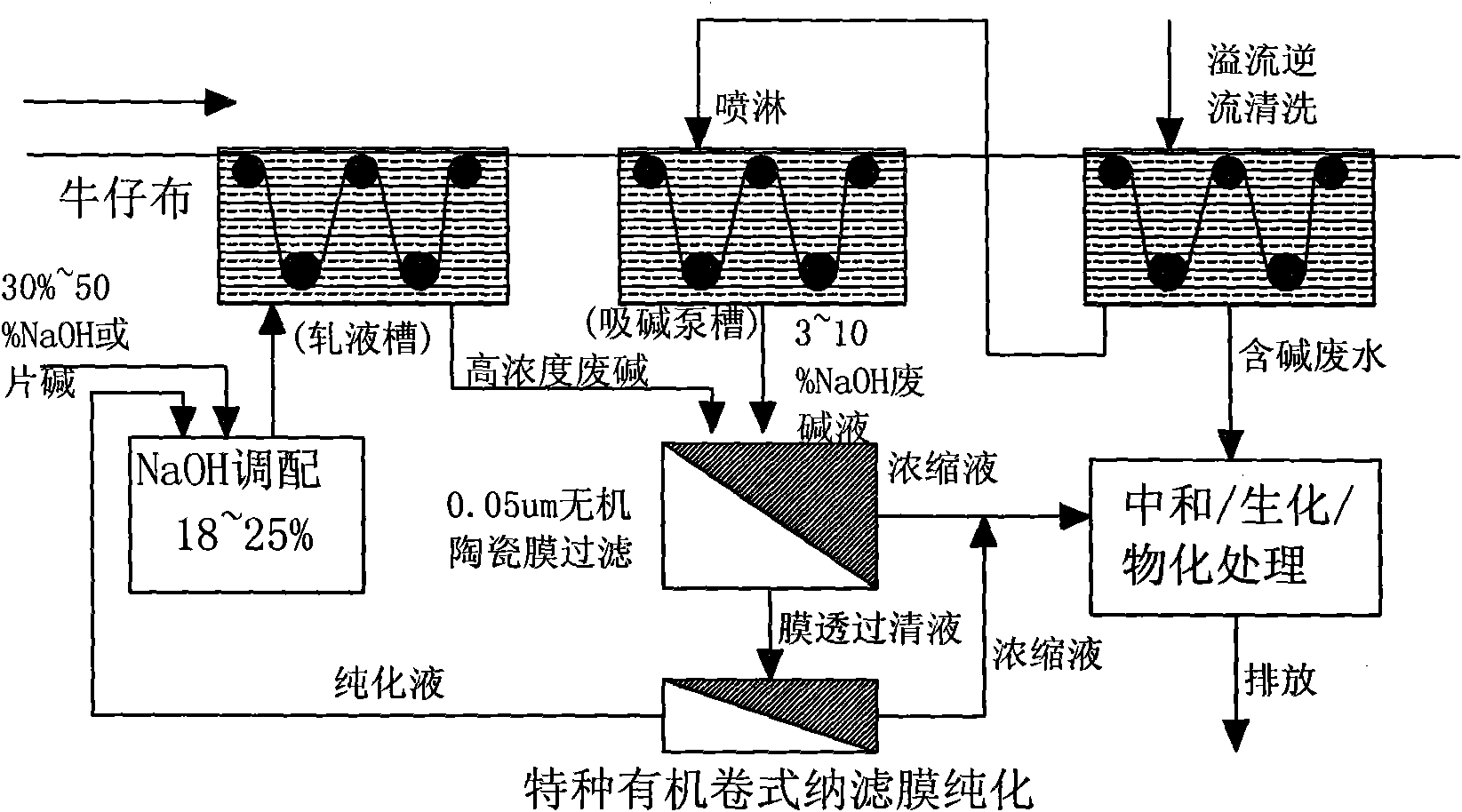

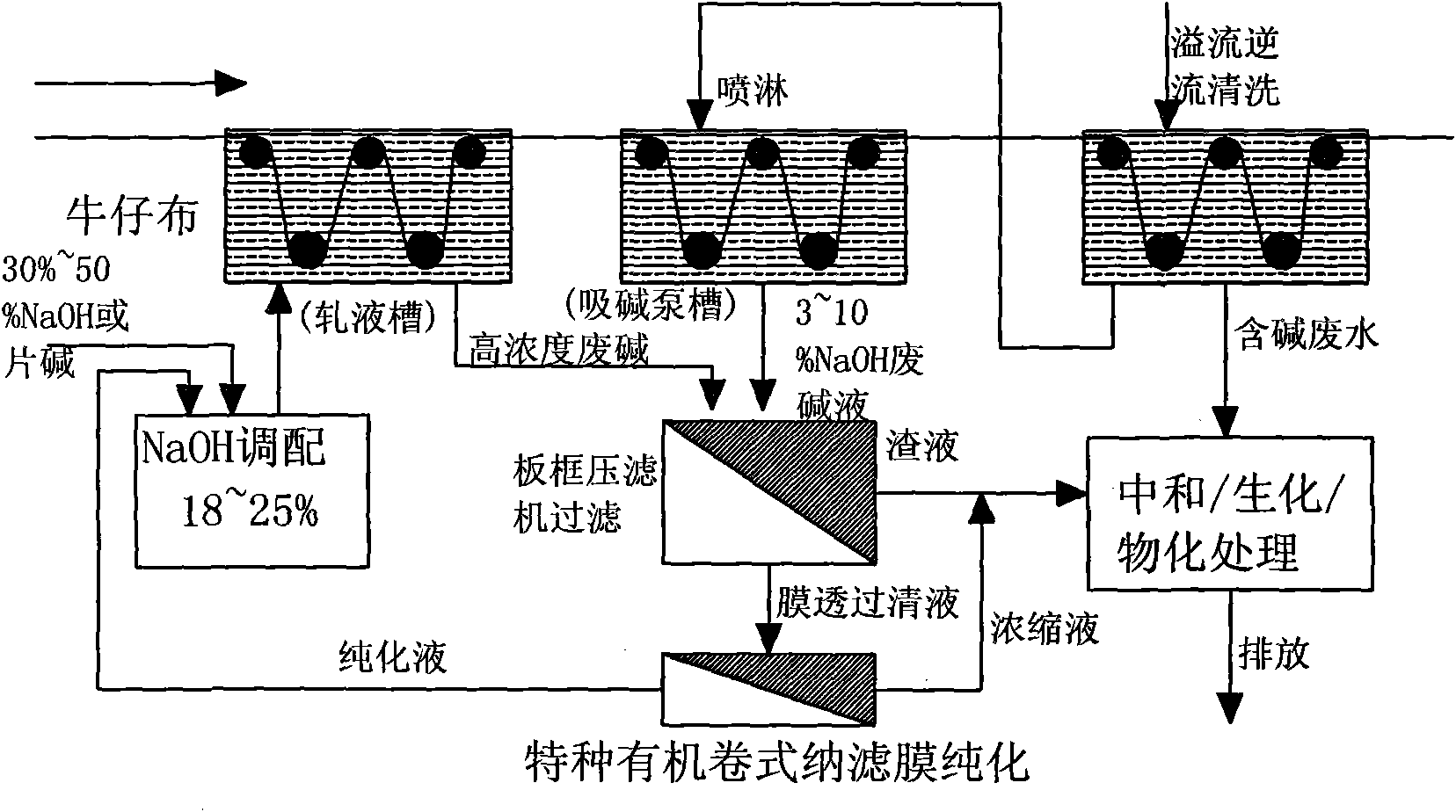

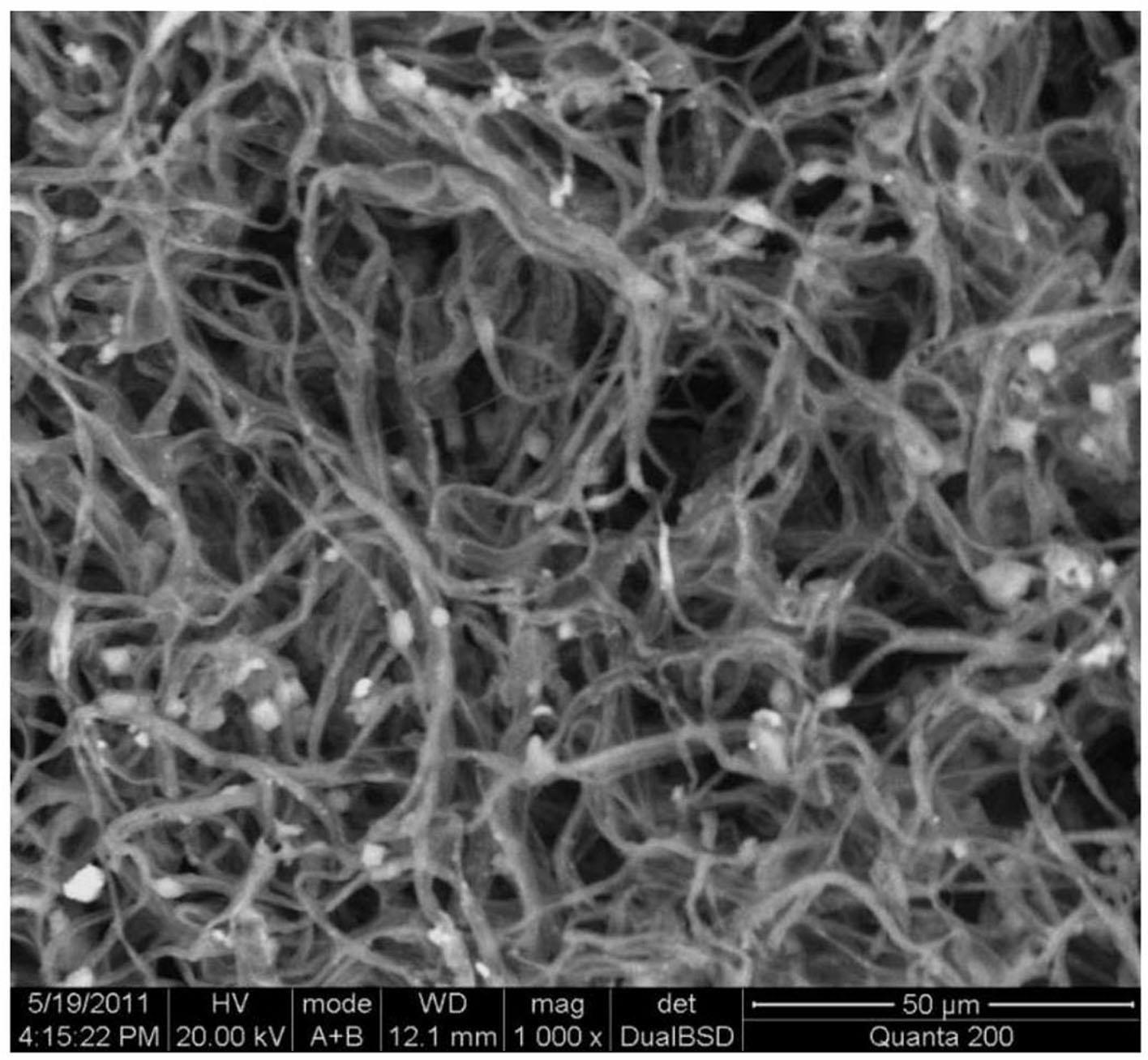

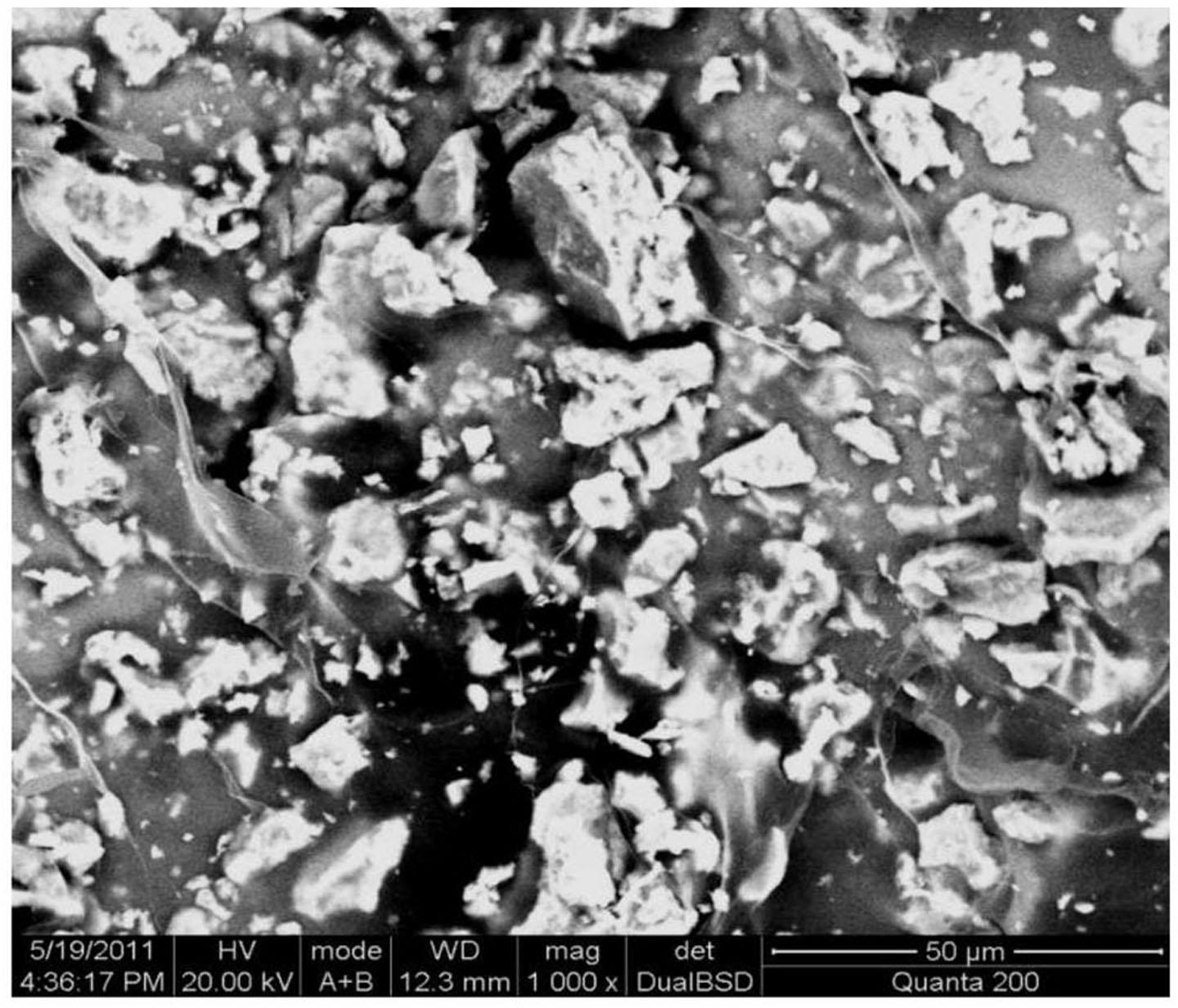

Technical method for purifying and reutilizing jean silkete alkali waste liquid by membrane method

InactiveCN101851030AReduce manufacturing costReduce usageMercerisingWater/sewage treatment bu osmosis/dialysisCircular economyChemistry

The invention discloses a technical method for purifying and reutilizing jean silkete alkali waste liquid by a membrane method, which comprises the steps of alkali waste liquid collection, alkali waste liquid pretreatment, alkali waste liquid purification treatment, secondary use of alkali liquid reused to a production line mangle tank after preparation and the like. The purified alkali liquid obtained by the invention has the same quality as commercial alkali. When the purified alkali liquid obtained by the invention is prepared into the concentration required by silkete threads with high-concentration sodium hudroxide to be reused, the effect of the purified alkali liquid obtained by the invention is the same as that of the commercial alkali, so the invention has the advantages that: firstly, a large amount of sodium hydroxide is saved, the production cost is reduced, and each silkete thread can generate the economic benefits near million Yuan per year; secondly, the waste water quantity of high-concentration alkali liquid is reduced, so the addition of acid used for neutralization is reduced, the load of original treatment facilities is reduced, the investment of the waste water facility in the new production line is reduced, and the biochemical stability is enhanced; and thirdly, the production idea of clean production, recycling economy and environment protection is advocated.

Owner:广州中科建禹环保有限公司

High-efficiency inorganic sludge dehydrating agent

InactiveCN102180582AOdor suppressionReduce odorSludge treatment by de-watering/drying/thickeningSludgeMoisture

The invention relates to a high-efficiency inorganic sludge dehydrating agent, which is characterized by consisting of the following components in percentage by weight: 25-50 percent of sodium chloride, 35-60 percent of magnesium chloride, 1-10 percent of ferric chloride and 1-5 percent of concentrated sulfuric acid with the concentration of 98 percent. The dehydrating agent has the advantages that: a remarkable dehydrating effect is achieved, moisture accumulated in sludge can be quickly separated out, the structure of an organic matter is damaged, microorganisms in sludge are dehydrated and deactivated, the aim of stabilizing dehydration is fulfilled, the generation of sludge odor is suppressed and secondary pollution is reduced; and in particular, the dehydrating agent is prepared from inorganic raw materials, so that the cost is low, the treatment cost of the sludge can be lowered greatly, produced waste water can be recycled by concentrating, standing and drying, environmental hazard is avoided and water resource is saved.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

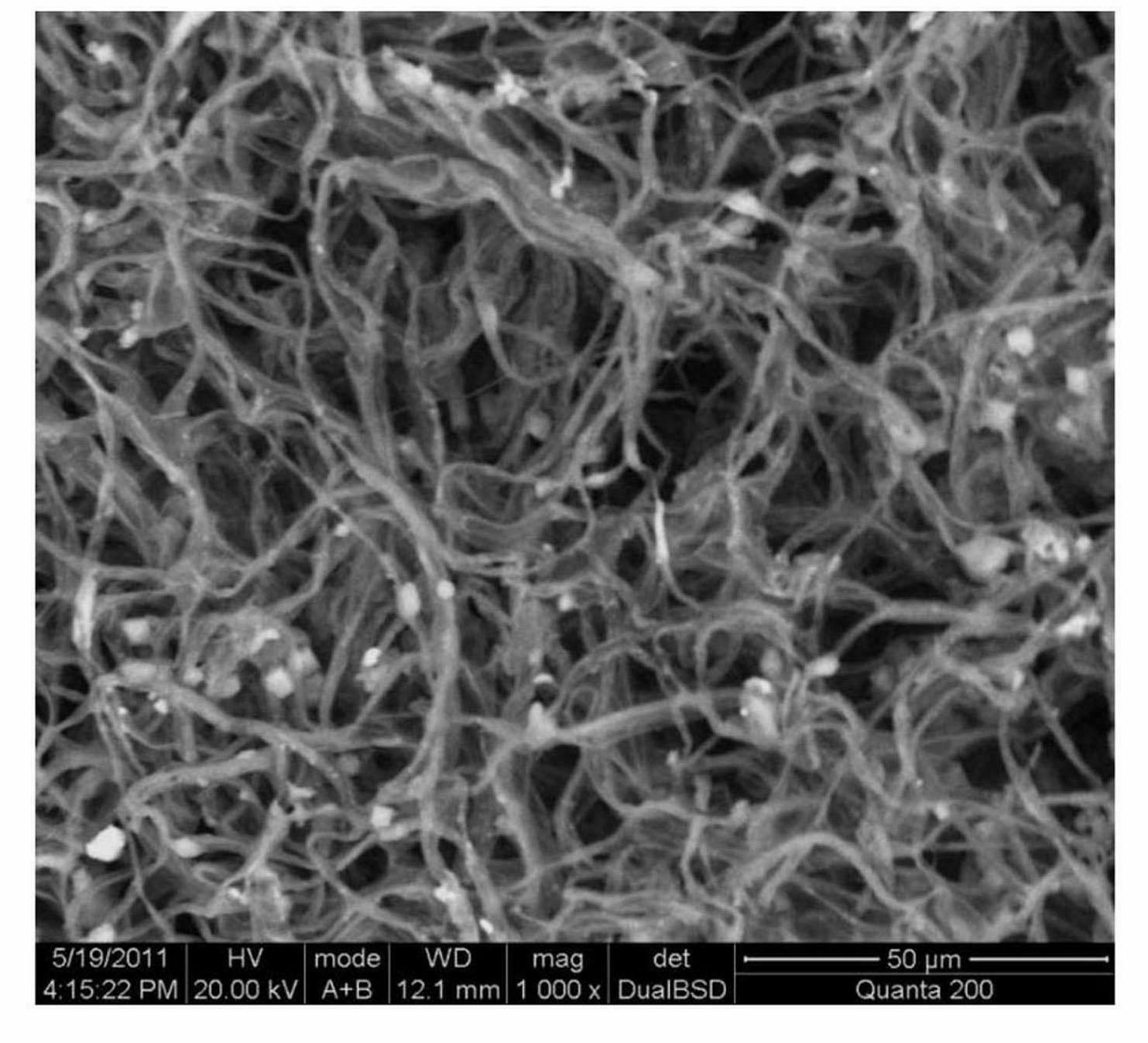

Compound magnetic biological adsorbent and preparation method for same

InactiveCN102614839ASimple manufacturing processEasy to makeOther chemical processesMicroorganism based processesBiotechnologySporeling

The invention discloses a compound magnetic biological adsorbent, which is characterized in that dry mycelia of white rot fungi are used as a carrier, the mycelia are wound to a ball, Fe3O4 nano particles and calcium alginate are embedded into the ball, and the calcium alginate serving as immobilized medium is tightly connected together with the Fe3O4 nano particles. The preparation method for the adsorbent includes the steps: inoculating spore suspension of the white rot fungi into aseptic mixed liquid of the Fe3O4 particles and the calcium alginate under the aseptic condition, mixing uniformly, dropwise adding the mixed liquid of one volume into aseptic CaC12 solution of 4-10 volumes, standing at the room temperature to obtain reaction liquid including Fe3O4-calcium alginate-white-rot fungus microspheres, and performing immobilized culture so as to obtain the compound magnetic biological adsorbent after culture is completed. The compound magnetic biological adsorbent has the advantages of high adsorption capacity, high adsorption speed, high reuse rate, cleanliness, no pollution and the like.

Owner:HUNAN UNIV

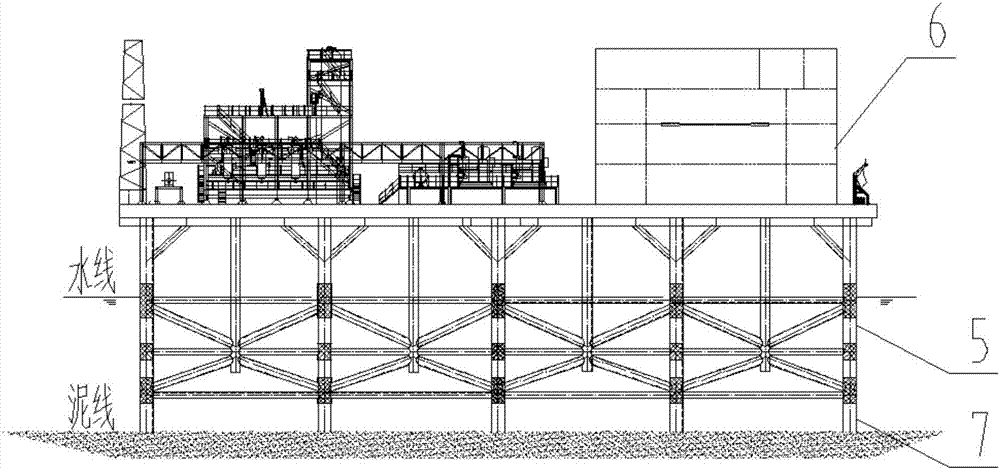

Offshore platform-type LNG receiving and distribution system

PendingCN107575738ARealize liquid distributionVersatilityArtificial islandsGas handling/storage effectsMarine engineeringDistribution system

The invention relates to an offshore platform-type LNG receiving and distribution system. The offshore platform-type LNG receiving and distribution system is composed of a storage platform, a regasification platform, a utility platform, an IOS tank box impact loading and storage platform and a wharf; and the offshore platform-type LNG receiving and distribution system works in water, the basic structure of the offshore platform-type LNG receiving and distribution system adopts a fixed platform or a movable self-lifting platform, and the functions of LNG receiving, gasification, distribution, power generation and the like are achieved. The offshore platform-type LNG receiving and distribution system is safe, economical and wide in application range.

Owner:上海壮举海洋工程有限公司 +1

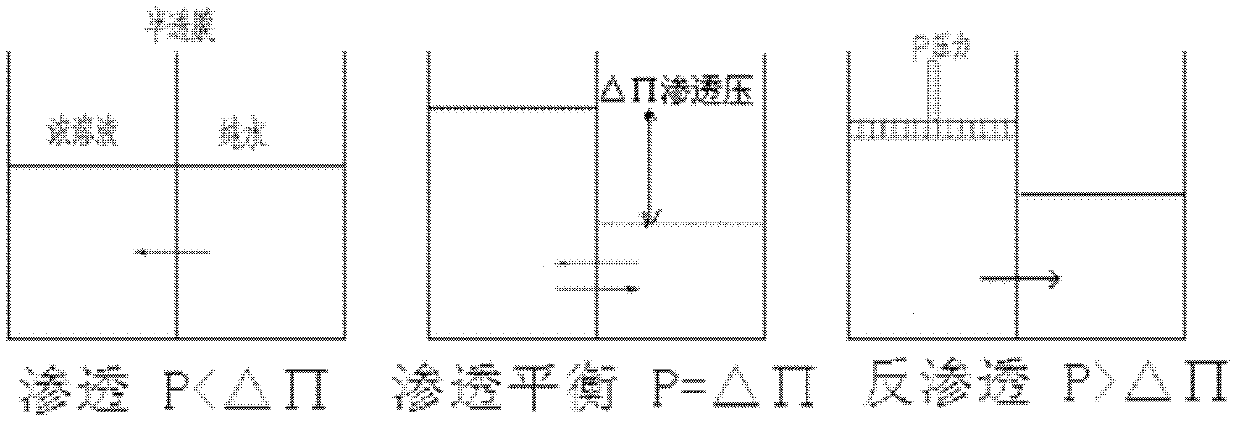

Membrane separation process for lead-zinc smelting wastewater

ActiveCN101492214ALow annual depreciation rateHigh recovery rateWater contaminantsWaste water treatment from metallurgical processIndustrial waste waterUltrafiltration

The invention discloses a membrane separation process for treating lead-zinc smelting wastewater, which comprises the following steps: pretreating lead-zinc smelting industrial wastewater through the processes of a multi-media filter, ultrafiltration, and the like after the wastewater reaches the discharge standard after the treatment of a heavy metal precipitation process; and performing desalinization treatment on the wastewater by a nanofiltration process, wherein water is produced for recycling and a concentrated solution reaches the standard after an intensified coagulation treatment and is discharged. The membrane separation process has the advantages of high wastewater recovery ratio by adopting a membrane process to perform recycling treatment on the lead-zinc smelting wastewater, good recycling water quality, advanced performance and economical practicability, high automation degree, and simple and convenient manual operation.

Owner:CHINA NERIN ENG +1

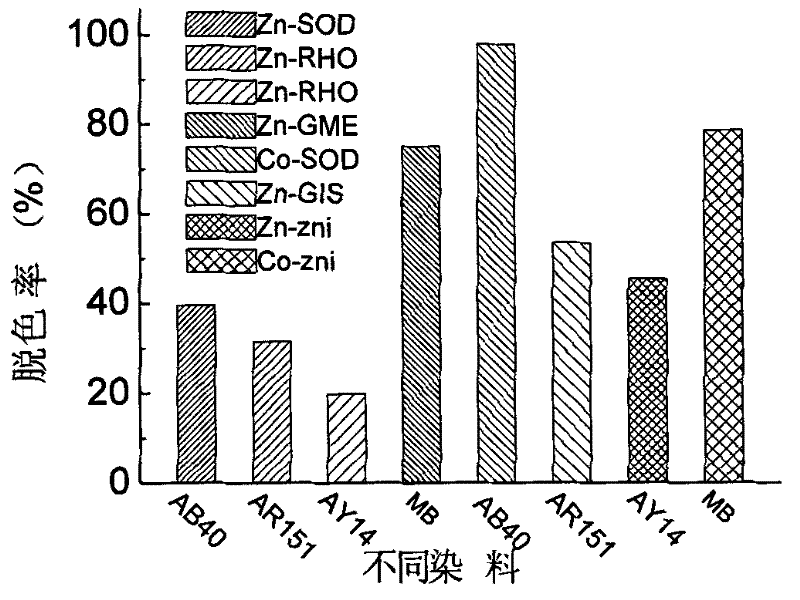

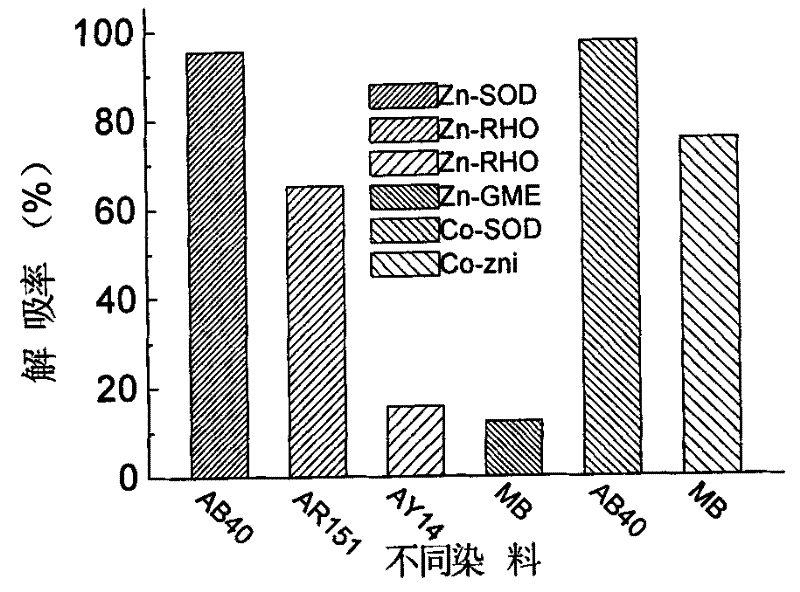

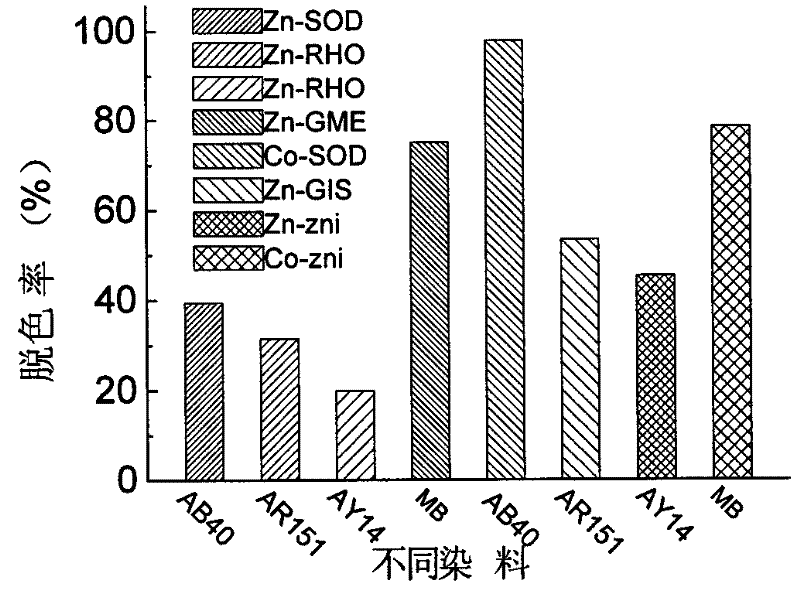

A method for decolorizing and adsorbing dyes in water by a zeolite-like imidazolate framework material

InactiveCN102267736AHigh yieldControllable shapeWater/sewage treatment by sorptionDesorptionStructure and function

The invention discloses a method for decolorizing and adsorbing a dye in water by using a zeolite-like imidazate framework material, relates to application of a decolorizing and adsorbing material in decolorization and adsorption of a dye in water, and belongs to the field of environment-friendly technology application. The method is characterized in that: the dye in the water is adsorbed by adopting the ZIFs material with structural diversity, large pore volume, high specific surface area and relatively high chemical and thermodynamic stability; the material has the characteristics of high yield, controllable shape and diverse structure and function change; and the ZIFs material of different structure is selected according to different dye molecules so as to achieve ideal decolorizing and adsorbing effects. The concentration and the color degree of the filtrate treated by the method are obviously reduced, the decolorizing rate can reach over 95 percent, the color degree can be reduced by 50 to 95 degrees, and the desorption rate reaches over 90 percent; and the ZIFs material can be circularly used in adsorption treatment of the dye, avoids secondary pollution of the water body and belongs to an environment-friendly sewage treatment material.

Owner:TAIYUAN UNIV OF TECH

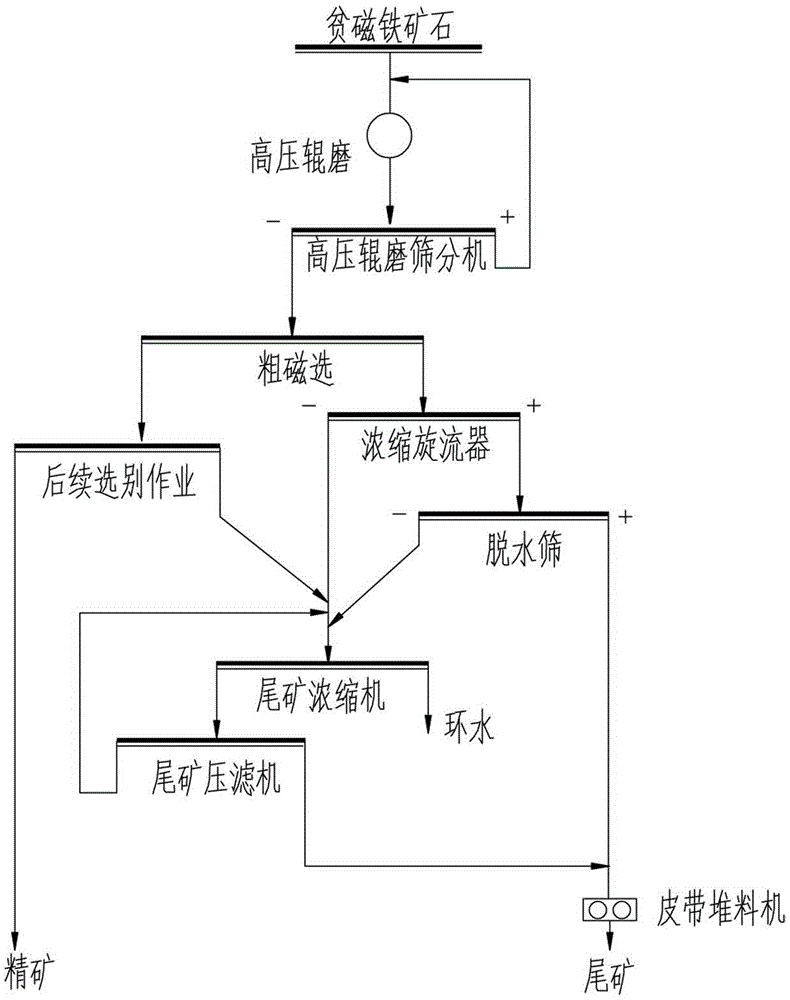

Tailing treatment process in poor magnetic iron ore beneficiation process

InactiveCN105233975AReduce processingReduce investment and footprintSolid separationMechanical material recoveryMagnetic separatorChemistry

The invention relates to a tailing treatment process in a poor magnetic iron ore beneficiation process. The tailing treatment process comprises the following steps: a poor magnetic iron ore is fed in a high-pressure grinding roller and a screening machine for a closed-circuit grinding operation; a screened product of the screening machine is fed to a roughing magnetic separator; and a concentrate thereof is fed to a subsequent operation. The tailing treatment process is characterized by further comprising the following steps: a tailing of the roughing magnetic separator is fed to a concentration cyclone; a underflow product of the concentration cyclone is fed to a tailing dehydration sieve; an overflow product of the concentration cyclone, a screened product of the dehydration sieve and a tailing in a subsequent separation operation are all fed to a tailing concentrator for a concentration operation; a underflow product of the tailing concentrator is fed to a tailing press filter for filtration; and an unscreened product of the dehydration sieve and a filter cake of the tailing press filter are fed to a tailing dry discharge belt conveyer for conveying to a tailing storage yard or a tailing pond for storage. The tailing treatment process has the following advantages: the dry discharge treatment is performed for a thick-particle tailing in nearly one half of the separation process, and the rest tailing is concentrated and filtered to realize the tailing dry discharge, so that the tailing treatment process in the poor magnetic iron ore beneficiation process is comprehensively optimized.

Owner:ANSTEEL GRP MINING CO LTD

Sewage and sludge treatment method for achieving good biological phosphorus removal and improving acid production of sludge

ActiveCN102774958AEnhanced properties for producing organic acidsImprove featuresSustainable biological treatmentBiological sludge treatmentSequencing batch reactorOrganic acid

The invention relates to a sewage and sludge treatment method for achieving good biological phosphorus removal and improving acid production of the sludge. An ordinary sequencing batch reactor is adopted to treat the sewage, and an alkaline fermentation pool is utilized to ferment excess sludge generated in the sewage treatment process. The sewage and sludge treatment method particularly comprises enabling the sewage to enter the sequencing batch reactor, and directly performing aerobic aeration on the sewage; discharging a certain amount of mud water mixture, controlling sludge age, enabling supernatant to return to the sequencing batch reactor after the mud water mixture subsides, performing aerobic aeration and subsiding on the excess sludge, and draining water; enabling the excess sludge generated in the sequencing batch reactor to enter the alkaline fermentation pool after water draining is finished; starting an agitator, starting an automatic alkali-adding device, and enabling pH in the alkaline fermentation pool to be 10+ / -0.1; and performing mud water separation after 4-day fermentation. According to the sewage and sludge treatment method, physicochemical properties of the excess sludge is controlled from a source of sewage treatment, yield of organic acid in the alkaline fermentation process of the excess sludge is improved, fermentation time is shortened, an organic matter part in the sewage is removed by microorganism accumulation simultaneously, the aeration amount is reduced, and sewage treatment running cost is reduced.

Owner:TONGJI UNIV

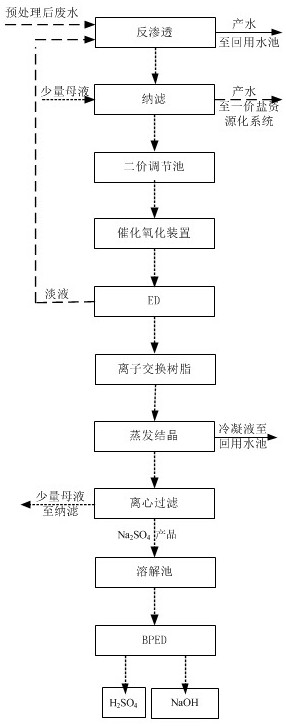

Synthetic ammonia organic wastewater divalent salt recycling and zero discharge process

PendingCN113716772AComponent cleanup and purificationRemove completelyGeneral water supply conservationWater contaminantsCatalytic oxidationReverse osmosis

The invention discloses a synthetic ammonia organic wastewater divalent salt recycling and zero discharge process which comprises the following steps: lifting pretreated effluent by a pump to enter reverse osmosis, conveying produced desalted water to a reuse water tank, conveying reverse osmosis concentrated water to a nanofiltration system, conveying nanofiltration produced water to a monovalent salt recycling system, conveying nanofiltration concentrated water to a divalent adjusting tank, enabling the nanofiltration concentrated water to enters a catalytic oxidation reaction device to be subjected to oxygenolysis after adjustment; carrying out electrodialysis for concentration, removing foreign ions by resin adsorption, and entering an evaporative crystallization device; preparing and obtaining a sodium sulfate product with the purity above 99%, centrifugally separating mother liquor to flow back to a nanofiltration system, conveying evaporation condensate to a recycling water tank, dissolving the sodium sulfate product to prepare a solution with a certain concentration to enter a bipolar membrane electrodialysis device so as to prepare an acid-base product. Through the combined process of pretreatment, reverse osmosis, nanofiltration, catalytic oxidation, electrodialysis and evaporative crystallization, and the reverse osmosis concentrated water of the wastewater, zero emission of the wastewater is realized in a real sense.

Owner:清创人和生态工程技术有限公司

Cleaning composition

InactiveUS20050261152A1Lower the volumeExtended service lifeInsulating substrate metal adhesion improvementSurface-active detergent compositionsAdjuvantPersulfate

A composition composed of a persulfate, boric acid, a fluorine containing acid and an inorganic acid. Adjuvants also may be included in the composition. The composition may be employed as a microetch solution in the fabrication of microelectronic packages.

Owner:SHIPLEY CO LLC

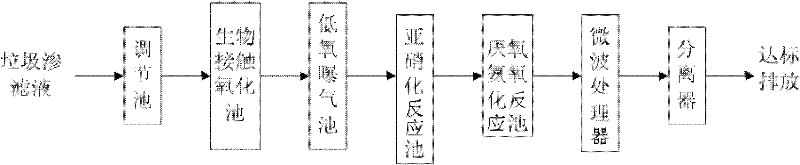

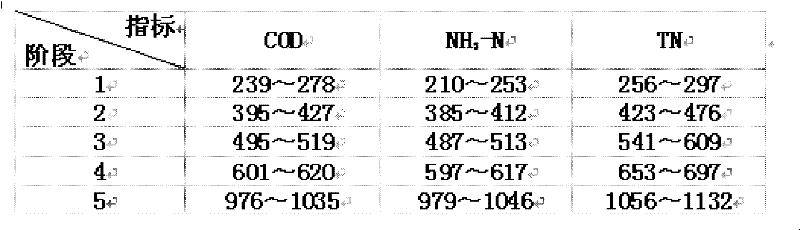

Method for treating landfill leachate

InactiveCN102674623APromote degradationEffluent water quality up to standardMultistage water/sewage treatmentWater/sewage treatment by oxidationOxidation pondLow oxygen

The invention discloses a method for treating landfill leachate. The method comprises the following steps of: feeding the landfill leachate into an adjustment tank first, sequentially feeding the landfill leachate into a biological contact oxidation pond, a low-oxygen aeration tank, a nitrosation reaction tank, an anaerobic ammonium oxidation reaction tank and a microwave treater, finally feeding the landfill leachate into a separator, performing precipitation separation to separate active carbon obtained after microwave treatment from the outlet water of the landfill leachate, and then discharging the outlet water which meets the standard. The technology for treating the landfill leachate saves energy and is high in efficiency and low in consumption; and by the method, pollutants such as organic pollutants, nitrogen (N) and phosphorus (P) can be effectively removed, and the environmentally acceptable treatment and discharge of the landfill leachate can be realized finally.

Owner:ARCHITECTURAL DESIGN RES INST OF GUIZHOU

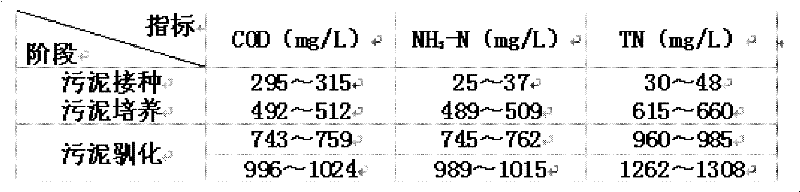

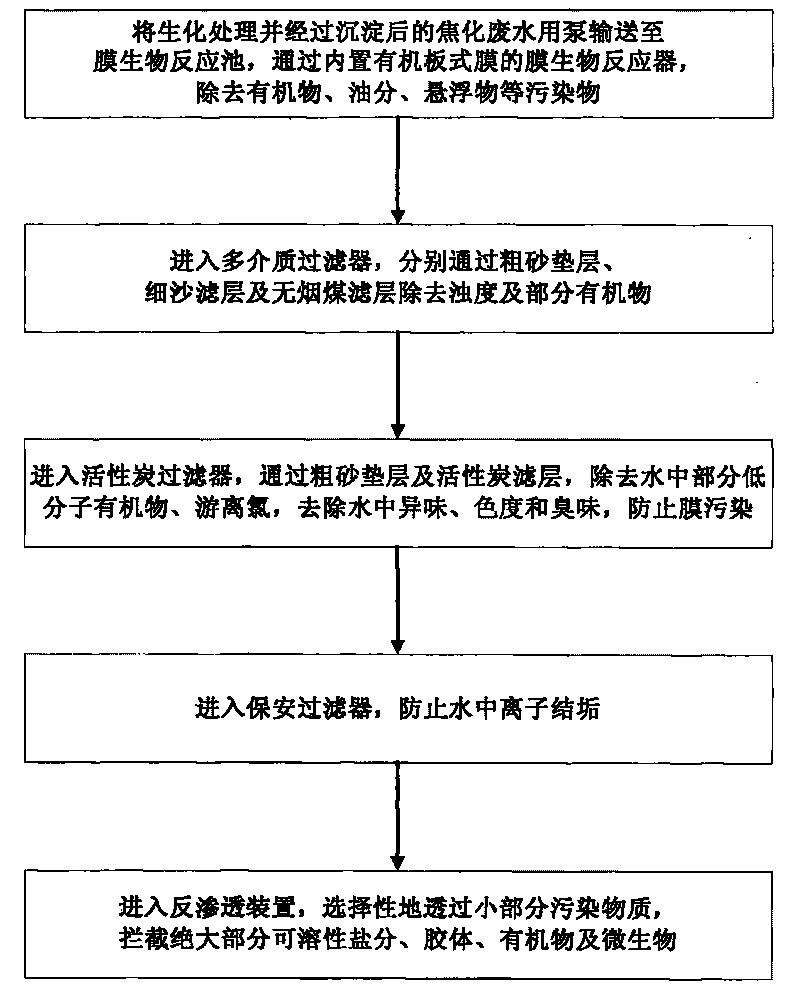

Method for treating recycling of coking wastewater

ActiveCN101723551AReduce usageReduce processingWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltrationActivated carbon filtration

The invention relates to a method for treating recycling of coking wastewater. The method comprises the steps of: A, conveying the coking wastewater which is subjected to biochemical treatment and precipitation into a membrane biological reaction tank by a pump, and removing pollutants such as organic substances, oil content and suspended substances through a membrane bioreactor internally provided with an organic plate type membrane; B, entering a multi-medium filter, and removing turbidity and the partial organic substances through a coarse sand cushion layer, a fine sand filtration layer and an anthracite filtration layer; C, entering an activated carbon filter, and removing partial low molecular organic substances and free chloride in water through the coarse sand cushion layer and the activated carbon filtration layer; D, entering a cartridge filter, and preventing ions in the water from scaling; and E, entering a reverse osmosis device, and intercepting most of soluble salt, colloids, organic substances and microorganisms. The treatment method has the advantages of steady treatment effect, low production running cost, and simple and convenient operation, can treat the effluent of a biochemical sedimentation tank, avoid a physicochemical treatment stage after conventional biochemical treatment, avoid using a medicament in a large quantity, reduce the treatment capacity of sludge of a system, and reduce the operation cost for wastewater treatment.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com