Patents

Literature

46results about How to "Solve separation and recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nickel foam supported bimetal MOF base ozone catalyst, production thereof and application

ActiveCN110302841ASolve separation and recyclingSimple and fast operationWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsDecomposition

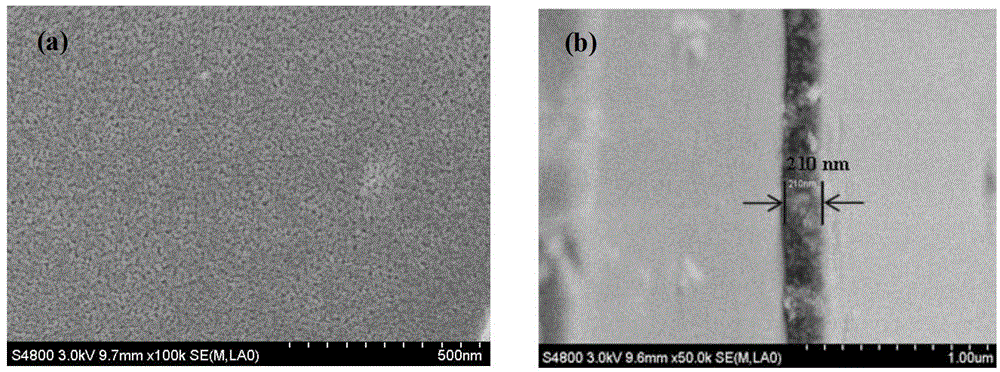

The invention relates to a preparation method of nickel foam supported bimetal MOF base ozone catalyst, a production thereof and application. The preparation method comprises the steps that a metal organic framework ZIF-67 is taken as a template, nickel foam serves as a carrier, an in-situ hydrothermal-impregnation synthesis method is adopted to prepare a supported porous Mn / Co bimetal MOF base ozone catalyst, bimetal Mn / Co oxide in situ grows on a nickel foam base through a hydrothermal method, the supported bimetal oxide is modified by ZIF-67 through a impregnation method, and thus the nickel foam supported bimetal MOF base ozone catalyst is prepared. According to the preparation method, the crystal size and morphology of the catalyst are regulated effectively and accurately, evenly-distributing of active sites is facilitated, the decomposition rate on ozone and the mineralization rate on organic matter of the nickel foam supported bimetal MOF base ozone catalyst are greatly improved, the problems of separating and recycling of suspended catalysts can be effectively solved, the operation cost of water treatment is lowered, and large application prospects are achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Process for producing para-amino-phenol

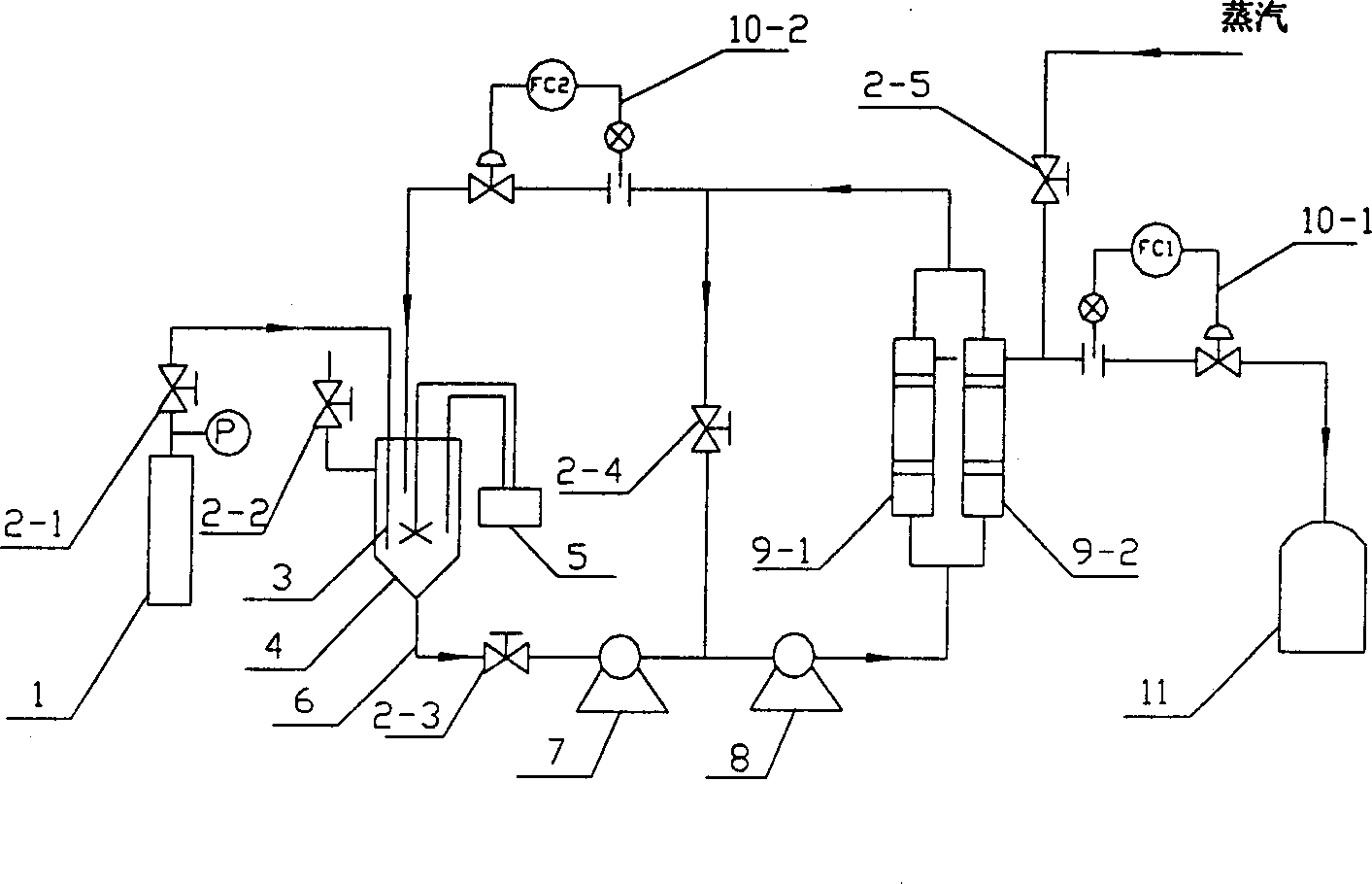

InactiveCN1377875AReduce energy consumptionHigh degree of automationOrganic compound preparationAmino compound preparationMetal catalystP-Aminophenol

The production process with p-nitrophenol material includes catalytic hydrogenation with Ni, Al or other metal catalyst with the reactant material being pumped to circulate between reactor and inorganic memobrane assembly; repeated filtering of circular material through inorganic membrane with the liquid phase product passing through the membrane pores; the conventional treatment of the collectedliquid phase product to obtain p-aminophenol crystal product; and the recovery and reuse of the solid catalyst in circular flow and finally in the reactor. During the process, fine suspended catalystis separated and recovered continuously.

Owner:NANJING UNIV OF TECH +1

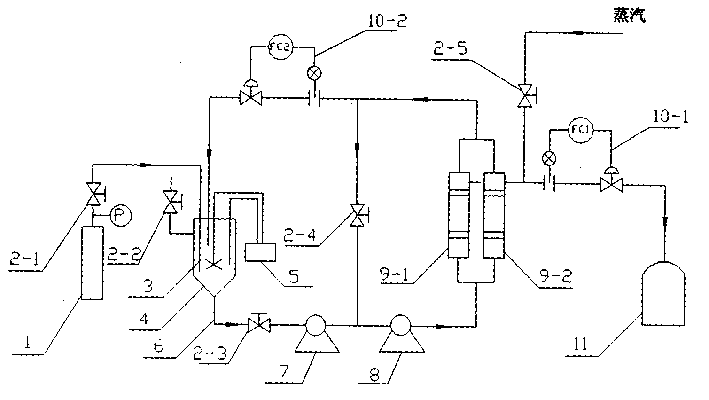

Nano-grade ZnO loaded magnetic biological carbon composite photocatalyst and preparation method thereof

ActiveCN108311153ASolve separation and recyclingHas a reducing effectWater/sewage treatment by irradiationWater treatment compoundsWater bathsCarbon composites

The invention provides a nano-grade ZnO loaded magnetic biological carbon composite photocatalyst and a preparation method thereof. The preparation method comprises the following steps: step 1: carrying out thermal hydrolysis on a biomass under an alkaline condition to extract plant fibers; after drying, carrying out pre-carbonization treatment; mashing and sieving with a sieve with the size of 10to 20 meshes; step 2: mixing a ferrous salt solution and a potassium hydroxide solution; adding soluble zinc salt; step 3: adding the sieved plant fibers into the solution formed by step 2; uniformlymixing and adding a potassium nitrate solution; after sufficiently stirring, treating a mixture in a water bath; continuously stirring and ageing until black gel is formed, so as to obtain a black gel solution; step 4: after washing and drying the black gel solution, generating dry gel; calcining the dry gel and continuously introducing inert gas; after washing and drying, obtaining the nano-grade ZnO loaded magnetic biological carbon composite photocatalyst. According to the nano-grade ZnO loaded magnetic biological carbon composite photocatalyst, magnetic biological carbon is used as a carrier of the photocatalyst, and the problem that the photocatalyst in chromium-containing sewage treatment is difficult to separate and recycle is solved.

Owner:湖南大辰环保股份有限公司

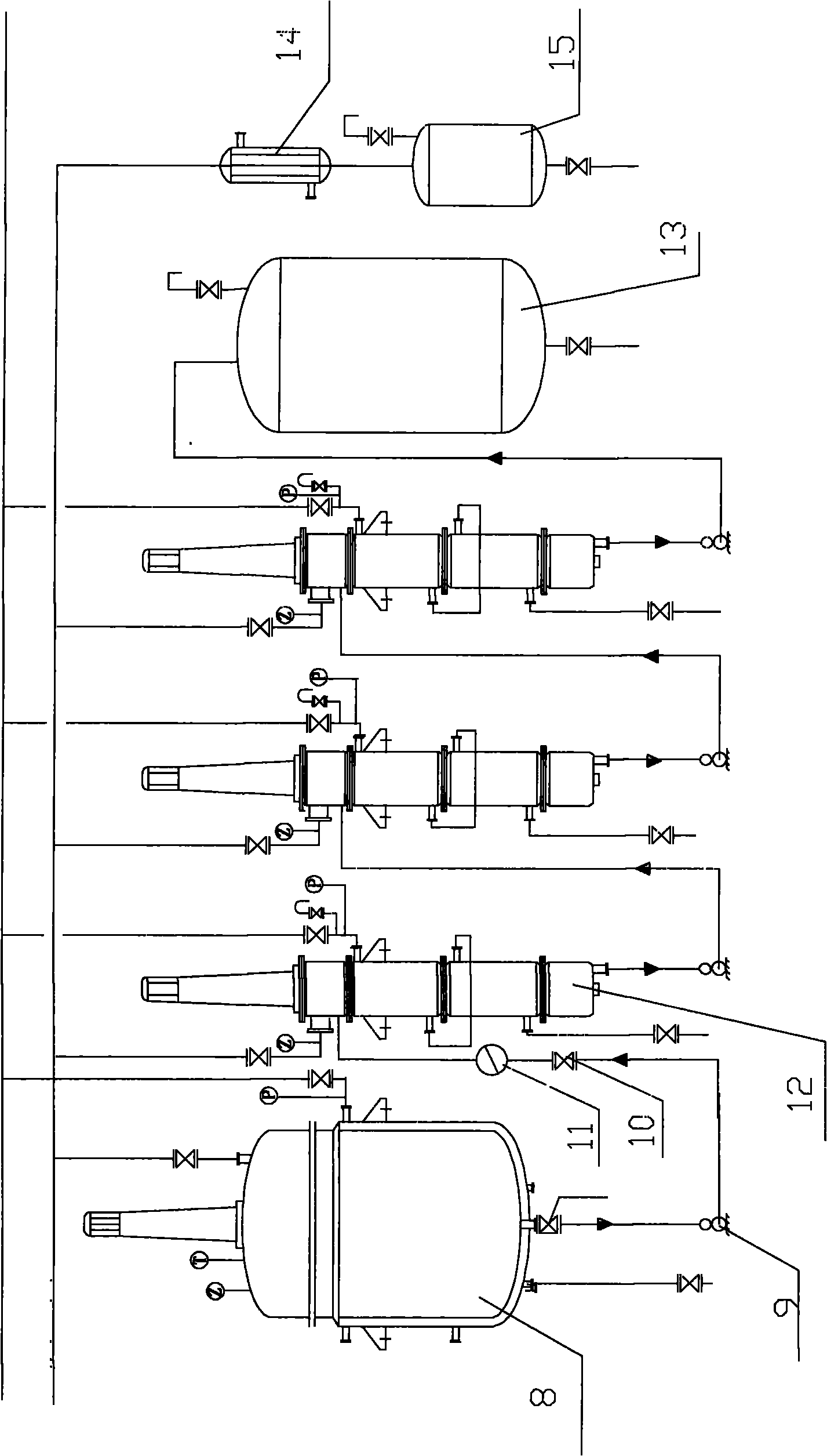

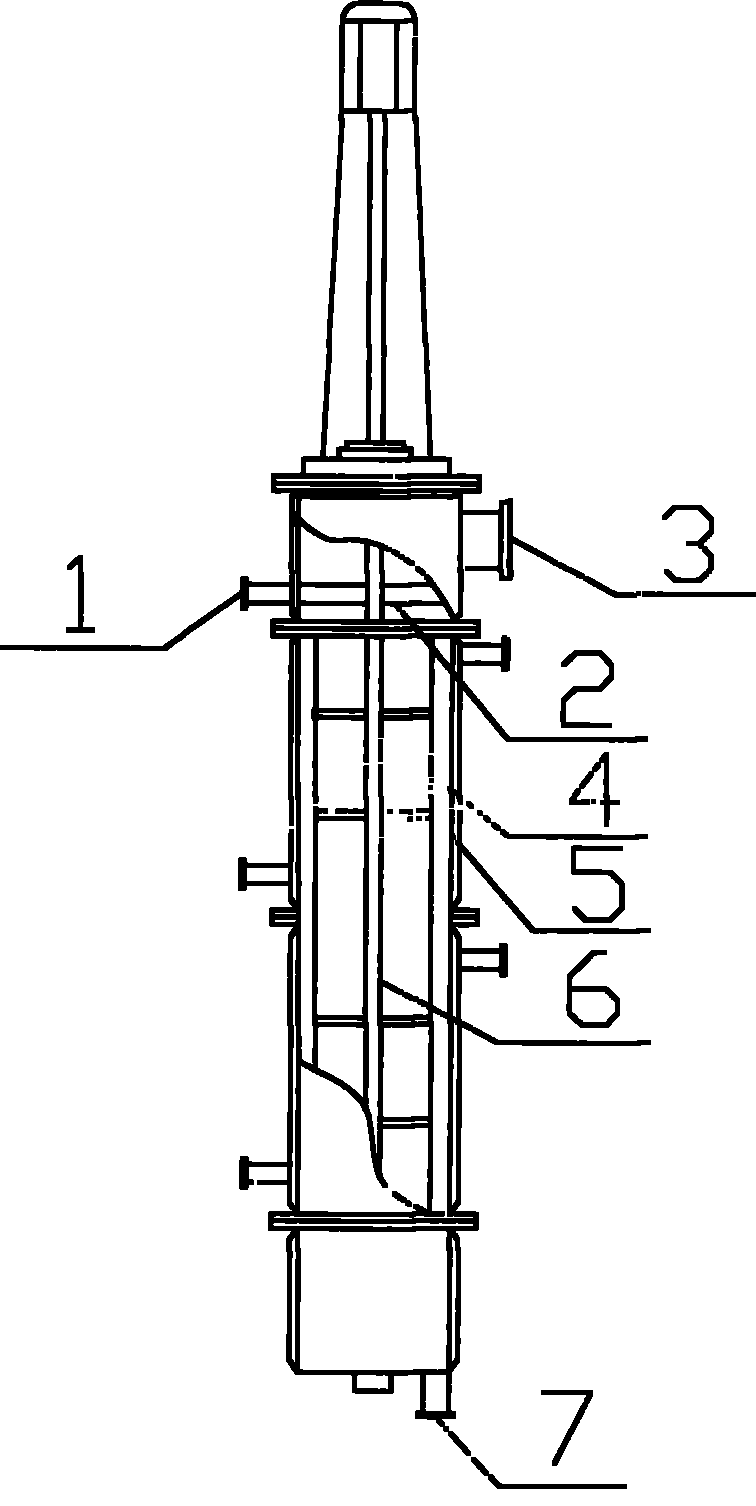

Process for synthesizing sucrose polyester by using rotating film transesterification flow reactor

InactiveCN102093438AIncrease contact areaSimple interfaceEsterified saccharide compoundsSugar derivativesResource utilizationPOTASSIUM STEARATE

The invention discloses a process for synthesizing sucrose polyester, particularly a process for synthesizing sucrose polyester by using a rotating film transesterification flow reactor. The process comprises the following steps: methyl oleate, sucrose powder, potassium stearate and potassium carbonate are added into a mixing kettle, and heated while stirring; the materials enter the rotating film transesterification flow reactor to react; the crude fatty acid sucrose polyester product obtained after the reaction enters a product storage tank, and the reaction product methanol enters a methanol receiver after being cooled by a condenser; and the crude product in the product storage tank is neutralized with acetic acid, washed and dried to obtain the sucrose polyester product. The low-boiling-point substances generated in the process provided by the invention are quickly removed out of the reaction system, thereby being beneficial to the generation of the product, greatly increasing the reaction speed and enhancing the product quality. The process can be used for continuous-feeding production, is beneficial to large-scale production, enhances the production efficiency, has the advantages of high yield and simple process, lowers the production cost and raises the resource utilization ratio.

Owner:ADANA FOOD TECH LIUZHOU

Preparation method of nitrogen and sulfur functionalized carbon foam magnetic microspheres

ActiveCN105013439AImprove adsorption capacityGood dispersionOther chemical processesAlkali metal oxides/hydroxidesMicrosphereMass ratio

The invention relates to a preparation method of nitrogen and sulfur functionalized carbon foam magnetic microspheres. The method comprises the following steps: weighing resorcinol, a formaldehyde solution, ethyl orthosilicate, L-cysteine, ammonia water, ethanol and water according to a mass ratio of 1:1.5-2.0:1.8-2.2:1.0-1.5:1.2-1.7:28-34:80-120, mixing, stirring, putting the obtained mixture in a hydrothermal reaction kettle, and reacting for 18-24h to obtain SiO2-containing polymer microspheres; and putting the microspheres in a tubular furnace, heating at a heating rate of 1-10DEG C / min under the protection of nitrogen to 550DEG C, charring for 4h to obtain nitrogen and sulfur functionalized SiO2 carbon foam microspheres, removing SiO2 in the microspheres, weighing iron nitrate nonahydrate, the nitrogen and sulfur functionalized carbon foam microspheres and anhydrous ethanol according to a mass ratio of 0.25-2.0:1:20-40, uniformly mixing, carrying out constant temperature oscillation, placing the obtained mixture in the tubular furnace, heating at a heating rate of 1-10DEG C / min under the protection of nitrogen to 400DEG C, and carrying out heat treatment for 1h to obtain the nitrogen and sulfur functionalized carbon foam magnetic microspheres. The nitrogen and sulfur functionalized carbon foam magnetic microspheres have important application values in adsorption and removal of heavy metal mercury ions in wastewater.

Owner:德昭科技(上海)有限公司

Bimetal supported magnetic visible-light composite catalytic material, and preparation method and application thereof

ActiveCN109201121AImprove adsorption capacityPromote degradationWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsWater solubleSolvent

The invention relates to a bimetal supported magnetic visible-light composite catalytic material, and a preparation method and application thereof, belonging to the technical field of photocatalytic degradation. The invention provides the bimetal supported magnetic visible-light composite catalytic material, and the preparation method and application thereof to overcome problems in realization ofboth high catalytic activity and easy recoverability. The visible-light composite catalytic material comprises Fe / Zr-MOF, Fe3O4 and g-C3N4. Fe3O4 is doped into g-C3N4 to form Fe3O4-g-C3N4; and Fe / Zr-MOF is used as a carrier. The method comprises the following steps: adding urea and Fe3O4 into a solvent, carrying out dispersion and mixing, and performing desolventization and drying; then performingcalcining at a high temperature to obtain Fe3O4-g-C3N4; and adding Fe3O4-g-C3N4, an iron source, a zirconium source and an organic ligand into a water-soluble solvent and performing sintering. The composite catalytic material can be used for catalytic degradation of organic pollutants, is easy to recover and has high catalytic activity.

Owner:TAIZHOU VOCATIONAL & TECHN COLLEGE

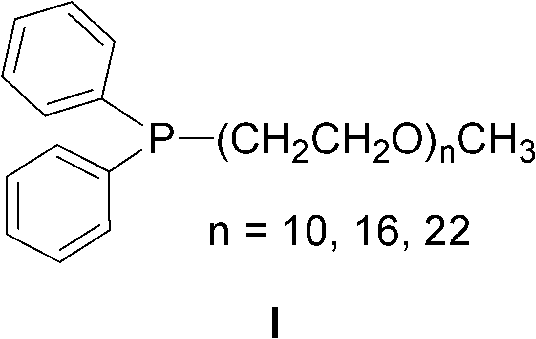

Method for preparing biaryl compound in pure water

InactiveCN101774871ATroubleshooting ResponsesSolve separation and recyclingCarboxylic acid nitrile preparationOrganic compound preparationWater insolubleBoronic acid

The invention relates to a method for preparing biaryl compound in pure water, which belongs to the technical field of catalytic chemistry. The method utilizes the Suzuki cross-coupling reaction between haloaromatic solution and aryl boronic acid to prepare the biaryl compound. According to the molar ratio of 0.5:0.75:1.0:0.0025 to 0.005:0.0025 to 0.02, the haloaromatic solution, the aryl boronic acid, alkali, catalyst and ligand are added in 1ml to 2ml of water, and react under the protection of nitrogen and the temperature of 100 DEG C for 10 to 120 minutes, the reaction mixture is added with 2ml of ether for extraction after the reaction is finished, and is kept still under the room temperature to separate phases, the water phase containing the catalyst is recycled, saturated salt water is added in the ether phase, ethyl acetate is used to extract reaction product, organic phases are merged, filtrate is concentrated, column chromatography is used for separation, and thereby the analytically pure biaryl compound is obtained. The method has the following characteristics that: reaction takes place in green solvent, i.e. pure water, and any organic solvent does not need to added; the method solves the problem that water-insoluble substrate in the pure water solvent system can hardly react; and the thermoregulated ligand is adopted to realize the separation and recovery of the catalyst.

Owner:DALIAN UNIV OF TECH

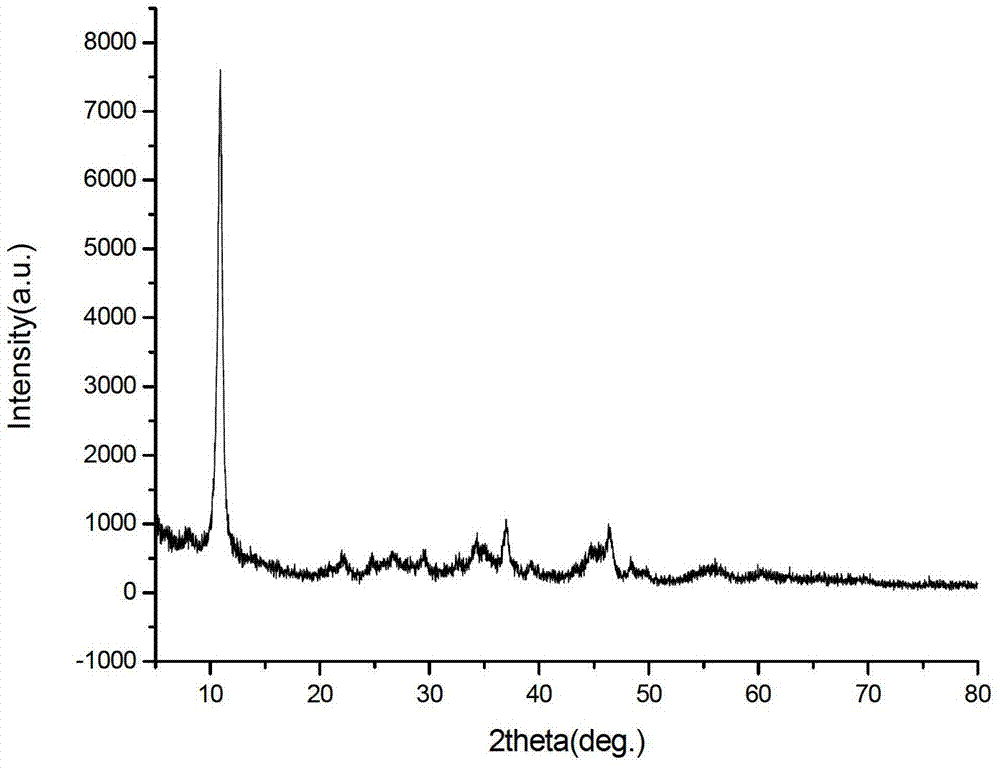

Composite modified montmorillonite photocatalysis material and preparation method thereof

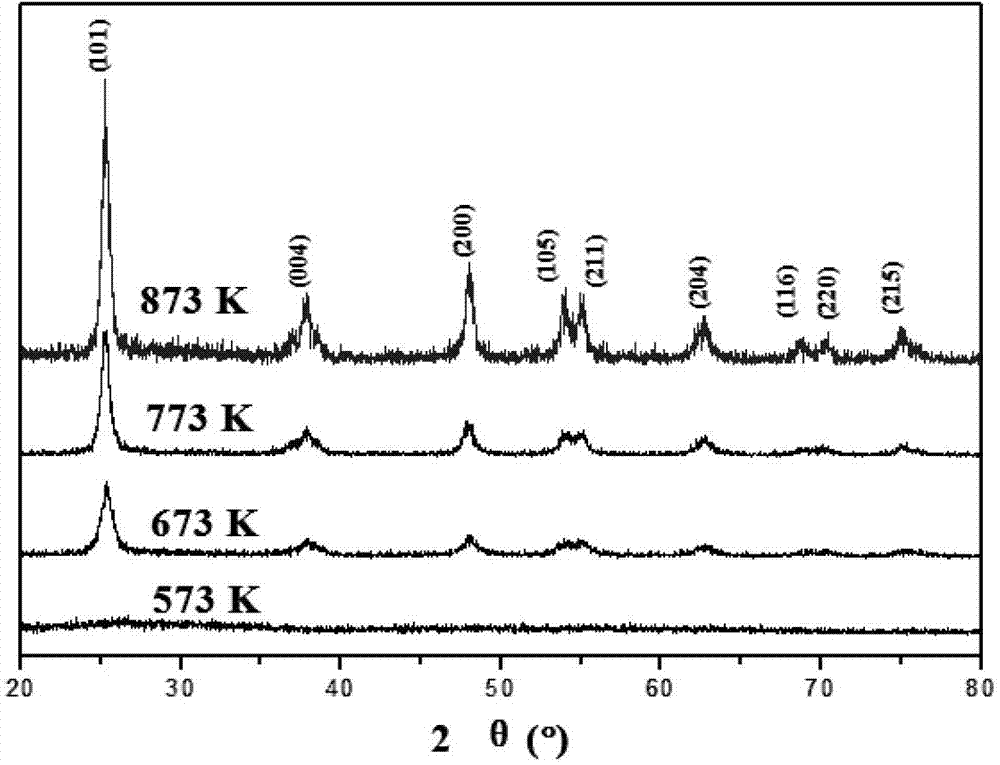

InactiveCN108311170AIncrease layer spacingImprove visible light photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsChemical reactionSOLUTION/DROPS

The invention discloses a composite modified montmorillonite photocatalysis material and a preparation method thereof. The photocatalysis material comprises sodium montmorillonite, an organic intercalator, an alcohol solution of butyl titanate, an alkaline solution, a zinc salt, distilled water and ethylene glycol. The method comprises the following steps: organically modifying the sodium montmorillonite with a long-chain alkyl group ammonium salt as the organic intercalator to obtain organic pillared montmorillonite, dropwise adding the alcohol solution of butyl titanate to the alkaline solution, performing stirring and reacting to obtain an intermediate, centrifuging and washing the intermediate, adding the washed intermediate to a nitric acid solution, stirring the intermediate and thenitric acid solution to dissolve the intermediate, adding the above organic montmorillonite suspension, and filtering, washing, drying and milling the obtained product to obtain the nanometer titaniumdioxide interlayer-loaded modified organic montmorillonite. The method has the advantages of simplicity in operation, low cost, and realization of energy saving and environment protection through omitting high-temperature sintering and ball milling processes due to physical and chemical reactions involved in the whole preparation process being low-temperature reactions.

Owner:田东昊润新材料科技有限公司

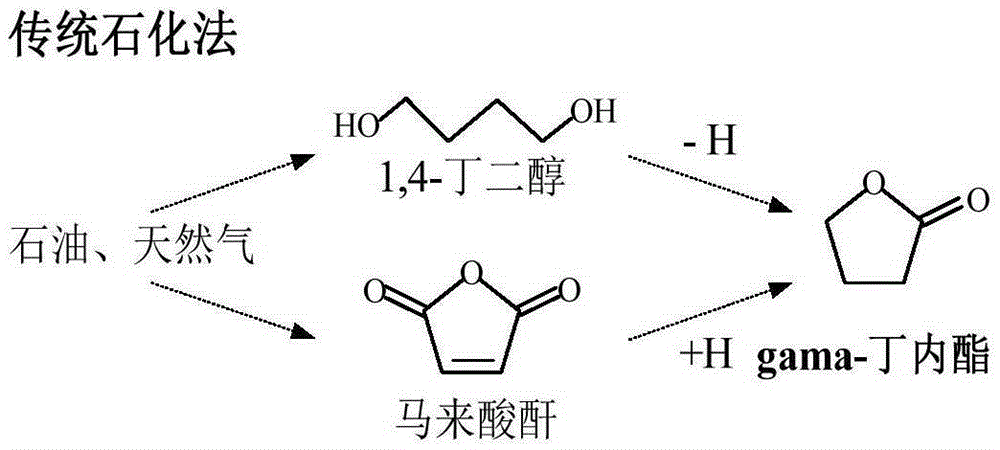

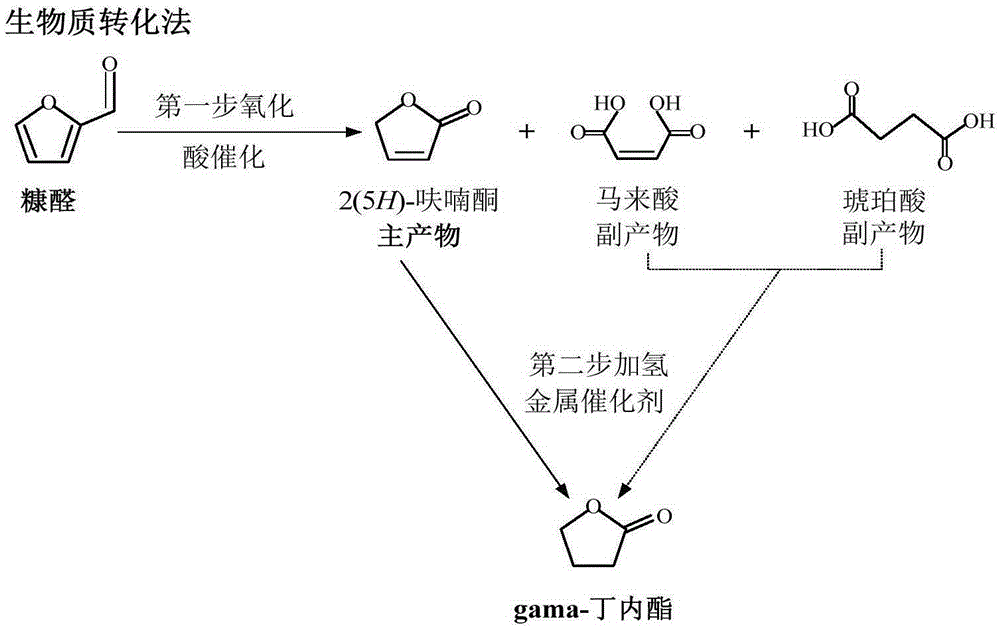

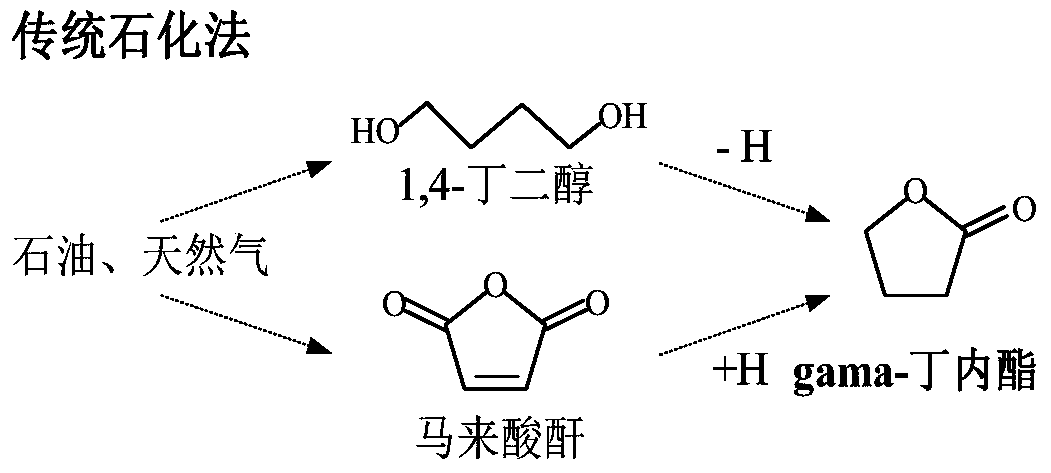

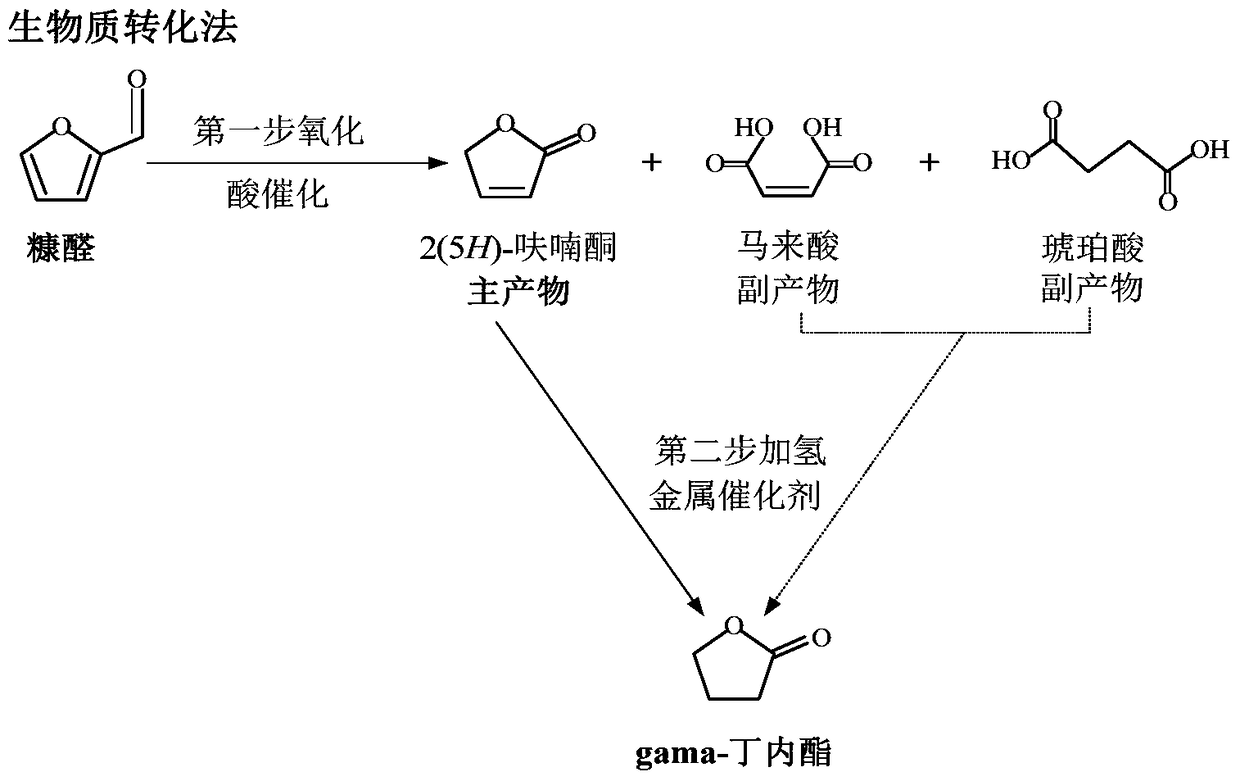

Method for preparing GBL (Gamma-Butyrolactone) by taking furfural as raw material

The invention discloses a method for preparing GBL (Gamma-Butyrolactone) by taking furfural as a raw material. The method comprises two steps of oxidizing the furfural to prepare 2(5H)-furanone and hydrogenating the 2(5H)-furanone to prepare the GBL, wherein the 2(5H)-furanone can be synthesized by the furfural by taking homogeneous-phase acid or solid acid as a catalyst and taking hydrogen peroxide as an oxidant under the conditions of mild temperature and pressure. The 2(5H)-furanone is further selectively hydrogenated to obtain the GBL under the effect of a metal catalyst in a hydrogen atmosphere. The GBL can be generated by commonly hydrogenating the 2(5H)-furanone serving as a main product and C4 binary acid serving as a byproduct of the oxidation of the furfural in situ under appropriate conditions. According to the method, high-efficiency conversion from the furfural serving as a biomass raw material to the GBL serving as a fine chemical product is realized; the method has a great application prospect.

Owner:TSINGHUA UNIV

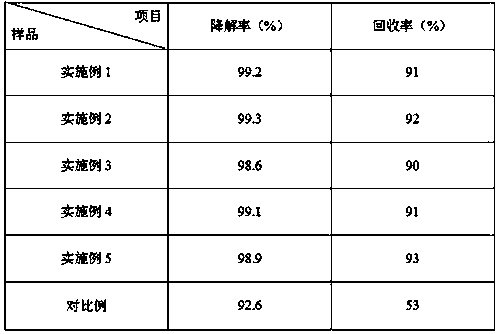

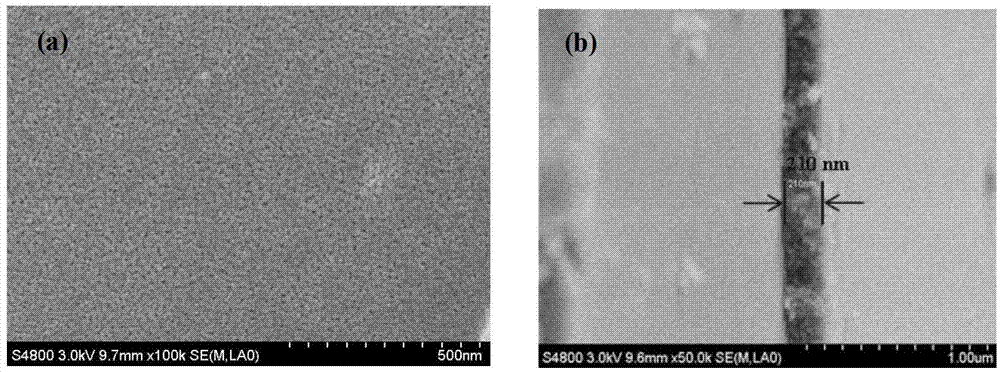

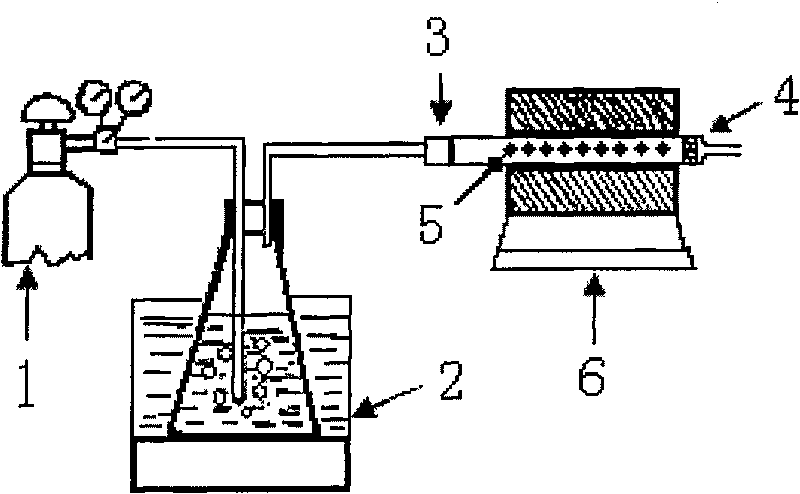

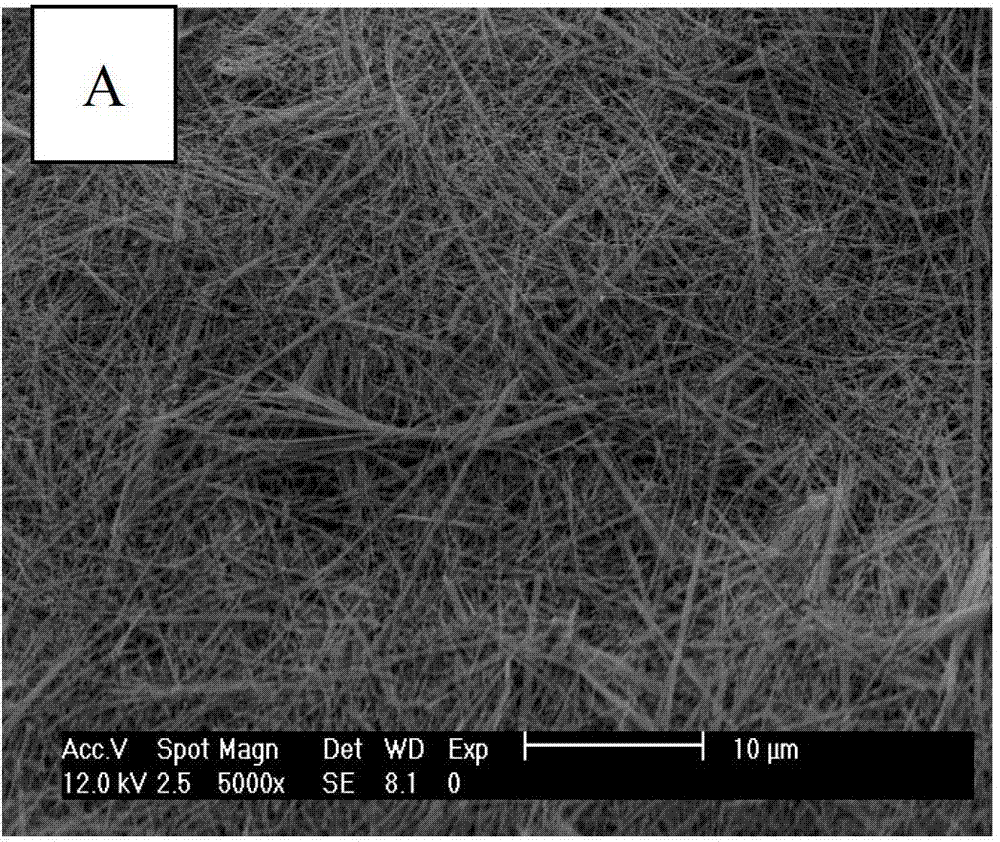

Ceramic membrane of loaded nanometer wire photocatalyst and preparation method thereof

InactiveCN109772292AImprove stabilityGood groomingCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive componentCeramic membrane

The invention discloses a ceramic membrane of a loaded nanometer wire photocatalyst and a preparation method thereof. The ceramic membrane comprises a ceramic membrane carrier, a catalytic active component and a modifying agent. The preparation method of the ceramic membrane comprises the steps of preprocessing of the ceramic membrane carrier, preparing the modifying agent, modifying the ceramic membrane carrier, preparing the catalytic active component, loading the catalytic active component to the modified ceramic membrane carrier, and obtaining the nanometer material loaded ceramic membrane; utilizing the obtained nanometer material loaded ceramic membrane for performing a photocatalytic degradation experiment on Rhodamine B, wherein the degrading rate for Rhodamine B is 98.6% or more,and the recycling rate is 90% or more. Experiment results show that the catalytic active component is loaded on the modified ceramic membrane carrier, the purpose of separating and recycling the catalytic active component is achieved, and due to loading, the catalytic performance of the catalytic active component is correspondingly improved.

Owner:殷红平

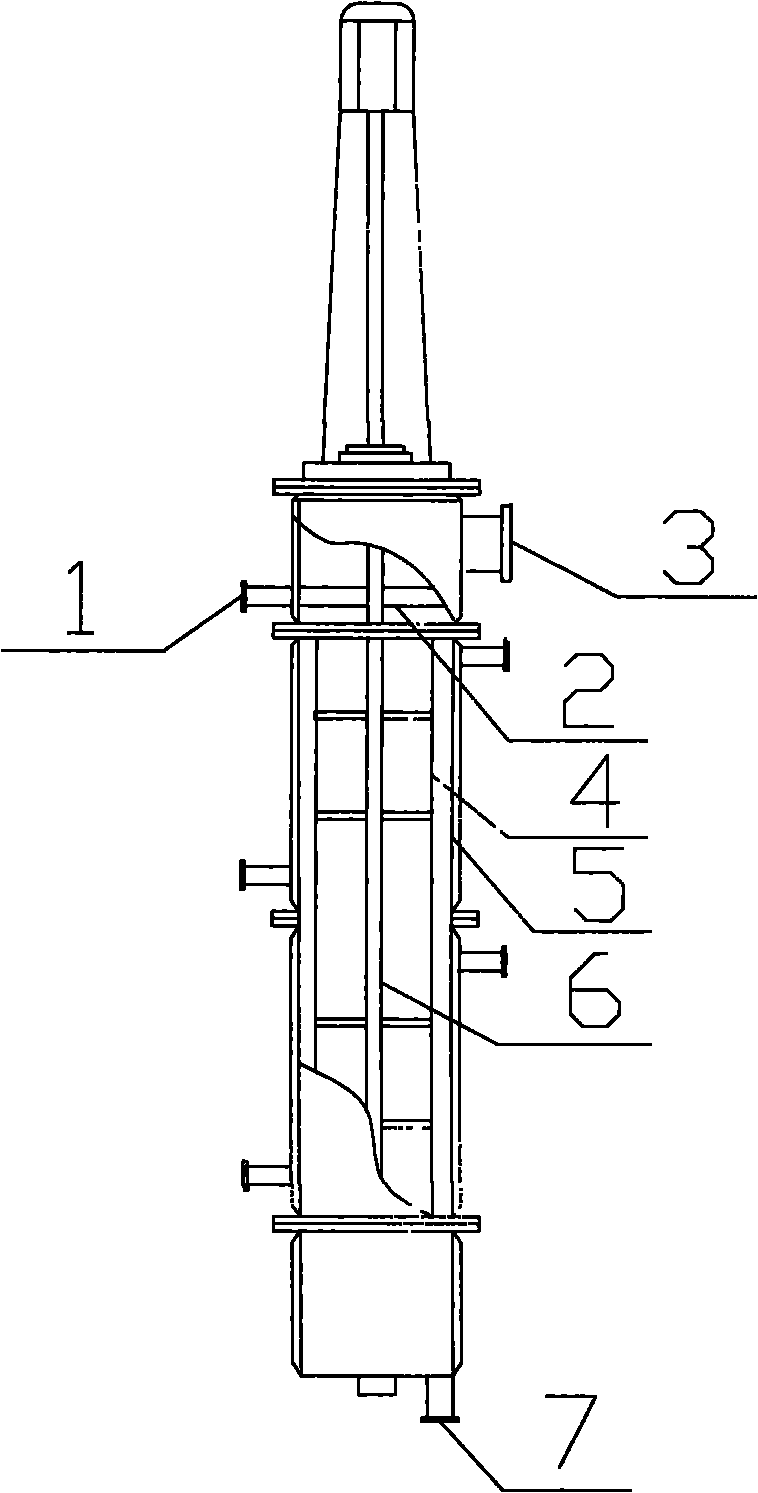

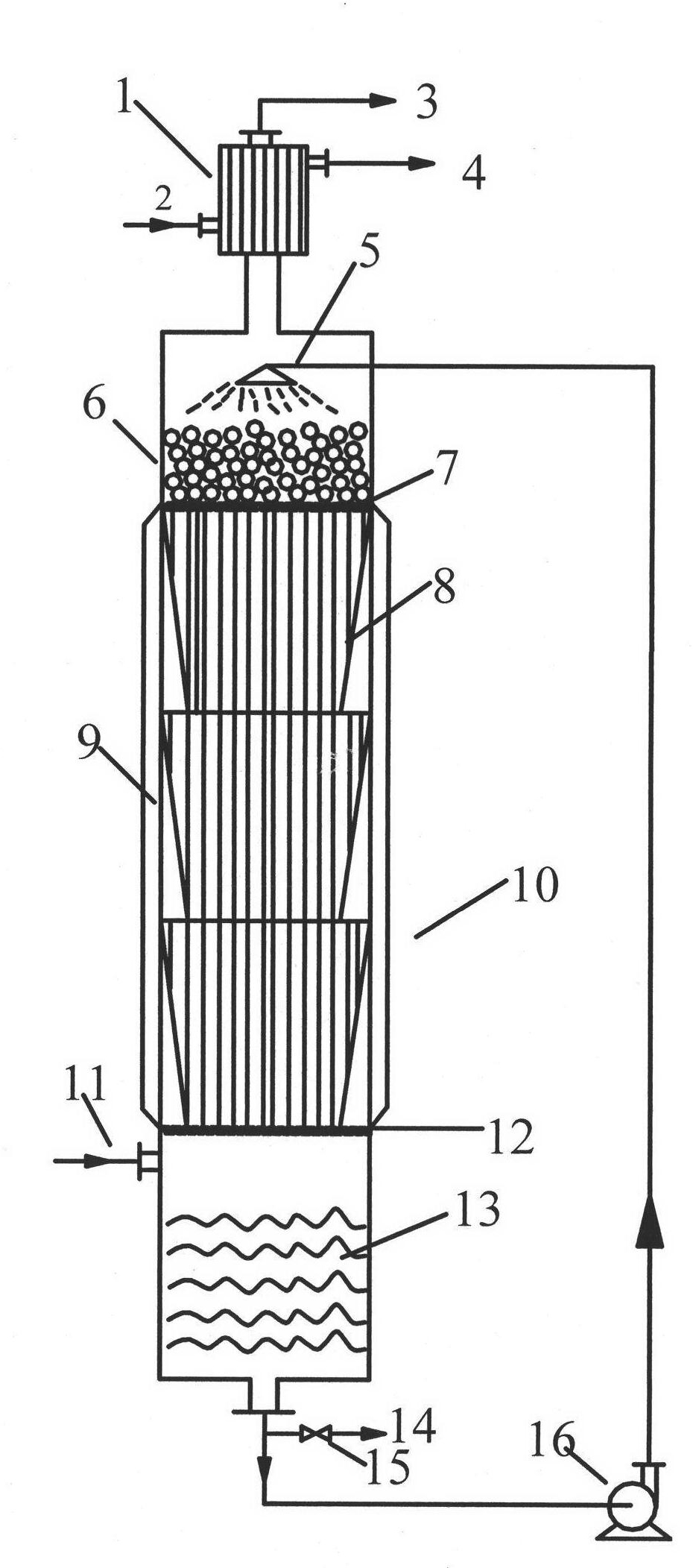

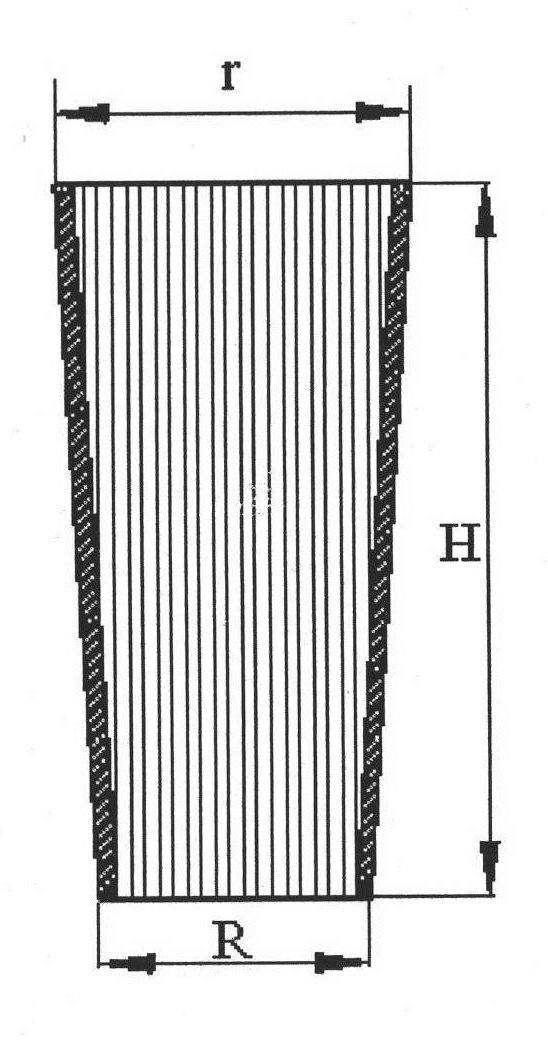

Device and method for preparing acetoxime

InactiveCN102500284AImprove conversion rateHigh selectivityOximes preparationChemical recyclingChemical industryMolecular sieve

The invention belongs to the technical field of chemical industry and relates to a device and a method for preparing acetoxime. The acetoxime is prepared from acetone, tertiary butanol, water, ammonia water and hydrogen peroxide by using an integrated TS-1 molecular sieve as a catalyst (an integrated titanium silicalite molecular sieve serves as a catalyst) and through liquid solid phase acetone ammoxidation. The device comprises a condenser, an integrated reactor and an external circulation pump. The integrated TS-1 catalyst (the integrated titanium silicalite molecular sieve serves as the catalyst) synthesized by using frustum-shaped cordierite as a carrier is loaded in the integrated reactor and is applied to preparation of the acetoxime. By adoption of the frustum-shaped cordierite carrier in the device, the wall flow phenomenon can be effectively avoided, so that activity of the catalyst and catalytic efficiency of the reactor are greatly improved. By the device and the method, the problem that the traditional powdered catalyst is difficult to recycle is solved. The device and the method have a wide market application prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

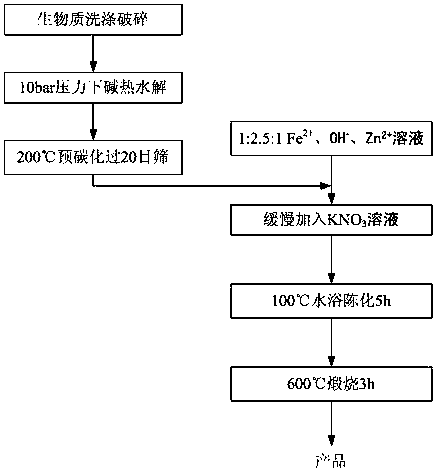

System and method for separating and recovering chlorine salts based on fly ash plasma melting

InactiveCN110282797ASolve dechlorination resource utilizationSolve separation and recyclingWater/sewage treatment by centrifugal separationWater contaminantsSulfate radicalsPotassium

The invention discloses a system and a method for separating and recovering chlorine salts based on fly ash plasma melting. The method comprises the following steps: high-salt and high-acid wastewater enters a wastewater regulating tank, and is homogenized, the wastewater is lifted into a coagulating sedimentation tank by a feeding pump, a reagent is added into the coagulating sedimentation tank, heavy metals and suspended matters in the wastewater are removed, solid-liquid separated wastewater in the sedimentation tank goes through an intermediate water tank, is pumped into a filtering or softening system by a pump, and is deeply treated, the obtained high-salt water enters an evaporative crystallization system, and undergoes sodium chloride and potassium chloride step-by-step separation, and the obtained mother liquor returns into the coagulating sedimentation tank to separate sulfates. The method and the system effectively remove pollutants in water, recover reuse water, can specially develop a sodium, potassium, chlorine and sulfate radical quaternary system salt separation system to obtain industrial byproducts meeting corresponding standards, solve the problem of separation and recovery of impurity salts in the "zero emission" process of high-salt wastewater, and also solve the problem of reuse of secondary fly ash after plasma melting.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

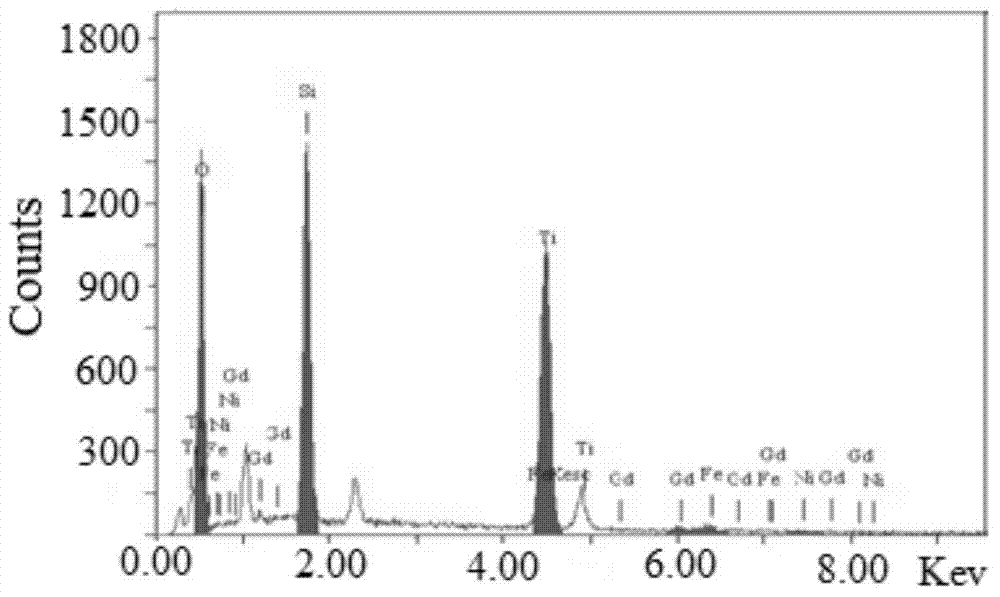

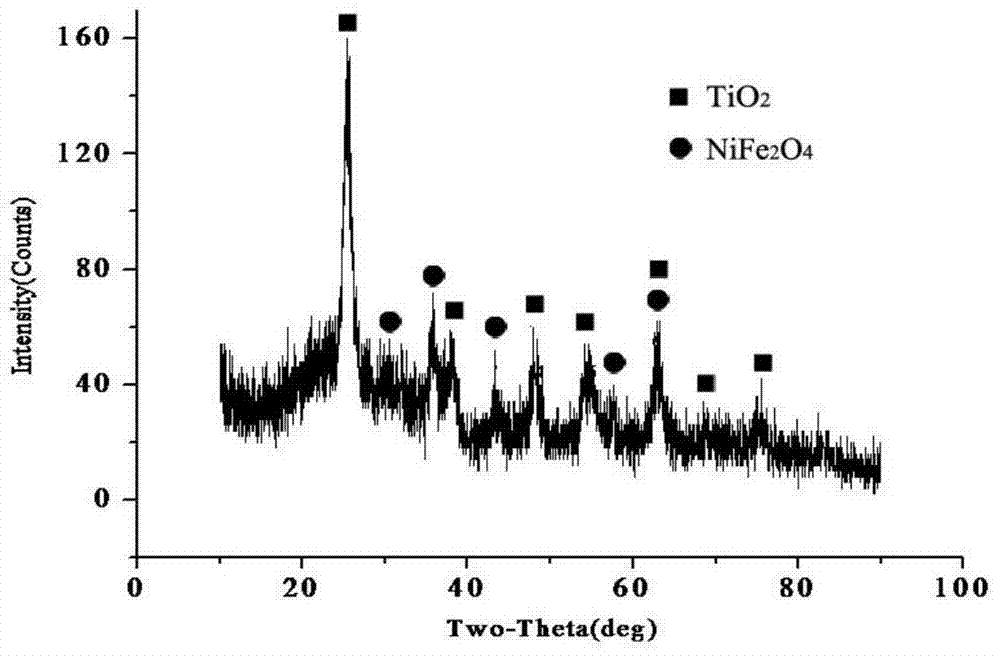

Preparation method of Gd-TiO2-SiO2-NiFe2O4 composite magnetic material

InactiveCN104722308ASolve the problem of separation and recyclingOvercome stabilityWater/sewage treatment by irradiationEnergy based wastewater treatmentSpectral responseAlcohol

The invention relates to a preparation method of a Gd-TiO2-SiO2-NiFe2O4 composite magnetic material. The preparation method comprises the following steps: firstly preparing Gd-doped TiO2; then preparing NiFe2O4 powder; then preparing a SiO2 / NiFe2O4 composite material; finally weighing 1-2g of Gd-doped TiO2 powder, adding 1mL of absolute ethyl alcohol, preparing into slurry by using a glass rod, then adding 10ml of a prepared Gd-doped TiO2 sol, and uniformly stirring to obtain a powder-sol precursor solution; and then adding 2-3g of a magnetic matrix into the powder-sol precursor solution, drying at 50-70 DEG C, calcining for 1.5 hours at 480 DEG C, taking out and quenching, grinding and magnetically sorting to obtain the Gd-TiO2-SiO2-NiFe2O4 composite magnetic material catalyst. According to the invention, a gadolinium-doped titanium dioxide-doped photocatalyst is fixed and can improve the TiO2 photocatalytic activity and expand the spectral response range of TiO2, so that industrial application and popularization of the TiO2 photocatalyst are facilitated.

Owner:XI'AN PETROLEUM UNIVERSITY

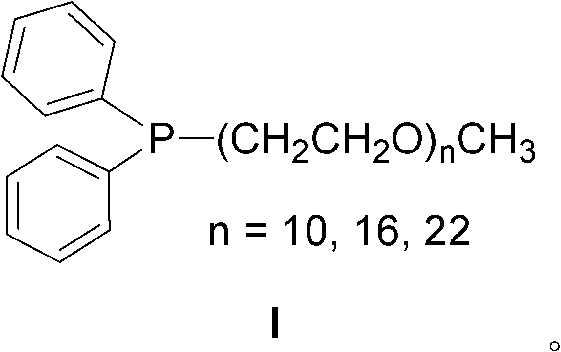

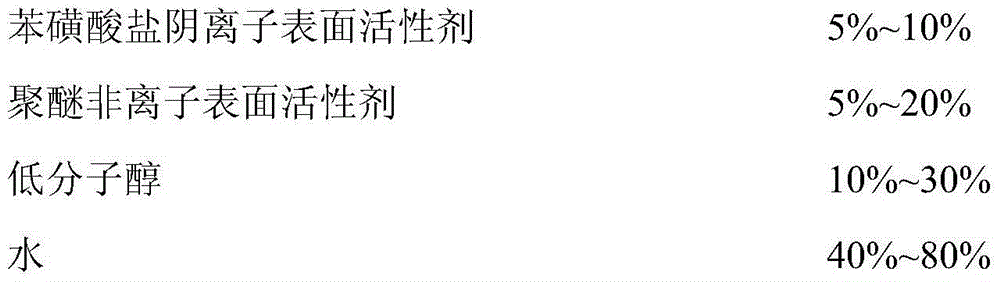

Condensate oil emulsion de-emulsifier and applications thereof

ActiveCN104629793ASolve separation and recyclingAccelerate the speed of demulsification and separationDewatering/demulsification with chemical meansAlcoholOil emulsion

The invention relates to a condensate oil emulsion de-emulsifier and applications thereof. The de-emulsifier is composed of the following components in percentage by weight: 5 to 10% of a benzene sulfonate anionic surfactant (branched sodium dodecyl benzene sulfonate), 5 to 20% of polyether nonionic surfactant (polyoxypropylene-polyoxyethylene-glycol ether), 10 to 30% of low-molecular-weight alcohol, which is one of ethylene glycol-butyl ether, ethanol, and isopropanol, and the balance being water. The de-emulsifier is applied to acidic gas fields producing condensate oil and is used to de-emulsifying emulsion, which is produced by using a cation-type corrosion inhibitor. The application concentration of the de-emulsifier by the production amount of the oil and water is 50 to 1000 ppm, the de-emulsifying temperature is 0 to 40 DEG C, and the de-emulsifying rate is not less than 95% within 10 minutes. The provided de-emulsifier has the characteristics of low de-emulsifying temperature, quick de-emulsifying speed, low mineral degree of applicable water, and good oil quality after de-emulsification.

Owner:PETROCHINA CO LTD

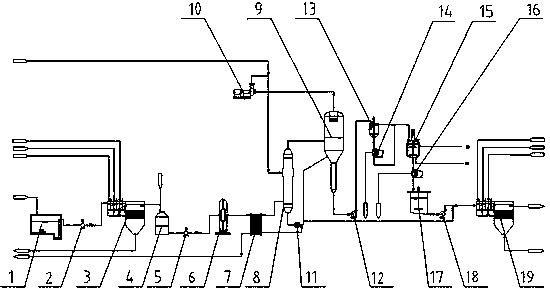

Continuous reaction method for catalyzing epoxidation of hydrogen peroxide oxyalkylene

InactiveCN104672178ASolve separation and recyclingOrganic chemistryChemical recyclingAlkenePhase-transfer catalyst

The invention discloses a continuous reaction method for catalyzing the epoxidation of hydrogen peroxide oxyalkylene. The method comprises the following steps: carrying out azeotropic treatment on water and components (solvent) in reaction liquid so as to remove most of water (water in hydrogen peroxide) in a system and then form an anhydrous hydrogen peroxide solution; adding olefin and a phase transfer catalyst, carrying out epoxidation reaction at certain temperature, and cooling the obtained object; and separating and recovering the catalyst for two times by using a horizontal screw decanter centrifuge and a butterfly separator, wherein the catalyst can be recycled; and carrying out further rectification and separation on a liquid phase obtained by separating, so as to obtain a product; and recycling a mixed solvent again.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

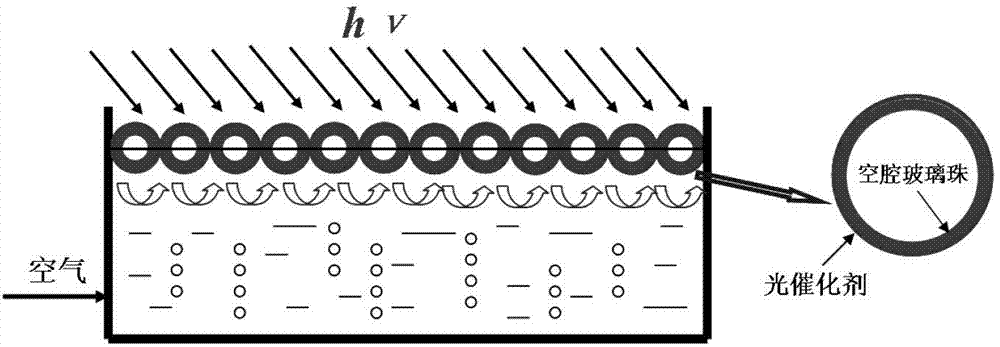

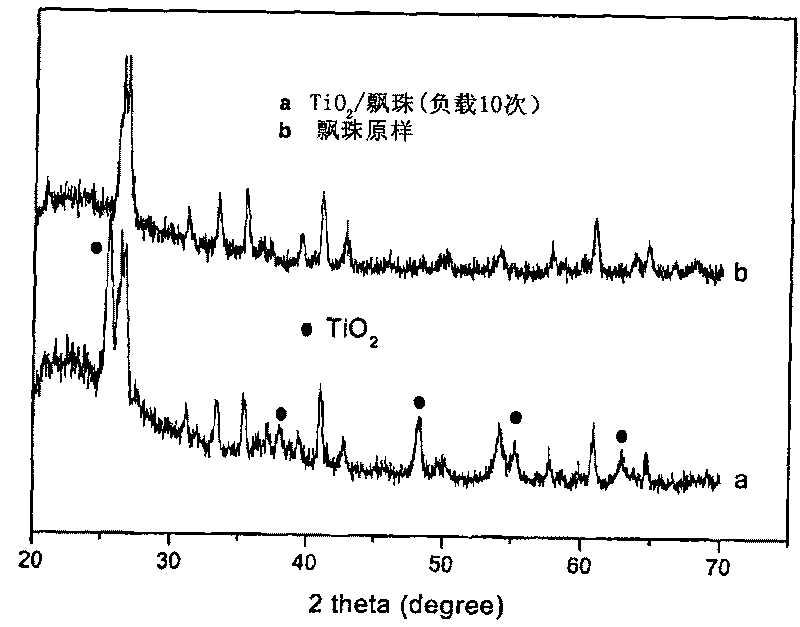

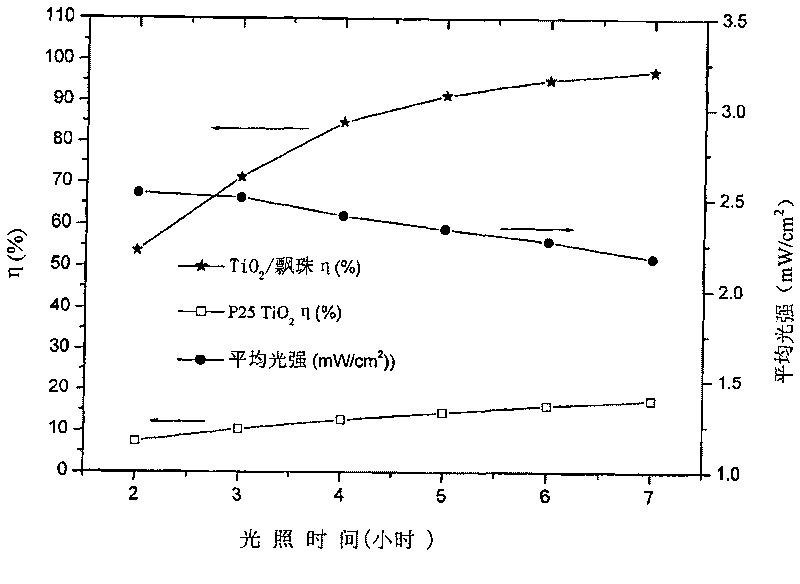

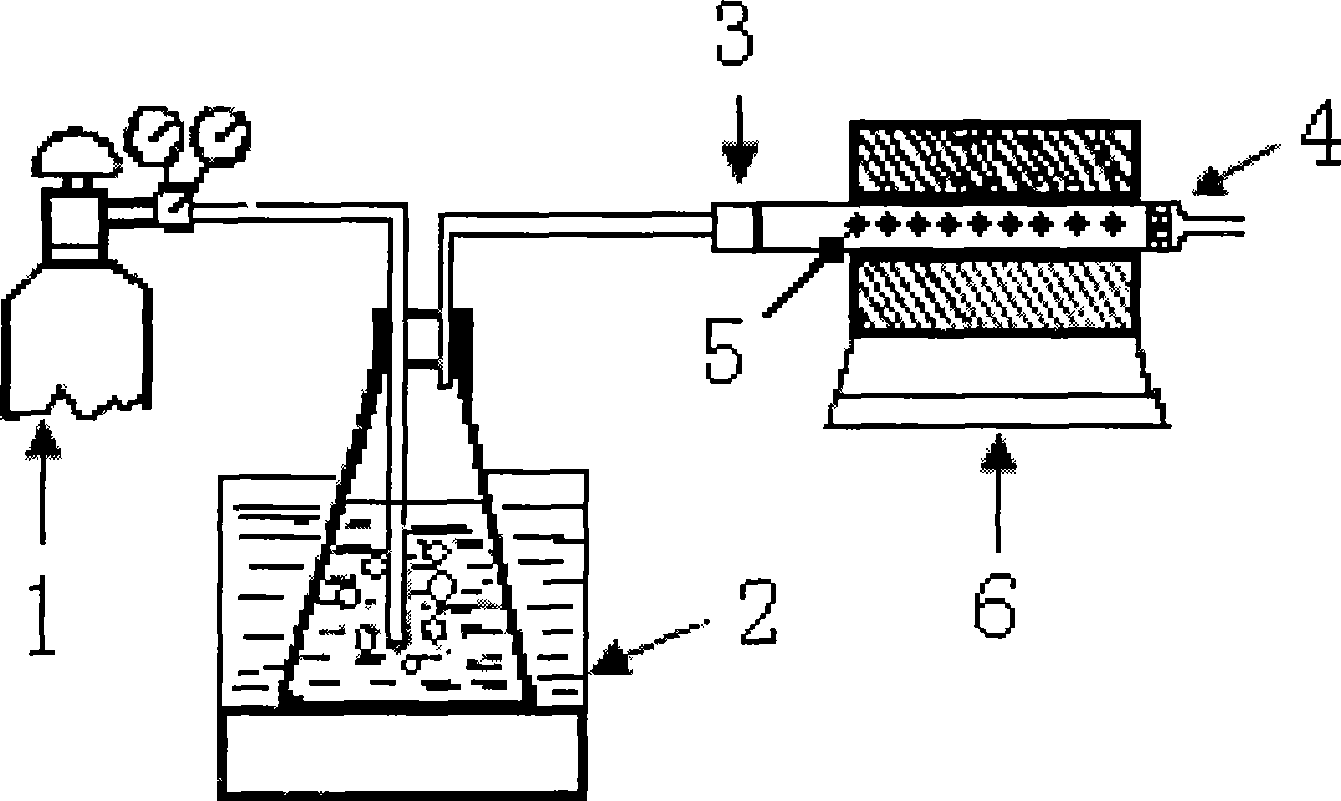

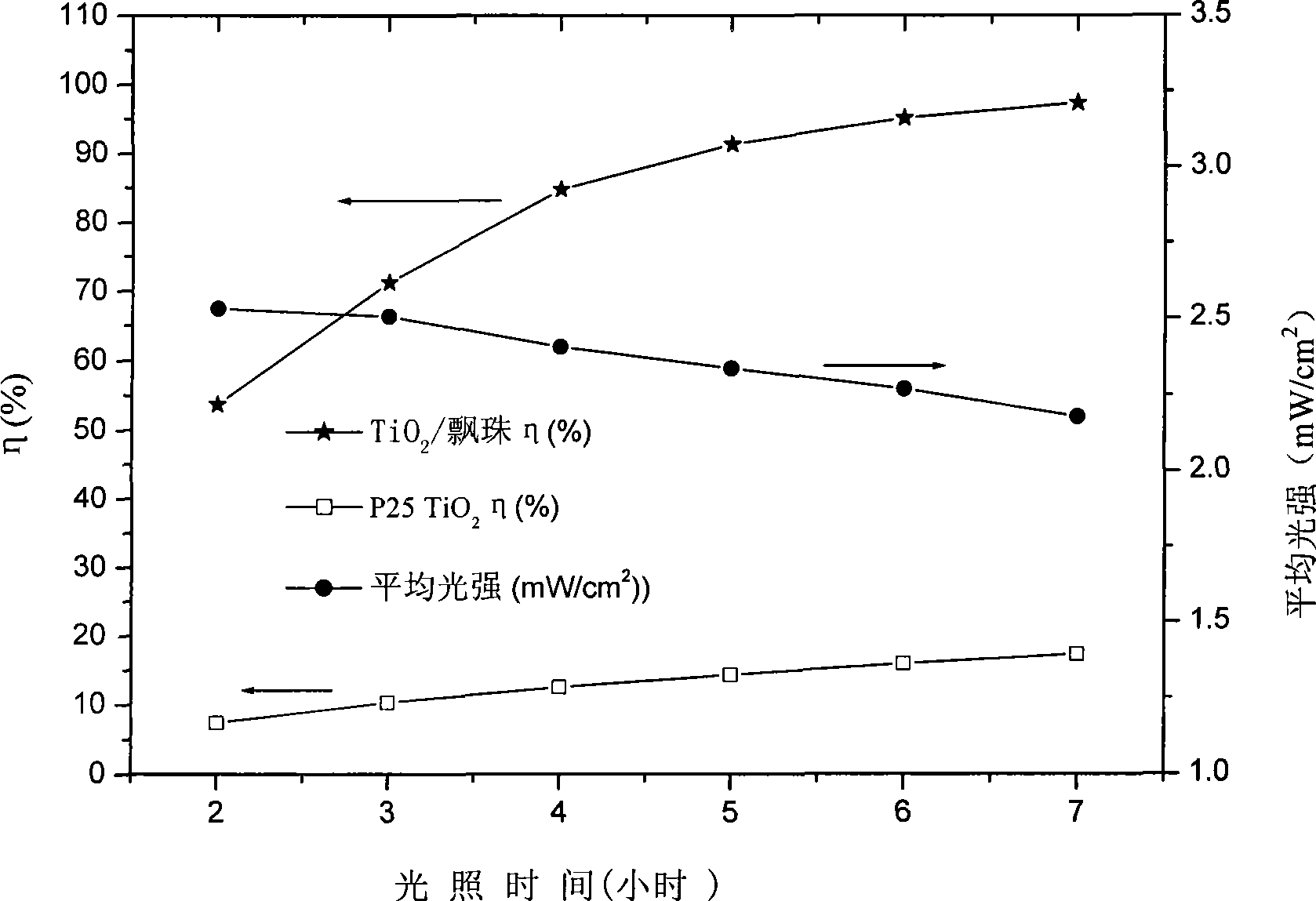

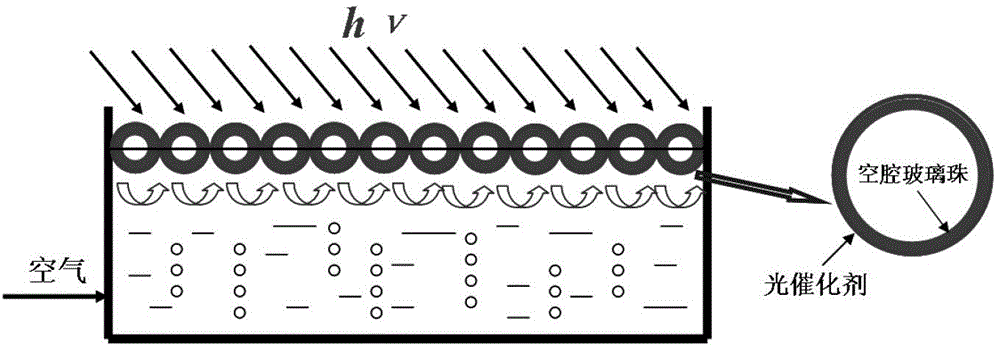

Process for coating Bi2O3/TiO2 photocatalysis film on surface of hollow lightweight glass sphere

InactiveCN103084163ASolve separation and recyclingHigh light utilization efficiencyMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionPolyethylene glycol

The invention discloses a process for coating a Bi2O3 / TiO2 photocatalysis film on the surface of a hollow lightweight glass sphere and discloses application of the hollow lightweight glass sphere with a surface coated with the Bi2O3 / TiO2 photocatalysis film. According to the process, bismuth nitrate, titanium tetrabutoxide, nitric acid, water, pentanediol, polyethylene glycol, acetylacetone and the like are adopted for forming a precursor solution; the sphere is rotatably coated with a film and then is quickly dried to obtain the uniform Bi2O3 / TiO2 catalyst film; the glass sphere with the Bi2O3 / TiO2 photocatalysis film coated on the surface is placed into a suspending type photocatalysis reactor and can be used for degrading organic pollutants such as methyl orange under illumination, and the glass sphere is excellent in photocatalysis performance; the process has the advantages that the raw materials are easily available, the preparation cost is low, the film coating process is simple, and the condition is easy to control; and the liquid film on the surface of the glass sphere is thin, has high light transmittance and high transfer efficiency, does not need to be separated and recycled and is capable of continuously working; and simultaneously, the process provides reference value respect to other film coating technologies and brings basic theoretical basis for designing and amplifying the photocatalysis reactor in future.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for producing vanadium pentoxide from vanadium-containing solution

InactiveCN110803714AAvoid it happening againSolve the problem of separation and recyclingChromates/bichromatesVanadium oxidesHydration reactionContinuous use

The invention discloses a method for producing vanadium pentoxide from a vanadium-containing solution. The method specifically comprises the following steps: adding a copper-containing reagent into asolution of vanadic acid or vanadate, adjusting the pH value to precipitate the vanadium or vanadium and chromium in a copper salt form, performing filtration to obtain vanadium-enriched residues anda vanadium-precipitated liquid, directly returning the vanadium-precipitated liquid to the vanadium leaching procedure for cycle use, or removing sodium and returning the sodium-removed vanadium-precipitated liquid to the vanadium leaching procedure for continuous use, performing acid leaching on the vanadium-enriched residues, performing filtration to obtain a pure hydrated vanadium pentoxide filter cake, and calcining the hydrated vanadium pentoxide to obtain the vanadium pentoxide product. The method has the advantages of simple process, convenience in operation, low production cost, good product quality and the like, and is suitable for industrial application.

Owner:CENT SOUTH UNIV +1

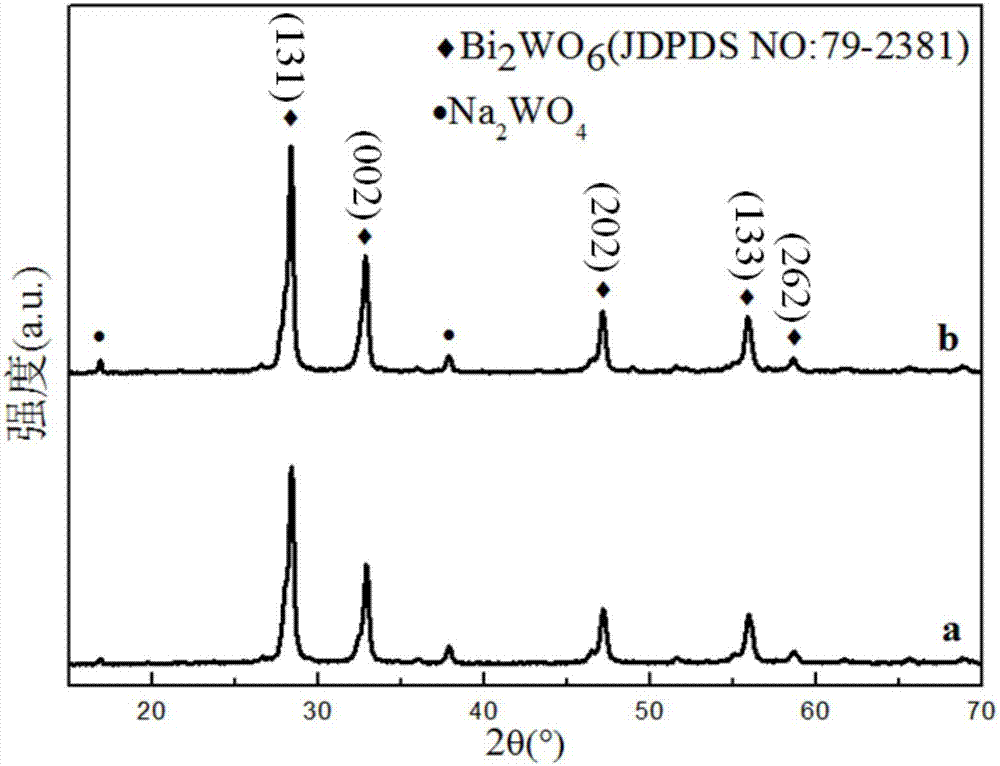

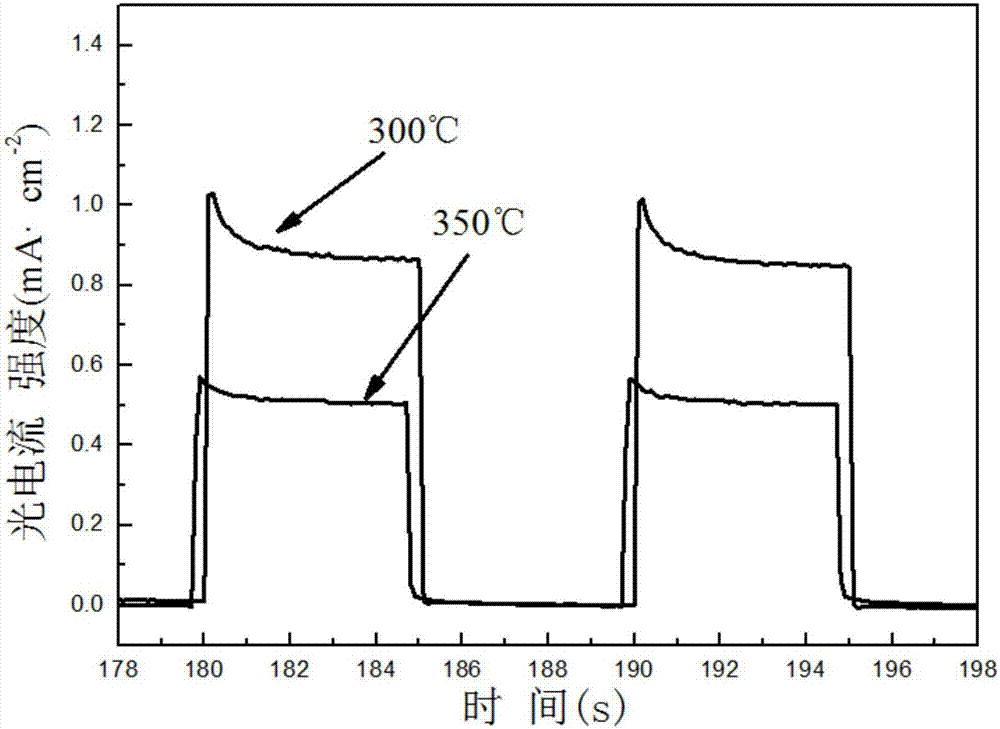

Porous lamellar-structured bismuth tungstate film as well as preparation method and application thereof

ActiveCN106865617AImprove uniformityUniform sizeWater/sewage treatment by irradiationWater treatment compoundsLayer wiseBismuth preparation

The invention discloses a porous lamellar-structured bismuth tungstate film as well as a preparation method and application thereof. The preparation method comprises the following steps: respectively dissolving Na2WO4 and Bi(NO3)3 into glycol so as to prepare a solution A with a certain concentration and a solution B with a certain concentration, dropwise adding the solution A into the solution B so as to obtain a precursor solution, and ageing the precursor solution, so as to obtain colorless and clarified sol; and preparing a Bi2WO6 film with a uniform, narrow and long duct net structure on an FTO glass substrate by virtue of a spin-coating method and a layer-by-layer annealing process. According to the preparation method, a sol-gel process is adopted, equipment requirements are simple, experimental conditions are mild, the stability of the prepared soil can be preserved for a long time, the concentration of the sol is accurate and controllable, and the prepared Bi2WO6 film has a light current of 0.84mA / cm<2> in the moment of visible light illumination and has wide application prospects in the photocatalysis field.

Owner:SHAANXI UNIV OF SCI & TECH

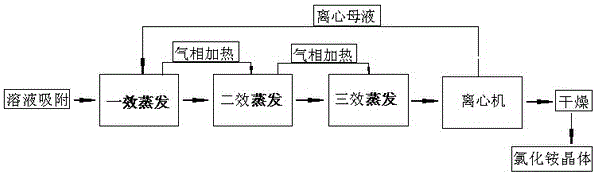

Method for preparing amides by-product industrial ammonium chloride

InactiveCN106746114AImprove the purity rateImprove economyWater contaminantsMultistage water/sewage treatmentResource consumptionAmmonium chloride mixture

The invention discloses a method for preparing amides by-product industrial ammonium chloride, and a working process with the following sequence is adopted: an adsorption process, an evaporation process and a drying process: the adsorption resin in the adsorption process is XDA- 11 type, the adsorption temperature is preferably 55 to 65 DEG C; the first-effect evaporation temperature in the evaporation process is 110 to 130 DEG C, the two-effect evaporation temperature is 90 to 110 DEG C, and the three-effect evaporation temperature is below 40 to 60 DEG C. The method of the invention can basically completely separate and recycle the ammonium chloride salts in the amide oil agent, so that the purity of the amides can be improved, and the invention can be directly applied to other fields, thereby saving the resource consumption.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

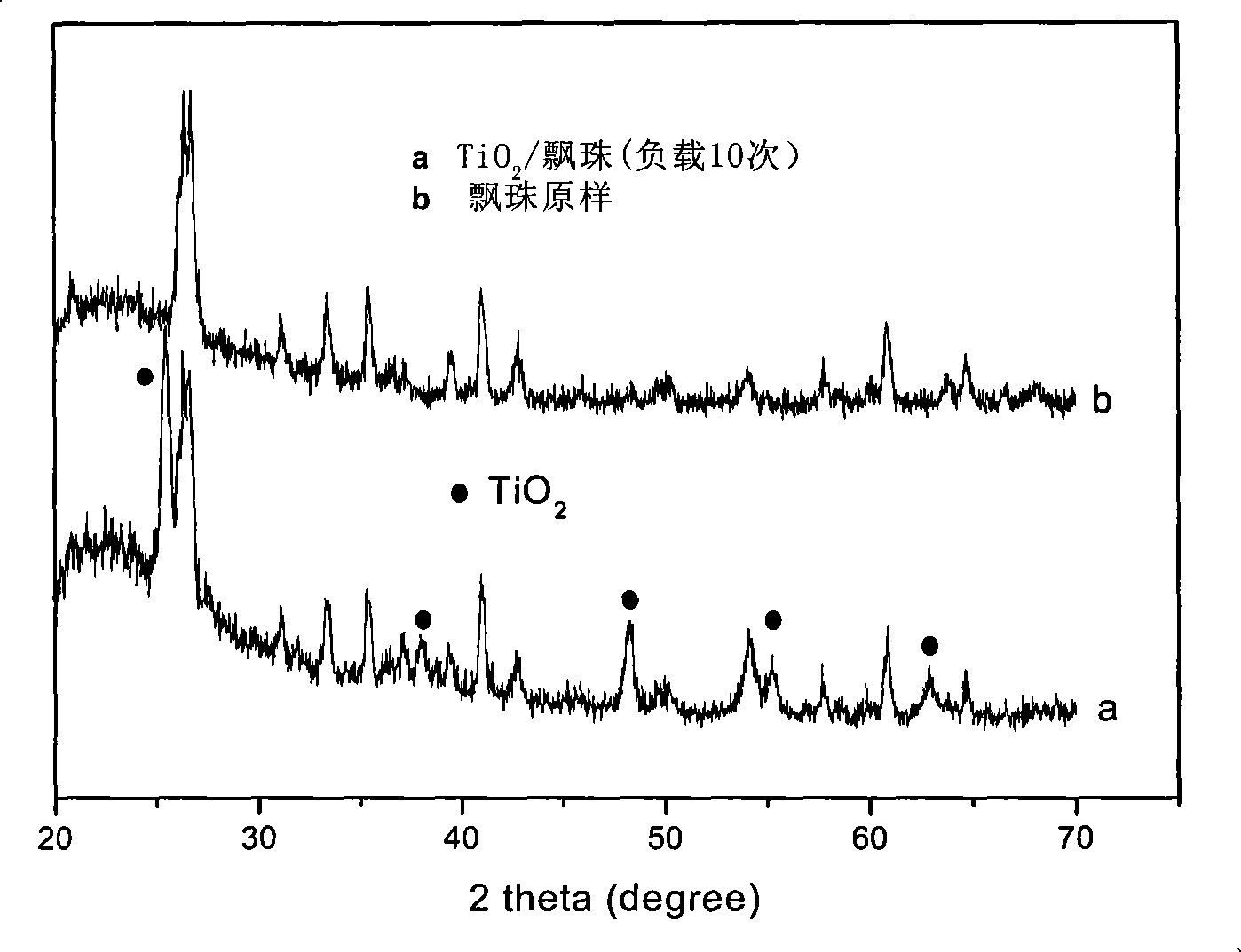

Nano- floating type supported photocatalyst, low-temperature preparation method and uses thereof

InactiveCN101367034BAvoid reunionImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereEvaporation

The invention discloses a nanometer floating type supported photocatalyst and a low-temperature preparation and application method thereof. The preparation method comprises the following steps of: firstly mixing the alcohol solution of butyl titanate and censphere floating beads sufficiently and evenly, loading the butyl titanate onto the censphere floating beads through a rotary evaporation method, and carrying out the outphase hydrolysis reaction of the censphere floating beads loaded with the butyl titanate to form Tio2 floating beads containing water; and then mixing the Tio2 floating beads containing water with water, cooling down, filtering, cleaning, drying the mixture in the vacuum after a crystallization reaction, and obtaining the photocatalyst. The invention can not only obtainthe high-activity photocatalyst at a low temperature, but also avoid the high-temperature after-treatment step of the floating type supported photocatalyst, thereby effectively reducing the energy sources consumed in the preparation process, simultaneously avoiding the sloughing of the carrier and the agglomeration of the catalyst during the subsequent high-temperature sintering process of the supported catalyst, and realizing the degradation of organic pollutants such as oil floating on the water surface through the photocatalyst with high efficiency.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Nano- floating type supported photocatalyst, low-temperature preparation method and uses thereof

InactiveCN101367034AAvoid reunionImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereEvaporation

The invention discloses a nanometer floating type supported photocatalyst and a low-temperature preparation and application method thereof. The preparation method comprises the following steps of: firstly mixing the alcohol solution of butyl titanate and censphere floating beads sufficiently and evenly, loading the butyl titanate onto the censphere floating beads through a rotary evaporation method, and carrying out the outphase hydrolysis reaction of the censphere floating beads loaded with the butyl titanate to form Tio2 floating beads containing water; and then mixing the Tio2 floating beads containing water with water, cooling down, filtering, cleaning, drying the mixture in the vacuum after a crystallization reaction, and obtaining the photocatalyst. The invention can not only obtain the high-activity photocatalyst at a low temperature, but also avoid the high-temperature after-treatment step of the floating type supported photocatalyst, thereby effectively reducing the energy sources consumed in the preparation process, simultaneously avoiding the sloughing of the carrier and the agglomeration of the catalyst during the subsequent high-temperature sintering process of the supported catalyst, and realizing the degradation of organic pollutants such as oil floating on the water surface through the photocatalyst with high efficiency.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

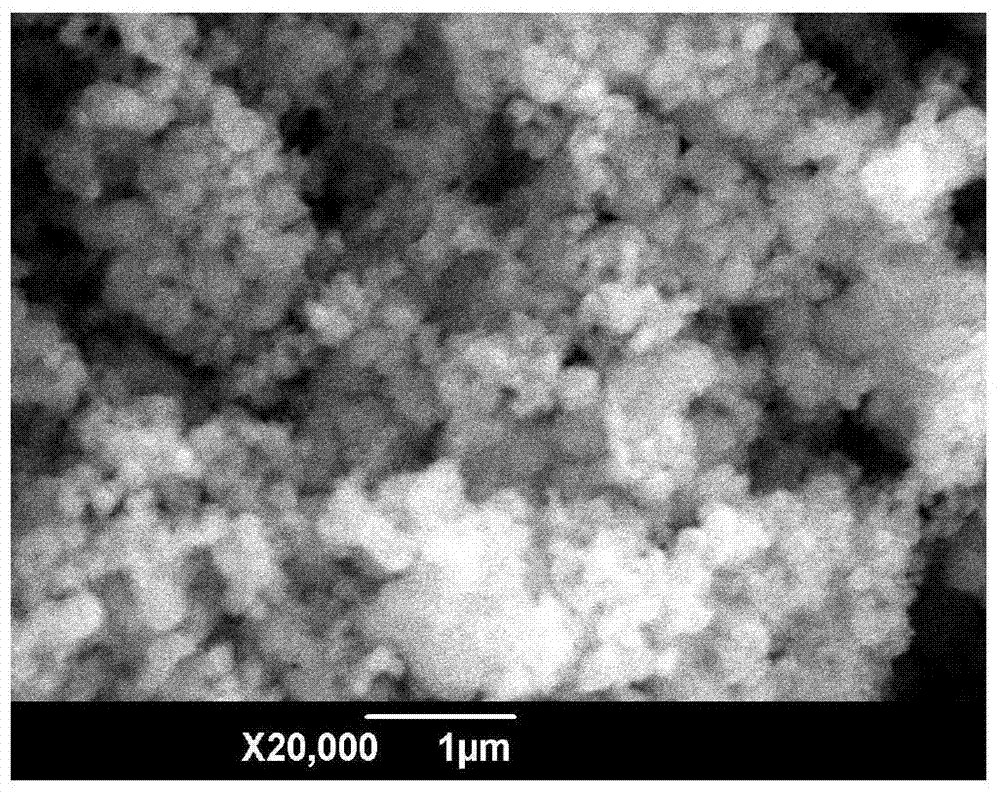

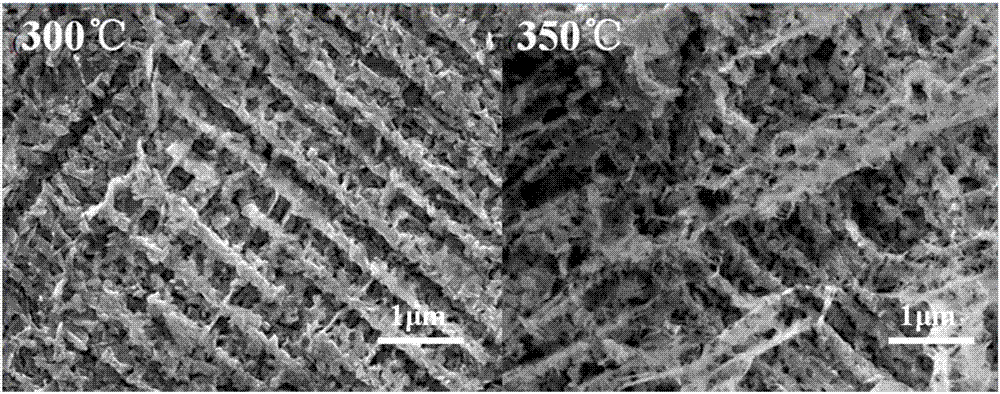

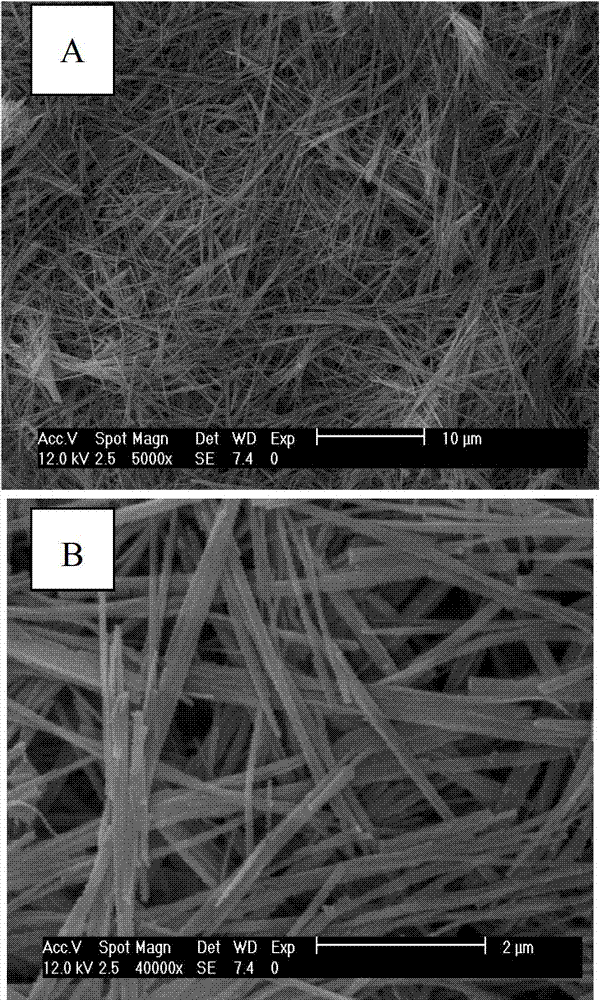

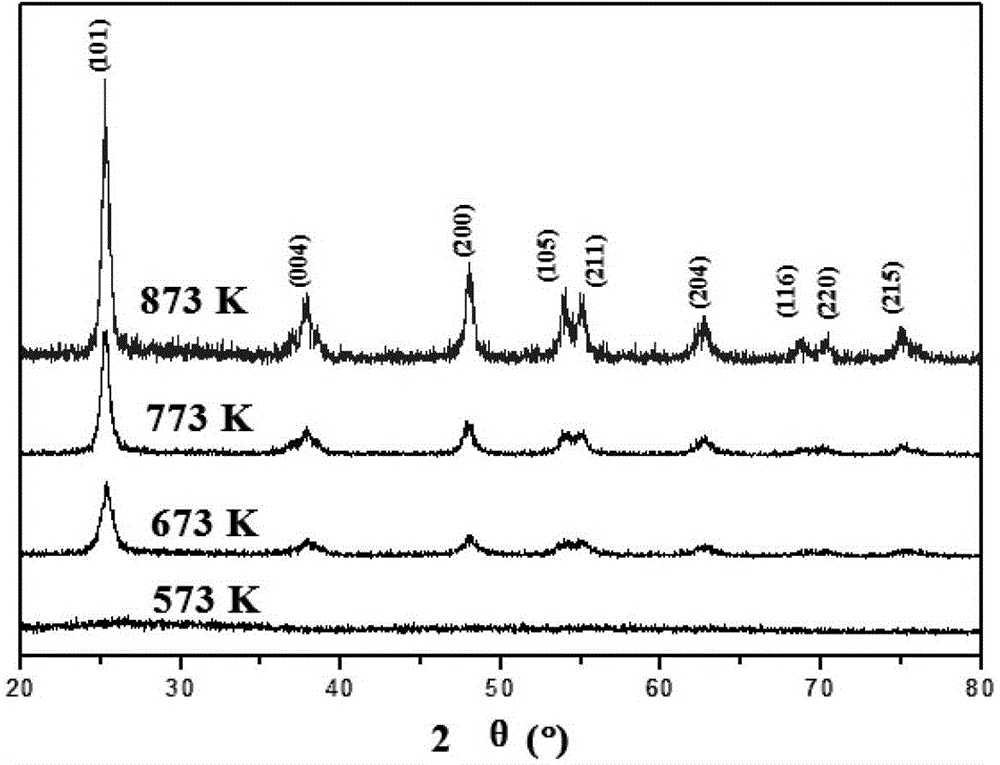

Method for preparing candied haw-shaped pure anatase type nano-titania wire in larger scale

ActiveCN102774882ASimple preparation processControllable parametersNanotechnologyTitanium dioxideDispersityNanowire

The invention relates to a method for preparing a candied haw-shaped pure anatase type nano-titania wire in a large scale, which is that a titanic acid nanowire is washed to be neutral, is put in a muffle to be heated at a heating rate of 2-5 DEG C / min, and is thermally insulated for 2-3 hours at the temperature of 650-800 DEG C, and accordingly, the required nano-titania wire is obtained. The method has a simple technology and is suitable for mass production; and the obtained nano-titania wire is of a candied haw shape, has good dispersity, larger slender proportion and large specific surface area, and is easy for settling separation, so the problems of separating and recovering titanium dioxide particles in the solution are solved.

Owner:铜陵鑫隆钢结构有限公司

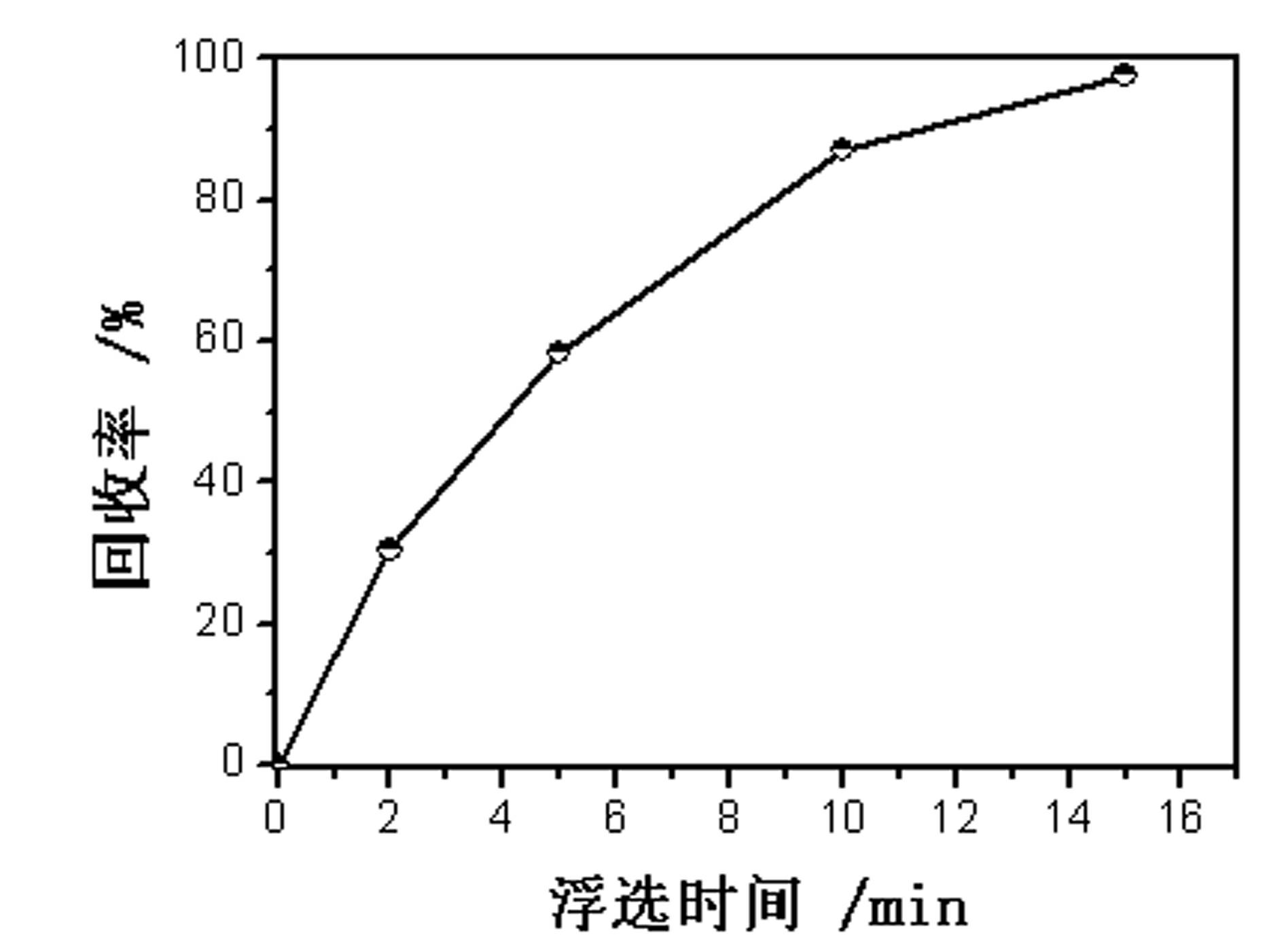

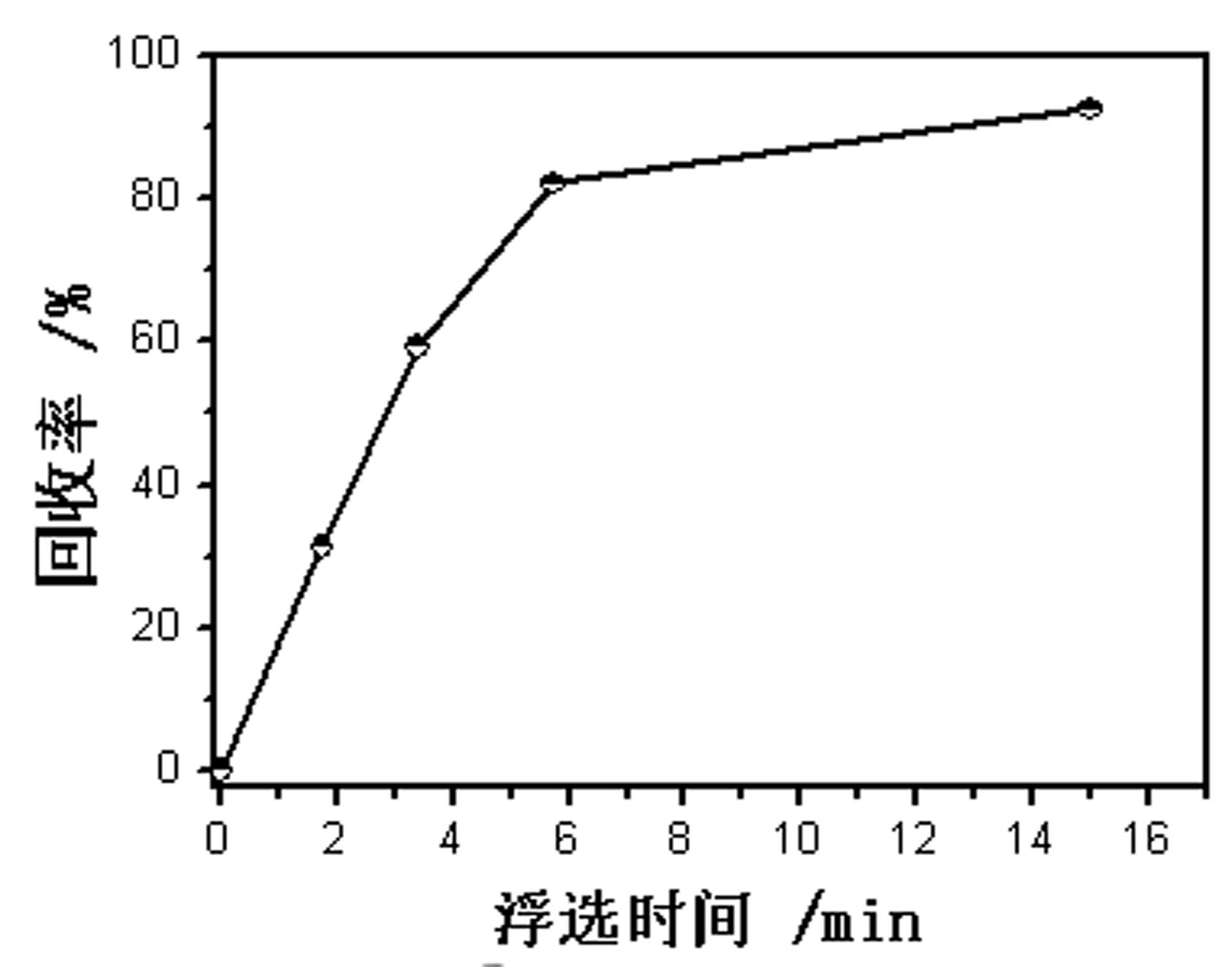

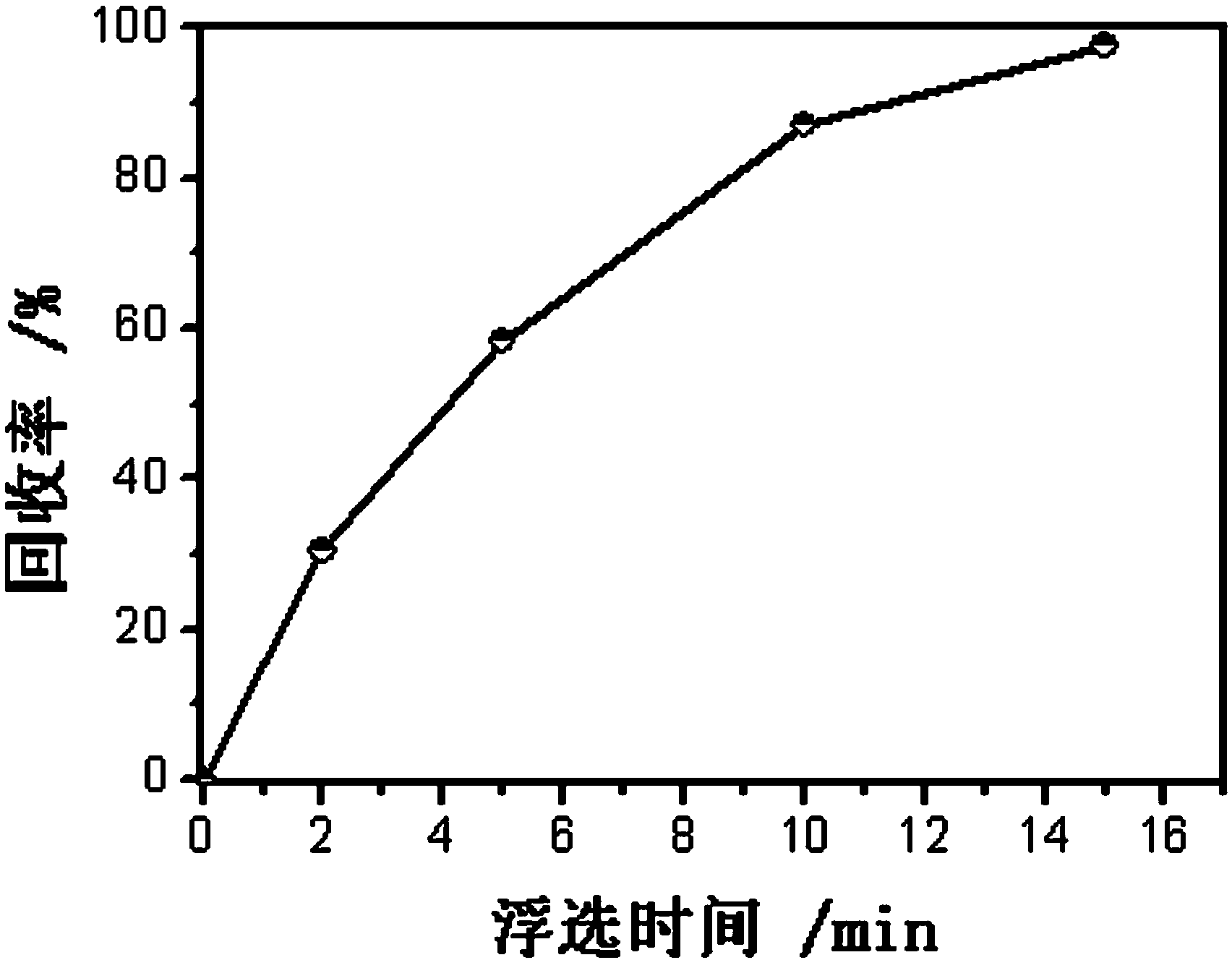

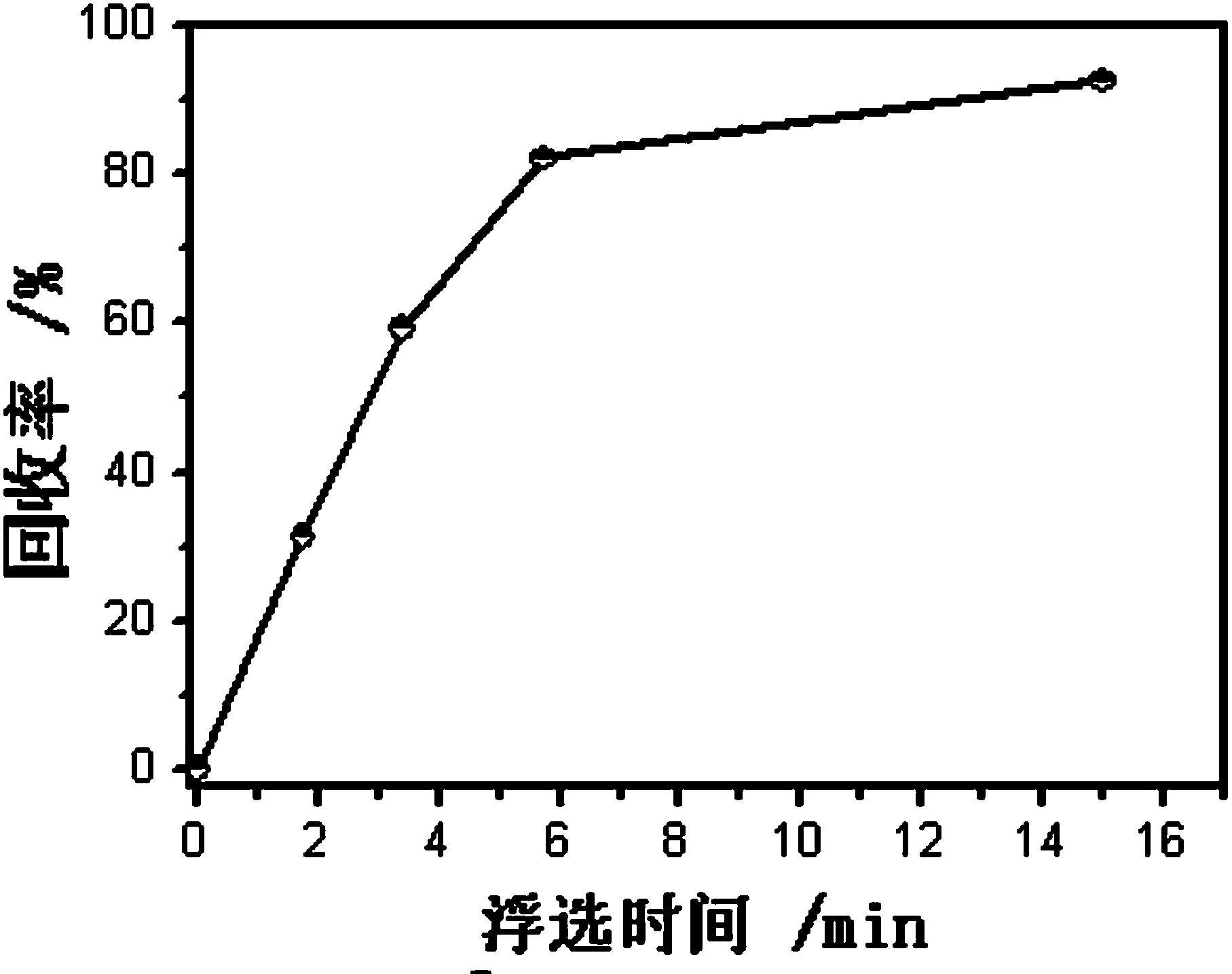

Method adopting microbe microbial enhanced oil recovery (MEOR) technology for water-based extraction of bitumen in oil sands

InactiveCN102585873AHigh recovery rateImprove qualityWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionWater basedMicrobial enhanced oil recovery

The invention provides a method adopting the microbe microbial enhanced oil recovery (MEOR) technology for water-based extraction of bitumen in oil sands and belongs to the field of oil sand separation technology. According to the method, the MEOR technology is adopted to perform the cultivation treatment of microbial bacteria before the water-based extraction to the oil sands, and the physico-chemical property of the oil sands is influenced through the selective action of the microbial bacteria on certain macromolecular materials in the bitumen in the oil sands, so that the recovery rate of the bitumen is effectively increased, the quality of the bitumen is improved, and the problems in bitumen separation recovery of oil sand mines, particularly high-electrolyte and high-clay-content oil sand mines, weathered oil sand mines or other mines which are difficult to treat. The practice proves that through the adoption of the method provided by the utility model for water-based extraction of the bitumen in the oil sands, the recovery rate is up to 98 percent. Therefore, the method has a favorable application prospect in industrial production of oil sand separation extraction.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of method using furfural as raw material to prepare gamma-butyrolactone

ActiveCN105254599BSolve separation and recyclingReduce energy consumptionOrganic chemistryHydrogen atmosphereSolid acid

Owner:TSINGHUA UNIV

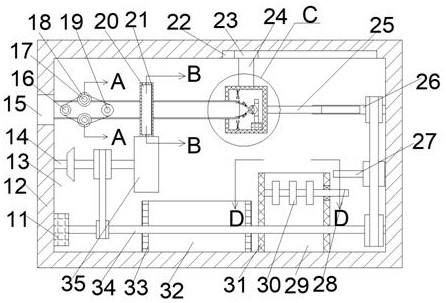

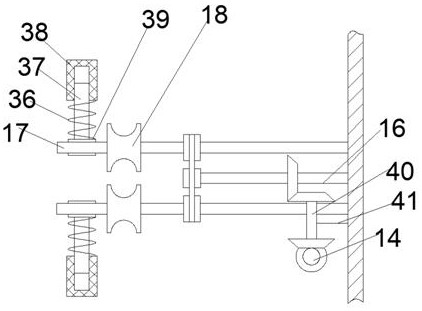

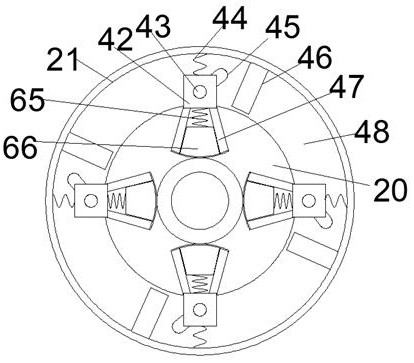

A waste optical cable stripping, sorting and recycling device

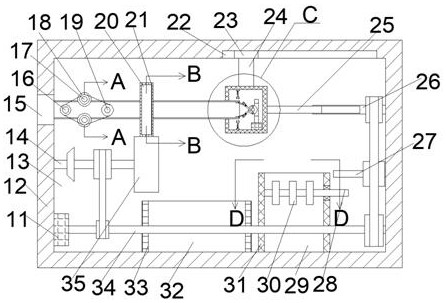

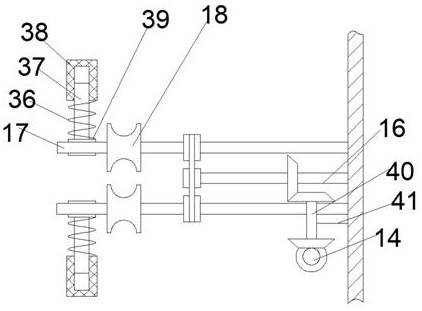

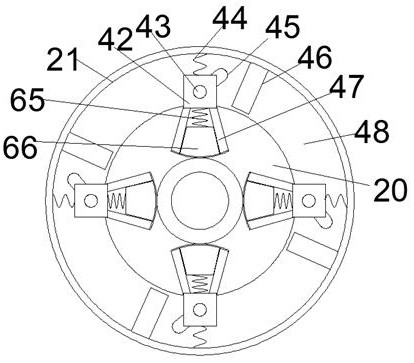

ActiveCN112363273BSolve separation and recyclingCoupling light guidesMechanical engineeringElectrical and Electronics engineering

The invention discloses a stripping, sorting and recycling device for waste and old optical cables, which comprises a casing, a working chamber is arranged inside the casing, a feeding port is provided through the left side wall of the working chamber, and a feeding port is provided on the right side of the feeding port. There is a feeding device for feeding waste optical cables into the device. The feeding device includes two guide rollers that are symmetrical up and down with respect to the feeding port. The right side of the guide rollers is provided with a ring cutting device for cutting waste and old optical cables. The device cuts the outer wall of the optical cable through the gear meshing transmission of the optical cable entering the device by setting a ring cutting mechanism, and fixes the outer wall of the optical cable by stretching the outer wall of the optical cable inside the optical cable and piercing the outer wall of the optical cable outside the optical cable at the other end of the cutting mechanism. The purpose of stripping the outer wall of the optical cable is achieved by setting the traction mechanism, and the outer wall of the optical cable and the core of the optical cable are respectively dropped into two collection chambers for classification and collection.

Owner:北京优通泰达电气新技术发展有限公司

Process for coating Bi2O3/TiO2 photocatalysis film on surface of hollow lightweight glass sphere

InactiveCN103084163BSolve separation and recyclingHigh light utilization efficiencyMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionPolyethylene glycol

The invention discloses a process for coating a Bi2O3 / TiO2 photocatalysis film on the surface of a hollow lightweight glass sphere and discloses application of the hollow lightweight glass sphere with a surface coated with the Bi2O3 / TiO2 photocatalysis film. According to the process, bismuth nitrate, titanium tetrabutoxide, nitric acid, water, pentanediol, polyethylene glycol, acetylacetone and the like are adopted for forming a precursor solution; the sphere is rotatably coated with a film and then is quickly dried to obtain the uniform Bi2O3 / TiO2 catalyst film; the glass sphere with the Bi2O3 / TiO2 photocatalysis film coated on the surface is placed into a suspending type photocatalysis reactor and can be used for degrading organic pollutants such as methyl orange under illumination, and the glass sphere is excellent in photocatalysis performance; the process has the advantages that the raw materials are easily available, the preparation cost is low, the film coating process is simple, and the condition is easy to control; and the liquid film on the surface of the glass sphere is thin, has high light transmittance and high transfer efficiency, does not need to be separated and recycled and is capable of continuously working; and simultaneously, the process provides reference value respect to other film coating technologies and brings basic theoretical basis for designing and amplifying the photocatalysis reactor in future.

Owner:SHANGHAI NORMAL UNIVERSITY

Waste optical cable stripping, classifying and recycling device

ActiveCN112363273ASolve separation and recyclingCoupling light guidesStructural engineeringMechanical engineering

The invention discloses a waste optical cable stripping, classifying and recycling device which comprises a shell, a working cavity is formed in the shell, a feeding port is formed in the left side wall of the working cavity in a penetrating mode, and a feeding device for feeding waste optical cables into the device is arranged on the right side of the feeding port. The feeding device comprises two guide rollers which are vertically symmetrical about the feeding port, the right side of each guide roller is provided with an annular cutting device used for cutting the waste optical cable, and byarranging an annular cutting mechanism, the outer wall of the optical cable entering the device is cut through gear engagement transmission. The outer wall of the optical cable is fixed by opening the outer wall of the optical cable inside the optical cable and pricking the outer wall of the optical cable outside the optical cable at the other end of the cutting mechanism, the purpose of stripping the outer wall of the optical cable is achieved by arranging the traction mechanism, and the outer wall and optical cable cores fall into the two collection cavities for classified collection treatment.

Owner:北京优通泰达电气新技术发展有限公司

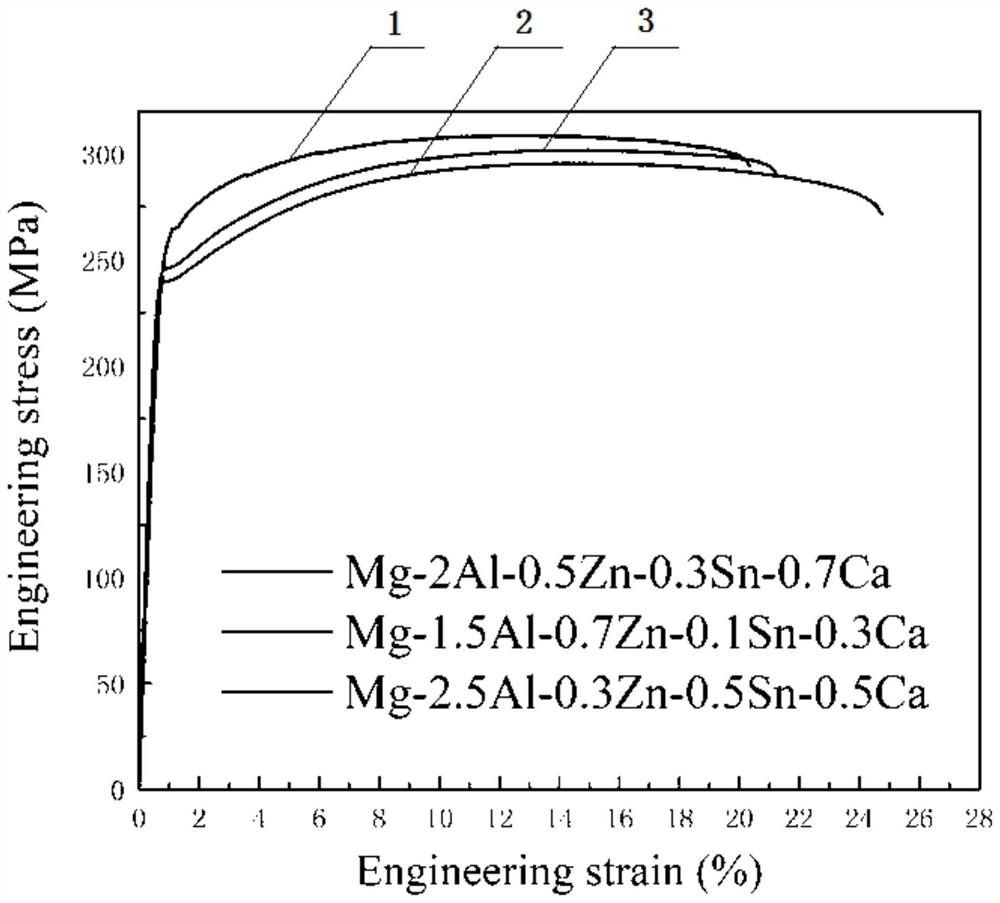

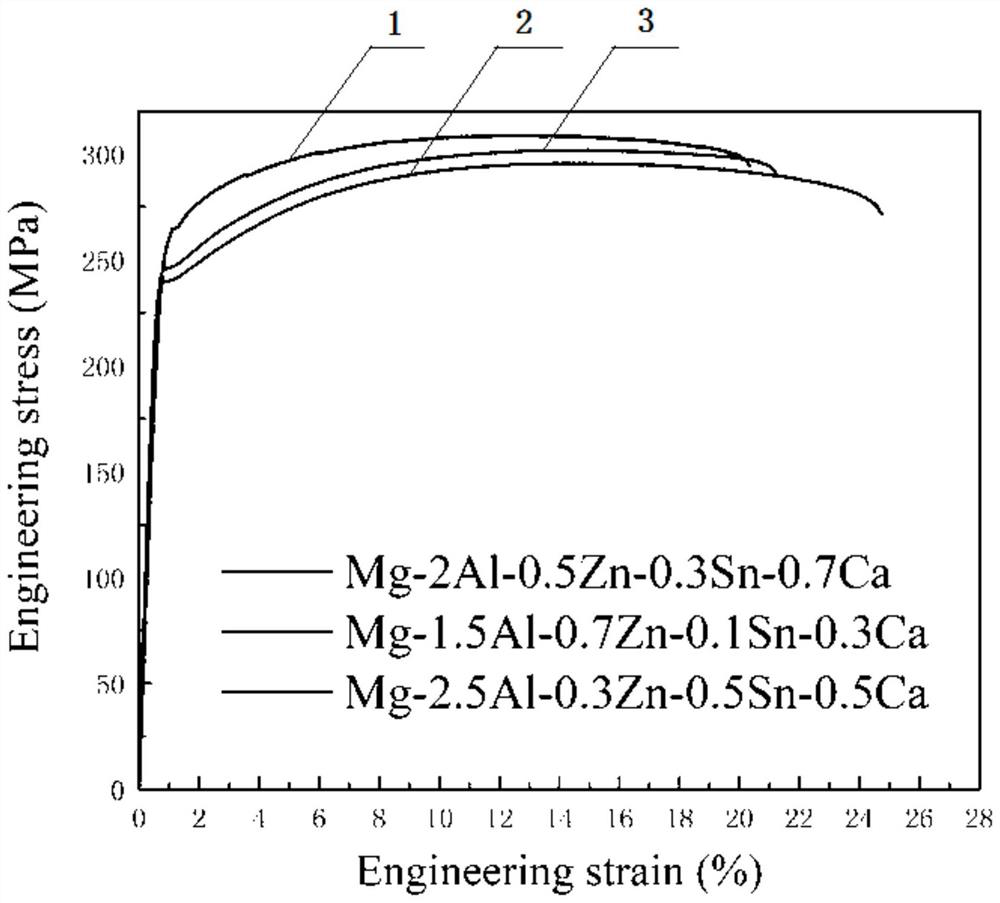

Novel high-strength plastic magnesium alloy plate and preparation process thereof

ActiveCN113953320AHigh strengthLow mobilityAuxillary arrangementsMetal rolling arrangementsComposite plateUltimate tensile strength

The invention provides a novel high-strength plastic magnesium alloy plate. On the basis of a traditional AT-series magnesium alloy, Zn and Ca elements are added at the same time, the grain boundary energy is further reduced through the separation eutectic of Zn and Ca at the grain boundary, the pinning effect of the grain boundary is induced, the mobility of the grain boundary is reduced, growth of grains is restrained, and therefore the grains are further refined, the strength of the magnesium alloy is improved, the texture of the AT-series magnesium alloy is weakened, and the forming performance of the alloy is improved. The magnesium alloy plate subjected to double-roller cast rolling is subjected to asynchronous rolling, and different deformation amounts are generated on the upper surface and the lower surface of the magnesium alloy plate through the difference of the roller speed. Finally, through accumulated stack rolling, through the difference of the grain size and the microstructure of the plate, asymmetric deformation is generated in the rolling process, a lamellar structure is formed, and the center segregation phenomenon of the cast rolling plate and the separation and recycling problem generated after a heterogeneous composite plate is used are solved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Method adopting microbe microbial enhanced oil recovery (MEOR) technology for water-based extraction of bitumen in oil sands

InactiveCN102585873BHigh recovery rateImprove qualityWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionWater basedMicrobial enhanced oil recovery

The invention provides a method adopting the microbe microbial enhanced oil recovery (MEOR) technology for water-based extraction of bitumen in oil sands and belongs to the field of oil sand separation technology. According to the method, the MEOR technology is adopted to perform the cultivation treatment of microbial bacteria before the water-based extraction to the oil sands, and the physico-chemical property of the oil sands is influenced through the selective action of the microbial bacteria on certain macromolecular materials in the bitumen in the oil sands, so that the recovery rate of the bitumen is effectively increased, the quality of the bitumen is improved, and the problems in bitumen separation recovery of oil sand mines, particularly high-electrolyte and high-clay-content oil sand mines, weathered oil sand mines or other mines which are difficult to treat. The practice proves that through the adoption of the method provided by the utility model for water-based extraction of the bitumen in the oil sands, the recovery rate is up to 98 percent. Therefore, the method has a favorable application prospect in industrial production of oil sand separation extraction.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

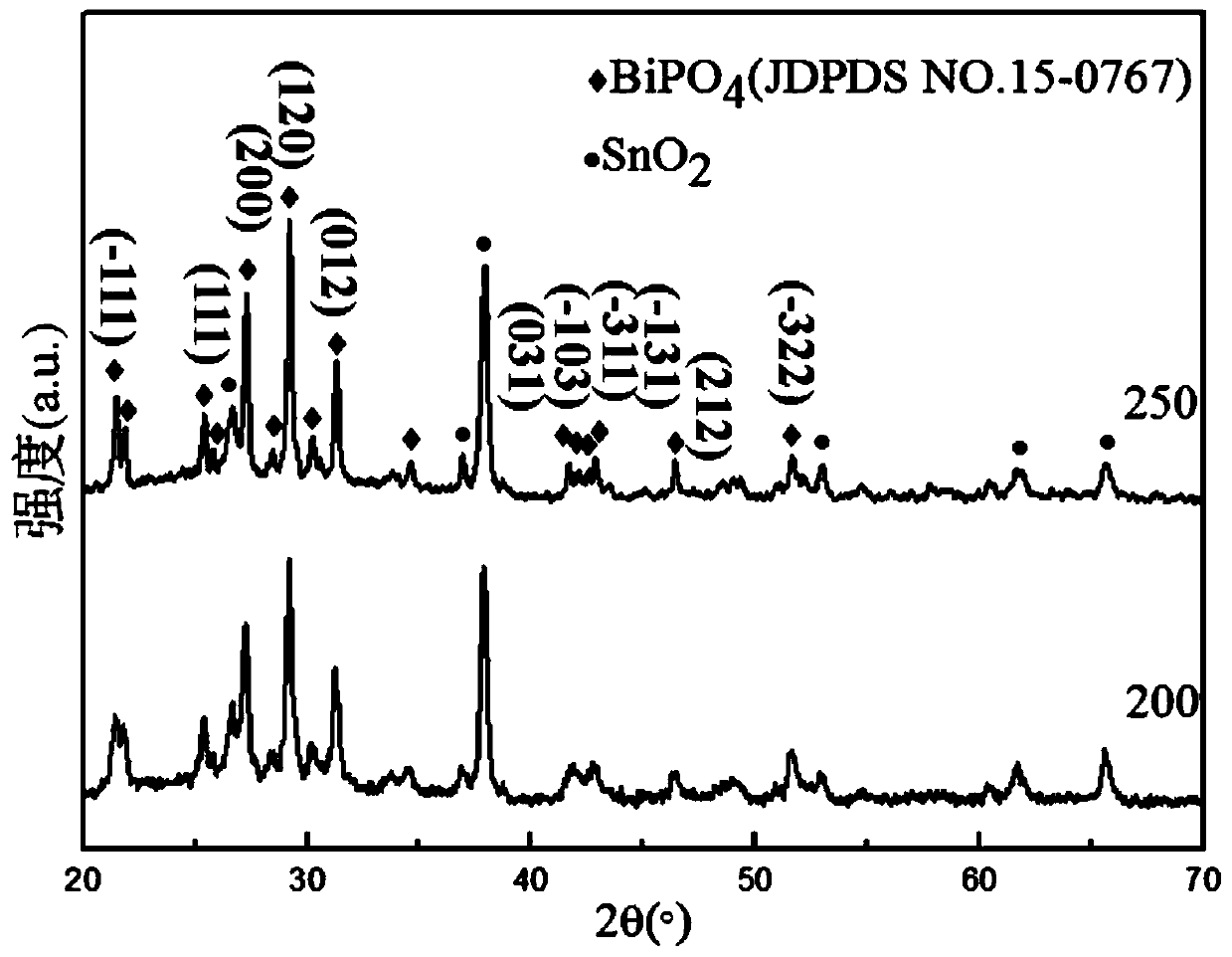

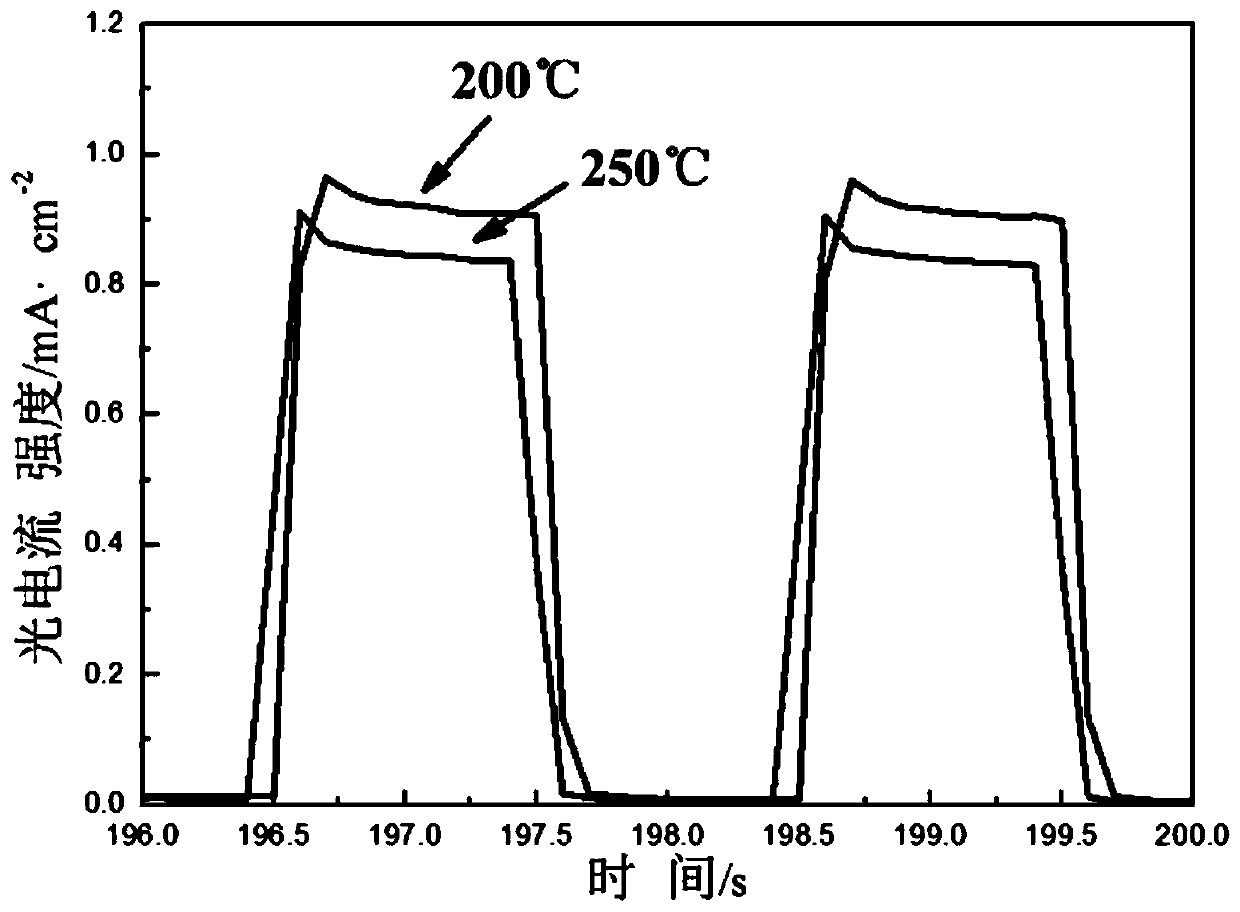

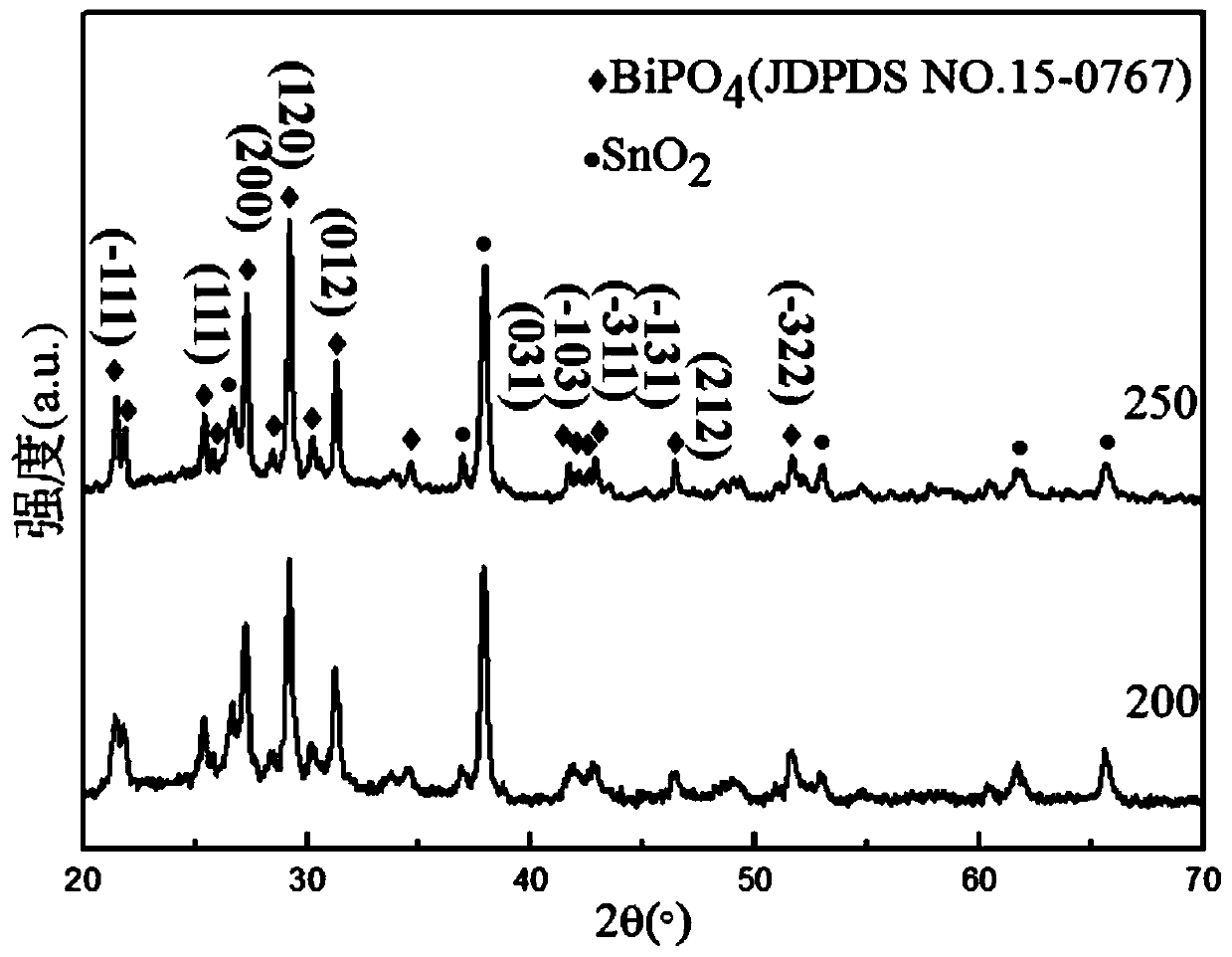

A bismuth phosphate thin film with photoresponse properties and its preparation method and application

ActiveCN106927691BHas photoresponsive propertiesPrecise and controllable concentrationPhysical/chemical process catalystsPhosphatesPhosphateDegradation aspects

The invention discloses a bismuth phosphate film with light response characteristics and its preparation method and application. Bi(NO 3 ) 3 and Na 3 PO 4 Dissolve in ethylene glycol respectively to prepare solution A and solution B of a certain concentration. Slowly add solution B dropwise to solution A, and add a certain amount of concentrated nitric acid to obtain colorless and clear BiPO. 4 precursor solution. After the precursor solution is aged, colorless and clear BiPO is obtained. 4 sol. A monoclinic phase structure BiPO with photoresponsive characteristics was prepared on a conductive glass substrate using a sol-gel spin coating method and a layer-by-layer annealing process. 4 film. The equipment requirements of the invention are simple, the experimental conditions are mild, the prepared sol can remain stable for a long time, and the sol concentration is accurately controllable. The prepared BiPO 4 The photocurrent of the film under simulated sunlight reached 0.861~0.934mA / cm 2 , can be used for the degradation of organic pollutants.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com