Process for producing para-amino-phenol

A p-aminophenol and production process technology, applied in the field of p-aminophenol production process, can solve the problems of mixing, difficult separation and recovery, etc., and achieve the effect of ensuring purity, high degree of automation, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

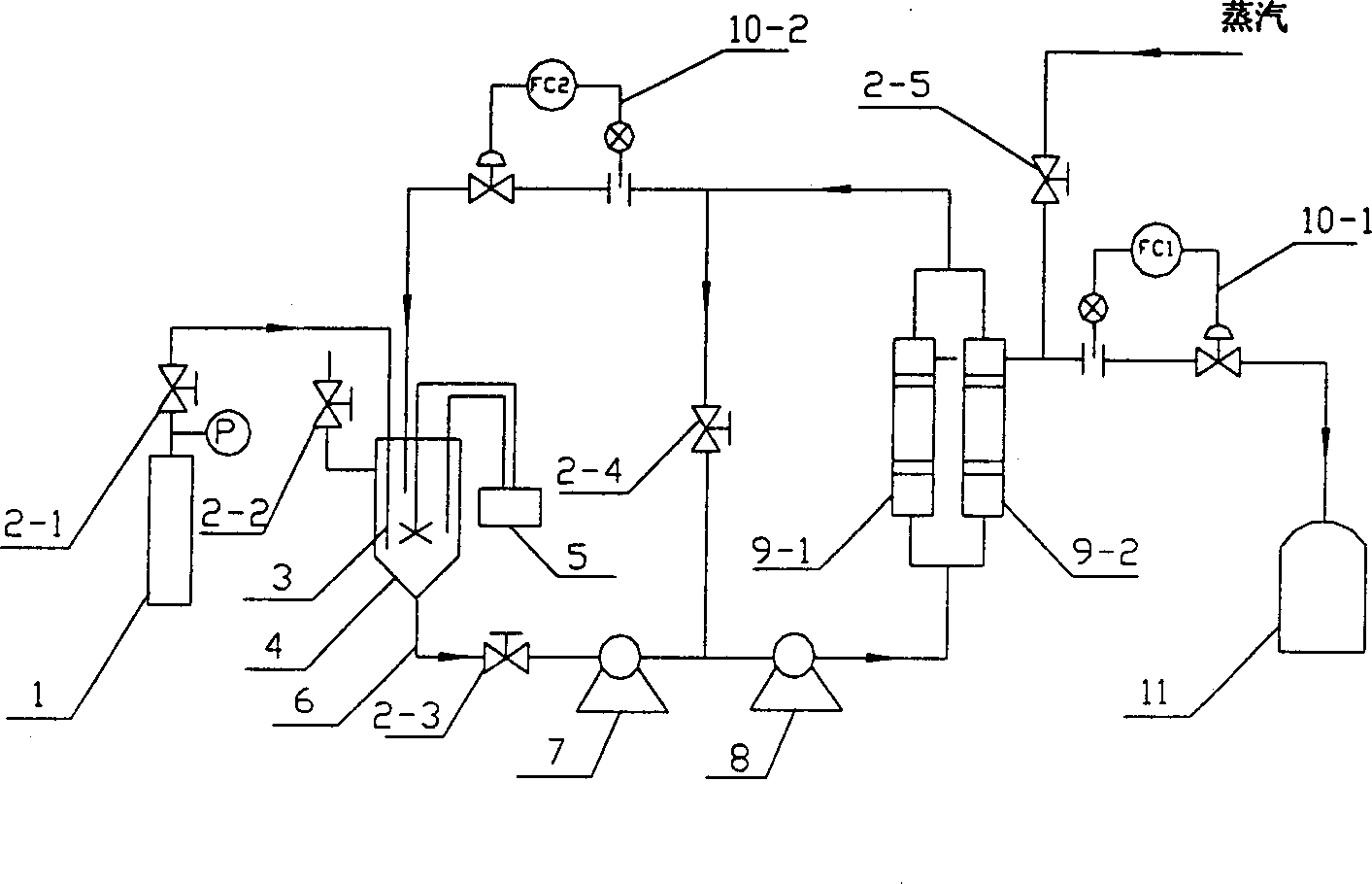

[0010] Below in conjunction with accompanying drawing illustrate the embodiment of p-aminophenol production process of the present invention.

[0011] Weigh a certain amount of p-nitrophenol, ethanol, water and catalyst nickel according to the conventional ratio, and add them into the autoclave 4. First feed hydrogen at 3 atmospheres, close valve 2-1; open vent valve 2-2, remove hydrogen and air; repeat the above steps four times to replace the air in the kettle. Feed hydrogen into the reaction kettle 4, adjust the pressure reducing valve of the hydrogen cylinder, keep the pressure in the reaction kettle 4 at 16-20 atmospheres, open the speed regulating temperature controller 5, adjust the stirring speed, and keep the temperature in the kettle at Stir the reaction in the range of 95-100°C. When the flow meter P on the reactor 4 shows that the hydrogen flow rate is zero, it means that the reaction is complete. Open valve 2-2, and close this valve after exhausting excess hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com