Patents

Literature

61results about How to "To achieve the purpose of solid-liquid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

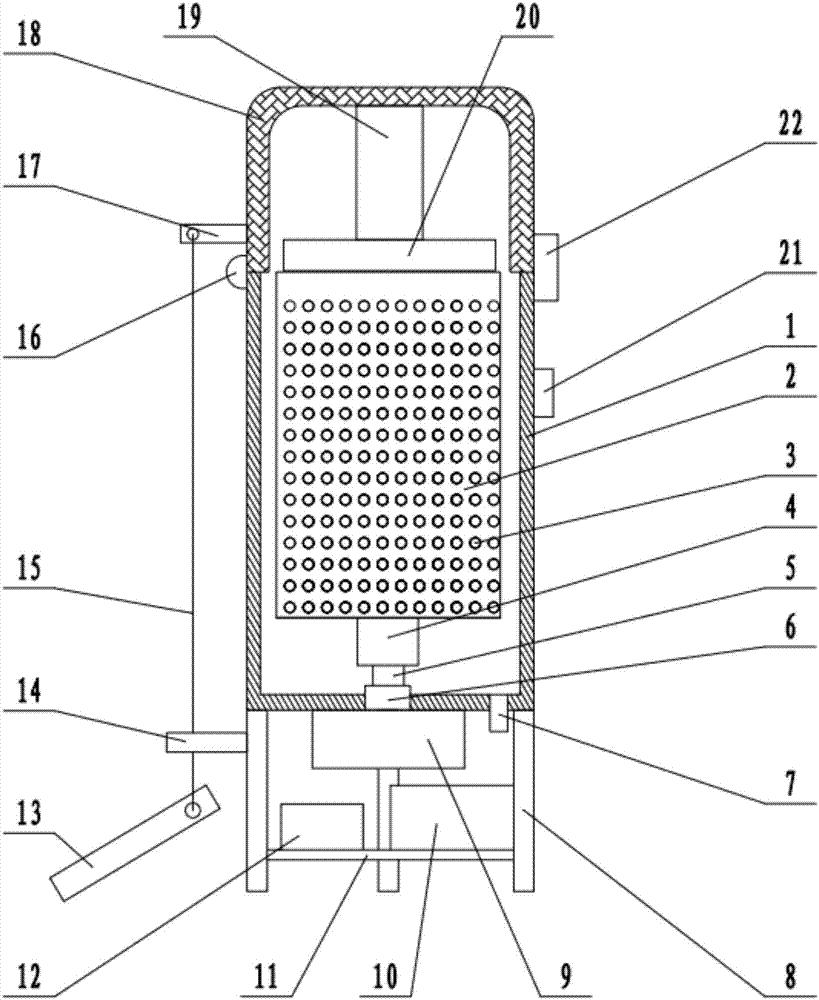

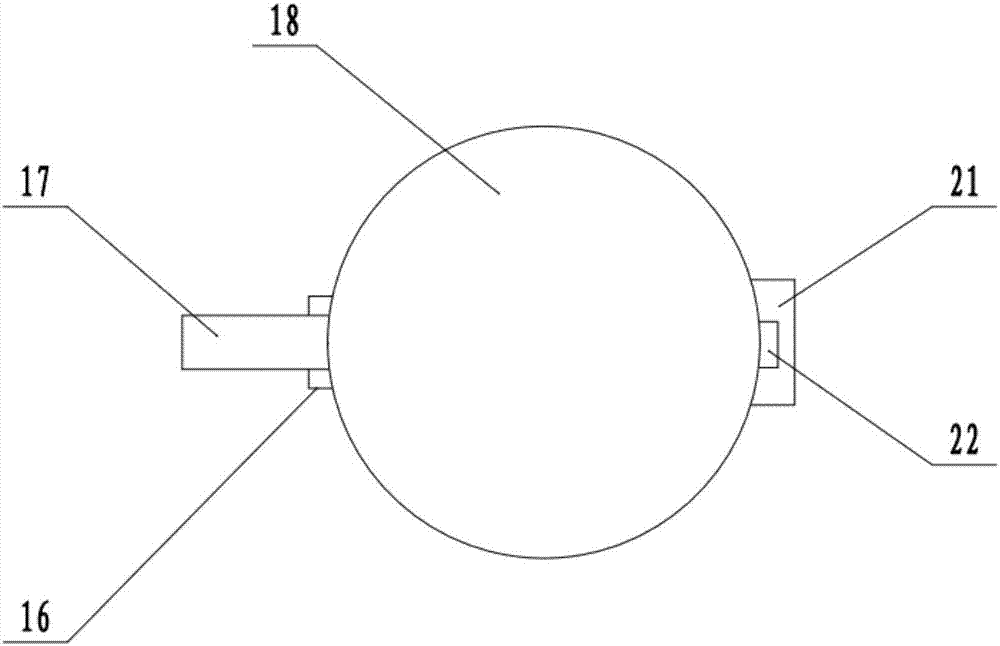

Rotary trash can with compressing function

InactiveCN106882510ATo achieve the purpose of solid-liquid separationEasy to cleanRefuse receptaclesPressesEngineeringCentrifugal force

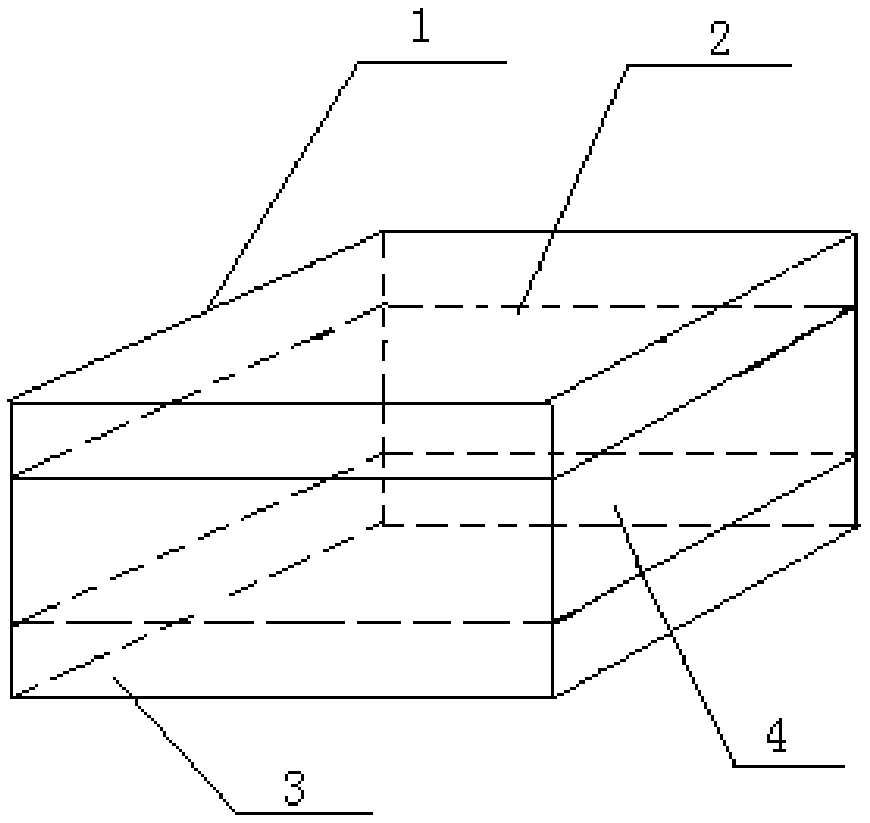

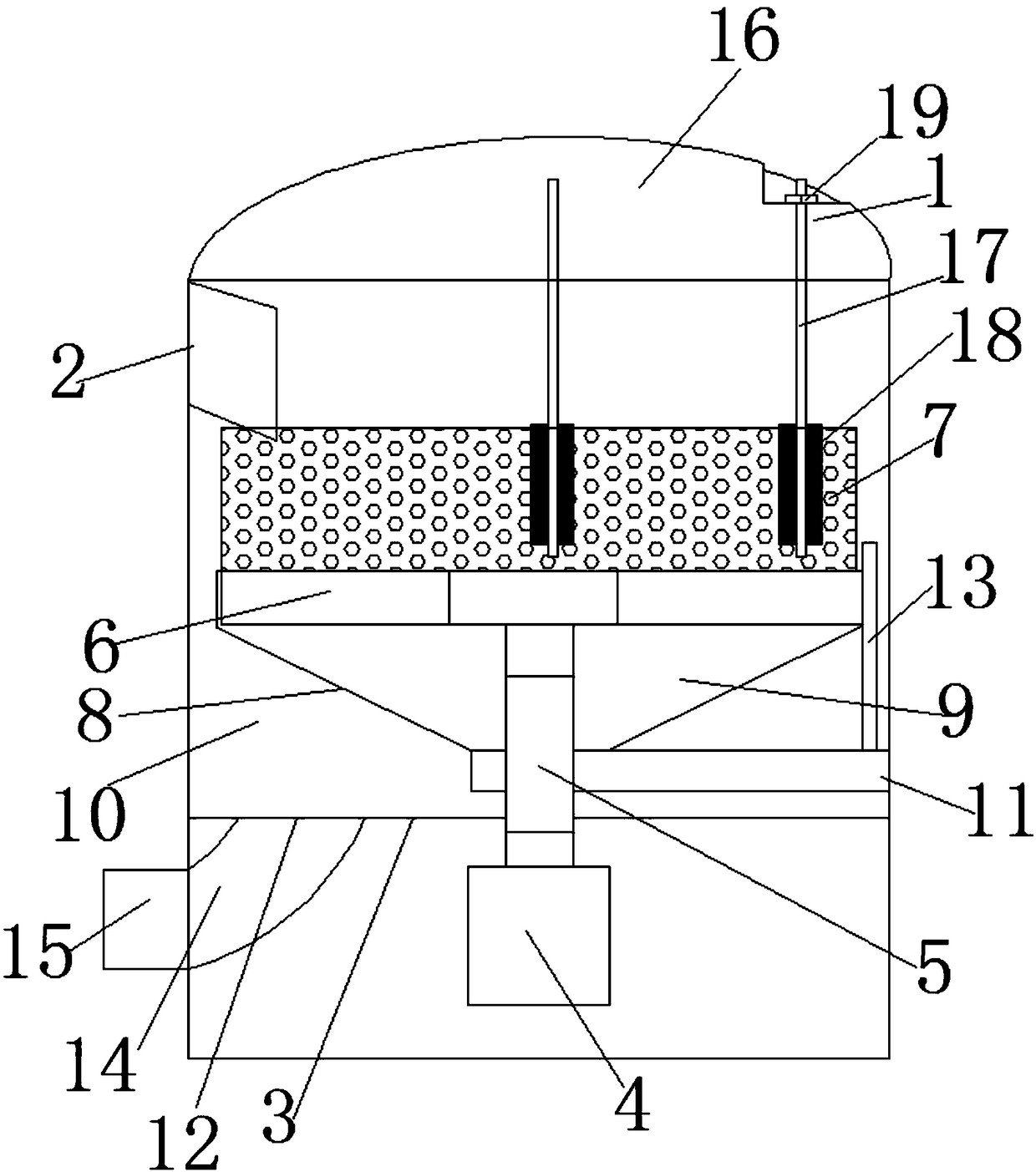

The invention discloses a rotary trash can with a compressing function. The trash can comprises a shell, an inner barrel, support legs and a can cover; a motor is fixedly connected on the lower surface of the shell, a shaft extension end of the motor is fixedly connected with a rotating shaft, the top part of a casing pipe is fixedly connected with the lower surface of the inner barrel, liquid drainage holes are distributed in the side wall of the inner barrel, the support legs are fixedly connected on the lower surface of the shell, a fixing plate is fixedly connected with the side wall of the support legs, a water tank and a storage battery are fixedly connected on the upper surface of the fixing plate, a telescopic device is arranged in the can cover, a compression disc is fixedly connected at the bottom part of the telescopic device, the can cover is opened through the traction of a steel wire rope to be cleaner and more sanitary; the motor is started, liquid in the trash is drained through the liquid drainage holes under the action of the centrifugal force and flows to the water tank, and then the purpose of separating the solid and the liquid of the trash is fulfilled; when the inner barrel is nearly full of trash, the telescopic device is started to drive the compression disc to extend into the inner barrel and compress the trash, so that the space is saved.

Owner:惠安县鑫泰信息科技有限公司

Graphene-loaded nanometer Fe<3>O<4>/ZnO composite and preparation method thereof

ActiveCN105384146AImprove conductivityEvenly distributedZinc oxides/hydroxidesMagnetic/electric field screeningSolubilityElectromagnetic shielding

The invention relates to a graphene-loaded nanometer Fe<3>O<4> / ZnO composite with an electromagnetic shielding function and a preparation method thereof. Te preparation method includes the steps that firstly, ferric chloride hexahydrate and Zn powder are mixed to be uniform after no sediment exists, an alkaline solution and a graphene oxide solution are added, and after the mixture is stirred to be uniform, suspension liquid is obtained; then, the suspension liquid is placed in a reaction kettle to be subjected to constant temperature heat treatment, centrifugal separation is conducted, and obtained paste-shaped solid is placed in a tube-shaped furnace to be subjected to thermal recovery under the mixed atmosphere of H<2> / Ar after being refrigerated and dried; finally, the graphene-loaded nanometer Fe<3>O<4> / ZnO composite is obtained. The graphene-loaded nanometer Fe<3>O<4> / ZnO composite prepared through the method is high in degree of dispersion and good in water solubility, the magnetic property and the electromagnetic shielding property are remarkably enhanced, the operation process is simple and efficient, and industrialized production and application is achieved easily.

Owner:TANGSHAN JIANHUA TECH DEV

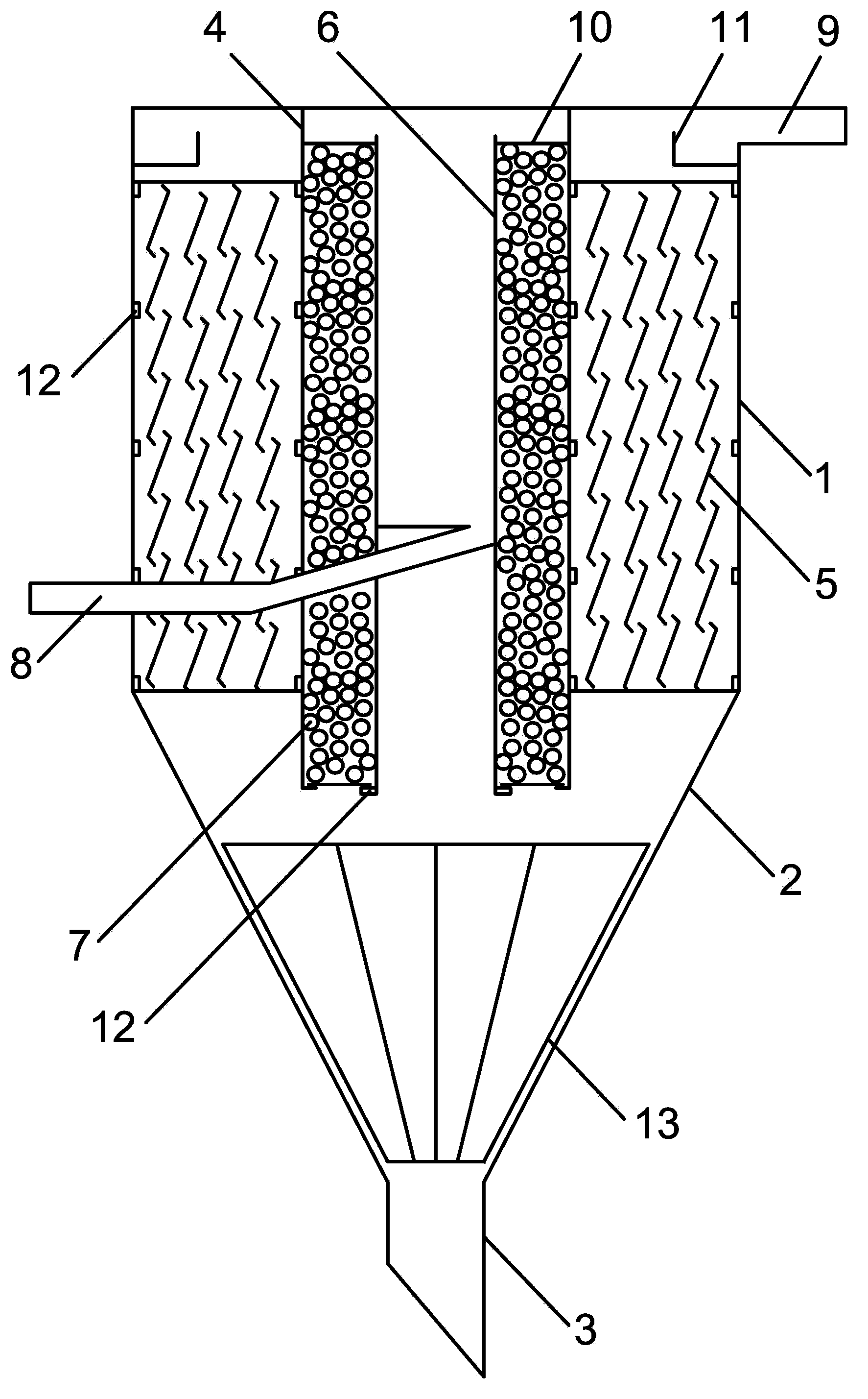

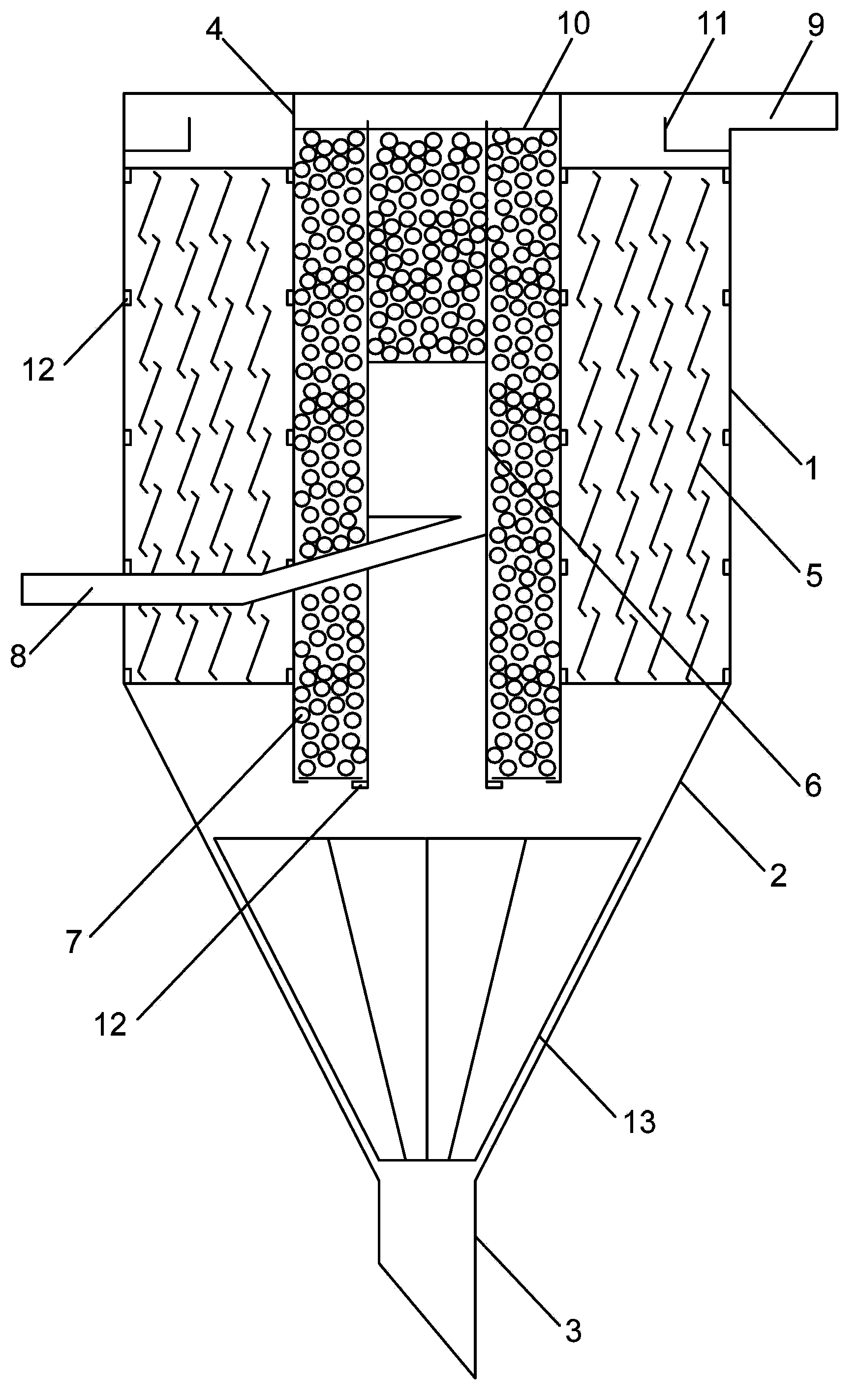

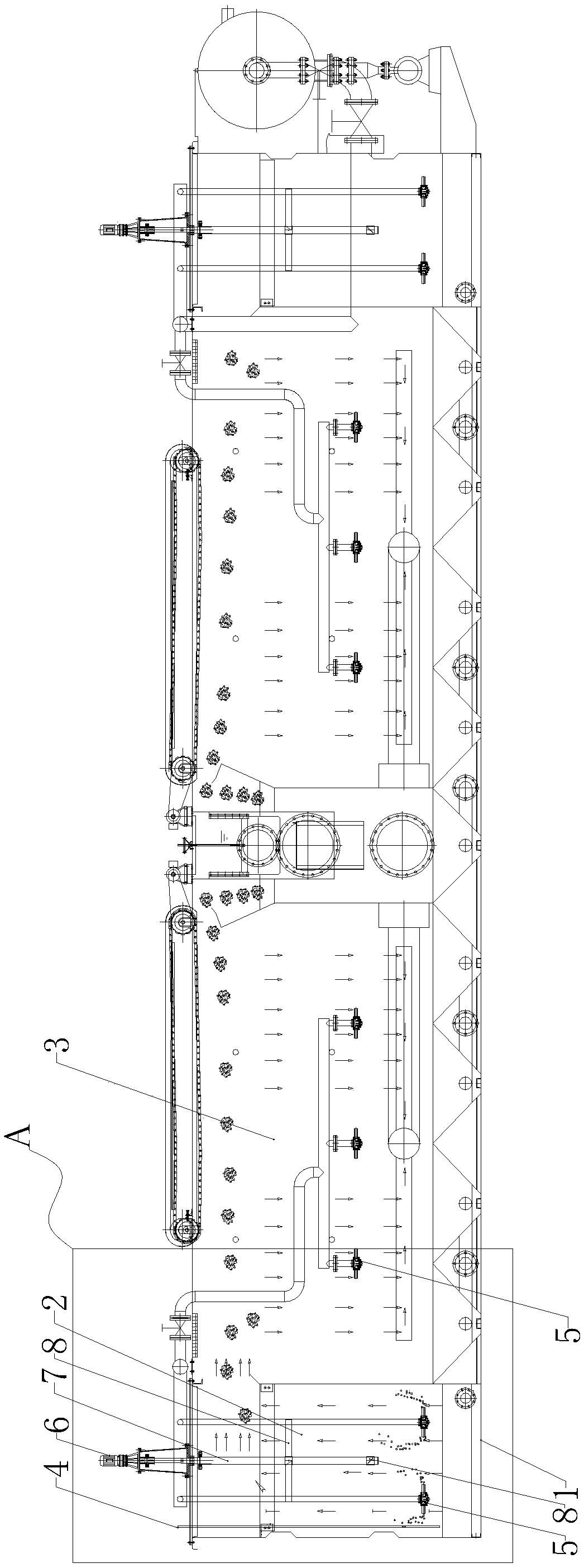

Micro-vortex high-efficiency clarification reactor and operation method for same

ActiveCN103880131ASimple structureLow running costWater/sewage treatment by flocculation/precipitationSettling basinEngineering

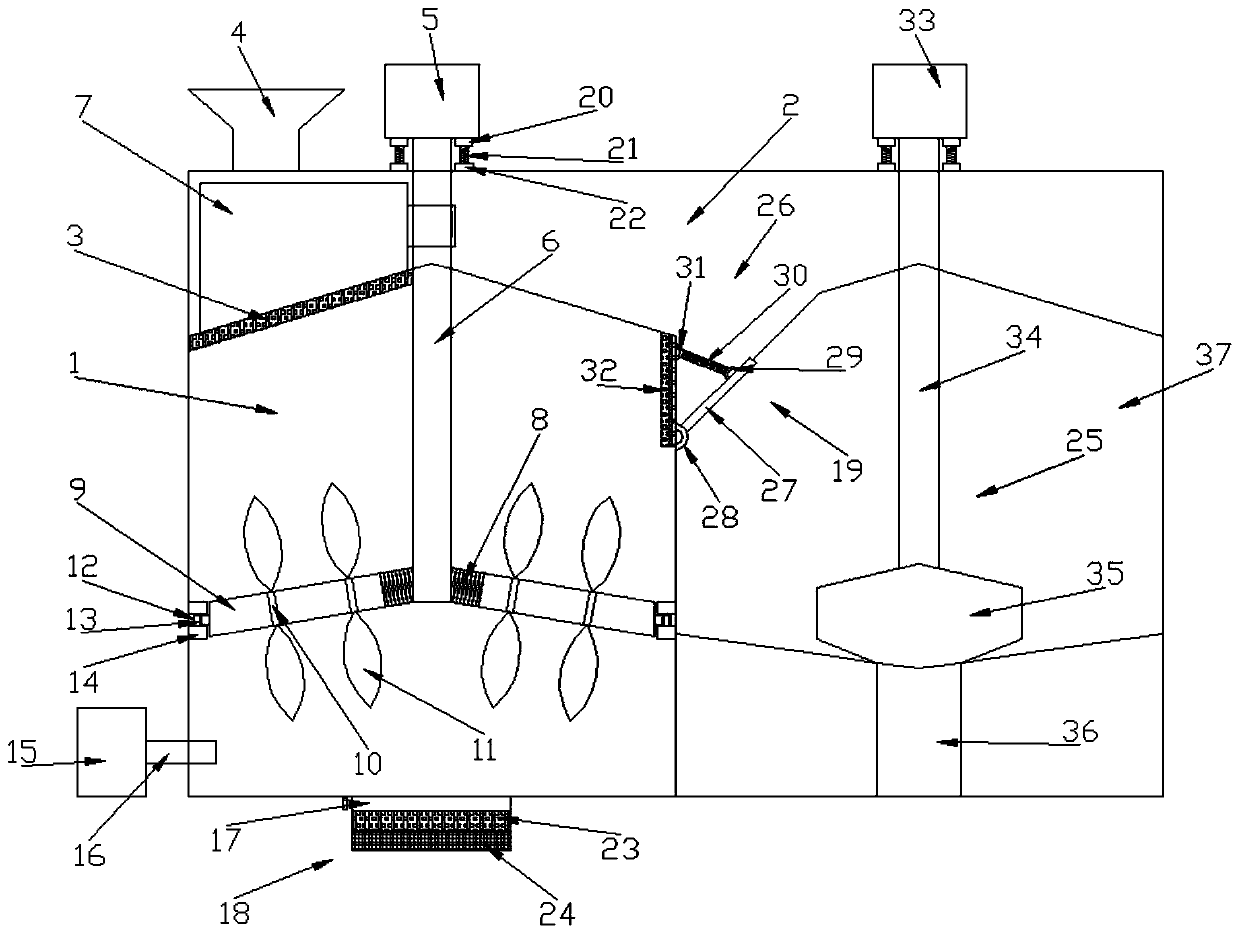

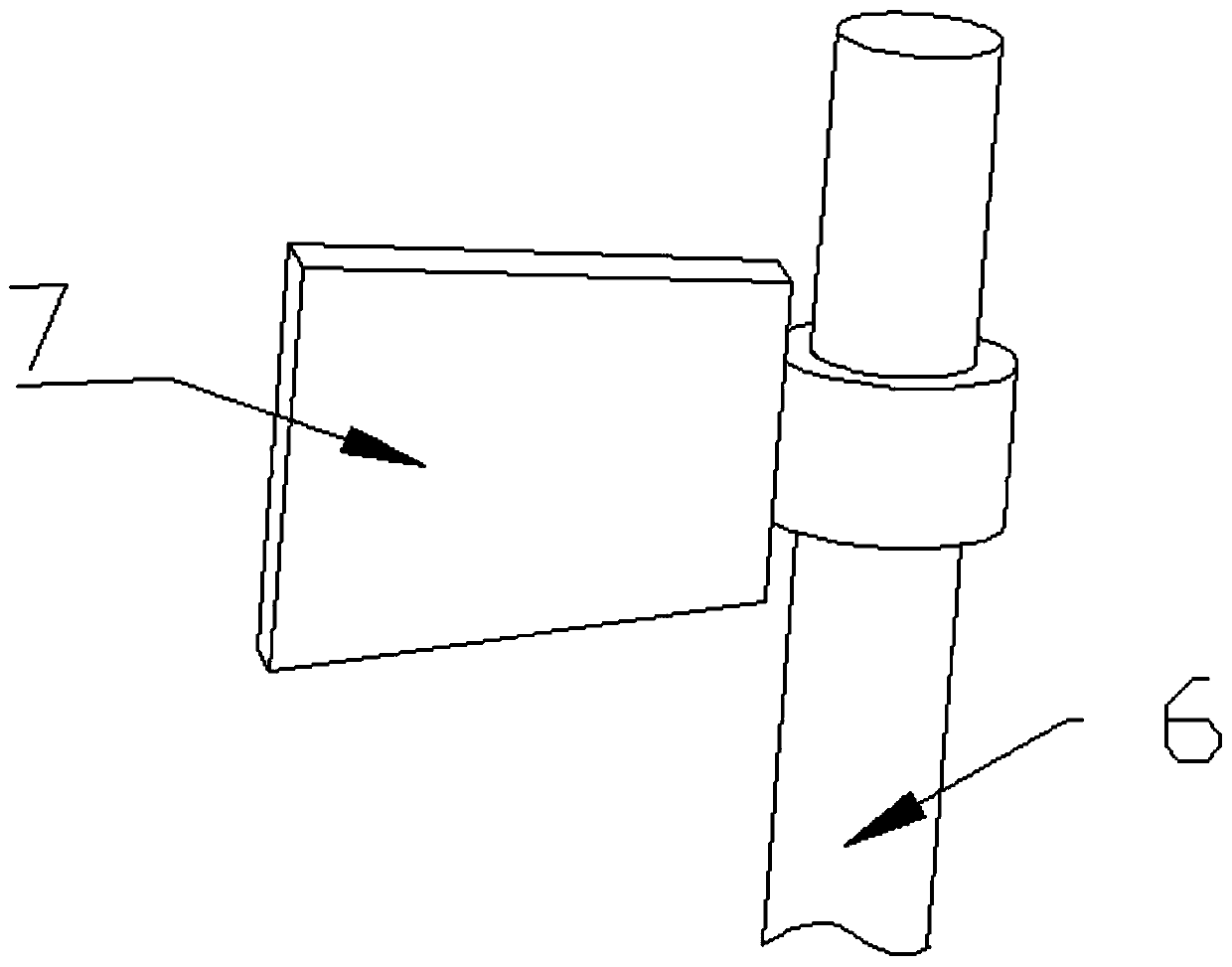

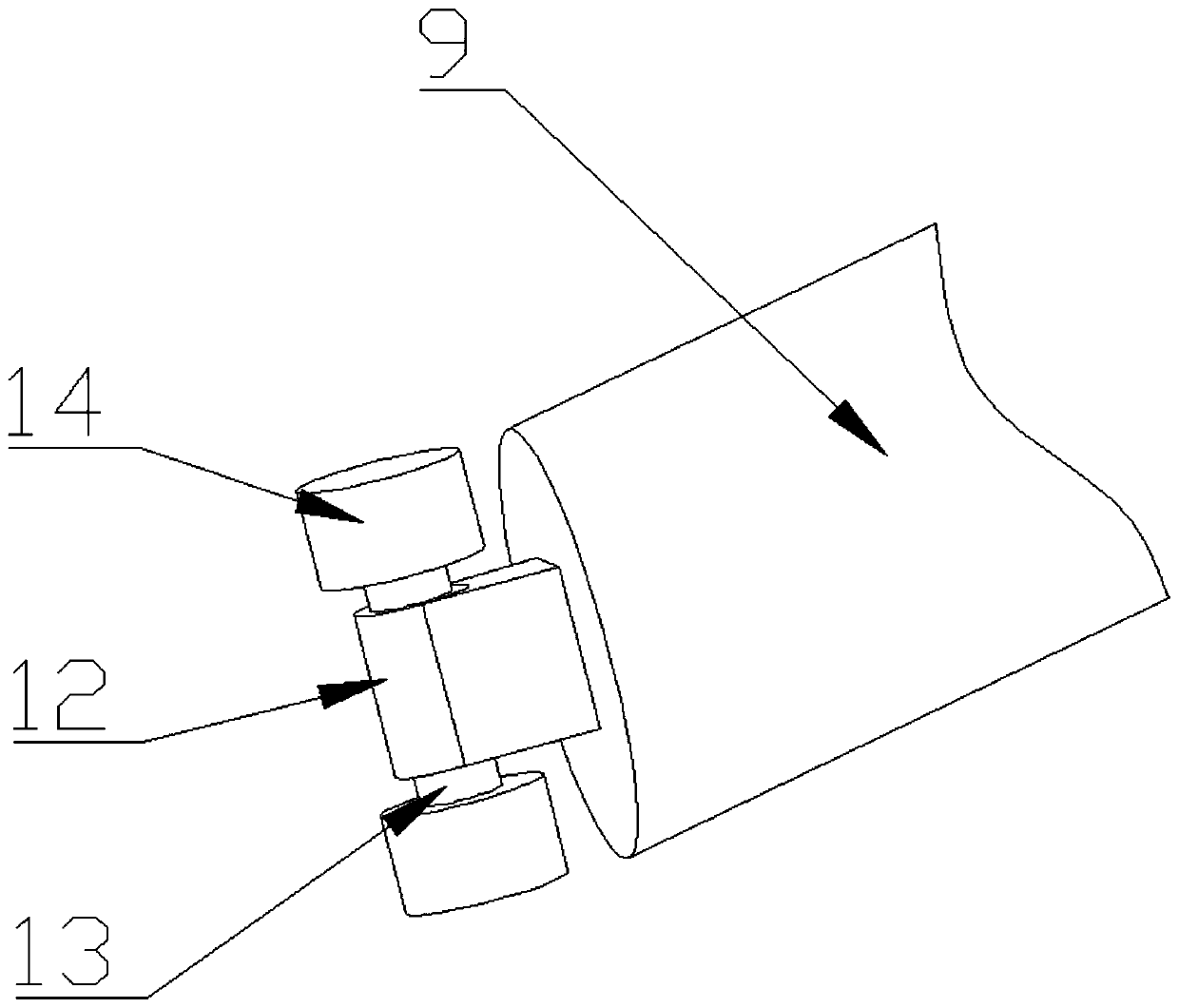

The invention discloses a micro-vortex high-efficiency clarification reactor and an operation method for the same. The reactor is used for solving the problem that devices are in the prior art is difficult to install, liable to obstruct, low in work efficiency, poor in using effect and short in service life. The micro-vortex high-efficiency clarification reactor includes: a clarification basin; a sludge settling basin which is disposed under the clarification basin and is communicated with the bottom of the clarification basin; a sludge discharge pipeline which is communicated with the bottom of the sludge settling basin; a flocculating reaction basin which is disposed in the clarification basin with the bottom of the flocculating reaction basin being communicated with the clarification basin and the sludge settling basin; an inclined plate settlement layer which is disposed between the clarification basin and the flocculating reaction basin and includes a plurality of inclined plates; a central basin which is disposed in the flocculating reaction basin with the top of the central basin being communicated with the upper part of the flocculating reaction basin; micro-vortex filling material which is arranged between the flocculating reaction basin and the central basin; a water inlet pipe which is tangentially connected to the lower part of the central basin; and a water outlet pipe which is communicated with the upper part of the clarification basin. The beneficial effects of the reactor are that the reactor is convenient to install and operate and is high in efficiency, excellent in processing effect, small in agent usage amount and long in service life. With the reactor, a mixing, a flocculating and a separating operation can be achieved synchronously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Preparation method of graphene-sulfur microcapsule composite

The invention relates to a preparation method of a graphene-sulfur microcapsule composite, comprising: first, introducing organic molecules of hydroxy, sulfydryl, amino, carboxy or other groups to thesurface of graphene oxide by means of physical adsorption or chemical grafting; second, preparing graphene-coated sulfur microcapsule by means of mechanical blending. A core material is common sulfur, and the surface of the core material is subjected to graphene oxide or graphene modification to form a core-shell structure. The graphene shell herein can effectively enclose the sulfur therein, andblooming during rubber processing is inhibited; the rich functional groups on the surface or edge of the graphene enable the sulfur to be evenly dispersed in a rubber base during mixing stage and engage in sulfurization reaction during sulfurization stage, thermal stability of the sulfur is improved, and excellent properties are imparted to the composite. The prepared graphene-sulfur microcapsulecomposite has high purity, good thermal stability, high coating rate, high sulfur utilization rate and low cost.

Owner:TANGSHAN JIANHUA TECH DEV

Preparation method of graphene/copper/active carbon composite material

InactiveCN109529777AEconomical and cost-effectiveGood size controlOther chemical processesCatalyst activation/preparationTube furnaceGranularity

The invention relates to a preparation method of a graphene / copper / active carbon composite material. According to the method, firstly, graphene oxide and copper salt are uniformly mixed; after no precipitate is generated, basic solution and active carbon are added; suspension liquid is obtained after the uniform stirring; next, the suspension liquid is put into a reaction kettle for constant temperature heat treatment; performing centrifugal separation; performing drying treatment on obtained paste solids; then, putting the materials into a tubular furnace to perform heat reduction in H2 / Ar mixed atmosphere; performing granulation on the obtained powder; finally preparing graphene / copper / active carbon composite material particles. The catalysis activity and the specific surface area of theprepared graphene / copper / active carbon composite material are obviously enhanced and increased; the advantages of developed pore structures, high intensity, low impurity content, proper granularity,small resistance, easy regeneration and the like are realized; the operation process is simple; the efficiency is high; the industrialized production and application can be easily realized.

Owner:河北宇轩纳米科技有限责任公司

Water treatment defluorination agent and preparation method thereof

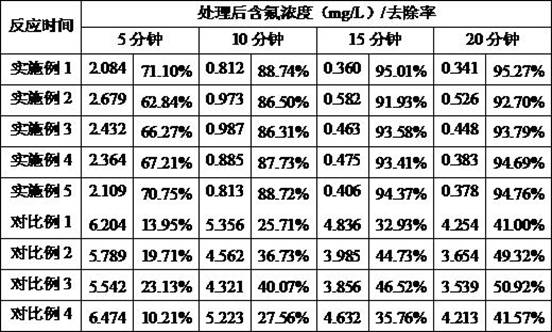

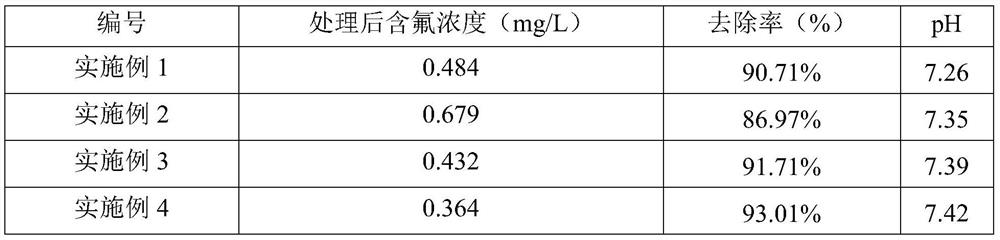

PendingCN113401996AHigh fluoride removal rateGood defluoridation effectWater contaminantsWater/sewage treatment by flocculation/precipitationCelluloseAluminium chloride

The invention discloses a preparation method of a water treatment defluorination agent. The preparation method is characterized by comprising the following steps: step 1, preparing a sodium silicate solution, and adding a diluted hydrochloric acid solution for activation to obtain a solution A; step 2, weighing a first fixed amount of aluminum chloride hexahydrate solid, adding the aluminum chloride hexahydrate solid into the solution A, stirring for 10-30 minutes, continuously weighing a second fixed amount of ferric chloride hexahydrate solid, slowly adding the ferric chloride hexahydrate solid into the solution until the color of the solution becomes dark and turbid, continuously stirring, gradually clarifying the solution, and finally turning into a reddish brown transparent solution, so as to obtain a solution B; step 3, preparing a sodium carboxymethyl cellulose solution, namely a solution C; and step 4, placing the prepared solution B and the solution C in a constant-temperature water bath kettle according to the proportion, fully mixing and reacting in a high-speed stirring and heating state, and after the reaction is finished, obtaining the final defluorination agent solution. The fluorine removal rate of the deep defluorination agent can reach 95% or above, the fluorine removal rate is high, the fluorine removal effect is obvious, and deep fluorine removal of fluorine-containing wastewater can be achieved.

Owner:神美科技有限公司

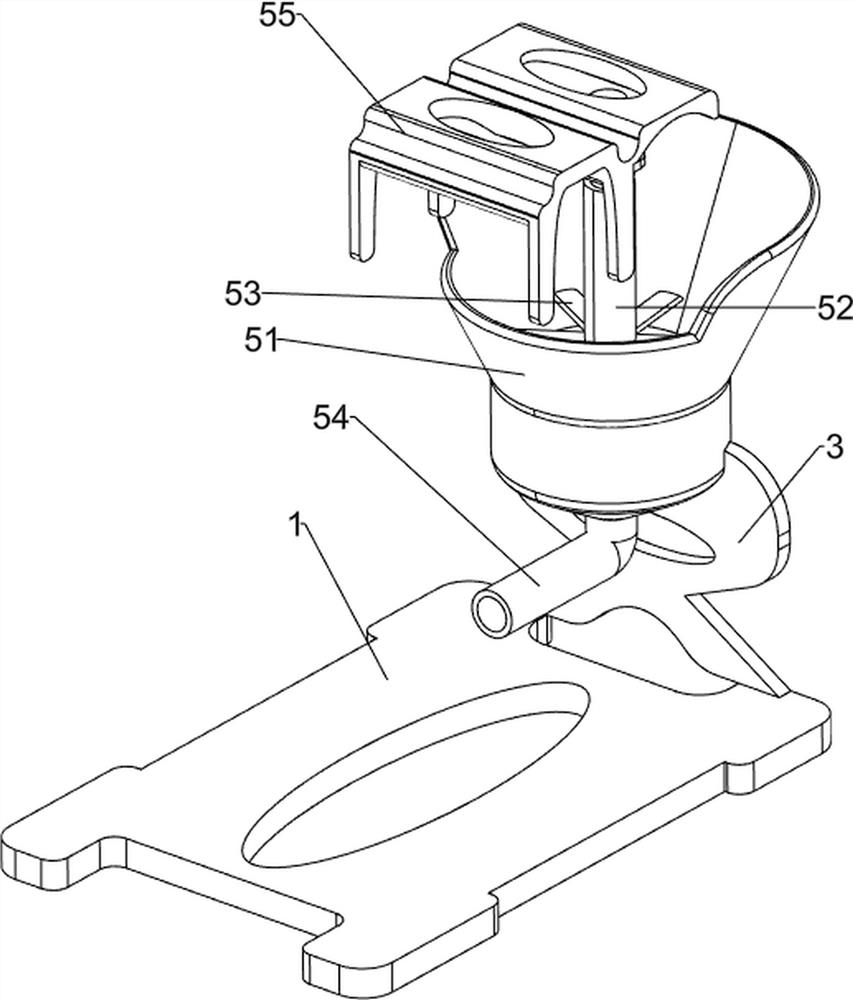

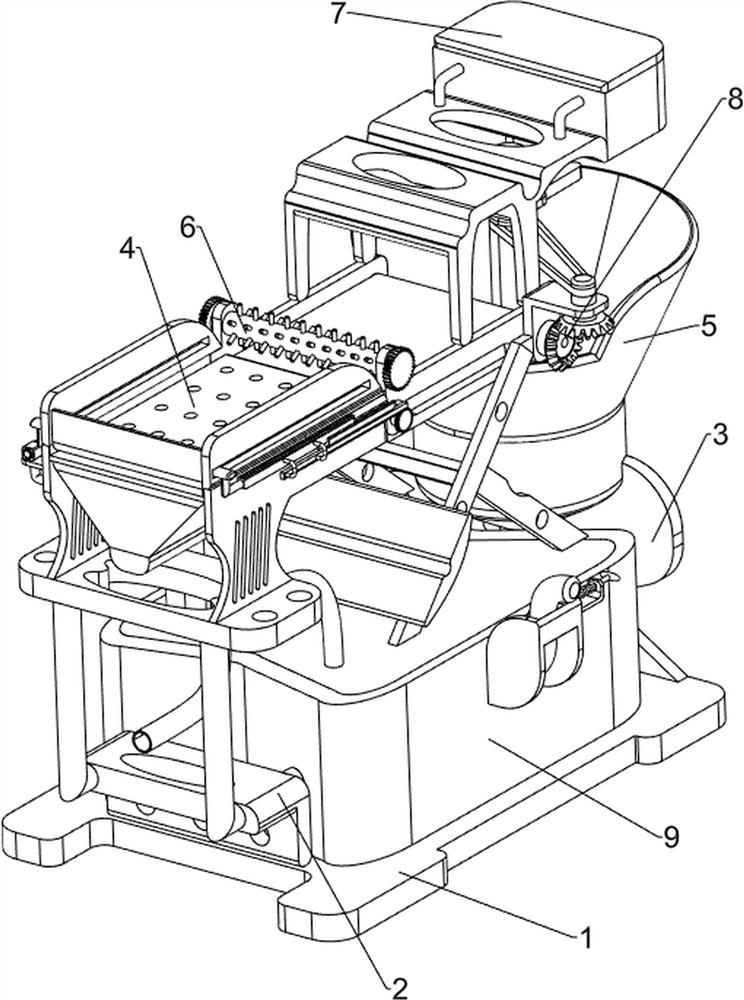

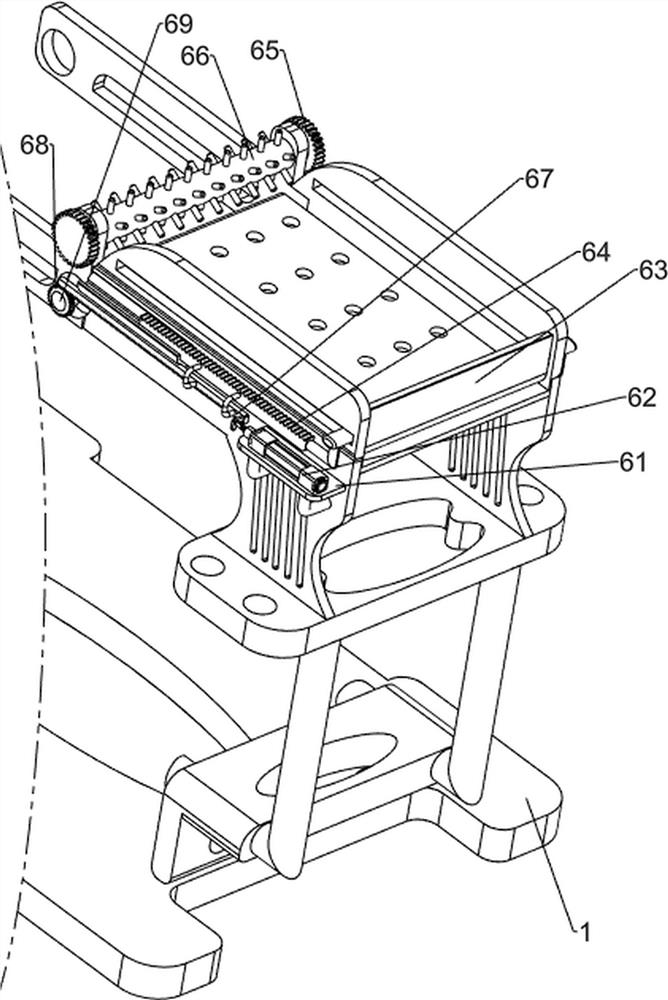

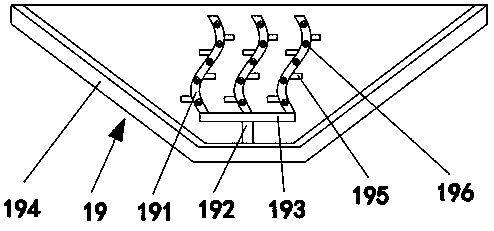

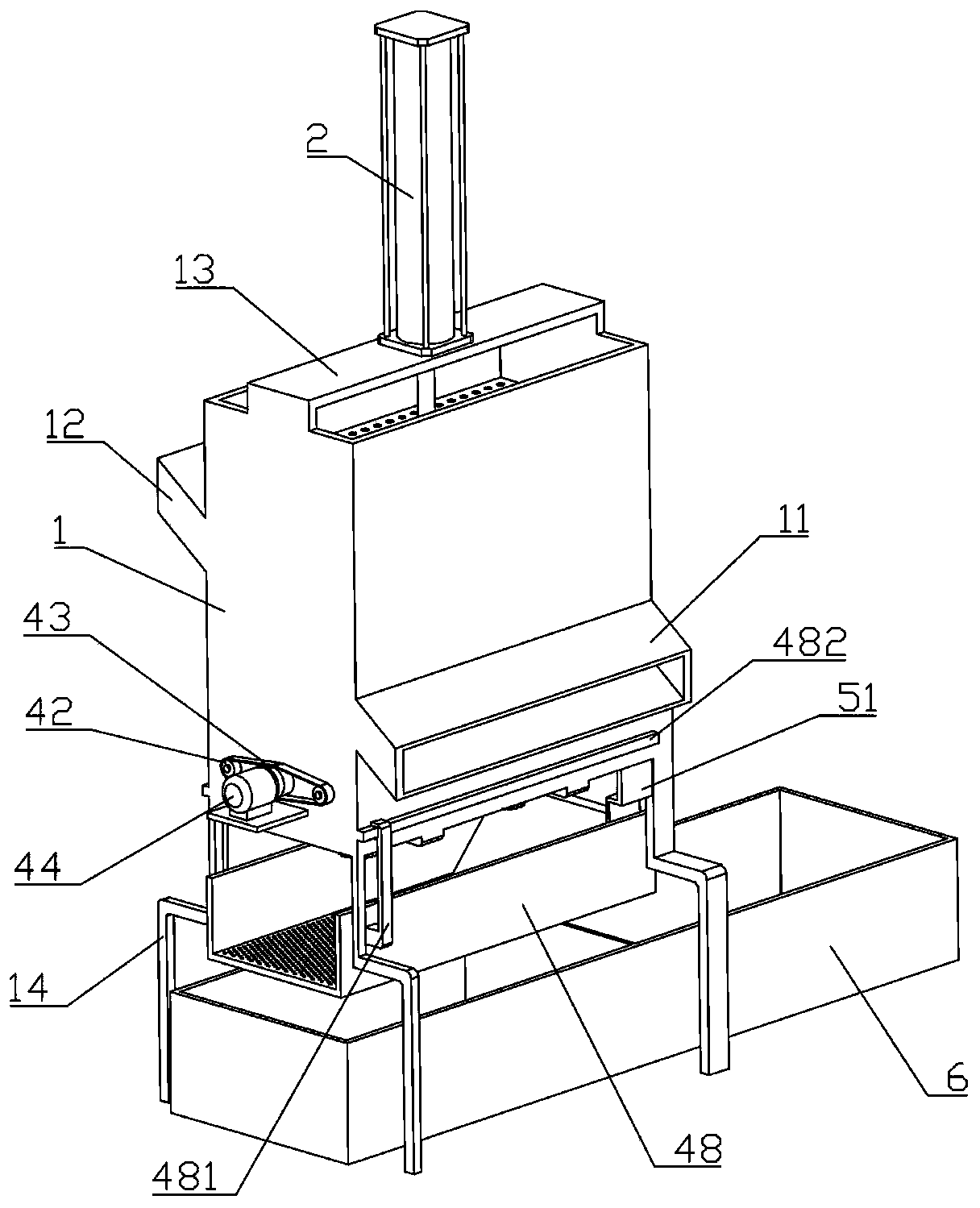

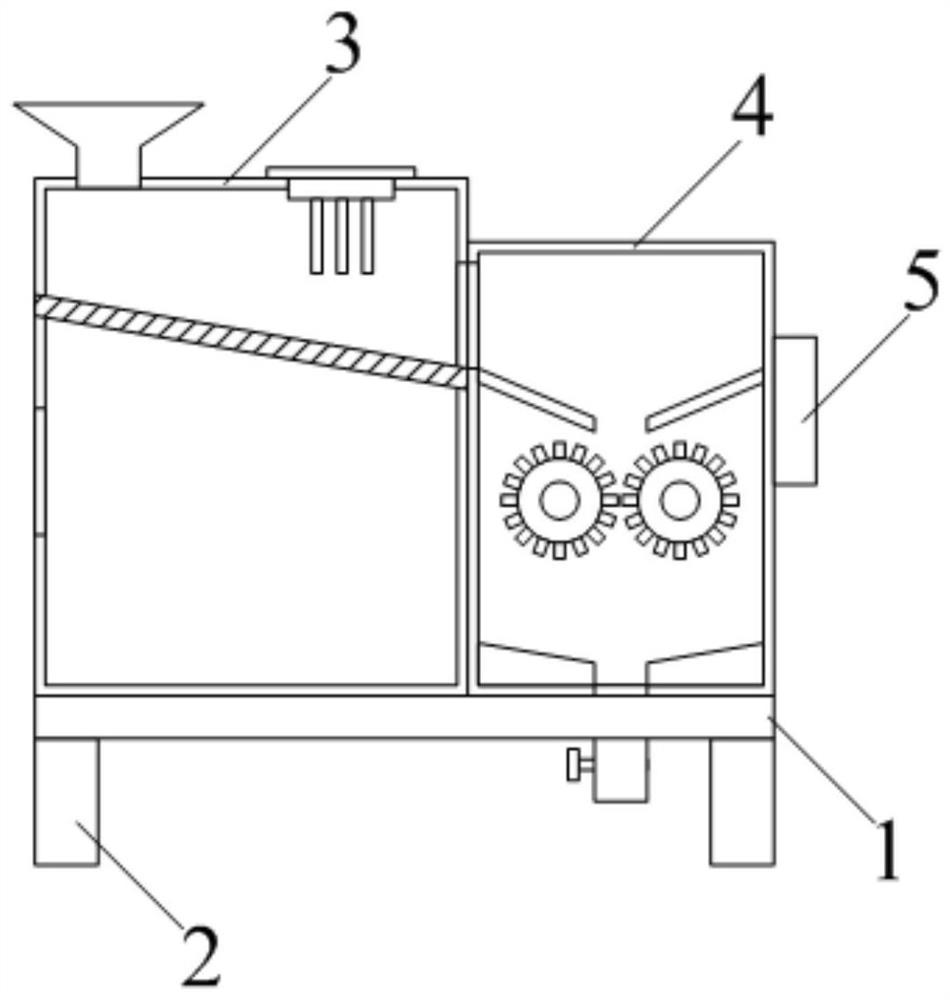

Energy-saving and environment-friendly kitchen waste treatment device

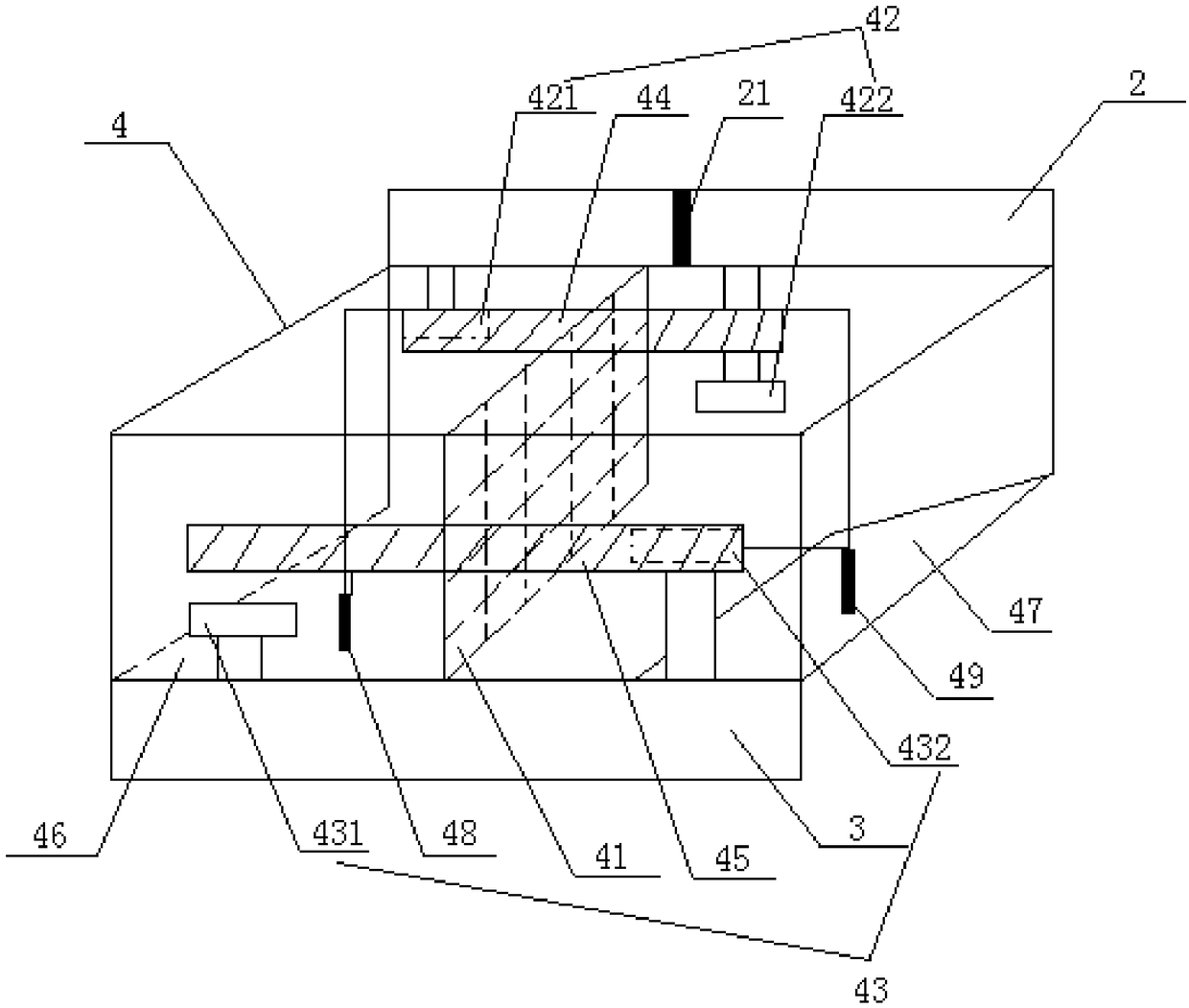

PendingCN112625872ATo achieve the purpose of solid-liquid separationAchieve the effect of automatic feedingBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringWaste treatment

The invention relates to a treatment device, in particular to an energy-saving and environment-friendly kitchen waste treatment device. The energy-saving and environment-friendly kitchen waste treatment device is capable of realizing automatic stirring, automatic and intermittent discharging and automatic feeding. The energy-saving and environment-friendly kitchen waste treatment device comprises a base, a supporting block arranged on the base, a first fixed frame arranged on the base, a filtering mechanism arranged on the supporting block, and a stirring mechanism arranged at the top of the first fixed frame and connected with the filtering mechanism. According to the invention, a roller on the rear side drives a bevel gear set to rotate, the bevel gear set rotates to drive a fourth rotating shaft to rotate, then a first transmission assembly rotates, a first rotating shaft rotates to enable a stirring block to move, the stirring block stirs waste and a catalyst to be fully mixed, and therefore the purpose of automatic stirring is achieved.

Owner:邱小芳

Solid-liquid separation device with self-cleaning function and septic tank

ActiveCN109336347AAvoid cloggingTo achieve the purpose of solid-liquid separationBiological sludge treatmentSewageSelf cleaning

The invention discloses a solid-liquid separation device with a self-cleaning function and a septic tank. The solid-liquid separation device comprises a separation space, wherein a separation net is arranged in the separation space, and a pair of water inlets is formed in one side wall of the separation net and located on two sides of the separation net respectively; a pair of water outlets is also formed in another side wall of the separation space and located on two sides of the separation net respectively; a first shielding plate and a second shielding plate are also arranged on the side walls of the separation space, the first shielding plate is movably mounted on a water inlet side of the water inlets, and the second shielding plate is movably mounted on a water outlet side of the water outlets. The solid-liquid separation device scours dirt attached to the separation net by changing the direction of flow of sewage in and out of the separation space so as to realize the self-cleaning effect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Inorganic-organic composite polymer water treatment defluorination flocculant and preparation method thereof

PendingCN113955837AHigh fluoride removal rateGood defluoridation effectWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chlorideSodium bisulfate

The invention discloses a preparation method of an inorganic-organic composite polymer water treatment defluorination flocculant, which is characterized by comprising the following steps of (1) stirring a sodium silicate solution at a constant temperature to obtain a colorless transparent solution, then adding diluted hydrochloric acid for acidification, and stirring to obtain a solution A, (2) dissolving aluminum chloride hexahydrate and ferric chloride hexahydrate in distilled water, adding the solution A while stirring, then adding sodium carbonate, and stirring to obtain a solution B, (3) dissolving modified chitosan, poly dimethyl diallyl ammonium chloride and sodium hydrogen sulfite in distilled water, adjusting the pH value with diluted hydrochloric acid, and stirring to obtain a solution C, and (4) adding the solution B into the solution C, and stirring for reaction to prepare the defluorination flocculant solution. When the flocculant disclosed by the invention is used for treating the fluorine-containing wastewater, the fluorine content in the effluent can reach the class III first-grade discharge standard of national Environmental Quality Standard for Surface Water (GB3838-2002), the fluorine removal rate is high, the fluorine removal effect is obvious, and deep treatment of the fluorine-containing wastewater can be realized.

Owner:神美科技有限公司

Antibacterial composite white carbon black material and preparation method thereof

InactiveCN107668032AEvenly dispersedHas antibacterial propertiesBiocideFungicidesWastewaterCvd graphene

The invention relates to an antibacterial composite white carbon black material and a preparation method thereof. Antibacterial white carbon black uses graphene and white carbon black as a substrate and is mixed with one or more of antibacterial elements Zn, Cu, Ag and Ti. The preparation method of the material comprises the following steps of preparation of an antibacterial ion solution, two-stepmixing reaction, solid-liquid separation and drying and post-treatment. In the antibacterial composite white carbon black material, the graphene and the white carbon black are interspersed, gatheringof the material itself can be effectively inhibited, and accordingly the highly dispersed composite material containing nano size of white carbon black is obtained. The novel antibacterial compositewhite carbon black material has the dual functions of antibacterial property and reinforcement, and the demands of come products needing to have an antibacterial function are met. An oxidized graphenesolution of low pH value is adopted as one of reaction raw materials, the problem of waste acid and water treatment is solved, and the material is green and friendly to the environment. In addition,the used raw materials are low in cost, the economic performance-cost ratio is high, the preparation process is simple, and industrial production and application are easy to achieve.

Owner:TANGSHAN JIANHUA TECH DEV

Sewage treatment device

ActiveCN112774311ATo achieve the purpose of deep filtrationImprove processing efficiencyFiltration circuitsTreatment pondWater flow

The invention discloses a sewage treatment device which comprises a treatment pond. One side of the treatment pond is communicated with a feeding pipe, the side, away from the feeding pipe, of the treatment pond is communicated with a discharging pipe, the bottom of the inner side of the treatment pond is fixedly connected with a precipitation frame, and the outer side of the discharging pipe is provided with a filtering frame. The position, close to the filtering frame, of the outer portion of the discharging pipe is sleeved with a bearing, the side, away from the discharging pipe, of the filtering frame communicates with a discharging pipe, a separation device is installed in the filtering frame, a filtering device is installed on the inner wall of the filtering frame, and a clearing device is installed on the position, close to the filtering device, of the inner wall of the filtering frame. A motor is mounted outside the filtering frame. The invention relates to the technical field of sewage treatment. According to the sewage treatment device, the purpose of deeply filtering sewage is achieved, the contact area of the filter screen can be changed along with the size of water flow, and the sewage treatment efficiency is improved.

Owner:湖北水云涧环保工程有限公司

Preparation method of graphene/white carbon black composite material

The invention relates to a preparation method of a graphene / white carbon black composite material. The method comprises the following steps: a graphene oxide solution containing sulfur acid is prepared with a hummers method and uniformly stirred, a sodium silicate solution is added dropwise after no precipitate is produced, the mixture is stirred and treated ultrasonically, sol is obtained and subjected to centrifugal separation, obtained pasty solids are dried and placed in a tube furnace for thermal reduction in H2 / Ar mixed atmosphere, and powder, namely, the graphene / white carbon black composite material is obtained finally. In the method, aggregation of the material can be inhibited effectively through interpenetration of graphene and white carbon black, so that the composite material which is highly dispersed and contains nanoscale white carbon black is obtained; the graphene oxide solution containing sulfur acid is taken as one of reaction raw materials, accordingly, the problem about treatment of waste acid and waste water produced in the hummers method is solved, a graphene oxide cleaning link is omitted, and energy and water are saved. The prepared graphene / white carbon black composite material is high in purity and can be widely applied to the fields of rubber, paint and the like.

Owner:TANGSHAN JIANHUA TECH DEV

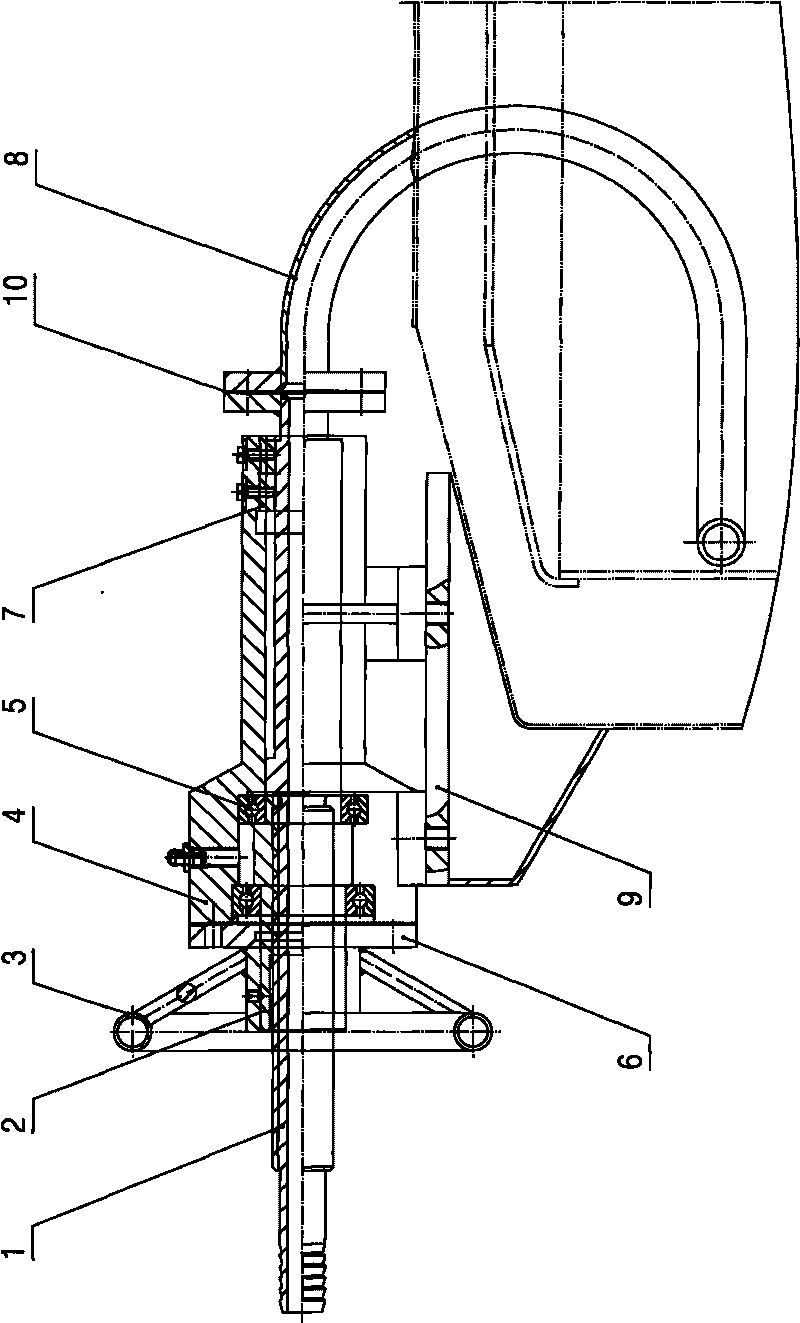

Liquid skimming device in settling and filtering type centrifuge

InactiveCN101703967ATo achieve the purpose of solid-liquid separationCentrifugesEngineeringMechanical engineering

The invention discloses a liquid skimming device in a settling and filtering type centrifuge which can suck liquid phase, comprising a bottom plate arranged on a shell, wherein a bearing seat is arranged on the bottom plate, a bearing cavity is arranged in the bearing seat, a bearing is arranged in the bearing cavity, the bearing seat is provided with a pressing cover at the outer side of the bearing, an adjusting nut is arranged in the bearing, an axial through hole which penetrates through the bearing seat is arranged at the bottom of the bearing cavity, the adjusting nut extends out of the pressing cover and is fixed with an adjusting handle wheel, a hollow screw rod which is arranged inthe axial through hole in a penetrating way is in threaded connection with the adjusting nut, axial key grooves which are mutually matched are respectively arranged on the inner wall of the axial through hole and the outer wall of the hollow screw rod, guide keys are arranged in the axial key grooves, and a liquid skimming pipe which is communicated with the hollow screw rod is connected to the tail part of the hollow screw rod. The invention broadens the application range of the settling and filtering type centrifuge.

Owner:JIANGSU PEONY CENTRIFUGE MFG

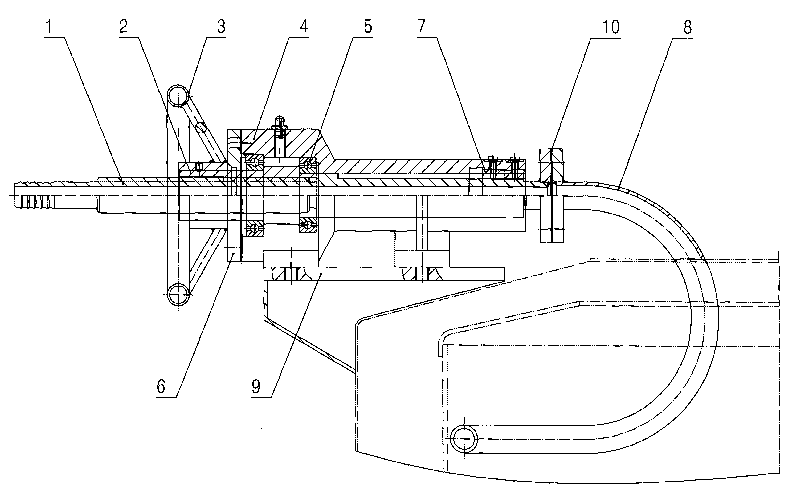

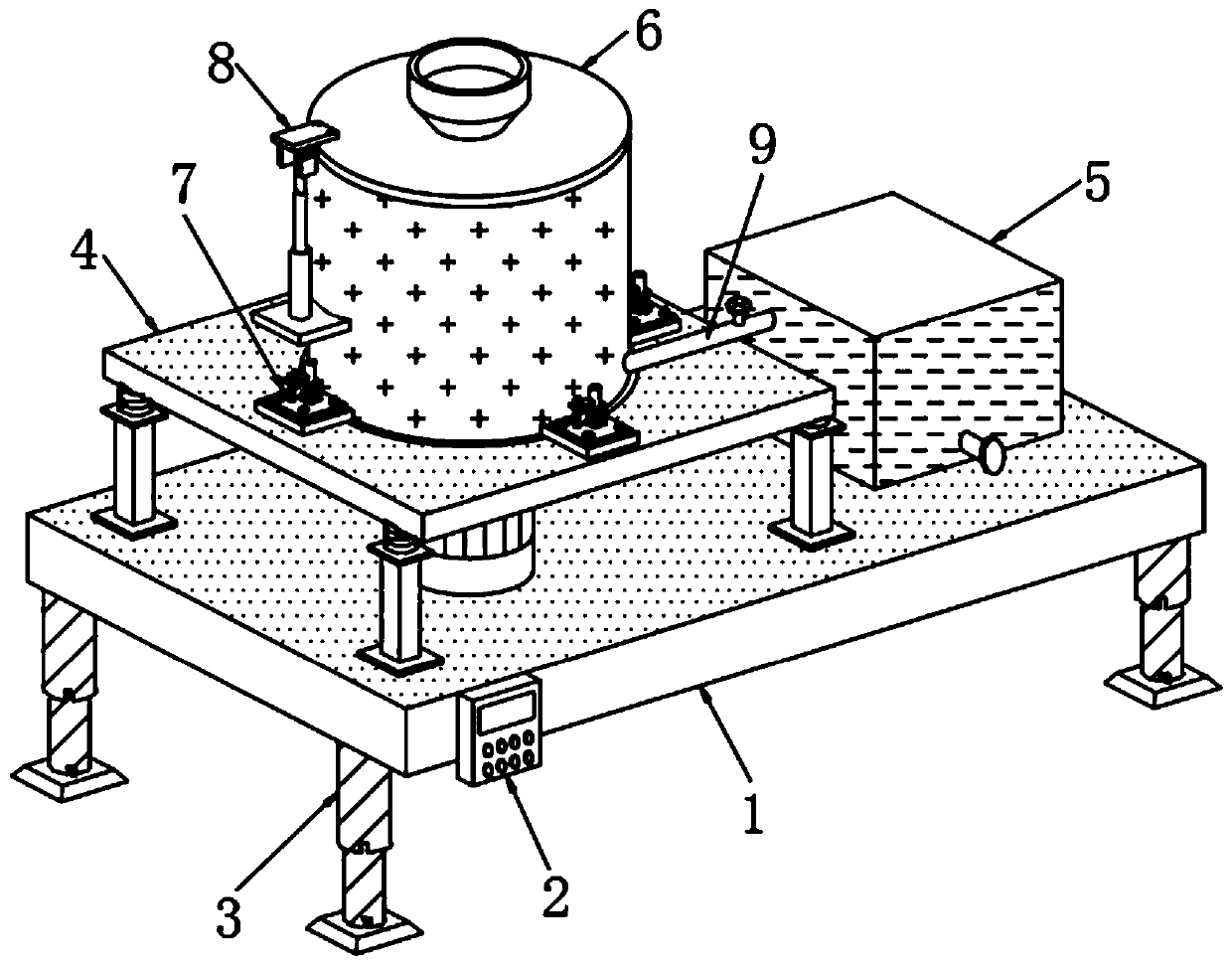

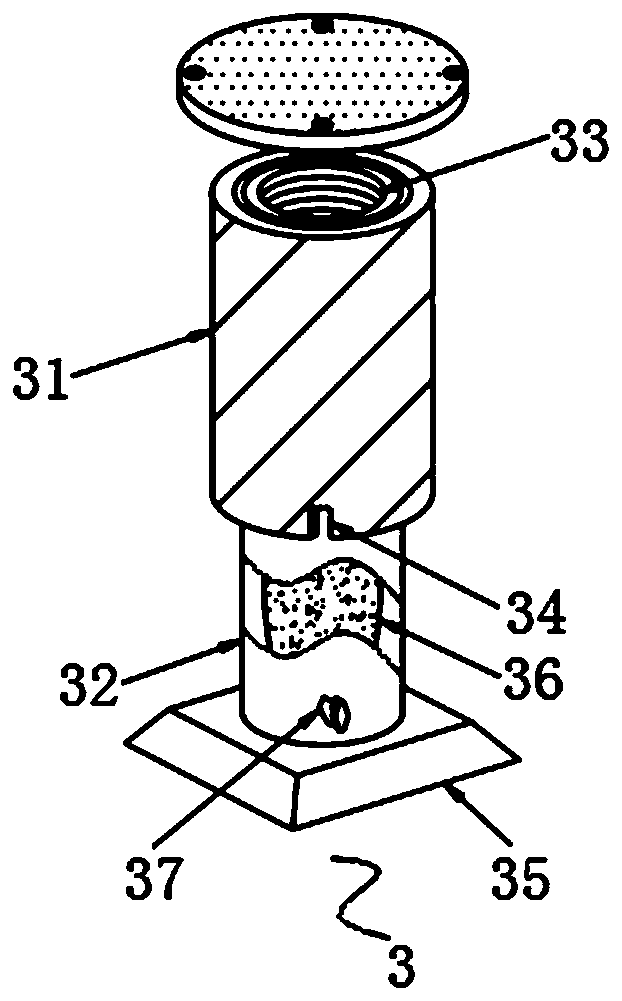

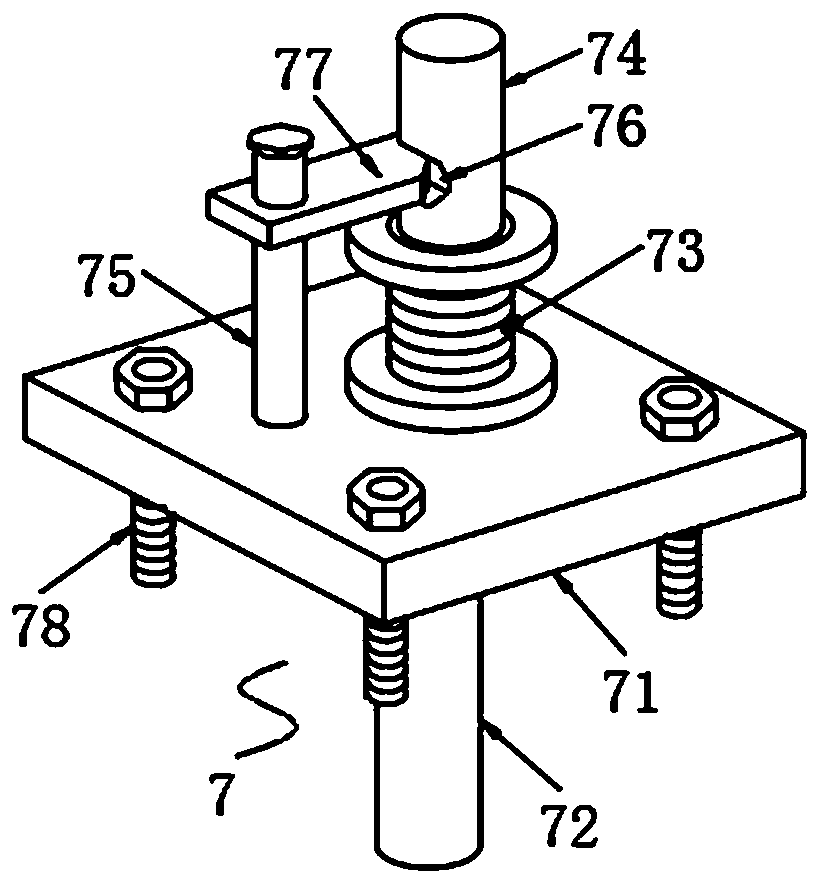

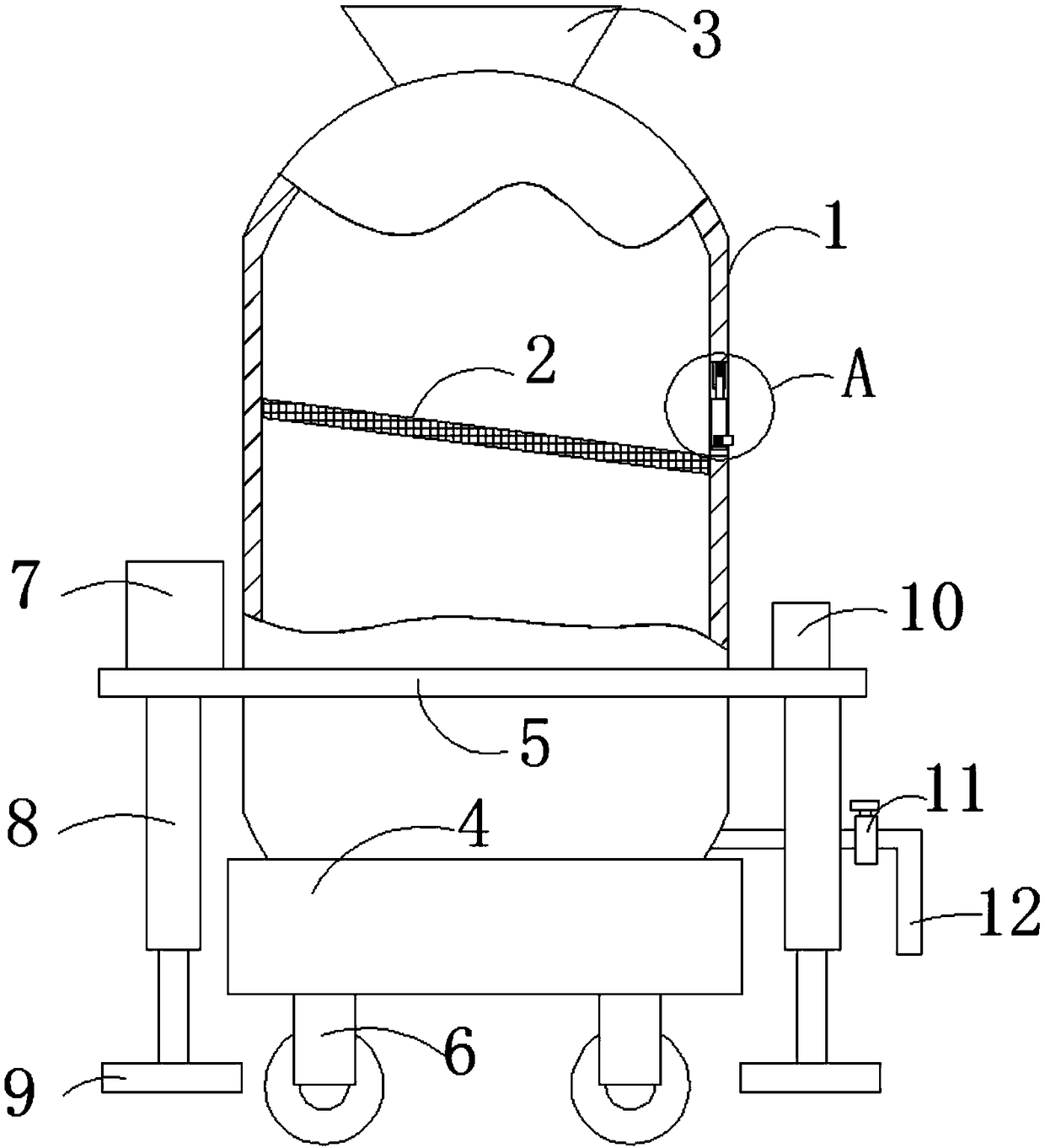

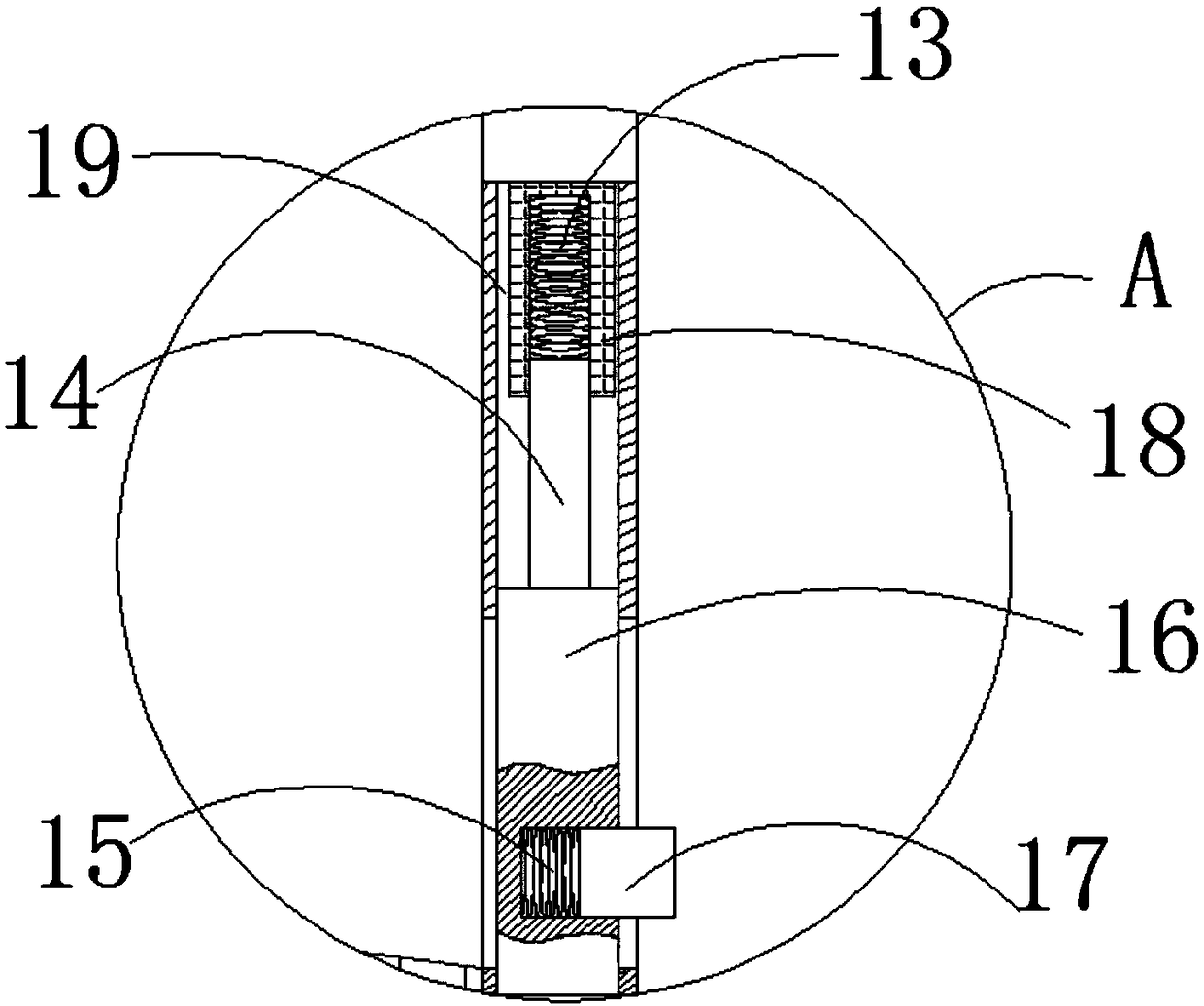

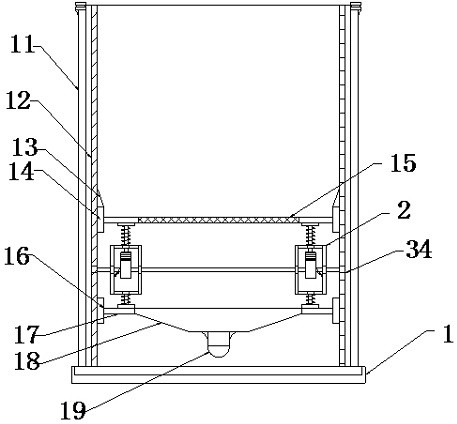

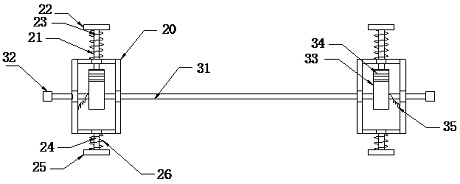

Centrifugation device for nano fluid preparation and use method

InactiveCN110732413ATo achieve the shock absorption effectImprove stabilityNon-rotating vibration suppressionRotary centrifugesCentrifugationEngineering

The invention discloses a centrifugation device for nano fluid preparation and a use method, and relates to the technical field of nano fluid preparation. The centrifugation device comprises a rack, wherein a control panel is arranged on the front side of the rack, damping supporting legs are fixedly installed on the lower surface of the rack, a fixing frame is fixedly installed on one side of theupper surface of the rack, a liquid storage box is fixedly installed at the position, located on one side of the fixing frame, of the upper surface of the rack, and a separation mechanism is embedded in the upper end of the fixing frame. The centrifugation device is reasonable in structure and convenient to use, by means of the arranged damping supporting legs, the heights of the damping supporting legs can be adjusted by adjusting the air inflation amount in air bags, and meanwhile, a certain damping effect can be achieved through arranged damping springs, so that the stability in the working process of the device is improved; through the arranged separation mechanism, the purpose of nano fluid solid-liquid separation can be achieved; and meanwhile, filter screens with hole diameters indifferent specifications can be quickly replaced, so that the application range of the centrifugation device is expanded, and the practicability of the centrifugation device cis improved.

Owner:南京二维纳米科技有限公司

Solid-liquid separation method of nanometer material

ActiveCN103120857AGood technical effectTo achieve the purpose of solid-liquid separationEvaporation by sprayingPentasil aluminosilicate zeoliteComplex problemsSeparation method

The invention relates to a solid-liquid separation method of a nanometer material, mainly aiming at solving the problem that a filter process of the nanometer material in the prior art is complicated. According to the solid-liquid separation method provided by the invention, a nanometer solid material is obtained by carrying out spray drying on serous fluid containing the nanometer material, wherein the spray drying condition is that the rotation speed of an atomizing disk is 1,000-20,000 revolutions / minute, the temperature of the hot air entering a tower body of a spray drying tower is 100-300 DEG C, the technical scheme that the hot air outputs the temperature at 50-200 DEG C of the tower body of the spray drying tower can preferably solve the problem, and the solid-liquid separation method can be used for industry solid-liquid separation production of the nanometer material.

Owner:CHINA PETROLEUM & CHEM CORP +1

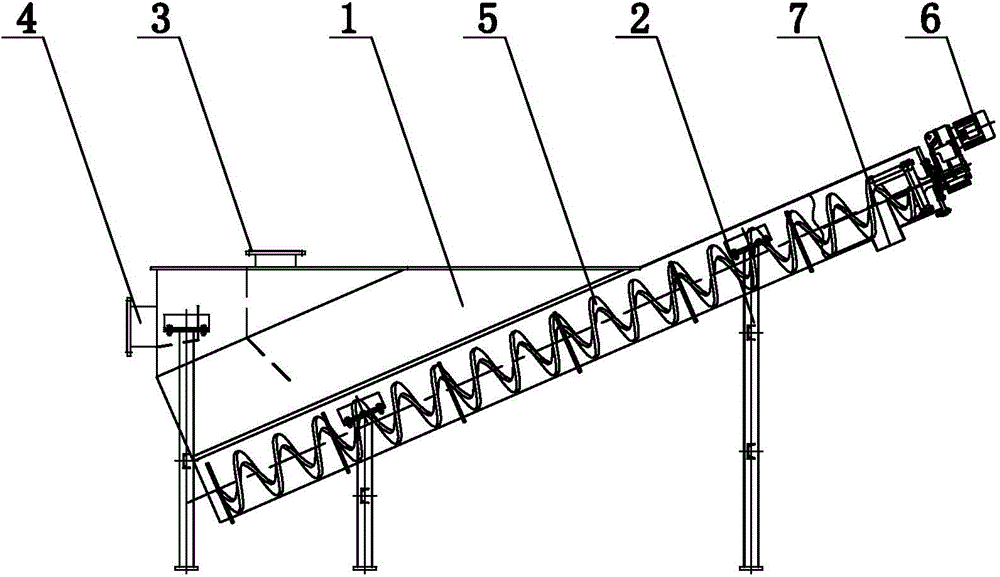

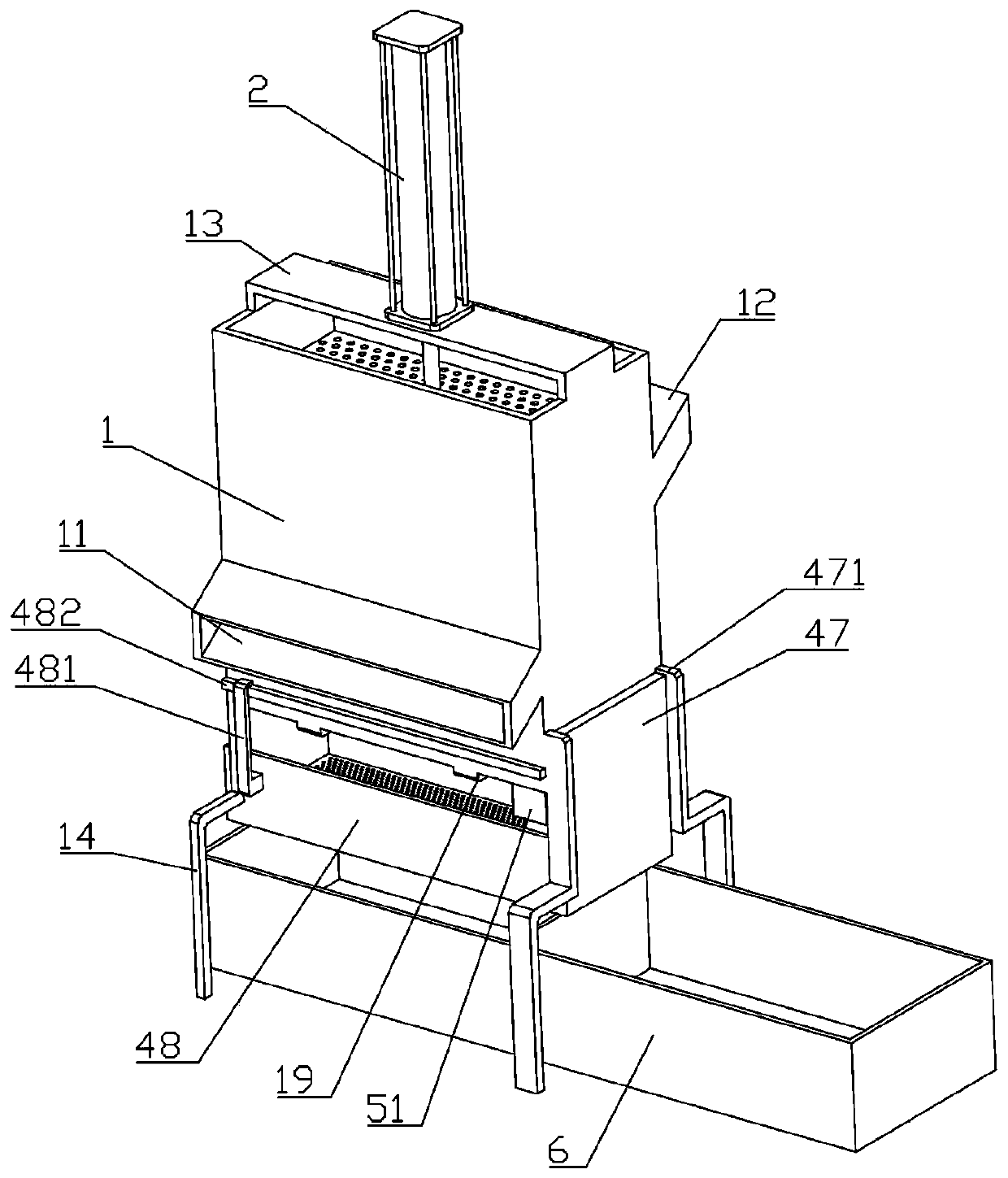

Sedimentation type impurity and water separating machine

InactiveCN104631184AEfficient removalTo achieve the purpose of solid-liquid separationPaper material treatmentSpiral bladePulp and paper industry

The invention provides a sedimentation type impurity and water separating machine and belongs to the field of paper pulp impurity separating devices. The sedimentation type impurity and water separating machine is provided with a groove. A fixed support is arranged on the groove. A feed inlet is formed in the top of the groove. A water outlet is formed in the tail of the groove. A spiral blade is arranged at the bottom inside the groove. The top of the spiral blade is installed on the groove through a motor. A discharge outlet is formed in the position, corresponding to the top of the spiral blade, of the groove. Paper pulp impurities can be processed well.

Owner:SHANDONG CHENZHONG MACHINERY

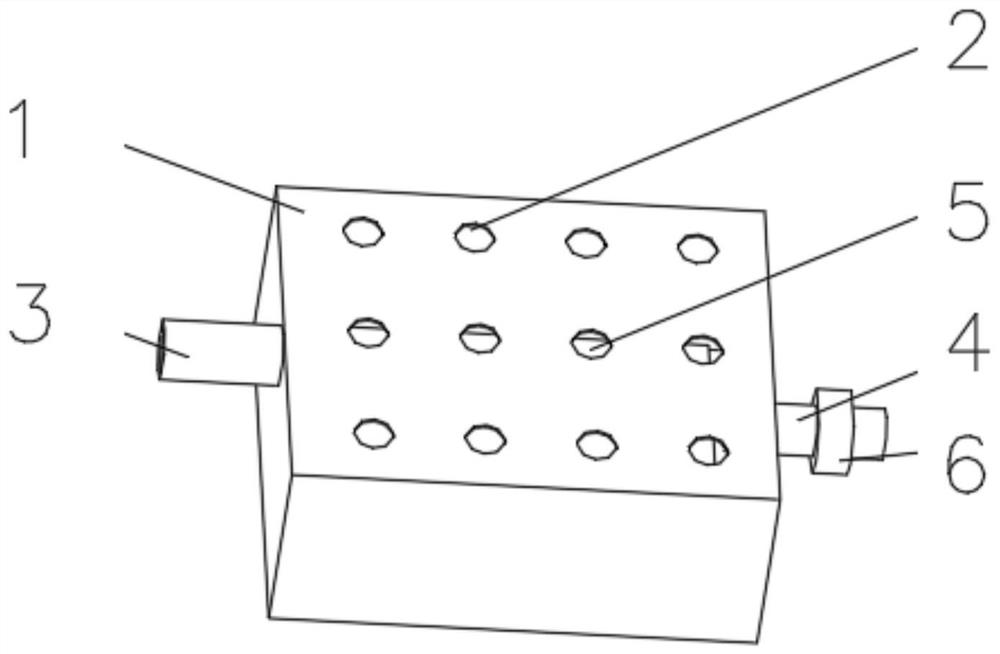

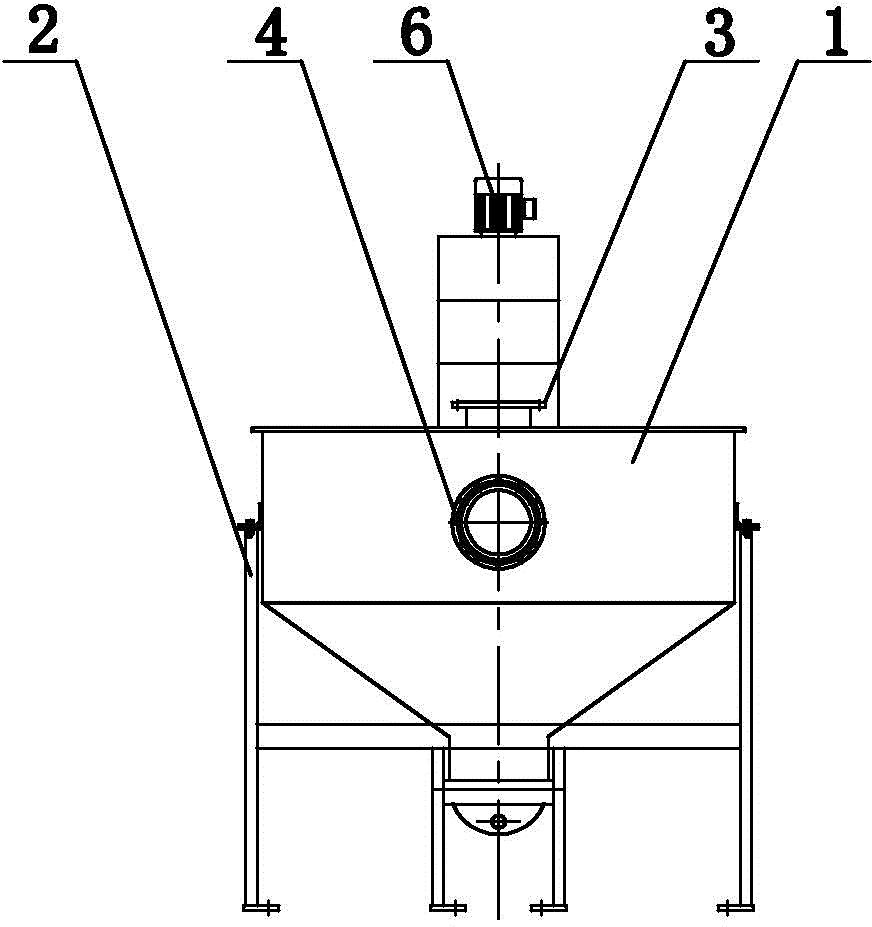

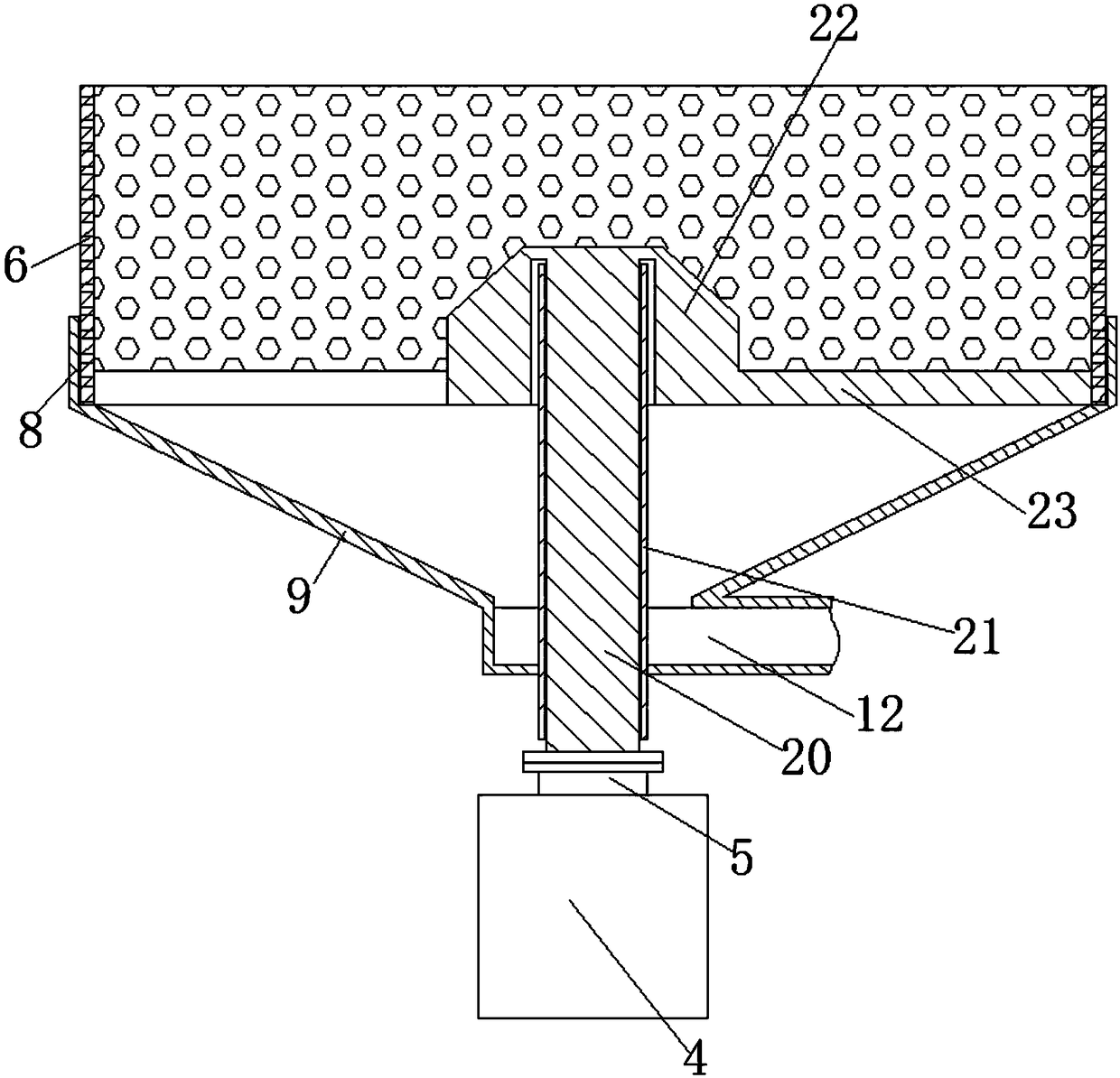

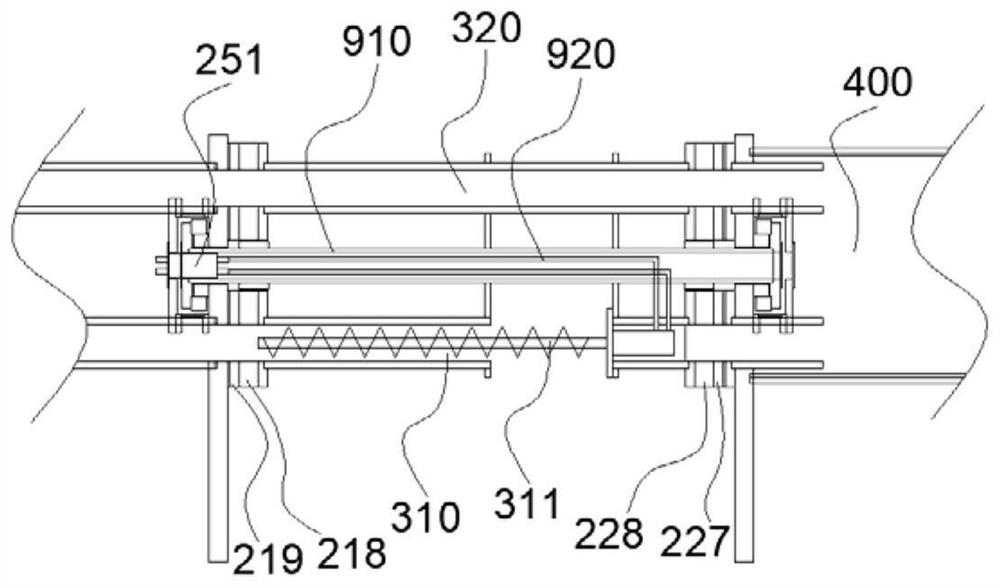

Solid-liquid separation device arranged in filtering tank

InactiveCN108114521ATo achieve the purpose of solid-liquid separationMoving filtering element filtersDrive shaftPulp and paper industry

The invention discloses a solid-liquid separation device arranged in a filtering tank. The solid-liquid separation device comprises a barrel body arranged in a tank body, a hollow dewatering roller sleeved at the upper parts of the barrel body, a residue collection bin connected to the lower part of the barrel body and a residue discharge pipeline arranged at the bottom of the residue collection bin, wherein the dewatering roller comprises a mesh barrel, a fixed base arranged in the middle of the bottom of the mesh barrel and at least three brackets connected between the mesh barrel and the fixed base; a transmission shaft is downwards arranged at the bottom of the fixed base; the transmission shaft penetrates through the residue collection bin and is connected with a motor. In the solid-liquid separation device, the barrel body with the tapered lower part and the dewatering roller sleeved at the upper part of the barrel body are arranged, so that the dewatering roller is driven by themotor to rotate for dewatering, stereoplasm generated after dewatering is accumulated at the lower part of the barrel body and is collected for residue discharge, and the purpose of solid-liquid separation is achieved.

Owner:KAIXIAN COUNTY WEIPENG TECH SERVICE CENT

Method for treating garbage penetrating fluid

PendingCN111533307AAvoid destructionTo achieve the purpose of solid-liquid separationSpecific water treatment objectivesTreatment involving filtrationSuspended particlesProcess engineering

The invention discloses a method for treating garbage penetrating fluid. The method comprises the following steps: (1) adding a flocculating agent into the garbage penetrating fluid to be treated to accumulate and settle suspended particles in the garbage penetrating fluid; (2) stirring the garbage penetrating fluid added with the flocculating agent, and standing for 1-3 hours; (3) conveying the garbage penetrating fluid treated in the step (2) into a filter press for filter pressing so that wastewater in the garbage penetrating fluid seeps out; (4) conveying the wastewater seeped in the step(3) into a sand filter for sand filtration; and (5) conveying the wastewater treated in the step (4) into a DTRO membrane for membrane filtration to obtain a discharge liquid meeting the discharge standard. According to the method, suspended particles in the garbage penetrating fluid are accumulated and settled by adding the flocculating agent so that the purpose of solid-liquid separation is achieved, impurities are further intercepted and the hardness is reduced by matching the press filter, the sand filter and the DTRO membrane, the wastewater meeting the emission standard is obtained, andthe damage to the environment is avoided.

Owner:江苏澳特克环境科技有限公司

Sewage cleaning device

InactiveCN110451731ATo achieve the purpose of solid-liquid separationEasy to oxidize and decomposeTreatment using aerobic processesWater contaminantsSewageEngineering

The invention discloses a sewage cleaning device. The sewage cleaning device comprises a stirring tank and a garbage tank, wherein the stirring tank is arranged in the garbage tank, the top of the stirring tank is an inclined plane which inclines downwards from center to outside, the side inner wall of the stirring tank is a wavy wall surface, and a filter screen I is arranged in the left part ofthe top of the stirring tank; a water inlet is further formed in the left side of the top of the garbage pool, wherein the water inlet is fixedly formed at the left part of the stirring tank; a firstmotor is further arranged at the right side of the water inlet, wherein the first motor is fixedly installed at the top of the garbage tank, the output end of the first motor is fixedly connected witha first shaft rod, and the first shaft rod is placed in the middle of the stirring tank and extends into the stirring tank; a push plate is further fixedly connected to the middle of the first shaftrod, wherein the bottom face of the push plate is attached to the top face of the stirring tank; an aeration device is arranged on the side surface of the lower end of the stirring tank and is connected with a pipeline, wherein the pipeline extends into the stirring tank; a water valve is further arranged at the bottom of the stirring tank, and the water valve is provided with an automatic switch;and a discharge port for discharging solid substances is formed in the right side of the garbage tank.

Owner:吴珍珍

Livestock farm sewage treatment device

InactiveCN109368827AReduce processingReduce wasteSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEngineeringSewage

The invention discloses a livestock farm sewage treatment device. The livestock farm sewage treatment device comprises a sewage treatment tank, wherein a feeding device is mounted at the top of the sewage treatment tank, a discharging pipe is formed in the middle of the left side of the sewage treatment tank, and a screen net is connected to the discharge pipe, a stirring device is mounted below the screen net; and the feeding device comprises a disinfection box, a feeding hole is formed in the middle of the disinfection box, air guns are arranged on two sides of the feeding hole, and a filtering plate is mounted in the disinfection box. According to the livestock farm sewage treatment device, sewage can be efficiently and rapidly treated, the purification degree can be maximized, and meanwhile, the wasting of energy resources in the purification process is reduced.

Owner:嘉兴市爵拓科技有限公司

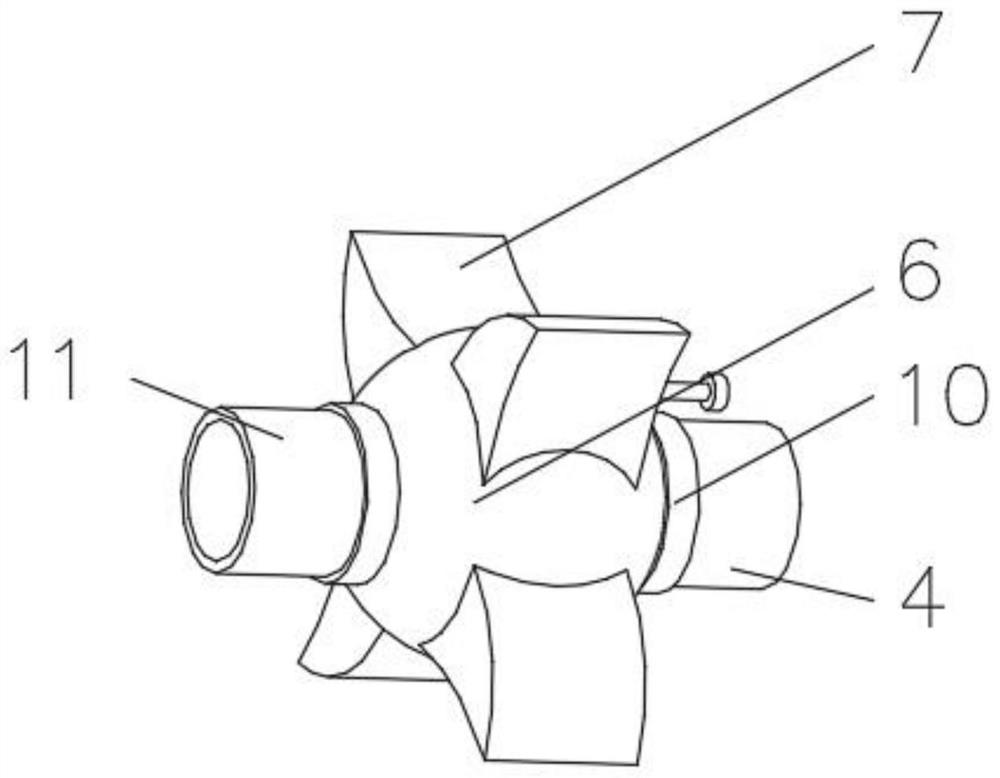

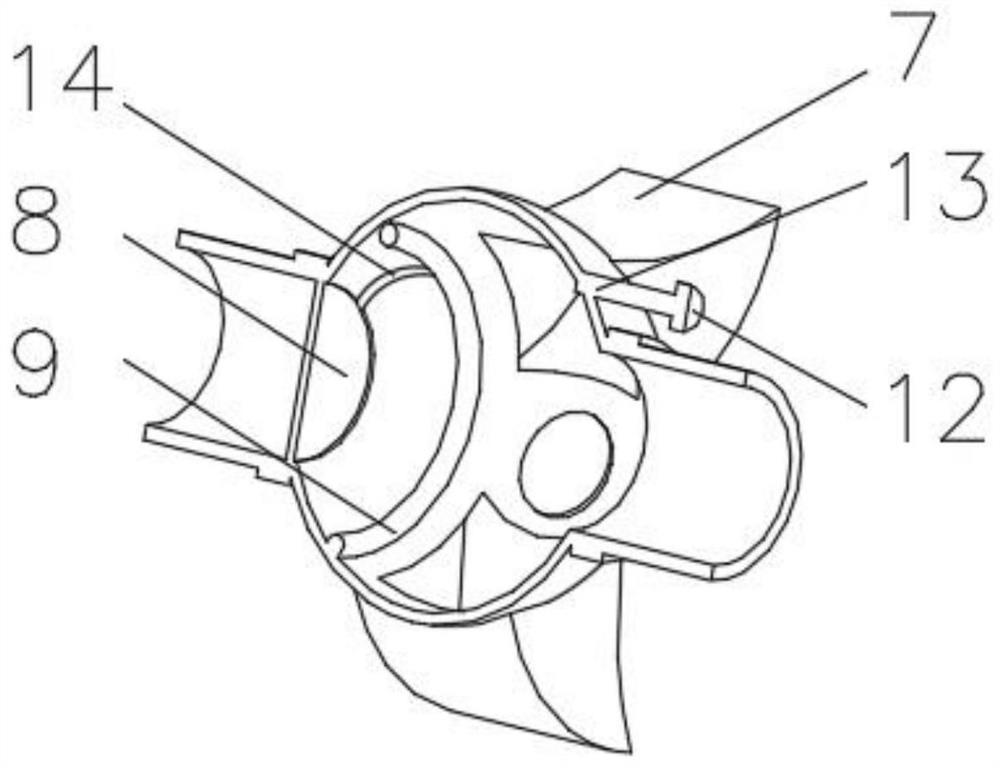

Dry-wet separation device for pig house excrement recycling

ActiveCN111362547ASimple structureImprove interference separation effectSludge treatmentWaste water treatment from animal husbandryAgricultural scienceMechanical engineering

The invention belongs to the technical field of excrement recycling equipment, and mainly relates to a dry-wet separation device for pig house excrement recycling. The device comprises a separation cylinder, a driving cylinder and a first collecting tank, a mounting frame is arranged at the top end of the separation cylinder, the driving cylinder is mounted on the mounting frame, an extrusion block is mounted on an output shaft of the driving cylinder, a plurality of first filter holes are uniformly formed in the extrusion block, the extrusion block is positioned in the separation cylinder, two communicating openings are formed in the side wall of the separation cylinder, a feeding cabin and a liquid discharging cabin are integrally formed at the two communicating openings of the separation cylinder respectively, two storage cabins are formed in the cylinder wall of the separation cylinder, the two storage cabins are located at the communicating position of the separation cylinder andthe feeding cabin and the communicating position of the separation cylinder and the liquid discharging cabin correspondingly, and movable baffles are installed in the storage cabins correspondingly. The problems that at present, dry-wet separation equipment is complex in structure and poor in separation effect are solved.

Owner:HANGZHOU XINGYUAN FILTER TECH +1

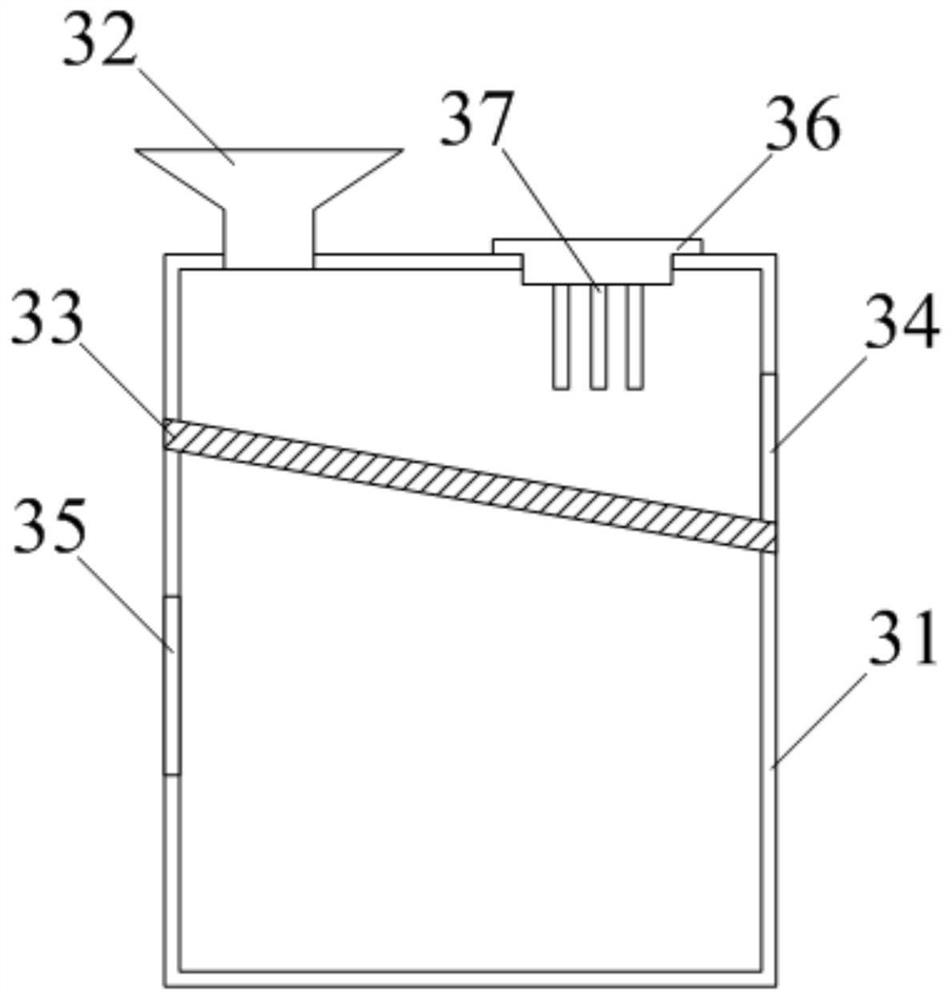

Chemical waste storing tank facilitating solid and liquid separation

ActiveCN108100508AEasy to separateTo achieve the purpose of solid-liquid separationLarge containersStationary filtering element filtersFiltrationEngineering

The invention discloses a chemical waste storing tank facilitating solid and liquid separation. The chemical waste storing tank comprises a tank body. A filtration screen plate is arranged in the tankbody in an inclined manner. The left side and the right side of the filtration screen plate are fixedly connected with the inner wall of the left side and the inner wall of the right side of the tankbody. An opening is formed in the portion, close to the connecting portion of the filtration screen plate, of the right side of the tank body. A limiting groove is formed in the bottom of the opening. The top of the opening is provided with a groove. An elastic telescoping rod is fixedly connected to the top of the groove. A stop block is fixedly connected to the bottom end of the elastic telescoping rod. A feeding opening is formed in the top of the tank body. A base is fixedly connected to the bottom of the tank body. The surface of the tank body is fixedly sleeved with a horizontal supporting plate. A storage battery and a control switch are fixedly connected to the upper surface of the horizontal supporting plate. Electric hydraulic push rods are fixedly connected to the four cornersof the lower surface of the horizontal supporting plate correspondingly. The chemical waste storing tank is simple in structure, convenient to use and capable of separating solid chemical waste and liquid chemical waste easily and efficiently, danger to environment is reduced, and moving of the chemical waste storing tank is facilitated.

Owner:洛阳市奇航化工有限公司

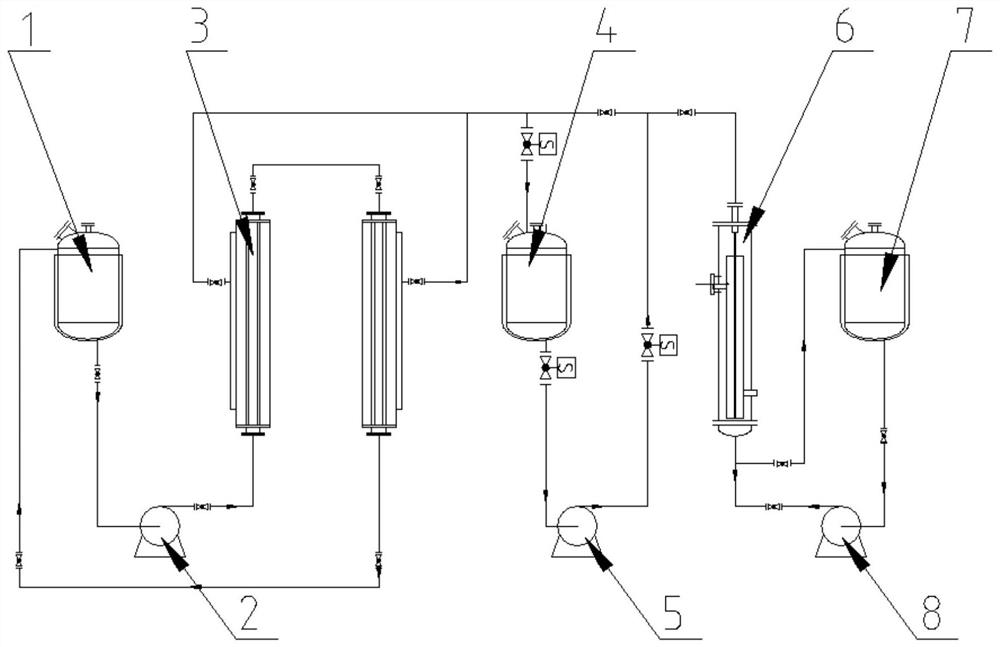

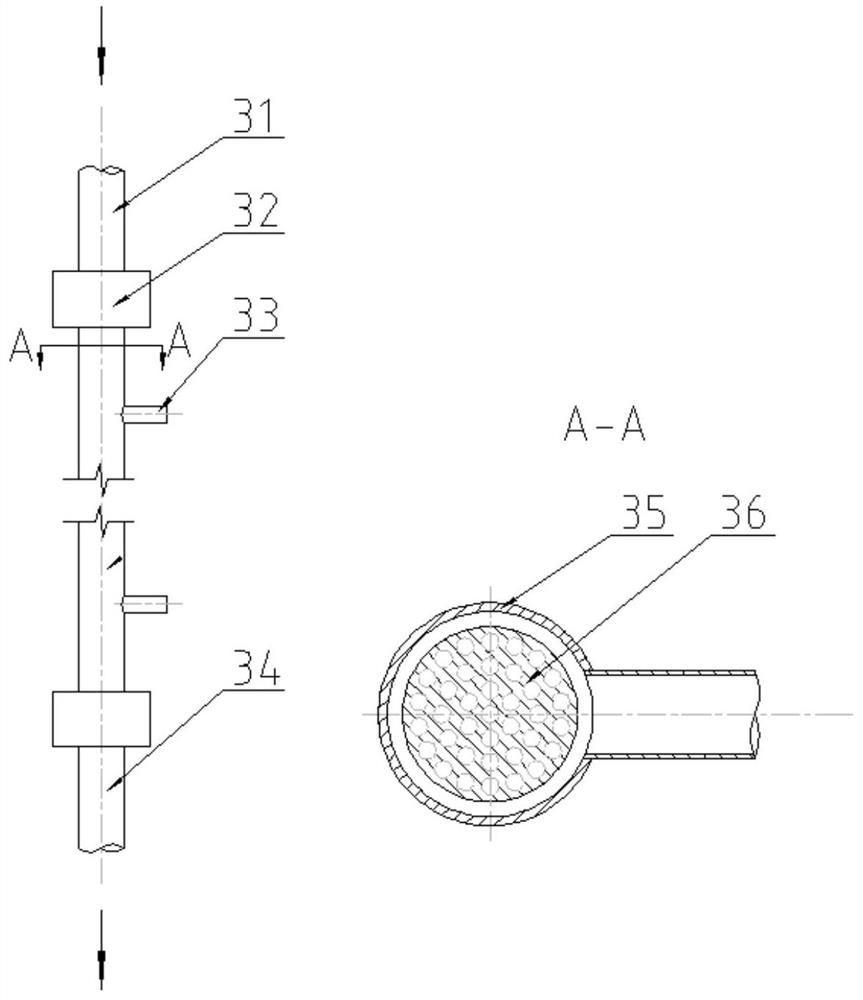

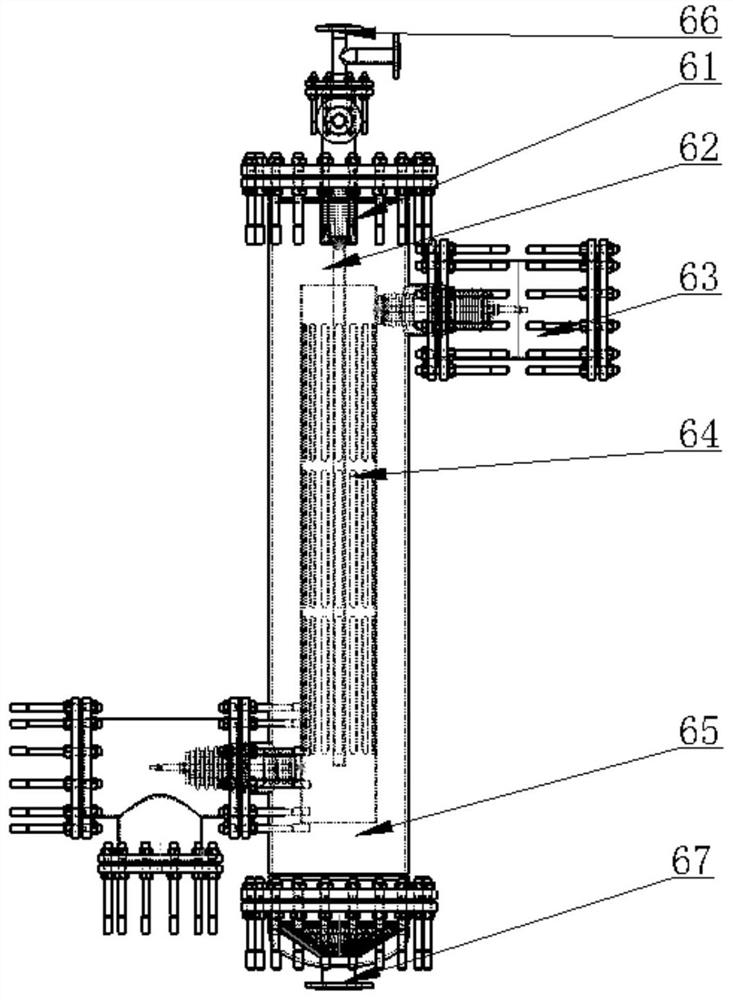

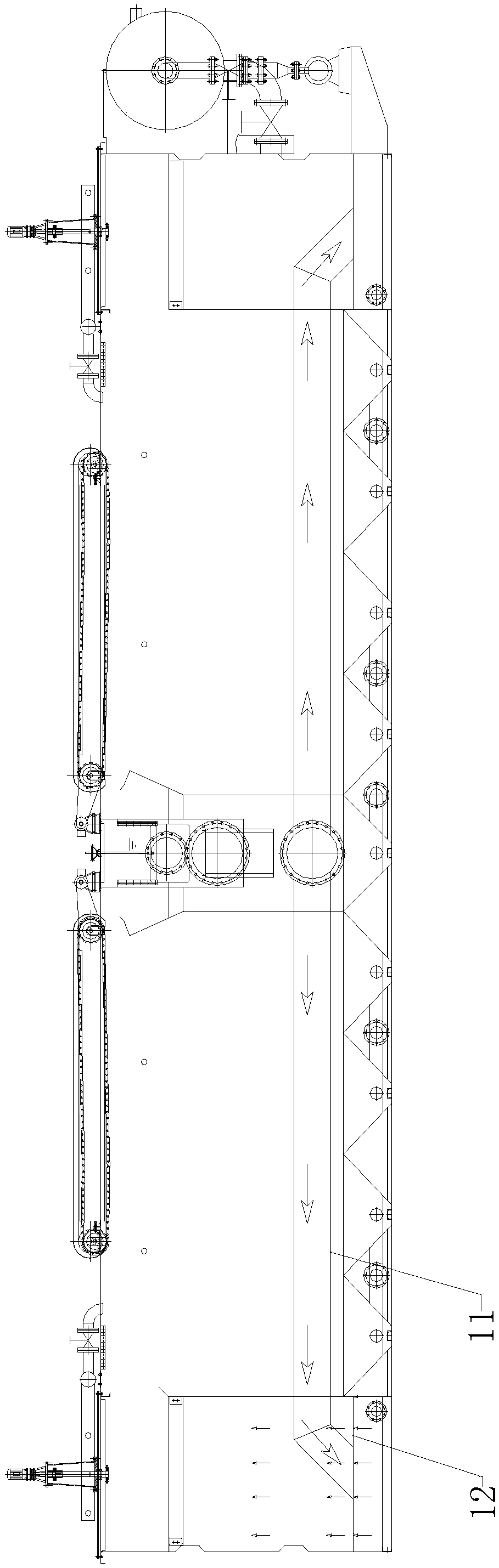

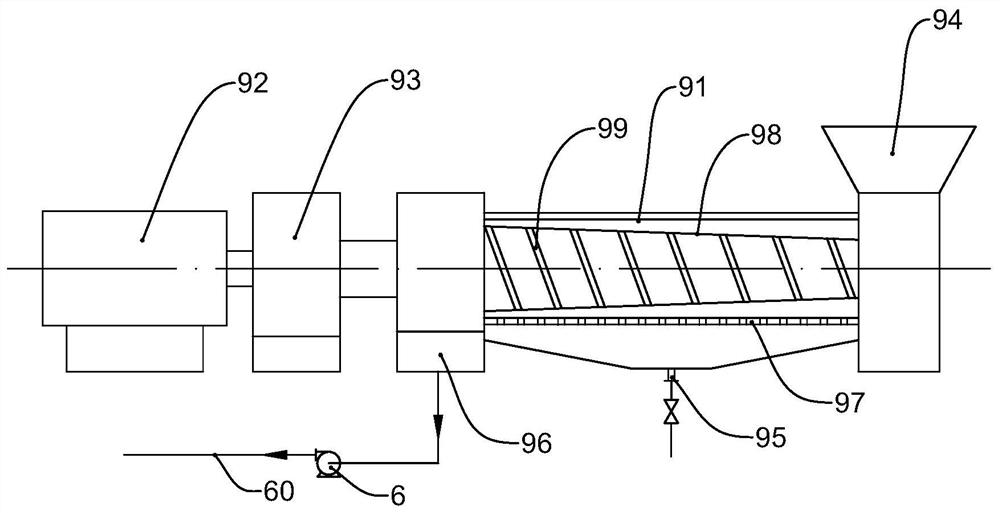

Oil slurry separation system and separation method

PendingCN112063416AReduce areaHigh open porosityPetroleum wax refiningFatty-oils/fats refiningCarbide siliconElectrostatic separation

The invention provides an oil slurry separation system and separation method, the oil slurry separation system comprises a silicon carbide ceramic membrane module separation process and an electrostatic separation process, the silicon carbide ceramic membrane module separation process adopts a silicon carbide ceramic membrane module as a main component to filter solid particles in a medium; in theelectrostatic separation process, an electrostatic separator is used as a main component to adsorb and remove solid particles in a medium. According to the invention, a process of combining a membrane filtration technology and an electrostatic separation technology is used, so that the purification grade and precision are improved, the method is effective for large-particle-size particles, and small-particle-size particles can be effectively removed through the electrostatic separator.

Owner:XIANGYANG JIUDING HAOTIAN ENVIRONMENTAL PROTECTION EQUIP

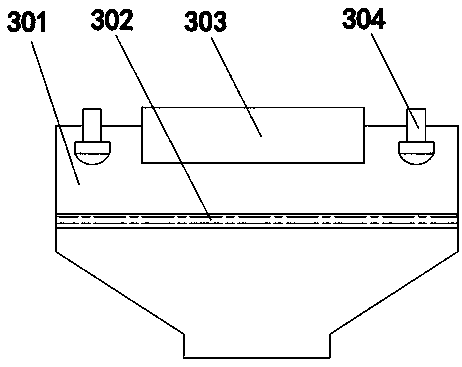

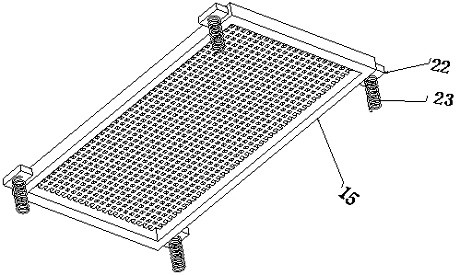

Dry and wet garbage separation sanitation box

InactiveCN112478498ASpeed up the fallImprove flowWaste collection and transferRefuse receptaclesWater filterAgricultural engineering

The invention relates to the technical field of sanitation boxes, and particularly relates to a dry and wet garbage separation sanitation box. The dry and wet garbage separation sanitation box comprises a box body, wherein a screening frame is arranged between a filtrate collecting cavity hopper and a water filtering net plate; the screening frame comprises medium vibration frames; the four mediumvibration frames are arranged at the four corners; upper edge supporting rods are arranged at the tops of the medium vibration frames; frame erecting plates are arranged at the four corners of the water filtering net plate; buffer springs are arranged on the bottom planes of the frame erecting plates; the tops of the upper edge supporting rods are erected in notches of the frame erecting plates but are not fixedly installed; the buffer springs are connected between the upper planes of the frame erecting plates and the medium vibration frames; lower edge supporting rods are arranged at the bottoms of the medium vibration frames; the lower edge supporting rods are telescopic movable rods; a fixed bottom block is arranged on the edge of the filtrate collecting cavity hopper; the bottom endsof the telescopic movable rods are fixedly installed on the fixed bottom block; and the telescopic movable rods are wound with the buffer springs. According to the dry and wet garbage separation sanitation box, the technical effect of triple vibration is achieved, flowing of the auxiliary retained water liquid is improved, and the purpose of solid-liquid separation is achieved.

Owner:湖南盛瑞环保科技有限公司

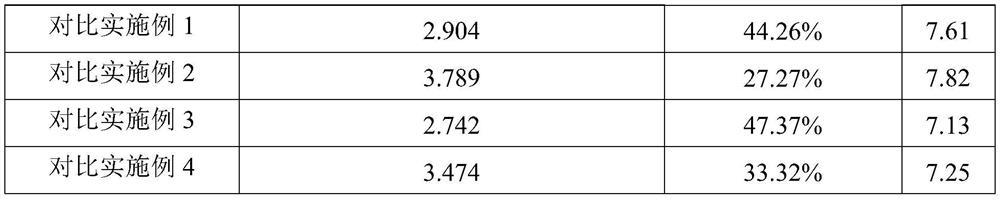

Bauxite separation flocculant and preparation method thereof

ActiveCN104607322ATo achieve the purpose of solid-liquid separationIncrease concentrationDifferential sedimentationFiltrationSolid content

The invention discloses a bauxite separation flocculant and a preparation method of the bauxite separation flocculant and relates to a separation process suitable for aluminosilicate minerals. The bauxite separation flocculant is characterized by being a comb-type quadripolymer, and the bauxite separation flocculant is formed by polymerizing four monomers of acrylamide, sodium acrylate, acrylic hydroximic acid and allyl sulfoacid. The acrylamide, the sodium acrylate, the acrylic hydroximic acid and the allyl sulfoacid are polymerized with the existence of a catalyst, namely NdCl3-ProH, and are synthesized to be the quadripolymer provided with a comb-type structure. By adjusting the ratio of the materials and technological parameters, the molecular weight, the hydrolyzing degree and the molecular structure of the flocculant are changed, so that the requirements of different types of minerals are met. According to the bauxite separation flocculant, the defects of an existing flocculant are overcome, and the vacancy of a special flocculant for bauxite separation is made up for. The bauxite separation flocculant has the advantages of being high in sedimentation velocity, high in ability to capture fine particles, low in viscosity, low in usage quantity and the like. Products which are separated and processed through the method are clear in backwater and can be directly reused. Sediment underflow is high in solid content and low in viscosity and improves the working efficiency of conveying and pressure filtration.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

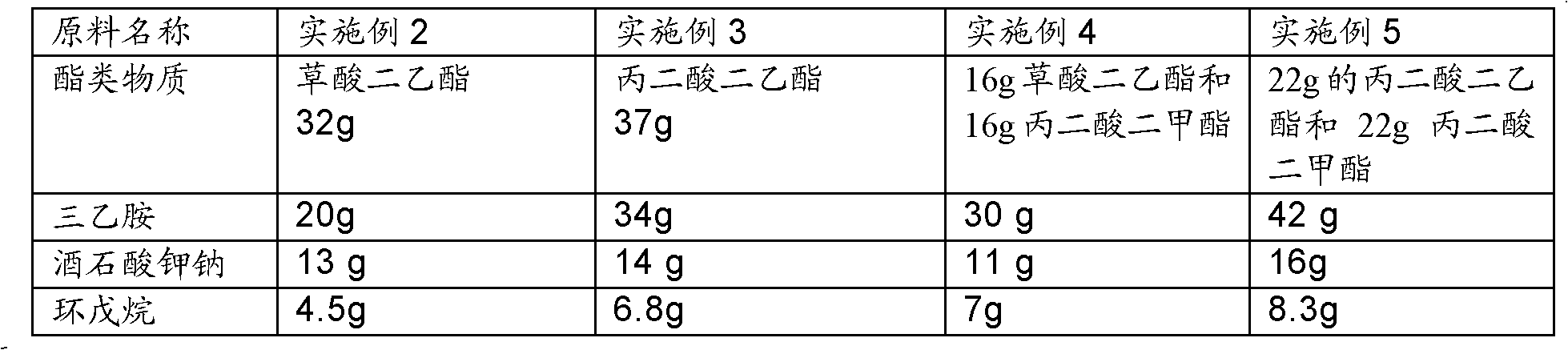

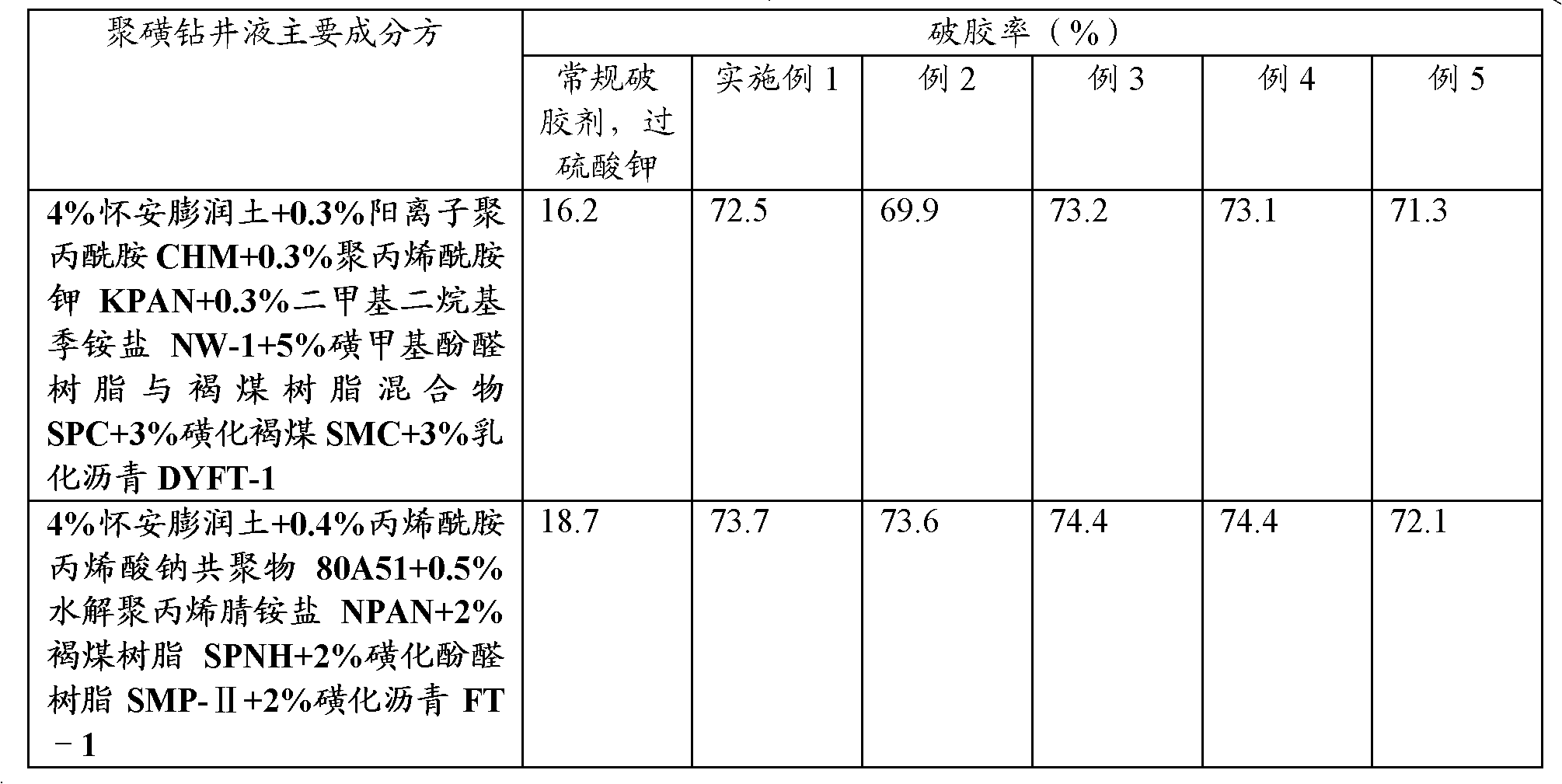

Solid-liquid separation gel breaker for waste polysulfide drilling fluid and preparation method thereof

ActiveCN102068936AGood glue breaking effectStable network structureTransportation and packagingMixingOrganic solventAlcohol

The invention relates to a solid-liquid separation gel breaker for waste polysulfide drilling fluid and a preparation method thereof. The solid-liquid separation gel breaker for waste polysulfide drilling fluid is prepared from the following steps of: a, adding 10 to 50 weight parts of ester substance selected from one or more of diethyl oxalate, dimethyl malenate and diethyl malonate and 20 to 70 weight parts of triethylamine into a reactor and raising the temperature to 80 DEG C under a continuously stirring condition; b, adding 10 to 20 weight parts of sodium potassium tartrate tetrahydrate and 3 to 10 weight parts of cyclopentane, raising the temperature to 120 DEG C, preserving heat at the temperature of 120 DEG C, heating for 6 hours and stopping heating; and c, when the temperaturein the reactor falls to be between 25 DEG C and 40 DEG C, taking a reactant out, washing with an alcohol organic solvent, filtering and drying.

Owner:CHINA NAT OFFSHORE OIL CORP +2

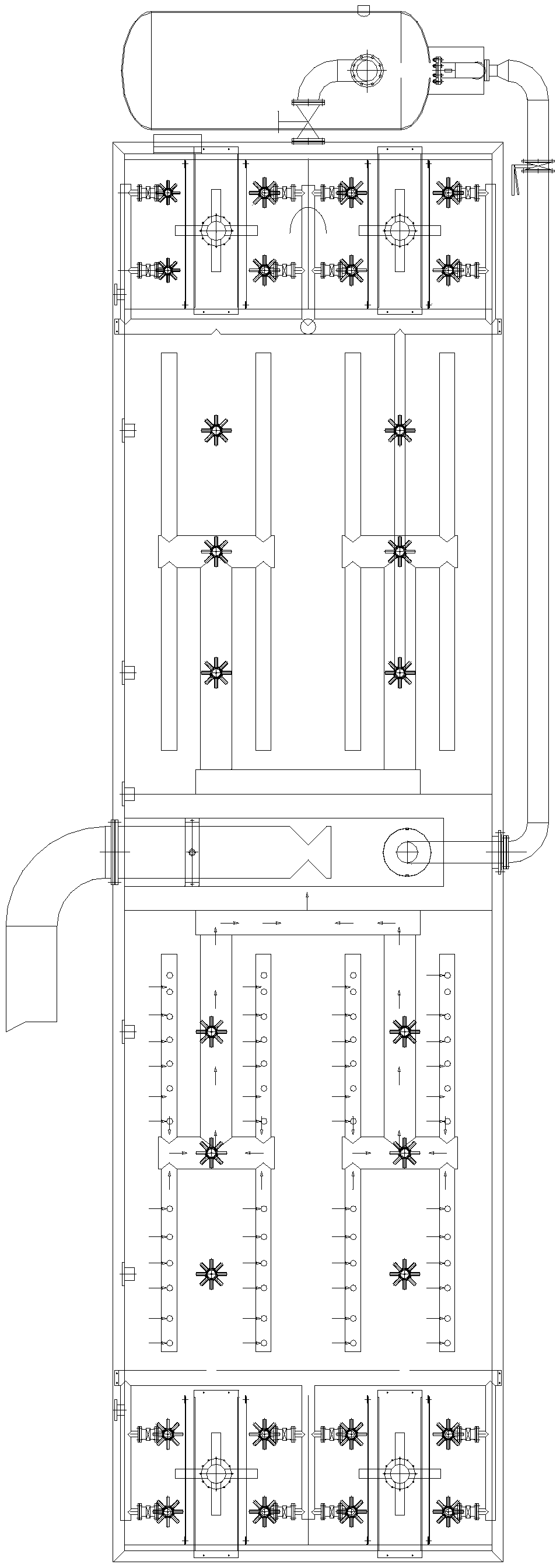

High-concentration sewage treatment air flotation equipment

PendingCN108975562ANot easy to sinkImprove the efficiency of sewage treatmentMultistage water/sewage treatmentWater/sewage treatment by flotationWater solubleHigh concentration

The invention relates to a high-concentration sewage treatment air flotation device. The device comprises a pool body in which a contact chamber and a separation chamber which are communicated with each other are arranged, and further comprises a medicament adding hole which is communicated with the contact chamber and used for throwing in a flocculating agent or medicament, and the contact chamber is further provided with a release device for releasing water-soluble gas and a stirring device for stirring liquid. According to the high-concentration sewage treatment air flotation device, the flocculating agent body is difficult to sink, and the sewage treatment efficiency is high.

Owner:WUXI HI TECH ENVIRONMENTAL PROTECTION EQUIP TECH

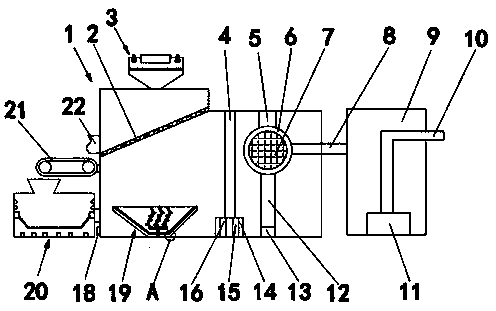

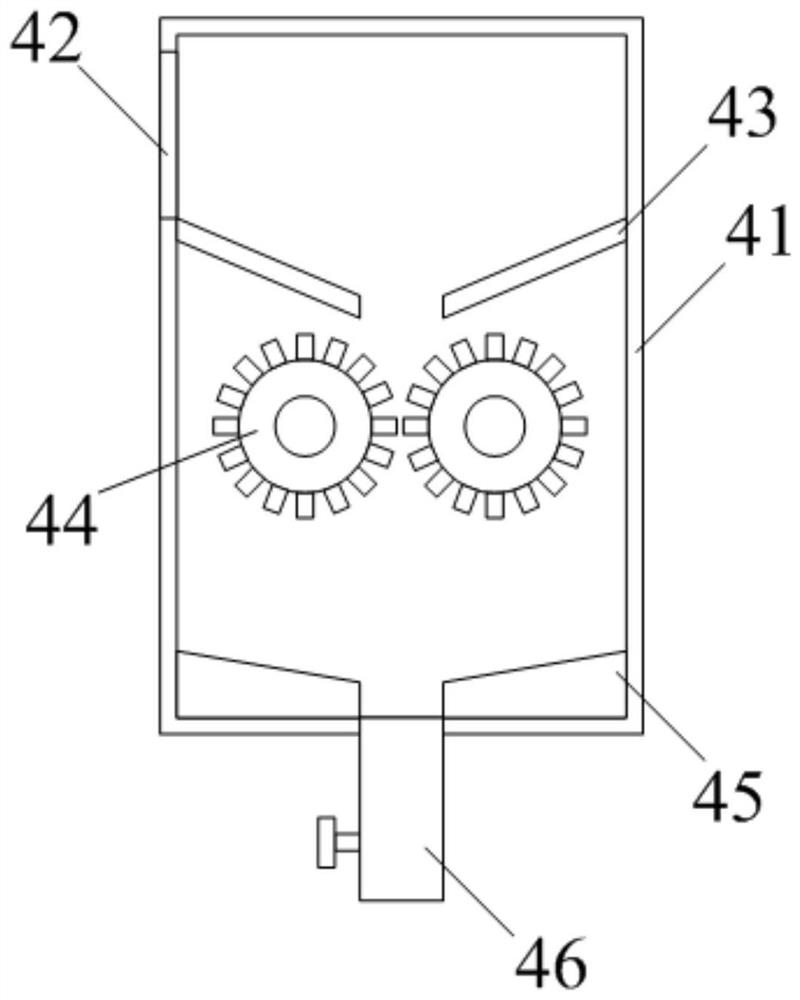

Smart city garbage environment-friendly treatment system

InactiveCN113042150ATo achieve the purpose of solid-liquid separationAvoid damageMagnetic separationGrain treatmentsElectric machineEngineering

The invention discloses a smart city garbage environment-friendly treatment system. The system comprises a bottom plate, supporting legs, an impurity removal assembly, a crushing assembly and an electric control cabinet. According to the system, through arrangement of the impurity removal assembly, garbage enters an impurity removal box through a feeding pipe, solid garbage enters the crushing assembly through a discharging opening and a through hole along a filter screen, liquid falls to the lower side of the interior of the impurity removal box through the filter screen, the purpose of solid-liquid separation of the garbage is achieved, and solid and liquid separation treatment is facilitated; strong magnetic strips attract magnetic metal in the solid waste, and the situation that the magnetic metal enters the crushing assembly and damages the crushing assembly is avoided; through arrangement of the crushing assembly, the solid waste enters the space between crushing rollers through a material guide plate, a driving motor connected with the crushing rollers is powered on to run, the driving motor drives the crushing rollers to rotate, the crushing rollers crush the solid waste, the crushed solid waste can be recycled subsequently, and the environment-friendly requirement for resource recycling is met.

Owner:中山市满鑫科技有限公司

Injection squeezing machine

PendingCN112793210ATo achieve the purpose of solid-liquid separationPressesSeparation technologyInjected material

The invention provides an injection squeezing machine and relates to the technical field of solid-liquid separation. The injection squeezing machine comprises a material injection device and a separation bin, wherein the separation bin comprises a separation bin feed port and a separation bin discharge port which are located at the two ends of the separation bin, the material injection device is communicated with the separation bin feed port, and the material injection device is used for injecting materials into the separation bin; and a filtering device is arranged on the side wall of the separation bin, is located between the separation bin feed port and the separation bin discharge port, and is used for filtering and discharging liquid substances in the materials.

Owner:吴苏

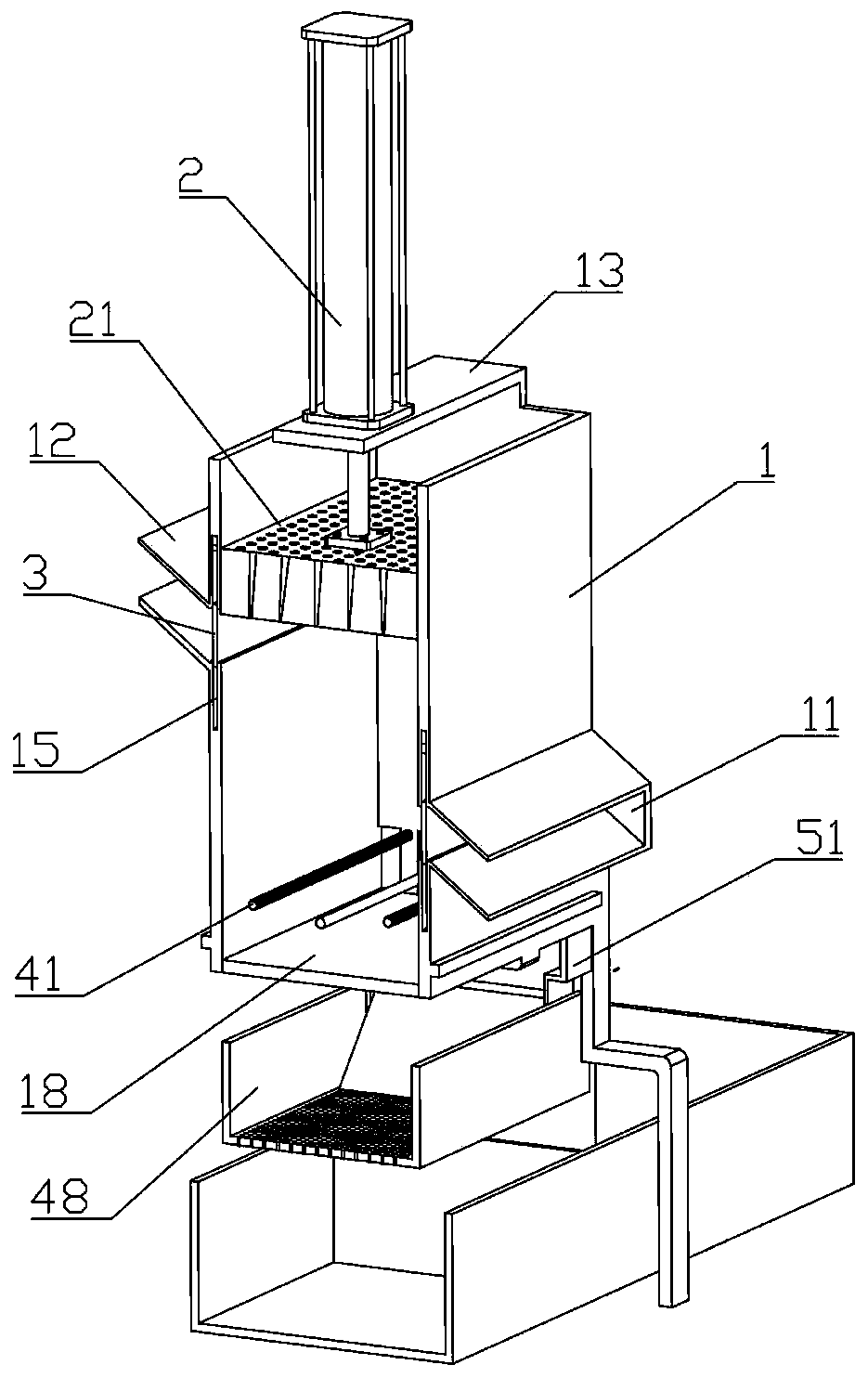

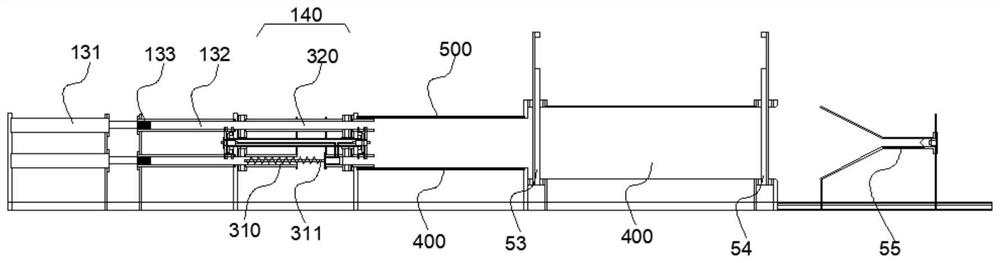

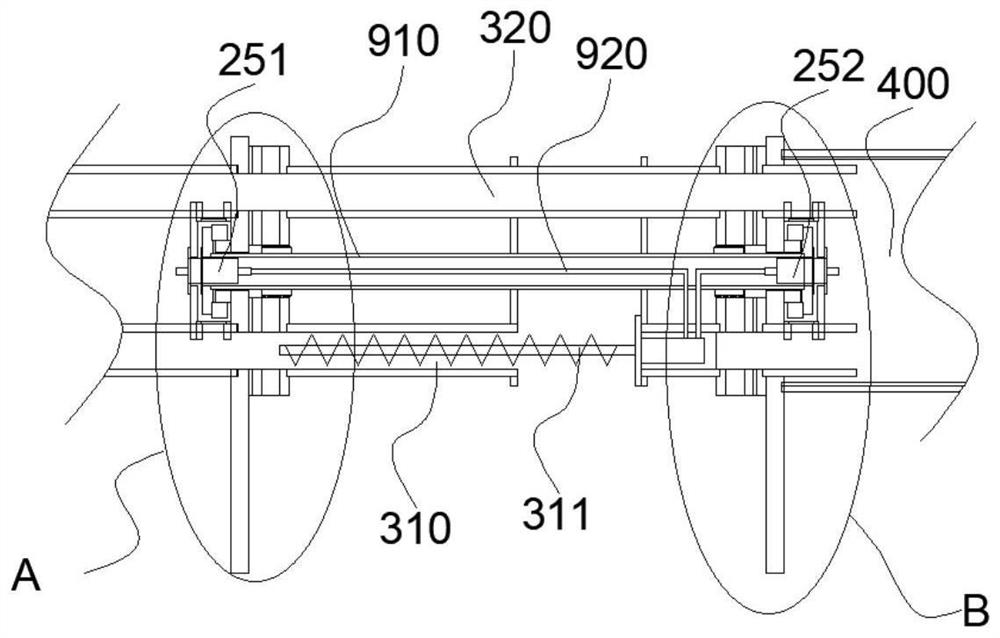

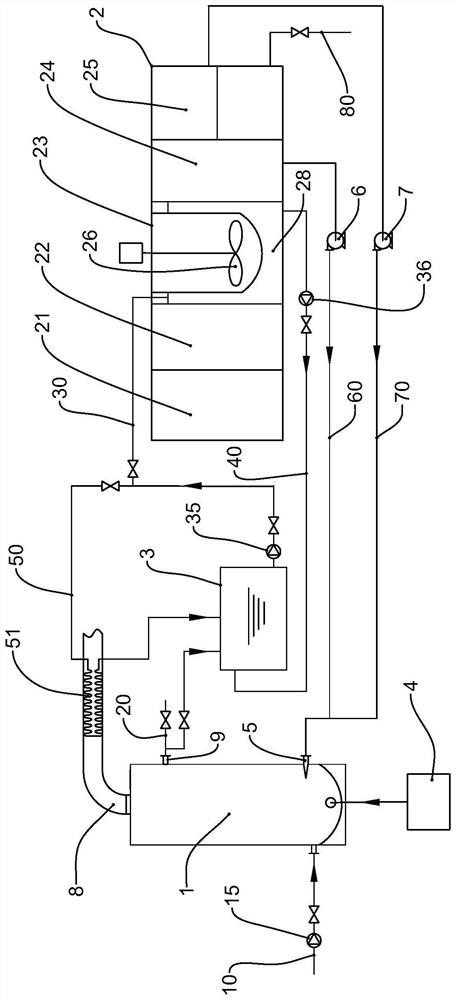

Kitchen waste hydrogen-rich energy machine

PendingCN111998357ASave fuelHelp the environmentSolid waste disposalWater heatersCombustion chamberWater jacket

The invention discloses a kitchen waste hydrogen-rich energy machine. The kitchen waste hydrogen-rich energy machine comprises a hot water boiler (1), a kitchen waste processor main body (2), a hot water tank (3) and a hydrogen-rich generating device (4), wherein the kitchen waste processor main body (2) comprises a compression finishing section (21), a crushing section (22), a stirring heating section (23) and a dewatering section (24), a stirrer (26) is arranged in a stirring cylinder (27) of the stirring heating section (23), a heating water jacket (28) is arranged outside the stirring cylinder (27), the hot water tank (3) supplies water to the heating water jacket (28) through a hot water circulating pump (35) via a hot water supply pipeline (30), water in the heating water jacket (28)flows back into the hot water tank (3) through a hot water return pump (36) via a water return line (40), slurry kitchen waste treated by the dehydration section (24) is pumped to a slurry ejector (5) through a slurry pump (6) via a slurry pipeline (60) and is ejected into a combustion chamber of the hot water boiler (1) to be combusted as biomass fuel, and hydrogen is fed into the combustion chamber of the hot water boiler (1) by a hydrogen-rich generating device (4) to support combustion. The kitchen waste hydrogen-rich energy machine can be widely applied to the energy combustion field.

Owner:慧生能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com