Solid-liquid separation gel breaker for waste polysulfide drilling fluid and preparation method thereof

A technology of solid-liquid separation and gel breaker, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of inability to perform flocculation and other treatment steps, and the difficulty of colloidal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 34g of dimethyl malonate and 35g of triethylamine into a stainless steel high-temperature and high-pressure reactor, and raise the temperature to 80°C under constant stirring; then add 15g of potassium sodium tartrate; and dropwise add 5.5g of cyclopentane, At the same time, the temperature rises to 120°C, and is heated at a constant temperature of 120°C for 6 hours, and then the heating is stopped; when the temperature in the high-temperature and high-pressure reactor drops to 40°C, open the reactor, pour the reactants into ethanol, and wash with ethanol (ethanol can be reused), filtered and dried to obtain a white solid gel breaker for waste polysulfide drilling fluid.

[0024] Take the obtained gel breaker, carry out solid-liquid separation waste polysulfide drilling fluid treatment on the offshore platform, add 0.2wt% waste polysulfide drilling fluid gel breaker of total weight to waste polysulfide drilling fluid, significantly improve waste polysulfide drilling ...

Embodiment 2-5

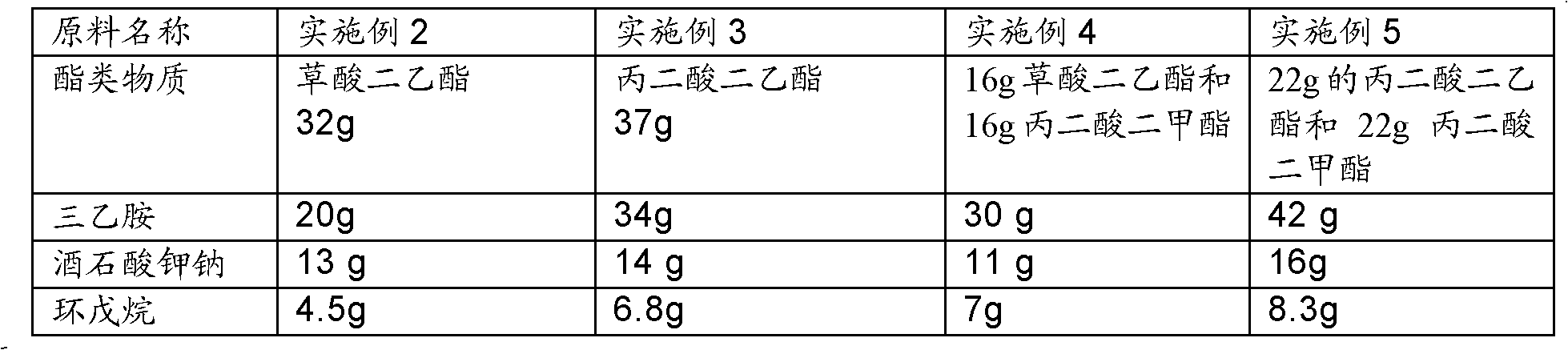

[0026] The amount of each component of Examples 2-5 is shown in Table 1 below, and the preparation process is the same as that of Example 1.

[0027] Table 1

[0028]

[0029] Performance evaluation:

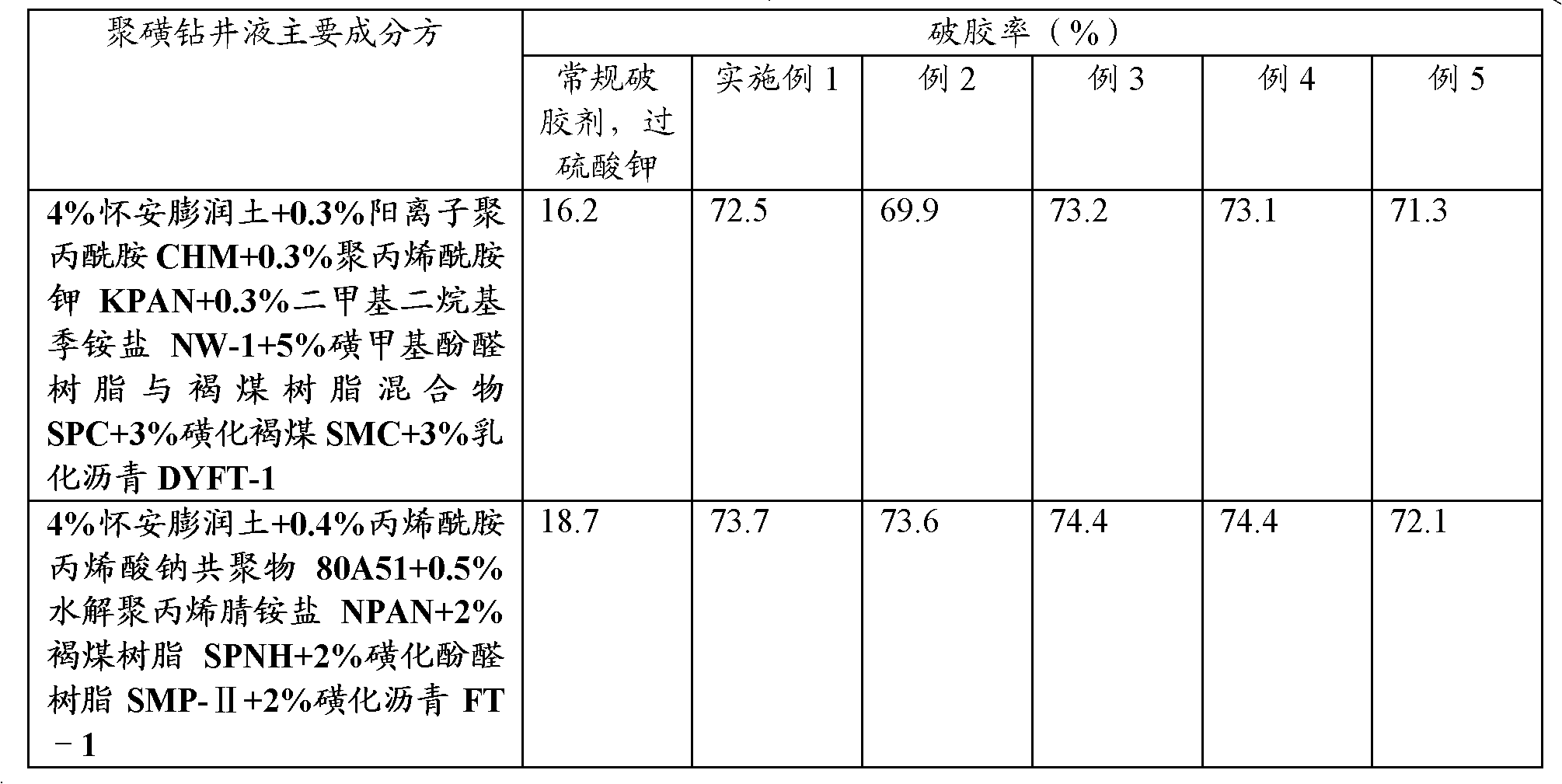

[0030] 0.2 wt% of the gel breaker prepared in Examples 1-5 was added to the waste polysulfide drilling fluid added with the conventional gel breaker potassium persulfate, and the gel breaking rate data are shown in Table 2.

[0031] Table 2

[0032]

[0033] Drilling fluid has a network structure. Due to the presence of sulfonated groups in the network structure of high temperature resistant polysulfide drilling fluid, its structure is more stable. How to destroy this stable network structure and destabilize it is the most efficient solidification method for waste polysulfide drilling fluid. The key to liquid separation technology. Potassium persulfate, a conventional gel breaker, is an oxidizing agent that destroys the network structure of drilling fluid through oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com