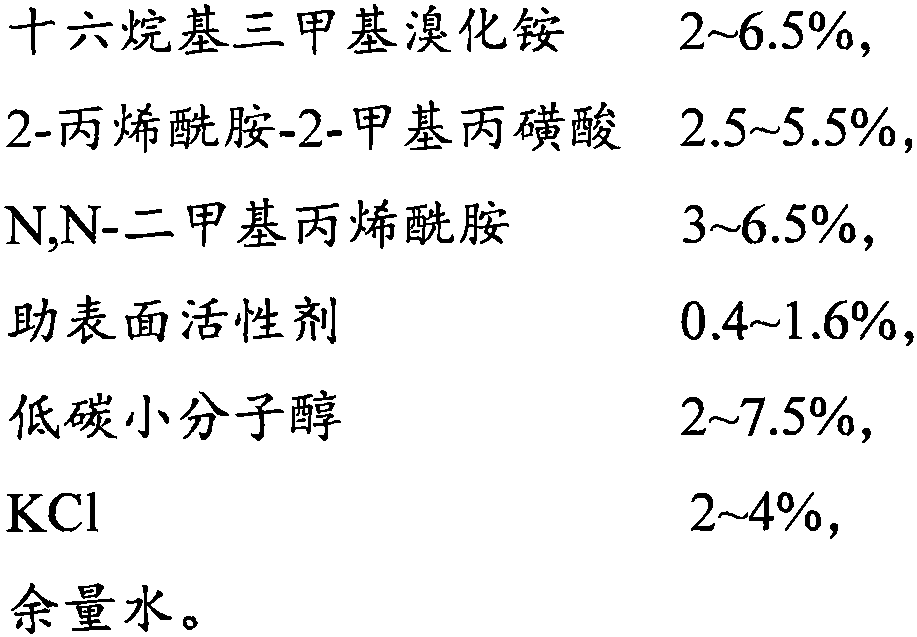

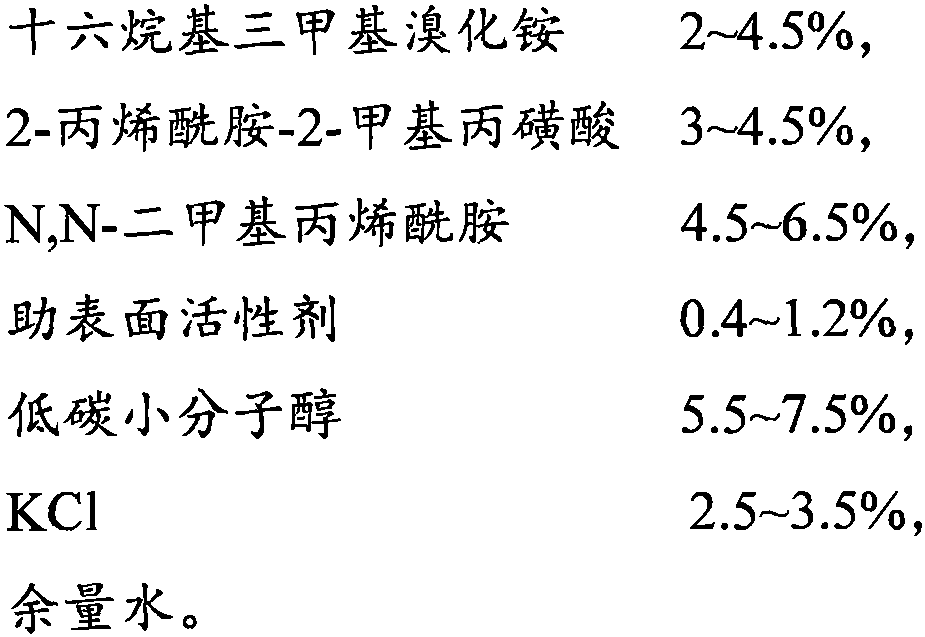

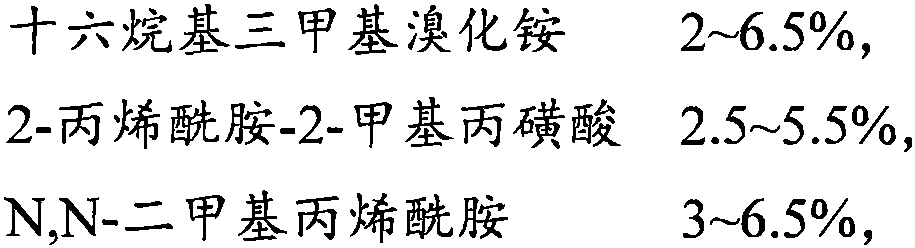

Shale gas fracturing fluid and preparation method thereof

A gas pressure and shale technology, which is applied in the field of shale gas fracturing fluid and its preparation, can solve the problems of formation permeability damage, affecting the effect of fracturing production increase, etc., and achieve formation permeability without damage, good gel breaking effect, easy The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides the preparation method of the shale gas fracturing fluid described in the above scheme, comprising the following steps:

[0033] (1) Mix cetyltrimethylammonium bromide, 2-acrylamide-2-methylpropanesulfonic acid, N, N-dimethylacrylamide, KCl and water under heating conditions, and after cooling get mixed solution;

[0034] (2) Mixing the mixed liquid with a co-surfactant and low-carbon small molecule alcohol to obtain the shale gas fracturing liquid.

[0035] In the present invention, cetyltrimethylammonium bromide, 2-acrylamide-2-methylpropanesulfonic acid, N, N-dimethylacrylamide, KCl and water are mixed under heating conditions, and obtained after cooling Mixture. In the present invention, the heating temperature is preferably 40-60°C, more preferably 50°C. The present invention has no special requirements on the heating method, and a heating method well known in the art can be used. In the present invention, the order of mixing is p...

Embodiment 1

[0040] A shale gas fracturing fluid, comprising the following components in mass percentage: cetyltrimethylammonium bromide 2%, 2-acrylamide-2-methylpropanesulfonic acid 3.5%, N, N - Dimethacrylamide 5%, Sodium Lauryl Sulfonate 0.7%, Propylene Glycol 3%, KCl 2%, balance water.

[0041] The fracturing fluid is prepared by the following method:

[0042](1) Mix cetyltrimethylammonium bromide, 2-acrylamide-2-methylpropanesulfonic acid, N, N-dimethylacrylamide, KCl and water under heating conditions, and after cooling Obtain a mixed solution; add cetyltrimethylammonium bromide into water to dissolve completely, raise the temperature to 40°C, and then add 2-acrylamide-2-methylpropanesulfonic acid, N,N-dimethyl Acrylamide and KCl were stirred for 70 minutes; each component was uniformly dissolved and cooled to room temperature, and aged at room temperature for 8 hours.

[0043] (2) Add sodium dodecylsulfonate and propylene glycol to the mixed liquid obtained in (1), and stir evenly...

Embodiment 2

[0059] A shale gas fracturing fluid, comprising the following components in mass percentage: cetyltrimethylammonium bromide 3.5%, 2-acrylamide-2-methylpropanesulfonic acid 3.5%, N, N -Dimethacrylamide 4%, sodium tetradecylsulfonate 1%, propylene glycol 3%, KCl 2.5%, balance water.

[0060] The fracturing fluid is prepared by the following method:

[0061] (1) Mix cetyltrimethylammonium bromide, 2-acrylamide-2-methylpropanesulfonic acid, N, N-dimethylacrylamide, KCl and water under heating conditions, and after cooling Obtain a mixed solution; add cetyltrimethylammonium bromide into water to dissolve completely, raise the temperature to 40°C, and then add 2-acrylamide-2-methylpropanesulfonic acid, N,N-dimethyl Acrylamide and KCl were stirred for 70 minutes; each component was uniformly dissolved and cooled to room temperature, and aged at room temperature for 8 hours.

[0062] (2) Add sodium tetradecylsulfonate and propylene glycol to the mixed liquid obtained in (1), and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com