Patents

Literature

969results about How to "Easy to achieve large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

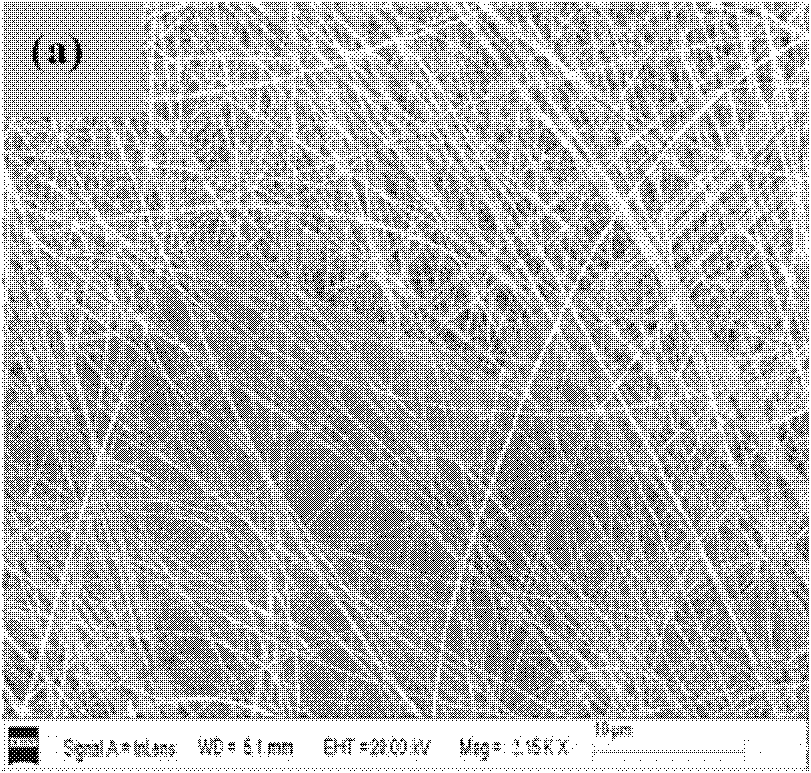

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

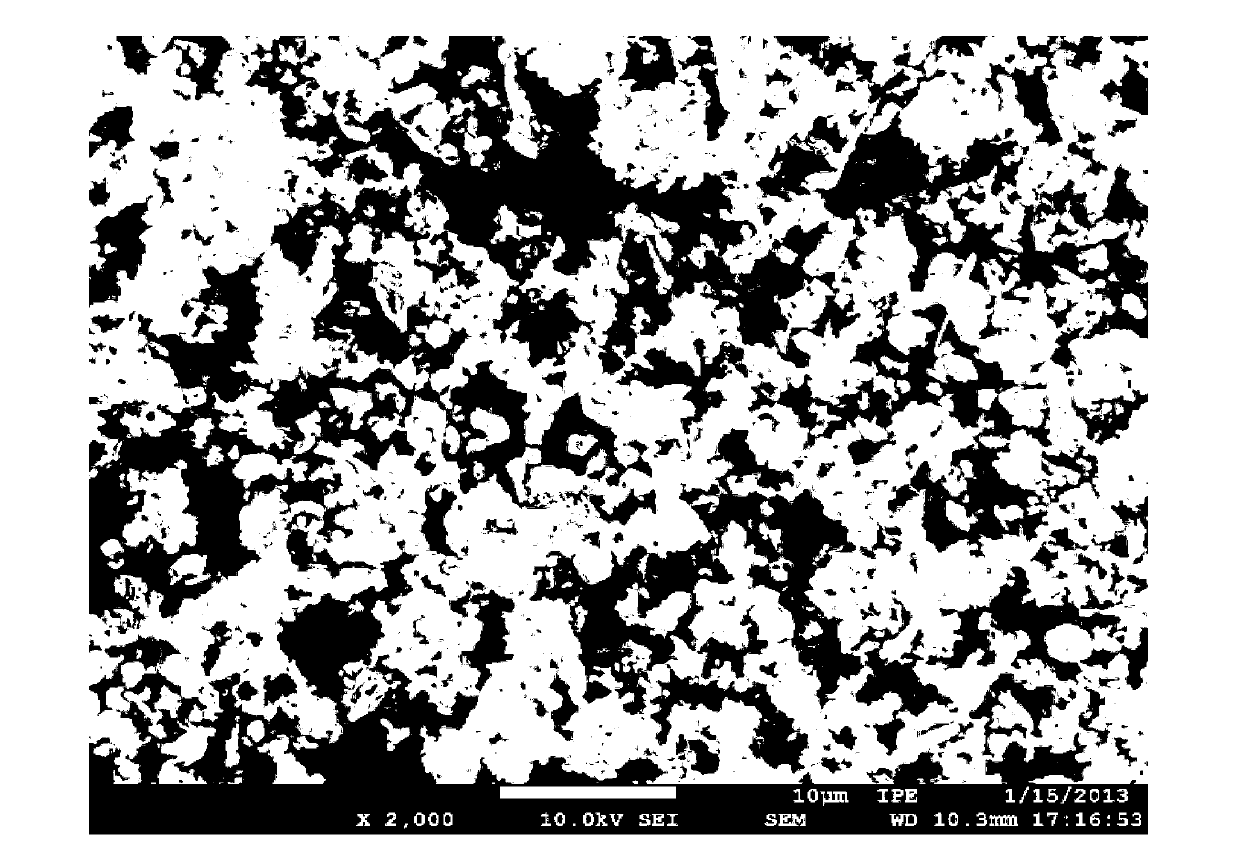

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

Silicon oxide/carbon cathode material of lithium ion battery and preparation method of material

ActiveCN103022446AHigh electrochemical activity and charge-discharge capabilityReduce volume expansion effectCell electrodesSilicon particleLithium electrode

The invention discloses a silicon oxide / carbon cathode material of a lithium ion battery and a preparation method of the material. The silicon oxide / carbon cathode material is a three-layer compound material with a core-shell structure and takes a graphite material as an inner core, porous silicon oxide as a middle layer and organic pyrolytic carbon as an outermost covering layer; and the preparation method comprises a process of preparing porous SiOx and a carbon covering process. Compared with the prior art, active metal is added to reduce SiOx partially, the volume expansion effect of silicon particles is greatly reduced as the volume expansion effect of the silicon particles in the charging and discharging processes can be automatically absorbed by the obtained product structure, and the initial charging and discharging efficiency and the cycling stability are remarkably improved. The initial reversible specific capacity is larger than 600 mAh / g, the initial charging and discharging efficiency is higher than 88%, the capacity retention ratio is higher than 98% after the capacity is cycled for 50 times, the synthetic process is simple and easy to operate, the manufacturing cost is low, and the large-scale production is easy to realize.

Owner:BTR NEW MATERIAL GRP CO LTD

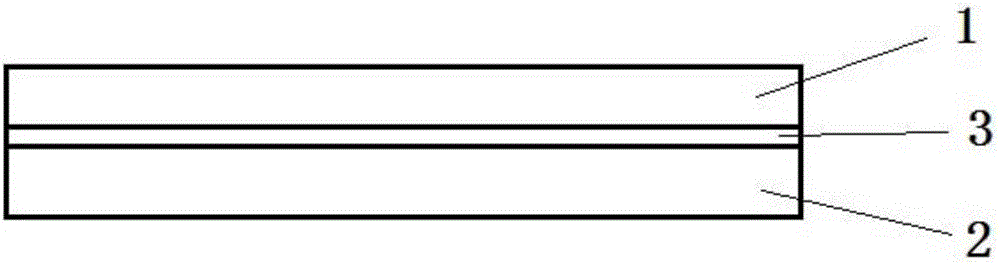

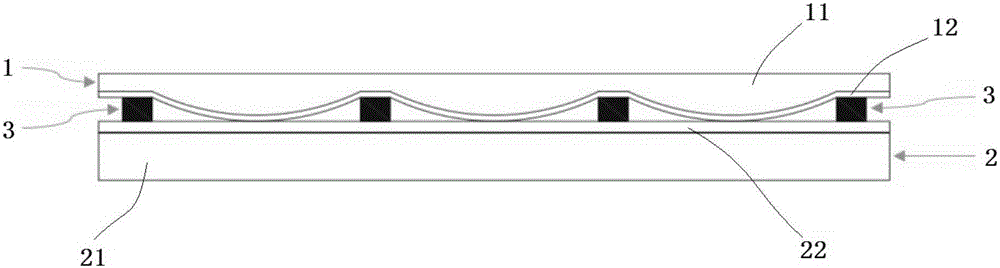

Flexible pressure sensor and preparation method thereof

ActiveCN106197772AHigh sensitivityImprove reliabilityForce measurement using piezo-resistive materialsElectrical resistance and conductanceIsolation layer

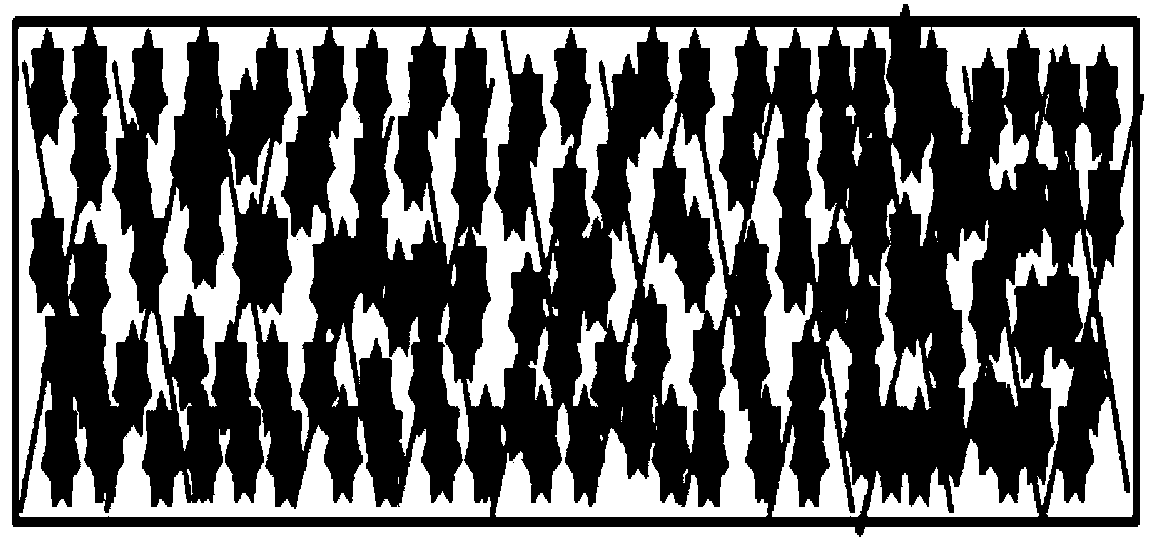

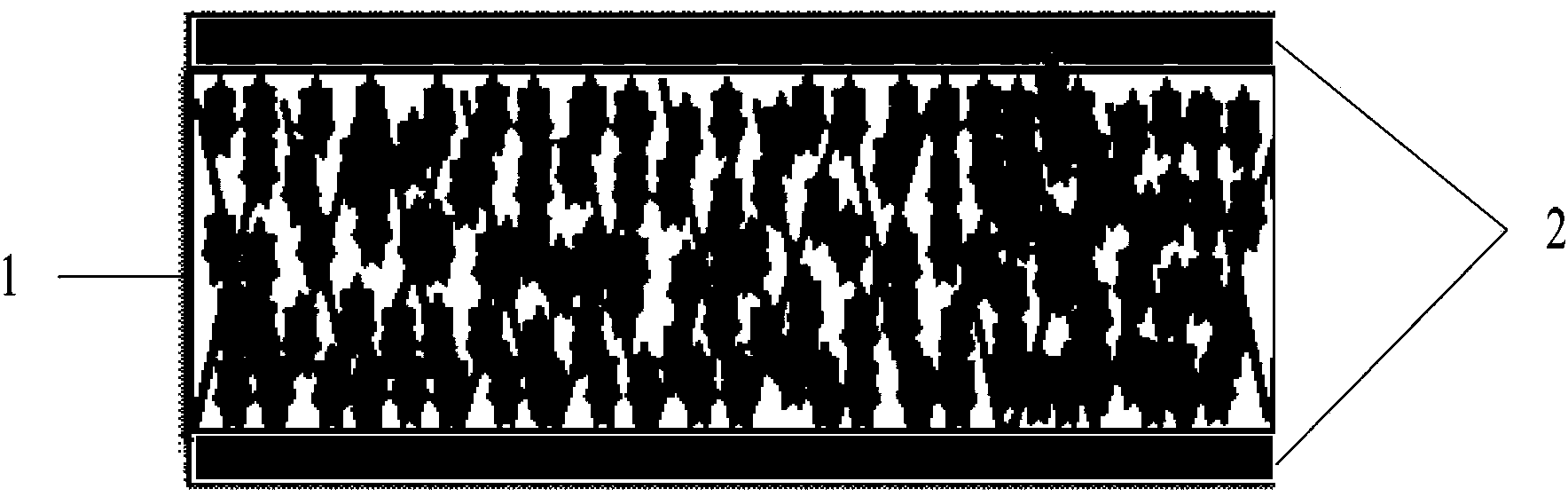

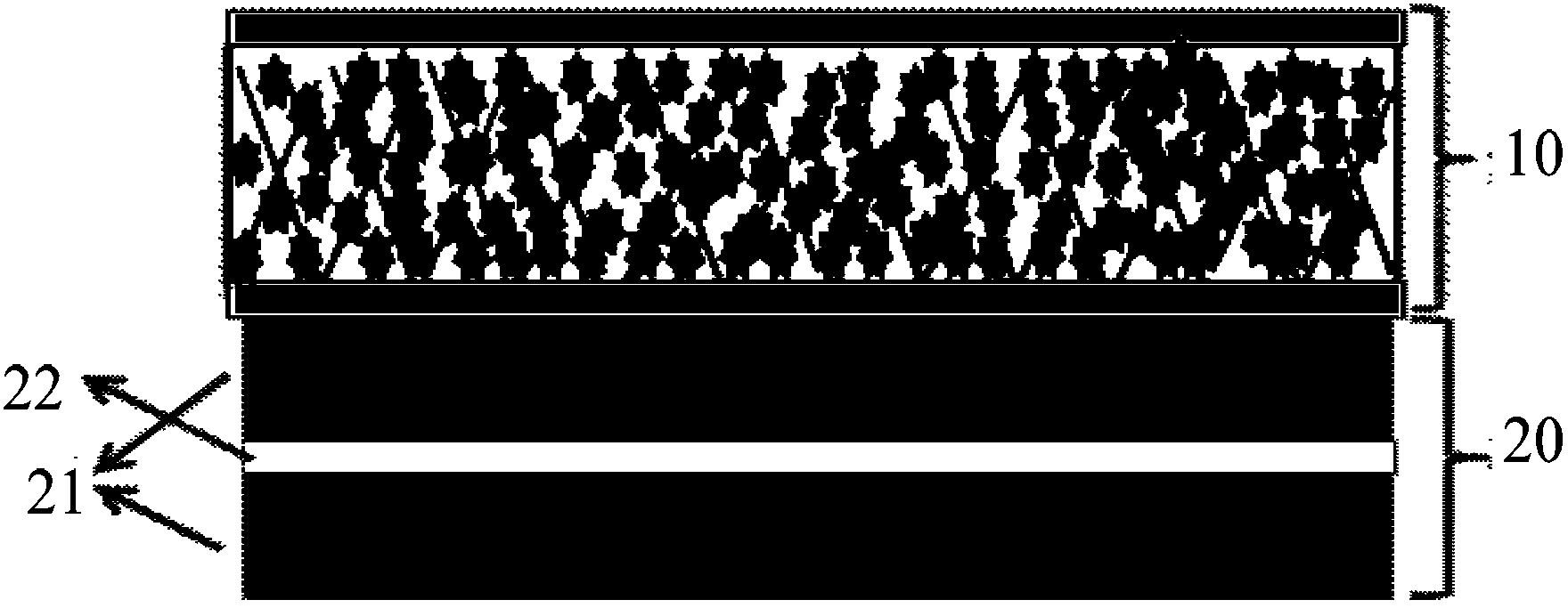

The invention discloses a flexible pressure sensor which comprises an induction layer, a substrate layer, an isolation layer and electrodes. The isolation layer is positioned between the induction layer and the substrate layer and bonded to the induction layer and the substrate layer, and enables electric contact between the induction layer and the substrate layer to be isolated discontinuously; the surface of the induction layer is provided with a first conductive layer, the surface of the substrate layer is provided with a second conductive layer, and the first and second conductive layers are bonded to the isolation layer in opposite directions; and the electrodes are led out of the first or second conductive layer and connected with an external circuit. The flexible pressure sensor is used to detect the size and fluctuation of pressure, a flexible conductive material on the specific substrate is bonded to other conductive substrate, the electrodes are led out, change of resistance between the electrodes is measured, and the size and fluctuation of the pressure is detected in directly. The pressure sensor of high flexibility and high reliability can be applied to a flexible bearing body, technology is simple, and the sensor can be compatible with a present processing technology of a resistant screen to realize scaled production and application.

Owner:常州第六元素半导体有限公司

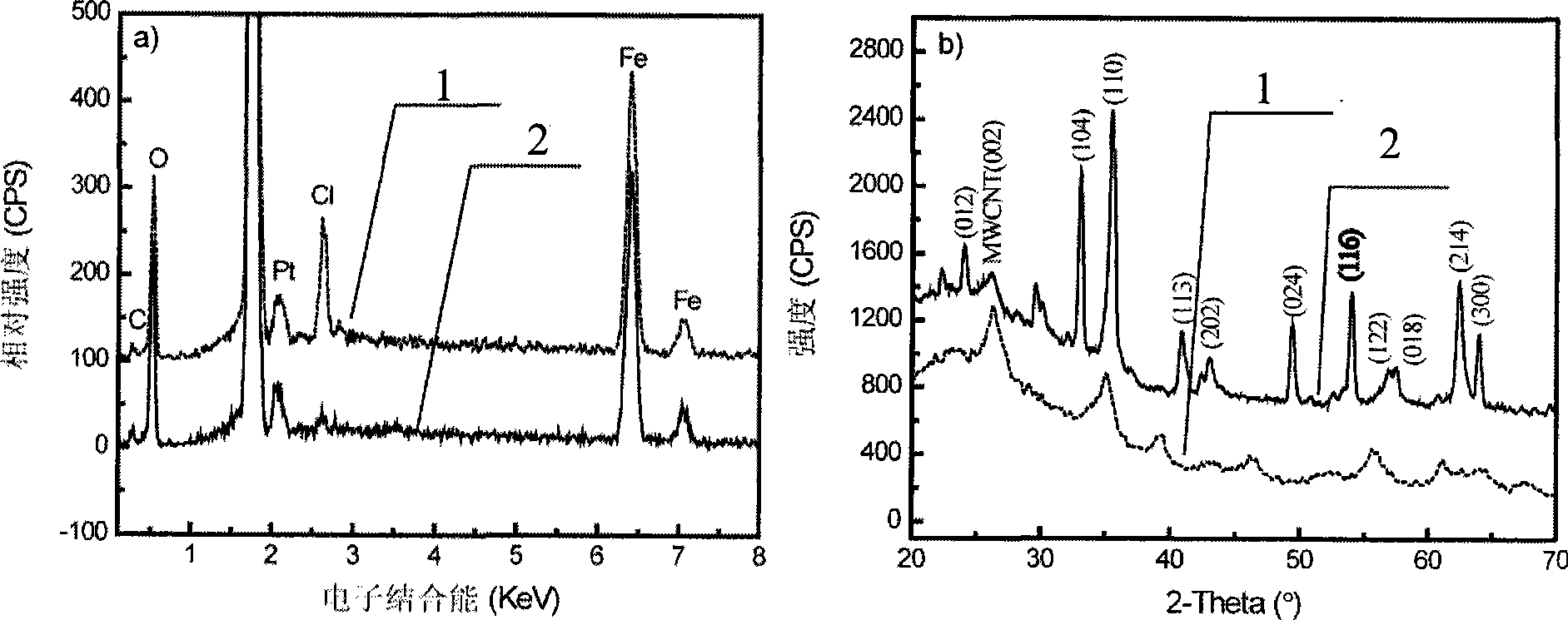

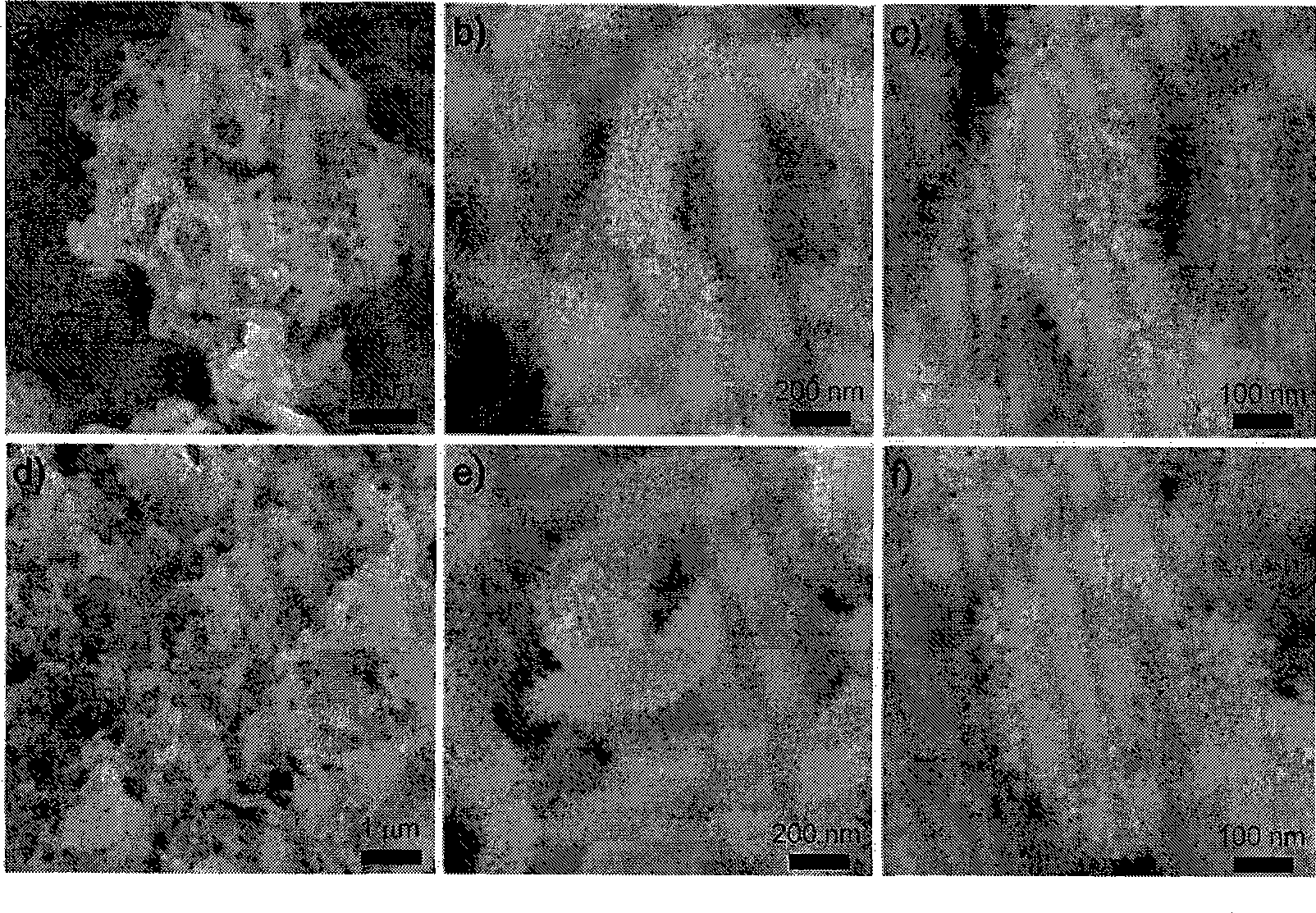

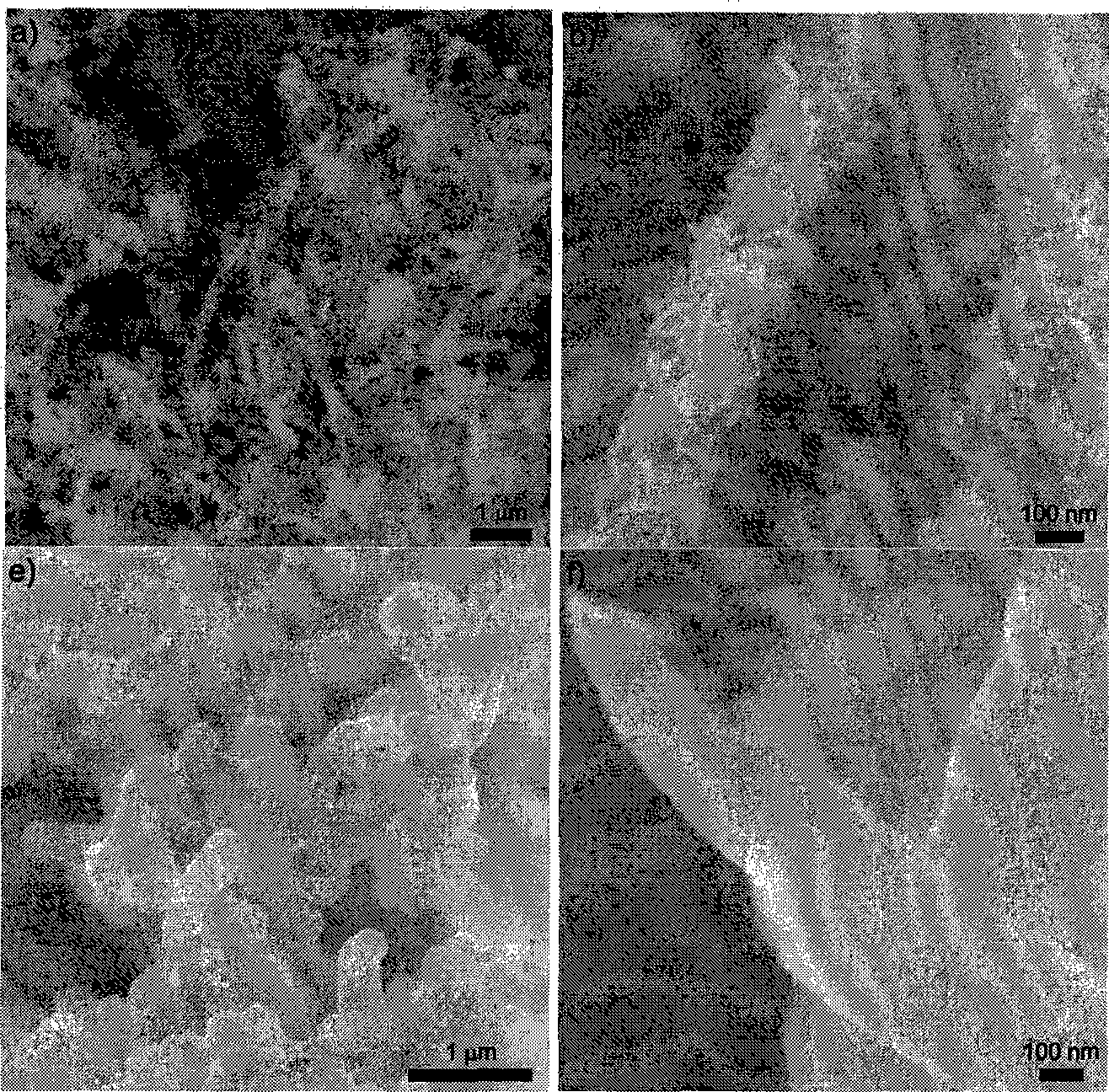

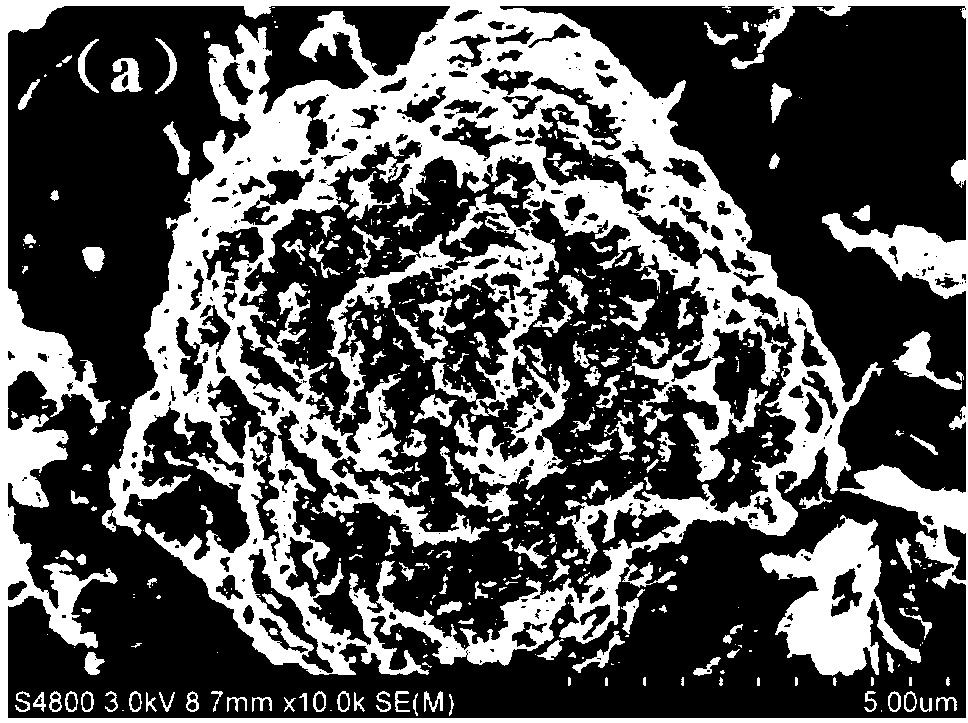

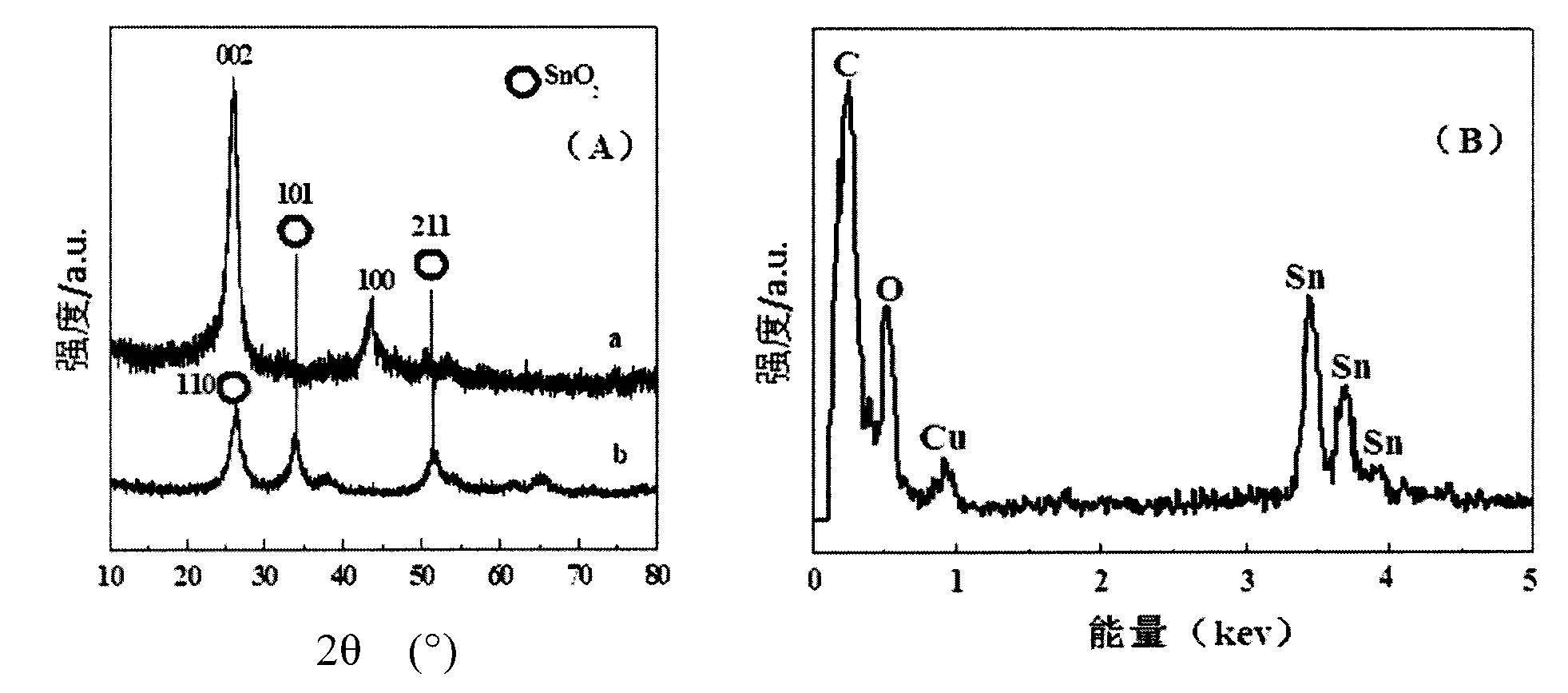

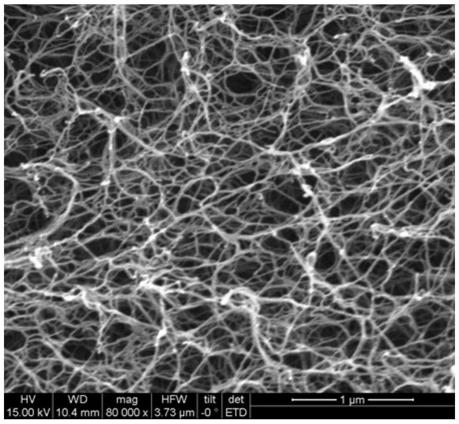

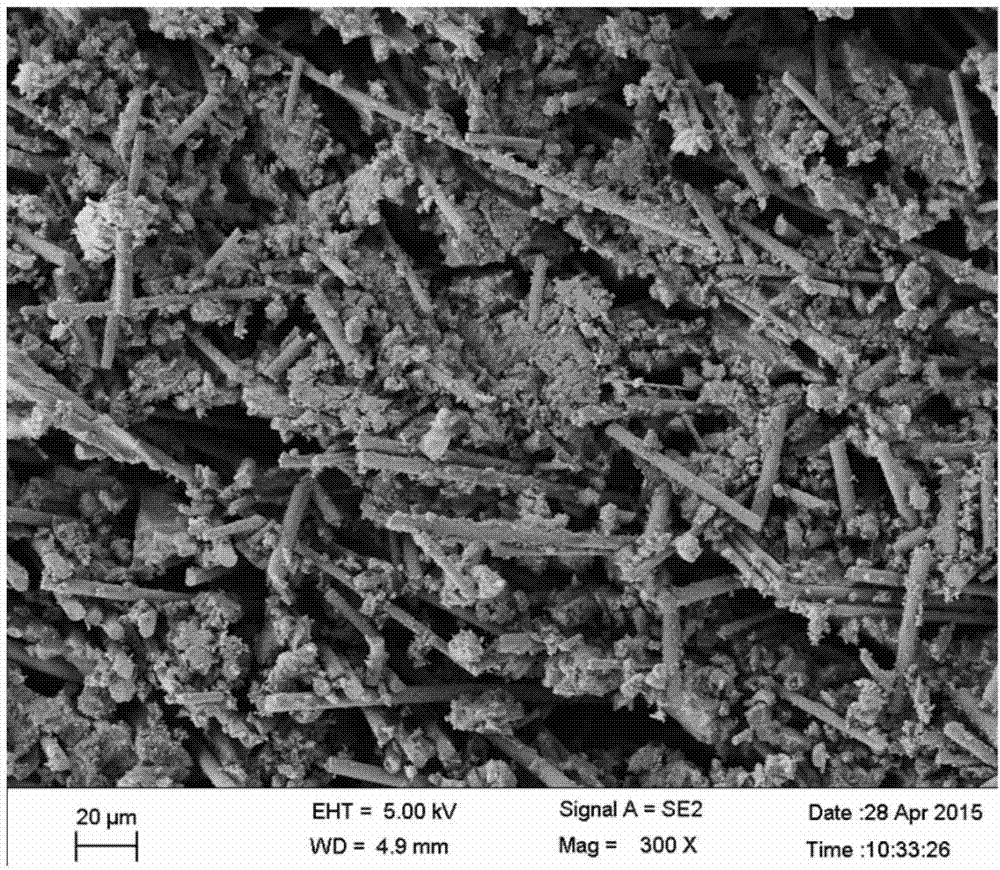

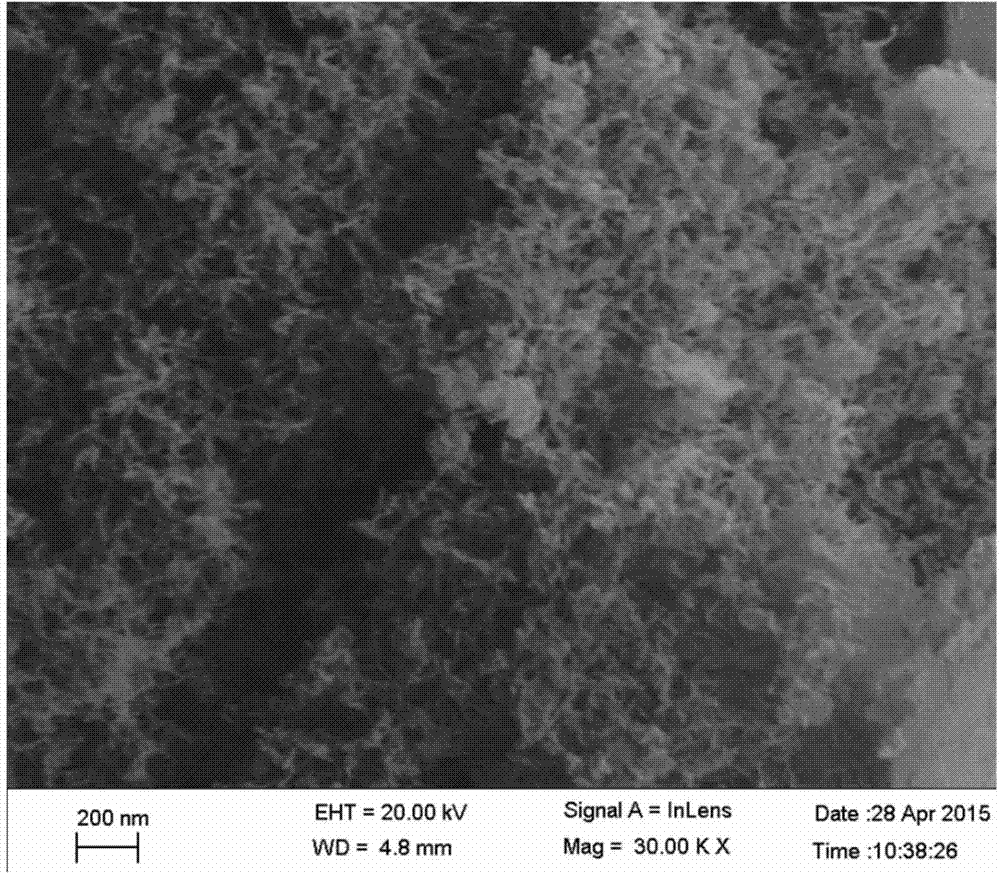

Metallic oxide/carbon nano-tube composite material as well as preparation method and application thereof

ActiveCN101497435AIncrease concentrationReduce energy consumptionElectrolytic capacitorsActive material electrodesCarbon nanotubeSURFACTANT BLEND

The invention discloses a metal oxide / carbon nano tube composite material and a preparation method and application thereof. The method for preparing the metal oxide / carbon nano tube composite material comprises the following steps: a) dispersing carbon nano tubes into ethanol or an ethanol solution taking a surfactant as a solute to obtain a solution A; b) dissolving soluble metal salts into the ethanol to obtain a solution B; c) adding urea into the solution A to obtain a solution C; d) adding water into the solution C according to the volume ratio of the water to the ethanol of 1:25-1:12.5 to obtain a solution D; e) adding the solution B into the solution D to obtain a solution E; f) refluxing the solution E at the temperature of between 100 and 150 DEG C for 2 to 20 hours to obtain a precursor of the metal oxide / carbon nano tube composite material; and g) heating the precursor from the temperature of between 20 and 25 DEG C to the temperature of between 350 and 400 DEG C according to the velocity ratio of 1 DEG C per minute in the anoxybiotic environment, and maintaining at the temperature for 1 hour to obtain the metal oxide / carbon nano tube composite material. The metal oxide / carbon nano tube composite material prepared by the method can be applied as an electrode material of an energy storage device.

Owner:INST OF CHEM CHINESE ACAD OF SCI

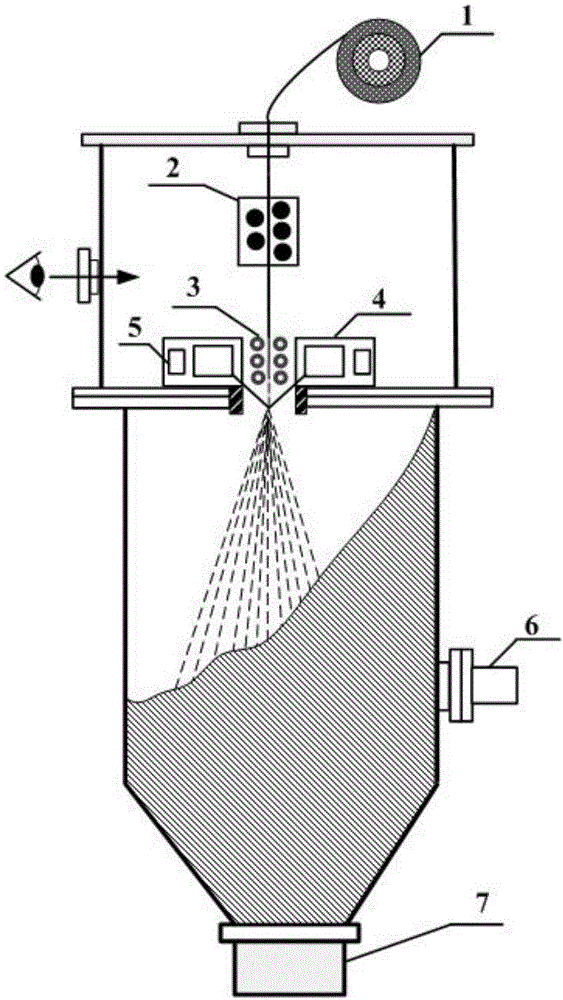

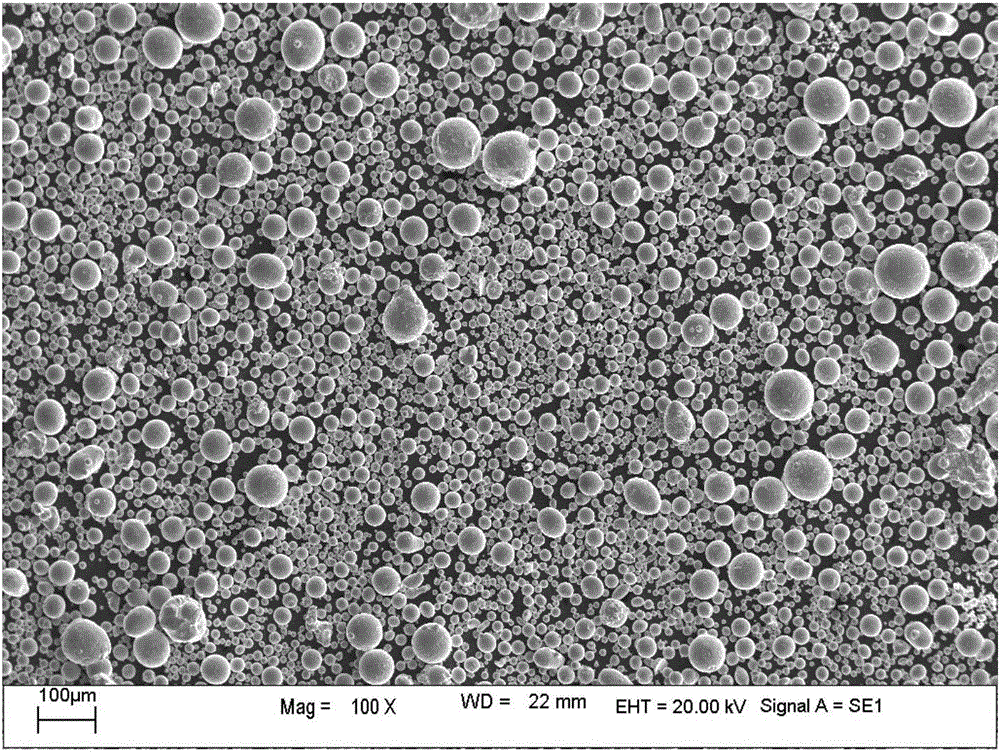

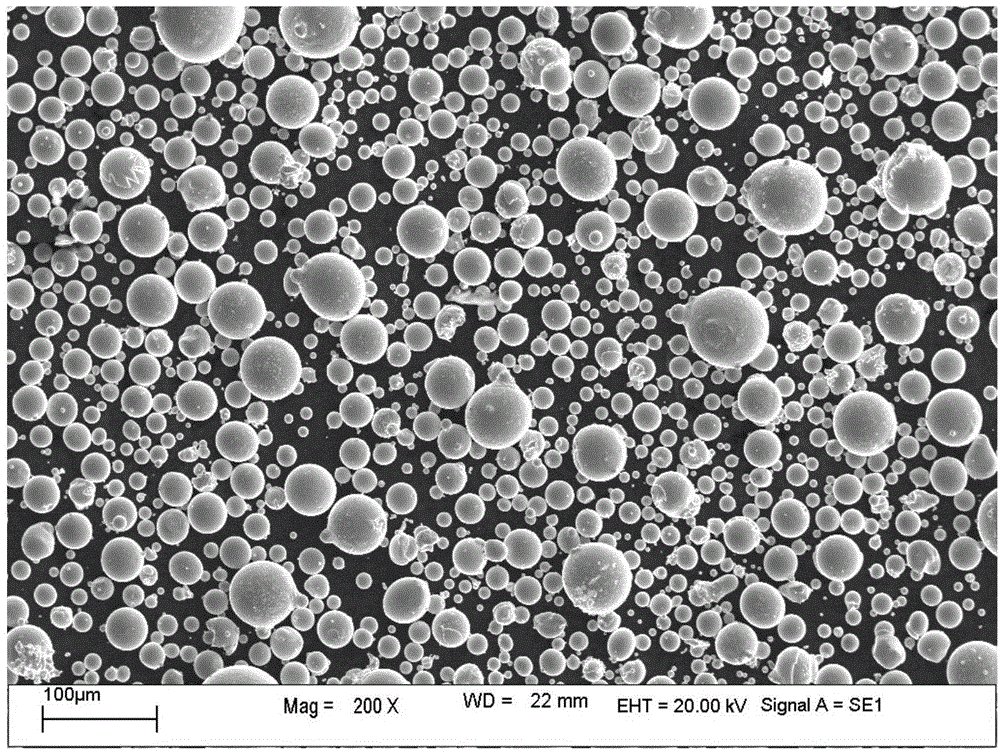

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

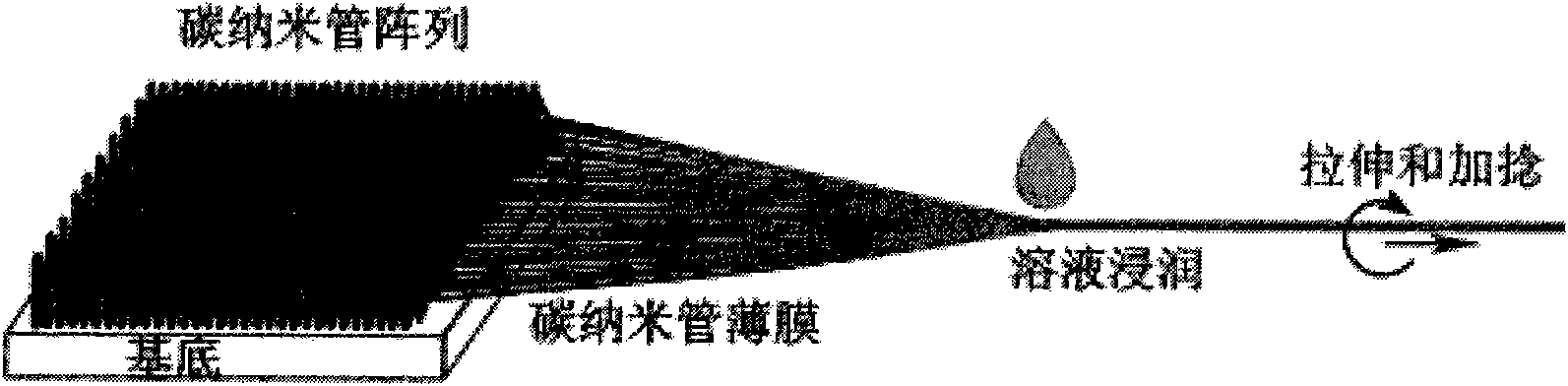

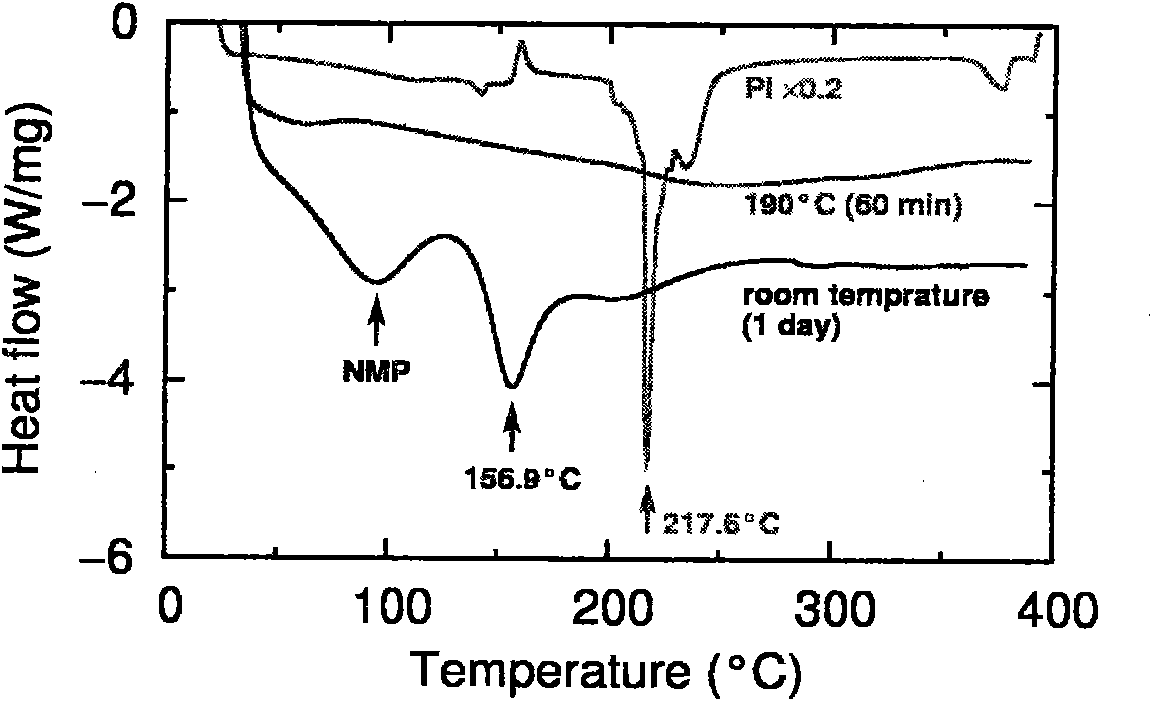

Preparation method of high-performance carbon nanotube fiber

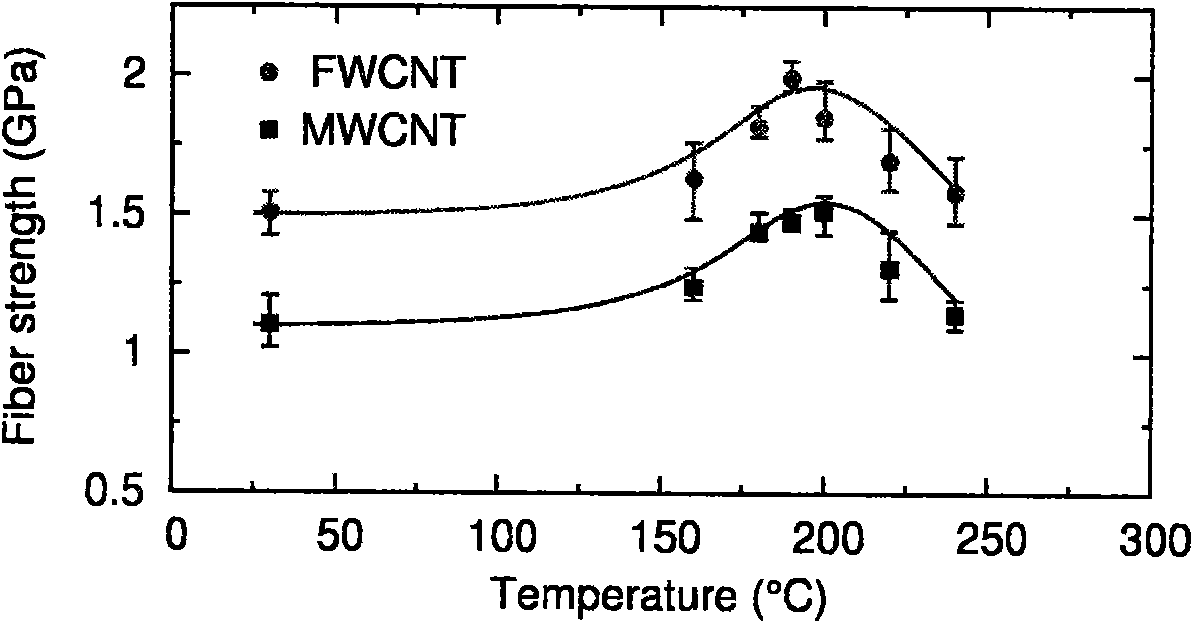

ActiveCN101967699AExcellent mechanical propertiesReduce dosageYarnArtificial filament chemical after-treatmentYarnMechanical properties of carbon nanotubes

The invention relates to a preparation method of a high-performance carbon nanotube fiber, which comprises the following specific steps of: drawing a carbon nanotube film from a spinning carbon nanotube array; then, immersing the carbon nanotube film in a thermosetting polyamic acid / N-methyl pyrrolidone solution, and twisting to form a carbon nanotube / polyamic acid composite fiber; subsequently, curing the carbon nanotube / polyamic acid composite fiber so that polyamic acid in the composite fiber forms polyimide with a net type crosslinking structure; and finally preparing the carbon nanotube / polyimide composite fiber. The invention has the advantages of simple and easy process, low cost and easy realization of large-scale production; moreover, the prepared carbon nanotube composite fiber has excellent mechanical performance, the strength can reach 2.06 GPa, the tenacity is superior to that of carbon fiber, and the conducting property is maintained unchanged as compared with that of pure carbon nanotube fiber; meanwhile, the carbon nanotube composite fiber also has the operability of common yarn, so that the requirements on subsequent treatment processes of stretching, stranding, weaving and the like can be satisfied.

Owner:SUZHOU CREATIVE CARBON NANOTECH

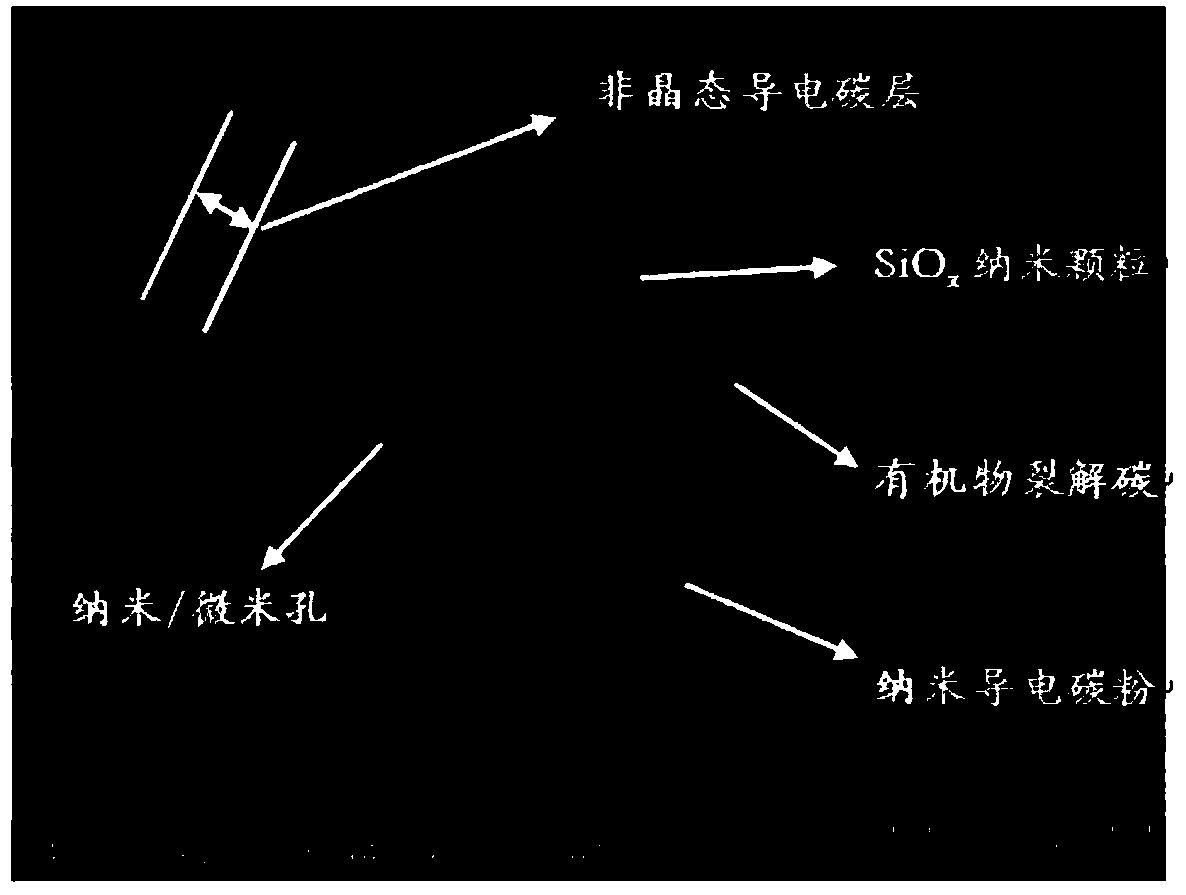

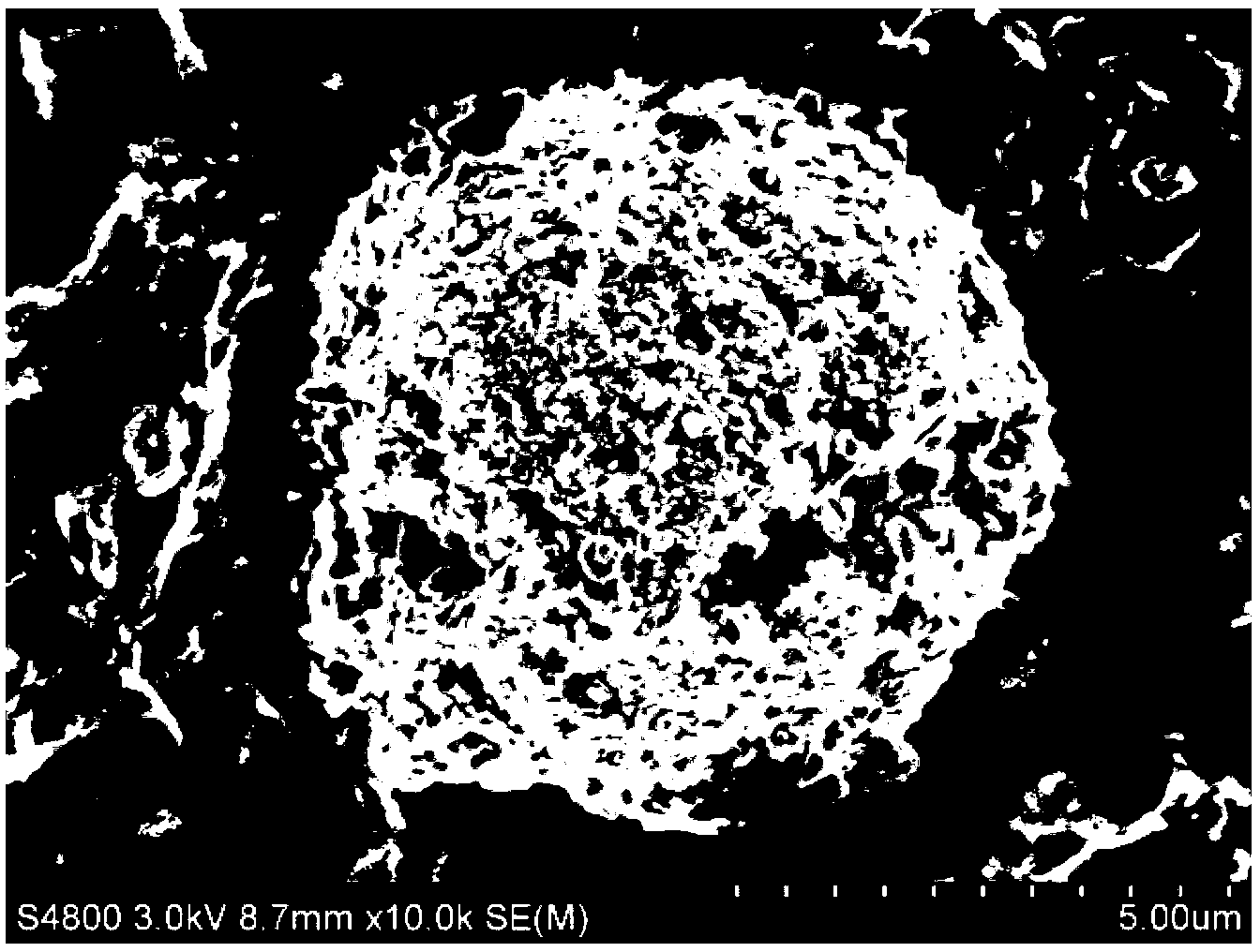

SiOx-based composite material, preparation method and lithium ion battery

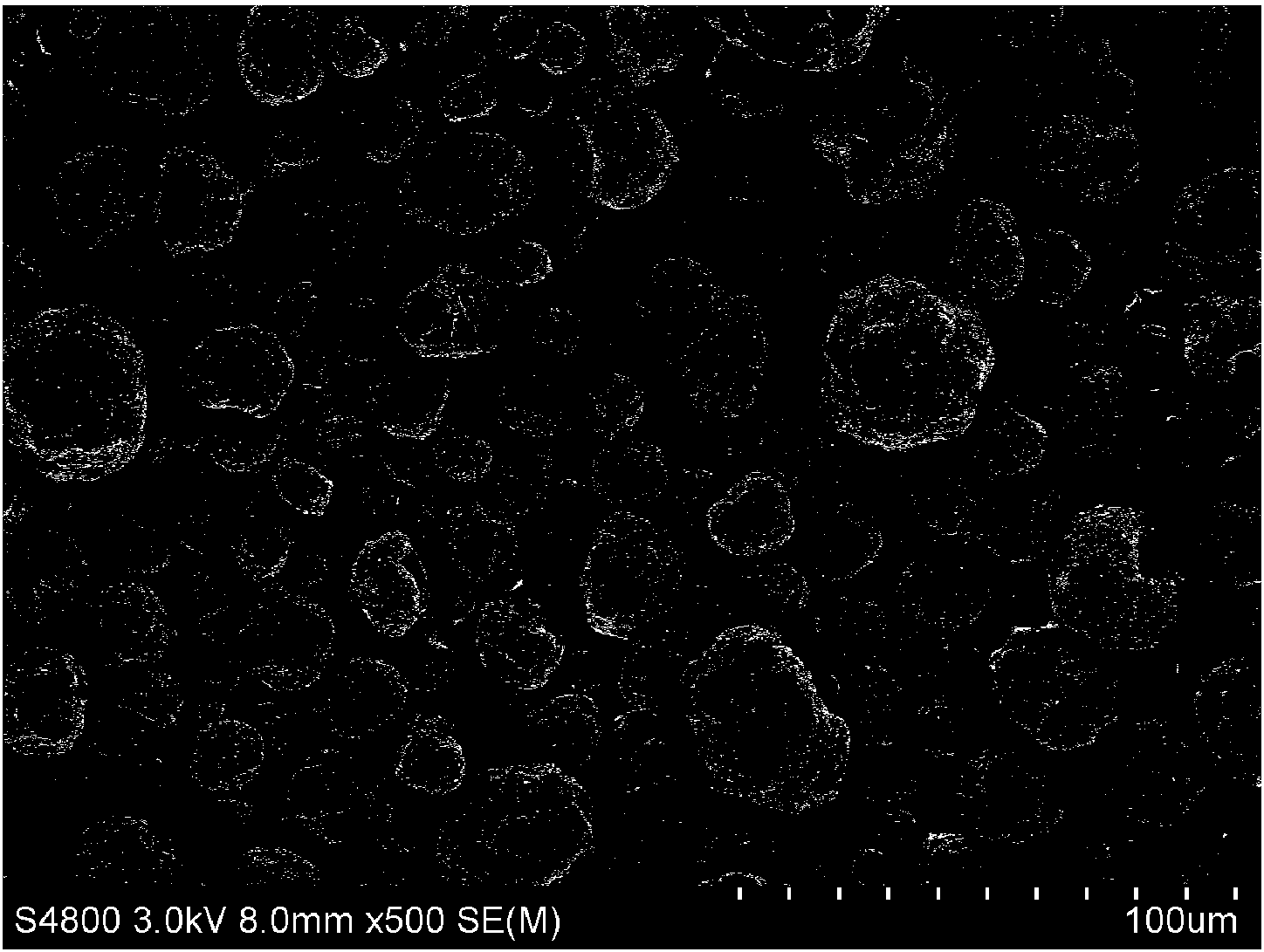

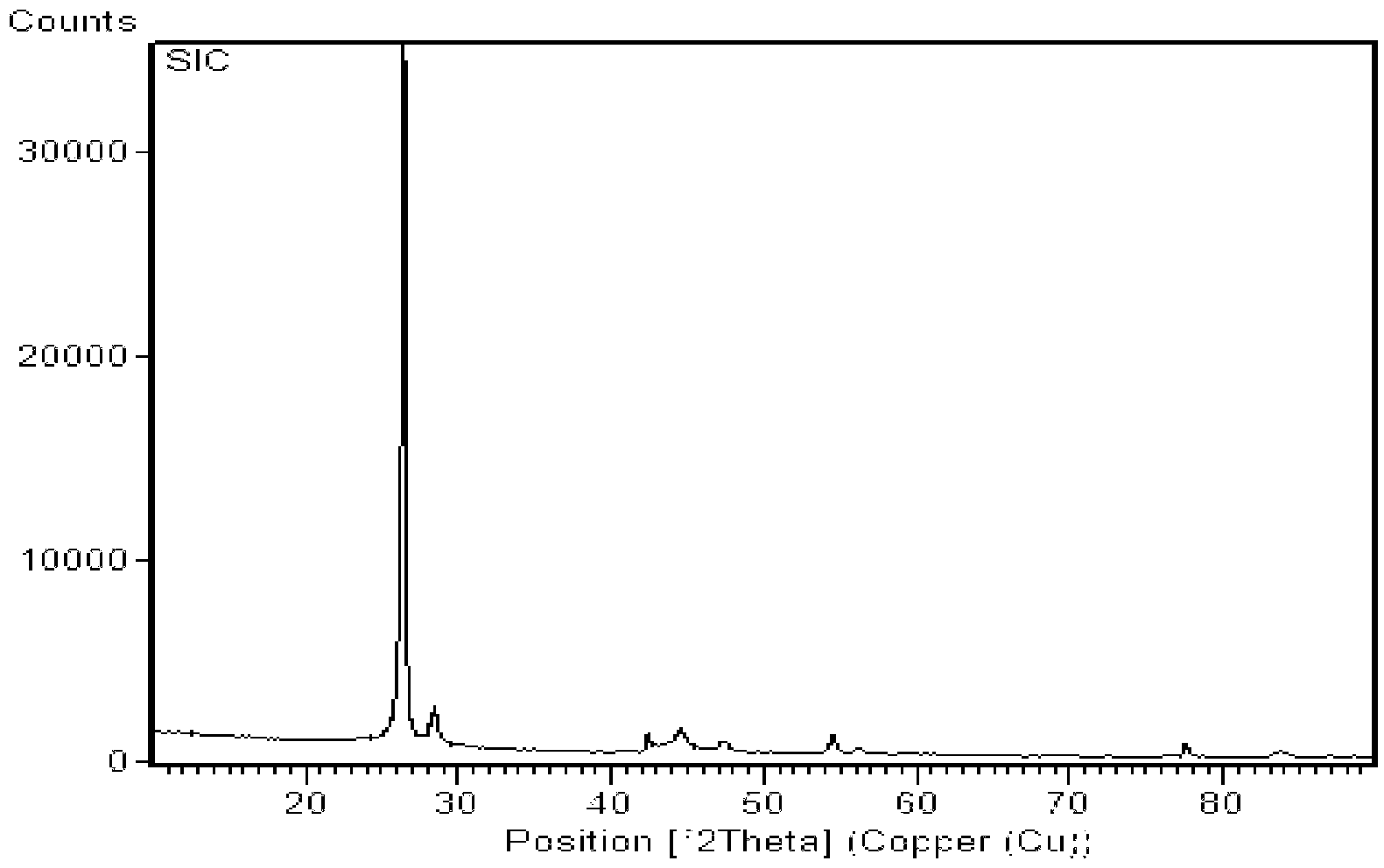

ActiveCN103855364AStable structureImprove electronic conductivityMaterial nanotechnologyCell electrodesCarbon layerSpherical shaped

The invention relates to a SiOx-based composite material, a preparation method and a lithium ion battery. The SiOx-based composite material comprises a SiOx / C material, wherein the SiOx / C material comprises SiOx nano particles, organism cracked carbon, nano conductive particles and amorphous conductive carbon layers, the SiOx nano particles, the organism cracked carbon and the nano conductive particles are wrapped in the amorphous conductive carbon layers, the SiOx / C material is in a spherical shape and comprises a porous structure, and x is more than or equal to 0.5 and less than or equal to 1.3. The composite material is used as a negative electrode material of the lithium ion battery, excellent in cycling performance, excellent in rate performance and low in size expansion effect, applicable to the fields such as top-grade digital electrons, electric tools and next-generation vehicle-mounted devices and wide in market prospect.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for preparing phosphaalkene

The invention discloses a method for preparing phosphaalkene. The method comprises the following steps: dispersing black phosphorus into a dispersion liquid, and performing ultrasonic treatment for 0.5-200 hours and then performing solid-liquid separation to obtain intercalation black phosphorus; dispersing the intercalation black phosphorus into a chemical foaming agent solution, performing ultrasonic treatment for 0.5-200 hours and then performing solid-liquid separation, and drying solids subjected to solid-liquid separation to obtain a solid mixture of black phosphorus and a chemical foaming agent; performing microwave treatment on the solid mixture of black phosphorus and the chemical foaming agent under the microwave powder of 100-1,000W, and preparing a finished product phosphaalkene after 1s-1h of microwave treatment. The phosphaalkene prepared by the method disclosed by the invention is proper and uniform in size; furthermore, the technology is simple, the cost is low, the peeling time is short, and the phosphaalkene yield is high; large-scale production is easy to realize.

Owner:延边中电阳光新能源科技有限公司

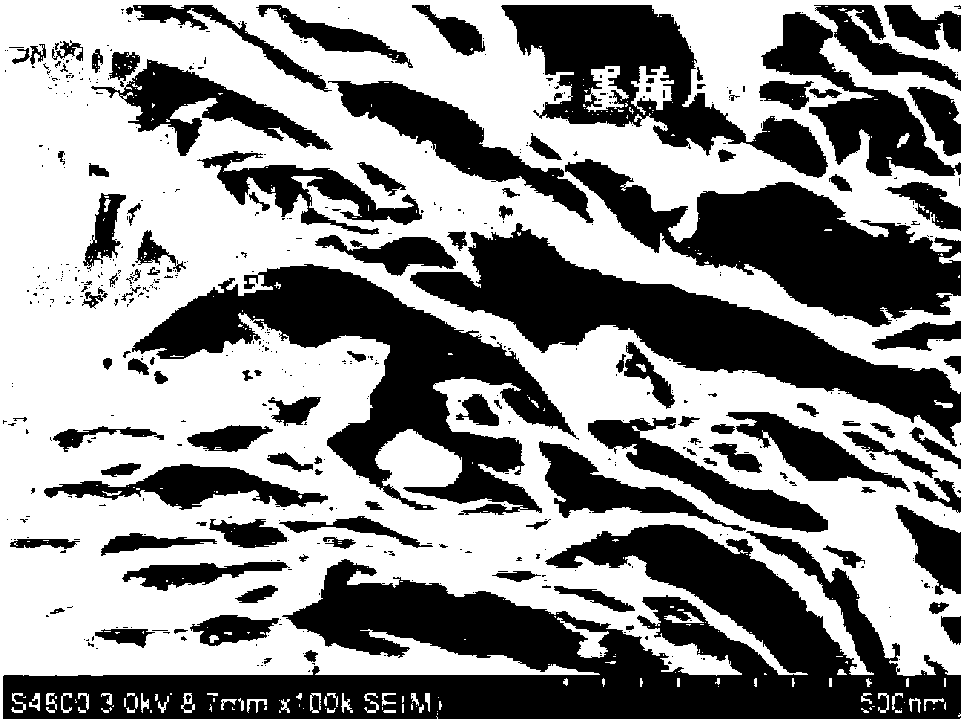

Monox/carbon composite material as well as preparation method and use thereof

InactiveCN103311526AGood electrical contactShorten the diffusion pathCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a monox / carbon composite material, comprising monox / graphene particles, organic matter pyrolysis carbon and graphite powder, wherein monox particles are adhered to the surface of a grapheme sheet; the organic matter pyrolysis carbon coats the monox / graphene particles, and then is compounded with graphite. The preparation method of the monox / carbon composite material comprises the steps of: mixing monox particles with graphene to obtain the monox / graphene particles; coating organic carbon by obtained monox / graphene particles, thereby obtaining the monox / graphene material coated by the organic matter pyrolysis carbon; and mixing the obtained monox / graphene material coated by the organic matter pyrolysis carbon with the graphite powder, so as to obtain the monox / carbon composite material. The monox / carbon composite material is used as a lithium ion battery cathode material. Thus, the monox / carbon composite material has the characteristics of high first charge and discharge efficiency, excellent cycle performance and power charge and discharge properties, and low volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

Metallic oxide/N-doped carbon nano tube as well as preparation method and application thereof

ActiveCN103170324AReduce energy consumptionEasy to operateMaterial nanotechnologyCell electrodesSolventHigh pressure

The invention discloses a preparation method of a metallic oxide / N-doped carbon nano tube composite material. The preparation method comprises the following steps of: (1) ultrasonically dispersing an N-doped carbon nano tube in a mixed solution of water and alcohol to obtain a solution A; (2) under the condition of stirring, dripping a solution B into the solution A, and stirring to obtain a mixed solution, wherein the solution B is water and / or alcoholic solution containing metal ions; and (3) carrying out solid-liquid separation on the mixed solution, and washing, drying and roasting to obtain the metallic oxide / N-doped carbon nano tube composite material. The invention also provides the composite material obtained through the method and an application thereof. According to the preparation method disclosed by the invention, as a method of solution phase synthesis under the condition of room temperature is adopted, hydrothermal reaction and solvothermal reaction with high temperature and high pressure are avoided, and the composite material with tighter combination of the metallic oxnide and the / N-doped carbon nano tube can be obtained. By adopting the preparation method, the preparation cost is low, the operation is simple, the preparation condition is mild, and the reaction period is also short.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

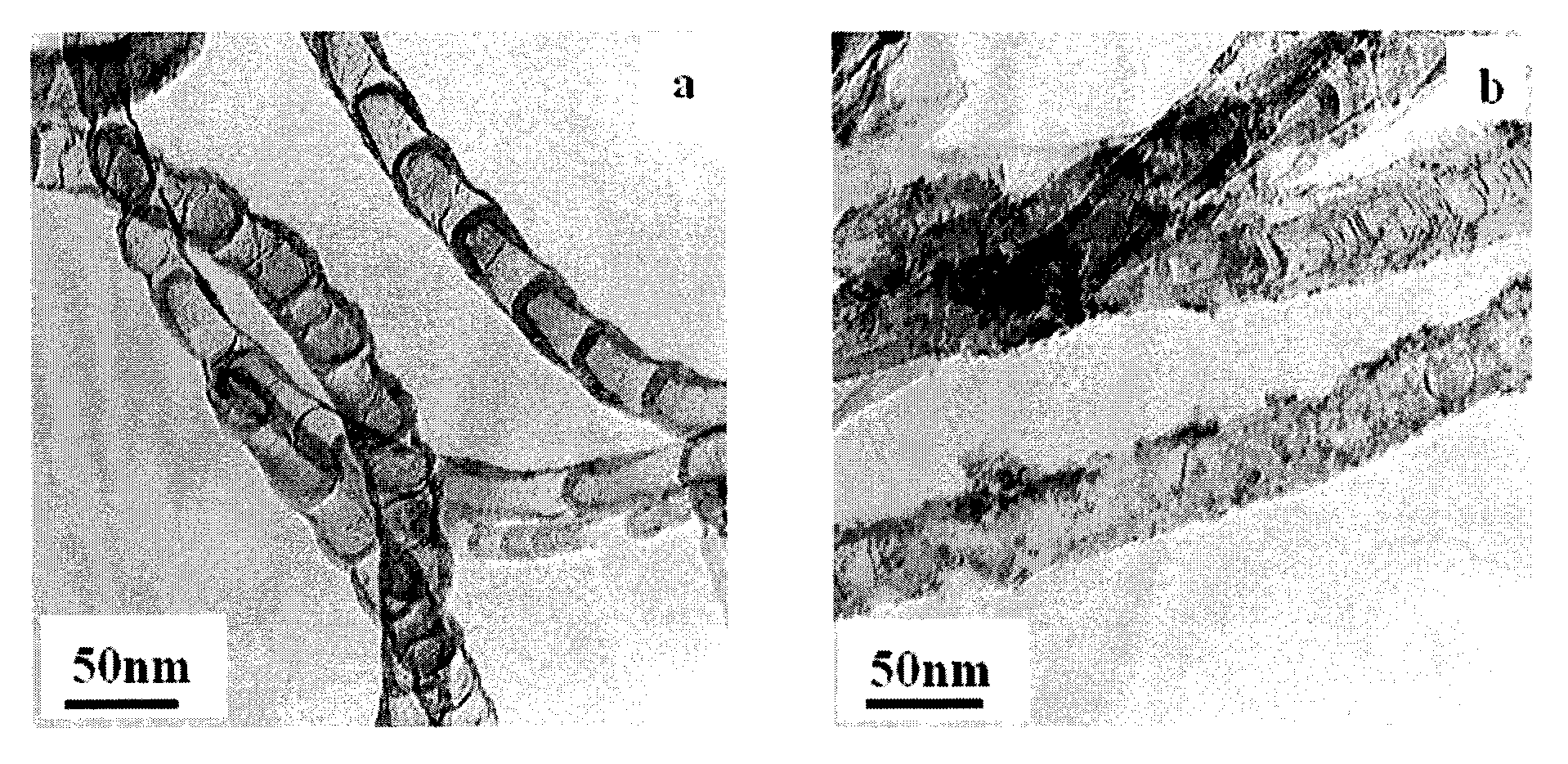

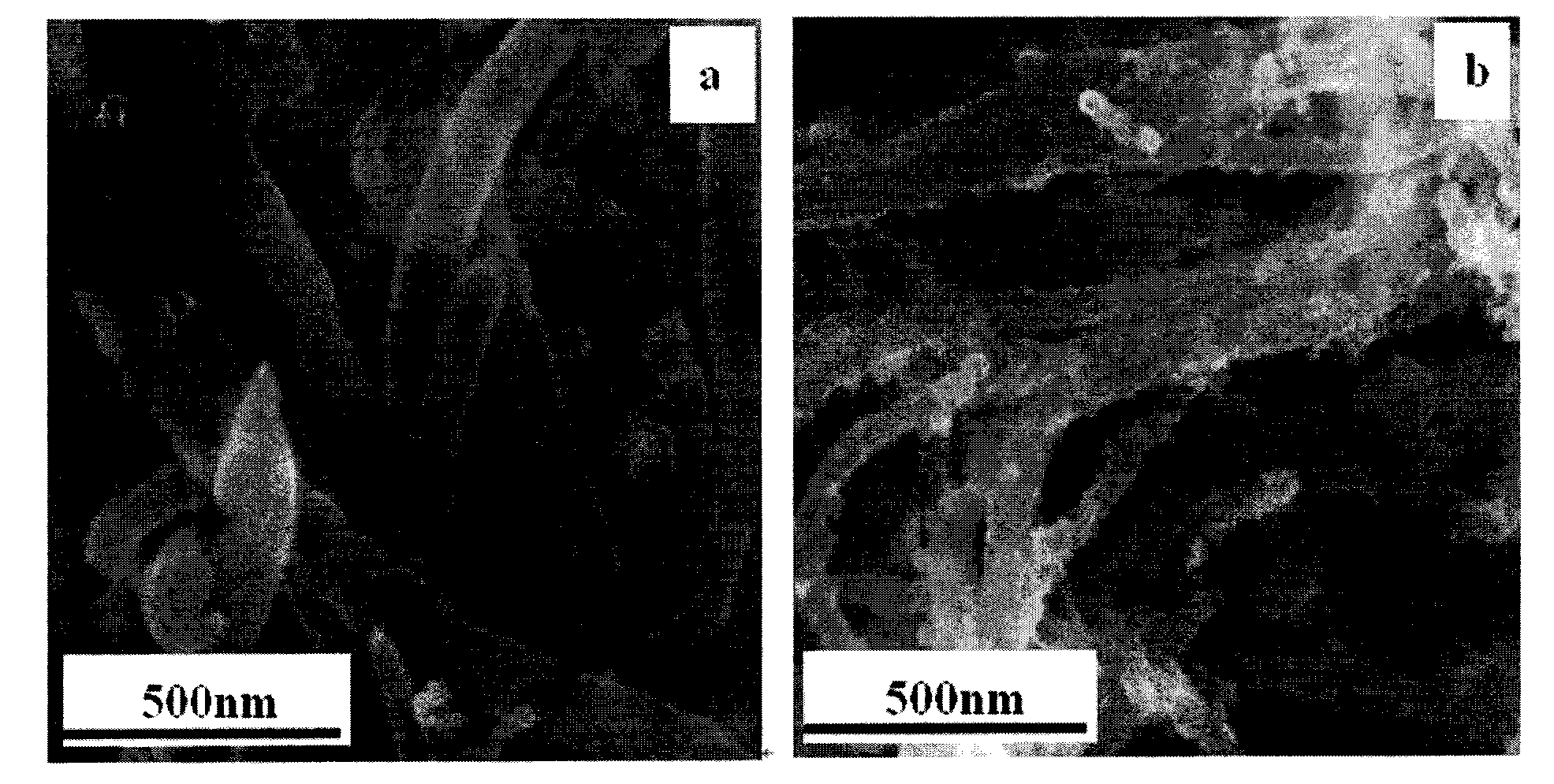

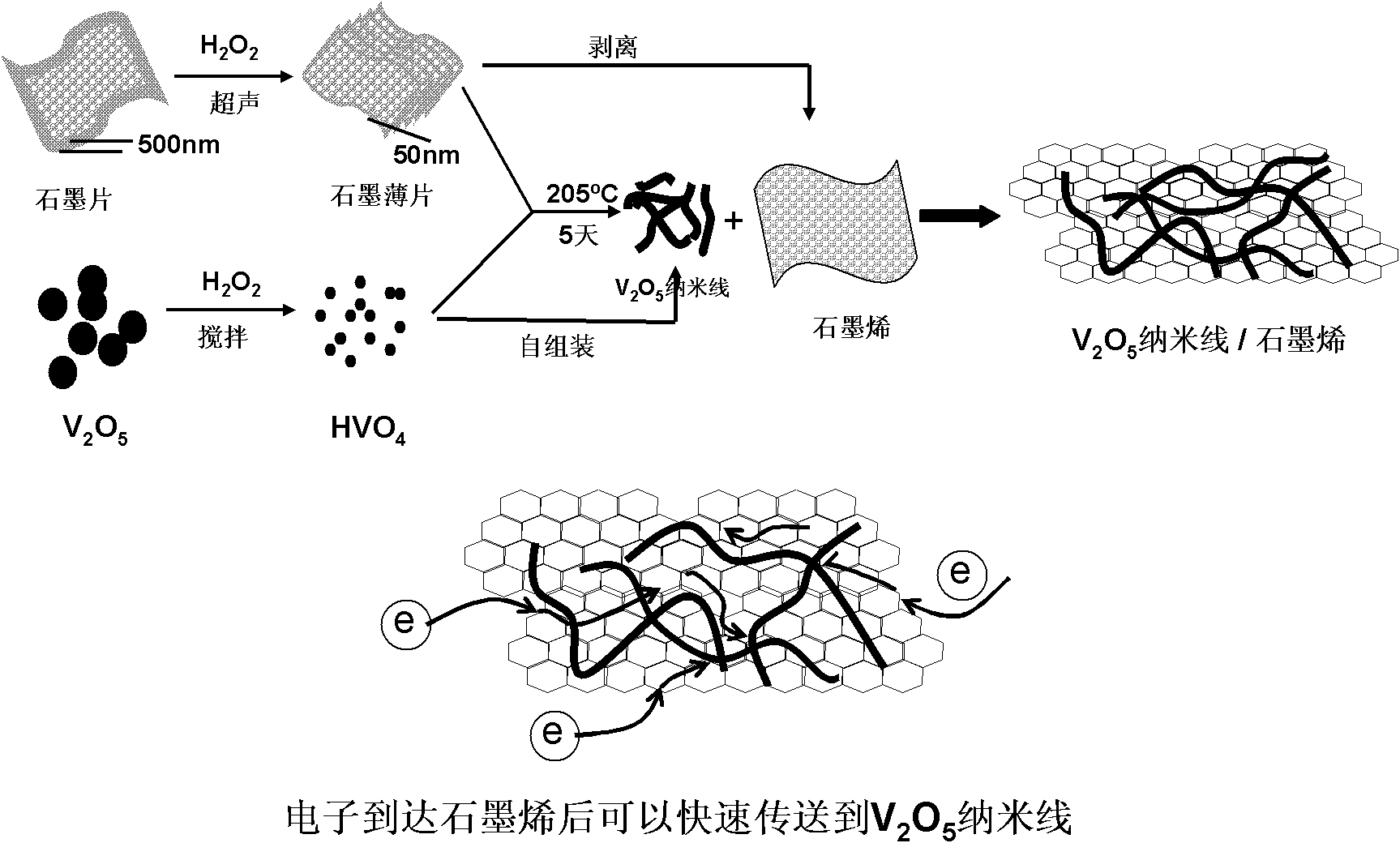

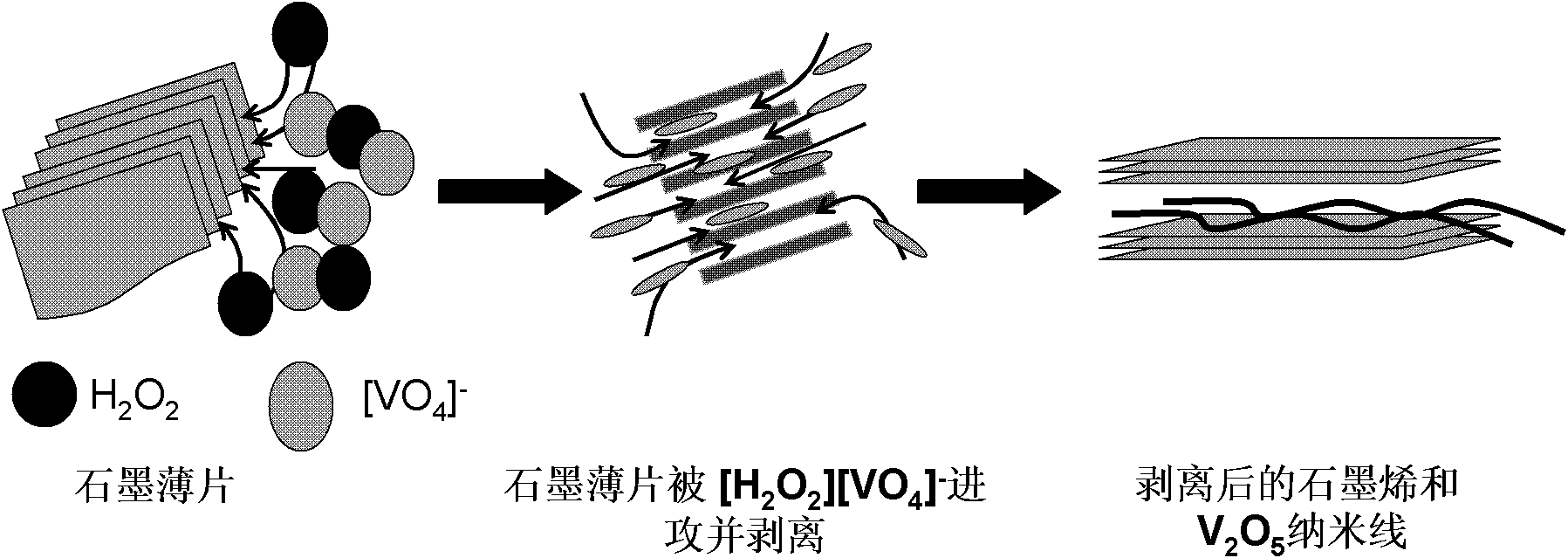

Ultra-long single crystal V2O5 nano wire/graphene anode material and preparation method

InactiveCN102208631AImprove the first discharge capacityImproved dynamicsCell electrodesIonCvd graphene

The invention discloses an ultra-long single crystal V2O5 nano wire / graphene anode material and a preparation method, and belongs to the field of lithium ion battery electrode materials and preparation thereof. The V2O5 nano wire / graphene anode material consists of a two-dimensional graphene nano sheet and one-dimensional V2O5 nano wires, wherein the ultra-long single crystal V2O5 nano wires are regularly distributed on the surface and the interlayer of the transparent graphene nano sheet to form a sandwich structure. The preparation method comprises the following steps of: dispersing vanadium oxide powder and merchant graphite into deionized water, adding an oxidant, fully stirring mixture uniformly, performing ultrasonic treatment, putting the mixture into an autoclave, keeping the mixture for certain time at a certain temperature, and performing vacuum drying to obtain the ultra-long single crystal V2O5 nano wire / graphene composite anode material. The invention has the advantages that: the first discharge capacity, the magnification performance and the electrochemical cyclical stability of the composite anode material are remarkably improved. The method is simple, environment-friendly, convenient for operation and easy to realize large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

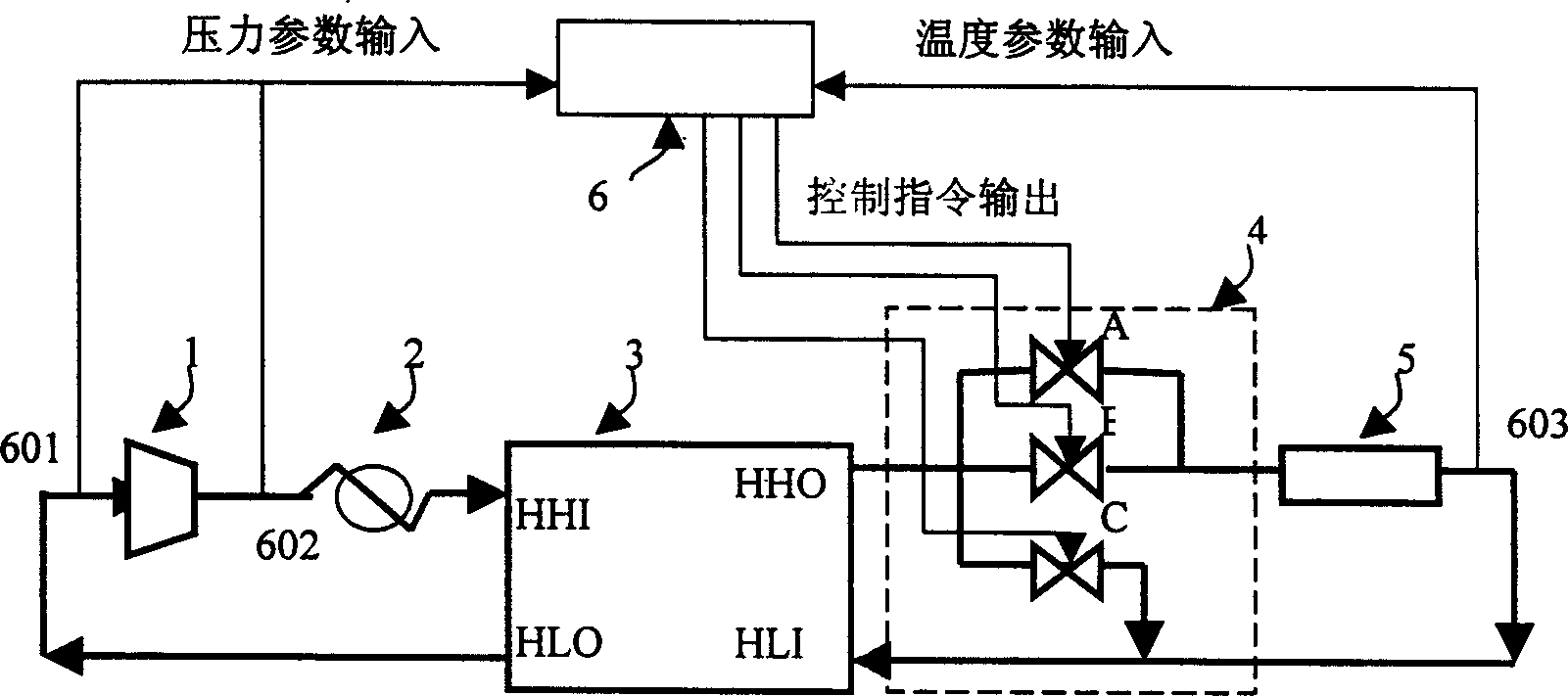

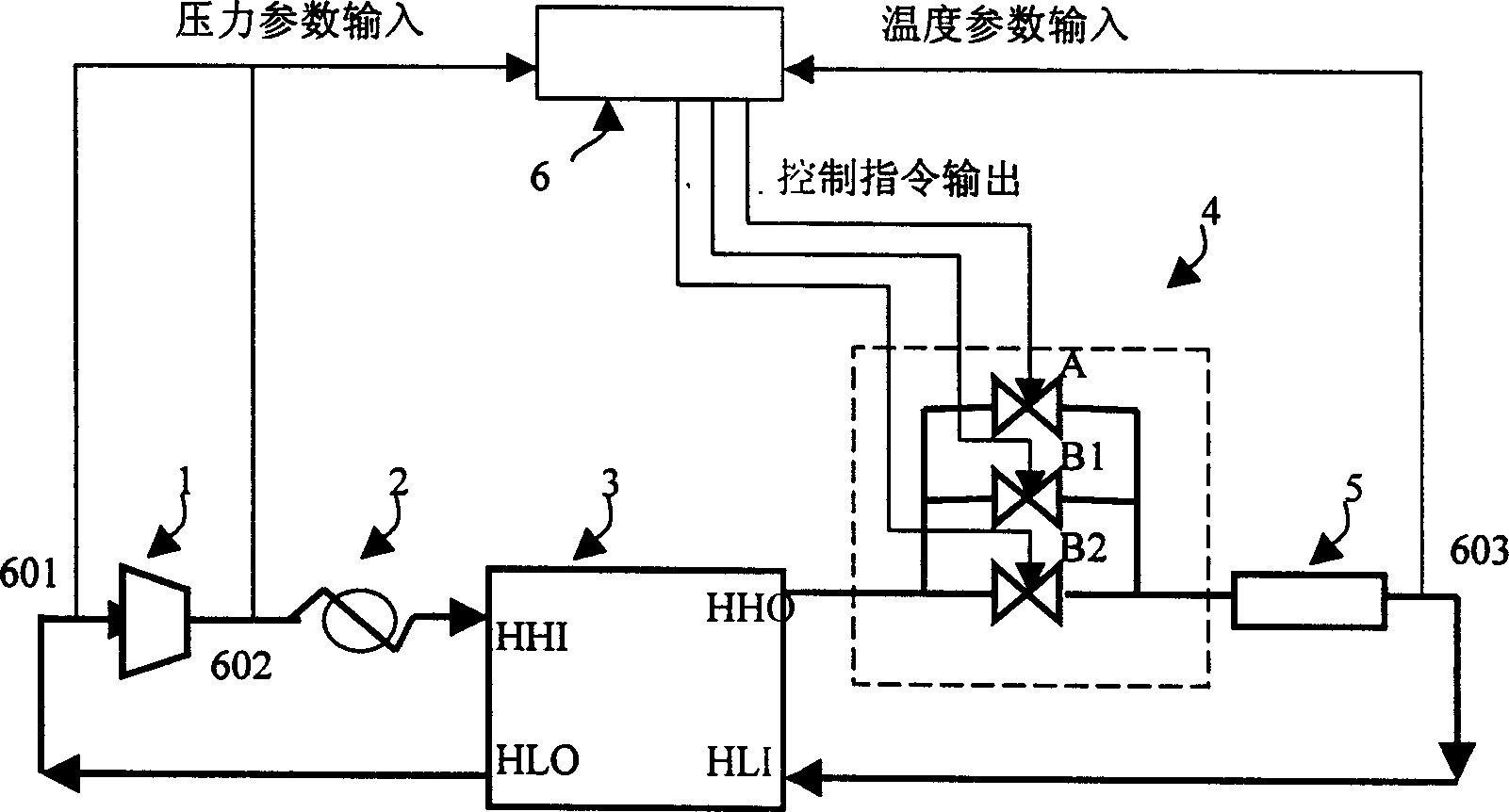

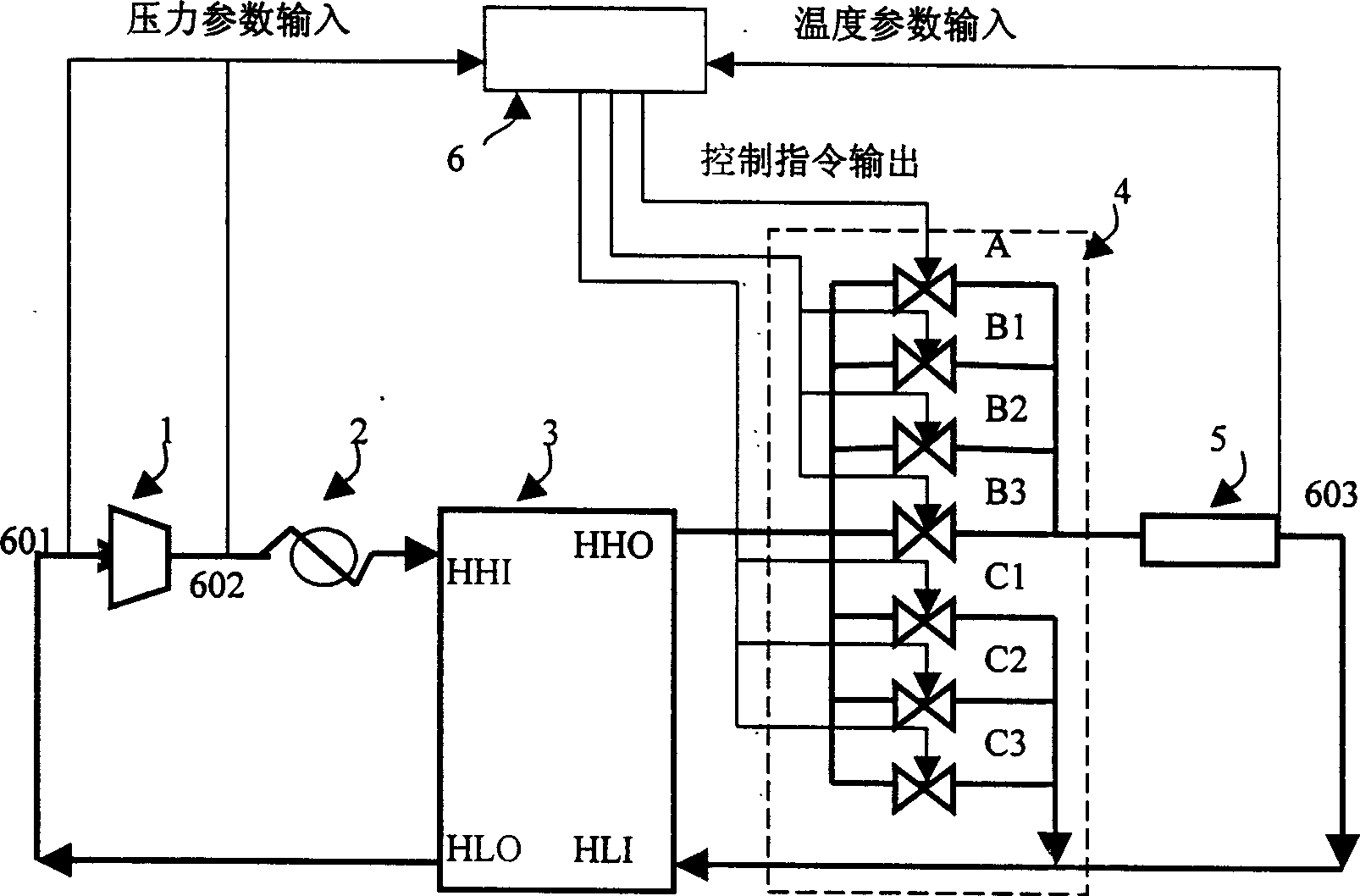

Control method for varying condition operation of throttling refrigerating system of deep freezing mixed working-fluid

The refrigerating system includes compressor unit in lubricant separator, cooler, heat returning unit, throttling control unit set, evaporator unit and controller unit. The input parameters of the controller unit include air admission pressure and exhaust pressure of compressor in refrigerant system and / or exit temperature of the evaporator; the output parameters are in the commands of opening and closing the throttling control unit set. The throttling control unit set includes main controllable throttle element A, auxiliary controllable throttle element B and by-pass controllable throttle element C. For cryogenic mixed work medium throttling refrigerating system with different operation states, the control method includes comparing preset value and the input parameter and controlling the opening and closing and flux of throttle element to realize the control of circulating work medium flow rate and ultimate stable and reliable operation of refrigerator in different work conditions.

Owner:中科赛凌(北京)科技有限公司

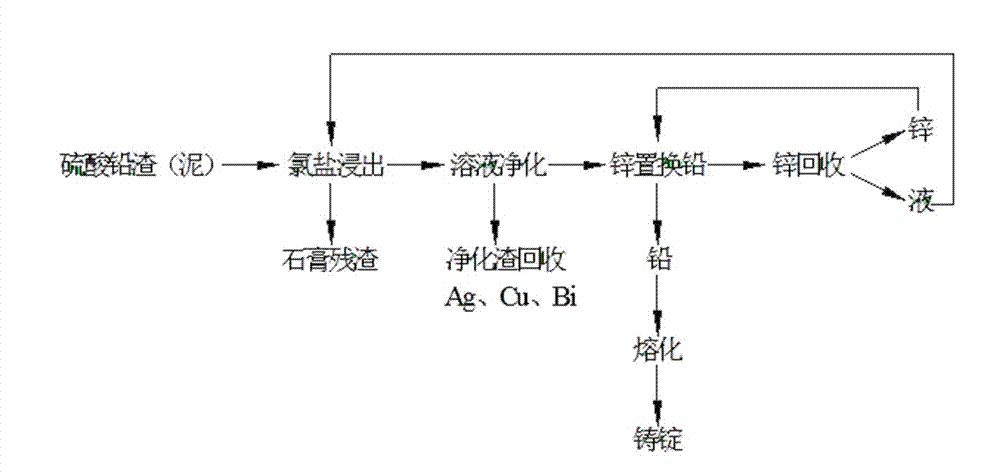

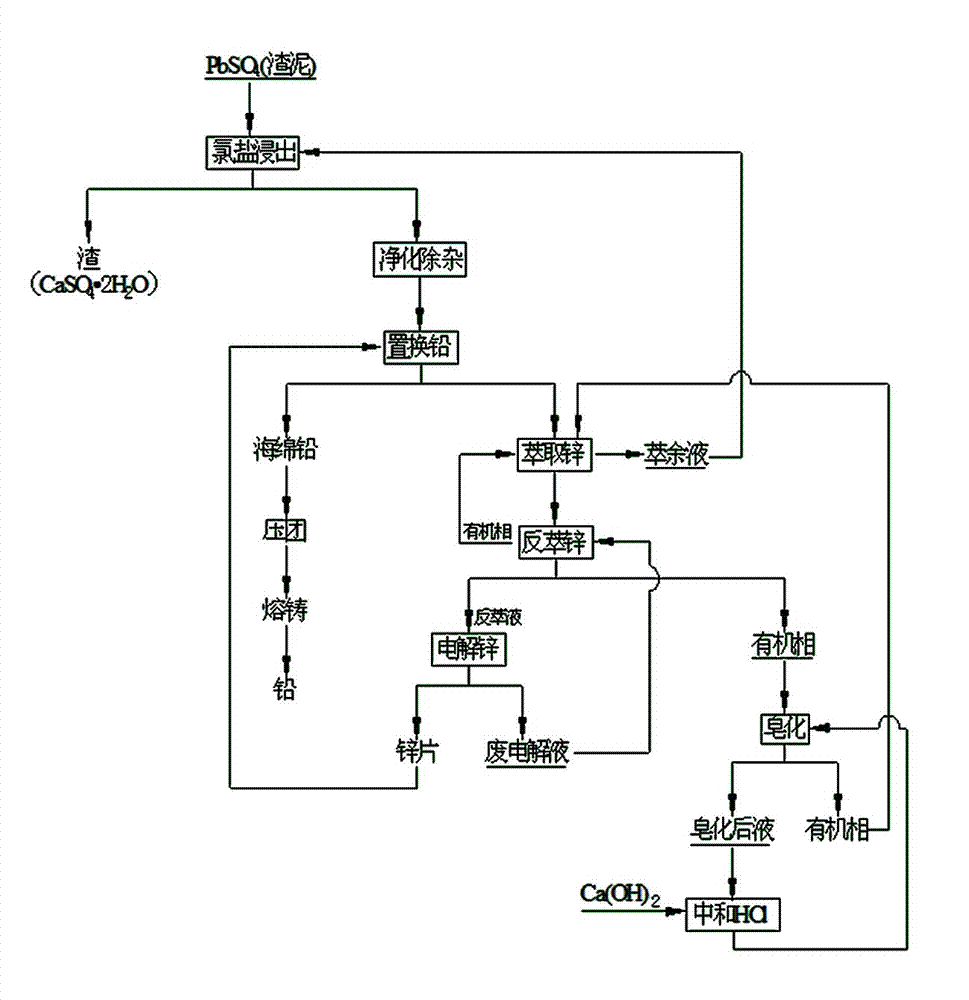

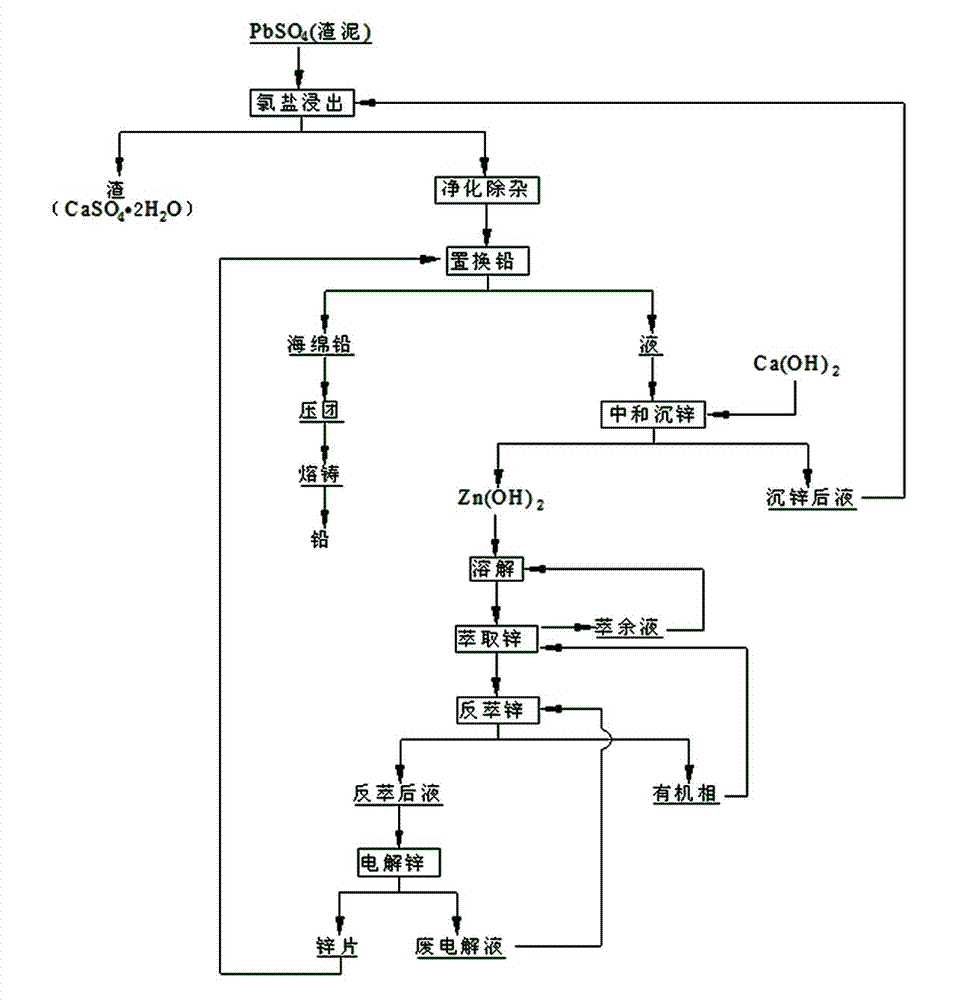

Lead hydrometallurgical technology through utilizing lead sulfate

The invention discloses a lead hydrometallurgical technology through utilizing lead sulfate, belongs to a hydrometallurgical technology, and relates to a technology which adopts a full-hydrometallurgical technology to produce lead through lead sulfate residuals or lead storage battery lead slime which is additionally produced in a zinc hydrometallurgical process. The method comprises steps of: with CaCl2 and NaCl as a leaching solvent; leaching high leaching residuals generated by zinc hydrometallurgy and containing lead sulfate, lead skims generated by leaching zinc out of lead-containing zinc oxides or the lead slimes generated by dismantling lead-acid storage batteries; using zinc to replace lead in the leaching solution; recovering zinc from the replacing solution; returning the recovered zinc to a lead replacement process; and circulating a Cl<->-containing liquid after zinc recovery to a lead sulfate chloride leaching process. The technology has the characteristics of low energy consumption, low cost and easiness in popularization and application; and smoke pollutions such as lead fume, lead dust and SO2 are thoroughly eliminated by utilizing the technology.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD

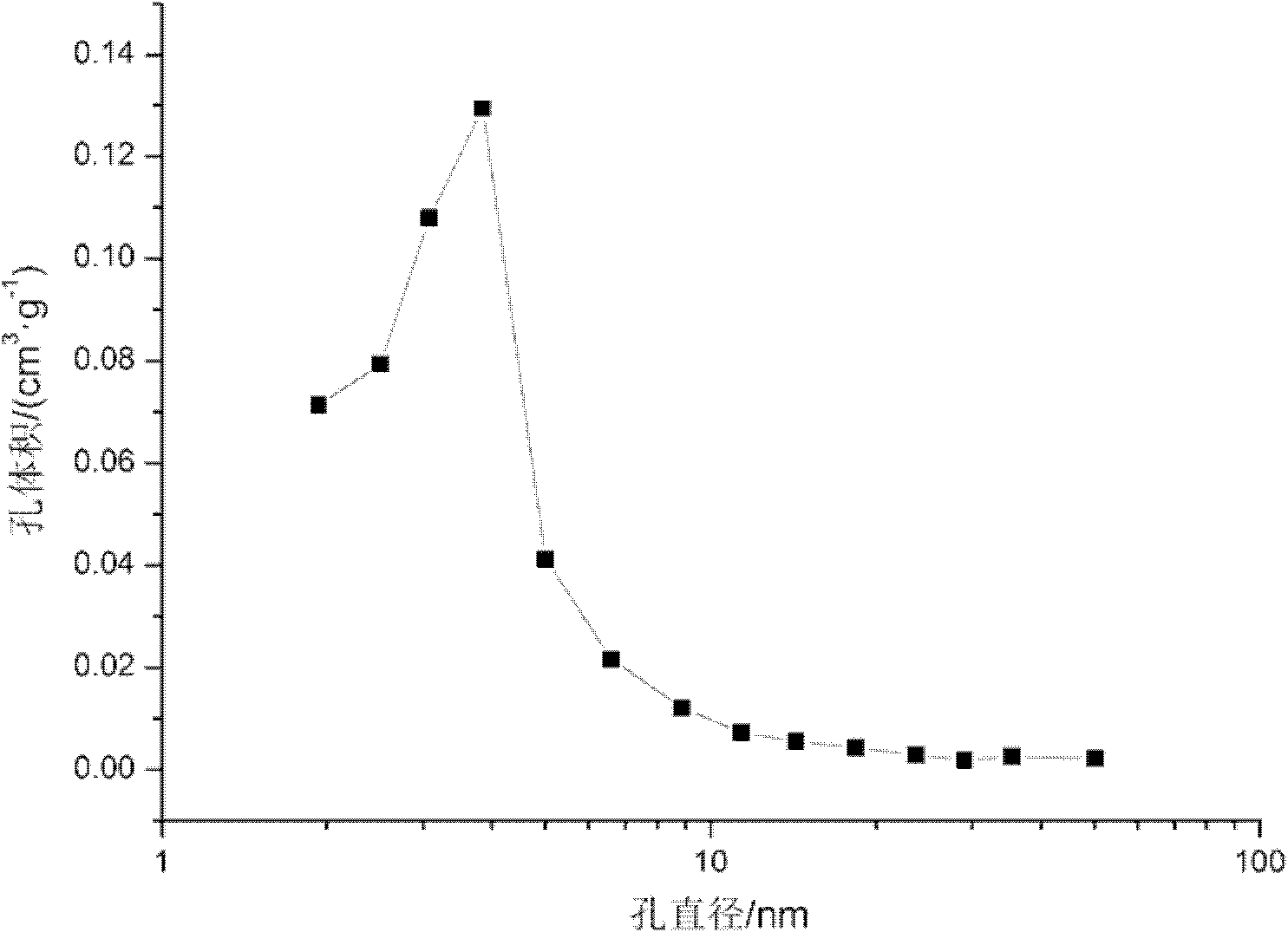

Preparation method of magnetized silicon dioxide aerogel

ActiveCN102179230AReduce manufacturing costEasy to achieve large-scale productionOther chemical processesAlkali metal oxides/hydroxidesMagnetizationSilicon dioxide

The invention belongs to the field of preparation of water treatment materials, and in particular relates to a preparation method of magnetized silicon dioxide aero-gel. The preparation method comprises the following steps of: with water glass as a silica source, adding nano-grade ferroferric oxide dispersed liquid and a drying control chemical additive to obtain the magnetized silicon dioxide aerogel at ordinary pressure and drying conditions through a sol-gel method and surface modification. The magnetized silicon dioxide aerogel is a nano-grade porous material, the average pore size of each pore is 3-5nm; the magnetized silicon dioxide aerogel has a saturated magnetization intensity of 0.4-0.8emu.g-1. The preparation method has low cost; and the magnetized silicon dioxide aerogel prepared by adopting the preparation method disclosed by the invention has magnetism, can realize the solid-liquid separation effectively under the action of an external magnetic field, and is suitable for mass production.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Silicon-carbon composite anode material, preparation method thereof and lithium ion battery

InactiveCN104103807ANot prone to the problem of electrochemical agglomerationReduce the effects of volume expansionMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

An embodiment of the invention provides a silicon-carbon composite anode material which includes a shell and an active and conductive material which is accommodated in the shell. The active and conductive material includes a silicon nano-material, a graphite material and carbon nano-tubes, wherein the silicon nano-material, the graphite material and the carbon nano-tubes are blended according to a weight ratio of 10-30:15-35:1-5. The shell is a cracked carbon layer. The silicon nano-material is silicon nano-sheets or silicon nano-belts with a length-width size being 50-5000 nm and a thickness being 10-500 nm. Surfaces of the silicon nano-sheets or silicon nano-belts are provided with Si-N-Si composite layers and Si-N-C composite layer. The silicon-carbon composite anode material is high in reversible capacity, is high in first-time charging-discharging efficiency, is good in circulating performance, can finally increasing a system capacity of a lithium ion battery and prolongs a cyclic service life of the lithium ion battery. The embodiment of the invention also provides a preparation method of the silicon-carbon composite anode material and the lithium ion battery containing the silicon-carbon composite anode material.

Owner:HUAWEI TECH CO LTD

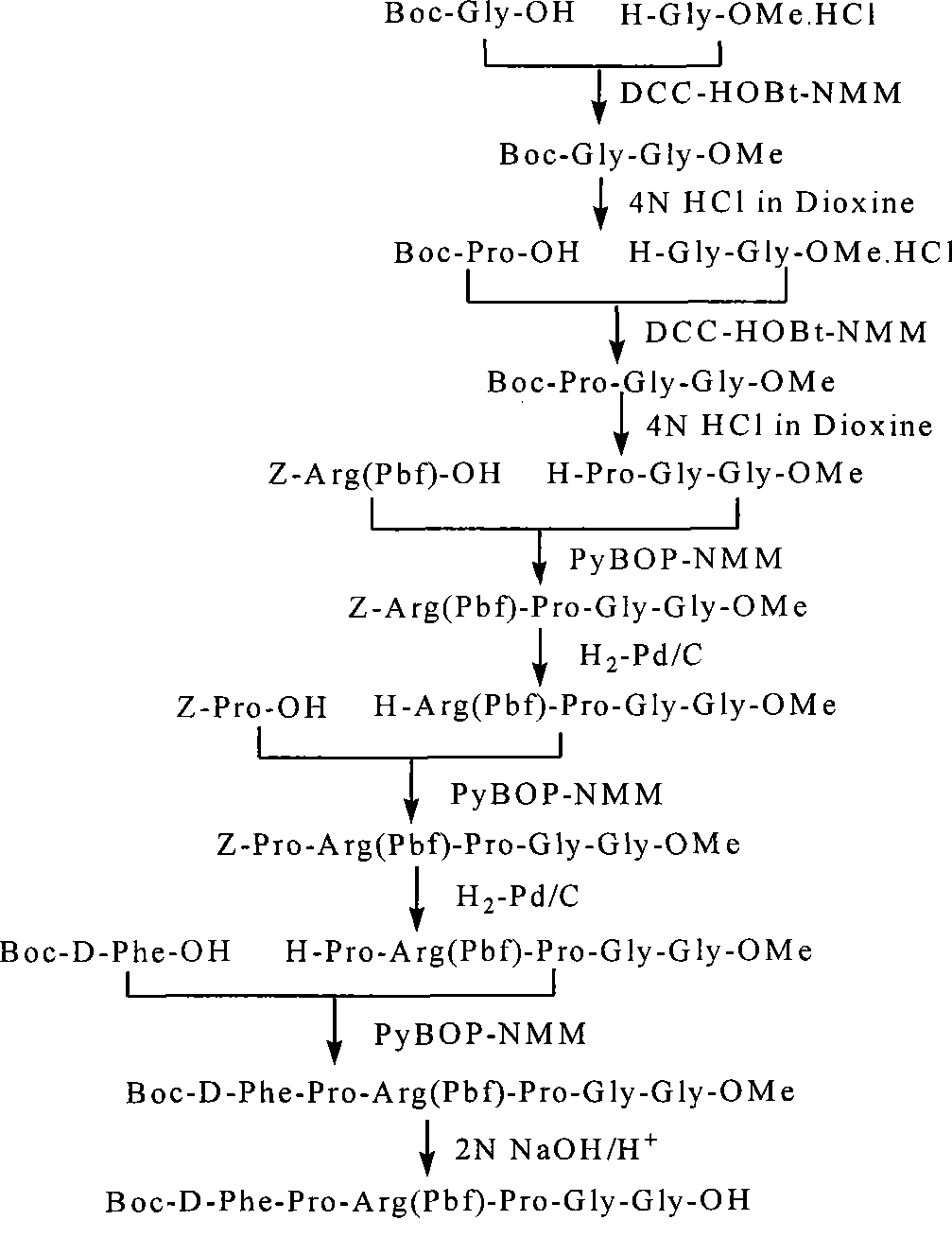

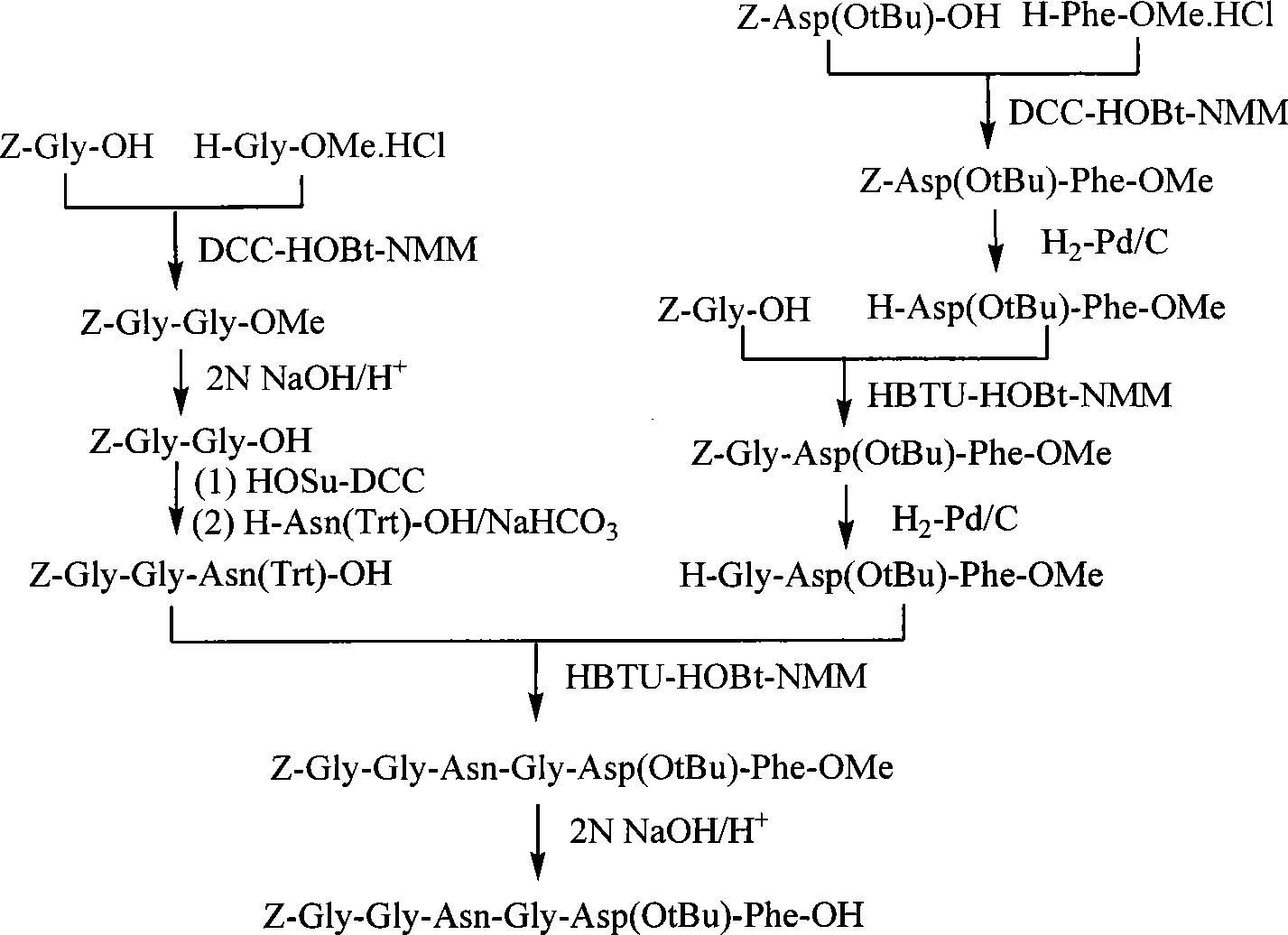

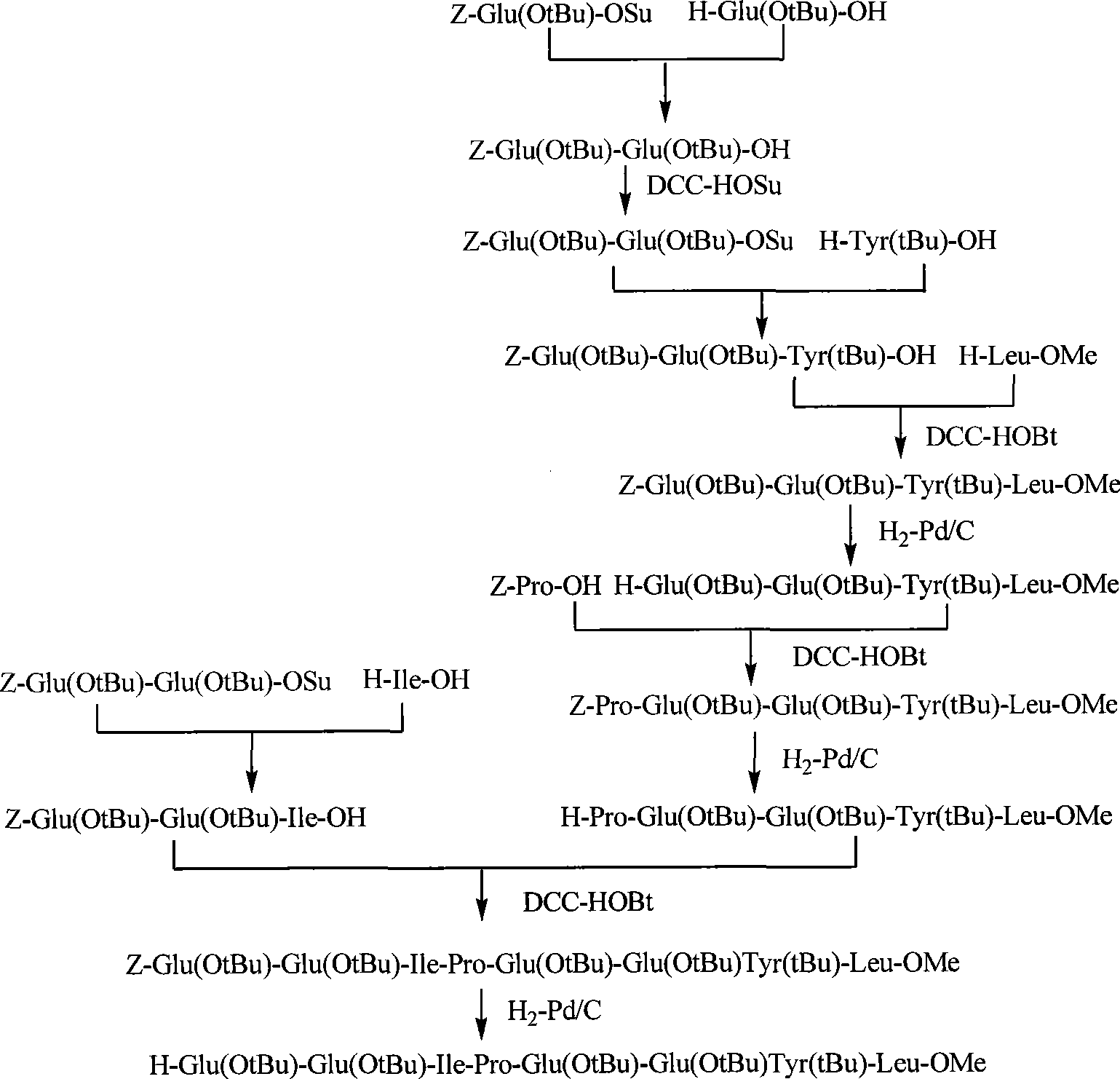

Liquid phase synthesizing method for bivalirudin

ActiveCN101475631ASimple equipmentEasy to achieve large-scale productionPeptide preparation methodsBlood disorderSynthesis methodsCombinatorial chemistry

The invention provides a liquid phase synthesis method for bivalirudin. Firstly, three all-protected fragments, namely 6 peptide with an all-protected N-terminal, 6 peptide with an all-protected middle segment and 8 peptide with an all-protected C-terminal are gradually synthesized, then all-protected bivalirudin is obtained by orderly condensing the three fragments, finally all protective genes are removed to obtain a crude product of the bivalirudin, and then a pure product of the bivalirudin is obtained through high-efficiency liquid chromatography purification. The method does not need a resin, excessive protected amino acid and a condensing agent, is easy to realize mass production, and has relatively lower production cost.

Owner:苏州天马医药集团天吉生物制药有限公司

Battery grade iron and manganese phosphate and preparation method thereof

The invention relates to battery grade iron and manganese phosphate and a preparation method thereof. The chemical composition of the battery grade iron and manganese phosphate is MnxFe(1-x)PO4, wherein x is greater than or equal to 0.1 and smaller than or equal to 0.9; the preparation method comprises the steps of adopting a hydrothermal oxidation-coprecipitation technology, putting a soluble phosphorus source, iron source and manganese source solution into a reaction kettle according to the chemical composition MnxFe(1-x)PO4 of the iron and manganese phosphate, adding a surfactant and nitric acid, controlling the system pH value to be within 1 to 4, stirring for 2 to 48 h at 100 to 250 DEG C, so as to perform hydrothermal reaction, obtaining turbid liquid containing MnxFe(1-x)PO4.yH2O precipitate, naturally cooling the turbid liquid to room temperature, filtering, washing and drying, obtaining MnxFe(1-x)PO4.yH2O, performing high-temperature roasting at 250 to 700 DEG C, and then obtaining the battery grade iron and manganese phosphate not containing crystal water. The method is simple and practicable, and is easy to realize scale production, the prepared iron and manganese phosphate has the advantages that size distribution is uniform, the purity is high, and iron and manganese elements realize atomic-scale uniform distribution, and the battery grade iron and manganese phosphate a belongs to the optimal precursor for preparing lithium ferric manganese phosphate battery materials.

Owner:杨志宽

Lithium titanate/titanium black anode material and preparation method thereof

ActiveCN102496704AImproved magnification performanceImprove cycle performanceCell electrodesTitanium compoundsElectrical batteryTitanium oxide

The invention relates to a lithium titanate / titanium black anode material and a preparation method thereof belonging to the technical field of lithium ion batteries. The lithium titanate / titanium black anode material has a chemical formula of (1-0.8x)Li4Ti5O12-xTi4O7, wherein x is more than 0,03 and is not more than 0.30. The lithium titanate / titanium black anode material can be synthesized by adopting two methods, the first method is as follows: lithium titanate is carbonized in vacuum, a compact titanium black high-conductive membrane is formed on the surface of the lithium titanate through controlling temperature, reaction time and pressure to have higher multiplying power performance; and the second method is as follows: Ti4O7 is directly added in the lithium titanate, and the lithium titanate / titanium black anode material is synthesized under an inert atmosphere at high temperature. The lithium titanate / titanium black anode material has a simple manufacture process and is beneficial to industrialized production. Compared with the current marketized anode material, the lithium titanate / titanium black anode material has higher electrical conductivity and corrosion resistance and higher large-current discharge cycling performance; and multiplying power charge and discharge performances and cycling performance of a lithium ion power battery can be further improved.

Owner:北京盟固利新材料科技有限公司

Soft carbon negative material of lithium ion battery, preparation method of soft carbon negative material and lithium ion battery

ActiveCN103708437AImprove electrochemical performanceReduce manufacturing costCell electrodesSecondary cellsCarbon layerAluminium-ion battery

The invention relates to the field of negative materials of lithium ion batteries and particularly relates to a novel high-volume soft carbon negative material, a preparation method thereof and a lithium ion battery utilizing the soft carbon negative material. The soft carbon negative material comprises a soft carbon powder particle kernel, a nanometer material coating and a conductive carbon layer, wherein the nanometer material coating is loaded on a surface layer of the soft carbon powder particle kernel in a monodisperse manner, and the outer surface of the nanometer material coating is coated by the conductive carbon layer. The soft carbon negative material has high volume and initial charge-discharge efficiencies and excellent rate capability and cycle performance. The soft carbon anode material is prepared by the steps of with soft carbon powder as a ram material, sequentially carrying preburning, nanometer material spraying and conductive carbon layer coating. The preparation method is simple and is easy to control, the manufacturing cost is low, and the scale production is easy to realize.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Kevlar aerogel film, and preparation method and application thereof

The invention discloses a Kevlar aerogel film, and a preparation method and application thereof. The Kevlar aerogel film has a communicating three-dimensional network-like porous structure formed by mutual overlapping of Kevlar nanofibers. The preparation method comprises: dissolving Kevlar fibers to form a Kevlar nanofiber sol; applying the Kevlar nanofiber sol to a substrate, and then transferring the substrate to a coagulation bath, and performing a sol-gel process and a subsequent solvent replacement process to form a Kevlar gel film; and finally, conducting drying to obtain the Kevlar aerogel film. The Kevlar aerogel film of the invention has high specific surface area and porosity, good flexibility, thermal stability and chemical stability, and the preparation process is simple, andis easy for continuous large-scale production. The Kevlar aerogel film can be directly used as a dielectric material, a sound insulation material, a heat insulation material, a filter film material, etc., and can also be used as a substrate of a flexible functional composite material.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method preparing catalyzer through liquid phase ball-milling partial reduction method and ternary copper catalyzer

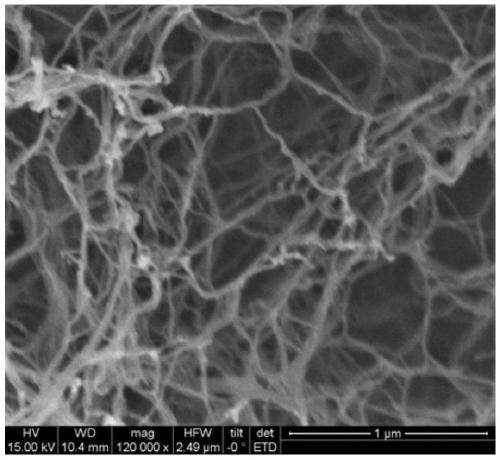

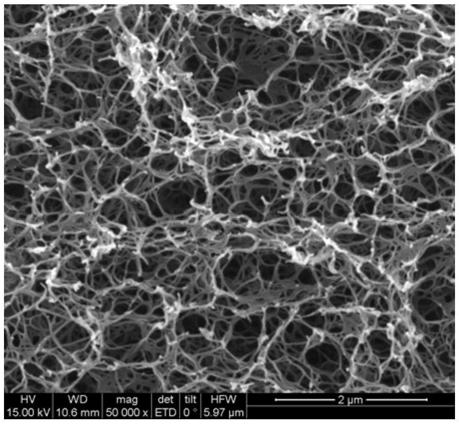

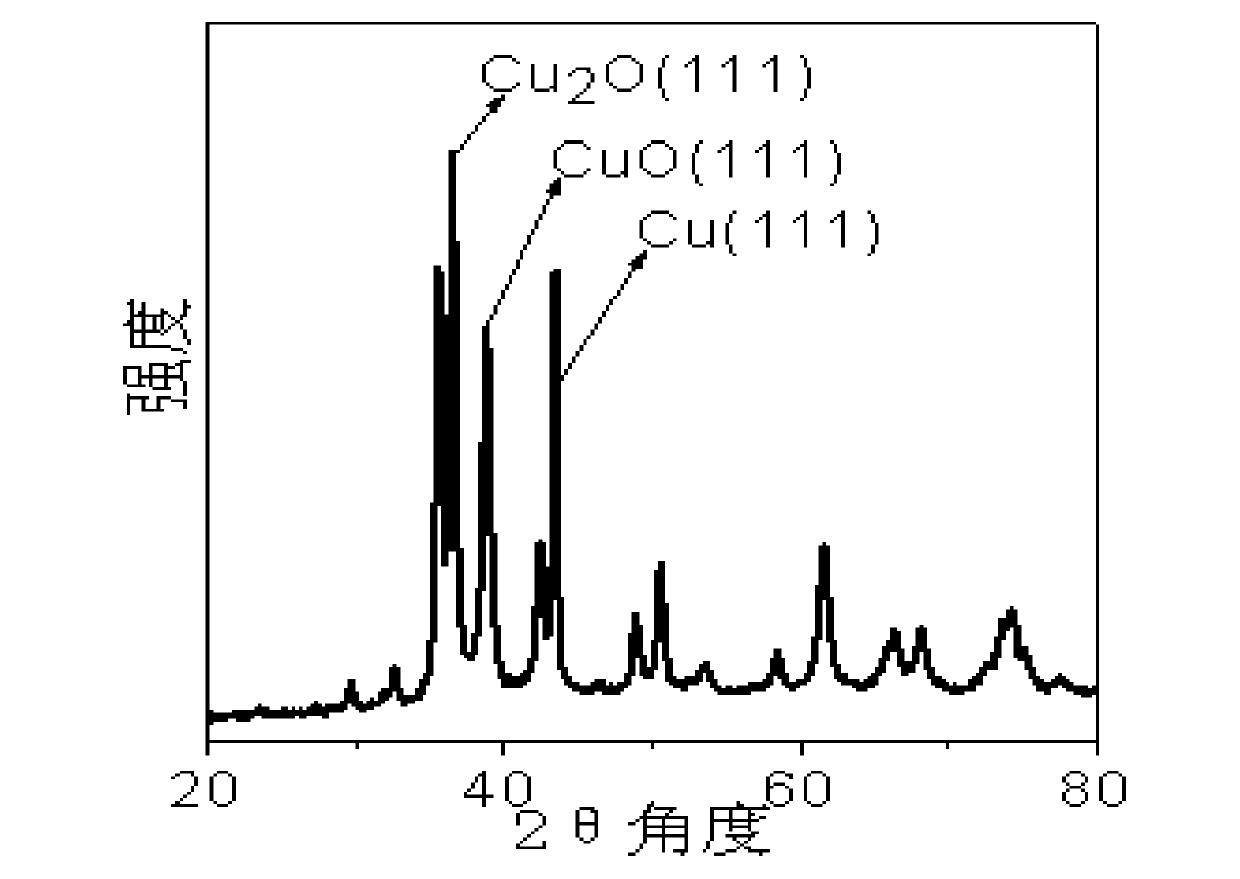

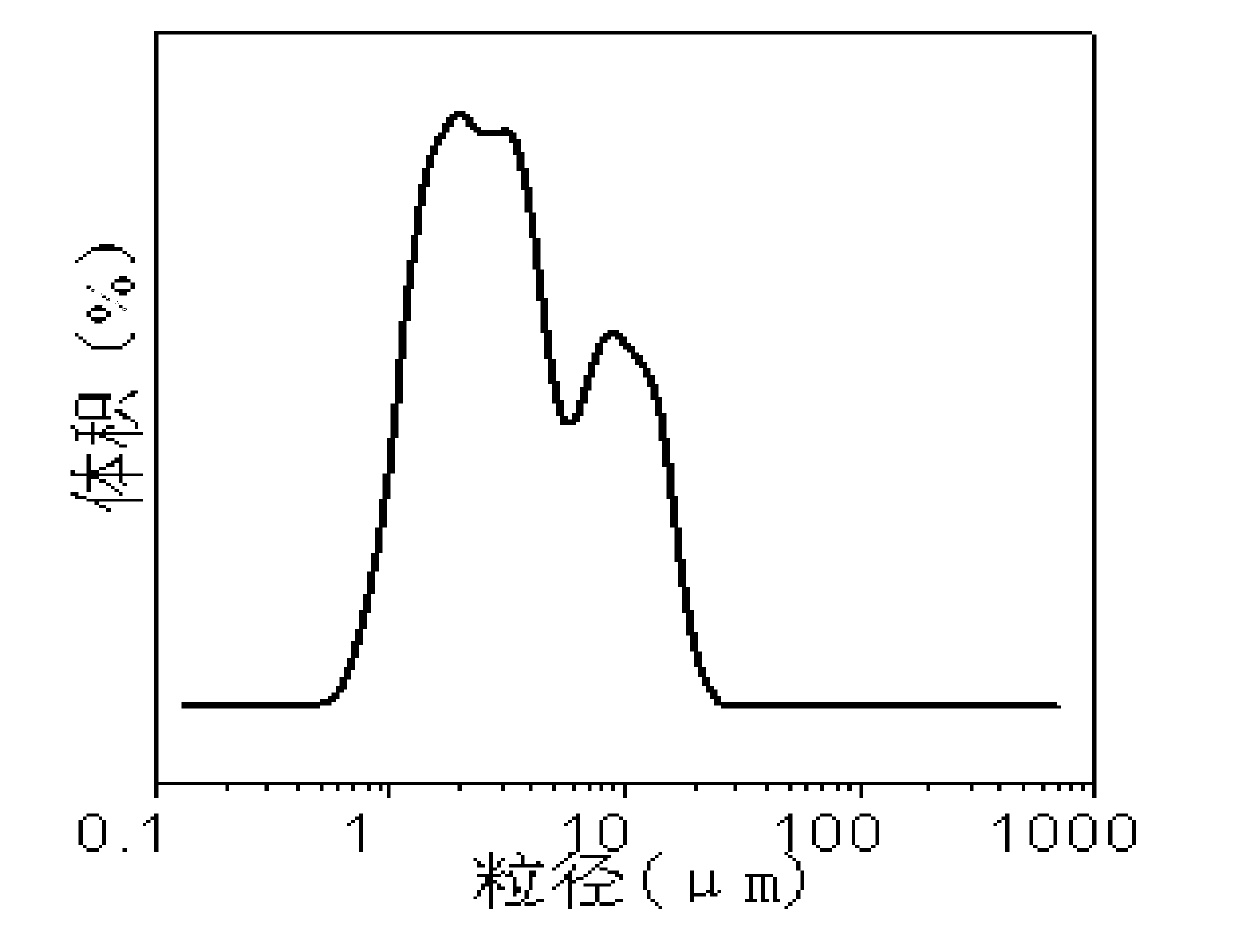

ActiveCN103127936AEnhanced ability to participate in reduction reactionsEnhanced interactionGroup 4/14 element organic compoundsCatalyst activation/preparationFiltrationCopper oxide

The invention relates to a method preparing a copper catalyzer used for dimethyldichlorosilance synthetic reaction through a liquid phase ball-milling partial reduction method. The method includes the steps of taking copper oxide as raw material, adding solvent media containing reducing substances, enabling copper oxide particles to become small and achieve partial reduction through mechanical ball-milling, obtaining the copper-based catalyzer containing the ternary components of copper, cuprous oxide, copper oxide after suction filtration, drying and smashing, and obtaining the ternary copper catalyzer with adjustable components and controllable particles through adjusting the parameters of reducing agent types, concentration and ball-milling conditions. In catalytic reaction of organosilicone monomer synthesis, the catalyzer is high in catalytic activity and selectivity and helpful for improving the processing ability of an existing organosilicone monomer device, reduces production cost, and improves the yield of target products. The method preparing the catalyzer through the liquid phase ball-milling partial reduction method is simple in process, mild in condition and convenient to operate, and brings convenience to achieve large scale production.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

Porous negative pole piece and preparation method thereof, and lithium ion battery

InactiveCN103779581AHigh specific capacityReduce difficultyElectrode carriers/collectorsSecondary cellsSystem capacityPole piece

The embodiment of the invention provides a porous negative pole piece which comprises a porous current collector and an active substance deposited in a hole of the porous current collector, wherein the active substance is one or more of Si, Sn, Al, Sb, Ge, Zn, Pb, Mg, and Na, the hole is a through hole, and the active substance is deposited on the inner wall of the hole. The negative pole sheet is high in capacity and stable in structure, so that the system capacity of a lithium ion battery is finally increased, and the recycling service life of the battery is prolonged. The embodiment of the invention further provides a preparation method of the porous negative pole sheet, and the lithium ion battery comprising the porous negative pole sheet.

Owner:HUAWEI TECH CO LTD

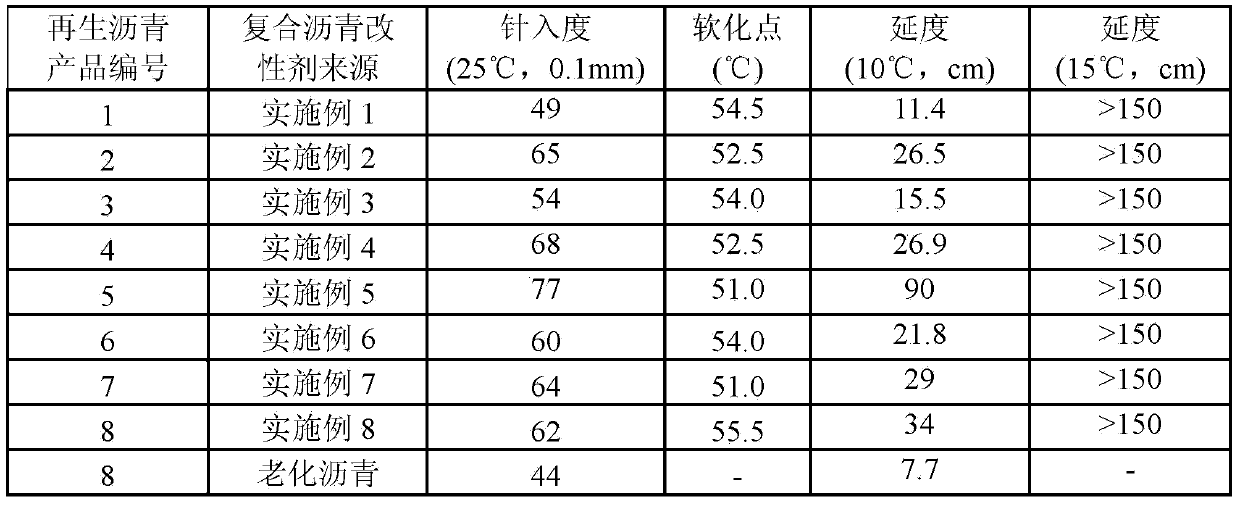

A vegetable oil-type asphalt recycling agent and a method for preparing the same

A vegetable oil-type asphalt recycling agent is composed of component A and component B, wherein the component A is one or two selected from asphalt and residual oil; and component B is a composition of vegetable oil and an alcohol, a composition of vegetable oil and a thermoplastic elastomer, or vegetable oil or vegetable oil prepolymer; and based on the total weight of the asphalt recycling agent, the content of component A is 40-95 % by mass, and the content of component B is 5-60% by mass. The present invention also discloses a method for preparing the vegetable oil-type asphalt recycling agent.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

A synthesis method for a high-capacity and high-nickel multi-metal oxide cathode material

ActiveCN103066261ACost effective high capacity highIncrease capacityCell electrodesSecondary cellsSynthesis methodsOxide cathode

The present invention discloses a synthesis method for a high-capacity and high-nickel multi-metal oxide cathode material, and the method comprises the steps of: (1) in the presence of water, an aqueous solution or a solvent, grinding lithium, cobalt, nickel, and a metal M compound; (2) spray-drying the above mixture; (3) high-temperature sintering the mixture to obtain LiNi[x]Co[y]M[z]O[2]; and (4) introducing a coating on the LiNi[x]Co[y]M[z]O[2] surface to obtain the cathode material. The coated LiNi[x]Co[y]M[z]O[2] material shows excellent electrochemical performance, for instance, under 0.1C and 3C, the discharge capacity of the LiNi[0.928]Co[0.069]Mg[0.003]O[2] material coated by LiCoO[2] can respectively be more than 200 and 165mAh / g (2.75-4.3V vs Li / Li <+>). The synthesis method of the present invention has the characteristics of being simple in the implementation of method, low in costs of processes and raw materials, and easy to realize industrialization.

Owner:LONG POWER SYST NANTONG CO LTD

Preparing method for fine sheet metal magnetically soft alloy powder

ActiveCN104858441AImprove permeabilityHigh strengthInorganic material magnetismMicrometerGranularity

The invention relates to a preparing method for fine sheet metal magnetically soft alloy powder and belongs to the technical field of metal and alloy powder preparation. The method comprises the steps that two or three of Fe, Si, Al, Ni and Mo are selected as raw materials to carry out alloy distributing; a medium-frequency induction furnace is adopted for carrying out alloy smelting; a two-flow atomization method is adopted for carrying out atomizing on a melt, and alloy powder approximately spherical is prepared; by means of mechanical milling, flattening is carried out on the alloy powder; annealing treatment is carried out on the obtained sheet powder, and by means of an ultrasonic vibrating sieve, the fine sheet metal magnetically soft alloy powder is prepared. The powder prepared through the method, the granularity ranges from 10 micrometers to 100 micrometers, the average thickness ranges from 0.1 micrometer to 5 micrometer, the radial thickness ratio ranges from 50 to 500, and the powder flattening rate reaches 90%. According to the method, the powder preparing process is simple, the production efficiency is high, the production cost is low, the quality of the magnetically soft powder core can be effectively improved, and the manufacturing cost is reduced.

Owner:有研增材技术有限公司

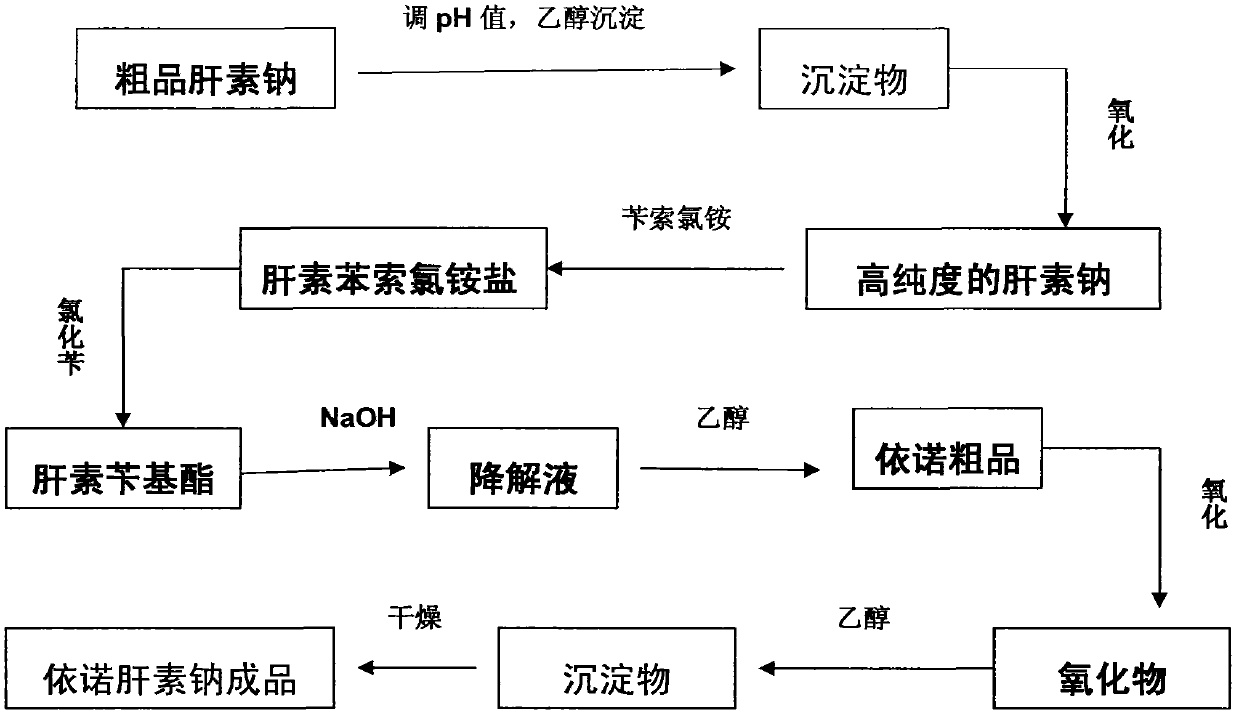

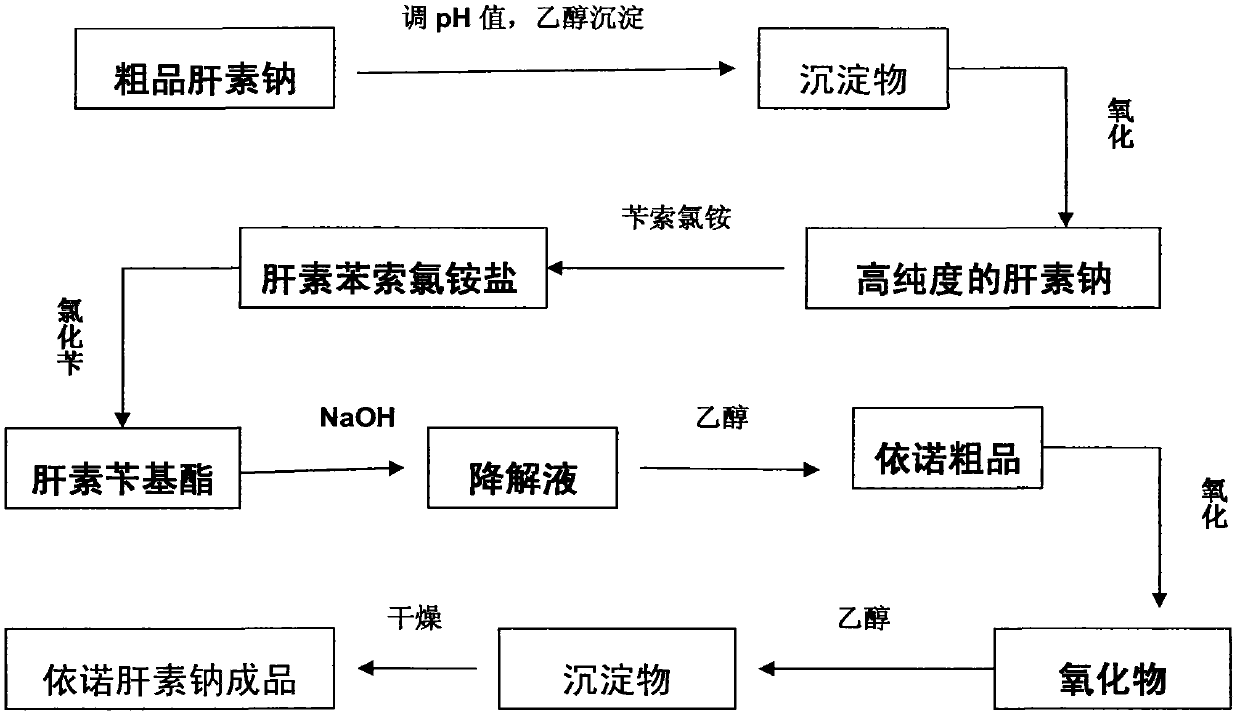

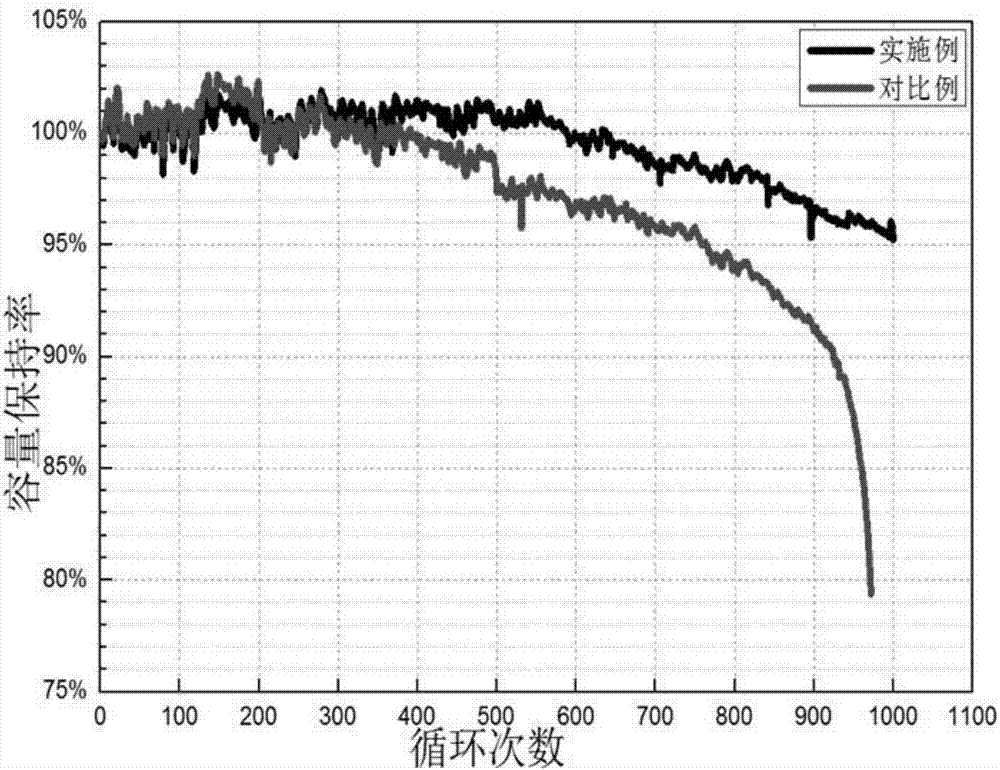

Method for directly producing enoxaparin sodium from crude product heparin sodium

ActiveCN102603925AControl impurity contentReduce intermediate environmentOrganic solventDepolymerization

The invention relates to a preparation method for directly producing enoxaparin sodium from crude product heparin sodium. The preparation method comprises the following steps of: taking the crude product heparin sodium as a raw material, performing fractionated precipitation through an organic solvent to remove most of impurities in the crude product heparin sodium, and then removing part of residual impurity proteins, pigments and other impurities by oxidation through hydrogen peroxide so as to get the high-purity heparin sodium which is in line with the production requirements of the enoxaparin sodium; and taking the high-purity heparin sodium as an intermediate product, preparing a heparin quaternary ammonium salt, preparing heparin benzyl ester, performing alkaline depolymerization on the heparin benzyl ester, neutralizing with an acid, performing alcohol precipitation, refining, decoloring, dehydrating and drying to get an enoxaparin sodium finished product. By adopting the method disclosed by the invention, the use of the organic solvent is greatly reduced, the production efficiency is improved, the influences on the environment are reduced, the enoxaparin sodium finished product which achieves or is better than European Pharmacopoeia 7.0 version is obtained, and the method is simple to operate and can realize industrialized production.

Owner:DONGYING TIANDONG PHARM CO LTD

Lithium ion secondary battery and preparation method thereof

ActiveCN102569896AExcellent high power discharge performanceImproved High Power Discharge PerformanceFinal product manufactureElectrolyte accumulators manufactureCharge currentPhysical chemistry

The invention provides a preparation method of a lithium ion secondary battery. The method comprises the following steps of: accommodating a battery pole in a battery shell; injecting non-aqueous electrolyte into the battery shell; and performing charging formation and then sealing the battery shell in which the non-aqueous electrolyte is injected, wherein the non-aqueous electrolyte contains one or more additives; the one or more additives are one or more of aniline monomers and pyrrole monomers; the charging formation comprises one or more constant current charging processes; at least one charging current in the constant current charging is 0.001-0.05 C; and the cut-off voltage of the charging formation is 3.6-4.2 V. The invention also provides the lithium ion secondary battery prepared by the method provided by the invention. The lithium ion secondary battery prepared by the method provided by the invention has superior high-power discharge performance. The method according to the invention is simple and practical and is easy for realizing large-scale production.

Owner:BYD CO LTD

Method for quickly forming soft power lithium-ion cell

ActiveCN107579302AHelps to formImprove conductivitySecondary cells charging/dischargingElectricityLithium

The invention discloses a method for quickly forming a soft power lithium-ion cell. The method comprises the following steps: (S1) supplying a heat source for heating a cell by using a heating plate;(S2) driving a pressurizing plate to pressurize the cell by using a servo motor; (S3) performing gradient charging on the cell; and (S4) charging the cell till reaching high charge state. According tothe invention, a stable, compact and uniform SEI film is formed on a cathode surface, the performance of the lithium-ion cell is greatly promoted, the early failure of the lithium-ion cell in the circulating process is avoided, the yield of the cell is increased, the cell quality is optimized, the forming time of the cell is shortened, the large-scale production of the cell is realized and the method has wide application prospect.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

Preparation method of mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material

The invention relates to a preparation method of a mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material, which comprises the following steps: by using surface-pretreated mullite fibrofelt as a reinforcer, tetraethyl orthosilicate as a silicon source, cheap inorganic aluminum salt as an aluminum source and epoxide as a network formation agent, uniformly mixing, and carrying out sol-gel, aging and supercritical drying to obtain the mullite-fibrofelt-reinforced SiO2-Al2O3 aerogel composite heat-insulating material. In the preparation process, no catalyst is needed, and a one-step method is adopted to greatly optimize the preparation technique. Thus, the heat-insulating material has the advantages of low cost, smooth surface and controllable thickness, and can resist the temperature of 1200 DEG C in an air atmosphere. The room temperature thermal conductivity is 0.023-0.027 W.m<-1>K<-1>, and the apparent density is 0.18-0.22 g / cm<3>. The method has the advantages of simple materials, low cost and simple technique, is simple to operate in the technical process, and can easily implement large-scale production.

Owner:NANJING UNIV OF TECH

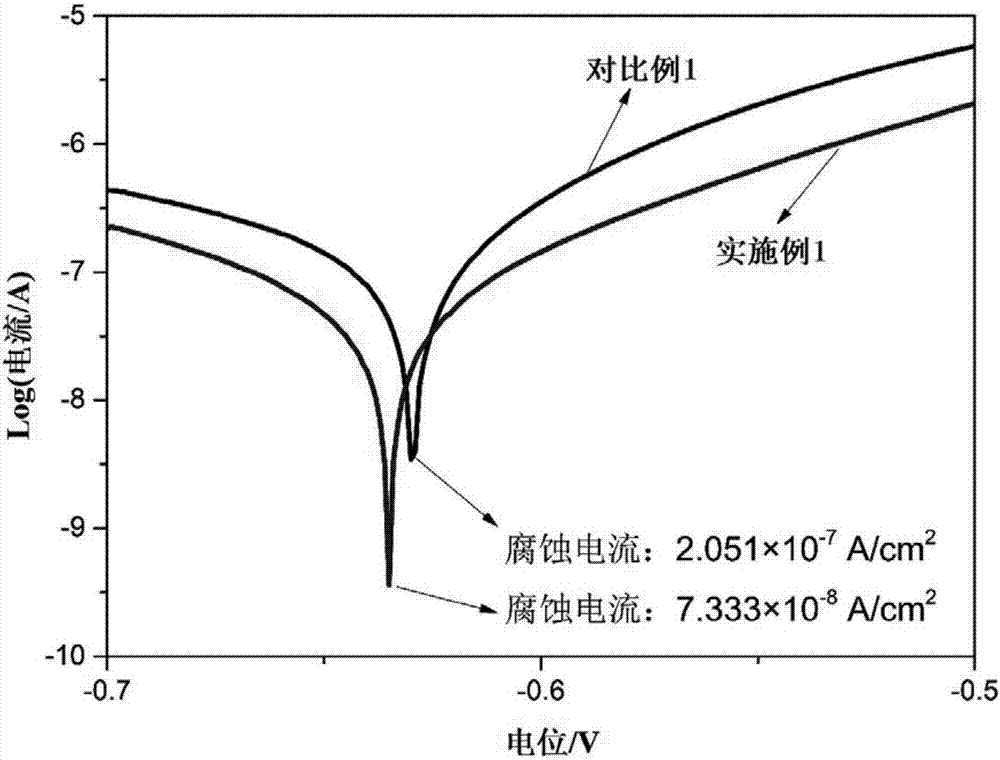

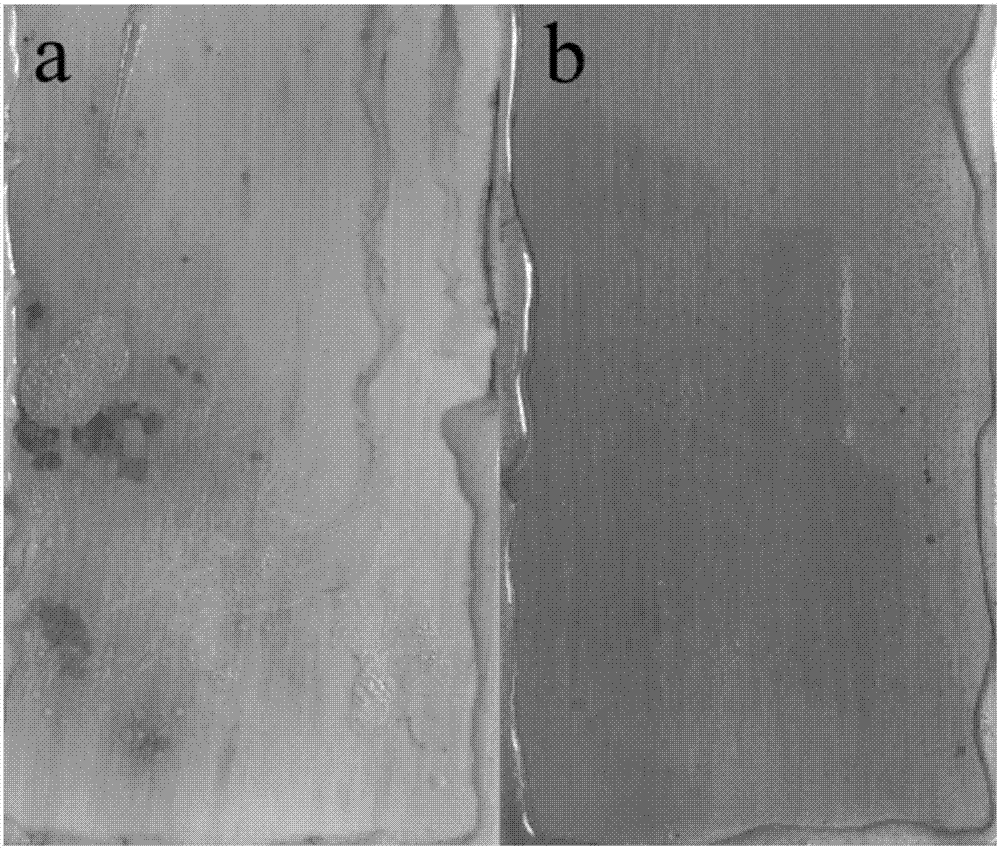

Water-based coating containing graphene/zinc-aluminum hydrotalcite nano composition and preparation method thereof

InactiveCN106995643AImprove compatibilitySolve reunionFireproof paintsAnti-corrosive paintsWater basedDefoaming Agents

The invention discloses water-based coating containing a graphene / zinc-aluminum hydrotalcite nano composition and a preparation method thereof. The water-based coating is prepared from the following components in parts by weight: 30 to 50 parts of water-based resin, 25 to 40 parts of water, 0.1 to 0.5 part of dispersing agent, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of defoaming agent, 0.1 to 0.5 part of thickening agent, 0.1 to 0.5 part of film forming aids, 0 to 10 parts of curing agent, 0 to 25 parts of titanium dioxide, 0 to 20 parts of calcium carbonate, and 0.1 to 2.5 parts of graphene / zinc-aluminum hydrotalcite nano composition. The graphene / zinc-aluminum hydrotalcite nano composition is added into the water-based coating, so that the high temperature resistance, the corrosion resistance, the flame retardant property, the weather resistance, the impact resistance, the abrasion resistance, the hardness and the obstruction property of the water-based coating are significantly improved, and the multiple functions of the water-based coating are improved.

Owner:东营聚强新材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com