Porous negative pole piece and preparation method thereof, and lithium ion battery

A technology of lithium ion battery and negative pole piece, which is applied to battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve problems such as battery structure damage, and achieve the effect of prolonging cycle life, reducing difficulty and high capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

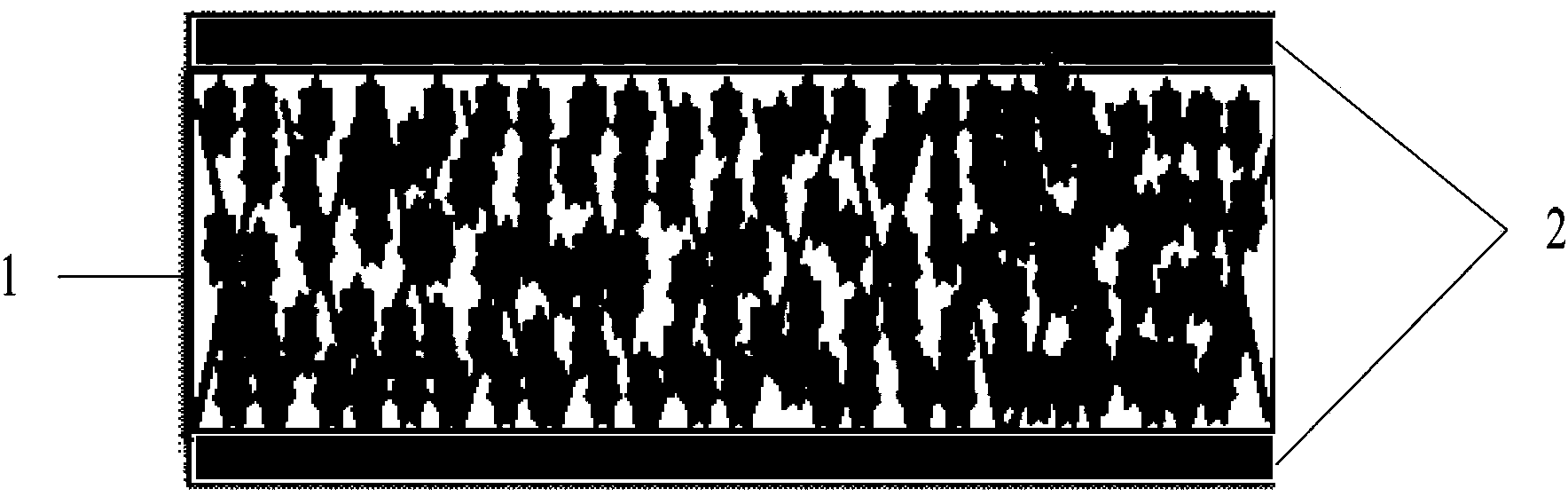

[0057] In the second aspect, an embodiment of the present invention provides a method for preparing a porous negative electrode sheet, including: providing a clean porous current collector, and depositing an active material on the porous current collector by chemical vapor deposition, hot gas deposition or electrochemical deposition. In the pores of the porous current collector, the active material is one or more of Si, Sn, Al, Sb, Ge, Zn, Pb, Mg and Na, the pores are through holes, and the active material is deposited on on the inner wall of the hole.

[0058] The specific description of the active substance is as mentioned above, and will not be repeated here.

[0059] The porous current collector may be porous nickel foam, copper foam, aluminum foam, stainless steel mesh, nickel mesh, copper mesh or aluminum mesh. The porous current collector requires routine cleaning operations before depositing active materials.

[0060] The thickness of the porous current collector can...

Embodiment 1

[0078] A method for preparing a porous negative electrode sheet, comprising:

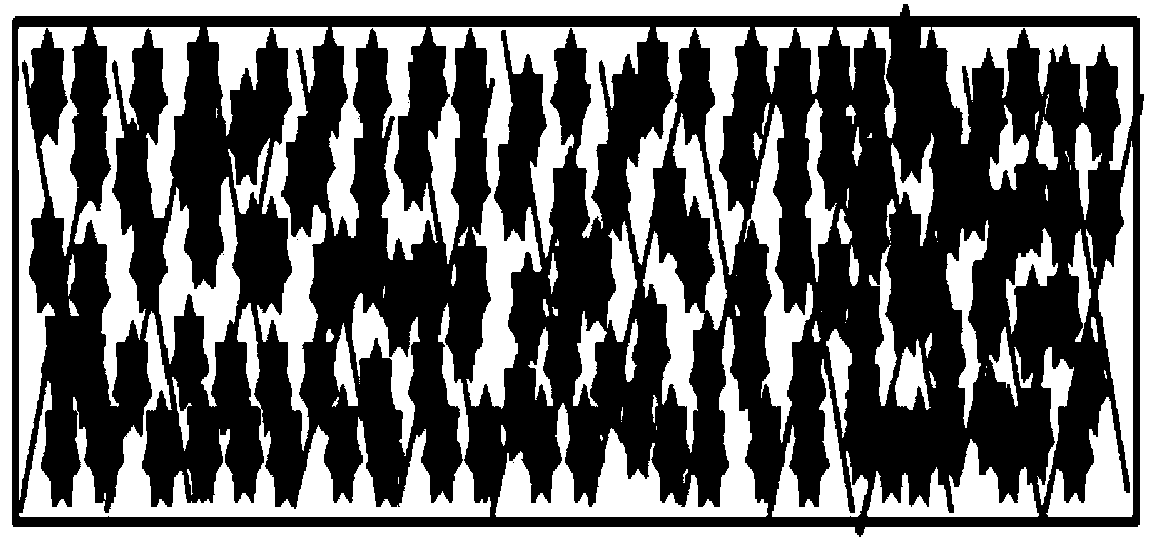

[0079] A clean porous copper foam current collector with a thickness of 100 μm is provided, and the active substance Sn is directly deposited in the pores of the current collector by electrochemical deposition. Specifically, the porous copper foam current collector is placed in a concentration of 1mol / L sulfurous acid In the tin electroplating solution, the electroplating current is 80mA, and the deposition time is 5h, so that the active material Sn fully occupies the pores of the foamed copper current collector, that is, a porous negative electrode sheet is obtained. In this embodiment, the hole spacing is 0.8 mm. figure 1Schematic diagram of the structure of the porous negative pole piece prepared for this example. It can be seen from the figure that the concentration of tin plating solution and the current density of electroplating can be reasonably controlled, so that the Sn particles of nanopar...

Embodiment 2

[0084] A method for preparing a porous negative electrode sheet, comprising:

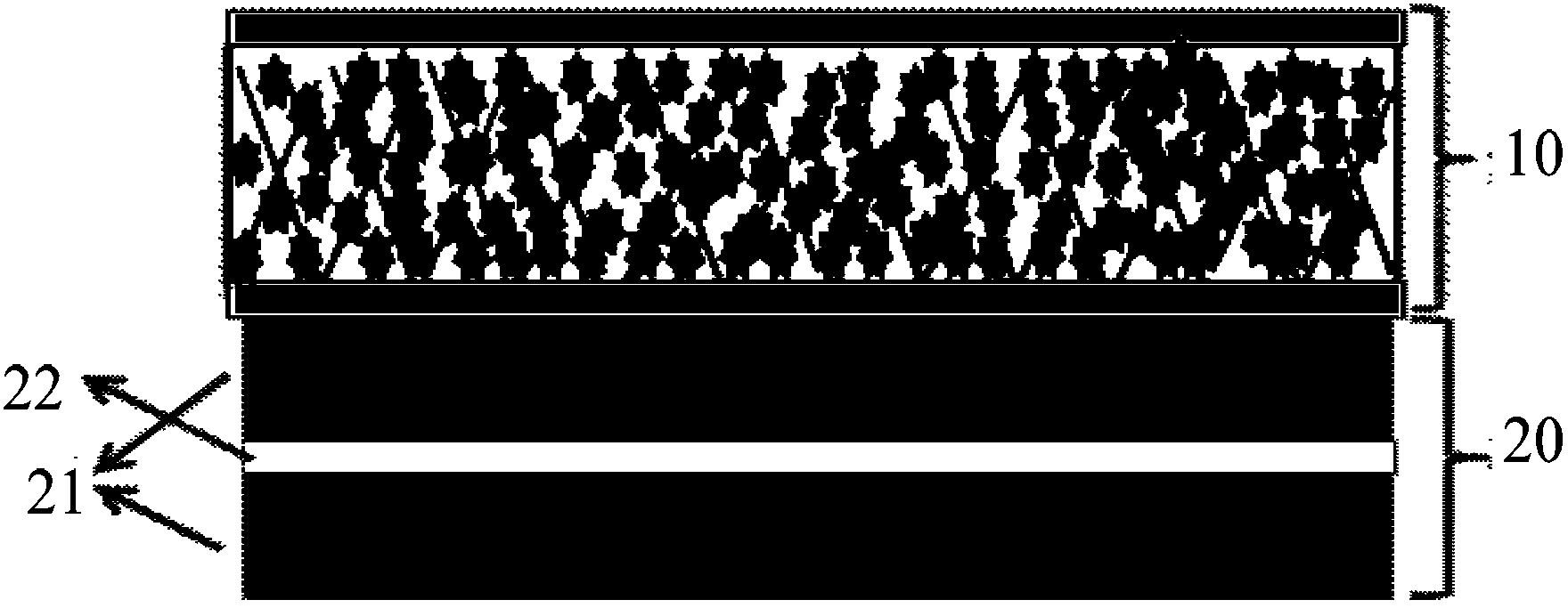

[0085] (1) Provide a clean porous nickel foam current collector with a thickness of 200 μm, and directly deposit active material Si in the pores of the current collector by chemical vapor deposition. Specifically, place the porous nickel foam current collector in chemical vapor deposition equipment, Introduce silane gas, and prepare nano-silicon material by cracking silane at 900~950°C, so that the pores of the foamed nickel current collector are filled with Si;

[0086] (2) On the surface of the current collector on which the active material Si is deposited, a protective coating with a thickness of 10 μm is coated on each of the two surfaces of the current collector by coating method. The materials of the protective coating include PVDF-HFP and Al 2 o 3 , the Al 2 o 3 The mass fraction is 30%. Specifically, PVDF-HFP and Al 2 o 3 It is added to the organic solvent NMP to prepare a slurry, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com