Patents

Literature

54results about How to "Reduce swelling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous negative pole piece and preparation method thereof, and lithium ion battery

InactiveCN103779581AHigh specific capacityReduce difficultyElectrode carriers/collectorsSecondary cellsSystem capacityPole piece

The embodiment of the invention provides a porous negative pole piece which comprises a porous current collector and an active substance deposited in a hole of the porous current collector, wherein the active substance is one or more of Si, Sn, Al, Sb, Ge, Zn, Pb, Mg, and Na, the hole is a through hole, and the active substance is deposited on the inner wall of the hole. The negative pole sheet is high in capacity and stable in structure, so that the system capacity of a lithium ion battery is finally increased, and the recycling service life of the battery is prolonged. The embodiment of the invention further provides a preparation method of the porous negative pole sheet, and the lithium ion battery comprising the porous negative pole sheet.

Owner:HUAWEI TECH CO LTD

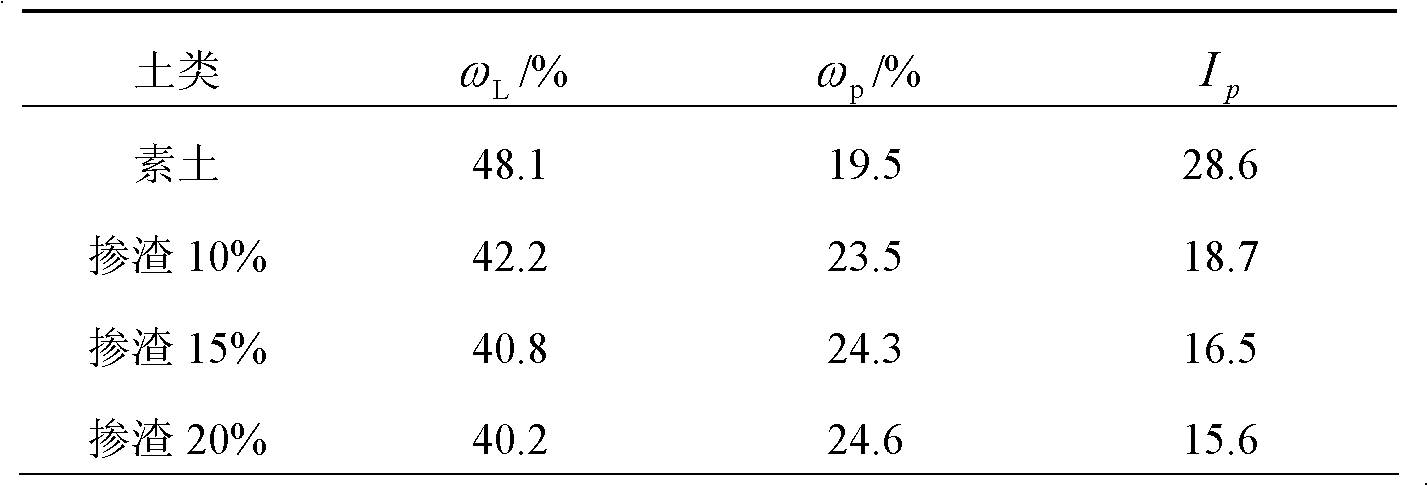

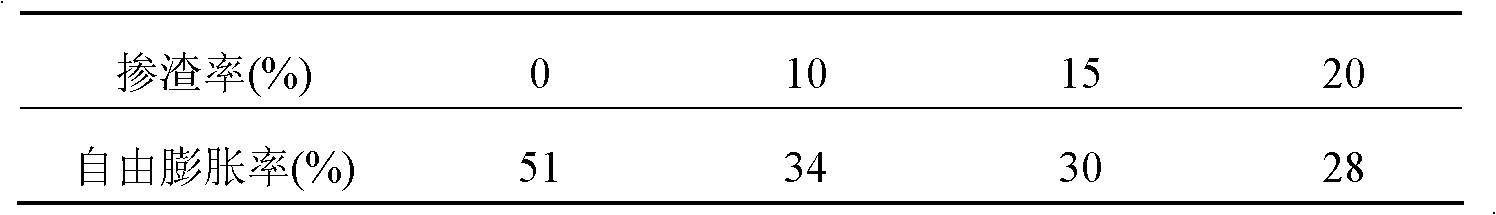

Method for improving expansive soil and construction method thereof

InactiveCN103184733AReduce swelling effectImprove water stabilityBuilding constructionsOrganic fertilisersSoil scienceSlag

The invention discloses a method for improving expansive soil and a construction method thereof. The method for improving expansive soil comprises the following steps of: 1) at the mass ratio of 15-20% of modifying agent and dry soil, evenly stirring the modifying agent and expansive soil to obtain composite soil; 2) determining the optimal moisture content of the composite soil; 3) regulating the moisture content of the composite soil obtained in step 1) to keep at the optimal moisture content; and under the natural condition, tightly covering materials to obtain the improved expansive soil. The method is characterized in that the modifying agent is blast furnace grain slag, and the blast furnace grain slag comprises the following main chemical ingredients in parts by mass: 38-43% of CaO, 33-38% of SiO2, 15-16% of Al2O3 and 4-8% of MgO. According to the improved expansive soil, the expansibility of the expansive soil can be eliminated, the water stability of the expansive soil is improved, and the strength required by the engineering is satisfied.

Owner:HOHAI UNIV

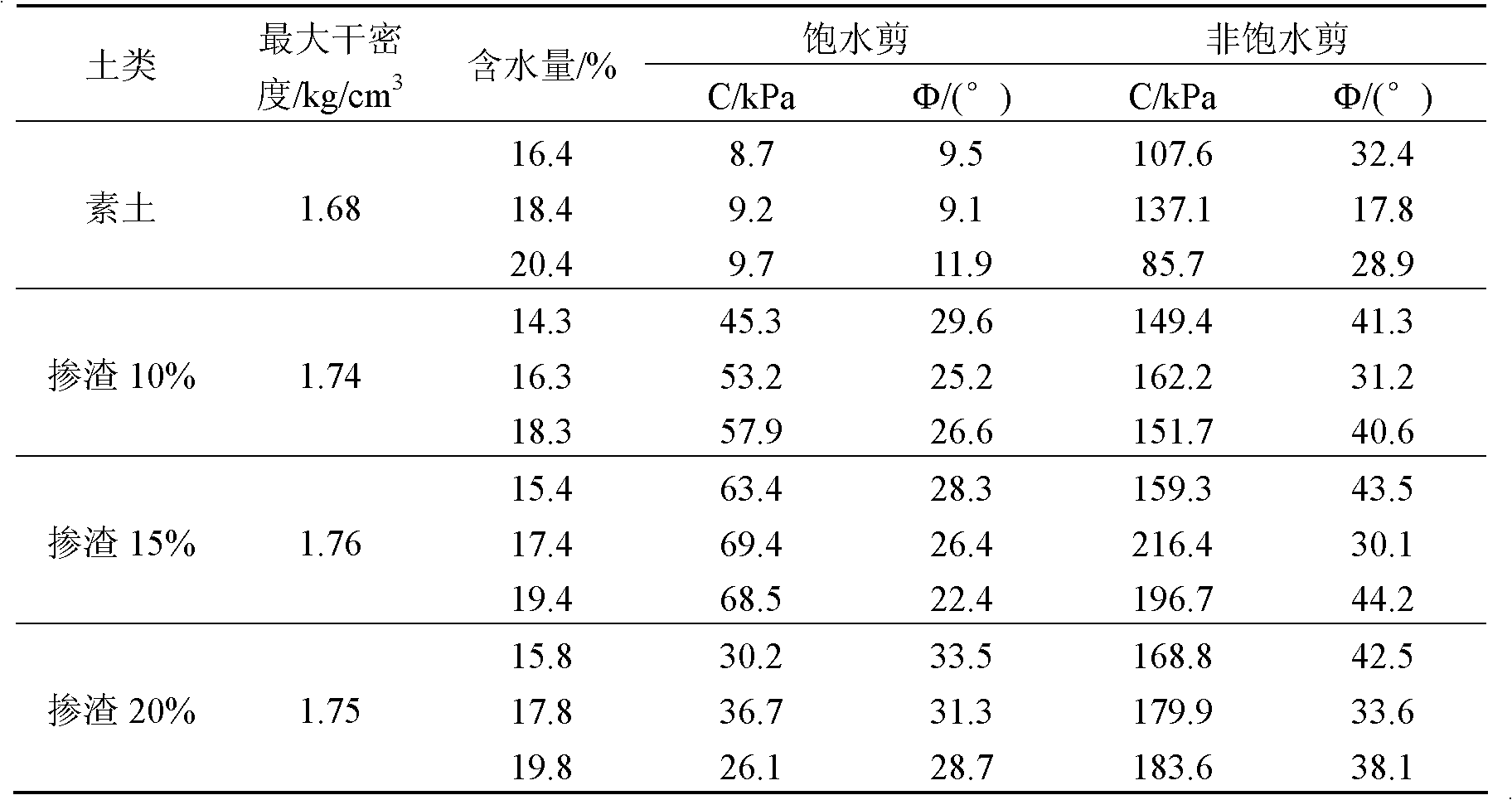

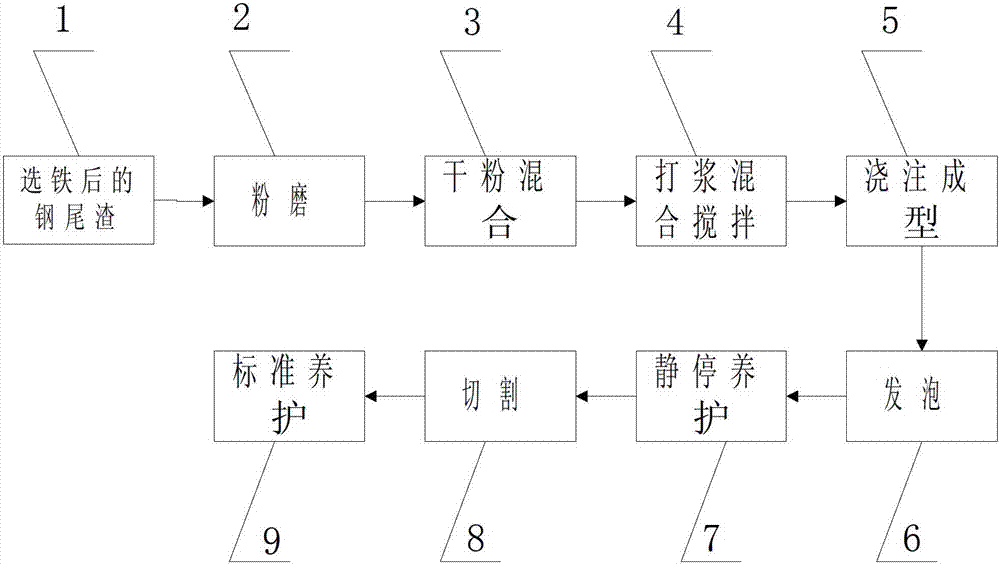

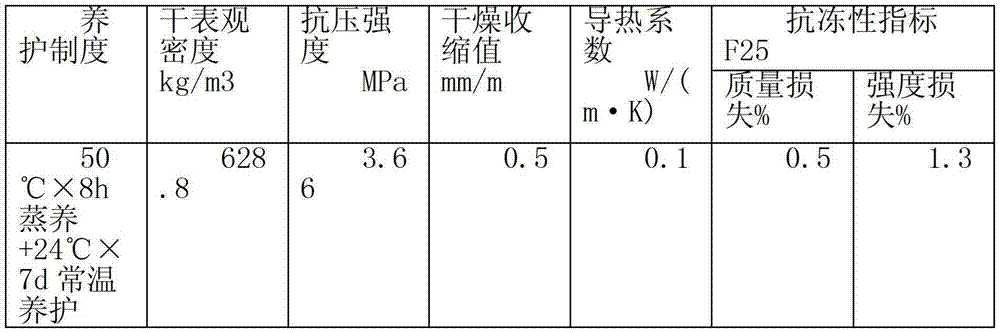

Production method of foamed concrete block manufactured from steel slag

ActiveCN103159450AReduced dry shrinkageIncrease profitSolid waste managementCeramicwareFoam concreteSlag

The invention relates to a production method of a foamed concrete block manufactured from steel slag. The work flow comprises the following steps: 1, taking tailing steel slag after iron dressing; 2, grinding; 3, mixing dry powder; 4, pulping, mixing, and stirring; 5, performing casting molding; 6, foaming; 7, performing static curing; 8, cutting; and 9, performing standard curing. The production method comprises the following specific steps: crushing the steel slag, screening, performing magnetic separation, grading, and drying; performing water quenching on blast furnace slag, and drying; mixing the ground steel slag and ore slag powder with cement clinker, gypsum, lime and the like according to certain weight percents, wherein the ground tailing steel slag powder accounts for 20-60%, the ground ore slag powder accounts for 20-55%, the natural gypsum accounts for 4-10%, the lime accounts for 3-9%, and the cement clinker accounts for 6-12%; mixing and stirring the raw materials, adding water of 40-60 DEG C, and quickly stirring for 1-2 minutes; adding gas-forming aluminum powder, uniformly stirring, and pouring into a mold; and placing in a steam curing box, performing gas forming and steam curing, dismounting the mold, cutting, and curing at normal temperature for 7-12 days. The invention has the following advantages: the produced foamed concrete block meets the requirements of standards; the production cost is low; and comprehensive utilization of resources, energy saving and emission reduction are realized.

Owner:北京中冶设备研究设计总院有限公司

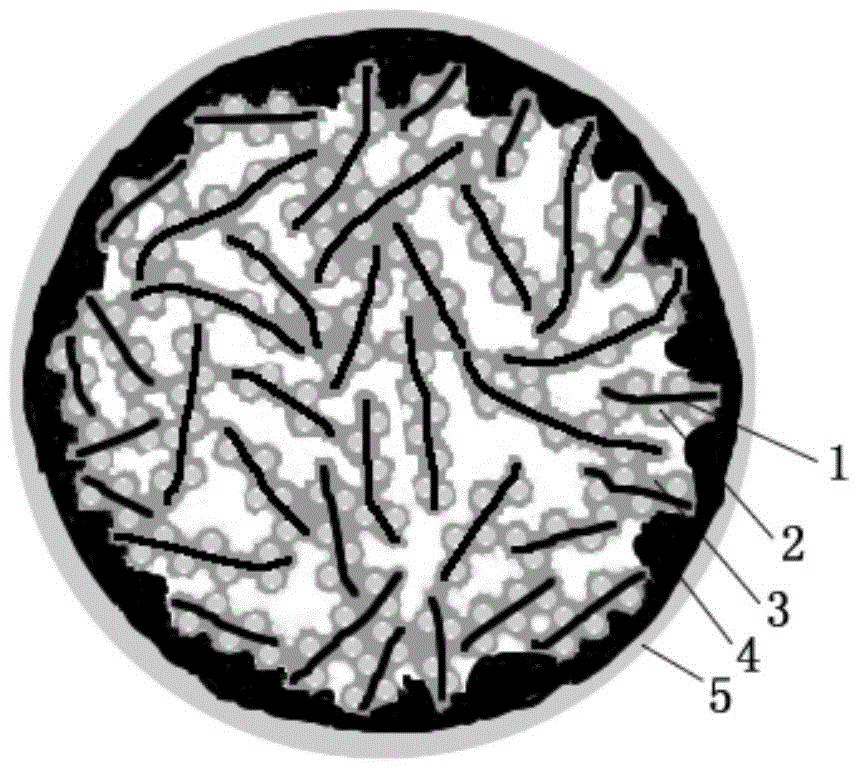

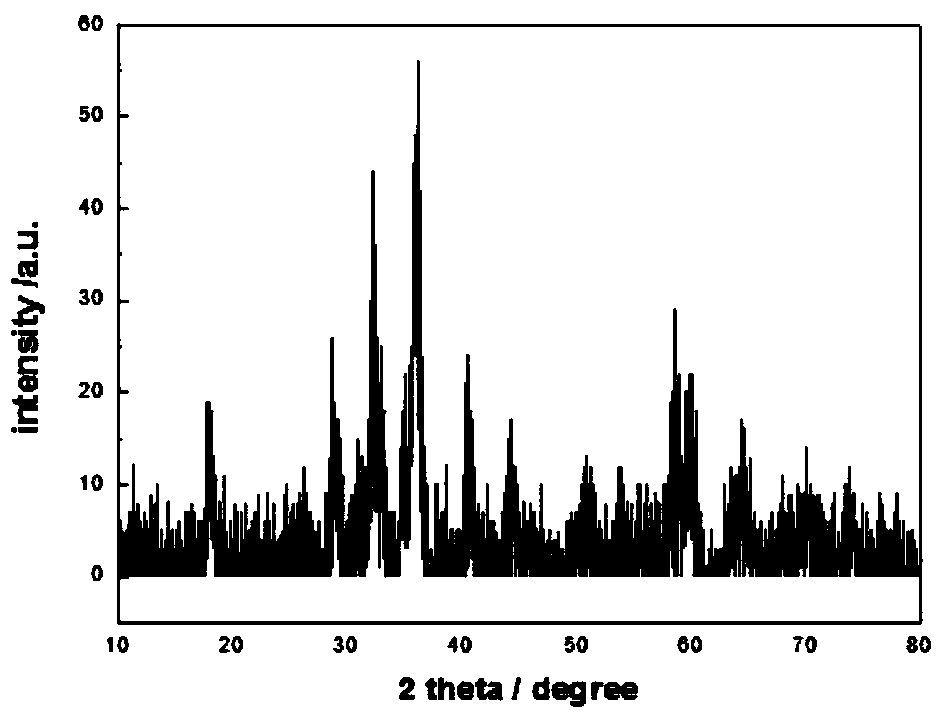

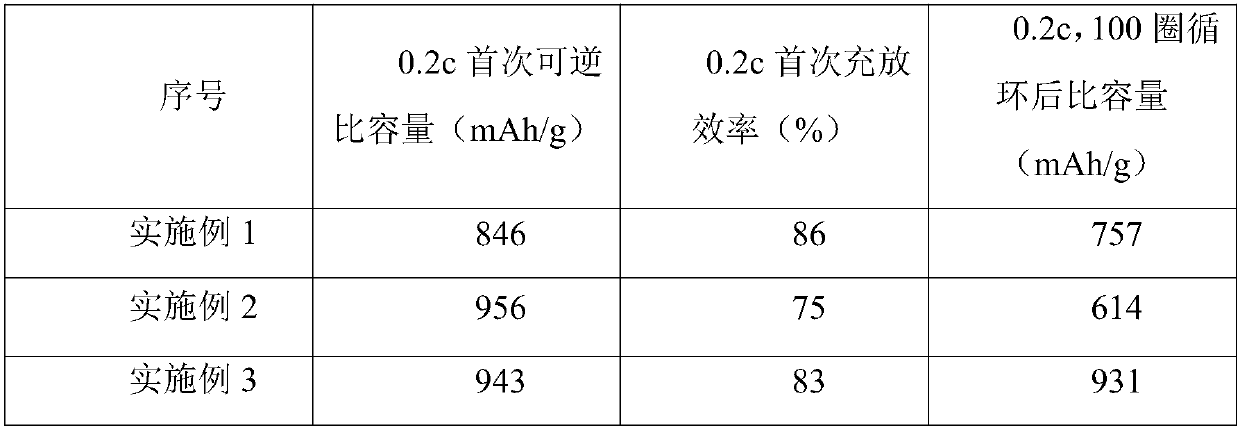

Lithium-ion battery silicon-carbon composite anode material and preparation method thereof

ActiveCN105006554AAlleviate the volume expansion effectReduce swelling effectCell electrodesSecondary cellsCarbon compositesNano silicon

The invention belongs to the field of lithium-ion battery anode materials, and provides a lithium-ion battery silicon-carbon composite anode material and a preparation method thereof. The lithium-ion battery silicon-carbon composite anode material comprises a core-shell structure and is characterized in that a core comprises nano silicon / graphene sheets and soft carbon, and the core is the nano silicon / graphene sheets and soft carbon composite particles which are obtained by performing heat treatment on a soft carbon precursor and the nano silicon / graphene sheets, the soft carbon is attached to the surfaces of the nano silicon / graphene sheets, and free spaces are formed among the nanometer silicon / graphene sheets; the shell is composed of a second carbon material and nano carbon which are coated on the surface of the core sequentially.

Owner:王凤鸣

Method for preparing composite cathode material by modification of graphite

InactiveCN105932320AImprove conductivityLarge specific surface areaCell electrodesSecondary cellsComposite cathodeOrganic solvent

The invention discloses a method for preparing a composite cathode material by the modification of graphite. The method comprises four processes of preparation of a solution A, preparation of a solution B, preparation of a solution C and preparation of the composite cathode material, wherein during the preparation process of the solution A, a polymer matrix, a pore forming agent, a conductive agent, an inorganic additive and an organic solvent are used; during the preparation process of the solution B, pitch and an organic solvent are used; during the preparation process of the solution C, the solution A and the solution B are used; and during the preparation process of the composite cathode material, the graphite, the solution C and a three-dimensional mixer are used. According to the method, the graphite is modified by the pore-forming technology and doping modification technology, the composite cathode material with high capacity, high specific surface area and good conductivity can be prepared, and liquid protection capabilities, rate performance and cycle performance of the composite cathode material in the lithium ion battery are improved, and the requirement of high-energy-density lithium ion battery on the cathode material is met.

Owner:赵晓锋

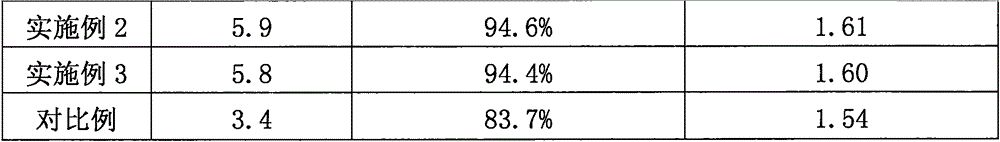

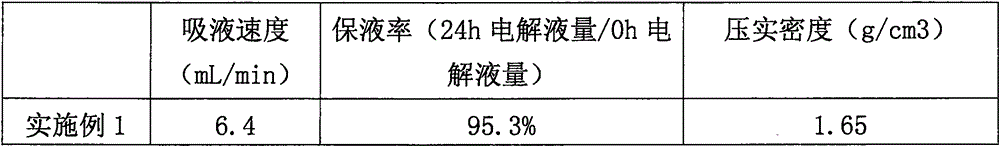

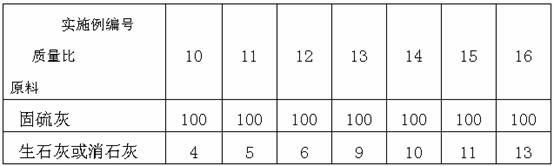

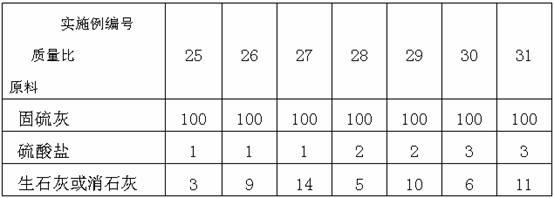

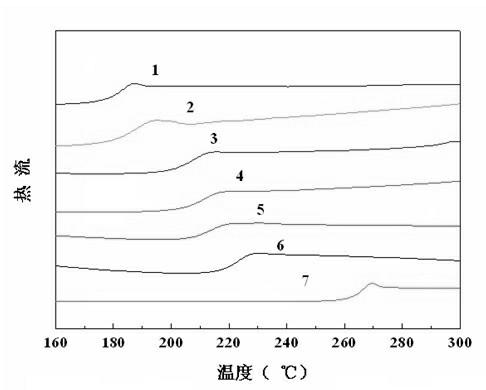

Method for preparing hydraulic cementing material by utilizing sulfur fixation ash

The invention discloses a method for preparing a hydraulic cementing material by utilizing sulfur fixation ash. The method is characterized by comprising the following steps of grinding raw materials, namely grinding the sulfur fixation ash serving as a raw material until the fineness (d50) of the sulfur fixation ash is less than or equal to 14 mu_m, and grinding calcined lime serving as another raw material until the fineness of the calcined lime is 80 mu_m and the screening residue of a standard screen is less than or equal to 10 percent; burdening, namely taking the raw materials according to a proportion that every 100 parts by weight of sulfur fixation ash is doped with 3 to 14 parts by weight of calcined lime or slaked lime or 1 to 3 parts by weight of CaSO4.2H2O; mixing the raw materials, namely uniformly mixing and stirring the raw materials, thus obtaining the hydraulic cementing material. According to the method, waste is turned into wealth, so that environment pollution is reduced; and the hydraulic cementing material prepared by the method can be used as a component of cement concrete, artificial aggregate, a steamed building block, a filling structure and a roadbed and has the advantage of high performance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

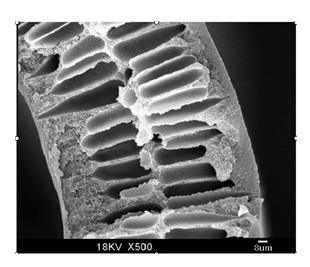

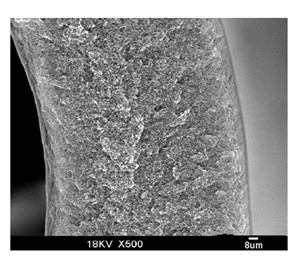

Hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and preparation method thereof

ActiveCN102512997AImprove connectivityHigh porosityUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberHollow fibre

The invention discloses a novel hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and a preparation method thereof. According to the invention, hydrophilic polyethersulfone with cardo (PES-C) and hydrophilic polyvinylpyrrolidone (PVP) with a high molecular weight are blended, and a flat or hollow fiber ultrafiltration membrane is prepared by using an immersion-precipitation process or a dry / wet phase inversion process; and then the PES-C / PVP alloy ultrafiltration membrane with permanent hydrophilicity is prepared through hydrophilic long-lasting aftertreatment. The preparation method provided in the invention is simple, convenient, highly efficient and economy and is favorable for realization of industrial application. The prepared ultrafiltration membrane has good high temperature resistance, chemical solvent resistance, acidic and alkaline corrosion resistance and osmotic separation performance and excellent anti-pollution ability and can be used in the fields of purification of water quality, treatment of industrial waste water, recycling of domestic sewage, purification and separation of biological medicine products, etc.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

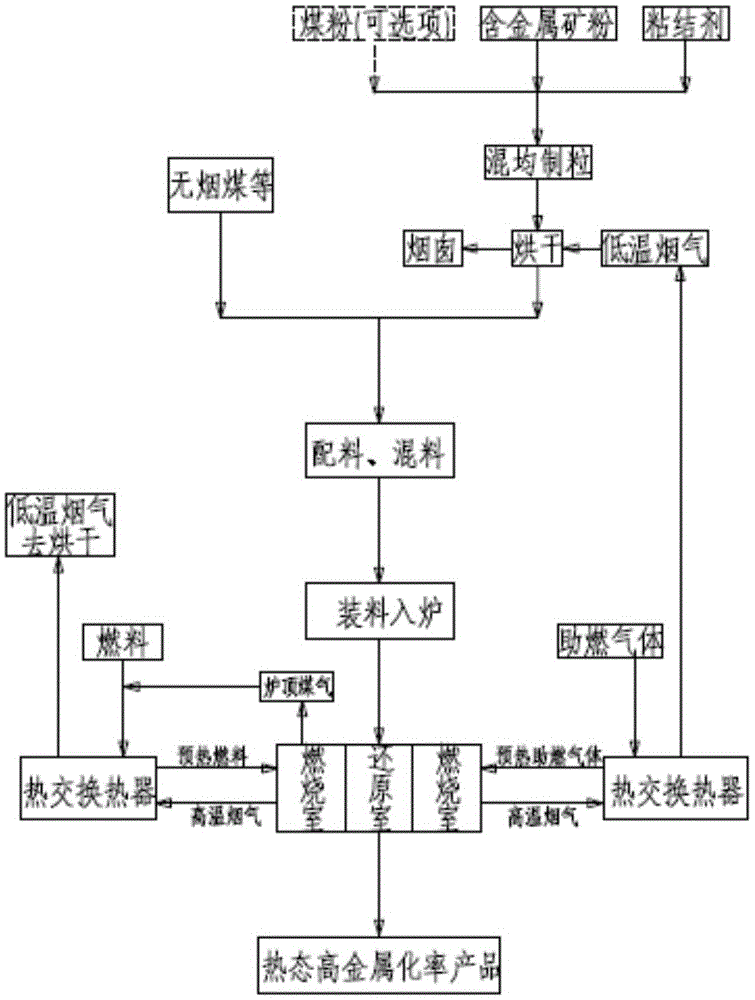

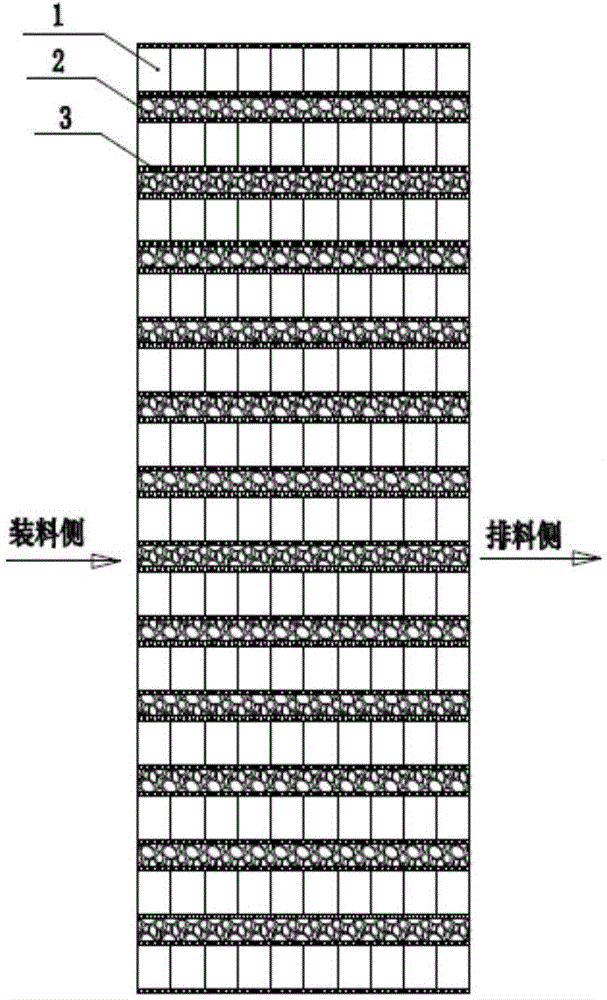

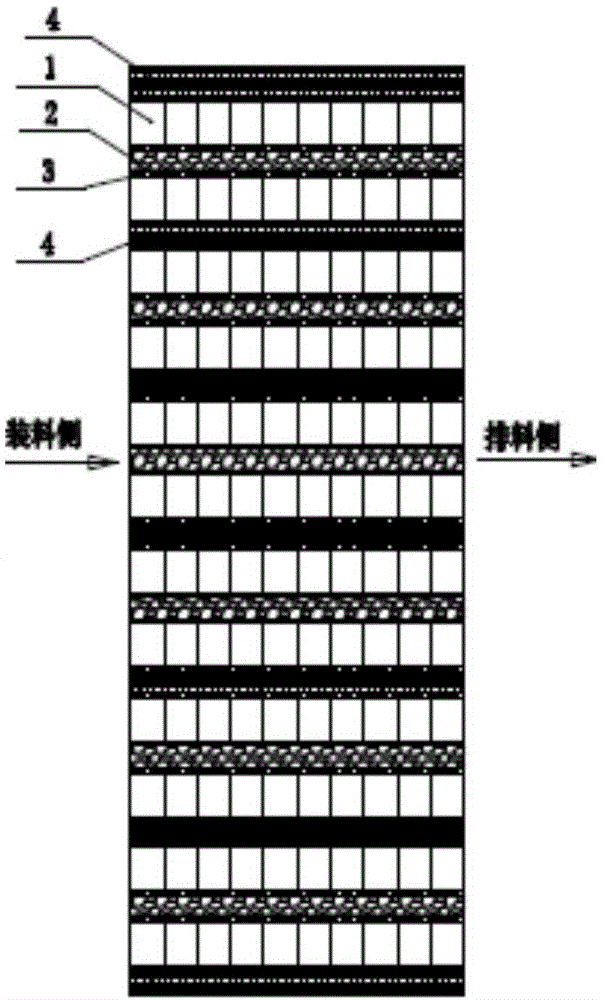

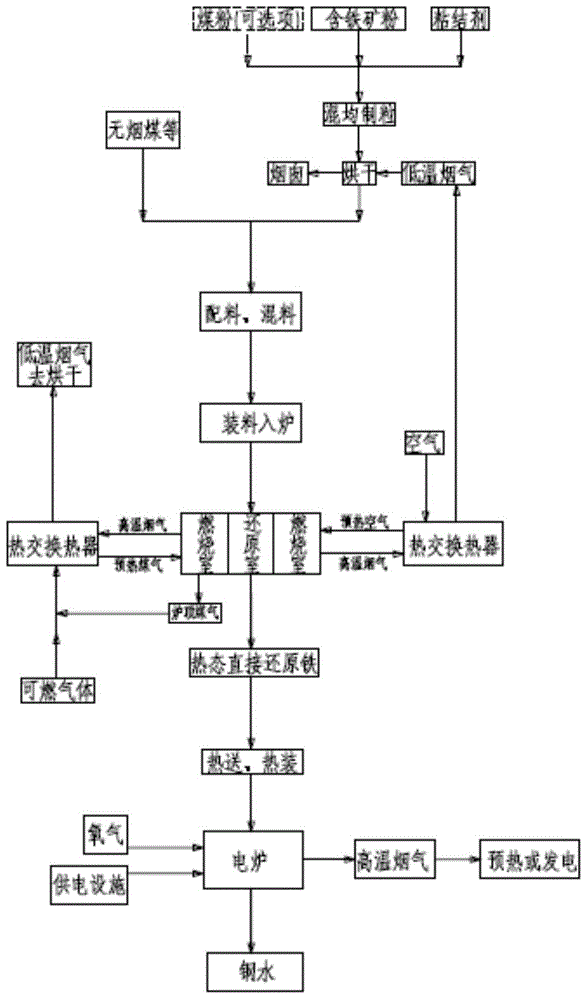

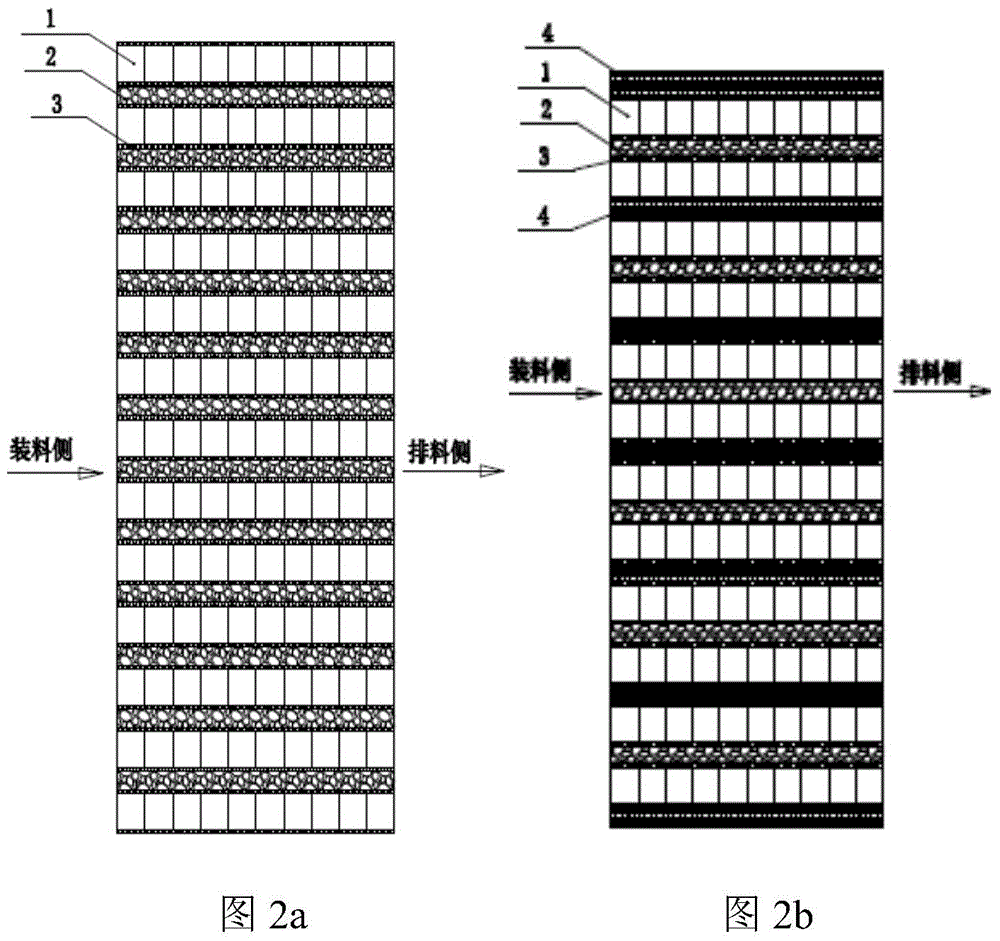

QDF (quiescent direct furnace) direct reduction technology

InactiveCN104630404AAchieve the desired effectReduced strength requirementsFluidised-bed furnacesCombustion chamberProduct gas

The invention relates to a QDF (quiescent direct furnace) direct reduction technology which comprises the following steps: uniformly mixing a metal-containing raw material and reducing agent powder, and putting into each reducing chamber, wherein in a reducing process, the reducing chambers and the reduced material are all kept in a stationary state; uniformly heating the materials in the reducing chambers by use of the heat generated by the combustion of the fuel in a combustion chamber and a combustion-supporting gas so as to perform a reduction reaction between the metal-containing raw material and the reducing agent, wherein each reducing chamber is a narrow long one-section reactor. According to the technology provided by the invention, the reducing chambers and the reduced material are all in a stationary state, the requirement on the strength of the granular raw material is reduced, and the production efficiency of a granulation process is improved; and the reducing time can be prolonged, and the metallization ratio of the reduction product is improved. The reducing chamber is not provided with a preheating area or a cooling area, the temperature is uniform, the atmosphere is uniform and consistent, and the overall quality of the reduction product is improved. The direct reduction technology has remarkable advantages of wide application range of raw materials, uniform temperature field, easy control on reduction process, high product metallization ratio, high yield and the like.

Owner:WISDRI ENG & RES INC LTD

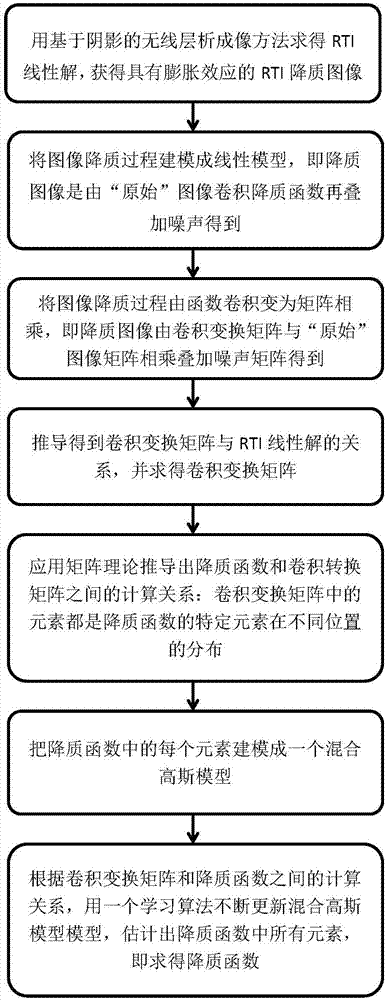

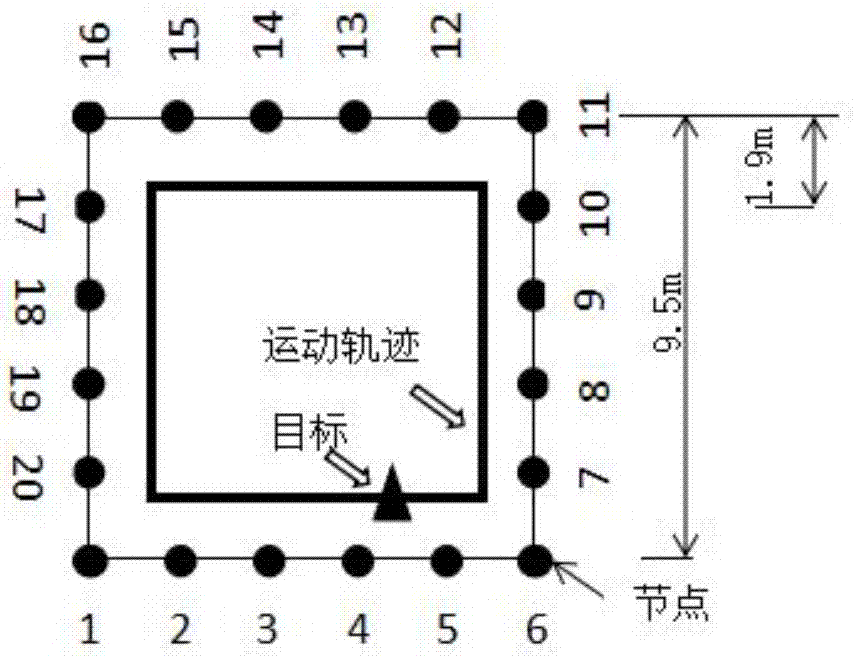

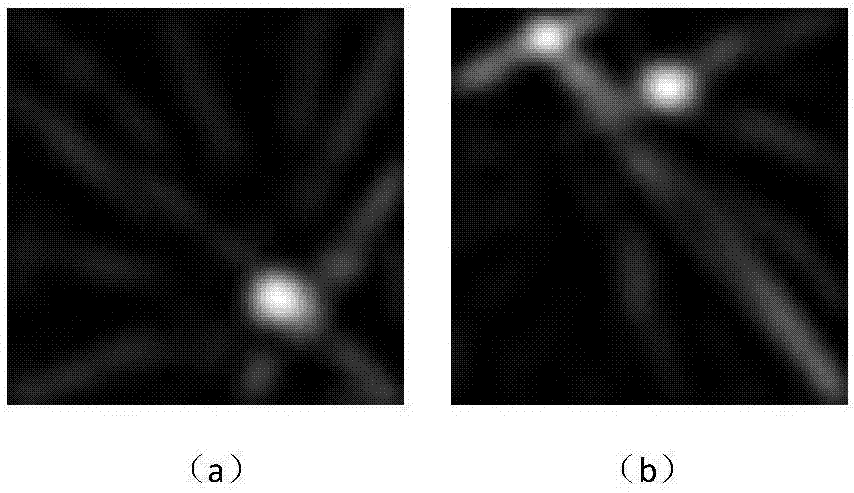

Estimation method of degradation function applied to radio tomography imaging system

ActiveCN106940895AReduce swelling effectHigh positioning accuracyImage enhancementReconstruction from projectionImaging processingEstimation methods

The invention discloses an estimation method of a degradation function applied to a radio tomography imaging system, and belongs to the field of image processing in a wireless network. The radio tomography imaging process is enabled to be a linear image degradation process, problems of target imaging blurring and dilation effect of the radio tomography imaging system can be solved by employing an image restoration method with the combination of the constraint least squares method criterion, and clear "original" images can be obtained. According to the method, a function convolution process is converted to a matrix multiplying form, and the relation between a convolution transformation matrix of the degradation function and a linear solution of the radio tomography imaging system is derived; and a mapping relation between the degradation function and the convolution transformation matrix is obtained through a matrix transformation theory, and the degradation function is estimated through establishment of a Gaussian mixture model. The method is applied to the radio tomography imaging system, the dilation effect of target imaging is effectively reduced, the imaging precision of the radio tomography imaging system is improved, and the method can be applied to the practical environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

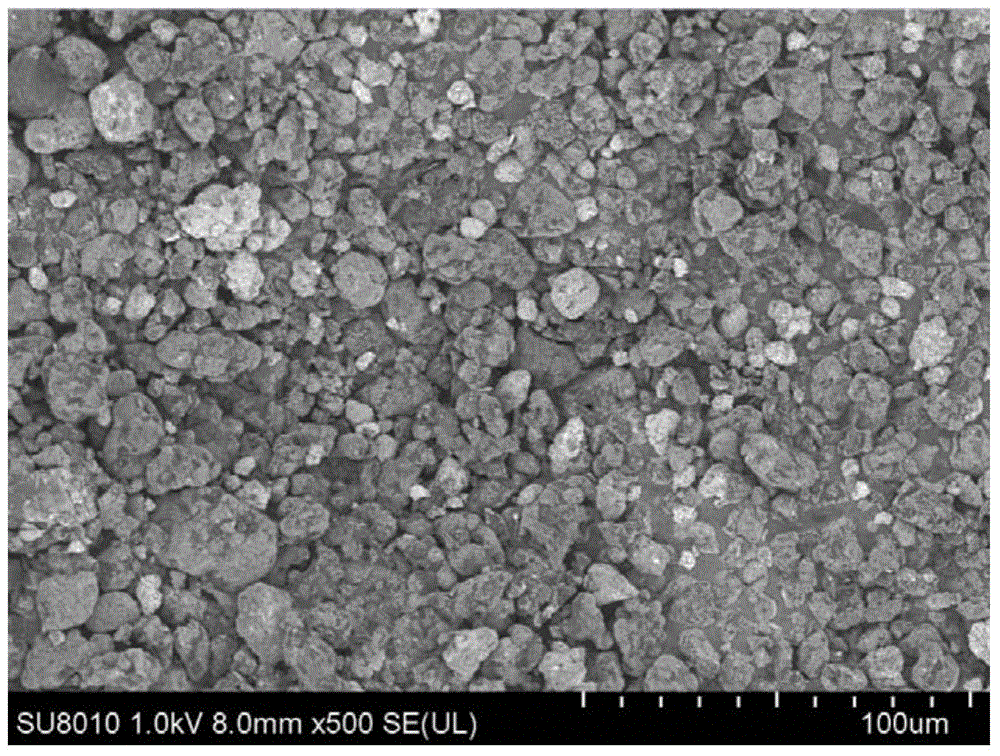

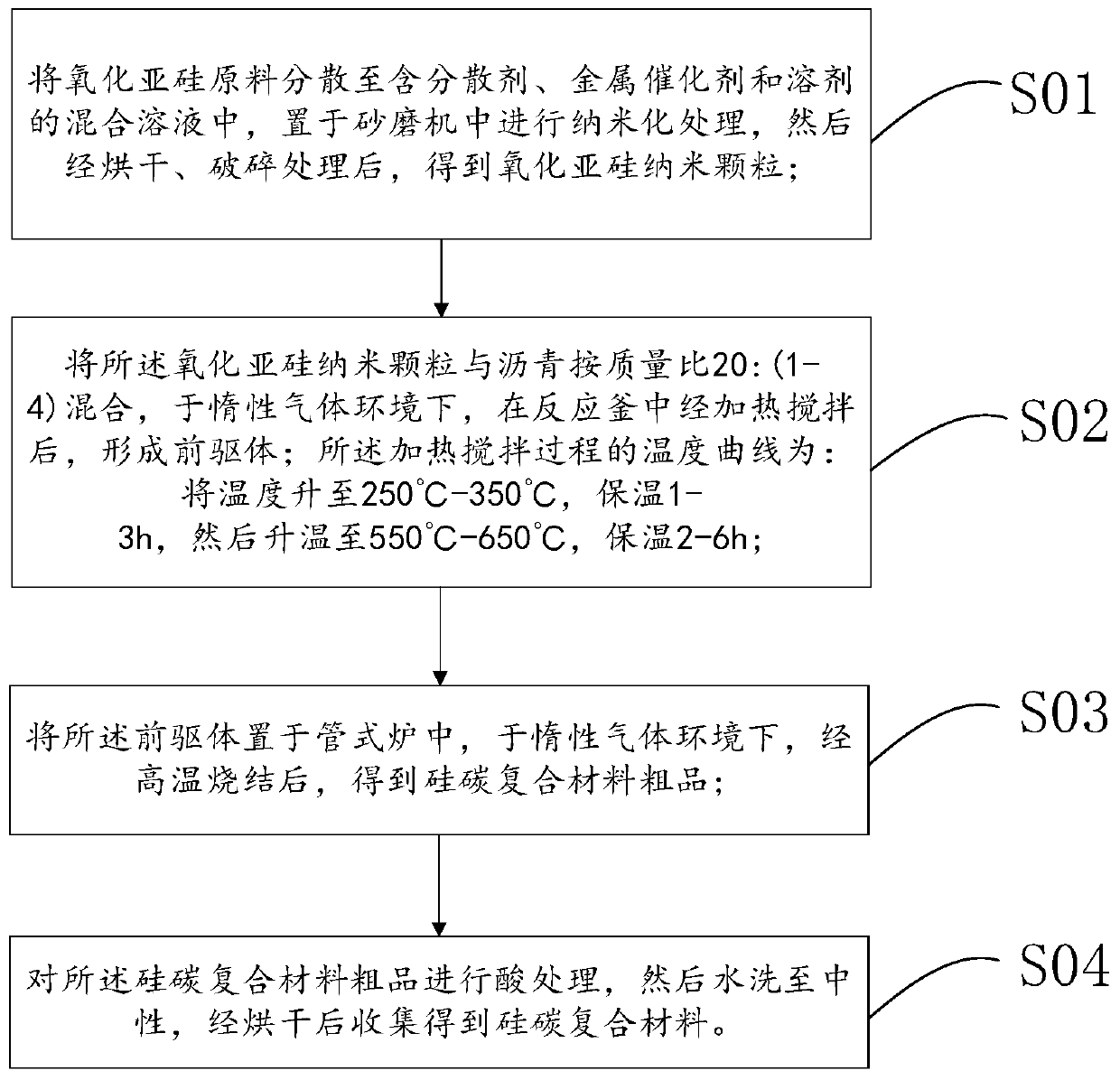

Silicon-carbon composite material, and preparation method and application thereof

ActiveCN110444743AHigh tap densityControl shapeCell electrodesSecondary cellsCarbon compositesSilicon oxide

The invention provides a preparation method of a silicon-carbon composite material. The preparation method comprises the following steps: (1) dispersing a silicon oxide raw material into a mixed solution containing a dispersing agent, a metal catalyst and a solvent, carrying out nano-treatment in a sand mill, and carrying out drying and crushing to obtain silicon oxide nanoparticles; (2) mixing the silicon oxide nanoparticles with asphalt according to a mass ratio of 20 : (1-4), and in an inert gas environment, carrying out heating stirring in a reaction kettle to form a precursor; (3) puttingthe precursor into a tubular furnace, and carrying out sintering at a high temperature in the inert gas environment to obtain a crude product of the silicon-carbon composite material; and (4) carrying out acid treatment on the crude product of the silicon-carbon composite material, washing the crude product to be neutral, and carrying out drying and collecting to obtain the silicon-carbon composite material. The preparation method is simple in process and can be used for industrial production; and the silicon-carbon composite material is good in electrical conductivity and has high cycling stability. The invention also provides the silicon-carbon composite material and an application thereof.

Owner:SHENZHEN DYNANONIC

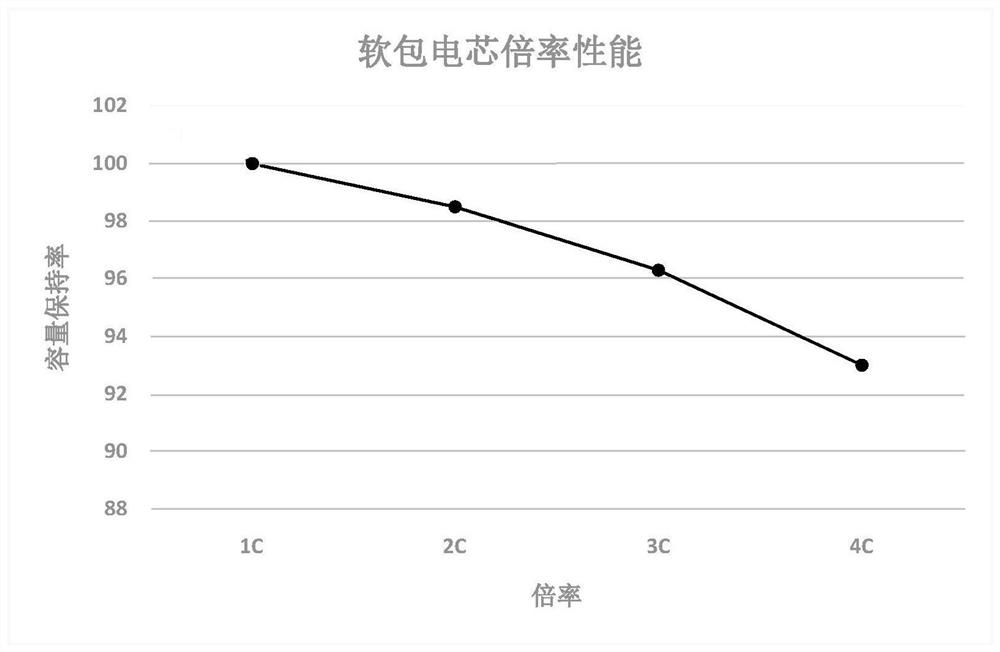

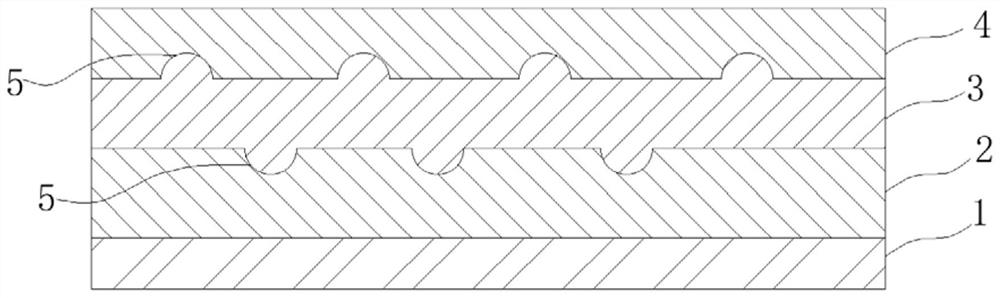

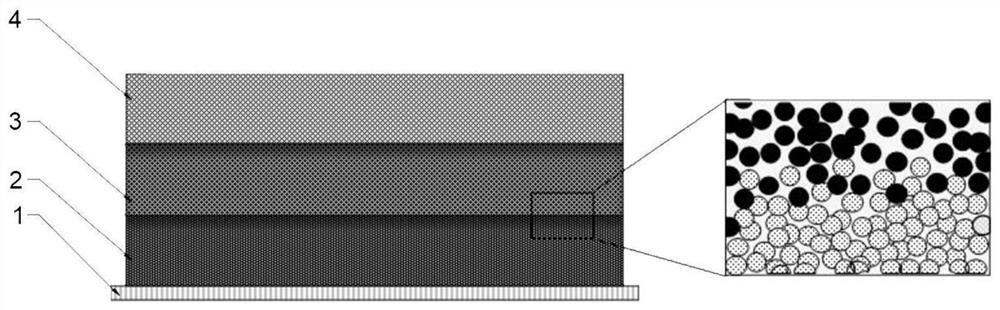

Multilayer electrode, preparation method of multilayer electrode and lithium ion battery

PendingCN111916757AIncrease energy densityIncrease charging rateElectrode carriers/collectorsSecondary cellsLithium-ion batteryBattery cell

The invention discloses a multilayer electrode and a lithium ion battery. The multilayer electrode comprises a current collector, a first conductive layer and a second conductive layer, wherein the first conductive layer and the second conductive layer are sequentially stacked on the surface of the current collector, the surface density of the first conductive layer is less than that of the secondconductive layer, and the surface density of the second conductive layer is less than that of the first conductive layer. The thickness of the first conductive layer is smaller than that of the second conductive layer, and the second conductive layer is partially embedded into the first conductive layer, so the expansion effect of the conductive layer of the battery pole piece is reduced.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

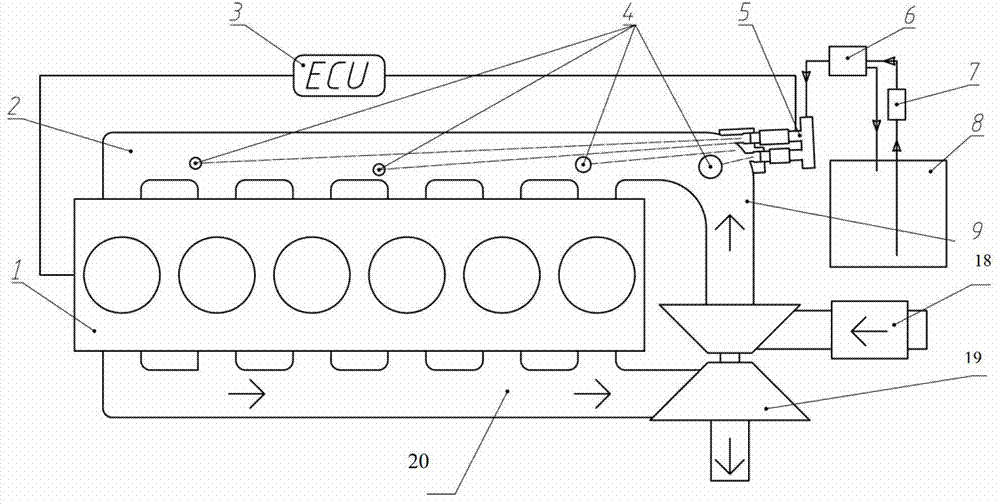

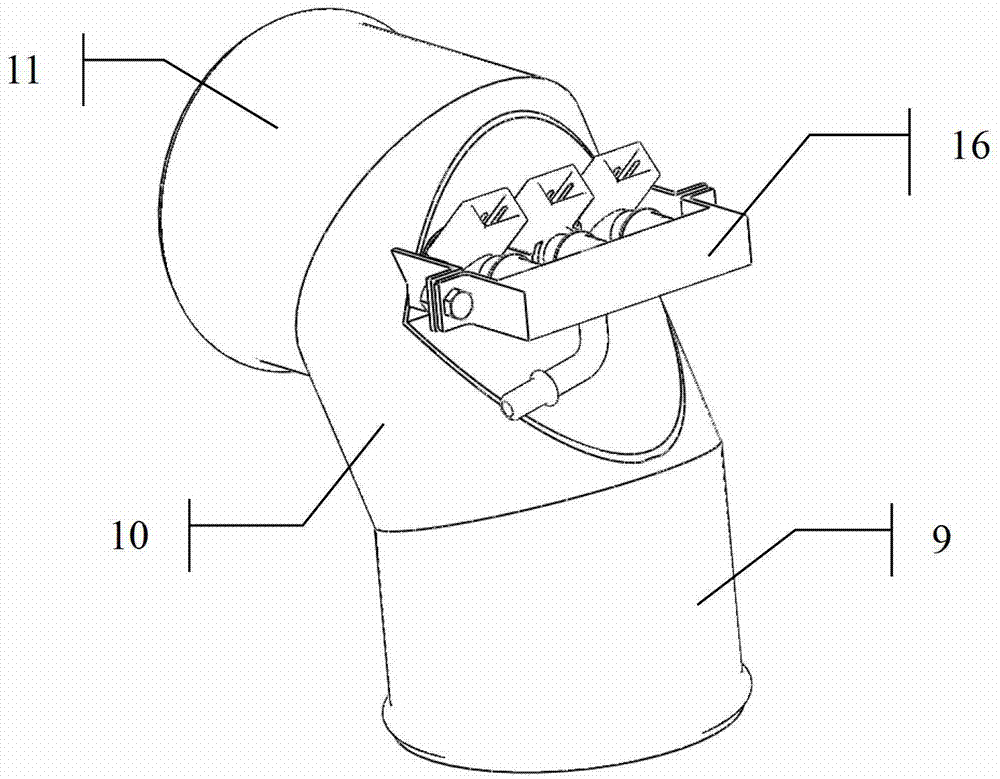

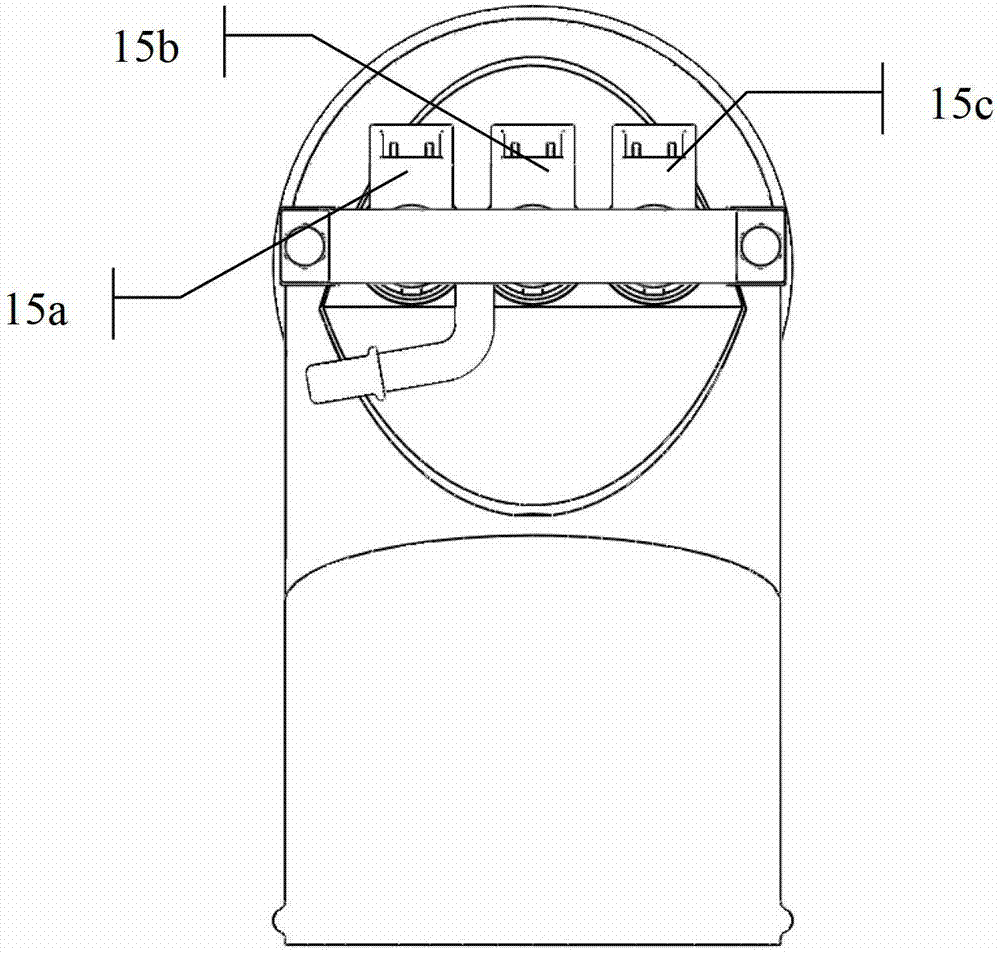

Penetration distance-composited alcohol spraying method and device

InactiveCN102953887AAlleviate heat load imbalanceReduce heat loadInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustionAlcohol

The invention relates to methyl alcohol spraying method and a device in mixed combustion of diesel oil and alcohol, and in particular relates to a penetration distance-composited alcohol spraying method and device, which speed up the evaporation and gasification of methyl alcohol drops and improves the uniformity of the mixtures of methyl alcohol and air which enter cylinders. The invention adopts the following technical scheme that an elbow is arranged at the joint of an intake manifold and an intake pipe of an engine; two or more spray nozzles with different penetration distances for spraying alcohol are installed at the elbow; center lines of the spray orifices of the spray nozzles are parallel to the axis of the intake manifold or incline downward with respect to the axis of the intake manifold. The alcohol spraying method and the device realize at least two alcohol spraying penetration distances and enable the alcohol to land at different parts of the intake manifold of the engine after being sprayed out from the spray nozzles. The multi-penetration-distance alcohol spraying device enables the alcohol liquid to reach different parts of the intake manifold of the engine, reduces the thermal load of the engine, and reduces the waste heat brought away by the cooling water of the engine.

Owner:TIANJIN UNIV

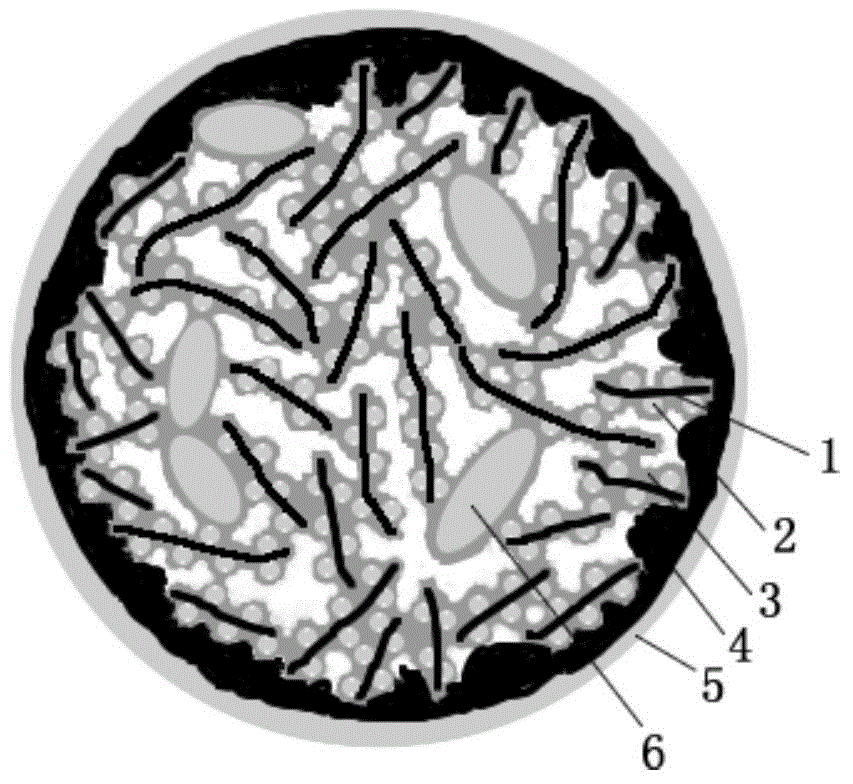

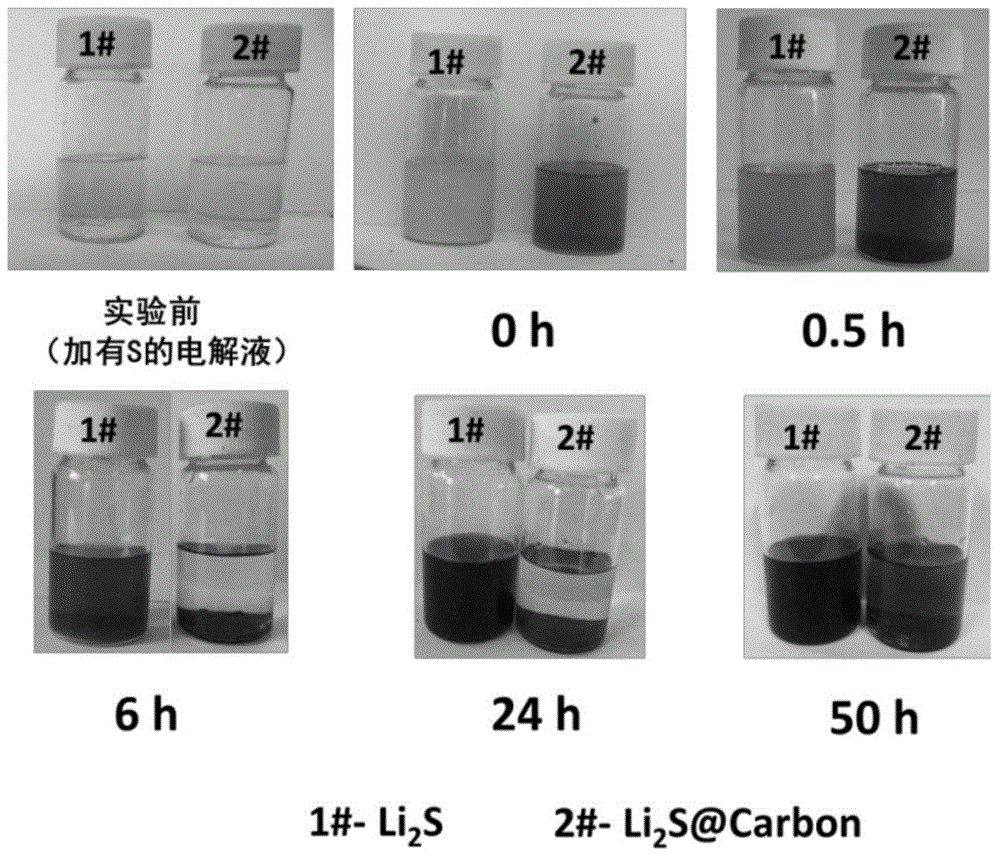

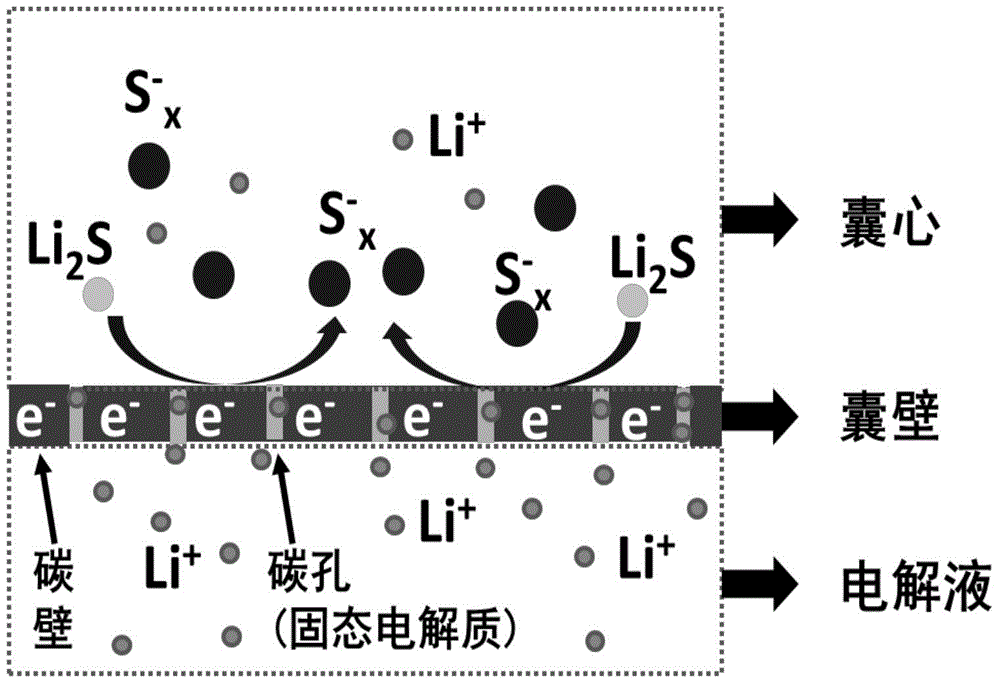

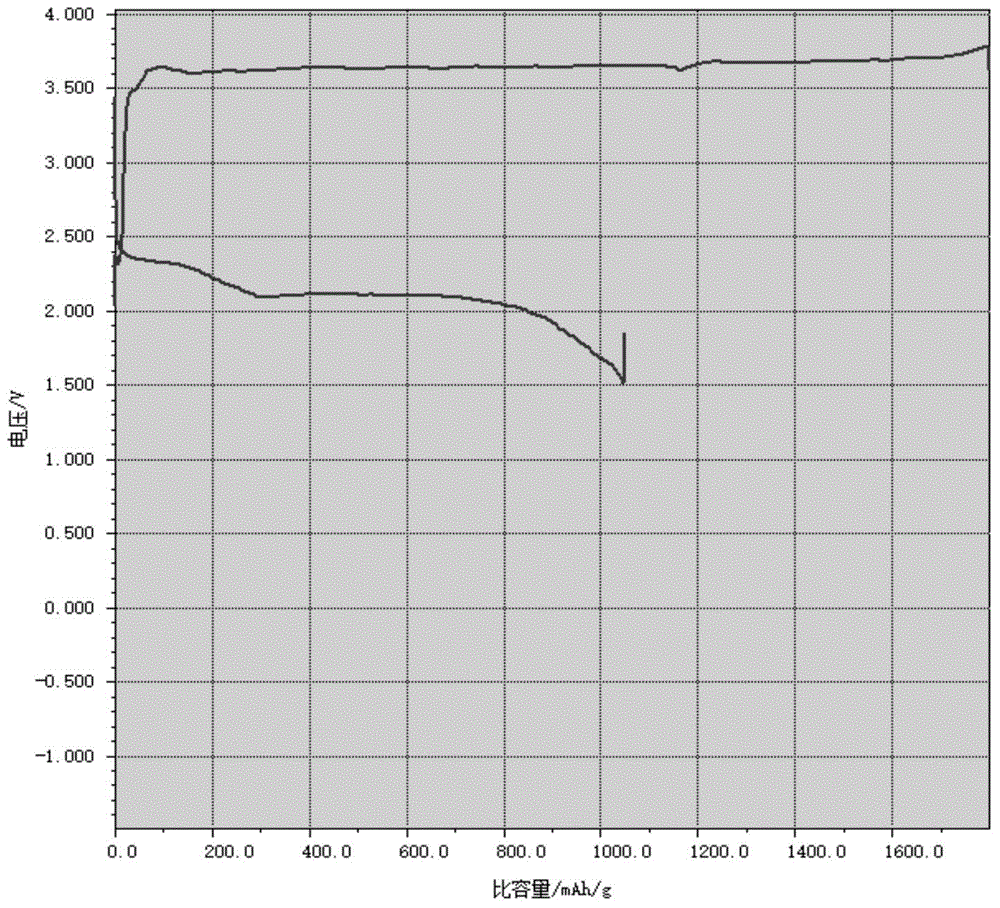

Micro-capsule-structured carbon-sulfur compound and preparation method and application thereof

ActiveCN106505182AIntegrity guaranteedReduce swelling effectMaterial nanotechnologyCell electrodesElectrical conductorMass ratio

The invention relates to a micro-capsule-structured carbon-sulfur compound and a preparation method and an application thereof. The compound takes lithium sulfide as a capsule-core material, and takes a carbon material and a lithium ion conductor as a capsule-wall material; the capsule-core material is positioned in the hollow capsule-wall material, wherein the capsule-core material is 20-300nm in grain diameter; the capsule wall is 2-50nm in thickness; the content of the capsule-core material accounts for 20-80wt% of the carbon-sulfur compound; and the mass ratio of the carbon material to the lithium ion conductor in the capsule-wall material is (1:99) to (99:1). Based on the structural advantage of the "micro-capsule", a positive electrode material design thought of "capsule core sulfur-carrying, capsule wall sulfur-fixing, hole wall electric conduction and hole channel sold-state lithium conduction" is proposed, so that the utilization rate and the cycling stability of the active material sulfur in a lithium-sulfur battery are greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

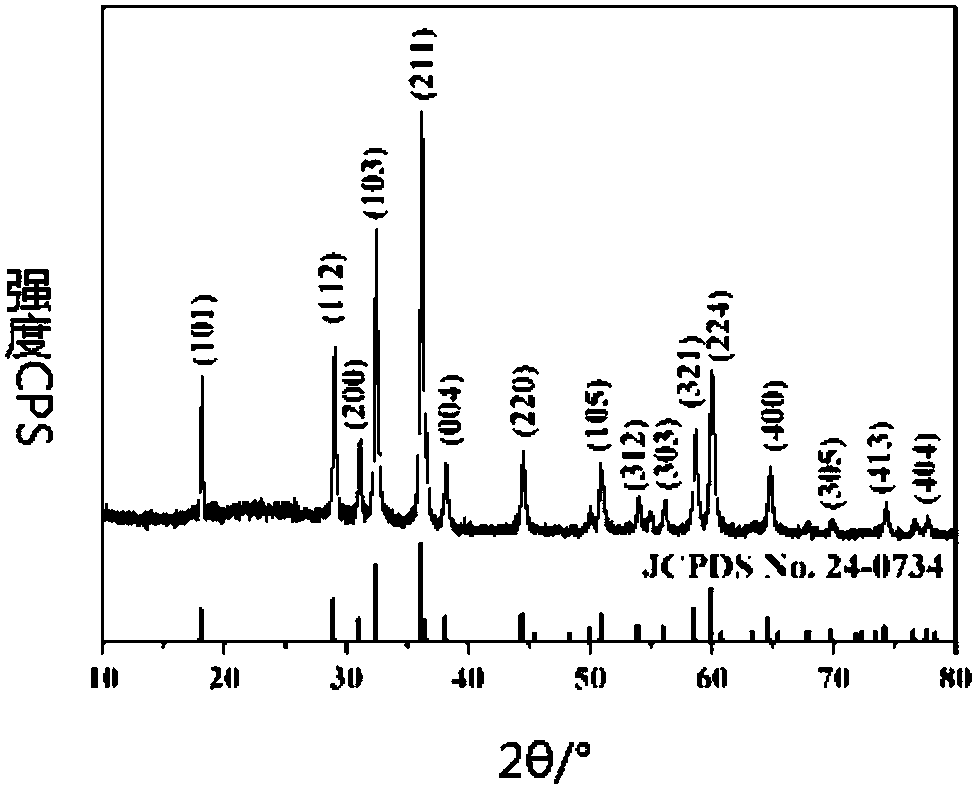

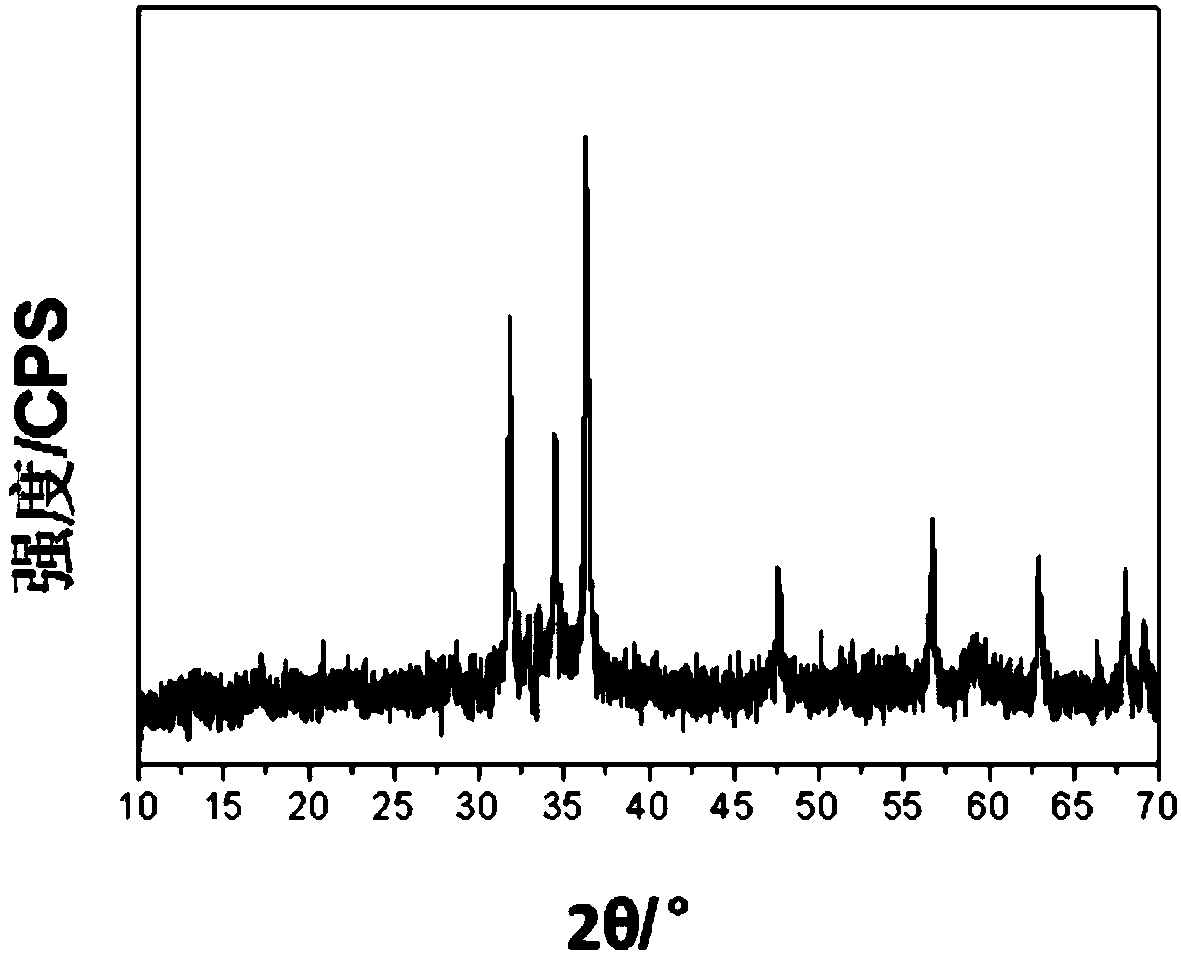

Carbon-coated manganese oxide negative electrode material and preparation method thereof

ActiveCN108269983AReduce swelling effectImprove conductivityNegative electrodesSecondary cellsHigh carbonNitrogen

The invention discloses a carbon-coated manganese oxide negative electrode material. The carbon-coated manganese oxide negative electrode material comprises the raw materials of a manganese source, anorganic ligand and a solvent, wherein the organic ligand is an organic small molecule compound comprising carboxylic acid or nitrogen and carboxylic acid. The invention also discloses a preparation method of the carbon-coated manganese oxide negative electrode material. The carbon-coated manganese oxide negative electrode material is high carbon coating efficiency, manganese dissolving out in anelectrolyte can be suppressed effectively, and high cycle stability is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

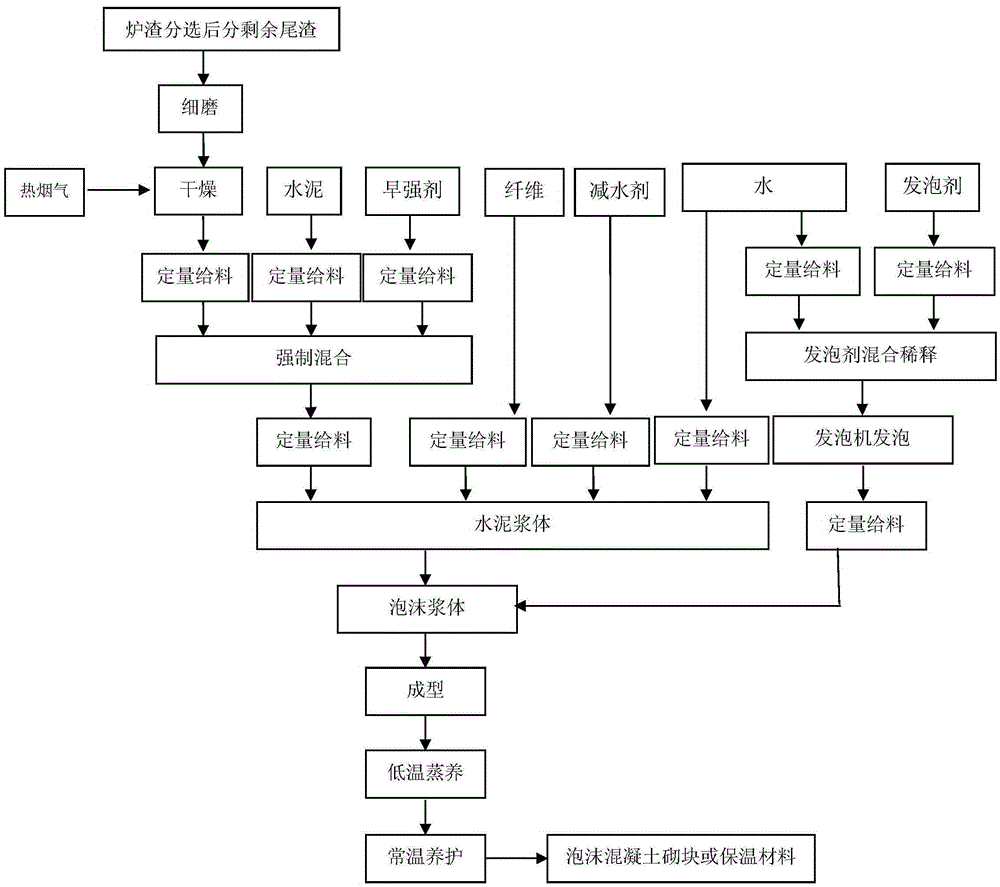

Resource utilization method of household garbage incineration residue sorting tailing

ActiveCN105294156AReduce swelling effectEliminate negative effectsSolid waste managementCeramicwareFoam concreteSlag

The invention relates to a resource utilization method of household garbage incineration residue sorting tailing. The household garbage incineration residue sorting tailing is subjected to fine grinding treatment and is directly dried by utilizing hot smoke, the obtained residue micro powder is forcedly mixed with cement, and processes such as pulping, bubble forming, mixing and soaking, casting moulding, low-temperature oxygen steaming, normal-temperature maintenance and the like are carried out, so that a foam concrete block or a thermal insulation material is prepared. The resource utilization method of the household garbage incineration residue sorting tailing has the advantages that negative effect of free calcium oxide and magnesium oxide on quality of foam concrete is eliminated, and final strength of a foam concrete product is improved; under the combined action of hydration products of cement, and toxic trace heavy metals are solidified, so that a tailing product produces no secondary pollution to the environment; and residue adding proportion is high, resource utilization and large-scale treatment on the garbage incineration residue sorting tailing can be realized, technology is simple, product cost is low, and good economic benefit and environmental benefit are realized.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

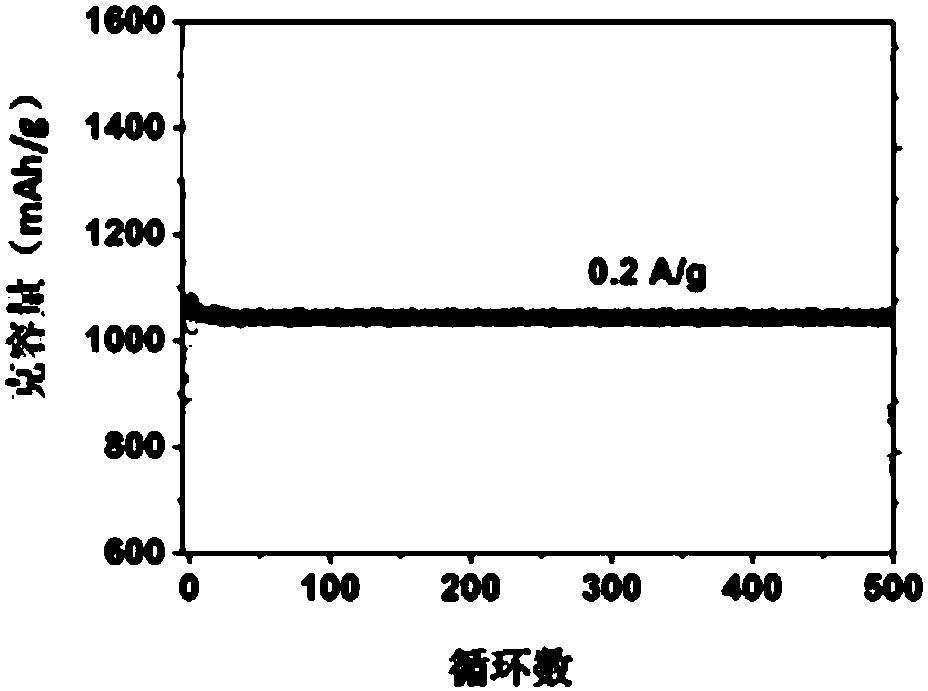

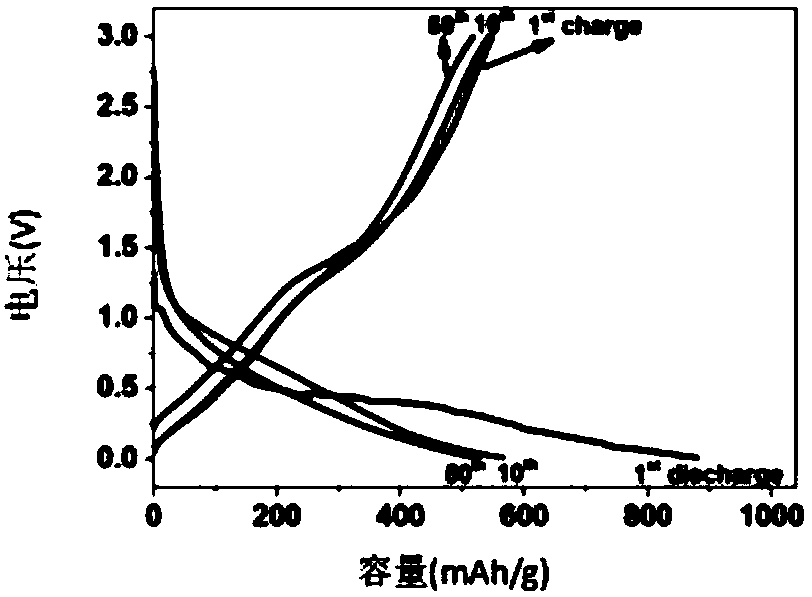

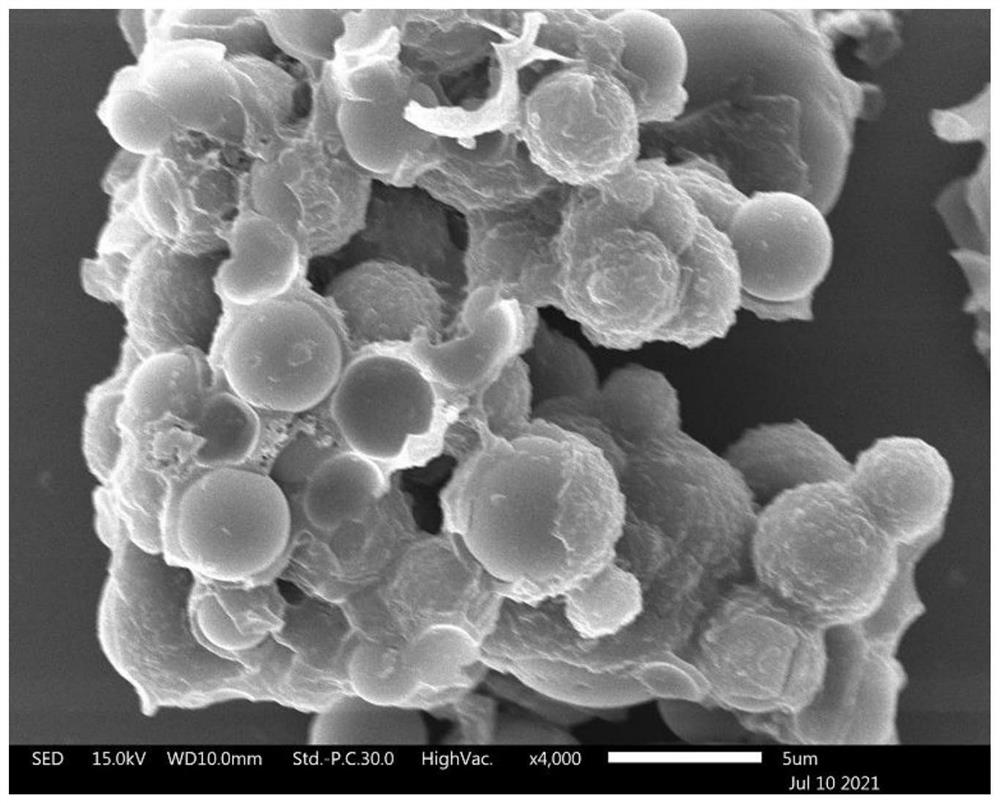

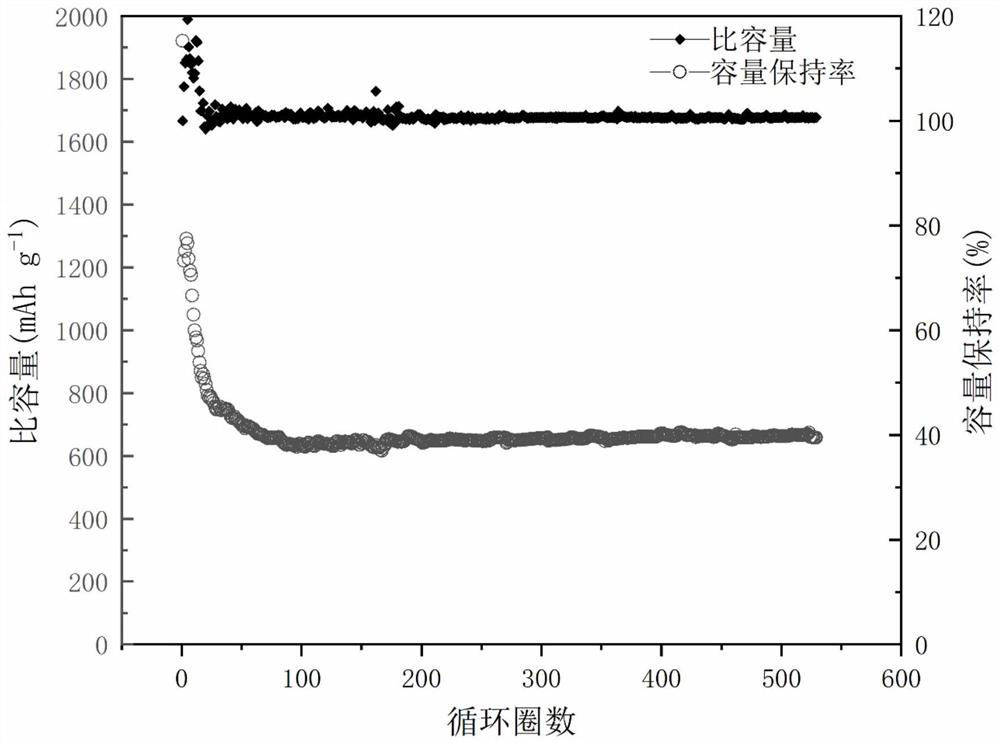

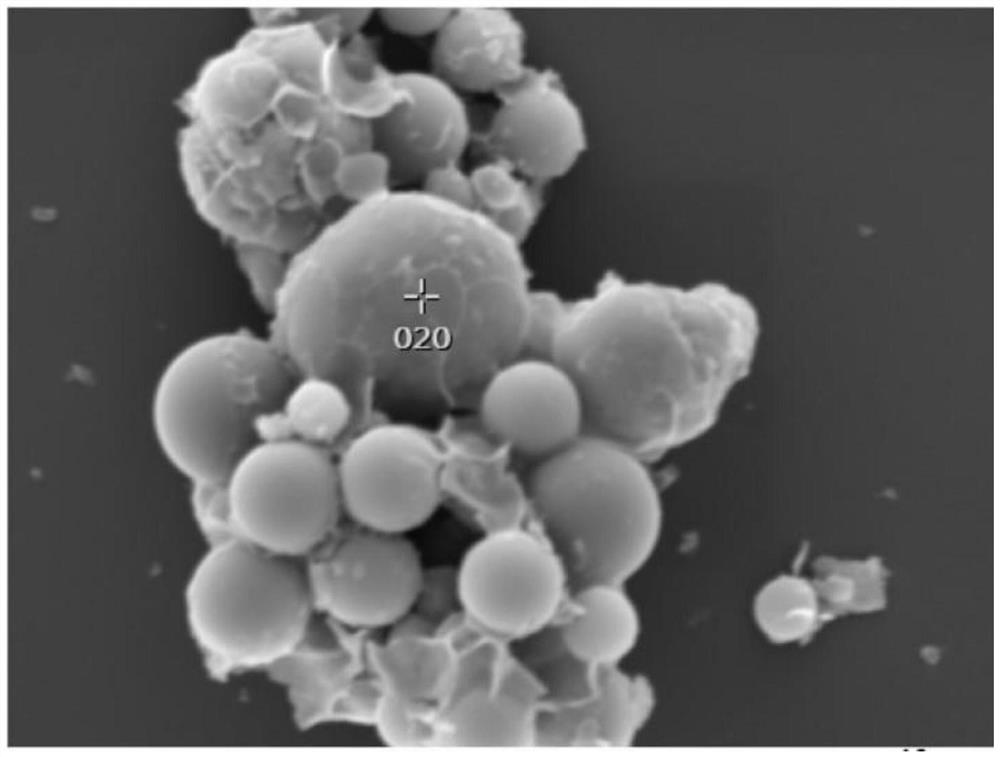

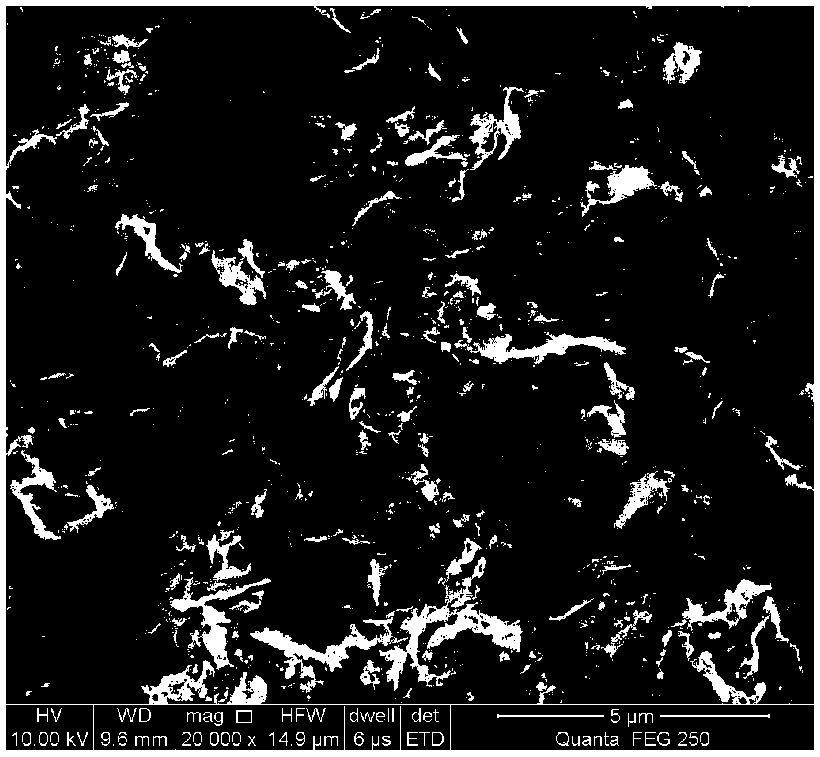

ZnNiO/C composite nano material and preparation method thereof

ActiveCN110247041ALow equipment requirementsReduced operating requirementsMaterial nanotechnologyCell electrodesNano structuringLithium-ion battery

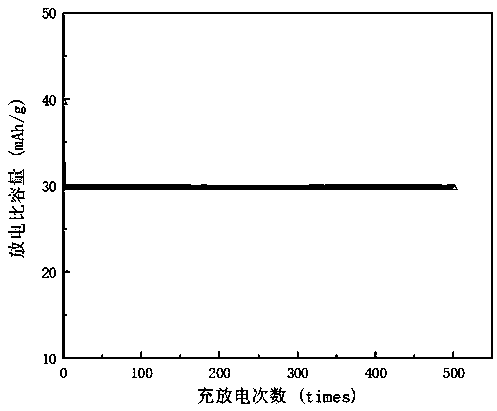

The invention discloses a ZnNiO / C composite nano material. The microstructure of the nano material is of a honeycomb structure. The scale of the honeycomb structure is 2.5-3.5 [mu]m, and the honeycomb structure is formed by granular nano-structures and lamellar structures arranged in a staggered manner, so a porous structure containing a large number of pores is formed. The invention also discloses a preparation method of the ZnNiO / C composite nano material. The method comprises the following steps: taking ZnCl2 and NiCl2 as metal sources of organic metal frame compounds, and taking glycolic acid as an organic ligand of an MOF material; synthesizing an MOF material containing nickel and zinc elements; and carbonizing in a quartz tube type furnace to obtain the ZnNiO / C composite nano material. The material is used as a lithium ion battery electrode material, shows a high specific capacity of 30mAh / g after 500 times of circulation at a discharge current of 600mA / g, and has good cycling stability.

Owner:ZHEJIANG UNIV

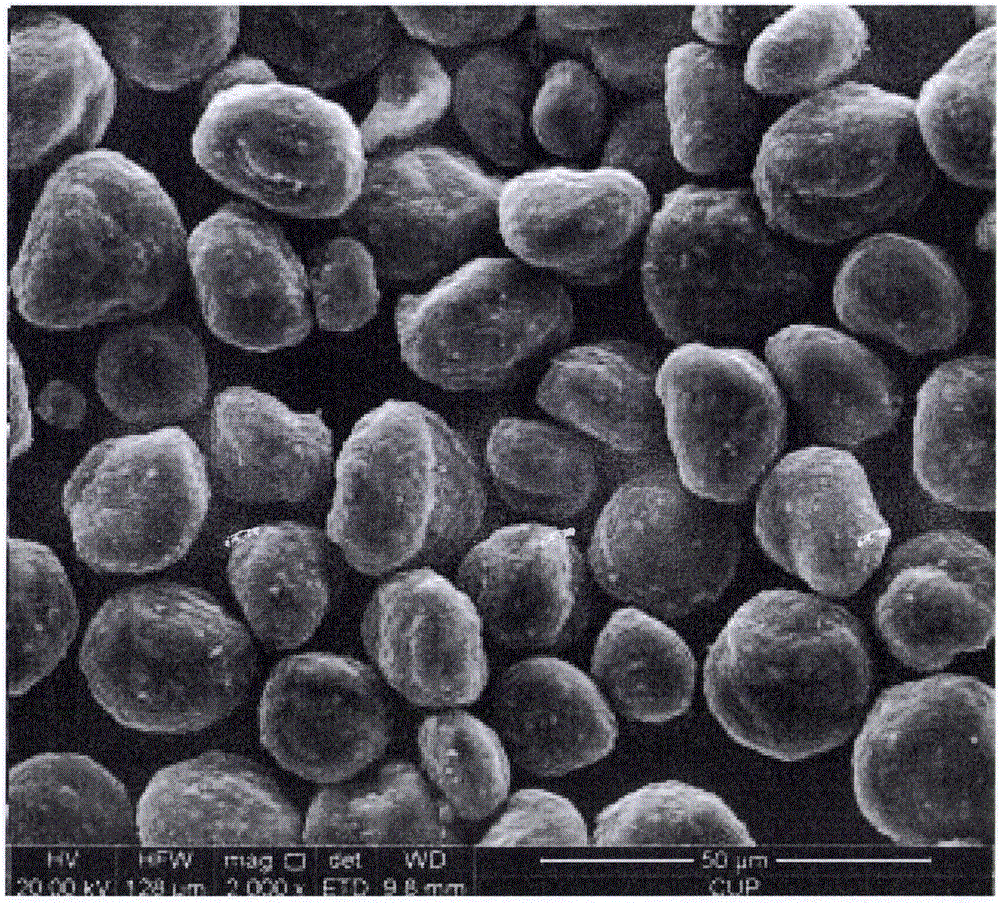

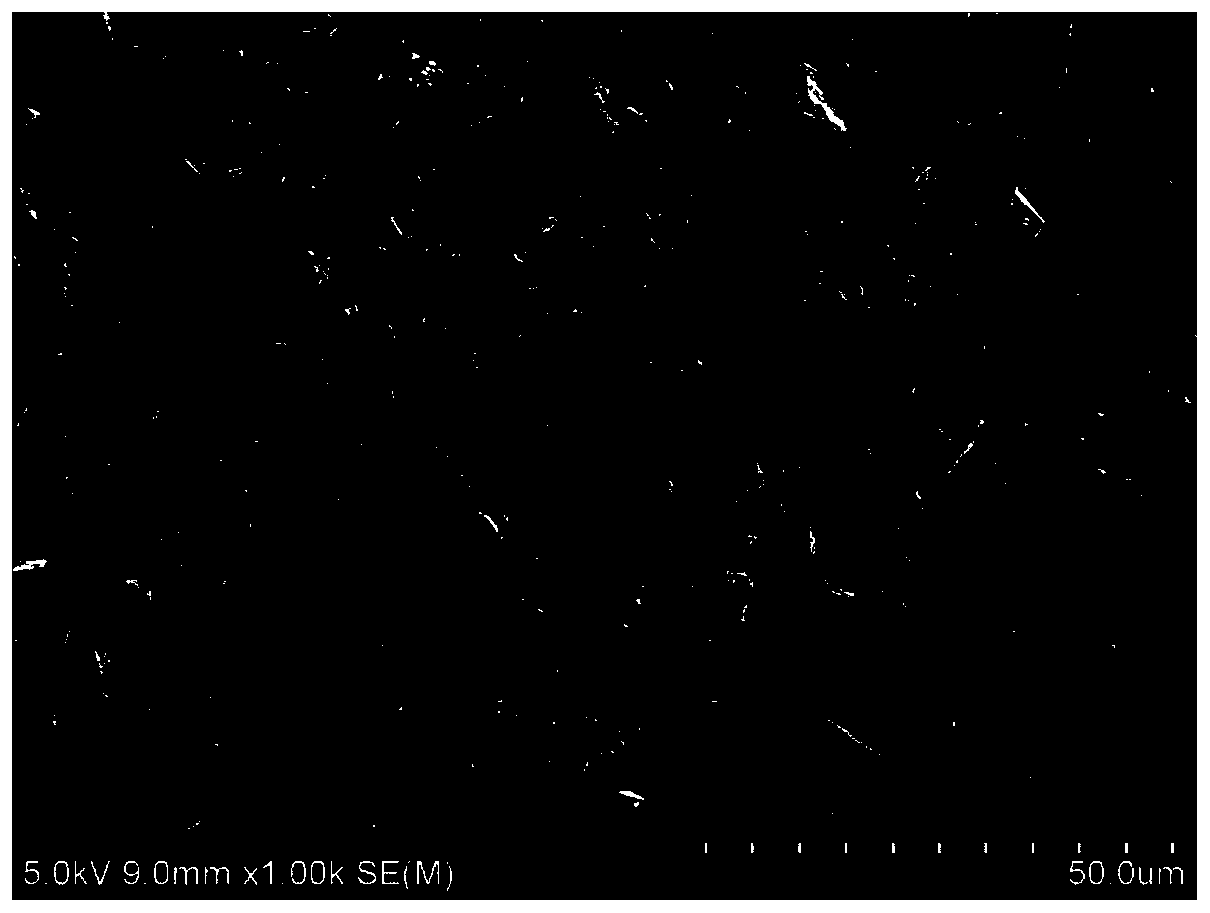

Preparation method of modified expanded micro-powder graphite negative electrode material for lithium ion battery

InactiveCN111029546ALow costWide variety of sourcesCell electrodesSecondary cellsPhysical chemistryGraphite

The invention relates to a preparation method of a modified expanded micro-powder graphite negative electrode material for a lithium ion battery. The preparation method is characterized by comprisingthe following steps: S1, carrying out ball-milling dispersion on expanded micro-powder graphite to obtain a material 1, and adding absolute ethyl alcohol which accounts for 5-10% of the weight of theexpanded micro-powder graphite as a dispersing agent; S2, uniformly mixing the material 1 with a coating agent in a mass ratio of 1: (0.1-0.15), and performing spray drying to obtain a material 2; S3,carbonizing the material 2 at high temperature, introducing protective gas, and carbonizing at 900-1200 DEG C for 1-2 h to obtain a material 3; S4, mixing and granulating the cooled material 3 and asphalt, wherein the mass ratio of the material 3 to the asphalt is (20-16): (1-4), and performing stirring reaction for 1-3 h at the temperature of 300-650 DEG C to obtain a material 4; S5, performingmechanical ball milling treatment on the material 4 to obtain a material 5 of 8-15 [mu] m; and S6, performing high-temperature graphitization treatment on the material 5 at 2400-3000 DEG C for 1-2 h.The preparation method has the advantages of wide raw material source, low cost, simple process and easiness in industrial production.

Owner:凯盛石墨碳材料有限公司

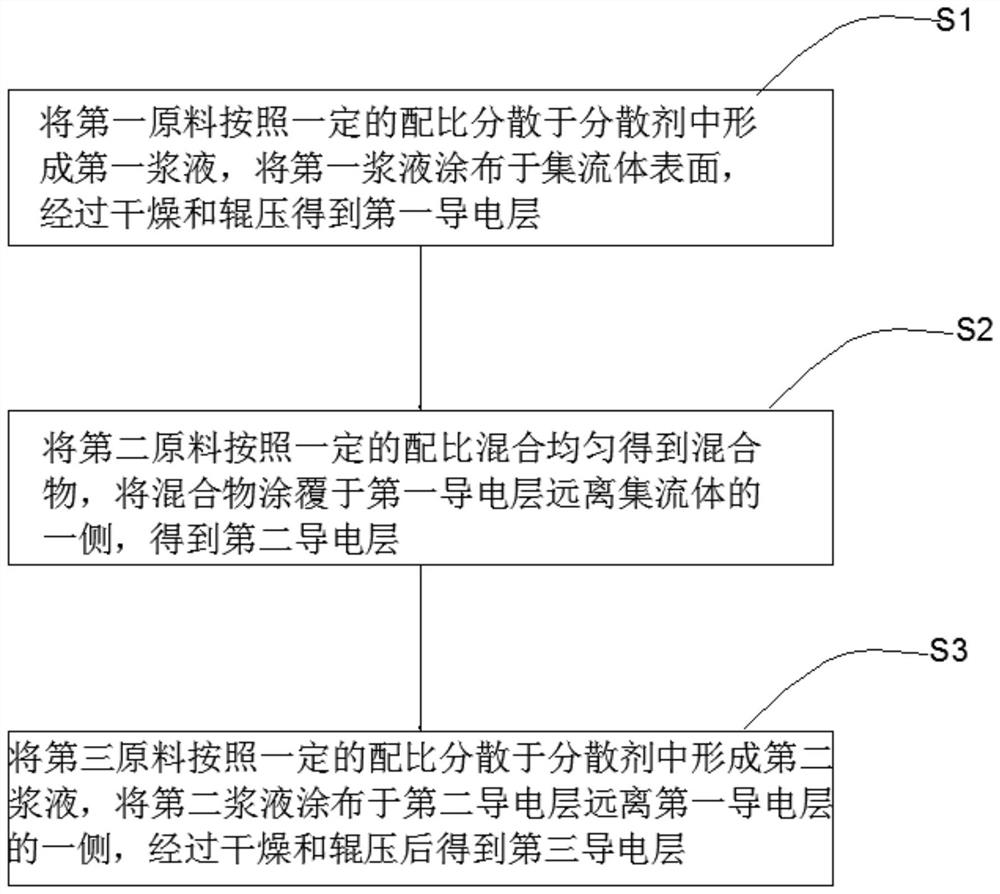

Battery pole piece and preparation method and application thereof

PendingCN113871567AControl thicknessImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh energyEngineering

The invention provides a battery pole piece and a preparation method and application thereof. The battery pole piece comprises a current collector, at least two layers of pole piece membranes are laminated on at least one side surface of the current collector, the porosity of the pole piece membranes is sequentially increased along the direction far away from the surface of the current collector, and the pole piece membranes are prepared by a dry method. The active layer is provided with at least two layers of pole piece membranes, the porosity of the pole piece membranes is sequentially increased in the direction away from the surface of the current collector, the pole piece membranes with the large porosity can relieve the expansion effect of the pole piece membranes with the small porosity, the requirement for high energy density can be met, and enough lithium ion transmission channels can be provided, so that the rate capability of the pole piece is improved.

Owner:CHINA AUTOMOTIVE INNOVATION CORP

QDF electric steelmaking process

InactiveCN104630411AAchieve the desired effectReduced strength requirementsProcess efficiency improvementElectric furnaceSteelmakingCombustion

The invention relates to a QDF electric steelmaking process. The process comprises the following steps: uniformly mixing an iron-containing raw material and a powdery reducing agent, and filling each reducing room, wherein the materials are in disperse and uniformly distributed state in the reducing room, and the reducing rooms and the reduced materials are maintained in static states in the reduction process; uniformly heating the materials in the reducing room by using the heat produced by the combustion of fuel and combustion-supporting gas in a combustion room to preform the reduction reaction on the iron-containing raw material and the reducing agent, wherein the reducing room is a narrow one-part form reactor; obtaining heat-state directly reduced iron after the materials in the reducing room are completely reacted, conveying the heat-state directly reduced iron to a charging device through a hot-delivery mode, and hot-filling an electric furnace to obtain molten steel. The process has the obvious advantages of being short in flow, strong in raw material adaptability, non-coke smelting, easy in control of the reduction process, sufficient in inter-process energy utilization, and capable of obviously reducing CO2 discharge; the process is a steelmaking method with shorter process flow, lower investment, lower cost and better environment protection in comparison with a converter steelmaking process.

Owner:WISDRI ENG & RES INC LTD

Preparation method of zinc oxide anode material for lithium ion secondary battery

InactiveCN108511741AImprove uniformityImprove conductivityCell electrodesSecondary cellsSingle crystalCarboxylic acid

The invention discloses a preparation method of a zinc oxide anode material for a lithium ion secondary battery. The preparation method comprises the following steps of firstly, synthesizing a zinc polymer monocrystalline dispersion solution by a compound containing carboxylic acid or nitrogen and carboxylic acid and a zinc source under hydrothermal and solvothermal conditions; adding a compound doped with metal ions into the zinc polymer monocrystalline dispersion solution, reacting under the microwave condition, washing the obtained zinc polymer after reaction, drying, and calcining, so as to obtain the carbon-coated zinc oxide anode material doped with the metals. The preparation method has the advantages that the zinc coordination-containing polymer monocrystalline is prepared, the zinc ions in the polymer framework are exchanged by the metal ions under the microwave condition, a carbon network with higher content of graphitized carbon is obtained by decomposing under the nitrogencondition at high temperature, and the zinc oxide particles are filled into the decomposed carbon network, so as to improve the conductivity and structure stability of the carbon-coated zinc oxide anode material; the crystal cell parameters and charge distribution in local areas of lattice are changed by the doped metal ions, so as to obviously improve the primary efficiency of the zinc oxide, andgreatly improve the cycle property of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of silicon-carbon composite material, silicon-carbon composite material and application thereof

PendingCN114050252AWide variety of sourcesSimple processCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a preparation method of a silicon-carbon composite material, the silicon-carbon composite material and application thereof, and the preparation method comprises the following steps: mixing a carbon source and a silicon source according to a certain proportion, and coating the silicon source with the carbon source to obtain a carbon-layer-coated SiO2 / C composite material; putting the obtained SiO2 / C composite material and a reducing agent into a reaction kettle for reaction, and naturally cooling to obtain a product SiOx / C; and carrying out acid pickling, etching, washing and drying on the obtained product to obtain the SiOx / C composite material. According to the method, the SiOx material can be simply and conveniently prepared, the expansion effect of the SiOx material can be relieved, and the conductive effect is improved. In addition, the SiOx / C composite material prepared by the method can keep the morphology of a precursor silicon source, and has certain advantages for preparing the SiOx / C material with special morphology. The SiOx / C composite material with different morphologies prepared by the method is used as a lithium ion negative electrode material, and the cycle performance of a lithium ion battery can be remarkably improved.

Owner:JILIN UNIV

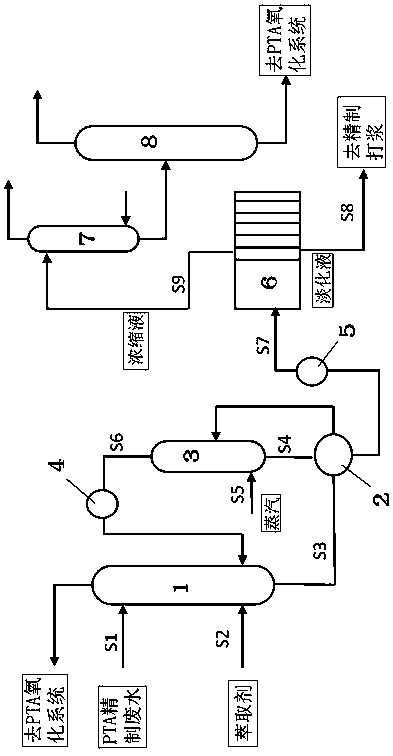

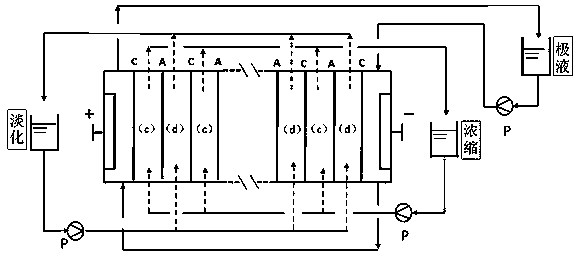

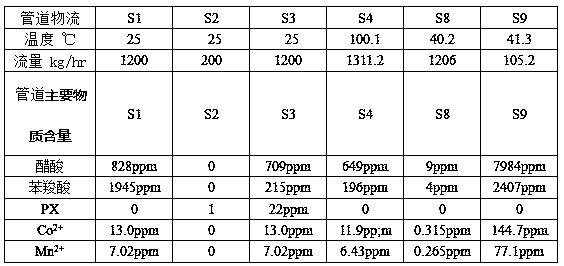

PTA refining wastewater resource recycling device and method based on electrodialysis

InactiveCN111348795AHigh recovery rateAvoid concentrated crystallizationSpecific water treatment objectivesWater contaminantsBenzeneAcetic acid

The invention provides a PTA refining wastewater resource recycling device and method based on electrodialysis. The method comprises the steps: firstly, pretreating by an extraction method to recovermost organic benzene carboxylic acid in wastewater; then removing the residual extraction agent in the wastewater by using a steam stripping method, finally, recovering acetic acid, residual organic benzene carboxylic acid and cobalt-manganese metal ions in the wastewater by using an electrodialysis method, and using the treated water for pulping of a PTA refining unit, thereby achieving the purpose of recycling reclaimed water. According to the method, electrodialysis, extraction and steam stripping technologies are combined, resource recycling of the PTA refining wastewater is achieved, andthe method has the advantages of being high in recycling rate, simple in process and the like.

Owner:FUZHOU UNIV

Metal-carbon composite negative electrode material as well as preparation method and application thereof

ActiveCN110061199AEvenly dispersedTightly boundElectrode thermal treatmentSecondary cellsCarbon compositesThree stage

The invention belongs to the field of battery materials, and particularly relates to a preparation method of a metal-carbon composite negative electrode material; the preparation method comprises thesteps of mixing bituminous coal with a metal source to obtain a mixture; and sequentially performing first-stage sintering, second-stage sintering and third-stage sintering on the mixture to obtain the composite negative electrodes material, wherein the sintering temperature is 300 DEG C or below in the first-stage sintering; the sintering temperature is 400-600 DEG C in the second-stage sintering; and the sintering temperature is 700-1,200 DEG C in the third-stage sintering. The invention also discloses the negative electrode material prepared by adopting the preparation method and an application of the negative electrode material in preparation of a negative electrode of a lithium ion battery. According to the method, bituminous coal is creatively adopted as a raw material; and the raw material is matched with the metal source, and the battery negative electrode material with excellent electrical property can be prepared under the special three-stage sintering mechanism.

Owner:HUNAN JINYE HIGH TECH CO LTD

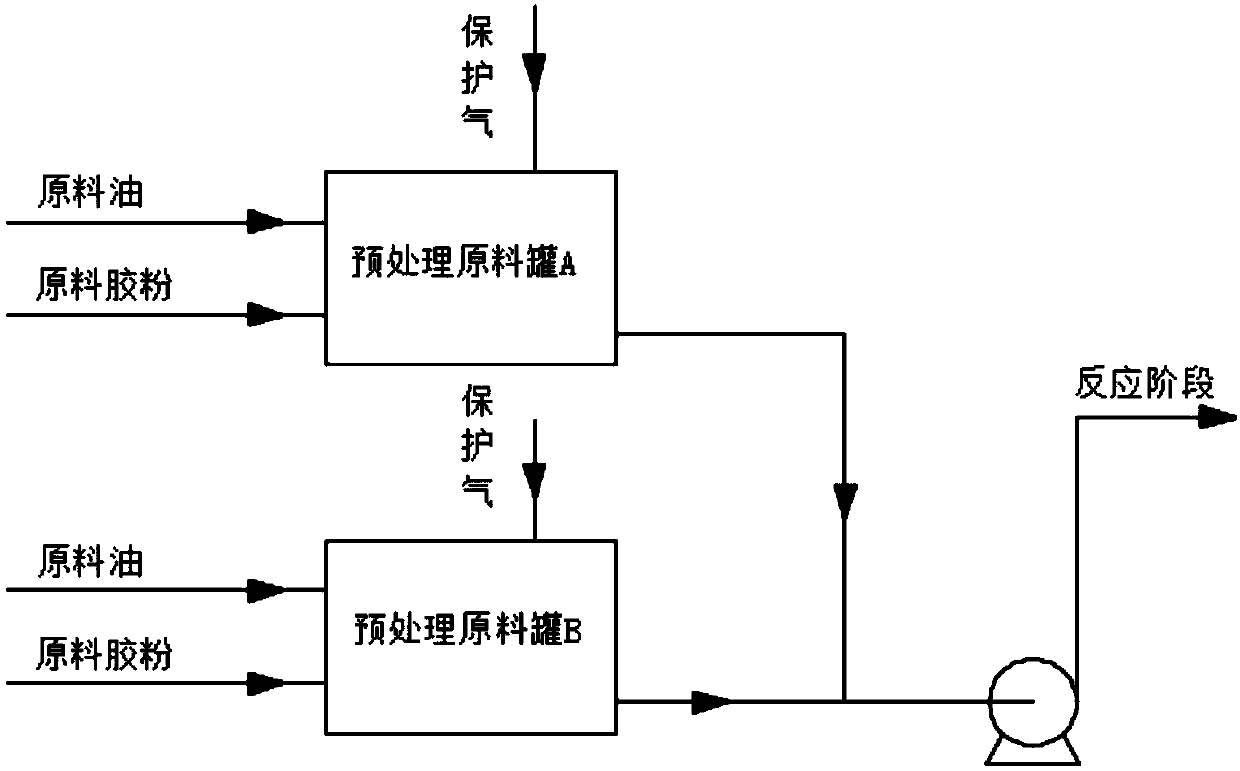

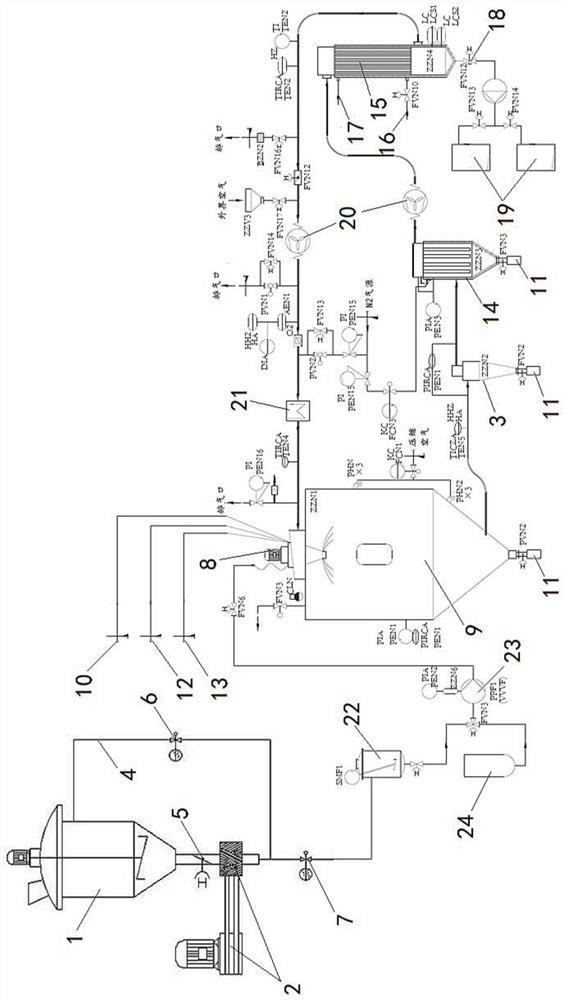

Pretreatment technology for co-refining of heavy oil and tire rubber powder

The invention provides a pretreatment technology for co-refining of heavy oil and tire rubber powder, and belongs to the technical field of rubber pyrolysis. The pretreatment technology includes the following steps that matched oil is preheated to 200-260 DEG C; the tire powder is uniformly added into the matched oil; under the atmosphere of protective gas, reaction is conducted for 20 minutes ormore at the temperature of 200 DEG C, and pretreatment is conducted under stirring conditions. Through simple and mild conditions, mixed paste is prepared, the swelling effect of the tire rubber powder in the matched oil is weakened to a great degree, and technical supports are provided for continuous operation of a co-refining device for heavy oil and tire rubber powder.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

In-situ leaching uranium mining drilling hole blockage removal and permeation enhancement technology

InactiveCN109989727AIncrease contact areaIdeal washing effectCleaning apparatusDrilling compositionIn situ leachAir compressor

The invention belongs to the technical field of in-situ leaching uranium mining, in particular to an in-situ leaching uranium mining drilling hole blockage removal and permeation enhancement technology, and aims to finally achieve the effects of uranium deposit blockage removal and permeation enhancement by a series of technological operations such as adding an activating agent, a comprehensive blockage removal agent and an anti-expansion displacing agent to a blocked ore bed, and parameter control, so as to well solve the problem of near-wellbore zone and ore bed blockage in a neutral leaching technology. The technology is characterized by comprising the steps of reagent preparation, surfactant injection, comprehensive blockage removal agent injection, anti-expansion displacing agent injection, standing and air compressor hole washing. When the technology is adopted in the specific Xinjiang uranium deposit well flushing process, the problem of ore deposit blockage is effectively solved, and the water amount after hole flushing is larger than the normal water level by 2-3m<3> / h, the maintenance time reaches 130d or more, the stratum can be prevented from being damaged for the second time, and the technology is simple and feasible in technique and economy and is a preferred hole washing technology for uranium deposit blockage removal and permeation enhancement.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

SiOx material surface coating treatment method and device

ActiveCN112993214AImprove conductivityReduce swelling effectFinal product manufactureNegative electrodesOrganic solventSlurry

The invention discloses a SiOx material surface coating treatment method which comprises the following steps: S1, pulping: taking SiOx, an additive A and an organic solvent, mixing, and then carrying out high-speed dispersion treatment to prepare slurry with required particle size distribution of SiOx particle surfaces coated with the additive A; and S2, granulating: atomizing the slurry, heating, evaporating and separating to obtain a SiOx particle product of which the surface is coated with the additive A. The invention also discloses a device for coating the surface of the SiOx material, which is used for the method for coating the surface of the SiOx material. According to the method, the surfaces of the SiOx particles can be uniformly coated.

Owner:新疆硅基新材料创新中心有限公司

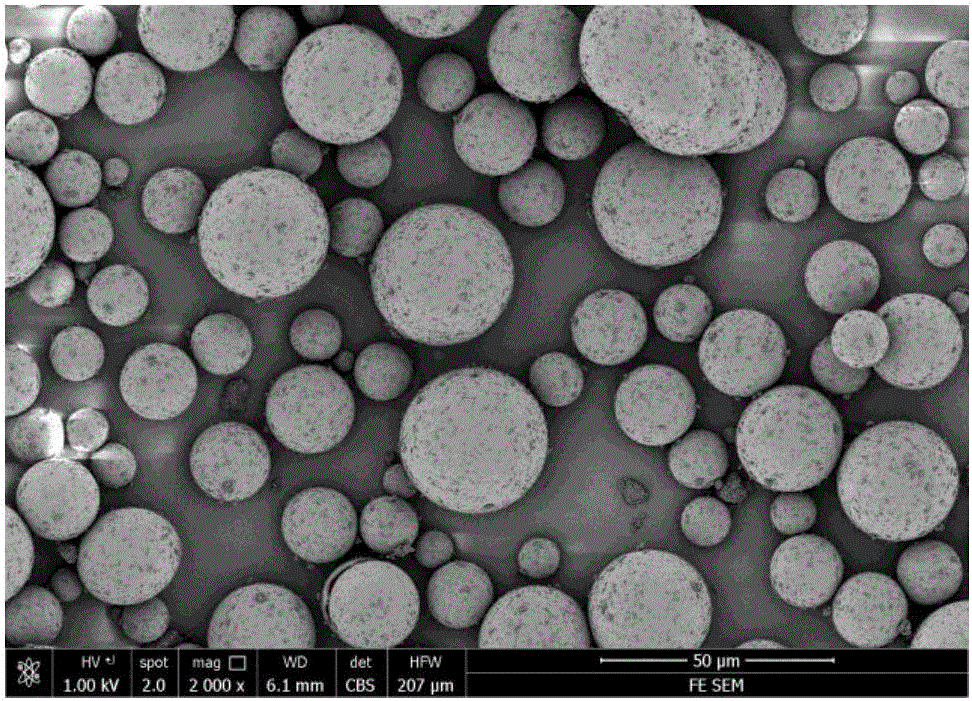

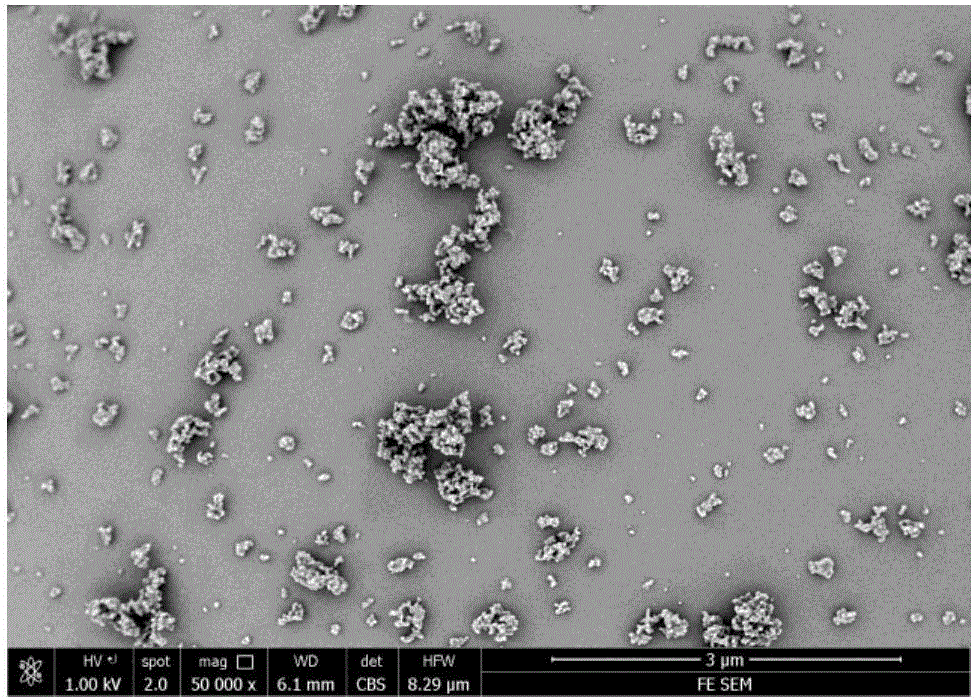

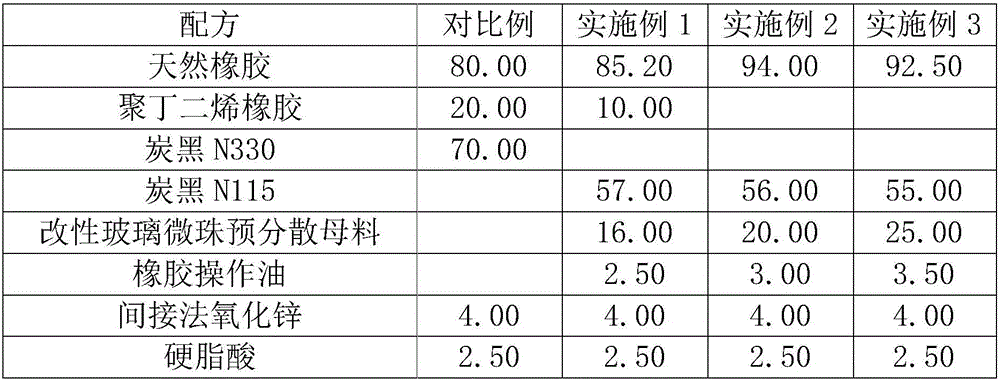

Formula and preparation process of lightweight elastic inner support body

The invention relates to the technical field of military automobiles and particularly relates to a formula and preparation process of a lightweight elastic inner support body. The formula contains the following components in parts by weight: 80-100 parts of natural rubber, 0-20 parts of polybutadiene rubber, 50-70 parts of carbon black, 10-40 parts of a modified glass bead pre-dispersion master batch, 4.5-7.5 parts of an active agent, 3-8 parts of rubber operation oil, 1.5-6.5 parts of an anti-aging agent, 1.0-2.5 parts of protecting wax, 0.5-2.5 parts of an accelerant and 0.8-1.8 parts of sulfur. The important physical properties of a rubber material of the elastic inner support body are improved, meanwhile, the formula density of the lightweight elastic inner support body can be reduced, the volume weight can be reduced, and the light weight of a military bulletproof safety tread is realized; the elastic inner support body has the characteristics of high strength, low themogenesis, ageing resistance and light weight.

Owner:SAILUN GRP CO LTD

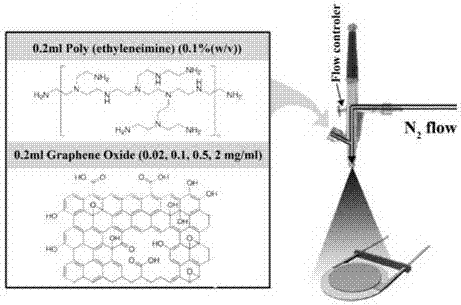

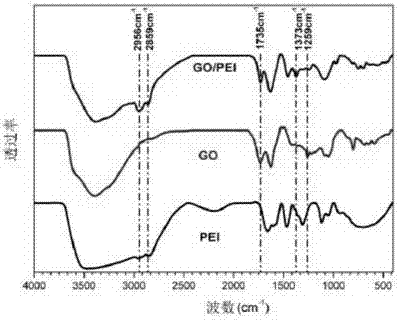

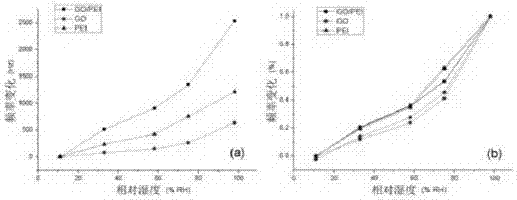

Humidity sensor film based on microregion redissolution reaction and preparation method thereof

InactiveCN106908514ASimple preparation processPerformance Tuning and ImprovementAnalysing fluids using sonic/ultrasonic/infrasonic wavesChemical reactionDissolution reaction

The invention discloses a humidity sensor film based on a microregion redissolution reaction and a preparation method thereof, and belongs to the technical field of the composite material and humidity sensor. The preparation method comprises the following steps: based on the technology and feature of an atomization process, such as the gas release, dissociating uniform solution to micron-type microdrops, conveying the microdrops to a film formation substrate by the gas, forming the micron-type redissolution reaction microregion in the guide layer film, and reacting by two or more materials in the microregion and finishing the film deposition process. The preparation method is capable of overcoming the problem in the traditional film preparation process that two or more materials cannot form the film because of the reaction deposition between the materials or the bad effect of the solution dispersion state caused by the generation. The humidity-sensitivity film prepared by the preparation method is capable of obviously improving the sensor feature characters, such as wet hysteretic property, because of the physical and chemical reactions, such as the bonding between the materials, and the electrostatic adsorption.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for improving bearing capacity of pile foundation under construction by replacing and filling soil between piles

InactiveCN110080266AIncrease frictionImprove mechanical propertiesFoundation testingEngineeringFrictional resistance

The invention discloses a method for improving the bearing capacity of a pile foundation under construction by replacing and filling soil between piles. The method comprises the following steps: step1, all the soil between the piles is dug out to a calculated depth of 1.0 m to 3.0 m; and step 2, when an excavation face is located above the underground water level, lime soil in the ratio of 2:8 orlime soil in the ratio of 3:7 is used for layered tamping, and the compaction coefficient Lambda c is larger than or equal to 0.95; when the excavated face is located below the underground water level, sand and stone materials are used for tamping layer by layer, and the compaction coefficient Lambda c is appropriate to be larger than or equal to 0.97. By adopting the method of replacing and filling the soil between the piles, the frictional resistance of the upper part of the pile foundation (or the rigid pile composite foundation) is greatly improved the requirement for the bearing capacityof the originally designed pile foundation is met, the mechanical property of shallow foundation soil can be improved, the mechanical defects such as collapsibility and expansibility of the shallow foundation soil are eliminated, the manufacturing cost is low, the construction period is short, and compared with a traditional pile supplementing construction method, the method is a better method for improving the bearing capacity of the pile foundation (or the rigid pile composite foundation).

Owner:李启民

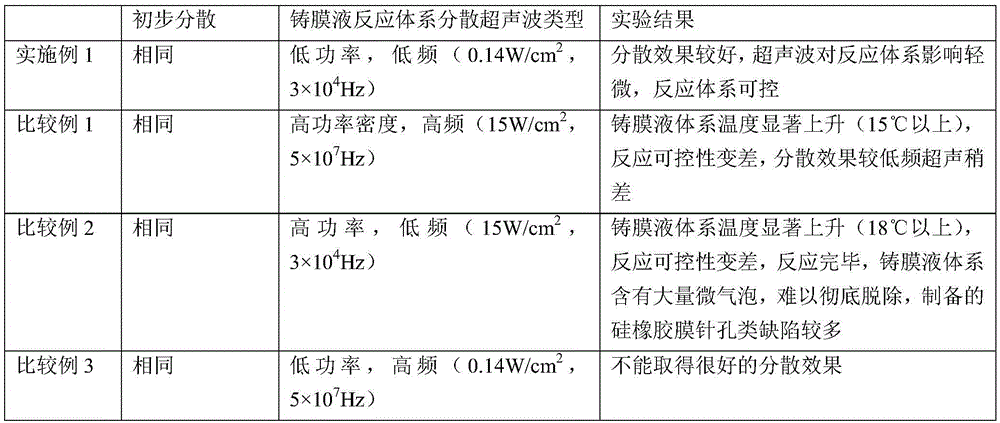

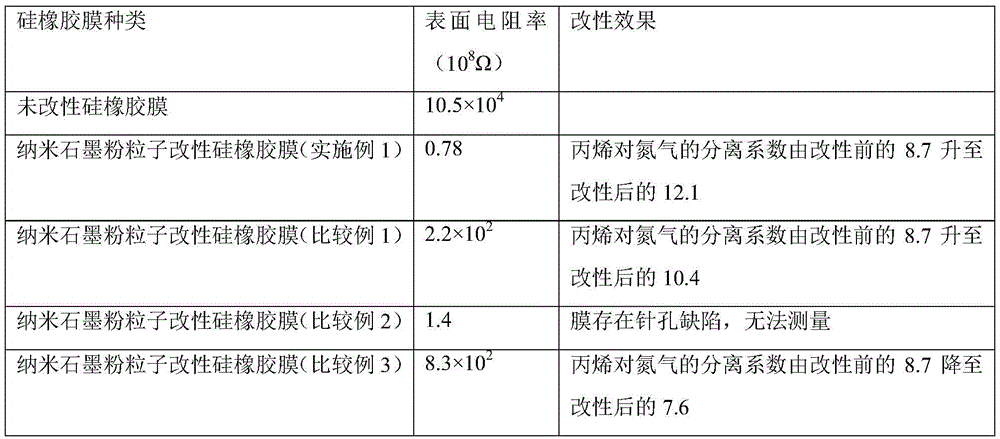

Preparation method of nanoparticle-modified silicone rubber composite film

ActiveCN106731906ALower surface resistivityImprove securitySemi-permeable membranesCross-linkComposite film

The invention discloses a preparation method of a nanoparticle-modified silicone rubber composite film. The preparation method comprises the following steps: adding polydimethylsiloxane, nanoparticles, a cross-linking agent and a catalyst into an organic solvent, and obtaining a suspension by stirring and mixing at a high rotating speed; performing ultrasonic dispersion on the suspension by adopting a high-power density and high-frequency ultrasonic instrument for a period of time; finally reacting under the condition of ultrasonic dispersion by adopting a low-power density and low-frequency ultrasonic instrument to obtain a film casting solution; pouring the film casting solution on a porous base film, scraping, drying under vacuum after the completion of cross-linking reaction and removing the solvent to obtain the nanoparticle-modified silicone rubber composite film. The preparation method disclosed by the invention has the benefits that a silicone rubber active separation layer of the composite film is modified by nanoparticles, the nanoparticle-modified silicone rubber composite film has anti-static performance, and the safety of the silicone rubber composite film in the field of oil and gas separation and recovery is significantly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com