Lithium-ion battery silicon-carbon composite anode material and preparation method thereof

A lithium-ion battery and silicon-carbon composite technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of poor cycle performance of lithium-ion batteries, failure to reduce the volume expansion effect of silicon-carbon lithium-ion battery negative electrode composite materials, and lack of freedom Problems such as space expansion and contraction, to achieve good electrical contact, reduce the expansion effect, and reduce the expansion rate of the pole piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Correspondingly, the embodiment of the present invention also provides a method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery, comprising the following steps:

[0035] S01. Prepare nano-silicon / graphene sheets, disperse the nano-silicon / graphene sheets in an organic solvent and then sand them to obtain a nano-silicon / graphene sheet solution; soft carbon precursor or soft carbon precursor and carbon material A are added to the nano-silicon / graphene sheet solution, mixed and treated, sprayed and granulated to obtain a nuclear precursor compound I; the nuclear precursor compound I is heat-treated to obtain the lithium-ion battery silicon A core of a carbon composite negative electrode material, wherein the heat treatment method is: heating at a constant temperature at 500-950°C for 1-5 hours;

[0036] S02. The core and the carbon material B precursor are respectively dispersed in a solvent, mixed, spray-dried to obtain a com...

Embodiment 1

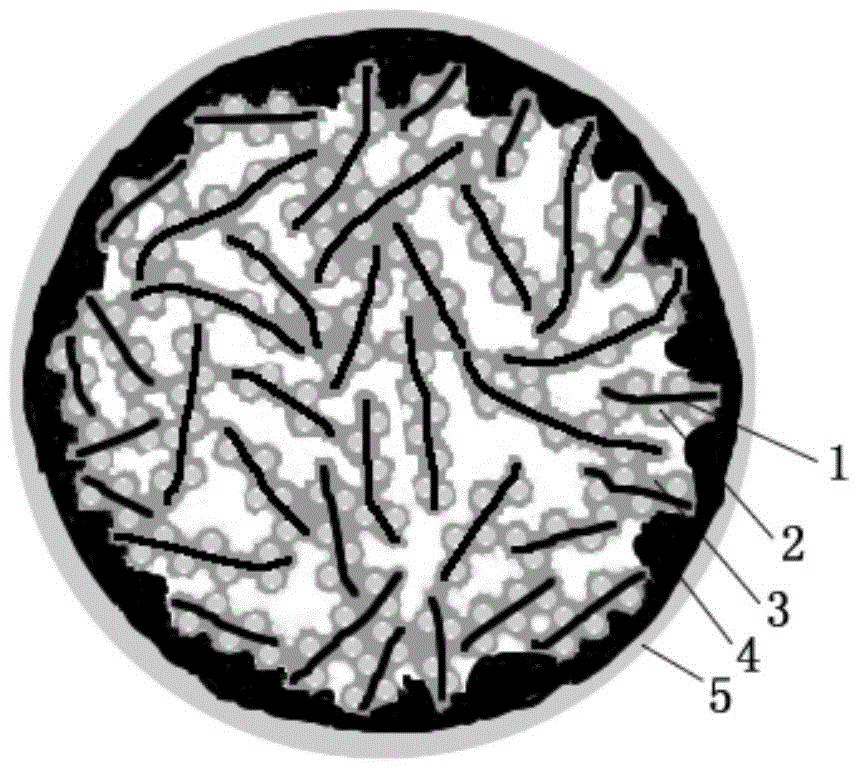

[0063] A silicon-carbon composite negative electrode material for a lithium-ion battery, the silicon-carbon composite negative electrode material for a lithium-ion battery includes a core-shell structure, the core includes a nano-silicon / graphene sheet, soft carbon, and the core is a soft carbon precursor and the nano-silicon / graphene sheet and soft carbon composite particles obtained after heat treatment of the nano-silicon / graphene sheet, wherein the soft carbon is attached to the surface of the nano-silicon / graphene sheet, and the nano-silicon / graphene sheet There are free spaces between the graphene sheets;

[0064] The shell is composed of carbon material B and nano carbon, and the carbon material B and nano carbon are coated on the surface of the core in turn.

[0065] The preparation method of the above lithium-ion battery silicon-carbon composite negative electrode material comprises the following steps:

[0066] S11. The nucleus of a silicon-carbon composite negative...

Embodiment 2

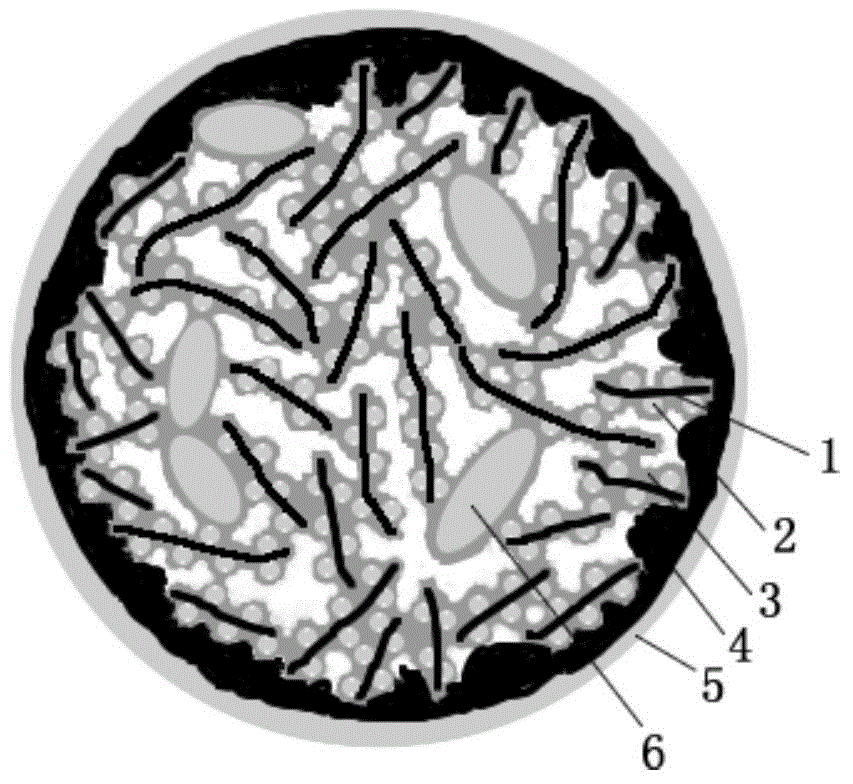

[0078] A silicon-carbon composite negative electrode material for a lithium-ion battery, the silicon-carbon composite negative electrode material for a lithium-ion battery comprises a core-shell structure, the core includes a nano-silicon / graphene sheet, soft carbon and carbon material A, and the core is The soft carbon precursor, the carbon material A and the nano-silicon / graphene sheet obtained after heat treatment, the carbon material A, and the soft carbon composite particles, wherein the soft carbon is attached to the Nano-silicon / graphene sheet and the surface of the carbon material A, and between the nano-silicon / graphene sheet, between the nano-silicon / graphene sheet and the carbon material A, and between the carbon material A have free space;

[0079] The shell is composed of carbon material B and nano carbon, and the carbon material B and nano carbon are coated on the surface of the core in sequence.

[0080] The preparation method of the above lithium-ion battery s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com