Multi-element alloy compound anode material, preparation method and lithium ion battery containing compound anode material

A technology of negative electrode material and multi-element alloy, applied in the application field of negative electrode material of lithium ion battery, can solve the problems of difficult industrialization, poor long-term cycle performance, excessive expansion, etc., to reduce material expansion, improve rate and cycle performance, improve The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

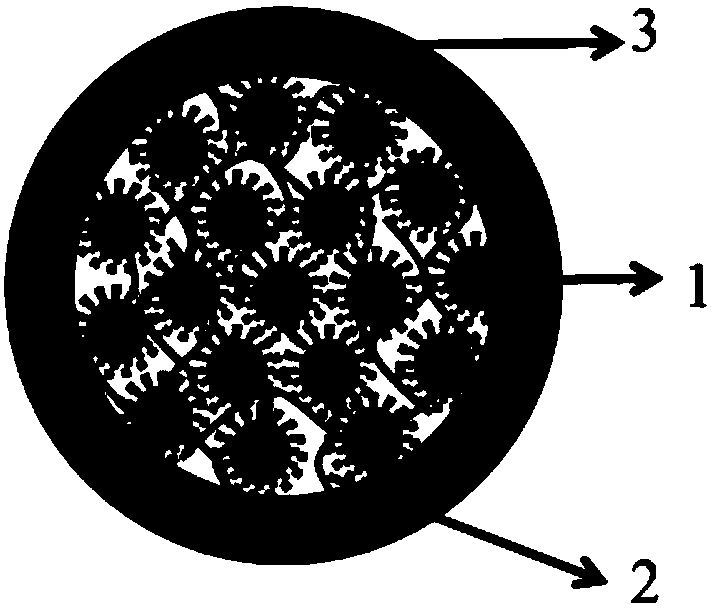

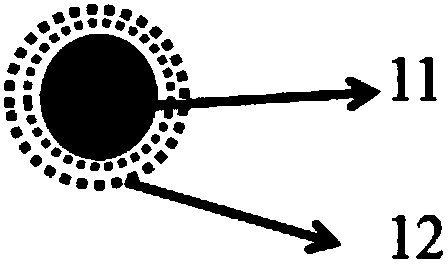

[0102] (1) Be that 50nm nano-silicon 10g, nano-germanium 5g, and nano-tin 5g are mixed evenly and placed in a rotary kiln with a median particle size of 50nm, and the air is ventilated to carry out high-temperature oxidation treatment. 0.5h to obtain nano-oxides (i.e., nano-silicon with oxide layer, nano-germanium with oxide layer and nano-tin with oxide layer), which are then uniformly dispersed in absolute ethanol, ultrasonically dispersed for 1h, and then heated in a nitrogen atmosphere 2 g of γ-methacryloxypropyltrimethoxysilane aqueous solution with a mass fraction of 90% was added under stirring, and reacted for 24 hours to obtain an alkylated nano-silicon suspension (i.e., realized alkylation), Slowly add 5g styrene in the stirring process, after adding, add 0.1g benzoyl peroxide and carry out polymerization reaction 10h as initiator, obtain surface macromolecule polymerization coating nano-silicon suspension (promptly realize macromolecular polymer coating Covering tre...

Embodiment 2

[0110] (1) The median particle size is 50nm nano-silicon 10g, nano-germanium 5g, and nano-tin 5g, mix uniformly, place in a rotary furnace, carry out high-temperature oxidation treatment with air, the air velocity control is 10sccm, heat treatment temperature 800 ℃, time is 2h to obtain the active nano-oxide, then uniformly disperse it in absolute ethanol, ultrasonically disperse for 1h, then add γ-methacryloyloxypropyl with a mass fraction of 90% under stirring in a nitrogen atmosphere Trimethoxysilane aqueous solution 2g, reaction 24h, obtains alkylated nano-silicon suspension (i.e. realized alkylation), slowly adds 5g styrene in stirring process, after adding, adds 0.1g benzoyl peroxide as The initiator was polymerized for 10 hours to obtain a nano-silicon suspension coated with polymer on the surface (i.e., the polymer coating treatment was realized, that is, the surface modification of the polymer), and then, under the action of ultrasonic stirring, a mass fraction of 5 %...

Embodiment 3

[0115] (1) The median particle size is 50nm nano-silicon 10g, nano-germanium 5g, and nano-tin 5g, mix uniformly, place in a rotary furnace, carry out high-temperature oxidation treatment with air, the air velocity control is 10sccm, heat treatment temperature 800 ℃, time is 0.5h to obtain the active nano-oxide, then uniformly disperse it in absolute ethanol, ultrasonically disperse for 1h, then add γ-methacryloxypropane with a mass fraction of 90% under stirring in a nitrogen atmosphere 2 g of trimethoxysilane aqueous solution, reacted for 24 hours, and obtained alkylated nano-silicon suspension (i.e. realized alkylation), slowly added 5 g of styrene during stirring, and added 0.1 g of benzoyl peroxide Carry out polymerization reaction 10h as initiator, obtain surface macromolecule polymerization coated nano-silicon suspension (that is to realize macromolecular polymer coating treatment, namely macromolecular surface modification), subsequently, add mass fraction under ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com