Patents

Literature

917results about How to "Reduce bloat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

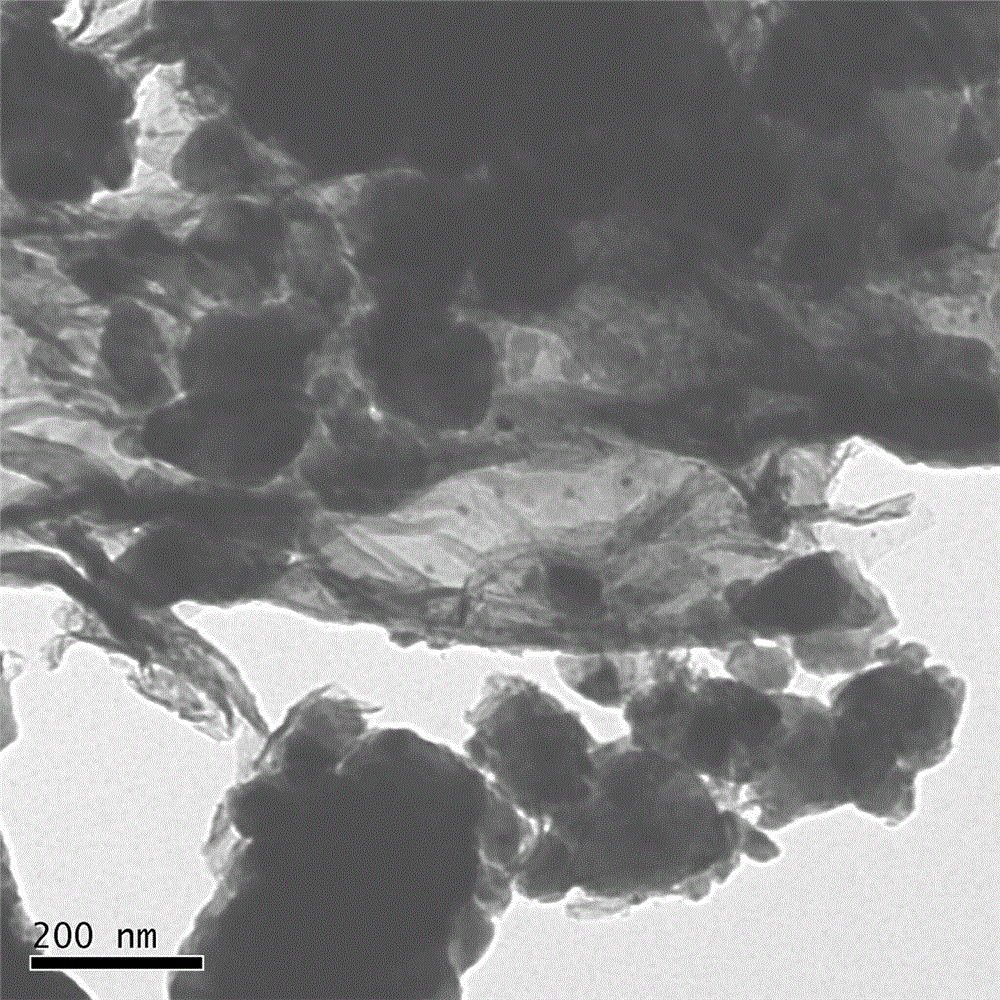

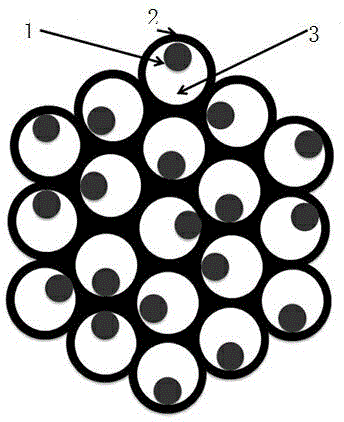

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

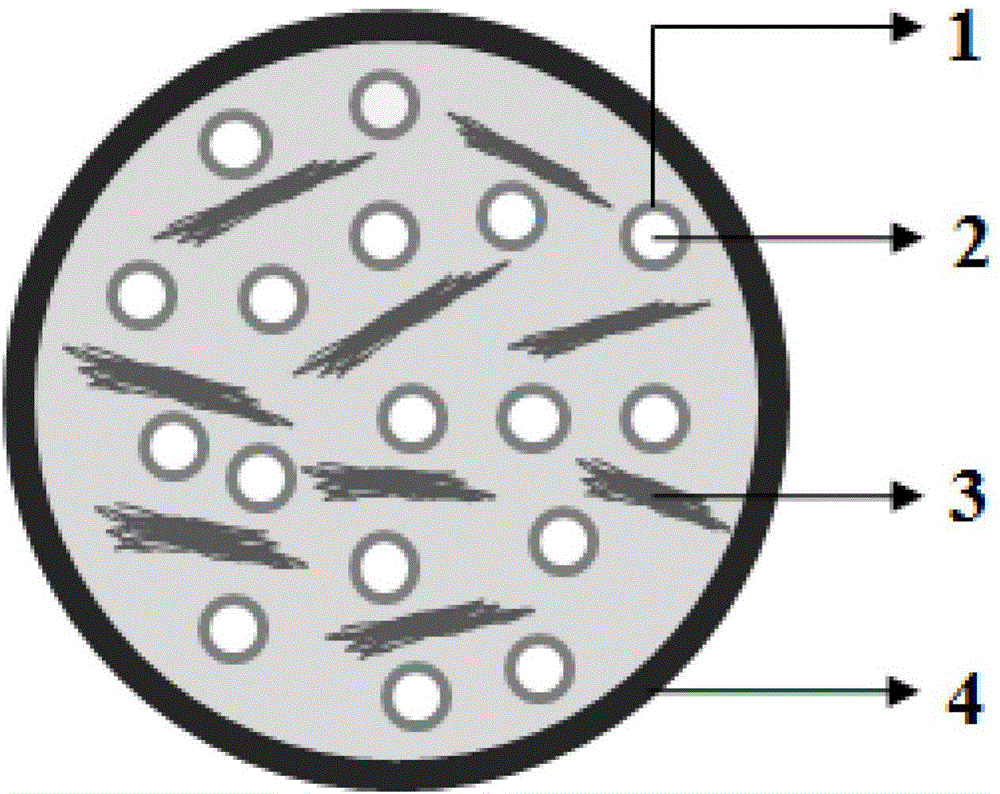

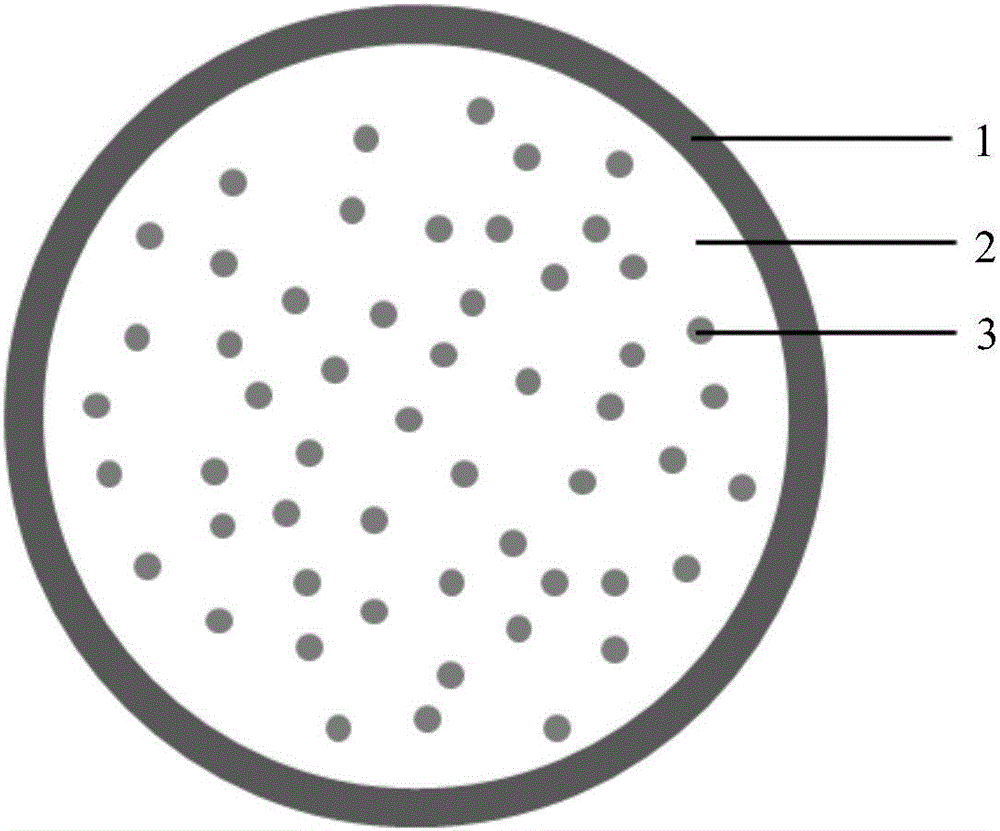

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

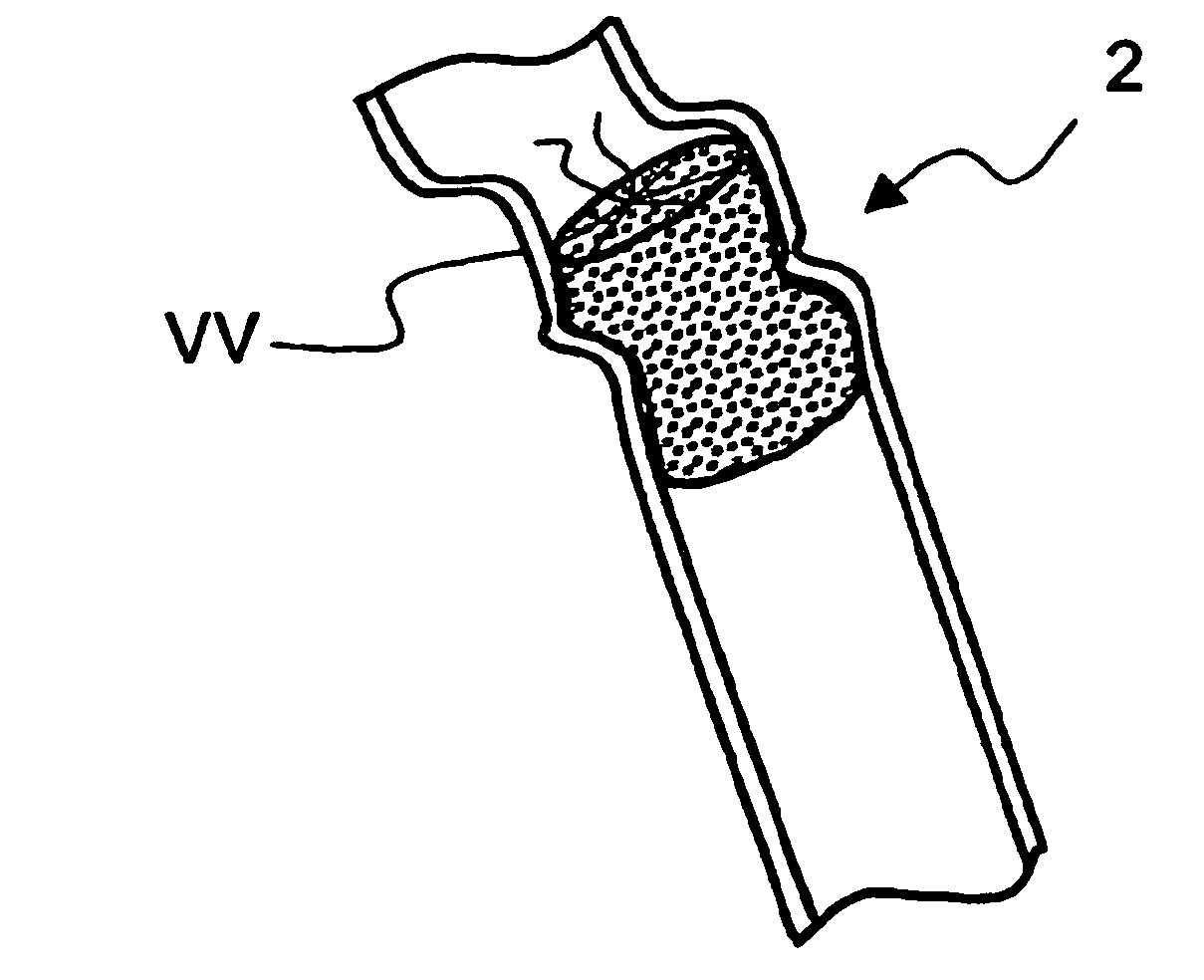

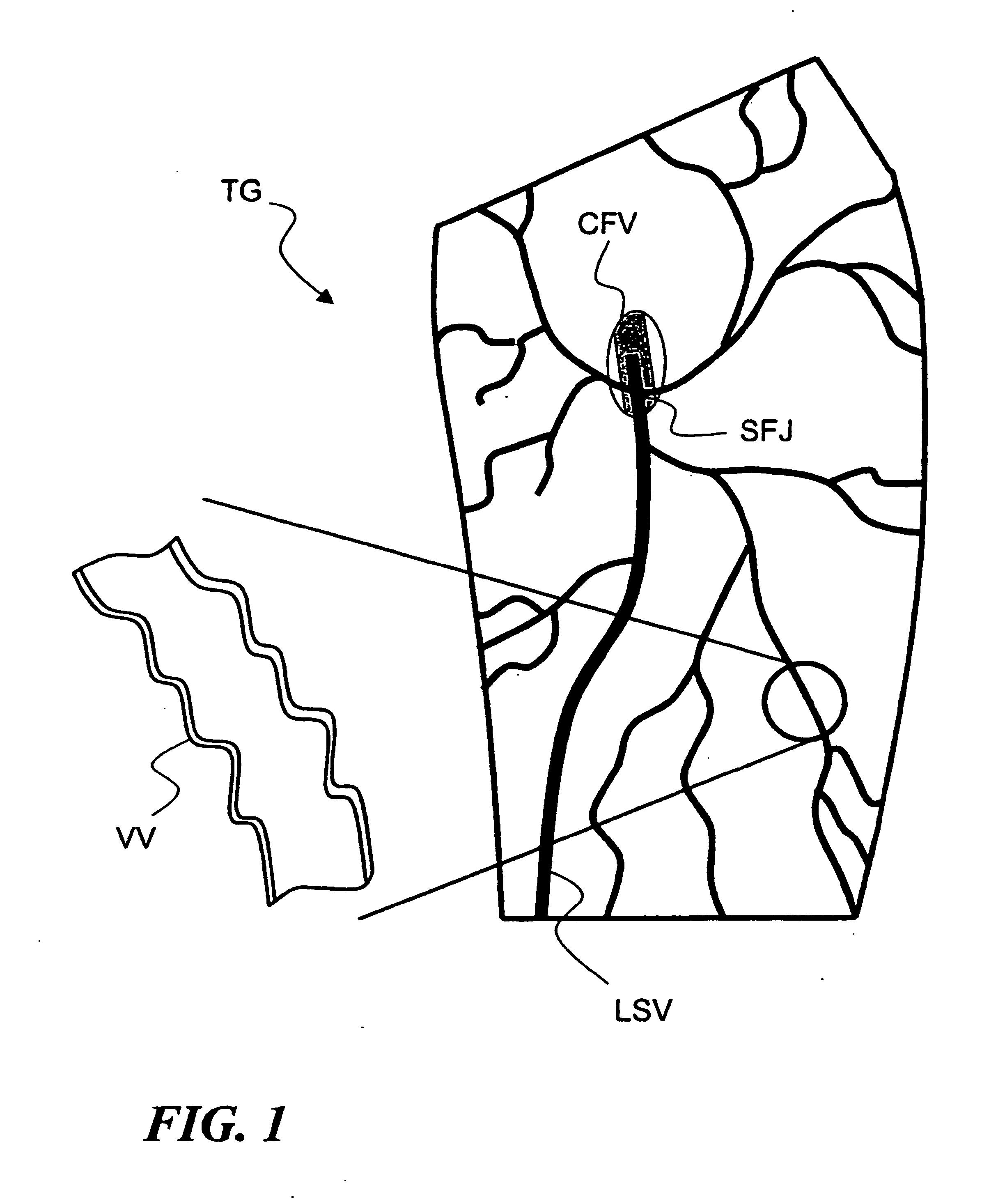

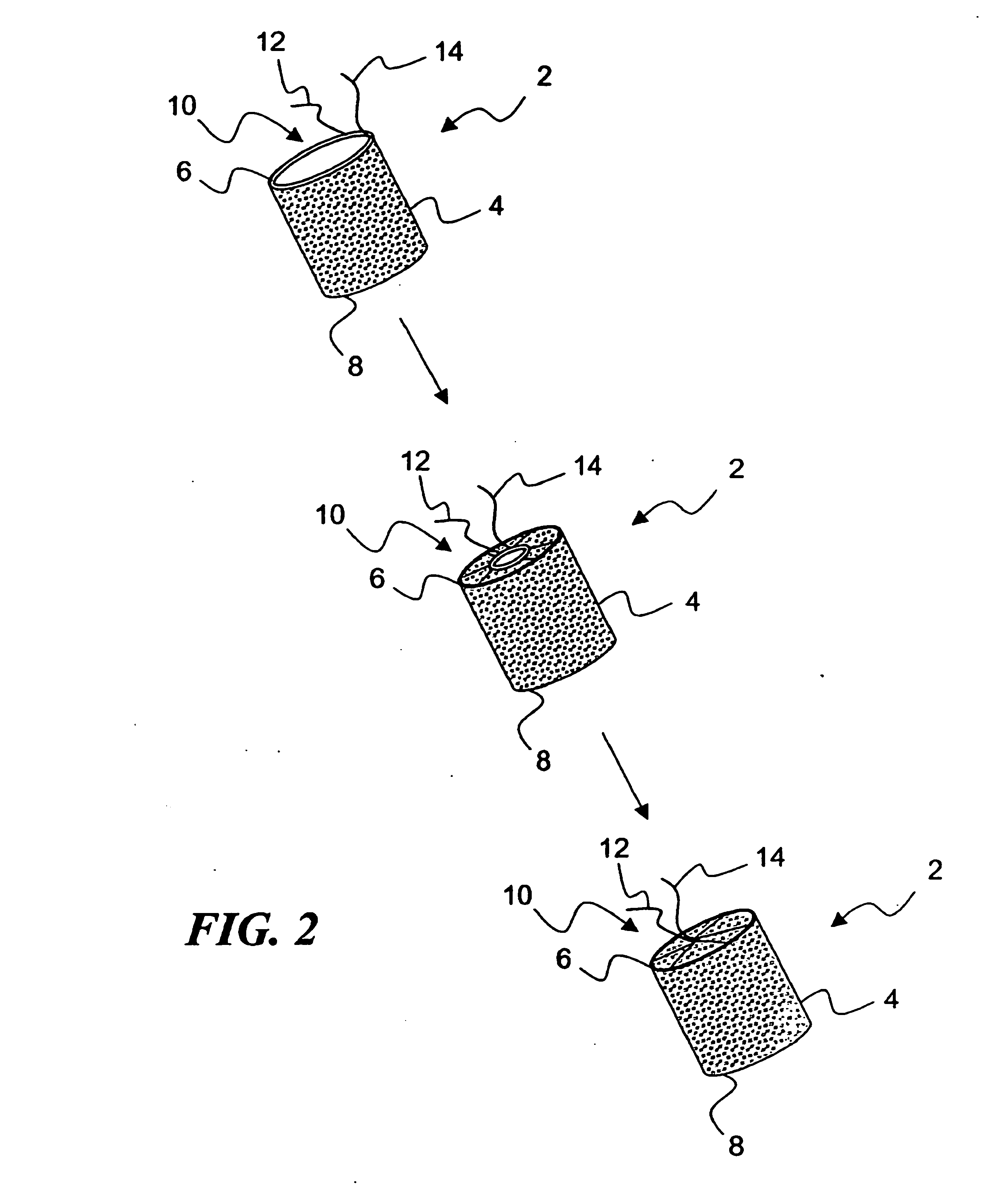

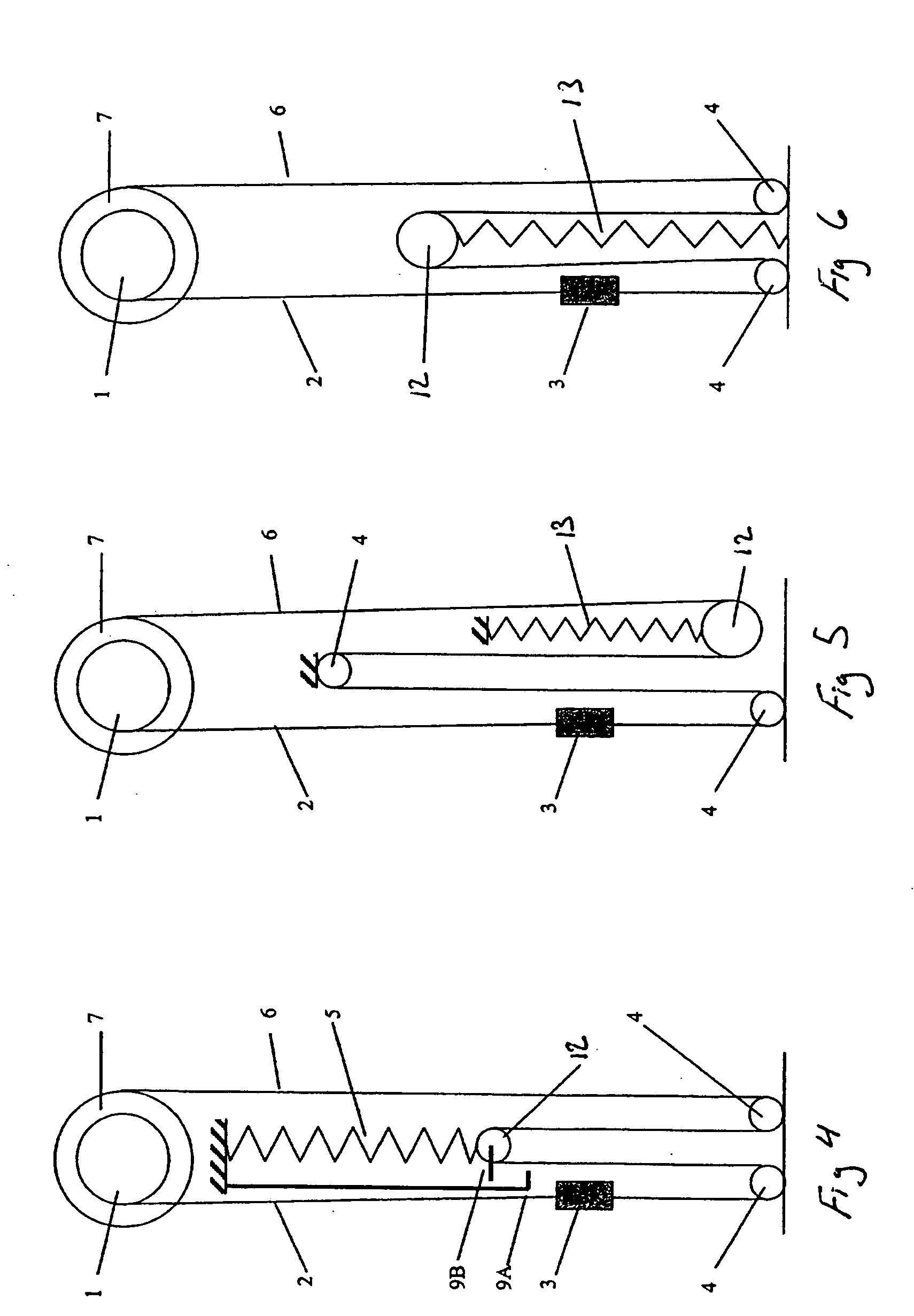

Temporary absorbable venous occlusive stent and superficial vein treatment method

InactiveUS20060190076A1Reduce bloatPromotes localized blood clotting, fibrosis and vein collapseSuture equipmentsHeart valvesSuperficial veinBlood flow

A temporary absorbable venous occlusive stent for use in a varicose vein treatment method includes a stent body, a bio-absorbable material associated with the body, and a closure for blocking blood flow past the stent when implanted in a vein. The stent produces localized blood clotting, fibrosis and vein collapse as it is absorbed. A permanent blockage is produced that prevents the undesirable back flow of blood from above the blockage site, thereby reducing distension of a varicose vein below the blockage site.

Owner:TYCO HEALTHCARE GRP LP

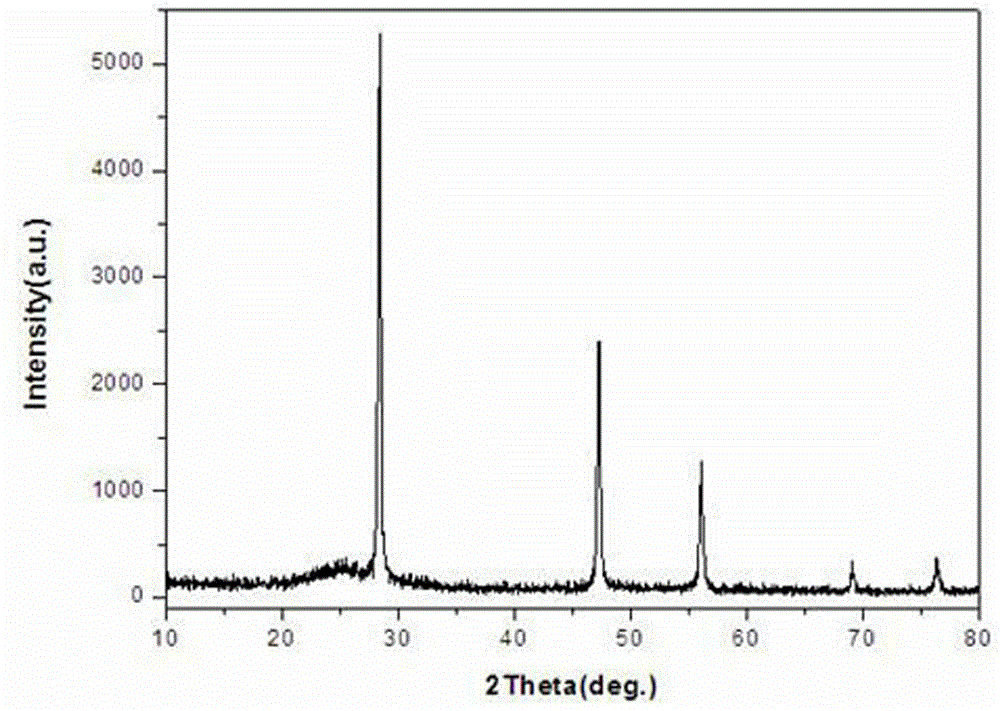

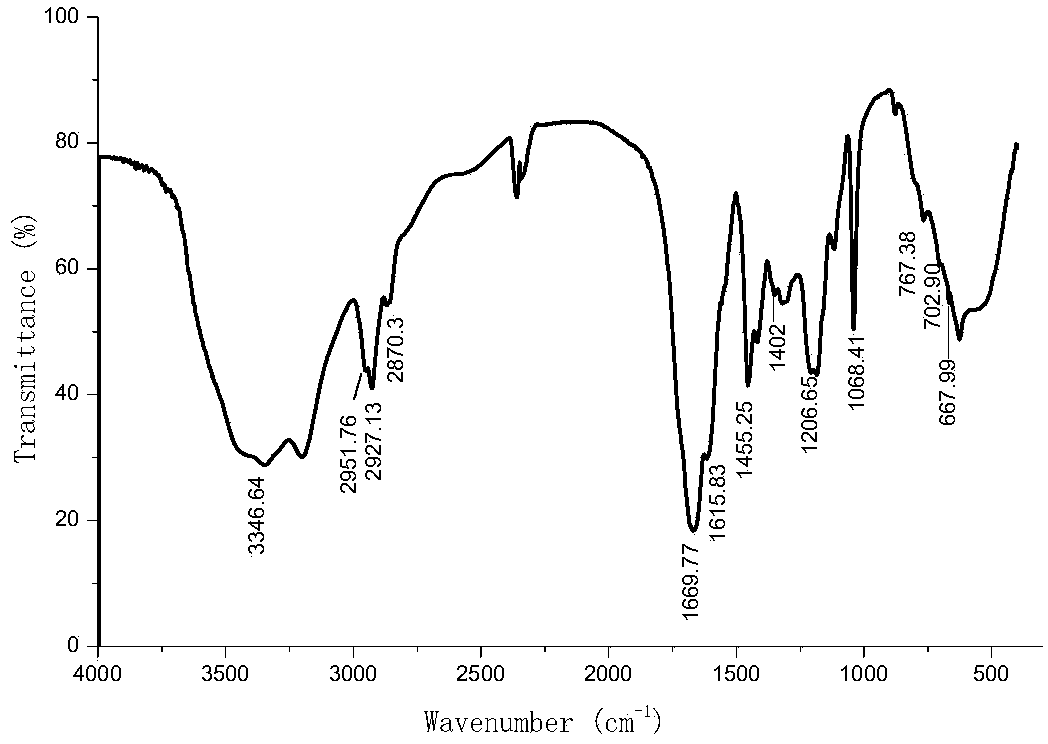

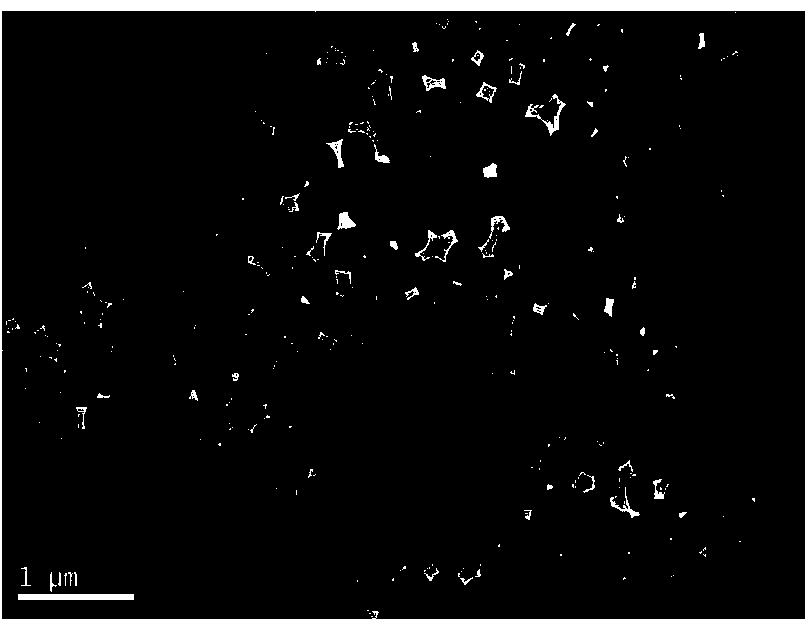

Silicon cathode material coated with graphene and preparation method thereof

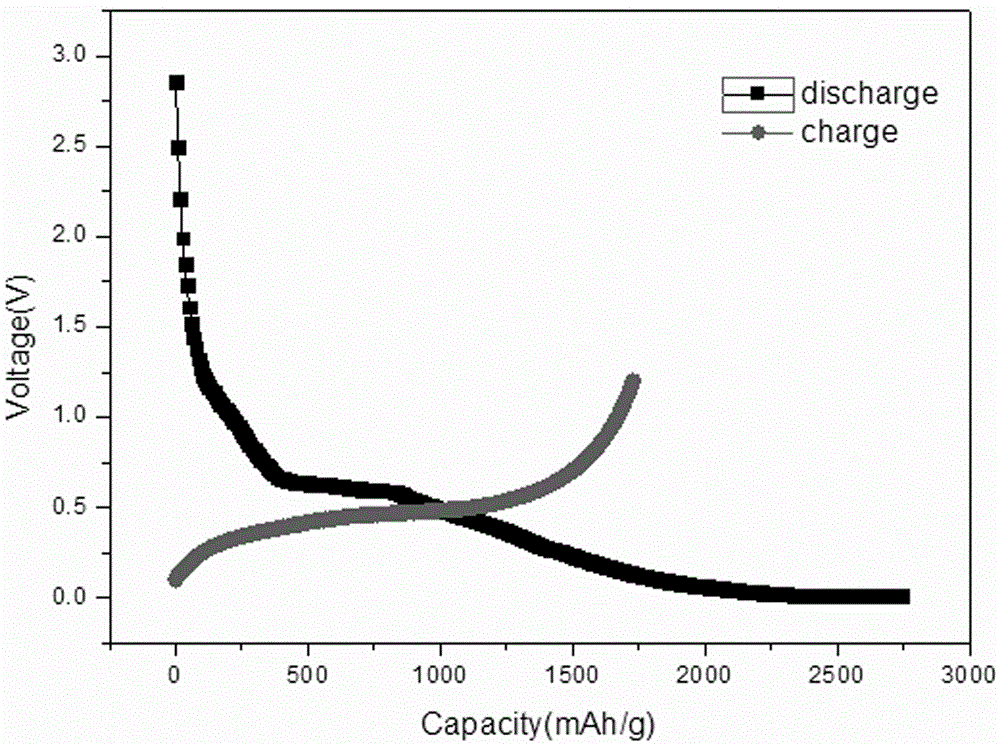

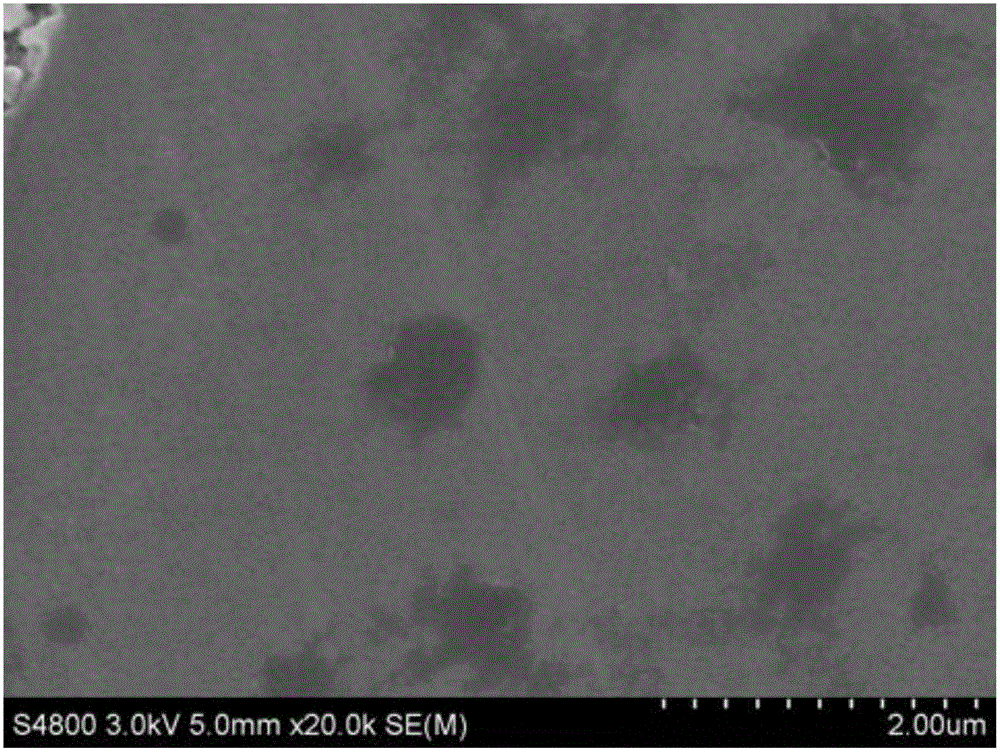

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

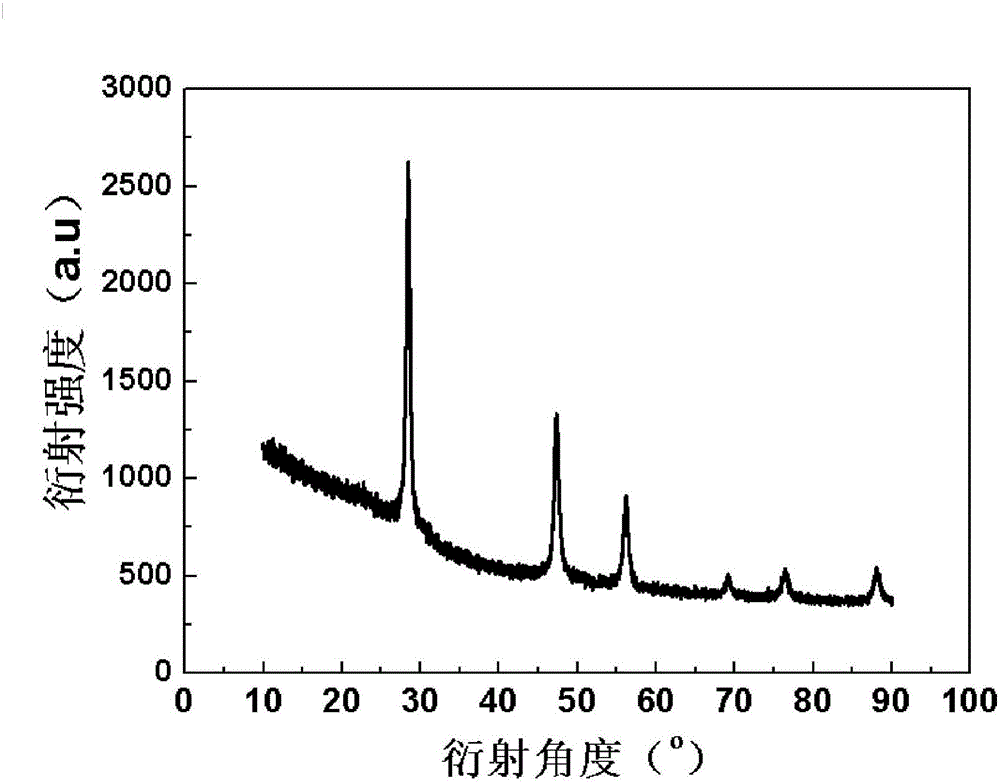

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

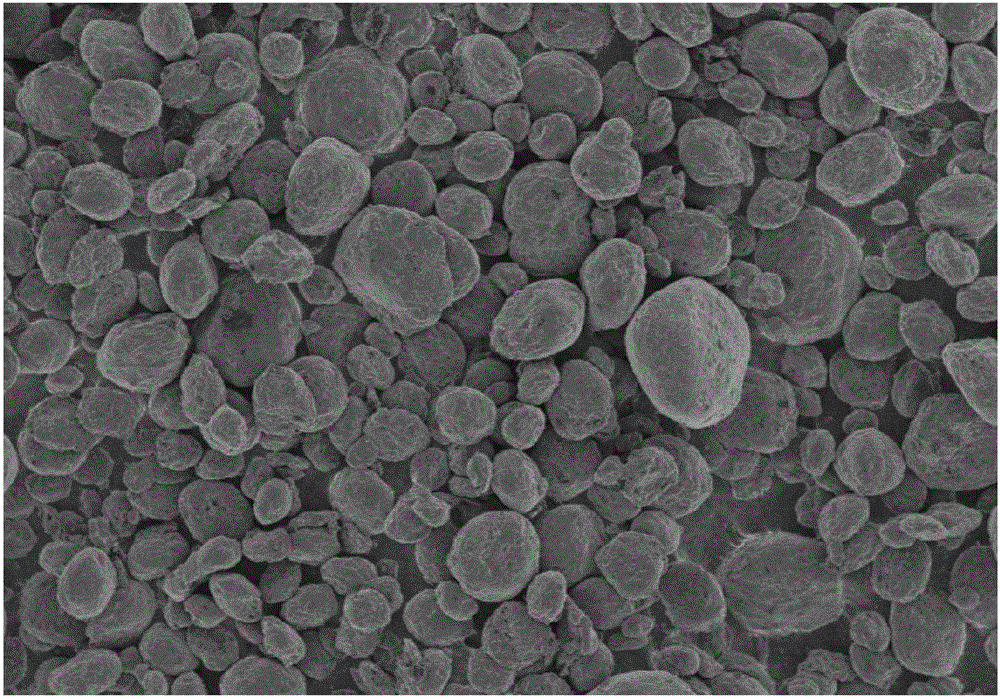

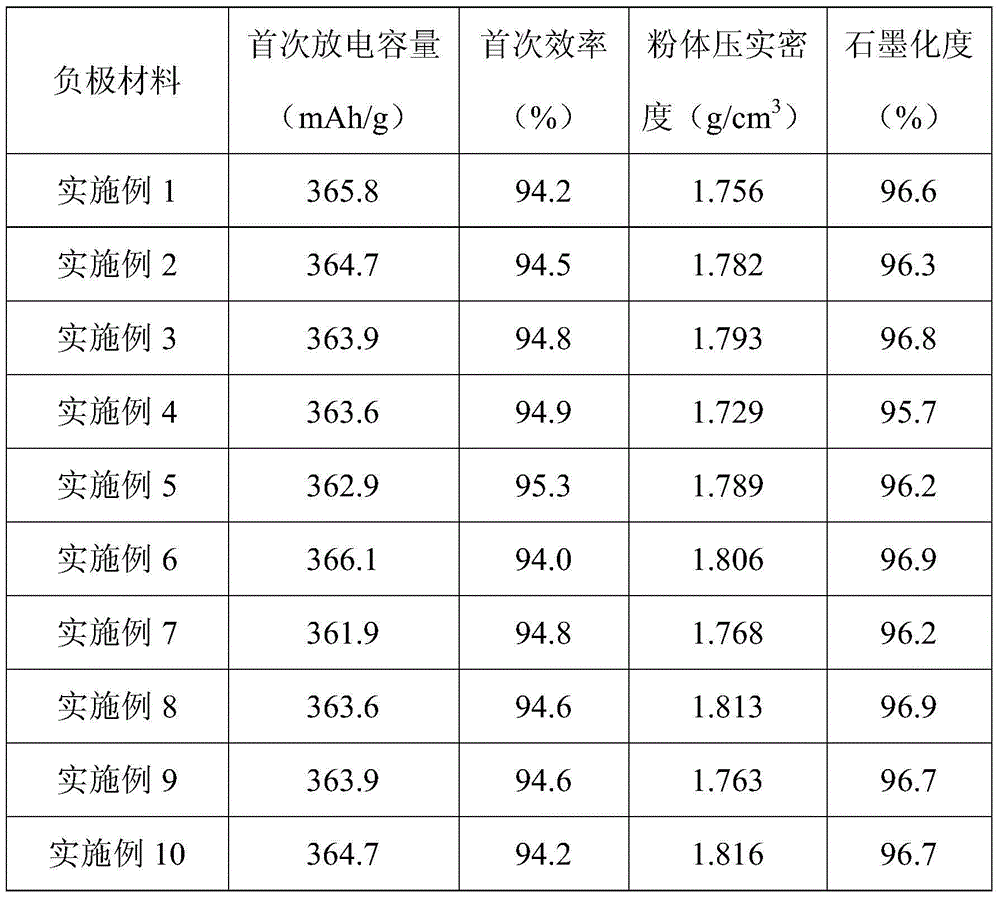

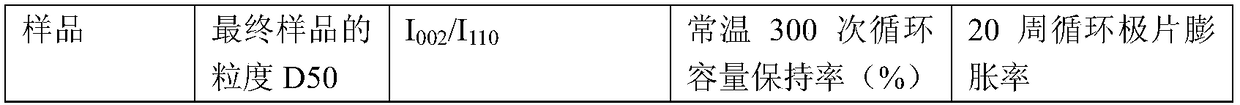

Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

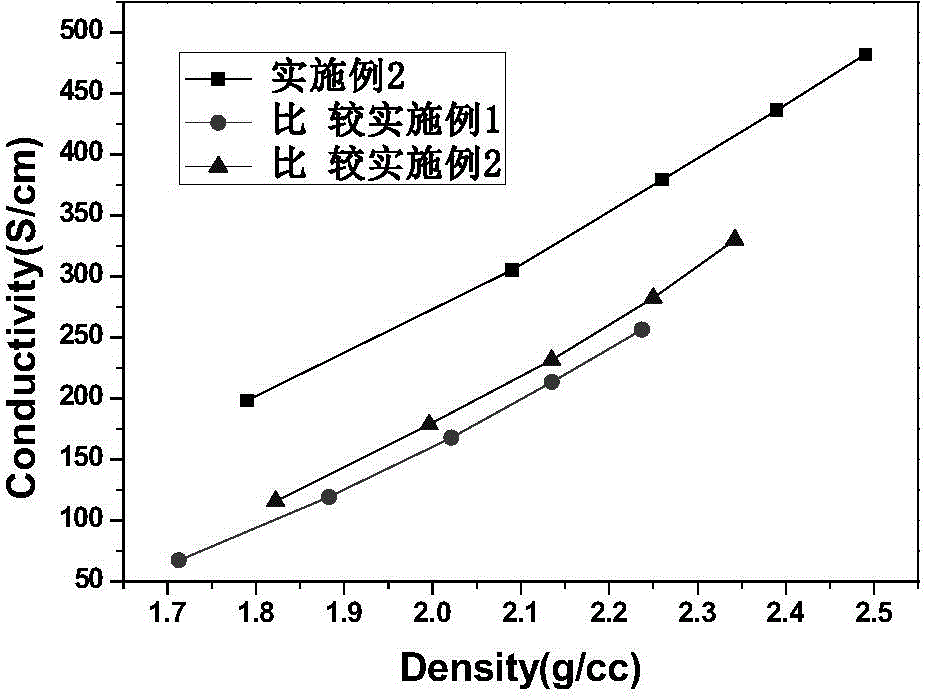

ActiveCN104085883AImprove cycle lifeImprove the degree of graphitizationCell electrodesSecondary cellsCompression moldingAluminium-ion battery

The invention discloses an artificial graphite negative electrode material for a lithium ion battery and a preparation method thereof. The preparation method for the artificial graphite negative electrode material comprises the following steps: preparing powder, adding a binder and / or a crystal nucleus-induced growth additive, kneading, carrying out compression molding, thermally roasting, carrying out nodulizing shaping and / or fusing, carrying out ultrahigh-temperature graphitization, screening, removing magnetism and screening. The preparation method disclosed by the invention is simple to operate, easy to control, lower in production cost and suitable for industrial production. The prepared artificial graphite negative electrode material has high graphitization degree, high compactness, high capacity, high coulombic efficiency, high conductivity and high multiplying power, and can be used for the lithium ion battery.

Owner:贝特瑞(江苏)新材料科技有限公司

Silicon-carbon composite material and preparation method thereof and application thereof in lithium ion battery

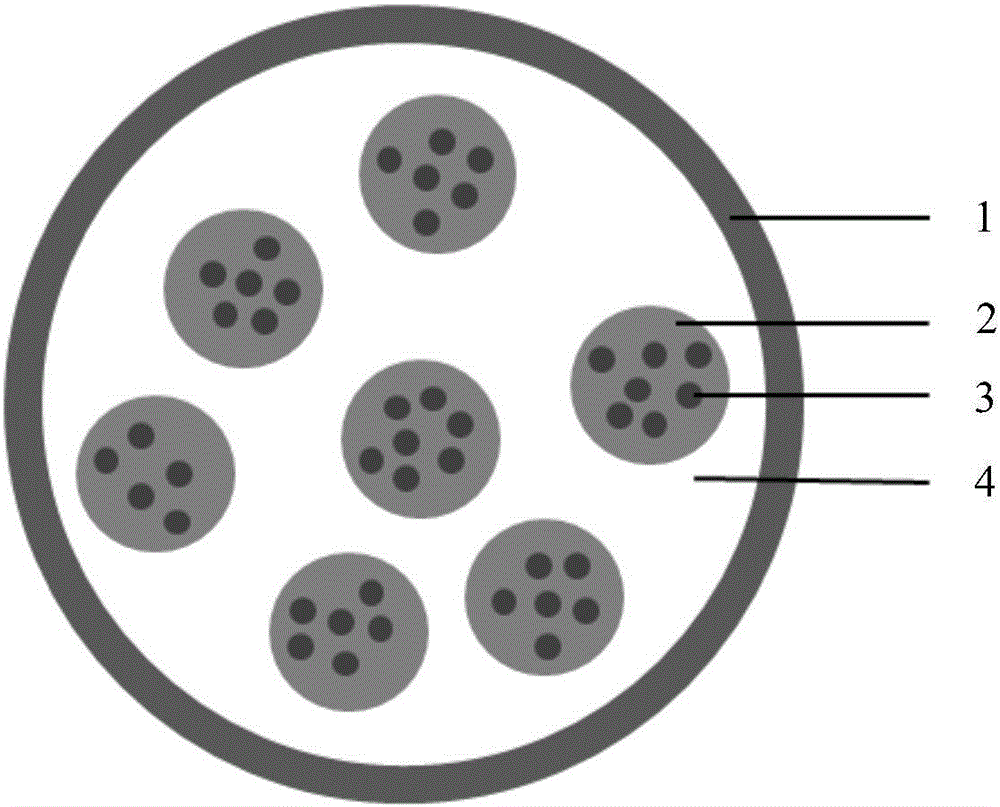

InactiveCN106159213ASimple preparation processLow costCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention relates to the battery field, and in particular relates to a silicon-carbon composite material and a preparation method thereof and application thereof in lithium ion battery. The following problems exist in the application of silicon-based materials in the lithium ion battery: 1. first coulombic efficiency of the lithium ion battery is low; 2, cycle life of the lithium ion battery is short; 3, the rate performance is poor; 4, the materials are low in production efficiency, and not conducive to large-scale industrial production. In order to solve the problems, the silicon-carbon composite material is provided, secondary-particles comprise a plurality of first particles containing core-shell structures, the core-shell structure comprises a carbon shell layer and silicon core particles which are completely wrapped by the carbon shell layer, and a gap is between the carbon shell layer and the silicon core particles. The preparation method of the silicon-carbon composite material and the application of the silicon-carbon composite material in the lithium ion battery are also provided.

Owner:BERZELIUS (NANJING) CO LTD

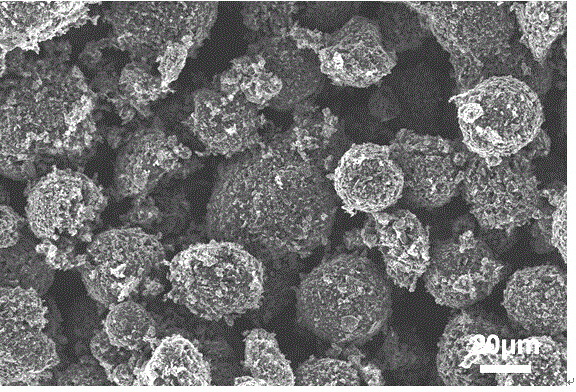

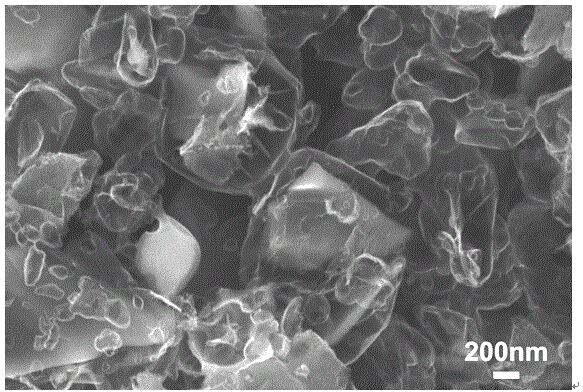

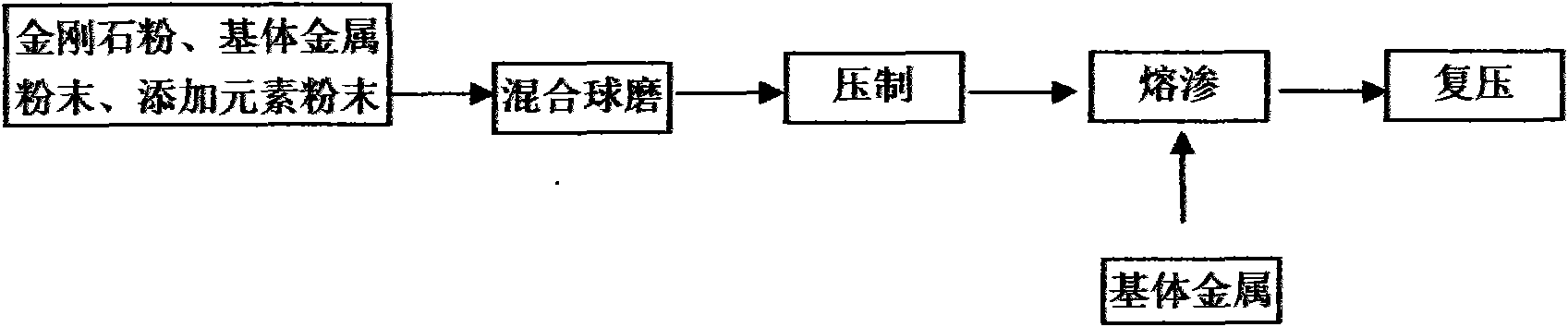

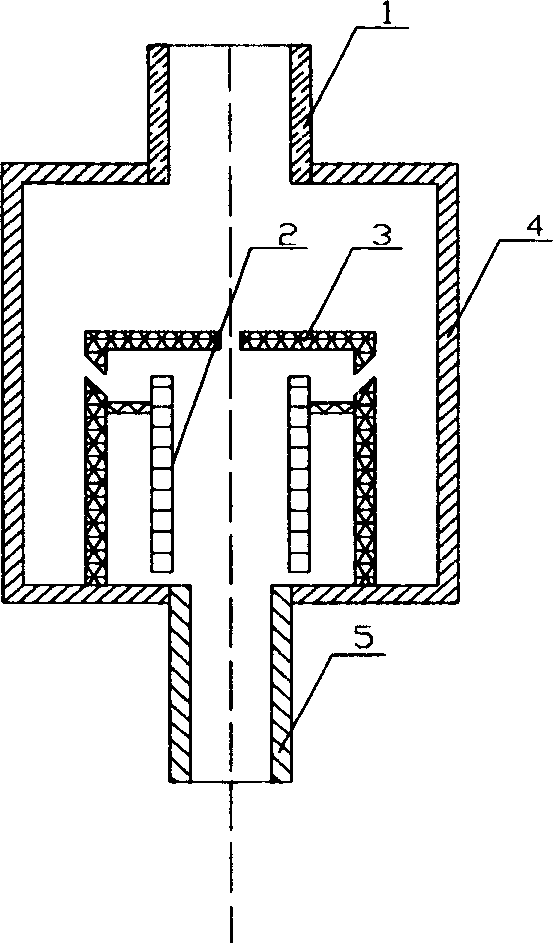

Diamond reinforced metal-base composite material for electronic packaging and preparation method thereof

ActiveCN101649400AImprove wettabilityImprove thermal conductivitySemiconductor/solid-state device manufacturingThermal expansionMetal matrix composite

The invention discloses a diamond reinforced metal-base composite material for electronic packaging and a preparation method thereof. The material comprises the following components by volume percent:30%-90% of diamond, 0.1%-5% of addition element and 10%-70% of metal substrate, wherein the addition element comprises one or more of Zr, Cr, Ti and B and the metal substrate comprises one metal of Ag, Cu and the like. The preparation method of the material comprises the following steps: mixing powder, pressing, infiltrating and pressing again. Owning to the adopted alloy element addition method,the wettability among phases is greatly improved. Therefore the material prepared by the method of the invention has better thermal conductivity, thermal expansion coefficient and mechanical properties compared with the former electronic packaging material and the adopted liquid phase infiltration method has the advantages of simple operation, low cost and capability of mass production.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

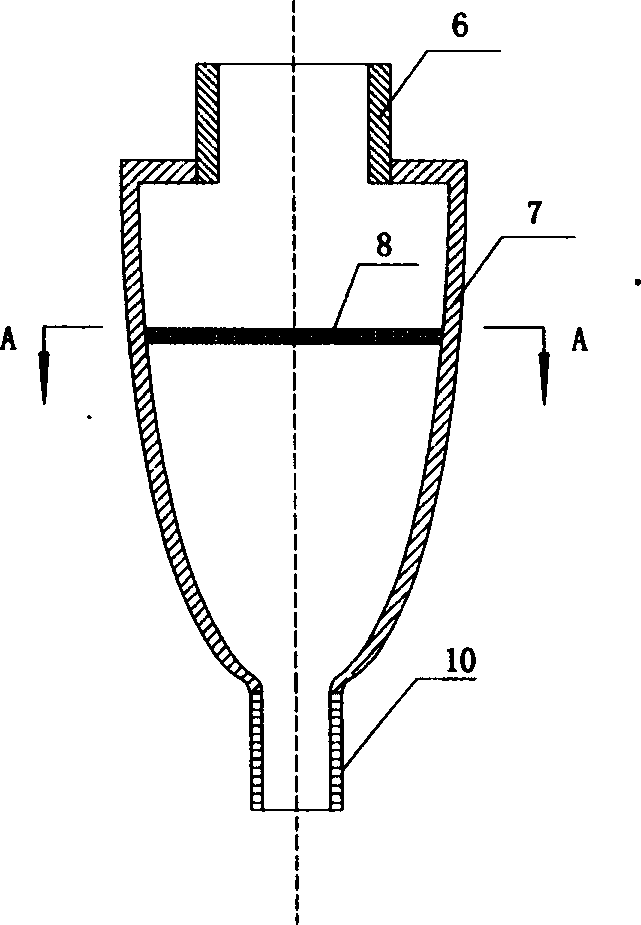

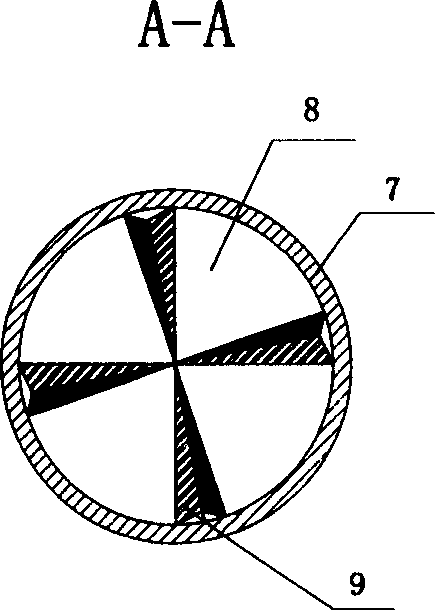

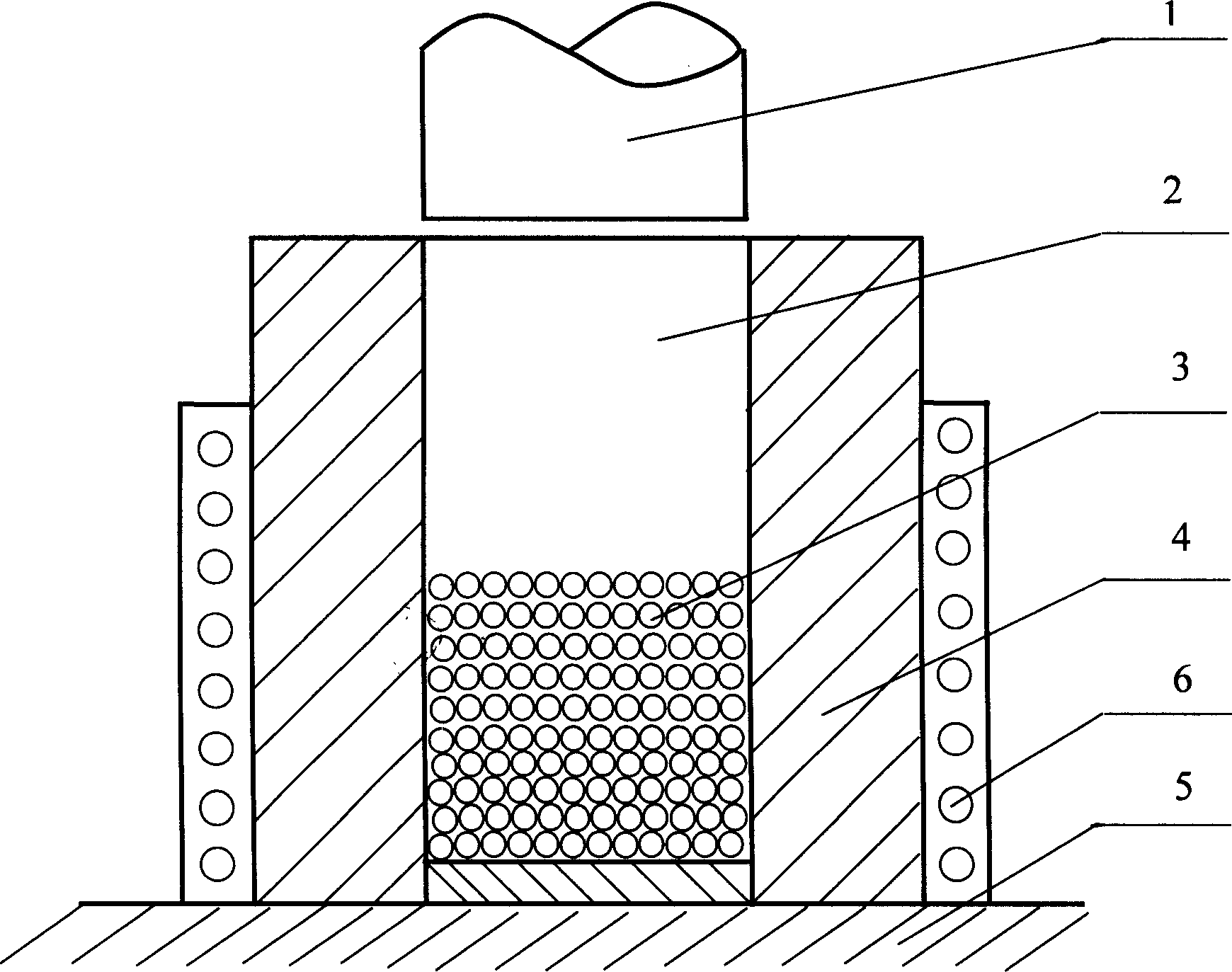

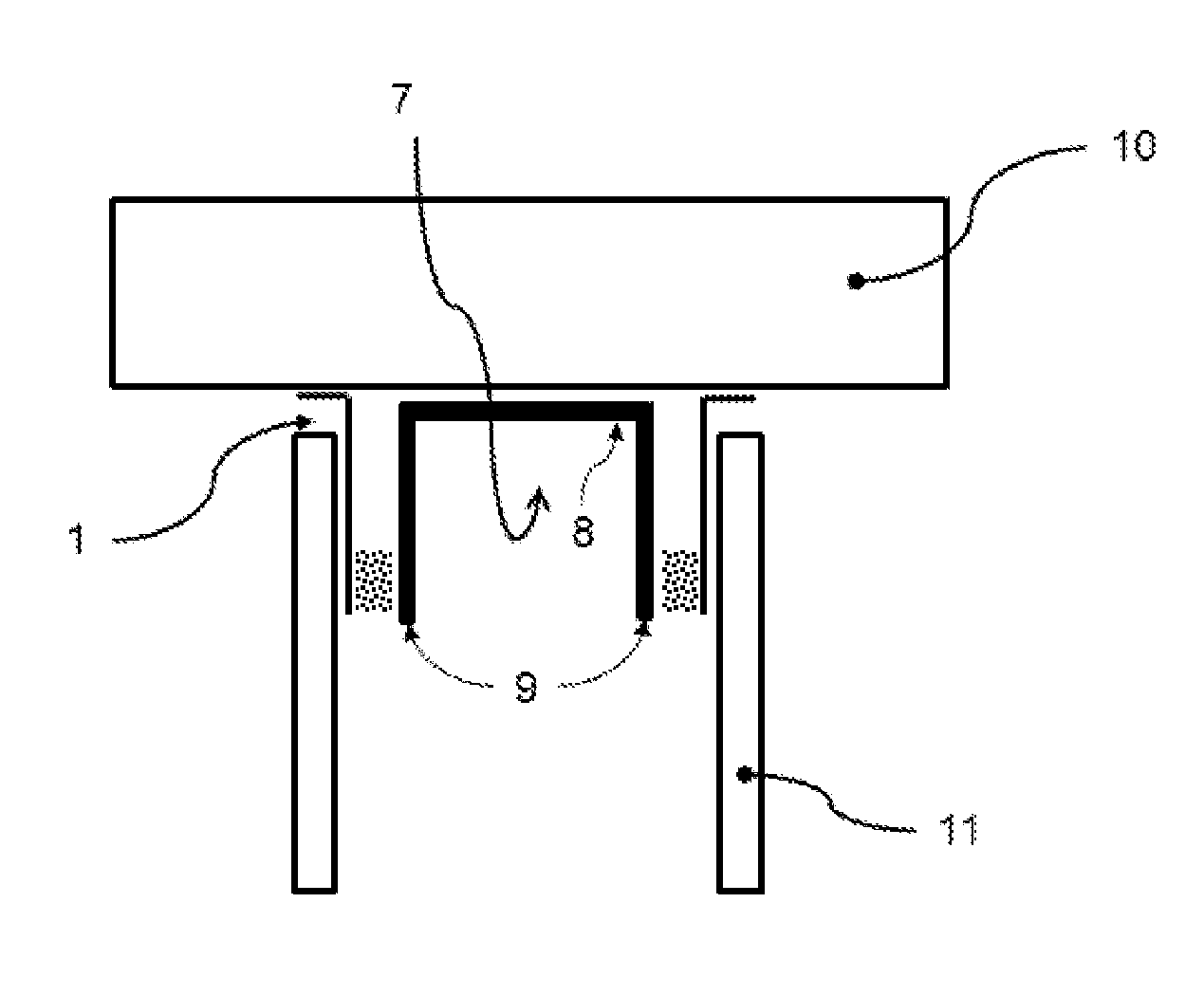

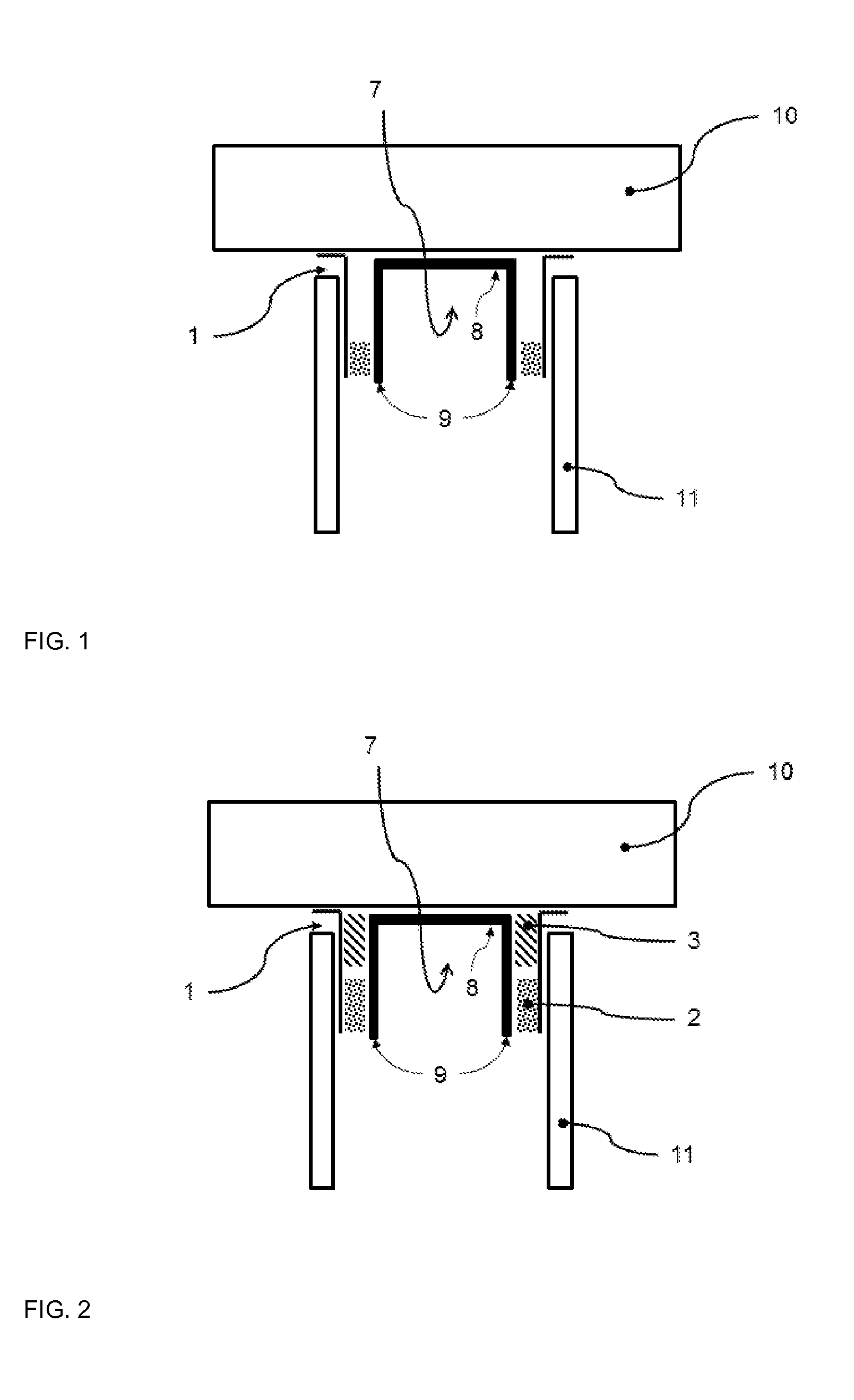

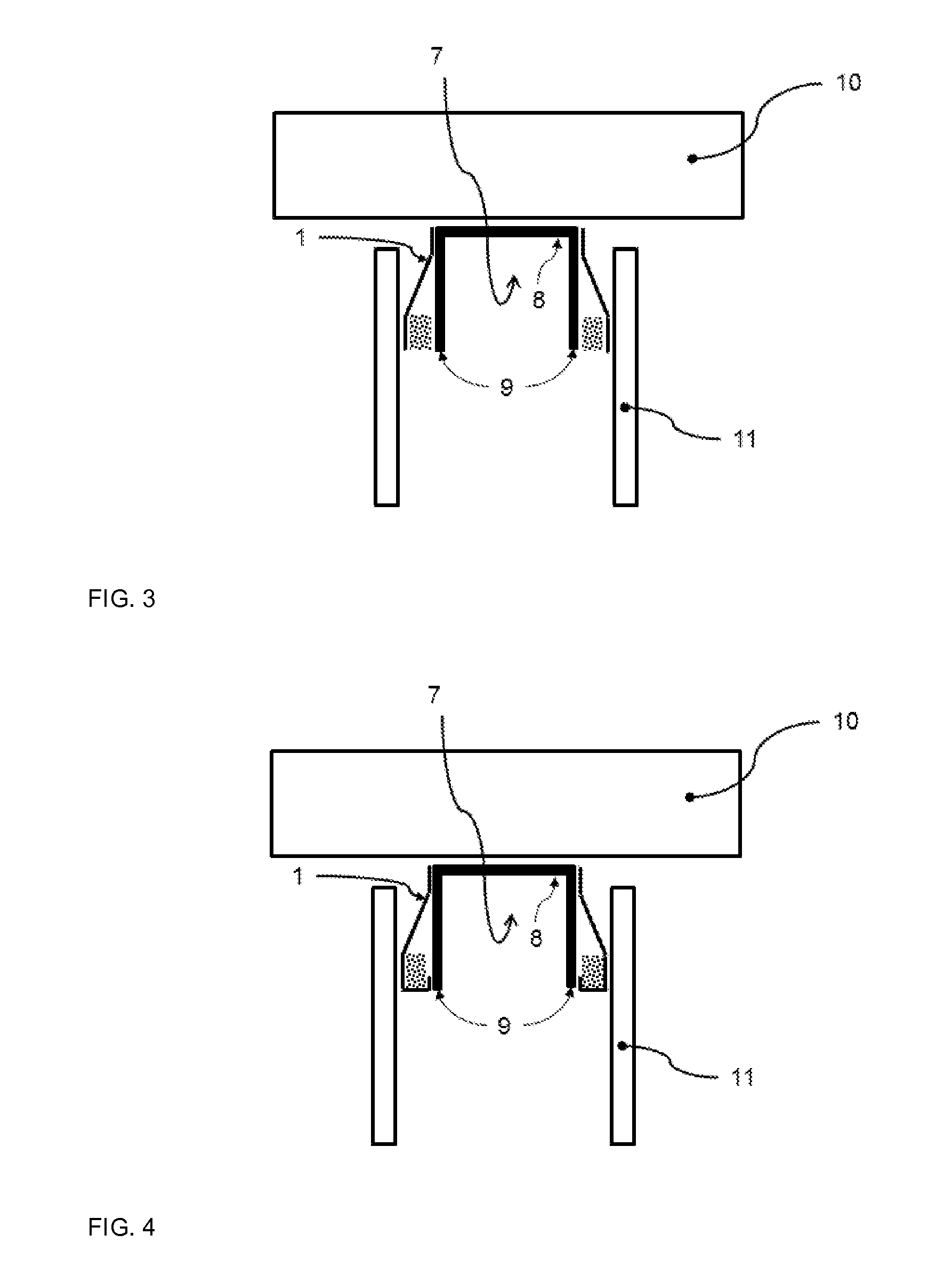

Convolution cavitation device

InactiveCN1605376ALarge amount of processingGood demulsification effectNon-miscible liquid separationHollow cylinderEngineering

The eddy cavitating unit used in the technological field of chemical separation consists of liquid inlet pipe and three coaxial cylinders including inner cylinder, middle cylinder and outer cylinder, the outer cylinder and the middle cylinder have individual tops with central inlet and common bottom, and the inner cylinder is a hollow cylinder and is connected to the middle cylinder via four radial cross beams. Or, the eddy cavitating unit consists of liquid inlet pipe, paraboloidal cone, disc with slit, flow guide plate and nozzle. Or, the eddy cavitating unit consists of liquid inlet pipe, outer paraboloidal cone, inner funnel cone and nozzle.

Owner:SHANGHAI JIAO TONG UNIV

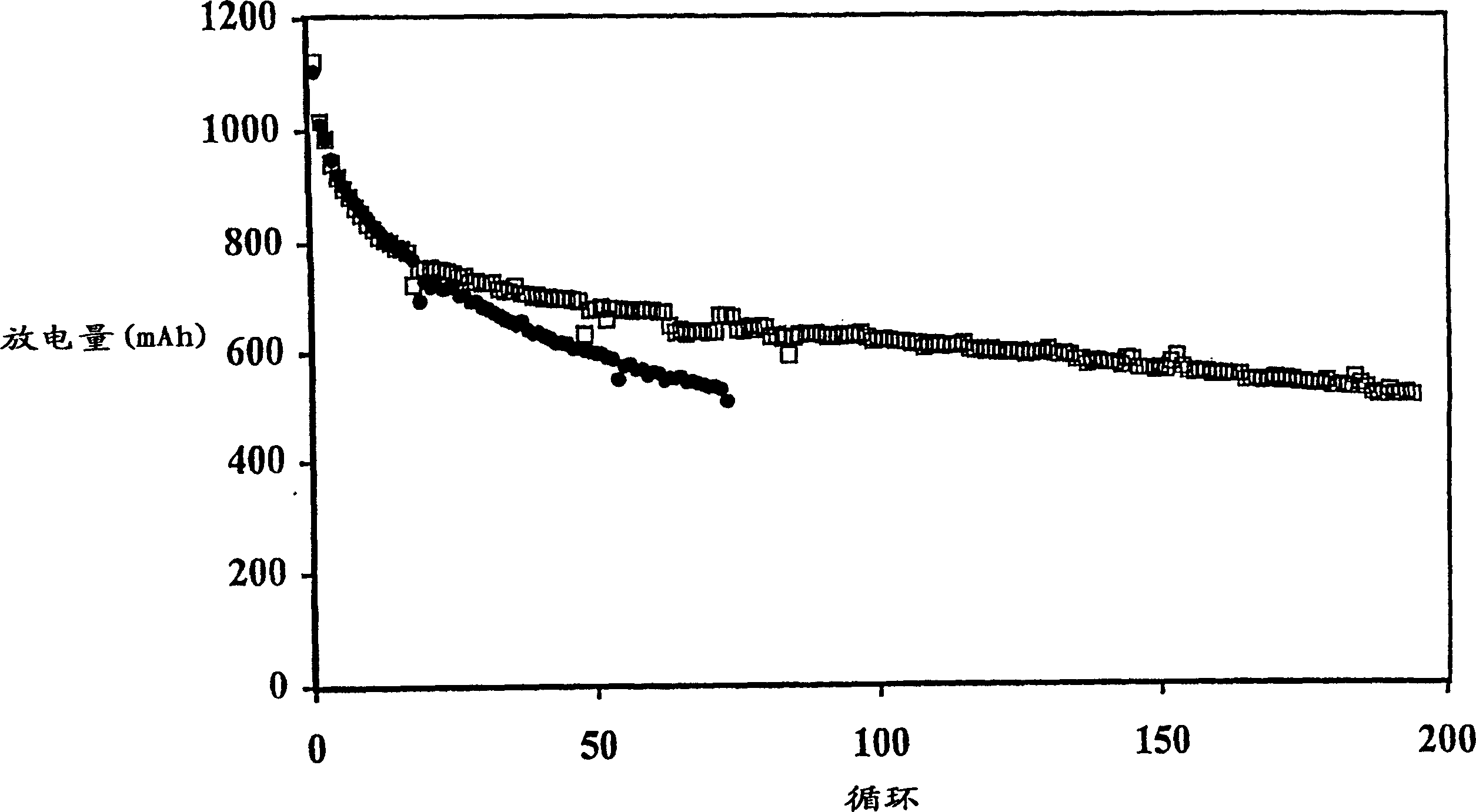

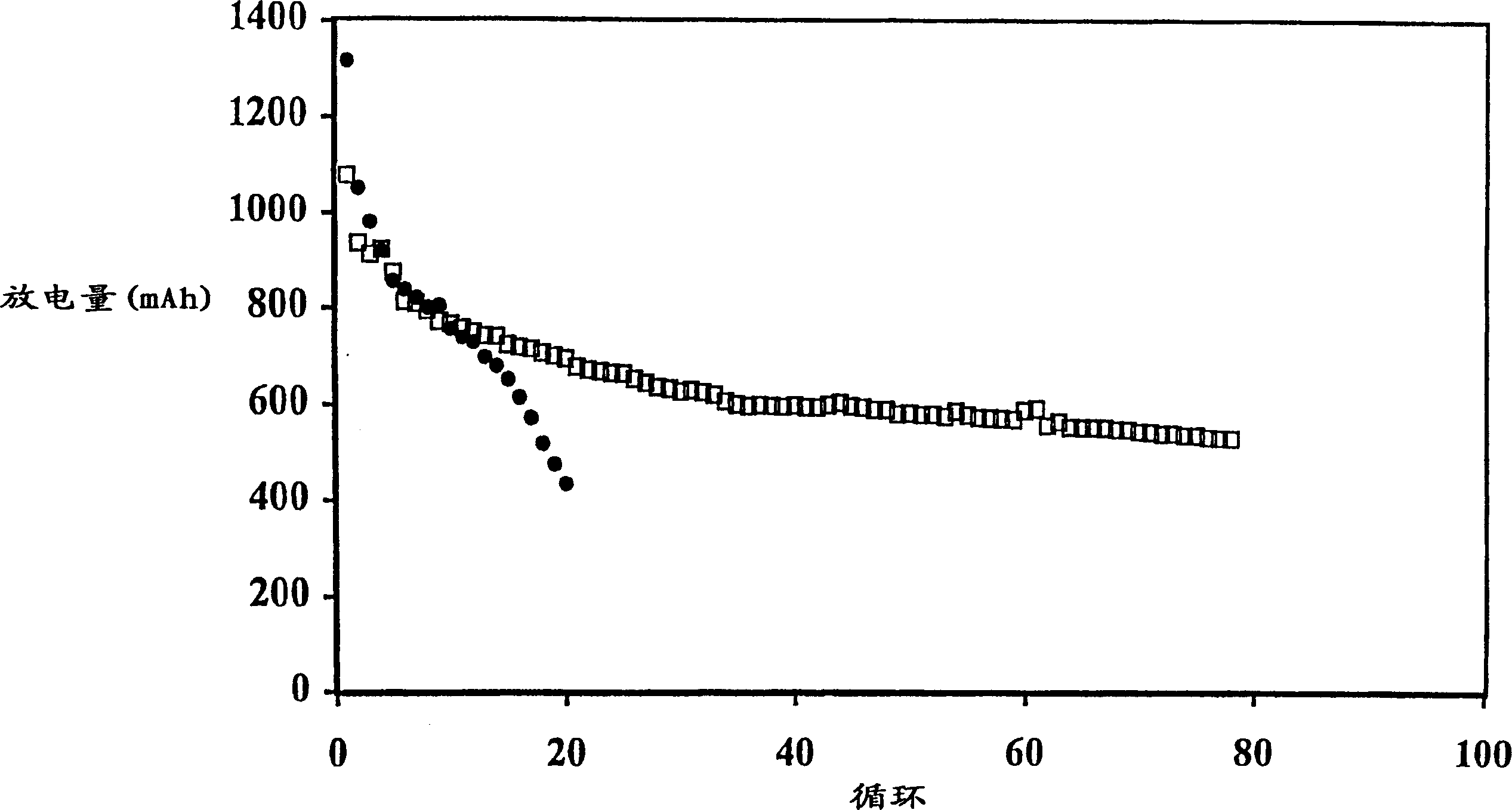

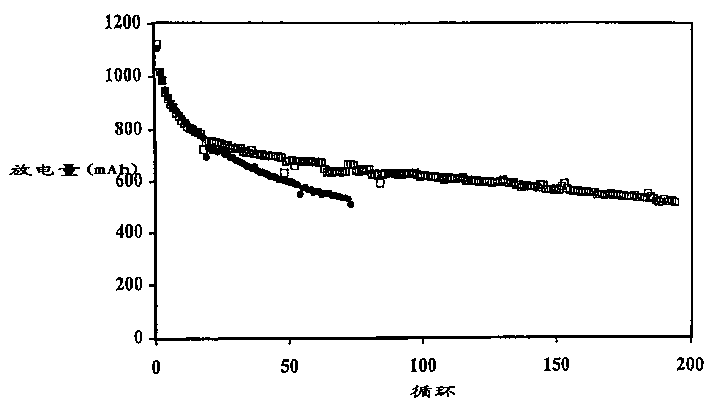

Methods of charging lithium-sulfur batteries

InactiveCN1435002AReduce bloatNon-aqueous electrolyte accumulatorsCell electrodesCharge currentLithium–sulfur battery

A method of increasing the cycle life of a discharged lithium electrochemical cell comprising (i) an anode comprising lithium; (ii) a cathode comprising an electrochemically active sulfur-containing species; (iii) an anode disposed between the anode and the cathode between liquid electrolytes; wherein said method comprises the steps of: (a) at less than 0.2mA / cm 2 Charge the battery to a battery voltage of 2.1-2.3V at an initial low charge current density; and (b) subsequently charge the battery at a rate higher than 0.2mA / cm 2 The high charge current density charges the battery to a battery voltage of at least 2.4V.

Owner:SION POWER CORP

Novel high-silicon aluminum alloy electronic packaging material and preparation method thereof

InactiveCN102978485AImprove thermal stabilityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesIngotElectronic packaging

A novel high-silicon aluminum alloy electronic packaging material and a preparation method thereof. The alloy of the present invention consists of the following ingredients, in percentage by mass: 12-40% of Si, 0.3-0.6% of Fe, 0.3-0.45% of Mn, 0.3 to 0.5% of Mg, and the balance being industrial pure aluminum. Spray deposition is used to prepare ingots; and then a plurality times of small deformation thermal densification are carried out for the ingots after annealing for elimination of thermal stress, to prevent cracking of the alloy during processing, thereby enhancing the density of the material. The alloy of the present invention has the characteristics of high strength, low coefficient of expansion, high thermal conductivity and good air tightness.

Owner:CHANGSHA HUAXI METAL MATERIAL

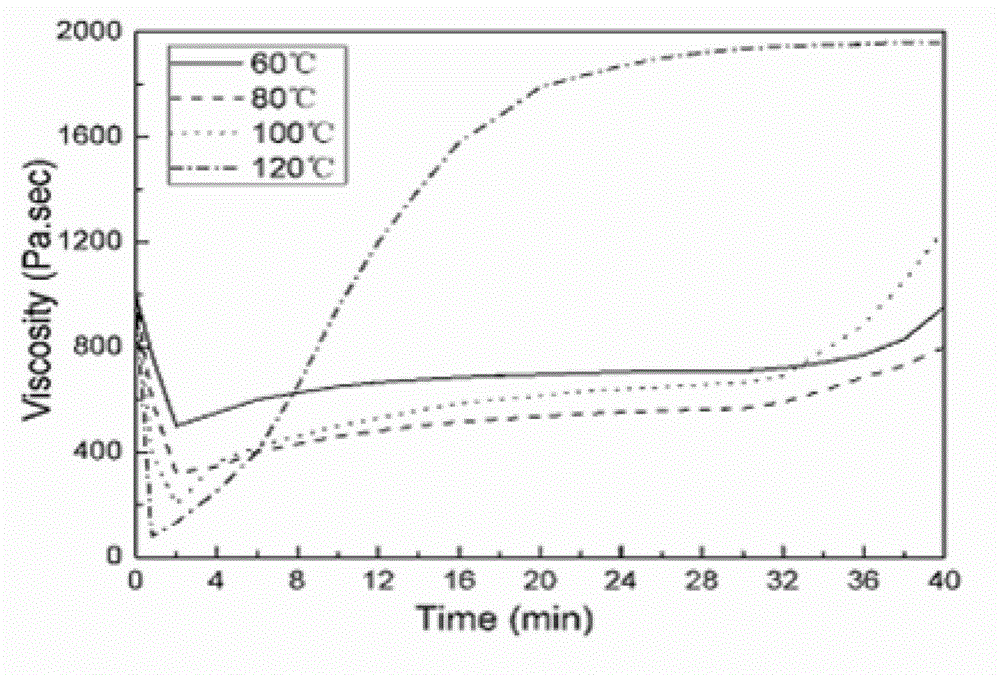

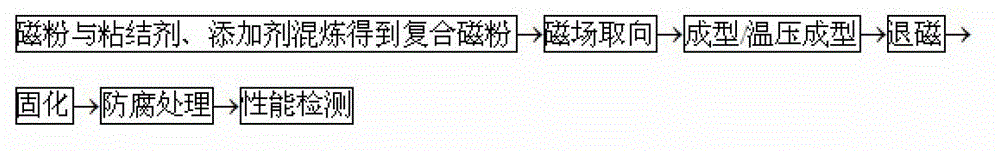

Method for preparing anisotropic bonded magnet by adopting pressure-keeping curing process

InactiveCN102982961AReduce bloatHigh densityPermanent magnetsInorganic material magnetismMagnetic powderHot isostatic pressing

The invention relates to a method for preparing an anisotropic bonded magnet by adopting a pressure-keeping curing process. The method uniformly mixes anisotropic magnetic powder, epoxy resin or other thermosetting adhesive, coupling agent, lubricating agent and the like, so that compound magnetic powder is produced, and orienting compression, compression molding and pressure curing are then carried out. In pressure curing, certain pressure stress is kept as the rough is heated to be cured. Pressure curing can adopts two methods: one method is in-situ pressure-prekeeping curing in a mould, i.e., after compression molding and demagnetization, demoulding is not carried out before pressure is kept until the cross-linking curing of the adhesive takes place to a certain degree (the viscosity of the epoxy resin is greater than 18000Pa multiplied by s); in the other method, after compression molding, demoulding is directly carried out, and pressure stress is then applied in the process of curing, for example, the hot isostatic pressing method or the like is adopted to cure the rough under pressure. The adoption of the pressure curing technique can effectively enhance the magnetic property of the bonded magnet.

Owner:UNIV OF SCI & TECH BEIJING

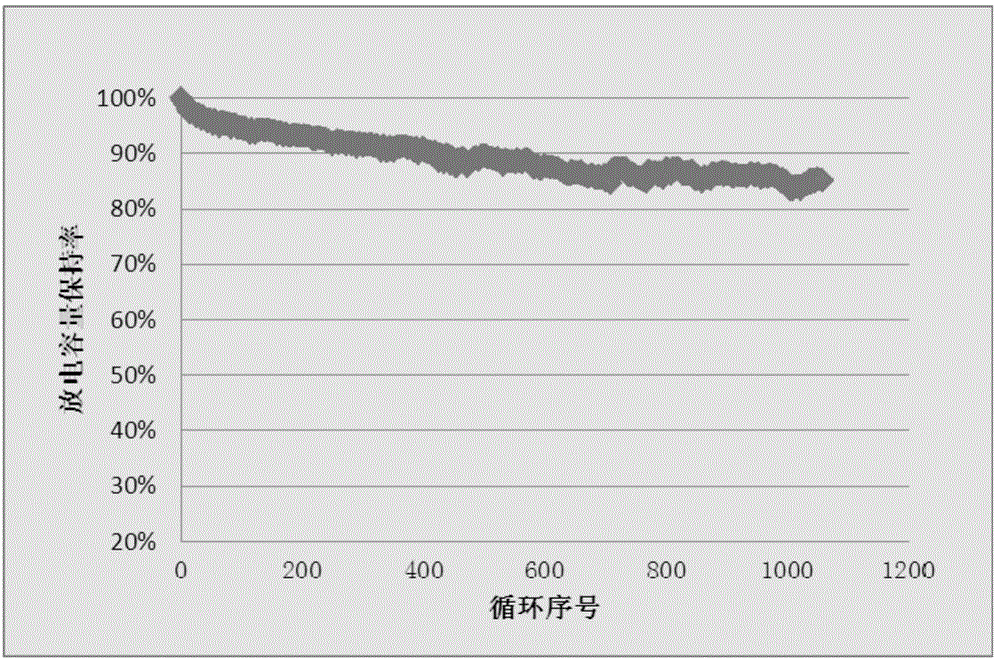

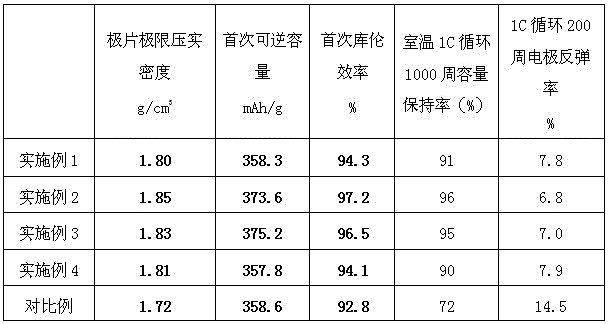

Artificial graphite composite negative electrode material for lithium-ion battery and preparation method of artificial graphite composite negative electrode material

ActiveCN105938906AAvoid easy disassemblyImprove bindingCell electrodesSecondary cellsIon beamLithium-ion battery

The invention provides an artificial graphite composite negative electrode material for a lithium-ion battery and a preparation method of the artificial graphite composite negative electrode material. The material is a secondary particle complex of pure artificial graphite, and is prepared by the technologies of crushing, grading, spheroidizing, ion beam bombardment, mixing, high-temperature compounding, grading, graphitizing, screening, demagnetizing and the like, and the needle coke is taken as a raw material and the asphalt is taken as a binder. The compaction density of the composite negative electrode material prepared by the method can reach 1.80g / cc; the reversible capacity is higher than 355mAh / g; the first efficiency is about 94%; and the electrode expansion ratio after circulating 200 cycles is lower than 8%. The adopted technologies are traditional powder processing technologies or carbon technologies; and industrialization is easy to achieve.

Owner:HUNAN SHINZOOM TECH

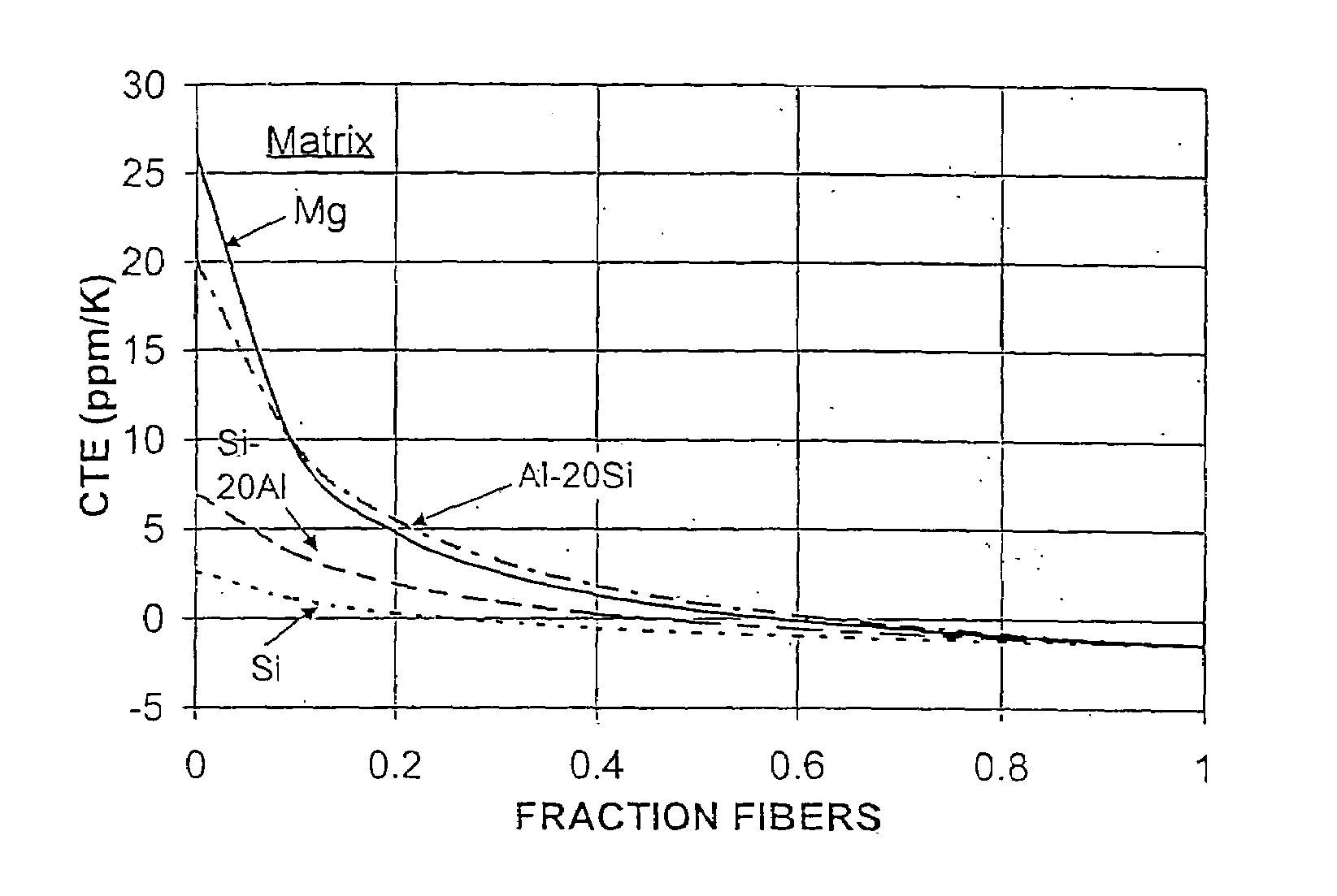

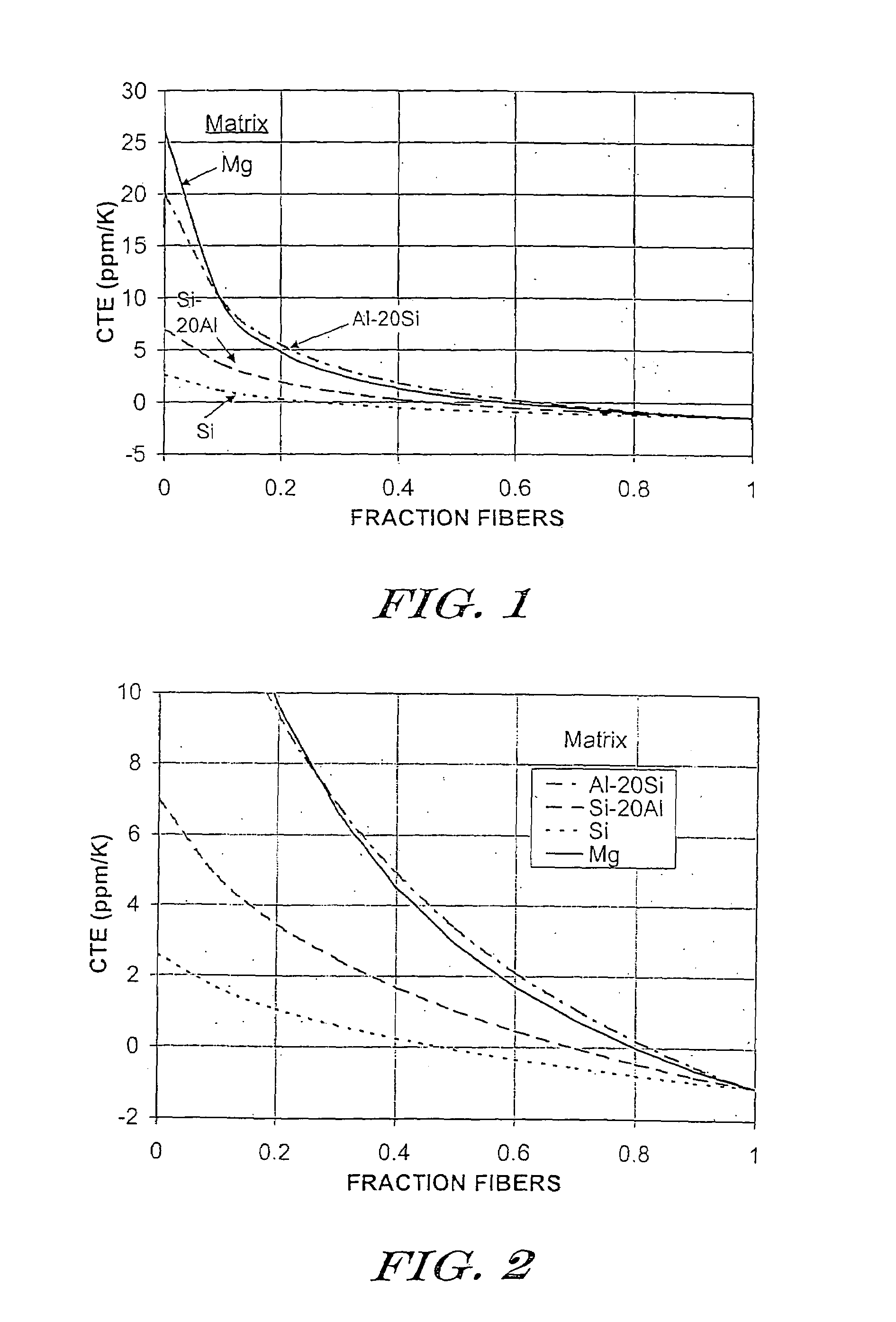

Low expansion metal-ceramic composite bodies, and methods for making same

InactiveUS7169465B1Reduce bloatMore impactMaterial nanotechnologyNatural cellulose pulp/paperFiberCeramic composite

A low CTE metal-ceramic composite material featuring carbon fibers reinforcing a matrix featuring silicon metal or silicon alloy. The fibers have a low coefficient of thermal expansion (CTE) in the axial direction, and preferably negative. The principles of making Si / SiC composites can be adapted to produce the instant Si matrix composites. The CTE of the composite body depends not only upon the relative CTE's of the fibers and matrix, and their relative amounts (e.g., loadings), but also upon the relative elastic moduli of the fibers and matrix. Thus, Si / SiC matrices produced by a reaction-bonding process inherently possess low CTE, but the instant inventors prefer to make such composites having relatively large fractions of unreacted silicon, thereby driving composite CTE lower still. Here, the carbon fibers are protected from reaction with the silicon infiltrant with one or more materials disposed between the fibers and the infiltrant. Providing at least a degree of toughness or impact resistance can also be realized in these composites. Laminates produce Isotropic or quasi-isotropic properties in the composite body can be realized by, for example, providing the fibers in the form of cross-plied laminates featuring the fibers in parallel or woven arrays.

Owner:II VI DELAWARE INC

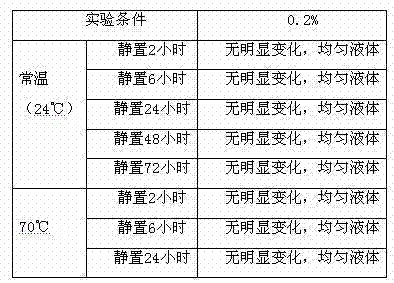

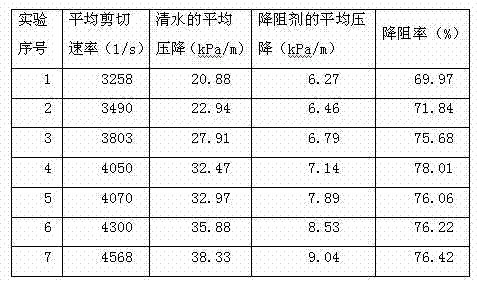

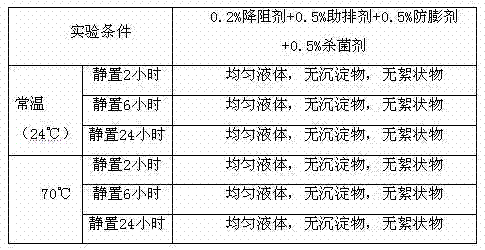

Resistance reducing agent for fracturing quick water of shale gas and preparation method thereof

ActiveCN103755868AHigh temperature resistantReduce frictionDrilling compositionEmulsion polymerizationOil phase

The invention relates to a resistance reducing agent for fracturing quick water of a shale gas and a preparation method thereof. The resistance reducing agent for fracturing quick water of the shale gas is formed by reverse emulsion polymerization by means of combination of a water phase and an oil phase, wherein the weight part ratios of monomers to water in the water phase are sequentially as follows: the ratio of acrylamide: 2-acrylamide-2-methyl propanesulfonic acid: water is (0.7-1.3):(0.7-1.5):1; the weight ratio of monomers to oil in the oil phase is sequentially as follows: the ratio of tween 80:OP-10: white oil is (0.1-0.35):(0.1-0.35):1; and the weight ratio of the water phase to the oil phase is 1:(0.35-0.85). The preparation method comprises the following steps: (1) selecting acrylamide and 2-acrylamide-2-methyl propanesulfonic acid, and dissolving acrylamide and 2-acrylamide-2-methyl propanesulfonic acid in proportion in deionized water to prepare the water phase; (2) selecting tween 80 and white oil and mixing the tween 80 and white oil in a certain proportion to form the oil phase; (3) proportioning the water phase and the oil phase in a certain proportion, and fully mixing to form a stable water-in-oil inverse emulsion base fluid; and (4) catalyzing and initiating by an initiator to synthesize the resistance reducing agent.

Owner:郑州三山石油技术有限公司

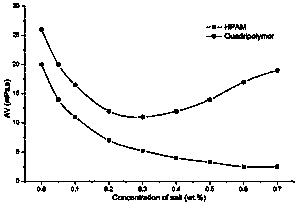

Polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and preparation method thereof

InactiveCN103525379ANew features of strong high temperature resistanceGood temperature and salt resistanceDrilling compositionPolymer scienceEmulsion polymerization

The invention discloses a polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and a preparation method thereof. According to the preparation method, in the presence of nano-silica, a polymer-base nanometer composite material with amphiphilic block hydrophobic associating polymer wrapping inorganic nano-silica is successfully synthesized by virtue of a micellar emulsion polymerization method and combines the rigidity and the heat stability of the inorganic nano-silica and the characteristics of the amphiphilic block hydrophobic associating polymer together, and the temperature resistance, the salt tolerance and the thickening property of the polymer are obviously improved by virtue of the polymer-base nanometer composite material on the basis of the existing good performances of the amphiphilic block hydrophobic associating polymer. As a temperature-resistant, salt-tolerant and fluid loss reducing agent for a drilling fluid in the drilling engineering, the polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent has a remarkable fluid loss reducing effect under high temperature and high salinity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

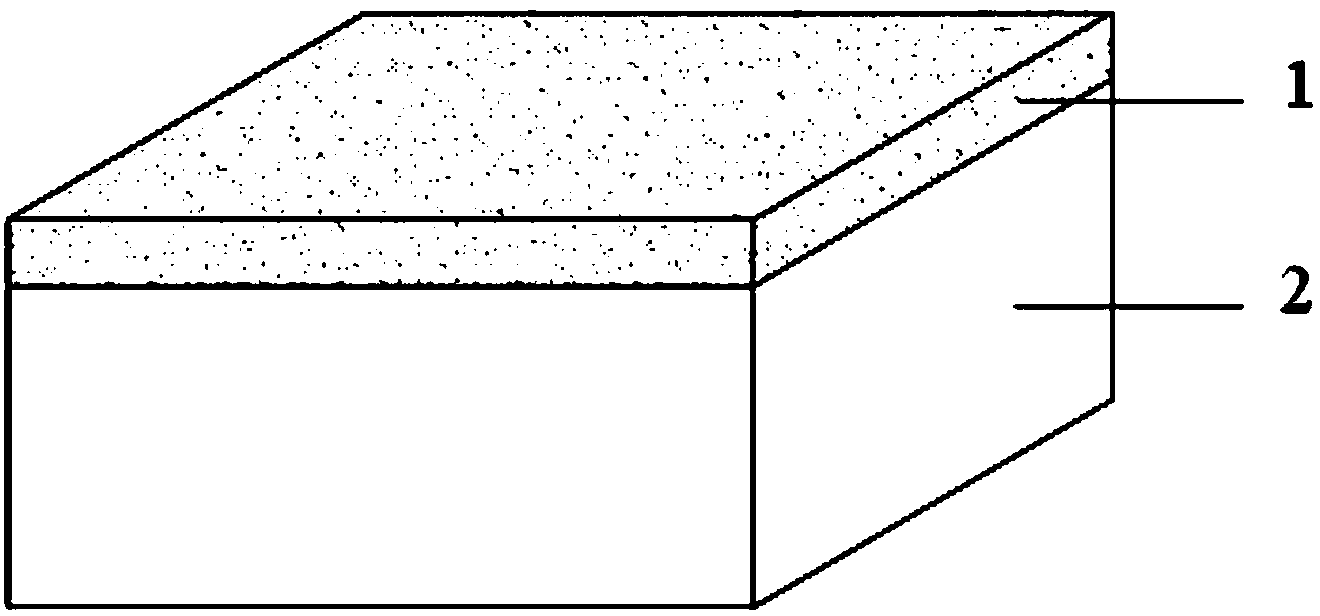

Aluminum silicon carbide composite material with laser welding layer and preparing method of aluminum silicon carbide composite material

ActiveCN103367270AImprove thermal conductivityReduce bloatSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationCarbide silicon

The invention discloses an aluminum silicon carbide composite material with a laser welding layer and a preparing method of the aluminum silicon carbide composite material. The composite material is composed of the laser welding layer and an aluminum silicon carbide layer, the laser welding layer is composed of pure aluminum or aluminum alloy comprising silicon and aluminum, the volume fraction of the silicon in the aluminum alloy is a, the volume fraction of the aluminum in the aluminum alloy is b, the a is greater than 0 and less than or equal to 30%, and the b is greater than or equal to 30% and less than 100%. The aluminum silicon carbide layer is composed of silicon carbide and pure aluminum or aluminum alloy, and the volume fraction of the silicon carbide ranges from 30% to 70%. The preparing method comprises the steps that silicon carbide pelleting powder is prepared firstly, then silicon carbide preformed parts are prepared, and the aluminum silicon carbide composite material with the laser welding layer is prepared in the vacuum pressure impregnation method finally. The aluminum silicon carbide composite material is good in weldability and gas tightness, high in heat conductivity, low in coefficient of thermal expansion, simple in preparing method, efficient and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

Natural graphite-based modified composite material and preparation method thereof, and lithium ion battery comprising modified composite material

InactiveCN108063229ASolve the problem of high expansion rateRealize simultaneous modification and integrationGraphiteNegative electrodesCarbonizationLithium-ion battery

The invention provides a natural graphite-based modified composite material and a preparation method thereof, and a lithium ion battery comprising the modified composite material. The natural graphite-based modified composite material comprises natural graphite and non-graphitized carbon which coats the inner surface and the outer surface of the natural graphite. The preparation method comprises the following steps of 1) performing isotropy treatment on the spherical natural graphite; 2) performing particle size control and shaping treatment; 3) performing synchronous modification on the innersurface and the outer surface of the material obtained in the step 2); and 4) performing carbonization treatment to obtain the natural graphite-based modified composite material. By virtue of the natural graphite-based modified composite material, synchronous modification on the defect sites of the inner and outer surfaces can be realized, so that cycle stability of natural graphite is greatly improved and expansion of a natural graphite electrode is lowered; and the natural graphite-based modified composite material has wide application prospect in the lithium ion battery used for a mobile phone, a digital camera and other mobile electronic equipment.

Owner:BTR NEW MATERIAL GRP CO LTD

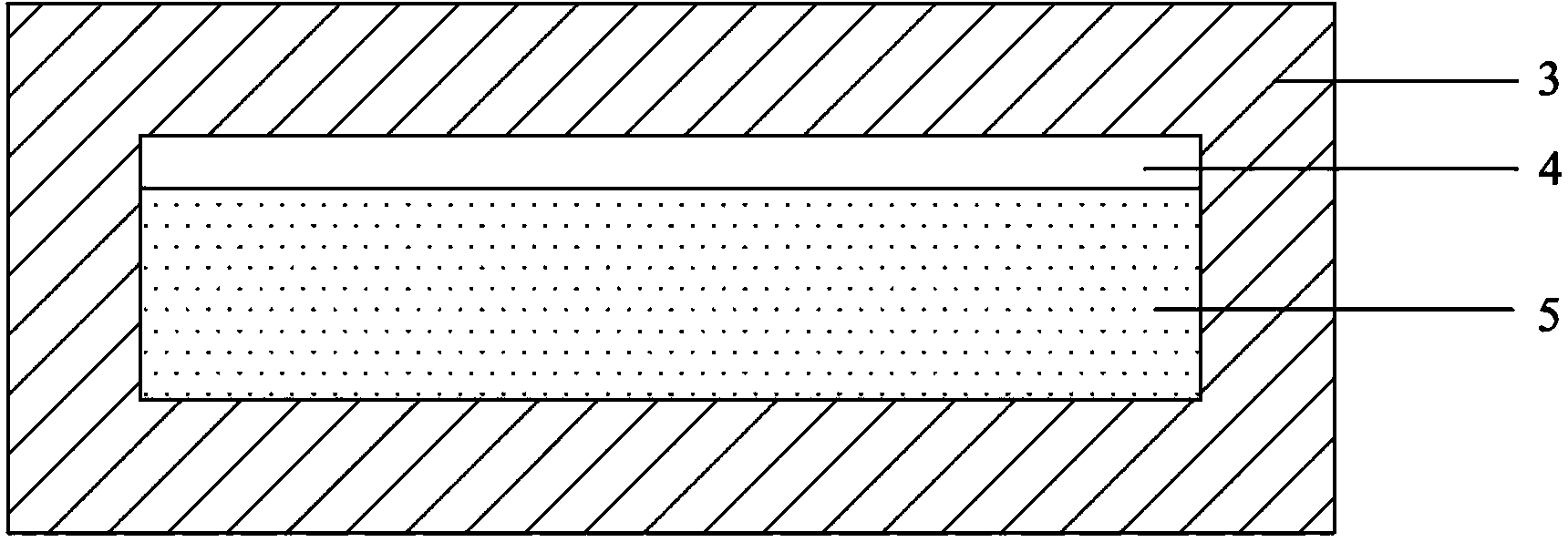

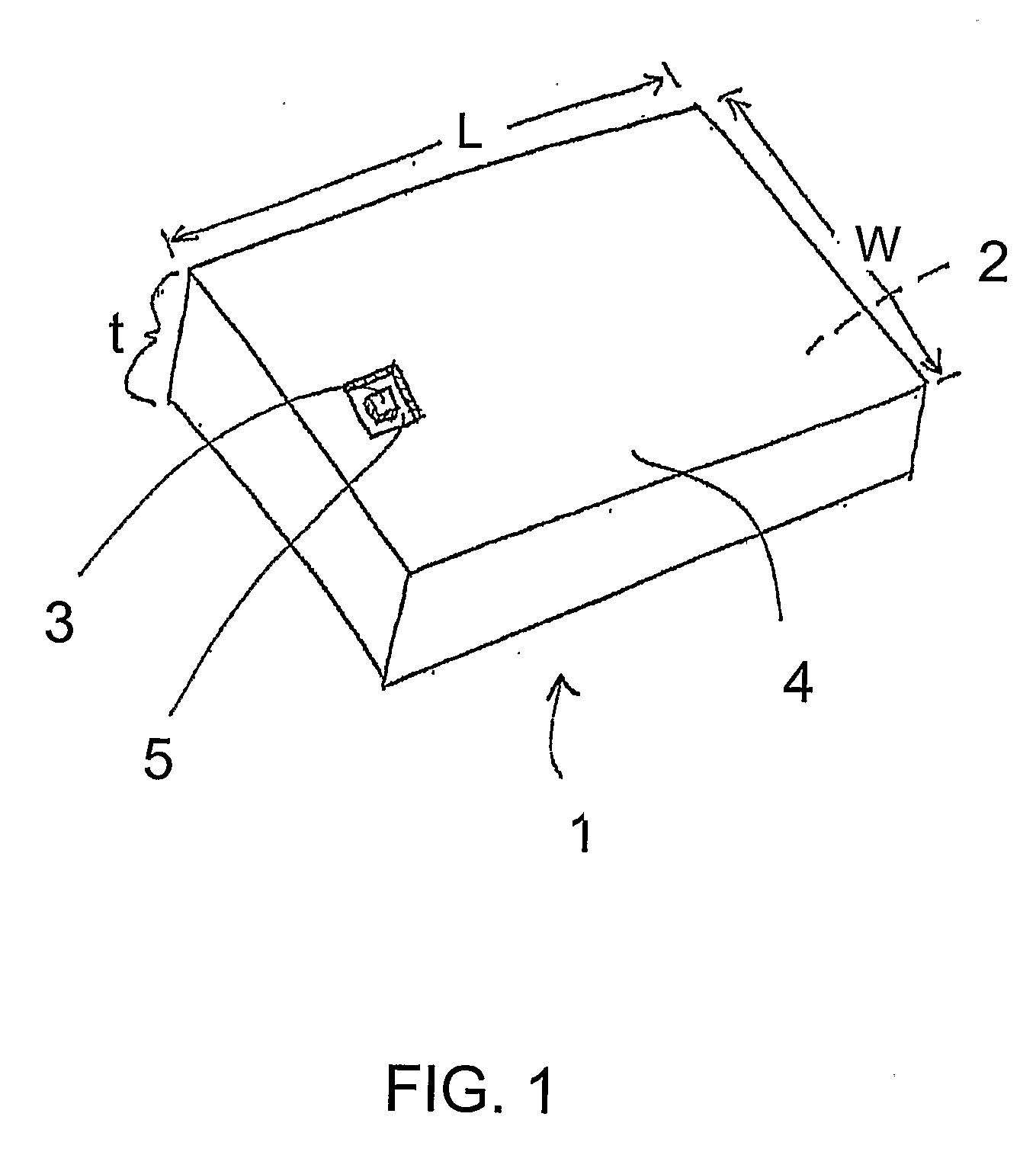

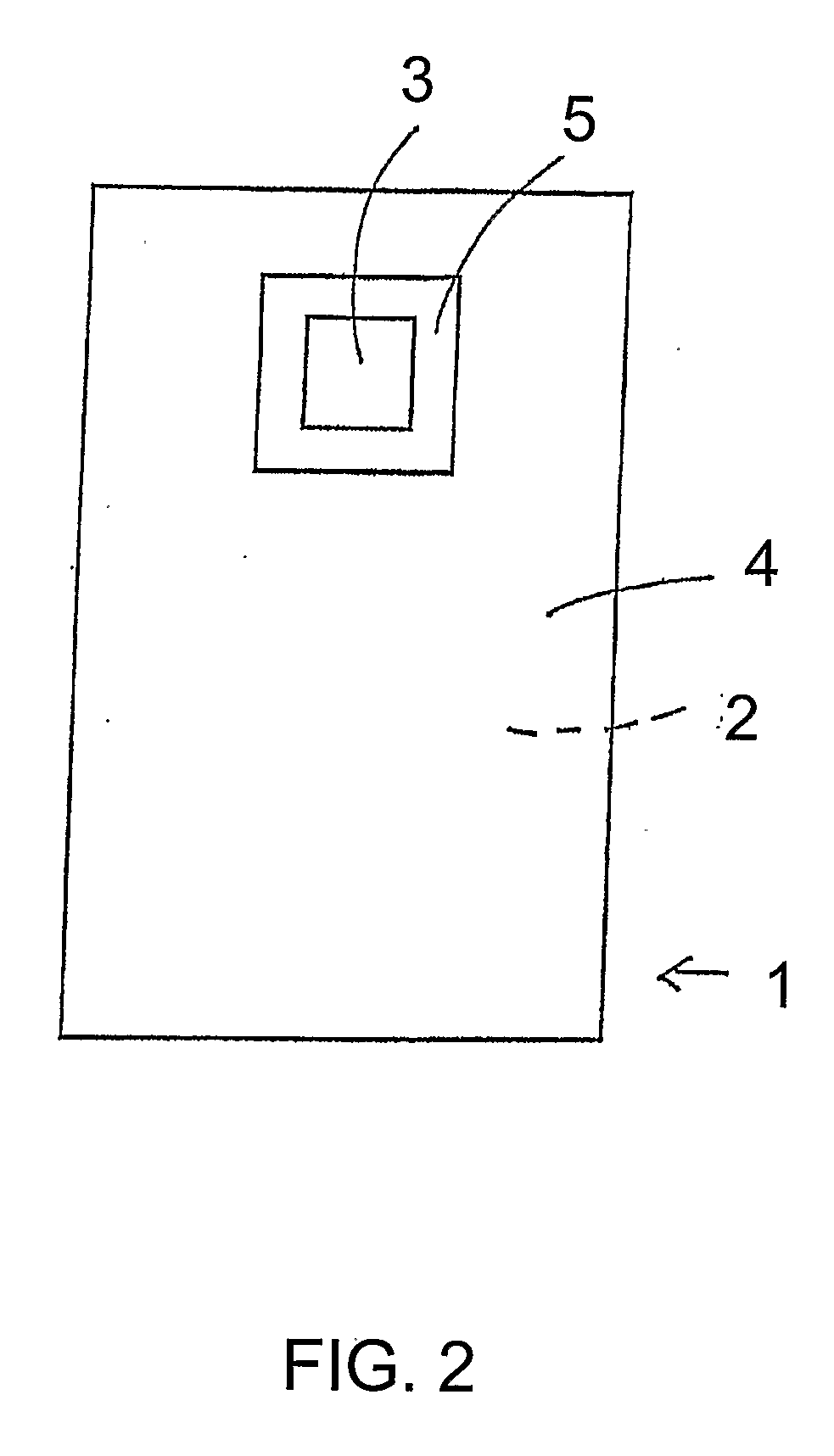

Discrete Voltage Tunable Resonator Made of Dielectric Material

ActiveUS20080211601A1Simple structureInexpensive to mass produceImpedence networksResonatorsDielectricCoupling

A voltage tunable resonator is provided, including a dielectric base made of a dielectric material having at least one of a voltage dependent dielectric constant and piezoelectric characteristics. A metal contact having a predetermined area is provided on an outer surface of the dielectric base at a predetermined location to provide a predetermined loaded Q for the resonator, and a metal ground coating is provided on the remaining exposed surfaces of the dielectric base, and an isolation region having a sufficient area to prevent significant coupling between the metal contact and the metal ground coating. A control voltage applied between the metal contact and the metal ground coating provides at least one of (i) a variable electric field to control the dielectric constant and a resonant frequency of the resonator and (ii) a piezoelectric response causing a dimensional change in the resonator to control the resonant frequency of the resonator.

Owner:DELAWARE CAPITAL FORMATION

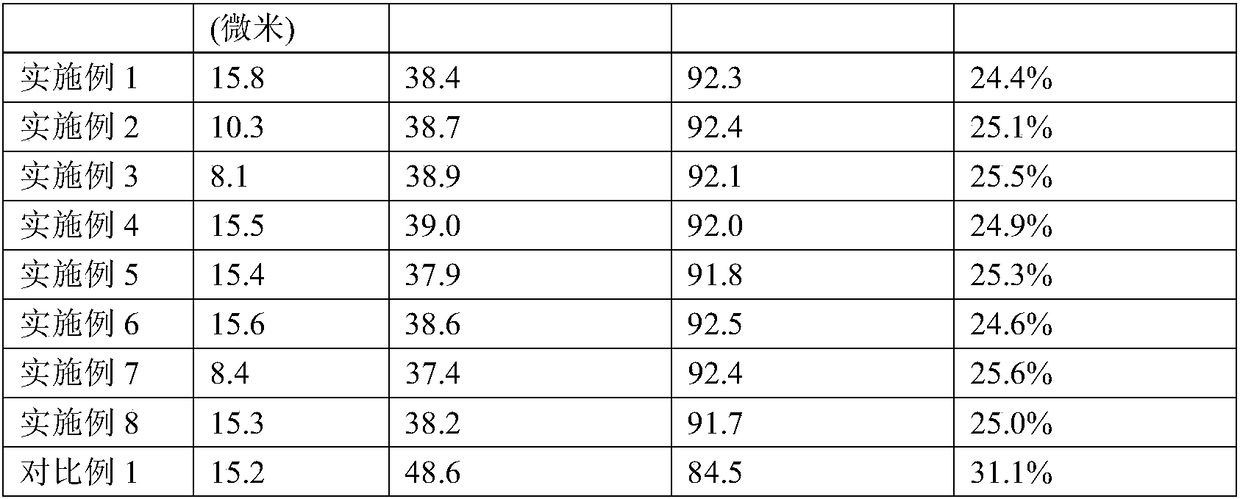

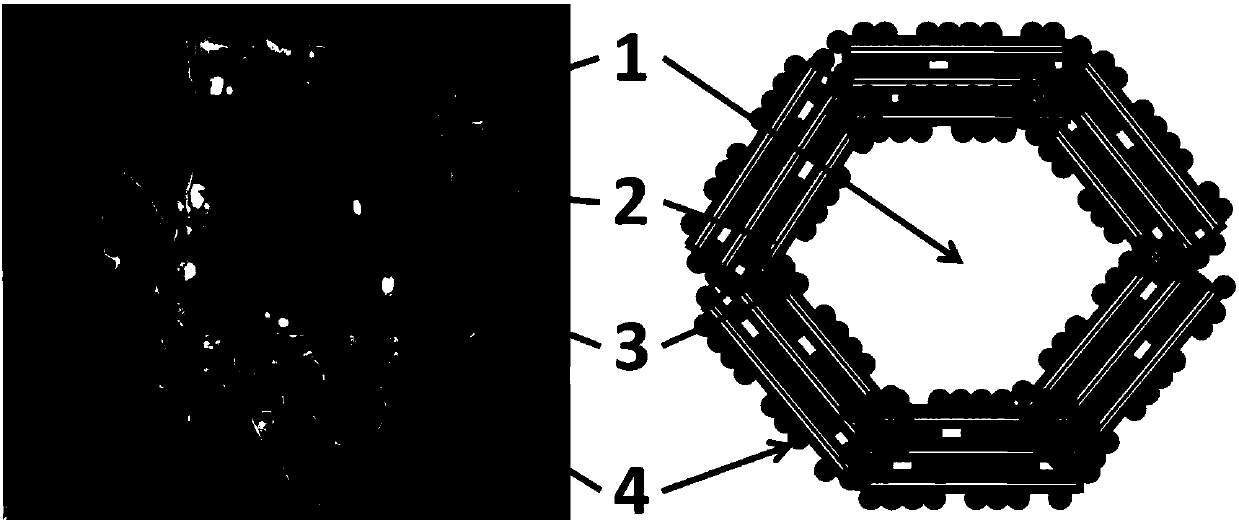

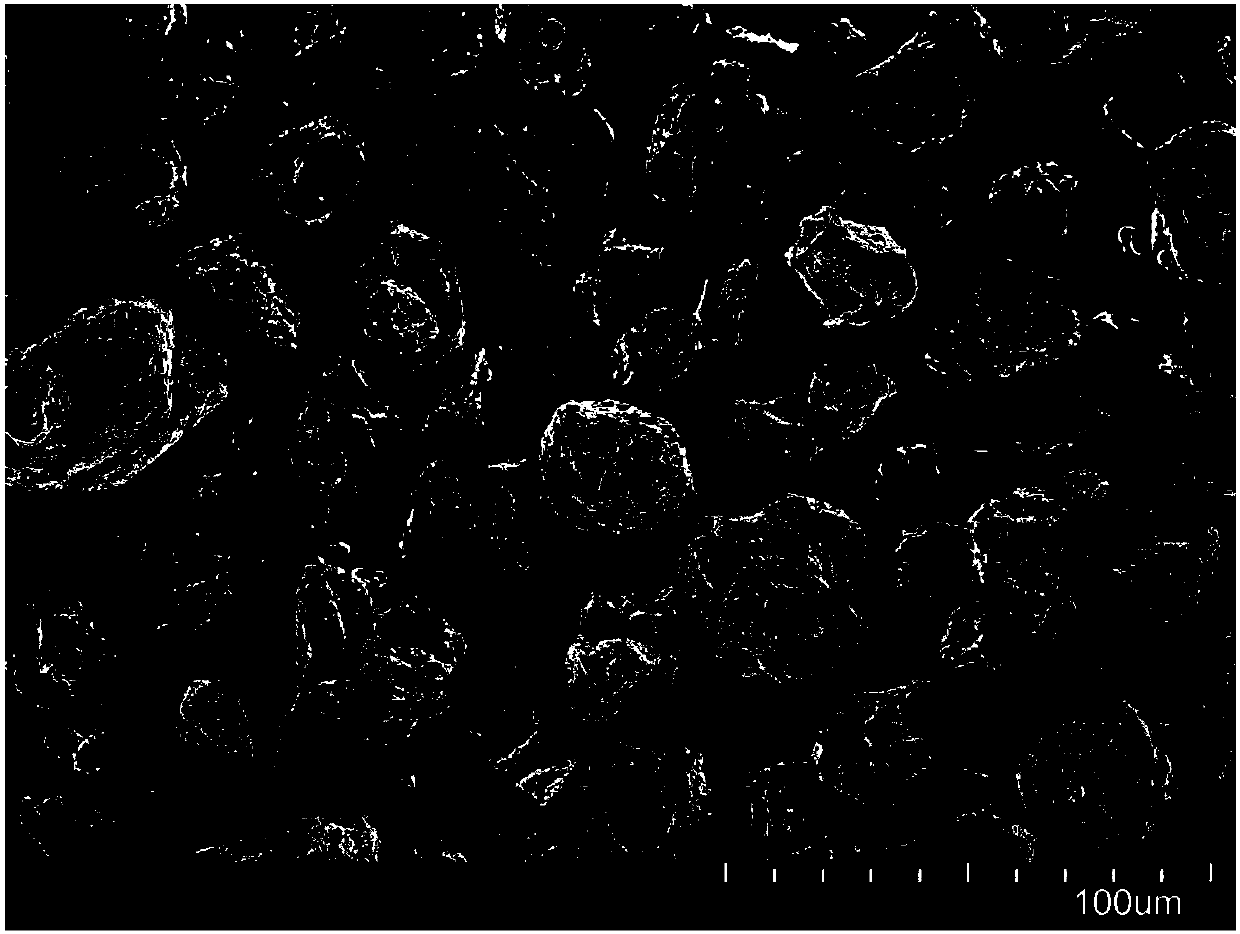

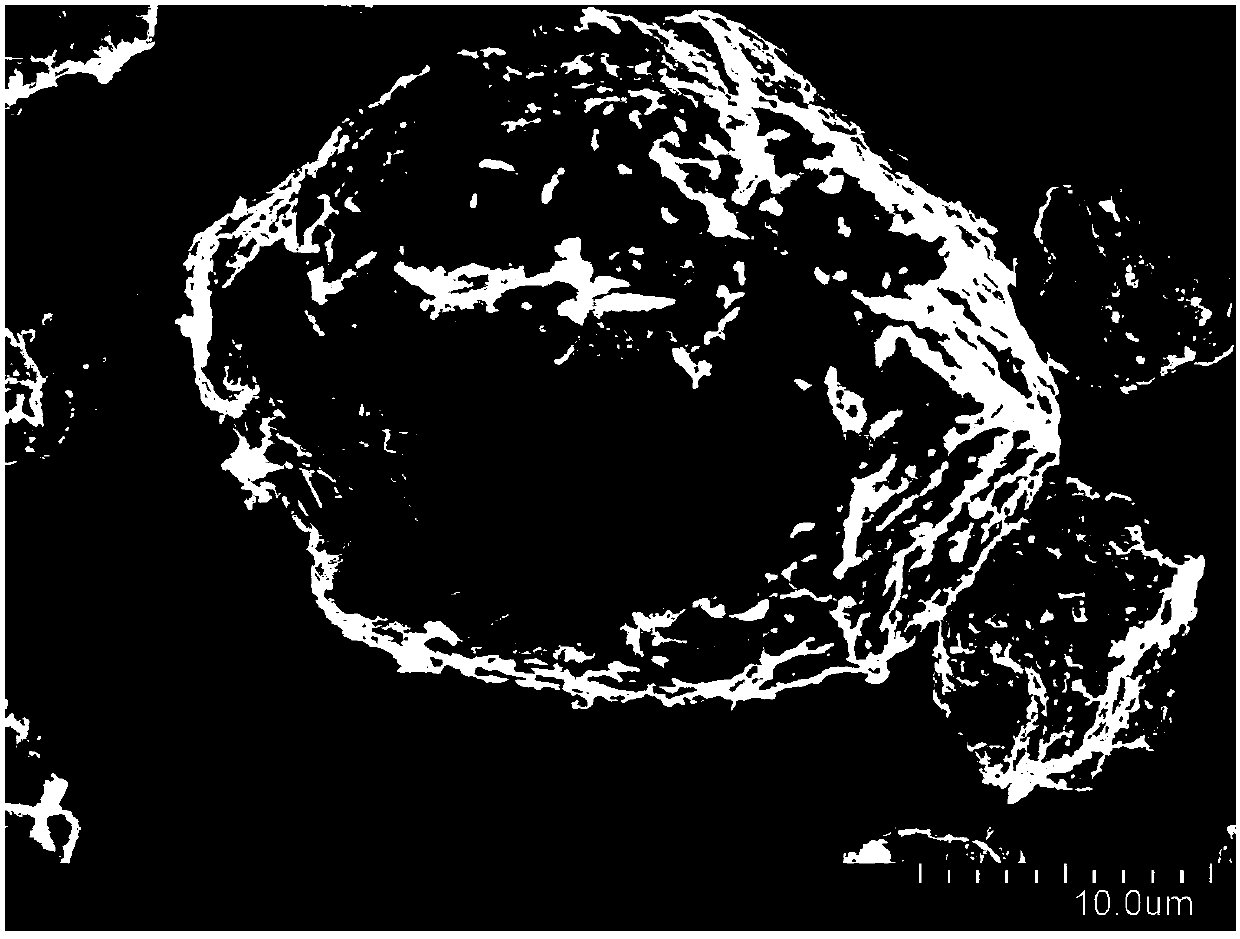

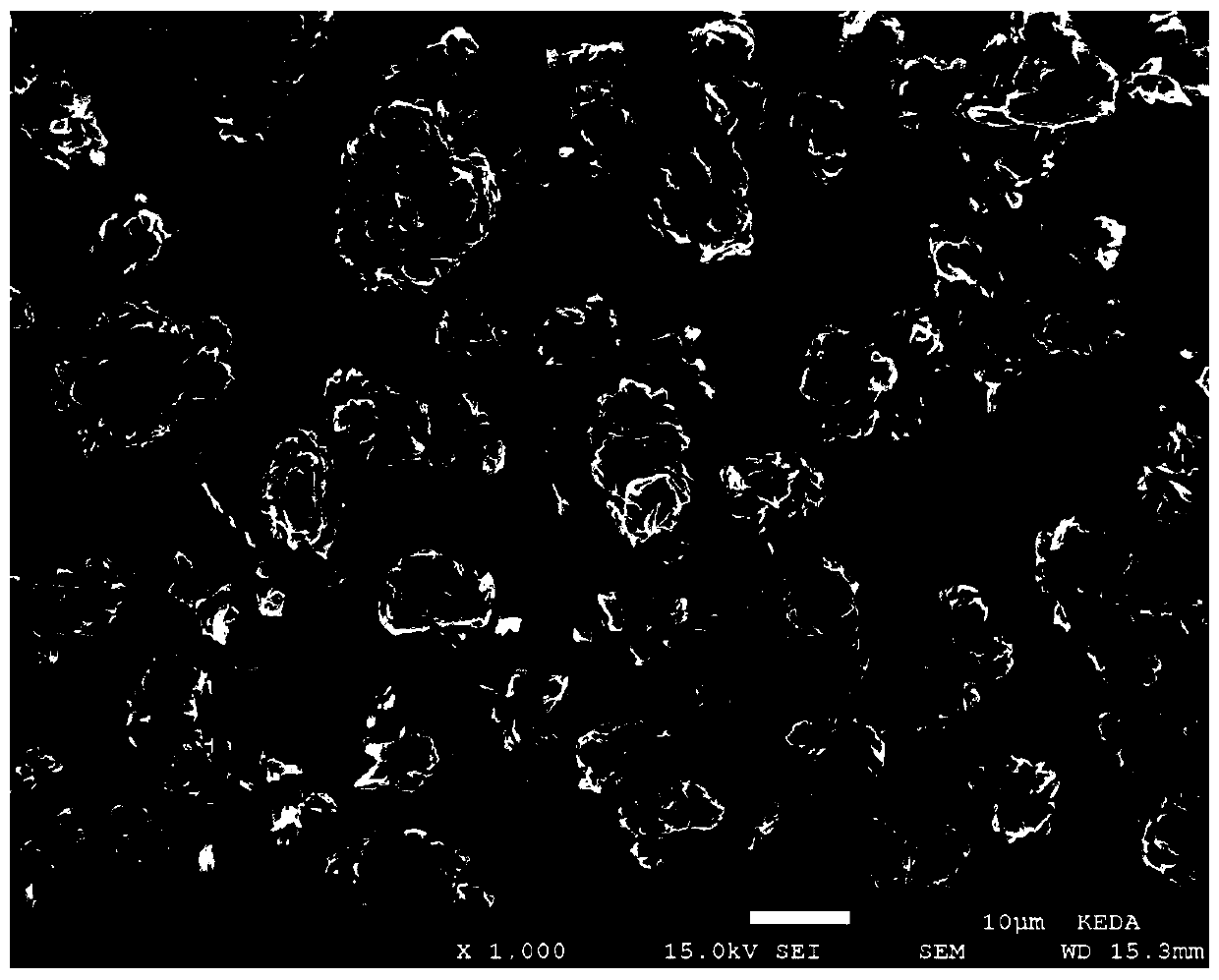

Hollow silicon-carbon composite material for lithium-ion batteries, and preparation method thereof

InactiveCN107799728AIncrease capacityImprove Coulombic efficiencyNegative electrodesSecondary cellsCarbon compositesElectrochemistry

The invention relates to a hollow silicon-carbon composite material and a preparation method thereof. According to the hollow silicon-carbon composite material, the silicon-carbon composite material is spherical or ellipsoid secondary particles; the secondary particles have hollow structures, the shell is formed by compounding graphite sheets, a silicon material and amorphous carbon, the silicon material is uniformly adhered on the surface of the graphite sheet and between the graphite sheets, and the surfaces of all the graphite sheets and the silicon material are covered with an amorphous carbon protection layer; and the graphite sheets for forming the secondary particles are randomly oriented to each other. According to the present invention, the silicon-carbon composite material used as the lithium-ion battery negative electrode has electrochemical characteristics of high capacity, high Coulomb efficiency, low expansion and good cycle performance; the lithium-ion battery prepared from the silicon-carbon composite material has characteristics of high volume energy density, low expansion and good cycle performance; and the preparation process has advantages of simpleness, wide raw material source and low cost, and can achieve the industrial application of the silicon-carbon composite material in the lithium battery field.

Owner:BERZELIUS (NANJING) CO LTD

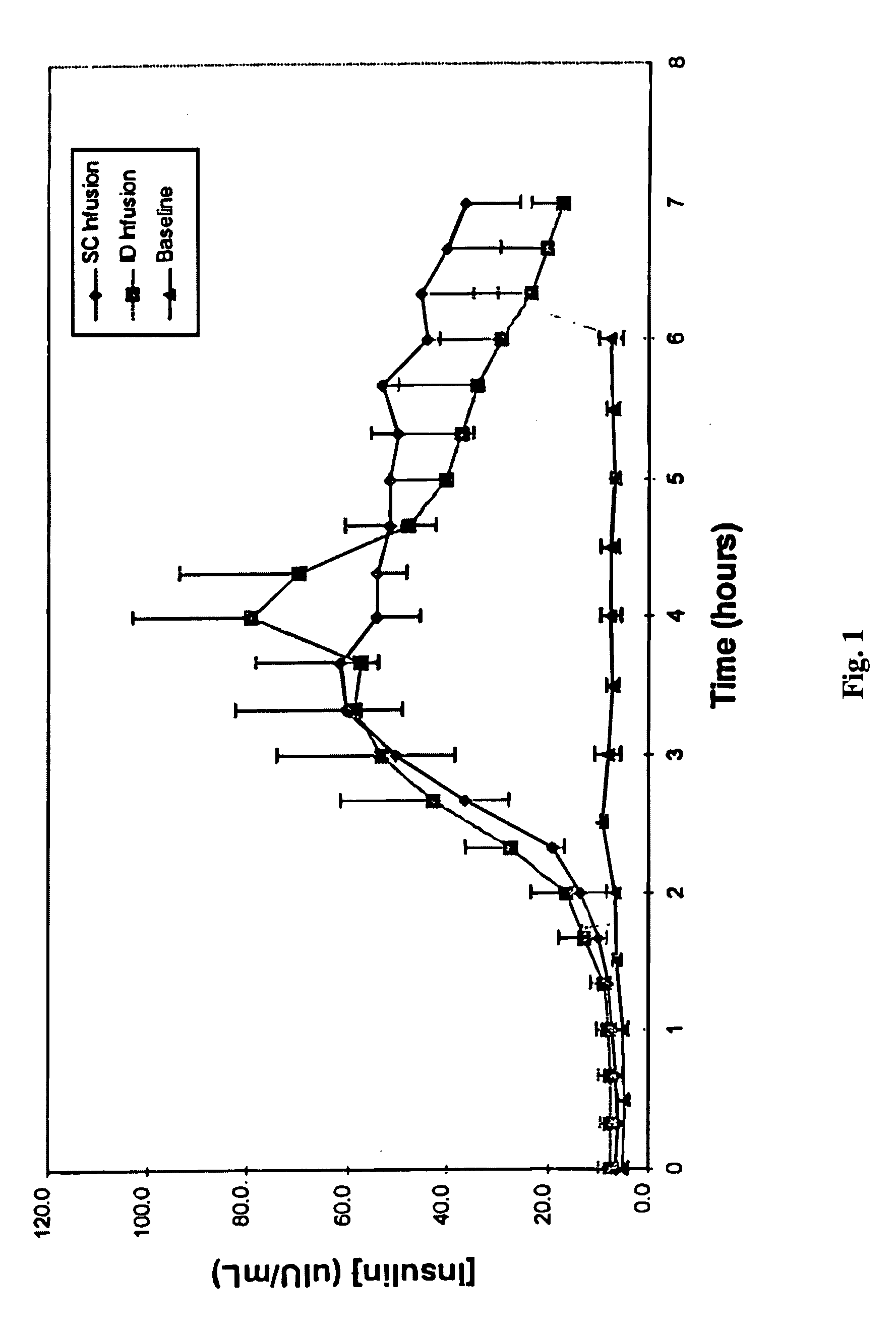

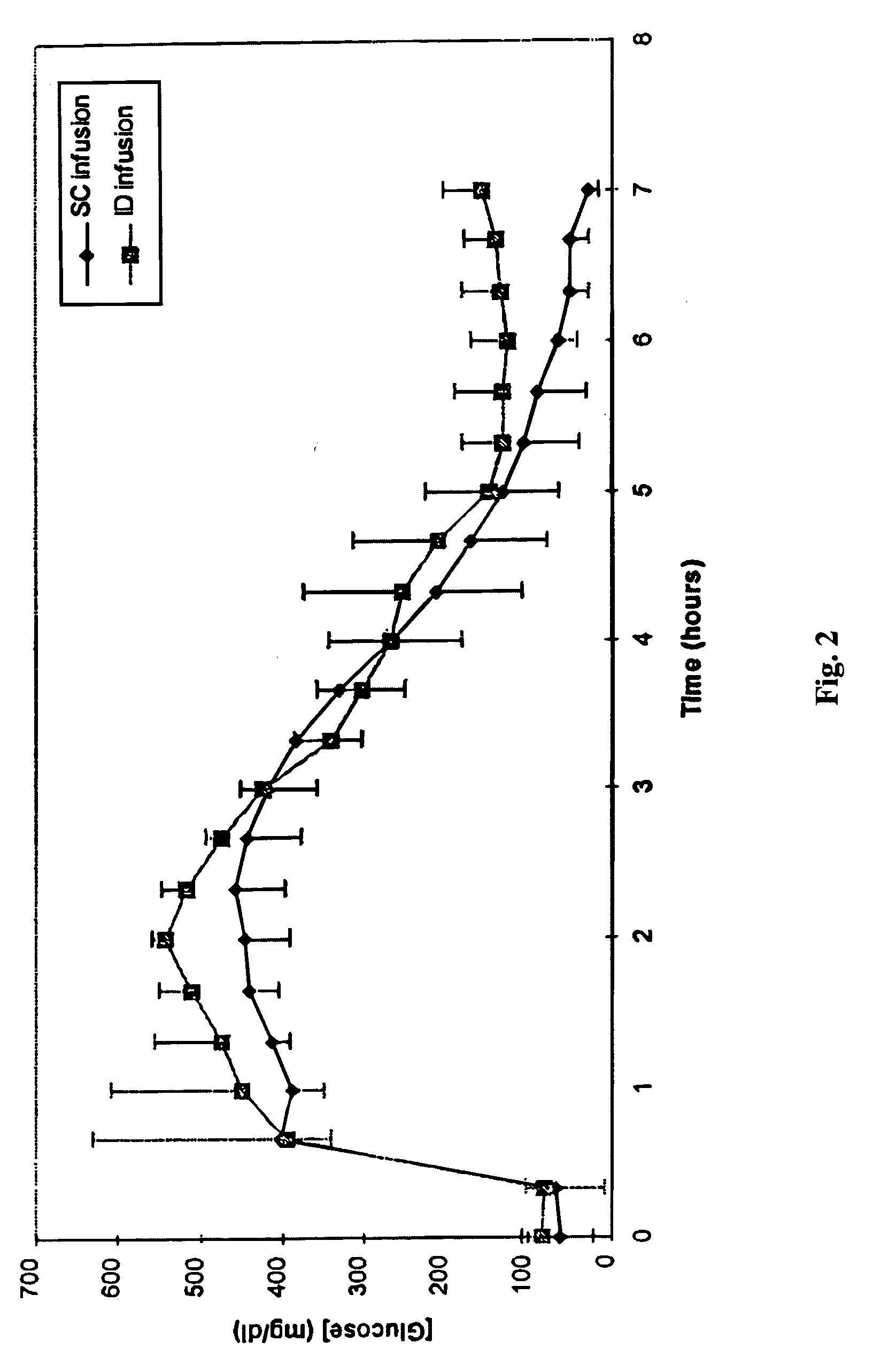

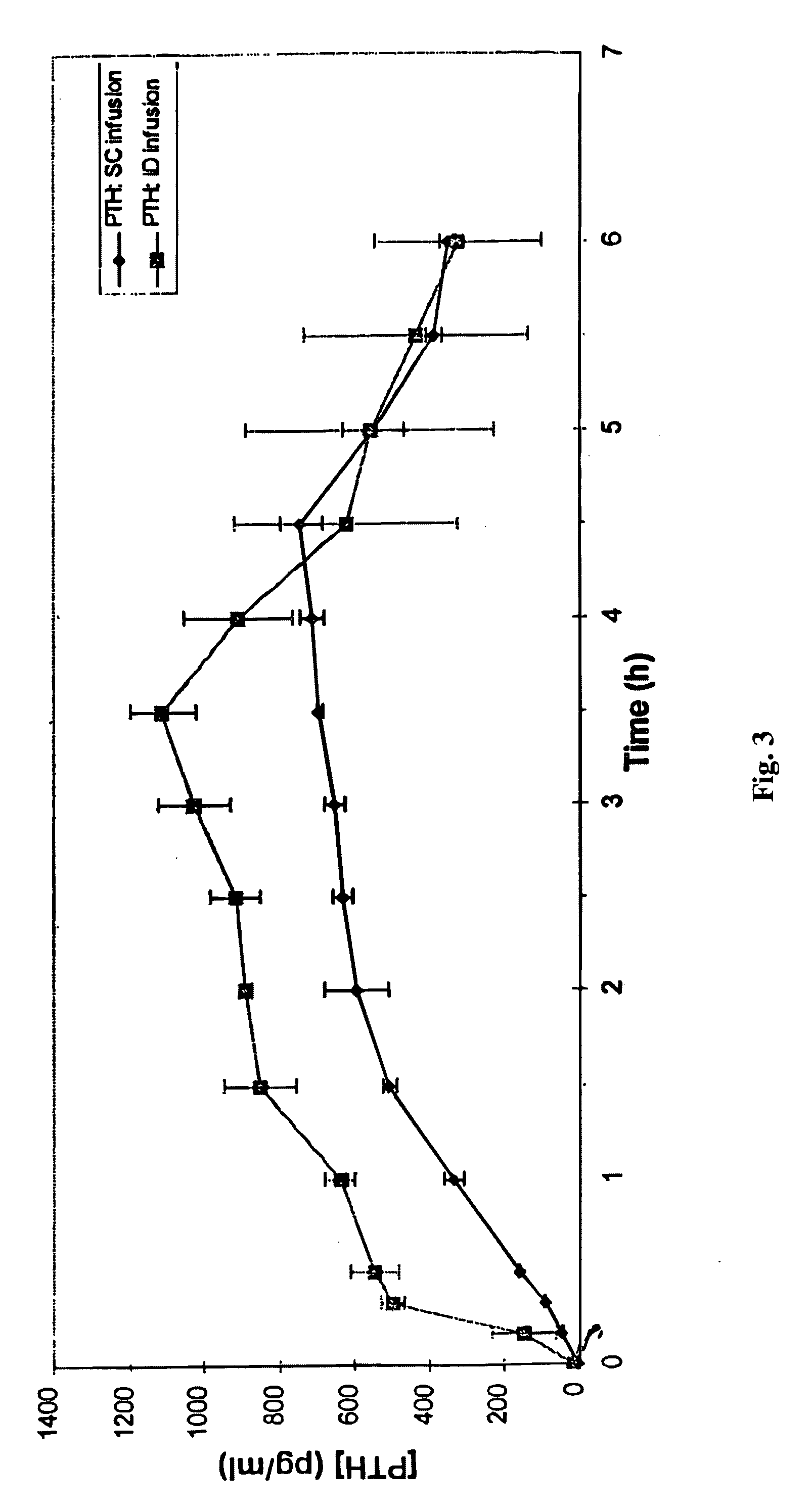

Intradermal delivery of substances

InactiveUS20050096632A1Improve clinical utilityMinimizes effusionJet injection syringesPeptide/protein ingredientsHormones regulationHormone drug

The present invention provides improved methods for ID delivery of drugs and other substances to humans or animals. The methods employ small gauge needles, especially microneedles, placed in the intradermal space to deliver the substance to the intradermal space as a bolus or by infusion. It has been discovered that the placement of the needle outlet within the skin and the exposed height of the needle outlet are critical for efficacious delivery of active substances via small gauge needles to prevent leakage of the substance out of the skin and to improve absorption within the intradermal space. The pharmacokinetics of hormone drugs delivered according to the methods of the invention have been found to be very similar to the pharmacokinetics of conventional SC delivery, indicating that ID administration according to the methods of the invention is likely to produce a similar clinical result (i.e., similar efficacy) with the advantage of reduction or elimination of pain for the patient. Delivery devices which place the needle outlet at an appropriate depth in the intradermal space and control the volume and rate of fluid delivery provide accurate delivery of the substance to the desired location without leakage.

Owner:PETTIS RONALD J +2

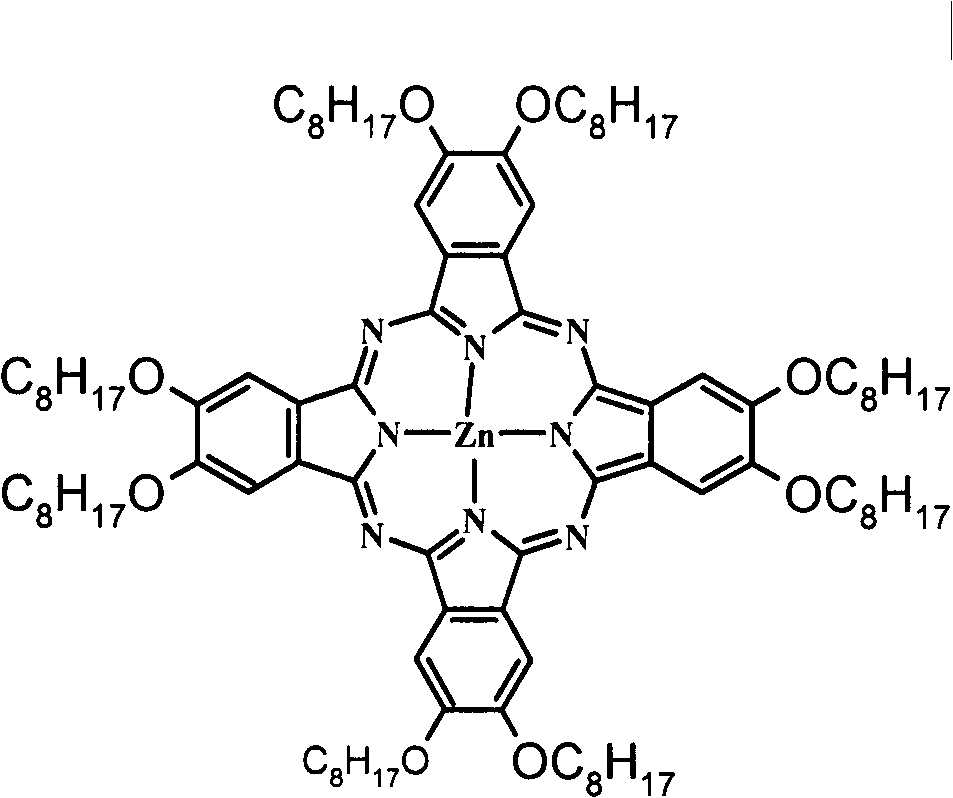

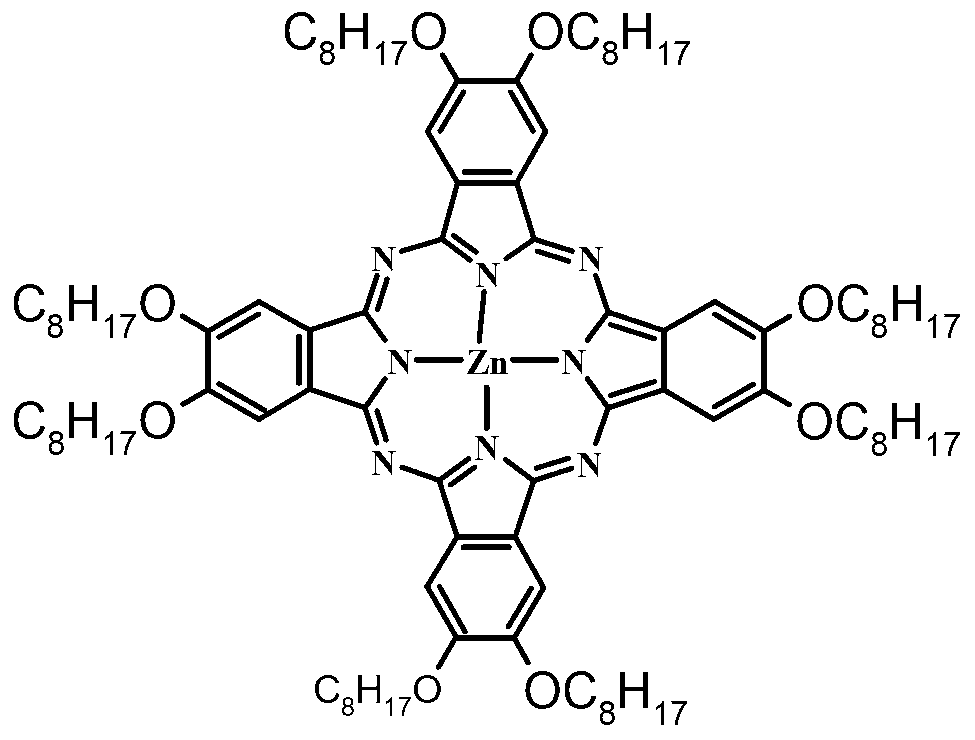

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841BReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

SiC/Cu composite materrial and preparation material

A SIC / Cu composite material is composed of SiC grains and Cu materials in which, SiC grains account for 50-75vol%, Cu material makes up of 25-50vol%. The invented preparation method includes: 1. filling, filling SiC grains into the cavity of a mold to be pressed into a frabricated block, 2. pre-heating: pre-heating the mold containing SiC grains to 900deg.C-1100deg.C and heating the Cu to be smelted 3. carting the melted Cu into the mold, 4. pressing and immersing: applying pressure by a press to immerse the Cu melt into the slots among SiC grains, 5. keeping pressure and cooling down 6. stripping and taking out the ingot.

Owner:HARBIN INST OF TECH

Insulating sealing element for head-of-wall joints

InactiveUS20150275506A1Sufficient fire resistanceImprove fire-resistanceEngine sealsWallsEngineeringMechanical engineering

Owner:HILTI AG

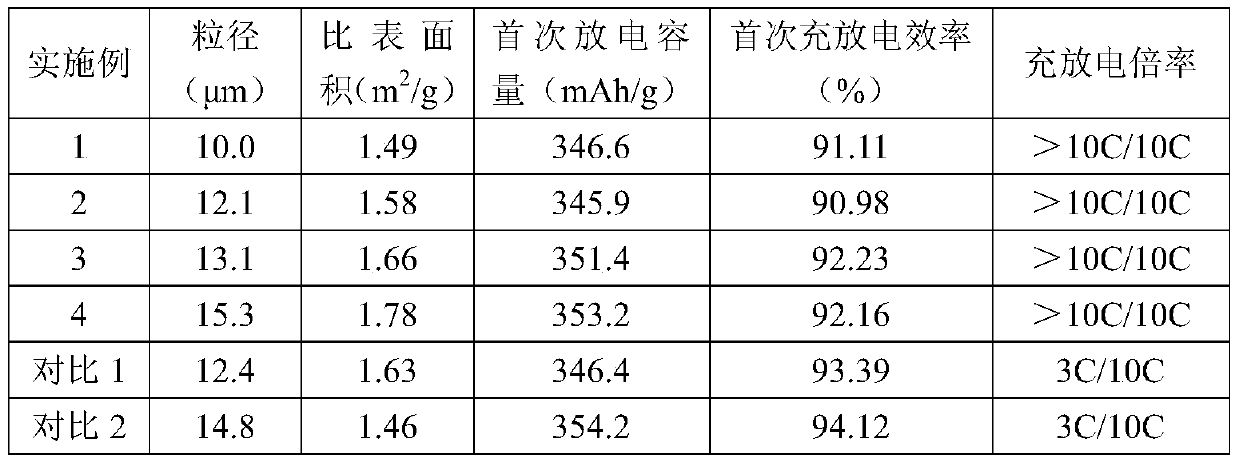

Method for preparing high-rate artificial graphite anode material

ActiveCN109830669AReduce processing costsReduce electrostatic attractionCell electrodesSecondary cells servicing/maintenanceHigh rateEconomic benefits

The invention belongs to the field of lithium ion batteries and relates to a method for preparing a high-rate artificial graphite anode material, comprising the following steps: (1) preferential selection of pulverized and shaped tailings; (2) mixing; (3) static coating and granulation; (4) breaking and spheroidization; (5) secondary mixing; (6) high-temperature graphitization; and (7) mixing andsieving. The anode material prepared by the method has excellent high rate charge / discharge performance, and has good cycle performance and low-temperature temperature. The method also fully processesand recycles the by-products produced in the processing of coke raw materials / asphalt raw materials in a high value-added manner, has broad market prospects, reduces the disposal cost of solid waste,and brings practical economic benefits.

Owner:KEDA (ANHUI) NEW MATERIAL CO LTD

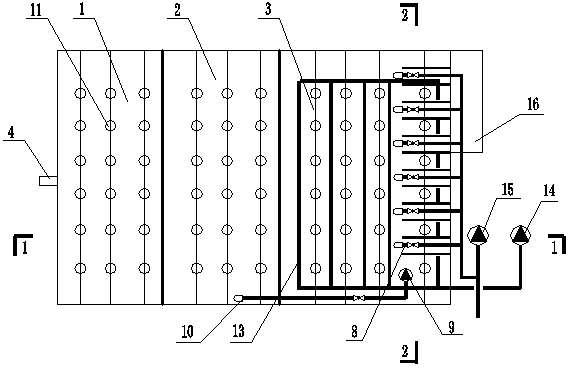

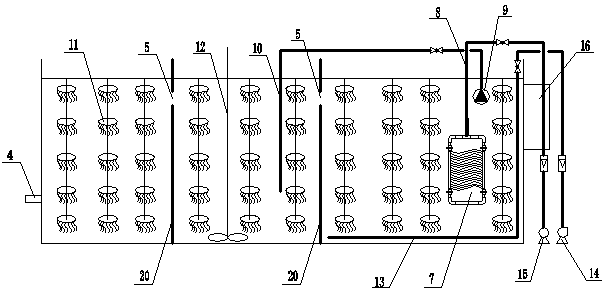

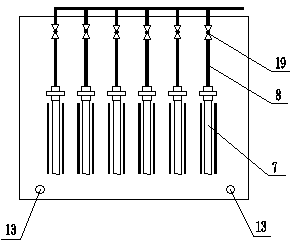

Membrane bio-reactor (MBR) used for treating preserved szechuan pickle wastewater and reinforcing biological phosphorous and nitrogen removal

ActiveCN103663696ASettling is not affected by salinityTo overcome the disadvantages of low nitrogen and phosphorus removal efficiencyTreatment with aerobic and anaerobic processesWaste water treatment from food industryNitrogen removalAeration system

The invention discloses a membrane bio-reactor (MBR) used for treating preserved szechuan pickle wastewater and reinforcing biological phosphorous and nitrogen removal. An integrated reactor is formed by an A<2> / O process, a biological membrane process and the MBR. The MBR comprises an anaerobic tank, an anoxic tank, an aerobic tank, a feeding system, an aerating system, a drainage system and automatic control equipment, wherein semi-soft biological membrane fillers are put in the anaerobic tank, the anoxic tank and the aerobic tank; a membrane component is put in the aerobic tank, and a membrane separation region is not independently arranged. The reactor has the advantages that anaerobic phosphorus release and phosphorus accumulation in the aerobic tank are carried out via the sludge on the biological fillers in the anaerobic tank, thus increasing the total removal rate of phosphorus in the sewage; organic matters undergo hydrolytic acidification and organic nitrogen is aminated after the preserved szechuan pickle wastewater passes through the anaerobic tank; nitrification liquor in the aerobic tank flows back to the anoxic tank to form denitrification in the anoxic tank. The MBR has a simple structure and high pollutant treatment efficiency, is light in membrane pollution, and can simultaneously treat the pollutants such as organic matters, total nitrogen, total phosphorus, SS and the like of high salinity wastewater.

Owner:CHONGQING UNIV

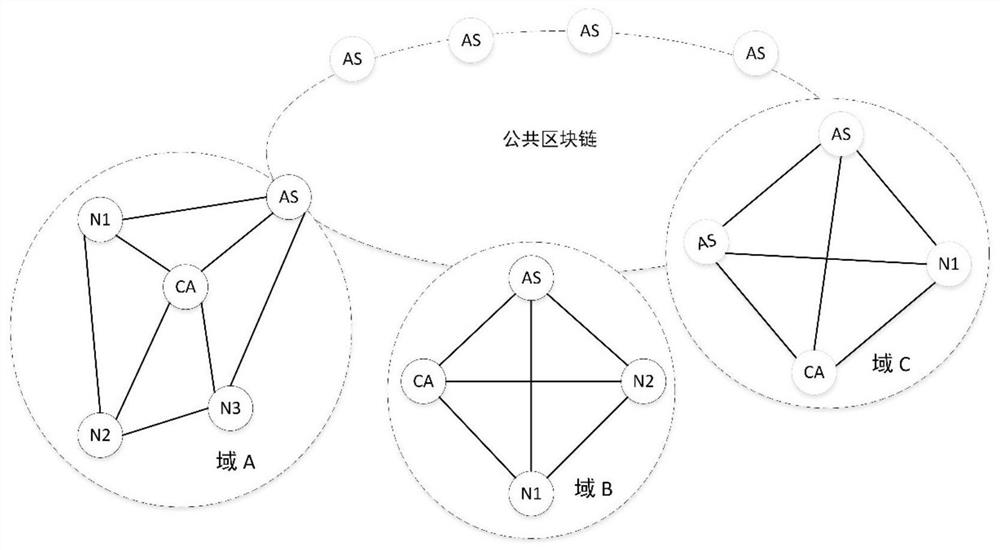

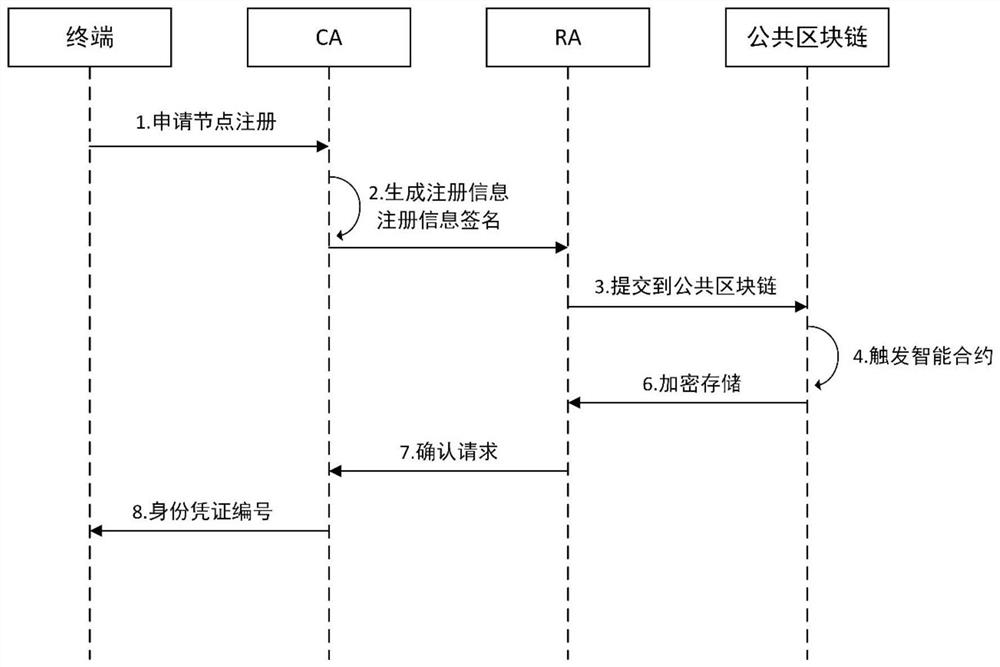

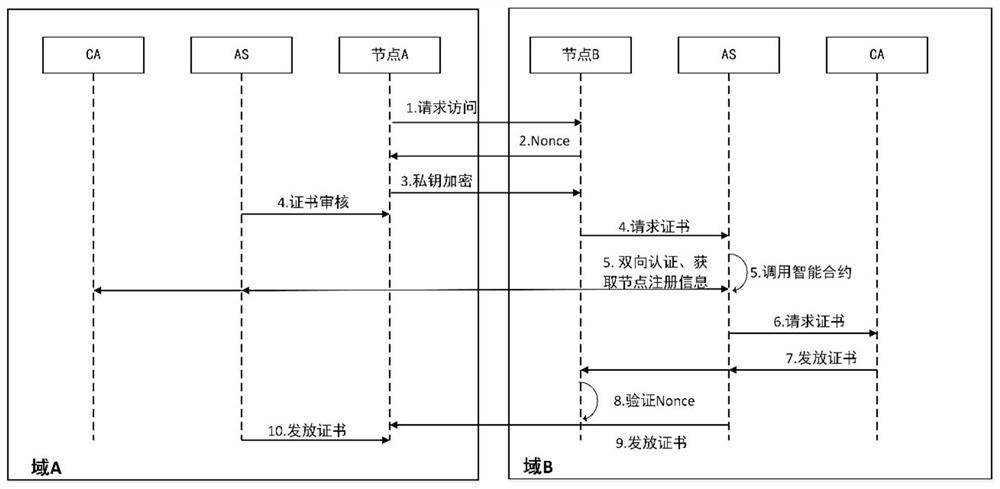

Multi-layer blockchain cross-domain authentication method in Internet of Things application scene

ActiveCN112637189AAvoid Privacy LeakageImprove space utilizationTransmissionInternet privacyThe Internet

The invention relates to a multi-layer blockchain cross-domain authentication method in an Internet of Things application scene, and belongs to the technical field of Internet of Things and blockchains. According to the method, a blockchain identity registration protocol, a cross-domain identity authentication protocol and a node trust degree evaluation method based on delegation proving of rights and interests are used for carrying out distributed node management and security protection on the blockchain in an application scene of the Internet of Things; and when nodes of different blockchains need to carry out cross-chain identity authentication and data exchange, the across-chain trusted identity authentication is carried out by using a public block chain, so that the user privacy and the data security are ensured. The technical scheme includes the contents in the specification. Compared with an original centralized identity authentication mode, the identity authentication efficiency under the distributed application scene of the Internet of Things is improved, the management problem of certificates under a heterogeneous network is solved, and good safety and usability are achieved.

Owner:CHONGQING UNIV +1

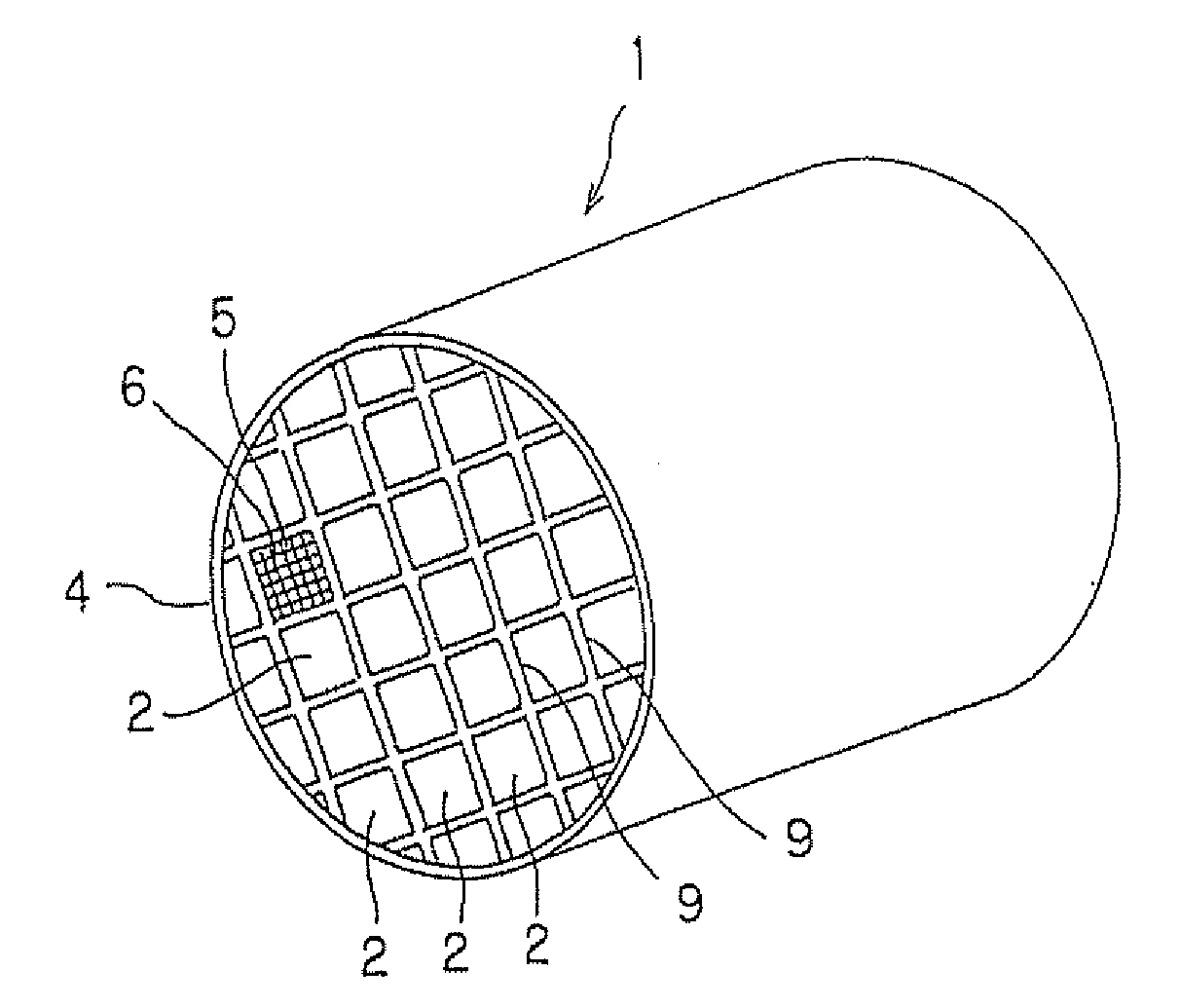

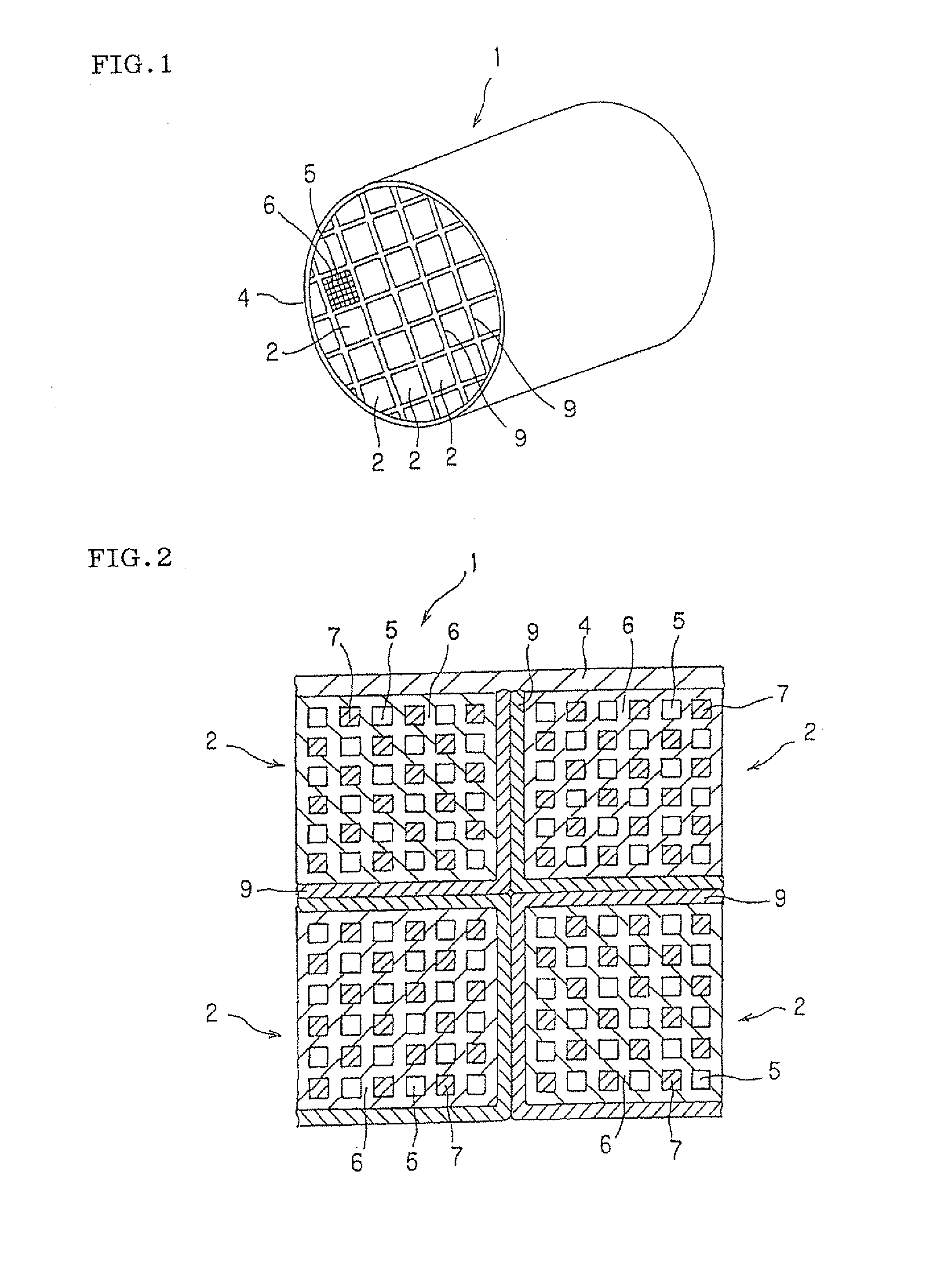

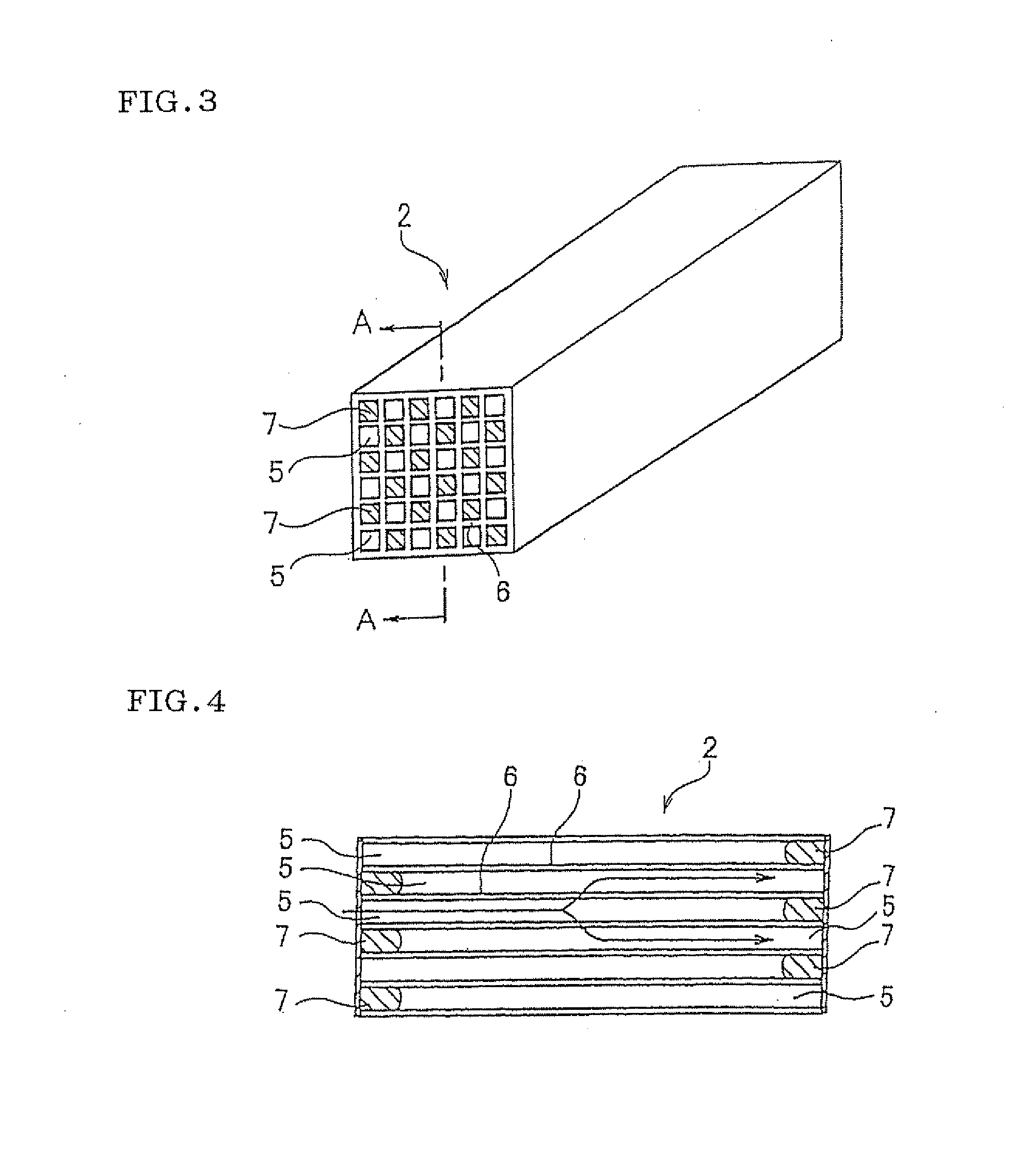

Bonding material, process for producing the same, and honeycomb structure made with the same

ActiveUS20080248238A1Reduce thermal stressReduce generationDispersed particle filtrationMembrane filtersDiesel particulate filterHoneycomb structure

There is provided bonding material having a Young's Modulus after hardening of not less than 20% of articles to be bonded, and an average linear coefficient of thermal expansion after hardening of not more than 70% of the articles to be bonded. This bonding material can suppress deformation of a honeycomb segment due to thermal stress to be generated by a bonding material layer and can suitably be used at the time of manufacturing exhaust gas trapping filters capable of reducing the generation of defects such as a crack, and above all, a diesel particulate filter (DPF) for trapping particulate matter (particulates) in exhaust gas from the diesel engine.

Owner:NGK INSULATORS LTD

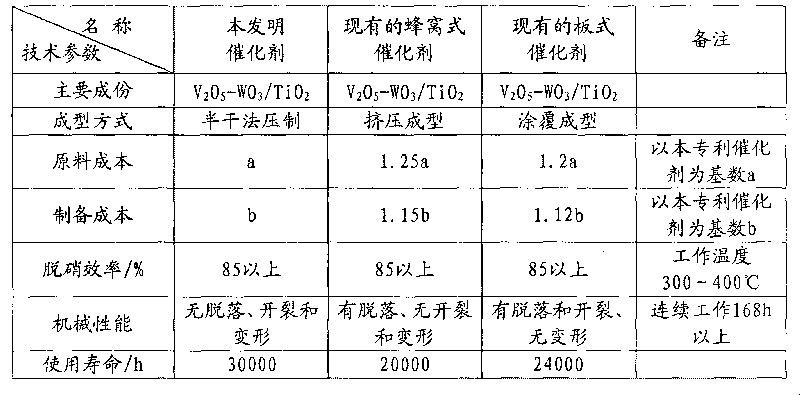

High mechanical property and low cost SCR denitration catalyst and preparation method thereof

ActiveCN101711978AGuaranteed performanceLow costDispersed particle separationCatalyst activation/preparationGlass fiberYarn

The invention provides a high mechanical property and low cost SCR denitration catalyst and a preparation method thereof. A steel screen or a reinforced glass fiber board is used as a framework material, and 78-80 weight parts of industrial grade and nano scale TiO2 is used as a composite carrier, wherein the weight parts of the industrial grade TiO2 are 5-8, and the balance is the nano scale TiO2; 13-27 weight parts of V2O5-WO3 / TiO2 roasting particle is used as batching seed crystal, and 9-10 weight parts of V2O5 and WO3 are used as active components, wherein the weight parts of the V2O5 are 1.5-2, and the balance is WO3; and 10-12 weight parts of ludox, methylcellulose, fiberglass yarn and ethanolamine are used as auxiliary agents, wherein the weight parts of the ludox, the methylcellulose, the fiberglass yarn and the ethanolamine are all 2.5-3.5. The invention reduces the preparation cost and the operation expense of the SCR denitration catalyst, and improves the mechanical properties of abrasion resistance, pressure resistance, strength, and the like of the catalyst.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

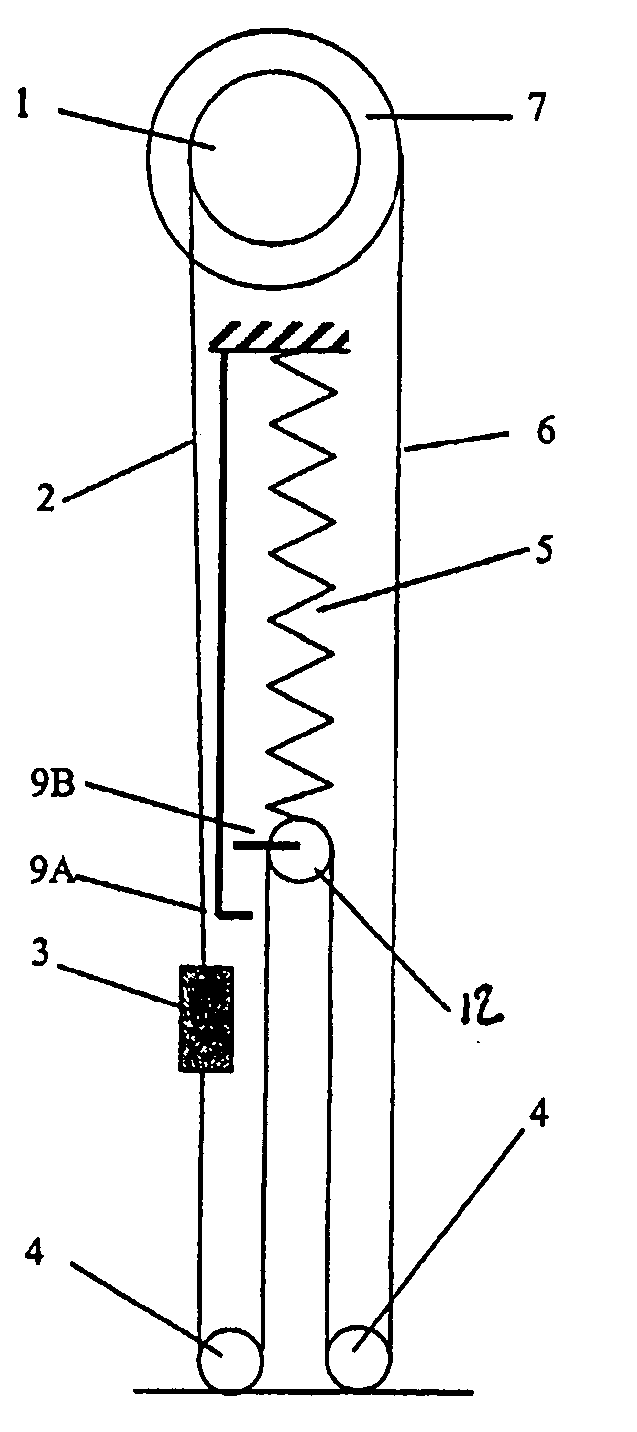

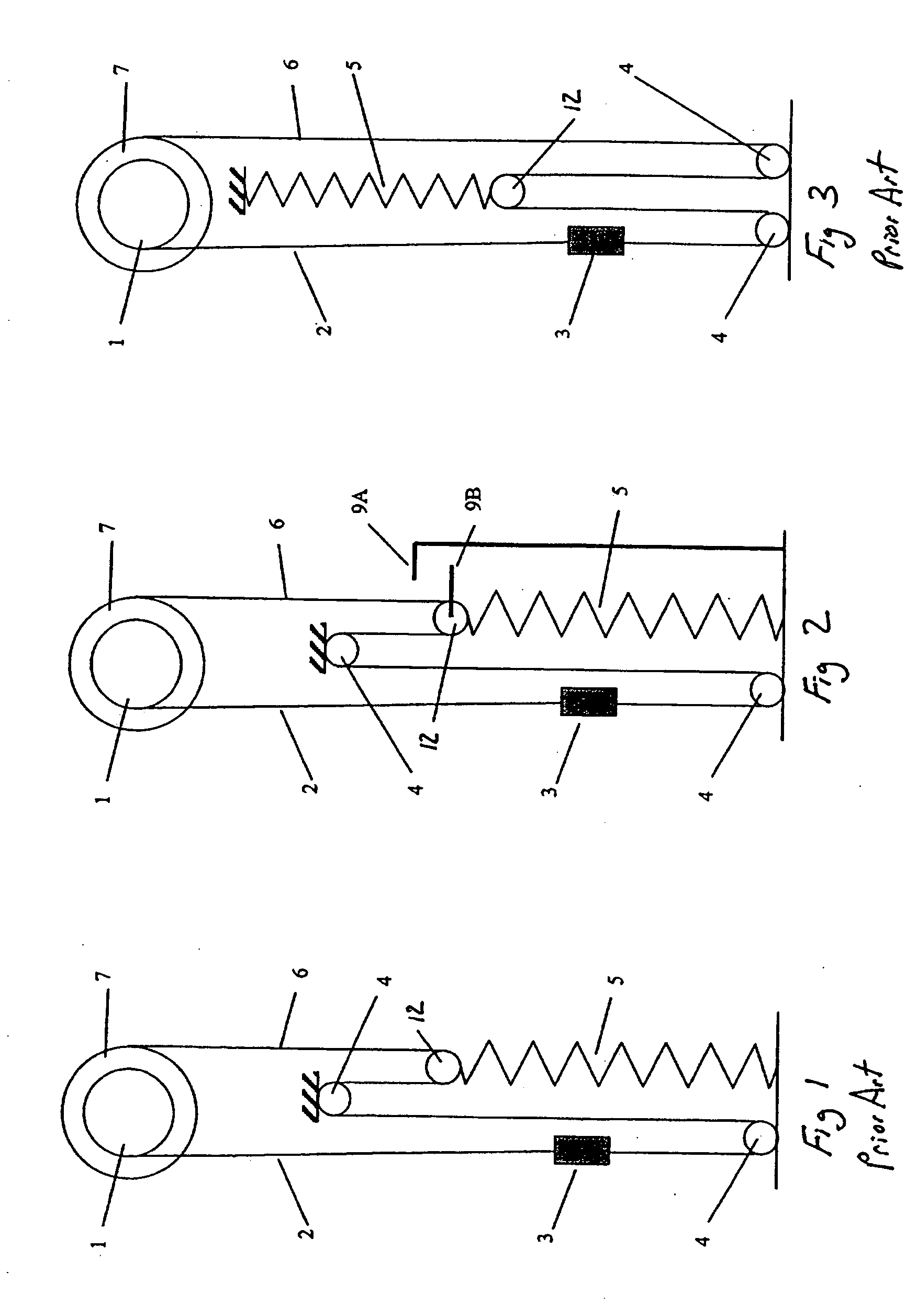

High load operation of an industrial roll door

InactiveUS20050247412A1Lower potentialReduce bloatScreensShutters/ movable grillesEngineeringHigh load

A high load operation industrial roll door, including a flexible door curtain windable about a top roll positioned above a door opening and provided with a drive system. The roll door includes a bottom beam fastened to the door curtain, and a biasing spring, for resisting movement of the door upon application of a load thereon, and a positive stop preventing movement of the biasing means beyond a predetermined point.

Owner:ASSA ABLOY ENTRANCE SYST

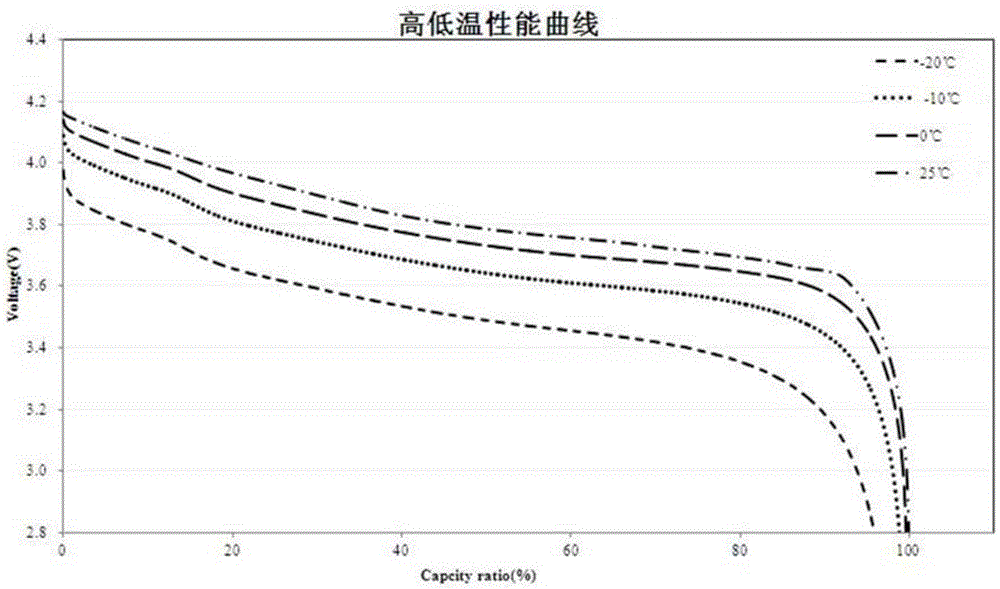

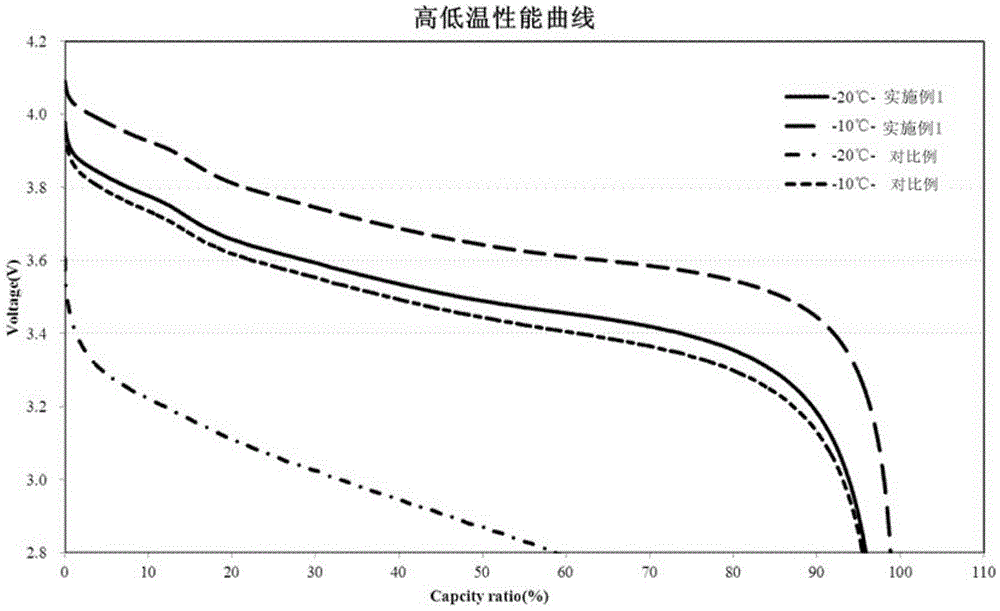

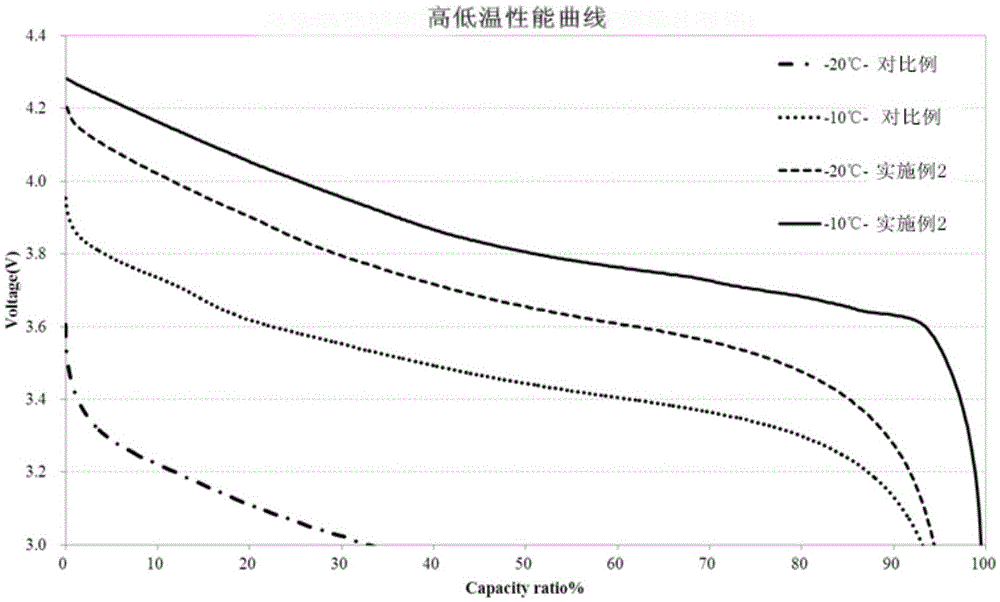

Low-temperature type lithium ion battery with high voltage and high volume energy density

InactiveCN105470519AExcellent liquid retentionReduce bloatCell electrodesFinal product manufacturePolyvinylidene fluoridePolyolefin

The invention provides a low-temperature type lithium ion battery with high voltage and high volume energy density. The low-temperature type lithium ion battery comprises a cathode, an anode, an isolating membrane and an electrolyte solution, wherein the isolating membrane is formed by coating polyvinylidene fluoride-hexafluoropropylene copolymer coatings on both sides of a polyolefin isolating membrane substrate. According to the low-temperature type lithium ion battery with high voltage and high volume energy density provided by the invention, the polyvinylidene fluoride-hexafluoropropylene copolymer coated on the surfaces of the isolating membrane can polymerize with polyvinylidene fluoride in positive and negative pole pieces, so that the cathode and the anode are tightly attached with the isolating membrane together, the expansion of the cathode and the anode is reduced, the inner volume of the battery is further reduced, and the energy density is improved; moreover, the polyvinylidene fluoride on the surfaces of the isolating membrane has good electrolyte retention, and is matched with the low-temperature type lithium ion electrolyte solution and good cathode and anode space conducting network, so that lithium ions can be relatively high in diffusion and disembedding speed between the electrolyte solution and the cathode and the anode under low temperature, and the discharging capacity of greater than or equal to 90% at -20 DEG C can be realized.

Owner:TIANJIN ENERGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com