Artificial graphite composite negative electrode material for lithium-ion battery and preparation method of artificial graphite composite negative electrode material

A lithium-ion battery and artificial graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficult to break through 800 cycles, battery cycle life decline, etc., to improve service life, reduce expansion, and not easy to loosen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

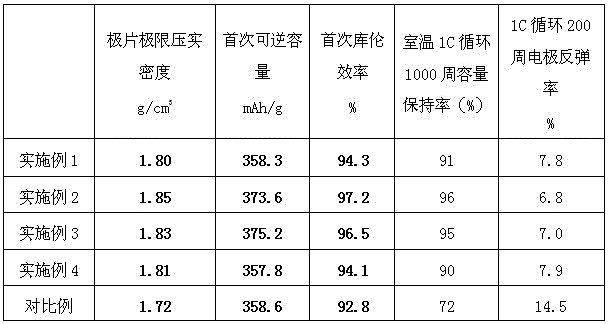

Examples

Embodiment 1

[0025] High-capacity, high-compression, low-cycle rebound artificial graphite composite materials for lithium-ion batteries, the specific steps are as follows:

[0026] S1. Crushing and grading commercially available needle-shaped green coke with a volatile fraction of 7% to D50=7μm;

[0027] S2. Using a spheroidizer to spheroidize the crushed and classified petroleum needle-shaped green coke, the speed of the spheroidizer is 2600rpm, and the time is 3min;

[0028] S3. Mix the primary particles obtained in step S2 with asphalt with a D50 of 3 μm and a softening point of 150°C in a mass ratio of 100:10, and compound them at a high temperature of 500°C under protective atmosphere conditions, and classify the obtained compound to Remove large particles;

[0029] S4. Put the compound obtained in step S3 into an Acheson graphitization furnace for graphitization treatment, and the graphitization temperature is 2800° C.;

[0030] S5. Sieving, demagnetizing and packaging the graphit...

Embodiment 2

[0032] High-capacity, high-compression, low-cycle rebound artificial graphite composite materials for lithium-ion batteries, the specific steps are as follows:

[0033] S1. Crushing and grading commercially available petroleum needle-shaped wrought coke to D50=10 μm;

[0034] S2. Use a spheroidizer to spheroidize the crushed and classified petroleum needle-shaped green coke, with a rotating speed of 3000rpm and a time of 5min;

[0035] S3. Heat the primary particles obtained in step S2 to 1600°C under protective atmosphere conditions, and then bombard them with an ion beam with an energy of 600-800eV and a beam current density of 0.1mA / cm2. The distance from the ion beam to the primary particles is 1mm, the bombardment angle is 30 °, and the primary particles are stirred and stirred while bombarding, and the bombardment time is 5min to obtain a composite precursor with micropores or irregular micro-pits on the surface; then the composite precursor and D50 are The asphalt with...

Embodiment 3

[0039] High-capacity, high-compression, low-cycle rebound artificial graphite composite materials for lithium-ion batteries, the specific steps are as follows:

[0040] S1. Crushing and grading commercially purchased coal series needle-shaped forged coke to D50=13 μm;

[0041] S2. Spherification treatment: the rotating speed is 3600rpm, and the time is 10min;

[0042] S3. Heat the primary particles obtained in step S2 to 2000°C under protective atmosphere conditions, and then bombard them with an ion beam with an energy of 600-800eV and a beam current density of 0.3mA / cm2. The distance from the ion beam to the primary particles 10mm, the bombardment angle is 150 °, and the primary particles are stirred and stirred while bombarding, and the bombardment time is 30min to obtain a composite precursor with micropores or irregular micro-pits on the surface; then the composite precursor is mixed with 5 μm, Asphalt with a softening point of 280°C is mixed evenly at a mass ratio of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com