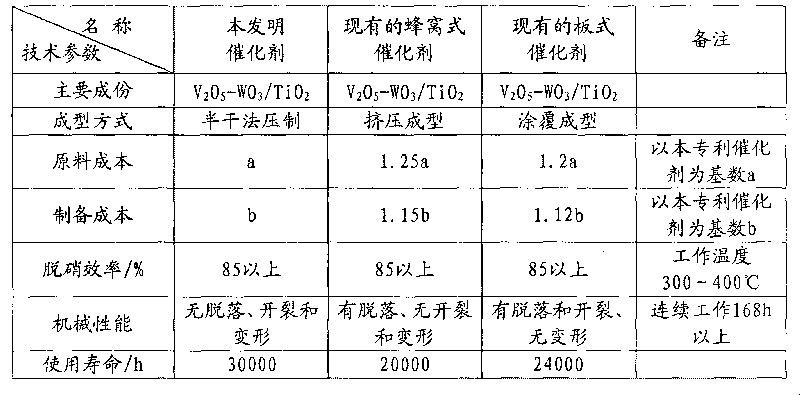

High mechanical property and low cost SCR denitration catalyst and preparation method thereof

A denitration catalyst and mechanical properties technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high price and unstable mechanical properties of catalysts, and achieve enhanced mechanical wedging effect , Reduce the preparation cost, good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The high-performance low-cost SCR denitrification catalyst described in this embodiment is based on steel mesh as a skeleton material, and industrial-grade and nano-scale TiO 2 As a composite carrier, V 2 o 5 -WO 3 / TiO 2 The calcined particles are used as batching seeds, with V 2 o 5 and WO 3 As the active component, silica sol, methyl cellulose, glass fiber and ethanolamine are used as auxiliary agents. 80 parts by weight of the composite carrier, wherein, technical grade TiO 2 The weight component is 5.6 parts, and the rest is nano-sized TiO 2 ; The weight component of the batching seed crystal is 13.4 parts; The weight component of the active component is 9.6 parts, wherein V 2 o 5 1.6 copies, the rest are WO 3; The weight component of the auxiliary agent is 10.4 parts; wherein, the weight component of silica sol, methyl cellulose, glass fiber silk and ethanolamine is 2.6 parts.

[0036] The low-cost SCR denitration catalyst with high mechanical propertie...

Embodiment 2

[0050] The high mechanical performance low-cost SCR denitrification catalyst described in this embodiment is based on reinforced glass fiber board as the skeleton material, with industrial grade and nano-scale TiO 2 As a composite carrier, V 2 o 5 -WO 3 / TiO 2 The calcined particles are used as batching seeds, with V 2 o 5 and WO 3 As the active component, silica sol, methyl cellulose, glass fiber and ethanolamine are used as auxiliary agents. 78 parts by weight of the composite carrier, wherein, technical grade TiO 2 The weight component is 7.8 parts, and the rest is nano-sized TiO 2 ; The weight component of the batching seed crystal is 26.4 parts; The weight component of the active component is 10 parts, wherein V 2 o 5 1.87 copies, the rest are WO 3 ; The weight component of the auxiliary agent is 12 parts; wherein, the weight component of silica sol, methyl cellulose, glass fiber silk and ethanolamine is 3 parts.

[0051] The low-cost SCR denitration catalyst w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com