Insulating sealing element for head-of-wall joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

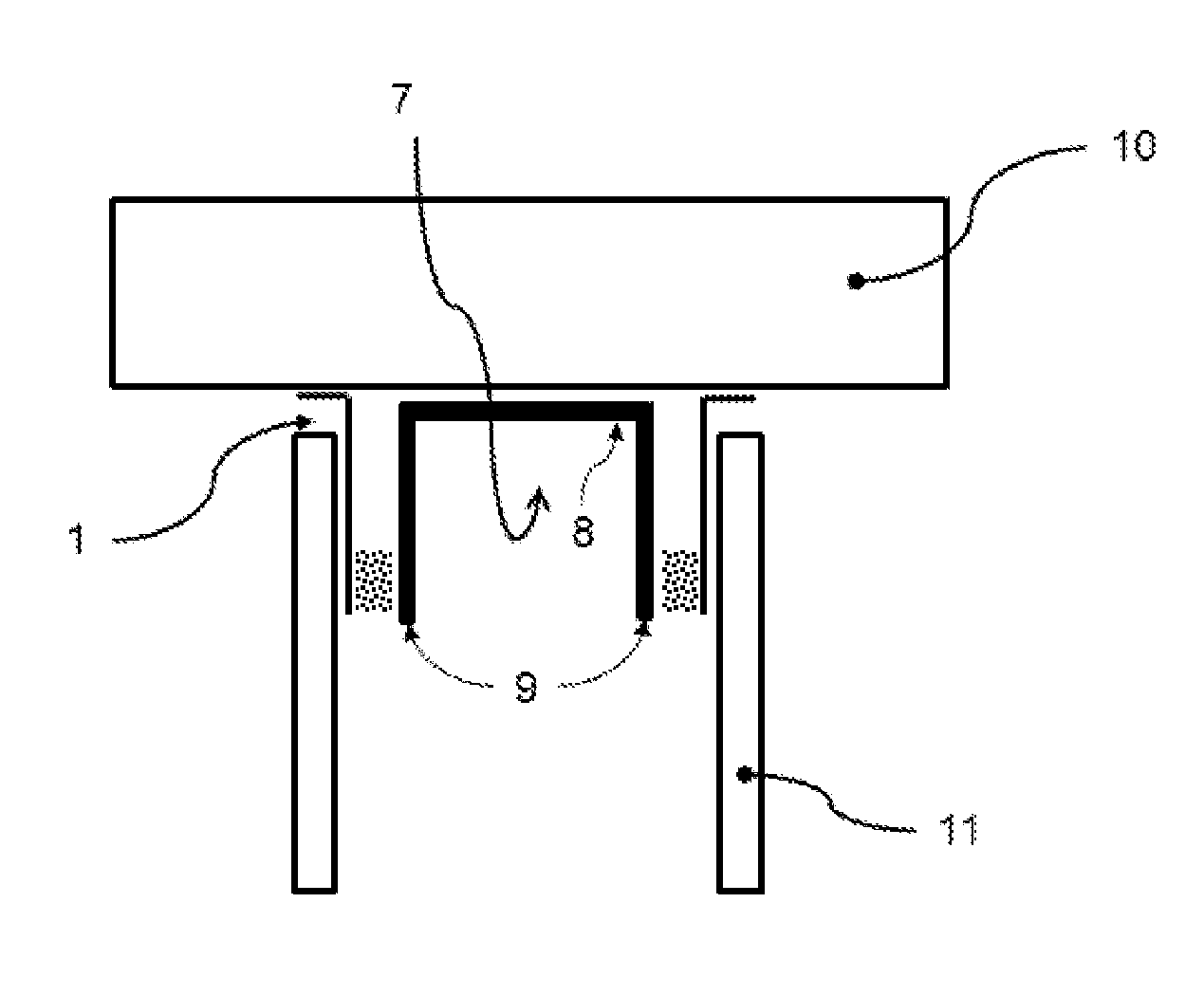

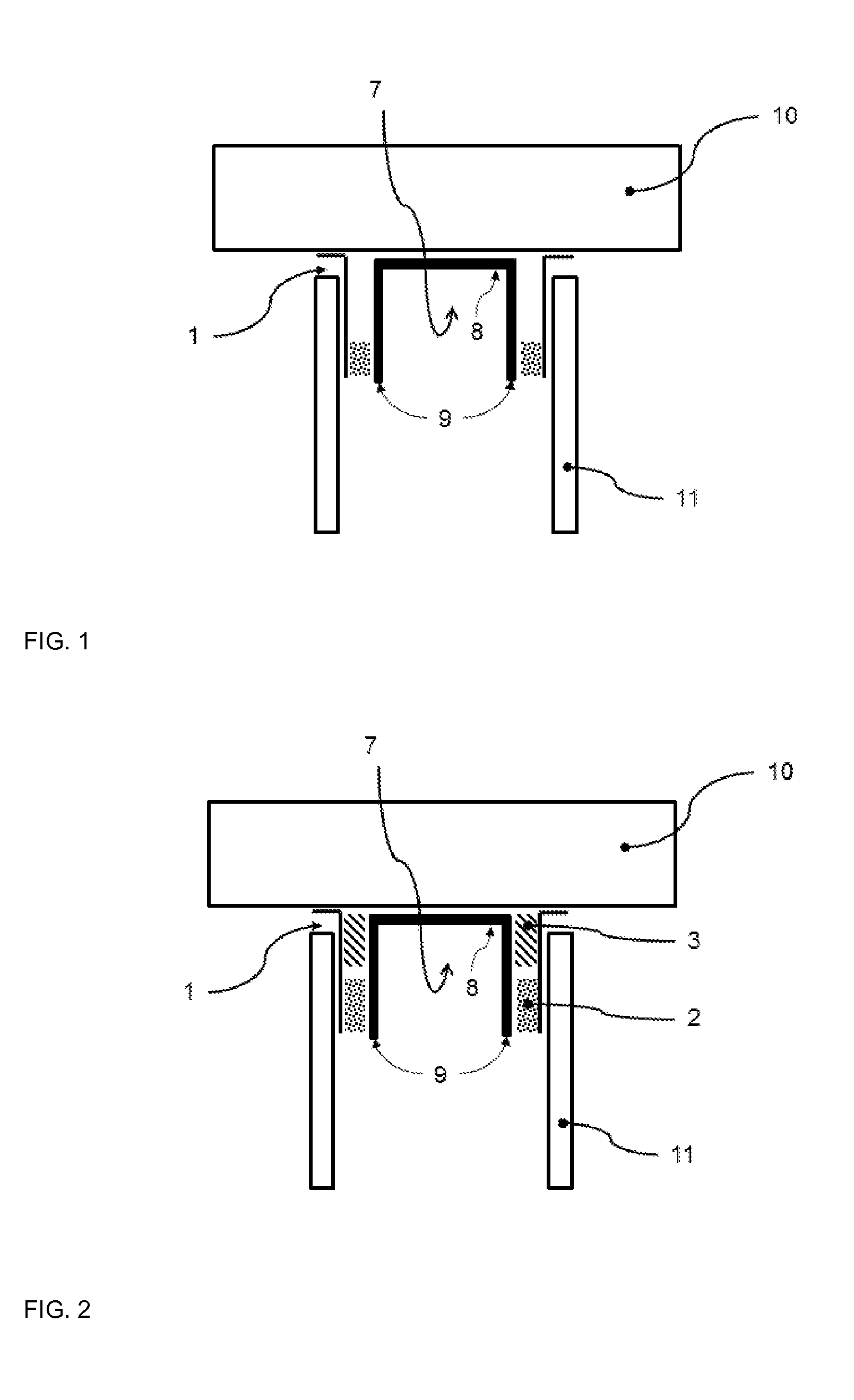

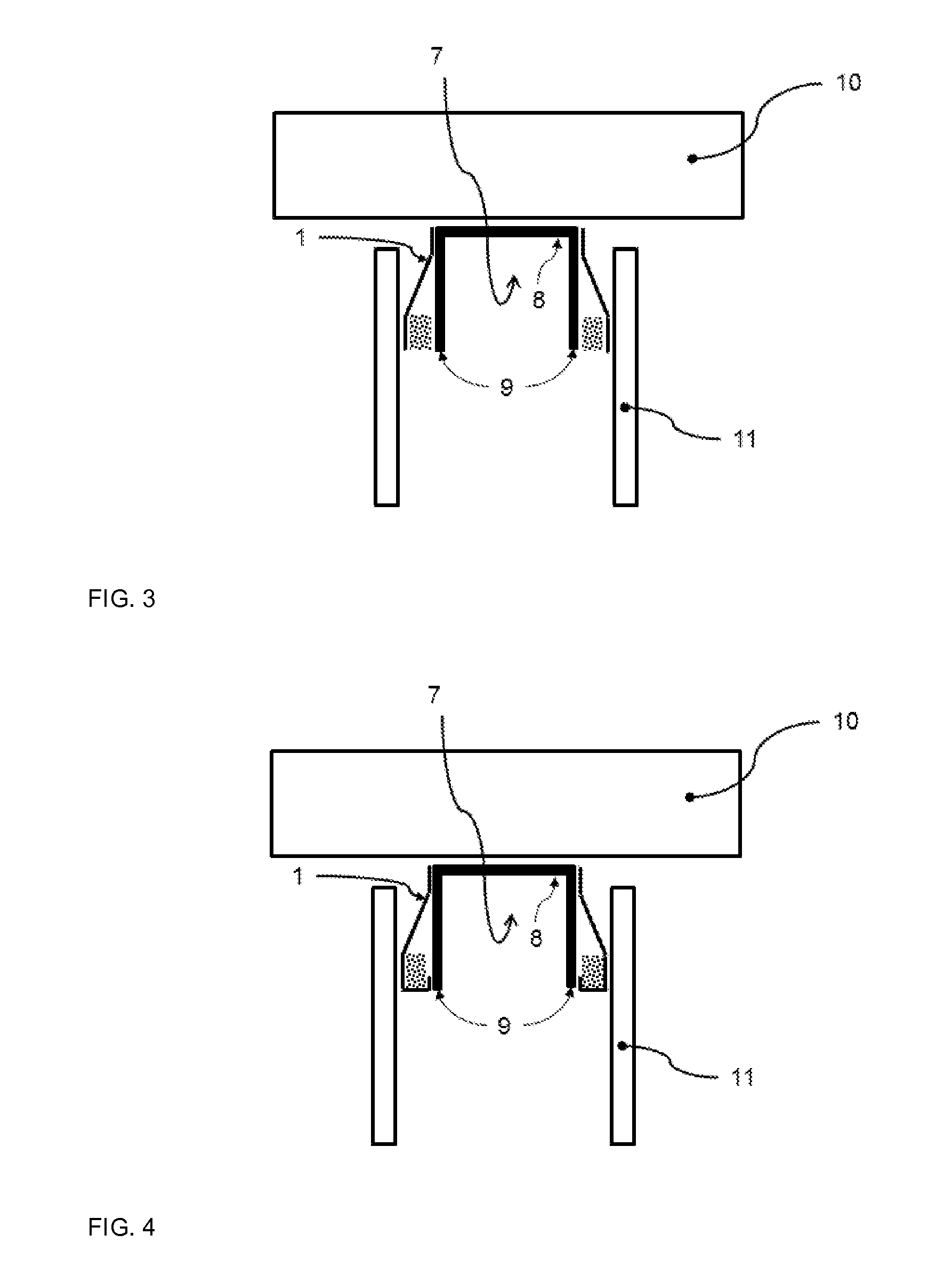

[0095]FIGS. 1, 3 and 5 illustrate various possibilities to fix the insulating strip 1 of the first aspect of the invention to the dry wall assembly. The dry wall assembly includes a header track 7 with a web 8, legs 9, wallboards 11 and studs (not shown). The header track is a U-shaped channel that is attached to an upper horizontal support structure 10 (also referred to as overhead structure10). Wall studs (not shown) are received in the header track 7 and may be configured for vertical movement relative to the header track 7. A wallboard 11 is attached to the studs such as by a plurality of suitable fasteners.

[0096]The insulating strip 1, in particular an elongated strip, according to the first aspect of the invention includes an insulating material strip and a cover layer which extends on one side beyond the insulating material strip. The insulating material strip is positioned on the cover layer so that one long edge of the elongated material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com