Patents

Literature

42results about How to "Realize electric heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

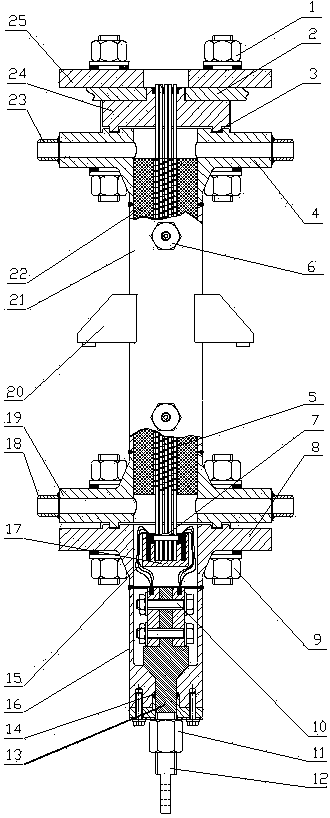

Spherical flue element equivalent model thermotechnical waterpower experimental apparatus

ActiveCN102855802AReflect thermal hydraulic characteristicsRealize electric heatingEducational modelsThermal expansionEngineering

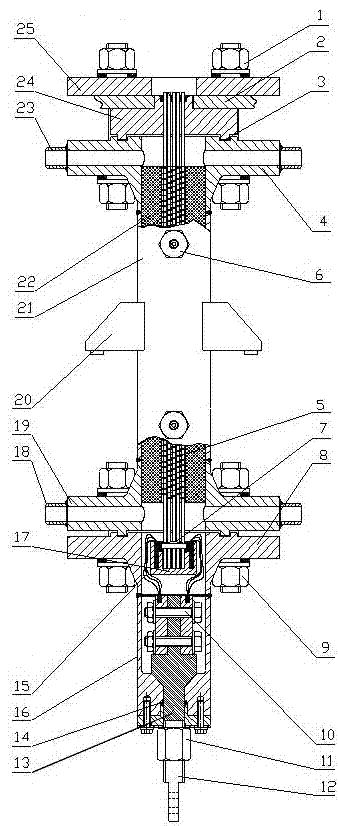

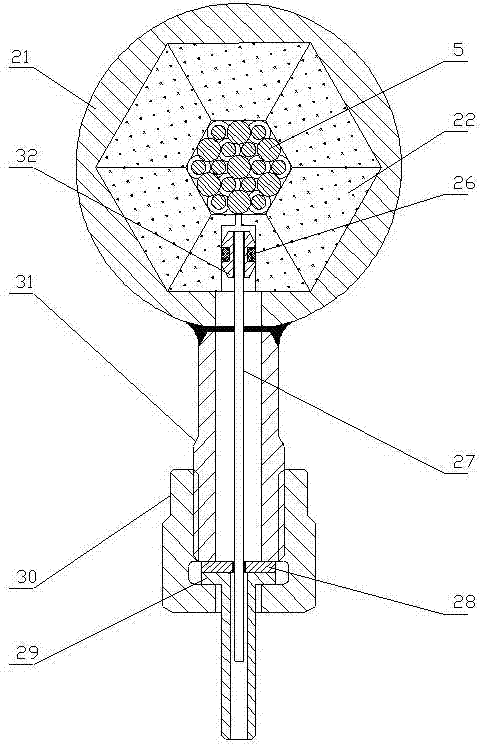

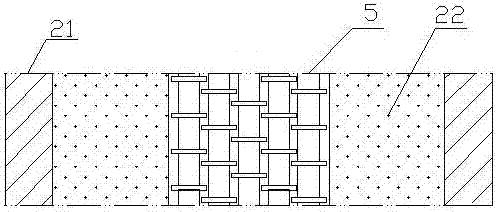

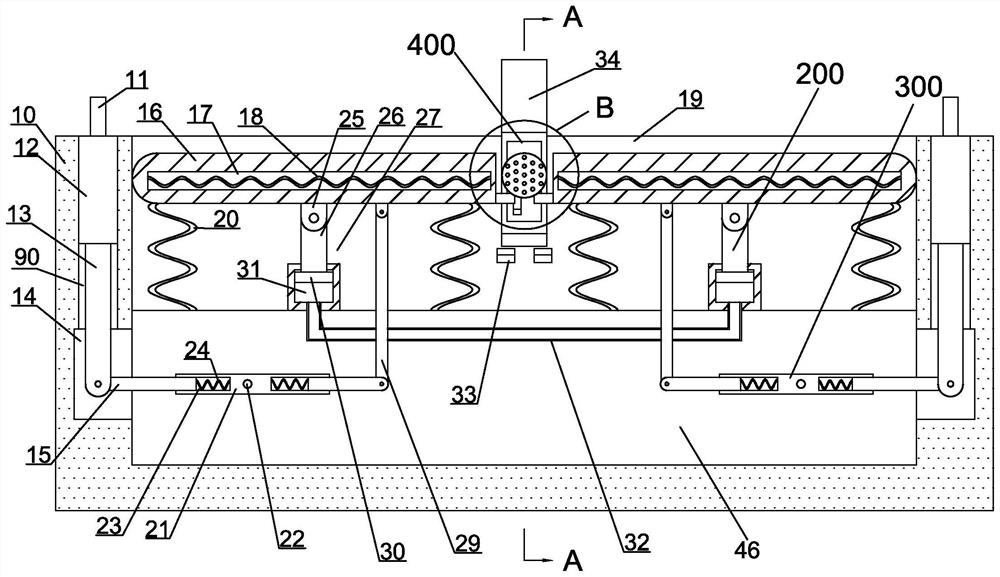

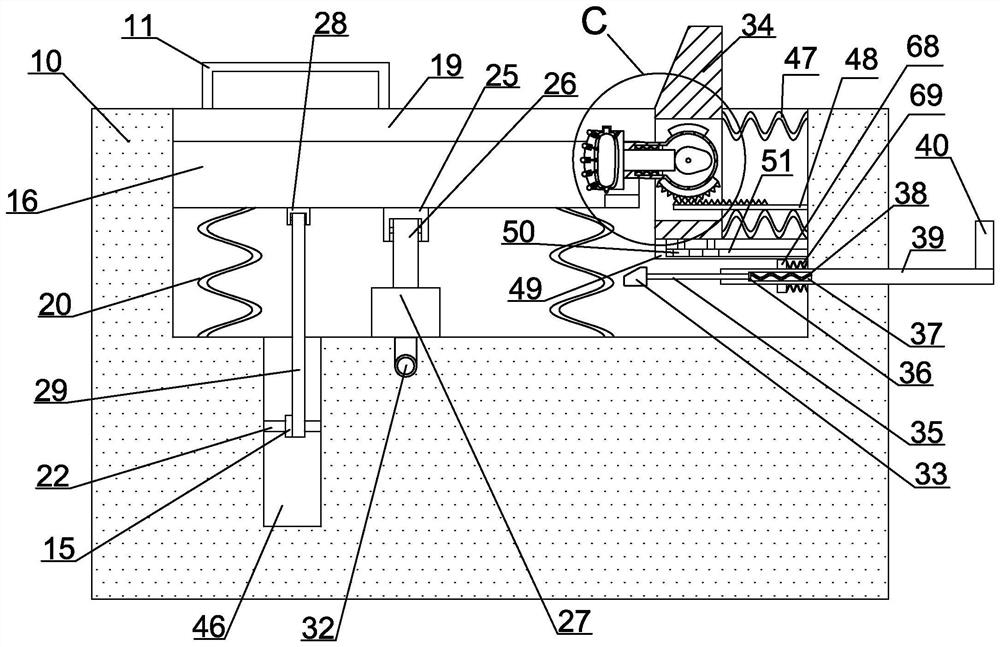

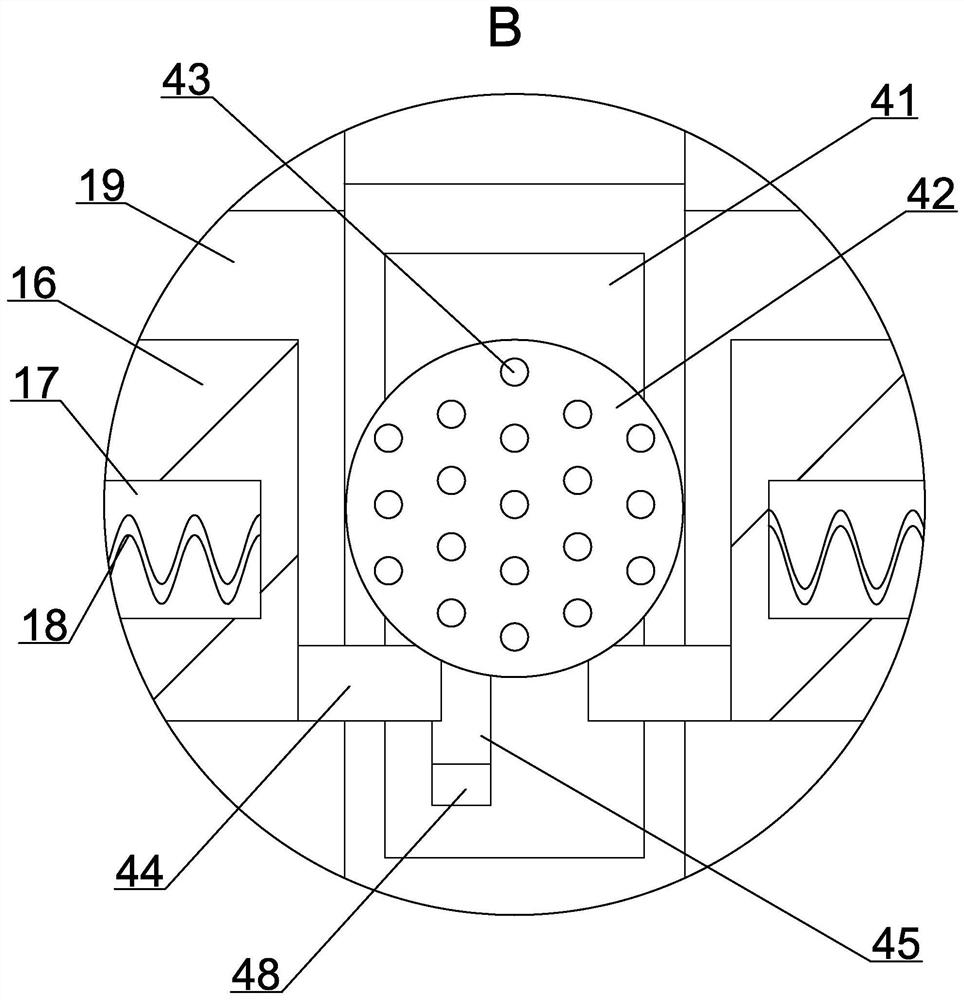

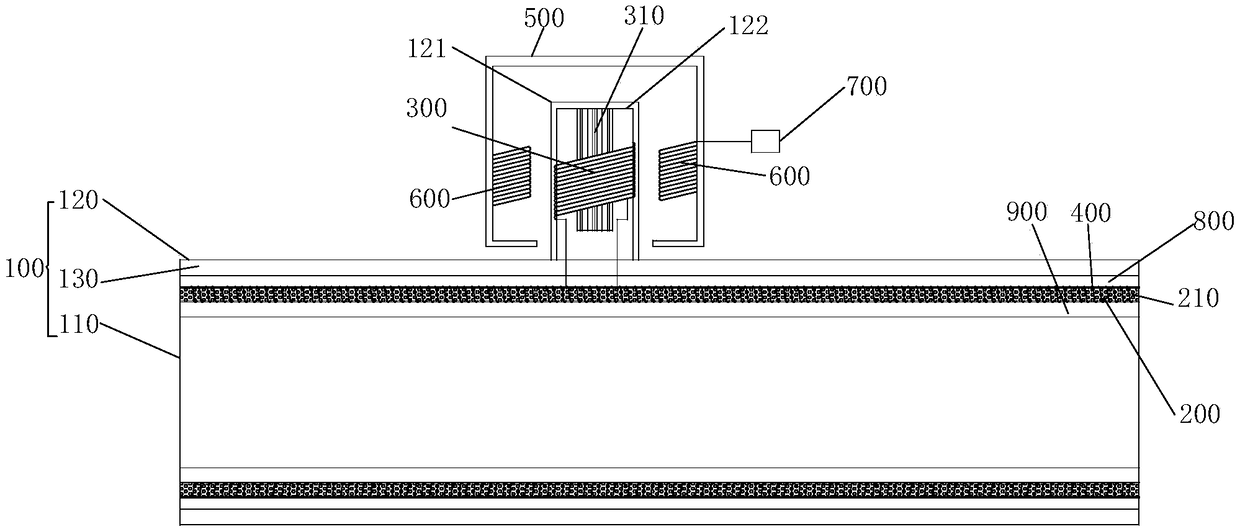

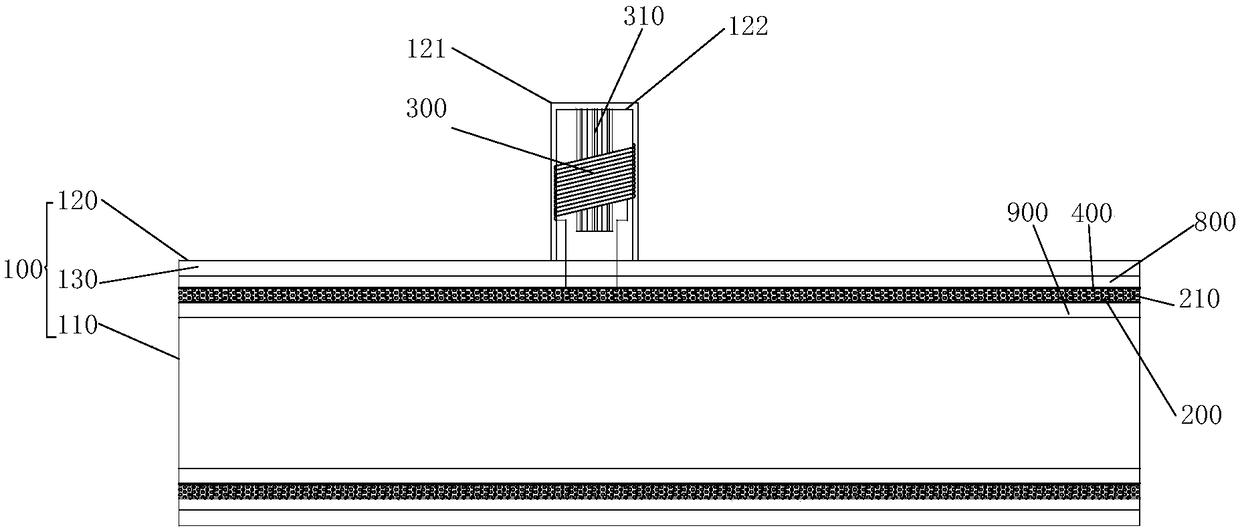

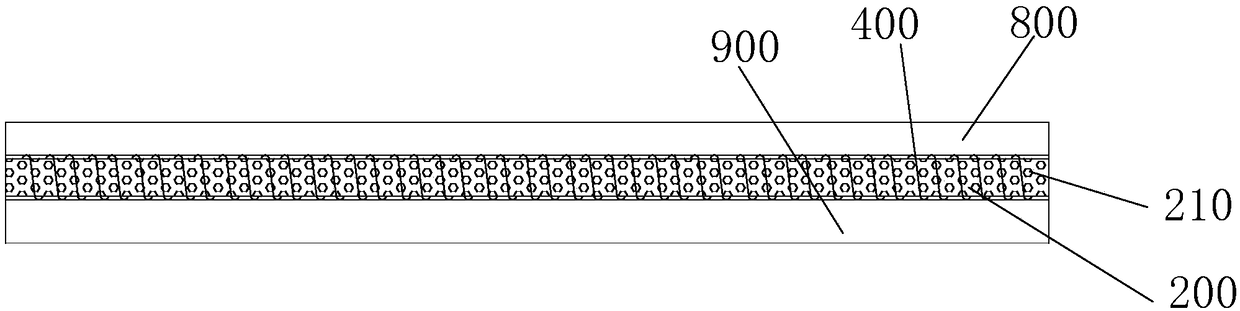

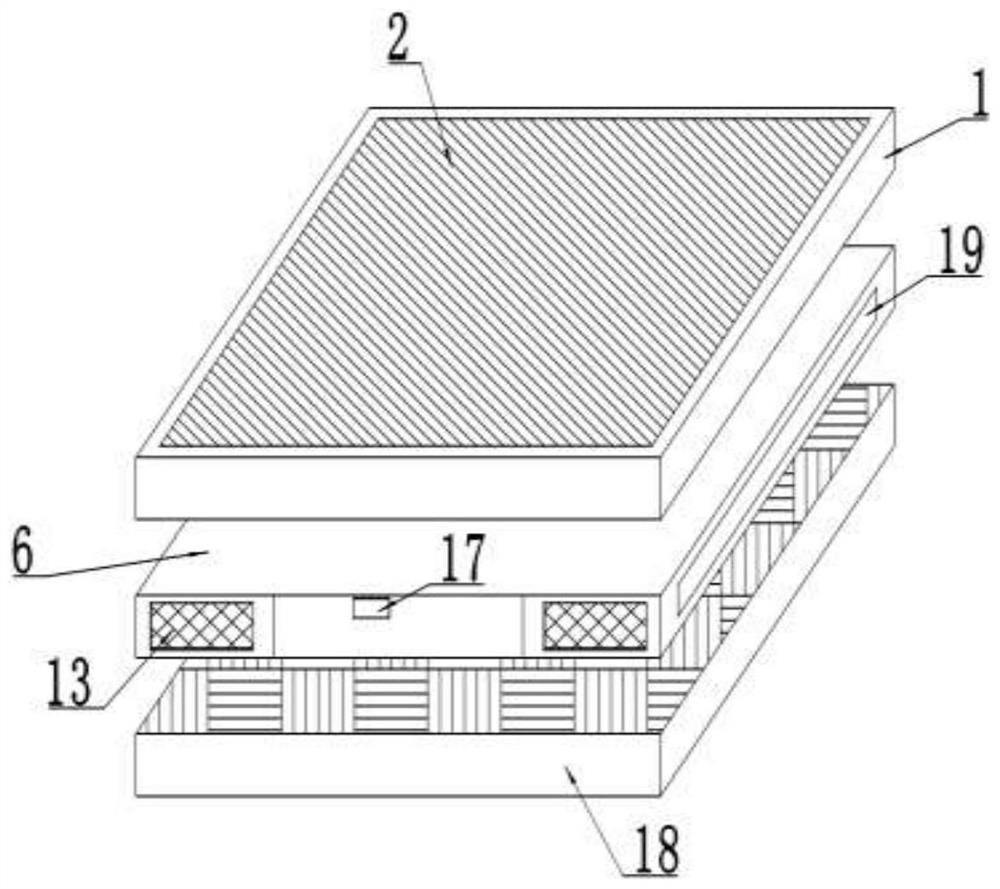

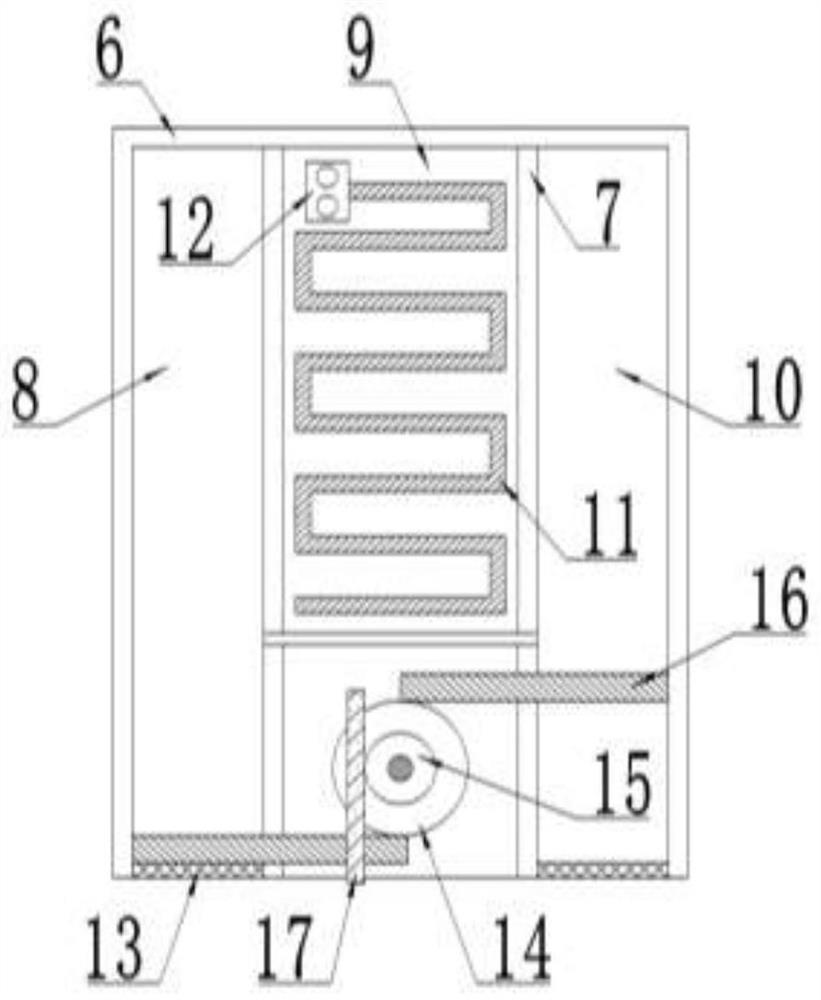

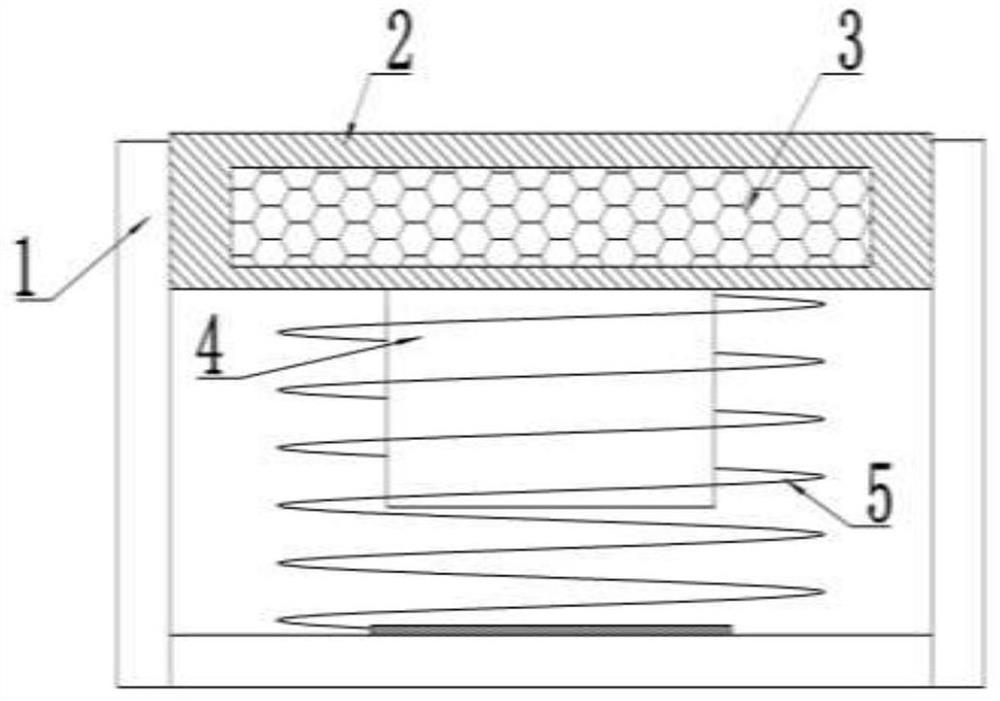

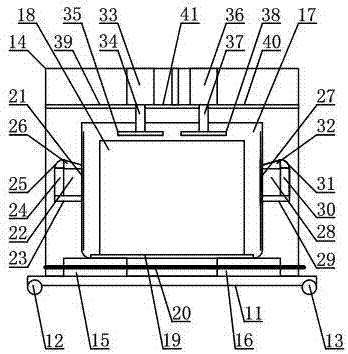

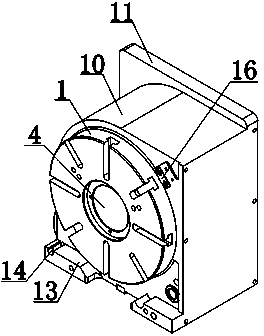

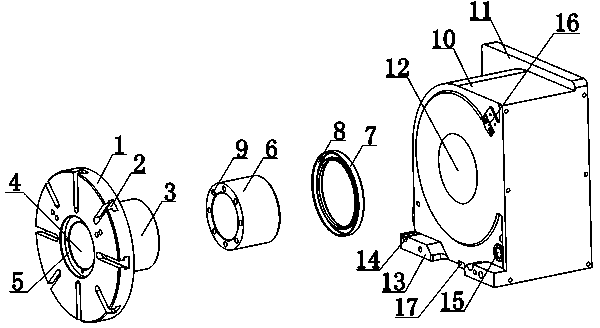

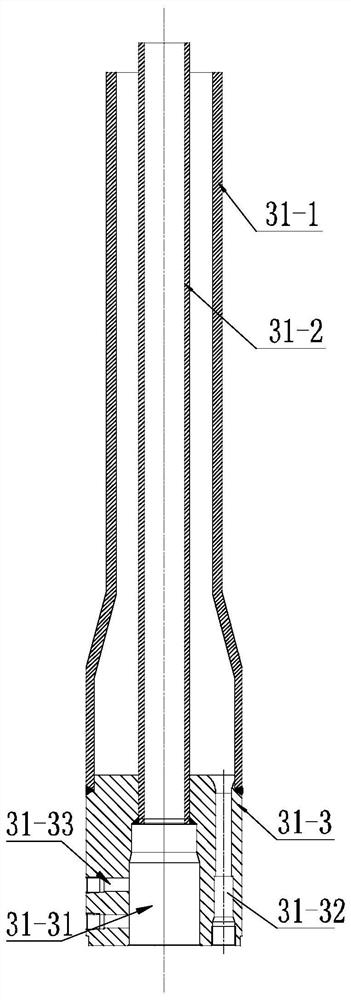

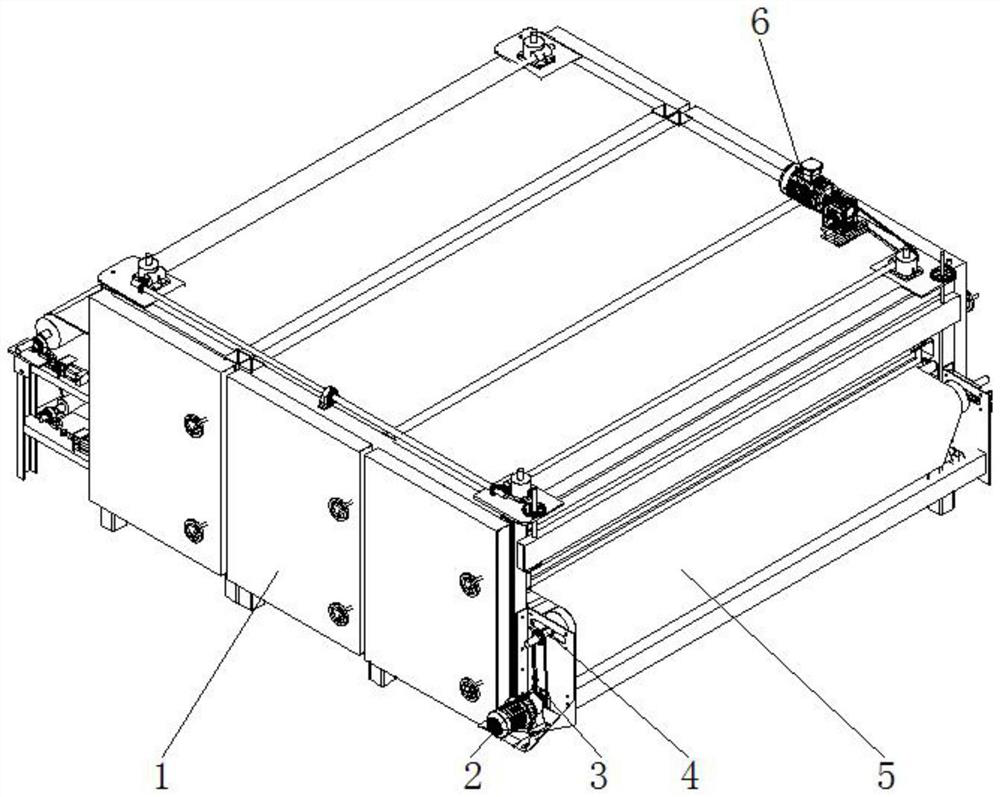

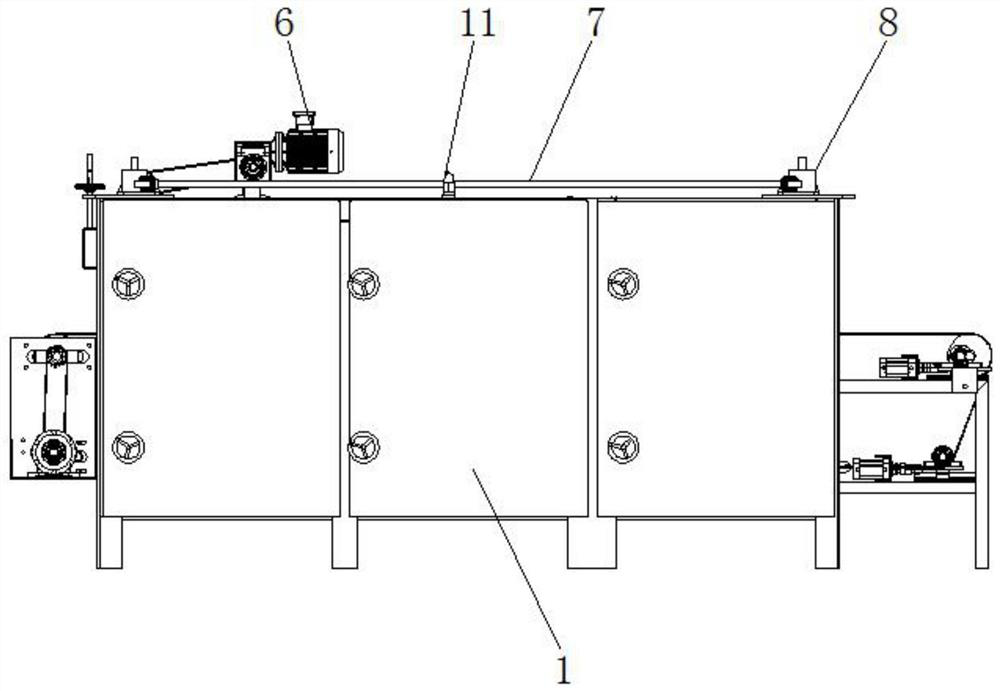

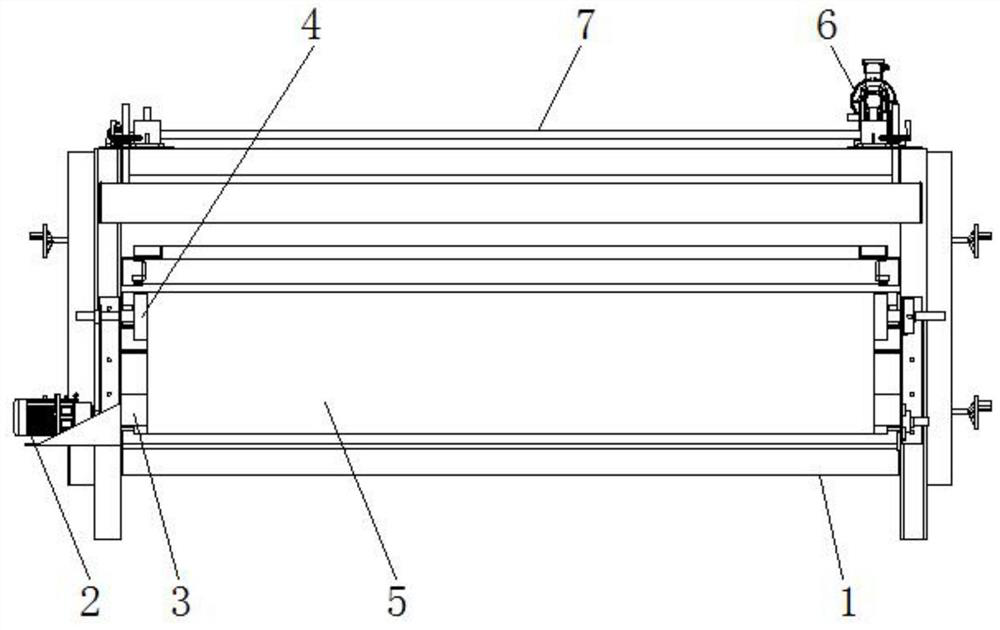

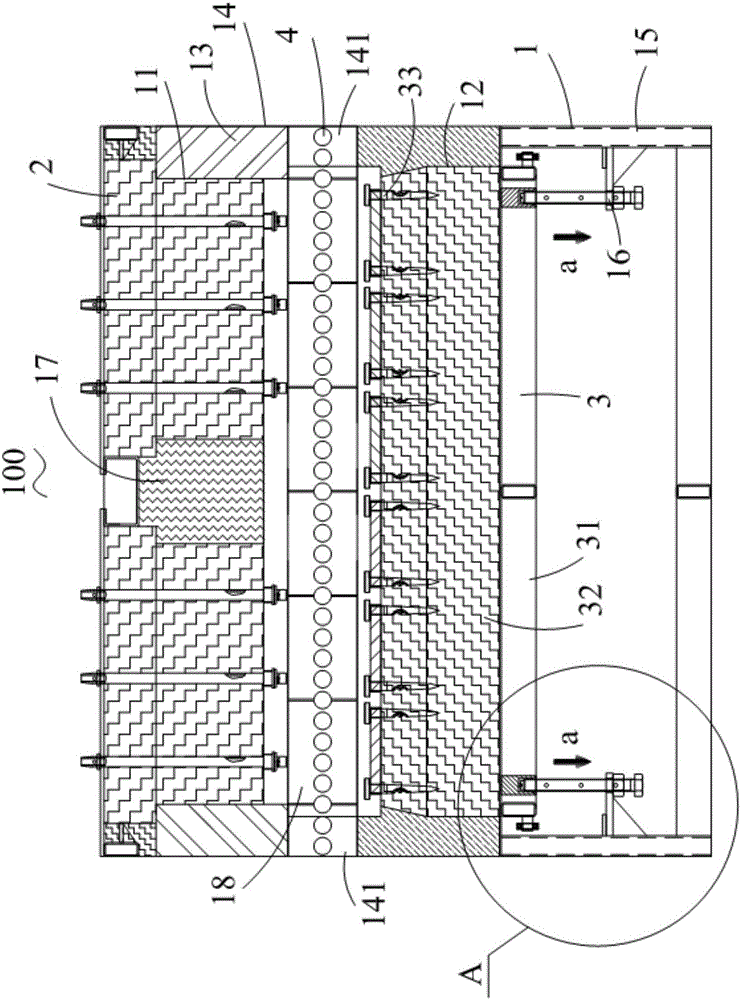

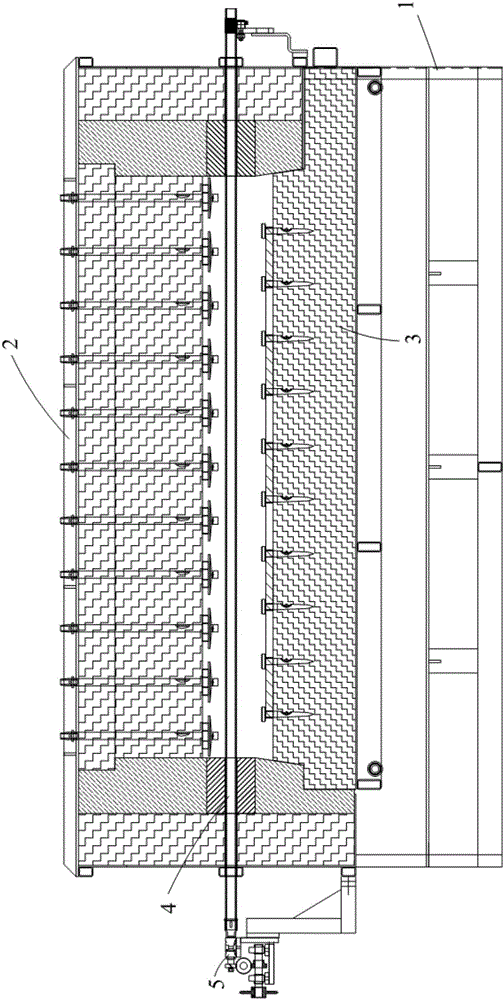

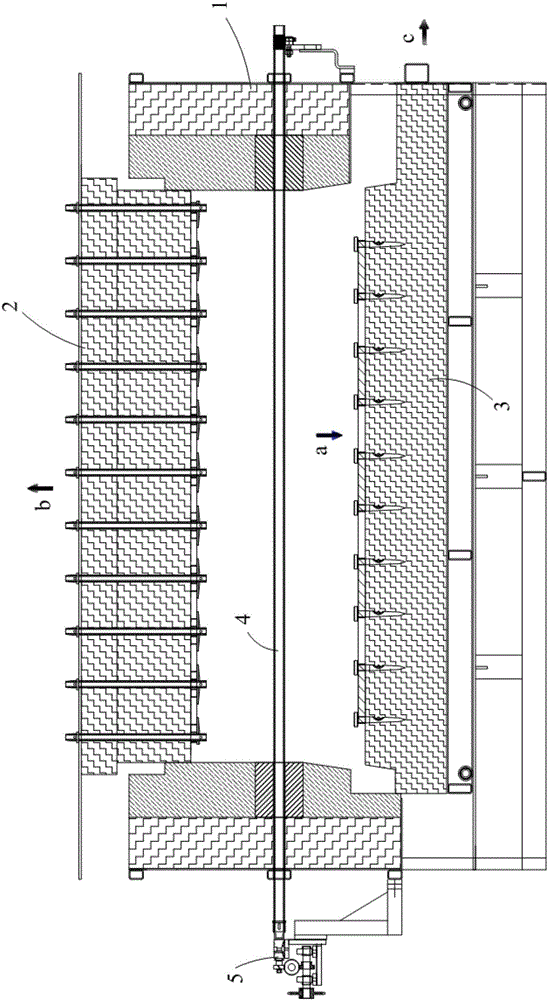

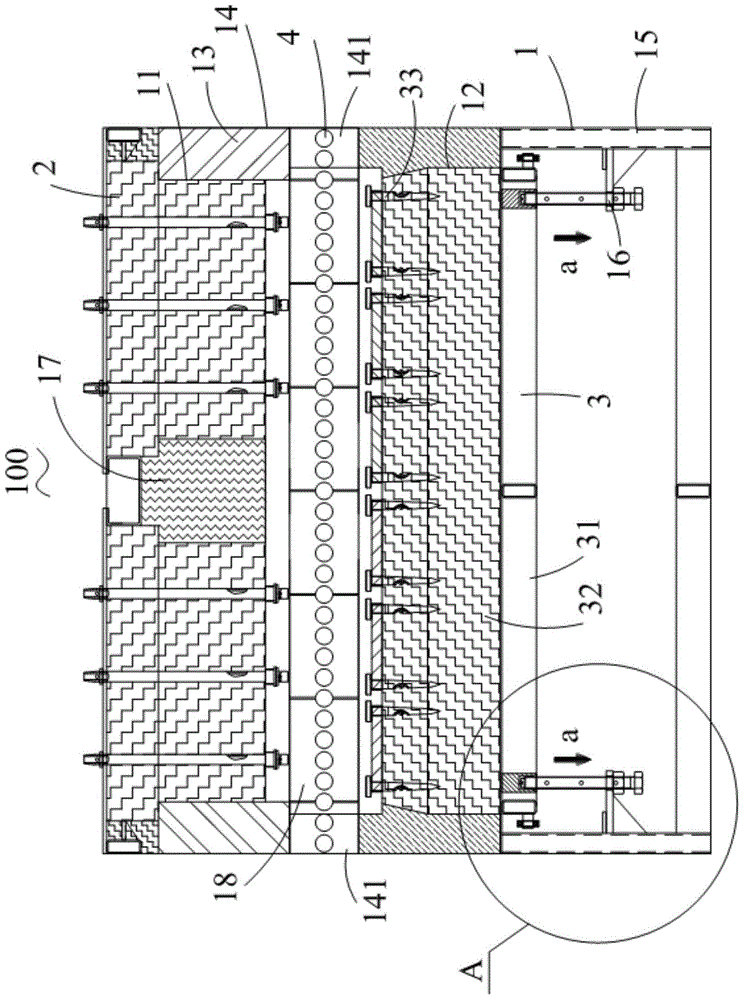

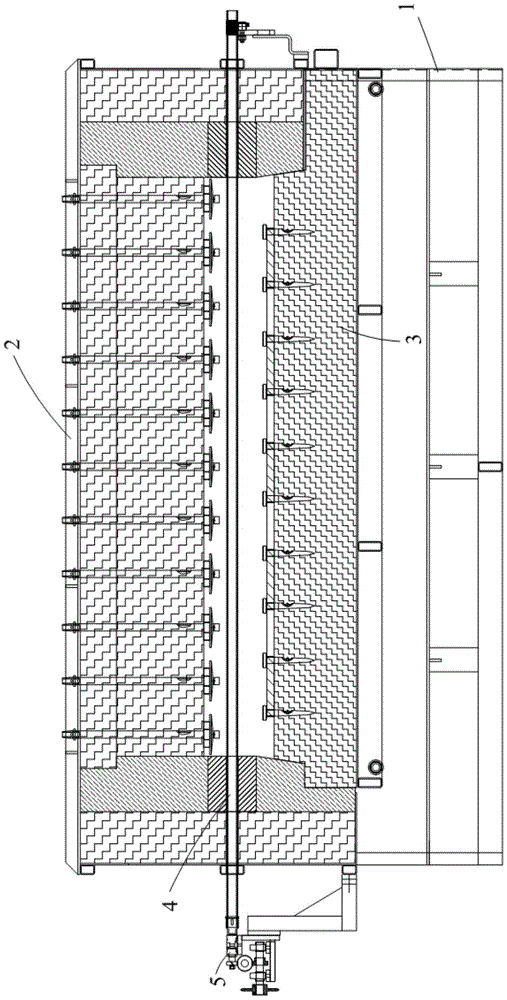

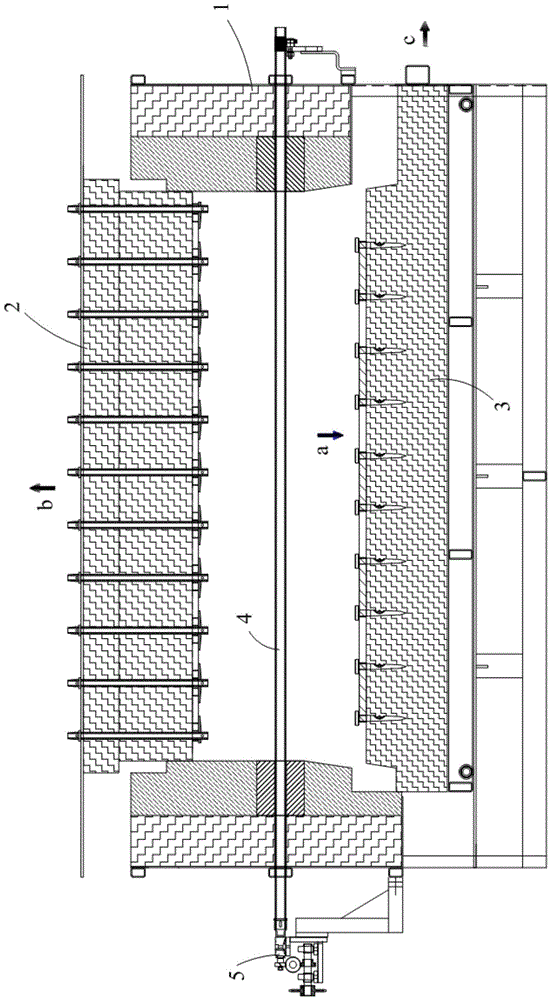

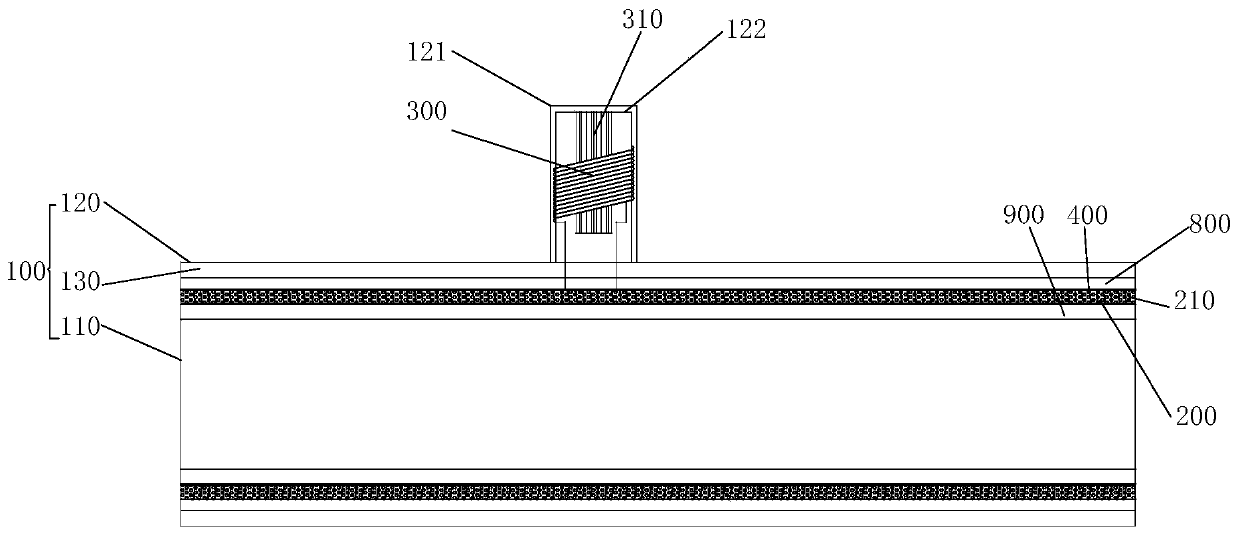

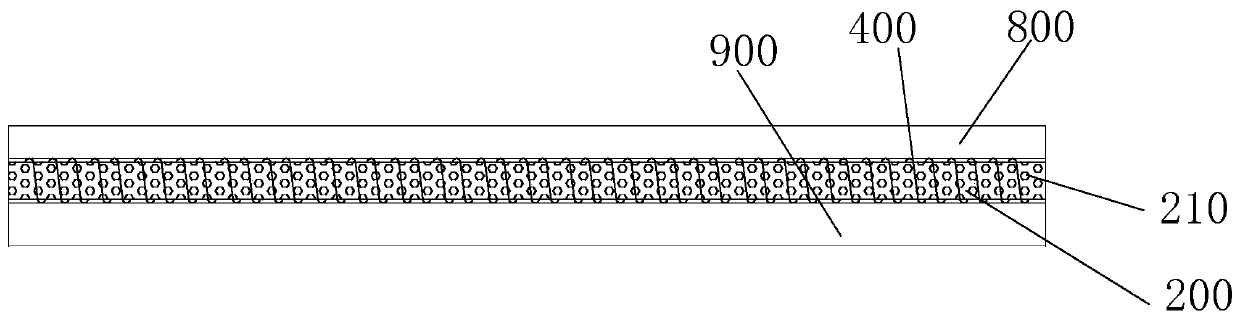

The invention discloses a spherical flue element equivalent model thermotechnical waterpower experimental apparatus comprising a pressure-bearing component, an electric heating component, an insulation component, a seal component, a pressure measurement component and the like, and field assembly and disassembly can be realized between the components. According to the spherical flue element equivalent model thermotechnical waterpower experimental apparatus, a banded fin thin rod bundle electric element is taken as an equivalent model structure of the spherical flue element, electrical heating method is realized, single-phase water flow and heat transfer experiment can be developed, and thermal-hydraulics of the spherical flue element can be reflected. The pressure measurement component can be assembled and disassembled on spot, consumables such as an O-shaped seal ring and a lead pressure pipe are convenient to replace, thereby reducing loss and cost. A grid spacer plays a role in transverse orientation for the banded fin thin rod bundle electric element, and a single-cone structure of the grid spacer can guide a plurality of the banded fin thin rod bundles to assemble, thereby reducing the difficulty of assembling and improving the efficiency of assembling. Copper braid is adopted to connect a lower conducting element and a lower conductive contact to realize flexible connection, so that the problem caused by electric component thermal expansion is effectively solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

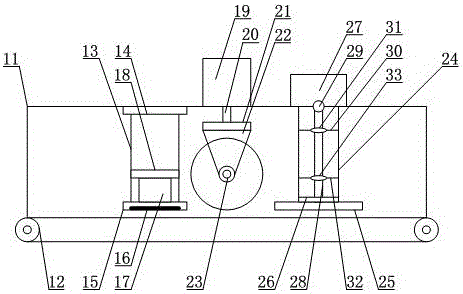

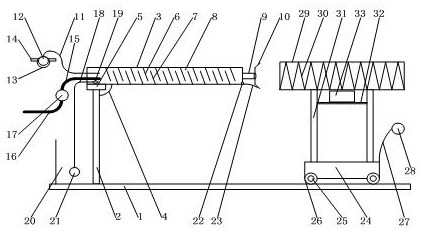

Hollow aluminum bar bending forming pneumatic device

InactiveCN106623517AImprove the efficiency of molding operationsRealize electric heatingShaping toolsMetal-working feeding devicesEngineeringElectric heating

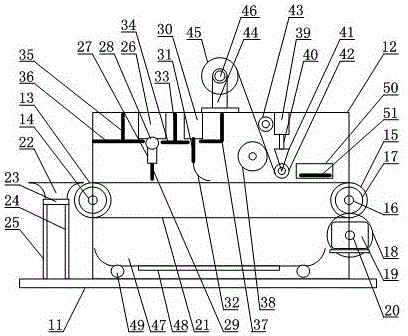

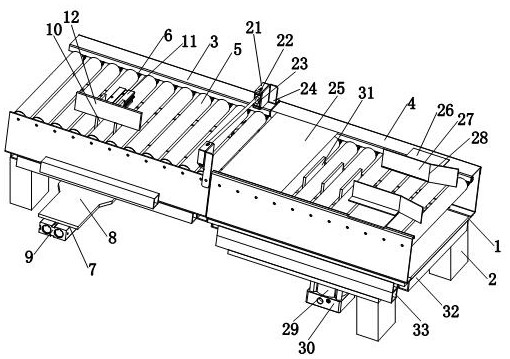

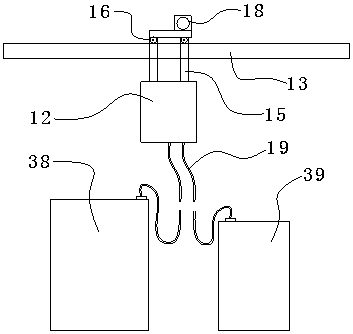

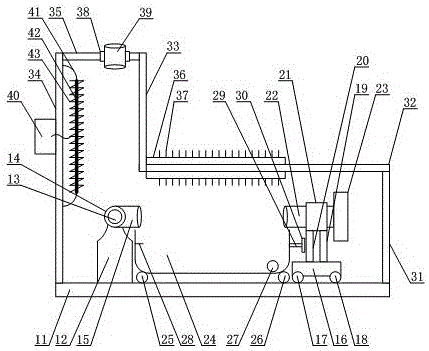

The invention discloses a hollow aluminum bar bending forming pneumatic device. The hollow aluminum bar bending forming pneumatic device comprises a base plate, wherein a side plate is arranged on the base plate, a carrying plate and a limiting plate are arranged at the position, inward facing surface, of the side plate, magnetic suction plates are arranged on the carrying plate, a magnetic suction piece is arranged between the limiting plate and the carrying plate, an air cylinder is arranged on the base plate, a telescopic shaft is arranged at the upper part of the air cylinder, the lower end of the telescopic shaft is connected with the upper part of the air cylinder, a forming head is arranged at the upper end of the telescopic shaft, and the forming head is arranged between the magnetic suction plates; a mounting plate and a supporting plate are arranged on the base plate, a carrying plate and an electric heating plate are arranged between the mounting plate and the end part of the supporting plate, a temperature controller is arranged on the carrying plate, and the temperature controller is electrically connected with the electric heating plate. The hollow aluminum bar bending forming pneumatic device disclosed by the invention has the advantages that the two ends of a hollow aluminum bar can be firmly mounted, heating treatment also can be carried out on the hollow aluminum bar, the air cylinder can carry out expansion control on the forming head through the telescopic shaft, bending forming can be carried out on the middle part of the hollow aluminum bar by virtue of the forming head, and the forming operation efficiency on the hollow aluminum bar is greatly improved.

Owner:广东易享家科技有限公司

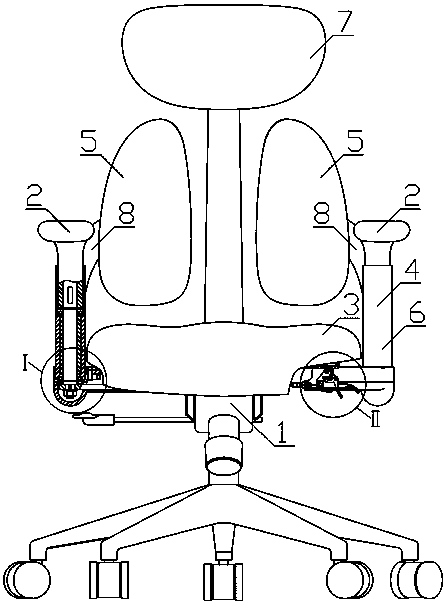

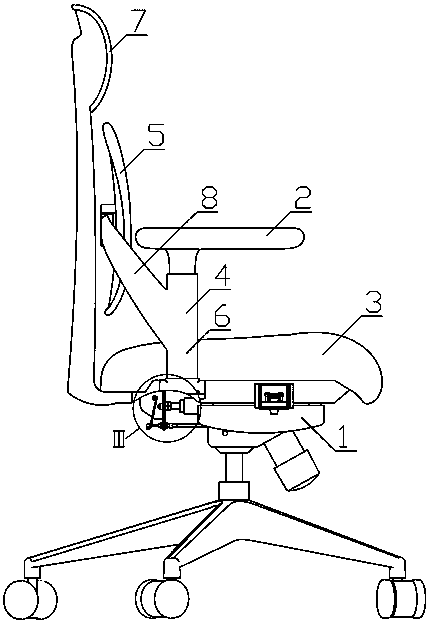

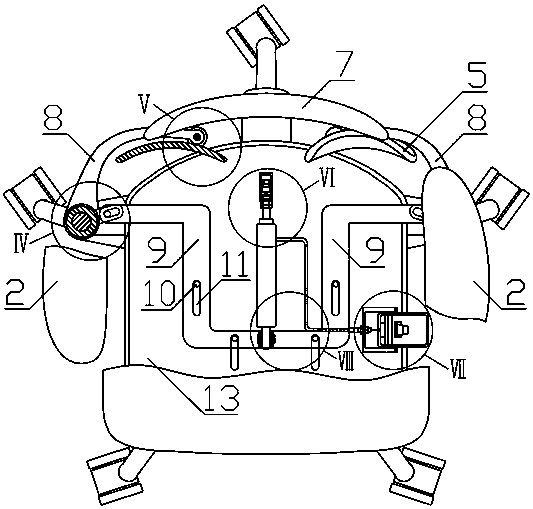

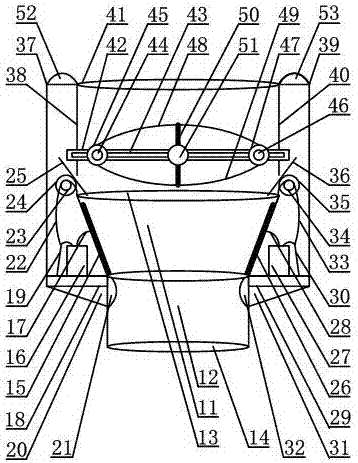

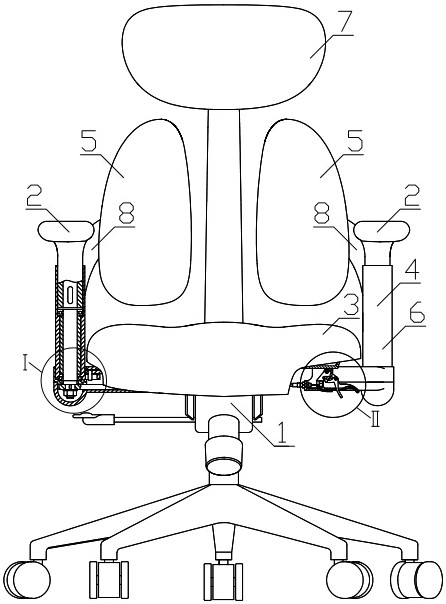

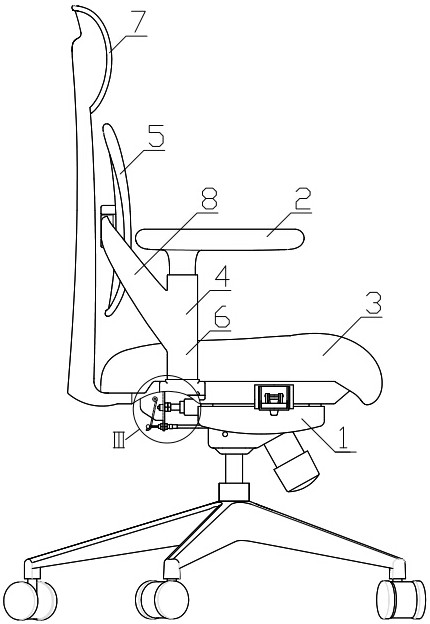

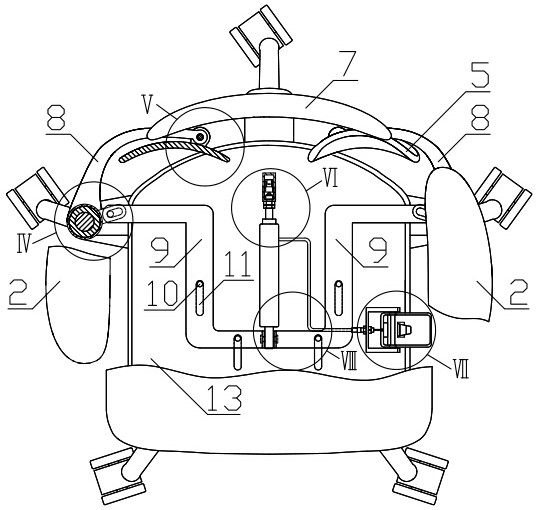

Lumbar support seat

The invention relates to the field of design and manufacture of seats, in particular to a lumbar support seat. The lumbar support seat is characterized by comprising a lumbar support and a gas spring,wherein the lumbar support realizes a close fit with a waist and a back of a human body during the movement of the waist and the back through the expansion and the contraction of the gas spring so asto provide continuous uniform force. The invention aims to overcome the defects in the prior art and provides the lumbar support seat. When a user moves back and forth on the seat, the lumbar supportcan be in close fit with the waist and the back of the human body to do synchronous movement and is in real-time fit with the waist, so that the supporting force to the waist position of the human body is increased.

Owner:ANJI SHENGXIN OFFICE FURNITURE

Injection molding machine hopper preheating device

InactiveCN107310102AControlled electric heat treatmentControl the first electric heating plate to realize electric heating treatmentEngineeringInjection molding machine

The invention discloses an injection molding machine hopper preheating device which comprises a guide bin. The lower portion of the guide bin is provided with a discharge bin. The end of the guide bin is provided with a feeding opening. The lower end of the discharge bin is provided with a discharge opening. Inner side positions of the guide bin are provided with electric heating plates. Outer side positions of the discharge bin are provided with fixing plates. The fixing plates are provided with temperature controllers. The temperature controllers are connected with the electric heating plates through cables. The fixing plates are provided with side frames. The inner sides of the side frames are provided with limiting plates. A butt connection ring is arranged between the tops of the limiting plates. A guide shell is arranged between the limiting plates. An inserting plate is inserted and connected to the side position of the guide shell. Outer sides of the inserting plate are provided with pull shafts. Pull pipes are arranged on the outer circumferential faces of the pull shafts. An operation pipe is arranged between the upper portions of the pull pipes. A butt connection pipe is arranged between the middles of the operation pipes. A pull wheel is arranged in the middle of the butt connection pipe. The interior of the guide bin can be controlled to be electrically heated, plastic granules can be poured into the guide bin, and the plastic granules can be electrically heated.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

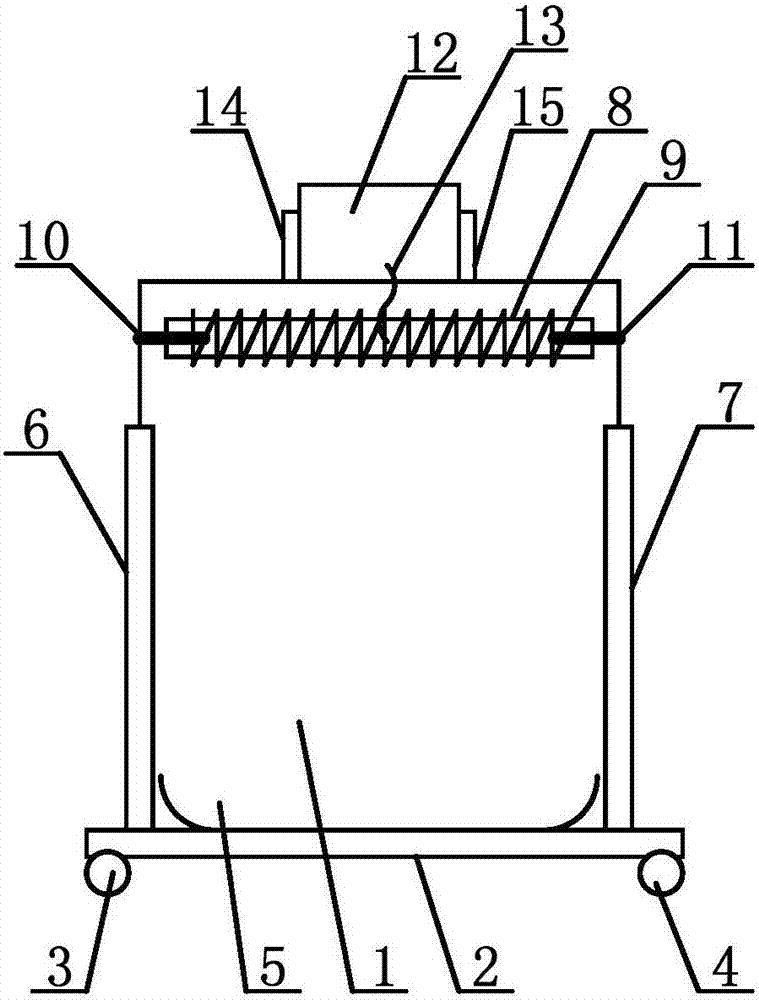

Hemorrhoid postoperative recovery nursing machine

ActiveCN112870057ARealize electric heatingPain reliefDevices for pressing relfex pointsMedical devicesPostoperative recoveryHemorrhoids

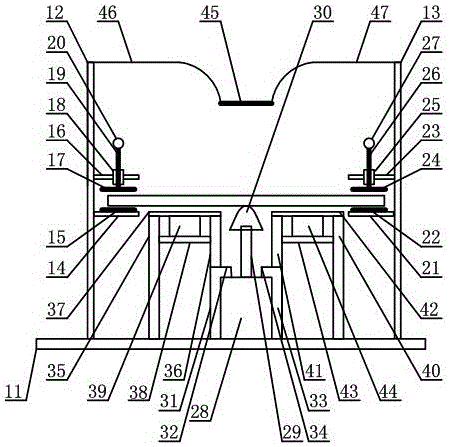

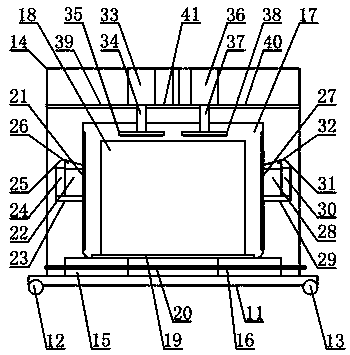

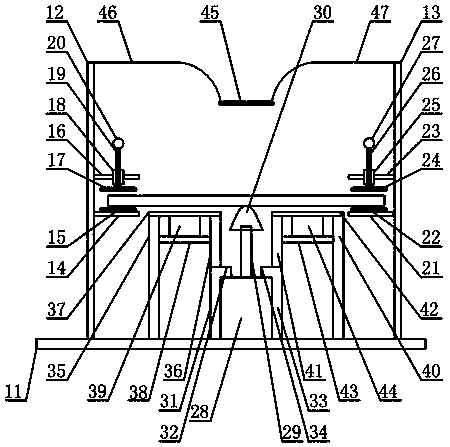

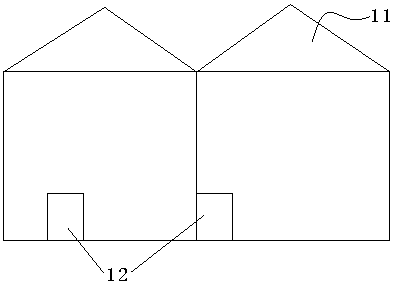

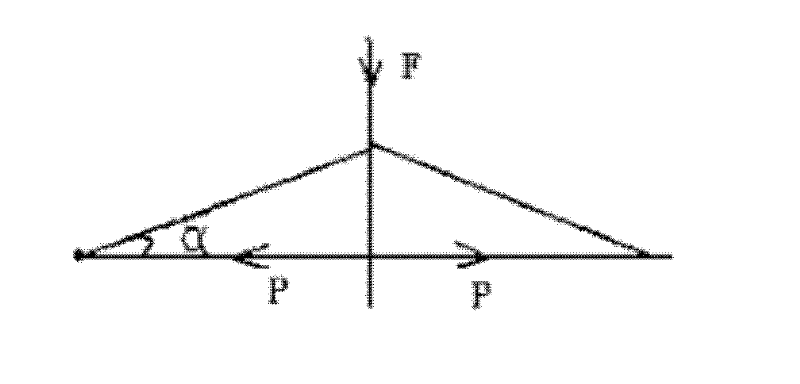

The invention discloses a hemorrhoid postoperative recovery nursing machine, which comprises a machine body, a working space with an upward opening is formed in the machine body, a transmission space is arranged on the lower side wall of the working space in a communicating mode, and a supporting device for supporting a patient is arranged on the lower side wall of the working space; the supporting device comprises two supporting mechanisms which are arranged in the working space in a bilateral symmetry mode, and connecting rod grooves are formed in the left side wall and the right side wall of the working space in a communicating mode respectively. The applicability of the machine is improved, the Changqiang acupoint is massaged, a patient feels comfortable, the patient is helped to recover quickly, medicine is sprayed to the wound during massage, the massage part and the periphery are in a relaxed state during massage, medicine absorption is facilitated, and the effect of the medicine can be exerted to a greater extent.

Owner:QINGDAO CITY CHENGYANG DISTRICT PEOPLES HOSPITAL

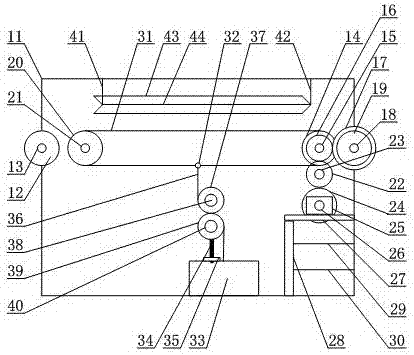

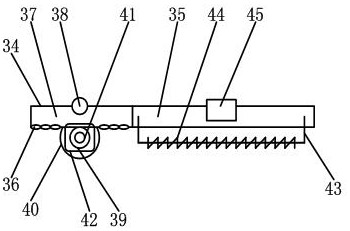

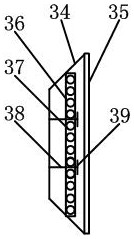

Gluing preparation device of aluminum alloy strip brush

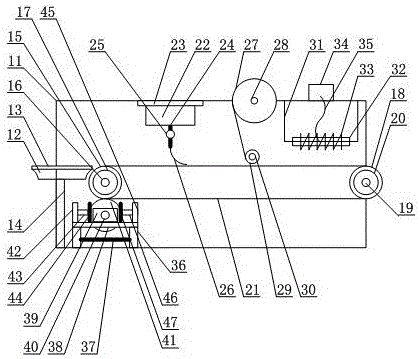

The invention discloses a gluing preparation device of an aluminum alloy strip brush. The gluing preparation device comprises a bottom plate, wherein the bottom plate is provided with a rack; a driven roller is arranged on one side of the rack; a driving roller is arranged on the other side of the rack; a driving wheel is arranged at the outer end of the driving roller; a drive wheel is arranged on the rack; a drive motor is arranged on the rack; a drive shaft is arranged at the front part of the drive motor; the drive wheel sleeves the peripheral surface of the drive shaft; the drive wheel is engaged with the driving wheel; a conveyor belt is arranged between the driven roller and the driving roller; a glue conveying machine is arranged at the top in the rack; a supporting frame is arranged at the end part of the rack; an unreeling wheel is arranged at the end part of the supporting frame; an electric heating box is arranged on the rack; an electric heating plate is arranged in the electric heating box; and the electric heating box is arranged above the conveyor belt. According to the gluing preparation device, the strip brush and an aluminum alloy plate can be firmly compounded through a glue layer, and the aluminum alloy strip brush can be rapidly manufactured.

Owner:ANHUI XIN FA ALUMINUM PROD

Anti-abrasion rubber sheet and soft magnetic stripe compound device

The invention discloses an anti-abrasion rubber sheet and soft magnetic stripe compound device. The device comprises a machine frame; the side wall of the machine frame is provided with an object stage; a conveying table is arranged on the object stage; the machine frame is provided with a driving wheel and a driven wheel, and the driving wheel is connected with the driven wheel through a conveying belt; the inner top of the machine frame is provided with a rubber conveyor; a ceiling board is arranged between the rubber conveyor and the machine frame; the lower portion of the rubber conveyor is provided with a rubber conveying pipeline; the lower portion of the rubber conveying pipeline is provided with a liquid conveying slice; the liquid conveying slice communicates with the rubber conveying pipeline; the lower portion of the liquid conveying slice is provided with a hole; the end of the machine frame is provided with an unwinding wheel, a traction wheel is arranged on the machine frame, and the unwinding wheel corresponds to the traction wheel; the end of the machine frame is provided with an installation frame, the installation frame is provided with an electric heating pipe, the outer surface of the electric heating pipe is provided with heating wires, the end of the machine frame is provided with a temperature controller, and the temperature controller is connected with the electric heating pipe through an electric wire; and the electric heating pipe is arranged above the conveying belt. Through the anti-abrasion rubber sheet and soft magnetic stripe compound device, a soft magnetic stripe and an anti-abrasion rubber sheet can be compounded conveniently.

Owner:SUZHOU XINHANG MICROELECTRONICS

Electric heating device for processing metal winding gasket

InactiveCN107354275AConvenient electric heat treatmentEasy to fixFurnace typesHeat treatment furnacesElectricityMetal

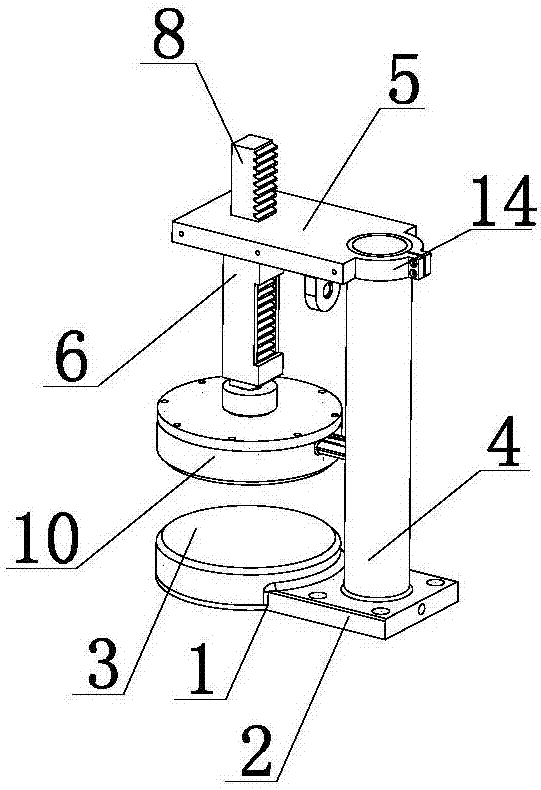

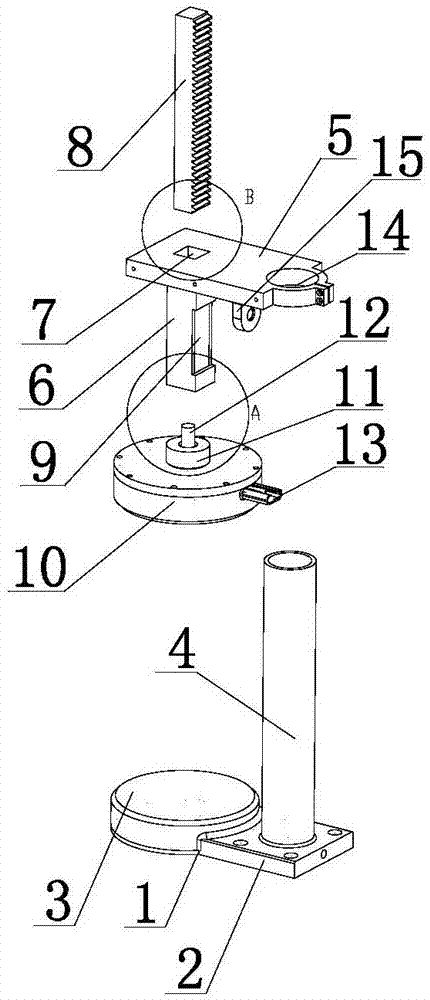

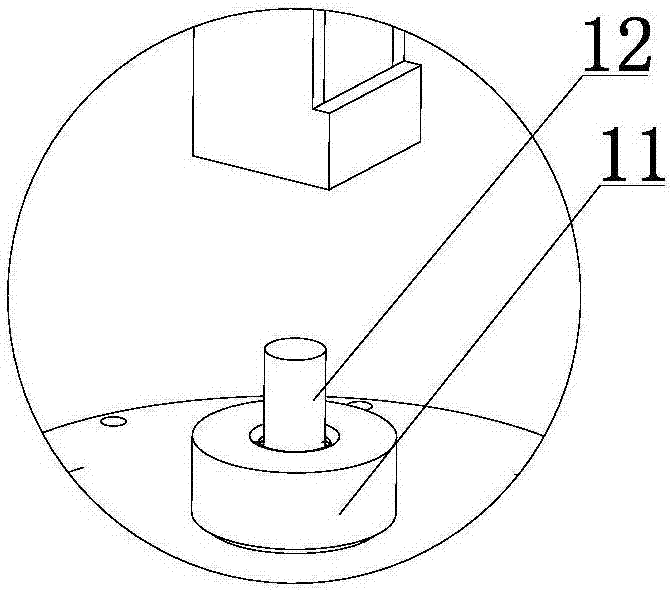

The invention discloses an electric heating device for processing a metal winding gasket. The electric heating device for processing the metal winding gasket comprises a supporting mechanism; the supporting mechanism comprises a fixing plate, the side portion of the fixing plate is provided with an electric heating mechanism; a supporting pipe is arranged on the fixing plate, a guide plate is arranged at the end of the supporting pipe, a guide shell is arranged on the front portion of the guide plate, and the vertical position of the guide shell is of a tapping structure; a guide trough is formed in the front portion of the guide plate, the guide trough communicates with the vertical position of the guide shell, a rack is arranged in the guide shell, the upper end of the rack is a free end, a pressing seat is arranged at the lower end of the rack, and the pressing seat is arranged above the electric heating mechanism; and the electric heating mechanism comprises a bottom shell, a cover plate is arranged at the top of the bottom shell, an electric heating pipe is arranged in the bottom shell, and electrical connecting ends are arranged at the two ends of the electric heating pipe correspondingly. According to the electric heating device for processing the metal winding gasket, the pressing seat can apply pressure on the metal winding gasket, the electric heating pipe is externally connected with a power supply through the electric connecting ends, so that electric heating of the electric heating pipe can be achieved, and the metal winding gasket can be conveniently subjected to electric heating treatment.

Owner:刘路清

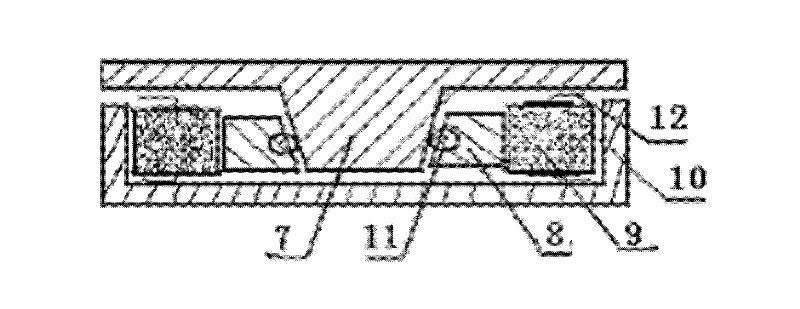

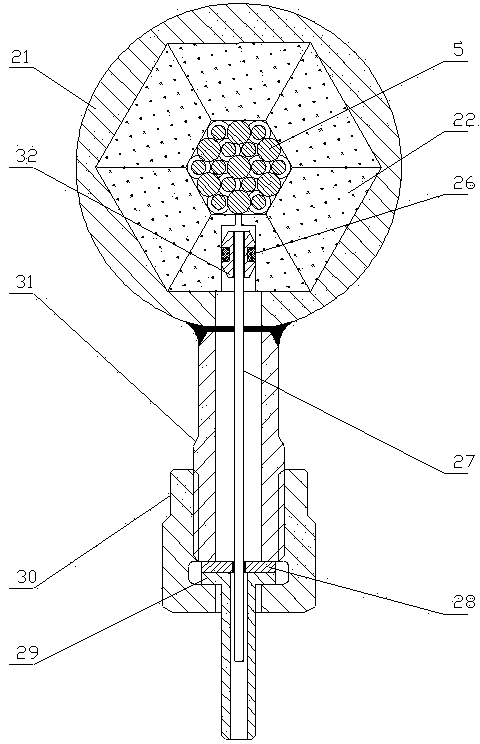

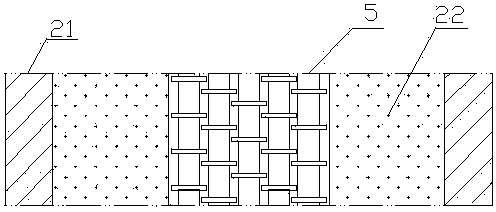

Wireless heating power module and wireless heating method of superconduction cable heat-isolation tube

ActiveCN108207045AHigh vacuum lifeRealize electric heatingInduction heating apparatusEngineeringHeating power

The invention provides a wireless heating power module and wireless heating method of a superconduction cable heat-isolation tube. The superconduction cable heat-isolation tube comprises an inner tubeand an outer tube, wherein the outer tube sleeves the inner tube, a vacuum sandwiched layer is arranged between the inner tube and the outer tube, an absorption layer is arranged in the vacuum sandwiched layer, an absorption piece is arranged in the absorption layer and is heated and simulated, a protruding cavity is formed in the outer tube and protrudes outwards, and the protruding cavity communicates with the vacuum sandwiched layer. The wireless heating power module comprises a secondary coil, a heating component and a magnetic conduction sleeve, wherein the secondary coil is arranged inthe protruding cavity, the heating component is arranged in the absorption layer or outside the absorption layer and is connected with the secondary coil, the magnetic conduction sleeve is used for sleeving the protruding cavity, a primary coil is arranged in the magnetic conduction sleeve and is corresponding to the secondary coil, and the primary coil is connected with a power supply. With the adoption of a wireless connection mode, electrical heating of the heating component is achieved, the superconduction cable heat-isolation tube is not needed to be disassembled or broken, on-line simulation of the absorption piece can be achieved, the vacuum lifetime of the superconduction cable heat-isolation tube is prolonged, and the maintenance process is simplified.

Owner:SHANGHAI INT SUPERCONDUCTION TECH CO LTD

Laser paper thermal-drying device used for laser printing

InactiveCN107571620AEasy to storeConvenient heat treatmentPrinting press partsElectricityPulp and paper industry

The invention discloses a laser paper thermal-drying device used for laser printing. The laser paper thermal-drying device comprises a drying box arranged on a bottom board. The inner bottom of the drying box is provided with a paper storage plate. One side of the drying box is provided with a first side door and the other side of the drying box is equipped with a second side door. The inner top of the drying box is provided with an electric heating pipe, the outer surface of which is provided with an electric-heating wire. One end of the electric heating pipe is equipped with a first installation shaft in a sleeving manner. The first installation shaft is arranged on the inner side wall of the drying box. The other end of the electric heating pipe is provided with a second installing shaft in a sleeving manner. The second installing shaft is arranged on the other inner side wall of the drying box. The end part of the drying box is equipped with a temperature controller which is electrically connected with the electric-heating pipe. The temperature controller is connected with the electric-heating pipe through a connecting wire. Through the paper storage plate, laser paper used forlaser printing can be conveniently stored. Through the temperature controller, the electric heating pipe can be controlled to achieve electric heating. As a result, laser paper used for laser printing can be conveniently subjected to heating operation.

Owner:天津市江源塑胶制品有限公司

a lumbar seat

ActiveCN108056613BTimely supportUniform and long-lasting supportStoolsChairsHuman bodyPhysical medicine and rehabilitation

The invention relates to the field of seat design and manufacture, in particular to a lumbar support seat. The present invention is achieved through the following technical solutions: a lumbar support seat, including a lumbar support and an air spring, and the lumbar support can be close to the human body's lumbar back when the lumbar back moves through the expansion and contraction of the gas spring so that Provides consistent and even support. The purpose of the present invention is to overcome the deficiencies of the prior art and provide a lumbar support seat. When the user moves back and forth on the seat, the lumbar support can move synchronously against the lower back of the human body, fit the waist in real time, and increase the support for the waist position of the human body.

Owner:ANJI SHENGXIN OFFICE FURNITURE

A heat treatment device for aluminum foil tape

InactiveCN106591748BEasy to installEasy to rewindFurnace typesHeat treatment furnacesAdhesiveAluminum foil

The invention discloses an aluminum foil adhesive tape heat treatment device. The aluminum foil adhesive tape heat treatment device comprises a frame; an unwinding wheel is arranged on the frame; a driven wheel is arranged on one side of the frame; the unwinding wheel corresponds to the driven wheel; a driving wheel and a second auxiliary wheel are arranged on the other side of the frame; the driving wheel is engaged with the second auxiliary wheel; a first auxiliary wheel is arranged between the driving wheel and a second mounting shaft; a winding wheel is arranged between the second auxiliary wheel and a third mounting shaft; a transmission wheel is arranged on the frame, and is mounted on the frame through a fifth mounting shaft; a side plate is arranged on the frame; a metal transmission belt is arranged between the driven wheel and the driving wheel; a metal heating chip is arranged in the metal transmission belt; a metal ring is arranged on the side wall of the metal transmission belt, and is electrically connected with the metal heating chip; a temperature controller is arranged at the bottom in the frame; and the temperature controller is connected with the metal ring through a connecting wire. The aluminum foil adhesive tape heat treatment device can heat an aluminum foil adhesive tape through the metal transmission belt so as to greatly improve the heat treatment efficiency of the aluminum foil adhesive tape.

Owner:苏州久巨电子有限公司

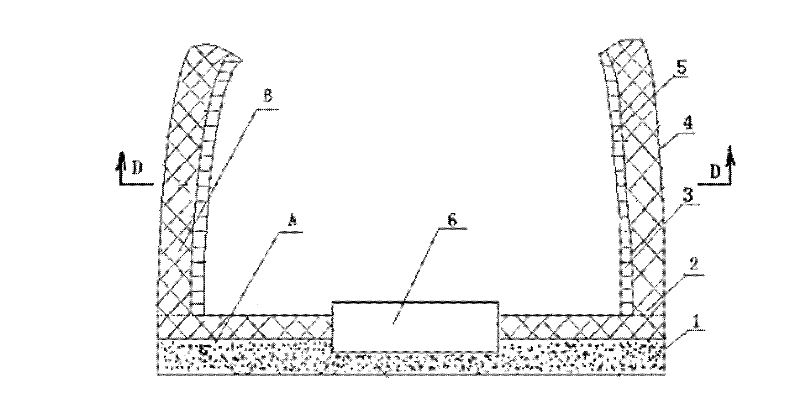

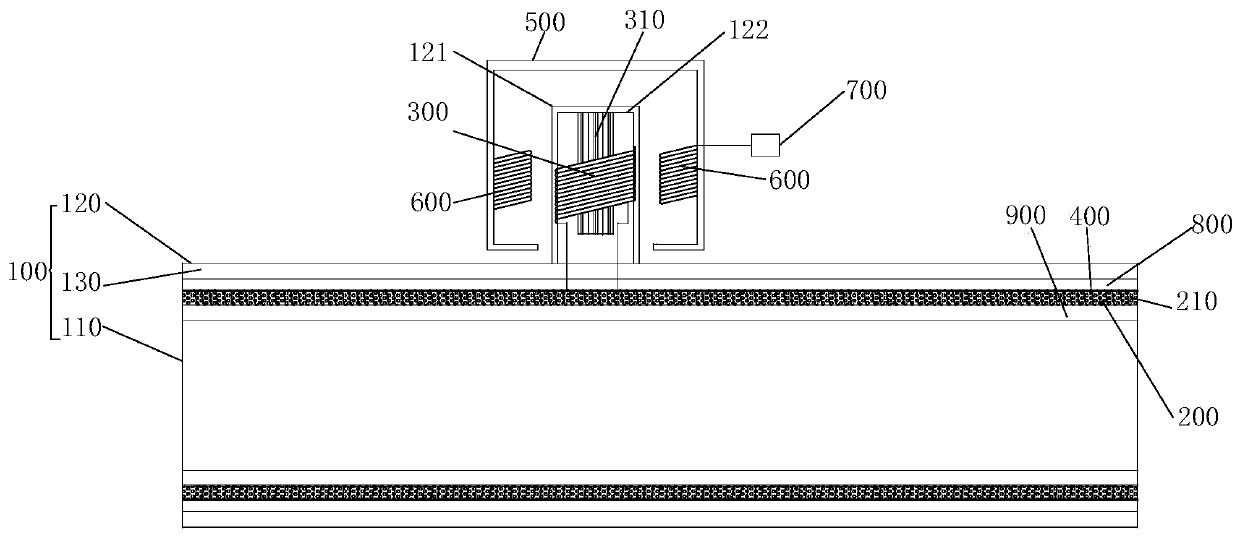

Ground heat preservation and sound insulation board with heating function

PendingCN112878618ARealize electric heatingGuaranteed heating needsHeating fuelLighting and heating apparatusElectrical batteryHeat conservation

The invention discloses a ground heat preservation and sound insulation board with a heating function, and relates to the technical field of buildings. The ground heat preservation and sound insulation board comprises a board body, wherein the board body comprises a top board, a base board and a bottom board, a groove is formed in the top board, a panel is connected to the interior of the groove in a sliding mode, a battery is fixedly installed in the panel, a conducting rod is installed at the bottom of the panel, a spring is fixedly connected between the bottom of the panel and the groove and sleeves the conducting rod, and a through hole is formed in the bottom of the top plate; two vertical plates are fixedly installed in the base plate, the interior of the base plate is divided into a first cavity, a second cavity and a third cavity by the two vertical plates, an electric heating tube is fixedly installed in the second cavity and is electrically connected with a connector, and the connector is fixedly installed on the outer top of the base plate; and the bottom plate and the base plate are bonded through liquid glue, and the base plate and the top plate are bonded through liquid glue. According to the ground heat preservation and sound insulation board, the problems of low heating speed, high power consumption and poor heat transfer effect across the floor when an electric heating film is used for heating in the prior art are solved, the operation is easy and convenient, and the practicability is high.

Owner:合肥神舟建筑集团有限公司

A rubber layer stopper for book preparation

ActiveCN106904019BStable supportEasy to recycleBook making processesStops devicePulp and paper industry

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

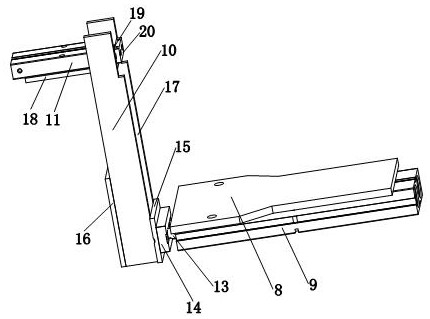

Rubber layer paper stop device for book preparation

ActiveCN106904019AStable supportEasy to recycleBook making processesStops devicePulp and paper industry

The invention discloses a rubber layer paper stop device for book preparation. The rubber layer paper stop device comprises a bottom plate. A rack is arranged on the bottom plate. A seat cushion is arranged on the inner bottom of the rack. A storage frame is arranged on the seat cushion. A rubber layer is arranged on the inner side of the back of the storage frame. An electric heat plate is arranged on one inner side of the storage frame. A temperature controller is arranged on one outer side of the storage frame and electrically connected with the electric heat plate. An air cylinder is arranged on the inner top of the rack. A telescopic shaft is arranged on the lower portion of the air cylinder. The upper end of the telescopic shaft is connected with the lower portion of the air cylinder. A lifting plate is arranged at the lower end of the telescopic shaft and arranged above the storage frame. By the adoption of the rubber layer paper stop device for book preparation, paper can be stopped by the rubber layer, the impact force of the paper on the inner side of the back of the storage frame can be reduced, the paper in the storage frame can be pressed through the lifting plate, and thus paper in the storage frame can be prevented from being blown away.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

Printing machine environmental protection plate positioning roller machine

ActiveCN110356106BImprove dust removal efficiencyPlay the role of air coolingArticle feedersPrinting press partsGear wheelDust control

The invention discloses a printing machine environment-friendly board positioning roller machine, comprising a conveying bed, on which a front conveying chamber and a rear conveying chamber arranged side by side are arranged, and a row of parallel conveying chambers is installed on the inner bottom of the front conveying chamber and the rear conveying chamber Conveying roller, the outer end of the conveying roller is provided with a rotating gear, and the driving chain is set between the rotating gears; the side of the conveying bed is provided with a driving motor, and the driving motor is connected with the outer end of the conveying roller; the front conveying warehouse and the rear conveying There are positioning shells on both sides of the connection position between the bins, electric heating tubes are set between the top of the positioning shells, and a main temperature controller is set on the side of the conveying bed. The main temperature controller and the electric heating tube are electric Connected, the top of the rear delivery bin is equipped with a blowing electric heating mechanism. The present invention greatly improves the efficiency of dedusting the environmental board of the printing machine, and at the same time plays the role of blowing and cooling the environmental board of the printing machine; greatly improves the efficiency of dedusting the environmental board of the printing machine; the effect of preheating is better .

Owner:温州崇坤印业有限公司

Powder processing convex block setting machine disk

The invention discloses a powder processing convex block setting machine disk. The disk comprises a disk body, wherein convex columns are arranged on the inward face of the disk body, a heat dissipation groove is formed in the center of the disk body, a plurality of processing grooves are formed in the outward face of the disk body, the cross section of each processing groove is in the shape of inverted T, the convex columns are connected with an electric coil, an electric ring is connected with the electric coil, the cross section of the electric coil is of an annular structure, the electric coil is provided with a plurality of electric heating wire holes, the disk body is arranged on a machine case, the machine case is of a hollow structure, vent holes are formed in the machine case, and the vent holes are communicated with the hollow structure; the convex columns and the electric coil are arranged in the machine case, open holes are formed in the machine case, the convex columns are inserted in the open holes, the machine case is provided with a case plate, bottom legs are arranged at the bottom of the machine case, and sliding grooves are formed in the bottom legs; the machine case is provided with a lock piece, and the lock piece is connected with the disk body. According to the powder processing convex block setting machine disk, electric heating can be achieved, and convex powder blocks and bars can be machined and set.

Owner:NANTONG YA TAI CANDLE ARTS & CRAFTS

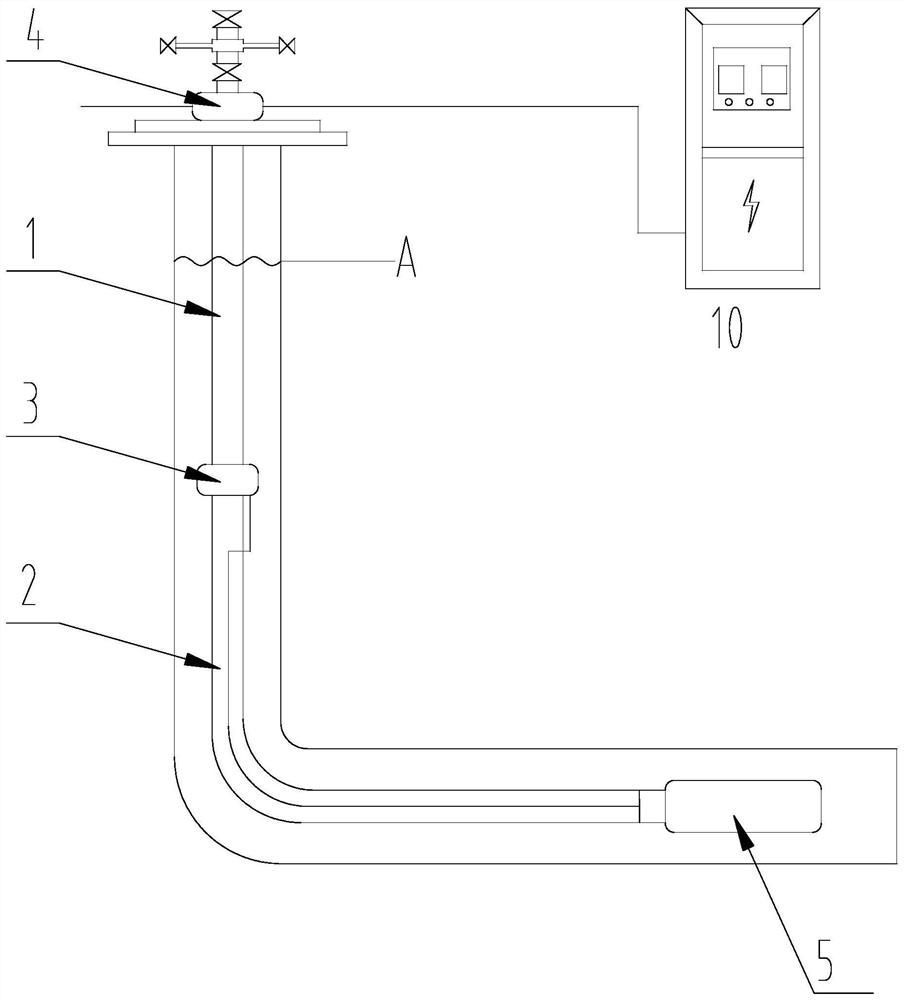

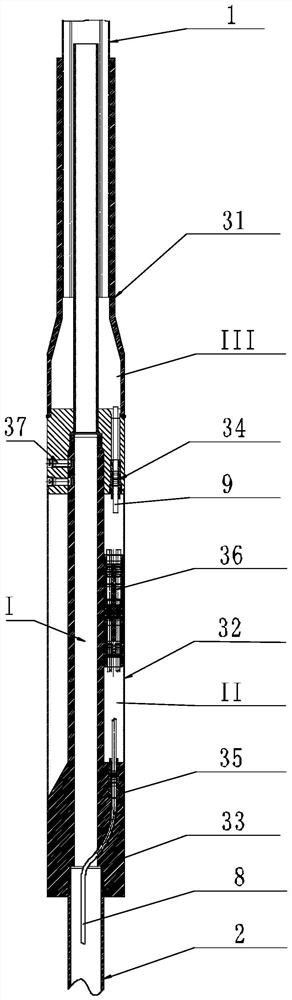

Oil extraction system adopting combined pipe column as oil extraction pipe

PendingCN114000833ARealize no fear of high temperatureOvercome aloneDrilling rodsDrilling casingsThermodynamicsPower cable

The invention discloses an oil extraction system adopting a combined pipe column as an oil extraction pipe. The oil extraction system comprises a composite material continuous pipe and a metal oil pipe, the upper end of the composite material continuous pipe is connected with a ground connector, the lower end of the composite material continuous pipe is fixedly connected with the upper end of the metal oil pipe through an underground connector, and the lower end of the metal oil pipe is connected with an electric submersible pump; and the underground connector connects the composite material continuous pipe with the metal oil pipe to form the combined pipe column, and connects a power cable led out from the lower end of the composite material continuous pipe with a submersible cable led out from the upper end of the metal oil pipe. The electric submersible pump and the combined pipe column can be used in cooperation to achieve rodless oil extraction, and therefore the defects that a metal oil pipe or a composite material continuous pipe is independently used in cooperation with the electric submersible pump can be overcome; and meanwhile, the advantages that electric heating is achieved through the composite material continuous pipe located on the upper portion and the metal oil pipe located on the lower portion is not fear of high temperature can be utilized, and the rodless oil extraction technology leaps.

Owner:SHANGHAI FB OIL EQUIP TECH

A hollow aluminum bar bending forming pneumatic device

InactiveCN106623517BImprove the efficiency of molding operationsRealize electric heatingShaping toolsMetal-working feeding devicesEngineeringElectric heating

Owner:广东易享家科技有限公司

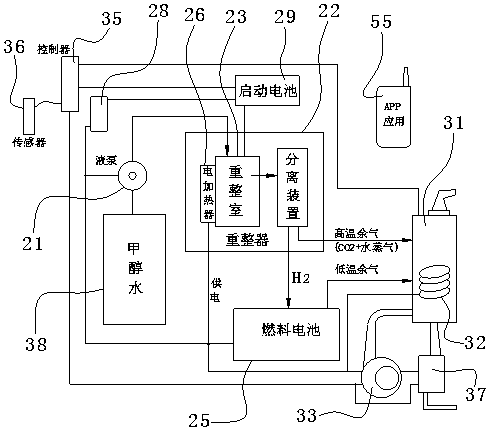

Temperature and humidity regulation system for vegetable greenhouse

PendingCN108338030ARaise the temperature in the shedIncrease humidityClimate change adaptationSaving energy measuresMethanol waterHydrogen

The invention discloses a temperature and humidity regulation system for a vegetable greenhouse. The temperature and humidity regulation system comprises a plurality of temperature and humidity regulating machines which are scattered and arranged or slidably mounted on a greenhouse frame, and each humidity regulating machine comprises a liquid pump for sucking a methanol water material, a reformerfor heating, gasifying and separating the methanol water material, a fuel cell for receiving and separating hydrogen gas, outputting battery residual gas and generating electric power, a gas mixing blower for receiving separated residual gas and the battery residual gas, a fan for injecting external gas to the gas mixing blower, a controller separately and electrically connected with the air mixing blower, the fan and an atomizer, and a temperature and humidity sensor connected with the controller. Each temperature and humidity regulating machine is individual and can be freely scattered andarranged according to the requirements, so that the environmental temperature and humidity of the greenhouse can be regulated safely in an energy saving mode; stepless speed regulation can be realizedin a regulation process, and the temperature and humidity regulating machines can slide on the rails back and forth, so that the heating of the space of the greenhouse area is more uniform, and the reciprocating sliding does not need external power supply.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

Indentation wheel device for rock wool insulation board

InactiveCN106738377AEasy transferEasy to form grooves and indentationsWorking accessoriesStone-like material working toolsElectricityCooling down

The invention discloses an indentation wheel device for a rock wool insulation board. The indentation wheel device comprises a rack, wherein a belt conveyor is arranged at the bottom of the rack; a heater case is arranged on the rack; an electric hot plate is arranged at the inner bottom of the heater case; a temperature controller is arranged at the top of the heater case and electrically connected with the electric hot plate; a cylinder is arranged at the top of the rack; a piston rod is arranged at the lower part of the cylinder; the upper end of the piston rod is connected with the lower part of the cylinder; a fixing support is arranged at the lower end of the piston rod; a lifting fine-tuning rack is arranged at the lower part of the fixing support; an indentation wheel mechanism is arranged at the lower part of the lifting fine-tuning rack; a cooling case is arranged on the rack; the interior of the cooling case is of a cavity structure; and a water conveyor is arranged at the top of the rack and connected with the cooling box through a water conveying pipe. According to the indentation wheel device, indentation control can be performed on two sides of the rock wool insulation board through indentation wheels; and the water conveyor can provide a cooling liquid for the cooling case through the water conveying pipe, and the indented rock wool insulation board can be cooled down through the cooling case, and grooved indentation can be conveniently performed on two sides of the rock wool insulation board.

Owner:安徽台利节能保温材料有限公司

Heat-generating and heat-preserving shoes

InactiveCN102150971BNot easy to damageRealize electric heatingPiezoelectric/electrostriction/magnetostriction machinesOhmic-resistance heating detailsFiberElectricity

The invention relates to a pair of heat-generating and heat-preserving shoes, a piezoelectric power generator is mounted on each sole, an upper heat-preserving layer is arranged in each upper, a heat-generating layer made of carbon fiber material is attached in each upper heat-preserving layer, and power cords are led out of two ends of each piezoelectric power generator and directly connected with two electrodes in carbon fiber in the heat-generating layer respectively. The piezoelectric effect of the piezoelectric power generators is utilized for converting pressure energy of vamps to the bottom parts of the shoes during alternate motion of double feet of a person in the vertical direction to electrical energy, thereby replacing the functions of a mechanical rotation structure and an ordinary electromagnetic power generator thereof, not only greatly reducing the thickness and the volume, but also eliminating the need of using a mechanical reset spring, and further thoroughly solving difficulty in walking and other adverse effects due to the presence of the reset spring. In addition, the carbon fiber which is similar to cloth material is used as an electro-thermal conversion material for replacing electric heating wires, thereby ensuring that any parts in the heat-preserving shoes which need heat can be electrically heated, and not affecting the comfort of the shoes.

Owner:SHAANXI UNIV OF SCI & TECH

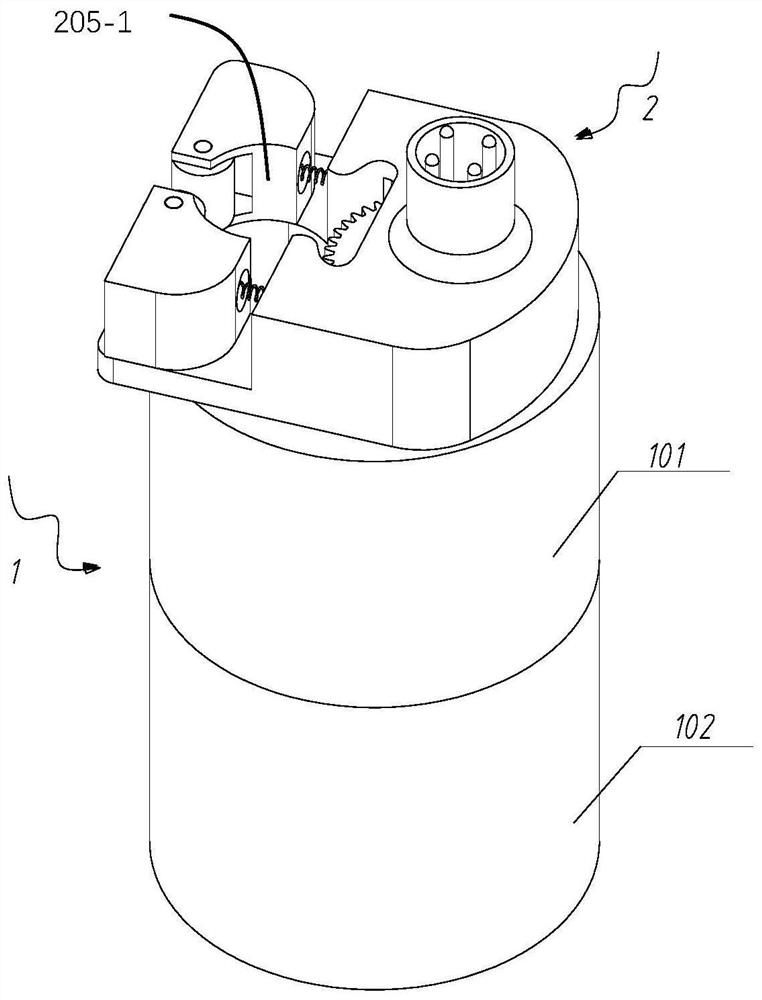

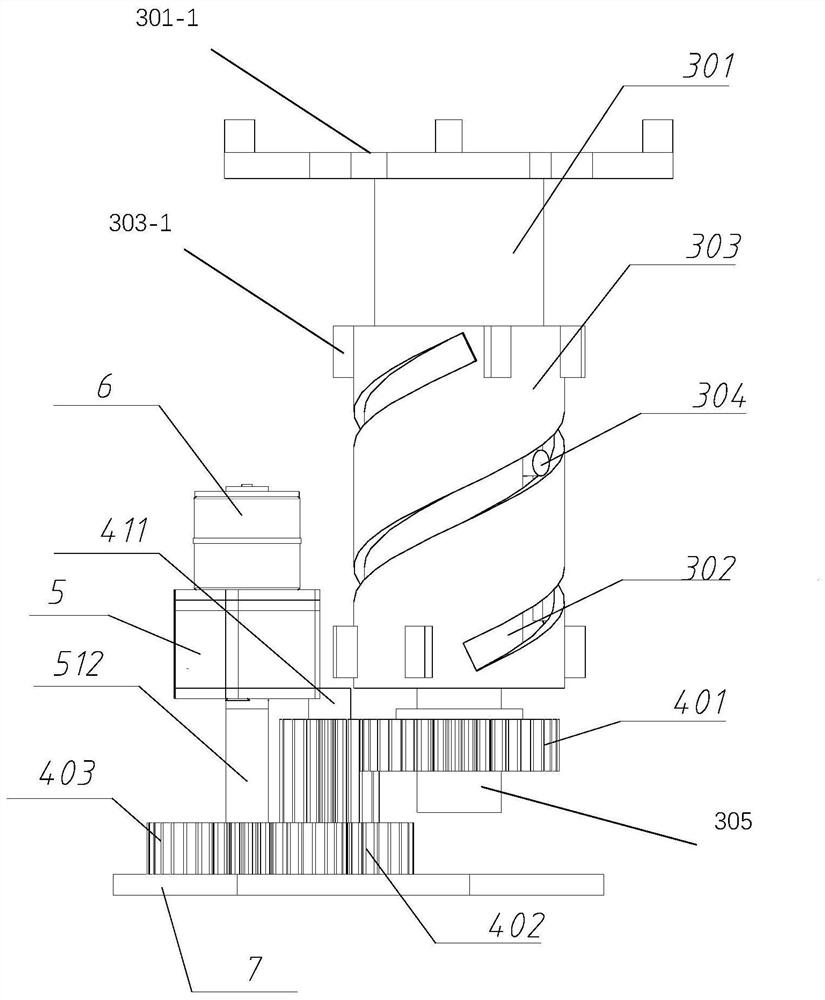

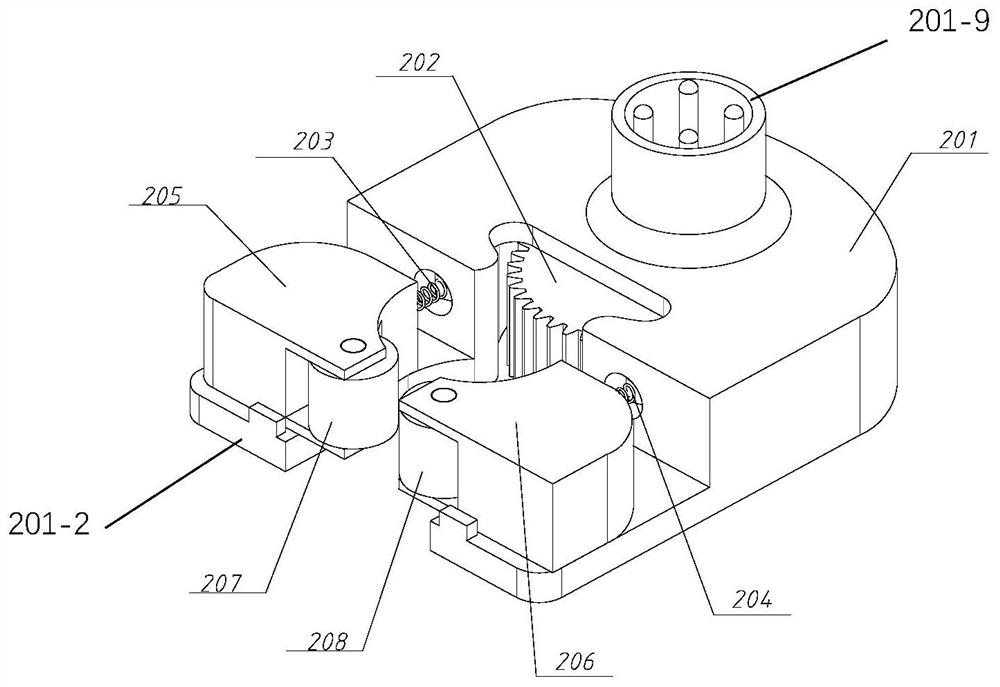

Multifunctional end effector for aerospace maintenance

The invention relates to a multifunctional end effector for aerospace maintenance, and solves technical problems that an effector capable of being mounted at a tail end of a soft mechanical arm is lacked at present, and maintenance can be performed aiming at a problem that a satellite solar panel cannot be unfolded or other faults cannot be performed. The multifunctional end effector comprises a cylindrical shell, a gripper mechanism, a lifting mechanism, a transmission wheel train, a reduction gear box, a lifting motor, a gripper motor and a bottom plate, and the gripper mechanism comprises a gripper base, a friction gear, a left memory alloy spring, a right memory alloy spring, a left gripper, a right gripper, a left rolling wheel and a right rolling wheel, wherein the lifting mechanism comprises an inner-layer sleeve, a middle-layer sleeve, an outer-layer sleeve, a driving shaft and a connecting shaft. According to the multifunctional end effector, a special connector for aerospace equipment can be effectively mounted and dismounted, and the special connector can be electrified and heated.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Cotton drying oven

PendingCN112240697ASmall footprintImprove space utilizationDrying chambers/containersDrying solid materialsElectric machineryDrive motor

The invention discloses a cotton drying oven which comprises a cotton drying oven body, a driving motor and a speed reducer. The left end and the right end of the inner side of the cotton drying ovenbody are both connected with limiting rollers through bearings, conveying wheels are connected to the upper portions of the limiting rollers through belts, and the conveying wheels are connected to the inner side of the cotton drying oven body through bearings; and a conveying mesh belt is arranged at the outer sides of the conveying wheels in an attached manner, the driving motor is fixed to therear left portion of the cotton drying oven body through bolts, the output end of the driving motor is connected with the rear ends of the limiting rollers, the speed reducer is fixed to the upper front side of the cotton drying oven body through bolts, and the output end of the speed reducer is connected with a worm through a belt. According to the cotton drying oven, the occupied area of the whole cotton drying oven is small, the space utilization rate is increased, an upper-layer heating pipe and a lower-layer heating pipe which are made of quartz tubes are directly used, electric heating of cotton is rapidly achieved, drying and shaping of the cotton are synchronously achieved through the low-power cotton drying oven, the processing technology is simplified, and the purposes of energyconservation, emission reduction and lean production are achieved.

Owner:QINGHE COUNTY XIANGZHI HOME TEXTILE

Steam waste heat circulation type exhaust gas catalytic device

InactiveCN110848718BConvenient electric heat treatmentImprove the efficiency of heating and catalysisTreatment involving filtrationIncinerator apparatusAir pumpExhaust fumes

The invention discloses a steam waste heat circulation exhaust gas catalytic device, which comprises a base, a support frame is arranged on the base, a catalytic chamber is arranged on the top of the support frame, one end of the catalytic chamber is a sealed structure, the other end of the catalytic chamber is an open structure, the catalytic chamber is The interior of the catalytic chamber is provided with an air guide cavity, the inner top of the catalytic chamber is provided with several upper air guide plates, the inner bottom of the catalytic chamber is provided with several lower air guide plates, and the upper air guide plate is between two adjacent lower air guide plates. The lower air guide is between two adjacent upper air guides; the other end of the catalytic chamber is provided with an air outlet pipe, one end of the air outlet pipe is connected to the other end of the catalytic chamber, and the other end of the air outlet pipe is provided with an air outlet chamber; The upper side of one end of the catalytic chamber is connected with an exhaust gas inlet pipe, one end of the exhaust gas inlet pipe is connected with the upper side of one end of the catalytic chamber, and the other end of the exhaust gas inlet pipe is provided with a suction pump. The invention conveniently conducts electric heating treatment on the catalytic chamber through the electric heating cylinder, and greatly improves the efficiency of heating and catalyzing the waste gas in the catalytic chamber.

Owner:中科科雄环保科技有限公司

Spherical flue element equivalent model thermotechnical waterpower experimental apparatus

ActiveCN102855802BReflect thermal hydraulic characteristicsRealize electric heatingEducational modelsThermal expansionEngineering

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Efficient environment-friendly continuous roller kiln

The invention relates to an efficient environment-friendly continuous roller kiln. The efficient environment-friendly continuous roller kiln comprises at least one kiln module. Each kiln module comprises a furnace framework provided with an upper opening and a lower opening, a furnace top cover covering the upper opening of the furnace framework, a furnace bottom cover covering the lower opening of the furnace framework, and a transmission device installed in the furnace framework, wherein the furnace framework comprises a furnace side wall filled with a heat insulation material, a hearth is defined by the furnace top cover, the furnace bottom cover and the furnace side wall, and a material input and output port is formed in the furnace side wall; the transmission device is arranged in the hearth, the end of the transmission device goes deep into the material input and output port, the furnace top cover comprises an upper cover body and an upper electric resistance belt fixed to the upper cover body, and the furnace bottom cover comprises a lower cover body and a lower electric resistance belt fixed to the lower cover body; the furnace top cover further comprises a fixing rod used for fixing the upper electric resistance belt onto the upper cover body, the fixing rod comprises a rod body and a retaining piece fixed to the rod body, the top end of the rod body is fixed to the upper cover body, and the upper electric resistance belt is clamped between the upper cover body and the retaining piece.

Owner:苏州新凌电炉有限公司

High-efficiency and environment-friendly continuous roller kiln

The invention relates to a high-efficiency and environment-friendly continuous roller kiln, which comprises at least one kiln module, and each kiln module includes a furnace frame with an upper opening and a lower opening, a furnace roof covering the upper opening of the furnace frame, and a cover Furnace bottom cover opened under the furnace frame and the transmission device installed in the furnace frame. The furnace frame includes the furnace side wall filled with heat insulating materials. The furnace top cover, furnace bottom cover and furnace side wall are surrounded to form a furnace. There is a material inlet and outlet on the wall, the transmission device is placed in the furnace and the end of the transmission device goes deep into the material inlet and outlet. The furnace roof includes an upper cover and an upper resistance band fixed on the upper cover. The furnace bottom cover includes a lower The cover body and the lower resistance band fixed on the lower cover body, the furnace roof cover also includes a fixing rod for fixing the upper resistance band on the upper cover body, and the fixing rod includes a rod body whose top end is fixed on the upper cover body and a rod body fixed on the rod body The resisting sheet and the upper resistance band are sandwiched between the upper cover and the resisting sheet.

Owner:苏州新凌电炉有限公司

Organic liquid impregnating, brushing and drying device for printing rubber rolls

The invention discloses an organic liquid impregnating, brushing and drying device for printing rubber rolls. The organic liquid impregnating, brushing and drying device comprises a base. A supporting base is arranged on the base. A positioning shaft is arranged on the end portion of the supporting base. The peripheral face of the positioning shaft is sleeved with a coiled pipe. A regulating sleeve is arranged on the upper portion of the coiled pipe. A movable base is arranged on the base. A supporting plate is arranged on the movable base. A guide pipe is arranged on the end portion of the supporting plate. A movable pipe is sleeved with the guide sleeve. One end of the movable pipe is a free end, and a hand wheel is arranged at the other end of the movable pipe. A first side plate is arranged on one side of the base. A third side plate is arranged on the other side of the base. A pair of guide shafts are arranged on the end portion of the first side plate. A second side plate is arranged on the end portions of the guide shafts. A top plate is arranged between the end portion of the second side plate and the end portion of the third side plate. Brushing rollers are arranged on the peripheral faces of the guide shafts in a sleeving manner. Bristles are arranged on the outer surfaces of the brushing rollers. A guide barrel is arranged on the top plate. A lock pipe is sleeved with the guide barrel. According to the brushing rollers, the surfaces of the printing rubber rolls can be brushed through the bristles.

Owner:SUZHOU XINHANG MICROELECTRONICS

Wireless heating power supply assembly and wireless heating method for superconducting cable insulation tube

ActiveCN108207045BHigh vacuum lifeRealize electric heatingInduction heating apparatusLine heatingElectric cables

Owner:SHANGHAI INT SUPERCONDUCTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com