Patents

Literature

984results about How to "Easy to rewind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

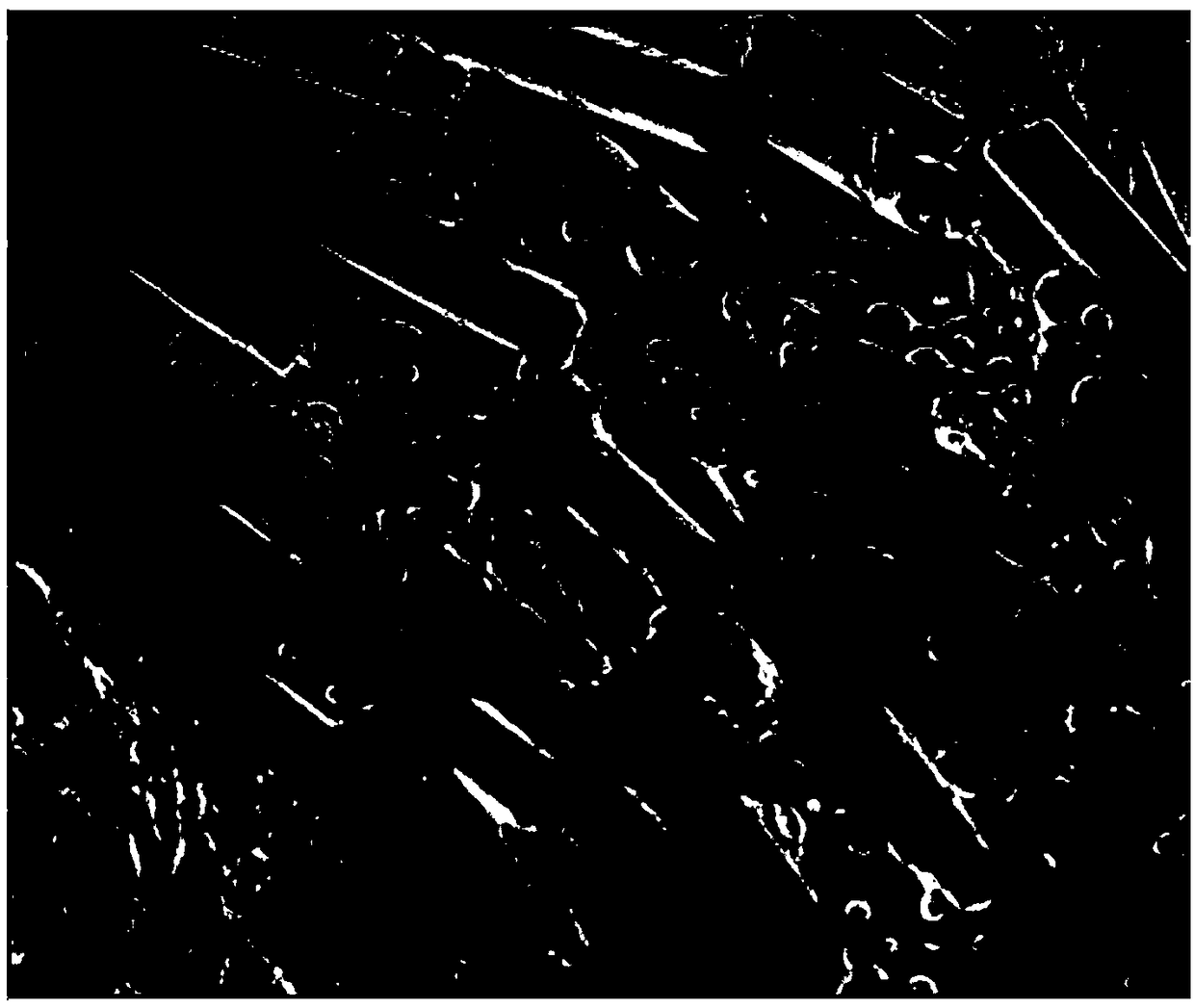

High transparent polyester film and process for producing the same

The high transparency polyester film contains nano level silica of grain size 20-50 nm and micron level silica of grain size 1.2-2.0 microns. The nano level silica accounts for 50-2000 ppm of total polyester film weight, and the micron level silica 1-300 ppm. The production process of the high transparency polyester film includes the first preparation of silica suspension, the subsequent conventional polymer producing course to produce polyester slice, and final conventional melting extrusion of the slice and bi-directional stretching. The product of the present invention has high transparency, waterproof property, blocking property, heat resistance and antiaging property.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

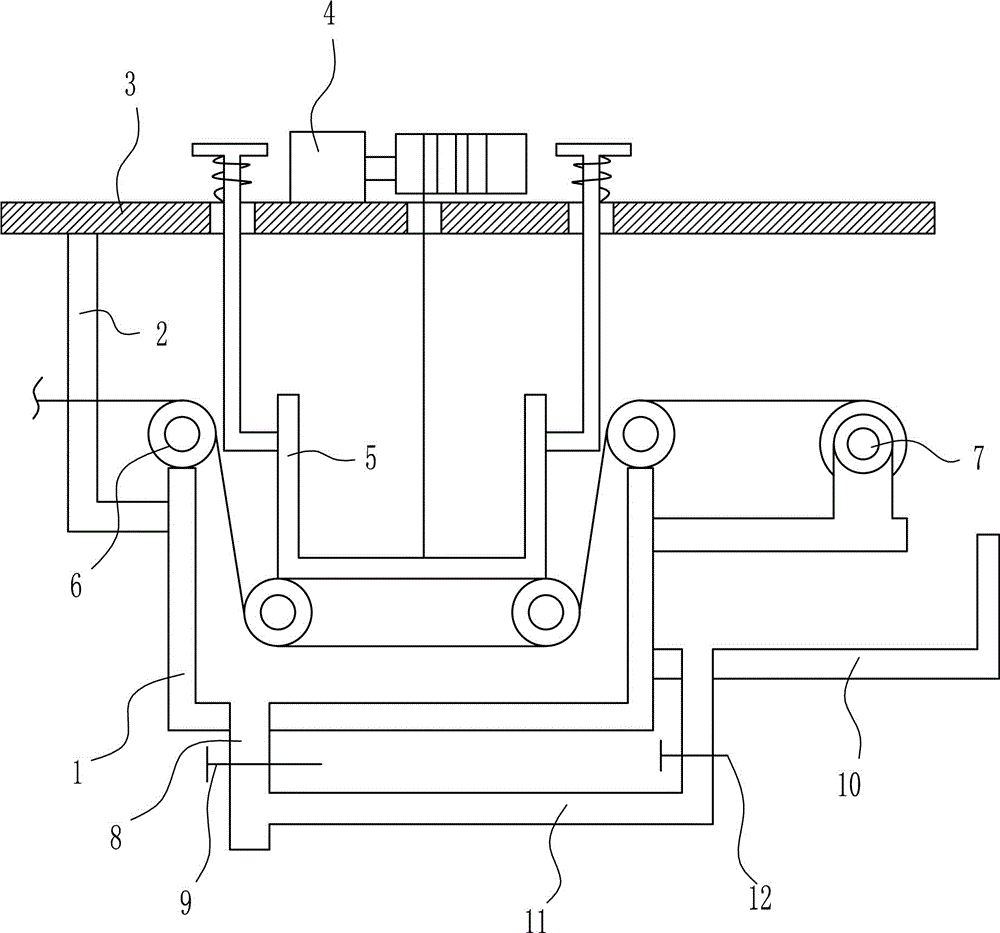

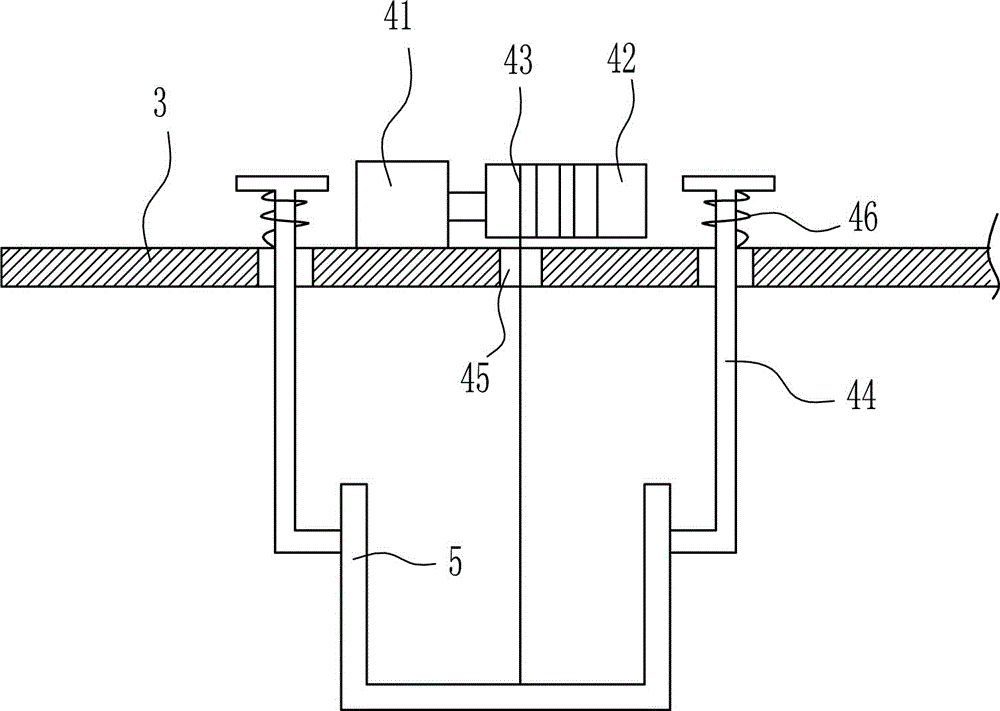

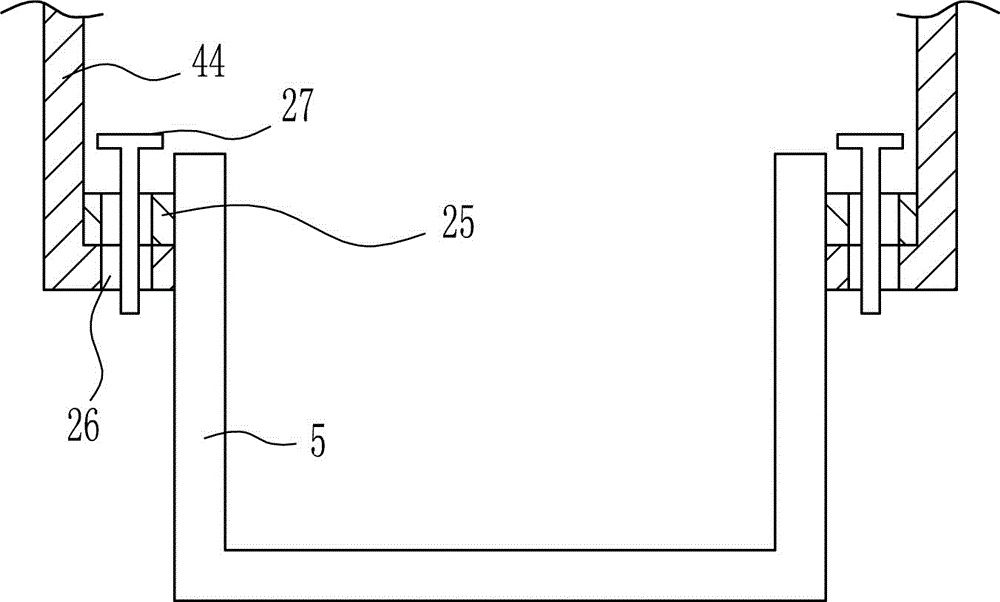

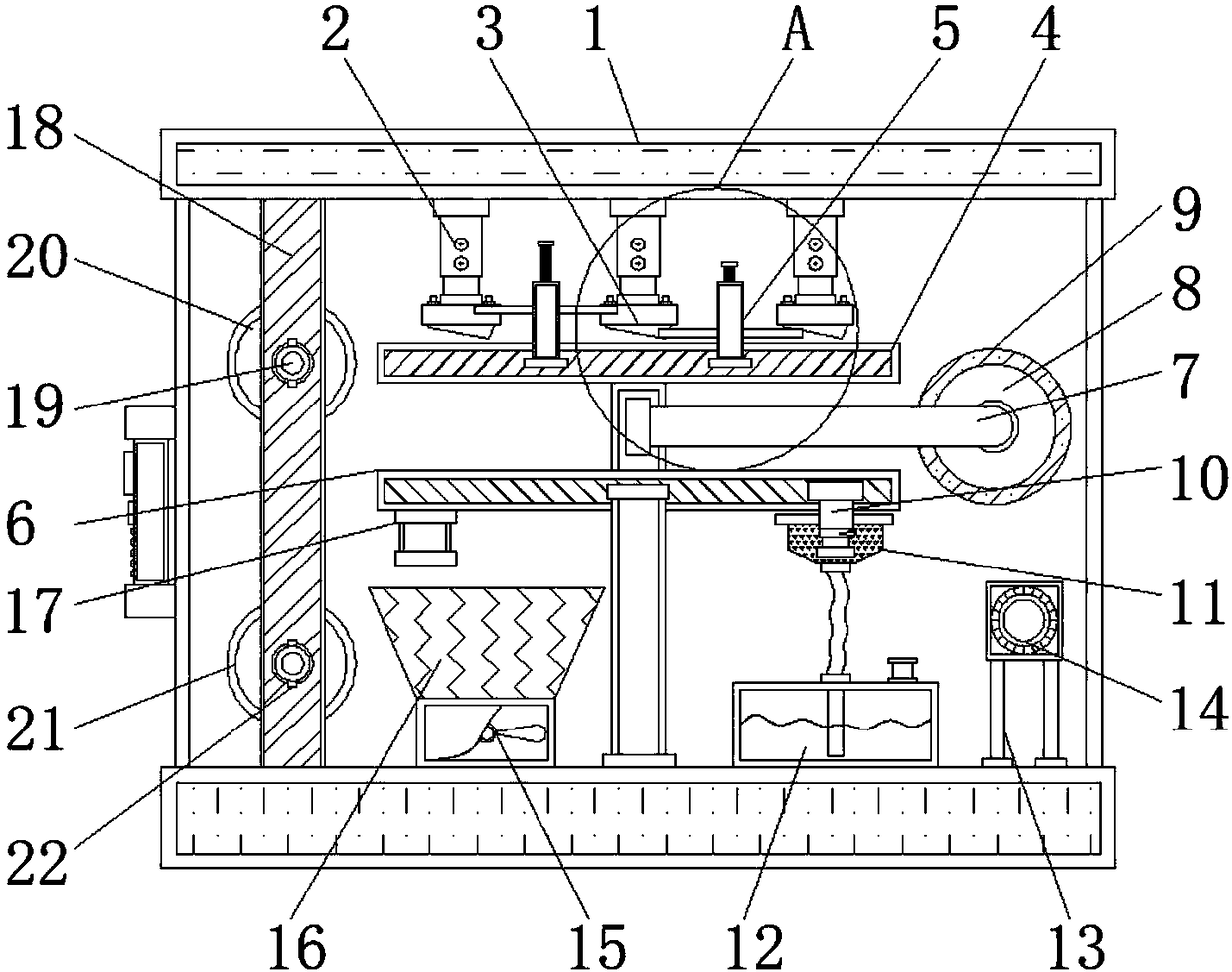

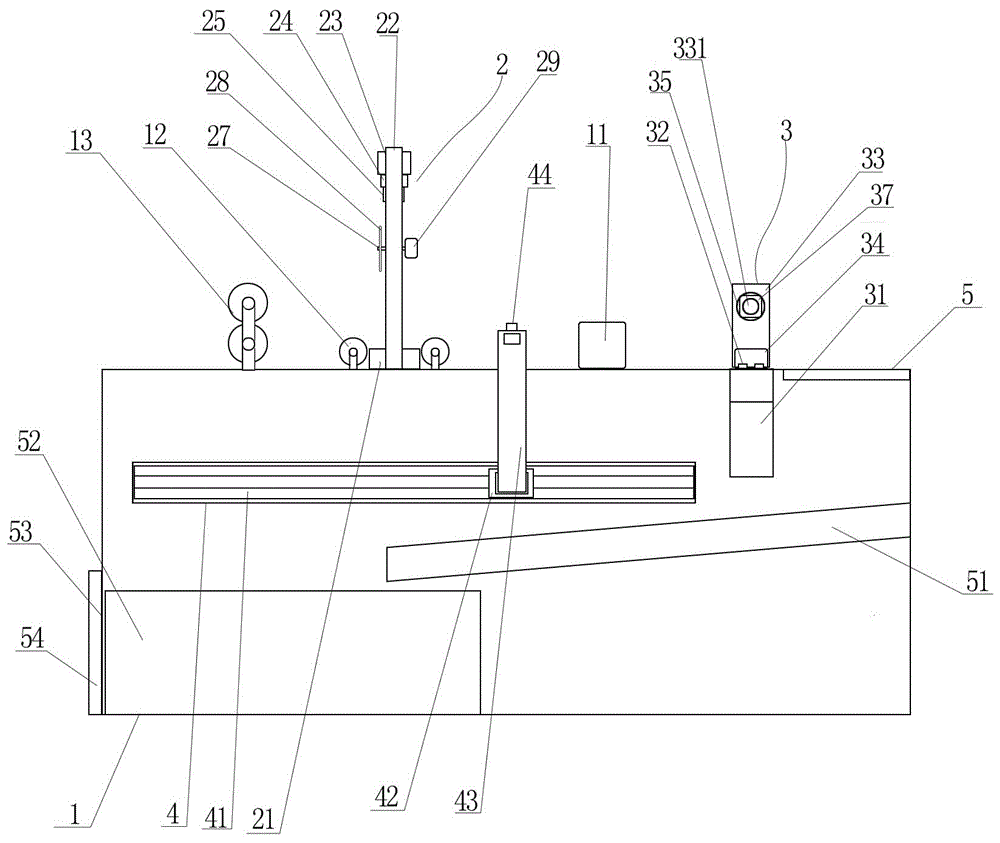

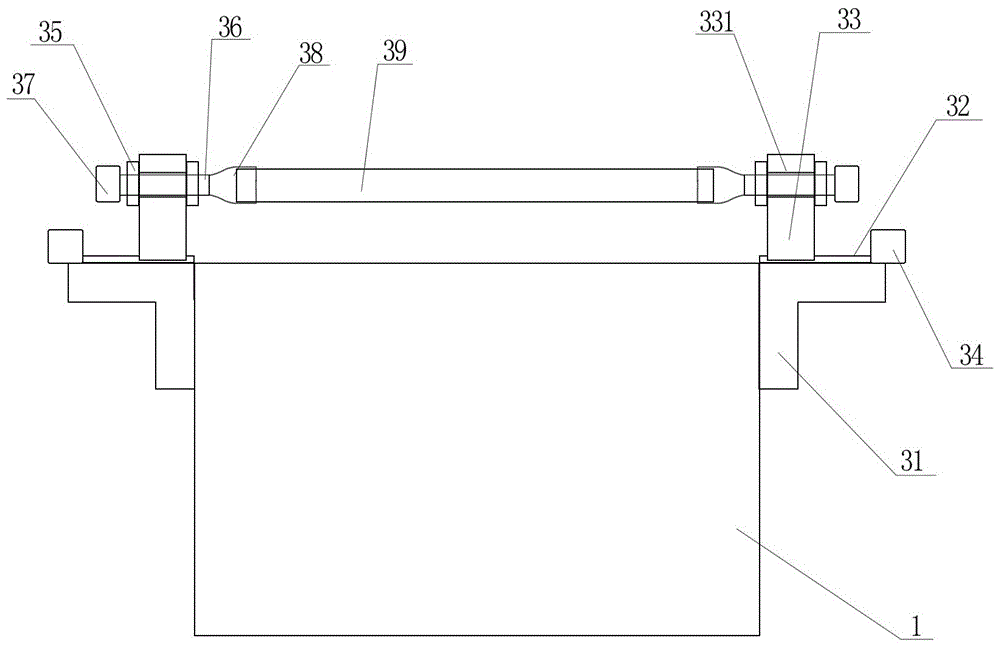

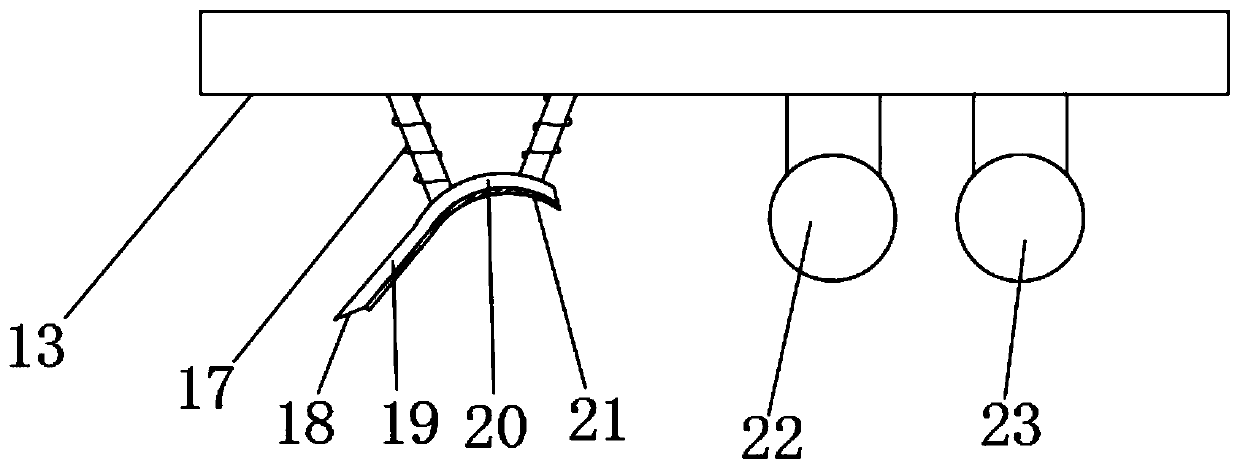

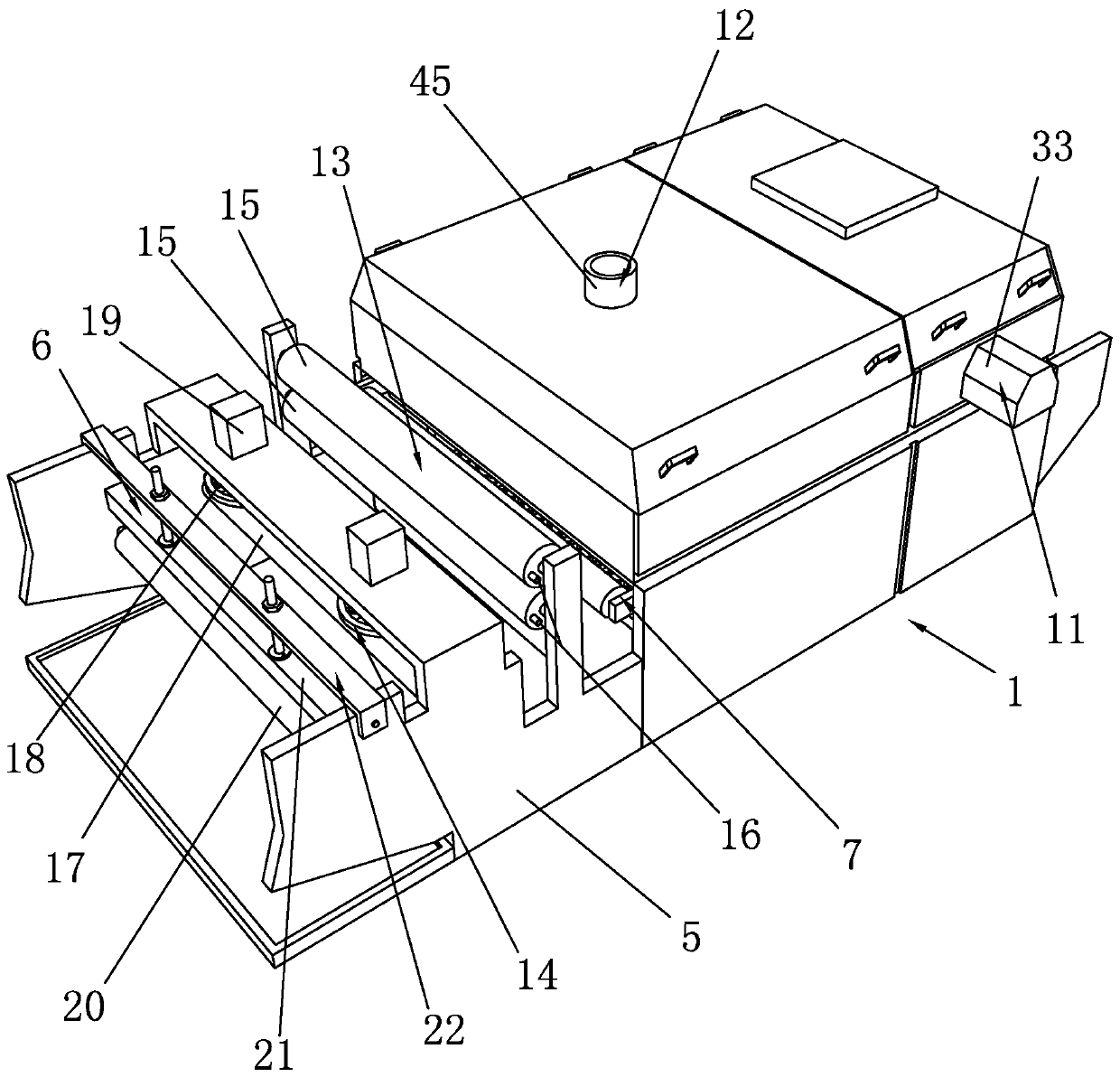

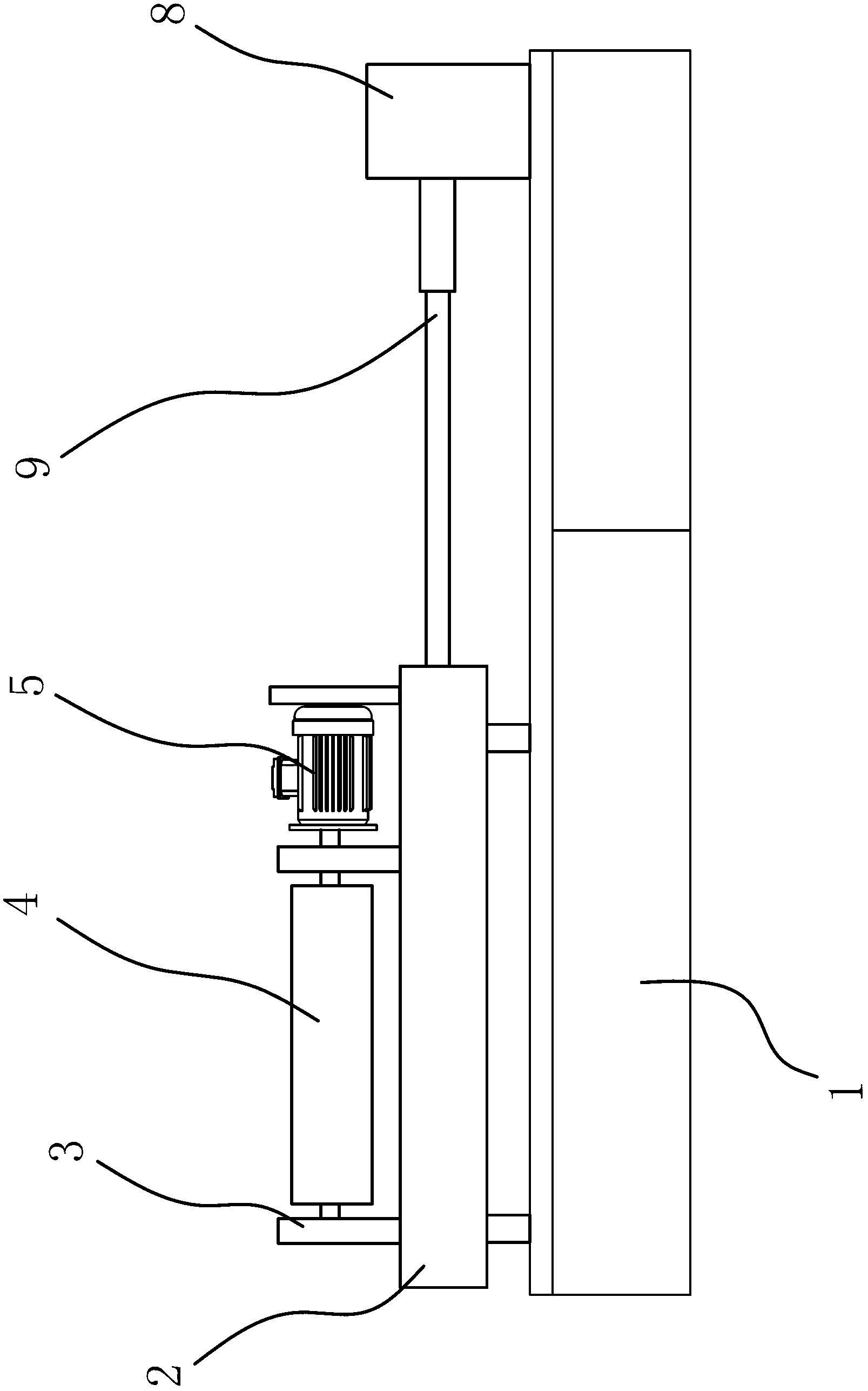

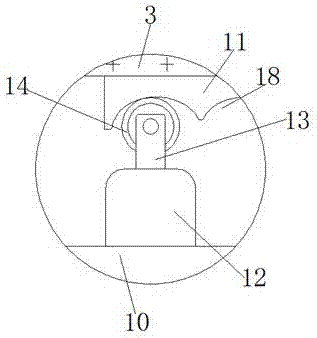

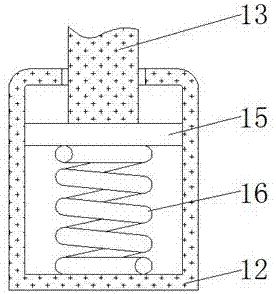

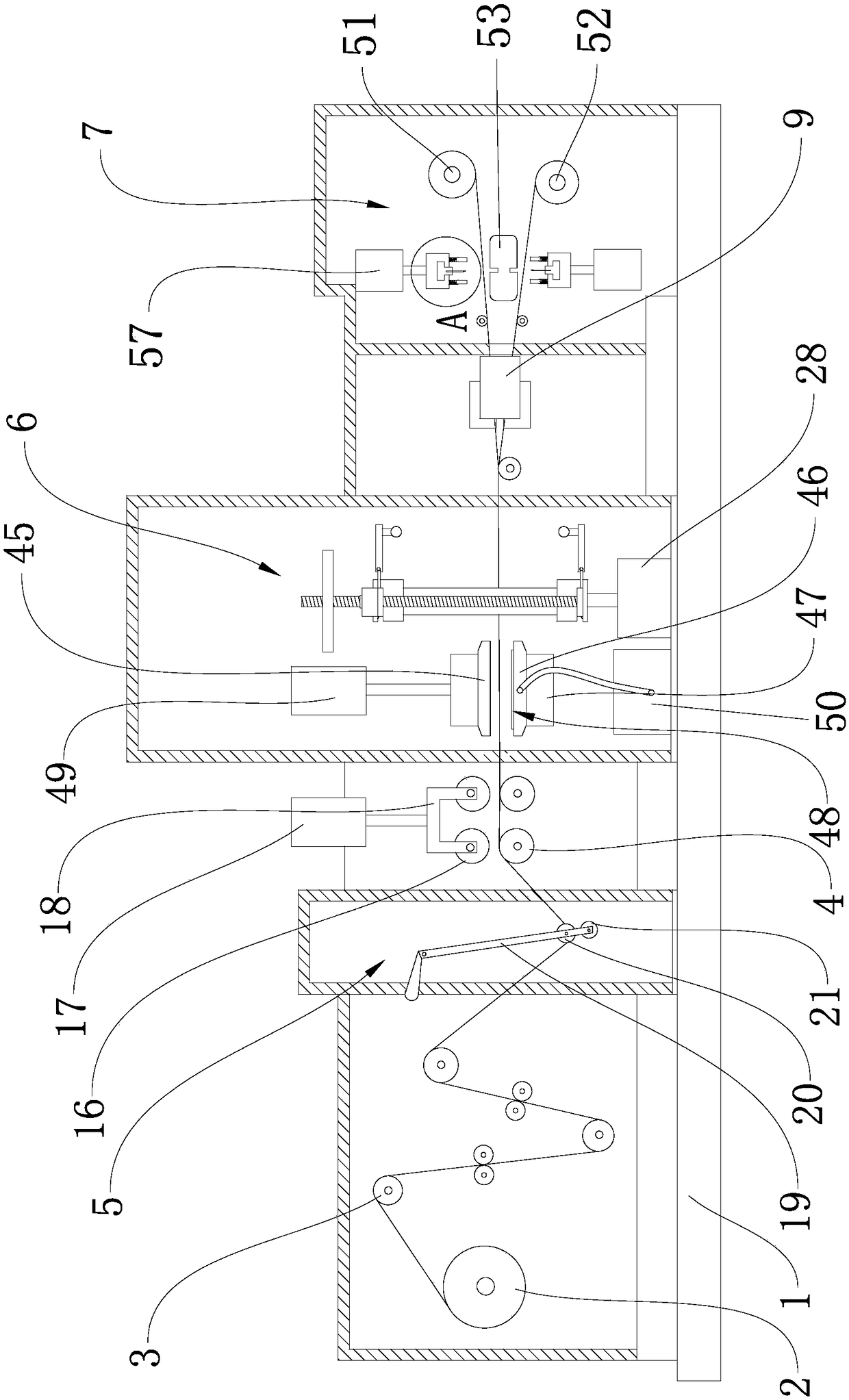

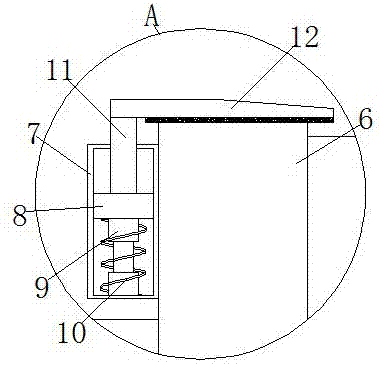

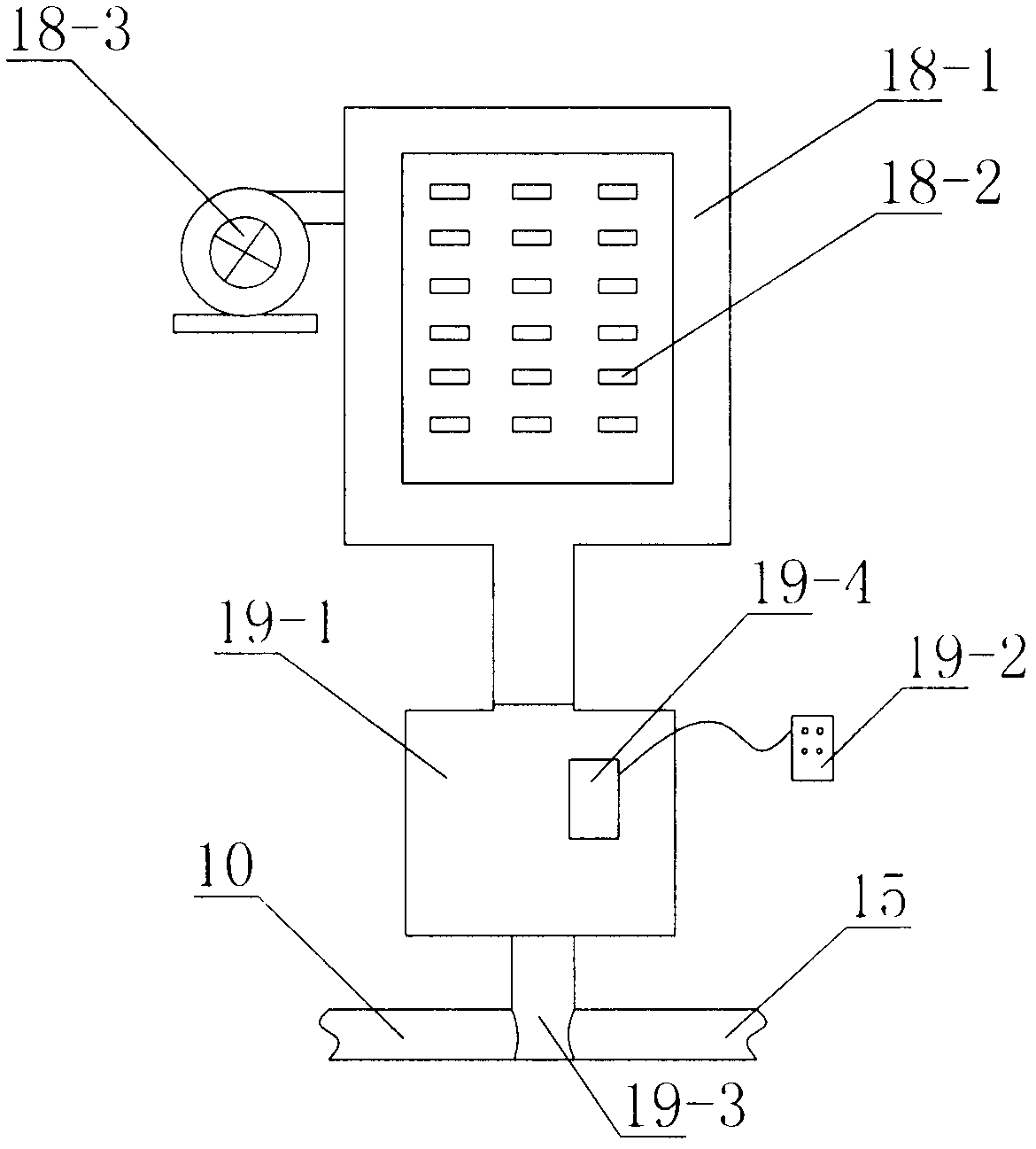

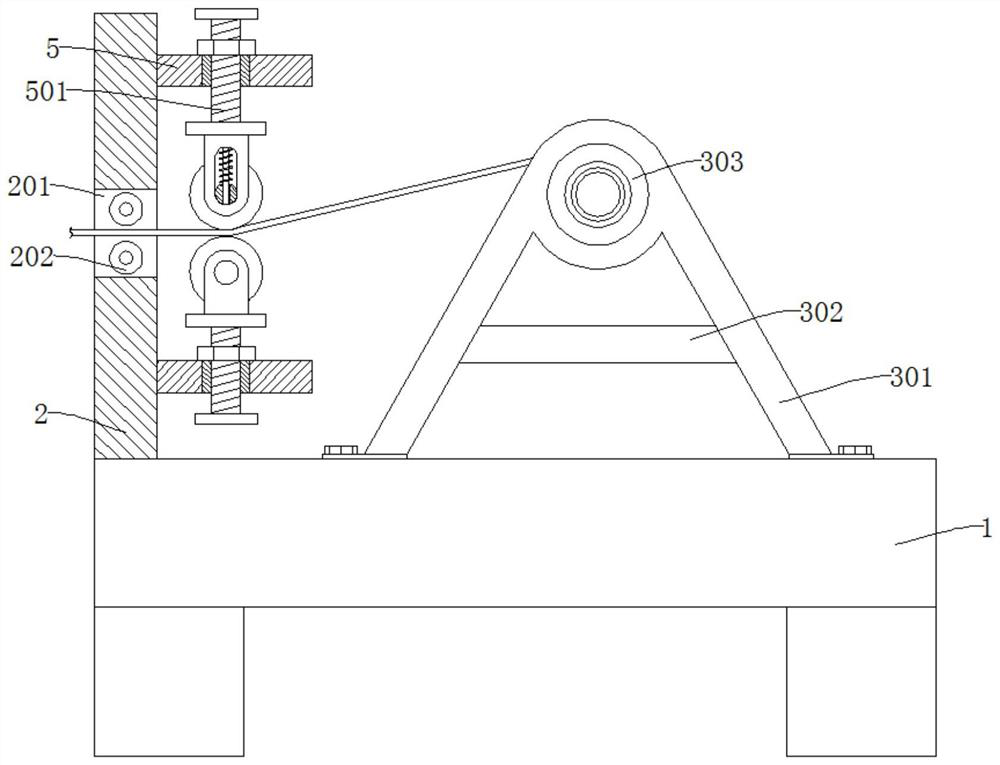

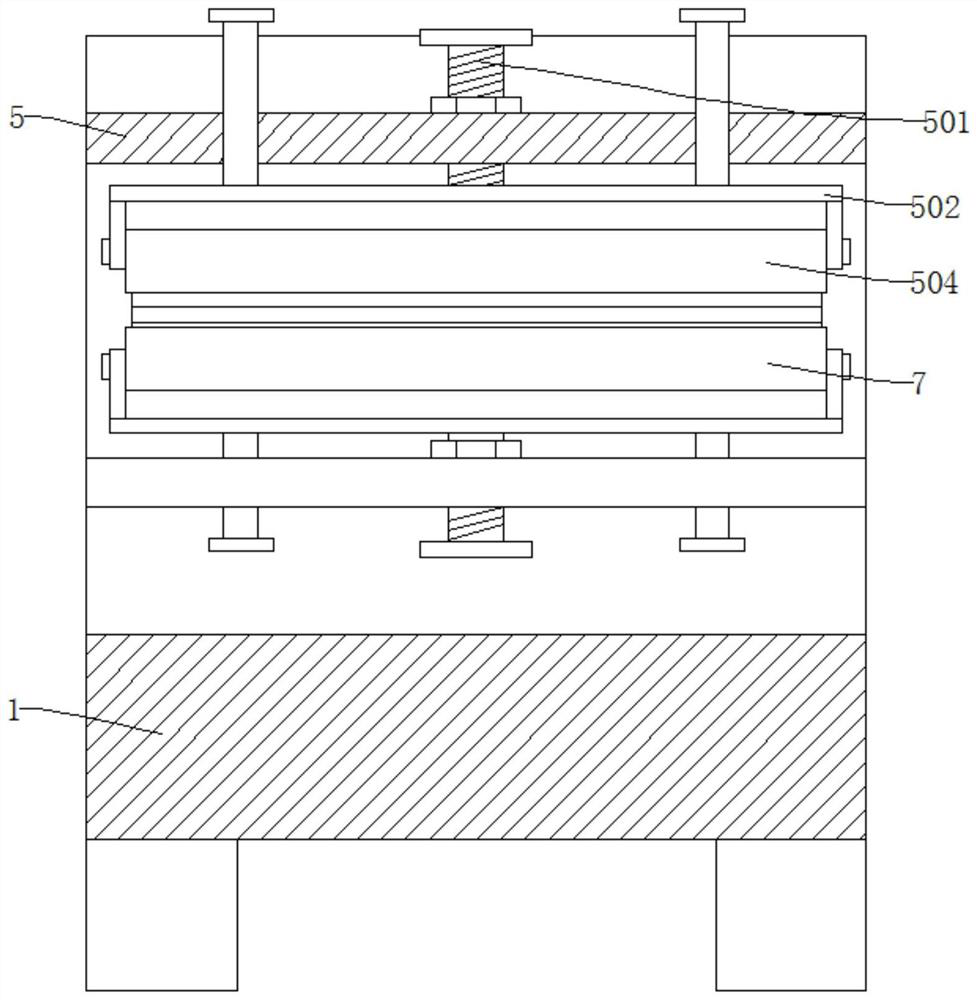

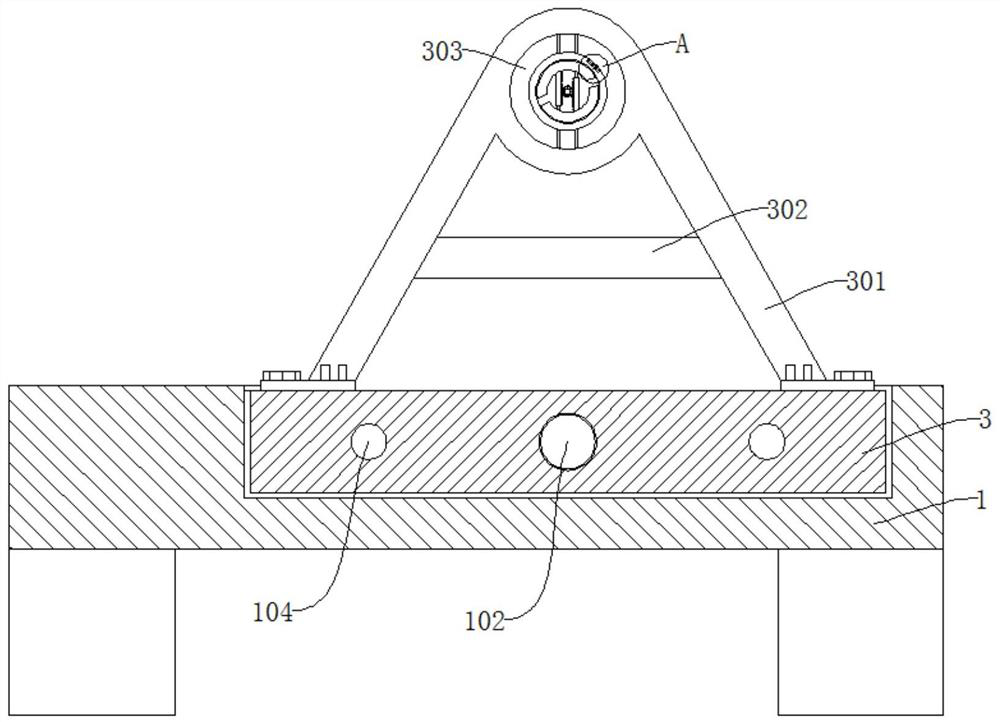

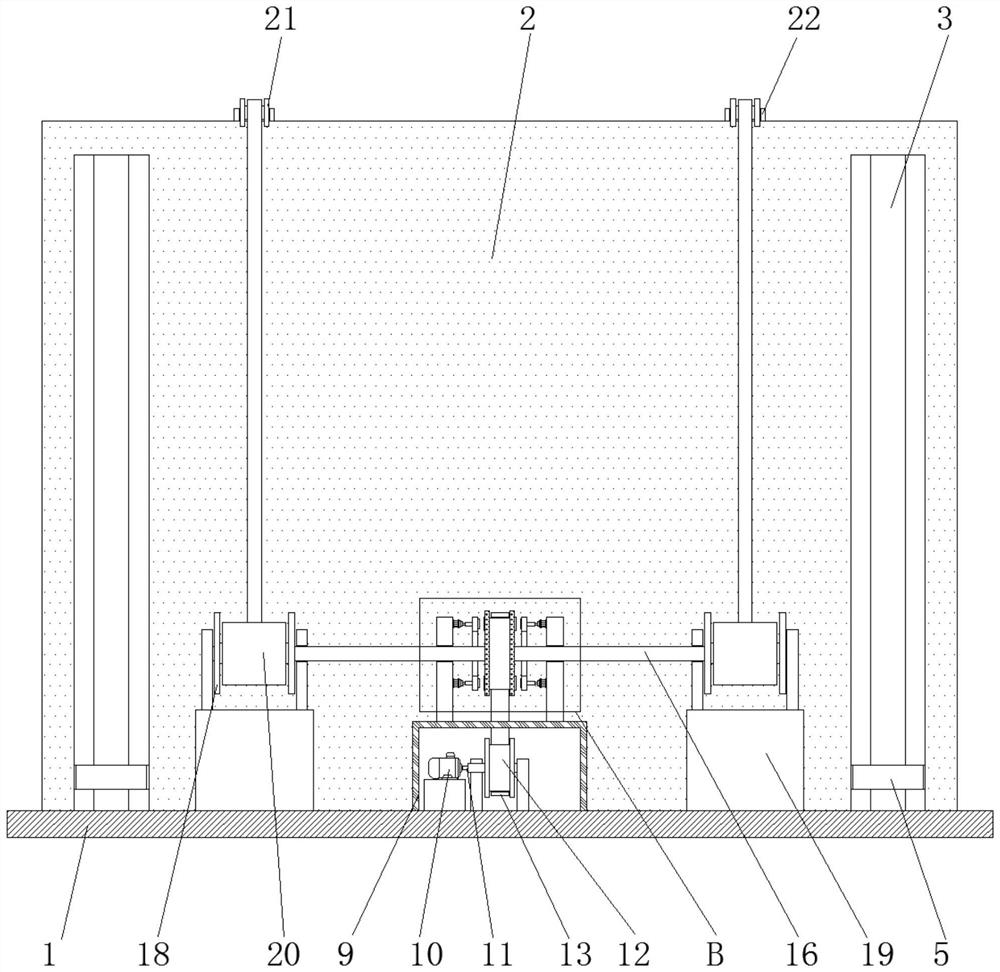

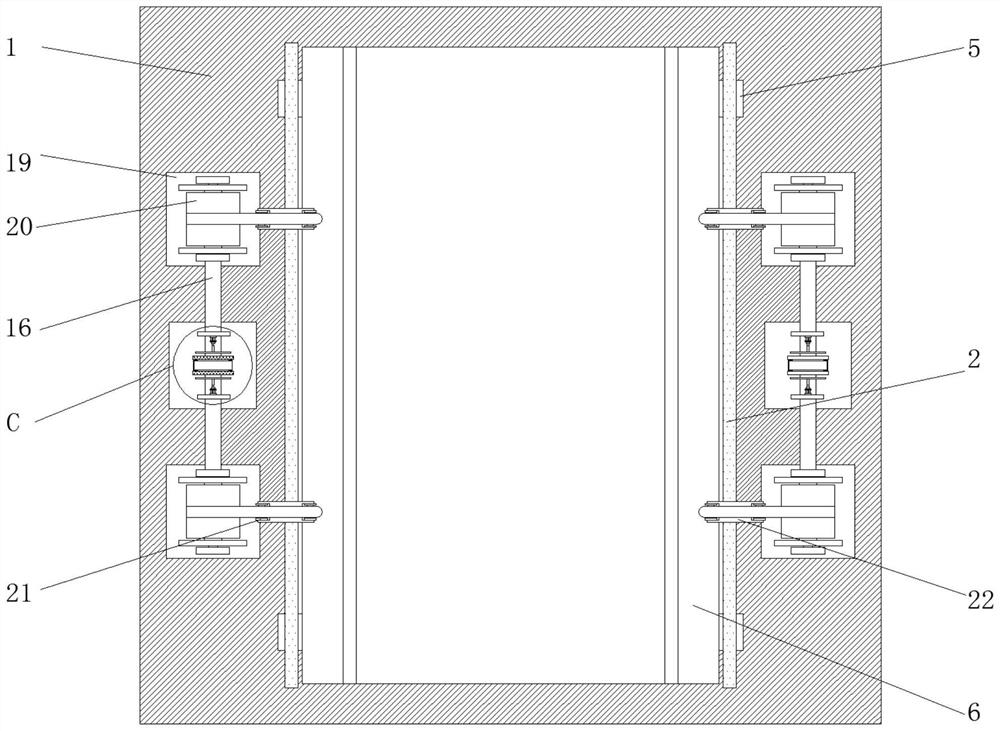

Non-woven lifting dye device for garment production

InactiveCN106835555AEasy to dyeEasy to rewindTextile treatment machine arrangementsTextile treatment carriersNonwoven fabricMechanical engineering

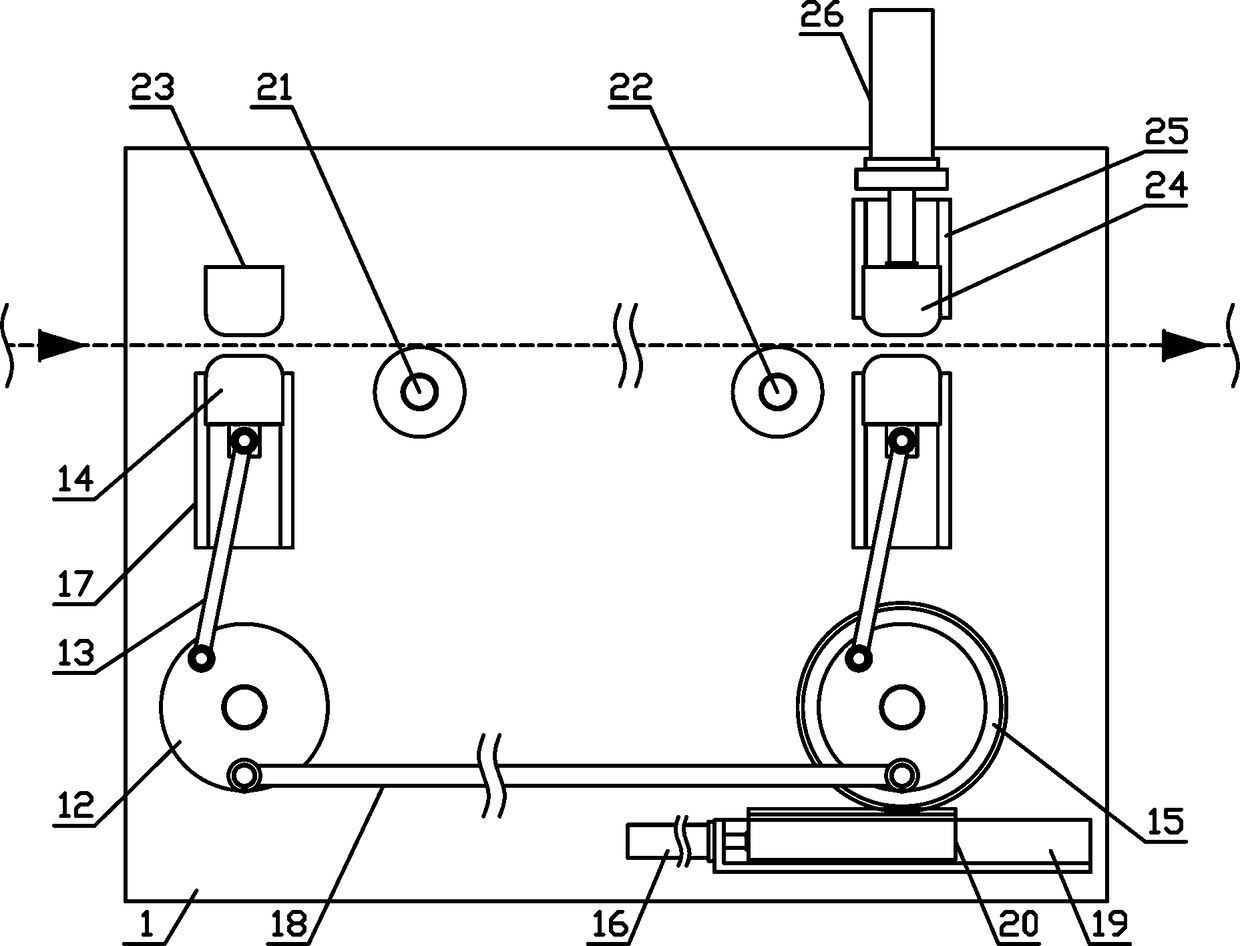

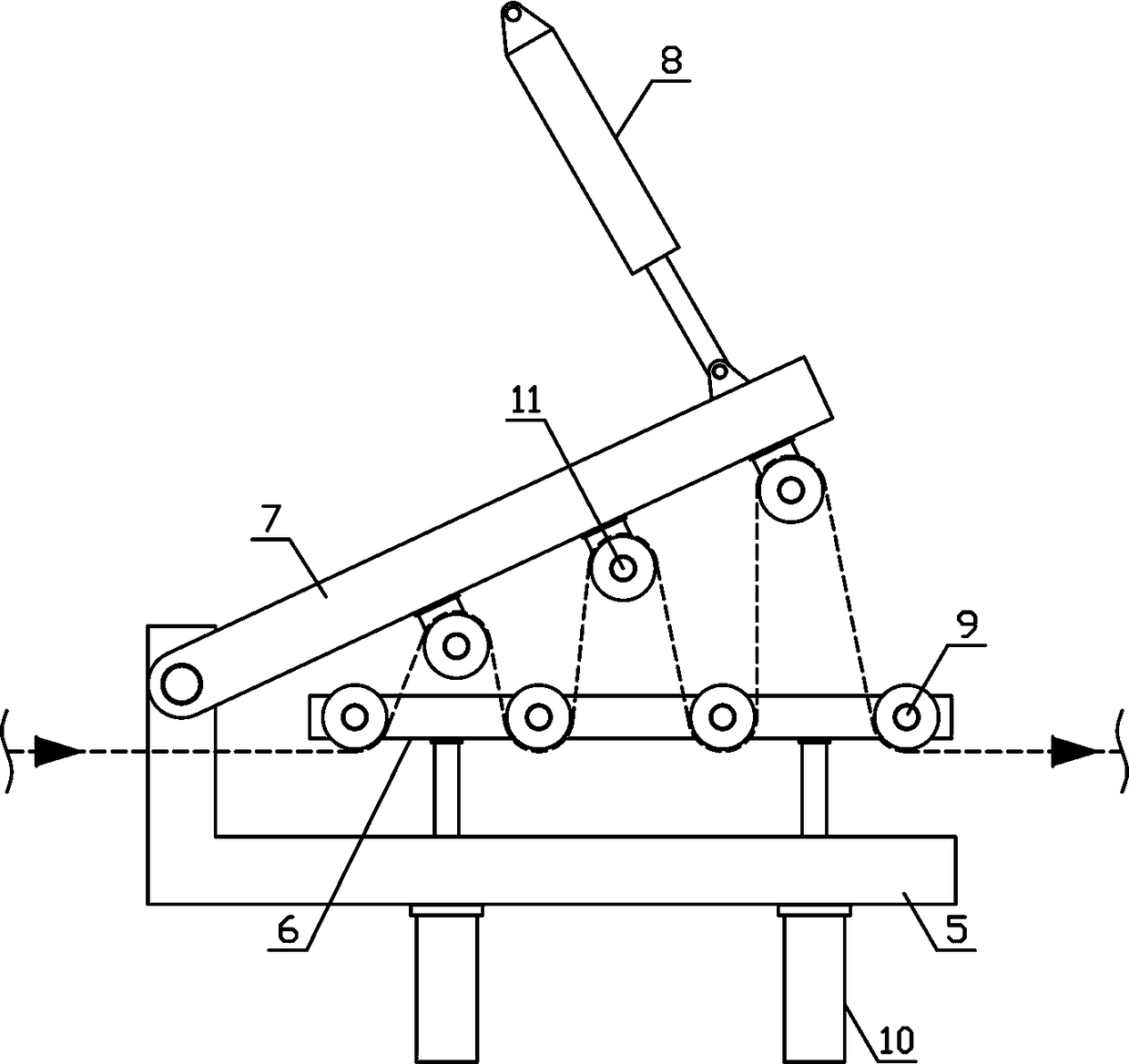

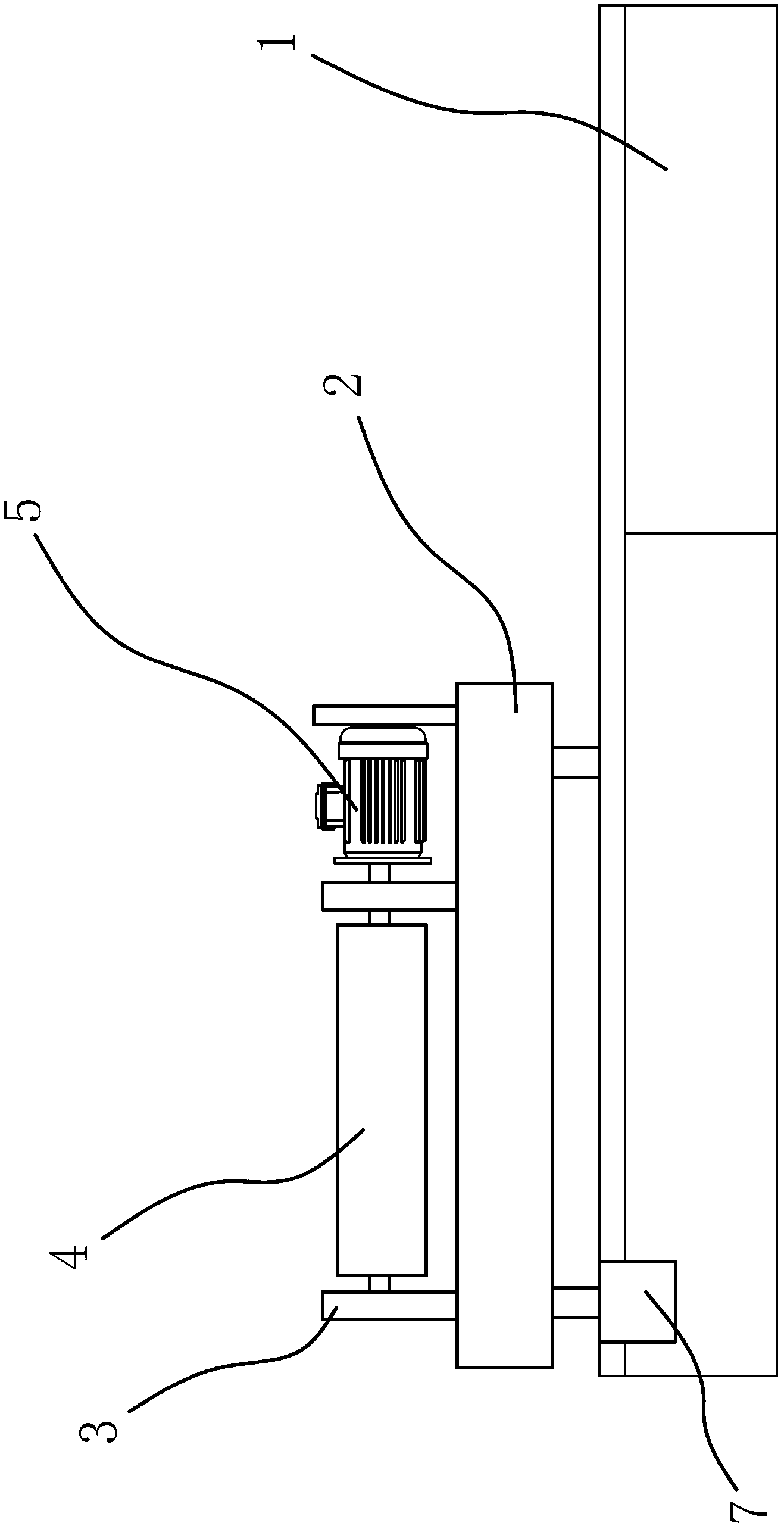

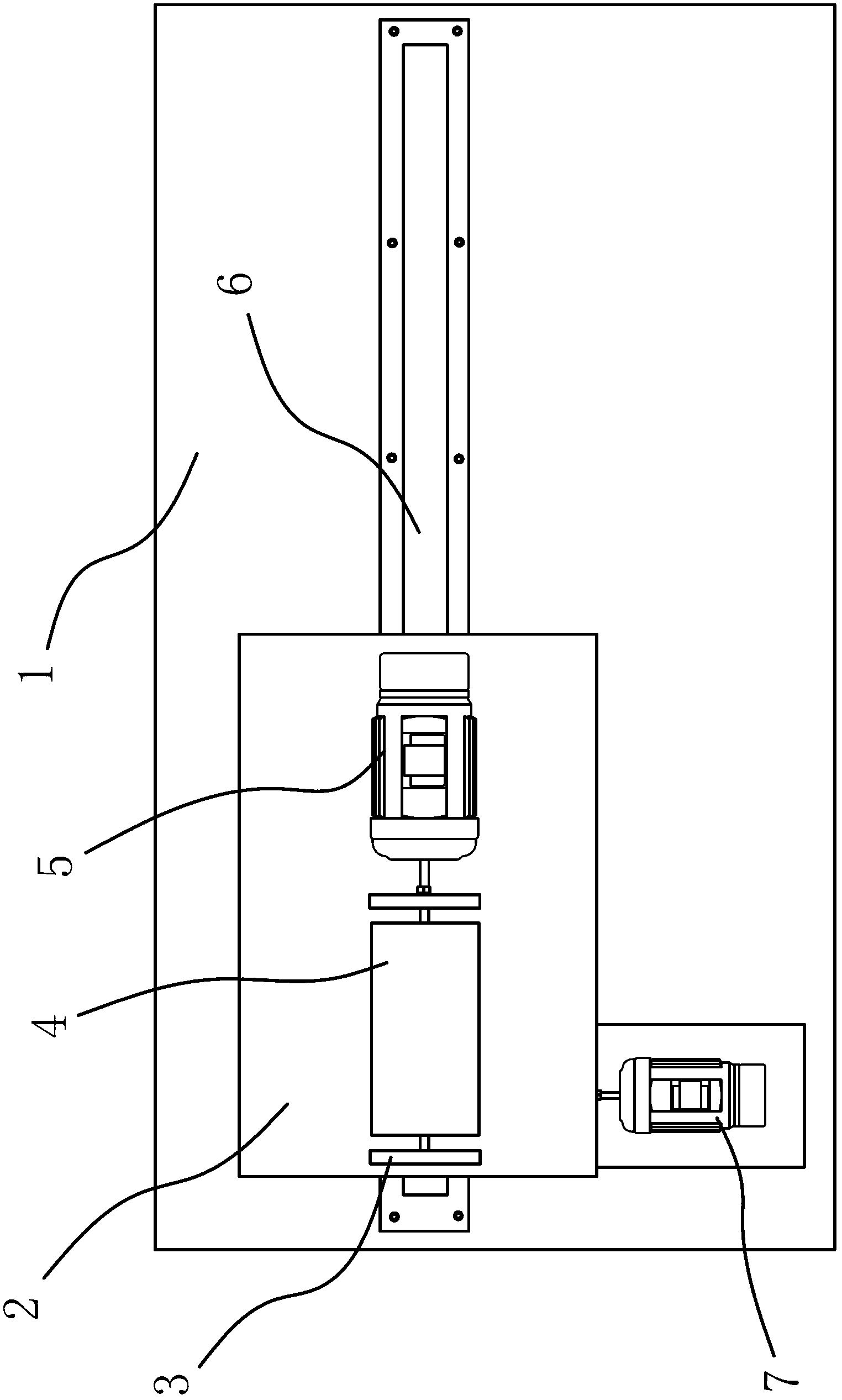

The invention relates to a dye device, particularly relates to a non-woven lifting dye device for garment production, and aims at solving the technical problem of providing a non-woven lifting dye device for garment production, which is capable of flatly putting non-woven into a dye for dyeing. In order to solve the technical problem, the invention provides the non-woven lifting dye device for garment production. The non-woven lifting dye device for garment production comprises a dye box, a connecting rod, a support rod, a lifting mechanism, a lifting frame, a guide roller and the like, wherein the upper part of the left side outside the dye tank is connected with the connecting rod; the top of the connecting rod is connected with the support rod; the support rod is connected with the lifting mechanism; and the lower side of the lifting mechanism is connected with the lifting frame. Through the lifting mechanism, the targets of driving the lifting frame to descend through the lifting mechanism, driving the guide roller at the inner side to descend through the lifting frame and flatly pressing the non-woven into the dye box for dip dyeing through the guide roller at the inner side are achieved.

Owner:绍兴金祥惠纺织印染有限公司

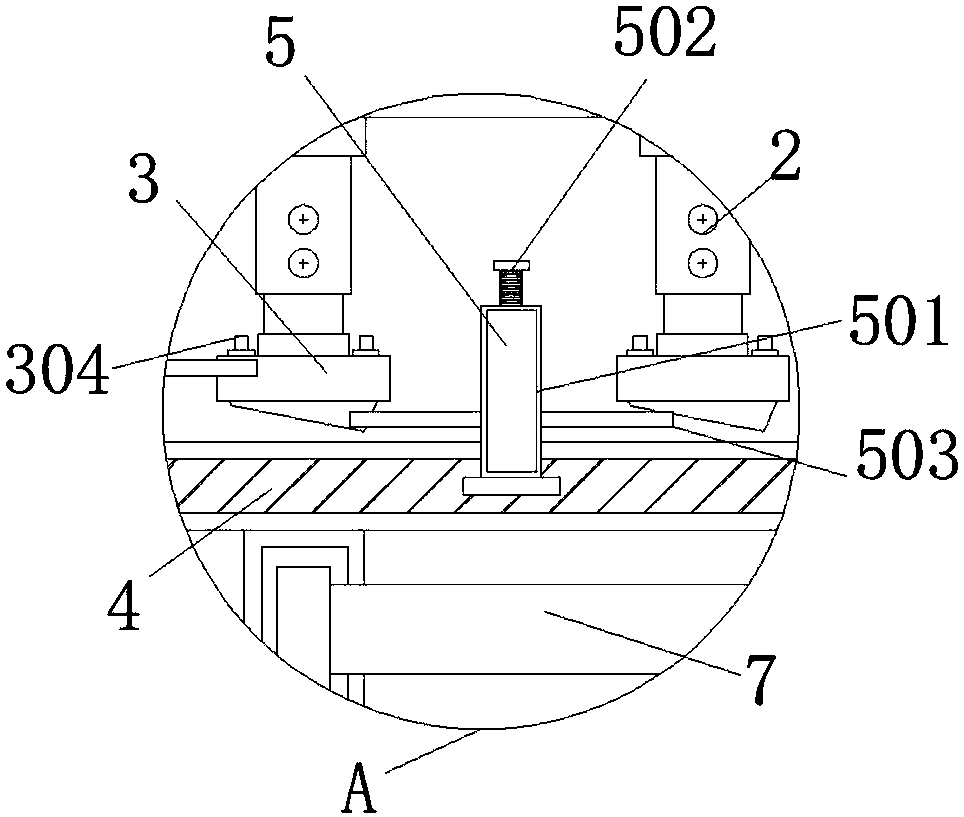

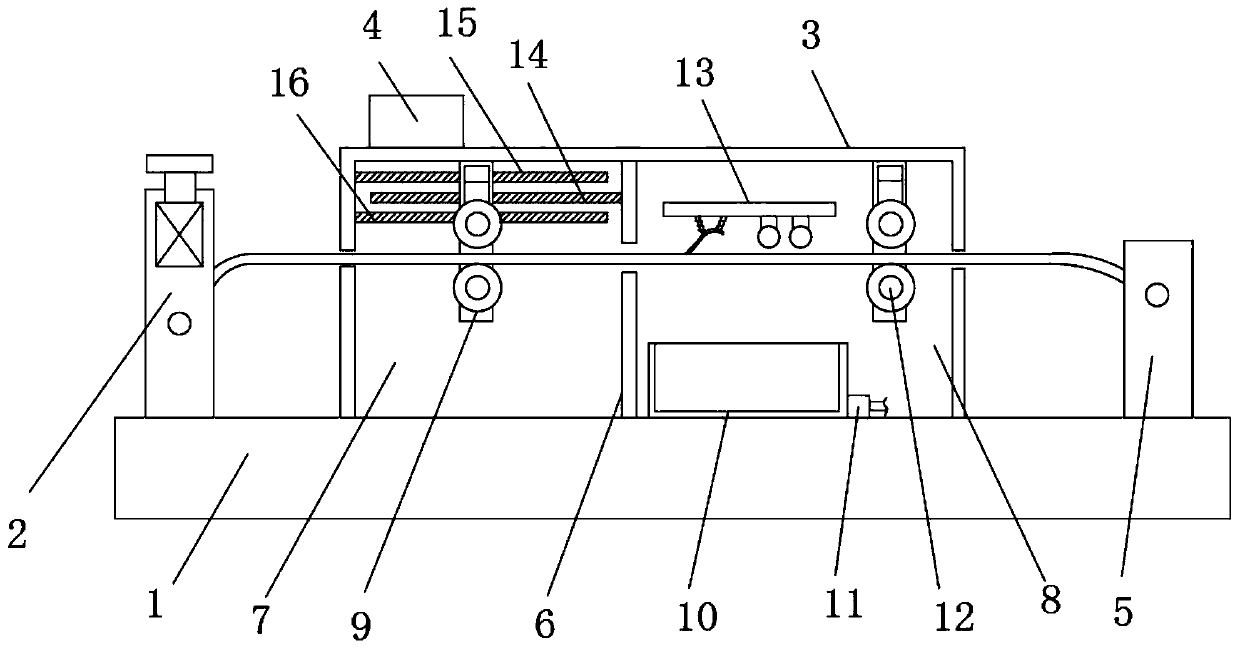

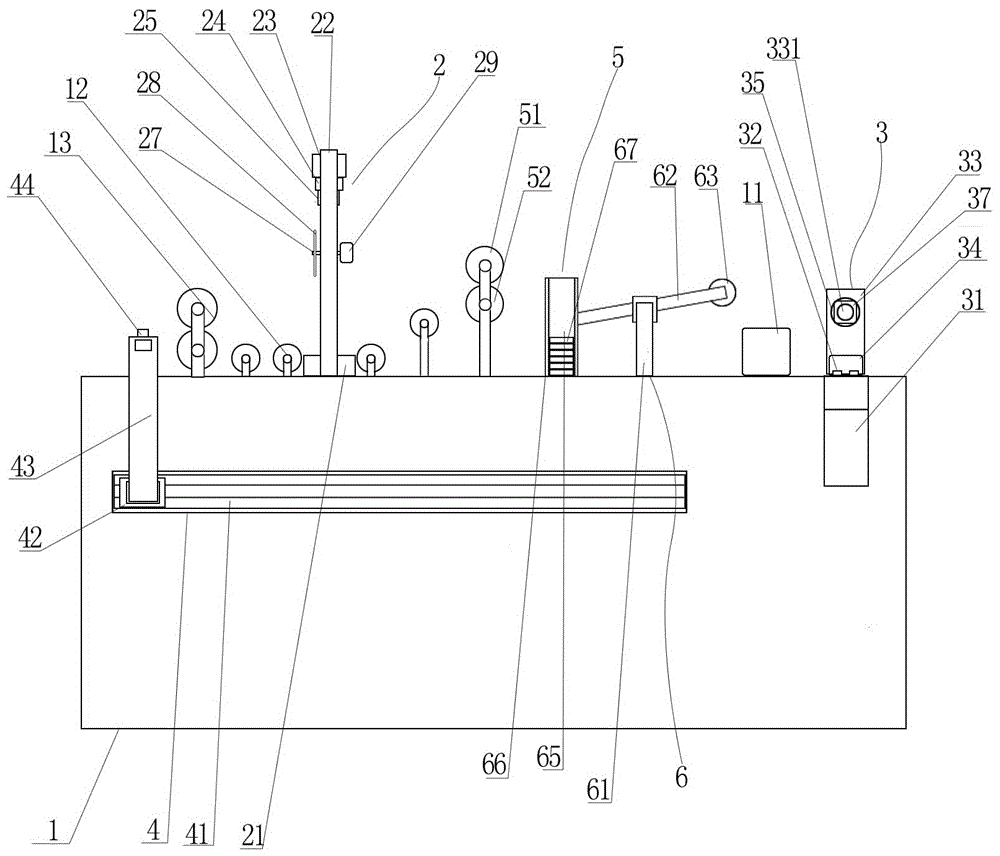

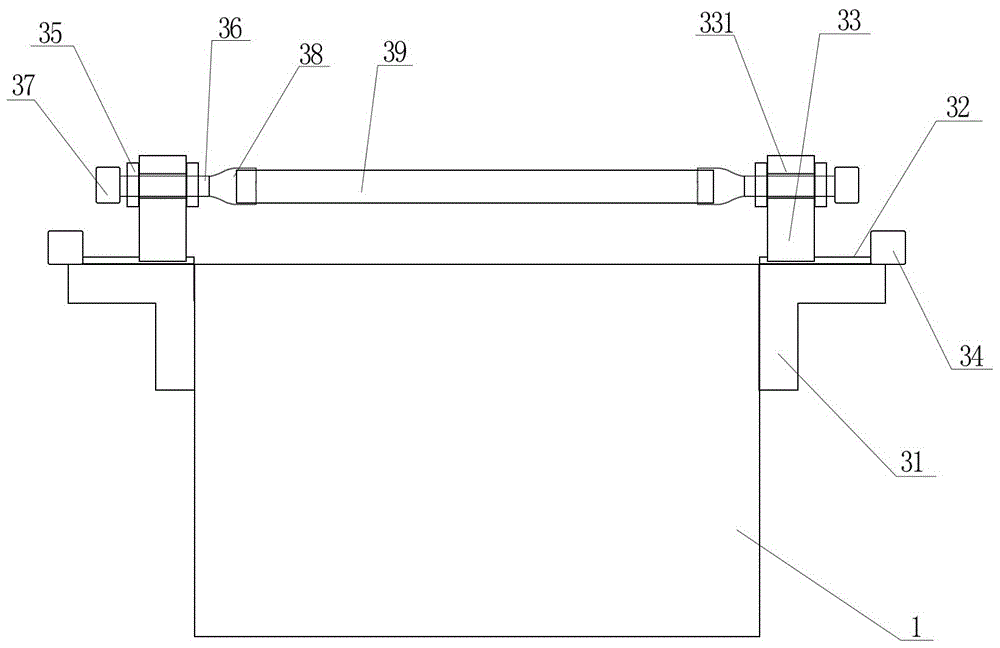

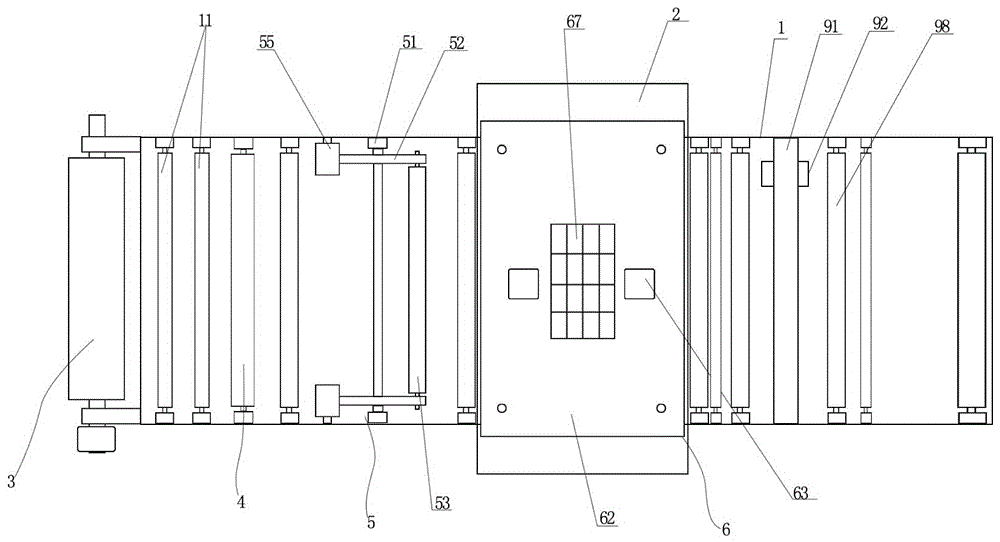

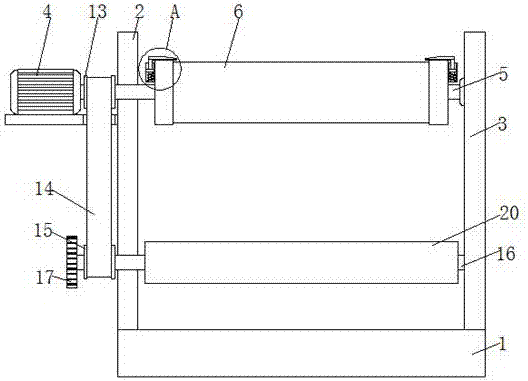

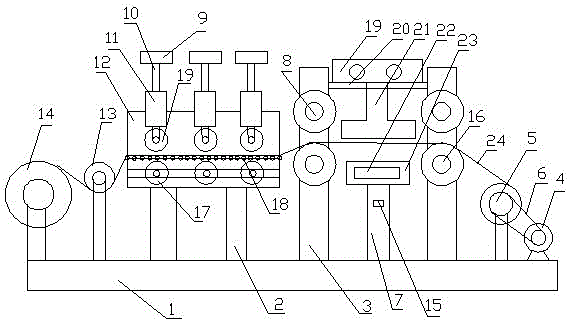

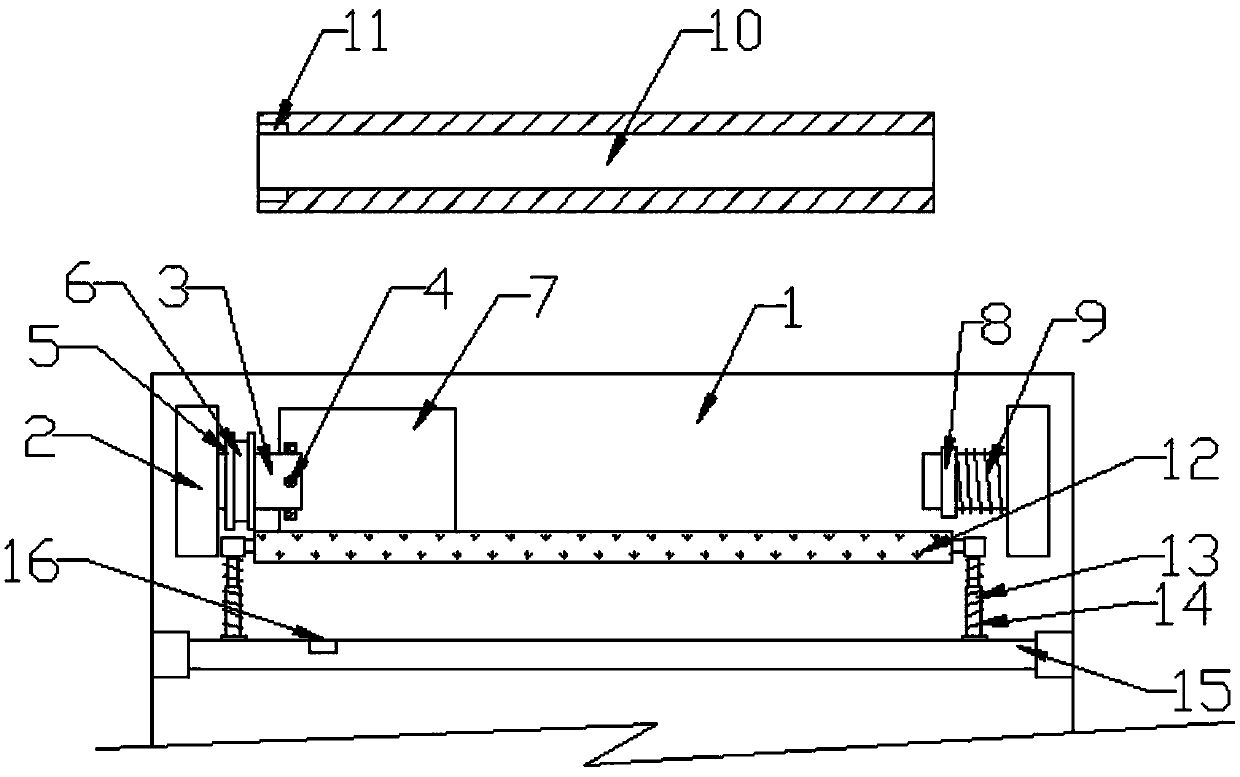

Film slitting machine preventing edge curling

ActiveCN108408455AImprove heating efficiencyExtended service lifeArticle deliveryWebs handlingEngineeringMechanical engineering

The invention provides a film slitting machining preventing edge curling and belongs to the mechanical technical field. The film slitting machining preventing edge curling solves the technical problemthat an existing film slitting machine is poor in cutting effect. The film slitting machining preventing edge curling comprises a machine frame. A feeding roller is rotationally arranged on the machine frame. A plurality of extension rollers and adhesion rollers are sequentially and rotationally arranged on one side of the feeding roller. The extension rollers and the adhesion rollers are rotationally arranged on the machine frame. A tensioning structure used for tensioning the film is arranged between the extension rollers and the adhesion rollers. The side, far away from the extension rollers, of the adhesion rollers is further sequentially provided with a cutting mechanism used for film slitting and a coiling mechanism for slit film. A heating roller used for preventing the edges of the film strips from curling and a strip separating block capable of separating adjacent cut film strips in a staggered manner are sequentially arranged between the cutting mechanism and the coiling mechanism. The strip separating block and the heating roller are fixedly arranged on the machine frame. The film slitting machine preventing edge curling has the advantage of being good in slitting effect.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

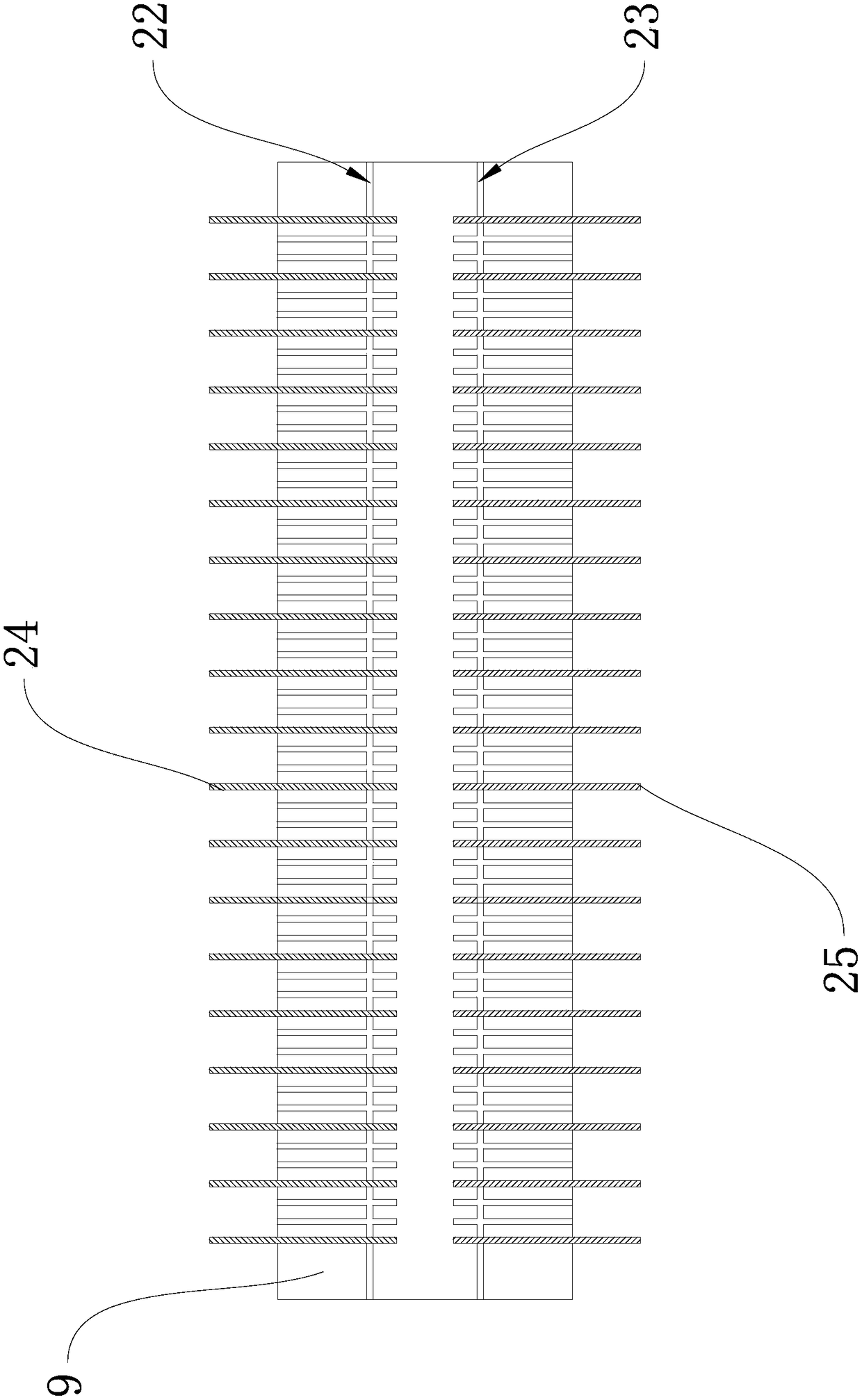

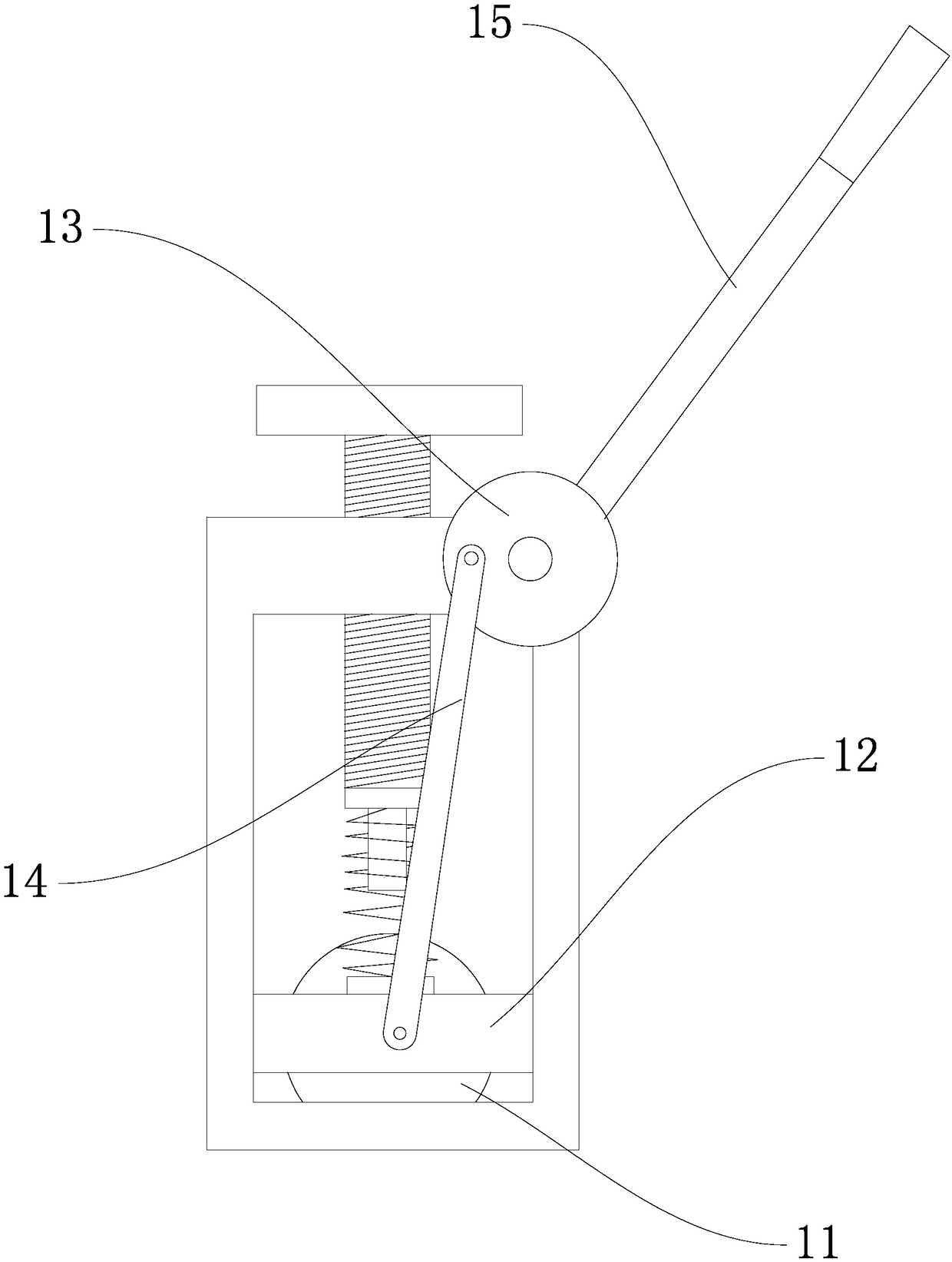

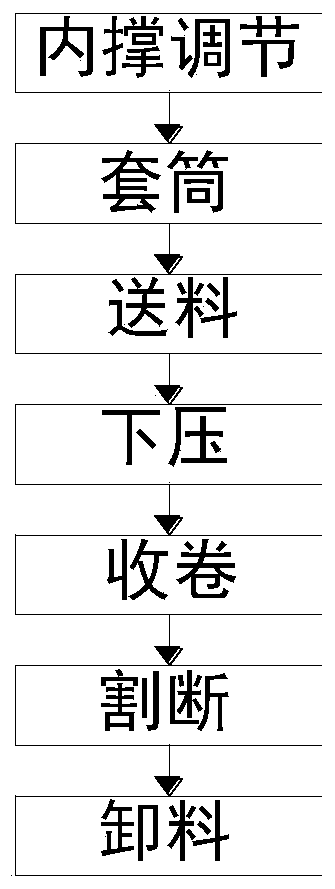

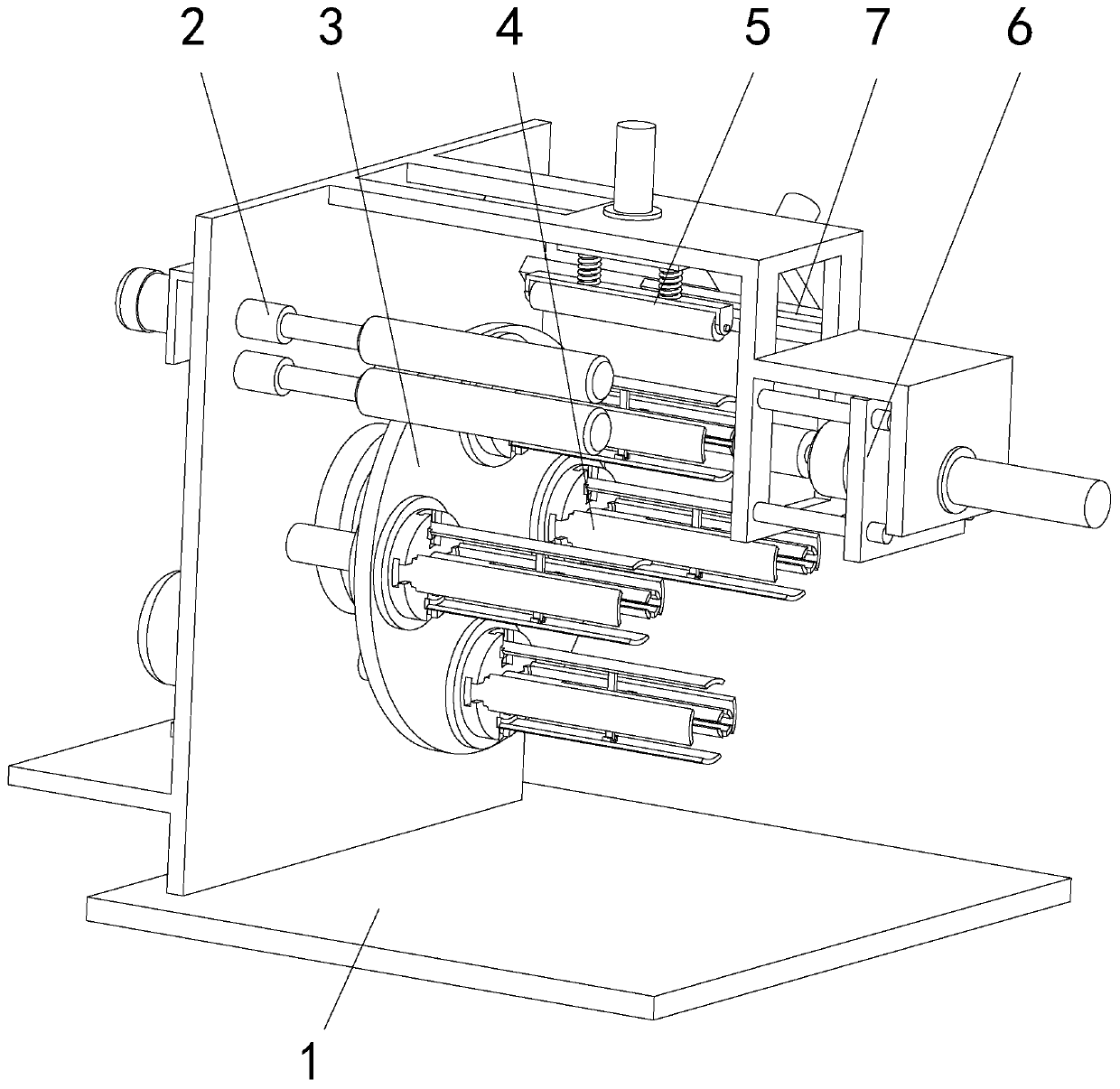

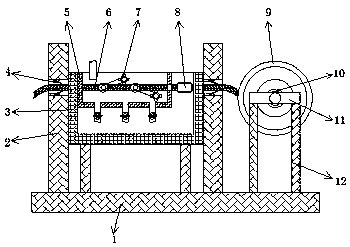

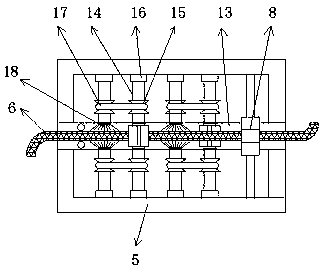

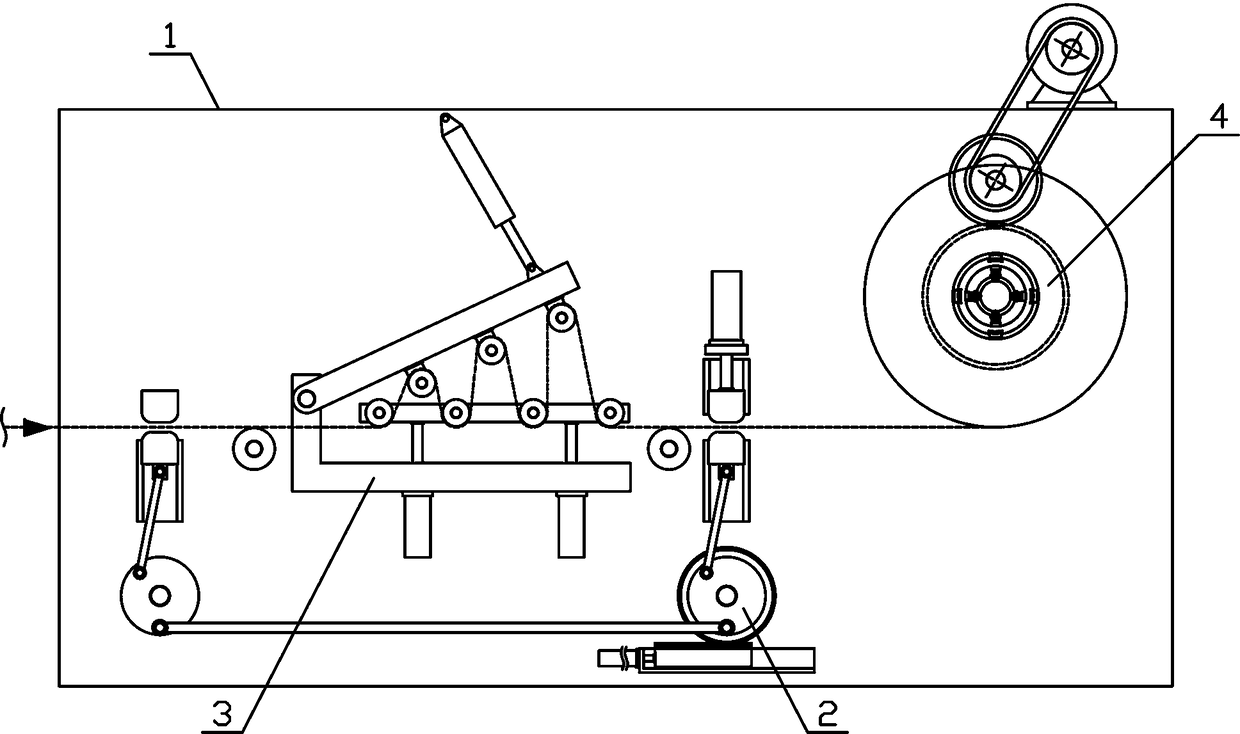

Plastic thin film preparing and coiling method

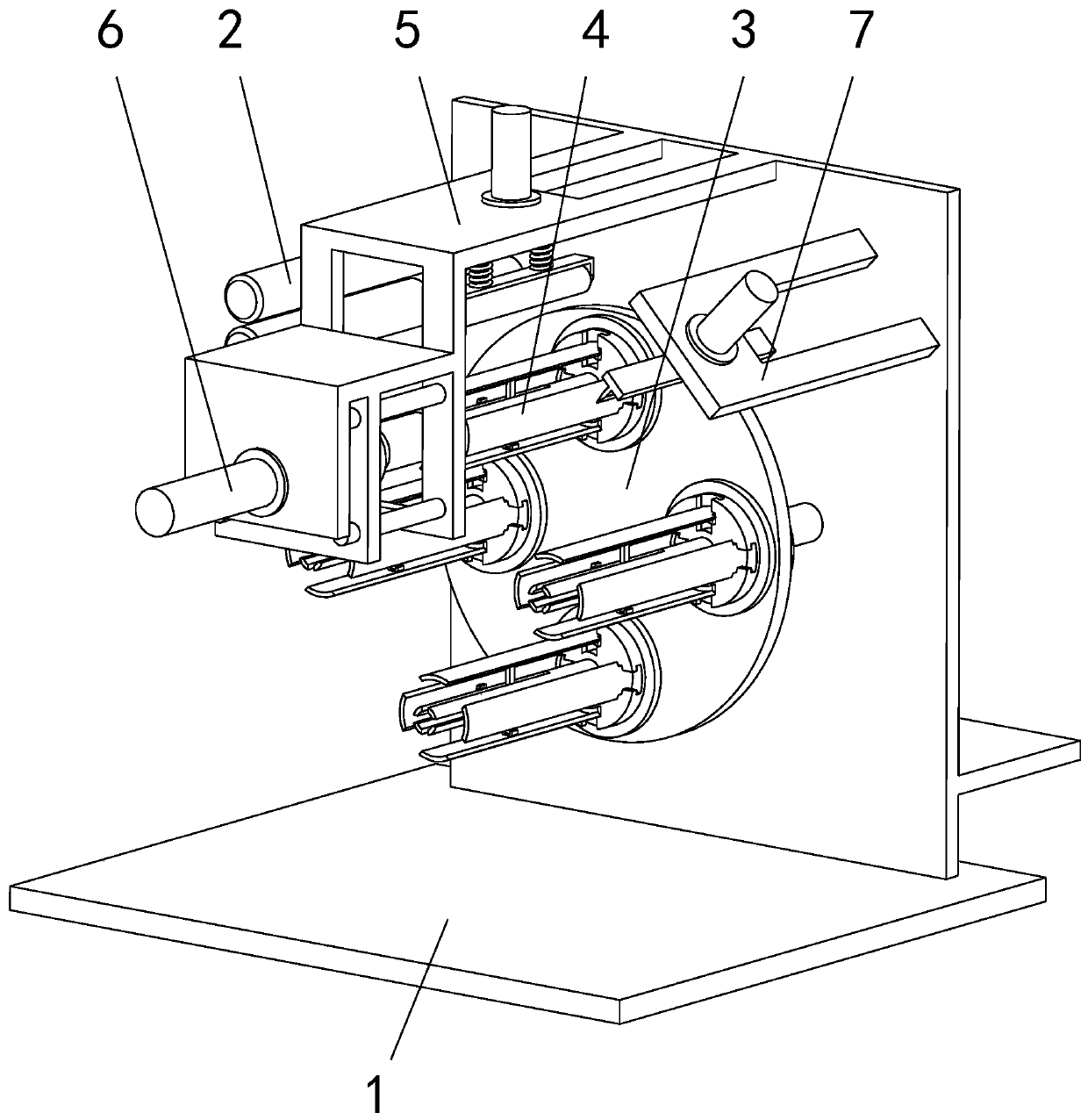

The invention relates to a plastic thin film preparing and coiling method, in particular to a plastic thin film preparing and coiling device. The device comprises a base, a feeding mechanism for conveying a plastic thin film, an intermittent rotation mechanism, four internal supporting mechanisms for internally supporting and clamping a paper tube, a press rolling mechanism for pressing the plastic thin film down, a coiling driving mechanism for driving the paper tube ro rotate to coil the thin film, and a film cutting mechanism used for cutting a plastic thin film belt off. The device involved in the method can be suitable for coiling the plastic thin film on the paper tubes with different internal diameters, continuous coiling operation can be completed at a batch, unnecessary repetitiveoperation is avoided, and the plastic thin film coiling efficiency is improved.

Owner:扬州晟至宝新材料科技有限公司

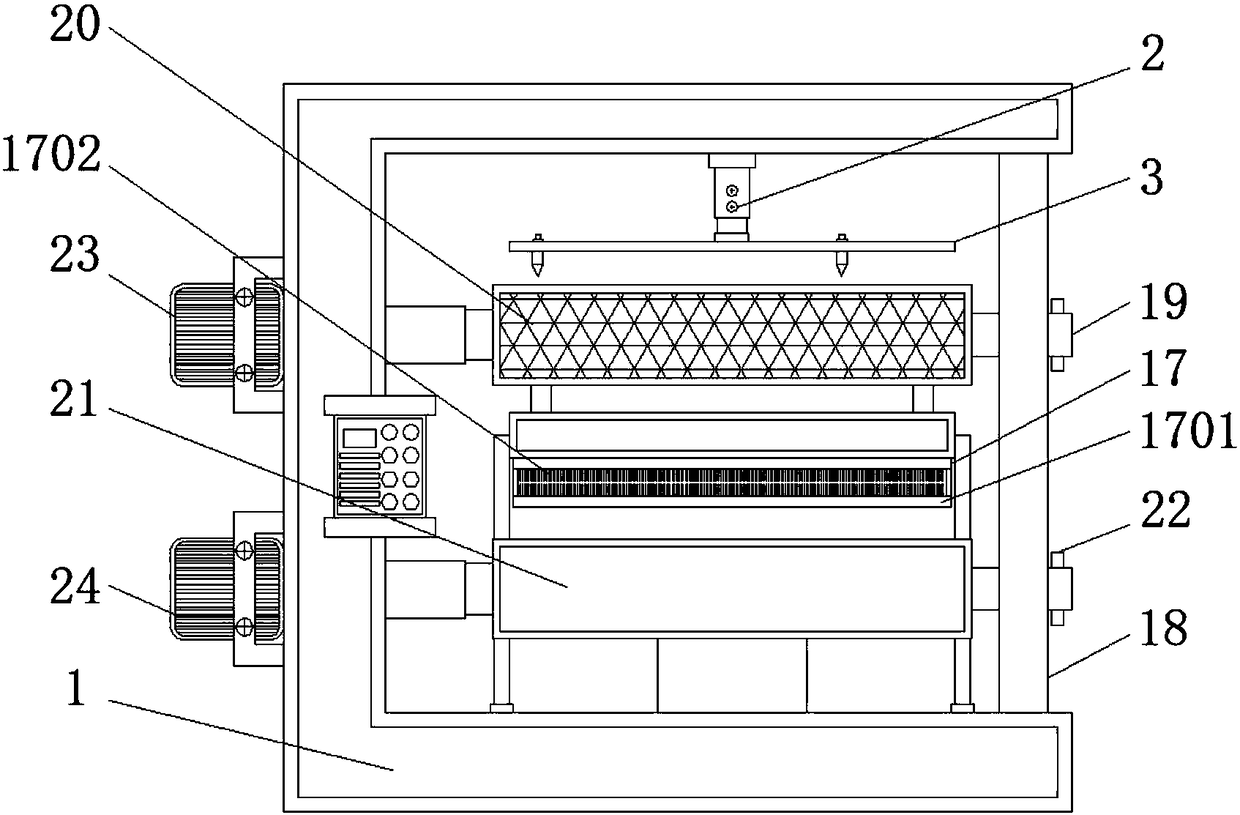

Cloth clipping and ironing integration device for garment production and processing

ActiveCN108179617AGood for collectionQuality improvementMechanical cleaningPressure cleaningEngineering

The invention discloses a cloth clipping and ironing integration device for garment production and processing. The cloth clipping and ironing integration device comprises an equipment frame body and acleaning device; the electric telescopic rods which are installed on the lower side in the equipment frame body are mutually connected with shearing devices; a connection rod which is installed abovean ironing table is connected with a transition cylinder; the front surface of the ironing table is connected with a steam iron through a manual telescopic rod; one side on the upper side in the equipment frame body is connected with an auxiliary motor through supporting seats; the cleaning device is arranged under the ironing table; a connection plate is fixed in the equipment frame body; one side of the outer part of the equipment frame body is sequentially provided with a first motor and a second motor; the auxiliary motor is rotationally connected with a connection rotary shaft; and the connection rotary shaft is provided with second limiting sleeves. By adopting the cloth clipping and ironing integration device for garment production and processing, cloth can pass through the steam iron firstly after being clipped, the certain auxiliary effect is provided to smoothness of the cloth, and subsequent garment processing is facilitated.

Owner:淮北新兴皇苑制衣有限公司

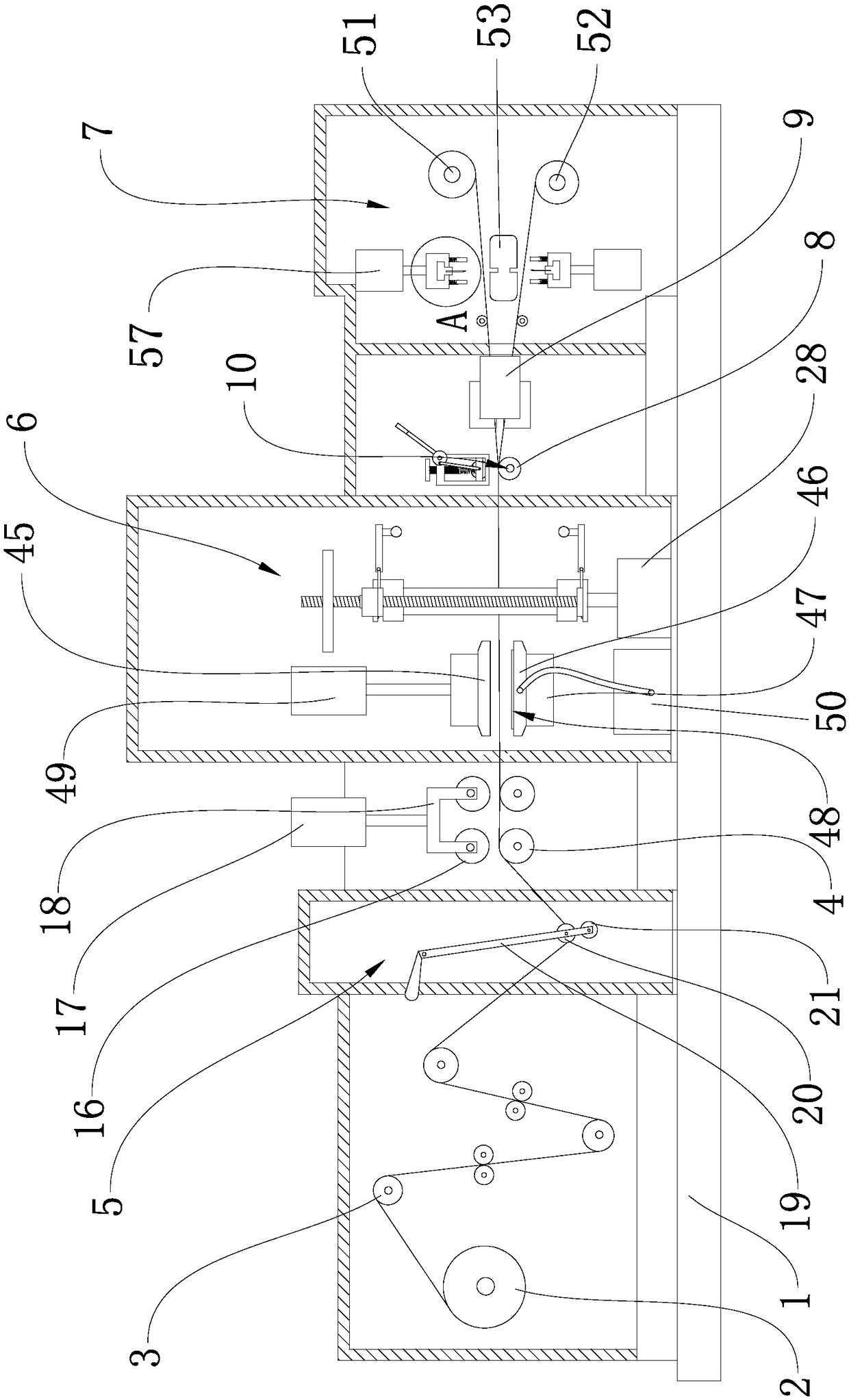

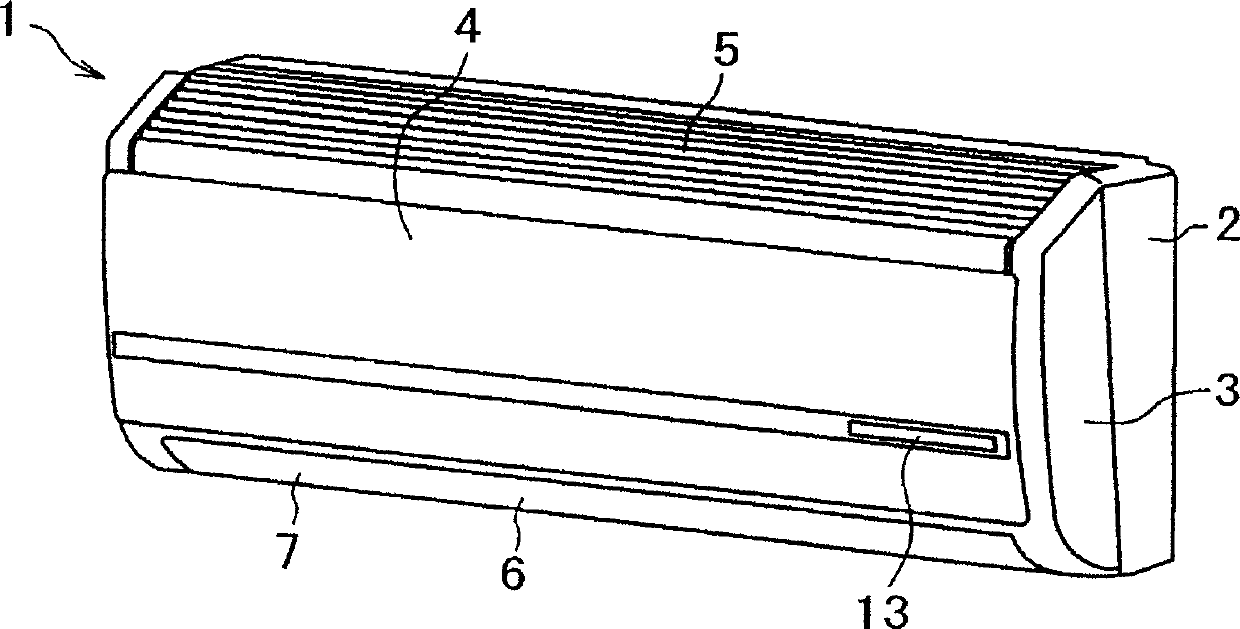

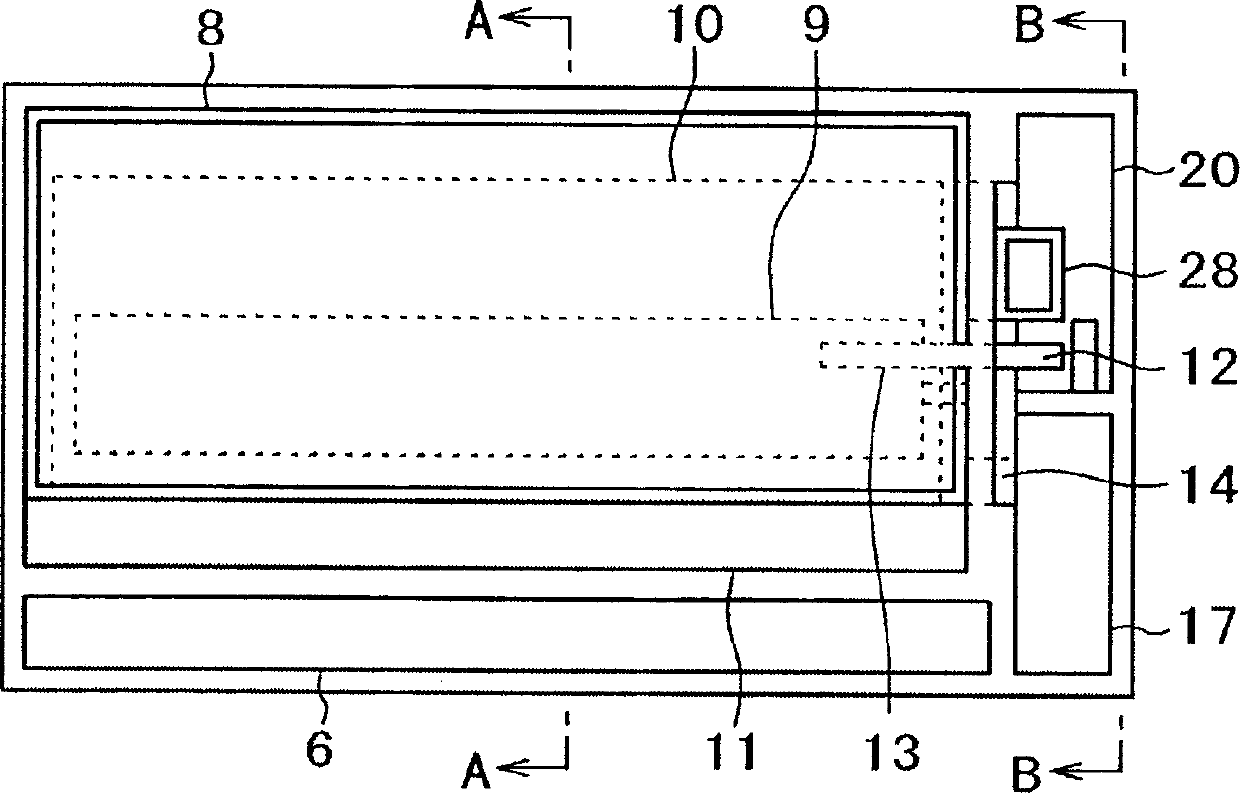

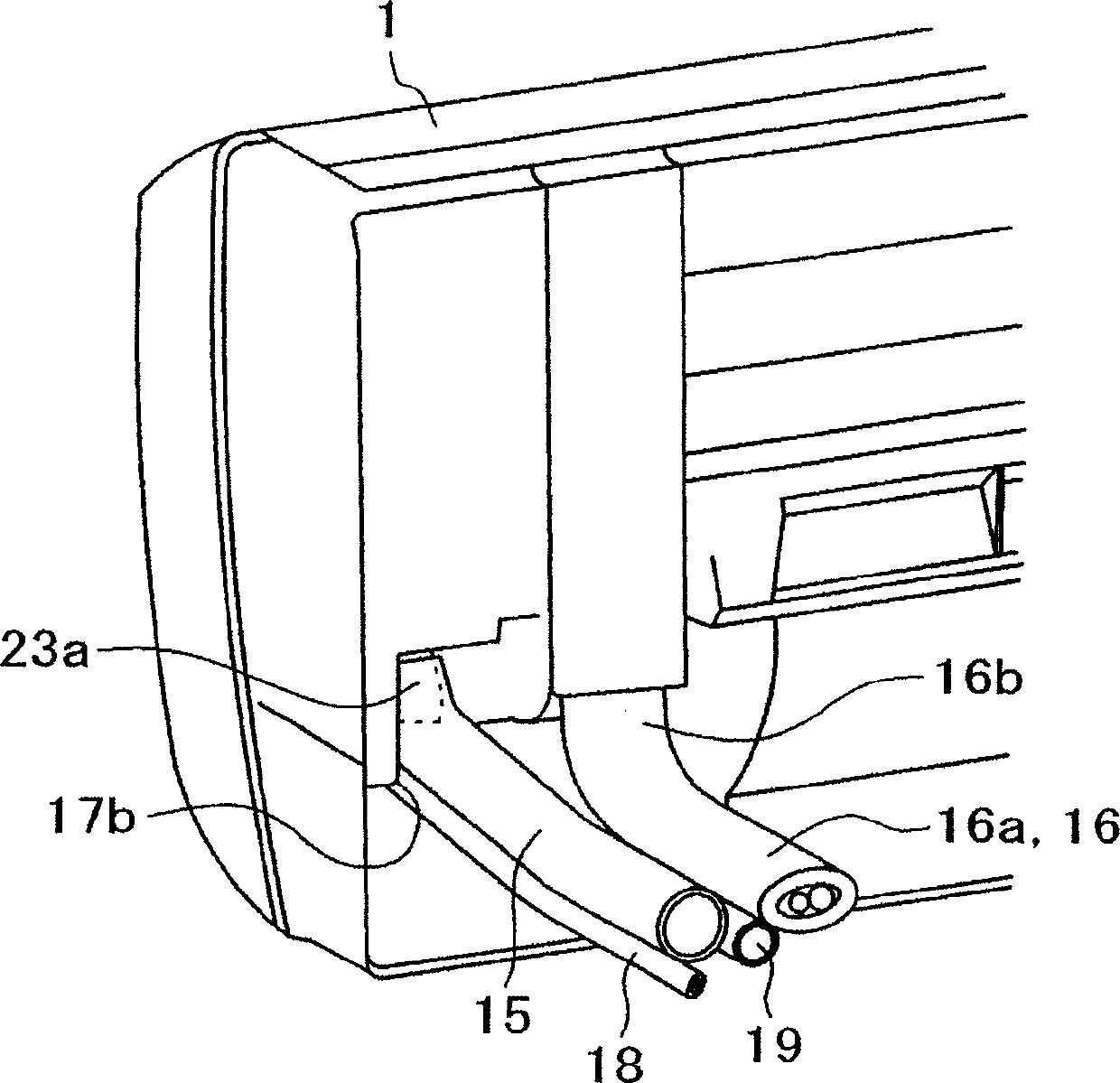

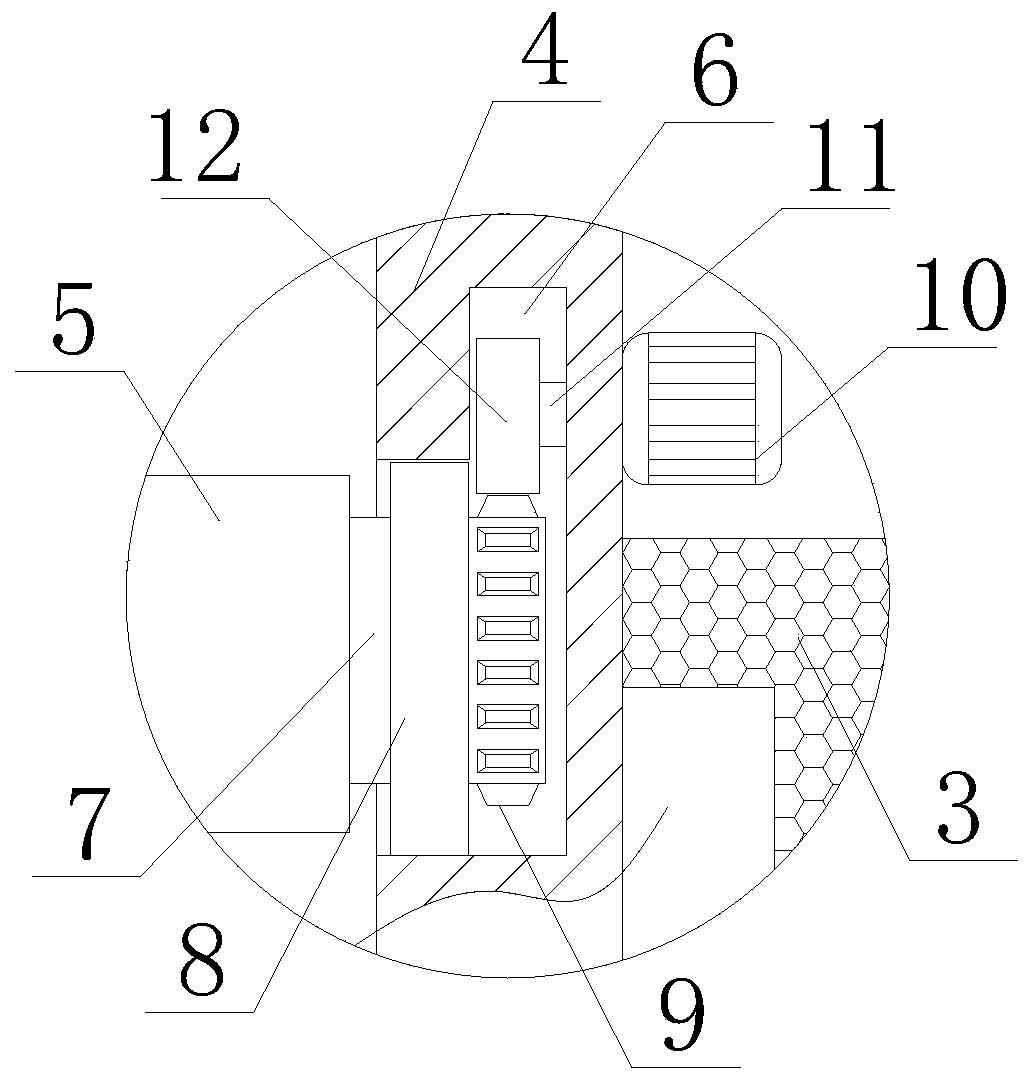

Air supply device and air conditioner using same

InactiveCN1752622ASimple structureImprove reliabilityLighting and heating apparatusHeating and ventilation casings/coversEngineeringIndoor air

To provide a small blowing device of high reliability, simple in constitution and capable of switching to air supply and exhaust. The blowing device 20 is provided with a blower section 50 and an air course switching device 40 for switching to an air course for supplying outdoor air into a room, and to an air course for exhausting indoor air to the outdoors. The blower section 50 is provided with a centrifugal blower 33 for sucking air from an axial direction and blowing off air in a circumferential direction, a suction chamber 31 formed larger than a suction port of the blower 33, and a blowoff chamber 32 formed on the blowoff side of the blower 33. The air course switching device 40 is provided with an outer shell 46 having a plurality of openings, an air course switching body 41 turnably arranged in the outer shell 46 and having a partition wall for dividing the inside into a plurality of air courses, and a driving device 47 for turning the air course switching body 41 to switch communication between the plurality of air courses of the air course switching body 41 and the plurality of openings of the outer shell 46. The air course switching device 47 is juxtaposed to overlap the suction chamber 31 of the blower section 50.

Owner:HITACHI APPLIANCES INC

Cloth clipping and ironing method for garment processing and production

ActiveCN108221351AGood for collectionEasy to cutMechanical cleaningPressure cleaningEngineeringIntegrated devices

The invention relates to a cloth clipping and ironing method for garment processing and production. The cloth clipping and ironing method is realized based on a cloth clipping and ironing integrated device. The cloth clipping and ironing integrated device comprises an equipment frame body and cleaning devices, wherein an electric telescopic rod and a clipping device which are mounted at the lowerpart in the equipment frame body are mutually connected, a connecting rod mounted above the ironing table is connected with a transition rotating cylinder, the front surface of the ironing table is connected with a steam iron by a manual telescopic rod, and one side of the upper part in the equipment frame body is connected with an auxiliary motor through a support seat; and the cleaning devices are arranged under the ironing table, a connecting plate is fixed in the equipment frame body, a first motor and a second motor are sequentially arranged outside the equipment frame body, the auxiliarymotor is rotatably connected with a connecting rotating shaft, and a second limiting sleeve is mounted on the connecting rotating shaft. According to the cloth clipping and ironing method for garmentprocessing and production, cloth is conveyed to pass through the steam iron after being clipped, so that an auxiliary effect is provided for the flatness of the cloth, and subsequent garment processing is promoted.

Owner:佛山市梦得斯服饰有限公司

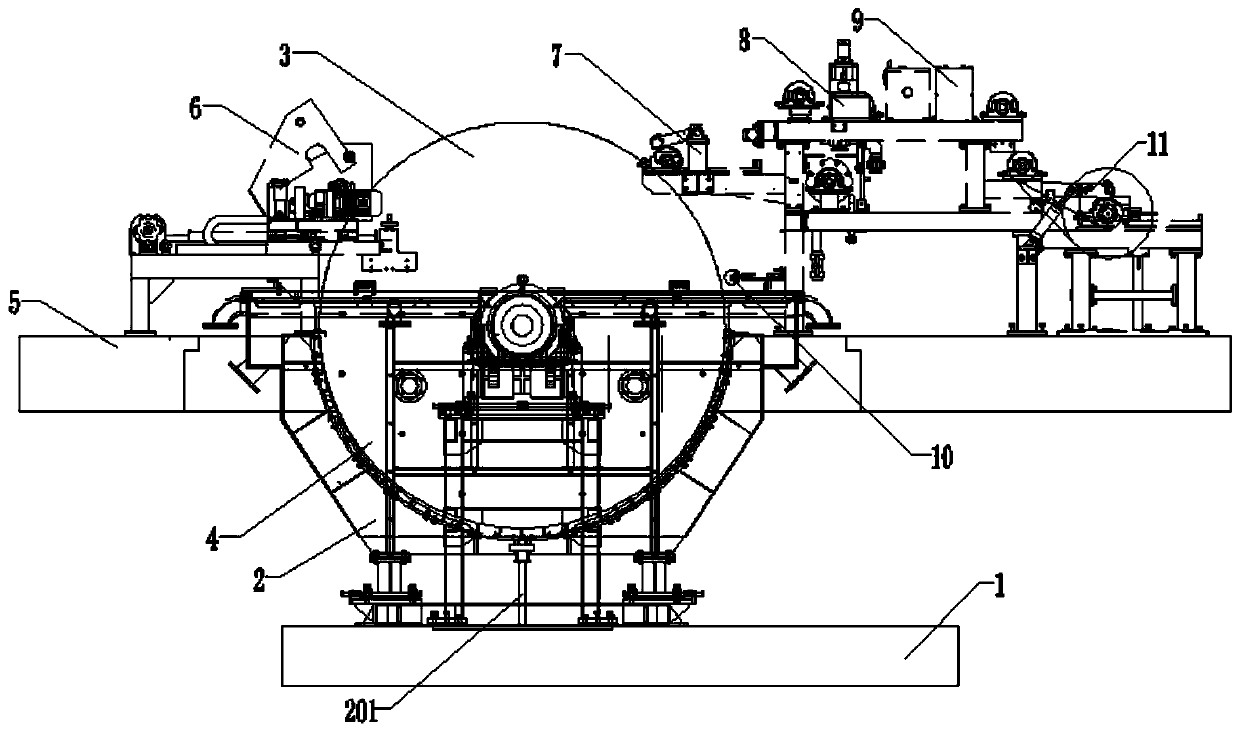

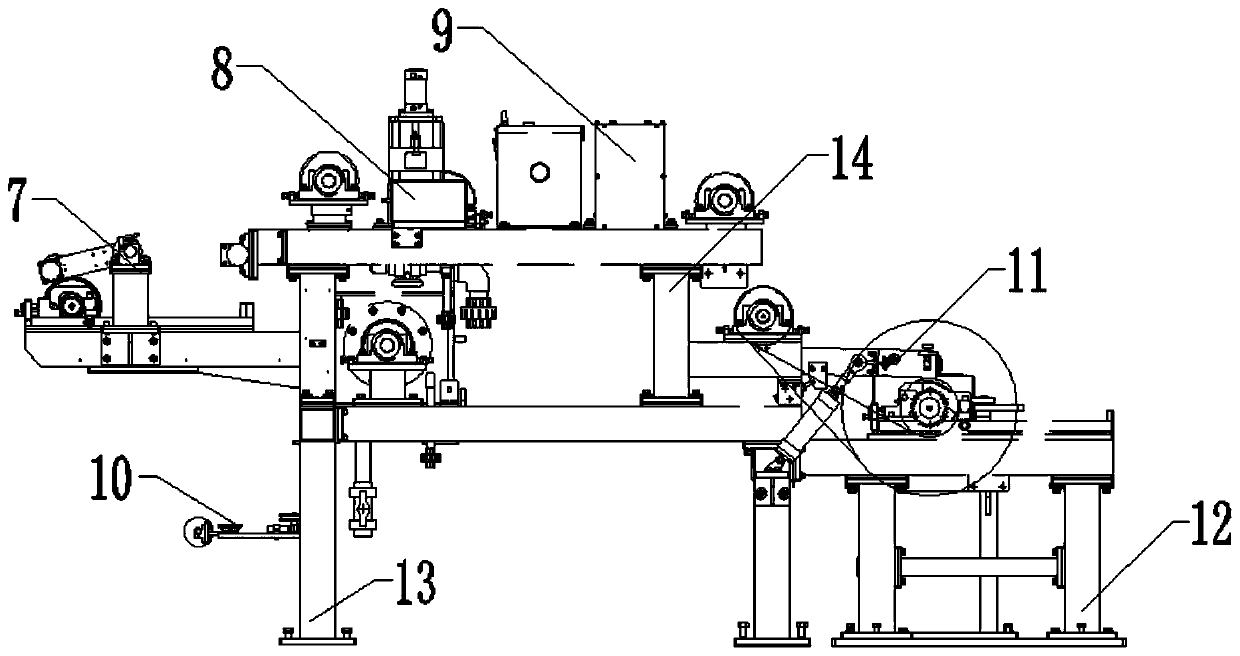

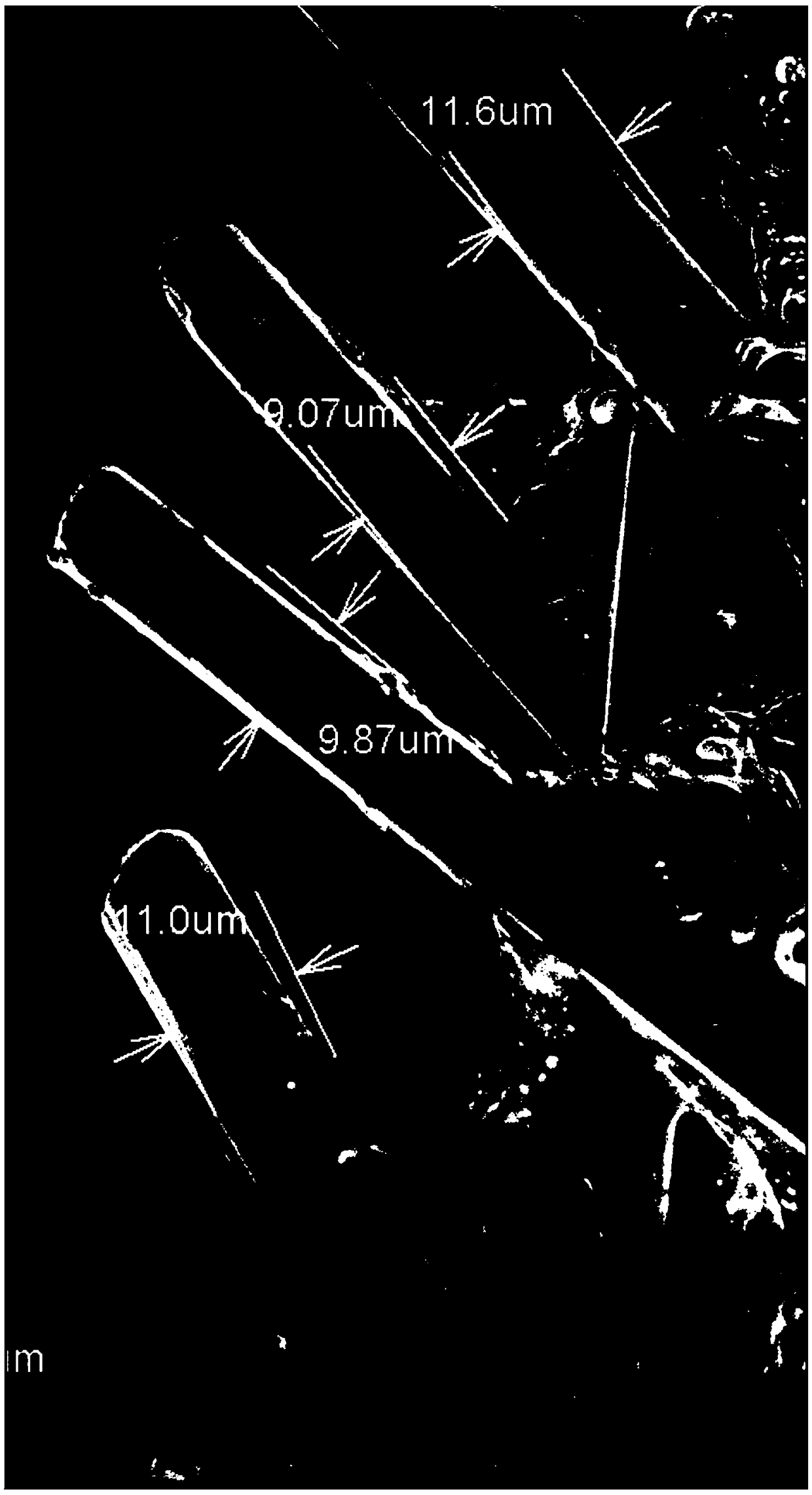

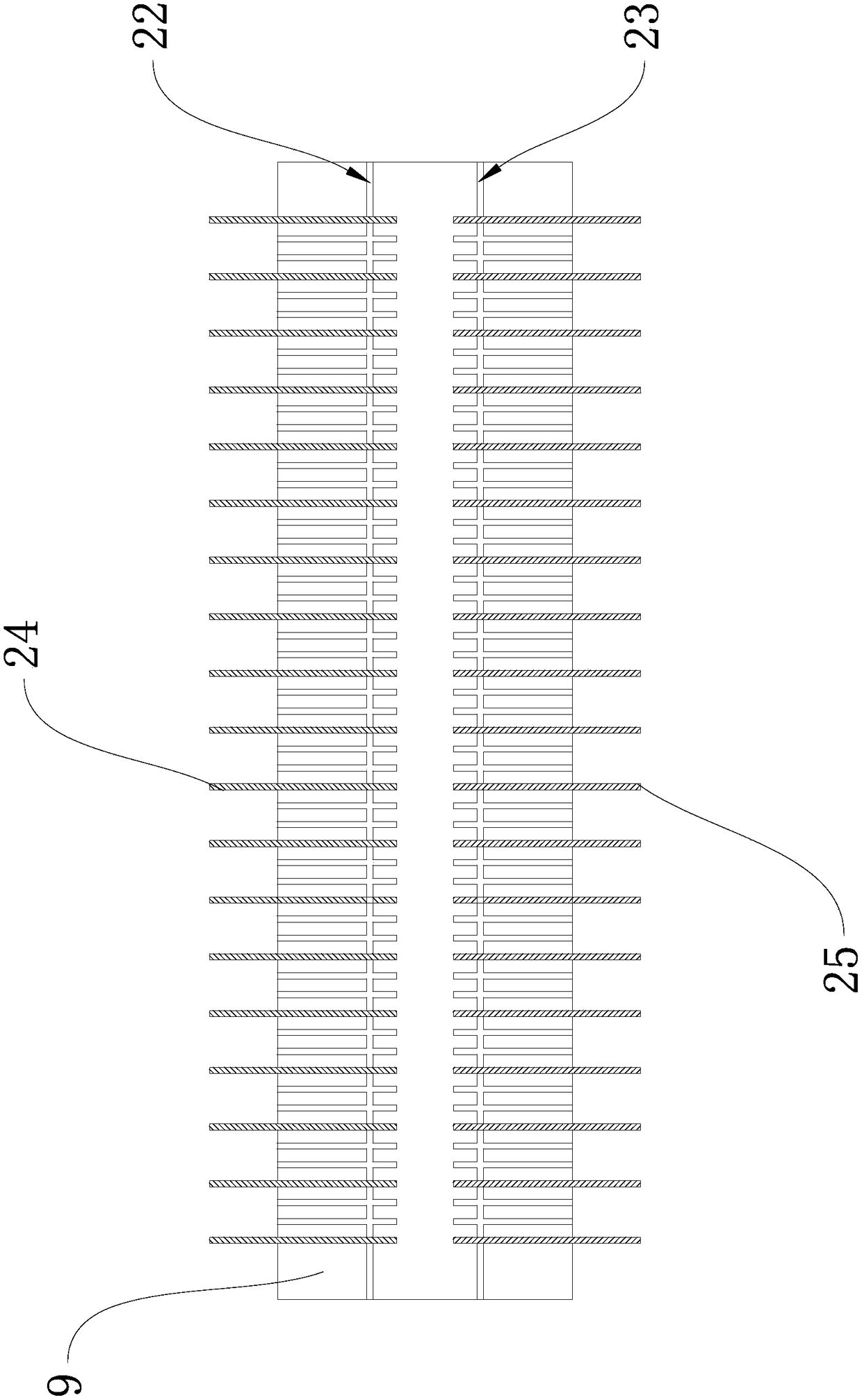

Preparation device for 4.5 microns ultrathin electrolytic copper foils and preparation process thereof

ActiveCN111155150ASolve the edge tearing problemSolve wrinkleElectroforming processesElectrolytic agentManufacturing technology

The invention discloses a preparation device for 4.5 microns ultrathin electrolytic copper foils and a preparation process thereof to achieve the purpose through the following technical scheme. The preparation device comprises an anode tank, a cathode roller, a conductive device, a online grinding mechanism, a water washing mechanism, a stripping and trimming mechanism, an oxidation preventing mechanism, a drying fan cooling mechanism, and a winding mechanism. The preparation process enables each performance of products to meet related index requirements mainly through control of the electrolyte flow, the electrolyte temperature, the electrolyte major constituents, the electrolyte micro-components, the direct current amount and the additive process. The invention effectively solves the edge tearing problem of the cathode roller and the corrugation problem of copper foils in the production process, and meanwhile, improves the tensile strength and ductility of products and meets the demands of high-end customers to key physical indexes of the copper foils through the research and development breakthrough on the key technologies such as an electrolyte preparation technology and a rawfoil manufacturing process.

Owner:TAIXING SHENGDA COPPER IND CO LTD

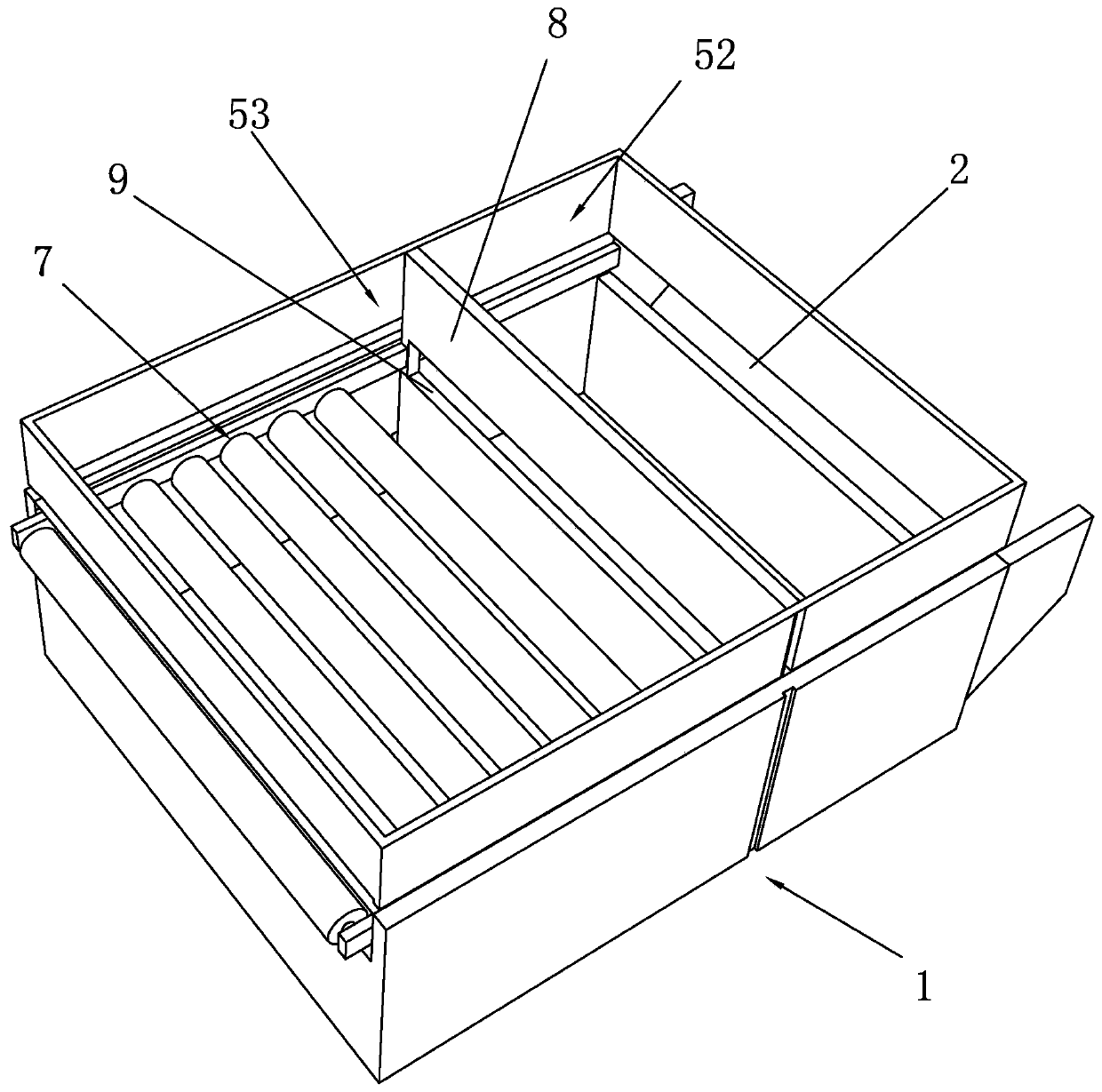

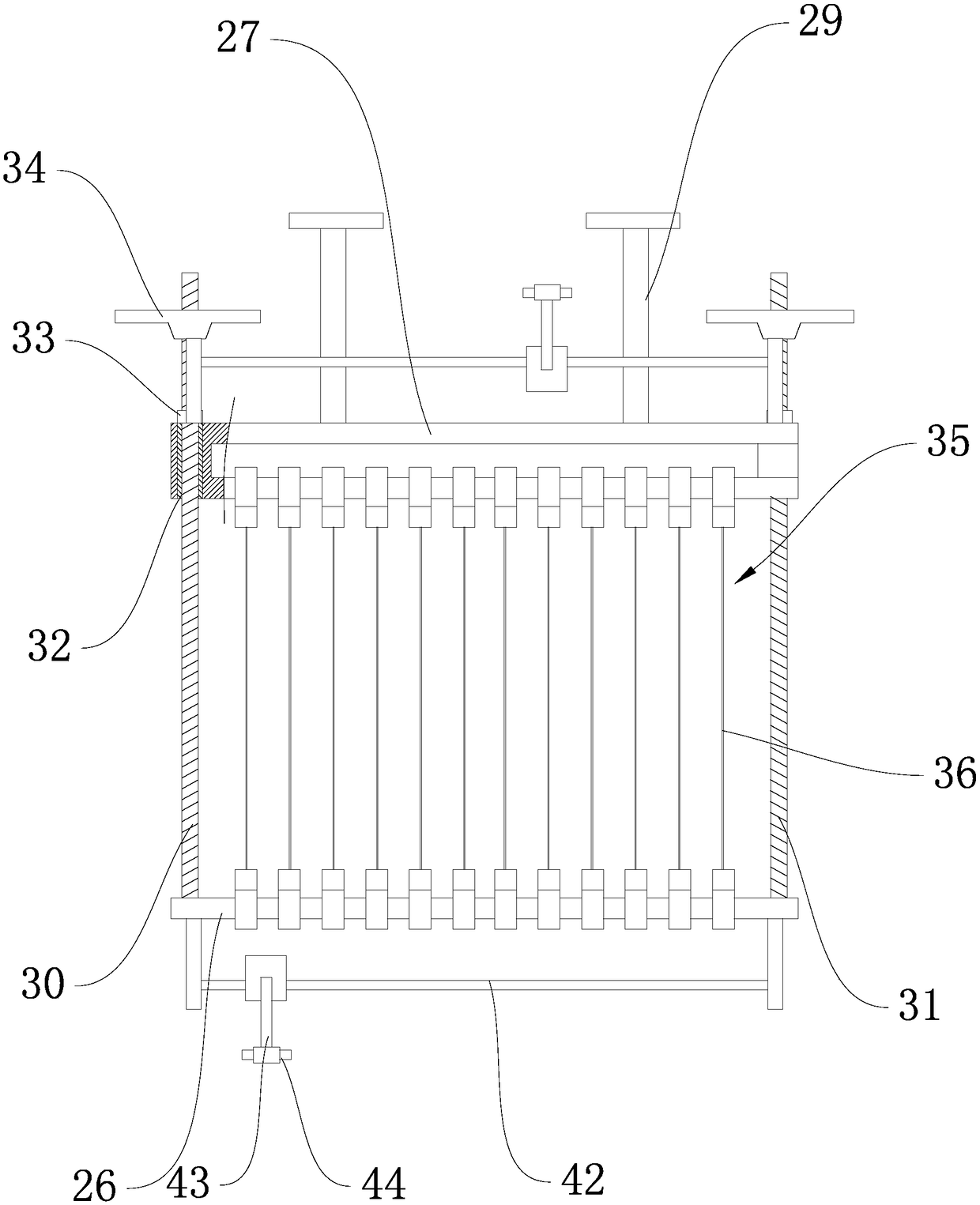

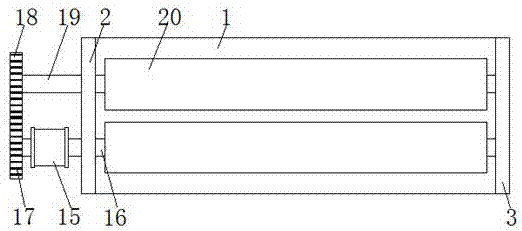

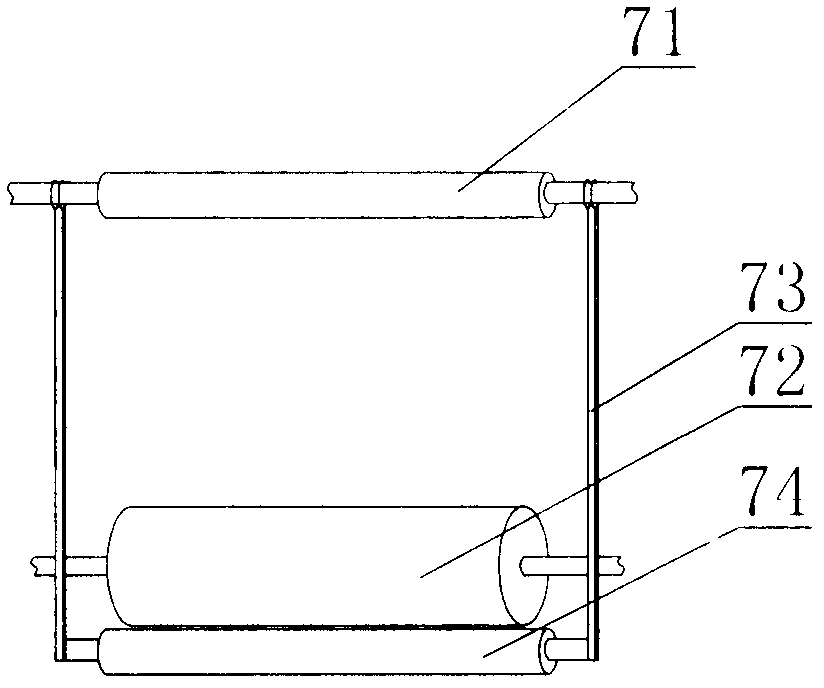

Woven-cloth winding and storing mechanism

InactiveCN105936435AConvenient for temporary storageEasy to rewindWebs handlingConductor CoilMechanical engineering

Owner:WUJIANG HUAYUN TEXTILE

Acrylic polyurethane coating and preparation method and application thereof

ActiveCN107216792AGood light transmissionGood light diffusion effectDiffusing elementsPolyurea/polyurethane coatingsPlasticizerAcrylic resin

The invention discloses an acrylic polyurethane coating and a preparation method and application thereof in manufacture of a connecting material or a protective coating. The acrylic polyurethane coating is prepared by mixing hydroxyl acrylic resin, a hydroxyl polyurethane plasticizer and a polyisocyanate curing agent. The acrylic polyurethane coating is mainly used for making the resin connecting material of an optical diffusion film, and the coating after the film formation has good light transmittance and light diffusion property and high scratch resistance, and has the advantages of prevention of falling off of resin micro beads in a diffusion layer. The acrylic polyurethane coating can also be used for making optical films such as brightening films and reflecting films, and the ratio of the three components can be adjusted according to the use and the substrate characteristics of different optical films so as to achieve the coating performances required by different purposes.

Owner:周建明

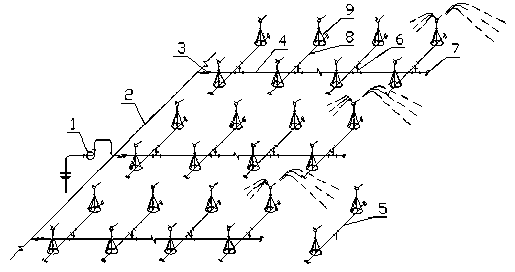

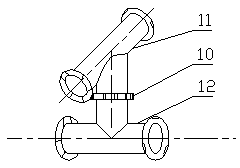

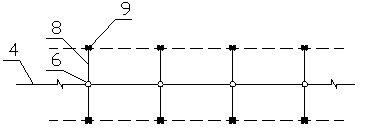

Combined-type, fixable and movable double-purpose sprinkling irrigation system with double branch pipes

ActiveCN103299879AAdjustable spacingEasy to rewindClimate change adaptationWatering devicesTerrainFour-way valve

A combined-type, fixable and movable double-purpose sprinkling irrigation system with double branch pipes comprises a pump unit, a main pipe, branch control valves, branch pipes, multiple groups of double-branch-pipe nozzle assemblies combined four-way valves and core plugs, wherein each group of double-branch-pipe nozzle assembly comprises symmetrically-arranged double branch pipes and two nozzles; the main pipe is connected with the pump unit; the branch control valves are arranged at the inlets of the branch pipes; and the double branch pipes are connected to the branch pipes through the four-way valves. The pipes are rigid plastic pipes or plastic-coated hoses, and each four-way valve is formed by staggered connection of two three-way valves through a quick connector. During assembly of the system, the main pipe and the branch pipes are arranged at first, then the double-branch-pipe nozzle assemblies are connected; and during moving, the combined four-way valves are unscrewed, and the double-branch-pipe nozzle assemblies can move simultaneously, or the main pipe and the branch pipes are fixed on the ground, other components can be moved. Nozzle space in the system is changeable, so that rectangle and triangle spraying can be realized easily; the system is high in suitability of terrain and crops; in the system, the branch pipes are used for dividing flow, the main pipe laying length is increased, and the development of the unit form is facilitated; and the system can be used in spraying and micro irrigation with high uniformity.

Owner:JIANGSU UNIV

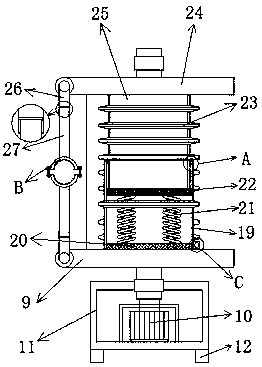

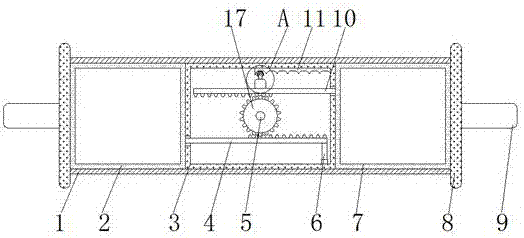

Winding device with decontamination function for submarine cable

The invention belongs to the technical field of submarine cables, and particularly relates to a winding device with a decontamination function for a submarine cable. Aiming at the problems that the surface of the cable is not decontaminated, the phenomenon of unwinding cannot be effectively avoided, and a winding cylinder is not fastened, the winding device comprises a supporting base, supportingcolumns are arranged on the outer wall of one side of the top of the supporting base, a waste water tank is arranged on the outer walls of one sides of the supporting columns, the inner wall of one side of the waste water tank is provided with a cleaning tank, and the outer wall of the top of the cleaning tank is provided with a cleaning groove; a circular hole is formed in the outer wall of one side of each supporting column, the inner wall of each circular hole is provided with eight-claw inverted teeth, and reset springs are arranged on the outer walls of the eight-claw inverted teeth. Thewinding device converts friction force into power, bristles are driven to clean the surface of the cable through the rotation of cross-shaped rotating plates, the unwinding phenomenon caused by the gravity of the cable is avoided, winding is more stable through the negative pressure in the winding cylinder, and the cable is prevented from getting loose.

Owner:安徽振瀚建设工程有限公司

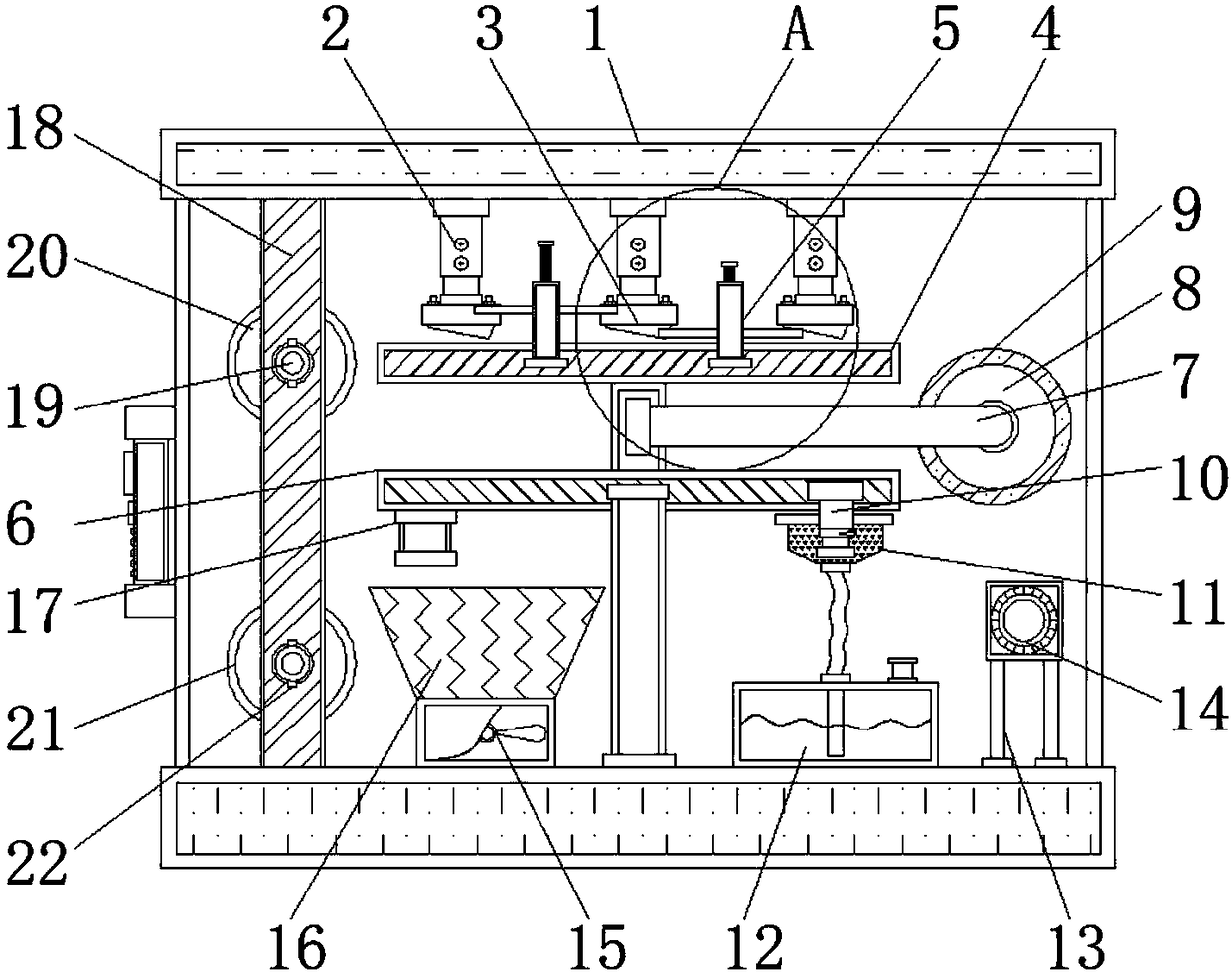

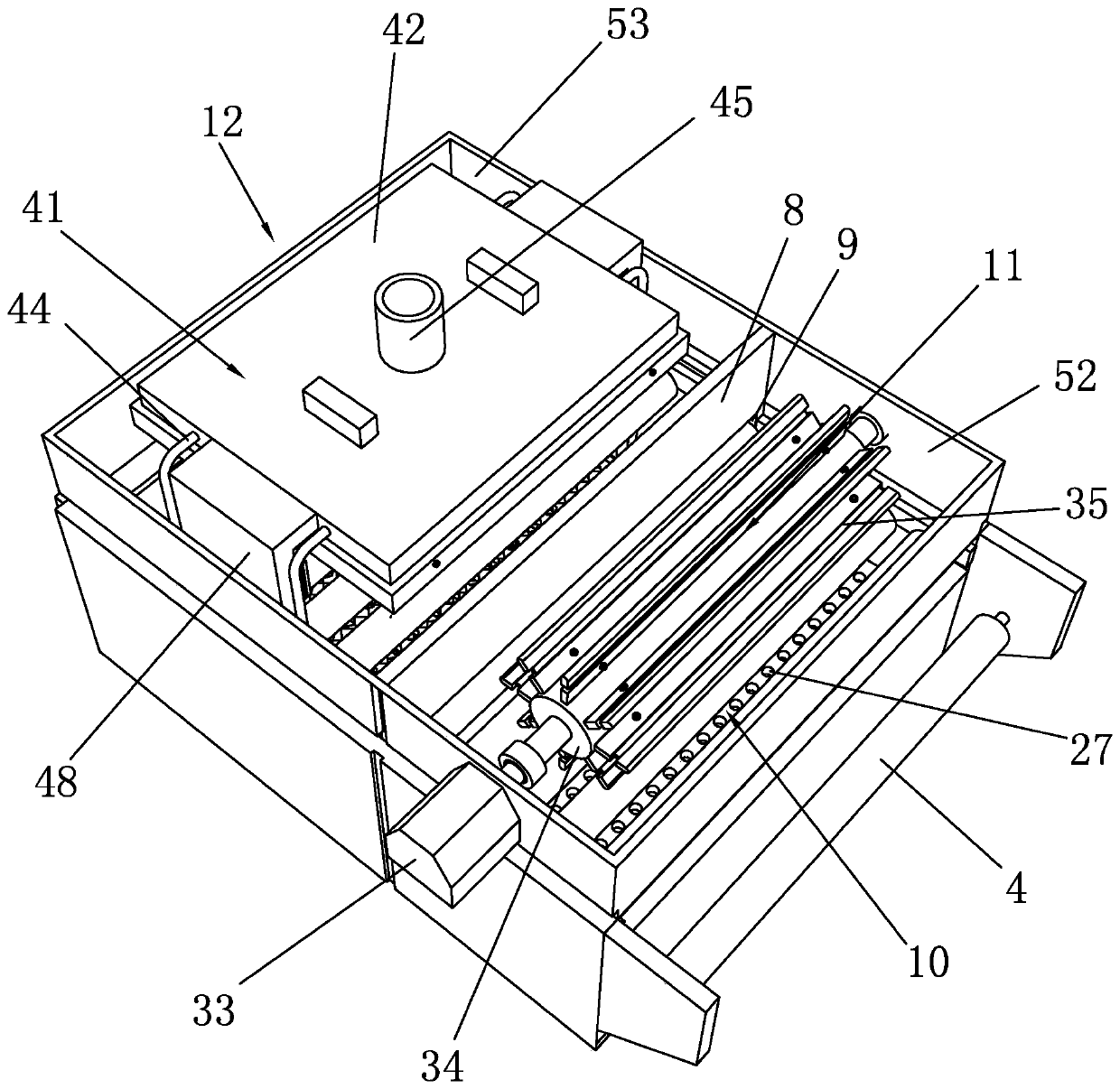

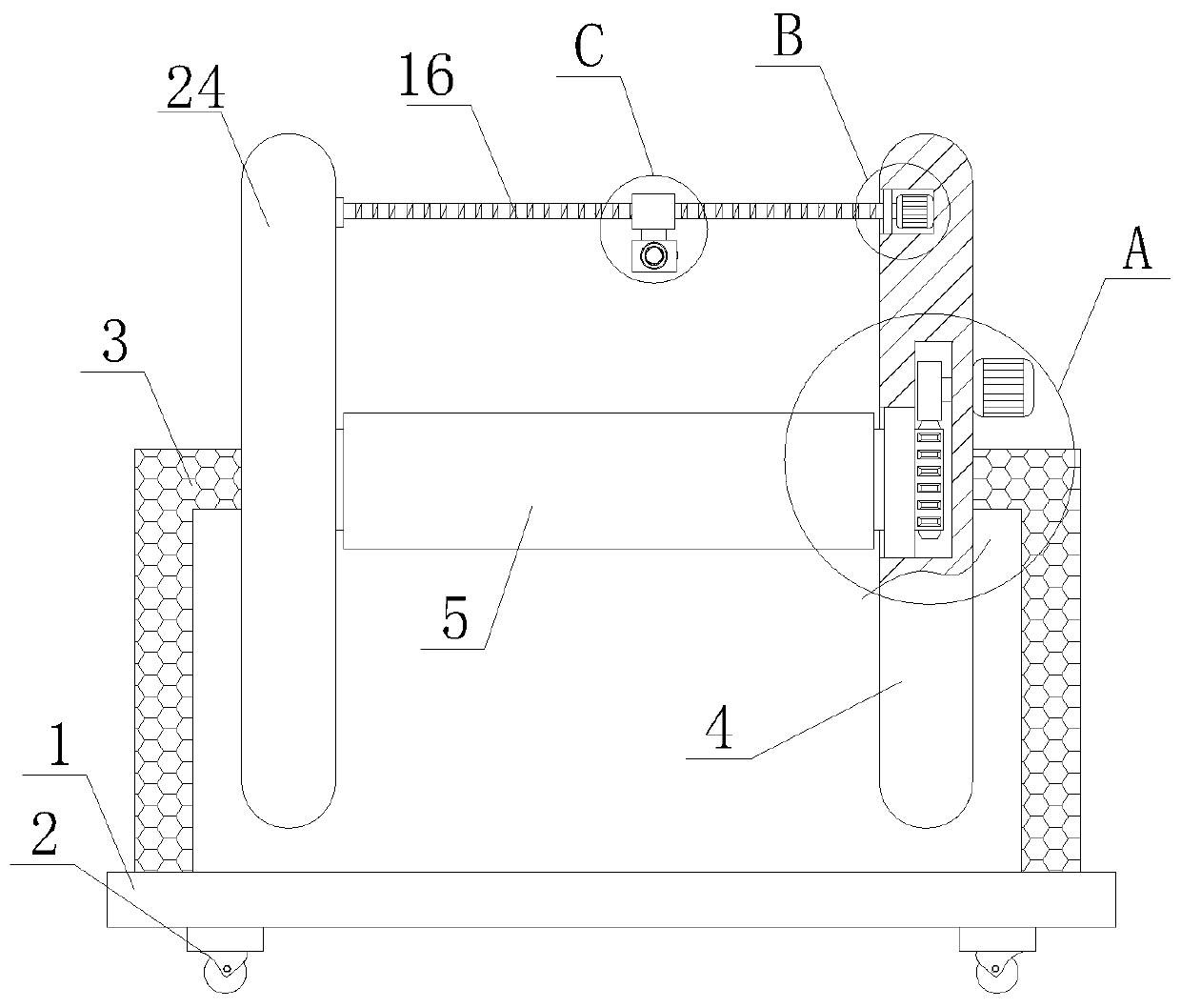

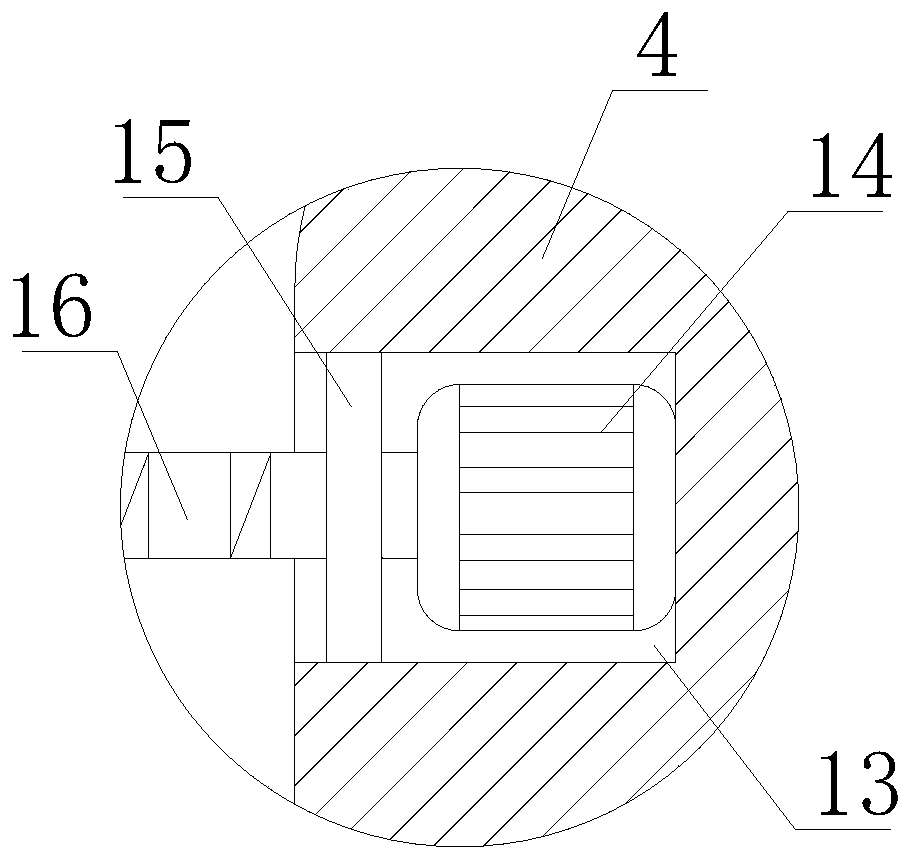

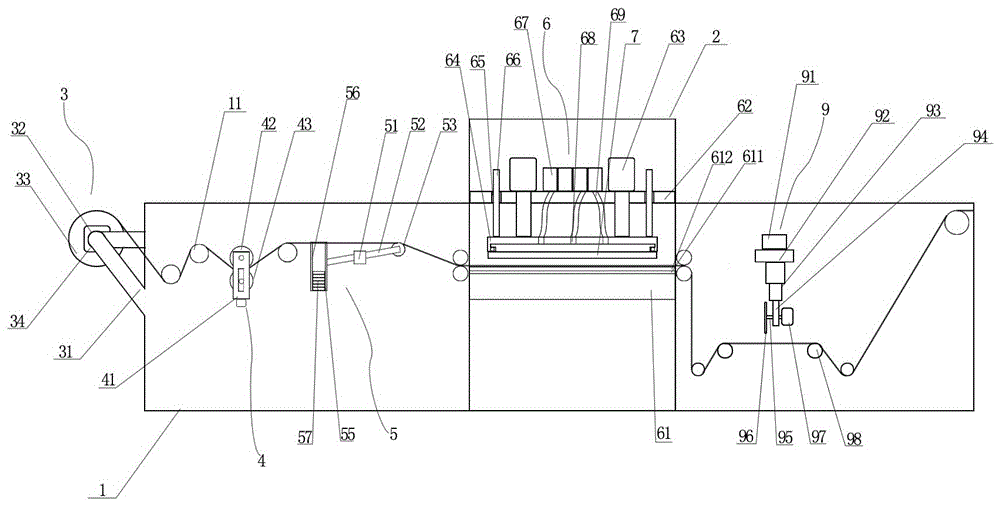

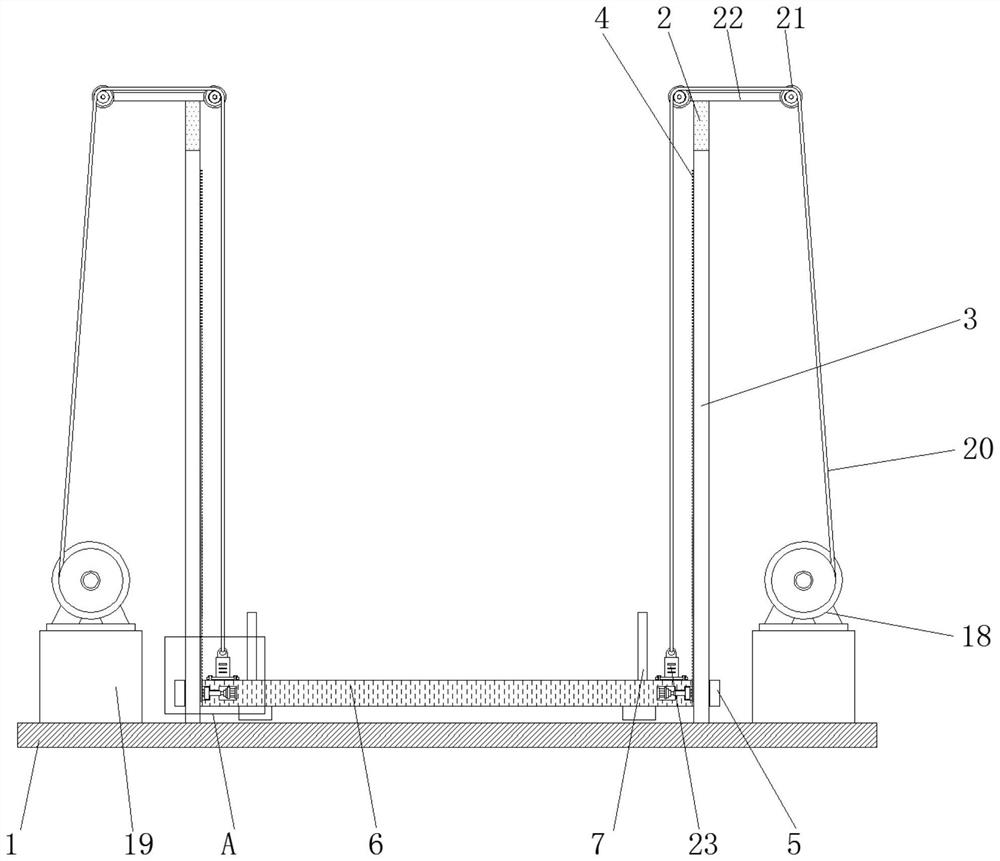

Jet-dyeing device with good cloth spraying uniformity and application method thereof

ActiveCN110424112AEasy to rewindNeatly rolledMechanical cleaningTextile storage in wounded formEngineeringMechanical engineering

The invention discloses a jet-dyeing device with good cloth spraying uniformity and an application method thereof. The jet-dyeing device comprises a base, a rack, a box body, a heating box and an unwinding roller. The unwinding roller is in drive connection with one end of the top of the base; the box body is fixedly mounted at the top center of the base; the inside of the box body is divided intoa drying chamber and a spraying chamber through a partition arranged; a second adjustment is fixedly mounted at the side, close to the unwinding roller, of the interior of the spraying chamber; a mounting plate is fixedly mounted at one side of the second adjustment. Processing and guiding can be performed on cloth different in thickness by adjusting a distance between an adjusting roller and a driving roller through the two adjustments; clamp rings are driven to move back and forth on the unwinding roller by enabling an electric telescopic bar to operate, a distance between the two clamp rings can be adjusted, and therefore, cloth different in width can be wound conveniently; winding evenness is better, operating is simple, and using is facilitated.

Owner:安徽宜民服饰股份有限公司

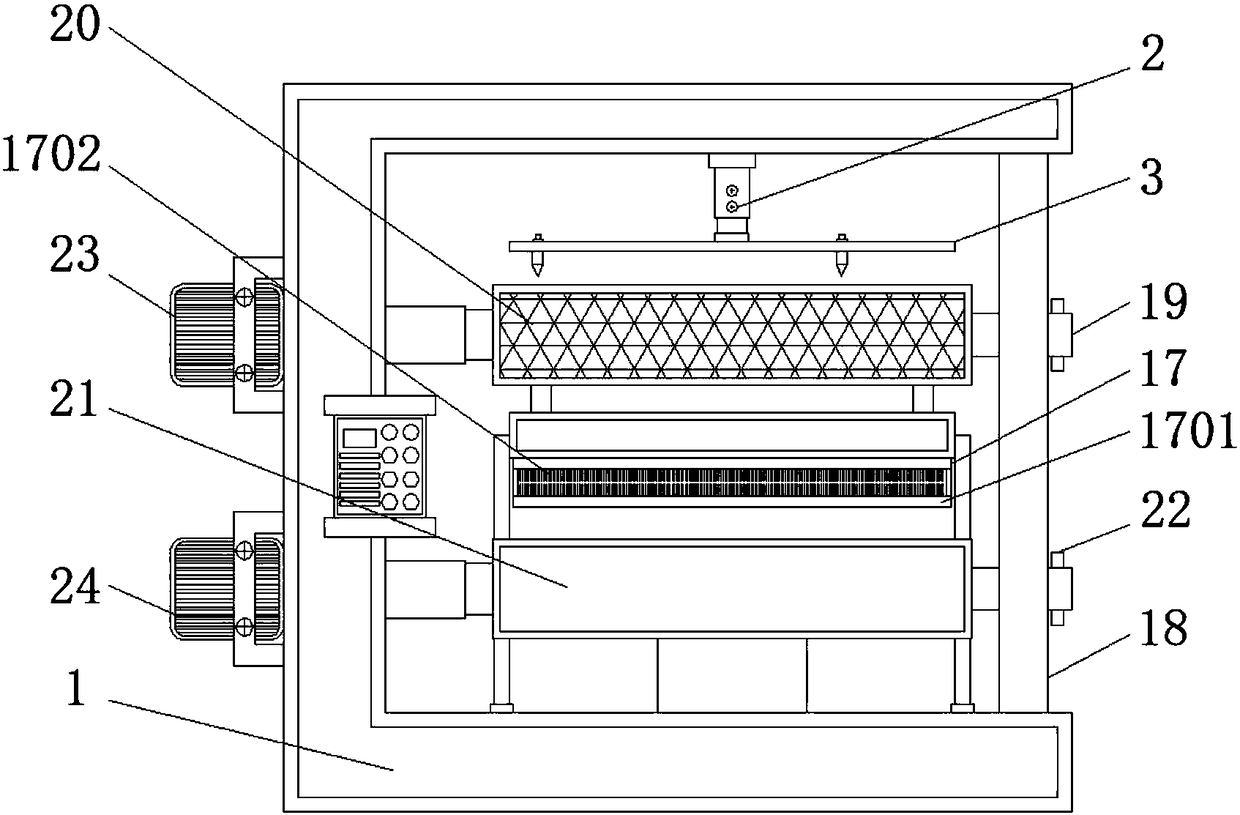

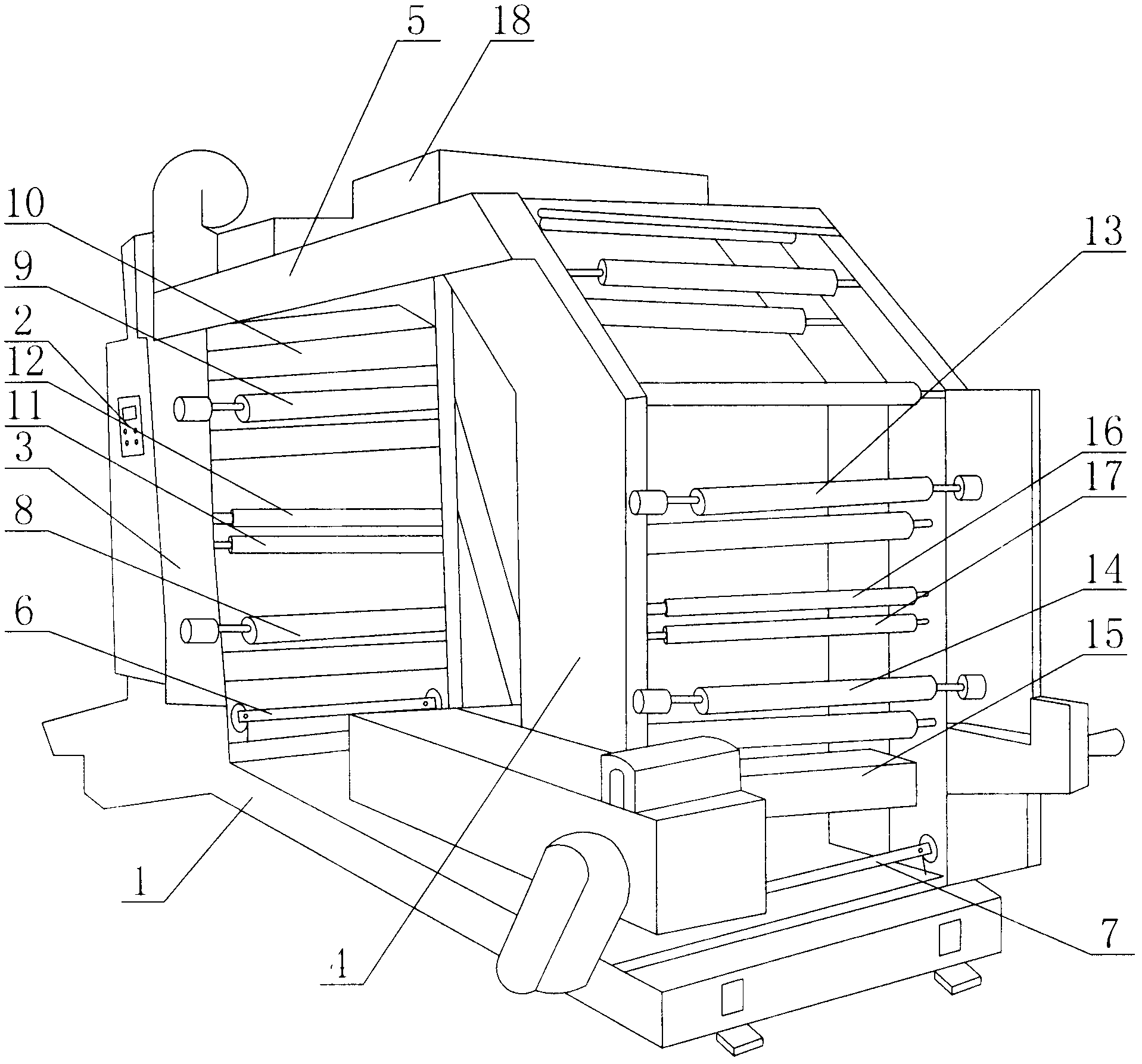

Shaping machine for after-finishing of fabrics

ActiveCN109944006AGuaranteed cooling rateConsistent cooling rateSucessive textile treatmentsHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a shaping machine for after-finishing of fabrics. The shaping machine comprises a box body, wherein a bracket is arranged on the left side of the box body; a cooling assembly and a static electricity removing assembly are sequentially arranged on the bracket from left to right; a conveying roller platform penetrates through the box body; the interior of the box body is divided into a preheating cavity and a drying cavity by a partition plate; a through groove is formed in the partition plate; a steam spraying disc and a flapping assembly are arranged in the preheating cavity, and a drying assembly is arranged in the drying cavity. The provided shaping machine for after-finishing of fabrics is ingenious and reasonable in structural design; fabrics are subjected to steam humidification and heating treatment through the steam spraying disc in the preheating cavity; the surfaces of the fabrics are humidified more uniformly through the cooperation of the flapping assembly; the fabrics are better loosened and softened and then enter the drying cavity to be dried by the drying assembly at the optimal temperature; after the fabrics are cooled through the cooling assembly, the fabrics are subjected to static electricity removal treatment through the static electricity removing assembly, so that winding and treatment of the fabrics are more convenient.

Owner:绍兴柯桥如川纺织科技有限公司

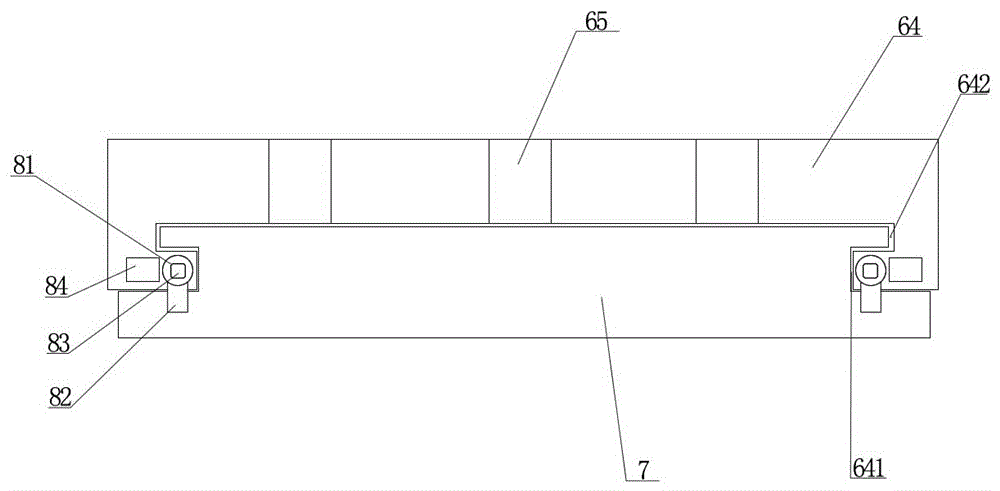

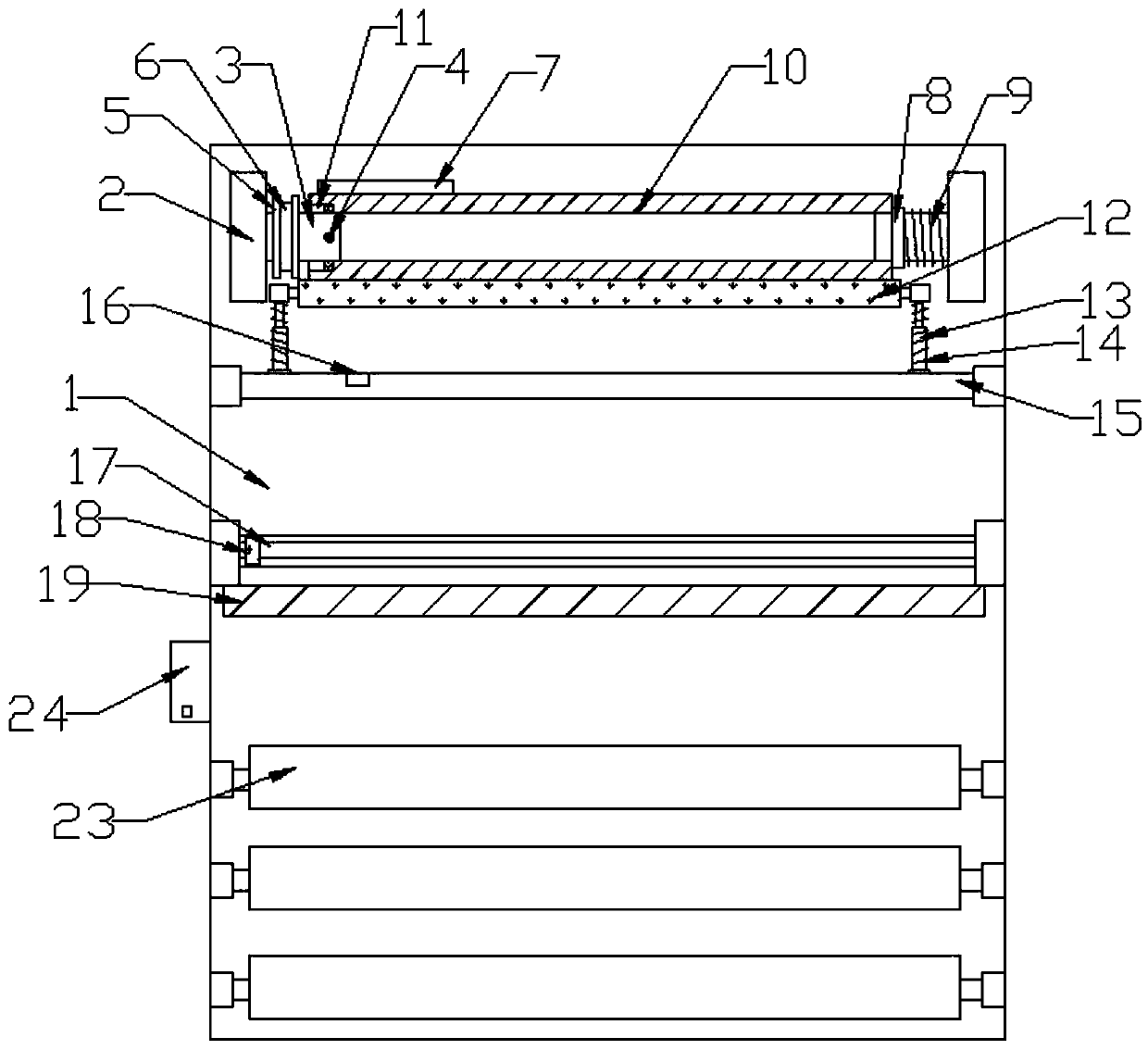

Yarn drafting and rolling mechanism

InactiveCN109230836AHigh degree of processing automationReasonable structural designFilament handlingTextiles and paperYarnMechanical equipment

The invention discloses a yarn drafting and rolling mechanism and belongs to the field of mechanical equipment for yarn conveying processing. Yarn press mechanisms are vertically arranged at the two sides of a drafting mechanism of the yarn drafting and rolling mechanism respectively, a rolling mechanism is arranged on a rolling support of one side of a yarn press mechanism, and multiple draftingrotation rollers are horizontally and rotatably connected to a lifting support of the upper side of a drafting support in the horizontal direction in sequence; multiple rotation rollers are horizontally and rotatably connected to a rotation support in the inclination direction in sequence, yarn press rotation discs are vertically and rotatably connected to rolling supports of the two sides of thelower portion of the drafting mechanism respectively, yarn press connection rods is arranged between lifting yarn press plates and the yarn press rotation discs, and a rolling yarn cylinder slidinglysleeves a rolling rotation roller in the horizontal direction. The yarn drafting and rolling mechanism is reasonable in structural design, the yarn can be stably and evenly drafted and processed segment by segment and can be conveniently and efficiently rolled, the automation degree of yarn processing is improved, and the demands of production and application are met.

Owner:桐乡市澳得利纤维股份有限公司

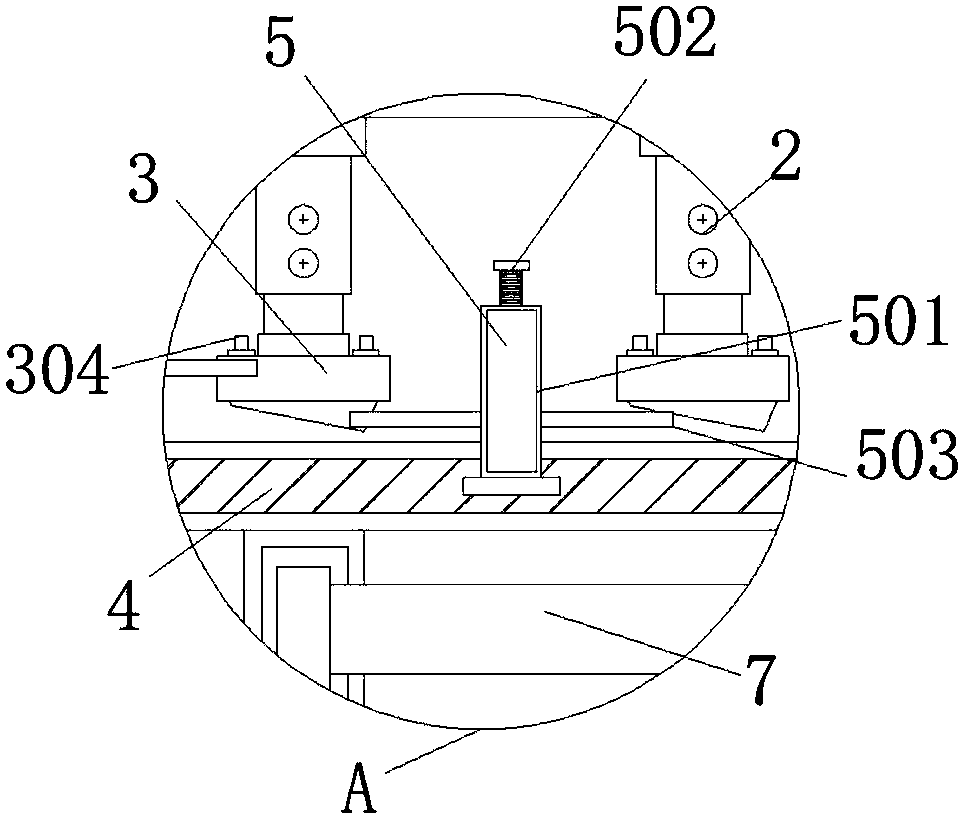

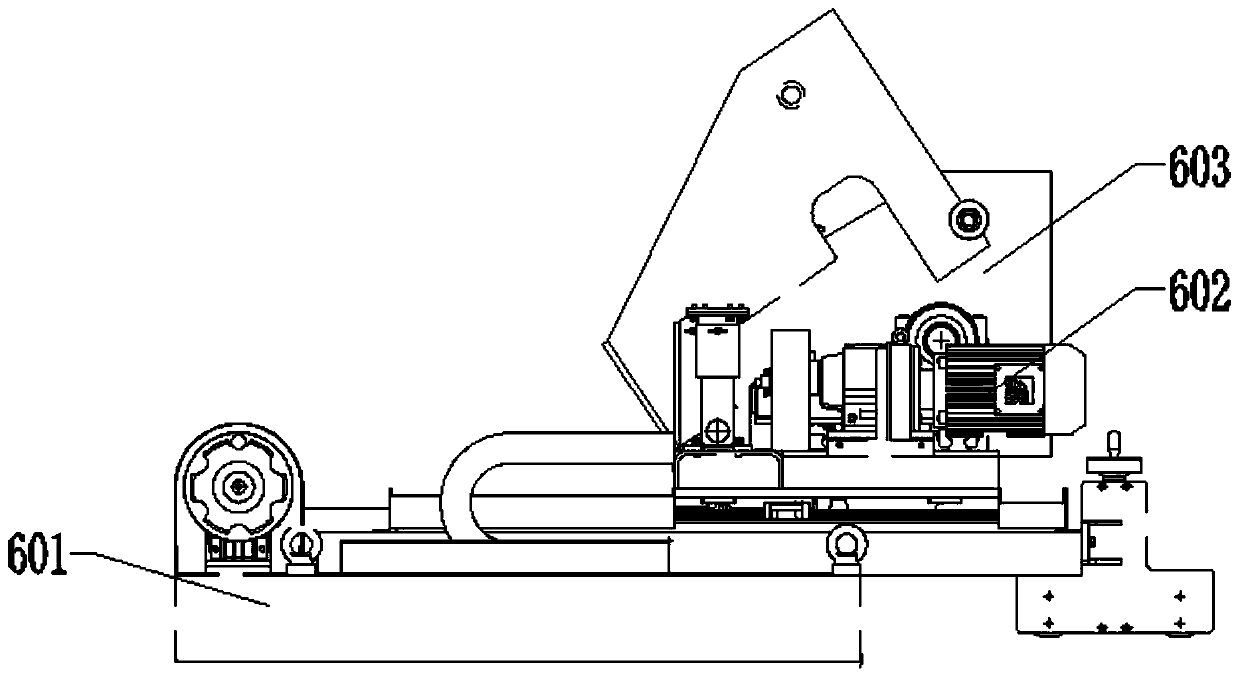

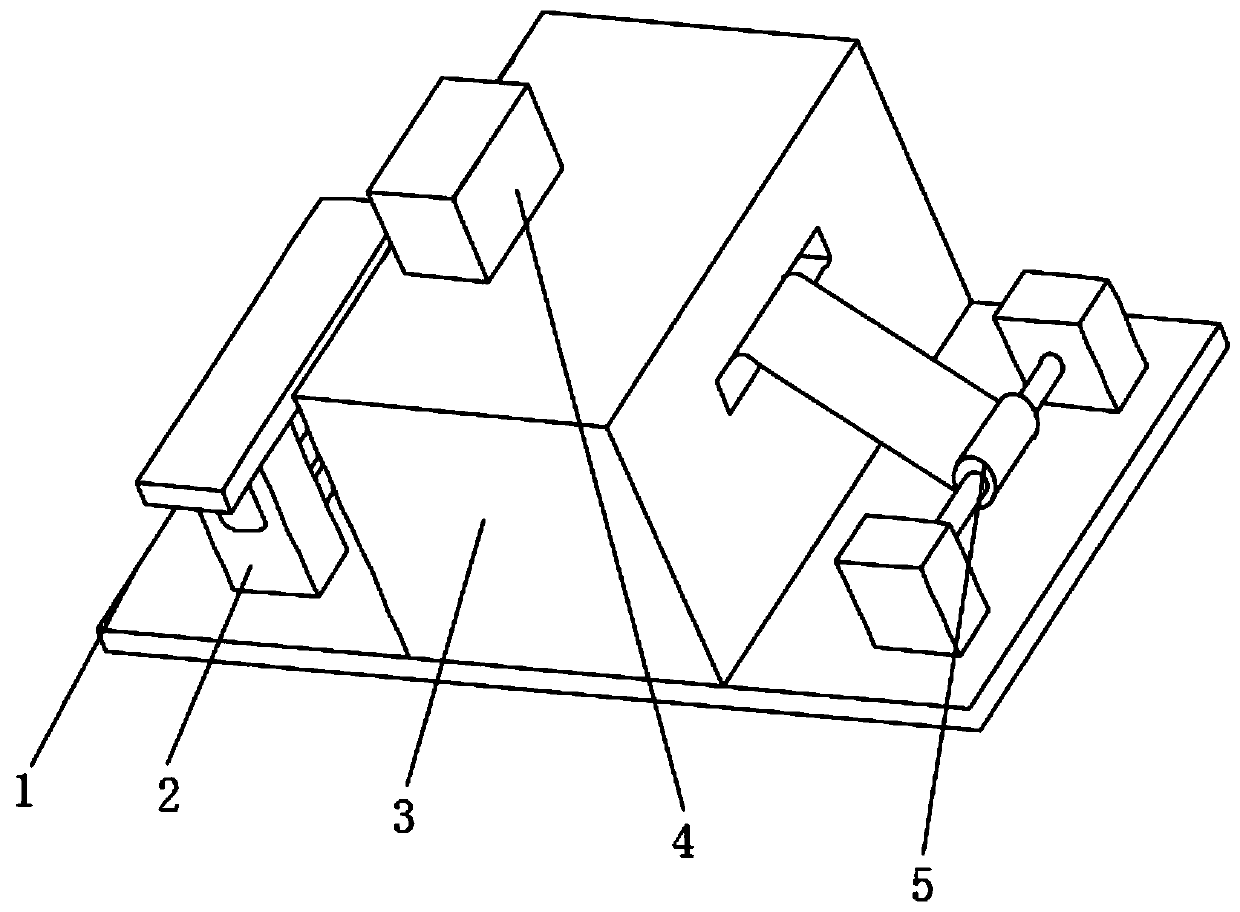

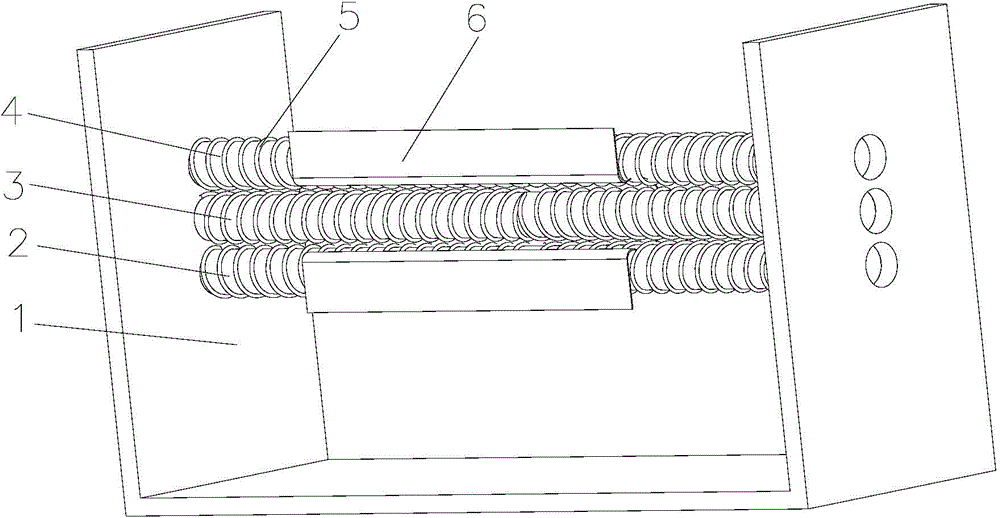

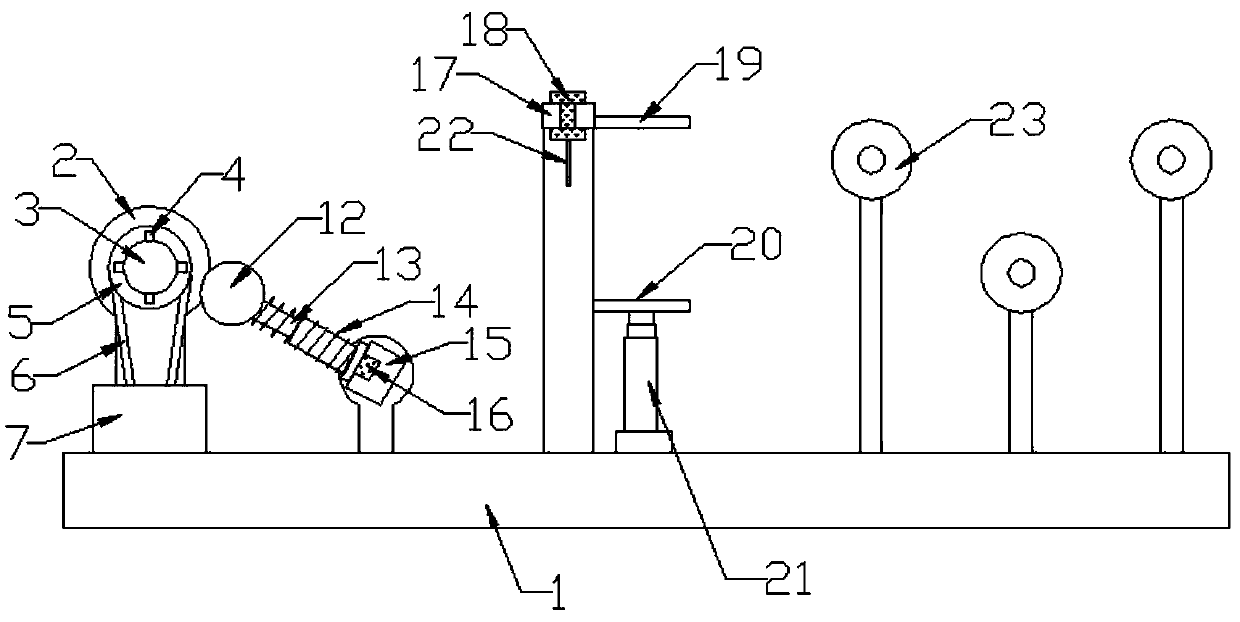

A manufacturing method for a continuous fiber winding reinforced thermoplastic tube and a winding device

The present invention provides a manufacturing method for a continuous fiber winding reinforced thermoplastic tube and a winding device, belonging to the technical field of tube manufacturing, and solving the problem of poor outer wall smoothness and poor robustness, and unstable strength properties of prepared tubes, because continuous fiber performances are reduced due to hairiness or breakage generated from secondary damages of continuous fiber which is easily produced in the prior manufacturing process of continuous fiber winding reinforced thermoplastic tube. The manufacturing method for the continuous fiber winding reinforced thermoplastic tube comprises the following steps of: A, loading and clamping members; B, rotation winding and heating; C, repeating the above step B; D, cooling and stripping. According to the manufacturing method for the continuous fiber winding reinforced thermoplastic tube, a molded continuous fiber band is adopted for direct winding through the winding device, extrusion and dipping are not required, and secondary damages may not be caused to produce hairiness or fiber breakage, thus ensuring the performances and strength of the continuous fiber, and good strength, stiffness, impact resistance and toughness of the prepared tube.

Owner:TAIZHOU JIADEBAO TECH

Flexible heat conduction sheet and preparation method thereof

The invention provides a flexible heat conduction sheet. The flexible heat conduction sheet is prepared by the following steps of mixing the following raw materials in parts by mass, calendering, primarily curing, coiling, curing at high temperature, and slicing. The flexible heat conduction sheet is prepared from the following raw materials in parts by mass: 80 to 90 parts of vinyl polysiloxane,10 to 20 parts of toughening agent, 1.2 to 1.5 parts of hydrogen-containing polysiloxane, 0.01 to 0.2 part of platinum catalyst, 0.001 to 0.01 part of inhibitor, 100 to 200 parts of carbon fiber, 5 parts of vapor-phase white carbon black, and 170 to 200 parts of one or multiple of aluminum oxide, zinc oxide, silicon carbide, aluminum powder, boron nitride and aluminum nitride.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

Spinning drum adjustable in length

InactiveCN107187952AImprove practicalitySolve the problem that the length cannot be adjustedGear wheelEngineering

The invention discloses a textile reel with adjustable length, which comprises a reel body, the inner cavity of the reel body is fixedly connected with a casing, the inner cavity of the casing is provided with a rotating shaft, and the inner cavity of the rotating shaft is A gear is sheathed on the surface, and a first tooth plate and a second tooth plate mesh with the top and bottom of the gear respectively, and the top of the first tooth plate is fixedly connected with a fixed shell. In the present invention, the reel body, the second reel, the casing, the second tooth plate, the rotating shaft, the positioning rod, the first reel, the baffle plate, the rotating rod, the first tooth plate, the positioning plate, the fixed shell, the telescopic The combined use of rods, positioning wheels, slide plates, springs, gears and positioning slots solves the problem that the existing textile reels cannot be adjusted in length. The adjustable length textile reel has the advantage of adjustable length, which is convenient for different The cloth of the same size is rewound, which improves the practicability of the existing reel and is worth popularizing.

Owner:SUZHOU DANFANG TEXTILE R & D

Novel wire coil for cable production

InactiveCN110371774ASolve the problem of messy winding and untidy windingEasy to rewindFilament handlingEngineeringConductor Coil

Owner:ANHUI CABLE

Tightening winding mechanism for fabrics

InactiveCN105905651ANo creasesImprove output qualitySevering textilesWebs handlingEngineeringConductor Coil

The invention discloses a tightening winding mechanism for fabrics. A cropping component and a rolling component are respectively arranged on a frame; the cropping component is used for cropping processed fabrics; the rolling component is used for reeling the fabrics; a slide rail is arranged on a bracket of the rolling component provided by the invention; after a roll of fabric is completely reeled, a winding roll can be conveniently taken out, another winding roll to be used for reeling a fabric is placed again conveniently, and the winding process of the fabrics of various lengths and widths is facilitated; a counter arranged between the cropping component and the rolling component is used for calculating the walking length of the fabrics, so that each roll of fabric is kept in certain quantity and the batched accurate reeling can be conveniently performed; a tightening component is arranged between the cropping component and the counter and is used for tightening the fabrics in the fabric transmission and reeling processes, so that the fabrics are kept under a tightening state all the time and thus are free of folds and are kept flat when reeled, and the output and quality of the fabrics are increased. The tightening winding mechanism for weaving has the advantages of high reeling efficiency, convenience in use and suitability for batched reeling.

Owner:WUJIANG HUAYUN TEXTILE

Fabric printing and cutting device for textiles

InactiveCN105926264AEasy to replaceEasy to receiveTransfer printingSevering textilesEngineeringTractor

The invention discloses a fabric printing and cutting device for textiles. The fabric printing and cutting device is provided with a first rack, wherein a feeding device used for conveying fabric is assembled in the first rack; the feeding device comprises a fabric tractor used for drawing and shifting the fabric, and a tensioning mechanism used for maintaining the fabric to be in a tight state in a conveying process, so as to facilitate the fabric to maintain a tight and smooth state when being moved to a printing mechanism and further enable the fabric to be better processed by a printing process; the fabric printing and cutting device is also provided with a second rack; the second rack and the first rack are arranged in a cross shape, so that the printing mechanism arranged in the second rack can conveniently work, and accessories of the printing mechanism are conveniently replaced; the printing mechanism comprises printing plates, and the printing plates are connected in a connecting plate; the plurality of printing plates are respectively provided with different patterns so as to meet the demands of printing; the first rack is internally provided with a cutting component at the right side of the second rack, and the cutting component is used for cutting the printed fabric so as to enable the fabric to be conveniently rolled up and packaged. The fabric printing and cutting device for textiles has the advantages of being high in production efficiency, convenient to use, suitable for batch production, and the like.

Owner:WUJIANG HUAYUN TEXTILE

Thin film slitting machine capable of preventing burrs

ActiveCN108393951AIncrease temperatureExtended service lifeMetal working apparatusMechanical engineering

The invention provides a thin film slitting machine capable of preventing burrs, and belongs to the technical field of machinery. The thin film slitting machine solves the technical problems of poor slitting effect and the like which exist in an existing thin film slitting machine. The thin film slitting machine capable of preventing the burrs comprises a machine frame, wherein a material feedingroller is rotationally arranged on the machine frame, and a plurality of extension rollers and adhesion rollers are sequentially and rotationally arranged on one side of the material feeding roller; the extension rollers and the adhesion rollers are all rotationally arranged on the machine frame, and a tensioning structure used for tensioning a thin film is arranged between the extension rollers and the adhesion rollers; the sides, far away from the extension rollers, of the adhesion rollers are also sequentially provided with a cutting mechanism and a winding mechanism, wherein the cutting mechanism is used for slitting the thin film and is adjustable in width, and the winding mechanism is used for winding the thin film after slitting; and a strip separating block capable of separating cut adjacent thin film strips in a staggered mode is arranged between the cutting mechanism and the winding mechanism, and the strip separating block is fixedly arranged on the machine frame. The thin film slitting machine has the advantage of being good in slitting effect.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Cloth flattening apparatus

The present invention relates to the technical field of textile, especially to a cloth flattening apparatus, which comprises a rack and a cloth to be flattened, wherein the rack is rotatably connected with a plurality of round rollers, threads with reversed rotation directions are distributed on both ends of the round rollers, the number of the round rollers are three, the round rollers are respectively the first round roller, the second round roller and the third round roller, the first round roller contacts the front surface of the cloth, the second round roller and the third round roller contact the back surface of the cloth, the rotation directions of the threads at the corresponding positions of the first round roller and the second round roller are reversed, the rotation directions of the threads at the corresponding positions of the second round roller and the third round roller are the same, the third round roller is arranged above the first round roller, and the first round roller is arranged just above the second round roller. According to the present invention, the reversed threads are arranged on both ends of the round rollers, such that the two forces respectively along the both end directions of the cloth can be produced during the rotation so as to make the cloth be easily wound; and the cloth flattening apparatus of the present invention has characteristics of simple structure, low cost, significant effect, and substantially enterprise market competitiveness improving.

Owner:李雪明

Nylon cloth winding device convenient to use

The invention discloses a nylon cloth winding device convenient to use. The nylon cloth winding device convenient to use comprises a bottom plate, wherein a first vertical plate and a second vertical plate are fixedly connected to the two sides of the upper surface of the bottom plate separately; a motor is fixedly connected to one side of the first vertical plate through a carrying plate; an output end of the motor is fixedly connected with one end of a rotary shaft; the other end of the rotary shaft penetrates through the first vertical plate and is movably connected with one side of the second vertical plate; a cloth winding roll sleeves the part, between the first vertical plate and the second vertical plate, of the rotary shaft; and slide rails are fixedly connected to the two sides of the cloth winding roll. According to the nylon cloth winding device convenient to use, the cloth winding roll is improved, press plates are released, and the press plates are enabled to clamp a cloth onto the cloth winding roll under the effect of a resilience force of extrusion springs, so that winding for the cloth is facilitated; and a drive rotary rod and a driven rotary rod are enabled to drive two leveling rolls to carry out reverse rotation simultaneously in combination with use of a drive gear and a driven gear, so that the surface of the cloth between the two leveling rolls can be leveled.

Owner:李赵和

Printed product drying and dedusting device

InactiveCN104669784AEasy loading and windingRealize continuous productionPrinting press partsContinuous productionEngineering

The invention relates to a printed product drying and dedusting device which comprises a base, wherein an extrusion cavity bracket is arranged on the base, an extrusion cavity is formed in the extrusion cavity bracket, a material guide roller is arranged on the lower part of the extrusion cavity, and a conveying roller is arranged on the material guide roller; two pressure roller support seats are arranged on the right side of the extrusion cavity, and upper pressure rollers and lower pressure rollers which are opposite are arranged on the pressure roller support seats; winding rollers are arranged on the right sides of the pressure roller support seats; a drying cavity bracket is arranged on the lower part between the two pressure roller support seats, a heating cavity is formed in the upper part of the drying cavity bracket, and a heating plate is arranged in the heating cavity; a support plate is arranged on the upper part between the two pressure roller support seats, a dust collector is arranged on the upper part of the support plate, and a dust collection cavity is connected to the lower part of the dust collector. According to the printed product drying and dedusting device, a printed product can be effectively extruded, dried and dedusted, feeding and winding are facilitated, continuous production is realized, the production effect is improved, the production efficiency is improved, and the use is convenient.

Owner:艾金富

High-speed flexographic printing machine for thin films

InactiveCN102615933ASolve the problem of multi-color printing at one timeOverprint stabilityRotary letterpress machinesPrinting press partsColor printingEngineering

The invention relates to a high-speed flexographic printing machine for thin films, which comprises a base, an n-shaped vertical column set and a control circuit. The n-shaped vertical column set fixed on the base is composed of a left vertical column, a right vertical column and a beam fixed between the left vertical column and the right vertical column. An unwinding roller mechanism is disposed on the left vertical column. A winding roller mechanism is disposed on the right vertical column. A first color printing mechanism, a second color printing mechanism and a first heating tank are sequentially disposed on the left vertical column, and a first transfer press roller and a first transfer ink roller are disposed between the first color printing mechanism and the second color printing mechanism. A third color printing mechanism, a fourth color printing mechanism and a second heating tank are sequentially disposed on the right vertical column, a second transfer press roller and a second transfer ink roller are disposed between the third color printing mechanism and the fourth color printing mechanism, and a heating device is disposed on the beam. The high-speed flexographic printing machine for thin films is novel in appearance, reasonable in mechanism design, simple in operation, long in service life and easy in maintenance.

Owner:张玉海

BOPP film winding device

InactiveCN109607266AAvoid shakingPrevent looseningArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses a BOPP film winding device. The BOPP film winding device comprises a working table, a supporting frame, a winding mechanism, a compressing mechanism, a cut-off mechanism, a control mechanism and undertaking rollers, the winding device comprises two fixing shafts, a winding roller is arranged between the two fixing shafts, the compressing mechanism comprises a compressing roller, the two ends of the compressing mechanism are connected with expansion rods with expansion springs, and the control mechanism is a control box; according to the BOPP film winding device, the winding roller can belocked through arranging fixing protrusions arranged in a cross shape on the fixing shafts, and the winding roller is compressed between the fixing protrusions and a fixing sleeve ring through the action of a spring, so that wobble of the winding roller is avoided in the winding process; the compressing roller is compressed on the winding roller through the action of the expansion springs, so that the winded BOPP film is closely connected between layers, and loosing cannot occur; a moving pressing plate and a fixing pressing plate compress the BOPP film together while an electric sliding block on an electric sliding rail moves, and a cutting device is driven to move left and right and cut the BOPP film, so that the automatic cutting off is conducted.

Owner:安徽长正升科技有限公司

Cloth winding device

Owner:钱杭健

Organic-inorganic composite electrolyte, preparation method thereof, and application in solid lithium ion secondary battery

ActiveCN109301316ANon stickyIncrease stickinessSolid electrolytesSecondary cellsComposite electrolyteOrganic solvent

An organic-inorganic composite electrolyte is disclosed and is composed of a medium-temperature viscoelastic-transformable polymer, lithium salt, and a fast ion conductor ceramic powder, wherein the medium-temperature viscoelastic-transformable polymer includes a hard monomer, a soft monomer containing ethoxyl group, an initiator, and an organic solvent. The organic and inorganic phases of the composite electrolyte film both have ion-conductivity, thus increasing room-temperature conductivity. The organic-inorganic composite electrolyte film has no viscosity at room temperature, so that the film is easy to reel and be composited with an electrode plate in a multilayer manner. The organic-inorganic composite electrolyte is suitable for industrial production.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Anti-falling device for elevator

InactiveCN112079279ALifting and moving smoothlyPlay a supporting roleSafety devices for lifting equipmentsLifting framesPull forceDrive shaft

The invention discloses an anti-falling device for an elevator. The anti-falling device for the elevator comprises a base, a first anti-falling mechanism, a cover frame, a second anti-falling mechanism and winding drums; a first belt wheel is connected to a second belt wheel through a transmission belt; a transmission shaft penetrates through the second anti-falling mechanism; the winding drums are connected to the front end and the rear end of the transmission shaft; a lifting rope is wound around the outer side of each winding drum; the lifting ropes bypass fixed pulleys to be connected withtension sensors; the tension sensors are fixed to the left side and the right side of the upper end face of a bearing plate through fasteners; and the tension sensors are located on the outer sides of the limiting plates. According to the anti-falling device for the elevator, after the lifting ropes lift the bearing plate, the tension sensors start to work; when the lifting rope is accidentally broken, the tension value detected by the corresponding tension sensor is zero; and at the moment, a movable block moves under the extension effect of a first piston rod, and a second clamping block moves along with the movable block and are connected to a first clamping block in a clamped mode, so that the bearing plate can be conveniently fixed in time, and the inclining or falling of the bearingplate can be avoided.

Owner:拉弗莱防坠落系统科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com