Shaping machine for after-finishing of fabrics

A finishing and setting machine technology, which is applied in the field of textile fabrics, can solve the problems of deviation of drying effect on the surface of fabrics, inability to adjust cooling speed, and decline in fabric quality, and achieve the advantages of easy drying, good shaping quality, and guaranteed moisture content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

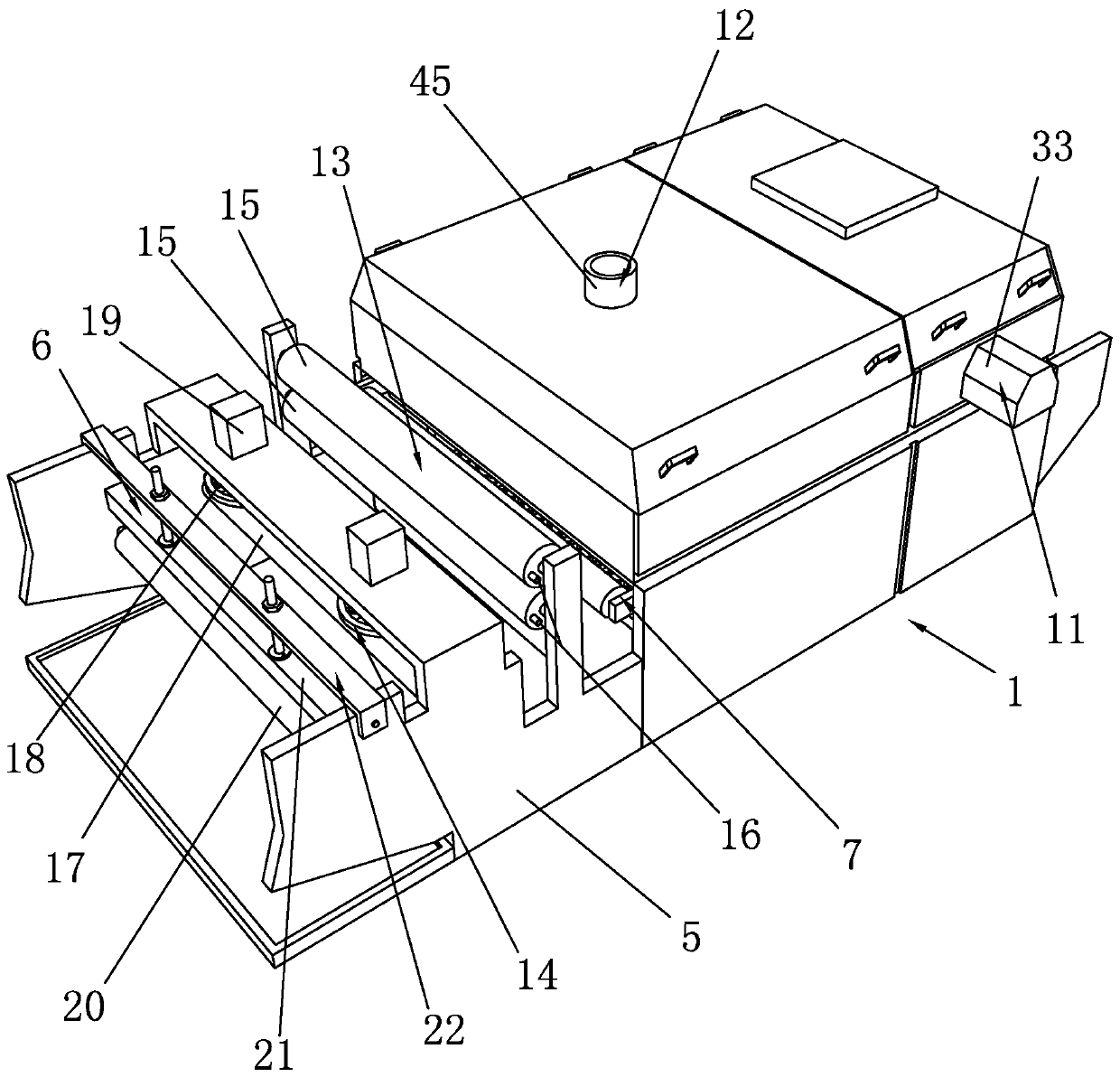

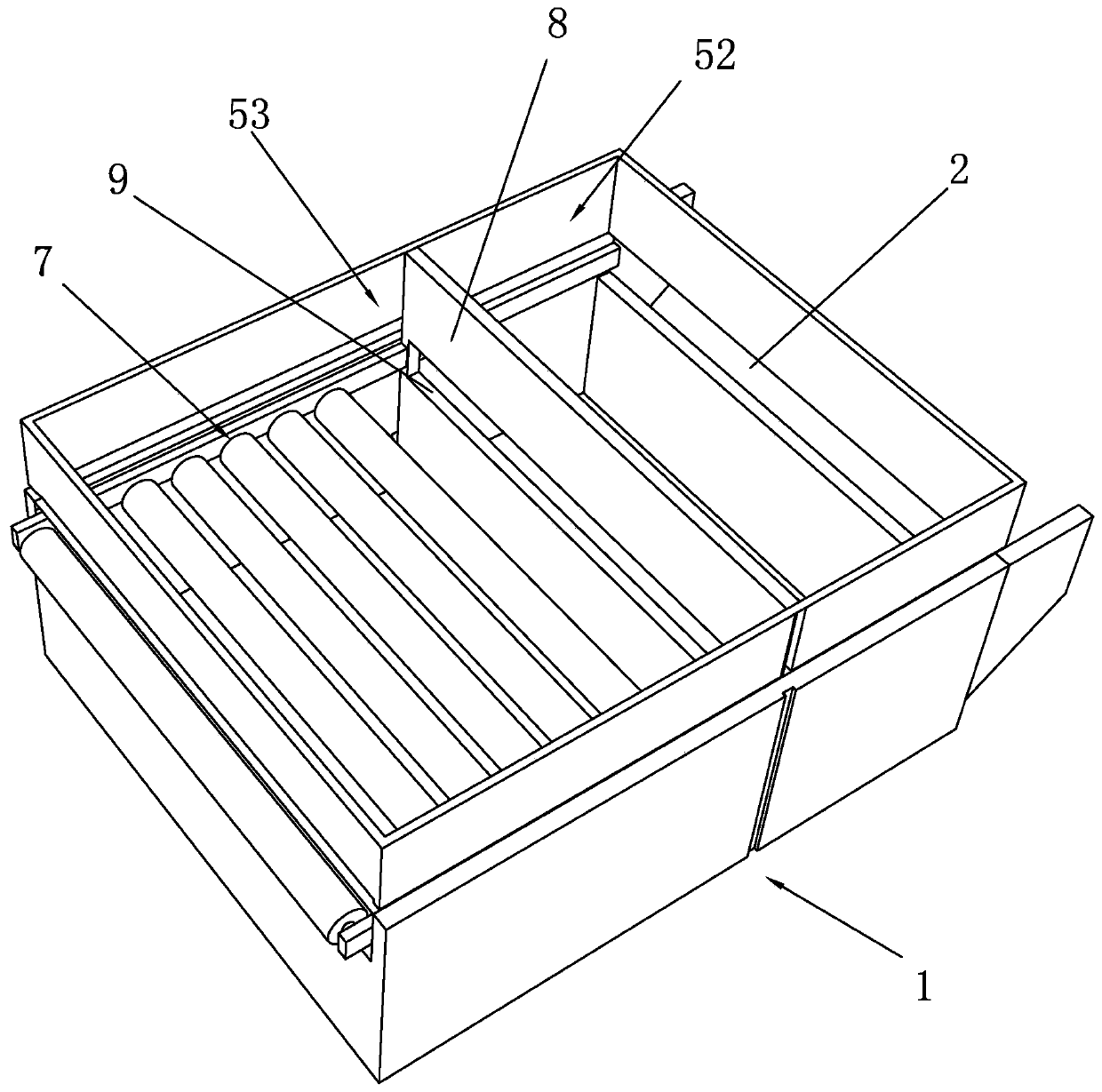

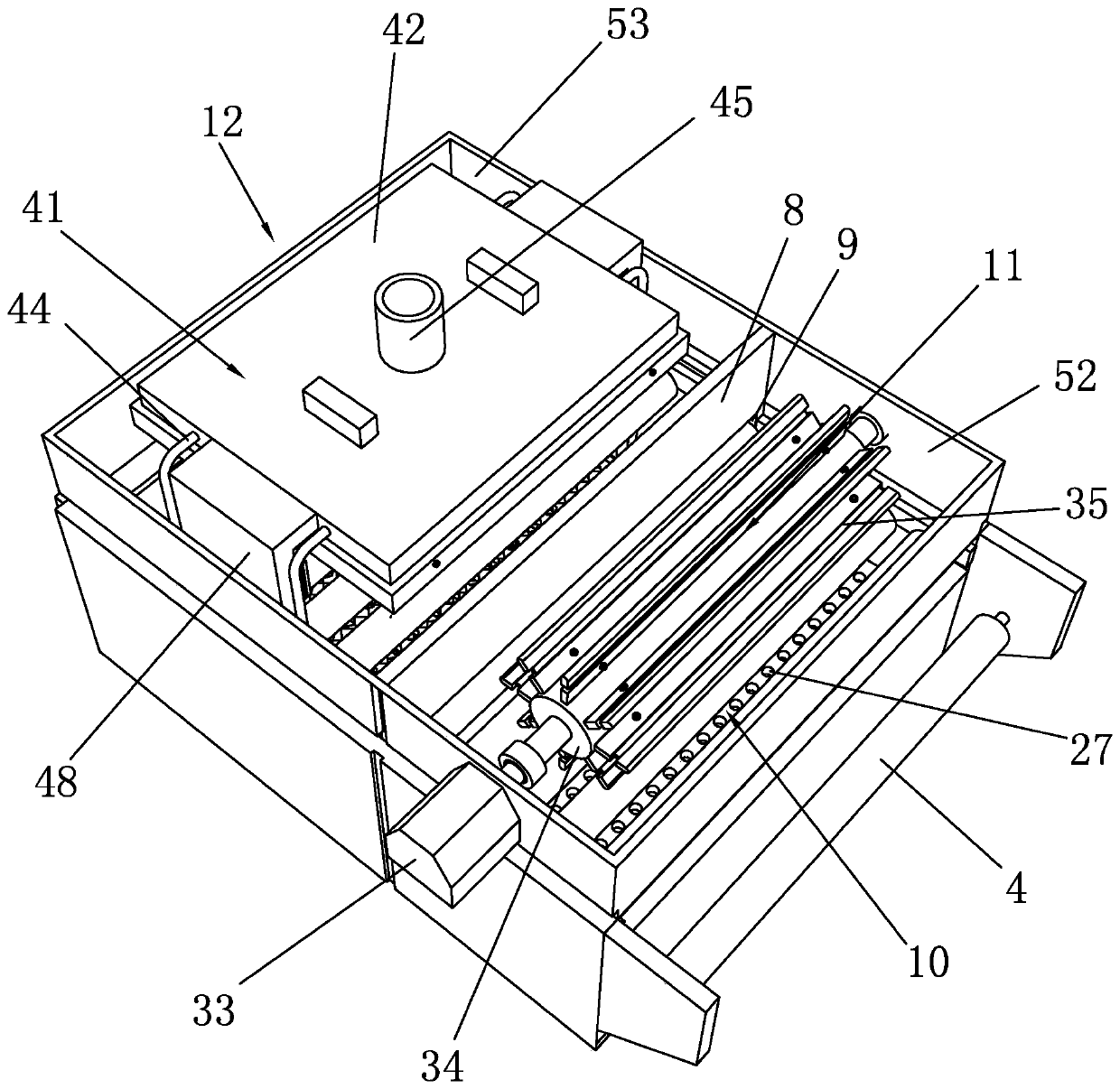

[0029] like Figure 1 to Figure 8 As shown, it is a sizing machine for finishing fabrics according to the present invention, comprising a box body 1, a cloth inlet 2 is arranged on the right end surface of the box body 1, and a cloth outlet 3 is arranged on the left end surface of the box body 1, There is a cloth feed roller 4 at the cloth inlet 2, a support 5 is provided on the left side of the box body 1, and a cooling assembly and an antistatic assembly 6 are arranged on the support 5 in sequence from left to right. The cooling assembly includes a cooling roller group 13 and a fan The cooling group 14 and the cooling roller group 13 include two cooling rollers 15 arranged up and down oppositely. Cooling roller group 13 and fan cooling group 14 can realize secondary cooling, guarantee the cooling rate of fabric, and can choose to adopt primary cooling or secondary cooling according to the fabric of actual setting during actual use, the design of two cooling rollers 15 up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com