Patents

Literature

96results about "Textile storage in wounded form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finishing method for non-ironing moisture-absorption soil-release fabric

InactiveCN101942752AGood non-ironing effectEfficient use ofTextile storage in wounded formFibre treatmentCooking & bakingEngineering

The invention relates to a finishing method for a non-ironing moisture-absorption soil-release fabric, which consists of the following processes in turn: fabric preparation, pre-softening, moist crosslinking resin rolling, storage reaction, water washing, tentering shaping, and pre-shrinkage. The finishing method is mainly and technically characterized in that: a moisture-absorption soil-release assistant immersion rolling and high-temperature baking process is implemented between the water washing and tentering shaping processes; and a moisture-absorption softening agent is added into the immersion rolling formula of the pre-softening, moist crosslinking resin rolling and tentering shaping processes. In the invention, by adding the moisture-absorption softening agent into the immersion rolling formula of the pre-softening, moist crosslinking resin rolling and tentering shaping processes and increasing the moisture-absorption soil-release assistant immersion rolling and high-temperature baking process, the finished pure cotton fabric has non-ironing performance and high moisture absorption and has the effect that the stains are easily removed by washing; and the clothes made of the fabric are comfortable to wear, beautiful and convenient to wash.

Owner:TIANJIN TIANGE TEXTILE

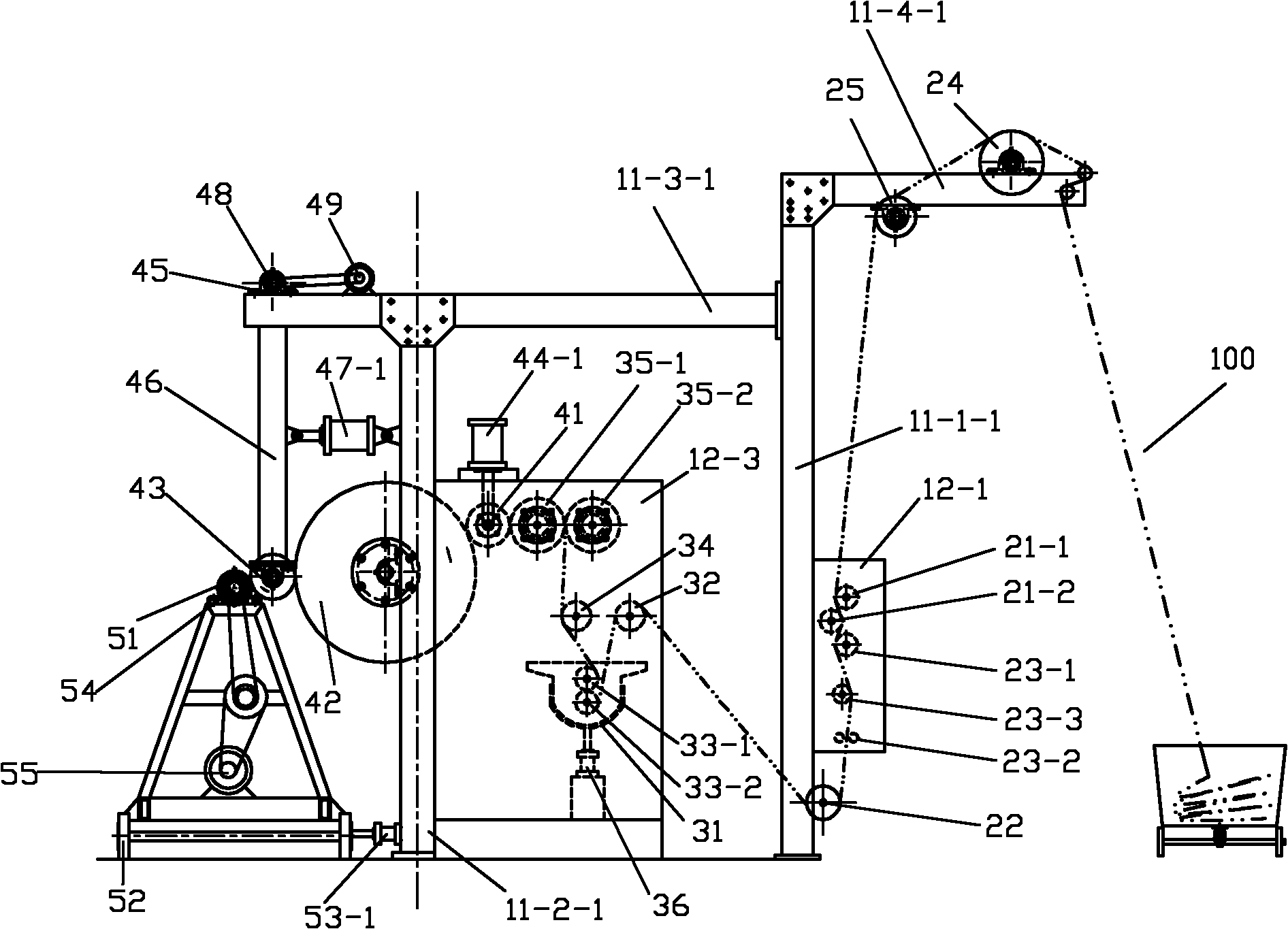

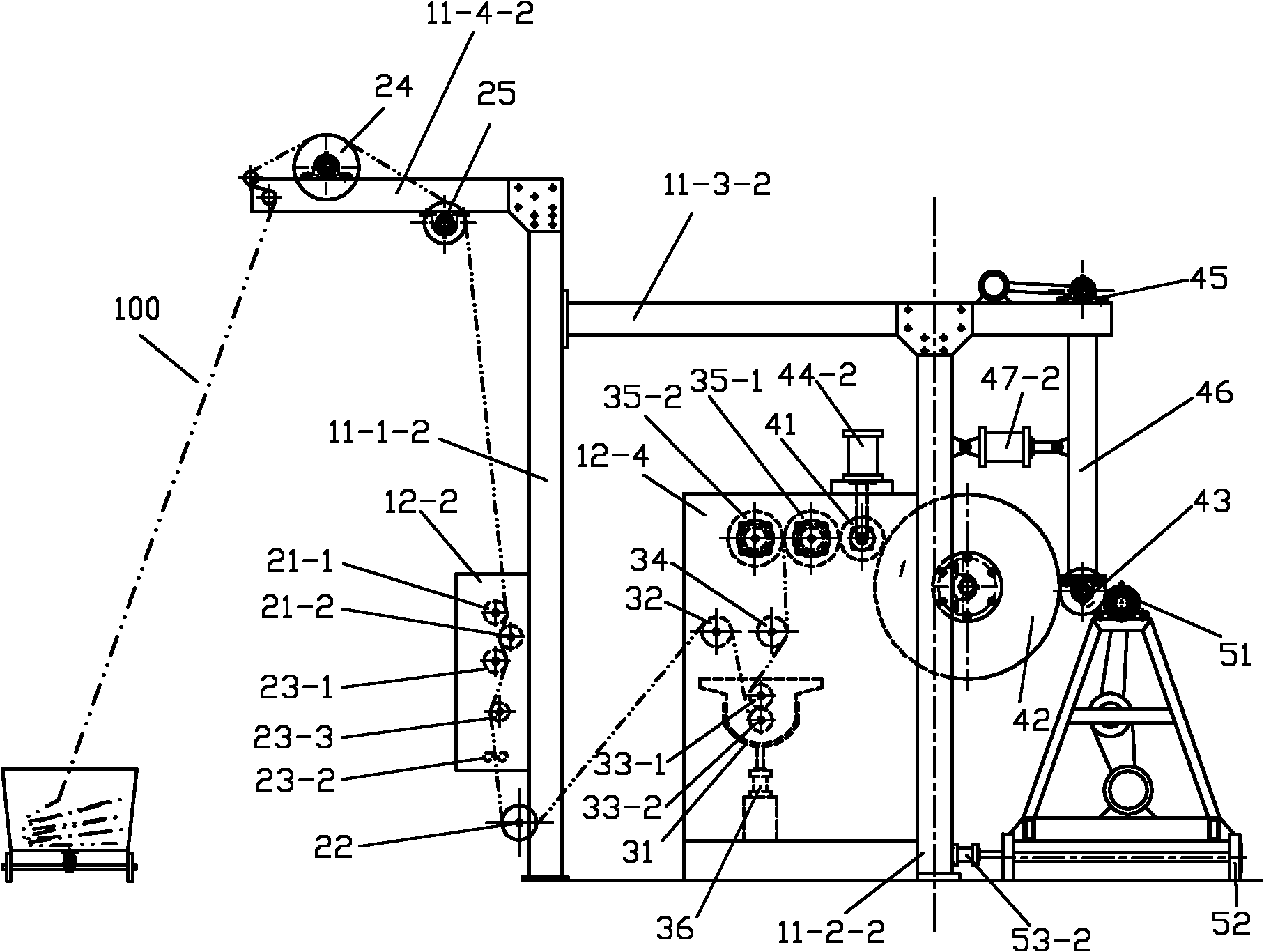

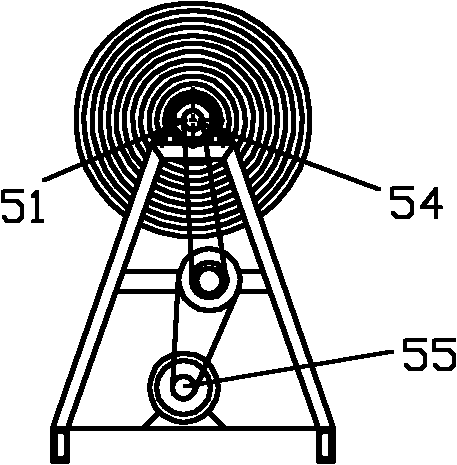

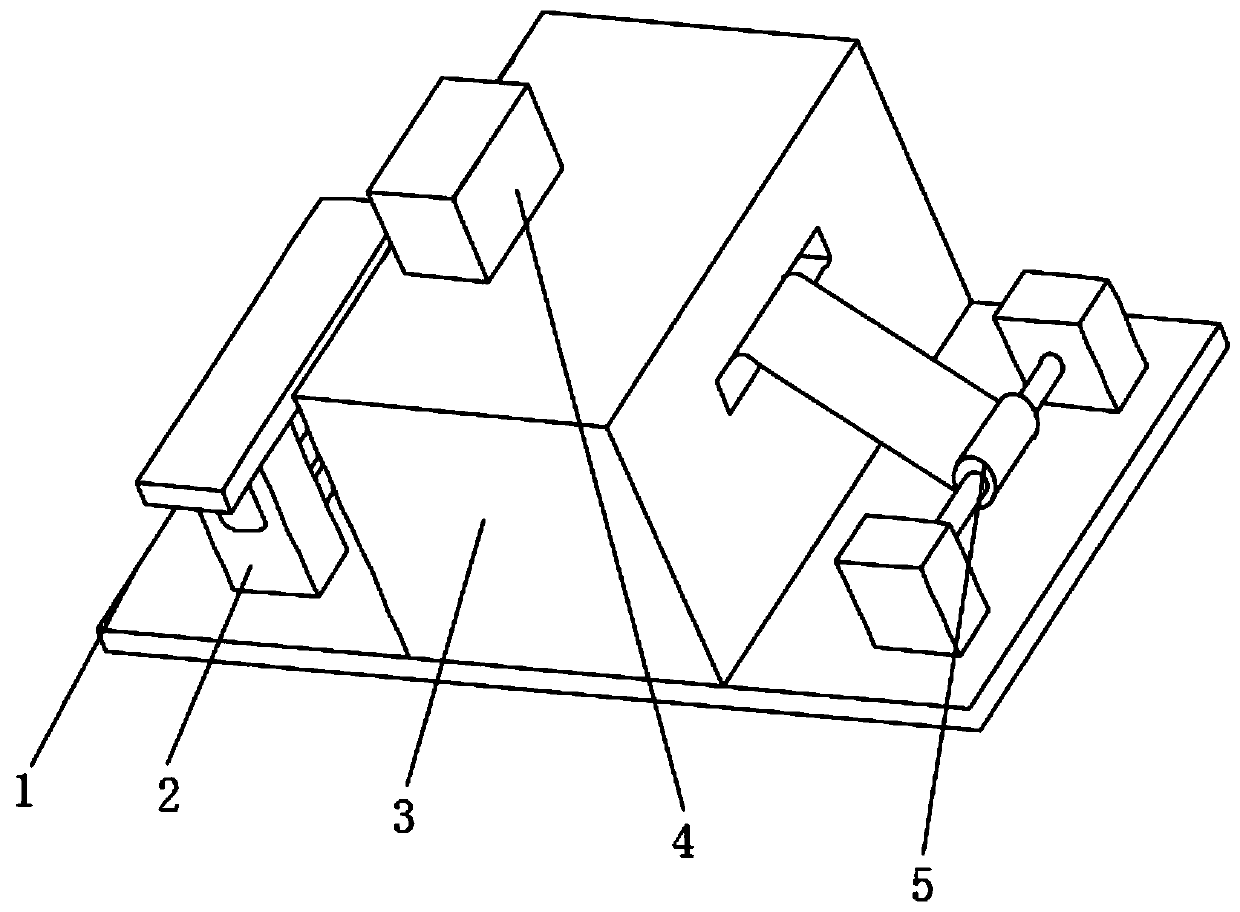

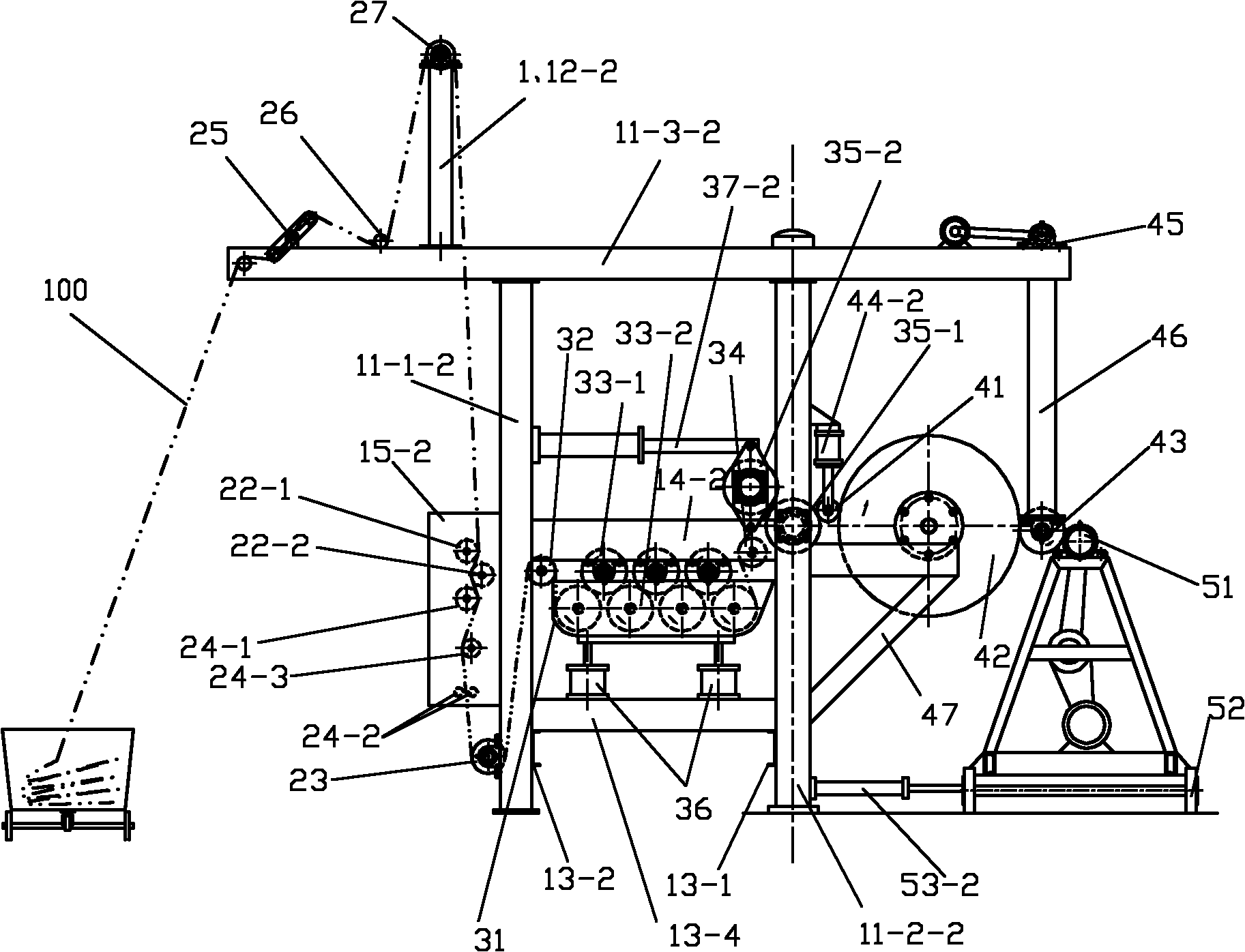

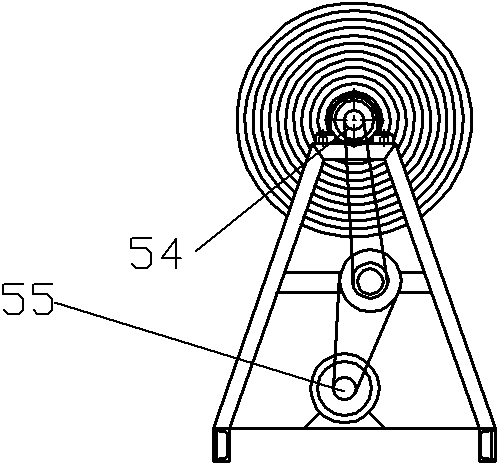

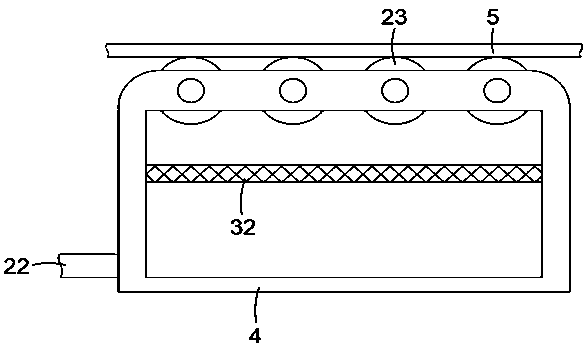

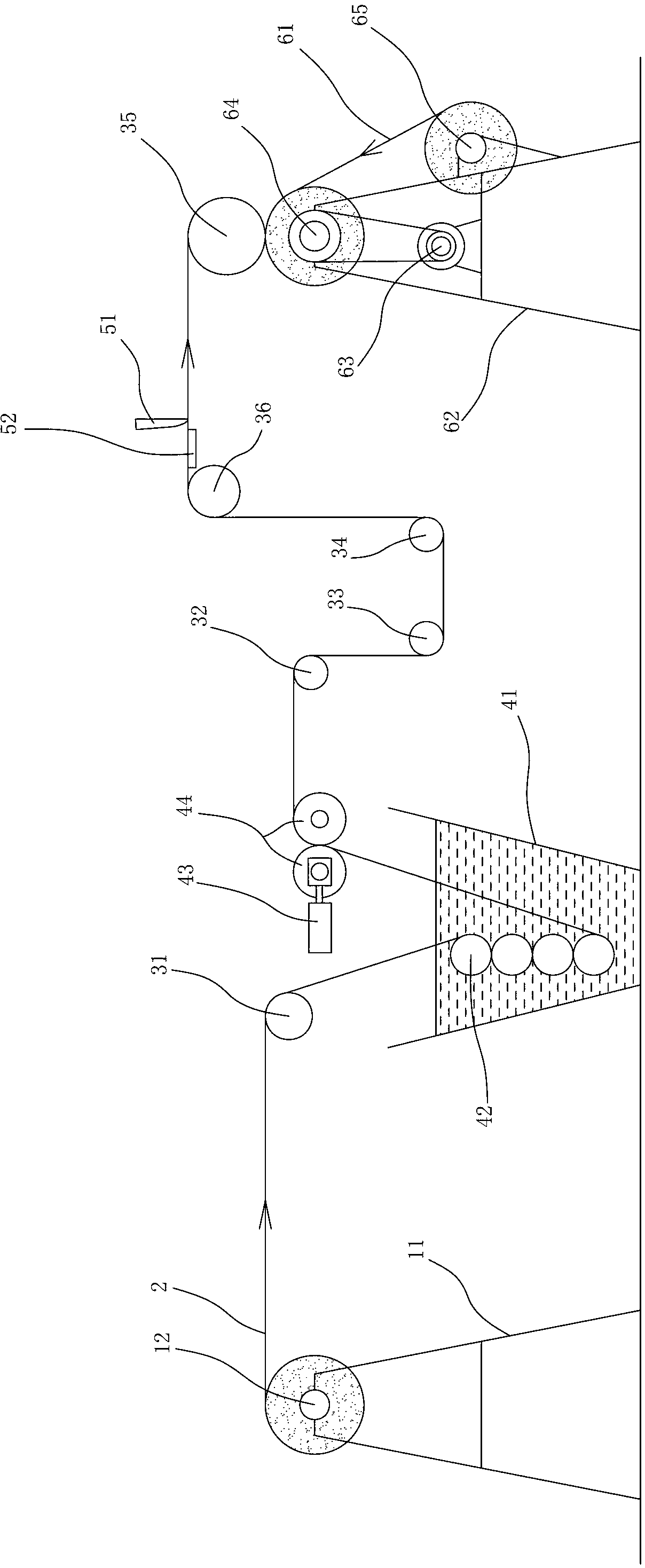

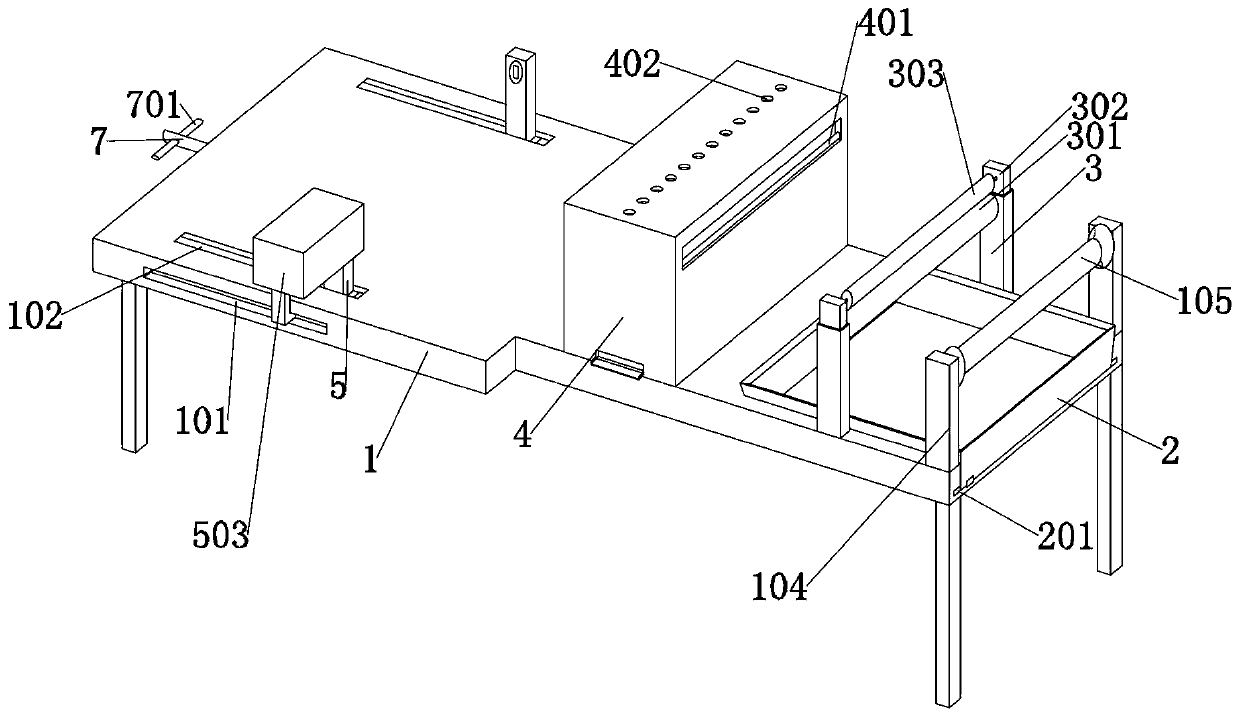

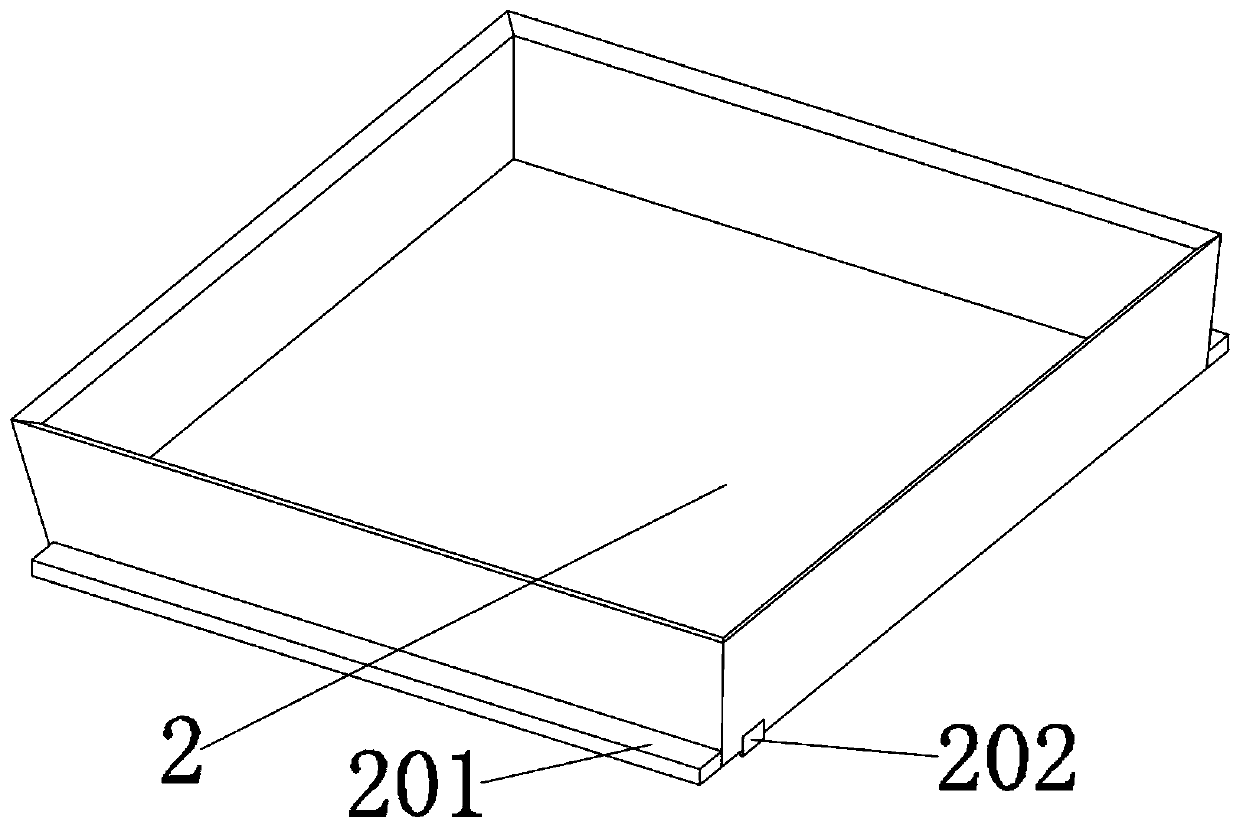

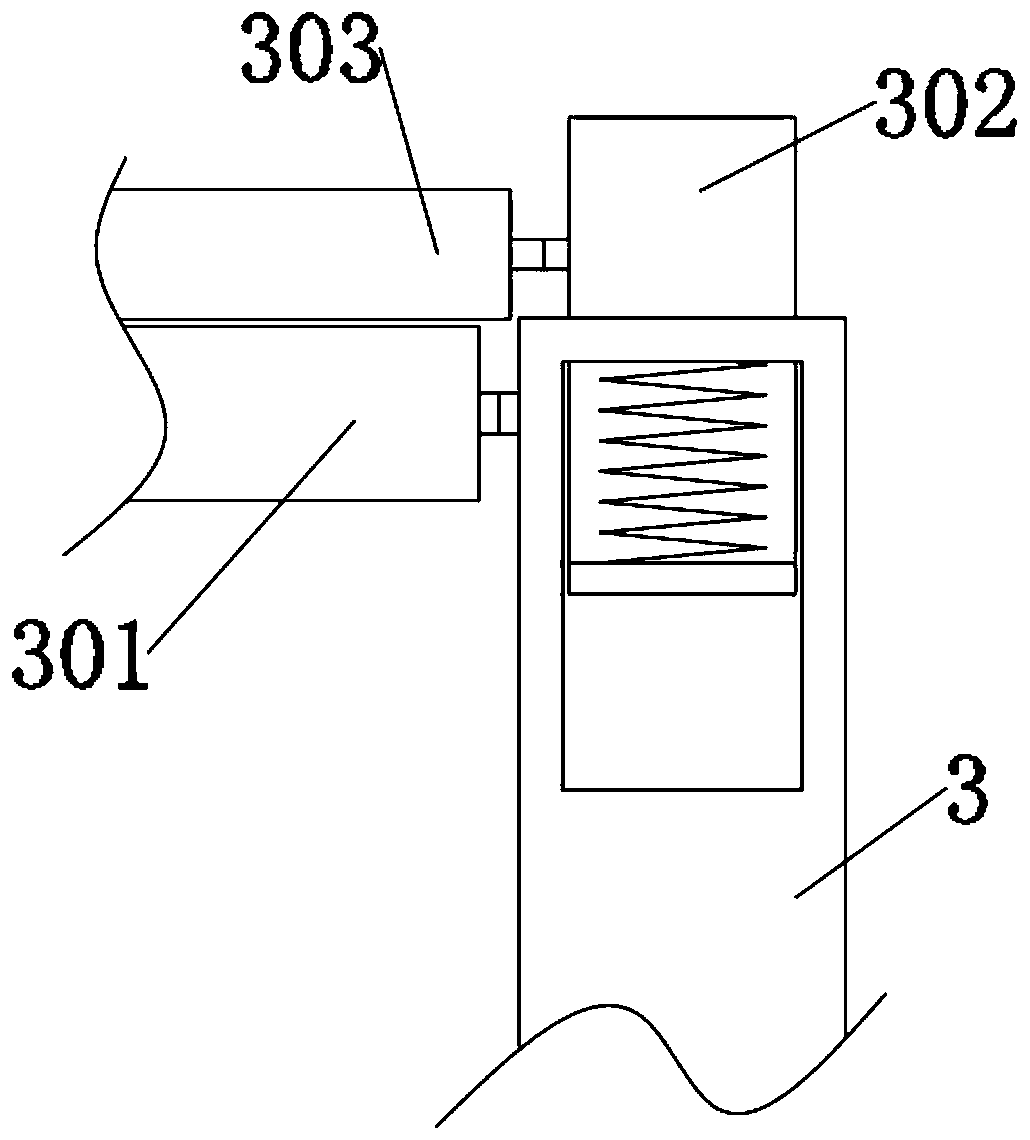

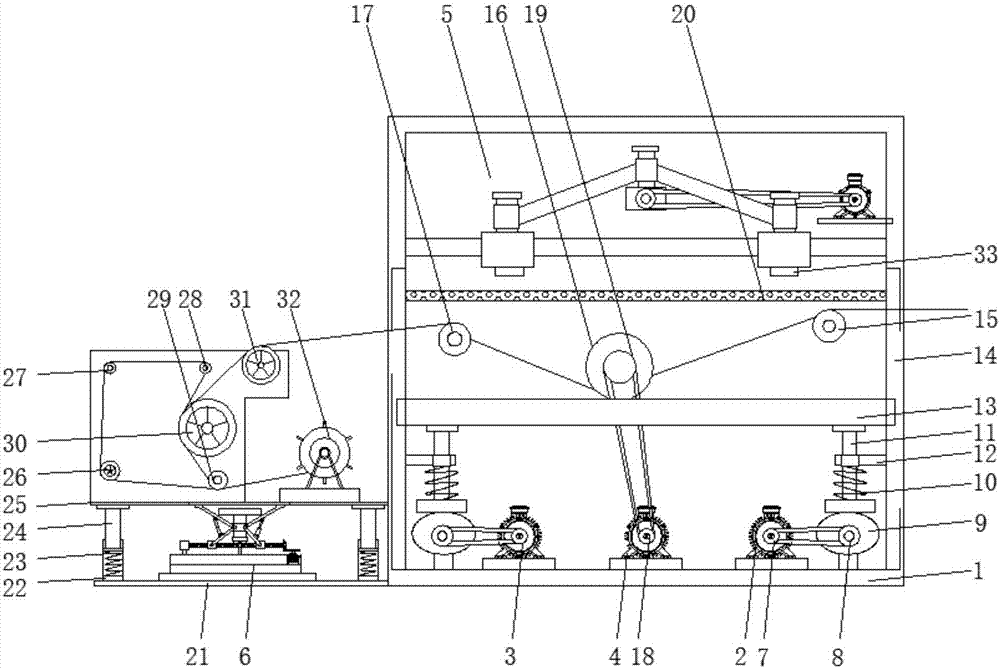

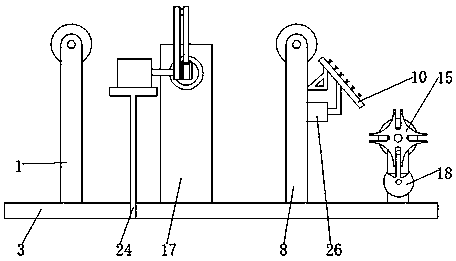

Cold pad-batch dyeing device for open-width knitted fabrics

InactiveCN101818422APrevent deviationAdjustable distanceTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersEngineeringControl circuit

The invention discloses a cold pad-batch dyeing device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a dyeing padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are arranged on the frame one after another; the cloth feeding device, the dyeing padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the dyeing padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and eventually, the open-width knitted fabrics are flatly rolled onto a cloth roller in the form of big batch which can be rotatably piled up like woven fabrics, and the dyeing is completed during the rotatable pile-up, which not only reduces various consumptions and saves cost remarkably, but also improves the quality of the knitted fabrics.

Owner:蔡宗义

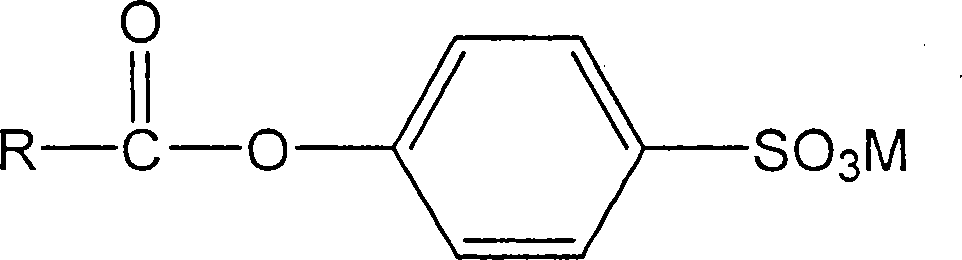

Cold-pad-batch method for textile materials

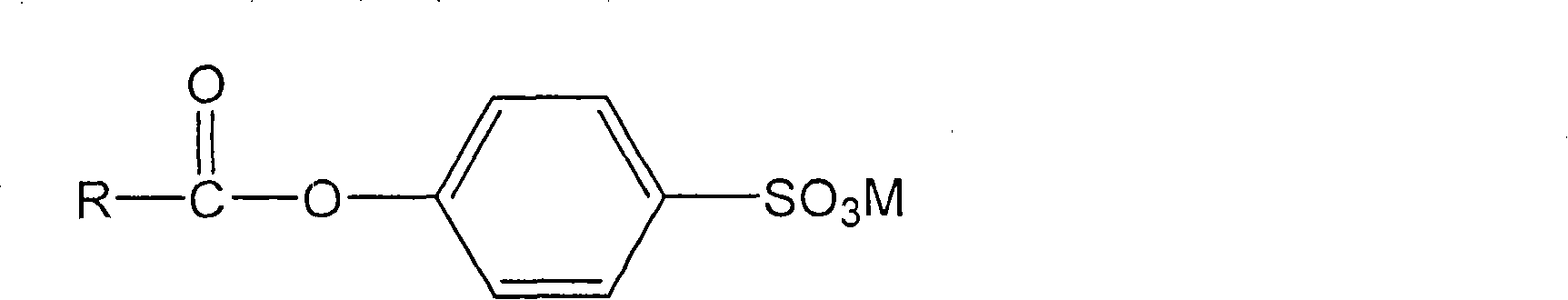

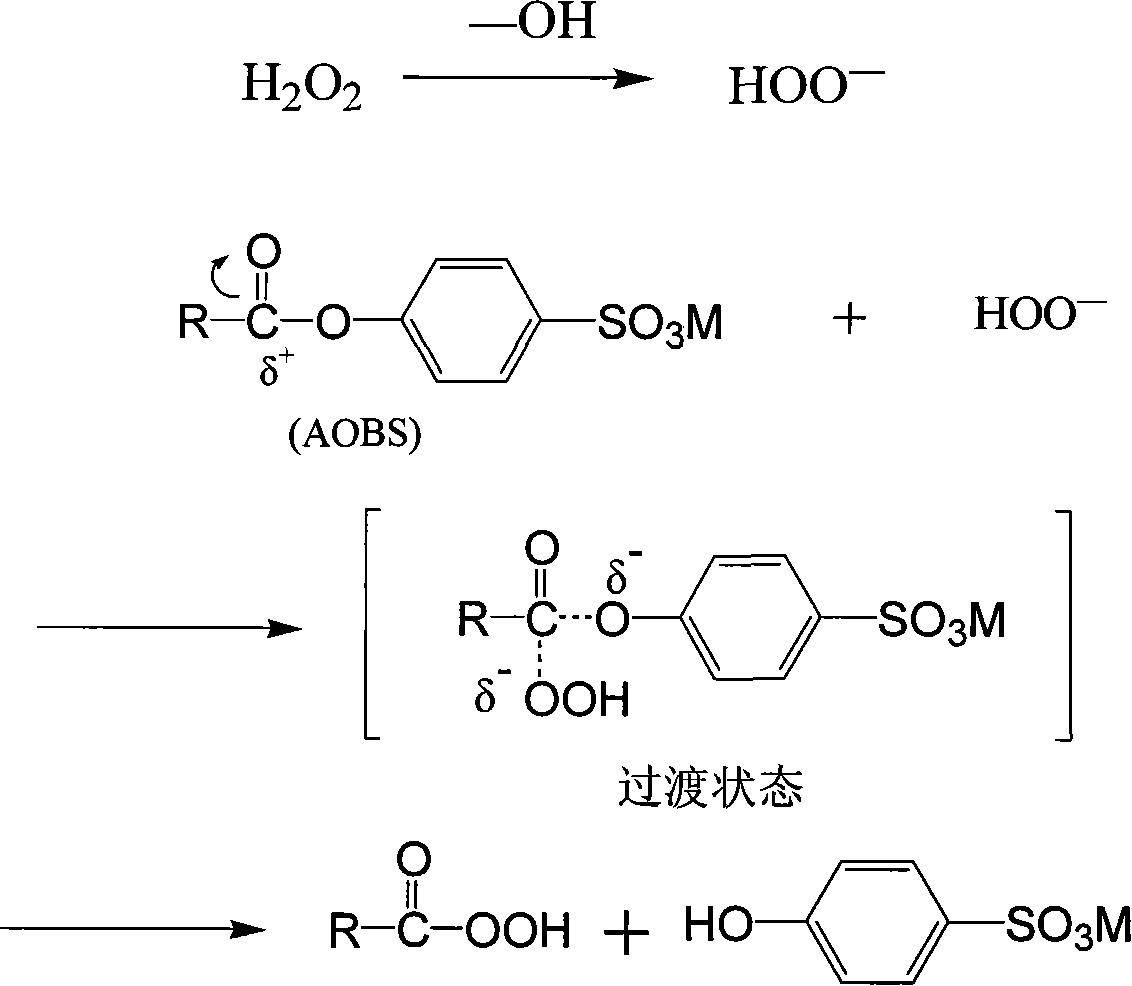

InactiveCN101135113AAchieve the bleaching effectAvoid damageTextile storage in wounded formFibre treatmentEngineeringBatch method

The present invention discloses process of cold padding, stacking and actively bleaching fabric. The process includes through steps, including one step of compounding bleaching solution and padding, one step of winding and stacking, and one step of hot water washing and cold water washing. The present invention adopts alkanoylxy benzene sulfonate bleaching activator, hydrogen peroxide / activator bleaching system, and cold padding and stacking treatment to reach excellent fabric bleaching effect. Compared with traditional bleaching technology, the present invention has the advantages of excellent fabric bleaching effect, lowered alkali consumption, reduced stacking time, less fabric damage, raised production efficiency and environment friendship.

Owner:ZHEJIANG SCI-TECH UNIV

Grey cloth cold batch mercerizing process method for cotton and cotton blended fabric

ActiveCN101858020AAvoid spendingReduce consumptionTextile storage in wounded formSingeingWastewaterEngineering

The invention provides a grey cloth cold batch mercerizing process method for cotton and cotton blended fabric, which belongs to a dyeing and finishing pretreatment process for cotton and cotton blended fabric. The process method comprises processes of singeing, alkali padding, rolling, reverse rolling and heaping, washing, oxygen bleaching, weft finishing and tentering; in the alkali padding process, alkali liquor is padded by using a padding liquor roller, the NaOH content of the alkali liquor in an alkali liquor tank is 160 to 180 grams per liter, the balance is water, and the alkali liquor in the alkali liquor tank is circulated by using a circulating pump; in the washing process, counter current washing is performed in a de-sizing machine by using 90 to 95 DEG C hot water, the speed is 48 to 52 meters per minute, and the cloth falls with tide; and in the oxygen bleaching process, the speed is 45 minutes per minute, the temperature in a track-type steam box is between 96 and 99 DEG C, and the heaping is performed for 45 minutes. The mercerizing process method combines the mercerizing process and the de-sizing process into a one-step process so as to shorten the process flow, reduce the steam consumption, relatively reduce the consumed caustic soda quantity and save the wastewater treatment expense.

Owner:YUYUE HOME TEXTILE

Cold pad-batch dyeing process for pure cotton fabric

InactiveCN102535201ALower average tensionLow frictionTextile storage in superimposed formTextile storage in wounded formRoom temperaturePlastic film

The invention discloses a cold pad-batch dyeing process for pure cotton fabric. The process flow comprises the steps of: padding and rolling a mixed liquor of a dye and an alkaline agent, coiling and plastic film coating, rotating stacking, primary water washing, soaping, secondary water washing and drying. In the padding and rolling process, an active dye at a concentration of 10g / l is adopted, 10-15 g / l of water glass is adopted as the alkaline agent, a concentration of urea is 3 to 5g / l and a concentration of sodium sulfate is 10g / l. The rotating stacking process is performed for 16h at a room temperature of 10-15 DEG C. By the adoption of the process of the invention, energy can be saved, consumption can be reduced, the fixation ratio of the dye is increased, the grade of the product is improved, and the process cost is low. Besides, the conditions of the cold pad-batch dyeing process are moderate, the fabric is subjected to low tension and small friction, and the apparent effects and hand-feel of the fabric are improved to a great extent.

Owner:CHANGSHU KAIDA PRINTING & DYEING

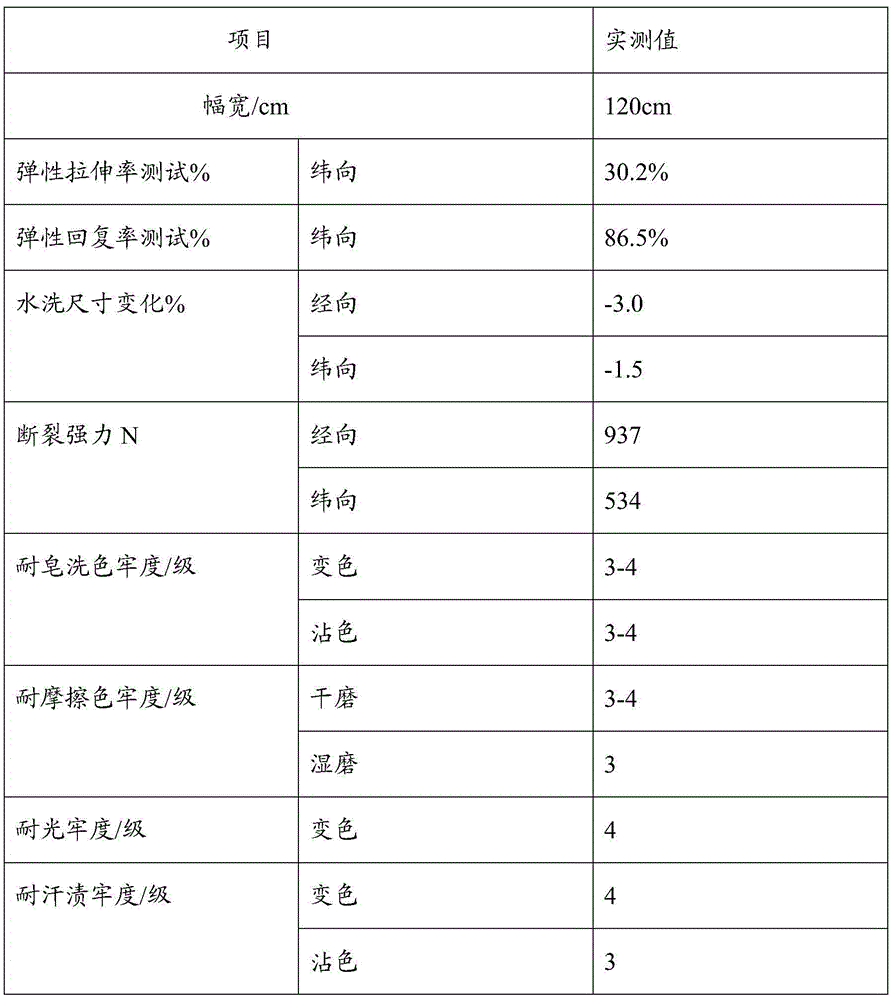

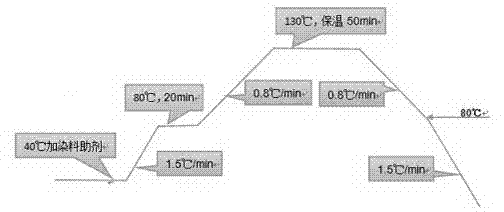

Dyeing and finishing technology for cotton/viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment

ActiveCN105544227ASoft touchFluffyMercerising of indefinite length fabricsTextile storage in wounded formTextile printerRoom temperature

The invention belongs to the technical field of textile printing and dyeing, and in particular relates to a dyeing and finishing technology for a cotton / viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment. The dyeing and finishing technology comprises a pretreatment technology, a dyeing technology and a post-finishing technology. According to the printing and dyeing method for a cotton / viscose stretch fabric, room-temperature stacked desizing is carried out by a biologic desizing enzyme; and an efficient refining agent is selected, so that various pretreatment indexes are effectively improved; soft and fluffy hand feeling of the cotton / viscose stretch fabric is achieved; energy conservation and emission reduction are achieved through low-temperature desizing; potential drapes in the fabric processing process are eliminated; and smooth production of the dyeing procedure is facilitated. A light-colored fabric is dyed from pad dyeing, and a dark fabric is subjected to cold pad-batch dyeing, so that an improvement of various color fastness indexes is met; dyeing process parameters are optimized; and uniform and full dying material quality is obtained. A softening agent is preferably adopted in fabric post-finishing, so that the hydrophilicity of the fabric is achieved; and the wearing comfort of the fabric is achieved.

Owner:HUAFANG

Dyeing and finishing technology for high-shrinkage polyester-polyamide composite filament fabric easy to dye

ActiveCN104727043ASoft lusterLuster light and softSucessive textile treatmentsTextile storage in wounded formPolyesterPolymer science

The invention discloses a dyeing and finishing technology for high-shrinkage polyester-polyamide composite filament fabric easy to dye. The technology comprises the steps of reduction scouring, splitting, tackification, overflow dyeing, dehydrating and drying and type approval, wherein the reduction scouring means firstly conducting cold-batch reduction processing on gray fabric and then conducting the step of open-width fine scouring reduction. The polyester-polyamide composite filament fabric produced by the dyeing and finishing technology is soft in luster and light and soft in material, the fabric downy feeling is natural, fine, smooth and full, the draping performance is greatly improved, and the fabric shrinkage percentage is controlled to be less than or equal to 25% within the range required by the technology; meanwhile, the dyeing rate of the fabric is increased by more than one time, the various fastnesses are improved by about one level, the color saturation and vividness are improved greatly, the color quality stability is stronger, and the fabric market value added is overall increased.

Owner:WUJIANG FUHUA WEAVING

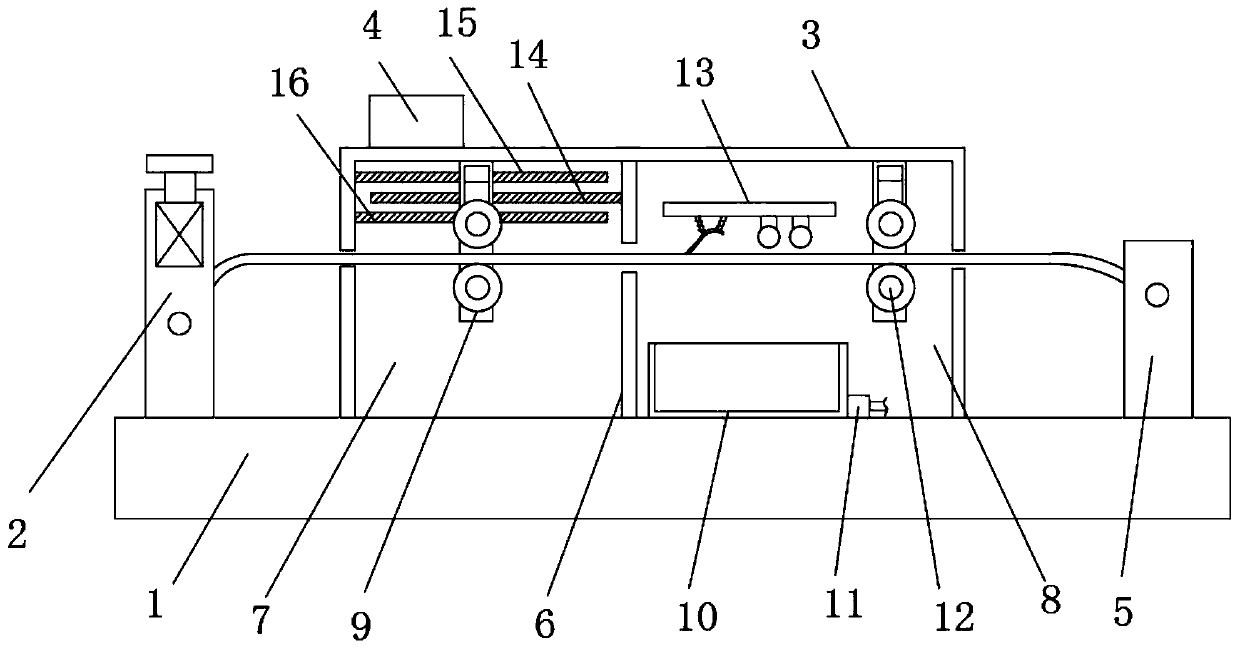

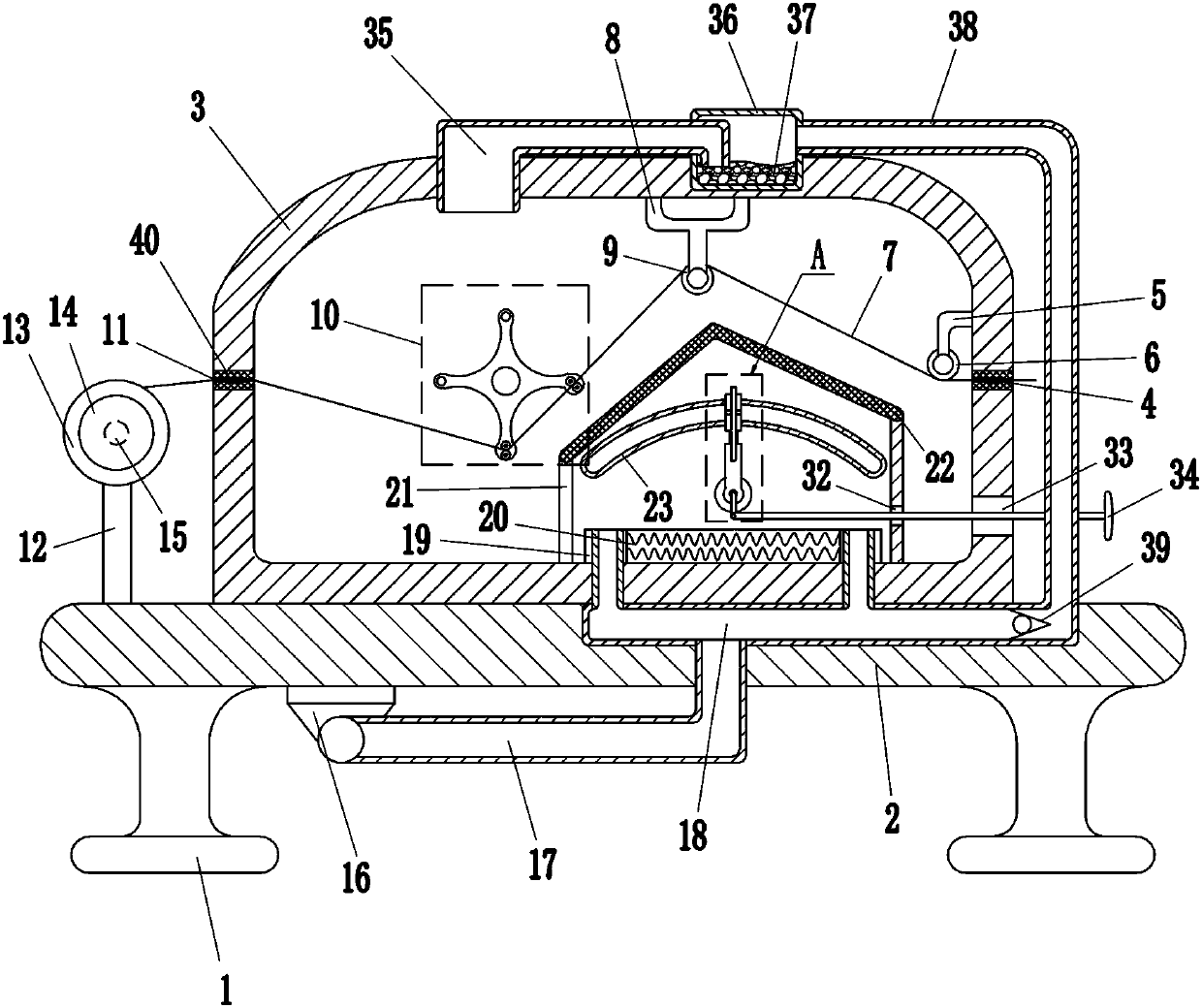

Jet-dyeing device with good cloth spraying uniformity and application method thereof

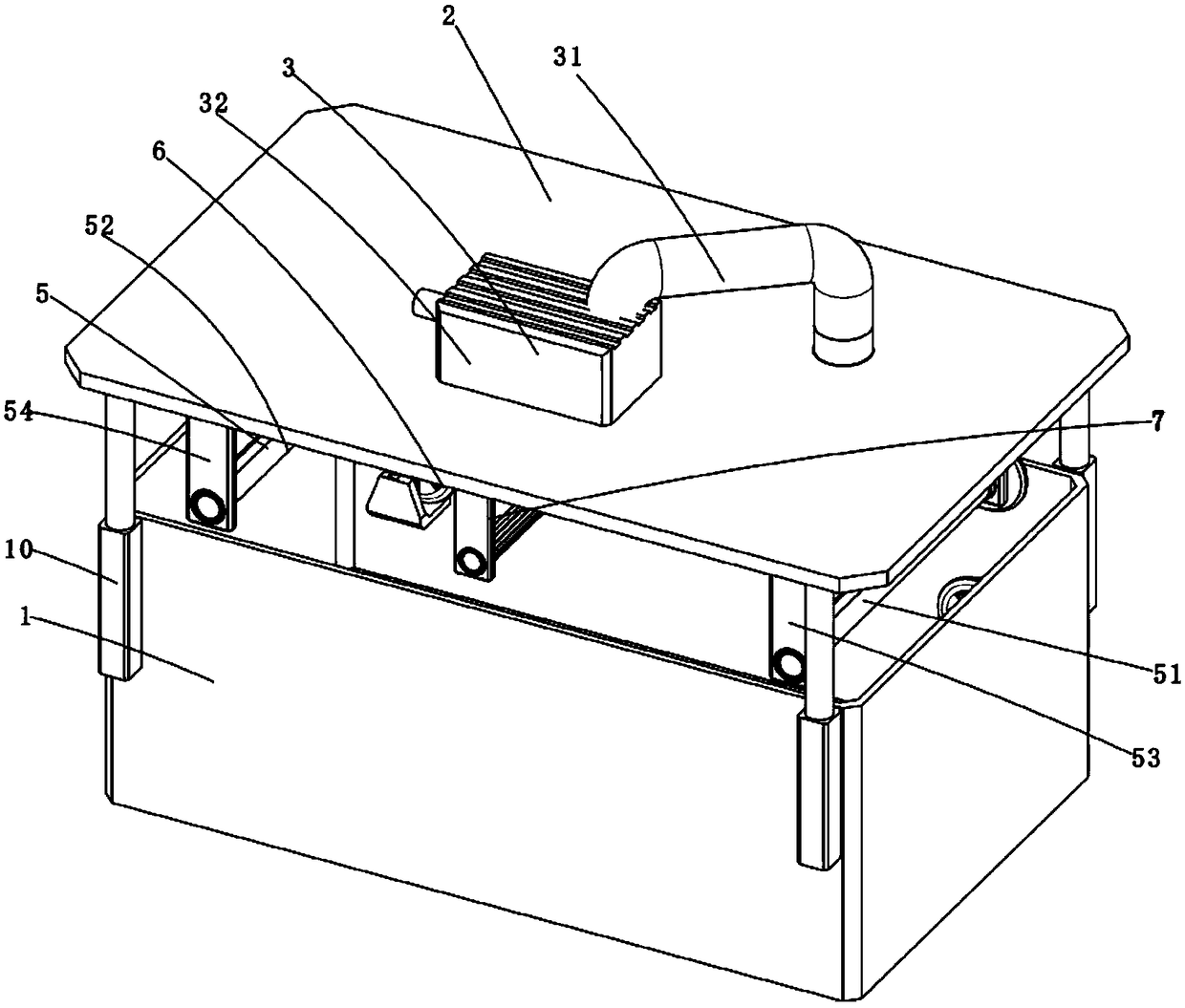

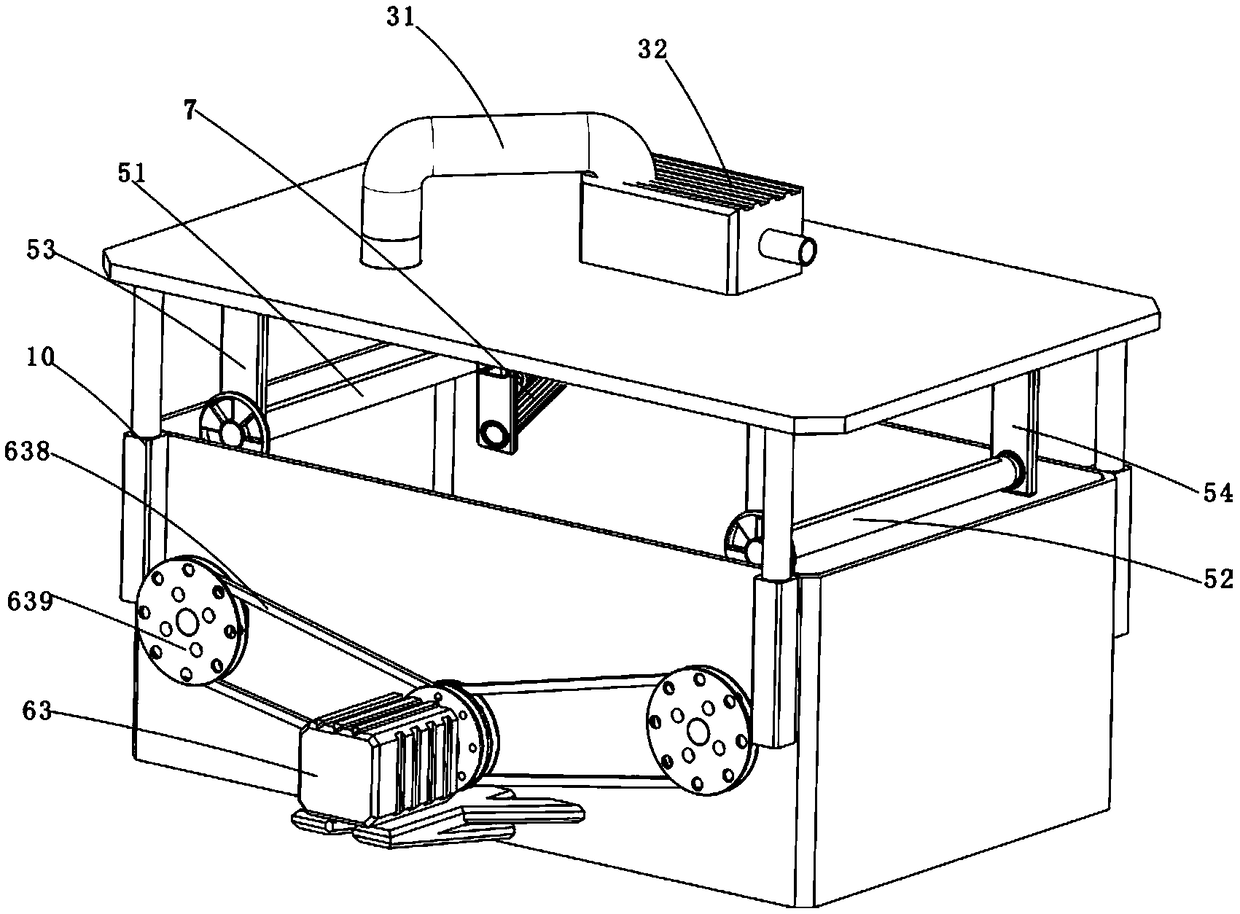

ActiveCN110424112AEasy to rewindNeatly rolledMechanical cleaningTextile storage in wounded formEngineeringMechanical engineering

The invention discloses a jet-dyeing device with good cloth spraying uniformity and an application method thereof. The jet-dyeing device comprises a base, a rack, a box body, a heating box and an unwinding roller. The unwinding roller is in drive connection with one end of the top of the base; the box body is fixedly mounted at the top center of the base; the inside of the box body is divided intoa drying chamber and a spraying chamber through a partition arranged; a second adjustment is fixedly mounted at the side, close to the unwinding roller, of the interior of the spraying chamber; a mounting plate is fixedly mounted at one side of the second adjustment. Processing and guiding can be performed on cloth different in thickness by adjusting a distance between an adjusting roller and a driving roller through the two adjustments; clamp rings are driven to move back and forth on the unwinding roller by enabling an electric telescopic bar to operate, a distance between the two clamp rings can be adjusted, and therefore, cloth different in width can be wound conveniently; winding evenness is better, operating is simple, and using is facilitated.

Owner:安徽宜民服饰股份有限公司

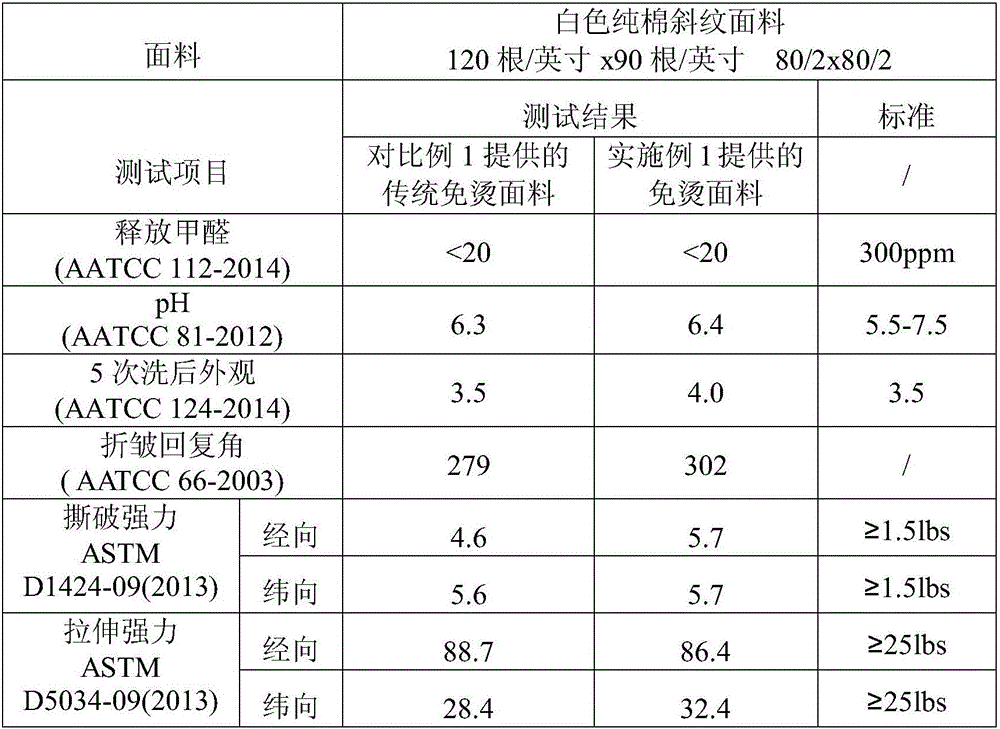

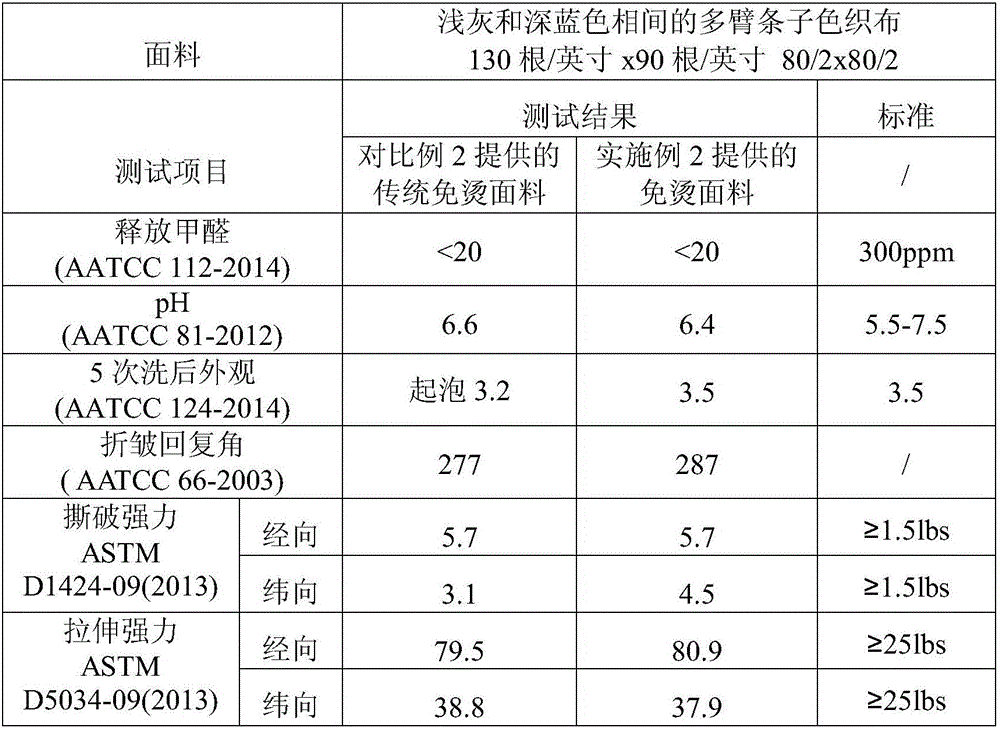

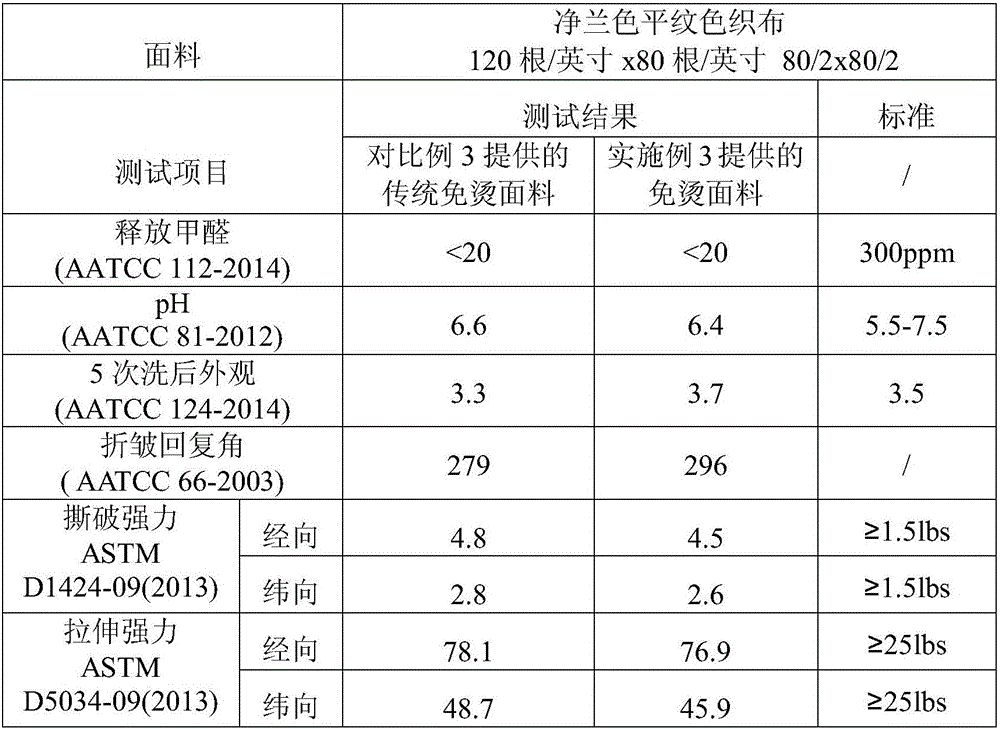

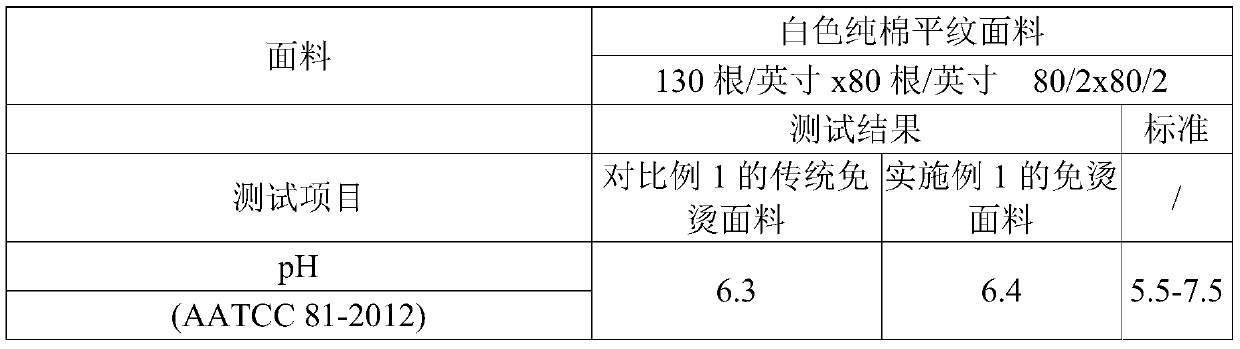

Non-ironing fabric and preparing method thereof

ActiveCN105821657ABalance anti-wrinkle abilityGood lookingTextile storage in wounded formLiquid/gas/vapor removalPolyolEngineering

The invention provides non-ironing fabric and a preparing method thereof .The preparing method includes the steps that double-dip-double-nip processing is conducted on the fabric in a non-ironing finishing solution, mangle expression of the fabric is controlled, and the fabric is rolled in a sealed mode and stored; the fabric is dried, the moisture content of the fabric is controlled, and the fabric is rolled in a sealed mode and stored; the fabric is baked, washed and shaped to obtain the non-ironing fabric .The pH value of the non-ironing finishing solution is 1-3, and the non-ironing finishing solution is prepared from, by mass, 10-30% of a non-ironing finishing agent, 4-15% of a catalyst, 3-10% of amino silicone softener, 3-10% of a powerful protective agent, 3-10% of polyalcohol, 0.1-1 part of a penetrating agent, 0.5-2% of acid, 0.5-2% of pH stabilizer and the balance water .The non-ironing fabric can keep good appearance when being washed, dried and worn in different seasons and weathers.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

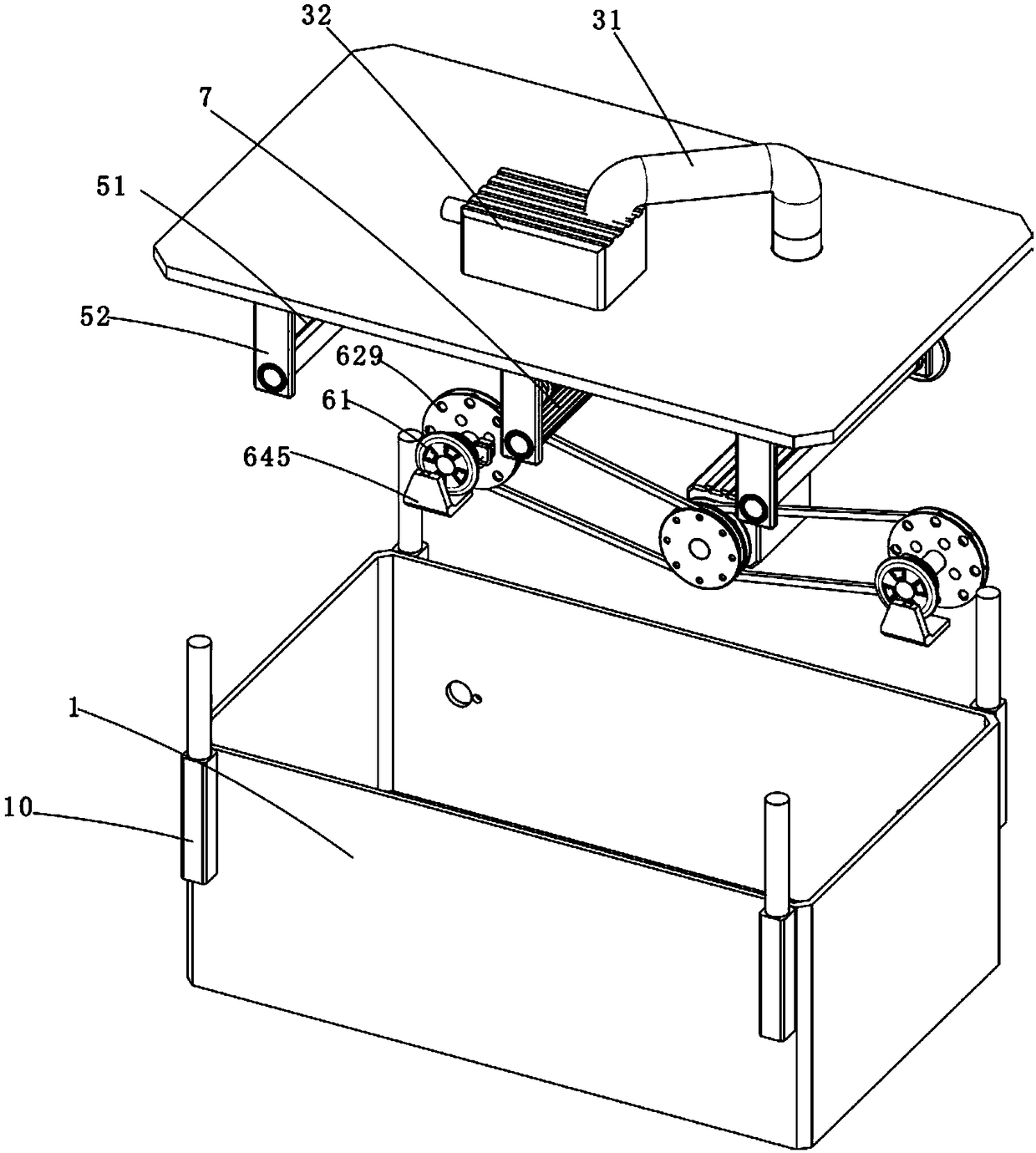

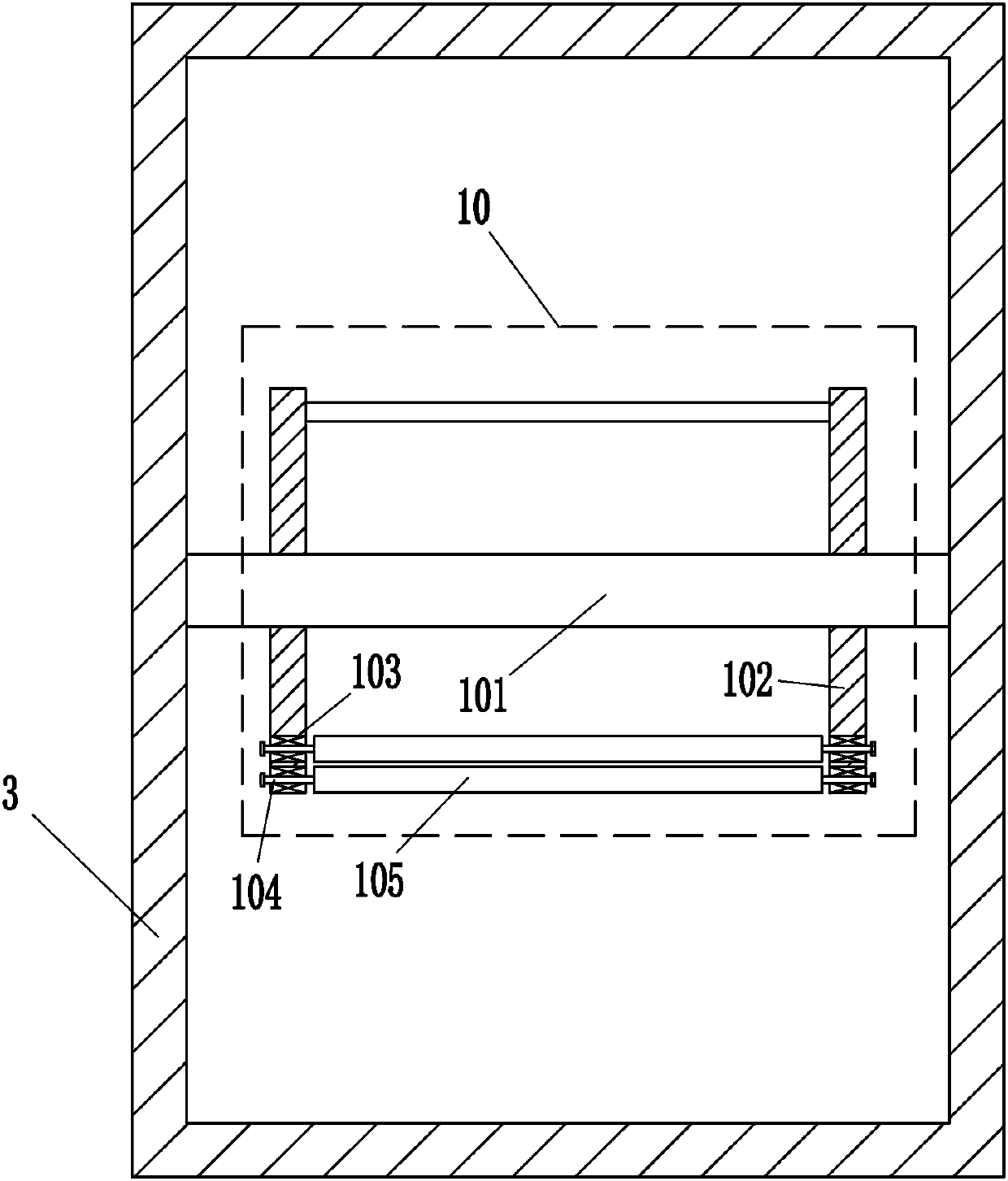

Cold bleaching device for open-width knitted fabrics

InactiveCN101818423AGuaranteed wrinkle-freeGood open width stateTextile storage in wounded formLiquid/gas/vapor removal by squeezing rollersOxygenControl circuit

The invention discloses a cold bleaching device for open-width knitted fabrics, which comprises a frame, a cloth feeding device and a immersion / padding liquid device, and further comprises a wet supported cloth conveying device, a rollup device and a control circuit. The cloth feeding device, the immersion / padding liquid device and the wet supported cloth conveying device are all provided with mechanical open-width components, and the open-width knitted fabrics are subject to open-width flattening before entering the units described above; the immersion / padding liquid device and the wet supported cloth conveying device are the devices capable of forming, during the use thereof, supported conveyance for wet fabrics; during the use, the control circuit controls the rotating speed of electric motors in an active manner so that the cloth feeding device, the immersion / padding liquid device, the wet supported cloth conveying device and the rollup device realize the conveyance of the open-width knitted fabrics under bearable tension in a manner of synchronous operation, the open-width knitted fabrics are free from crumpling and curling in the entire treatment process, and can also be flatly rolled onto a cloth roller in the form of big batch which can be rotated, thus the fabrics, after being immersed in cold-bleaching liquid, can be completely piled up under movable state, thereby ensuring the consistent effect of cold batch oxygen bleaching.

Owner:蔡宗义

Cloth textile device with jet feeding function

InactiveCN108914430AWith jet feeding functionImprove permeabilityTextile storage in wounded formLiquid/gas/vapor removalEngineeringProduction cycle

The invention discloses a cloth textile device with a jet feeding function. The cloth textile device comprises a mounting plate and support legs; a plurality of support legs are symmetrically ad fixedly connected to the lower end of the mounting plate; a feeding box is fixedly connected to the upper end of the mounting plate; a supporting mechanism is fixedly connected to an inner bottom wall of the feeding box; two pulling rods are symmetrically and fixedly connected to an inner top wall of the feeding box; the lower ends of the two pulling rods are fixedly connected to a fixing pipe; one side of the fixing pipe communicates with a plurality of branch pipes symmetrically; one end away from the fixing pipe, of each branch pipe communicates with a nozzle, and each nozzle is disposed above the supporting mechanism; and the upper end of the feeding box is fixedly connected to a material barrel. The cloth textile device is stable in structure, is easy to operate, is scientific and reasonable in design, is short in production period, and can spray the cloth with a dye, so that the cloth can be fully dyed, and the cloth can absorb the dye well.

Owner:巴益增

Loose type yarn beam salt-free cold-stacking dyeing processing technique

ActiveCN101705592AHigh color yieldEasy to handleSucessive textile treatmentsTextile storage in wounded formSizingElectricity

The invention provides a loose type yarn beam salt-free cold-stacking dyeing processing technique, which relates to the technical field of textiles, in particular to a technique and a method for yarn dyeing. The technique comprises the following sequential steps: warping yarn in a loose type, carrying out preliminary treatment on the yarn in an dye vat, dyeing, and forming a loose type dyeing beam, coiling and stacking for 16-18 hours under a condition of the environmental temperature of 20-30 DEG C, soaping and dewatering in the dye vat, sizing by a yarn beam on a sizing machine and forming a loom beam. The invention changes the traditional production mode and procedure of colored woven cloth, does not use salt during dyeing and is beneficial to the subsequent sewage treatment, and the coloration rate of dye is as high as 90%. In the invention, yarn is coiled into a beam for stacking during dyeing, subjected to dyeing at normal temperature and does not need steam; the invention also saves electricity and has obvious advantages in the aspects of energy saving and consumption reduction.

Owner:JIANGSU LIANFA TEXTILE

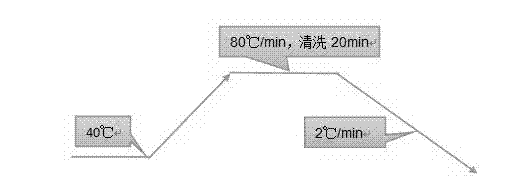

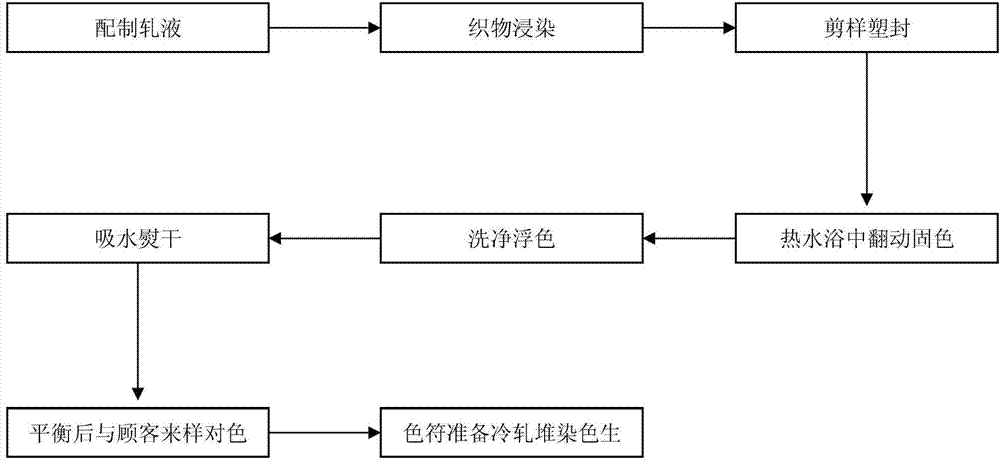

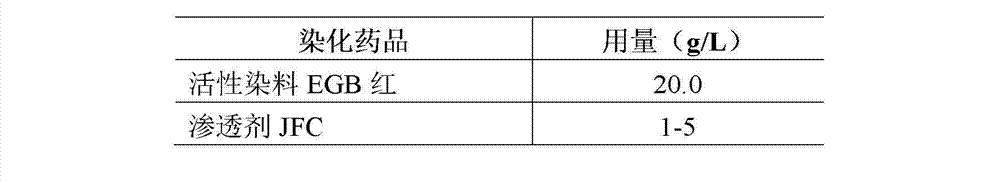

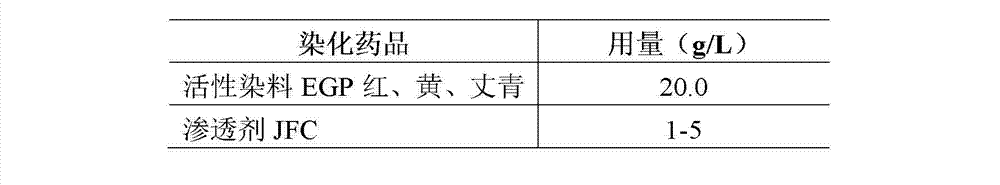

New rapid proofing method for cold pad batch dyeing

ActiveCN102787462AEasy to operateProcess equipment requirements are simpleTextile storage in wounded formTextile treatment dyeing devicesWater bathsThermal insulation

The invention relates to a new rapid proofing method for cold pad batch dyeing. The method comprises the following steps of: (1) preparing the reactive dye pad dyeing solution which is consistent with the production formulation of a large sample, and using up reactive dye, penetrant solution and reactive dye cold pad batch alkaline agent which are mixed together in 40-90 minutes; (2) according to the soaking time and mangle expression which are consistent with the large sample production, alternately soaking and rolling a small cotton sample; (3) rolling the pad dyed small cotton sample along a glass rod which has the same breadth as the small cotton sample, putting the rolled small cotton sample into a plastic hermetic bag which is matched with the small cotton sample, extracting the gas in the plastic bag, and keeping tight; (4) slightly putting the plastic hermetic bag which contains the small cotton sample into a water bath of 20-40 DEG C to be banked up for 20-60 minutes in a thermal insulation manner, pulling the hermetic bag out, and putting the hermetic bag into a water bath of 40-70 DEG C to be banked up for 5-30 minutes in a thermal insulation manner, pulling the hermetic bag out, and taking the dyed cotton fabric out; and (5) according to the dyeing which is consistent with the technology of the large sample production, matching the colors of the small dyed cotton sample. The method has the following beneficial effects that the method is simple to operate, the requirements on the technological equipment are low, the proofing colors can be accurately produced by corresponding to the colors of the large sample, and delta E (DE) is not more than 1 according to color measurement committee (CMC).

Owner:ZHEJIANG YIDE CHEM

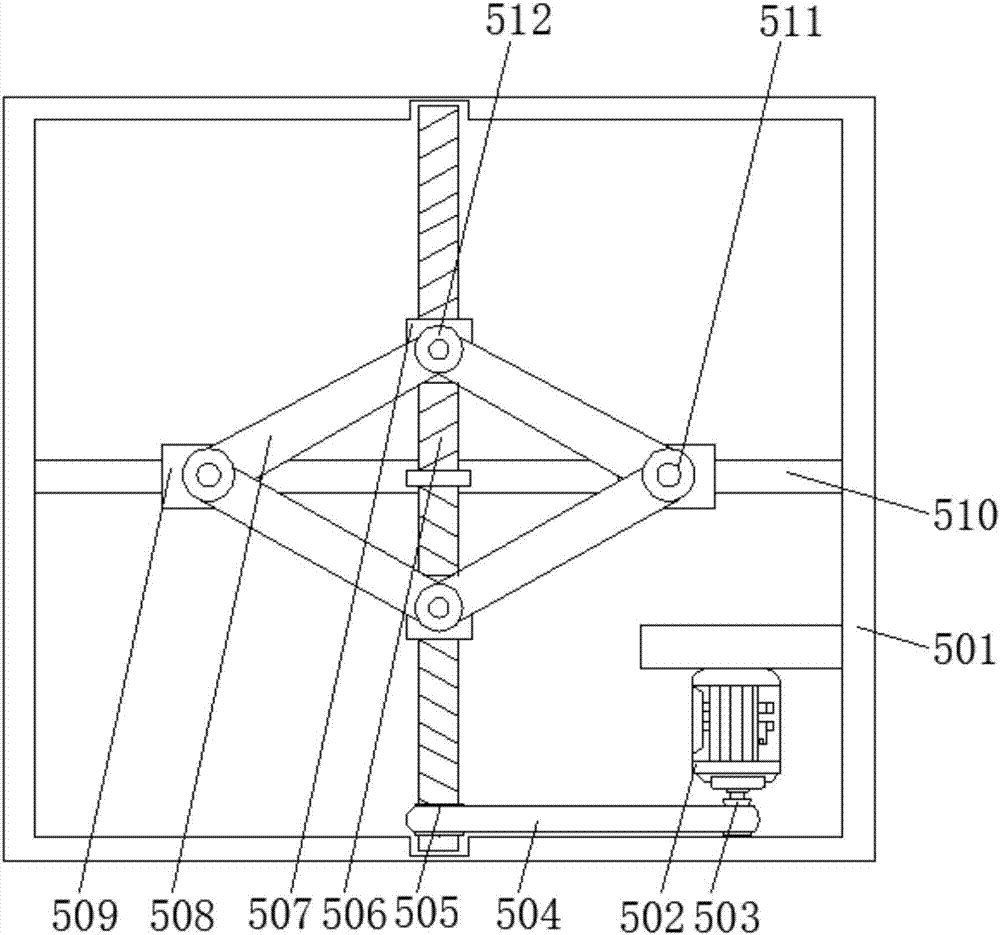

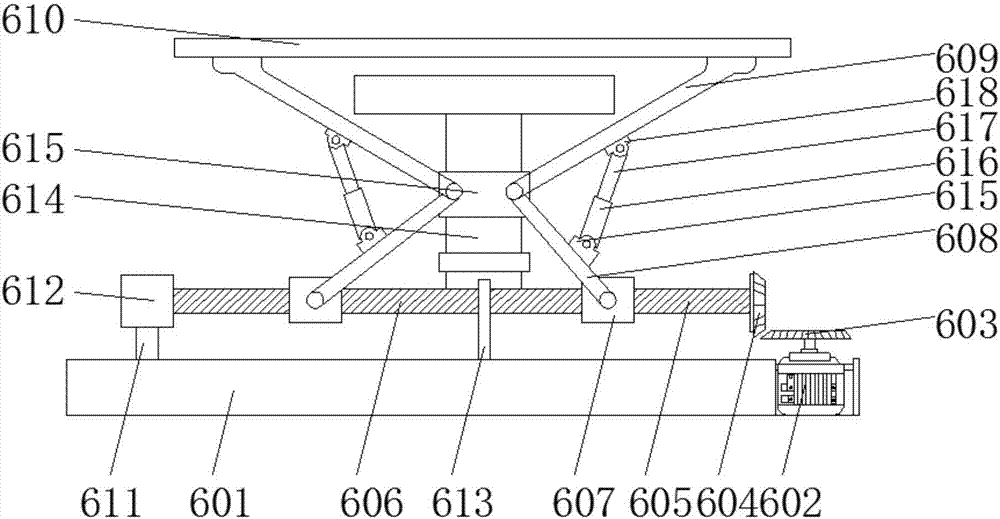

Production process and production equipment for pure cotton fabric with white space effect

InactiveCN103215830AUniform and natural whitening effectReduce pollutionTextile storage in wounded formDyeing processPulp and paper industryReactive dye

A production process and production equipment for pure cotton fabric with white space effect. The production process includes pretreatment, lye padding, dye paste scraping, stack cooling and fixation, and floating color washing. The dye paste scraping step refers to scraping a reactive dye paste on the back of pure cotton fabric subjected to lye padding. The stack cooling and fixation step refers to rolling up the pure cotton fabric scraped with the reactive dye paste; in the rolling process, isolating membranes are introduced to separate each layer of the cotton fabric, so that the reactive dye paste on the back of the pure cotton fabric to gradually diffuses, permeates, adsorbs to a right side, and finally reacts into bonds to fix the color. As the reactive dye is in a paste shape, diffusivity and permeability of the dye are limited to a certain extent that only part of the dye can reach the right side of the pure cotton fabric; in addition, the pure cotton fabric has bump woven texture; therefore, uniform and natural white space effect is formed on the right side.

Owner:HUAHAN QUANZHOU NEW FABRIC DEV

Method for producing worsted fabrics with carved patterns

ActiveCN103710807ASpecial drapabilityFeel slipperyTextile storage in wounded formPattern makingPersonalizationWorsted

The invention relates to a method for producing worsted fabrics with carved patterns. The method is characterized by comprising the following the steps of milling, inflaming retarding treatment, napping, decatizing and pattern carving. The worsted fabrics manufactured through the production method have the advantages that because fabric bodies are blended, counts, gram weight and colors can meet production requirements of customers; the worsted fabrics can be designed according to pattern types provided by the customers, and fabric bodies of one piece of clothing can be produced as well; the fabric bodies have special draping, good hand feeling, even, fine and smooth woolen cloth faces, and the taste and fashions of a wearer can be better embodied when the wearer wears clothes made of the worsted fabrics; requirements for personalization are met.

Owner:HEILAN HOME

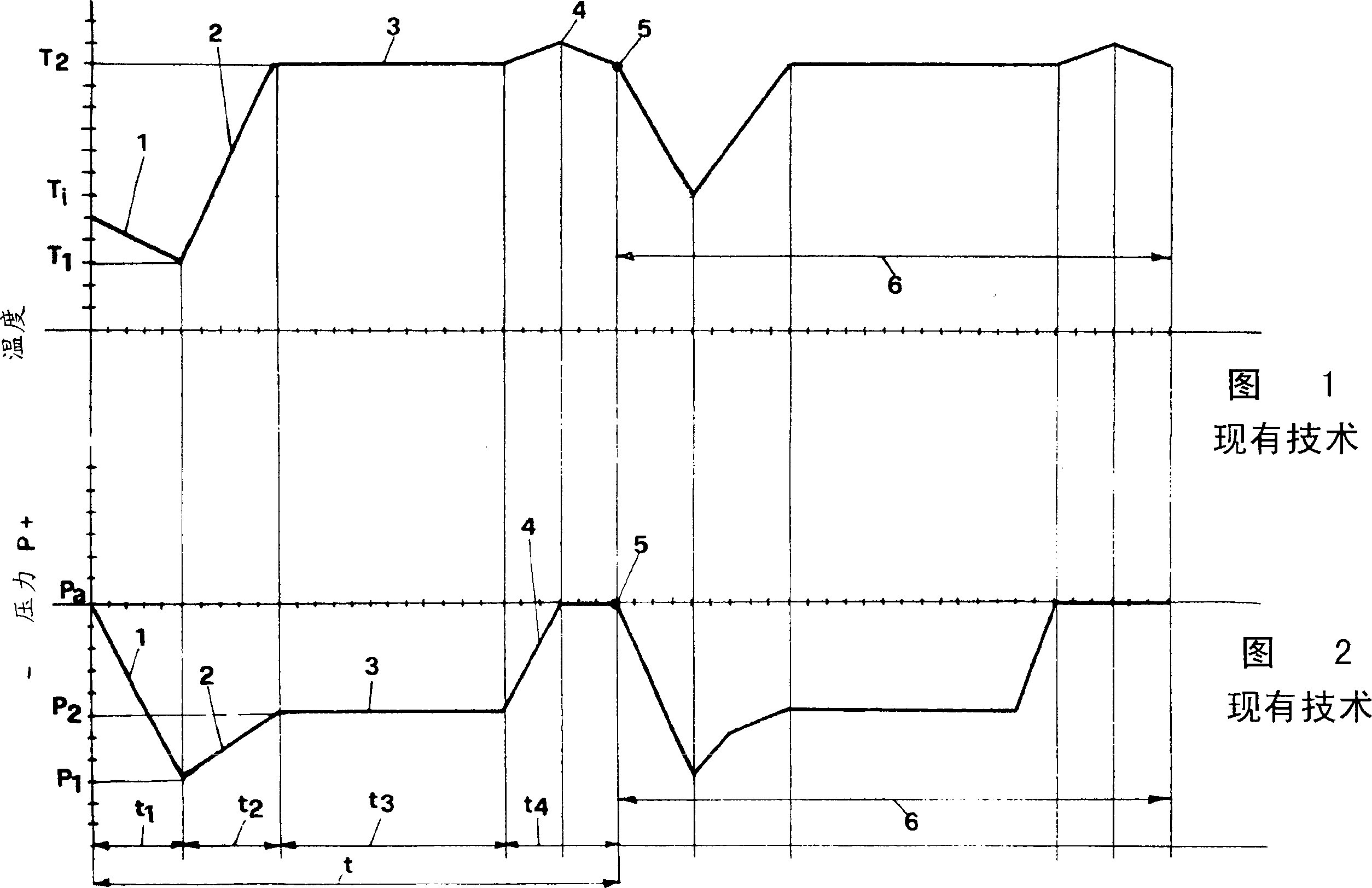

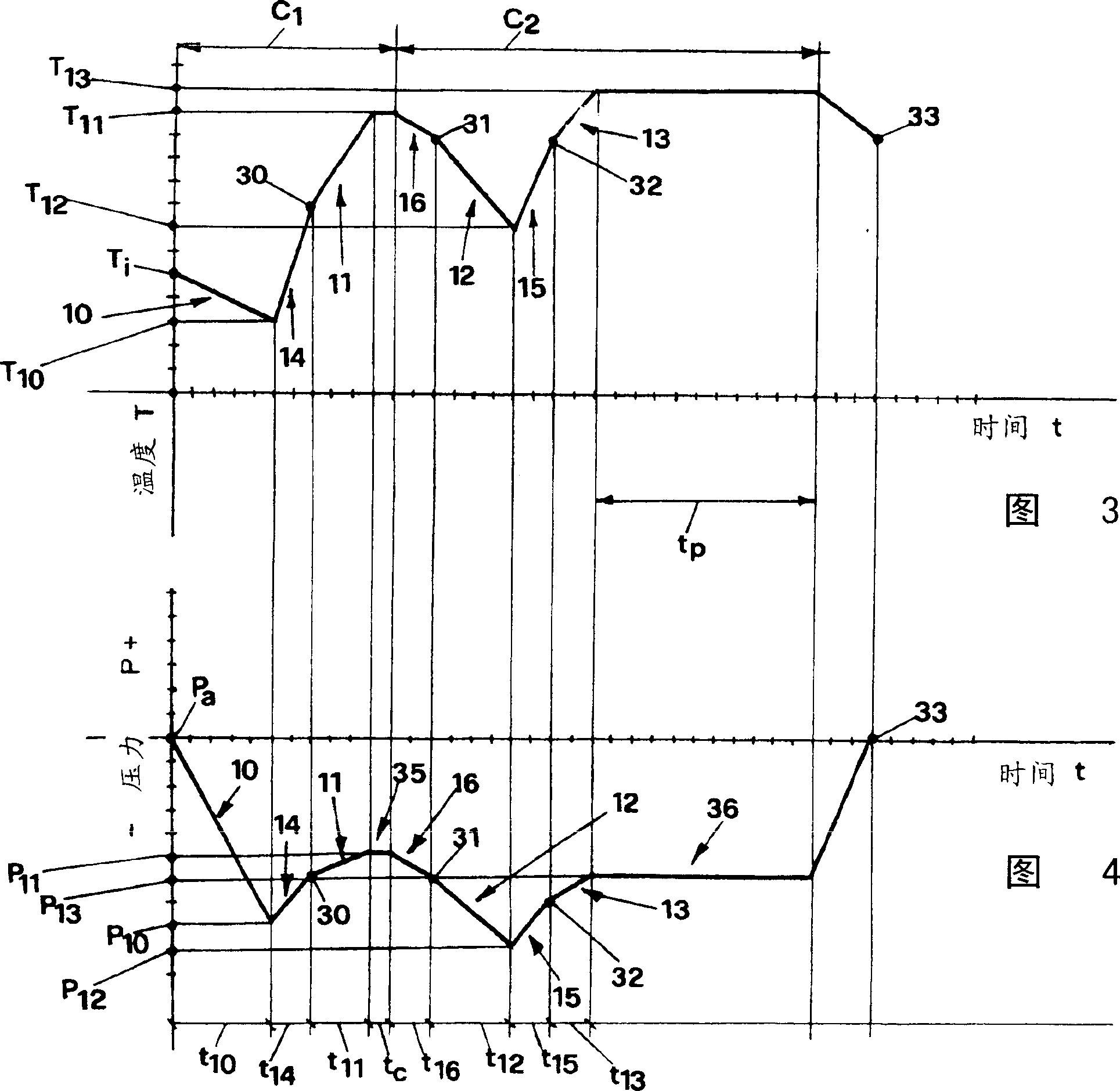

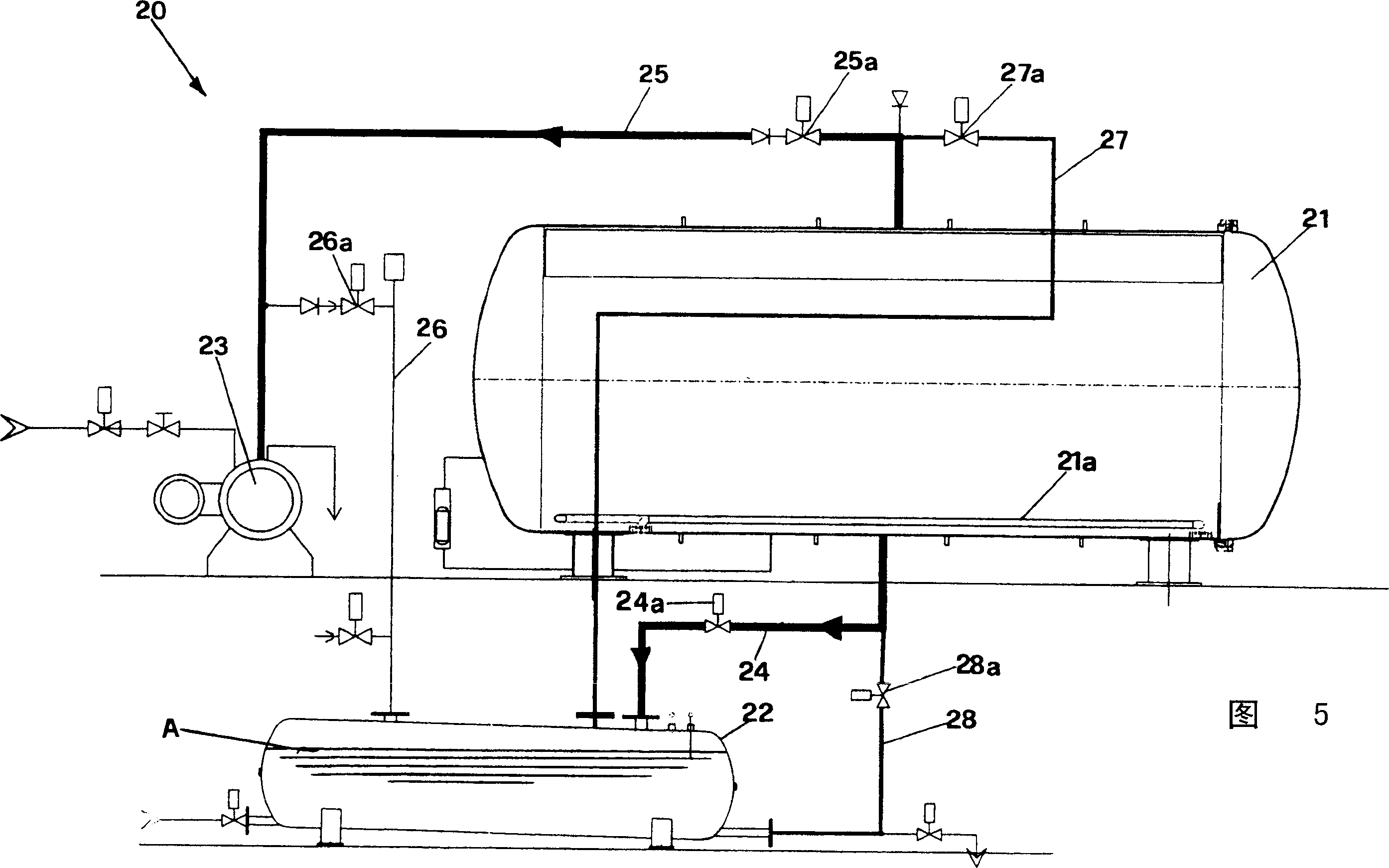

Method and equipment for conditioning and heat-setting textile articles

InactiveCN1524994AQuality improvementEvenly distributed humidityTextile storage in wounded formHeating/cooling textile fabricsAmbient pressureEngineering

A method of conditioning and heat-setting textile products in an autoclave (21) is disclosed comprising: two or more thermal cycles (C1, C2), at least one of which comprising a transfer phase (16) of water present in the autoclave (21) to inside a recovery tank (22), a suction phase (10, 12) to put the autoclave (21) under vacuum, a water return phase (14, 15) from the recovery tank (22) to the autoclave (21), a heating phase (11, 13) of water contained in the autoclave (21) to generate saturated steam, a stay phase (35, 36) in the autoclave (21) for a predetermined time (tc, tp) of the reached conditions of temperature (t11, t13) and pressure (p11, p13), restoring in the autoclave (21) the ambient pressure (Pa) at the end of the last stay phases (36). Each phase of transfer (16) and return (14, 15) of said water occurs spontaneously by suction produced by the difference of pressure existing between autoclave (21) and recovery tank (22).

Owner:莱奥波尔多.波齐机械建造股份公司

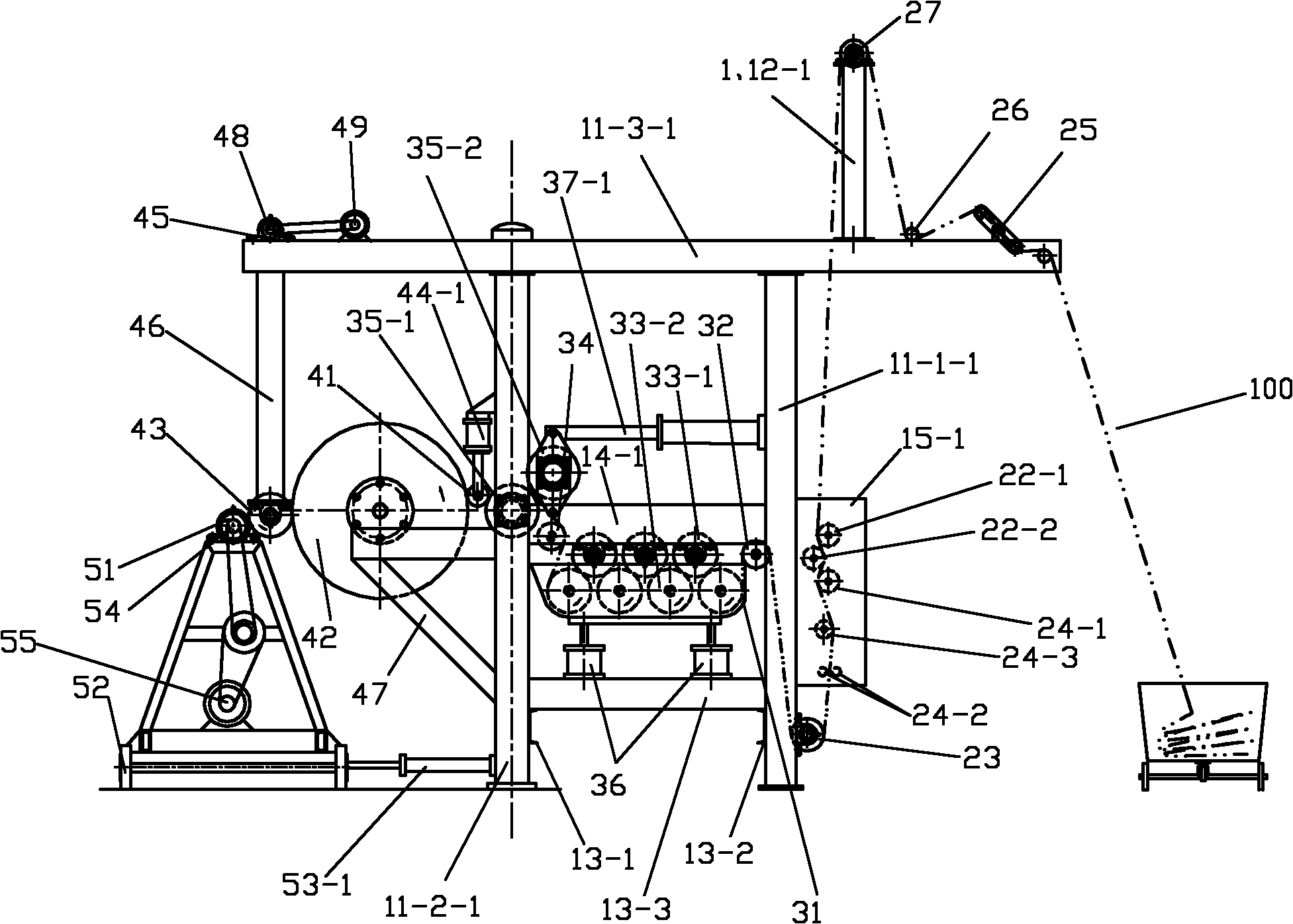

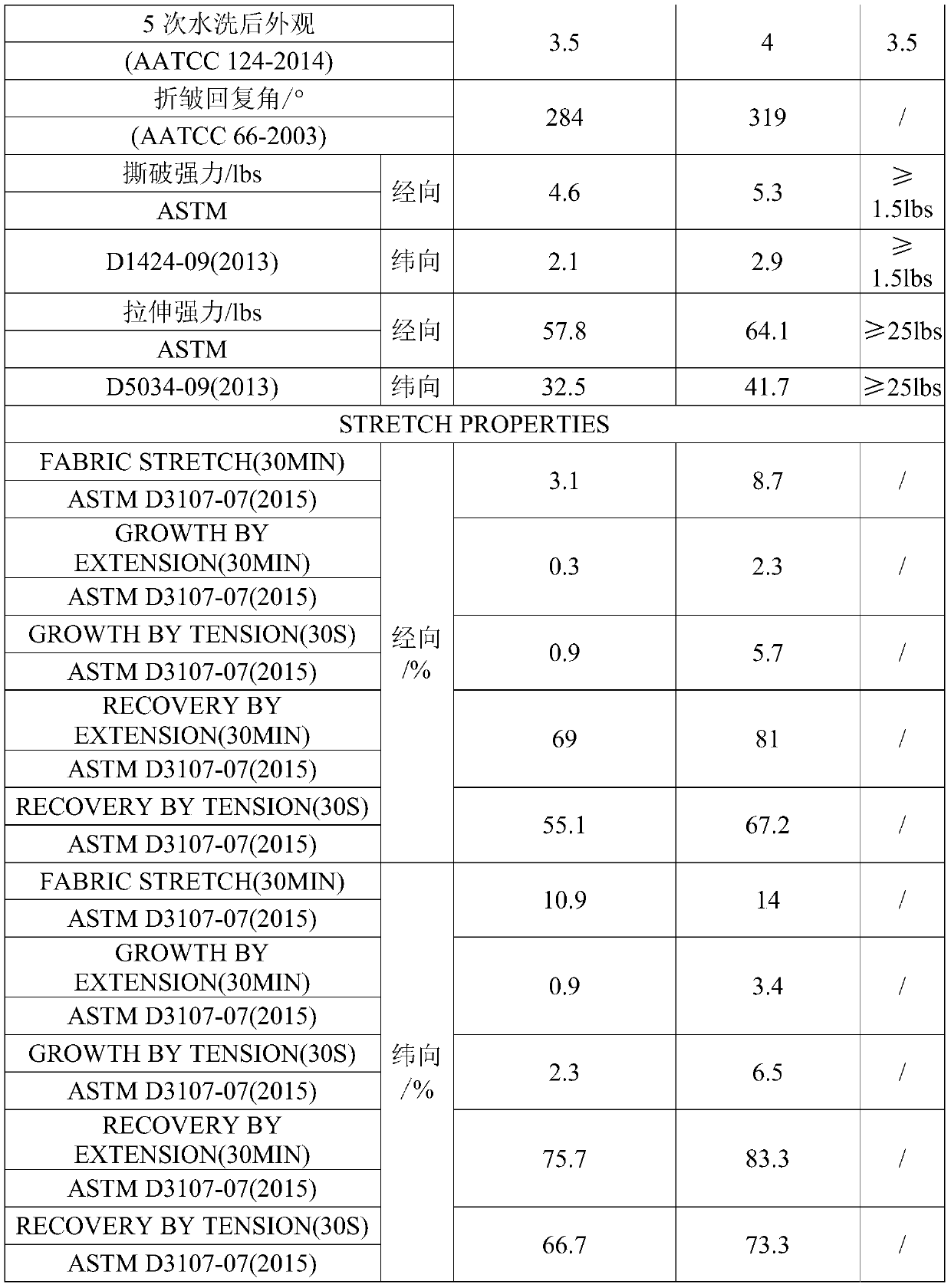

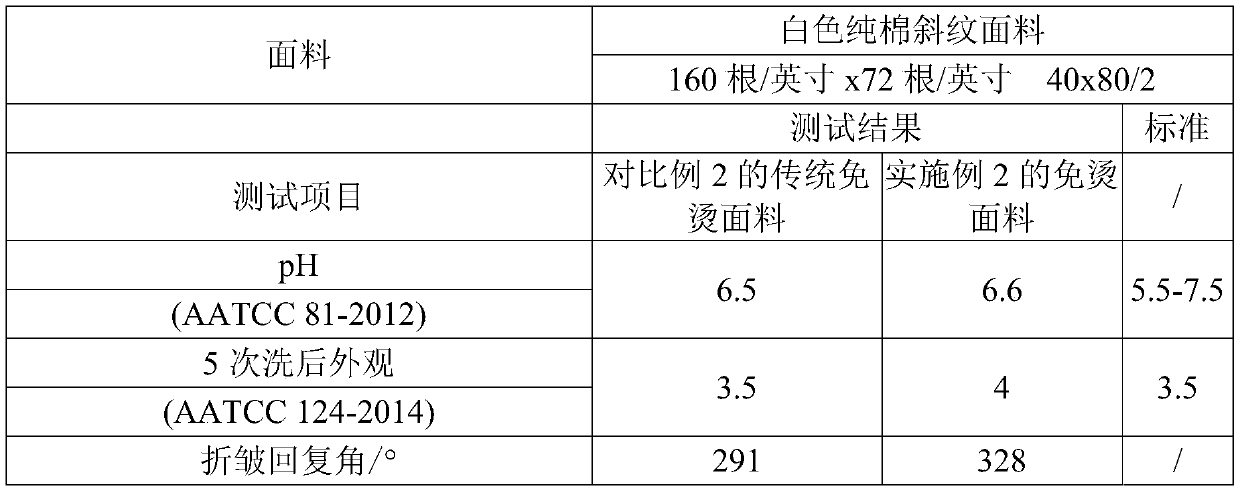

Pure cotton fabric and non-ironing finishing method thereof

ActiveCN110306342AEffective shock mitigationIncreased warp tear strengthTextile storage in wounded formLiquid/gas/vapor removalEngineeringSteaming

The invention provides a pure cotton fabric and a non-ironing finishing method thereof. The non-ironing finishing method comprises the following steps: after desizing a pure cotton fabric, carrying out scouring and bleaching finishing by scouring and bleaching finishing liquid; rolling and stacking; and carrying out scouring, bleaching, steaming and resin finishing on the rolled and stacked fabricto obtain the pure cotton fabric subjected to non-ironing finishing. The pure cotton fabric finished by the method not only has permanent warp and weft elasticity, but also has high non-ironing appearance.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

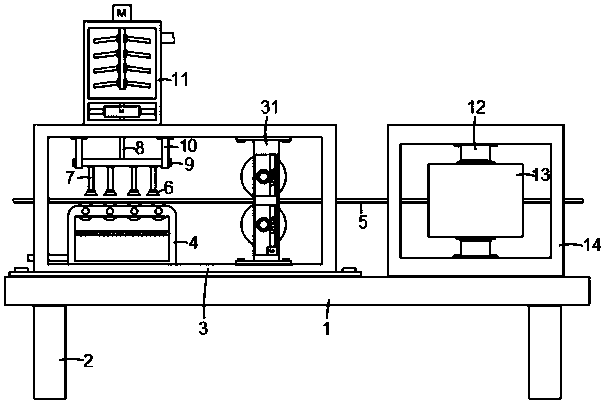

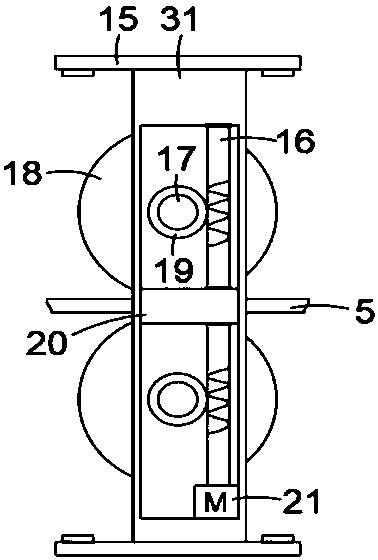

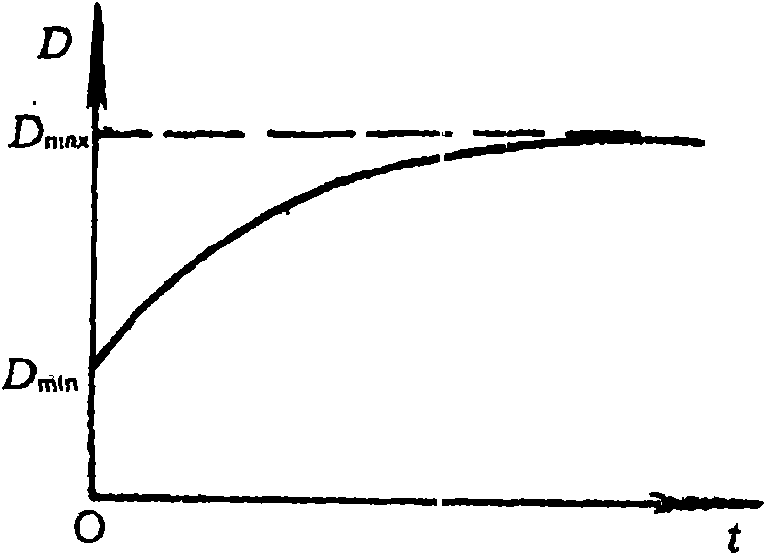

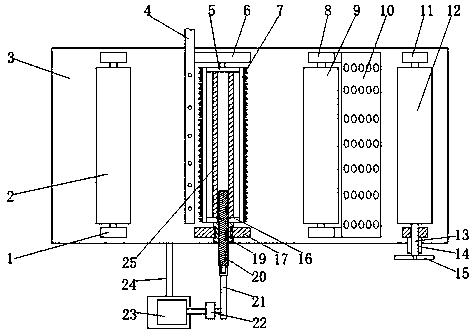

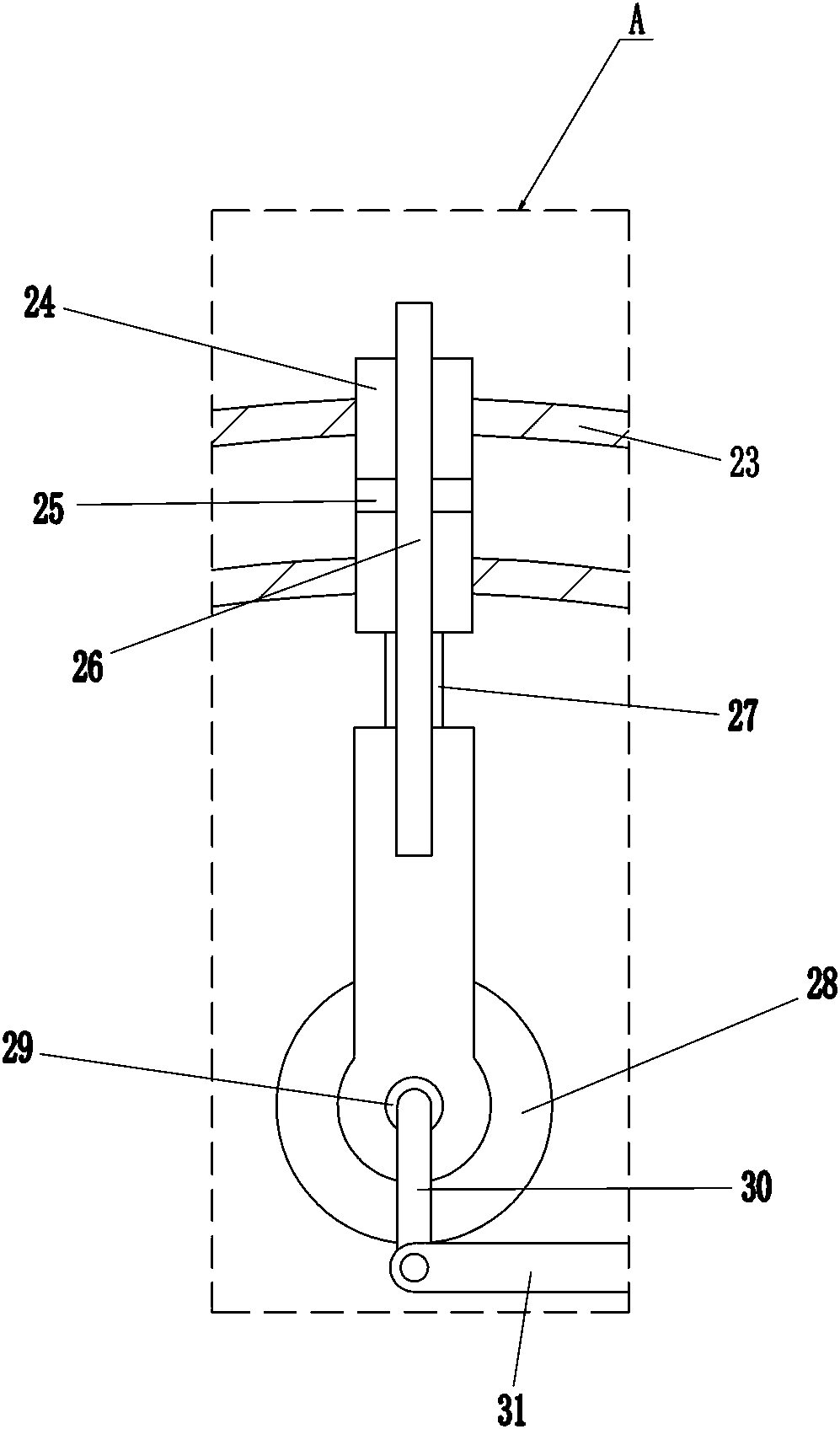

Fixation method and equipment for screen printing of natural fiber fabrics by reactive dye

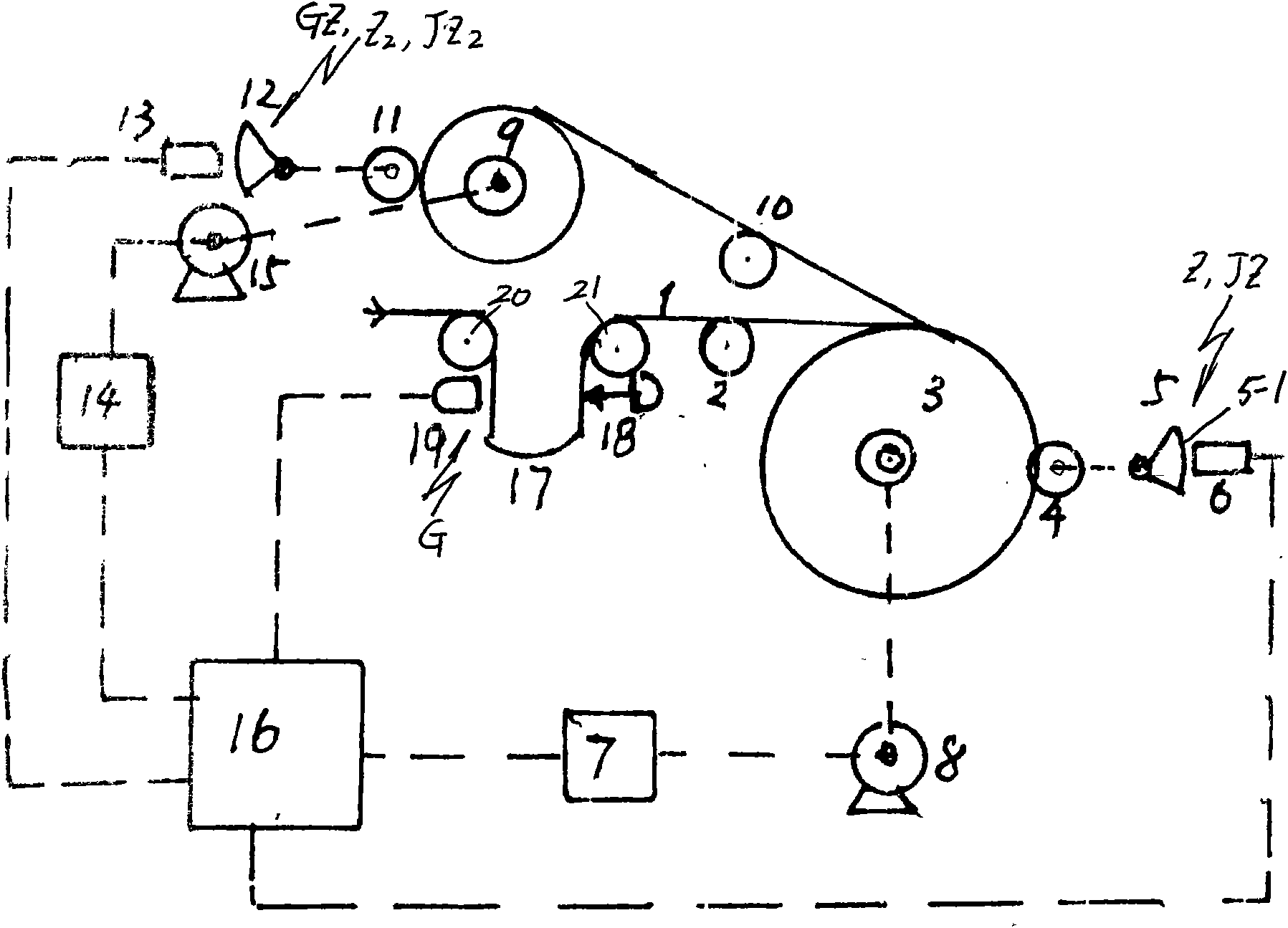

InactiveCN101575783ALoose with each otherShort processTextile storage in wounded formTextile treatment machine arrangementsFrequency changerEngineering

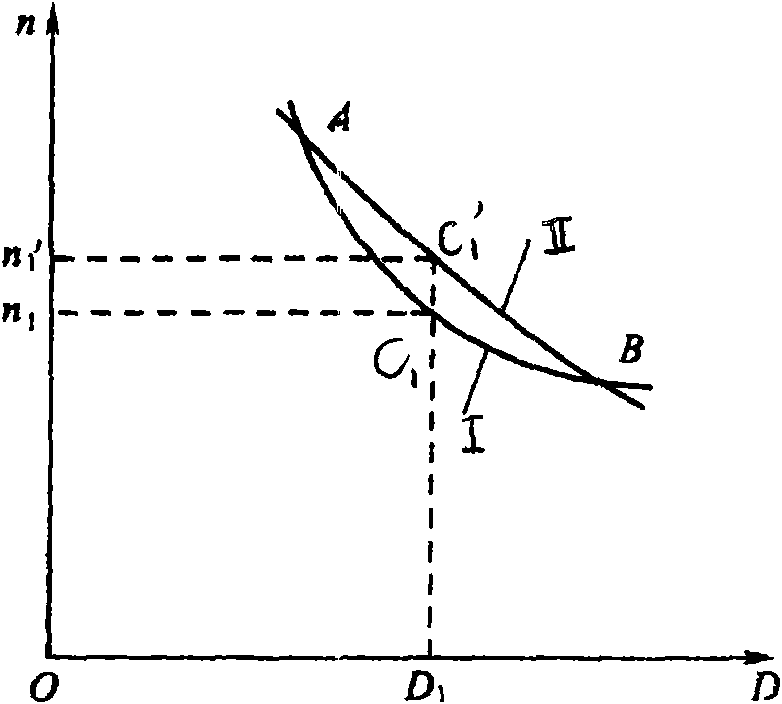

The invention discloses a fixation method and fixation equipment for screen printing of natural fiber fabrics by reactive dye. The fixation method is mainly characterized in that: the fixation method adopts constant linear speed and low and even tension of a humid heap wind-up roll for winding, and adopts statistic humid heap fixation; the fixation equipment is mainly characterized in that: the fixation equipment comprises the humid heap wind-up roll, a motor coaxially connected with a wind-up roll shaft, a frequency convertor electrically connected with the motor, a controller electrically connected with the frequency convertor, a pair of cloth guide rollers, a spreading roll, a photoelectric controller pair and a constant linear speed tension controller which are connected with the controller through electric signals, a constant linear speed tension control device separating chemical blended fabrics, and a second spreading roll; and the constant linear speed tension controller is the tension controller according with a winding machinery characteristic curve mu K=f(D). The fixation method has the characteristics of short process flow, no occurrence of color paste adhesion, color overlapping contamination and pattern distortion, energy conservation, consumption reduction and emission reduction, and the like; and the equipment has the characteristics of reasonable structure, low preparation cost, good quality of finished products printed cloth, and the like. The invention initiates a novel method for the screen printing of the natural fiber fabrics by the reactive dye.

Owner:陈立秋 +1

Dyeing machine for dip-dyeing cloth

ActiveCN108998911AIncrease temperatureHigh activityTextile treatment containersTextile storage in wounded formEngineeringTextile dye

The invention discloses a dyeing machine for dip-dyeing cloth. The dyeing machine comprises a dyeing tank containing dyeing liquid; a cover plate sealingly matching the dyeing tank; a vacuuming devicefor evacuating the gas inside the dyeing tank; a winding device for winding a cloth and immersing the cloth in the dyeing liquid; a driving device for driving the winding device to wind the cloth back and forth in the dyeing liquid; and a heating device for heating the dyeing liquid in the dyeing tank to a preset temperature. The heating device can heat the dyeing liquid in the dyeing tank to allow the temperature of the dyeing liquid in the dyeing tank to reach the preset value, the temperature of the dyeing temperature is increased, the activity of dye in the dyeing liquid is improved, andthen the dye can adhered to the cloth well; since the temperature of the dyeing liquid is increased, the drying speed of the cloth can be improved during a subsequent drying process.

Owner:SHAOXING UNIVERSITY

Preparation method of anti-mite, crease-resist and soil-releasing clean shell fabric

ActiveCN103696234AGood compatibilityReduce production processTextile storage in wounded formFabric breaking/softeningResistPolyester

The invention discloses a preparation method of anti-mite, crease-resist and soil-releasing clean shell fabric. The shell fabric is formed by mixing 65-67% of cotton and 33-35% of dacron. A product employs an air treatment technology in order to obtain heaviness, softness, drapability and glossiness after functional finishing. Treatment is carried out in an air softness machine, high-speed air pulls the shell fabric to impact onto a baffle continuously at the speed of 200m / min, the softness and drapability of the shell fabric are improved, and a polyester peach skin like hand feeling is obtained at the same time. The shell fabric innovatively integrates anti-mite, crease-resist and soil-releasing functions, three functional finishing assistants having good compatibility and stable working solutions are found through assistant screening and many technical experiments, a cross point of working temperatures of various assistants is obtained successfully, a one bath one-step method is used for production, various functions meet design requirements, a production technology is greatly shortened, and energy sources are saved to a greater extent.

Owner:安徽中天新材料科技股份有限公司

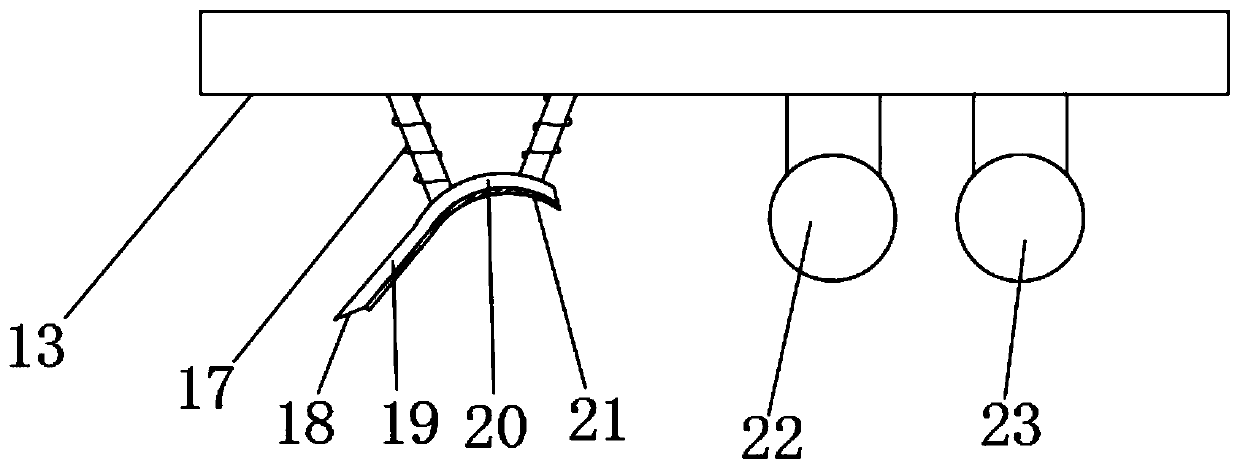

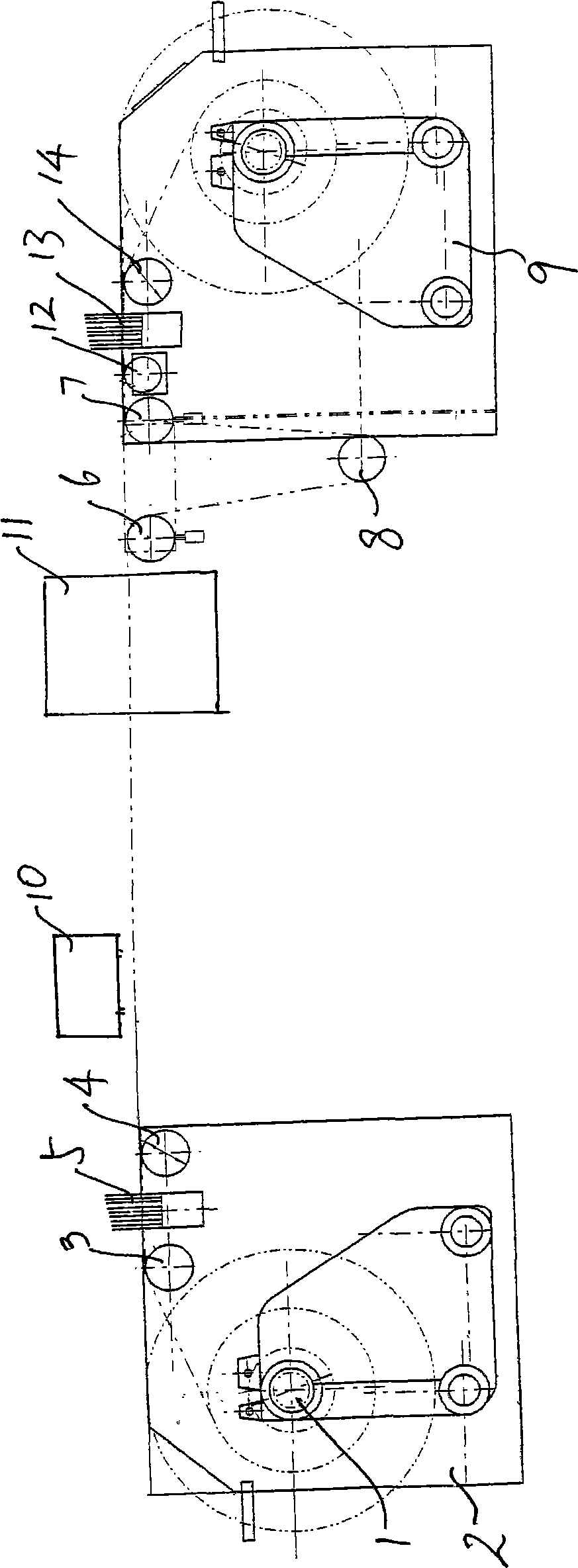

Production method for jet printing and dyeing warp yarns of knitted fabric and special device

InactiveCN101532226AReasonable structureImprove work performanceTextile storage in wounded formLiquid/gas/vapor removalYarnDyeing

The invention discloses a production method for jet printing and dyeing warp yarns of knitted fabrics and a special device. The production method comprises the following steps that: warp yarns of knitted fabrics are warped on a warp beam during production; the warp beam is arranged on a warp yarn jet printing, dyeing, drying and conveying mechanism, wherein the conveying mechanism comprises a warp yarn feeding mechanism and a warp yarn rolling mechanism; and warp yarns fed by the warp yarn feeding mechanism are subjected to jet printing or spray dyeing, and after being dried, the jet printed or dyed warp yarns are rolled by the warp yarn rolling mechanism onto the warp beam. With the method and the device, the production of the warp printing achieves ideal effects of simplicity, high efficiency, reduced cost, controllable quality and mass production. The production device is simple in structure and good in operation effect.

Owner:葛荣德

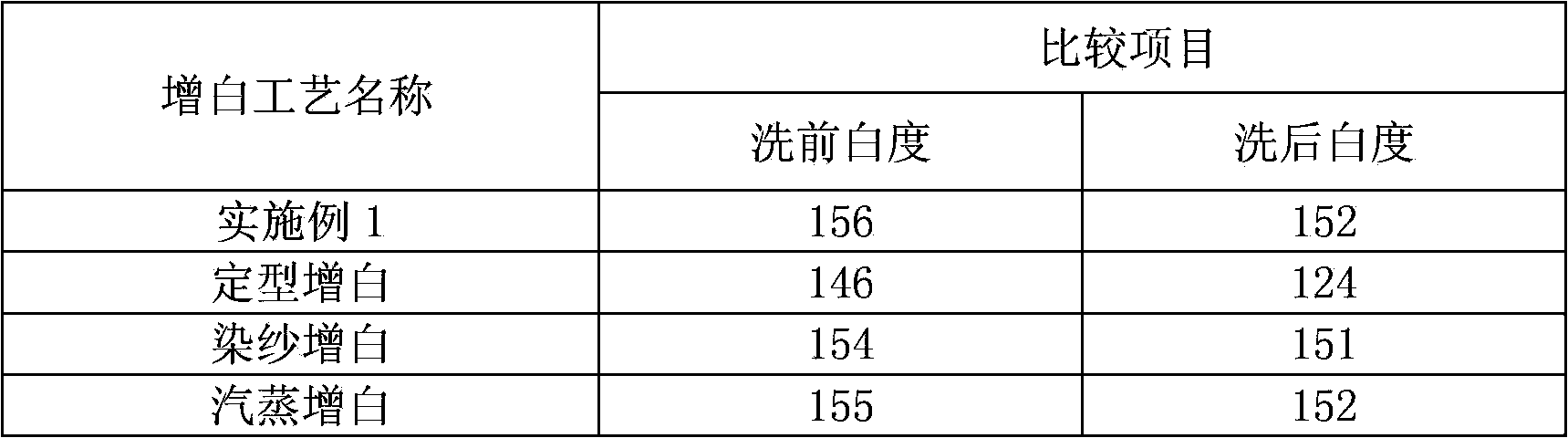

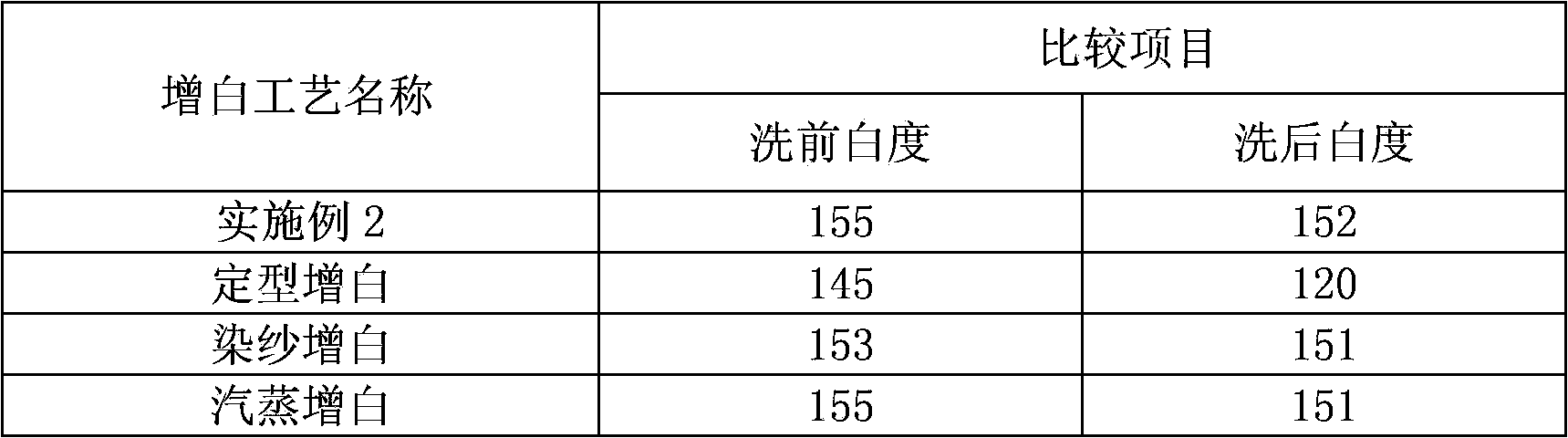

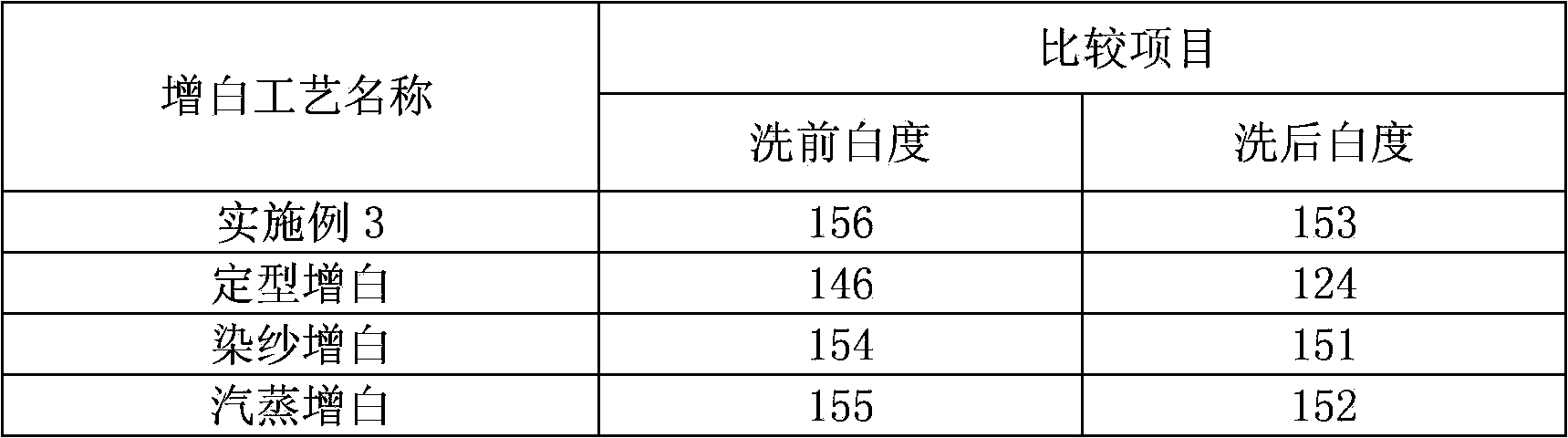

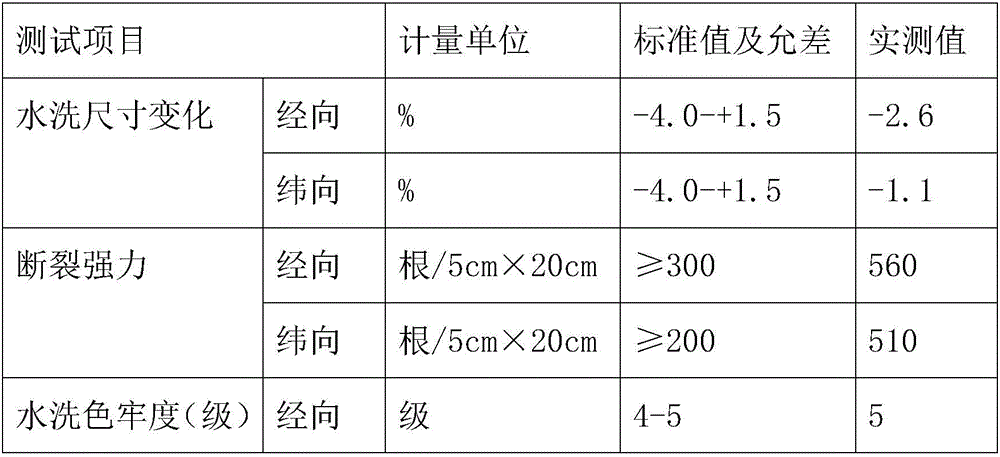

Cold pad-batch whitening method for cotton fabric

ActiveCN103668826AIncrease volumeImprove washing fastnessSolvent-treatmentTextile storage in wounded formEngineeringInvestment cost

The invention discloses a cold pad-batch whitening method for cotton fabric. According to the method, a storage procedure is added between a padding feeding procedure and a drying procedure, the whiteness washable performance of the cotton fabric can be greatly improved, and compared with the unwashed cotton fabric, the whiteness value of the cotton fabric is only lowered by within 4 degrees after the whitened cotton fabric is washed five times at home according to an AATCC standard. The method has the advantages of being fewer in equipment loss, and lower in equipment investment cost.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

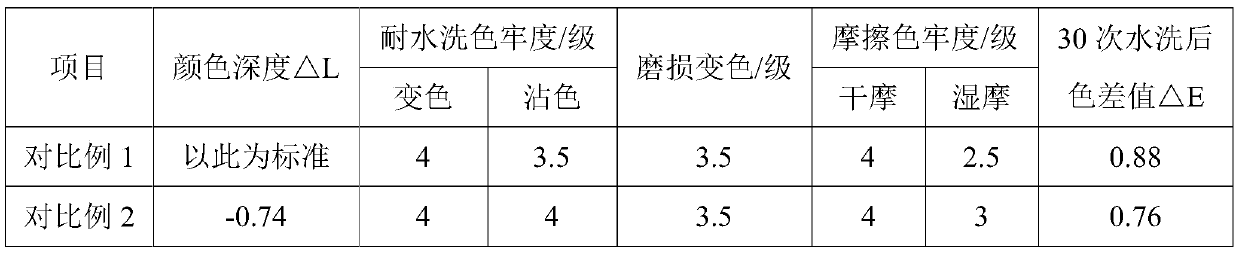

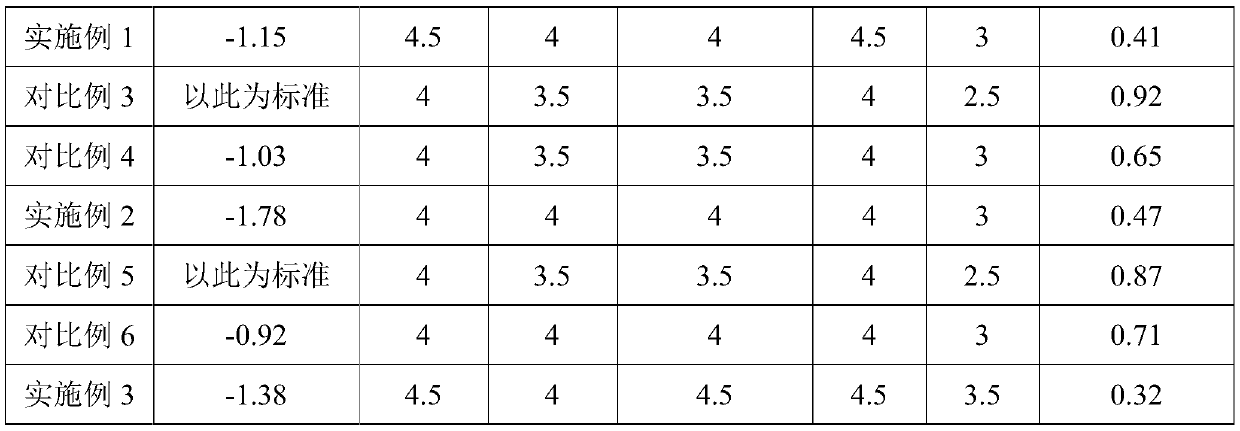

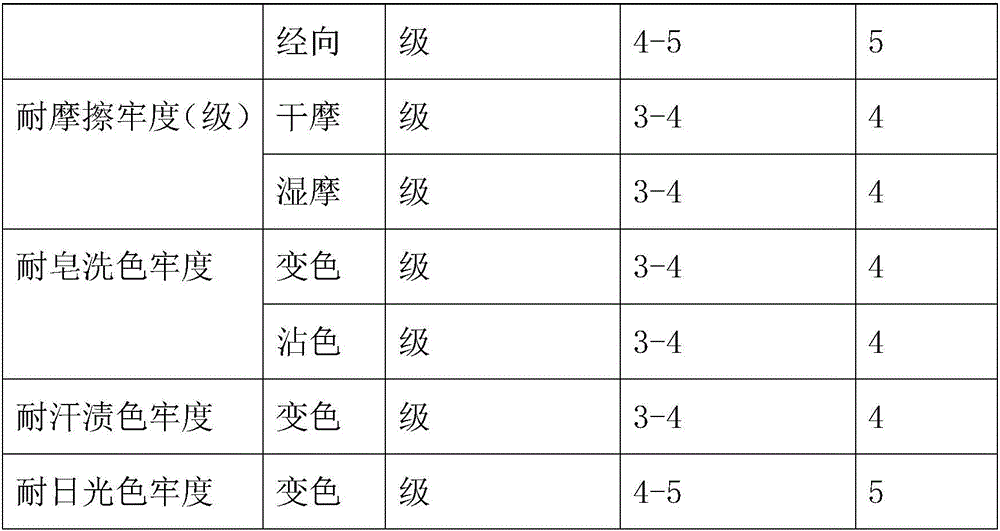

Method for improving active dyeing depth of pure cotton fabric

InactiveCN110952347AFull penetrationAdd depthTextile storage in wounded formLiquid/gas/vapor removalTextile printerPolymer science

The invention relates to the technical field of textile printing and dyeing, in particular to a method for improving active dyeing depth of a pure cotton fabric. According to the method for improvingthe active dyeing depth of the pure cotton fabric, the pure cotton fabric is dyed by the process of pressing, rolling and stacking, drying, steaming and color fixing, wherein the steaming and color fixing process comprises the steps of padding and color liquid fixing, steaming, water washing and soaping. According to the method for improving the active dyeing depth of the pure cotton fabric, the problem that the color quantity is low in continuous rolling dyeing is solved, the dyeing depth of the printed and dyed fabric can be improved by 25% or above on the original basis, the washable colorfastness of the dyeing fabric reaches 4 grade or above, the abrasion color change can reach 4 grade or above, the dry friction color fastness reaches 4 grade or above, the wet friction color fastnessreaches 3 grade or above, and the color change delta E after 30 times of water washing is within 0.5.

Owner:鲁丰织染有限公司

Reactive dye cold-pad batch dyeing process for pure cotton fabric

InactiveCN104420364AEasy to operateUniform colorSucessive textile treatmentsTextile storage in wounded formColor differenceReactive dye

The invention discloses a reactive dye cold-pad batch dyeing process for a pure cotton fabric. The process comprises the following steps: preparing dyeing liquor, rolling, batching, yarding and performing fixation, and washing. The problems that before and later color difference, left-center-right color difference, fabric covering black gas, seam mark and shallow edge easily occur in the dyeing production process and the like are solved, and the process is convenient to operate, uniform in coloring and high in color fastness.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Ramie and viscose interwoven fabric

InactiveCN105970696AIncrease elasticityImprove fullnessTextile storage in wounded formHeating/cooling textile fabricsAfter treatmentViscose fiber

The invention discloses a ramie and viscose interwoven fabric. The fabric is obtained by blending and interweaving ramie fibers and viscose fibers and then performing pretreatment, dyeing and after-treatment. The weight percentage occupied by the ramie fibers in the fabric is 55-75 percent, and the weight percentage occupied by the viscose fibers in the fabric is 25-45 percent; the pretreatment comprises cold-batch, desizing and oxygen bleaching; the dyeing adopts wet short steaming, pad-dyeing and dyeing processes of vat dyes; the after-treatment includes soft finishing, drying and setting. In addition, in the invention, the ramie and viscose interwoven fabric has the advantages of being uniform in dyeing, high in color fastness, rich in color and luster, soft in hand feeling and close in texture.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Wool fabric complex phosphoesterasum padding-room temperature rolling yarding anti-felting tidying craft

InactiveCN102978956AImproves felting resistanceHigh surface flatnessTextile storage in wounded formBiochemical fibre treatmentWater dischargeCutinase

The invention discloses a wool fabric complex phosphoesterasum padding-room temperature rolling yarding anti-felting tidying craft, and belongs to the technical field of dyeing, finishing and processing wool fabric. A full width and semi continuous padding-room temperature rolling yarding method is adopted. Full wool exquisite textile fabric is padded in composite biological enzyme liquid composed of cutinase, keratinase, protease and wool sweller urea. The full wool exquisite textile fabric is rolled up for certain time under the room temperature, and then is washed by hot water ( combined with enzyme deactivation treatment), and is fully washed by cold water to eliminate various enzyme decomposition products, inactivated enzyme and impurities on the wool textile fabric, and is dried at last. According to the wool fabric complex phosphoesterasum padding-room temperature rolling yarding anti-felting tidying craft, working efficiency of the keratinase and the protease and anti-felting effect of the wool textile fabric can be remarkably improved. Surface smoothness of the fabric is improved, and wearability of the fabric is improved. And the semi continuous method of room temperature rolling yarding is adopted, and therefore the water consumption is remarkably reduced, waste water discharge is obviously reduced, production efficiency is remarkably improved, and steam is saved and the like.

Owner:JIANGNAN UNIV

Improved clothing textile cloth dyeing, drying and winding device

ActiveCN109930334AClose contactQuick contaminationTextile storage in wounded formTextile treatment machine arrangementsPulp and paper industryPulley

The invention provides an improved clothing textile cloth dyeing, drying and winding device, which comprises a rotating piece, a motor cabin, a shaft rod, a guide piece, insertion rods, a rotating rod, a manual rod and a baffle plate; the bottom of the motor bin is provided with a supporting plate, the inner end of the supporting plate is arranged in the side groove through a pulley, the bottom ofa moving piece is embedded in an inner bin, and the side edge of the moving piece is connected with the inner part of the inner bin through a spring; the shaft rod is arranged at the inner side of the moving piece through the insertion rods at the two ends; a bottom piece is used for tensioning a bottom rod and a tensioning rod, so that the dyed cloth passing through the bottom rod and the tensioning rod can remove redundant dye, so that the cloth can be more quickly dried; and the bottom rod and the tensioning rod also play a role in extruding and leveling the dye contaminated by the cloth,so that the cloth can be more quickly dried, and the dye is more uniformly contaminated.

Owner:新昌县衣锦纺织机械有限公司

Textile automatic drying and packing equipment

InactiveCN107503059ARealize moving up and downEasy to moveTextile storage in wounded formLiquid/gas/vapor removal by gas jetsEngineeringCam

The invention discloses textile automatic drying and packing equipment, and relates to the technical field of textile product machinery. The textile automatic drying and packing equipment comprises a tank. A first motor and a second motor are fixedly connected with two sides of the bottom of the inner wall of the tank and are rotationally connected with first belt pulleys by output shafts, second belt pulleys are rotationally connected with the first belt pulleys by belts, rotary cams are rotationally connected with the second belt pulleys by rotary shafts and are fixedly connected with the bottom of the inner wall of the tank by mounting frames, and support rods are slidably connected with the tops of the rotary cams. The textile automatic drying and packing equipment has the advantages that textile fabrics can be stably dried by the textile automatic drying and packing equipment without unevenness during drying, the drying efficiency can be improved, and the production cost can be reduced; the height of an integral packing platform can be controlled, tensile force on the textile fabrics can be reduced, and accordingly the packing quality and the yield of products can be guaranteed.

Owner:HUZHOU BORUN IND

Textile fabric cleaning and drying device

InactiveCN108315911ATextile storage in wounded formLiquid/gas/vapor removal by gas jetsEngineeringMechanical engineering

The invention discloses a textile fabric cleaning and drying device which comprises a bottom plate. Two first supporting plates are symmetrically and fixedly connected onto the upper side of the bottom plate and jointly rotatably connected with a first round roller, a second supporting plate and a third supporting plate are fixedly connected onto the upper side of the bottom plate, a first rotating disk is rotatably connected onto the side wall of the second supporting plate, a second rotating shaft penetrates the side wall of the third supporting plate and is rotatably connected with the third supporting plate, a second rotating disk is fixedly connected onto the side wall of the second rotating shaft, a round tube is jointly arranged between the second rotating disk and the first rotating disk, a plurality of brushes are circumferentially, equidistantly, jointly and fixedly connected onto the side walls of the first rotating disk and the second rotating disk, and a motor supporting frame is fixedly connected onto the side wall of the bottom plate. Textile fabrics can be flushed and brushed, can be dried after cleaning and can be directly furled after drying, and time and labor are saved.

Owner:SUZHOU HUAZONG TEXTILE NEW MATERIAL TECH CO LTD

Gauze ageing equipment after dyeing

ActiveCN109778467AAvoid wrinklesReduce workloadTextile storage in wounded formTextile treatment machine arrangementsWrinkle skinEngineering

The invention relates to ageing equipment, in particular to gauze ageing equipment after dyeing. The technical aim is to provide the gauze ageing equipment after dyeing, and by means of the equipment,the workload of people can be reduced, and gauze wrinkles can be avoided. According to the technical implementation scheme, the gauze ageing equipment after dyeing comprises supporting racks, a baseplate, an aging box, a first mounting rack, a first idler wheel, a second mounting rack, a second idler wheel, a flattening device, a first supporting rod, a cloth collection wheel and the like; the supporting racks are fixedly connected to the left and right sides of the bottom of the baseplate, the aging box and the first supporting rod are fixedly connected to the top of the baseplate, the firstsupporting rod is located at the left side of the aging box, and a long-strip-shaped first opening is formed in the middle of the right side of the aging box. According to the gauze ageing equipmentafter dyeing, a motor rotates and can drive the cloth collection wheel to rotate, the aged gauze is rolled, people do not need to manually roll the aged gauze, and accordingly the workload of people can be reduced; through the flattening device, gauze wrinkles after dyeing can be avoided.

Owner:杨利人

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com