Cold pad-batch whitening method for cotton fabric

A cotton fabric, cold pad stacking technology, applied in the field of textile printing and dyeing, can solve the problems of high cost of dyeing and whitening, poor whiteness resistance to washing, and high energy consumption for steam whitening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

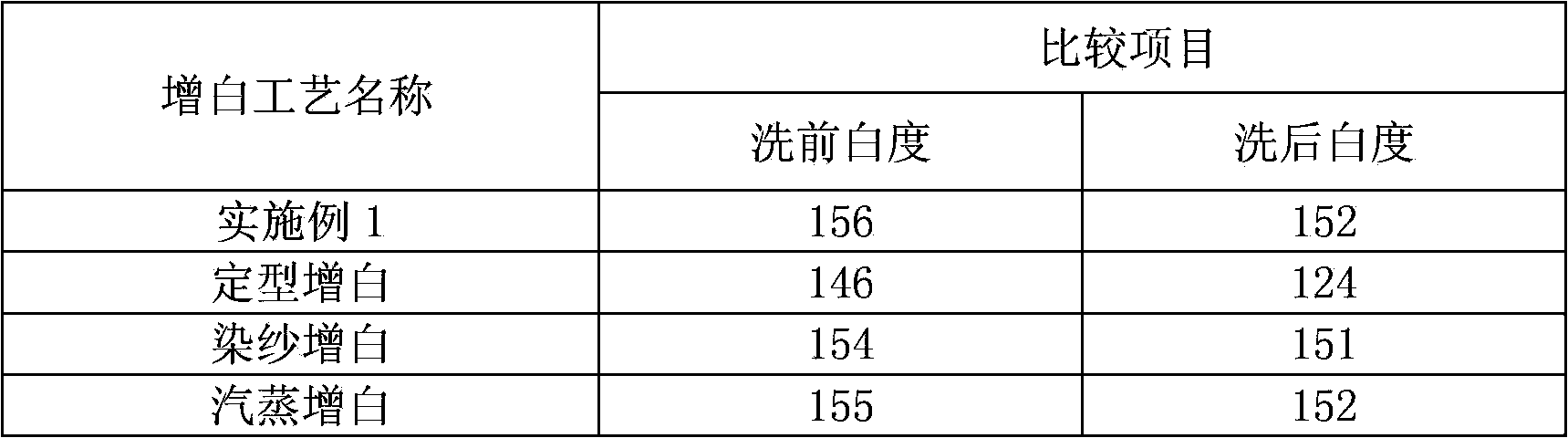

Embodiment 1

[0036] Select the pure cotton plain weave fabric with the background white of 80 after mercerizing, and the processing process is:

[0037] (1) Padding: First prepare a fluorescent whitening agent finishing solution with a fluorescent whitening agent of 5g / L, a softener of 10g / L, and a penetrating agent of 1g / L. The fluorescent whitening agent is Tinopal CBS-X (China Produced by Chuanhua Chemical Co., Ltd.), softener is XQS-1 (produced by Dongguan Xianqiao Chemical Co., Ltd.), penetrant is Lipotol TM (produced by Guangzhou Rihua Chemical Co., Ltd.), put the finishing liquid in the rolling trough, and adjust the rolling mill The pressure of the nip roller is 20N to control the nip rate to 70%, and then the dry cotton fabric enters the nip tank at a speed of 60m / min to pad the brightener solution.

[0038] (2) Rolling: The cotton fabric passing through the rolling mill is dropped and rolled, and the outer layer of the rolled fabric is covered with plastic to prevent the whitening age...

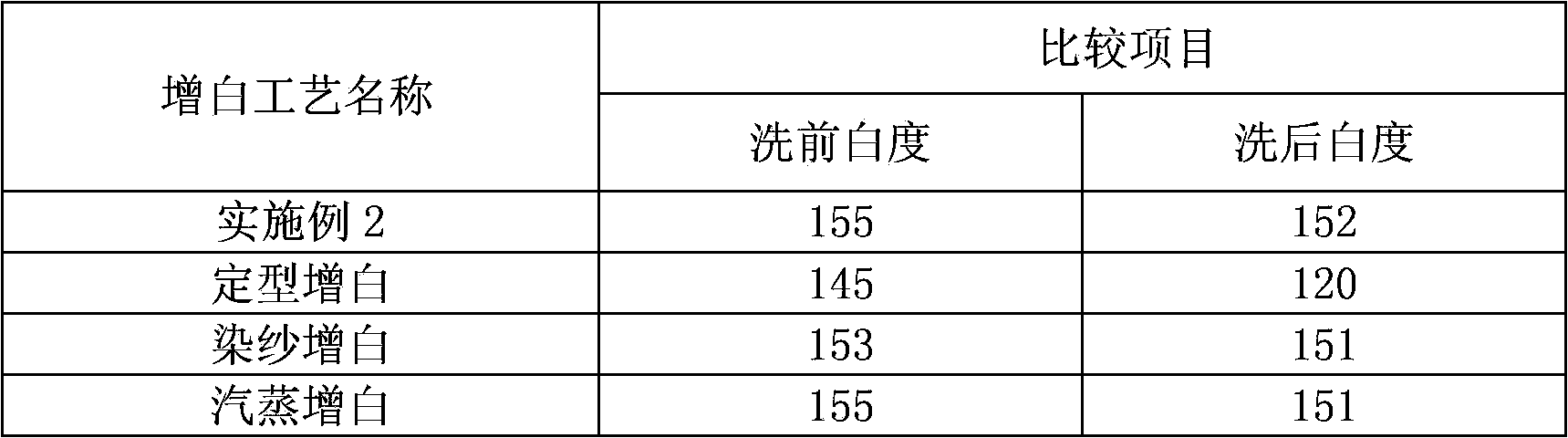

Embodiment 2

[0045] Choose a cotton and viscose blended twill fabric with a mercerized base white of 75. The processing process is:

[0046] (1) Padding: First prepare a fluorescent whitening agent finishing solution with a fluorescent whitening agent of 10g / L, a softener of 20g / L, and a penetrating agent of 2g / L. The fluorescent whitening agent is Uvitex BHT180% (China Heng Sime Chemical Co., Ltd.), softener is Sunmorl 66EG (Guangzhou Rihua Chemical Co., Ltd.), penetrant is DM-1232 (manufactured by China Demei Chemical Co., Ltd.), put the finishing liquid in the rolling trough, adjust the roll The pressure is 20N to control the nip rate to 70%, and then the dry cotton fabric is put into the nip to pad the whitener solution at a speed of 60m / min.

[0047] (2) Rolling: The cotton fabric passing through the rolling mill is dropped and rolled, and the outer layer of the rolled fabric is covered with plastic to prevent the whitening agent finishing liquid padding on the fabric from volatilizing.

[...

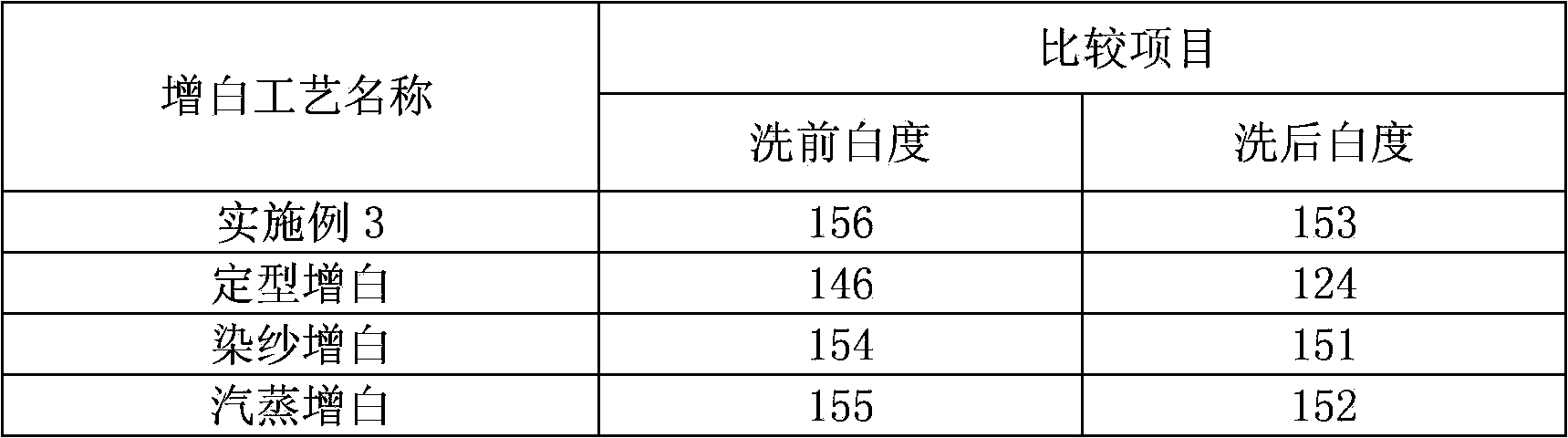

Embodiment 3

[0054] The pure cotton double-sided knitted fabric with a base white of 83 after mercerizing is selected, and the processing process is:

[0055] (1) Padding: Prepare a fluorescent whitening agent finishing solution with 20g / L of fluorescent whitening agent, 25g / L of softening agent, and 3g / L of penetrant, wherein the fluorescent whitening agent is Blancophor BBu 250% (Hong Kong Extension Na Chemical Co., Ltd.), the softener is Cerantine HDP (produced by Shanghai Clariant Chemical Co., Ltd.), the penetrant is Kieralon F-ALB (produced by BASF China Chemical Co., Ltd.), and the finishing liquid is put into the rolling trough to adjust the roll pressure It is 20N to control the nip rate to 70%, and then the dry cotton fabric is put into the nip tank to pad the whitening agent solution at a speed of 60m / min.

[0056] (2) Rolling: The cotton fabric passing through the rolling mill is dropped and rolled, and the outer layer of the rolled fabric is covered with plastic to prevent the whit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com