Non-ironing fabric and preparing method thereof

A fabric and non-ironing finishing technology, which is applied in the field of textile dyeing and finishing, to achieve the effect of improving the anti-wrinkle performance in the wet state, expanding the freedom of movement, and improving the anti-wrinkle performance in the wet state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

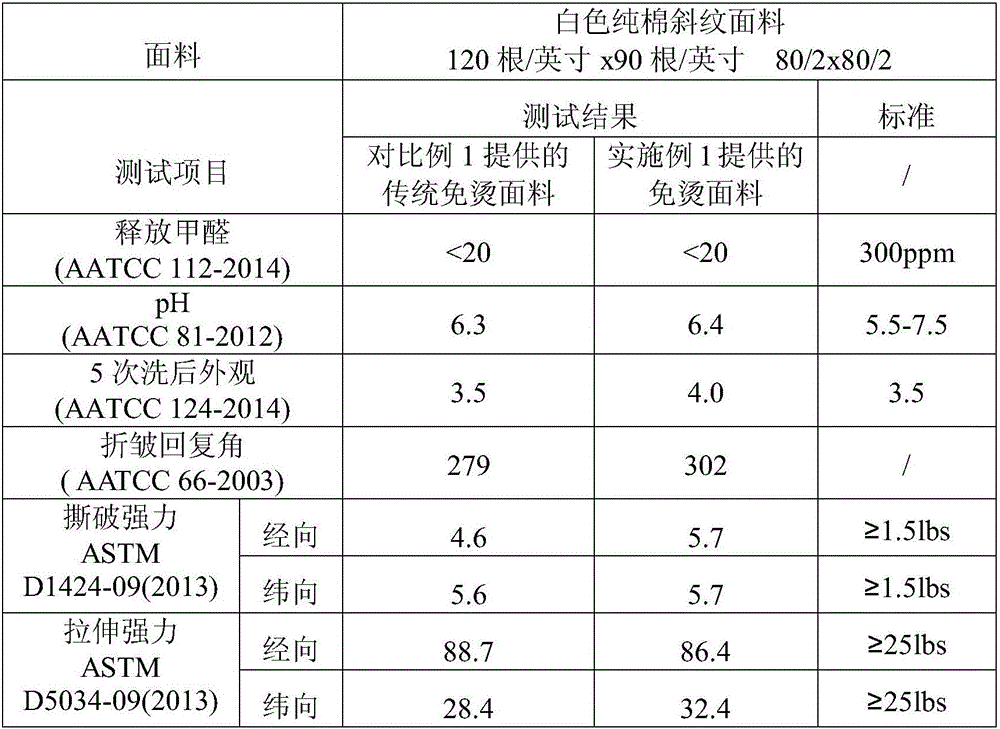

Embodiment 1

[0030] The present embodiment provides a kind of preparation method of non-ironing fabric, and it comprises the following steps:

[0031] 1) prepare non-iron finishing liquid: in terms of mass percentage, the composition of non-ironing finishing liquid includes 14% non-ironing cross-linking agent SDP1 (produced by BASF (BASF) company), 7% catalyst UMP (produced by Huntsman ( Huntsman) company production), 4% amino silicone oil softener AS-250 (no requirement, product commonly used in this field gets final product), 4% strong protective agent PE (no requirement, product commonly used in this field gets final product), 0.1 % penetrant JFC (no requirement, commonly used products in this field can be used), 0.5% acid cracking agent INVATEXAC (produced by Huntsman), 0.5% NaH 2 PO 4 , 3% 1,4-butanediol (produced by Hubei Xinmingtai Chemical Co., Ltd.), the balance is water, and the pH value of the non-ironing finishing solution is about 2.5;

[0032] 2) Dip the white pure cotton t...

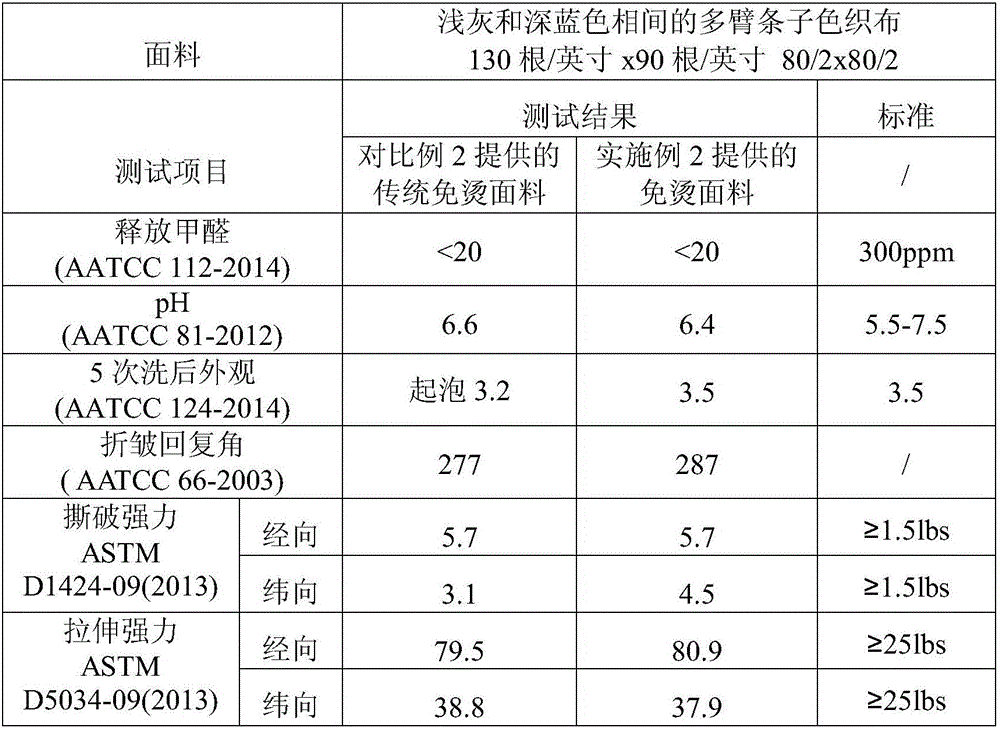

Embodiment 2

[0034] The present embodiment provides a kind of preparation method of non-ironing fabric, and it comprises the following steps:

[0035] 1) Preparation of non-iron finishing liquid: in terms of mass percentage, the composition of non-ironing finishing liquid includes 10% of non-iron crosslinking agent SDP1, 4% of catalyst UMP, 3% of amino silicone oil softener AS-250, 3% of Strong protective agent PE, 0.1% penetrating agent JFC, 2% citric acid monohydrate, 2% disodium hydrogen phosphate, 10% 1,4-butanediol, and the balance is water. The pH value is around 2.0;

[0036]2) Dip the dobby yarn-dyed fabric with alternate colors of light gray and dark blue in the above-mentioned finishing solution twice and roll it twice, under the condition that the liquid carrying rate is 55%, seal and roll it and store it at 33°C for 7 hours, then Dry at 100°C for 20 seconds, control the moisture content of the falling cloth to 8%, after drying, continue to seal and roll the cloth and store it ...

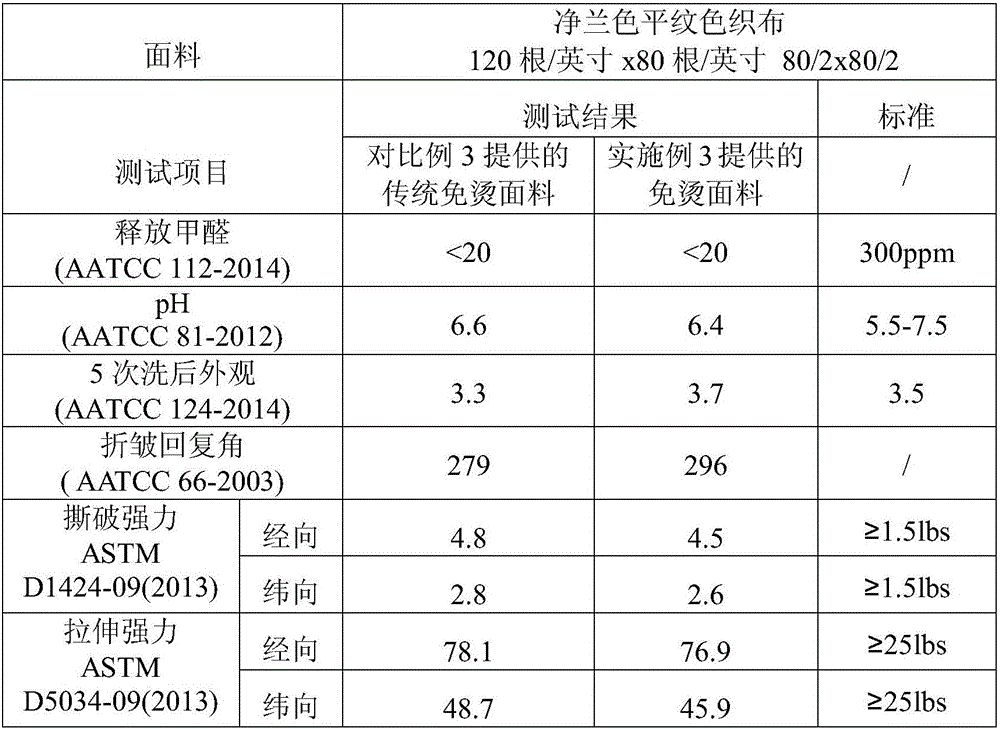

Embodiment 3

[0038] The present embodiment provides a kind of preparation method of non-ironing fabric, and it comprises the following steps:

[0039] 1) prepare non-iron finishing liquid: in terms of mass percentage, the composition of non-ironing finishing liquid includes 30% non-iron crosslinking agent SDP1 (produced by BASF (BASF) company), 15% catalyst UMP (produced by Huntsman ( Huntsman) company), 10% amino silicone oil softener AS-250 (no requirement, commonly used products in this field can be), 10% strong protective agent PE, 0.5% penetrating agent JFC, 1% hydrochloric acid, 1 % of phthalic acid, 8% of 1,4-butanediol, and the balance of water, the pH value of the easy-care finishing solution is about 2.5;

[0040] 2) Dip the net blue plain cloth twice in the above finishing solution and roll twice. When the liquid retention rate is 55%, store it in a sealed roll at 33°C for 6 hours, and then bake it at 100°C for 20 seconds. Control the moisture content of the falling cloth to 8%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com