Cold-pad-batch method for textile materials

A technology for textiles and cold-rolled stacking, which is used in textiles and papermaking, textile material processing, bleaching products, etc., can solve problems such as explosion, skin burns, low stability, etc., to reduce stacking time, reduce fabric damage, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

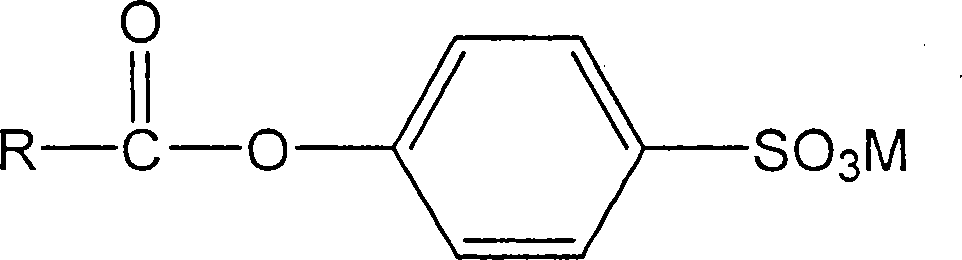

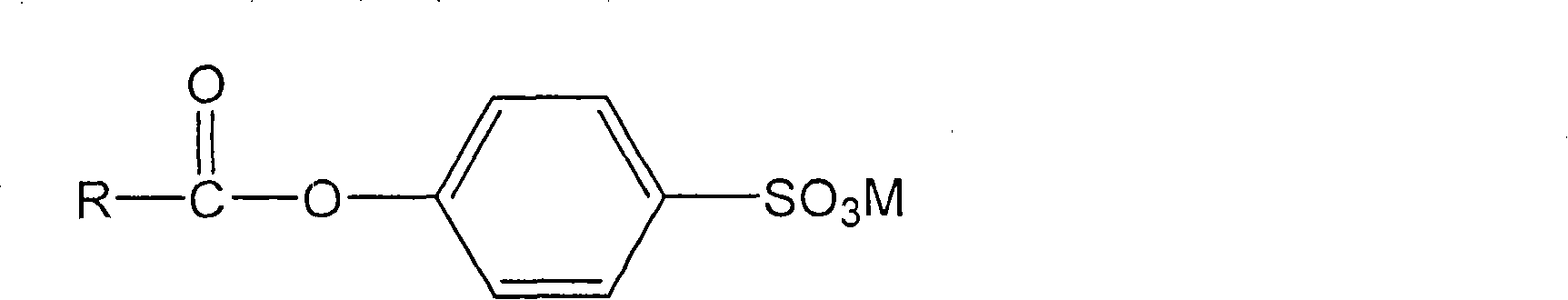

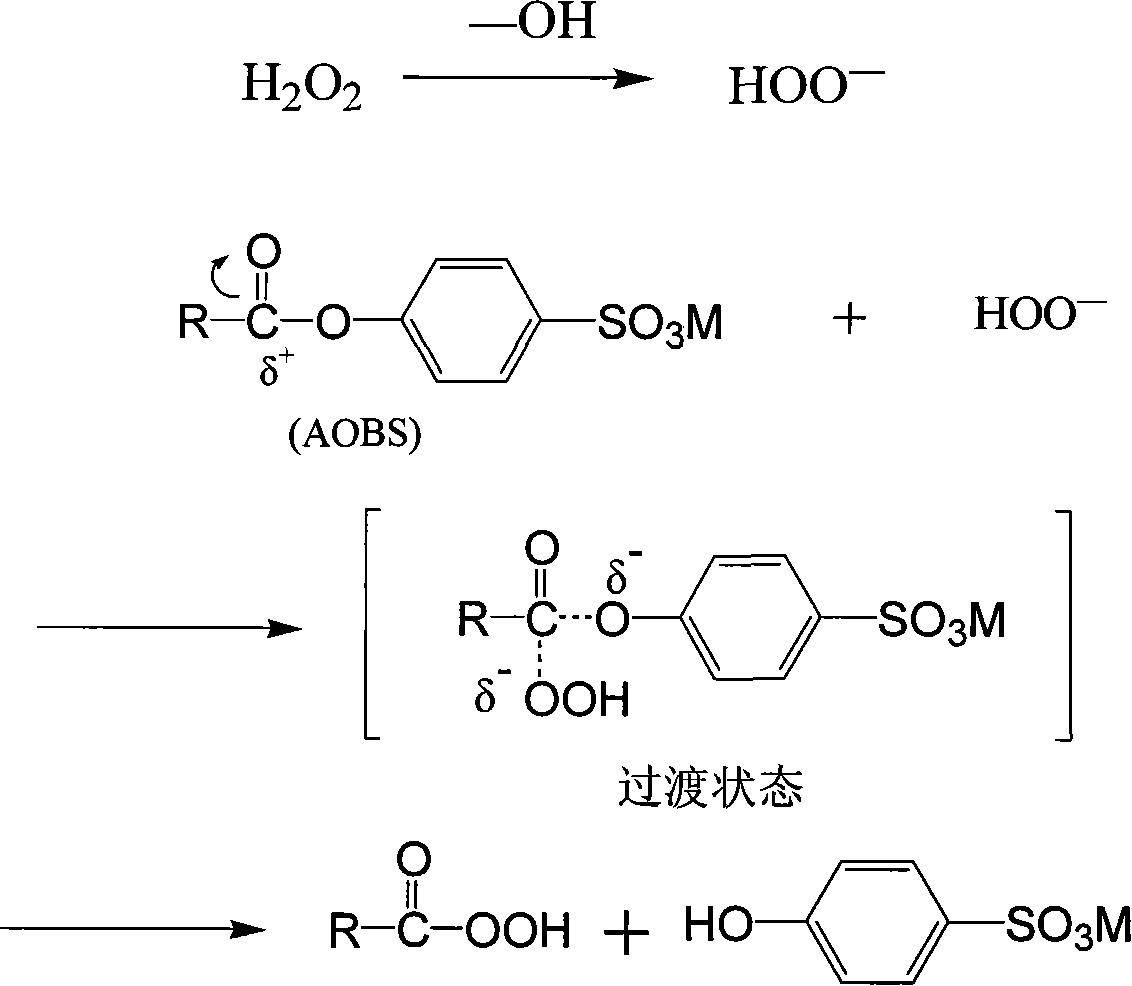

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of working solution: In a 1000ml container, add 5g of wetting agent JFC and stabilizer Na 2 SiO 3 5g, activator sodium nonanoyloxybenzenesulfonate NOBS 22.2g, 30% H 2 o 2 30g, NaOH 6g, add and stir evenly and treat the fabric immediately.

[0030] (2) Padding treatment: Pour the working liquid prepared in the above (1) into the rolling groove, and dip the 40S pure cotton fabric twice and roll it twice, and the rolling liquid rate is 80%

[0031] (3) Rolling and stacking: the cotton fabric after the above-mentioned padding treatment is rolled and sealed with a plastic film, and slowly rotated and stacked at room temperature for 6 hours.

[0032] (4) Water washing: wash the above-mentioned piled cotton fabric twice with 50-80°C hot water, and then fully wash with cold water.

Embodiment 2

[0034] (1) Preparation of working fluid: In a 1000ml container, add 10g of wetting agent JFC and stabilizer Na 2 SiO 3 1g, activator sodium nonanoyloxybenzenesulfonate NOBS 1.5g, 30% H 2 o 2 10g, NaOH 3g, add and stir evenly and treat the fabric immediately.

[0035] (2) Padding treatment: Pour the working liquid prepared in the above (1) into the rolling groove, and dip the 40S pure cotton fabric twice and roll it twice, and the rolling liquid rate is 95%.

[0036] (3) Rolling and stacking: the above-mentioned cotton fabric after the padding treatment is rolled and sealed with a plastic film, and slowly rotated and stacked at room temperature for 12 hours.

[0037] (4) Water washing: wash the above-mentioned piled cotton fabric twice with 50-80°C hot water, and then fully wash with cold water.

Embodiment 3

[0039] (1) Preparation of working fluid: In a 1000ml container, add 1g of wetting agent JFC and stabilizer Na 2 SiO 3 10g, activator sodium nonanoyloxybenzenesulfonate NOBS 14.8g, 30% H 2 o 2 50g, NaOH 20g, add and stir evenly and treat the fabric immediately.

[0040] (2) Padding treatment: Pour the working liquid prepared in the above (1) into the rolling groove, and dip the 40S pure cotton fabric twice and roll it twice, and the rolling liquid rate is 105%.

[0041] (3) Rolling and stacking: the above-mentioned cotton fabric after the padding treatment is rolled and sealed with a plastic film, and slowly rotated and stacked at room temperature for 9 hours.

[0042] (4) Water washing: wash the above-mentioned piled cotton fabric twice with 50-80°C hot water, and then fully wash with cold water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com