Patents

Literature

59 results about "Textile bleaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile bleaching is one of the stages in the manufacture of textiles. All raw textile materials, when they are in natural form, are known as 'greige' material. This greige material will have its natural color, odor and impurities that are not suitable for clothing materials. Not only the natural impurities will remain on the greige material but also the add-ons that were made during its cultivation, growth and manufacture in the form of pesticides, fungicides, worm killers, sizes, lubricants, etc. The removal of these natural coloring matters and add-ons during the previous state of manufacturing is called scouring and bleaching.

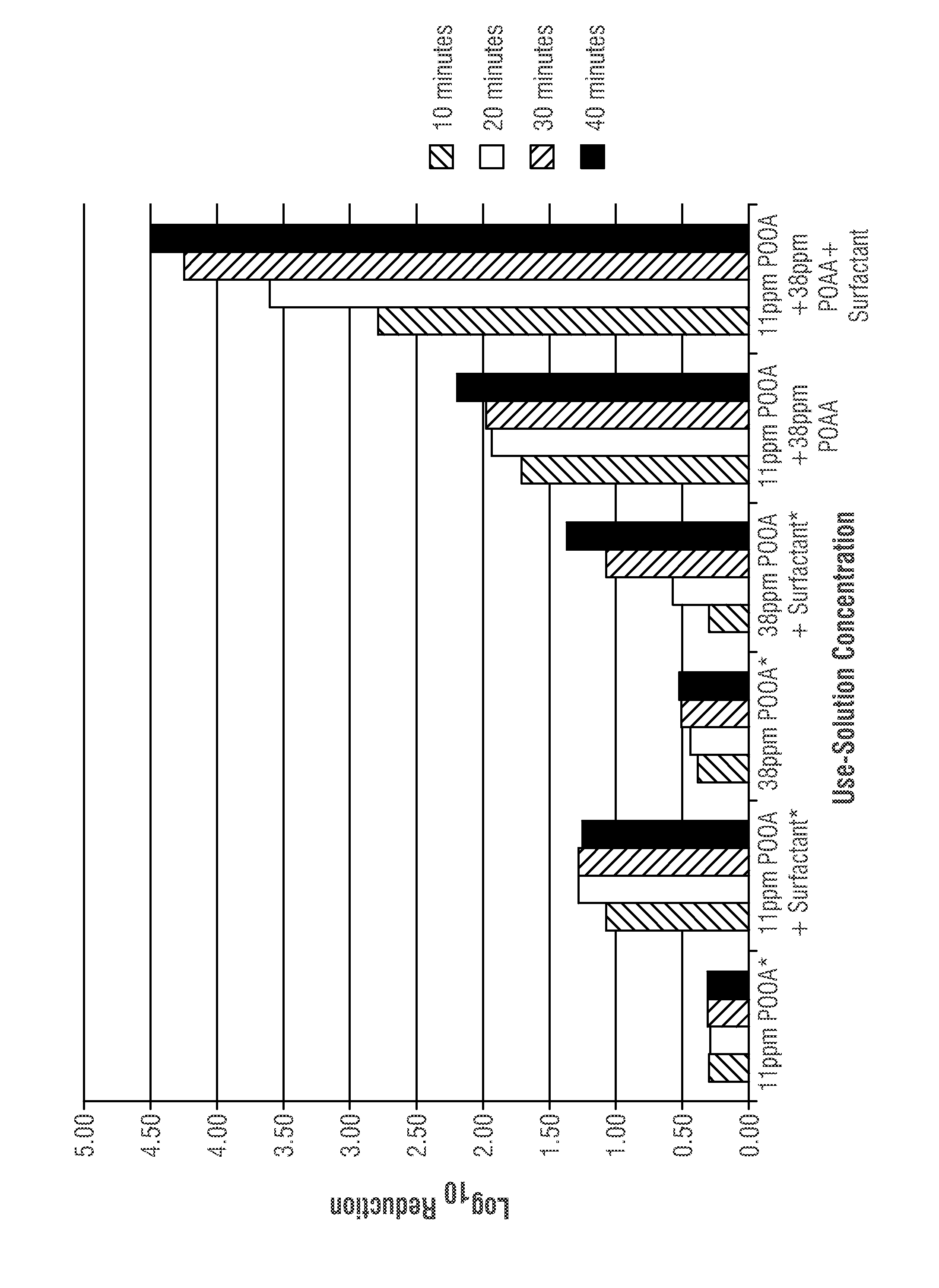

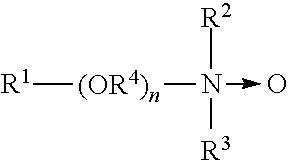

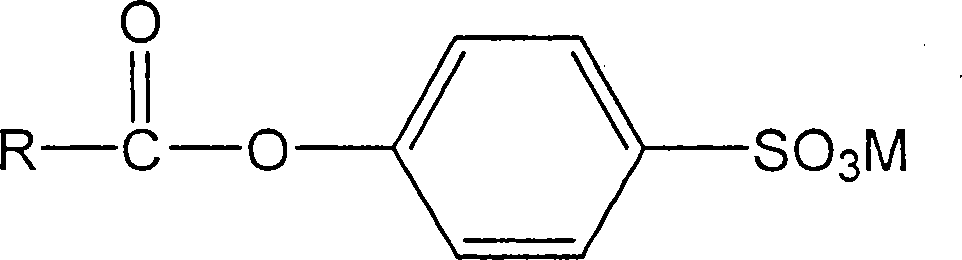

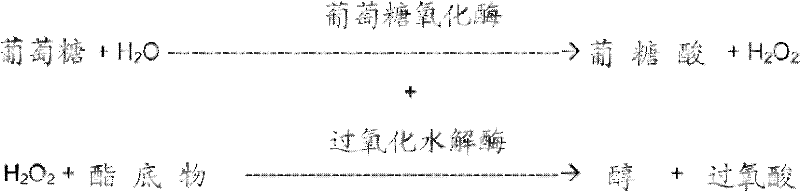

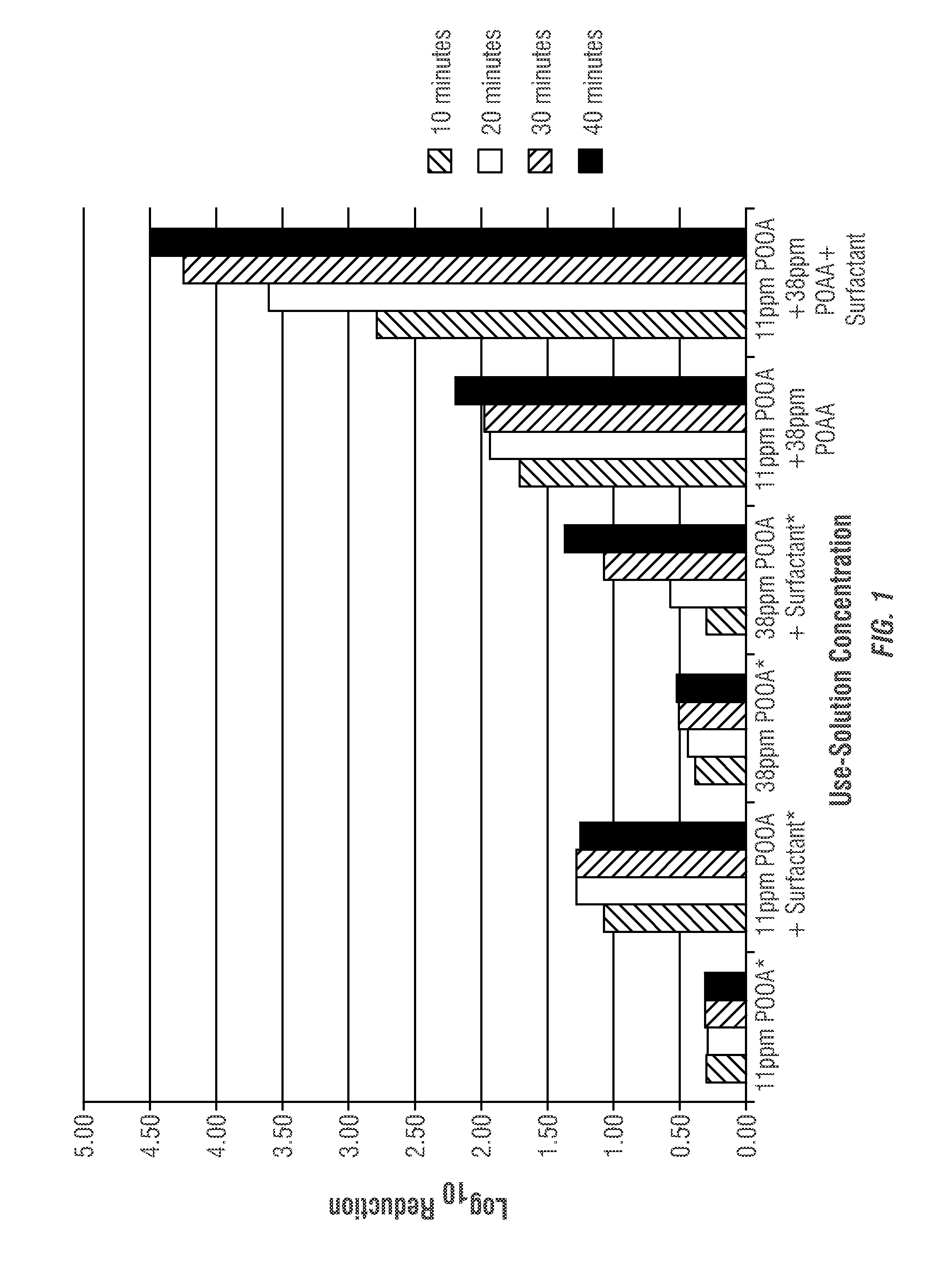

Generation of peroxycarboxylic acids at alkaline pH, and their use as textile bleaching and antimicrobial agents

The present disclosure provides methods for generating percarboxylic acid compositions and / or peroxycarboxylic acid compositions formed external to a point of use in non-equilibrium reactions for use in certain bleaching and antimicrobial applications, in particular laundry applications. The compositions are generated external to a point of use, at alkaline pH levels, viz. greater than about pH 12, and optionally suitable for use with detergents and / or surfactants for synergistic bleaching efficacy. Methods of bleaching and / or disinfecting are further provided.

Owner:ECOLAB USA INC

Cold-pad-batch method for textile materials

InactiveCN101135113AAchieve the bleaching effectAvoid damageTextile storage in wounded formFibre treatmentEngineeringBatch method

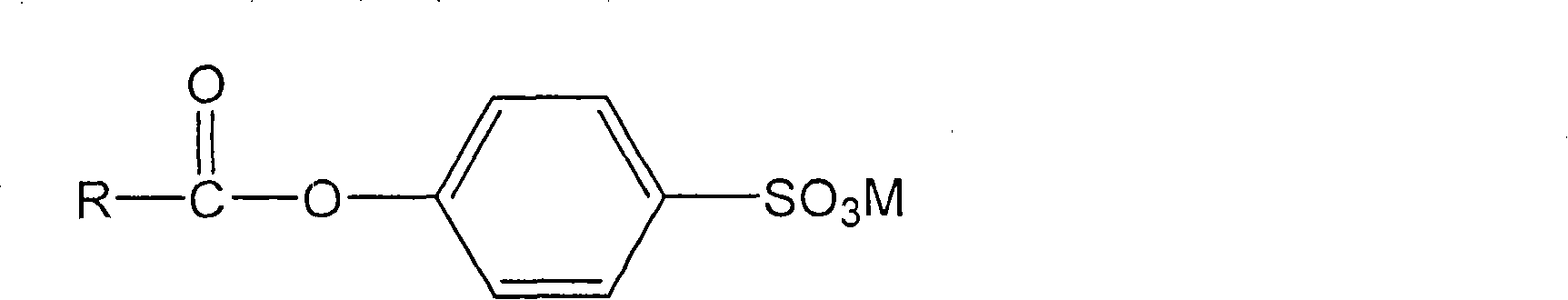

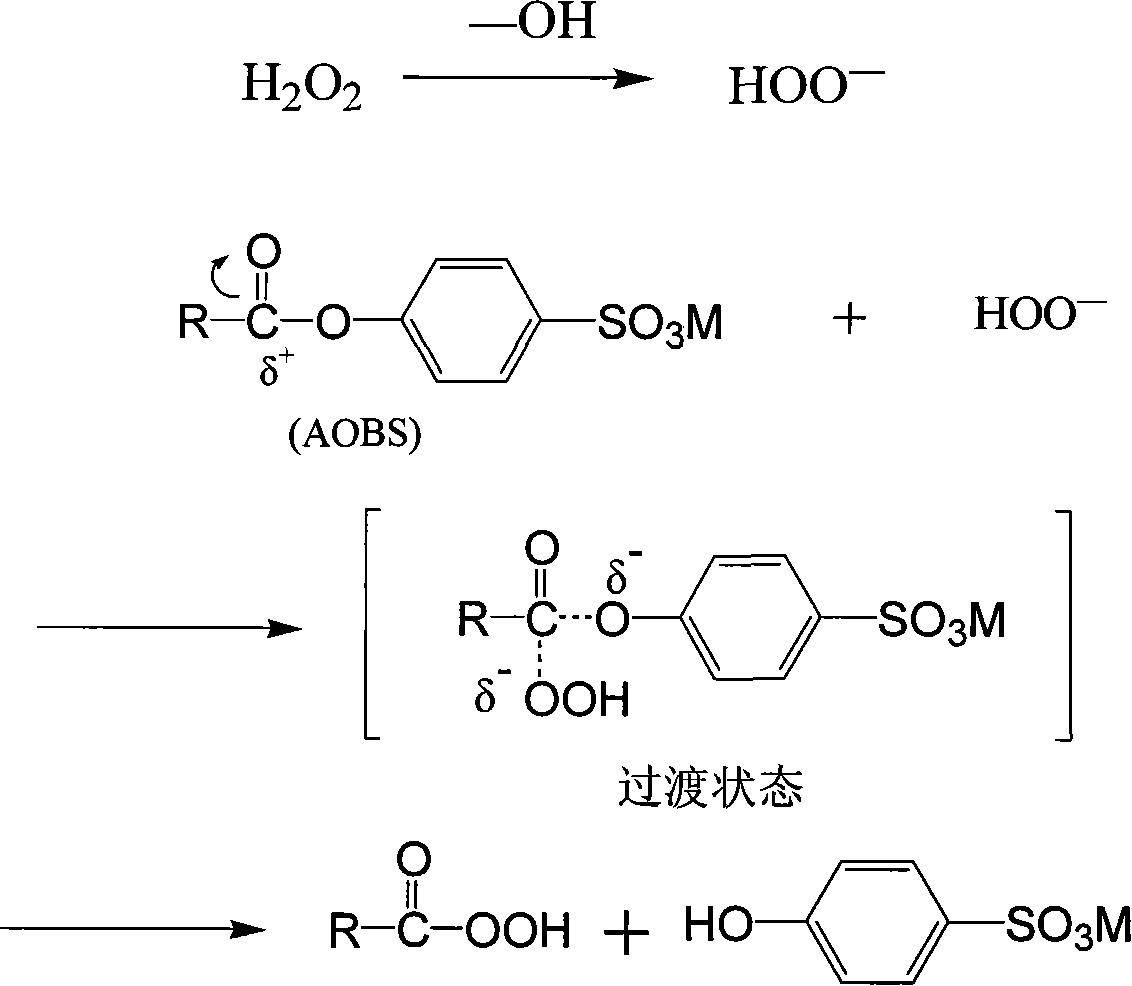

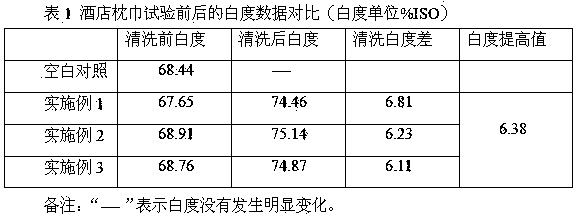

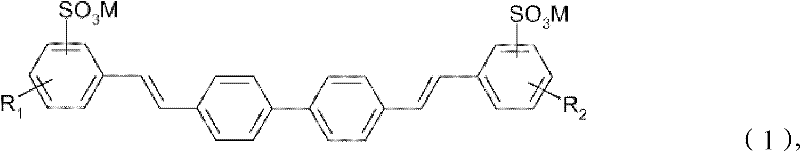

The present invention discloses process of cold padding, stacking and actively bleaching fabric. The process includes through steps, including one step of compounding bleaching solution and padding, one step of winding and stacking, and one step of hot water washing and cold water washing. The present invention adopts alkanoylxy benzene sulfonate bleaching activator, hydrogen peroxide / activator bleaching system, and cold padding and stacking treatment to reach excellent fabric bleaching effect. Compared with traditional bleaching technology, the present invention has the advantages of excellent fabric bleaching effect, lowered alkali consumption, reduced stacking time, less fabric damage, raised production efficiency and environment friendship.

Owner:ZHEJIANG SCI-TECH UNIV

Enzymatic textile bleaching compositions and methods of use thereof

InactiveUS20120036649A1Reduce harmSoft handleHydrolasesSurface-active detergent compositionsEnzymeTextile bleaching

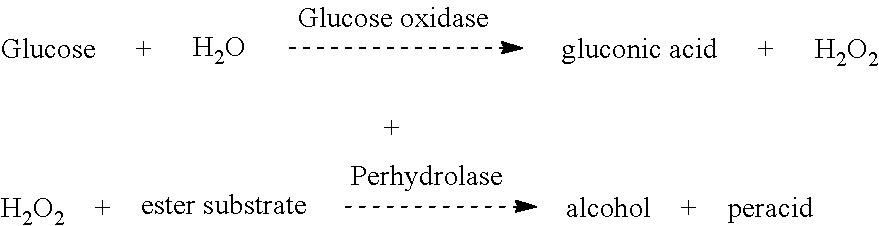

Described are compositions and methods for enzymatic bleaching of textiles. A perhydrolase enzyme is used in combination with an ester substrate and hydrogen peroxide to produce a peracid for textile bleaching. Textiles bleached by the methods herein exhibit increased dye uptake, decreased textile damage, and / or bulkier softer handle than textiles bleached by conventional chemical bleaching processes.

Owner:DANISCO US INC

Textile bleaching cleaning agent

ActiveCN104263547ANo damageReduce the impactInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWhitening AgentsCleansing Agents

Owner:濮阳圣恺环保新材料科技股份有限公司

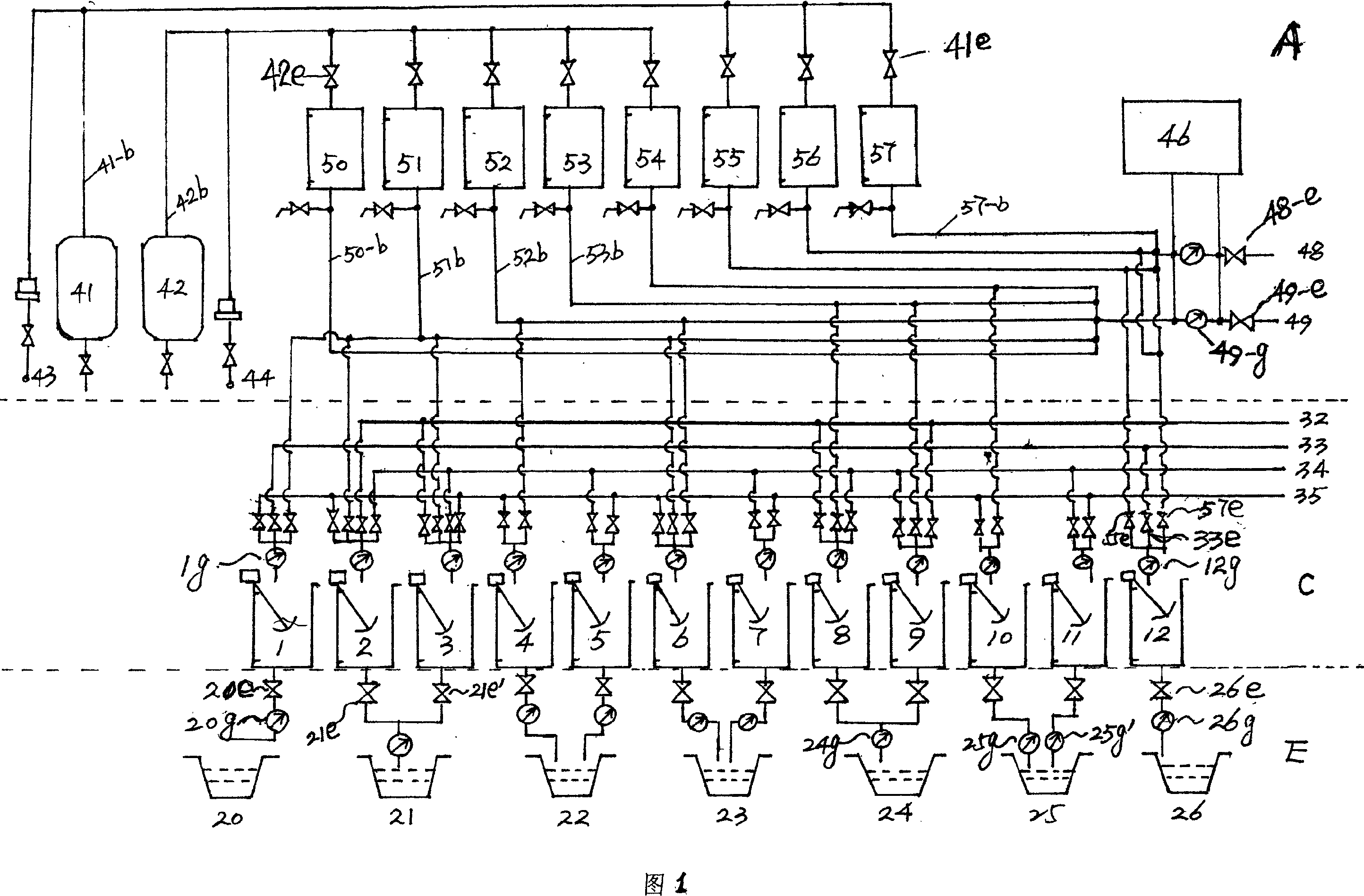

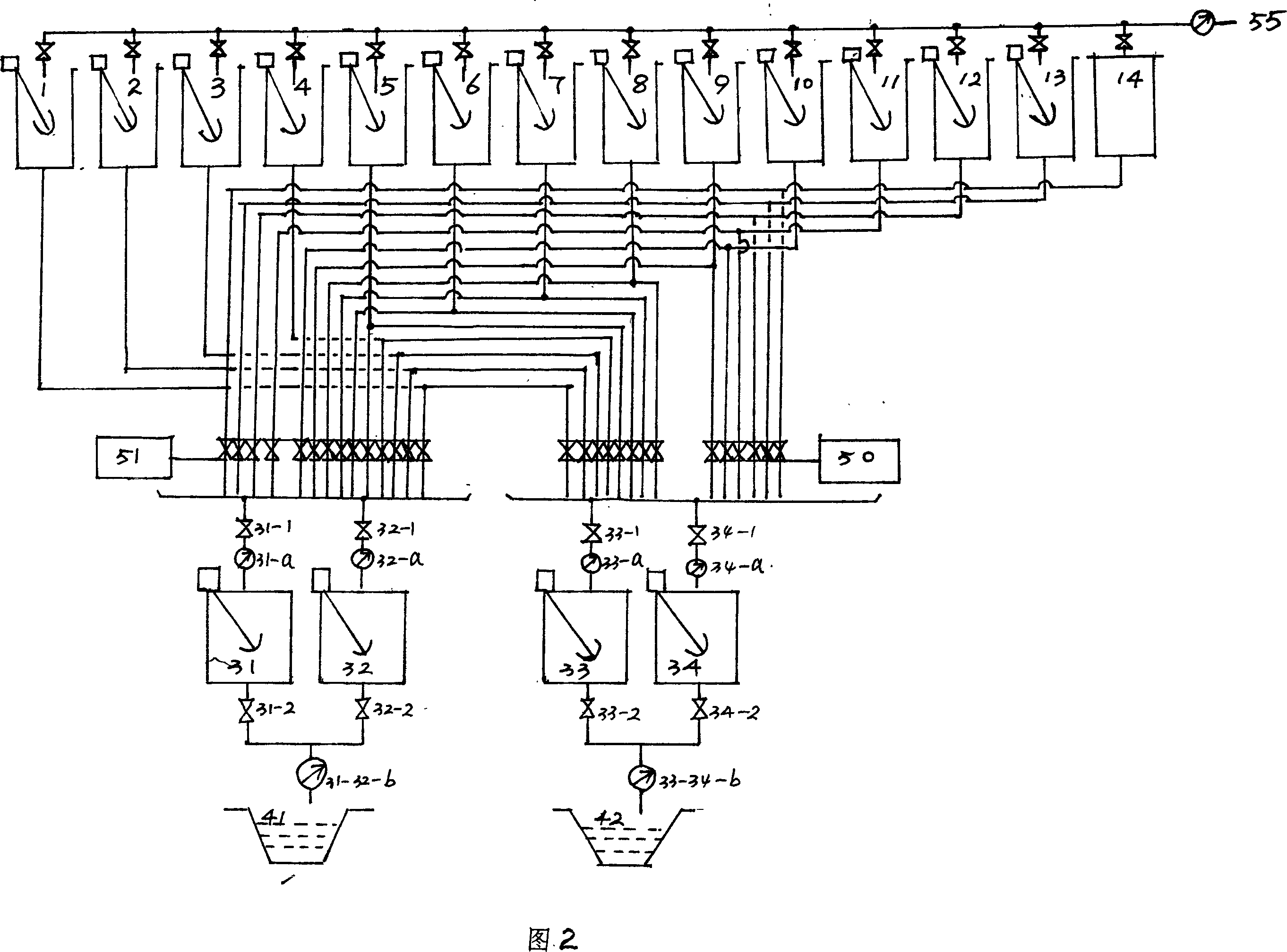

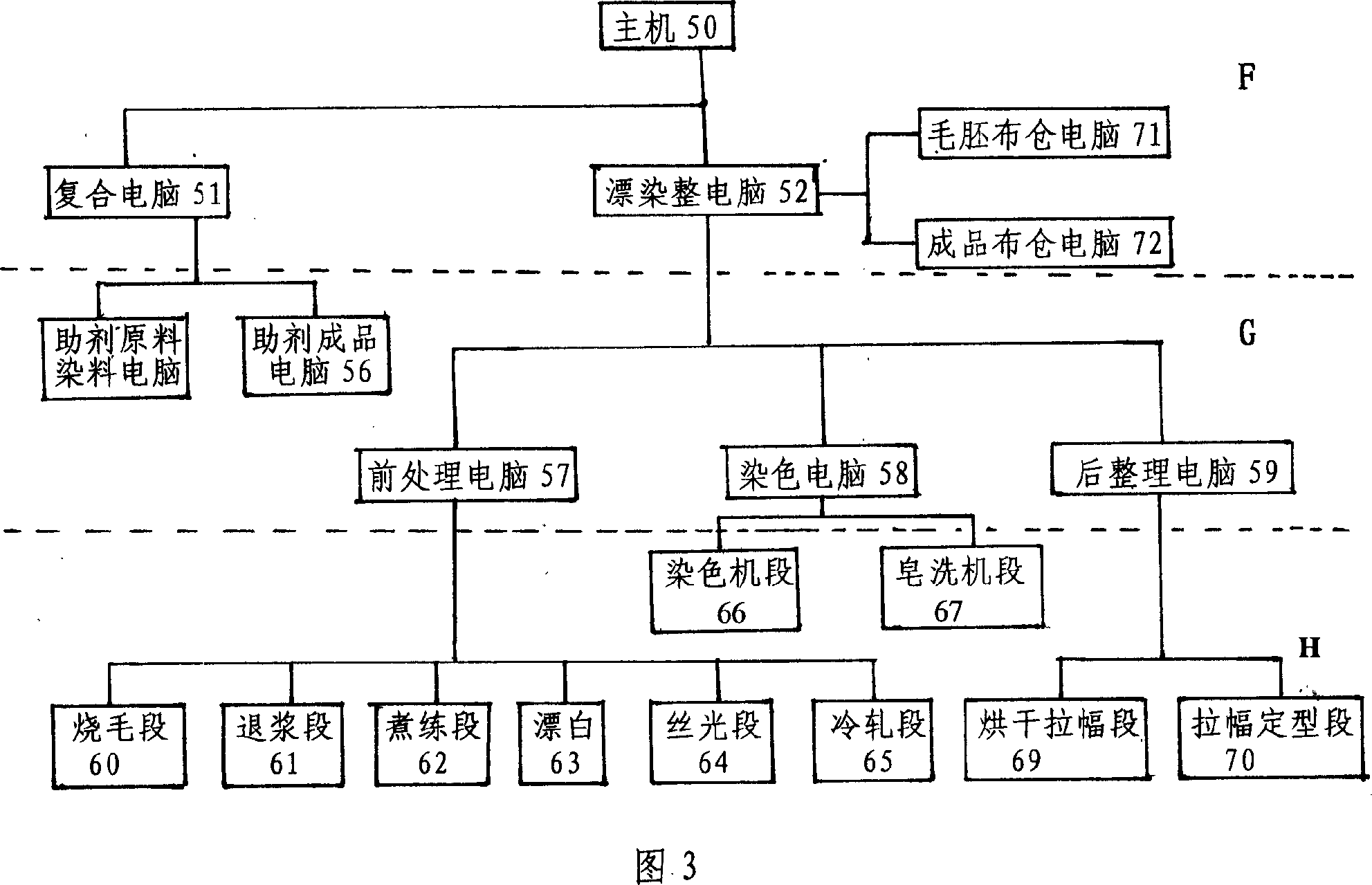

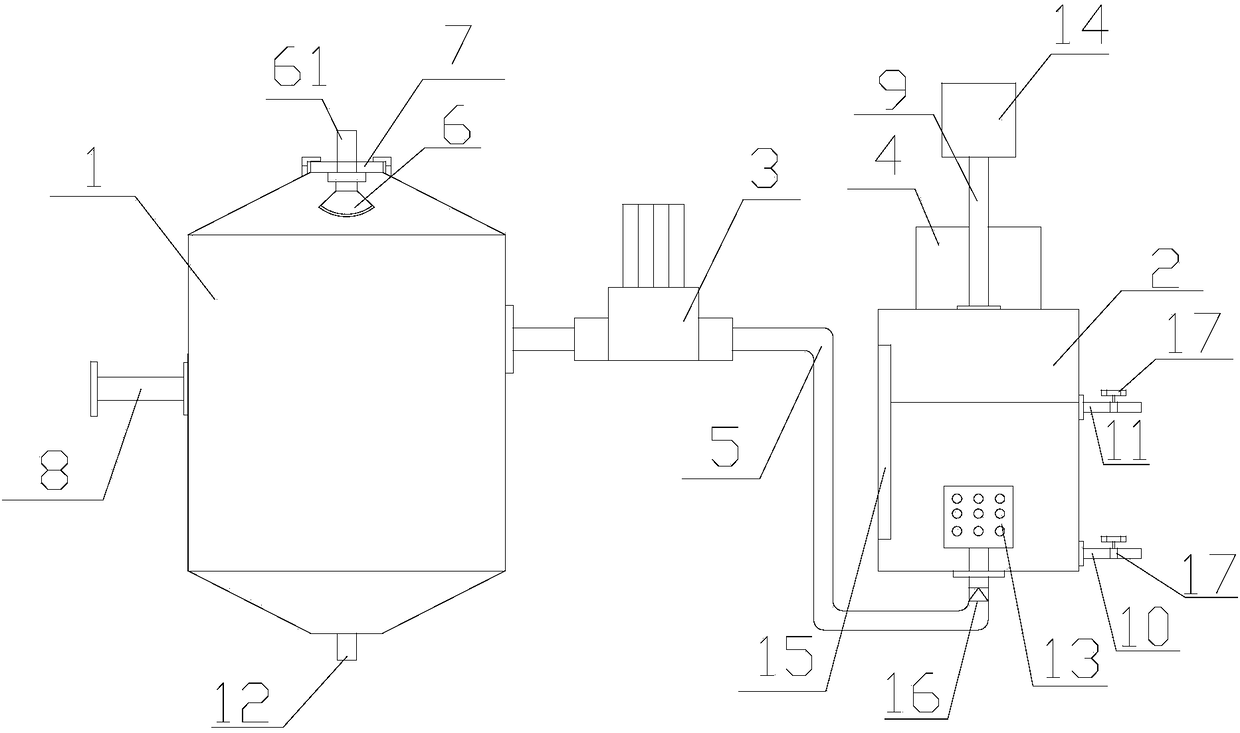

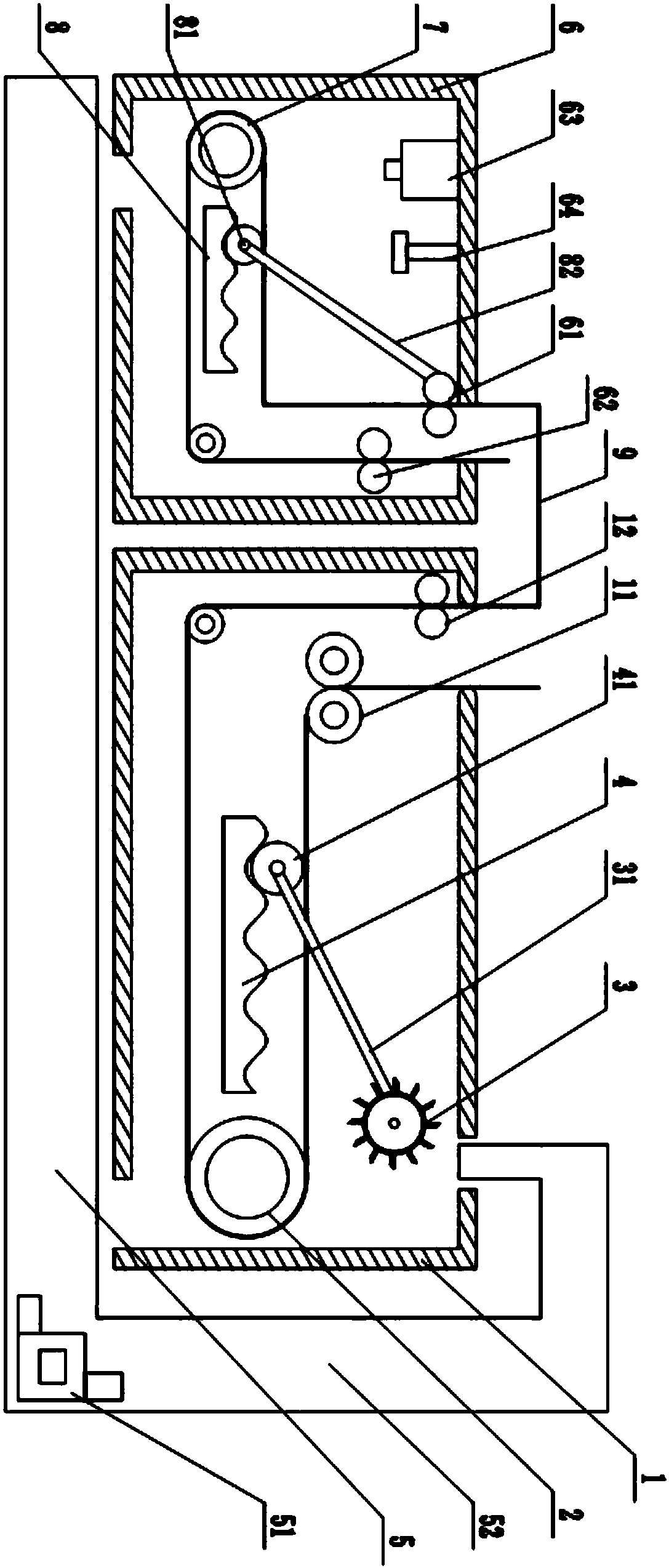

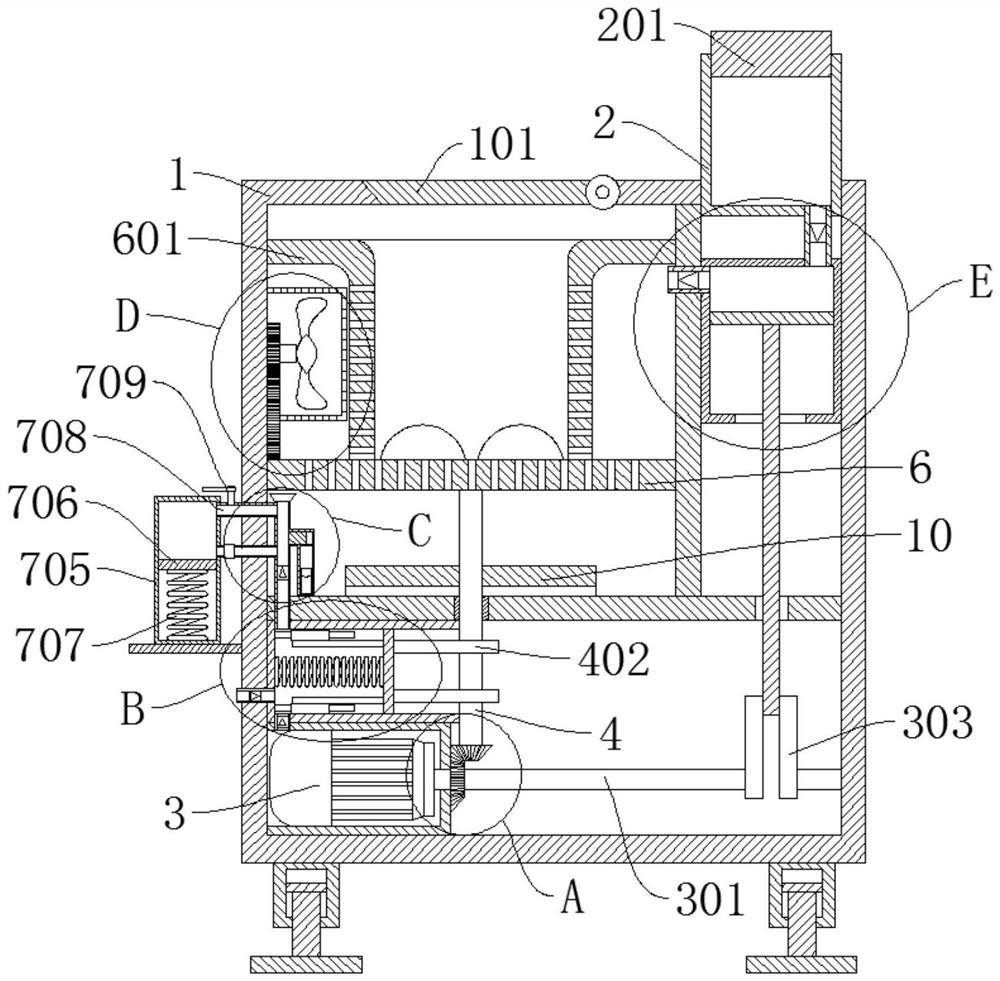

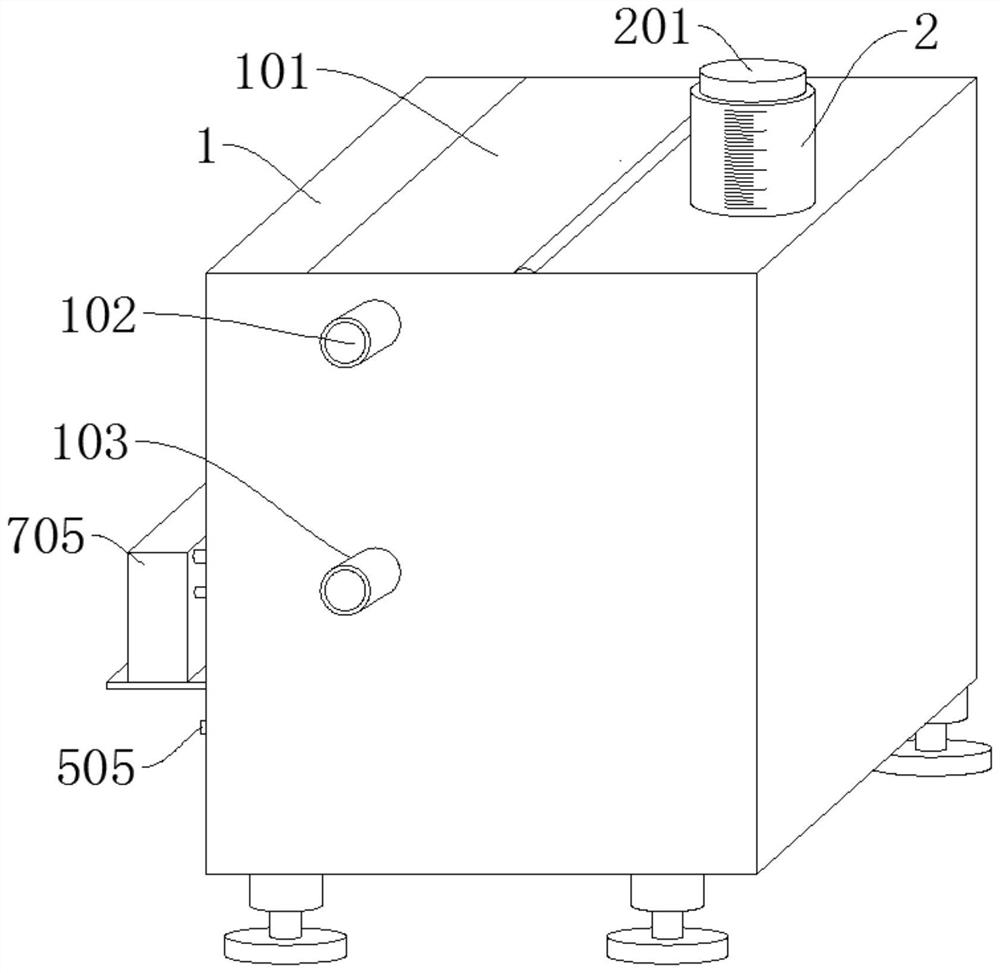

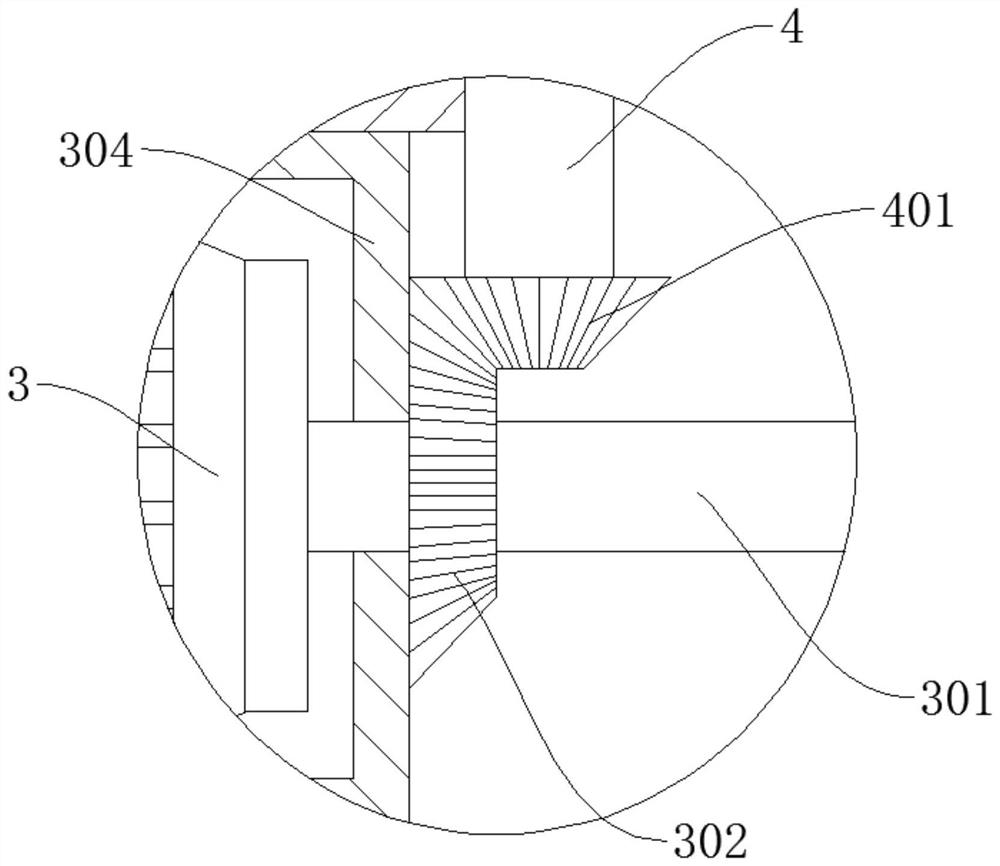

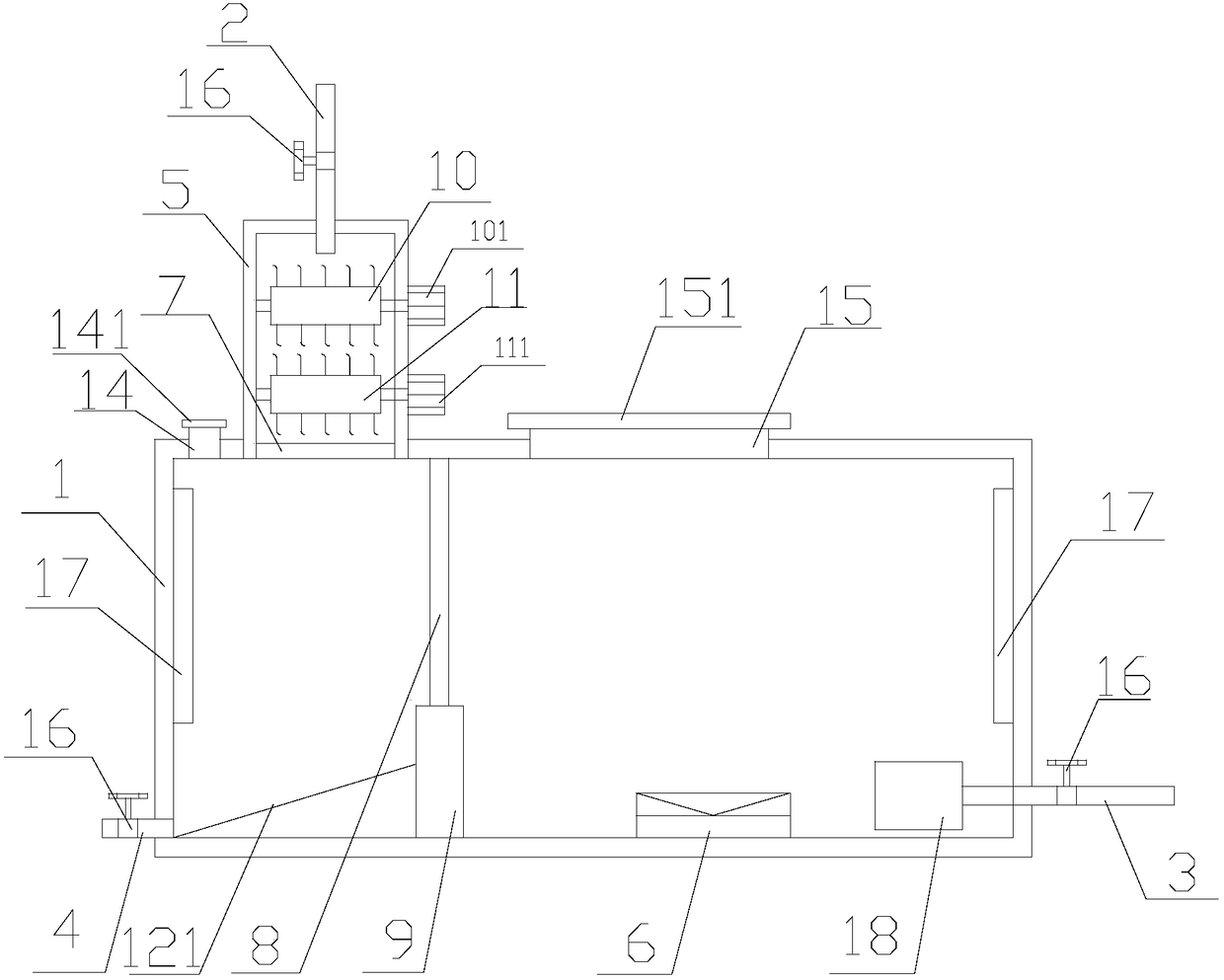

Full automatic feeding chemical material operating device for bleaching and dyeing

InactiveCN101067272AAvoid secondary pollutionAvoid stabilityTextile treatment machine partsProgramme control in sequence/logic controllersEngineeringTextile bleaching

The automatic bleaching and dyeing material throwing and dissolving apparatus for use in textile bleaching and dyeing has a dye and assistant dispersing and dissolving set, a bleaching and dyeing material storing set and material feeding set combined together. The automatic bleaching and dyeing material throwing and dissolving apparatus is controlled with one intelligent controller with built-in chip or one computerized controller. The present invention realizes automatic operation and is especially suitable for continuous production.

Owner:胡红湘

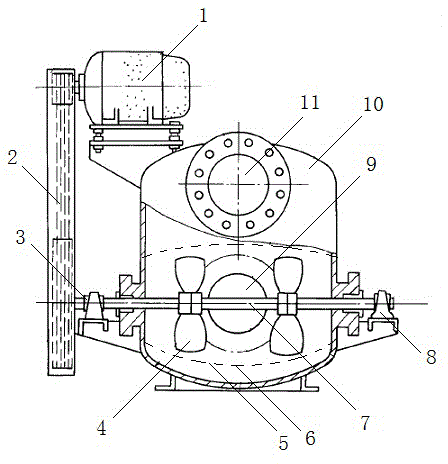

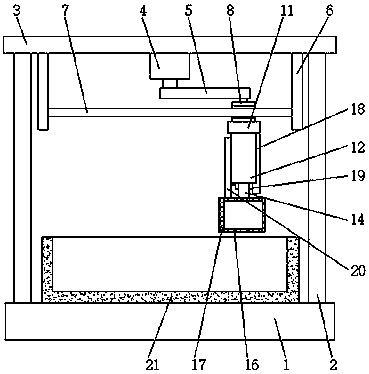

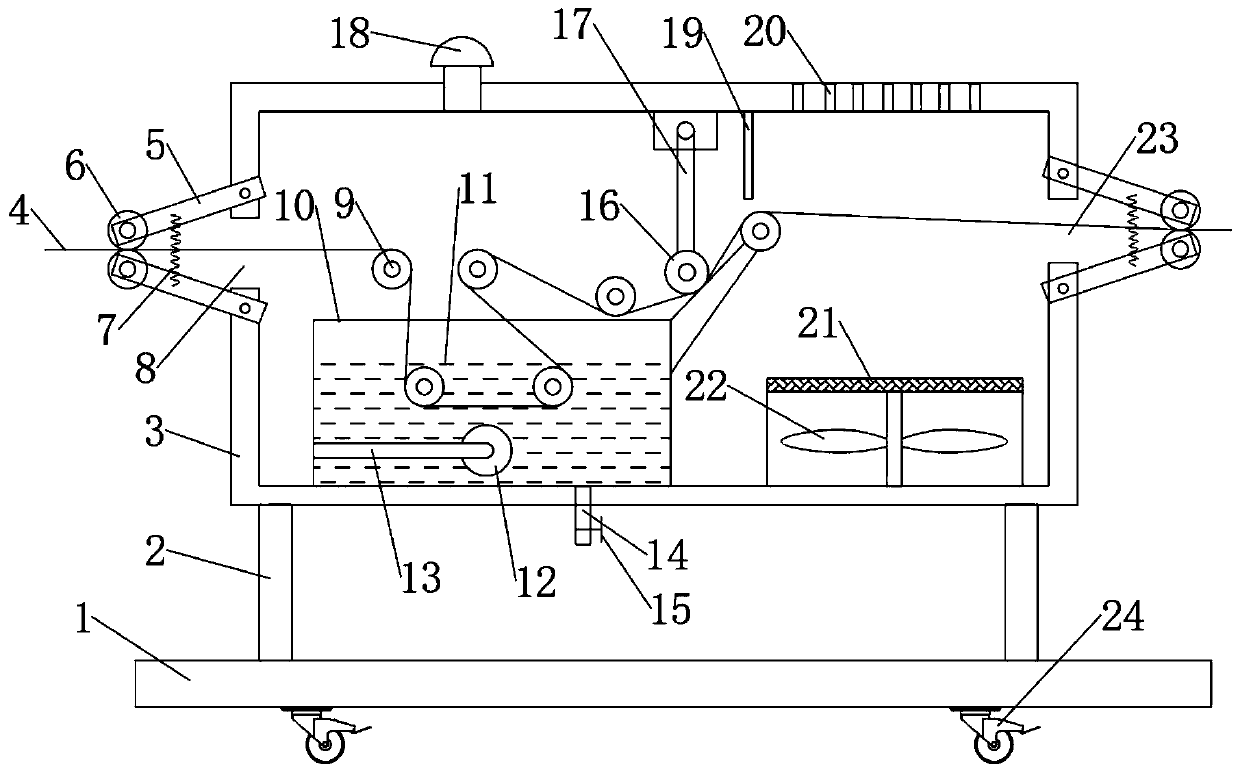

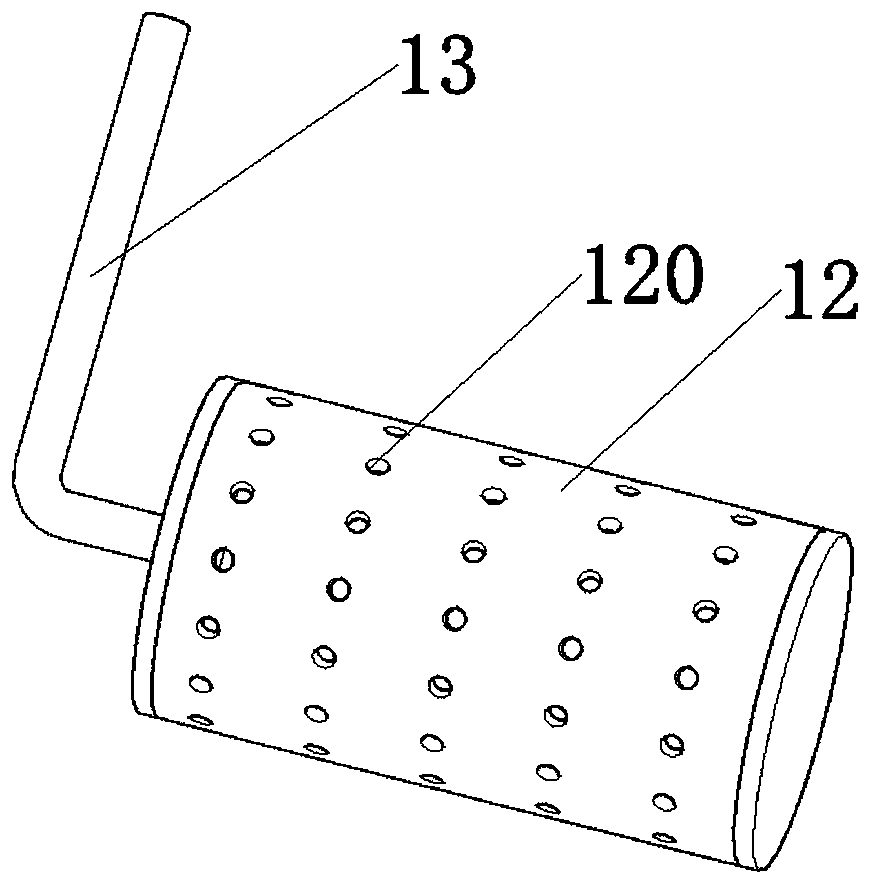

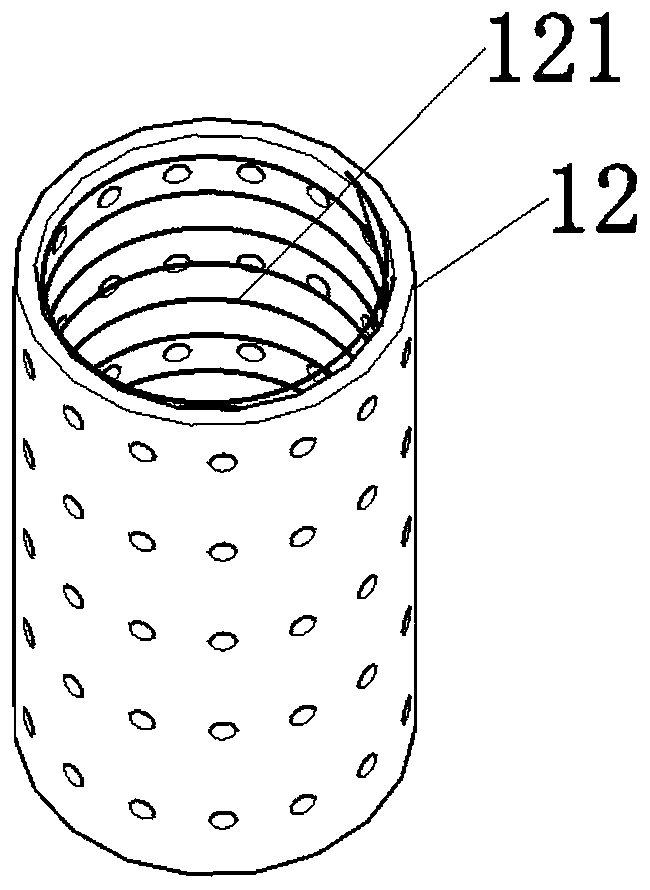

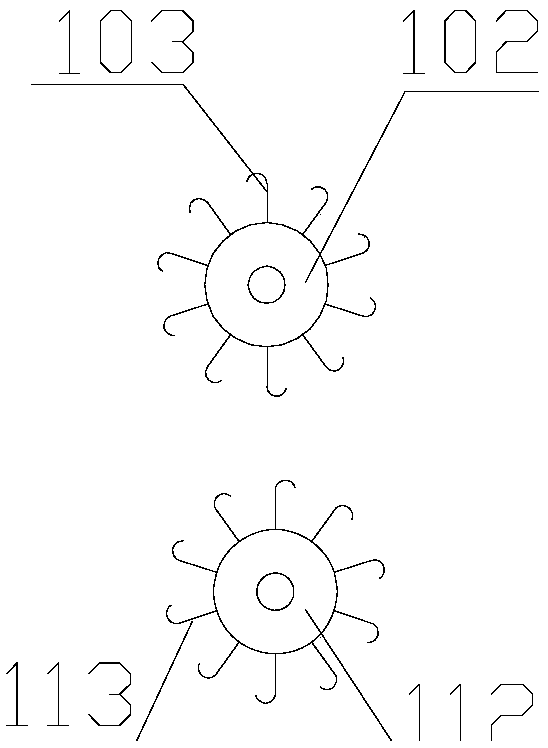

Textile bleaching device

ActiveCN104480659AFast bleachingBleach evenlyTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsPropellerTextile bleaching

The invention discloses a textile bleaching device, which comprises a motor, a bleaching box, a bleaching separating plate, a main shaft and a plurality of propellers, wherein the bleaching box is provided with a material inlet and a material outlet which are positioned at the two sides of the bleaching box, the material inlet is positioned at the upper part of the bleaching box, the material outlet is positioned at the lower part of the bleaching box, the main shaft penetrates through the bleaching box, and is rotationally connected with the bleaching box, the propellers are arranged along the axial direction of the main shaft, the bleaching separating plate is in a cylinder shape, circulating holes are uniformly formed in the side wall of the bleaching separating plate along the circumferential direction, the bleaching separating plate is coaxial with the main shaft, the two ends of the bleaching separating plate are connected with the bleaching box, the propellers are positioned in the bleaching separating plate, and the main shaft is driven by the output end of the motor. The textile bleaching device has the advantages that the bleaching speed is high, and a textile can be uniformly bleached.

Owner:响水县连桥纺织有限公司

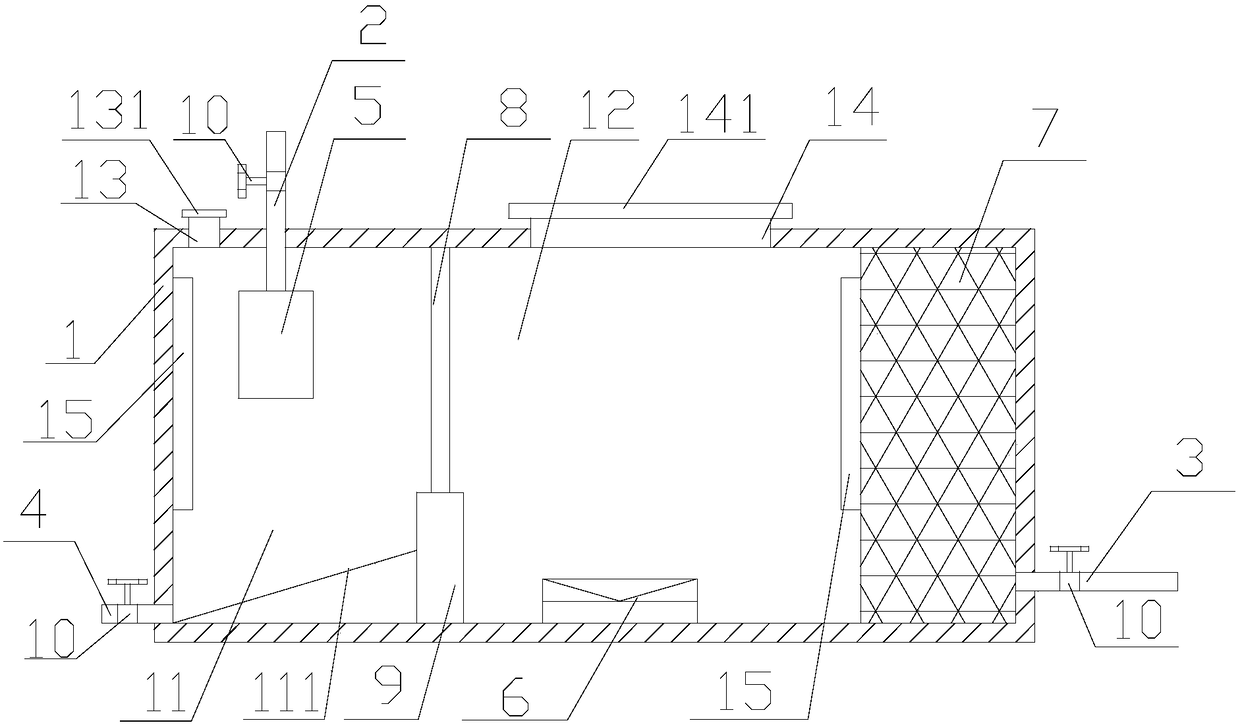

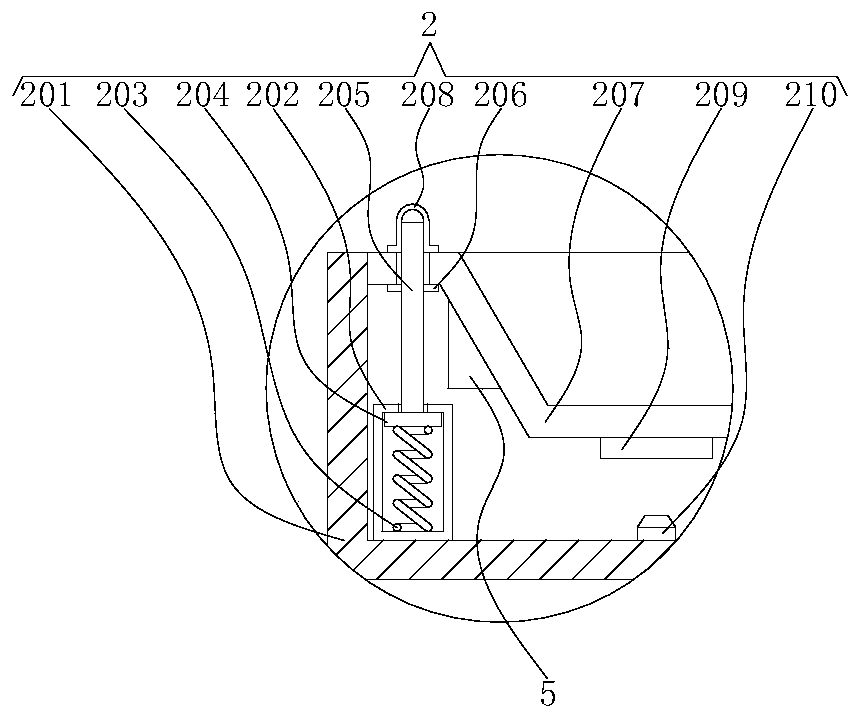

Textile bleaching and dyeing exhaust-gas treatment plant

PendingCN108554060ALess pungent tasteReduce moisture contentGas treatmentUsing liquid separation agentActivated carbonTreatment effect

The invention discloses a textile bleaching and dyeing exhaust-gas treatment plant, which comprises a first tank, a second tank, a suction pump, a cooler, a connecting pipe, a spray device, a first cover, an air inlet pipe, an air outlet pipe, a water inlet and a water outlet. By arranging the two tanks, exhaust gas entering the first tank through an air inlet undergoes first-stage spray purification adsorption through the spray device, and granular pollutants in the exhaust gas are adsorbed by sprayed water; the exhaust gas treated in the first tank is pumped into the second tank through thesuction pump, and the exhaust gas passes through water in the second tank to undergo second-stage adsorption; through an active carbon device arranged at an exhaust port, the exhaust gas can undergo third-stage adsorption, and irritant smell of the exhaust gas can be reduced effectively; and through the cooler arranged on the outer wall of an exhaust pipe, the discharged exhaust gas can be cooled,and water vapor in the exhaust gas is condensed so as to reduce water content of the exhaust gas. In comparison with a traditional technology, the invention has the following advantages: the textilebleaching and dyeing exhaust-gas treatment plant has a simple structure and has better exhaust gas treatment effects, and pollution is reduced.

Owner:海盐县于城漂染股份有限公司

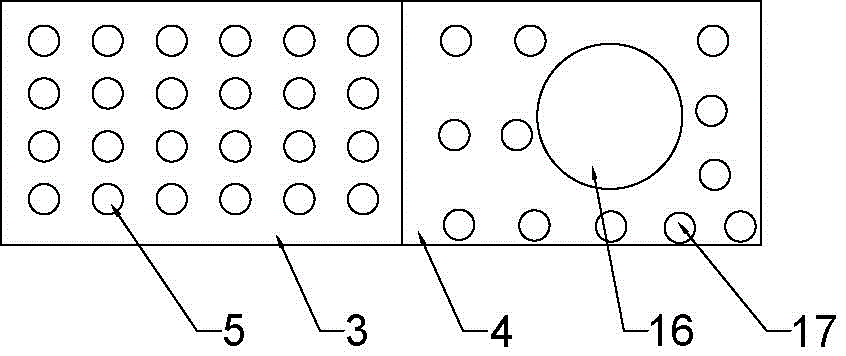

Textile bleaching device

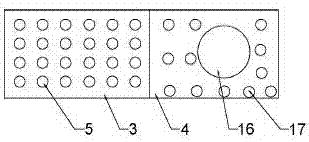

PendingCN106498695AReach adriftImprove efficiencyTextile treatment machine partsLiquid/gas/vapor textile treatmentState of artEngineering

The invention relates to the field of textile production devices, and discloses a textile bleaching device which comprises a rack and a bleaching tank, wherein one end of the bleaching tank is an opening end; a first plate and a second plate are arranged on the rack below the opening end of the bleaching tank; a plurality of first filtering holes are formed in the first plate; a rotating shaft is arranged on the rack below the first filtering holes; a waterwheel is arranged on the rotating shaft; a cam is connected with one end, far away from the bleaching tank, of the rotating shaft; an ejector rod matched with the cam is arranged above the cam; the ejector rod is connected with the rack in a sliding manner; a connecting rod is connected with the upper part of the ejector rod; an extrusion hammer is connected with the lower part of one side close to the bleaching tank, of the connecting rod; the extrusion hammer is of a hollow structure; a water tube is communicated with the upper end of the extrusion hammer; an opening is formed in the lower end of the extrusion hammer; a first magnet for sealing the opening is arranged inside the opening in the sliding manner; a second magnet is embedded into the second plate below the first magnet; the first magnet and the second magnet are expelled by each other. Compared with the prior art, operation of bleaching, washing and extrusion drying of a textile can be integrally completed.

Owner:CHONGQING DATONGMAO TEXTILE TECH CO LTD

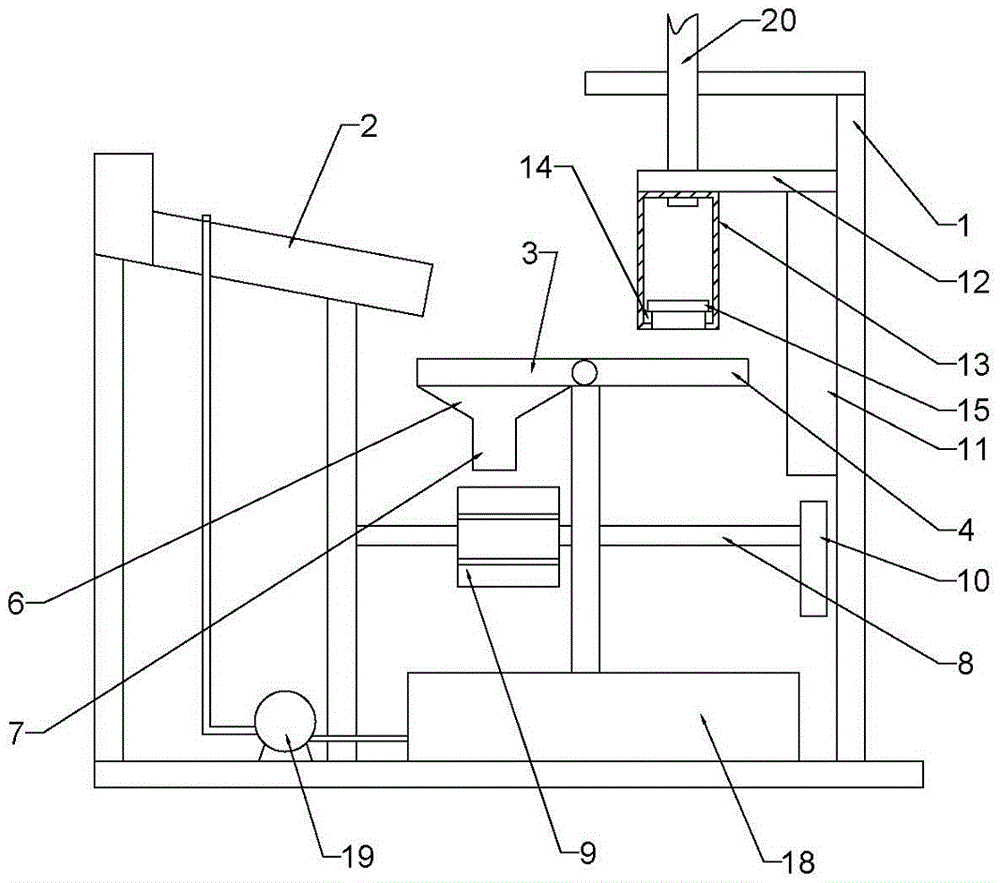

Bleaching device for producing textiles

InactiveCN108457024AControl liftEasy to take outLiquid/gas/vapor treatment machines driving mechanismsArchitectural engineeringTextile production

The invention discloses a bleaching device for producing textiles. The bleaching device comprises a base, wherein support pillars are fixed on four sides of the top end of the base; a top plate is fixed at the top ends of the support pillars; a servo motor is mounted at the bottom end of the top plate; a transmission rod is fixed on an output shaft of the servo motor; vertical plates are fixed ontwo sides of the bottom end of the top plate; two groups of guide rods are fixed between the vertical plates and are in sliding connection with movable blocks; a connection rod is fixed between the movable blocks and is in sliding connection with a sliding block; a fixed plate is fixed at the bottom ends of the two groups of movable blocks; sleeve rods are fixed on two sides of the bottom end of the fixed plate; stop blocks are arranged in the sleeve rods; movable rods are fixed at the bottom ends of the stop blocks; the bottom ends of the movable rods extend to the outside of the sleeve rodsand are fixed with storage baskets. The bleaching device is ingenious in design, reasonable in structure, simple to operate and high in flexibility; the labor is reduced; the storage baskets can be conveniently controlled to rise and fall; the bleaching efficiency of the device can be improved; the textiles can be more uniformly bleached; the popularization of the bleaching device is facilitated.

Owner:南陵百绿汇农业科技有限公司

Peroxygen release compositions and method for producing them

Stabilized peroxygen containing compositions are disclosed, both in thickened viscous form and in dry form. The compositions contain newly synthesized calcium sulfate crystals that function as a thickener and stabilizing agent against metal-catalyzed decomposition. The invention discloses a composition comprising 0.5 wt % to 50% wt of hydrogen peroxide. 2.0 wt % to 80.0% wt of newly synthesized calcium sulfate crystals, being of individual sheet or needle shape, and water, said composition having a viscosity of 200 cP to 20,000 cP. The invention further provides a process for making same, comprising the reaction of a water soluble calcium containing salt with sulfuric acid or a salt thereof in an aqueous hydrogen peroxide solution at a reaction temperature of up to 80 C in a mixing apparatus, followed by a concentration step in order to thicken into a stable viscous dispersion or paste containing at least 2 wt % and preferably 10 wt % to 15 wt % of CaSO4. The compositions are suitable for use as disinfectants, as cleaning agents, and in a variety of personal care, pharmaceutical, textile bleaching and industrial applications.

Owner:CREACHEM

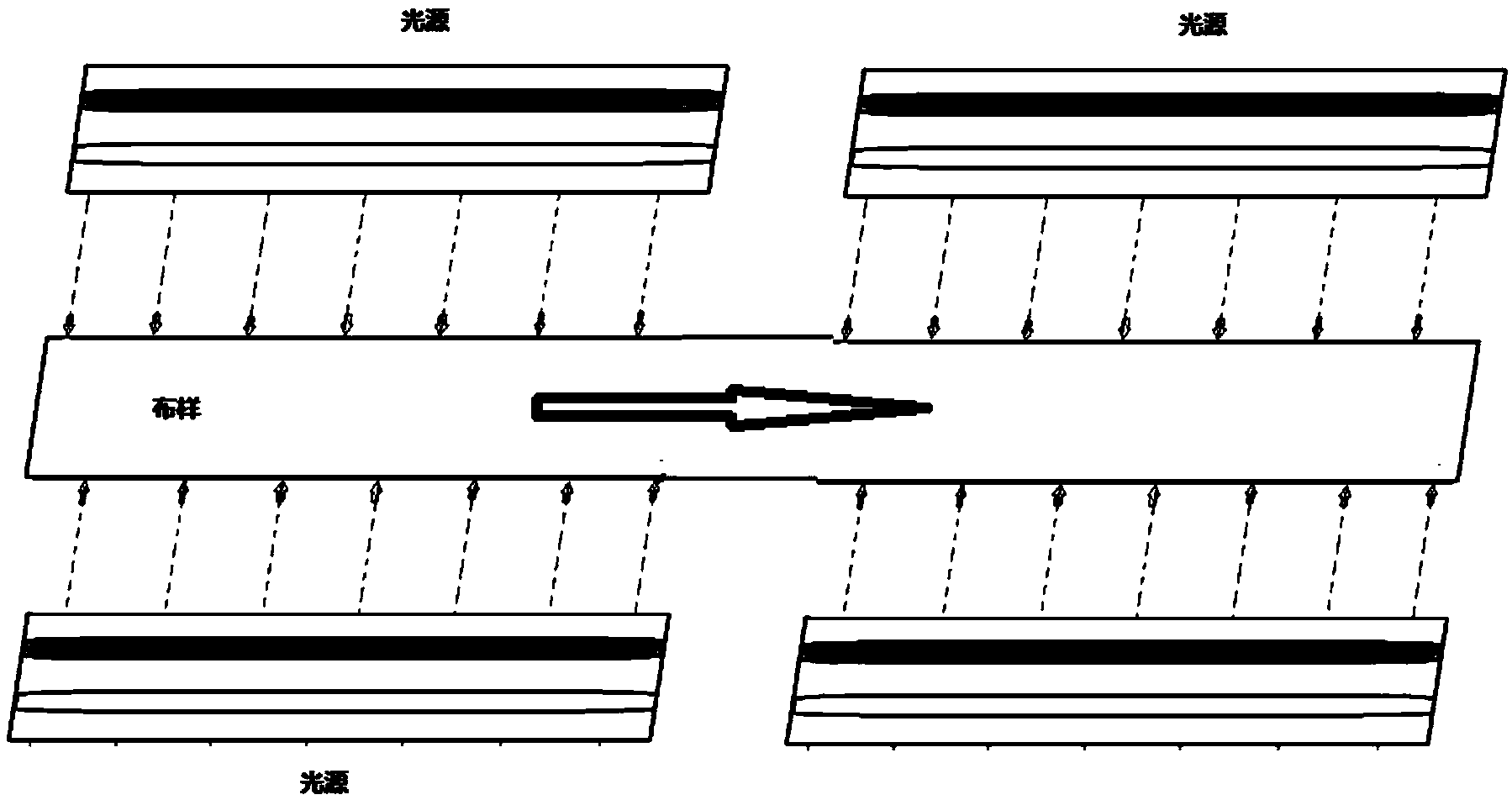

Method for preparing composite photocatalysis bleaching system and textile bleaching technology

The invention discloses a method for preparing a composite photocatalysis bleaching system and a textile bleaching technology. The bleaching technology can be finished by the following steps: firstly, a textile is soaked in a hydrogen peroxide blenching system containing inositol hexaphosphate ammonium salt and then soaked in a titanium dioxide dispersing system containing sodium dodecyl benzene sulfonate and sodium hexametaphosphate; then, the textile is put in an ultraviolet circulating irradiation device. Compared with the prior art, the bleaching technology has the advantages that the bleached textile has high whiteness and small strength losses, the treatment time is short, no three wastes are discharged, technical advantages of energy conservation and emission reduction are achieved, and the photocatalysis bleaching performance of yarns can be inherited by down-stream products, such as fabric.

Owner:WUHU FUCHUN DYEING & WEAVING

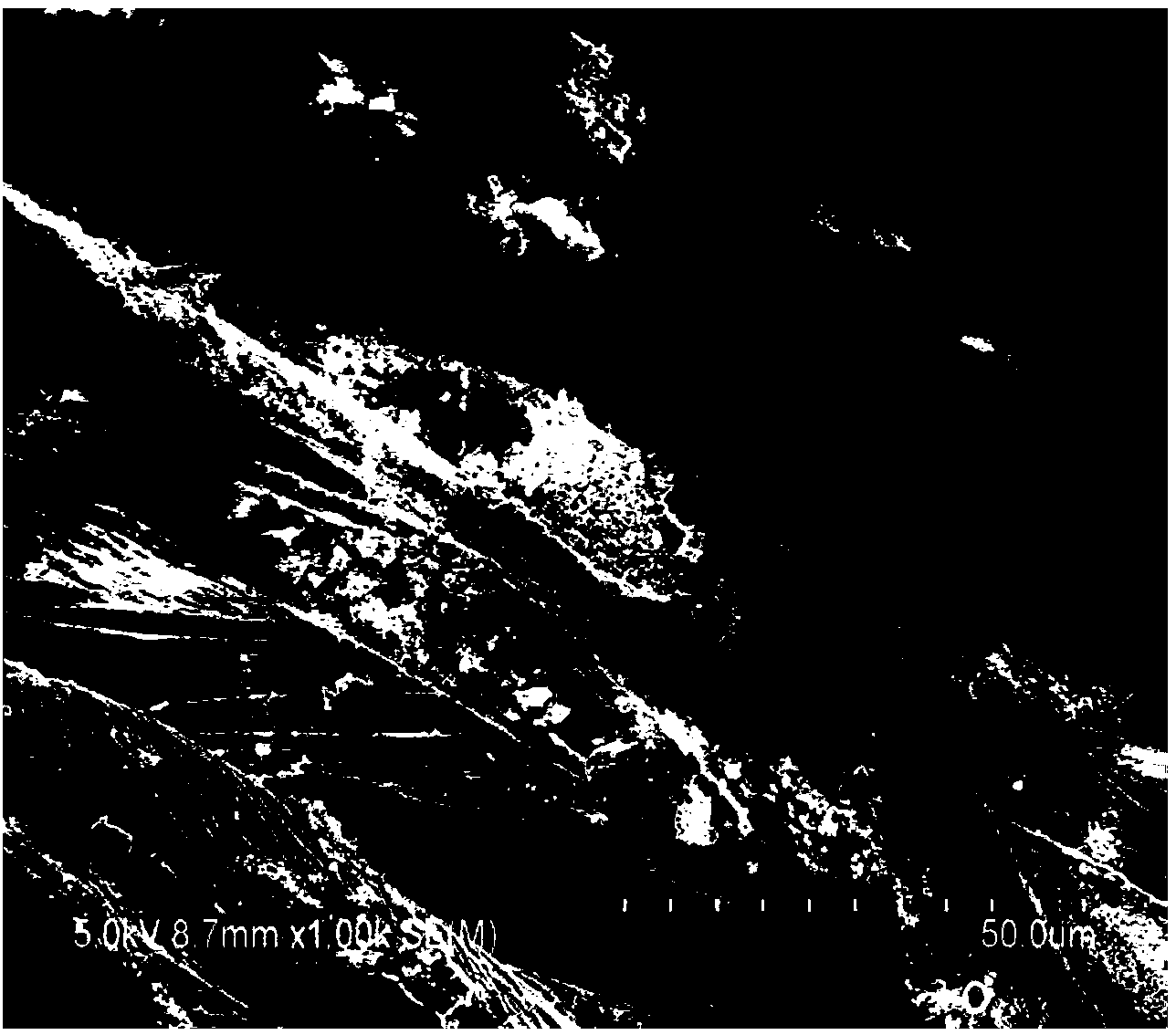

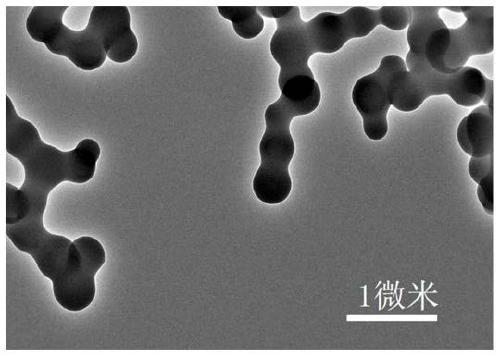

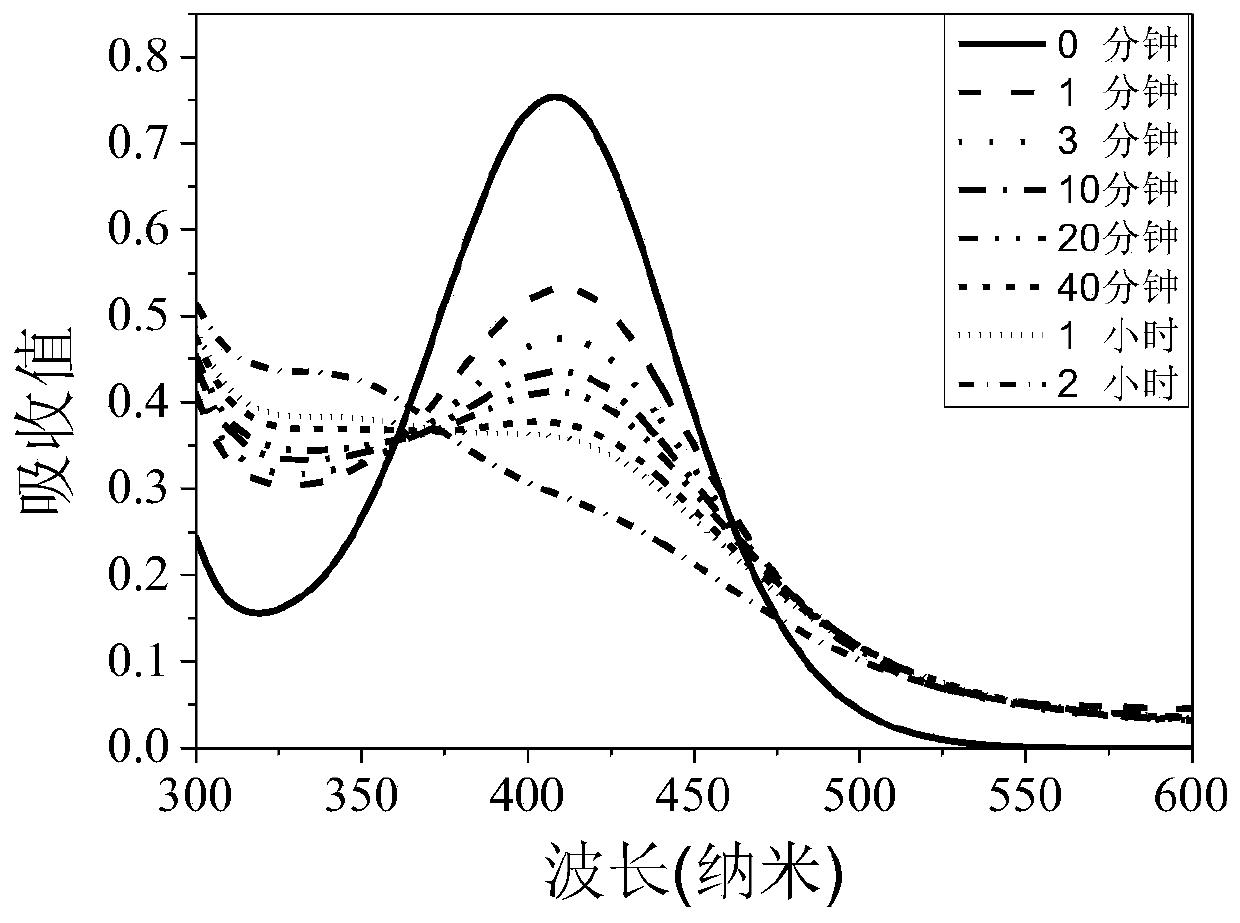

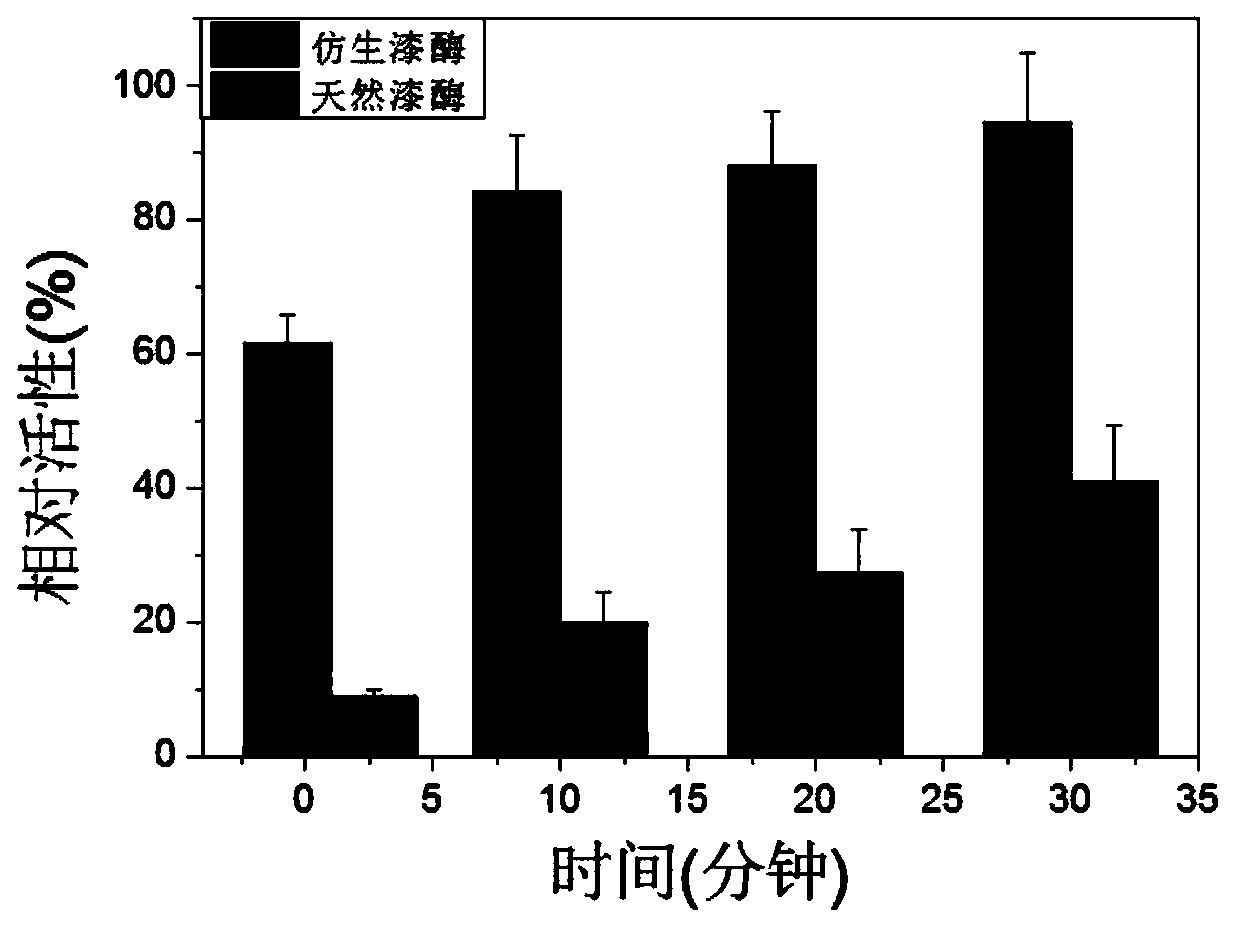

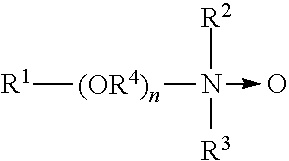

Preparation method and application for bionic laccase based on dipeptide

ActiveCN111185229AGood biocompatibilityThe metabolic mechanism is clearQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsDipeptideOrganic chemistry

The invention relates to a preparation method and an application for bionic laccase based on dipeptide. The bionic laccase based on the dipeptide takes metal ions as a catalytic active center and dipeptide as an organic framework, and has laccase-like activity; and the bionic laccase based on the dipeptide is a dipeptide-crosslinking agent-metal compound. The bionic laccase prepared by using the method provided by the invention has the following advantages: the preparation process is simple, and the preparation conditions are mild; the prepared bionic laccase has the catalytic activity of simulating natural laccase; the catalytic efficiency of the bionic laccase is far higher than the catalytic efficiency of natural laccase; and the bionic laccase has high stability and good biocompatibility. The preparation method for the series of bionic laccase based on the dipeptide has potential application in development of industrial applications of wastewater treatment, textile bleaching, foodsafety and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Spandex cloth bleaching device

InactiveCN108286140AExtension of timeIncrease contact areaLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsReciprocating motionEngineering

The invention relates to the technical field of textile bleaching and dyeing, and discloses a spandex cloth bleaching device. The bleaching device comprises a shell, a first cloth conveying roller, afirst cloth clamping roller group and a second cloth clamping roller group are arranged inside the shell, a first track is arranged on one side of the cloth conveying roller, a first roller is arranged on the first track, a small waterwheel composed of a rotating shaft, a rotating wheel and blades is further arranged inside the shell, and the rotating wheel and a center shaft of the first roller are connected with a first connecting rod. During bleaching, spandex cloth is placed inside the shell, bleaching liquid flows into the shell, the bleaching liquid falls onto the blades of the small waterwheel and then falls onto the spandex cloth, the small waterwheel rotates to drive the first roller to conduct reciprocating motion in the horizontal and vertical directions, the surface of the first roller is in contact with the spandex cloth and supports the spandex cloth to be stretched and expanded, and the spandex cloth is in full contact with the bleaching liquid during the continuous stretching and contracting action, so that the bleaching efficiency is improved, and the bleaching effect is improved.

Owner:宁波希奇服饰有限公司

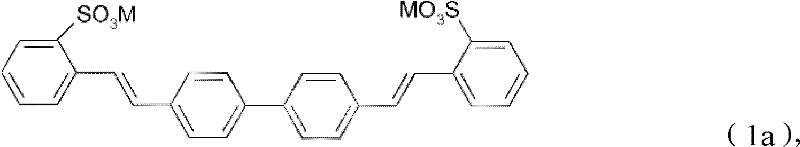

Enzymatic textile bleach-whitening methods

InactiveCN102333914ADetergent dyesOrganic/inorganic per-compounds compounding agentsBleachOptical brightener

A method for bleach-whitening of synthetic textile material is provided comprising contacting said textile material with (a) an enzymatic textile bleaching composition comprising (i) a perhydrolase enzyme, (ii) an ester substrate for said perhydrolase enzyme, (iii) a hydrogen peroxide source, (iv) a surfactant and / or an emulsifier, (v) a peroxide stabilizer, (vi) a sequestering agent, (vii) a buffer which maintains a pH of about 6 to about 8, and (b) at least one fluorescent whitening agent, and, optionally, (c) at least one acid or disperse shading dye for shaded variations of white, for a length of time and under conditions suitable to permit measurable whitening of the textile material, thereby producing a bleached-whitened textile material.

Owner:HUNTSMAN ADVANCED MATERIALS (SWITZERLAND) GMBH

GENERATION OF PEROXYCARBOXYLIC ACIDS AT ALKALINE pH, AND THEIR USE AS TEXTILE BLEACHING AND ANTIMICROBIAL AGENTS

The present disclosure provides methods for generating percarboxylic acid compositions and / or peroxycarboxylic acid compositions formed external to a point of use in non-equilibrium reactions for use in certain bleaching and antimicrobial applications, in particular laundry applications. The compositions are generated external to a point of use, at alkaline pH levels, viz. greater than about pH 12, and optionally suitable for use with detergents and / or surfactants for synergistic bleaching efficacy. Methods of bleaching and / or disinfecting are further provided.

Owner:ECOLAB USA INC

Textile bleaching stabilizer

InactiveCN102965903ANo roughnessImprove bleaching effectBleaching apparatusInorganic saltsSurface-active agents

The invention discloses a textile bleaching stabilizer which comprises the components based on parts by weight: 1-4 parts of scale inhibition dispersing agent, 15-20 parts of chelating agent, 1-5 parts of surface active agent, 2-4 parts of magnesium inorganic salt and 5-8 parts of sodium silicate. The textile bleaching stabilizer is good in bleaching effect, and the bleached textile is free from roughness.

Owner:WUJIANG JIANGXU TEXTILE

Peroxygen release compositions and method for producing them

InactiveCN104364190ABiocidePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPersonal careDecomposition

Stabilized peroxygen containing compositions are disclosed, both in thickened viscous form and in dry form. The compositions contain newly synthesized calcium sulfate crystals that function as a thickener and stabilizing agent against metal-catalyzed decomposition. The invention discloses a composition comprising 0.5 wt % to about 50 % wt of hydrogen peroxide, 2.0 wt % to about 80.0 % wt of newly synthesized calcium sulfate crystals, being of individual sheet or needle shape, and water, said composition having a viscosity of about 200 cP to about 20,000 cP. The invention further provides a process for making same, comprising the reaction of a water soluble calcium containing salt with sulfuric acid or a salt thereof in an aqueous hydrogen peroxide solution at a reaction temperature of up to 80 °C in a mixing apparatus, followed by a concentration step in order to thicken into a stable viscous dispersion or paste containing at least 2 wt % and preferably 10 wt % to 15 wt % of CaSO 4 . The compositions are suitable for use as disinfectants, as cleaning agents, and in a variety of personal care, pharmaceutical, textile bleaching and industrial applications.

Owner:CREACHEM

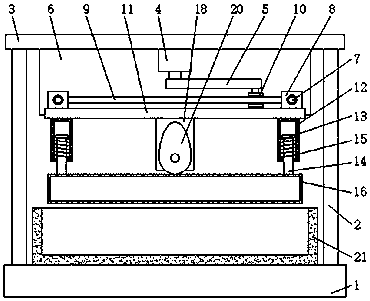

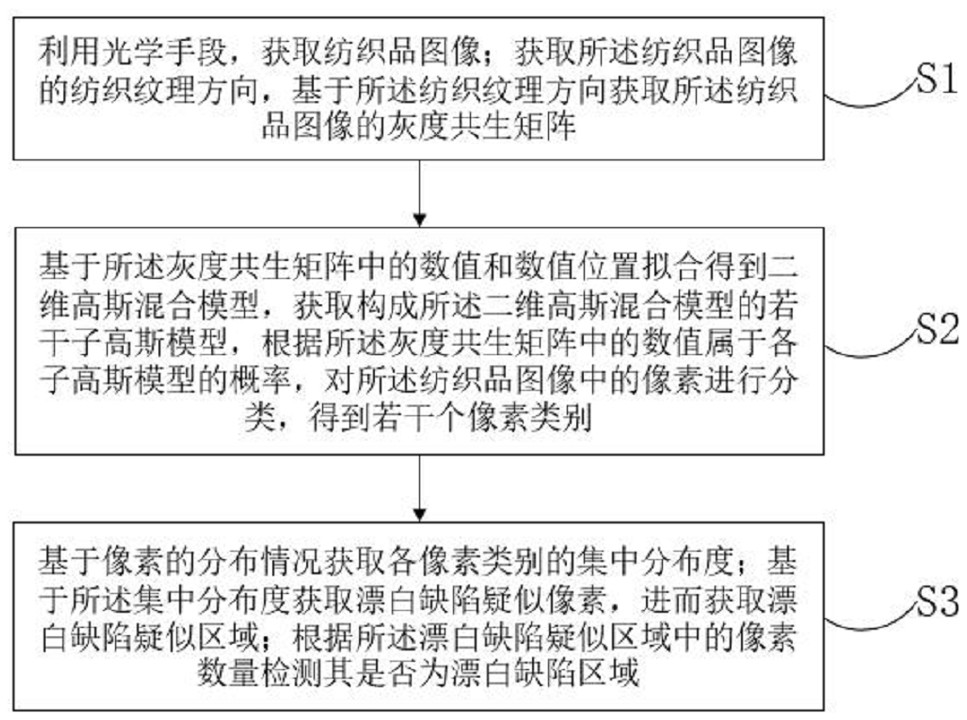

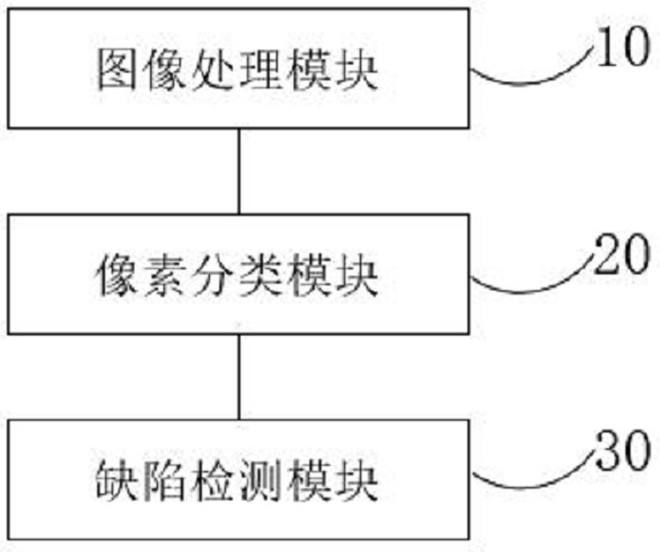

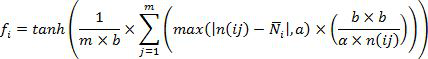

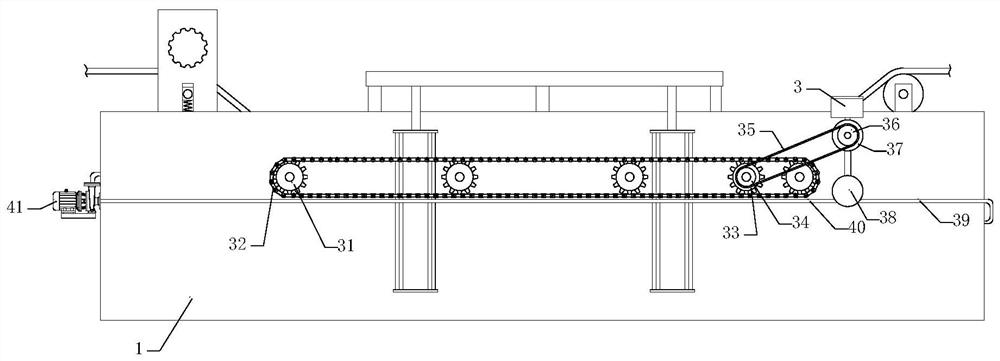

New material textile bleaching defect optical detection method and device

ActiveCN114693676AAvoid Color Noise MessagesAvoid interferenceImage enhancementImage analysisGray levelEngineering

The invention relates to the field of defect detection, in particular to a new material textile bleaching defect optical detection method and device, and the new material textile bleaching defect optical detection method is a method for testing or analyzing the new material textile bleaching defect by acquiring a visible light image through an optical means. The method comprises the following steps: acquiring a textile image by using an optical means; classifying pixels in the textile image based on a gray level co-occurrence matrix to obtain a plurality of pixel categories; acquiring the centralized distribution degree of each pixel category based on the distribution condition of the pixels; obtaining bleaching defect suspected pixels based on the concentrated distribution degree, and further obtaining a bleaching defect suspected area; and detecting whether the bleaching defect suspected area is a bleaching defect area or not according to the number of pixels in the bleaching defect suspected area. And the bleaching defect detection precision is improved. In addition, the new material textile bleaching defect optical detection method and device provided by the invention can realize new material detection, metering and the like.

Owner:南通市通州翔鹏纺织品有限公司

Bleaching and dyeing device for textile machinery

InactiveCN110983689AImprove the effect of bleaching and dyeingReduce the probability of decontaminationLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsProcess engineeringMaterials science

The invention discloses a bleaching and dyeing device for textile machinery, relates to the technical field of textile processing, and mainly solves the problem that the textile quality is reduced dueto the fact that an existing textile bleaching and dyeing device easily causes destaining. The device comprises a base; a stand column is arranged on the base; a shell is mounted on the stand column;the shell is provided with a feeding hole and a discharging hole; clamping cylinders are arranged at the positions of the feeding hole and the discharging hole; a woven fabric body enters the interior of the shell through the clamping cylinders; the woven fabric body enters a bleaching and dyeing pool through a tensioning cylinder in the shell; a bubbling cylinder is arranged in the bleaching anddyeing pool; a first electric heating wire is arranged in the bubbling cylinder; a slope is arranged on the right side of the bleaching and dyeing pool; a hanging rod is arranged at the top of the shell; an extrusion cylinder is rotationally connected to the hanging rod; and a dewatering device and a drying device are arranged on the right side of the bleaching and dyeing pool. High-quality bleaching and dyeing of a woven fabric are achieved through the tensioning cylinder, the bleaching and dyeing pool, the bubbling cylinder and the first electric heating wire.

Owner:赵婷

Textile bleaching device

InactiveCN112127070AEasy to dryEasy to moveTextile treatment machine arrangementsTextile treatment cleaning apparatusElectric machineryDrive motor

The invention discloses a textile bleaching device, and belongs to the field of textile mechanical equipment. The textile bleaching device comprises a box body, a discharging pipe and a box door, wherein the box door is rotatably connected to the box body, the discharging pipe is fixedly connected to the box body, a partition plate is arranged in the box body, a driving motor is arranged in the box body and located below the partition plate, and a rotating shaft is fixedly connected to the output end of the driving motor; and a bevel gear is arranged on the rotating shaft. According to the bleaching device, through the arrangement of a rotary disc, water in the box body can be conveniently driven to flow in an accelerated mode, a bleaching agent can be conveniently and rapidly mixed and dissolved, the bleaching agent can be conveniently added for multiple times through the arrangement of a material guide barrel, it is guaranteed that the bleaching agent is fully mixed with water, and then the bleaching agent makes uniform contact with textile to avoid chromatic aberration; Through the arrangement of an air cylinder, a friction rod and a friction ring, the water is conveniently heated, the bleaching efficiency is improved, besides, the textile is conveniently dried, and through the arrangement of a control pipe, the water temperature is conveniently prevented from being too high.

Owner:朱官玲

Textile bleaching device

InactiveCN107513832AReach adriftImprove efficiencyTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingState of artEngineering

The invention relates to the field of textile production devices, and discloses a textile bleaching device, comprising a frame and a bleaching box, one end of the bleaching box is an open end, and a first plate and a second plate are arranged on the frame below the open end of the bleaching box, A number of first filter holes are arranged on the first plate, a rotating shaft is arranged on the frame below the first filter holes, a water wheel is arranged on the rotating shaft, a cam is connected to the end of the rotating shaft away from the bleaching box, and a top rod that cooperates with the cam is arranged above the cam , the ejector rod is slidably connected to the frame, the upper part of the ejector rod is connected with a connecting rod, and the lower part of the side of the connecting rod close to the bleaching box is connected with a squeezing hammer, the inside of the squeezing hammer is a hollow structure, and the upper end of the squeezing hammer is connected with a water pipe , the lower end of the extrusion hammer is provided with an opening, a first magnet for closing the opening is slidably arranged in the opening, a second magnet is embedded in the second plate below the first magnet, and the first magnet and the second magnet repel each other; Compared with the prior art, the invention can perform the bleaching, washing and squeezing of the textile fabrics in an integrated manner.

Owner:孙斌

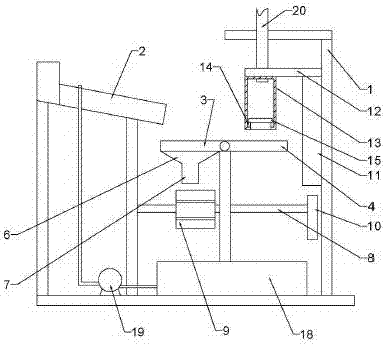

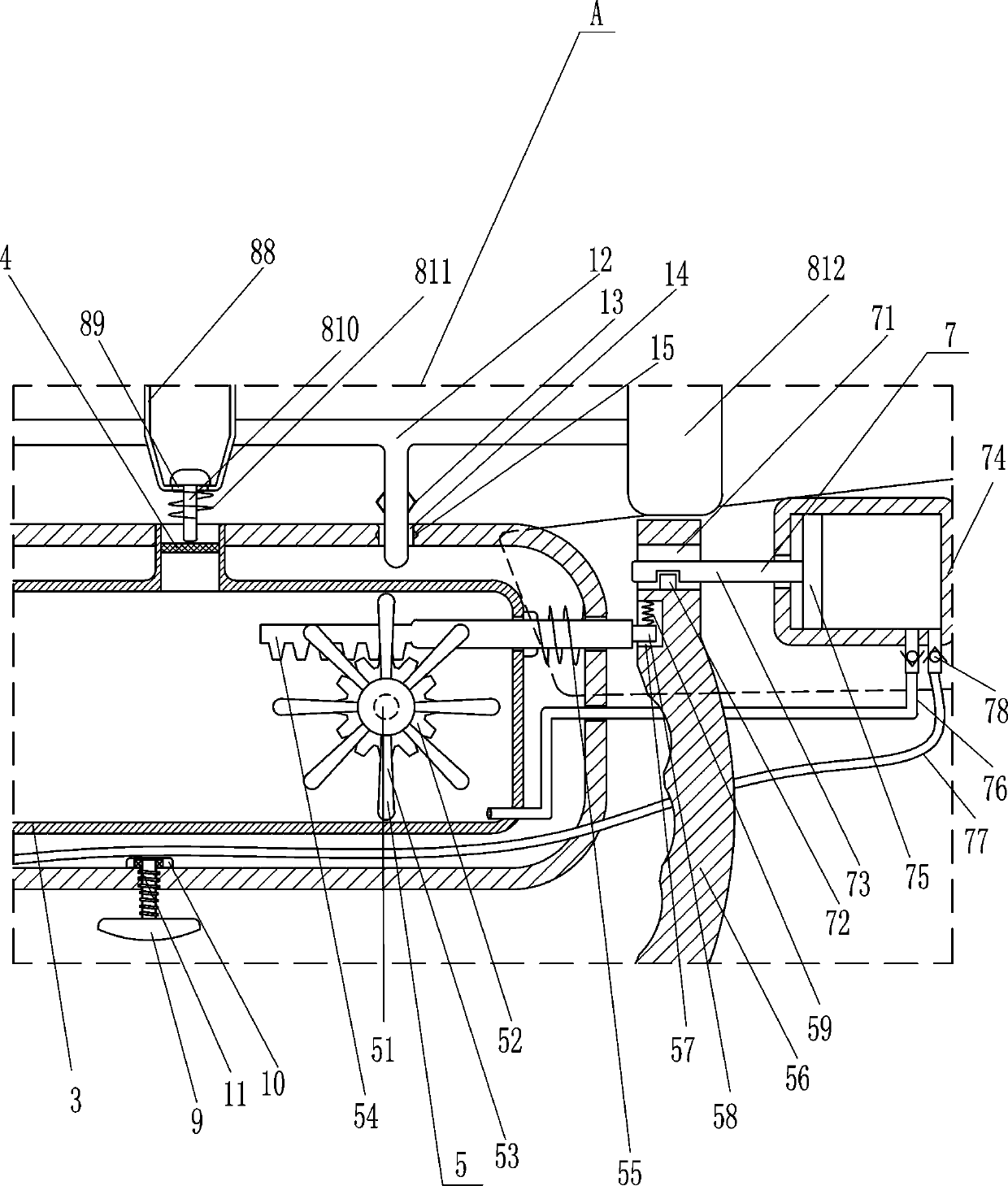

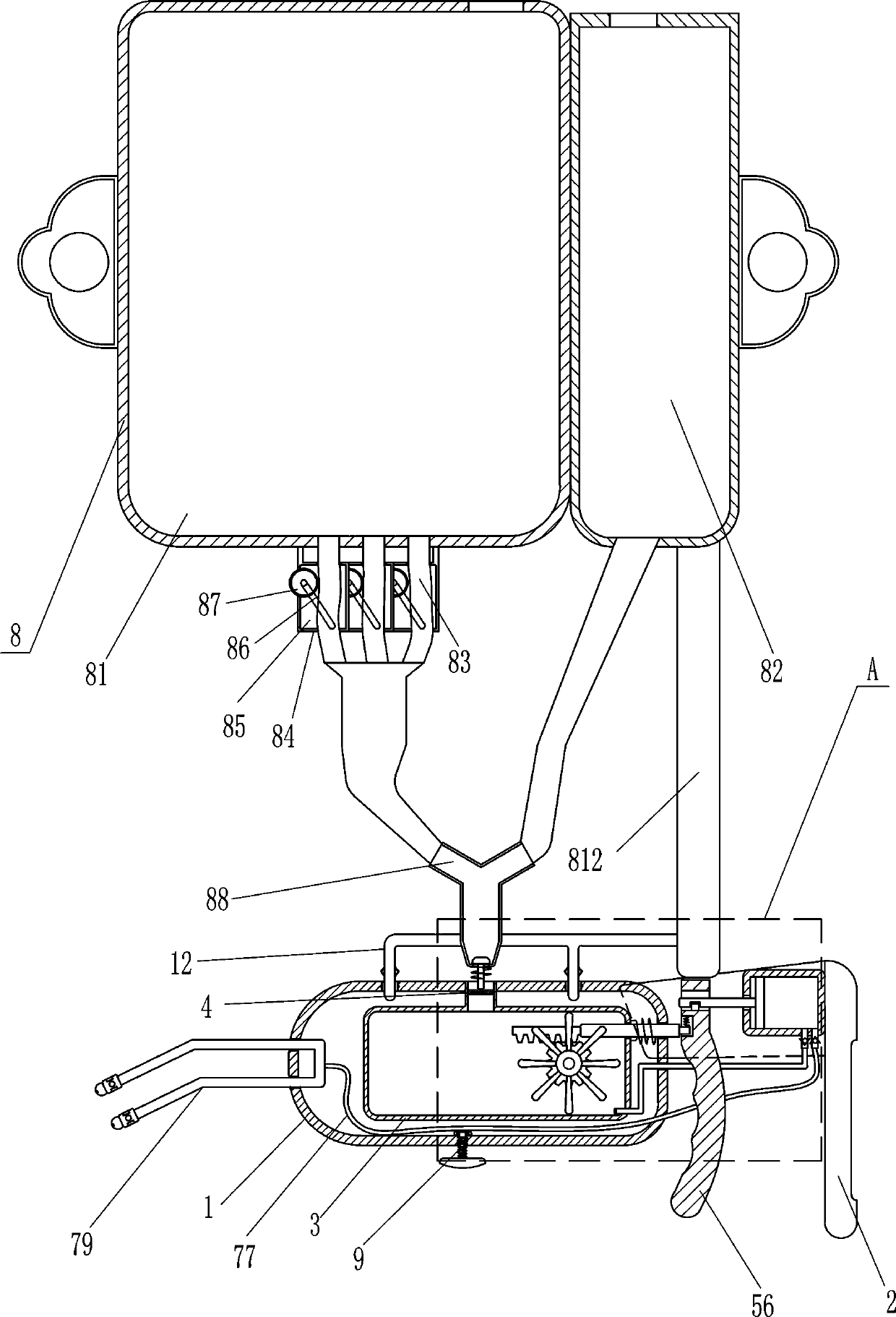

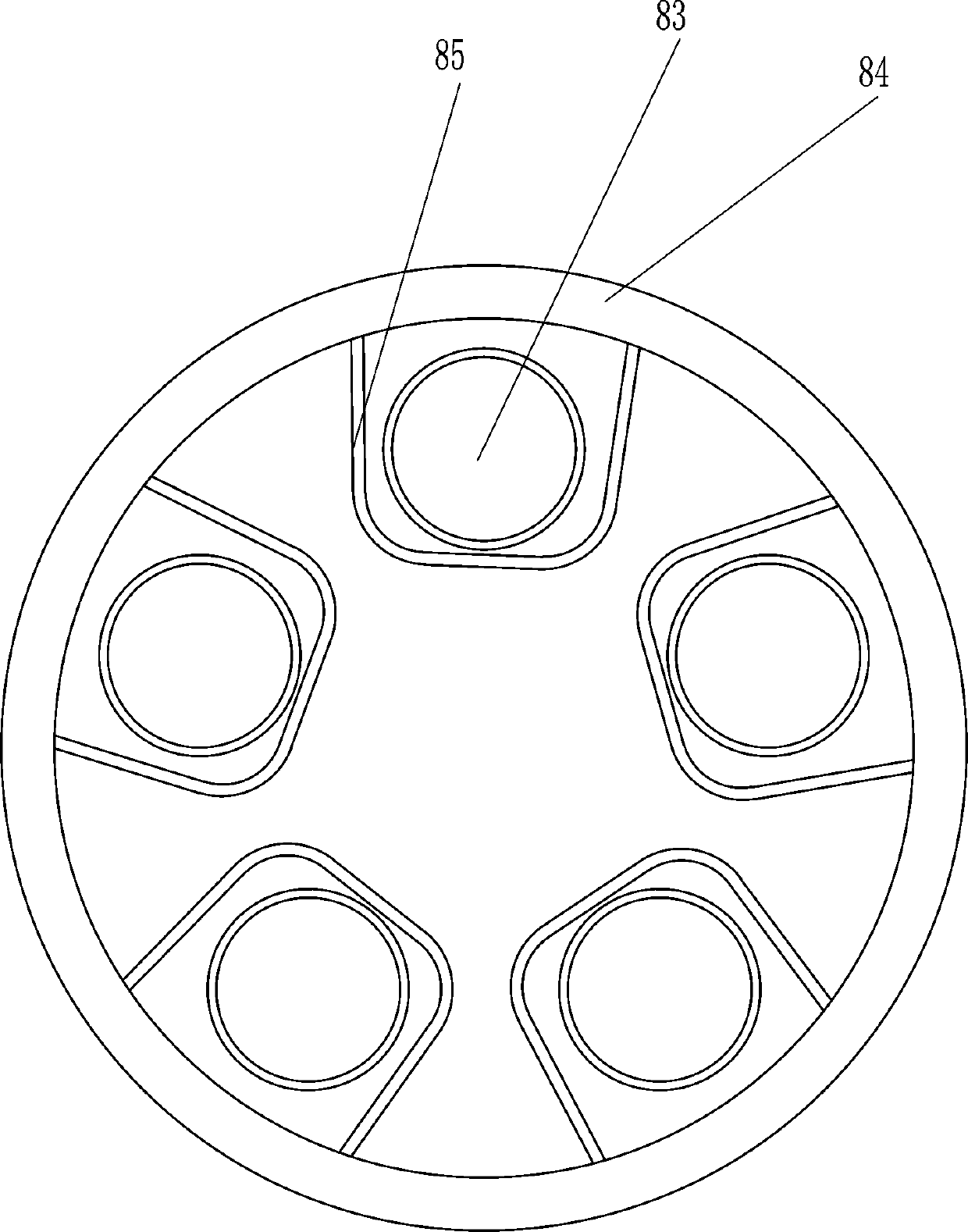

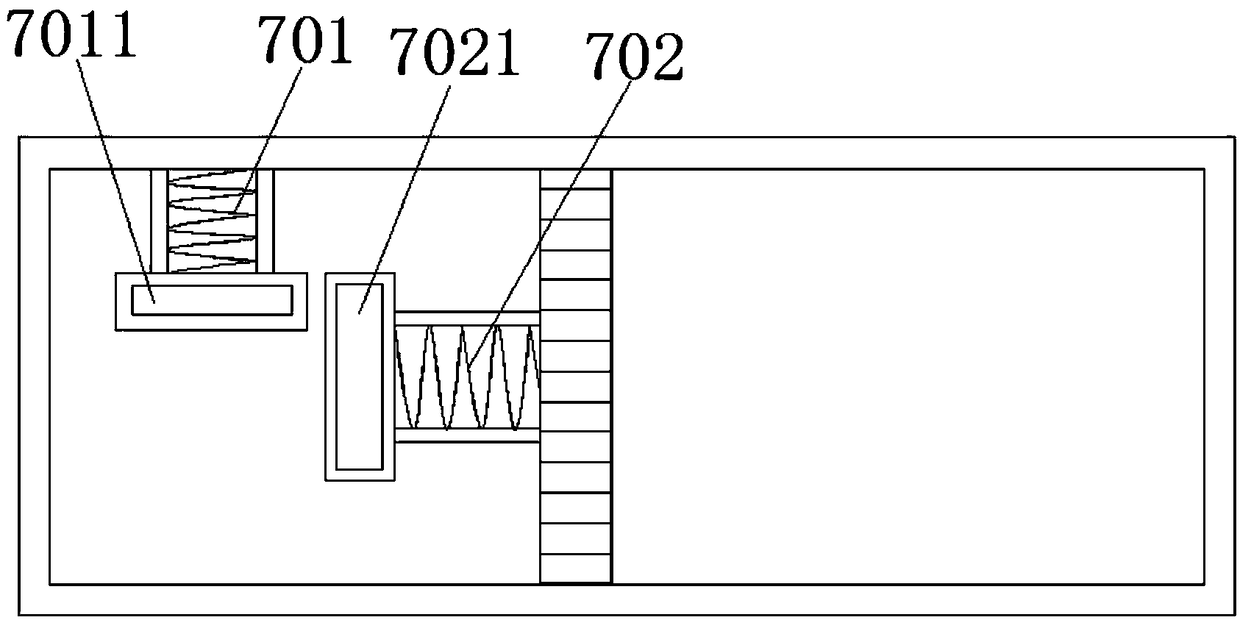

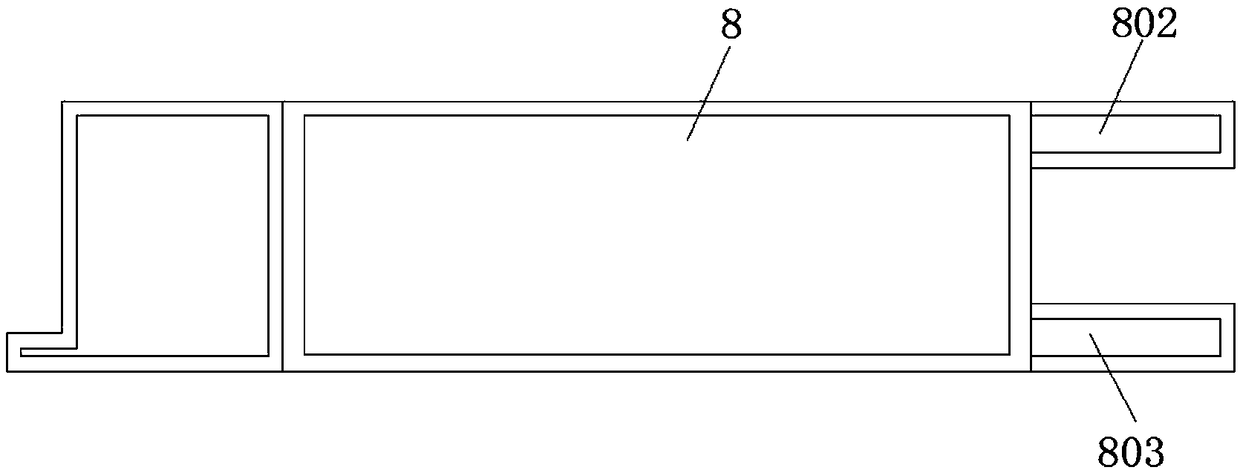

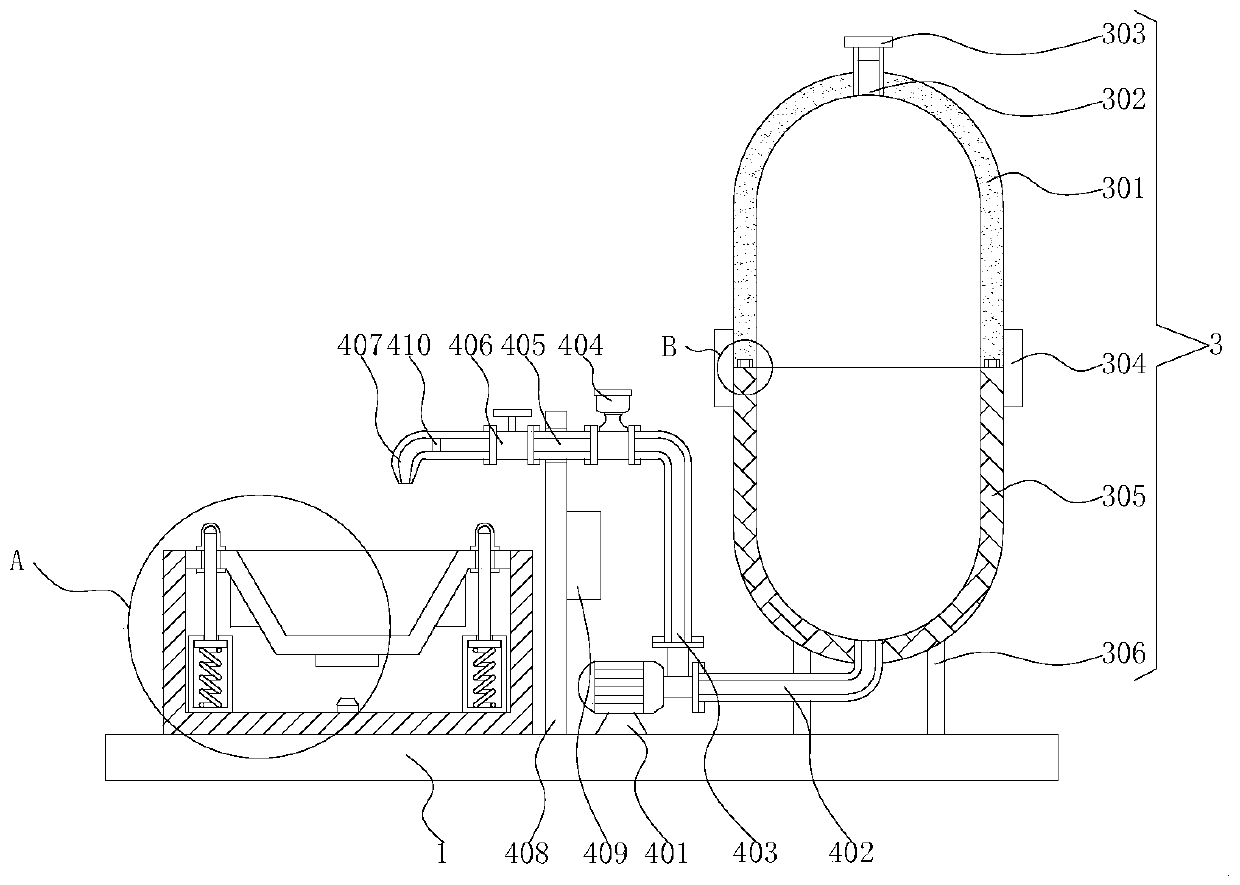

Diluting-proportioning device for cleaning oil stains on table of textile machine

InactiveCN110449059AIncrease water pressureTransportation and packagingRotary stirring mixersEngineeringCleansing Agents

The invention relates to a proportioning device, in particular, a diluting-proportioning device for cleaning oil stains on the table of a textile machine. The provided diluting-proportioning device issimple to use, and can precisely control the ratio of a detergent to water; and the time and labor for preparing a large amount of detergents can be saved. The diluting-proportioning device comprisesa shell, a handle, and a framework. The external right side of the shell is provided with the handle, and the framework is arranged in the shell. The handle is moved horizontally to drive a stirringdisc to rotate; through the rotation of the stirring disc, water and detergents in the framework can be stirred and mixed; at the same time, during the stirring process, through the cooperation between a cylinder and a piston, the water and detergents are sprayed on the table of a textile machine, the oil stains on the table of the textile machine are emulsified and cleaned; and moreover, a bolt can drive a press block to tightly press a liquid outlet pipe so as to increase the water pressure of sprayed water and detergents.

Owner:廖彬

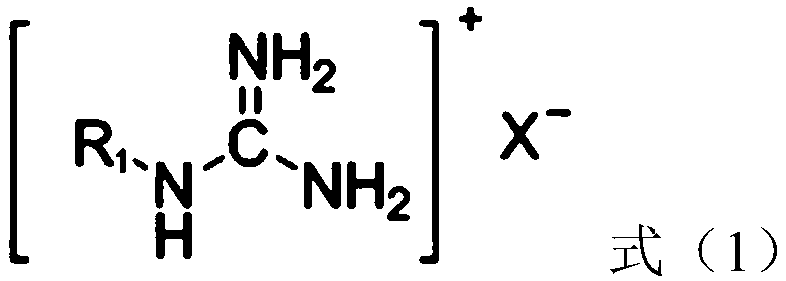

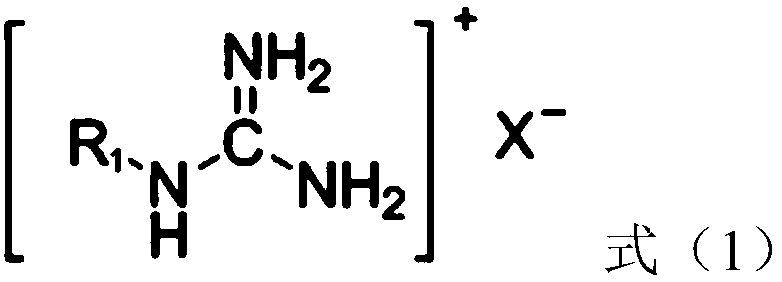

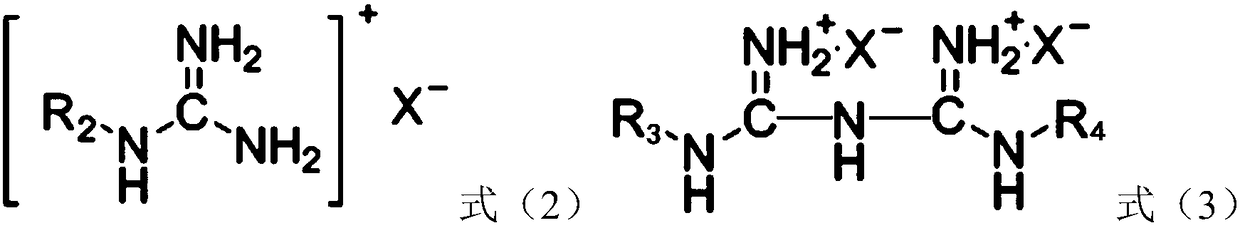

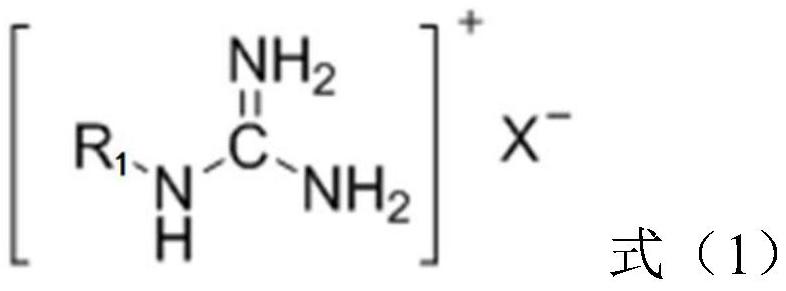

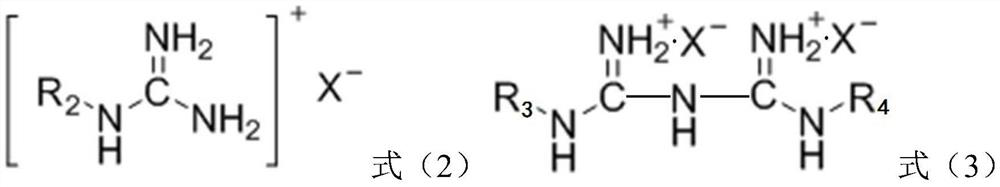

Reagent composition for bleaching of textiles, and textile bleaching method

The invention relates to the field of textile processing and discloses a reagent composition for bleaching of textiles, and a textile bleaching method. The reagent composition for bleaching of the textiles is prepared from hyperoxide, an activating agent, a penetrating agent, a stabilizer, a pH buffering agent and water, wherein the activating agent contains a first guanidine salt component. The reagent composition and the textile bleaching method are based on constructing a guanidine salt activated hydrogen peroxide system to enable the textiles to efficiently bleached at a low temperature under a near-neutral condition. The technology has the advantages of energy saving, low consumption, textile protection, short process and simple operation. Meanwhile, bleaching objects are in a wide range, and low-temperature bleaching of a cellulose type fabric, a protein type fabric and a chemical fiber type fabric can be achieved; and a novel bleaching way is provided for special fabrics which are poor in alkali resistance.

Owner:WUHAN TEXTILE UNIV

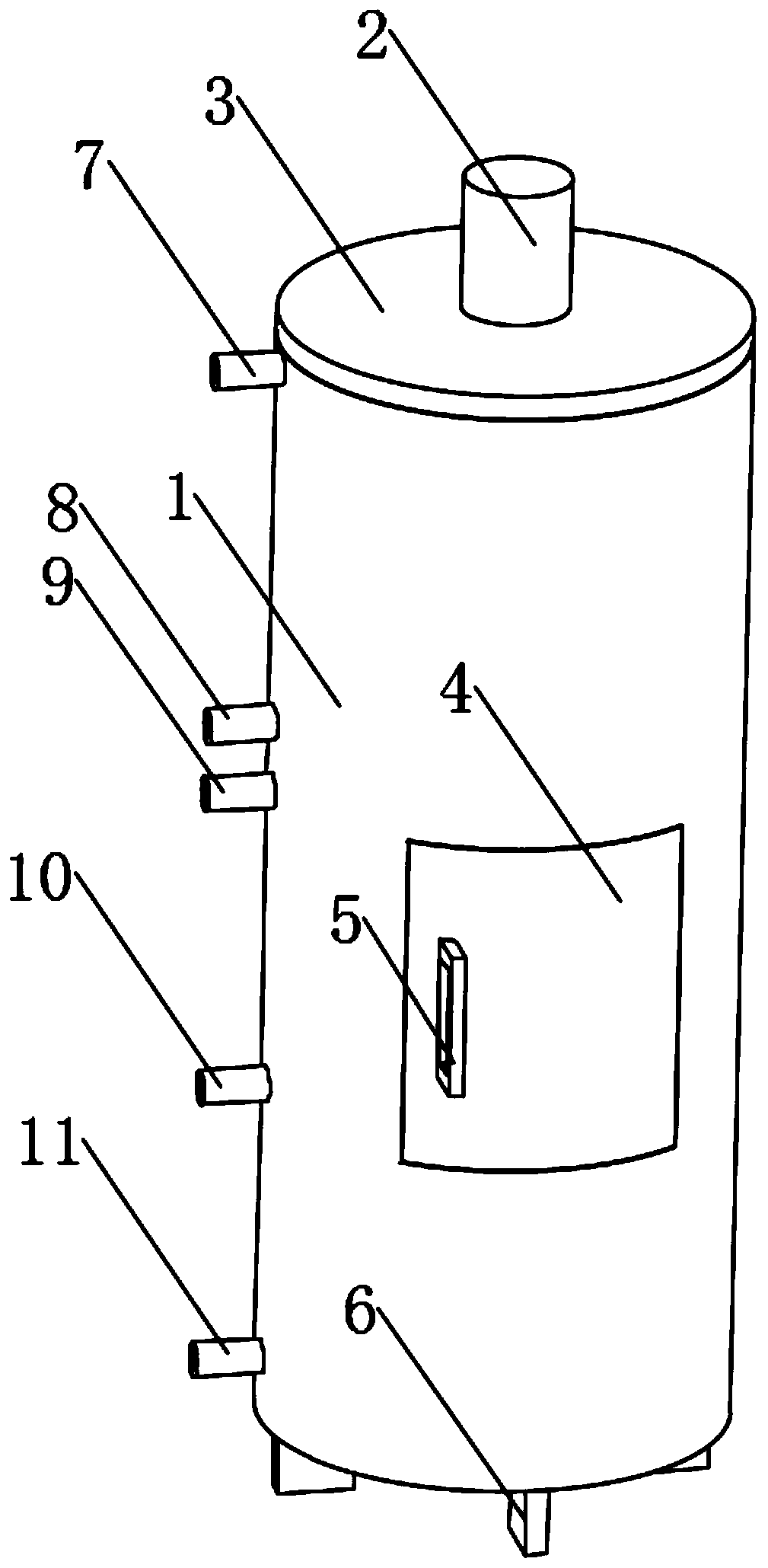

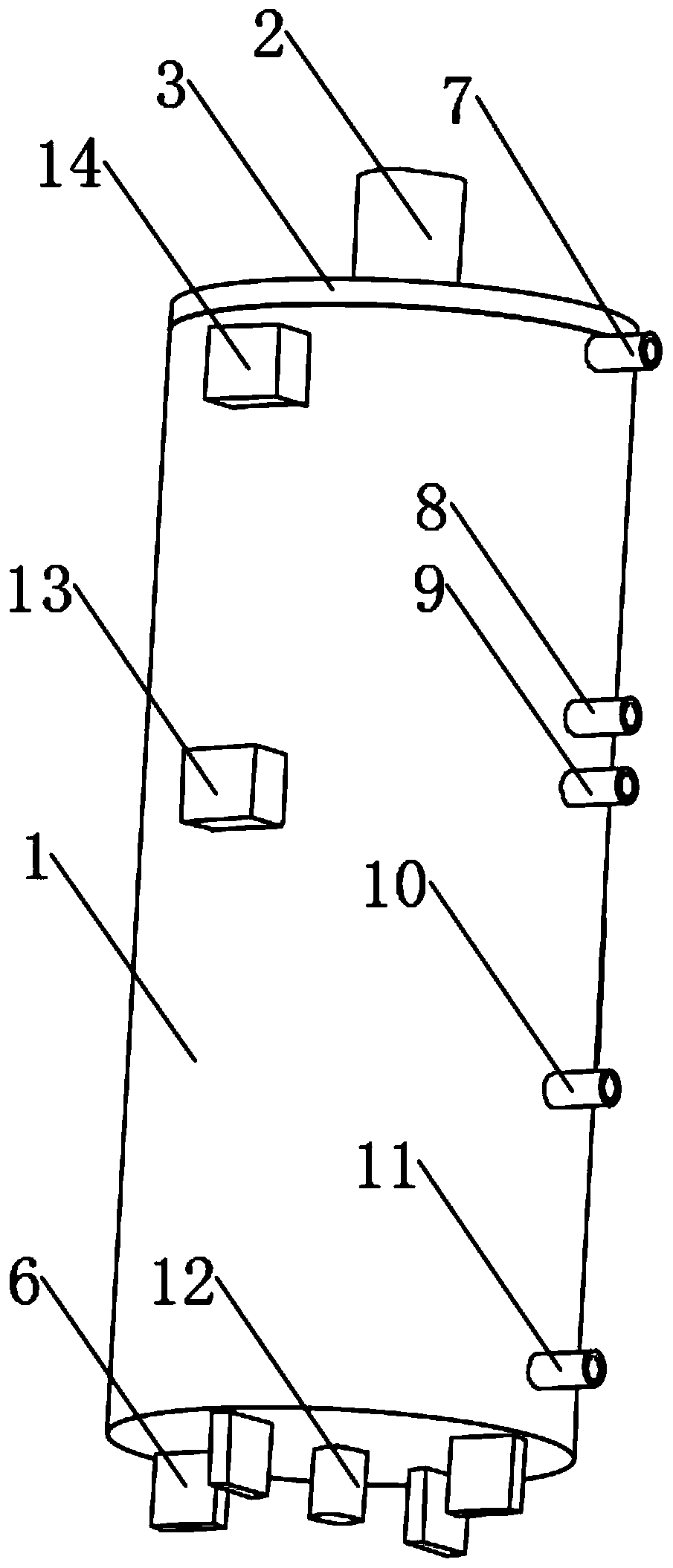

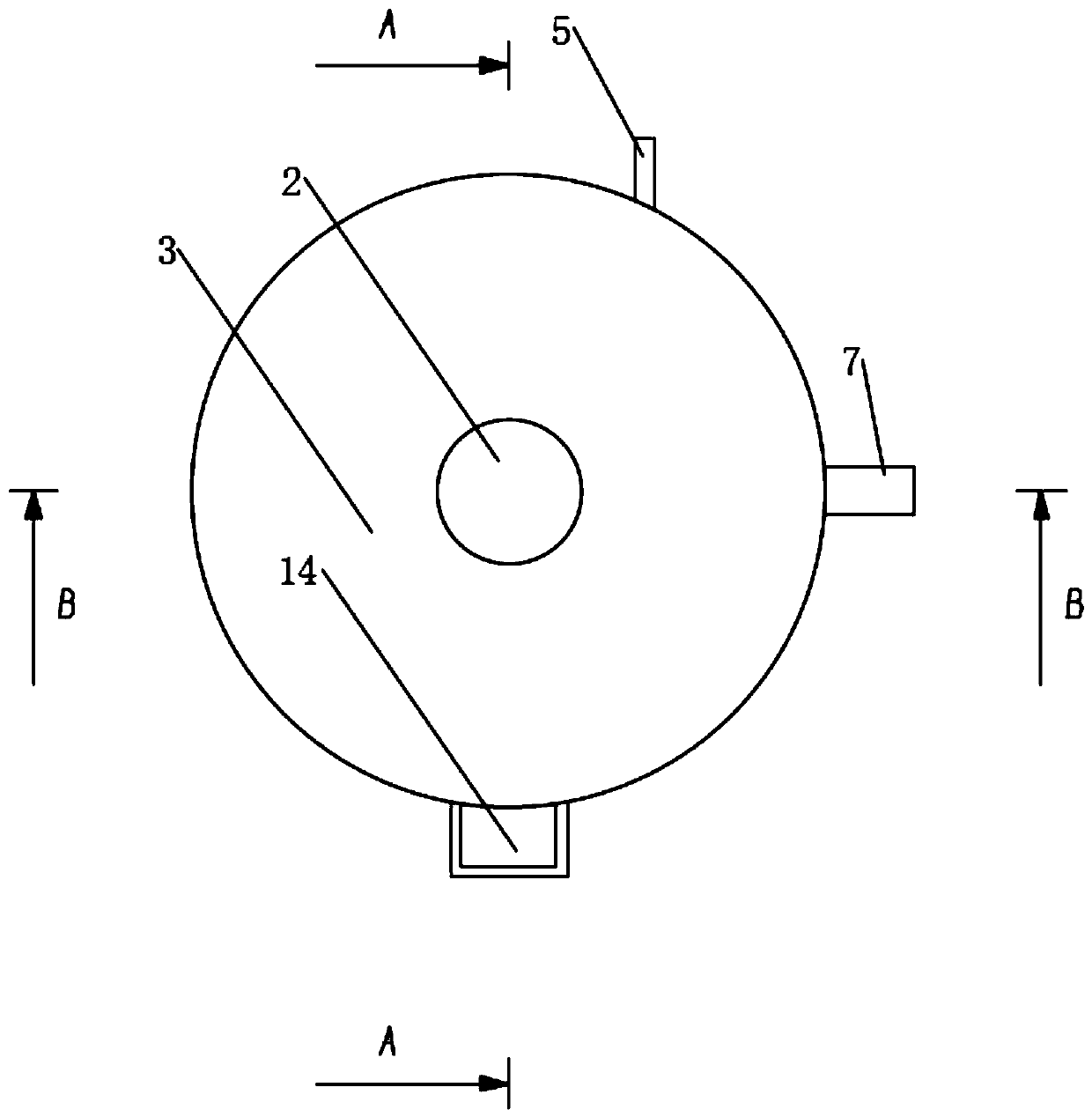

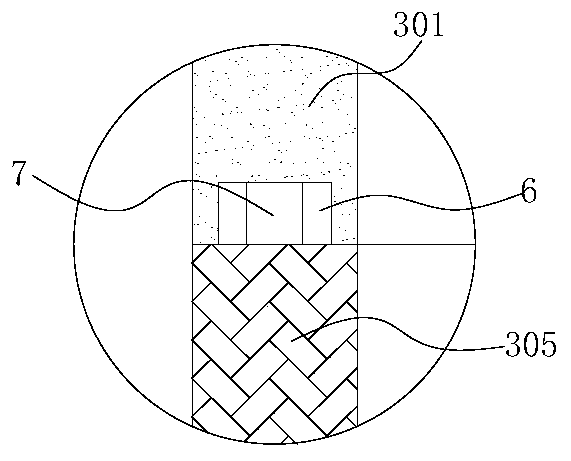

Waste textile bleaching and recycling equipment

ActiveCN110952243AImprove recycling efficiencySmall footprintTextile treatment containersTwo or more solvent application treatmentProcess engineeringTextile bleaching

The invention discloses the technical field of waste textile bleaching and recycling equipment, and particularly relates to waste textile bleaching and recycling equipment. The waste textile bleachingand recycling equipment comprises an integral box, wherein the integral box is of a cylindrical structure; the upper end of the integral box is provided with an opening; an upper sealing cover is clamped in the opening position; and the inside of the integral box is sequentially divided into a cleaning cavity, a bleaching cavity and a spin-drying cavity from top to bottom. The cleaning, bleachingand spin-drying on waste textiles are completed in one step through the integral box, so that the recycling efficiency of the waste textiles is improved; and the occupied space is small. The upper sealing cover arranged in the waste textile bleaching and recycling equipment can be conveniently opened for putting the waste textiles; the textiles are cleaned in a separated way through a plurality of groups of stirring plates; a jamming phenomenon cannot occur; and the textiles can be conveniently cleaned. A lateral sealing door is arranged at one side of the bleaching cavity of the waste textile bleaching and recycling equipment, so that the lateral sealing door can be opened for taking out the textiles in the spin-drying cavity; and the textiles can be conveniently taken out.

Owner:绍兴柯桥彬达化纤有限公司

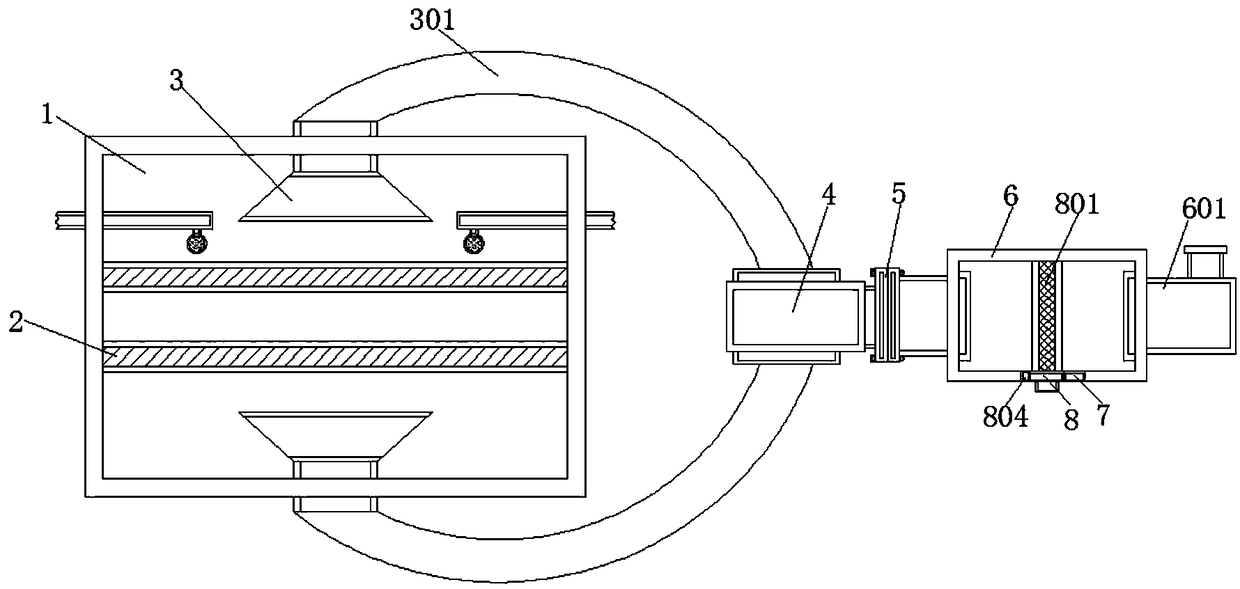

Textile bleaching and dyeing sewage treatment device

PendingCN108545879AReduce breedingEmission reductionWater/sewage treatment by irradiationTreatment involving filtrationDraining tubeWastewater

The invention discloses a textile bleaching and dyeing sewage treatment device. The textile bleaching and dyeing sewage treatment device comprises a main box body, a sewage inlet pipe, a drain pipe, ablow-off pipe, a filter element, an ultraviolet sterilizing lamp, an active carbon bag, a filter screen board and a vertical baffle plate, wherein the vertical baffle plate is arranged at the lower end inside the main box body; the filter screen board is arranged at the upper end of the vertical baffle plate; the inside of the main box body is partitioned into two cavities through the vertical baffle plate and the filter screen board. Textile bleaching and dyeing sewage is filtered by three times with the filter element, the active carbon bag and the filter screen board arranged in the main box body, so that harmful substances in the textile bleaching and dyeing sewage can be reduced effectively; the ultraviolet sterilizing lamp is provided for sterilizing the textile bleaching and dyeingsewage, so that bacteria breeding is reduced. Compared with the prior art, the textile bleaching and dyeing sewage treatment device has the advantages that most water can be recycled in production, so that the wastewater discharge can be reduced, the resource is saved, and the environment is protected. Meanwhile, the textile bleaching and dyeing sewage treatment device has the advantages of low investment cost, low energy consumption, high treatment efficiency and the like.

Owner:海盐县于城漂染股份有限公司

Dust removing device for two surfaces of textile machine for flax textile processing

InactiveCN108729180AImprove adsorption capacityAdsorption fineMechanical cleaningPressure cleaningEngineeringTextile bleaching

The invention discloses a dust removing device for two surfaces of a textile machine for flax textile processing, and relates to the technical field of textile dust removing. The dust removing devicecomprises a dust removing room, and the interior of the dust removing room is fixedly provided with a plurality of conveying belts. The central parts of the upper and lower surfaces of the dust removing room are fixedly connected with dust suction ports, and one end of each dust suction port is located in the dust removing room. The other ends of the two dust suction ports pass through the centralpart of the upper surface of the dust removing room, and are fixedly connected with one end of one dust suction pipe. The other ends of the dust suction pipes are respectively fixedly connected withthe upper and lower ends of a combiner. The dust removing device enables textile fabric to be conveyed to the dust removing room through a conveying belt, and achieves the absorption of the flocculesand accumulated dust on the textile fabric through the two dust suction ports. Moreover, the combiner enables the ends of the two dust suction pipes to be combined, and to enter an accommodation roomfrom one side of the combined through an attracting force of an air pump.

Owner:浙江载信亚麻科技有限公司

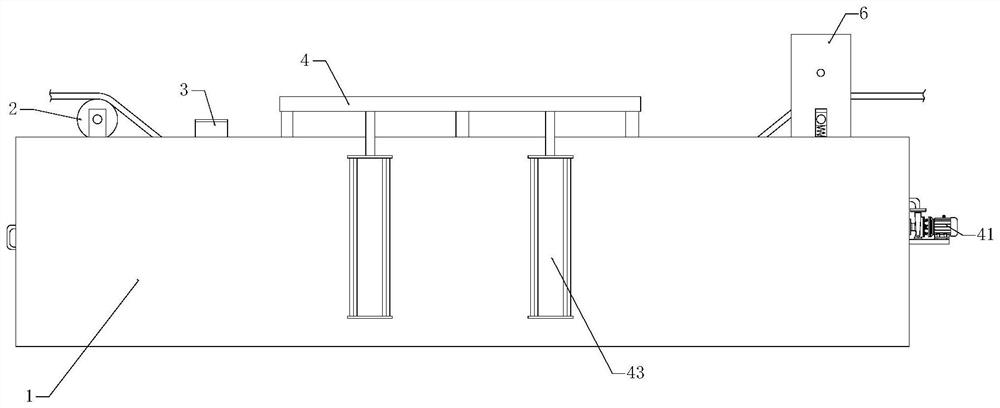

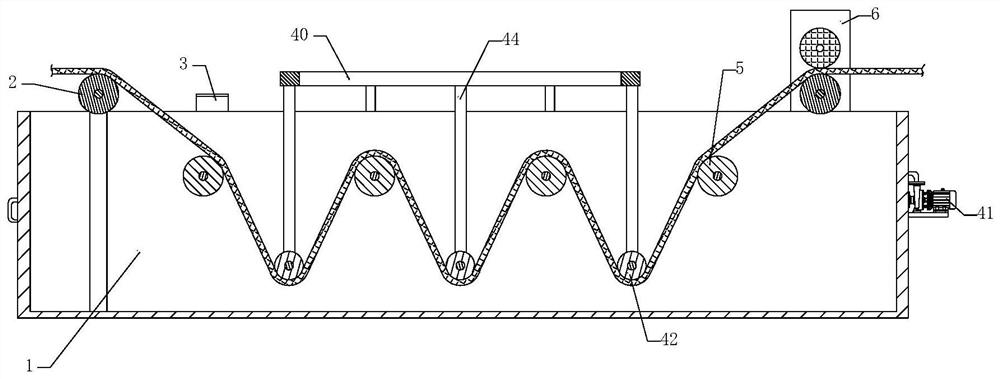

Bleaching device for textile bleaching

ActiveCN113106662AAvoid accumulationImprove bleaching effectTextile treatment machine arrangementsTextile treatment carriersEngineeringMechanical engineering

The invention relates to the technical field of textile bleaching, in particular to a bleaching device for textile bleaching. The device comprises an electric cylinder, a connecting frame, third guide rollers, a box body and second guide rollers. The electric cylinder drives the connecting frame to move upwards to drive the third guide rollers to move upwards until the third guide rollers move to the upper side of the box body, then textiles penetrate from the left end of the box body to the right end of the box body, then the third guide rollers are driven by the electric cylinder to move downwards to a proper position, and the textiles are arranged in an S shape through at least two third guide rollers and at least two second guide rollers, so that the textiles are placed layer by layer while enough textiles are placed in the box body, the textiles are prevented from being stacked, and the bleaching effect of the textiles is improved.

Owner:HANGZHOU XINSHENG PRINTING & DYEING

Textile shaping and sizing liquid supply device based on textile machine

InactiveCN109877008AReduce gravityEasy to adjustLiquid surface applicatorsCoatingsMeasuring instrumentElectromagnetic valve

The invention provides a textile shaping and sizing liquid supplying device based on a textile machine, and relates to the field of textile machinery. The textile shaping and sizing liquid supply device based on the textile machine comprises a base, wherein the upper surface of the base comprises a liquid storage mechanism, a liquid supply mechanism and a flow guide mechanism; the left side of theupper surface of the base is fixedly connected with a bottom of the liquid storage mechanism. According to the textile shaping and sizing liquid supply device based on the textile machine, the gravity of the storage tank is reduced, the distance between a reflecting plate and a infrared distance measuring instrument is increased under the action of a spring, after the infrared distance measuringinstrument detects that the distance is changed, an electromagnetic valve and a pump body are opened through a controller, the material is fed into the material storage tank, so that the sizing agentlevel in the material storage tank is always kept at a proper position, and the problem that the horizontal plane of the sizing agent in the material storage tank cannot be always kept at a proper position, when the liquid level is lower than the proper position, the sizing agent on a sizing roller is smaller, so that the quality of the manufactured fabric is poor is effectively solved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Anti-clogging textile bleaching and dyeing sewage treatment plant

PendingCN108558095AAvoid cloggingReduce breedingFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationFiberWastewater

The invention discloses an anti-clogging textile bleaching and dyeing sewage treatment plant, which comprises a main box, a sewage inlet pipe, a drainpipe, a second box, an ultraviolet germicidal lamp, a first filter screen plate, a second filter screen plate, a vertical baffle plate, a first silk thread grabbing device and a second silk thread grabbing device. Through the silk thread grabbing devices for grabbing silk threads and fibers in textile bleaching and dyeing sewage, silk threads and fibers are prevented from blocking the sewage treatment plant. by arranging the first filter screen plate, the second filter screen plate and a filter core inside the main box to filter the textile bleaching and dyeing sewage for three times, harmful substances in the textile bleaching and dyeing sewage can be effectively reduced. Through the arrangement of the ultraviolet germicidal lamp for sterilizing the textile bleaching and dyeing sewage, breeding of bacteria is reduced. In comparison withthe traditional technologies, the invention has the following beneficial effects: most water meets requirements of industrial reuse, discharge of wastewater can be reduced, resources are saved, and the environment is protected; and the anti-clogging textile bleaching and dyeing sewage treatment plant has advantages of low investment cost, low energy consumption, high treatment efficiency and the like.

Owner:海盐县于城漂染股份有限公司

A kind of reagent composition and textile bleaching method for textile bleaching

The invention relates to the field of textile processing, and discloses a reagent composition for bleaching textiles and a textile bleaching method. The reagent composition for bleaching textiles contains peroxide, activator, penetrant, stabilizer, pH buffer and water, wherein the activator contains the first guanidinium salt component. Based on the construction of a guanidinium salt activated hydrogen peroxide system, the invention realizes low-temperature, near-neutral high-efficiency bleaching of textiles. The process has the advantages of energy saving, low consumption, fabric protection, short process and easy operation. At the same time, it has a wide range of bleaching objects, and can realize low-temperature bleaching of cellulose fabrics, protein fabrics, and chemical fiber fabrics. At the same time, it can also provide a new bleaching method for those special fabrics with poor alkali resistance.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com