Diluting-proportioning device for cleaning oil stains on table of textile machine

A technology for textile machines and countertops, applied in cleaning methods and utensils, mixers with rotary stirring devices, mixers, etc., can solve the problems of long time, the ratio of water and cleaning agent cannot be well controlled, and the use is complicated. , to increase the water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

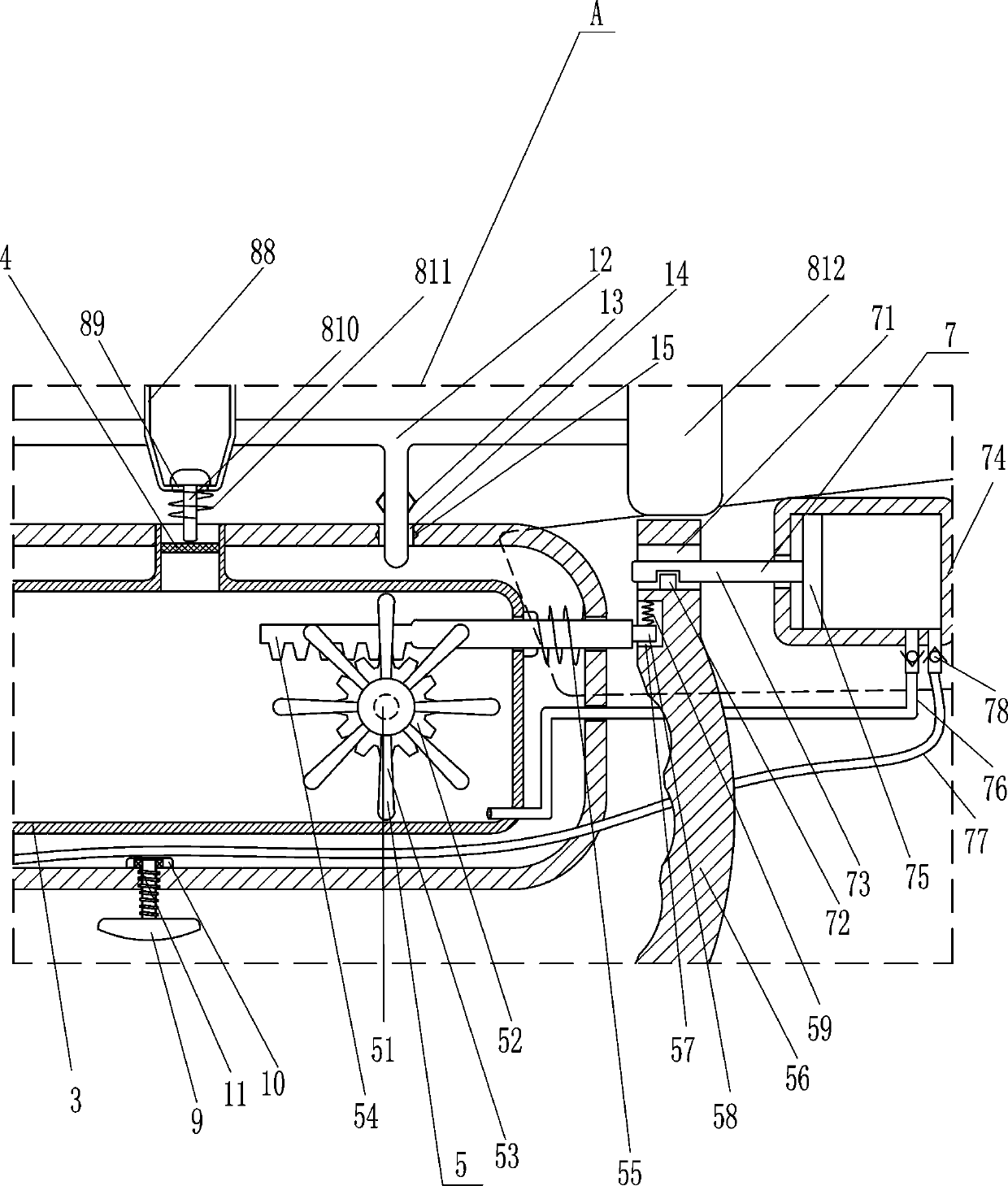

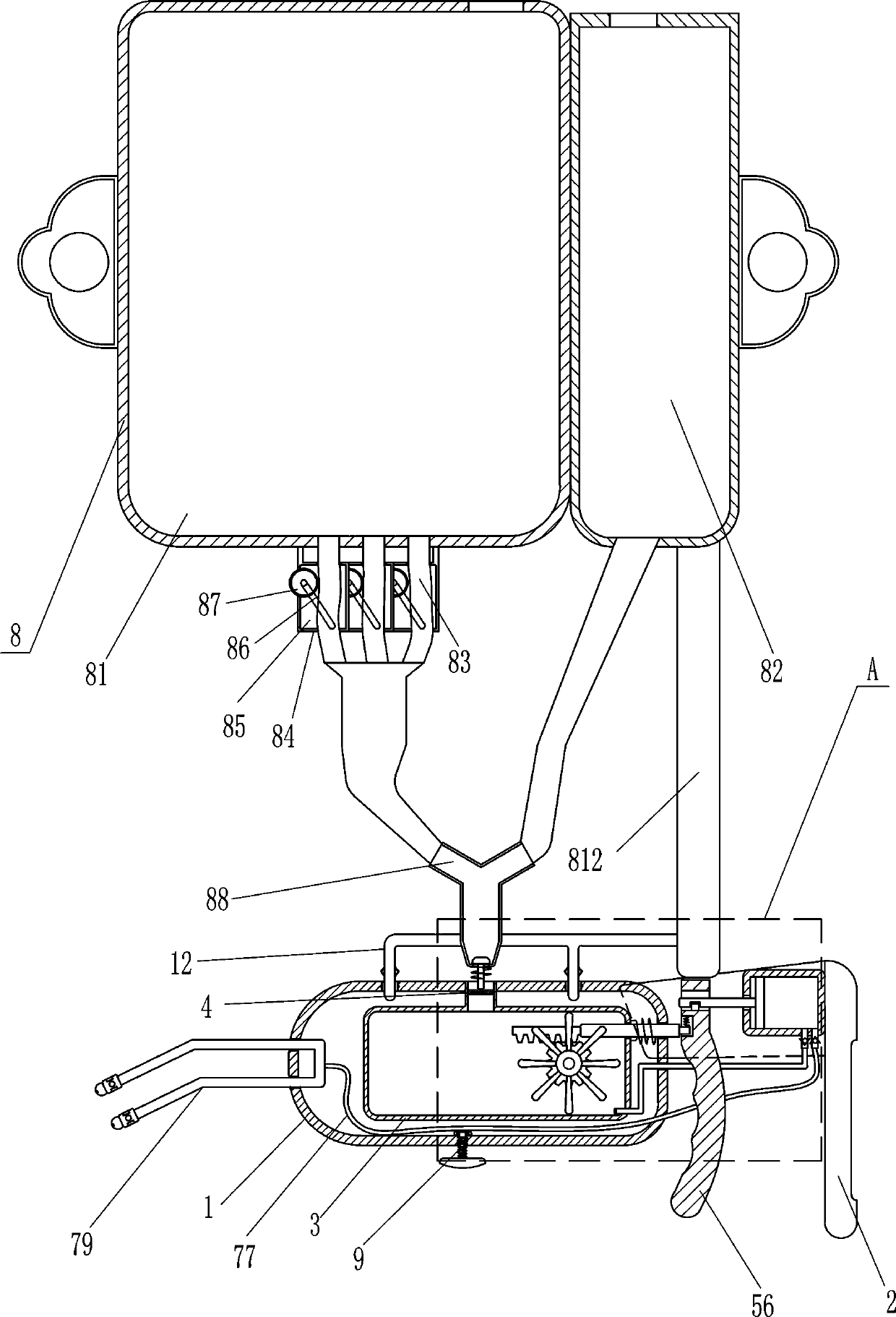

[0019] A dilution proportioning device for cleaning oil stains on textile machine table, such as Figure 1-2 As shown, it includes a housing 1, a handle 2, a frame body 3, a mesh plate 4, a stirring device 5 and a liquid outlet device 7, a handle 2 is installed on the outer right side of the housing 1, and a frame body 3 is arranged inside the housing 1. The liquid inlet at the top of the frame body 3 is in sealing connection with the housing 1, the liquid inlet port of the frame body 3 is provided with a mesh plate 4, and the frame body 3 is provided with a stirring device 5, and the right part of the stirring device 5 is located outside the housing 1. The left side of the handle 2 is provided with a liquid outlet device 7 .

[0020] Agitator 5 includes rotating shaft 51, gear 52, stirring disc 53, rack 54, first spring 55, handle 56, slide block 58 and second spring 59, and the rotating type in frame body 3 is provided with rotating shaft 51, rotating shaft 51 The rear side...

Embodiment 2

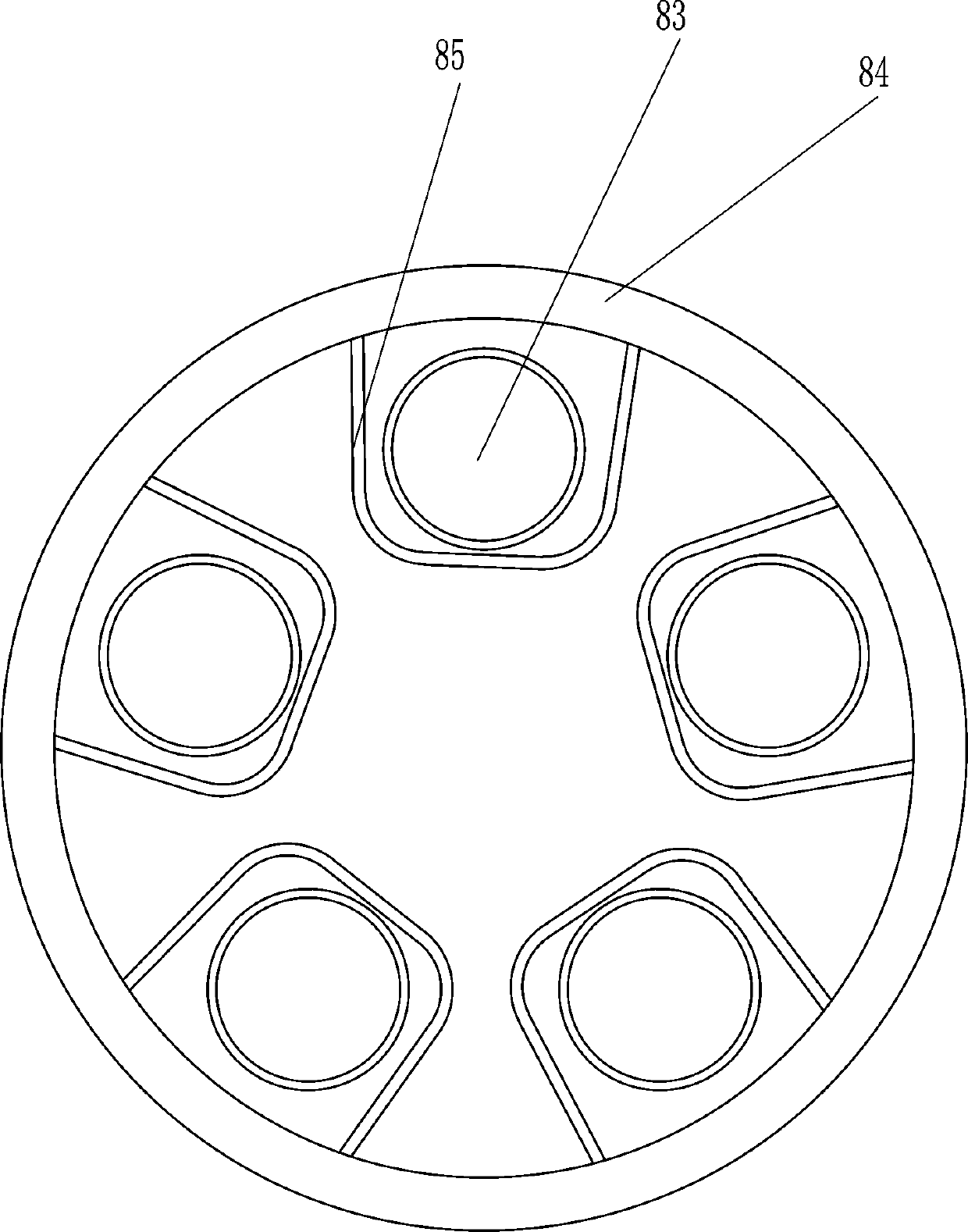

[0026] On the basis of Example 1, such as Figure 1-3As shown, a liquid inlet device 8 is also included, and the liquid inlet device 8 includes a first liquid storage tank 81, a second liquid storage tank 82, a liquid outlet hose 83, a cylinder 84, a square frame 85, a roller 87, a tee Pipe 88, T-shaped block 810, third spring 811 and baffle plate 812, the first liquid storage tank 81 and the second liquid storage tank 82 are all wall-hanged on the wall, and a cylinder 84 is installed at the bottom of the first liquid storage tank 81. Five square frames 85 are evenly distributed in the cylinder 84, and five liquid outlet hoses 83 are evenly installed on the bottom of the first liquid storage tank 81. The liquid outlet hoses 83 are located in the square frame 85, and there are second Chute 86, sliding type is provided with roller 87 in the second chute 86, and roller 87 cooperates with liquid hose 83, is provided with tee pipe 88 below the first liquid storage tank 81, and the ...

Embodiment 3

[0029] On the basis of Example 1, such as Figure 1-3 As shown, it also includes a bolt 9, a pressure block 10 and a bearing seat 11, a bolt 9 is screwed in the middle of the bottom of the housing 1, a pressure block 10 is arranged above the bolt 9, a bearing seat 11 is installed at the bottom of the pressure block 10, and the inside of the bearing seat 11 The bearing is connected with the top of bolt 9.

[0030] Also include F-shaped bar 12 and elastic sheet 13, F-shaped bar 12 is installed on the lower left side of baffle plate 812, elastic sheet 13 is installed on the left and right sides of the F-shaped bar 12 bottom, and the left and right sides of the top of the housing 1 are provided with the first Two through holes 14, the second through hole 14 cooperates with the F-shaped bar 12 bottom, the left and right sides in the second through hole 14 have grooves 15, the grooves 15 cooperate with the elastic sheet 13.

[0031] The working process of the present invention is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com