Reverse osmosis water purifier

A technology of reverse osmosis water purifier and reverse osmosis filter element, which is used in osmosis/dialysis water/sewage treatment, non-polluting water treatment, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

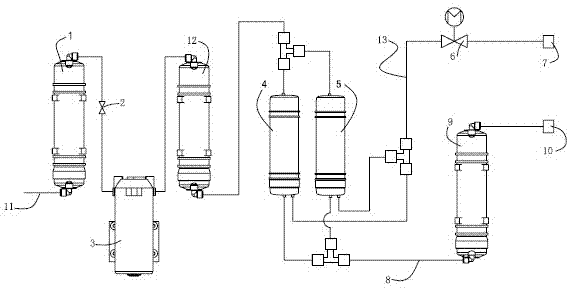

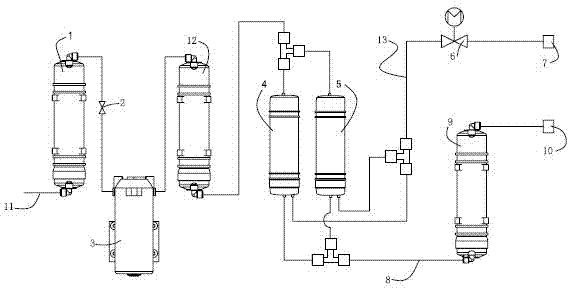

[0011] Such as figure 1 As shown, a reverse osmosis water purifier without a water storage tank includes first, second and third pretreatment filter elements 1, 9, 12, electronic liquid flow meter 2, booster pump 3, reverse osmosis filter element 4, 5. The tap water inlet 11 is sequentially connected to the first pretreatment filter element 1, the electronic liquid flow meter 2, the booster pump 3, the second pretreatment filter element 12, the reverse osmosis filter elements 4 and 5 connected in parallel, and the two reverse osmosis filter elements 4, The concentrated water branch 13 of 5 is connected in parallel to the concentrated water solenoid valve 6 and leads to the concentrated water outlet 7, and the filtered water branch 8 of the two reverse osmosis filter elements 4 and 5 is passed through after being filtered again by the third pretreatment filter element 9. To the pure water outlet 10 of the faucet.

[0012] The working process of the water purifier in the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com