Patents

Literature

113results about How to "No roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

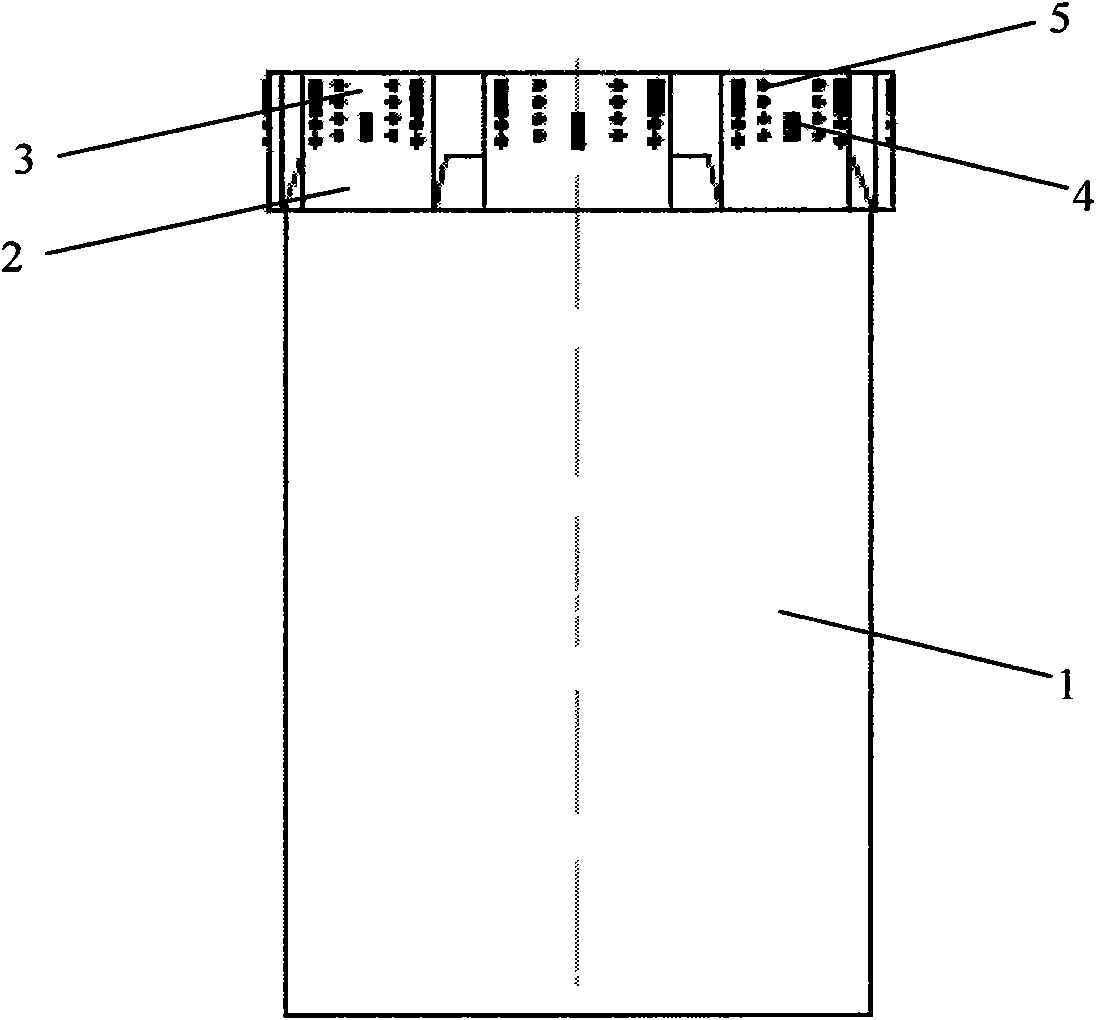

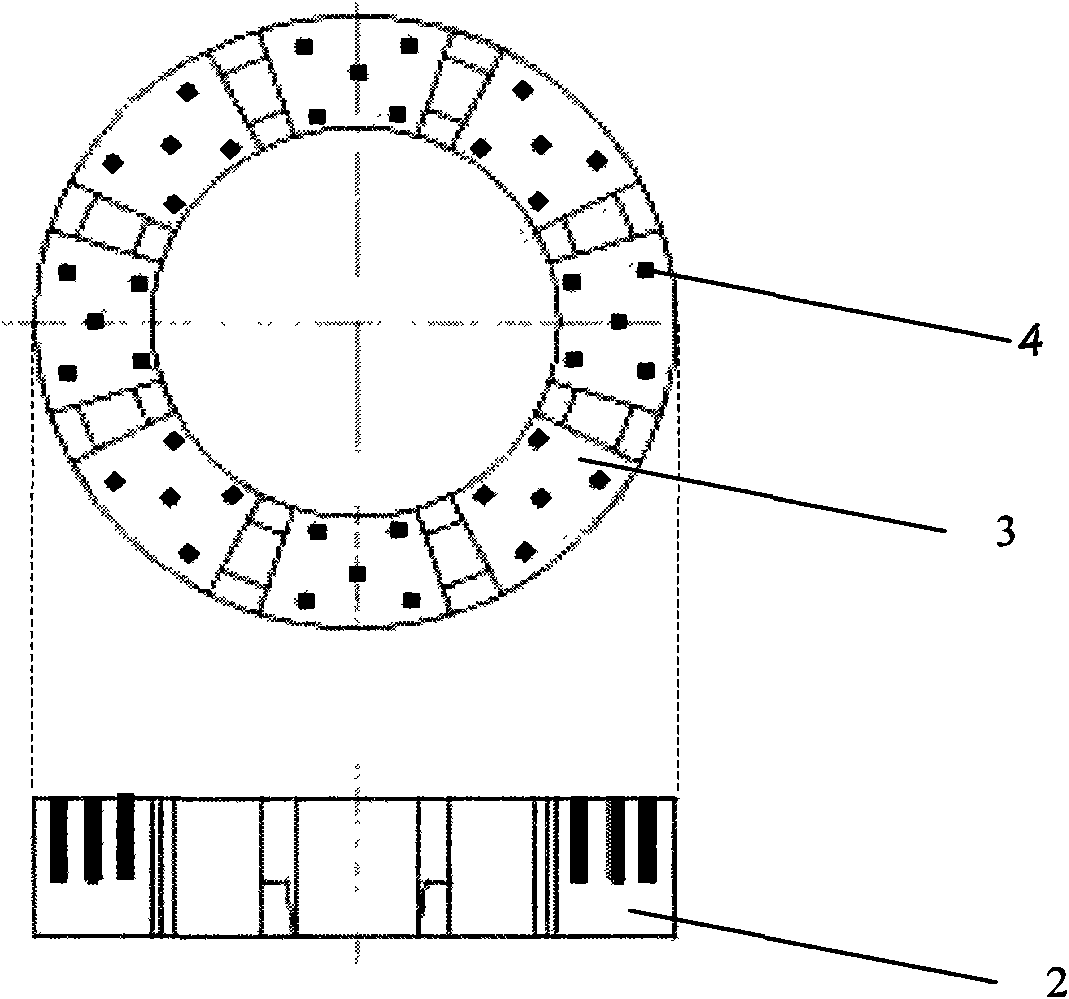

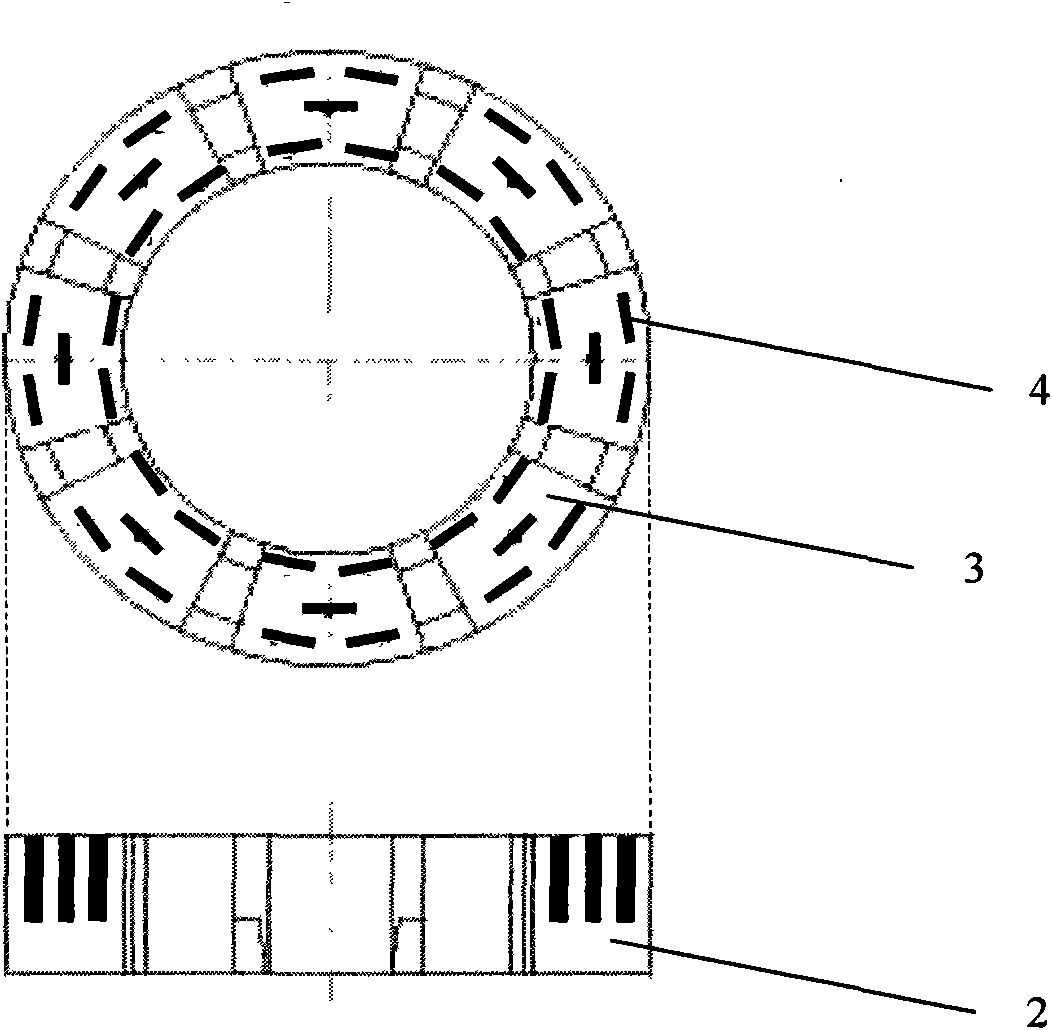

Drill bit impregnated with diamond film and manufacturing method thereof

InactiveCN101608533AExtended service lifeImprove work efficiencyDrill bitsChemical vapor deposition coatingChemical vapor depositionMachining

The invention relates to a drill bit impregnated with a diamond film and a manufacturing method thereof, belonging to the field of mechanical processing. The drill bit is formed by a steel body (1) and a working layer (2), wherein the working layer (2) comprises the chemical vapor phase deposition diamond film (4) and hard matrix material (3). The diamond film (4) is distributed in the working layer (2) according to the required form. Molding ways of the drill bit comprise one-step forming and mosaic block type two-step forming. The one-step forming relates to the sintering type hot-press diamond drill bit, and the mosaic block type two-step forming relates to the drill bit formed by firstly sintering impregnated diamond segments and then welding the sintering impregnated diamond segments on the milled steel body. The drill bit can enhance abrasive resistance, reduces cutting adhesion, ensures the roughness and effective exposure of the bottom surface of the drill bit, and has effective gauge protection, thus improving the cutting efficiency and prolonging the service life of the tool. Compared with the common diamond drill bit, the drill bit impregnated with the diamond film has the characteristics of long service life, high drilling efficiency, long working distance, low energy consumption, strong anti-sticking rock dust capacity, etc.

Owner:JILIN UNIV

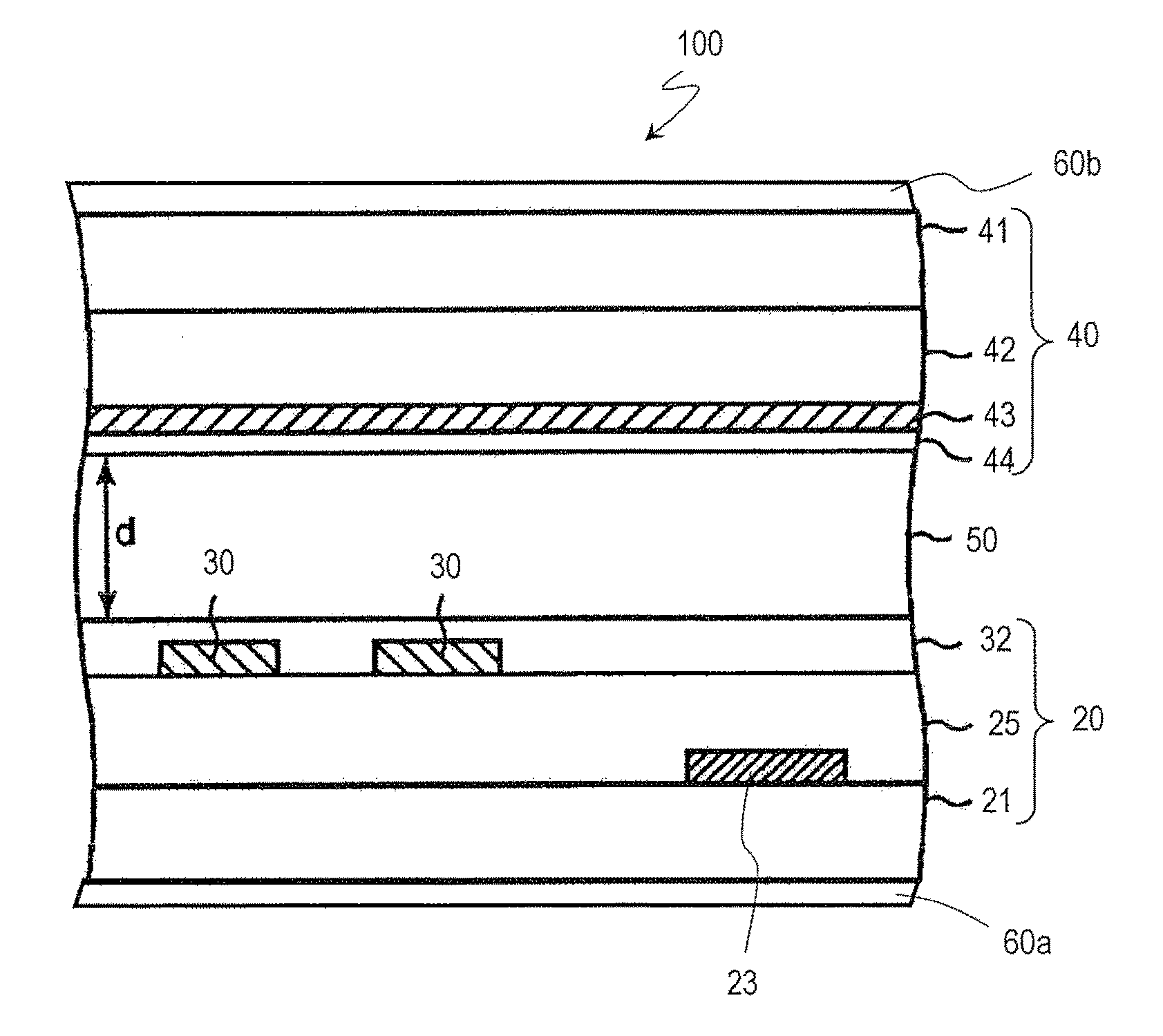

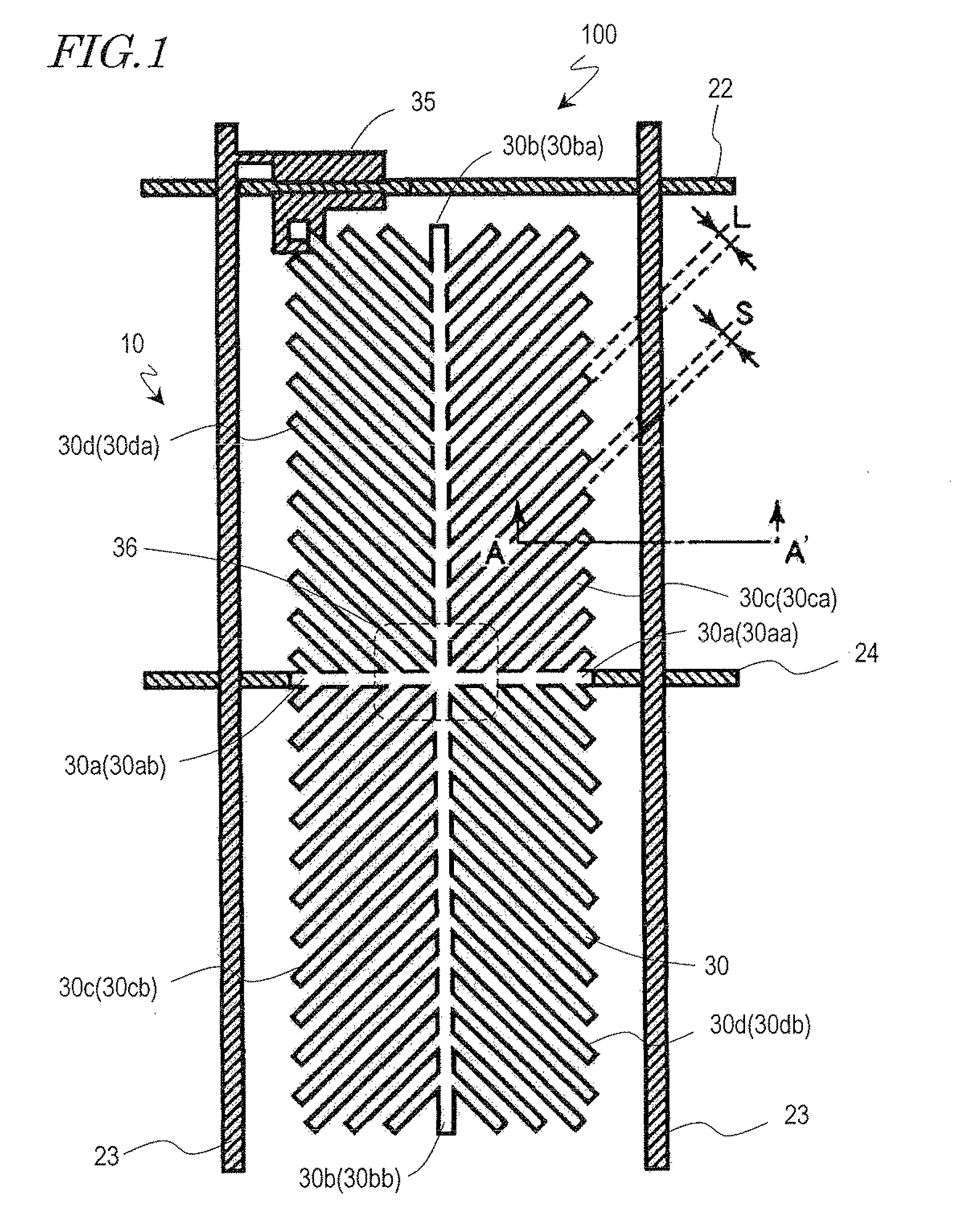

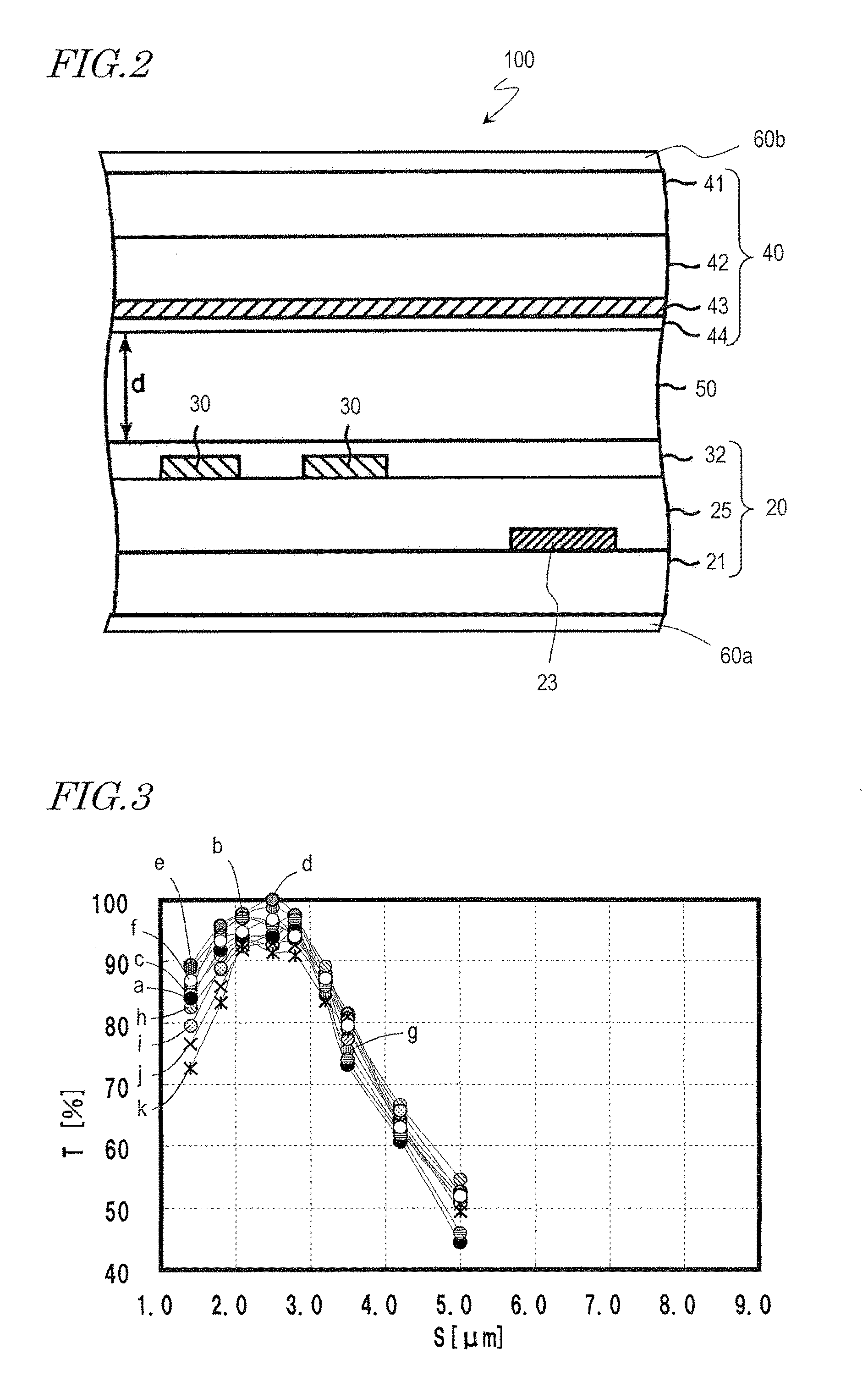

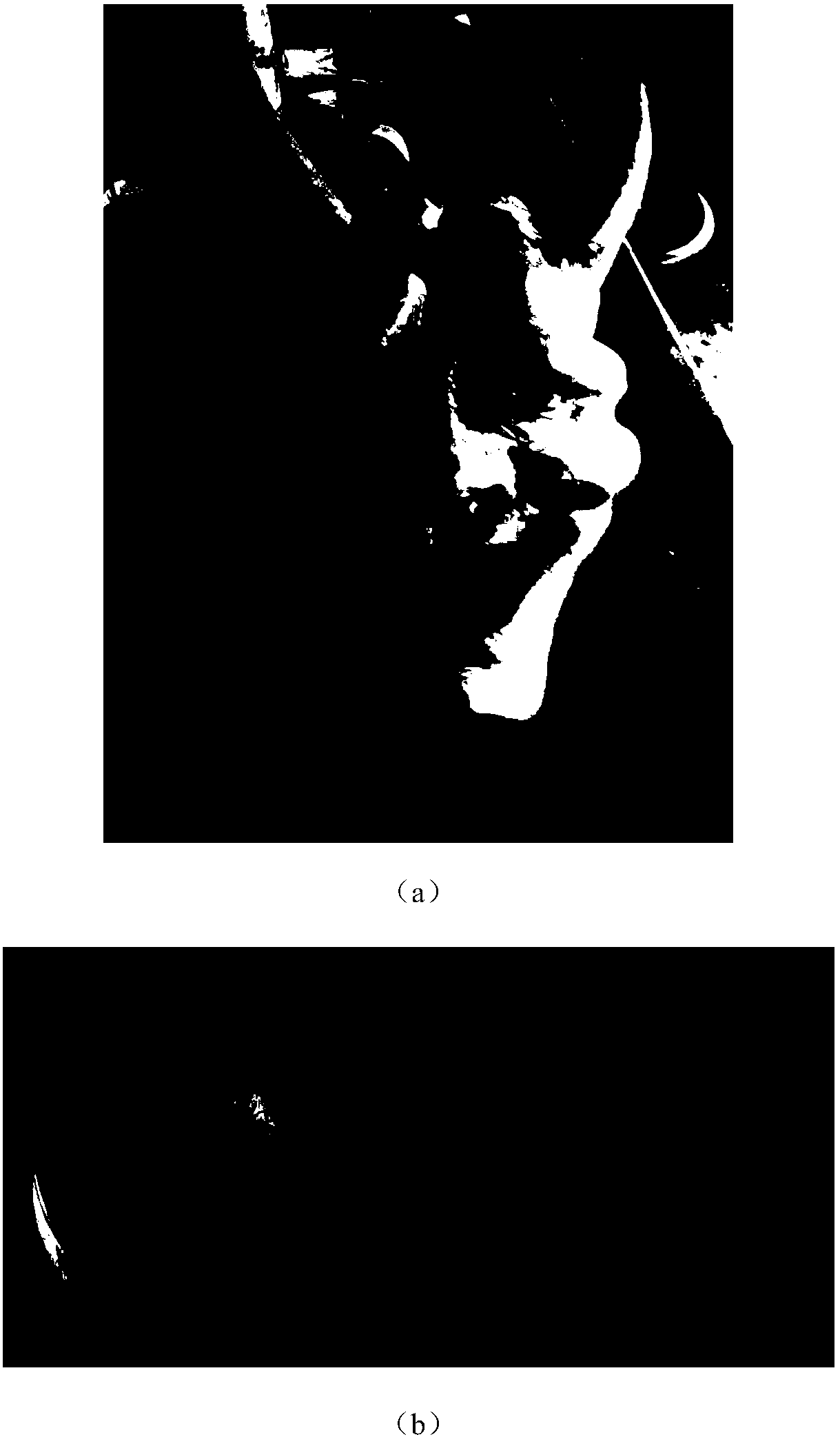

Liquid crystal display device

ActiveUS20100253897A1High quality displayAbnormal alignmentNon-linear opticsVertical alignmentEngineering

There is provided a liquid crystal display device of high picture quality with high brightness and small display unevenness.A vertical alignment type liquid crystal display device which has a plurality of pixels includes: a first electrode which includes, in each of the plurality of pixels, a plurality of first branch portions extending in a first direction and a plurality of second branch portions extending in a second direction that is different from the first direction; a second electrode disposed so as to oppose the first electrode; and a liquid crystal layer interposed between the first electrode and the second electrode, wherein a width of each of the plurality of first branch portions and the plurality of second branch portions is in a range not less than 1.4 μm and not more than 8.0 μm.

Owner:SHARP KK

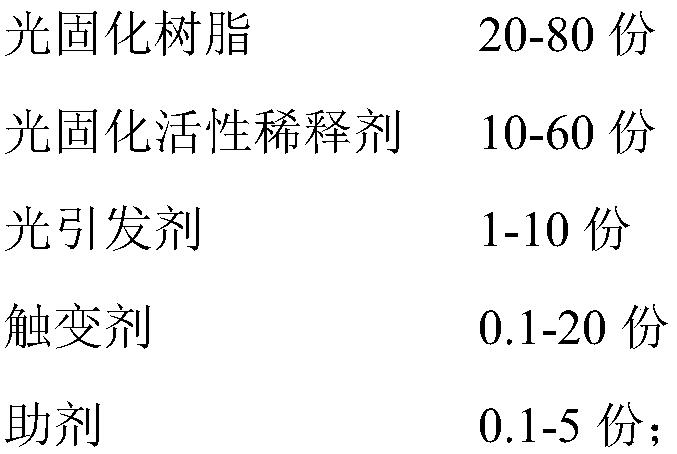

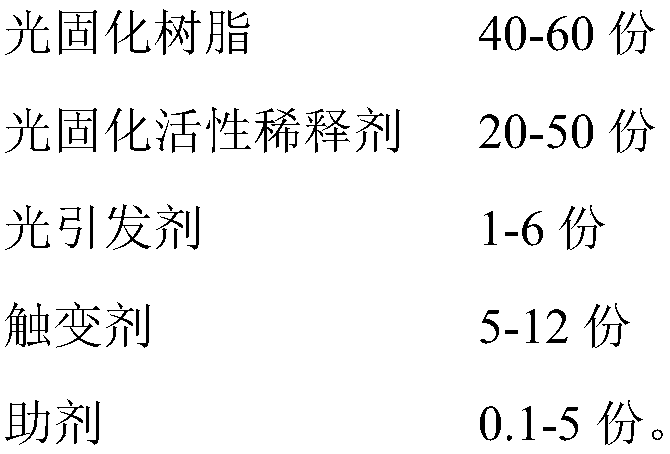

Photocurable 3D printing material as well as preparation method and application thereof

ActiveCN108410162AImprove thixotropyHigh forming precisionAdditive manufacturing apparatusSodium BentonitePolyamide

The invention relates to a photocurable 3D printing material as well as a preparation method and application thereof. The photocurable 3D printing material is prepared from the following raw materialcomponents in parts by weight: 20 to 80 parts of photocurable resin, 10 to 60 parts of photocurable active diluent, 1 to 10 parts of photo-initiator, 0.1 to 20 parts of thixotropic agent and 0.1 to 5parts of auxiliaries, wherein the thixotropic agent is at least one of attapulgite, montmorillonite, bentonite, fumed silica, polyamide wax and mica powder; the photocurable resin is at least one of aliphatic polyurethane and aliphatic epoxy resin. The photocurable 3D printing material has high thixotropy, and can be applied to the nozzle printing process of FDM (Fused Deposition Modeling). Compared with an SLA (Stereolithigraphy Apparatus), the photocurable 3D printing material has the advantages that the production cost of 3D printing products can be lowered effectively, high molding speed and high precision are achieved, complex-contour or large-sized 3D printing products can be made.

Owner:广州有得新材料科技有限公司

Sweet potato residue cookie and production method thereof

The invention relates to a sweet potato residue cookie and a production method thereof and belongs to the technical field of food processing. Sweet potato residue cookie is utilized comprehensively, and the sweet potato residue cookie is made from main raw materials of the sweet potato residue and self-raising wheat flour, auxiliary materials of cream, eggs and xylitol, and additives of baking powder, fresh milk flavor powder, nano-calcium, polylysine and the like. Curing, modification and drying of the sweet potato residue are completed integrally, the technology is simple, rapid and energy saving, and nutritional ingredients of the sweet potato residue are preserved to the utmost degree; the sweet potato residue cookie high in fiber and calcium and free of sucrose, thereby being suitable for middle-aged and aged people and diabetic patients to eat.

Owner:杭州诺丁食品有限公司

Preparation method of rice bran dietary fiber

InactiveCN101785831AWide variety of sourcesReduce manufacturing costMetabolism disorderDigestive systemAmylaseFiber

The invention relates to a preparation method of rice bran dietary fiber, which comprises the following steps that: (1) rice bran is crushed, passes through a screen which is more than or equal to 30mesh, is added with water to be stirred uniformly, and stays still for 30 to 50min; (2) the prepared water-absorbing swelling rice bran material is added with dilute hydrochloric acid, the pH value is adjusted to be 4.5 to 5.5, and then 1.0 to 1.5 percent of hot temperature resistant amylase is added to be heated to 85 to 100DEG C, and the temperature is maintained for 30 to 40min; (3) dilute sodium hydroxide or potassium hydroxide solution is added, the pH value is adjusted to be 7.5 to 8.5, 1.0 to 1.5 percent of protease with the enzyme activity more than or equal to 500U / g to be heated to 45 to 55 DEG C, and the temperature is maintained for 60 to 90min; (4) the intermediate product is pressed, filtered and washed by water; (5) diluted phosphoric acid is added in to adjust the pH value to be 5.0 to 5.5, 0.1 to 0.2 percent of cellulose is added in to be heated to 45 to 55DEG C, and the temperature is maintained for 50 to 70min; (6) 2 to 5 percent of hydrogen peroxide is added into a sealed container to be stirred for 20 to 30min; and (7) and the product is dried and crushed. The dietary fiber prepared by the invention has delicate taste without roughness, and can serve as the additive in medicine, health food, bread, biscuits, drinks and the like.

Owner:邯郸市嘉瑞生物科技有限公司

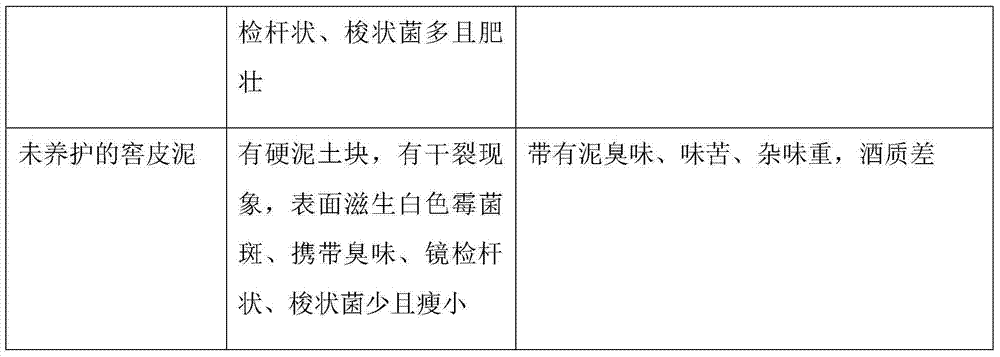

Preparation method of pit mud for esterifying enzyme compound bacterium liquid

The invention discloses a preparation method of pit mud for esterifying enzyme compound bacterium liquid, and the preparation method relates to the technical field of spirits. The preparation method comprises the steps of preparing various tools and containers, cleaning an operation field, preparing 6m<3> loess, mixing 24kg KH2PO4, 0.75kg MgSO4, 487kg soybean cake powder, 172kg alcohol, 500kg feint, 150kg fresh pig bone powder, 20kg silkworm chrysalis, 750kg vinasse, 200kg yellow water compound liquid, 350kg esterifying enzyme bacterium liquid, 0.5kg aroma-producing yeast, 100kg red rice, 660kg hard-liquor producing yeast power and 1000kg pure water, and conducting fermenting management. The cultured mature pit mud is fluorescent in the sun, and moist, delicate and smooth in feeling; when a person rubs the pit mud, the person does not feel harsh; the pit mud is rich in aroma without odor or foreign smells when the person smells the pit mud; and multiple bacilli and clostridia are available, and stout and strong through microscopy.

Owner:安徽省金裕皖酒业有限公司

Method for producing grape skin health-care beverage

ActiveCN102138687AIncrease the juice yieldEfficient degradationFood preparationFilter materialEnzyme

The invention relates to a method for producing grape skin health-care beverage and belongs to the technical field of beverage processing. The method comprises the following steps of: selecting and cleaning fresh grape skin serving as a raw material; adding 0.02 percent of isoVc sodium and 0.15 percent of citric acid to protect color; crushing and pulping the grape skin to prepare grape skin pulp; promoting composite enzymolysis ultrasonically; filtering by using a filtering material with 100 to 350 meshes or performing centrifugal separation at 3,000 to 5,000 r / min; mixing; performing vacuumdegassing under vacuum degree of 0.09 MPa for 20 to 25 minutes; homogenizing under 30 to 40 MPa; after performing encapsulation, performing sterilization at the temperature of between 135 and 150 DEGC for 35 to 60 seconds; cooling; performing labeling; spraying codes; and preparing the finished product after the product is inspected to be qualified. In the method, the enzymolysis reaction time is shortened by 50 percent and the enzyme adding amount is reduced by 20 percent, so that enzymolysis efficiency is improved and production cost is reduced. The processed health-care beverage has rich nutrients and good quality and is suitable for people of all ages to drink. The quality guarantee period of the beverage is more than 12 months. By the method, the grape skin is utilized at high value; waste is changed into treasure; and obvious economic, social and ecological benefits are achieved.

Owner:内蒙古云飞酒业有限公司

Antistatic cotton-polyester blend clothing material

InactiveCN1811034AHigh cotton contentImprove breathabilityOther chemical processesWoven fabricsPolyesterFiber

The antistatic cotton-polyester blend clothing material contains cotton of 21*21 count in 50-70 wt%, chemical fiber of 127*66 or 45 / 2*21 count in 29-49 wt% and conducting fiber of 130*66 count in 1 wt%. It has high cotton content and embedded conducting fiber resulting in excellent antistatic effect, high permeability from proper cotton / polyester ratio, certain brightness, high stiffness, high color fastness and fire retarding function, and can meet the requirement of antistatic clothing for workers in petrochemical and other industry.

Owner:YI HE STOCK

Nonslip tile and production method thereof

The invention discloses a nonslip tile. The nonslip tile comprises a body layer, a decorating glaze layer and a dry-particle transparent glaze mixed layer, wherein the glazing amount of the transparent glaze layer is 160+ / -5 g / m<2>. By applying transparent glaze to the dry particles in the ceramic tile having a nonslip function, the transparent glaze wraps the dry particles in a half manner to form the dry-particle transparent glaze mixed layer, surface staining of the nonslip tile is effectively avoided, and the nonslip tile has good antifouling property and has good nonslip performance.

Owner:FOSHAN OCEANO CERAMICS

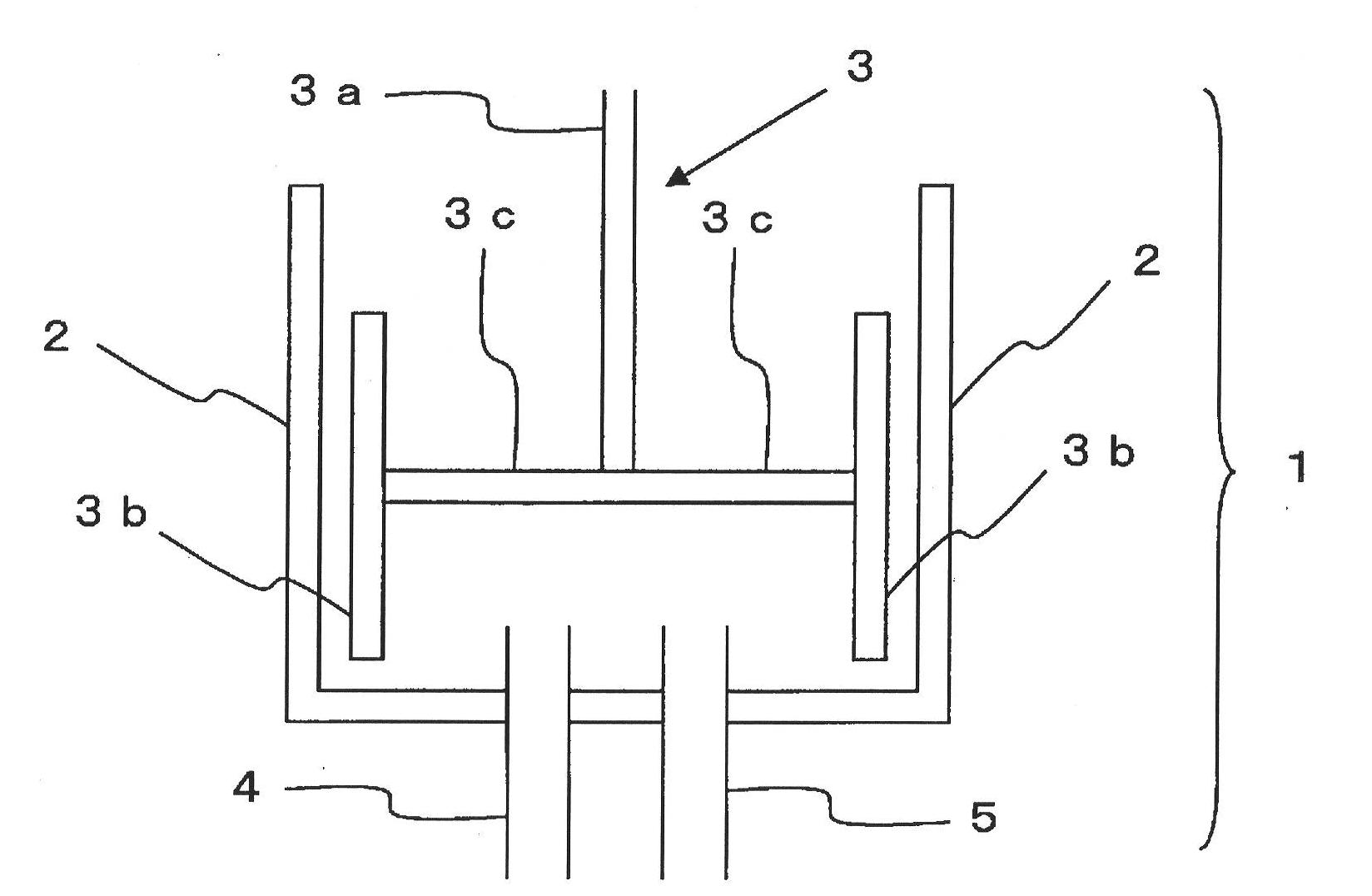

Method of denaturing whey protein

Owner:MORINAGA MILK IND CO LTD

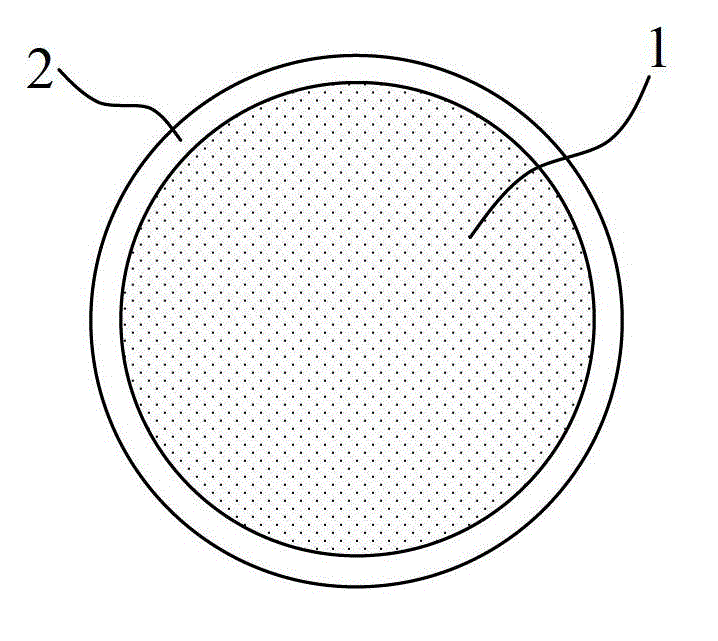

Polyvinyl chloride insulating layer for automotive electric wire

ActiveCN103059459AImprove heat resistanceReduce dosagePlastic/resin/waxes insulatorsPolymer chemistryTerephthalic acid

The invention discloses a polyvinyl chloride insulating layer for an automotive electric wire. The polyvinyl chloride insulating layer 2 is wrapped on the outer surface of a cable core 1, and the polyvinyl chloride insulating layer 2 is obtained by processing the following components in part by weight: 100 parts of polyvinyl chloride resin, 24 to 26 parts of trioctyl trimellitate, 10 to 12 parts of fine dioctyl terephthalate, 4.5 to 5.5 parts of epoxy soybean oil, 18 to 20 parts of calcium carbonate, 6.5 to 7.5 parts of calcium-zinc composite stabilizer (105 DEG C), 1 to 1.5 parts of high-melting polyethylene wax, 0.14 to 0.16 part of phenolic antioxidant, 0.5 to 2 parts of acrylate resin, 2.8 to 3.2 parts of barium sulfate, and 1.4 to 1.6 parts of silicone powder, wherein the melting point of the high-melting polyethylene wax is more than 105 DEG C. The polyvinyl chloride insulating layer can effectively reduce the odor, meanwhile, has excellent abrasion resistance and heat resistance, and keeps good surface and mechanical performance at a high processing speed.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

Whole-wheat bread and production method thereof

The invention provides whole-wheat bread and a production method thereof. The bread is made of whole wheat flour, amaranth seed flour is further added in the whole wheat flour, salt, cane sugar, egg liquid, yeast, milk powder, vital gluten, glutaminase, cream and water are added in the processing process, and the whole-wheat bread containing amaranth seeds is prepared through the steps of stirring, fermentation, standing, fermenting, baking and the like. According to the whole-wheat bread and the production method, a specially-made process is utilized to enable the amaranth seeds and the whole-wheat bread to be perfectly mixed, the prepared bread is soft in taste, roughness-free and fluffy appropriately, and is good breakfast integrating taste and nutrition.

Owner:ANHUI YANZHIFANG FOOD

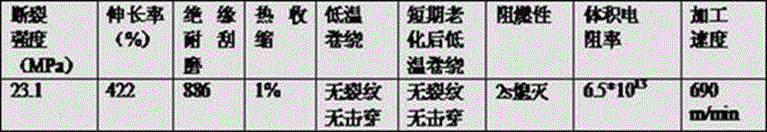

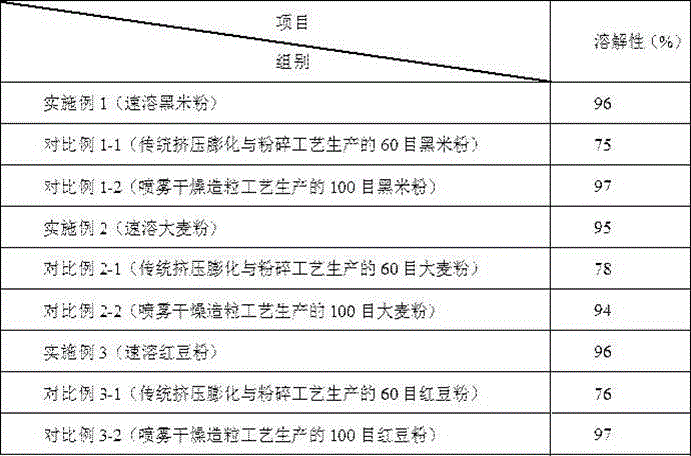

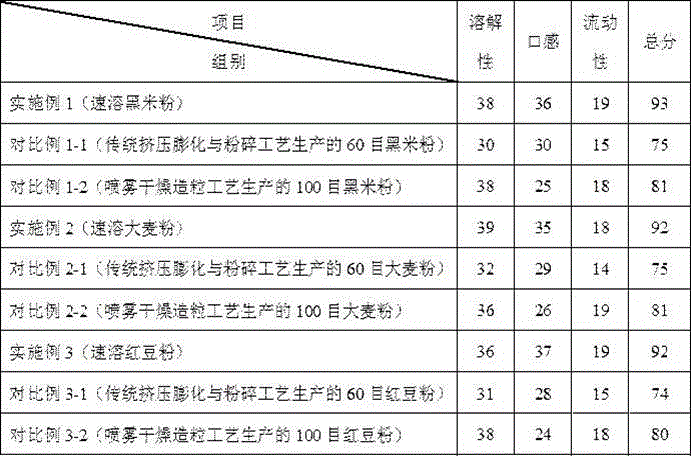

Production method of instant whole grain flour

InactiveCN105661328APreserve the whole component nutritionNo roughnessFood scienceWater contentBrewing

The invention discloses a production method of instant whole grain flour, comprising: micronizing whole grains, acquiring expanded particles by an extrusion and expansion process, drying at low temperature so that water content is controlled less than 8%, and finally acquiring the instant whole grain flour via cutting and granulating.The processing technique of the invention is simple, energy efficient and environmentally friendly, and a product retains all component nutrients of grains, is free of roughness from grain skin, can disperse fast in water, has good brewing performance and is a good instant meal-replacing food.

Owner:BEIJING SHUOFANG SCI & TECH DEV CO LTD

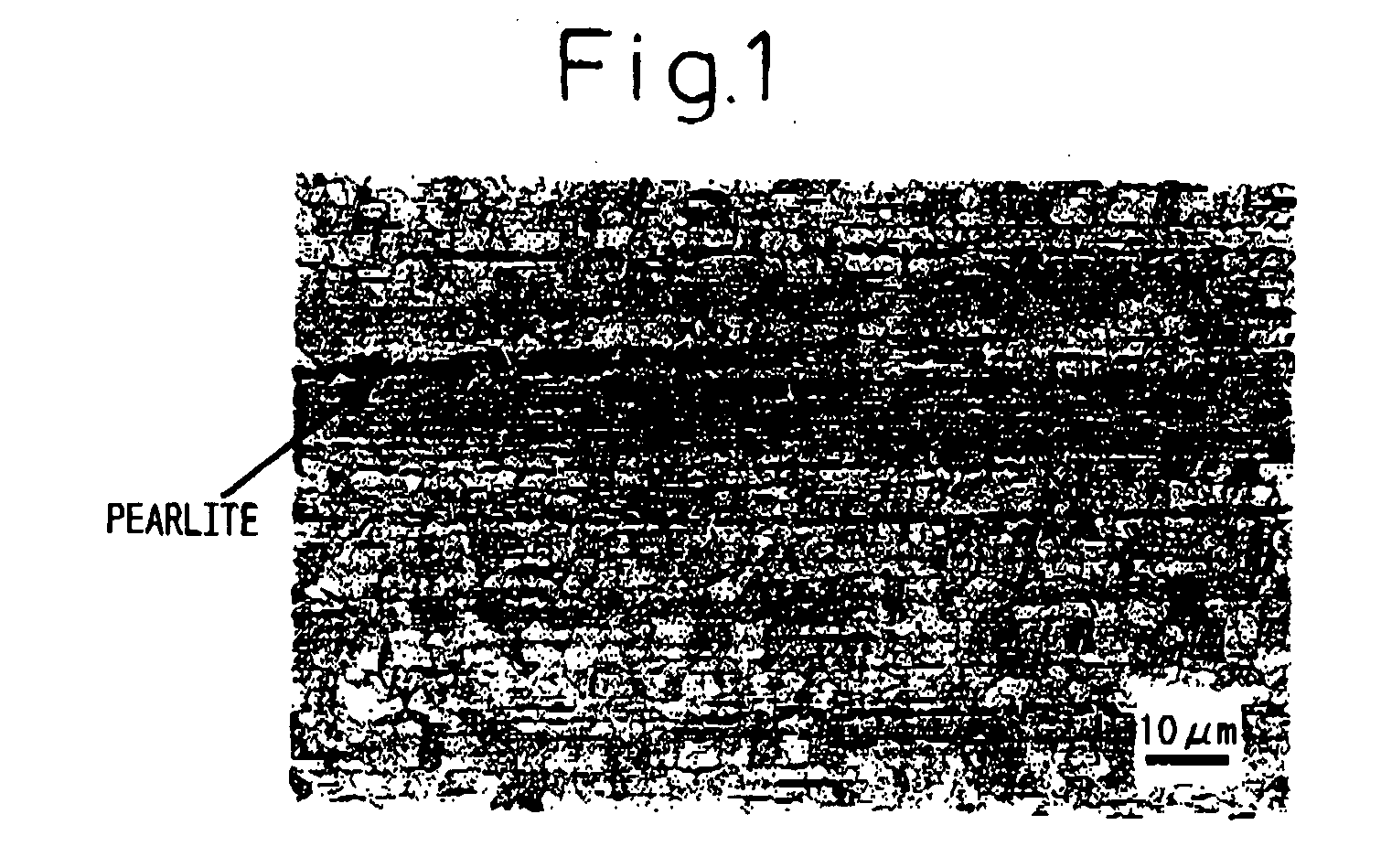

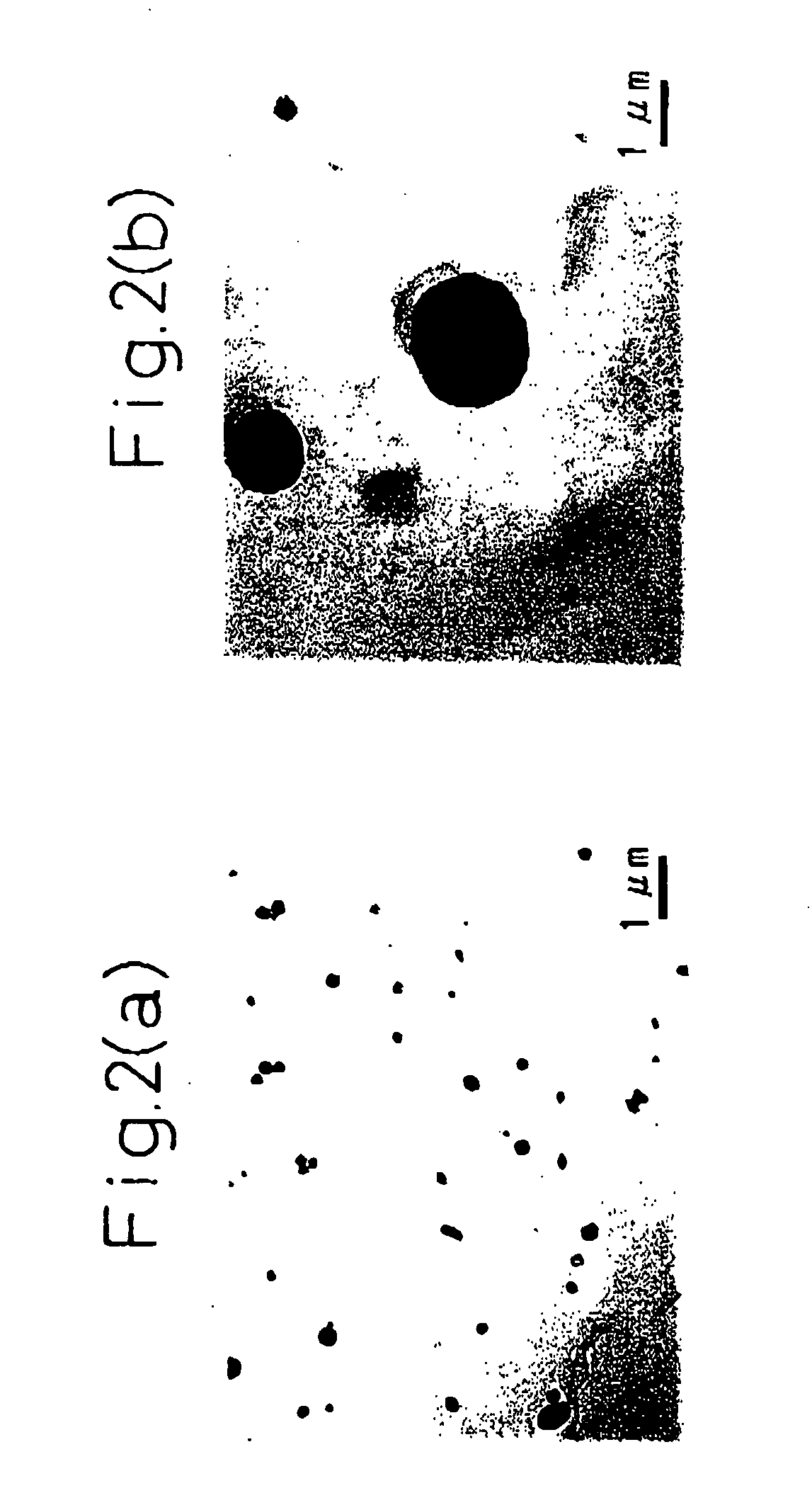

Steel superior in machinability and method of production of same

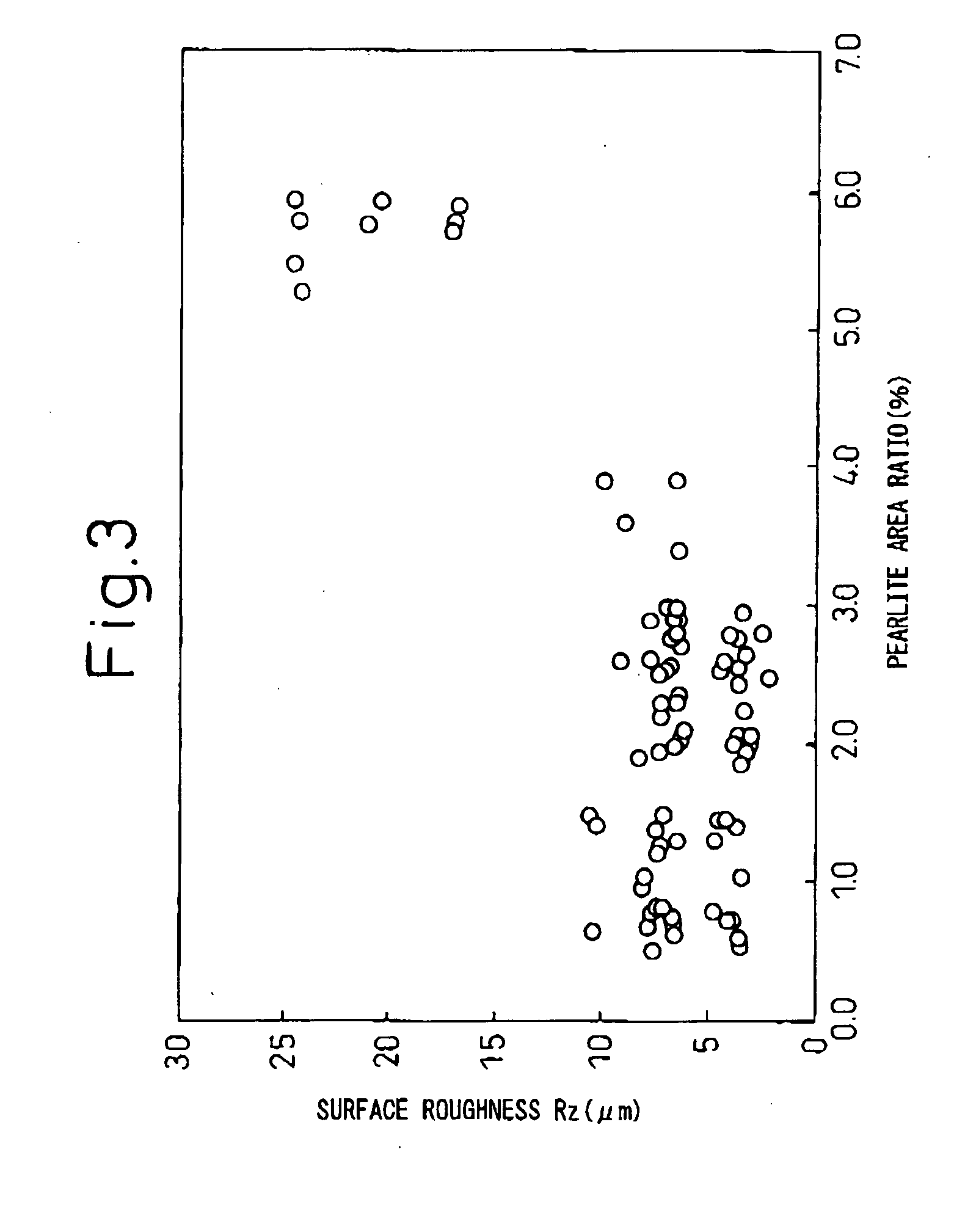

The present invention provides steel superior in machinability comprised of, by wt %, C: 0.005 to 0.2%, Si: 0.001 to 0.5%, Mn: 0.2 to 3.0%, P: 0.001 to 0.2%, S: 0.03 to 1.0%, T.N: 0.002 to 0.02%, T.O: 0.0005 to 0.035%, and the balance of Fe and unavoidable impurities, said steel satisfying one or both of Mn / S in the steel being 1.2 to 2.8 or an area ratio of pearlite over a grain size of 1 μm in a microstructure of the steel being not more than 5%.

Owner:NIPPON STEEL CORP

Seasoning powder for scented barbecue

The invention discloses seasoning powder for scented barbecue, which belongs to the field of food processing and mainly comprises 3.7 parts of meat tenderizer, 6.8 parts of hot pepper powder, 2.2 parts of Sichuan pepper powder, 1.8 parts of fresh ginger powder, 3.2 parts of star anise, 8.2 parts of perilla seed powder, 2 parts of clove powder, 2.8 parts of fennel powder, 3.7 parts of curry powder, 2.5 parts of cumin powder, 3.3 parts of peanut kernel powder, 2.4 parts of cinnamon, 2.8 parts of amomum powder, 6.5 parts of chicken essence, and 2.7 parts of refined salt. The chicken essence and the refined salt are added into the raw materials placed in a dry container to mix well. Meat can be pickled with the seasoning powder for 15 minutes before barbecuing, and the seasoning powder can also be added during barbecuing. The seasoning powder has the advantages that the seasoning powder is fine, the meat barbecued with the seasoning powder is smooth to eat and tastes no rough, the seasoning powder with a plurality of nutrients is hygienic, and the seasoning powder with herbal ingredients is health-care, fresh, scented and delicious and has a long aftertaste.

Owner:韩雪

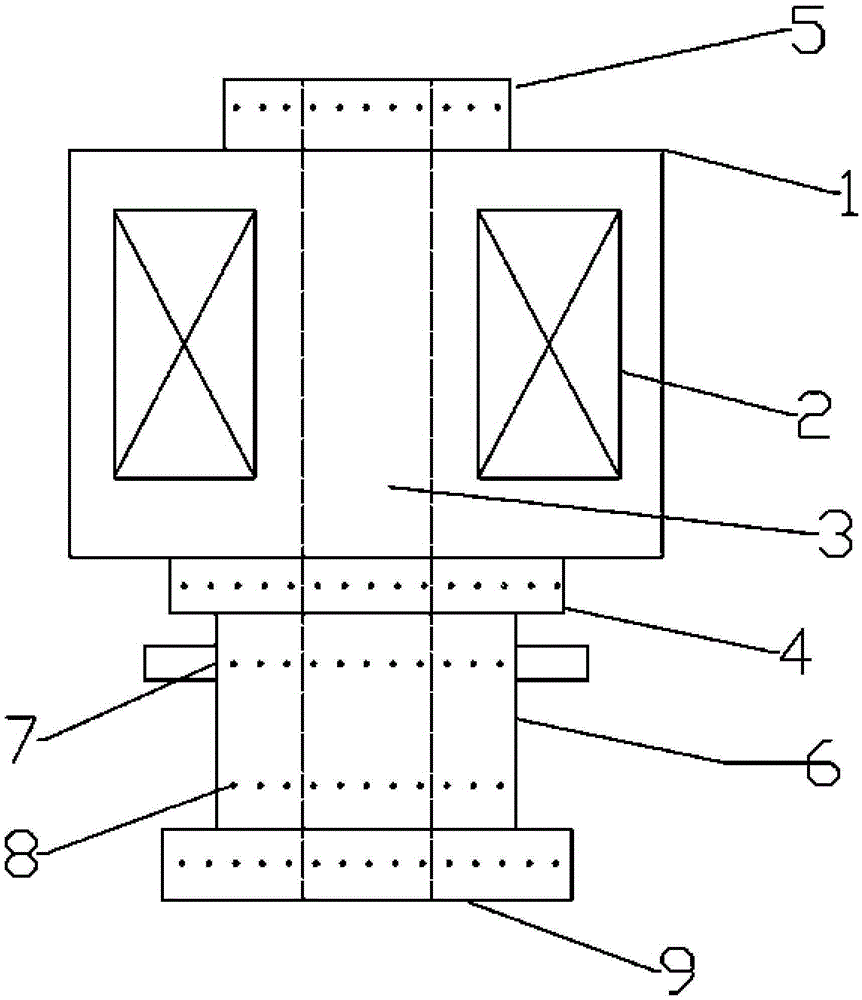

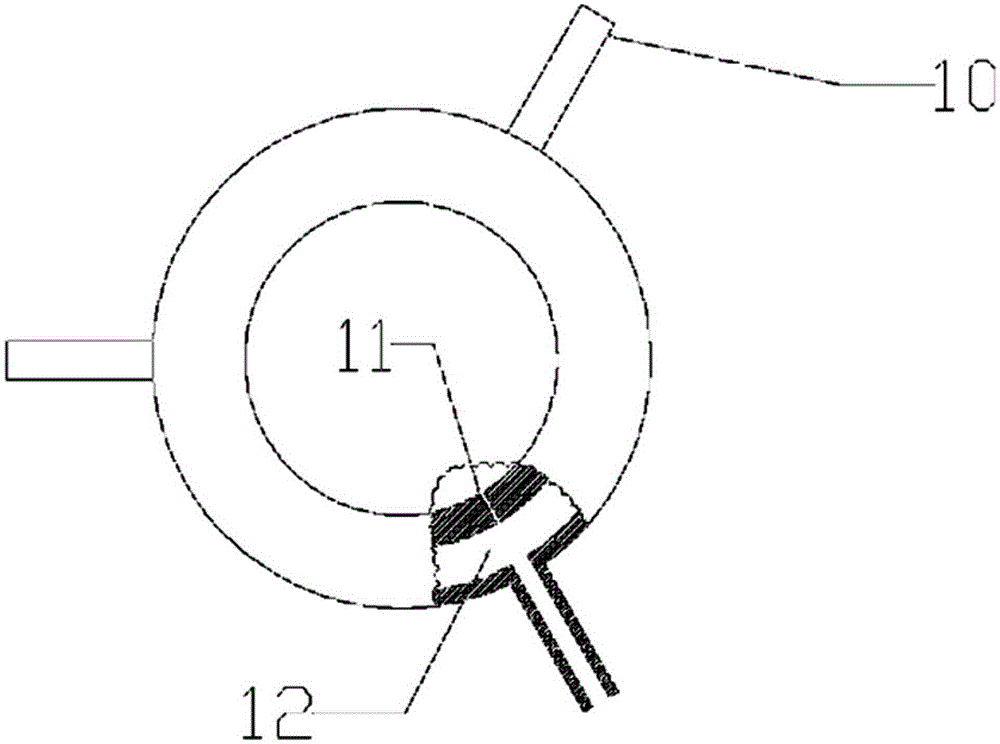

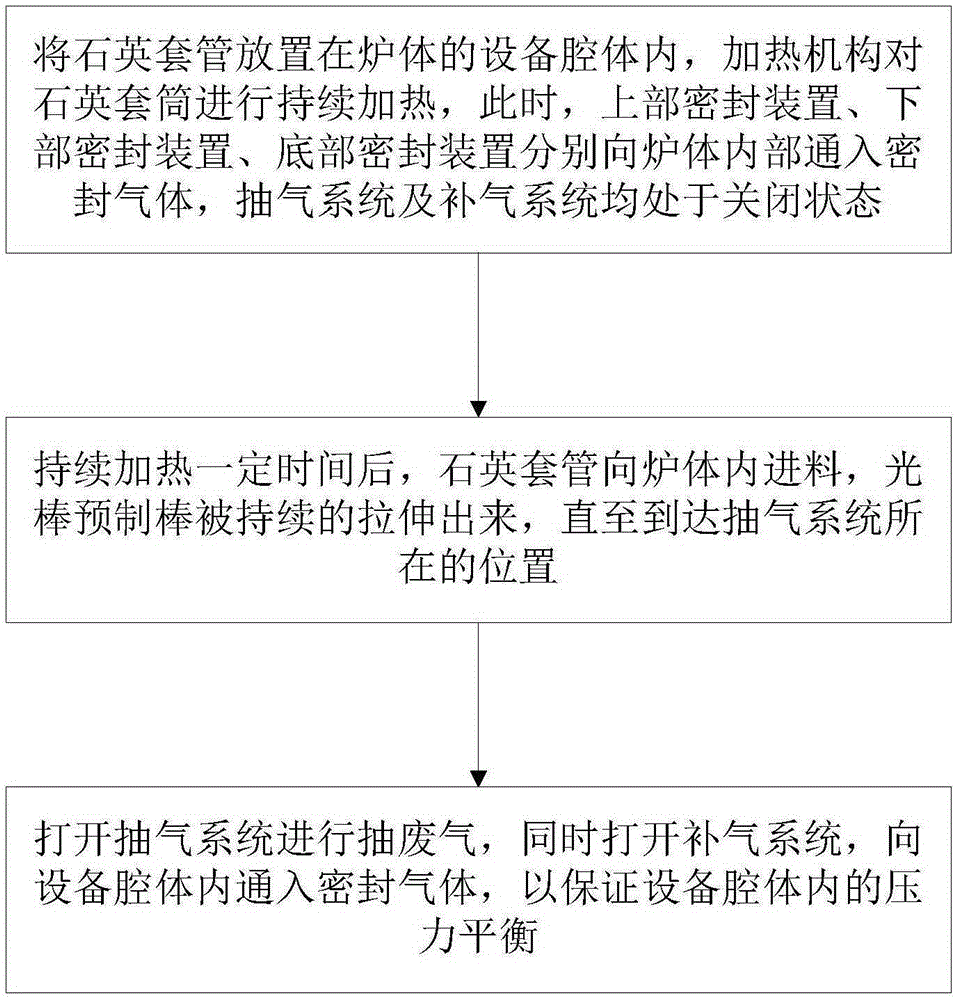

Large-sized optical fiber preform stretching furnace and use method thereof

The invention discloses a large-sized optical fiber preform stretching furnace and a use method thereof. The large-sized optical fiber preform stretching furnace comprises an upper sealing device, a furnace body, and a lower sealing device, an internal air purifying system and a bottom sealing device which are arranged in sequence below the furnace body, wherein a cavity and a heating mechanism are arranged inside the furnace body; an equipment cavity is communicated with hollow parts of the lower sealing device, the internal air purifying system and the bottom sealing device; and the lower sealing device and the bottom sealing device are provided with ventilation holes for introducing sealing gas. Through the arrangement of the bottom sealing device, extended, so that production of large-sized optical fiber preforms can be realized. Moreover, air extraction and air supplement operations can be performed, so that an environment inside the furnace is purified, the service life of a graphite part is prolonged, and the surface quality of the optical fiber preforms is improved. Through use of the graphite part, the service life of the stretching furnace is prolonged by 40 percent compared with an original stretching furnace, the surfaces of the produced optical fiber preforms are in good conditions, and abnormities such as coarseness and surface impurities do not appear.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

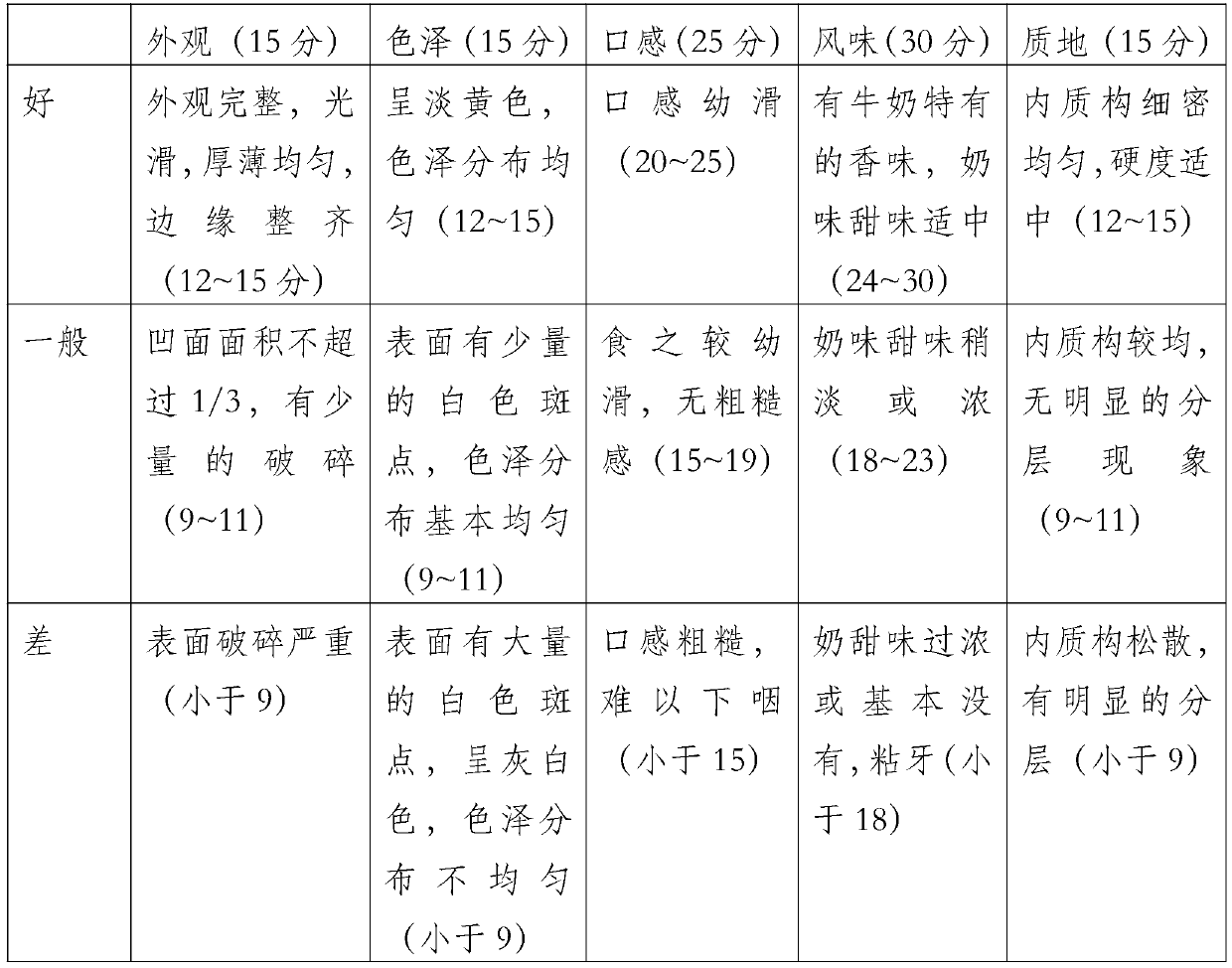

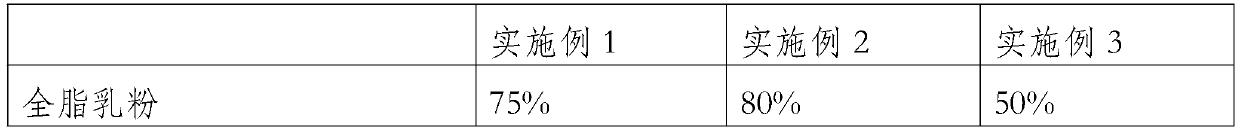

Nutritious chewable milk tablet added with DHA algae oil microcapsule powder and preparation method of nutritious chewable milk tablet

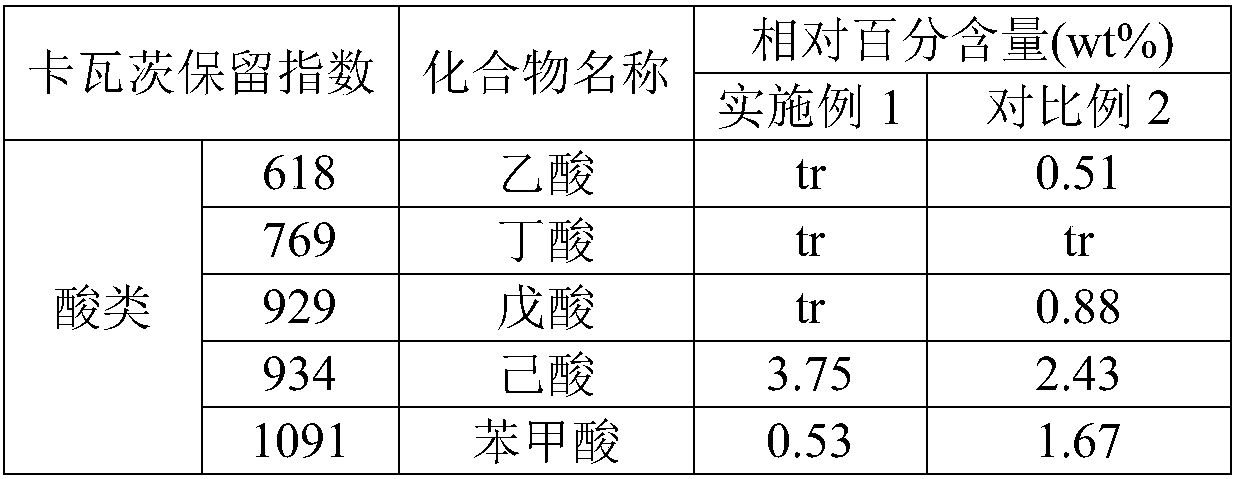

PendingCN110074191AFull of nutritionComplete shapeMilk preparationChemistrySodium carboxymethylcellulose

The invention discloses a nutritious chewable milk tablet added with DHA algae oil microcapsule powder and a preparation method of the nutritious chewable milk table. The nutritious chewable milk tablet is prepared from the following materials by mass percent: 50-80% of whole milk powder, 8-12% of edible glucose, 6-9% of maltitol, 4-10% of the DHA algae oil microcapsule powder, 1-2% of hawthorn powder, 1-2% of sea buckthorn powder, 0.4-1.2% of zinc gluconate, 4-6% of taurine, 0.1-0.5% of magnesium stearate, 0.2-0.4% of silicon dioxide and 0.5-0.8% of sodium carboxymethylcellulose. The nutritional chewing milk tablet prepared by the method is rich in nutrition and good in product stability, and has a better shelf life.

Owner:广东新乐食品有限公司

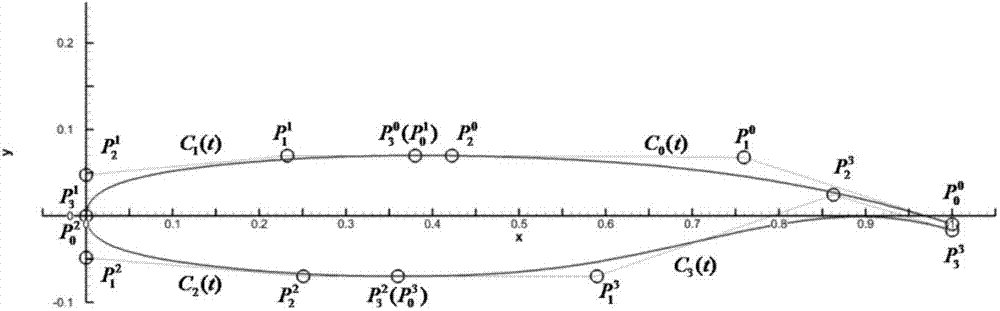

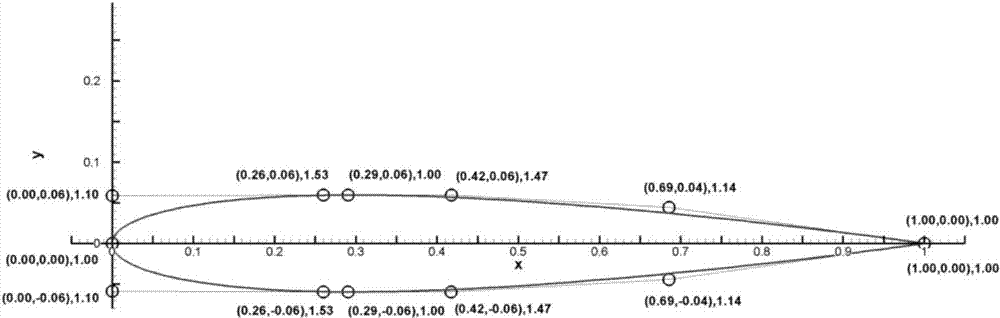

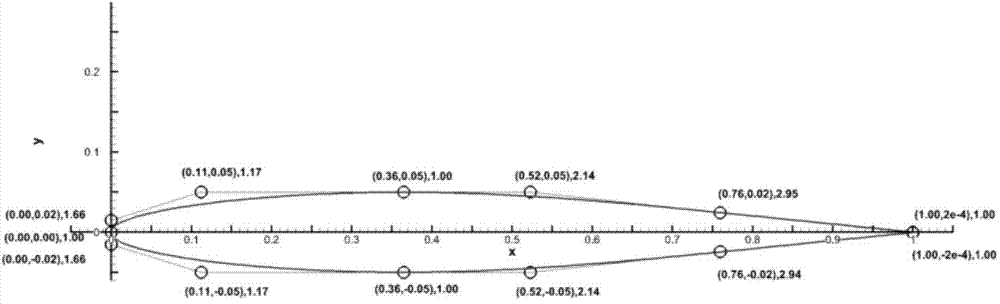

Continuous-curvature airfoil profile represented on basis of four rational Bezier curves, and generation method for continuous-curvature airfoil profile

The invention discloses a continuous-curvature airfoil profile represented on the basis of four rational Bezier curves, and a generation method for the continuous-curvature airfoil profile. The front edge portion of an upper molded line and the tail edge portion of the upper molded line are represented by two rational Bezier curves, the front edge portion of a lower molded line and the tail edge portion of the lower molded line are represented by the other two rational Bezier curves, and the four rational Bezier curves are sequentially connected by adjusting the positions and the weights of control vertexes near the splicing points so that the continuous-curvature airfoil profile can be generated. Parameters in a function have clear geometrical significance, the expected airfoil profile or an expected airfoil profile family can be generated by adjusting parameter values, the curvature radius of the front edge of the airfoil profile can be controlled, the position and the curvature of the highest point of the upper molded line are matched with those of the tail portion of the airfoil profile so that the closed airfoil profile with the thick tail edge can be generated, and reverse design is achieved; the four rational Bezier curves are made to approach an existing airfoil profile by adjusting the parameter values, and therefore approximate expression of the existing airfoil profile can be obtained, and the continuous-curvature airfoil profile can be applied to forward direction aerodynamic optimization design.

Owner:BEIHANG UNIV

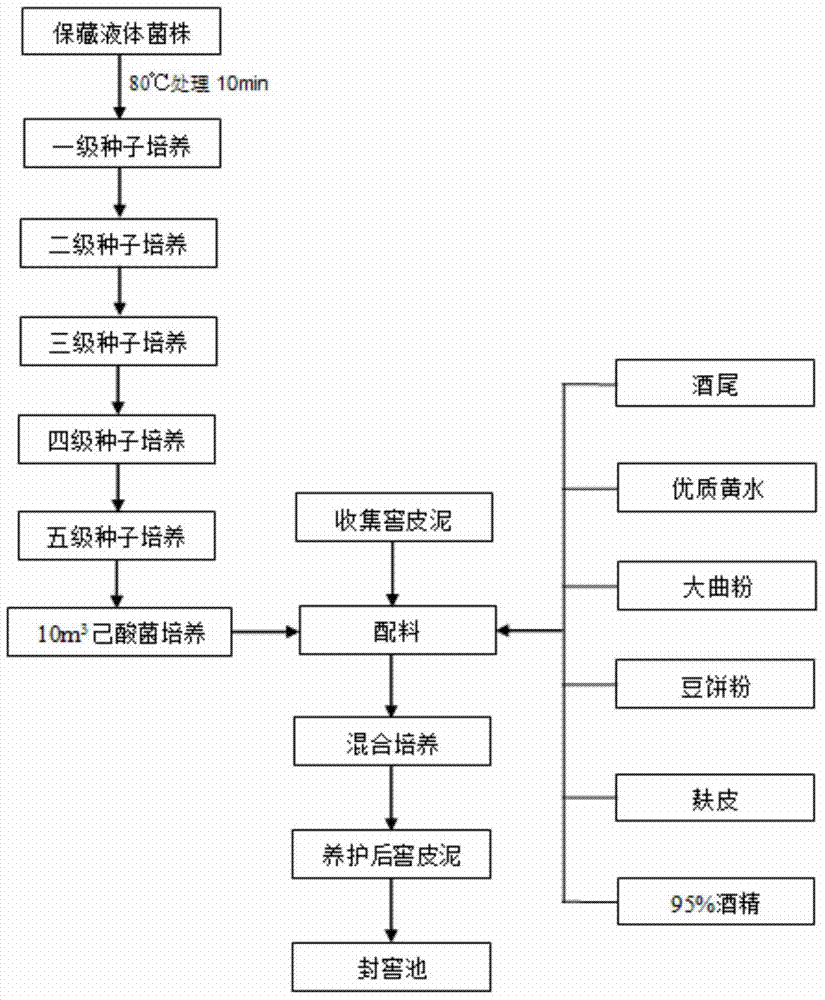

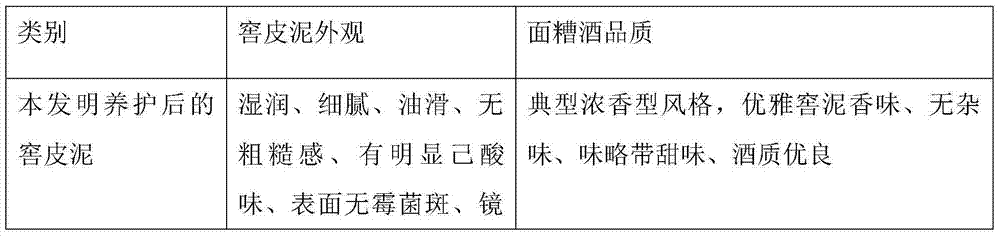

Method for curing pit mud

InactiveCN104513752AAvoid quality degradationQuality improvementAlcoholic beverage preparationCulture fluidDistillation

The invention discloses a method for curing pit mud. The method comprises the following steps: preparing a caproic acid bacteria five stage seed liquid; preparing a material according to a formula of caproic acid bacteria culture medium, sterilizing, cooling to 35 DEGC, adding 1-5% ethanol, and theninoculating caproic acid bacteria five stage seed liquid according to the proportion of about 10%, stirring, and conducting static cultivation at 30-37 DEG C for 5-11 d, so as to obtain a caproate bacteria culture fluid; collecting pit mud, adding a certain amount of the caproic acid bacteria culture medium, hard liquor powder, soybean powder, wheat bran, distillation tails, alcohol and water to obtain a pit mud curing mixture, uniformly stirring the mixture, and controlling the moisture content of the mixture t at 30-50%, so as to obtain treated pit mud; transferring the treated pit mud to a cement pool, sealing with film and cultivating under natural conditions for 10-40 d. The obtained curing pit mud has moist, delicate and smooth handle feel, no rough sense for rubbing, obvious caproic acid flavor; and microscopic examination shows abundant and strong Bacillus and clostridium.

Owner:ANHUI YINGJIA TRIBUTE WINE

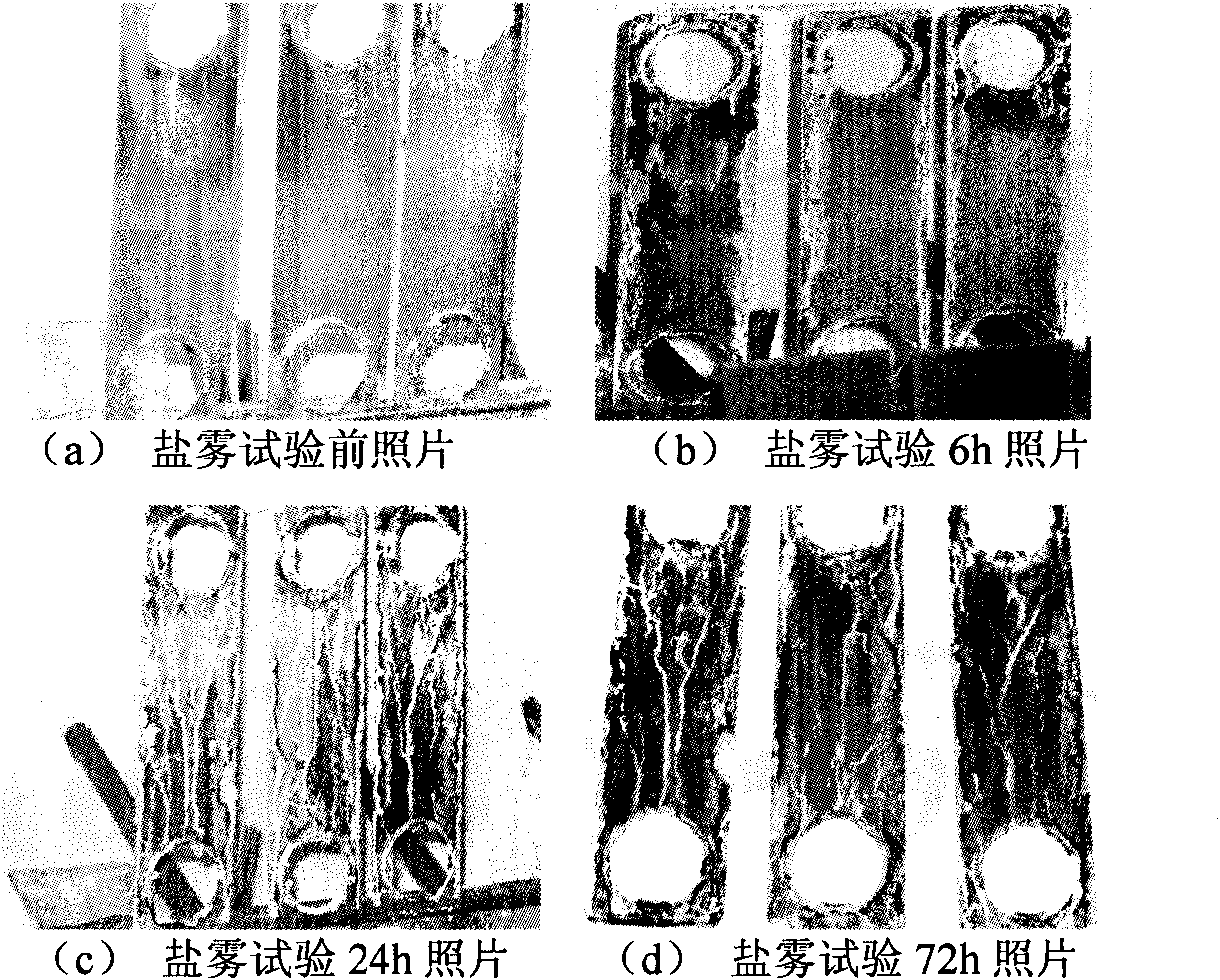

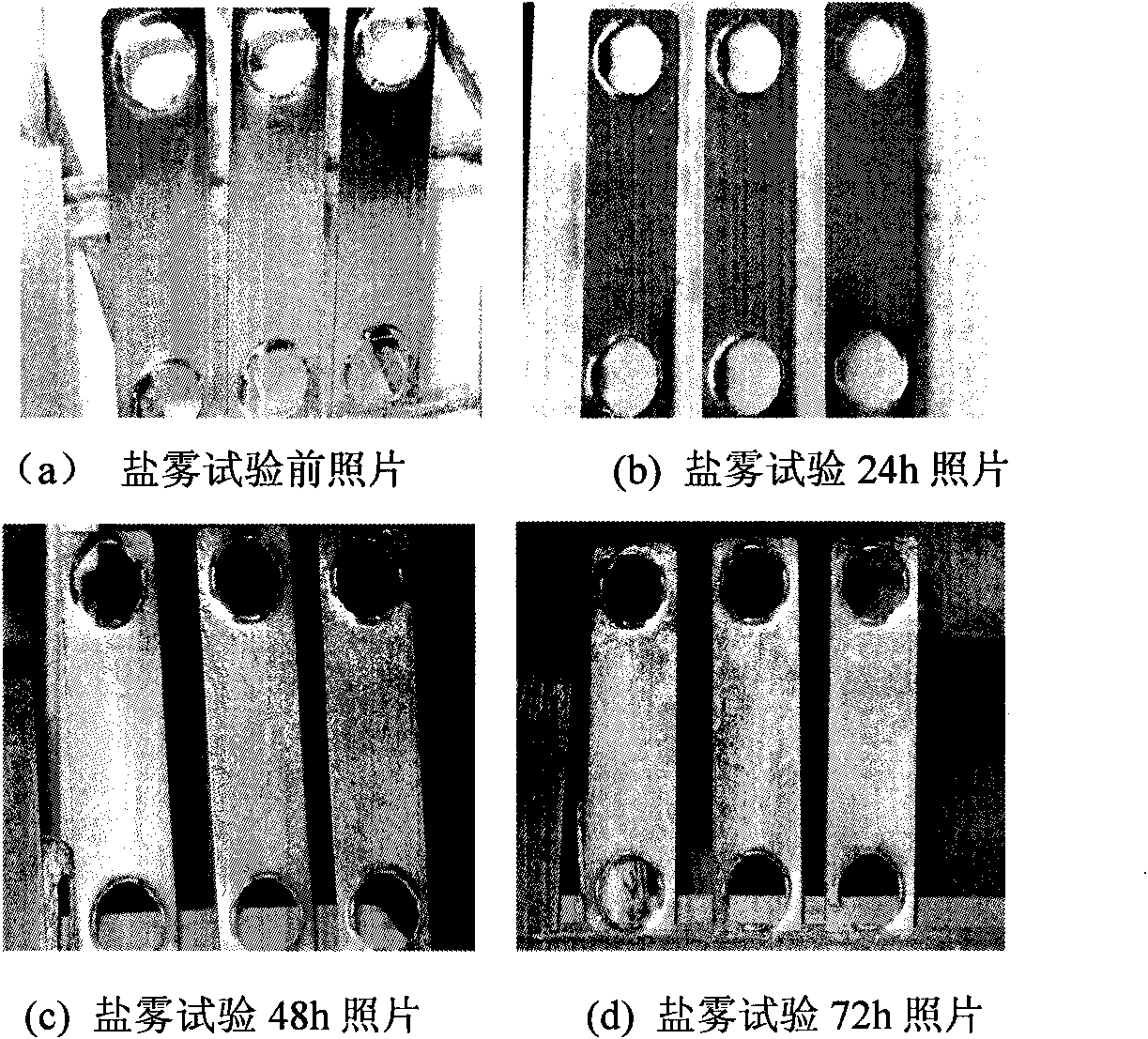

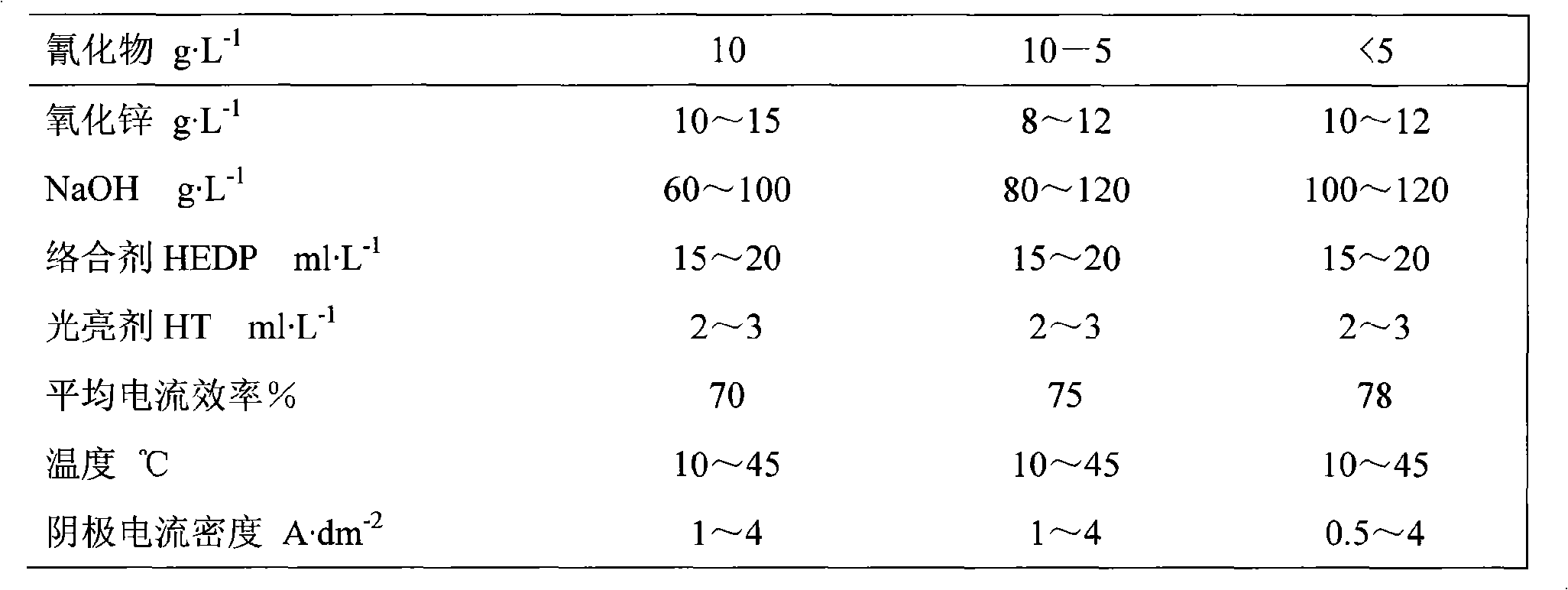

Non-cyanide converting method for cyanide plated zinc

The invention relates to a non-cyanide converting method for cyanide plated zinc. Non-cyanide conversion is as follows: a brightening agent (HT) and a complexing agent (HEDP) are added into plating liquid to carry out zinc plating by stopping adding NaCN and ZnO into the plating liquid. The plating liquid comprises the following components (g*L-1): 10-less than 5 of cyanide, 8-15 of zinc oxide, 60-120 of NaOH, 15-20 of HEDP and 2-3 of HT. The electroplating technical condition comprises the temperature of 10-45 DEG C, the cathode current density (A*dm<-2>) of 0.5-4 and the average current efficiency of 70-78 percent. The corrosion resistance, the bonding capability and the color change resistance of a plating layer completely meet the practical production requirement. The plating liquid has high impurity resistance and is still stable for continuously using for one month. The converted process does not use the cyanide, is easy to process electroplating wastewater and is a more clean production process, thereby replacing a cyanide zinc plating process in a peace way.

Owner:DALIAN MARITIME UNIVERSITY

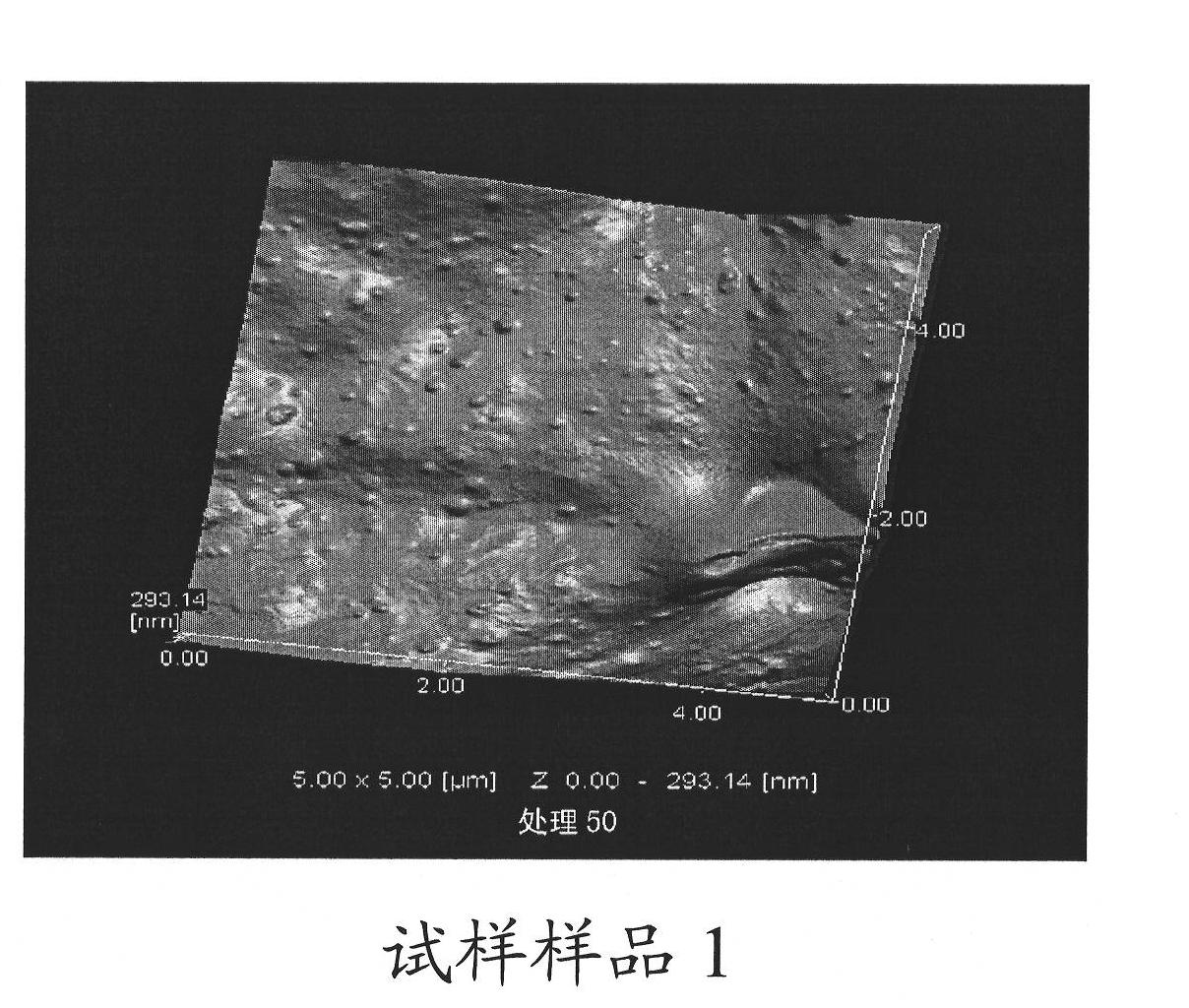

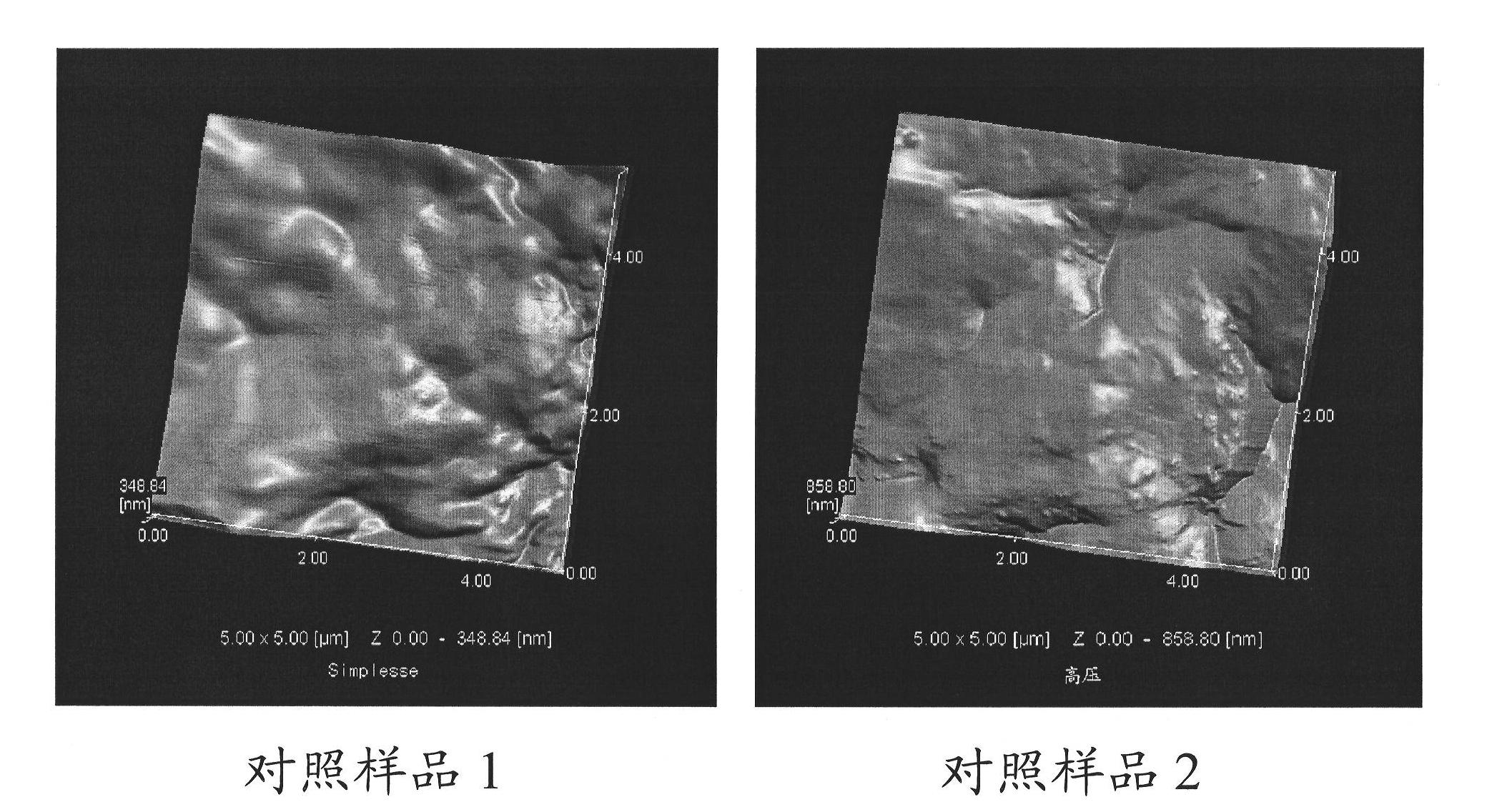

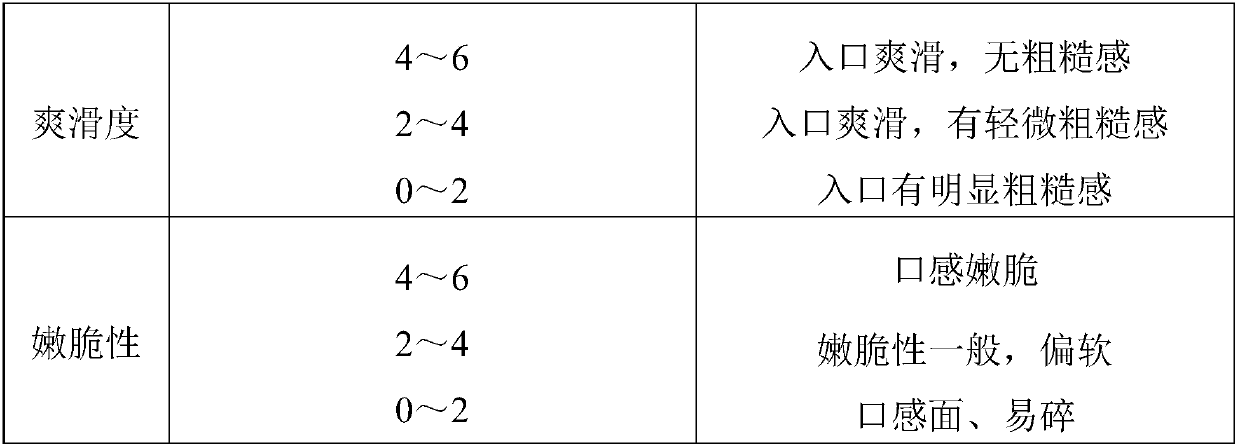

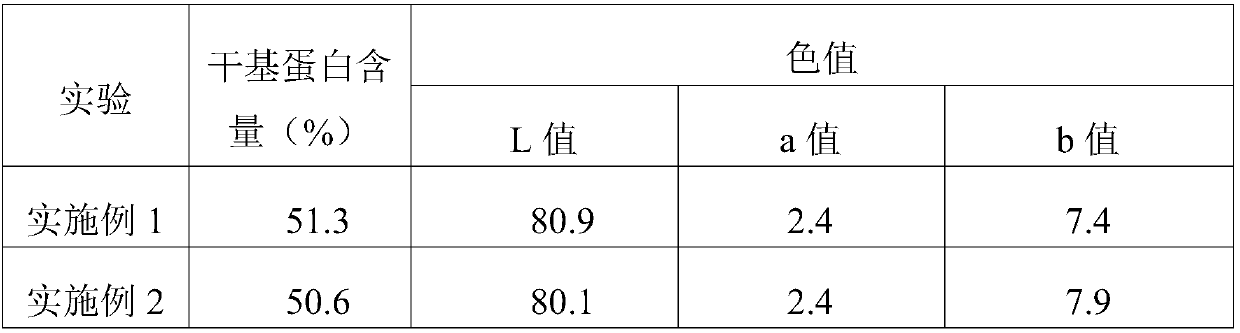

High-protein bean curd with smooth, tender and crisp taste and preparation method of bean curd

The invention relates to high-protein bean curd with a smooth, tender and crisp taste and a preparation method of the bean curd. The method comprises the following steps: (1) grinding low temperatureedible soya bean meal to form low temperature edible soya bean meal powder, mixing with water for extra high pressure treatment to form slurry, (2) mixing, grinding and adding soy isolate protein andthe water into soybean oil for regrinding, (3) adding the slurry obtained in step (1) into a mixture obtained in step (2), and performing grinding, filling, refrigeration, cooking and cooling in the presence of a cross-linking agent to form the bean curd. The prepared bean curd is good in color, is not red, has a high protein content, and is smooth, tender and crisp in taste.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

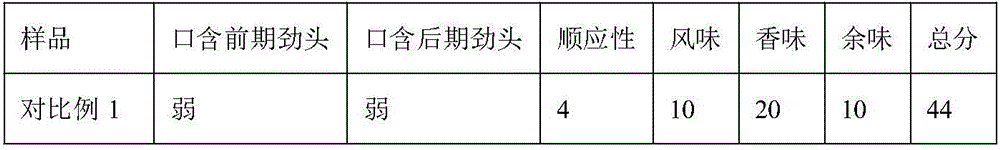

Tobacco stem particles suitable for preparing mouth holding cigarettes and application thereof

ActiveCN105831797AImprove taste comfortEliminate green miscellaneous gasTobacco preparationTobacco treatmentFlavorMicrowave

The invention discloses tobacco stem particles suitable for preparing mouth holding cigarettes and application thereof. The tobacco stem particles are obtained through the steps that tobacco stems are shredded after microwave puffing, the stem shreds are micro-smashed after fermentation treatment, and screening is conducted. The tobacco stem particles can be well applied to preparing the mouth holding cigarettes, the utilization efficiency of tobacco raw materials is improved, the bitterness and pungent taste of the tobacco stems are removed through scientific treatment, and fragrance matter is rich and mellow. The tobacco stems are scientifically matched with tobacco leaf particles and auxiliary materials, in combination with reasonable and safe seasoning treatment, the new mouth holding materials are obtained, the taste is richer, the special flavor is coordinated, quality is high, the mouth holding cigarettes are gradually kept in the mouth and melted during eating, no granular feeling or roughness is generated in the oral cavity, and the cigarettes do not need to be abandoned after being eaten.

Owner:CHINA TOBACCO GUANGDONG IND

Bitter gourd cake and making method thereof

InactiveCN103609643AHigh nutritional valueHeat-clearing and detoxifyingDough treatmentBakery productsNutritive valuesFlavor

The invention discloses a bitter gourd cake and a making method thereof. The bitter gourd cake comprises bitter gourd, eggs, white granulated sugar, citric acid, flour, salad oil, cream, malt syrup, peanut oil and blend oil. The making method of the bitter gourd cake comprises the steps of preparation of bitter gourd juice, stirring, mixing, injection molding, baking, oiling and demolding. The bitter gourd cake has the advantages that the taste is soft, fine and smooth, the cake tastes sweet, slightly bitter, tasty, and refreshing, the elasticity is good, the rough sense is avoided, the cake does not stick to teeth, the fragrance is strong and pure, and the flavor is special; the cake can clear away heat and toxic materials, relieve summer heat, nourish the kidney and the spleen, improve the immunity, and reduce blood fat, the nutritive value is high, and the cake is a high-grade product which is suitable for both the old and children; the cake is instant dietetic food and can meet requirements of different special populations, and the market of bitter gourd is developed.

Owner:陈思远

CMOS technique compatible silicon optical waveguide preparation method

InactiveCN101013181ALow production costReduce transmission lossPhotomechanical exposure apparatusMicrolithography exposure apparatusPlanar processCorrosion

The invention discloses a silicon waveguide preparation method compatible with CMOS process. On the top silicon layer of the SOI substrate, produce a layer of silicon dioxide, or silicon nitride, or silicon oxynitride mask layer, and process lithography and etching to the mask layer, to produce the waveguide mask pattern, and then process oxidation to the SOI substrate with the mask pattern, which can produce silicon waveguide. The invention uses the silicon oxidation characteristics, combining selective etching technology, and the provided silicon waveguide preparation method is fully compatible with the CMOS planar process, no longer needed silicon etching or corrosion, and other non CMOS standard processes.

Owner:ZHEJIANG UNIV

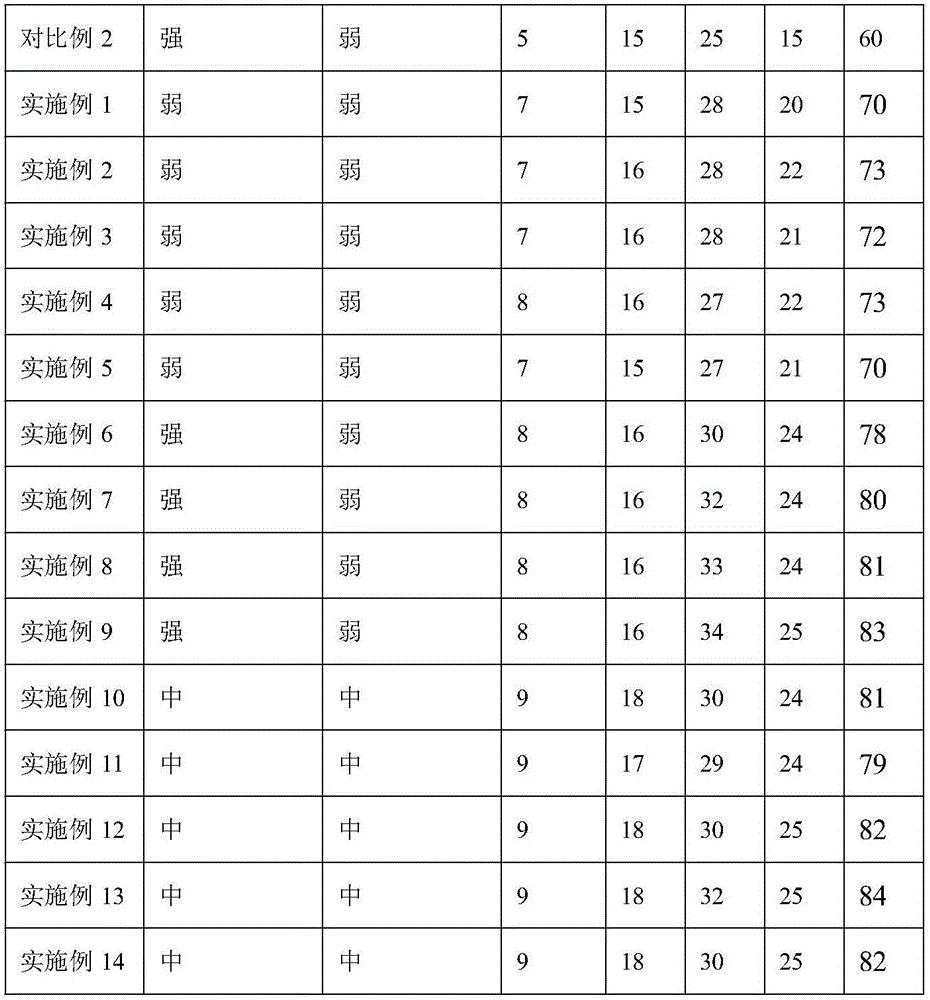

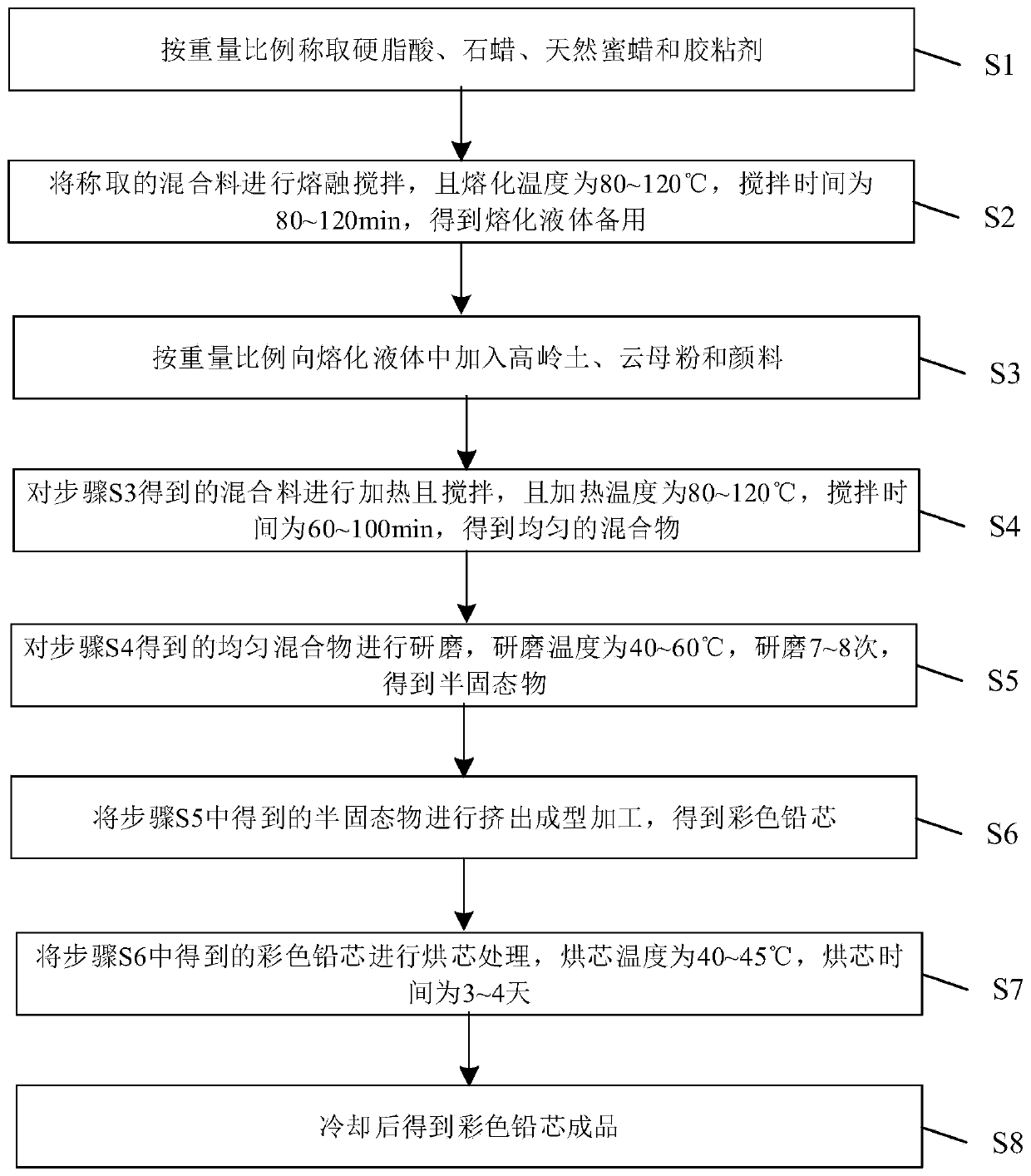

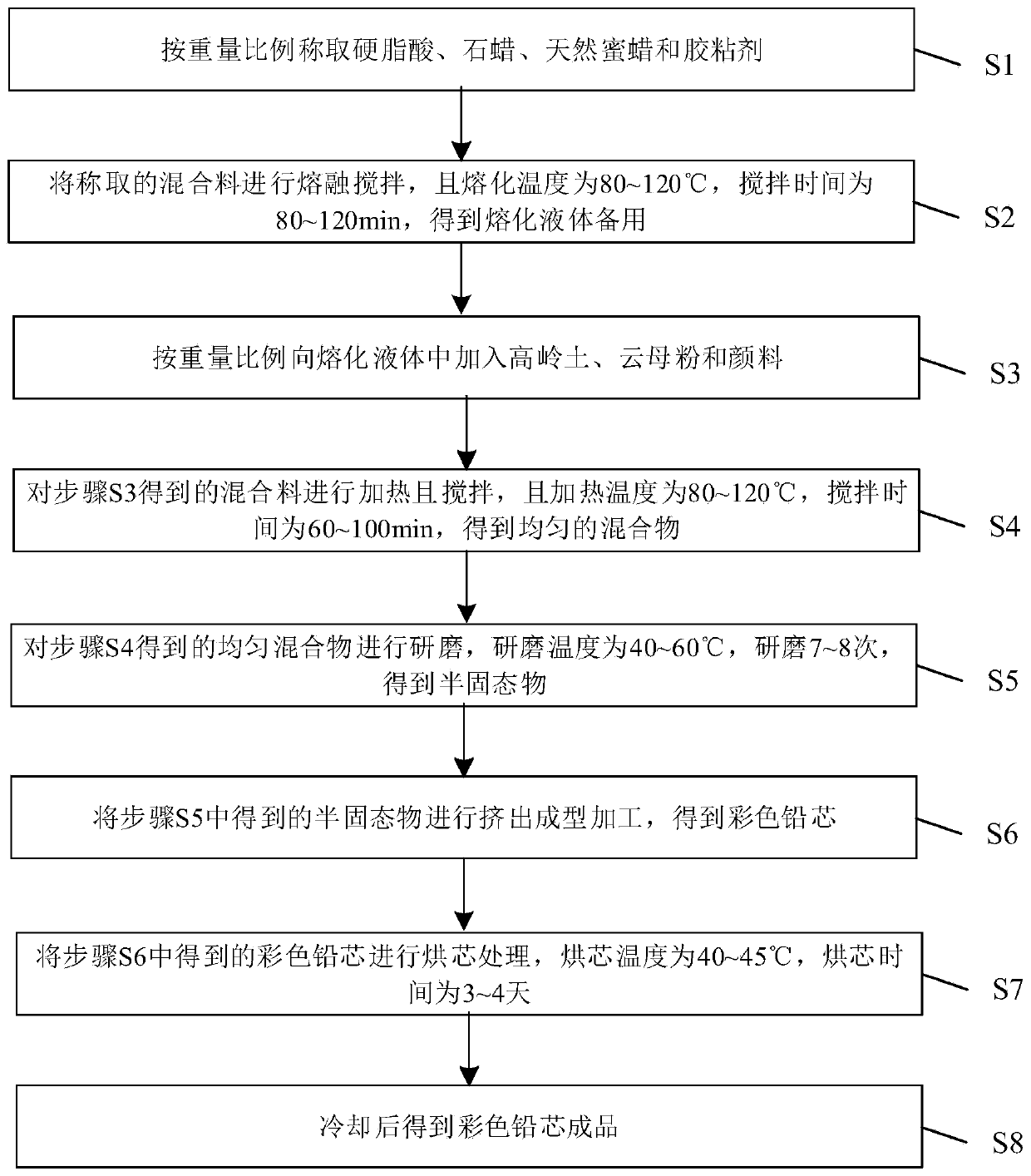

Colorful pencil lead writing smoothly and preparation method of colorful pencil lead

The embodiment of the invention discloses a colorful pencil lead writing smoothly and a preparation method of the colorful pencil lead. The colorful pencil lead writing smoothly comprises the following preparation materials in parts by weight: 40-55 parts of kaolin, 8-11 parts of mica powder, 20-25 parts of stearic acid, 6-10 parts of paraffin, 2-5 parts of natural beeswax, 5-15 parts of a pigmentand 1-3 parts of an adhesive. By adopting the preparation materials, cancerogenic substances such as talcum powder can be avoided, environmental-friendly health requirements can be met, and the smoothness, the hardness and the covering capability of the colorful pencil lead can be greatly improved.

Owner:AXUS STATIONERY (SHANGHAI) CO LTD

Potassium titanate whisker modified polystyrene microsphere composite material and preparation method thereof

InactiveCN106147057AReduce contentFast molding speedAdditive manufacturing apparatusMicrospherePolystyrene microsphere

The invention provides a potassium titanate whisker modified polystyrene microsphere composite material and a preparation method thereof, and is characterized in that the potassium titanate whisker modified polystyrene microsphere composite material comprises the following raw materials in parts by weight: 100 parts of polystyrene microspheres, 5-35 parts of potassium titanate whiskers, 0.1-0.5 part of a coupling agent, 0.1-0.5 part of a light stabilizer, 0.5-4.5 parts of a defoaming agent, 0.5-1 part of a leveling agent, and 0.1-0.5 part of an antioxidant. The prepared composite material has the characteristics of fast forming speed, large mechanical strength, high wear resistance and the like, the apparent quality of products is improved, and at the same time, with introduction of the potassium titanate whiskers, the manufacturing cost of the polystyrene microsphere composite material is greatly reduced. In addition, the preparation process of the composite material is simple, can be directly applied and popularized in the field of laser sintering and rapid forming, and is used for preparing products having high performance and relatively high apparent quality requirements.

Owner:HEFEI GENIUS NEW MATERIALS

Tropical custom whole wheat oatmeal and preparation method thereof

The invention discloses tropical custom whole wheat oatmeal and a preparation method thereof. The whole wheat oatmeal comprises the following raw materials in parts by weight: 40-50% of whole wheat flour, 30-40% of whole oat flour, 3-5% of glutinous rice flour, 3-5% of diced mango, 3-5% of diced pineapple, 3-5% of diced melon, 4-6% of white granulated sugar and moderate salt. The tropical custom whole wheat oatmeal, provided by the invention, has abundant nutrition and a healthcare effect; after the tropical custom whole wheat oatmeal is directly soaked by the boiling water, the tropical custom whole wheat oatmeal can be eaten, and has the advantages of convenience for eating, pure taste, no rough feel and good taste.

Owner:ANHUI YANZHIFANG FOOD

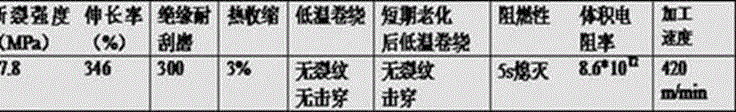

Electric wire and cable plastic

InactiveCN103589090ANo roughnessImprove heat resistancePlastic/resin/waxes insulatorsEpoxyZinc compounds

The invention discloses an electric wire and cable plastic, which is composed of the following components in parts by weight: 30-60 parts of polyvinyl chloride resin, 6-10 parts of epoxy resin, 5-12 parts of stearic acid, 3-8 parts of quartz powder, 8-10 parts of flame retardant, 5-10 parts of zinc oxide, 2-5 parts of electrical insulating modifier, and 3-5 parts of lubricant. According to the invention, a situation that a good surface of the plastic is still kept at a high-speed machining speed of above 600-800 m / min in automotive wire production fields is guaranteed, and the surfaces of wires have no coarse phenomenon; and furthermore, through adding a calcium-zinc compound stabilizer at 105 DEG C to cooperate with an antioxidant, the heat resistance of an insulating material at 105 DEG C can be enhanced well.

Owner:QINGDAO HAOYUAN ENVIRONMENTAL ENG TECH

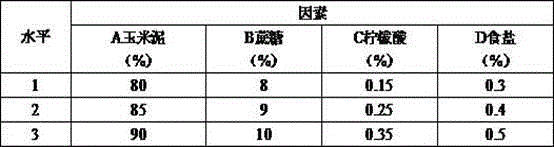

Healthy beverage type corn paste and preparation method thereof

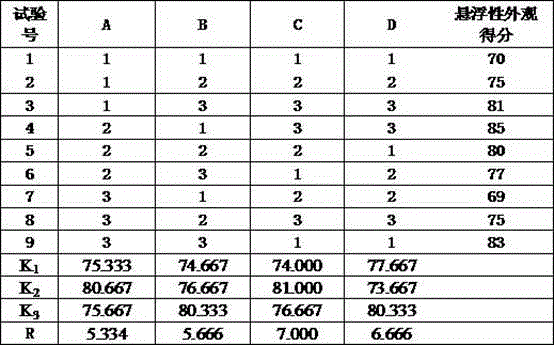

The invention discloses a preparation method for healthy beverage type corn paste. By taking sweet corn as a raw material, the beverage type corn paste is prepared by refining after cleaning, threshing and blanching, gelatinizing, passivating, carrying out enzymolysis, mixing, adding a compound stabilizer, homogenizing and carrying out vacuum packaging after sterilizing. In the mixing step, the materials are as follows in percentage by weight: 80-90% of corn, 8-10% of saccharose, 0.15-0.35% of citric acid and 0.3-0.5% of table salt. The compound stabilizer is prepared from the following components in percentage by concentration: 0.25-0.45% of CMC-Na, 0.04-0.06% of monoglyceride and 0.07-0.09% of xanthan gum. By taking the sweet corn as the raw material and adding saccharose, citric acid and salt, the healthy beverage type corn paste is moderate in sweetness and sourness and has obvious special flavor and aroma of corn. The corn paste which is continuously processed is free of sediments and good in solubleness and flowability. The corn paste is good in stability if being mixed to a corn juice beverage.

Owner:FUJIAN BISHAN FOOD CO LTD

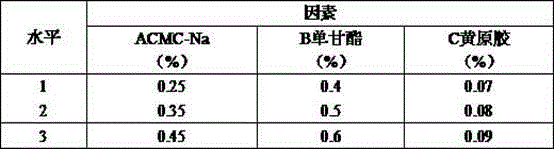

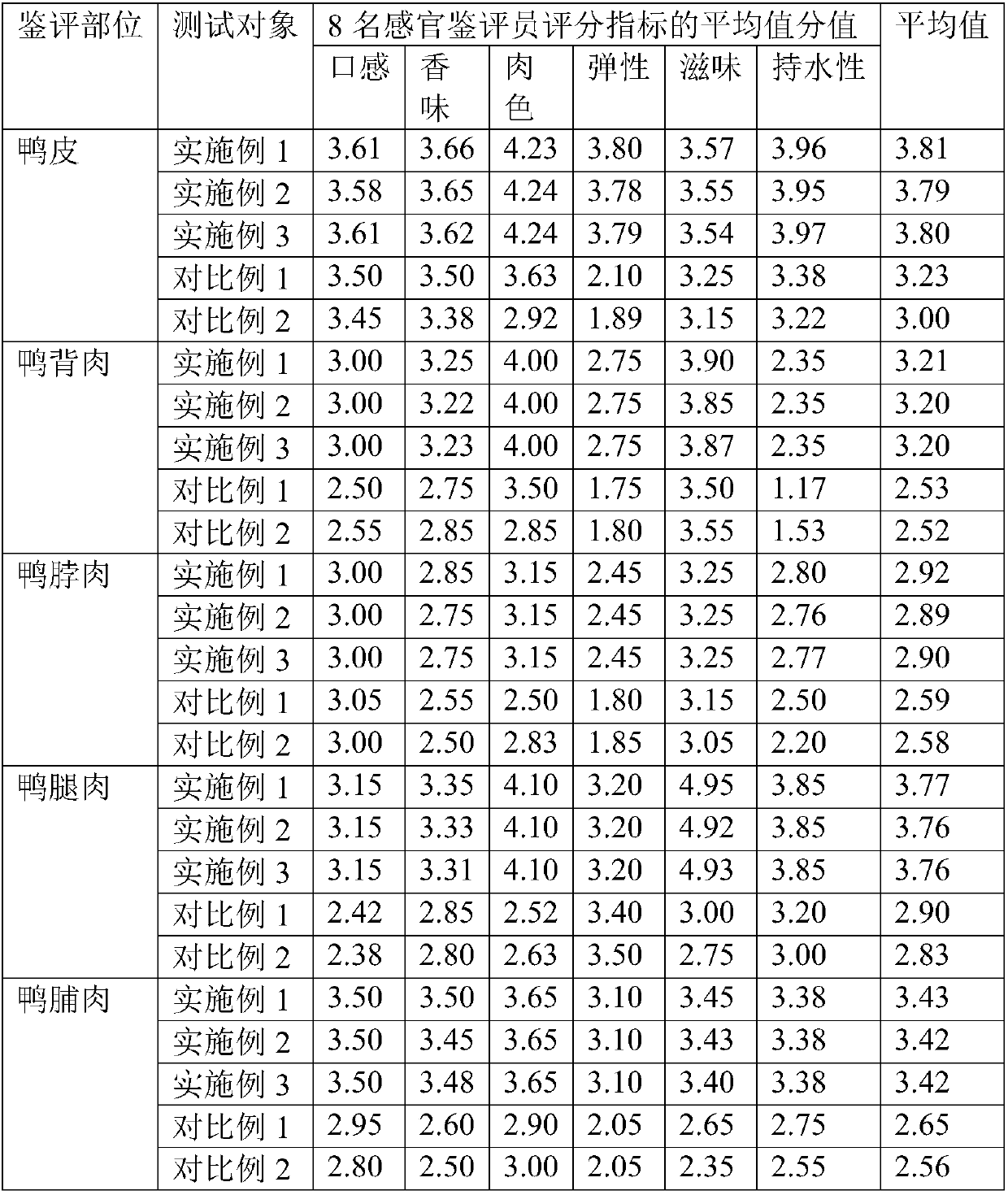

Roast duck and manufacturing method thereof

InactiveCN107927606AGreat tasteUniform tasteFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFlavorRoast duck

The invention relates to a roast duck and a manufacturing method thereof, and belongs to the technical field of food production. The roast duck and the manufacturing method thereof is characterized inthat the manufacturing method of the roast duck comprises the following steps that (1) material water is decocted; (2) skin water is prepared; (3) bulging is conducted; (4) pickling is conducted, specifically, the material water in the step (1) is added into a duck billet chest in the step (3), a duck cutting incision is seamed and tied tightly, and the duck is placed flatwise and pickled, and turned over once every half hour; (5) the dust skin is burned; (6) coloring is conducted; (7) the duck skin is air-dried; and (8) roasting is conducted, specifically, the duck cutting incision of the duck billet in the step (7) is opened, the material water in the step (1) is poured into the duck billet chest, then the duck cutting incision is seamed again, and the duck billet is placed into a baking oven to be roasted. According to the manufacturing method, the material water is adopted to conduct first step of pickling, second step of pickling of the material water and roasting of the duck areconducted simultaneously, so that the flavoring effect of the roast duck is good, flavoring is even, the roast duck is tasty, the flavor is aromatic, the color is bright, the roast duck is fresh andtender and tasty and refreshing, no obvious roughness exists, the chewiness is relatively good, and the structure of the roast duck is complete and compact and has elasticity.

Owner:北京六合坊食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com