Photocurable 3D printing material as well as preparation method and application thereof

A 3D printing and light curing technology, applied in the field of 3D printing materials, can solve the problems of limited strength and stiffness of 3D printing products, difficulty in applying large 3D printing products, and expensive SLA system, so as to shorten the curing time and achieve good printing stability , Improve the effect of printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

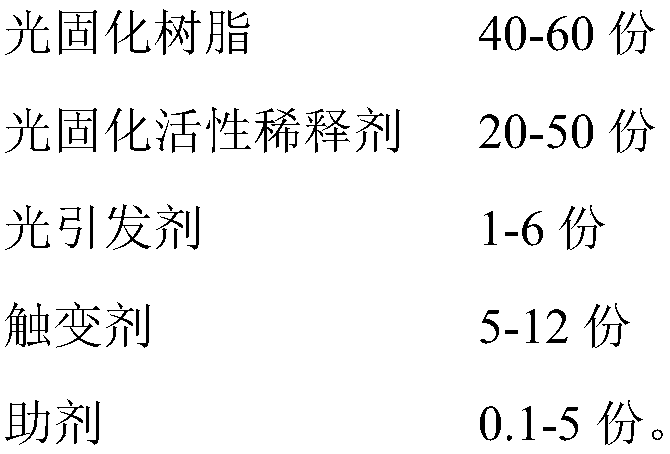

[0037] The five photocurable 3D printing materials in this example are composed of the raw material components shown in Table 1 in parts by weight:

[0038] Table 1

[0039]

[0040] The above additives consist of 0.2 parts of polyether modified polydimethylsiloxane defoamer, 0.1 part of leveling agent polyacrylate, 0.1 part of titanate coupling agent, 0.2 part of alkyl ammonium carboxylate dispersant, It is composed of 2 parts of filler calcium carbonate and 0.5 part of color paste.

[0041] The preparation method of the above photocuring 3D printing material, the steps are as follows:

[0042] Weigh each raw material component by weight, sequentially add the photocurable reactive diluent, photoinitiator, thixotropic agent and auxiliary agent into the photocurable resin, mix uniformly in the reaction kettle, and then gradually heat up to 50 At -60°C, vacuumize to a negative pressure of 0.1 MPa at the same time, and disperse and stir for 1.5 hours under the condition of 1...

Embodiment 6-10

[0044] The five photocurable 3D printing materials in this example are composed of the raw material components shown in Table 2 in parts by weight:

[0045] Table 2

[0046]

[0047] The above additives consist of 0.2 parts of polyether modified polydimethylsiloxane defoamer, 0.1 part of leveling agent polyacrylate, 0.1 part of titanate coupling agent, 0.2 part of alkyl ammonium carboxylate dispersant, It is composed of 2 parts of filler calcium carbonate and 0.5 part of color paste.

[0048] The preparation method of the above-mentioned photocurable 3D printing material is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com