Patents

Literature

42results about How to "Variation is suppressed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

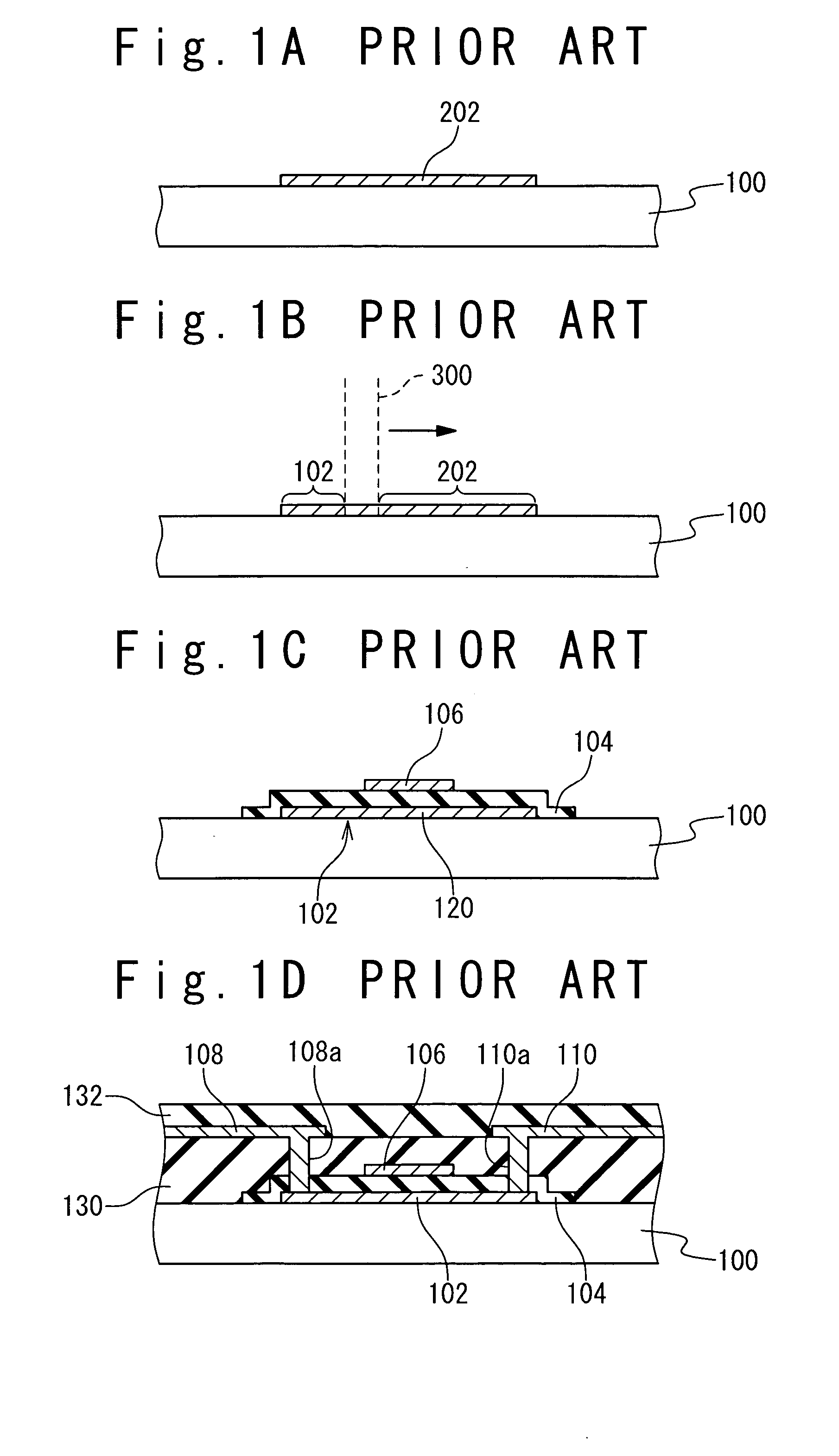

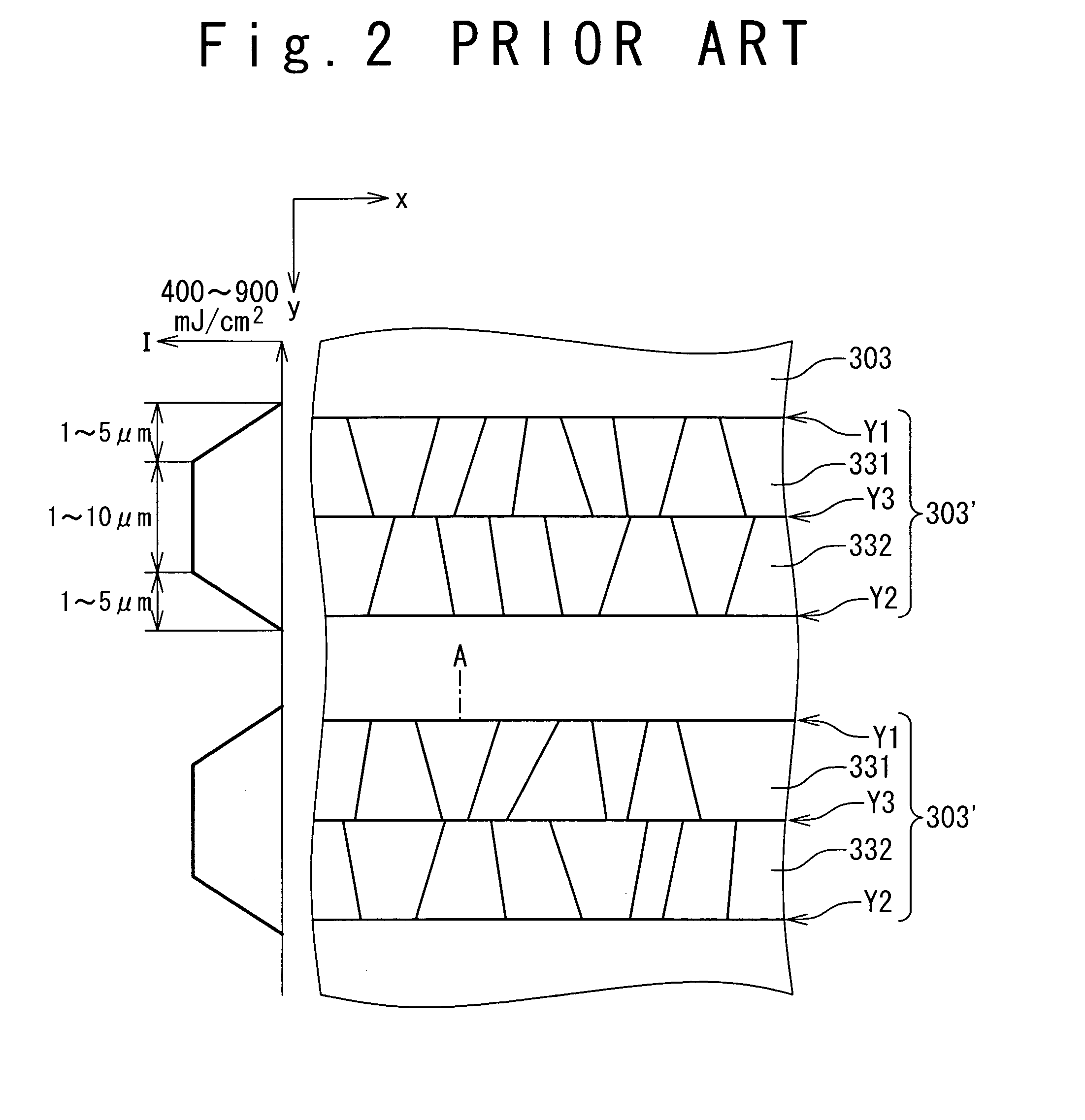

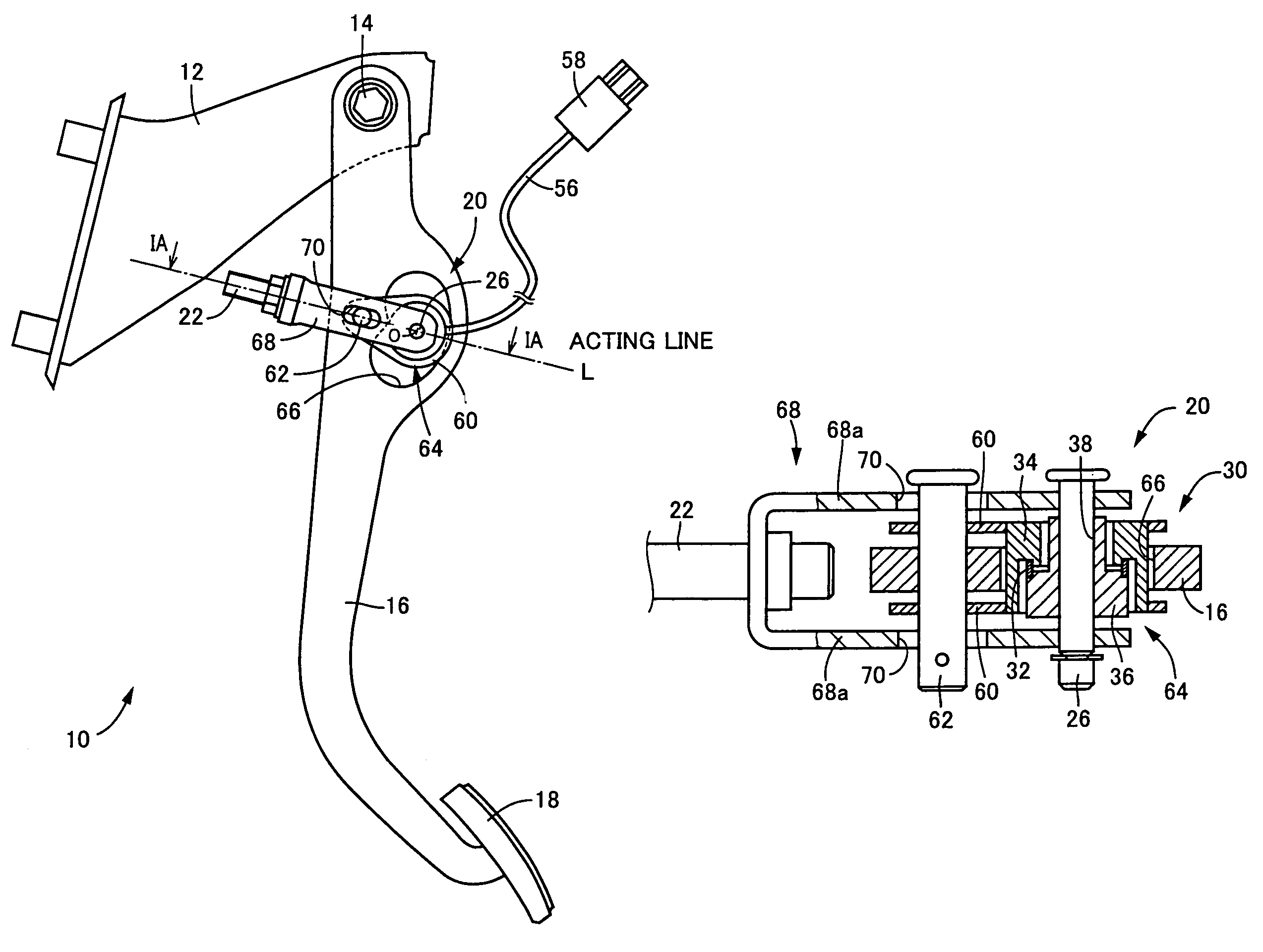

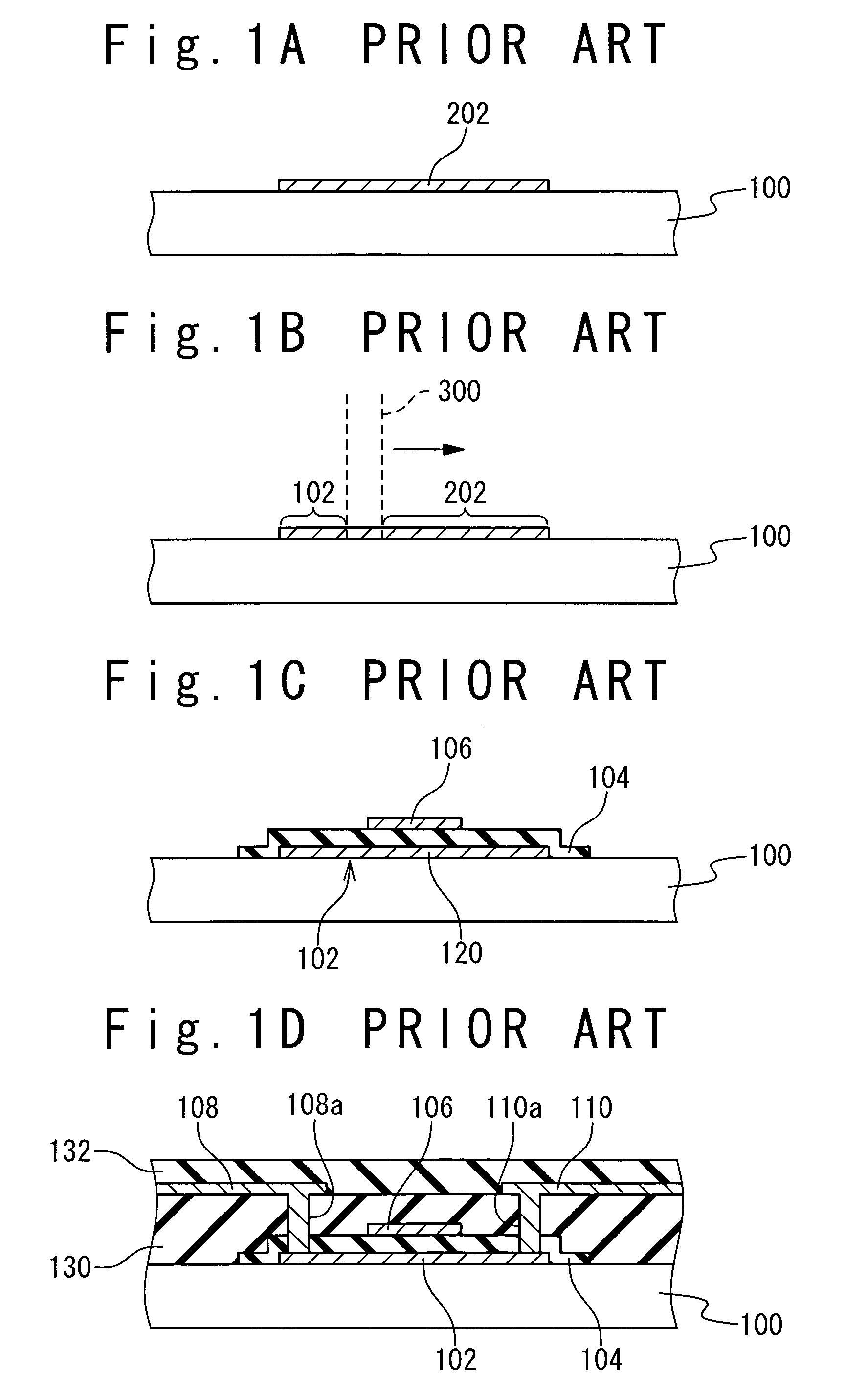

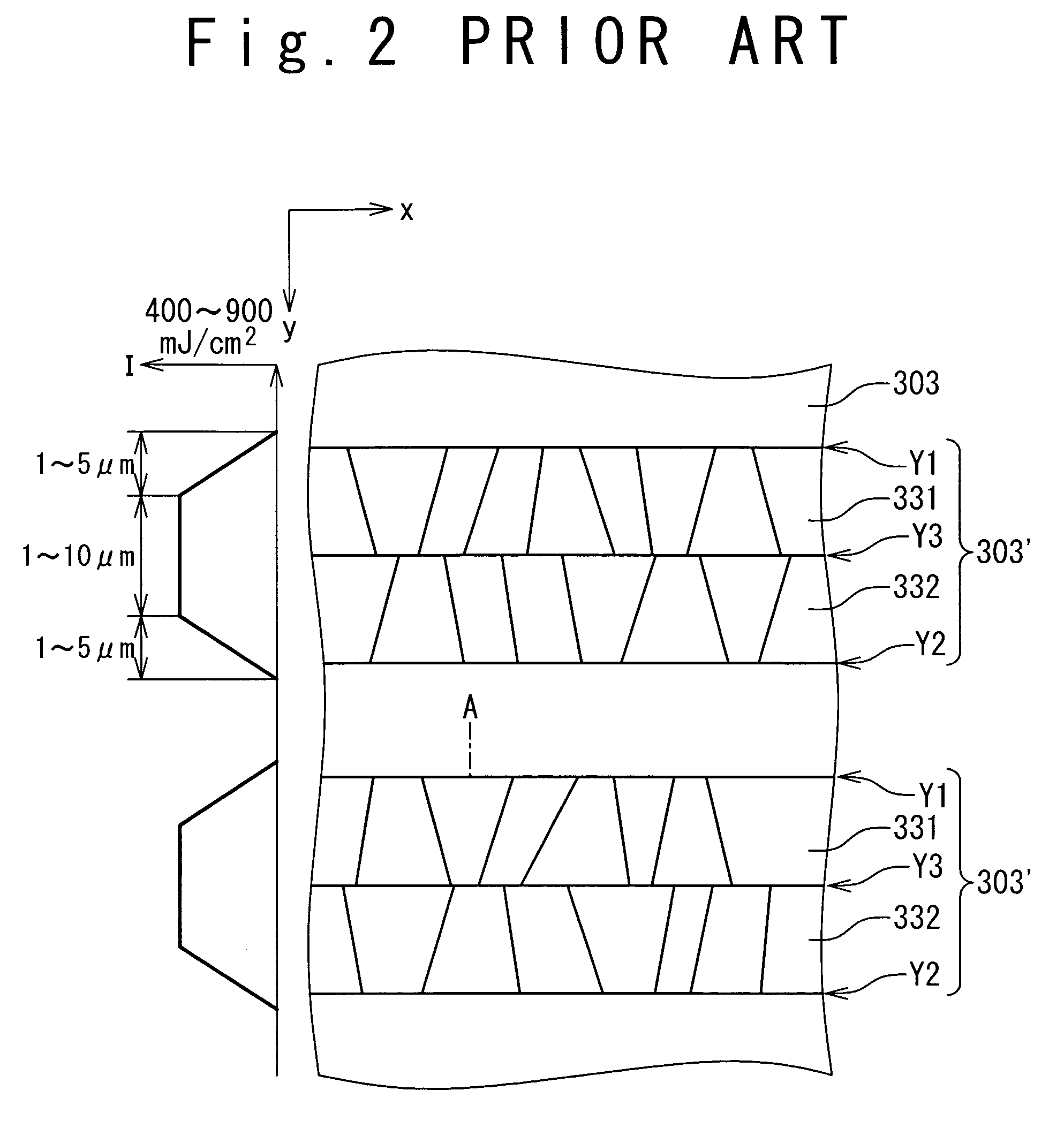

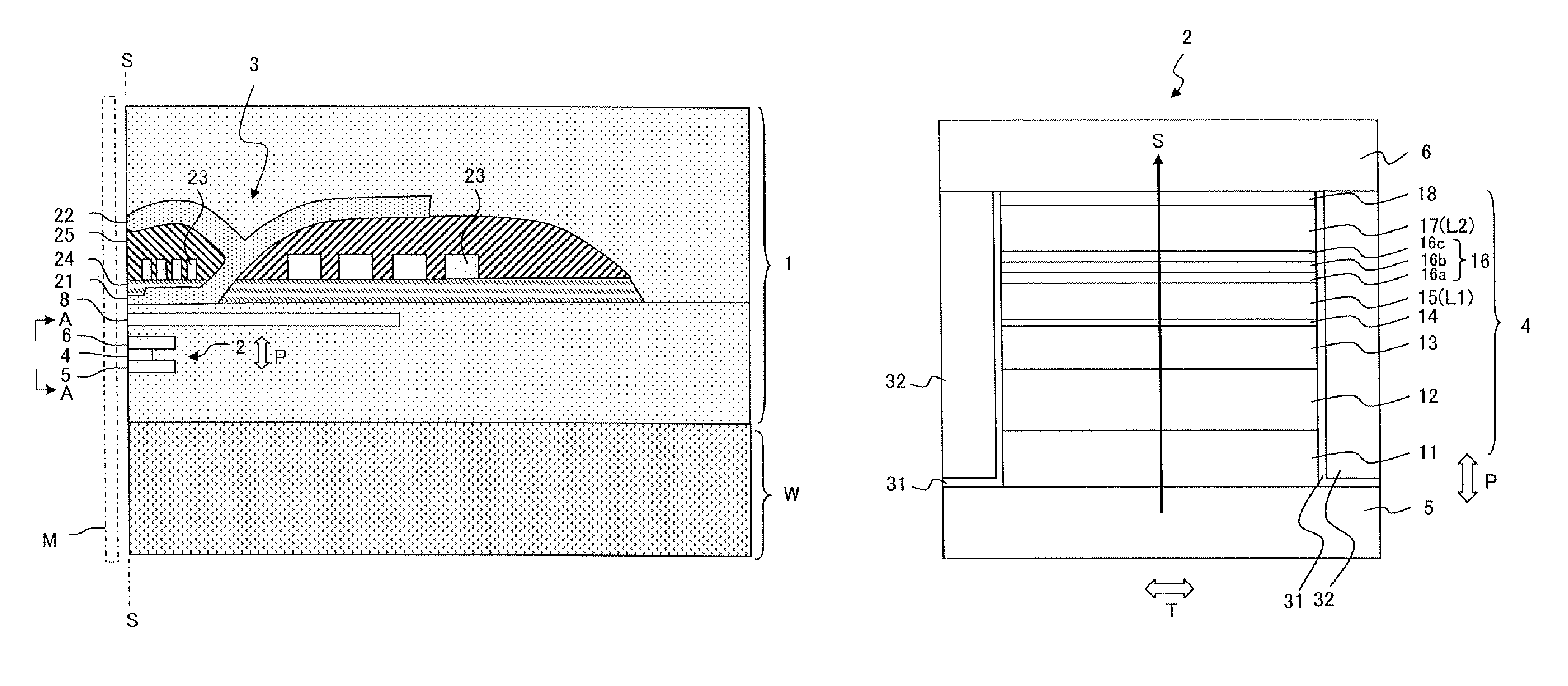

Method of and apparatus for manufacturing semiconductor thin film, and method of manufacturing thin film transistor

InactiveUS20050003591A1Reduce numberControl positionTransistorFrom gel stateAmorphous semiconductorsSemiconductor

A method of manufacturing a semiconductor thin film includes (A) forming an amorphous semiconductor film on a substrate, (B) irradiating a beam to a surface of the amorphous semiconductor film such that a predetermined region of the amorphous semiconductor film is melted and solidified to form a crystallized semiconductor film, and (C) scanning the beam in a first direction. A second direction is a direction on the surface of the amorphous semiconductor film perpendicular to the first direction. A length along the second direction of a cross section of the beam is substantially equal to or less than two times a width along the second direction of the crystallized semiconductor film.

Owner:VISTA PEAK VENTURES LLC

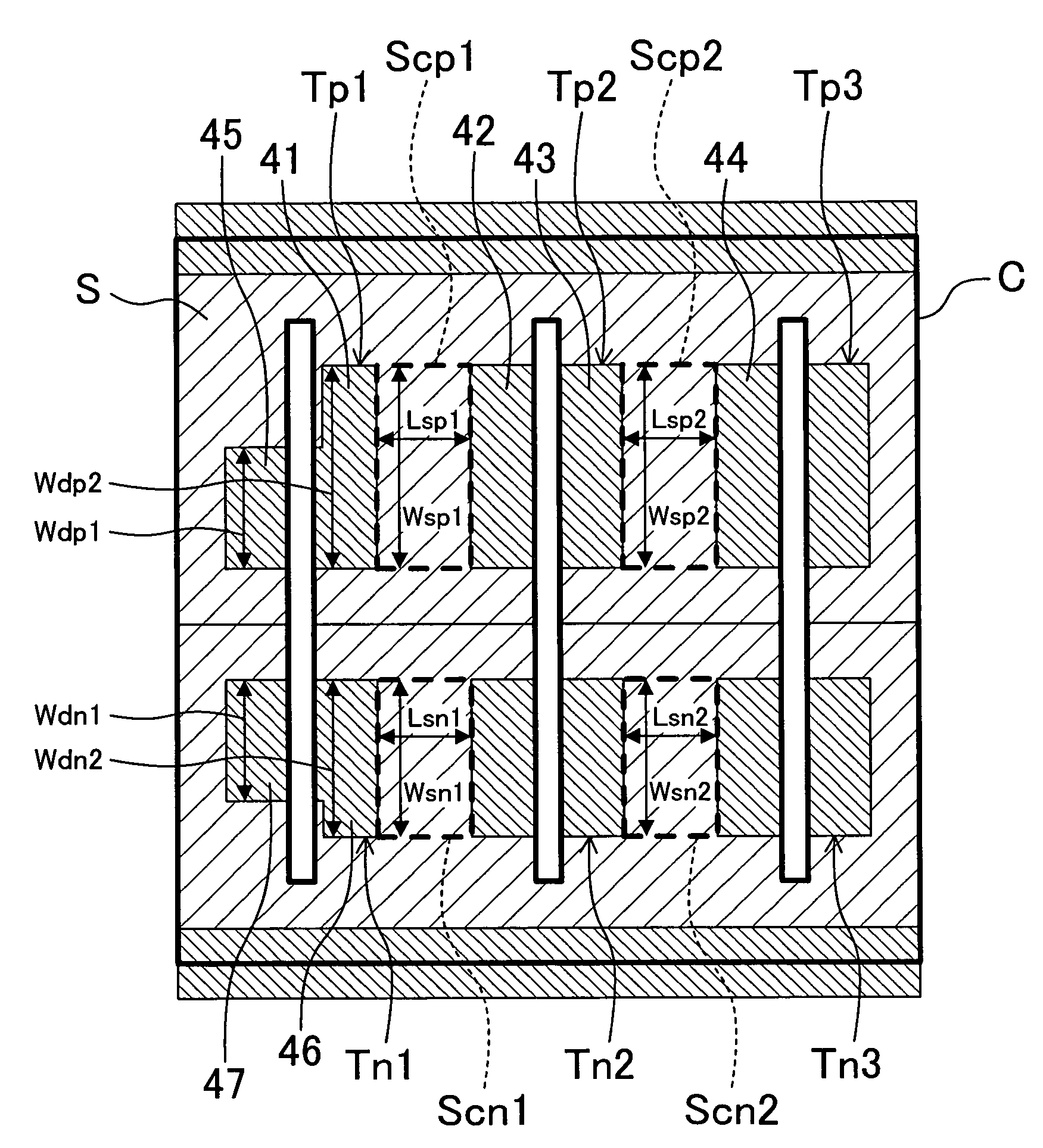

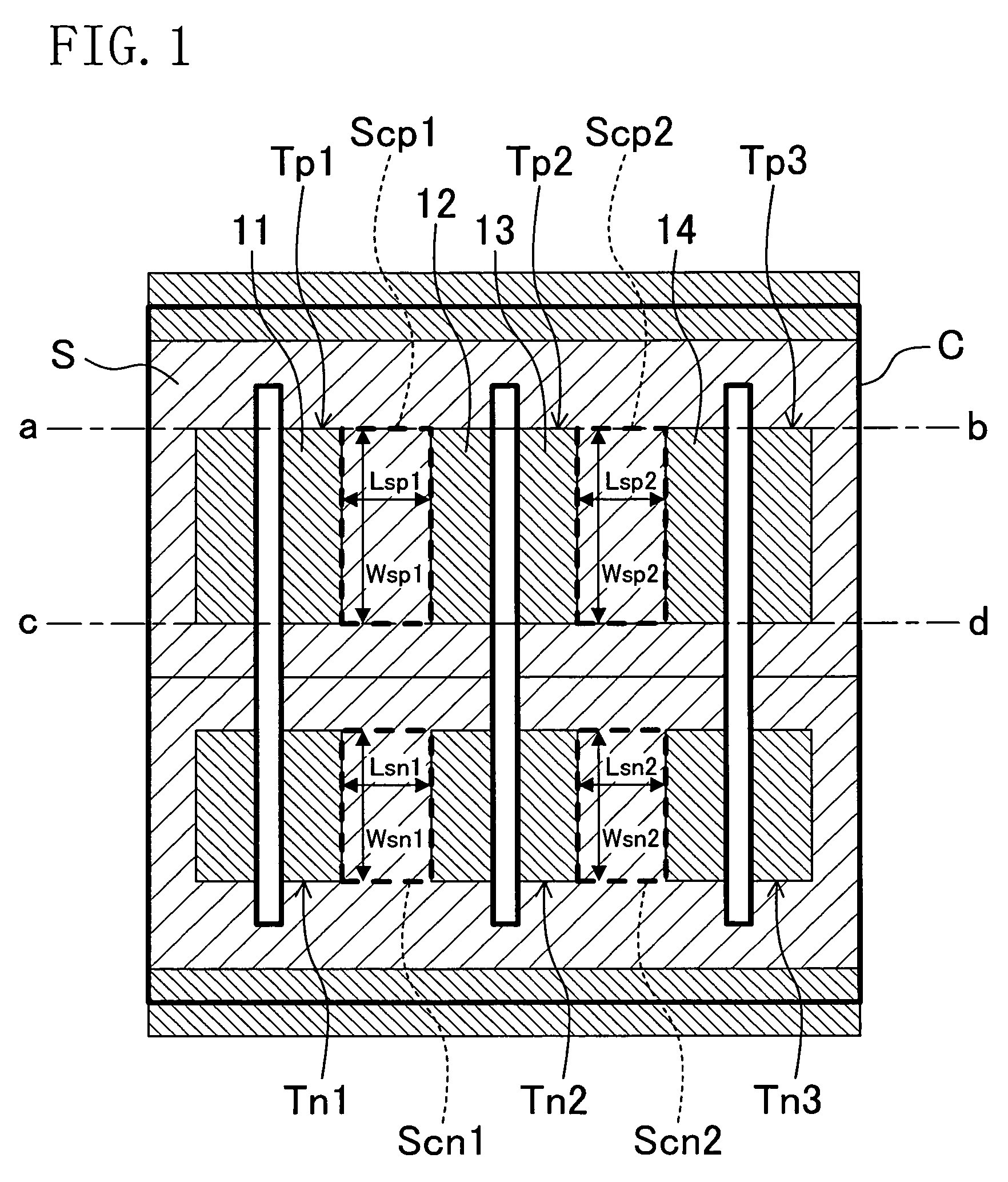

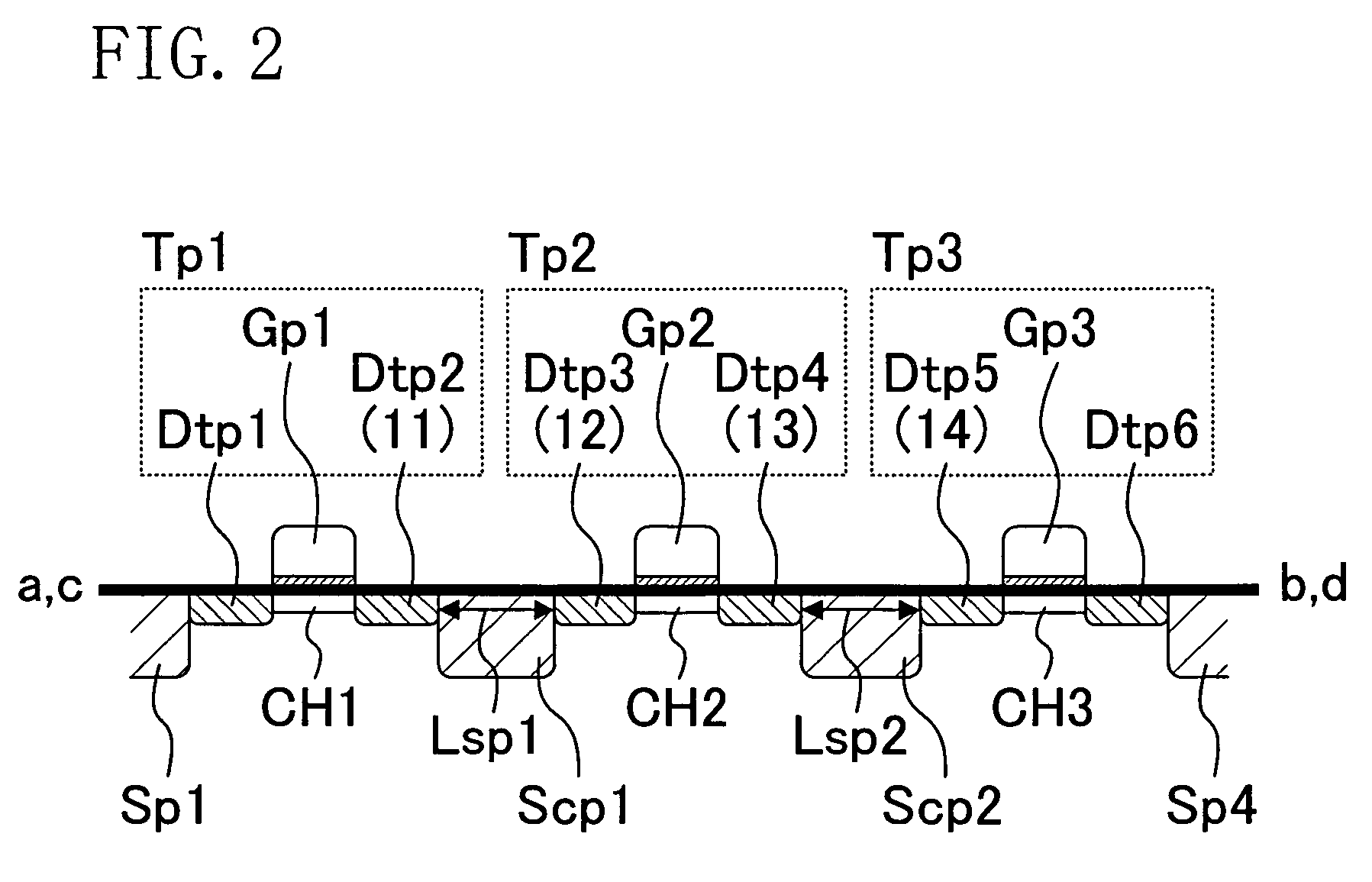

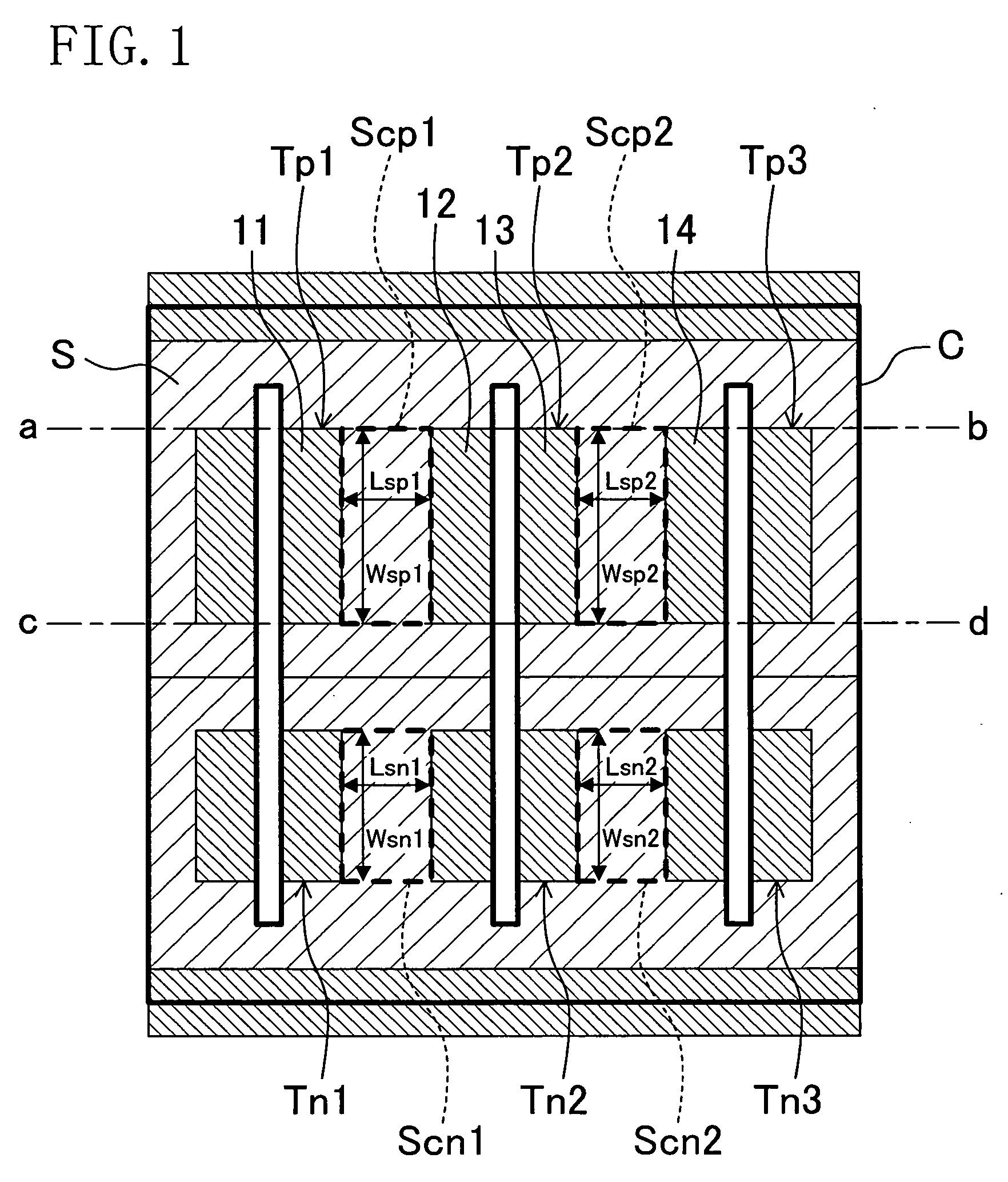

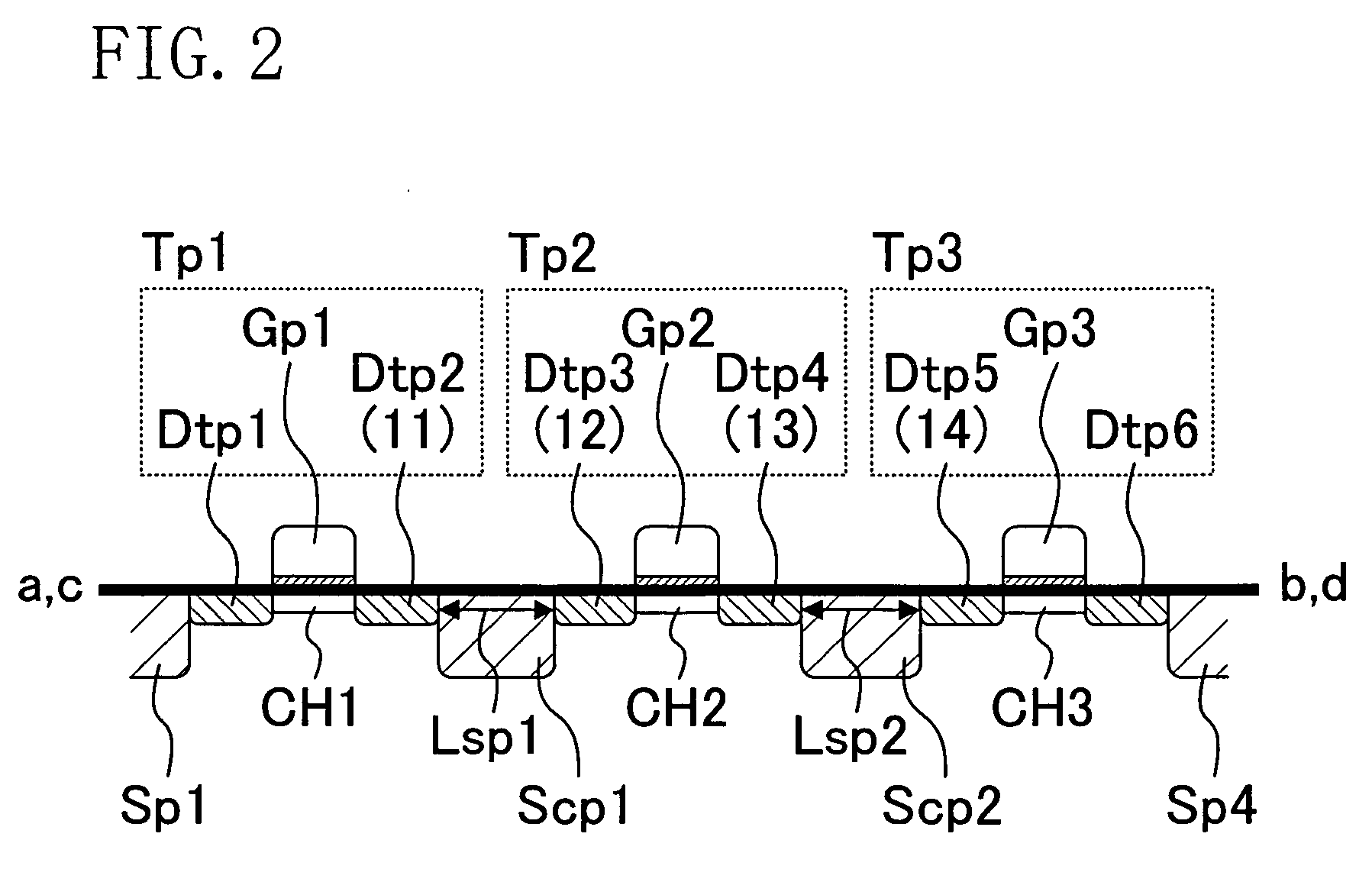

Semiconductor device with a transistor having different source and drain lengths

InactiveUS7592676B2Constant separationVariation is suppressedSolid-state devicesSemiconductor/solid-state device manufacturingImpurity diffusionCondensed matter physics

A cell includes a plurality of diffusion region pairs, each of the diffusion region pairs being formed by a first impurity diffusion region which is a constituent of a transistor and a second impurity diffusion region such that the first and second impurity diffusion regions are provided side-by-side in a gate length direction with a device isolation region interposed therebetween. In each of the diffusion region pairs, the first and second impurity diffusion regions have an equal length in the gate width direction and are provided at equal positions in the gate width direction, and a first isolation region portion, which is part of the device isolation region between the first and second impurity diffusion regions, has a constant separation length. In the diffusion region pairs, the first isolation region portions have an equal separation length.

Owner:SOCIONEXT INC

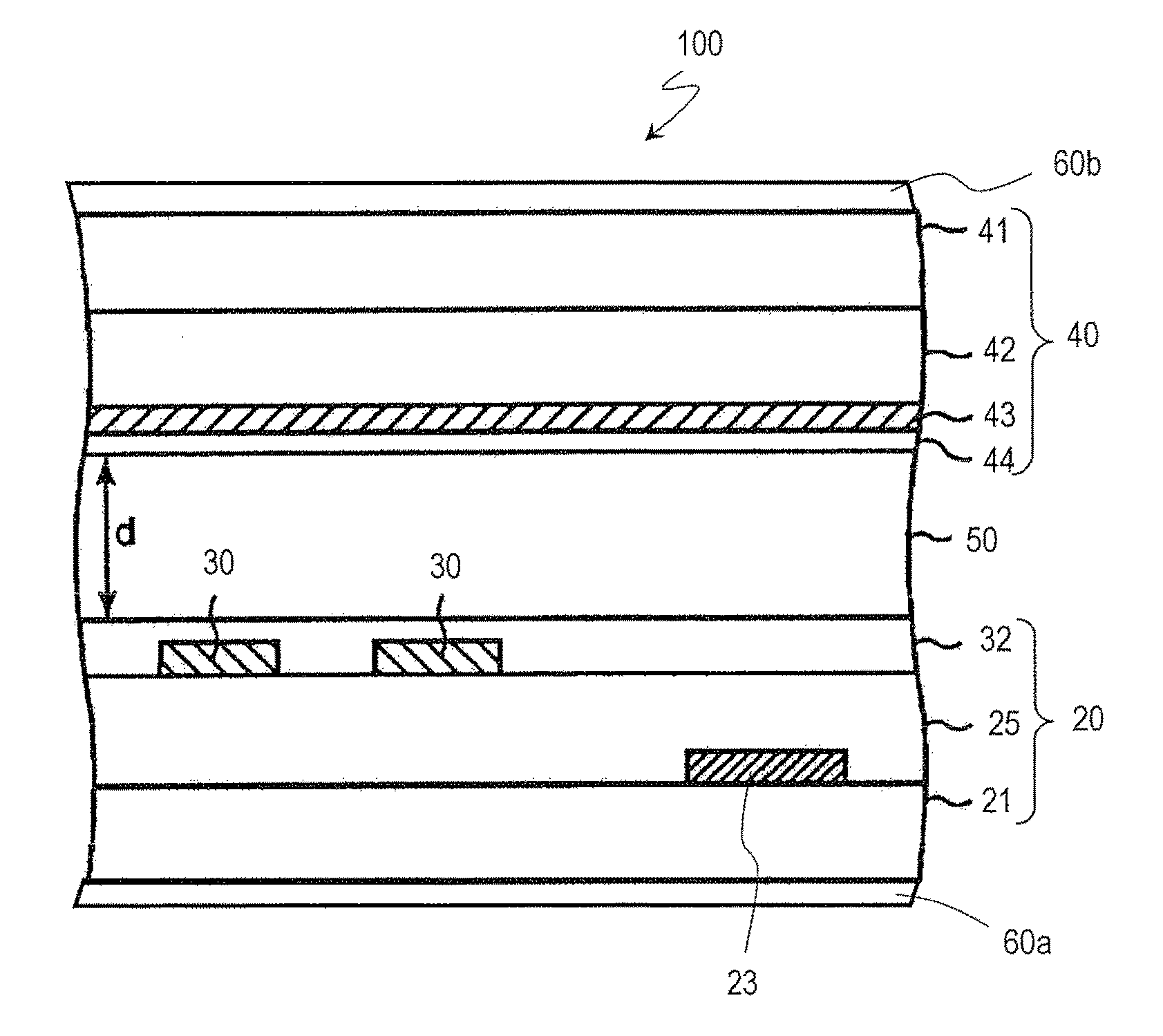

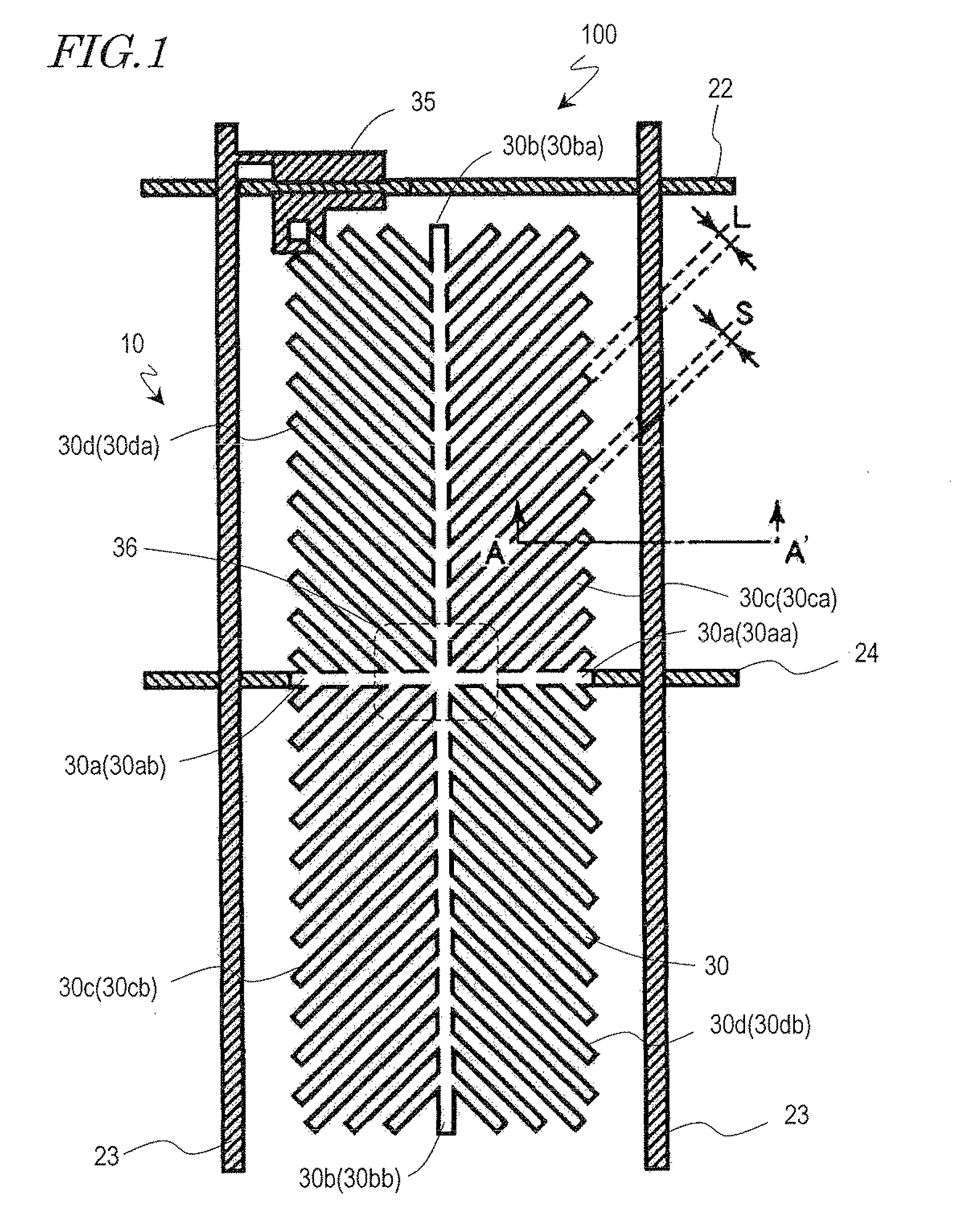

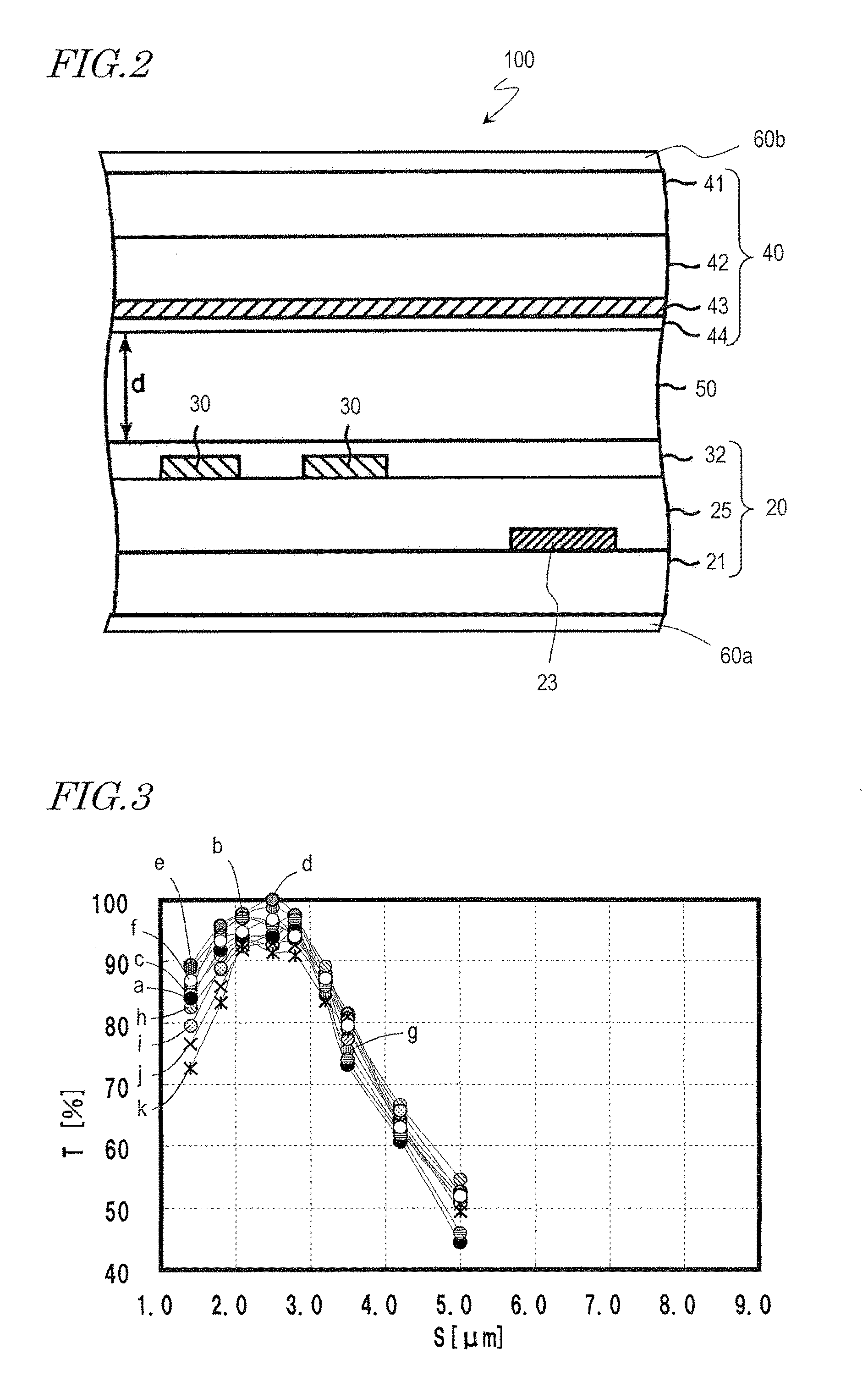

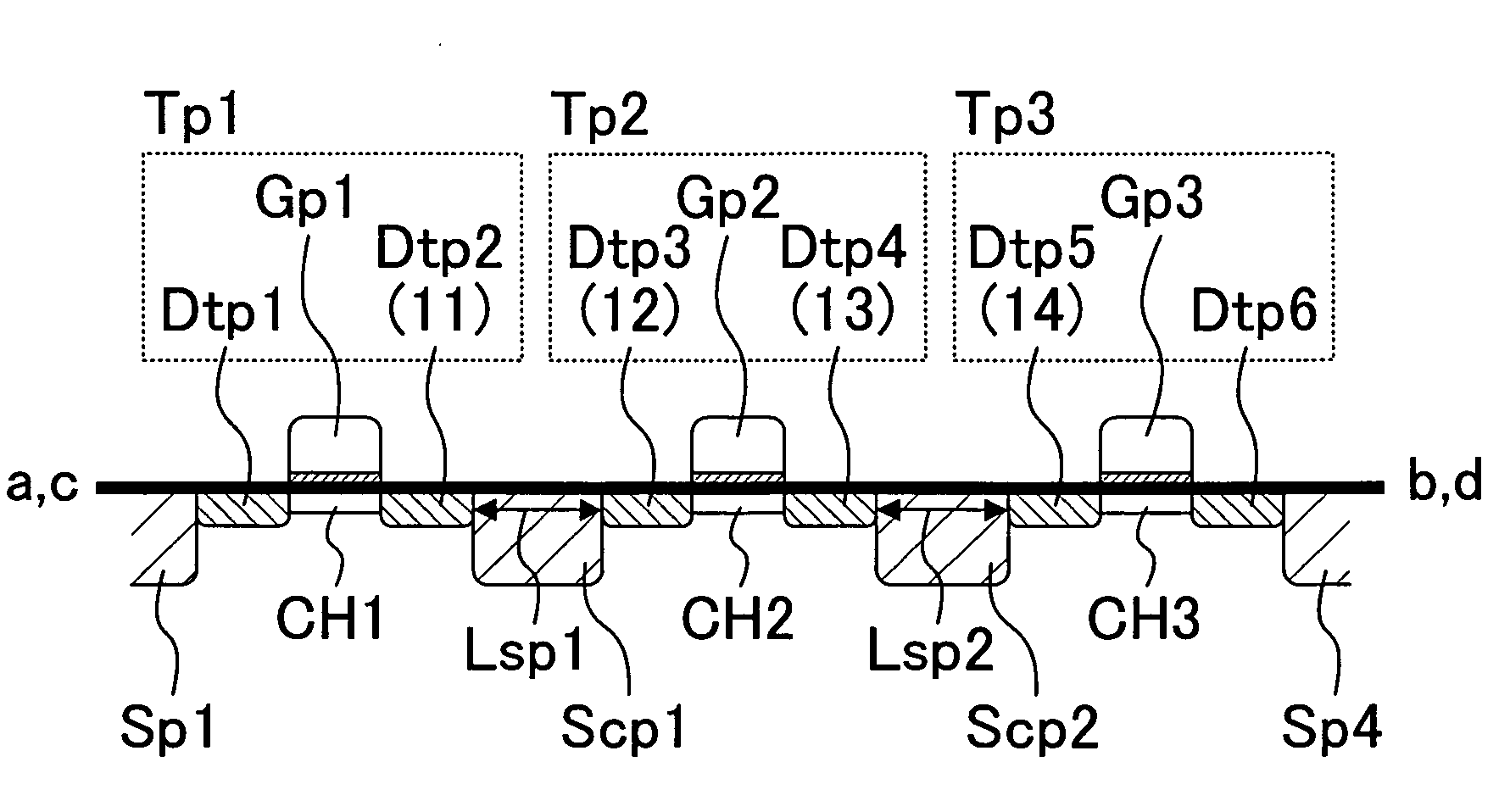

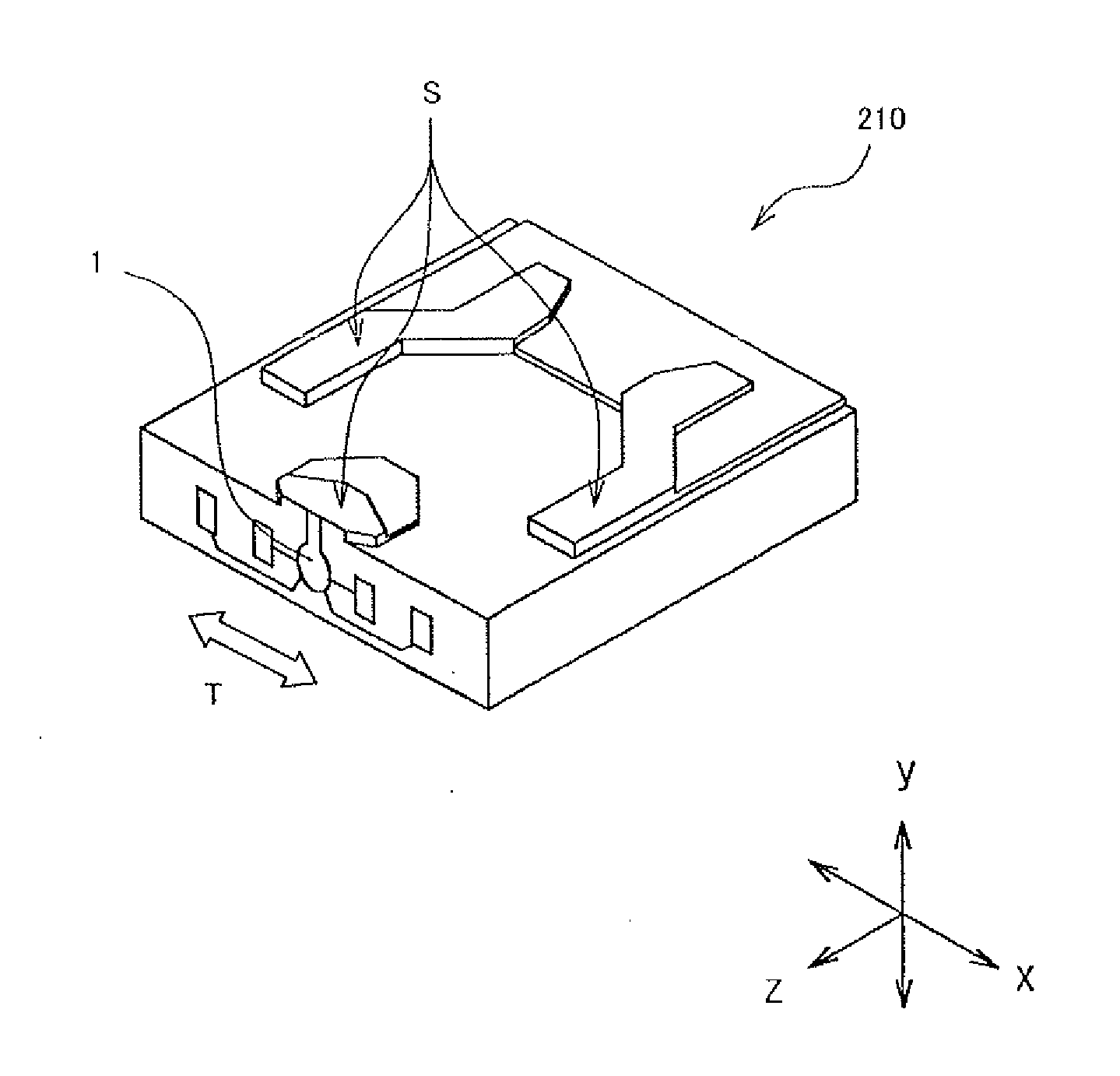

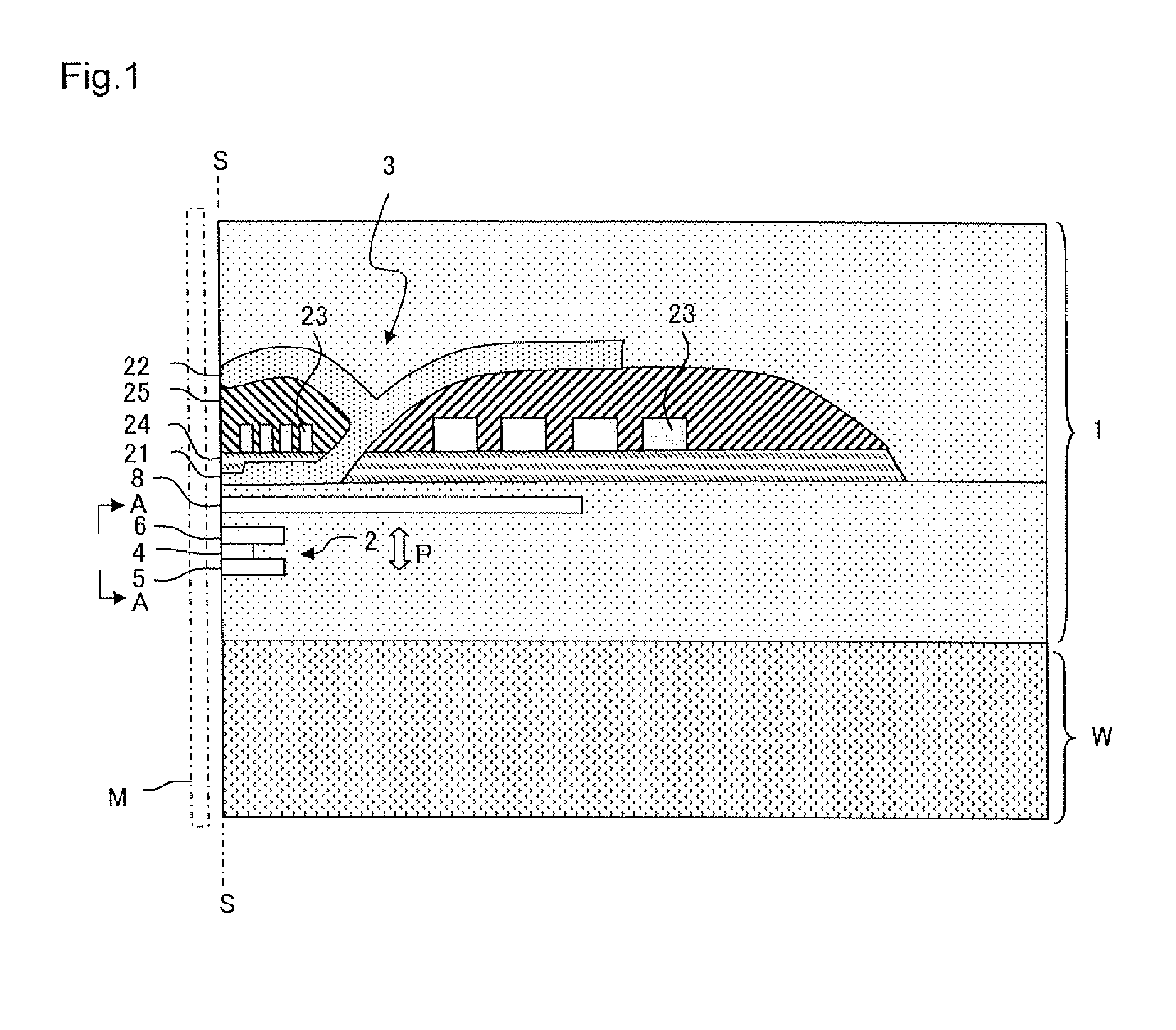

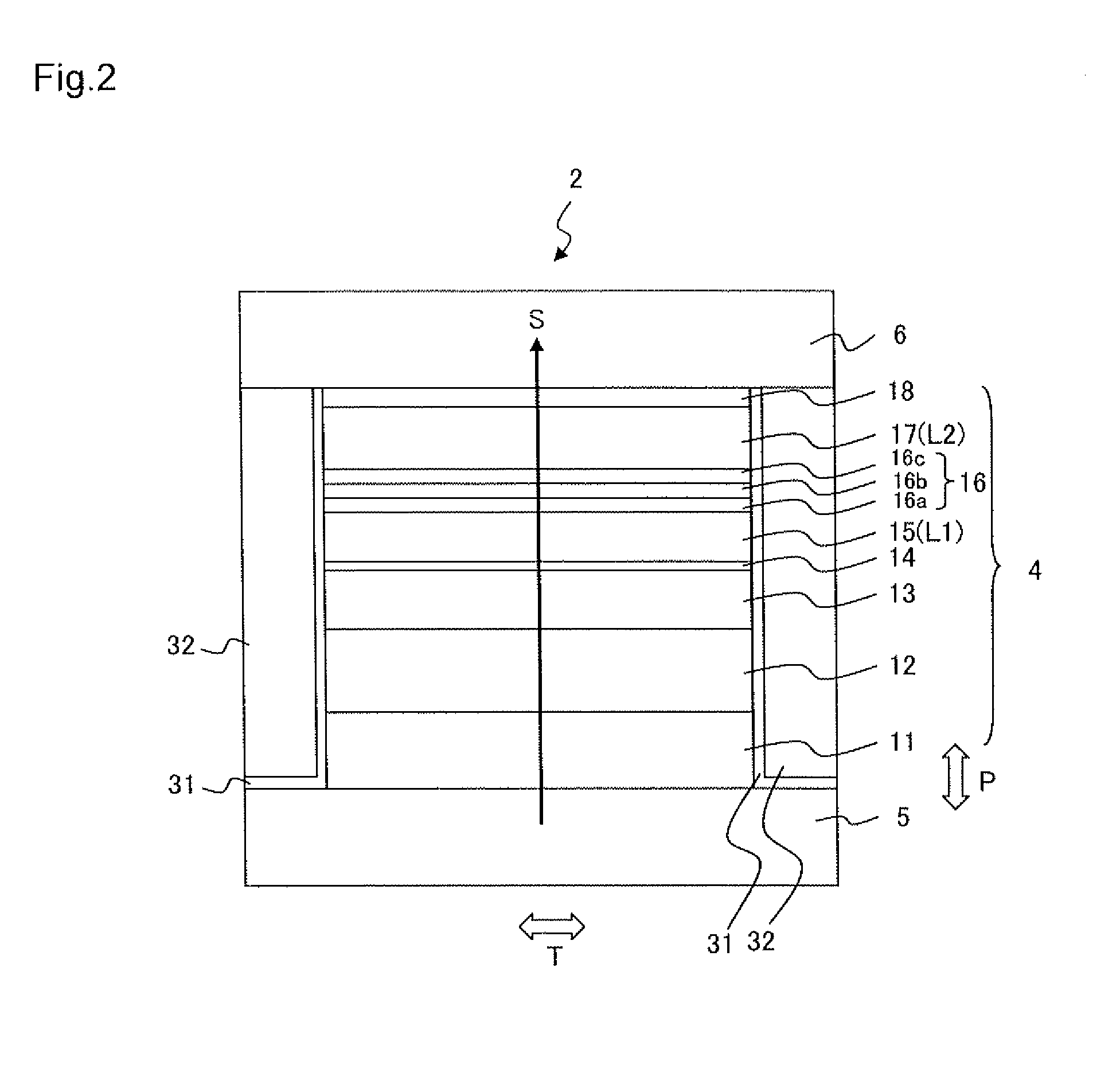

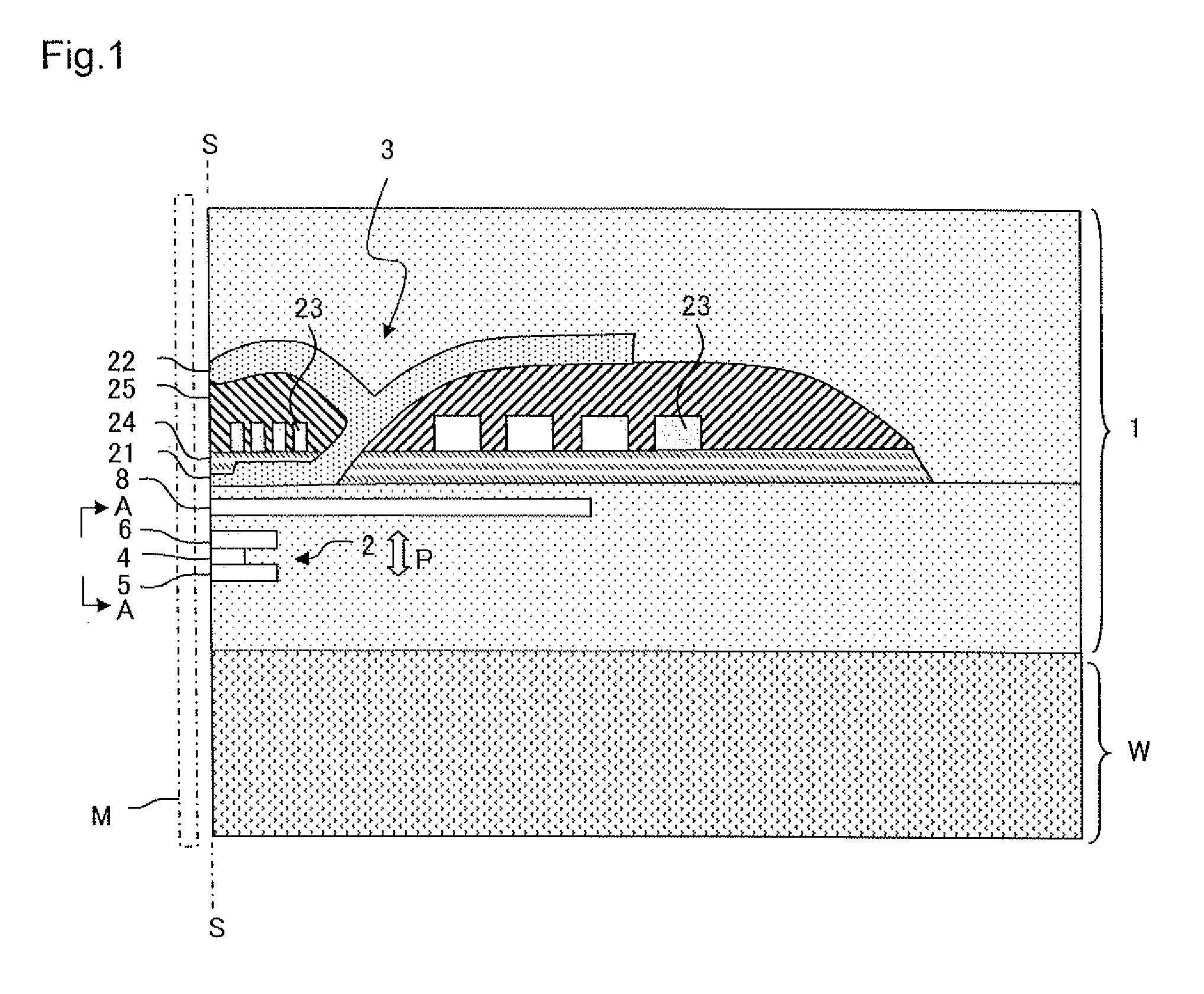

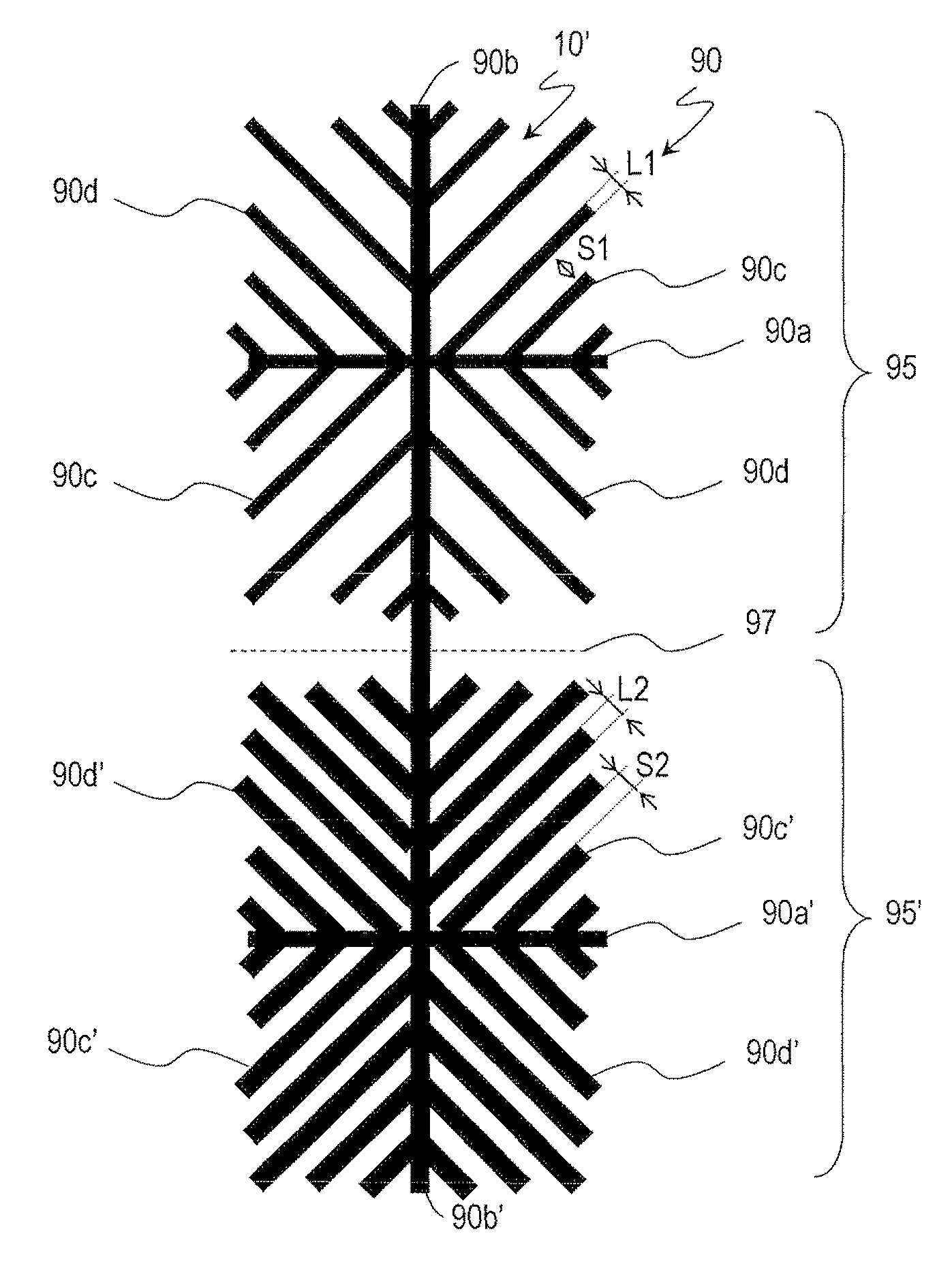

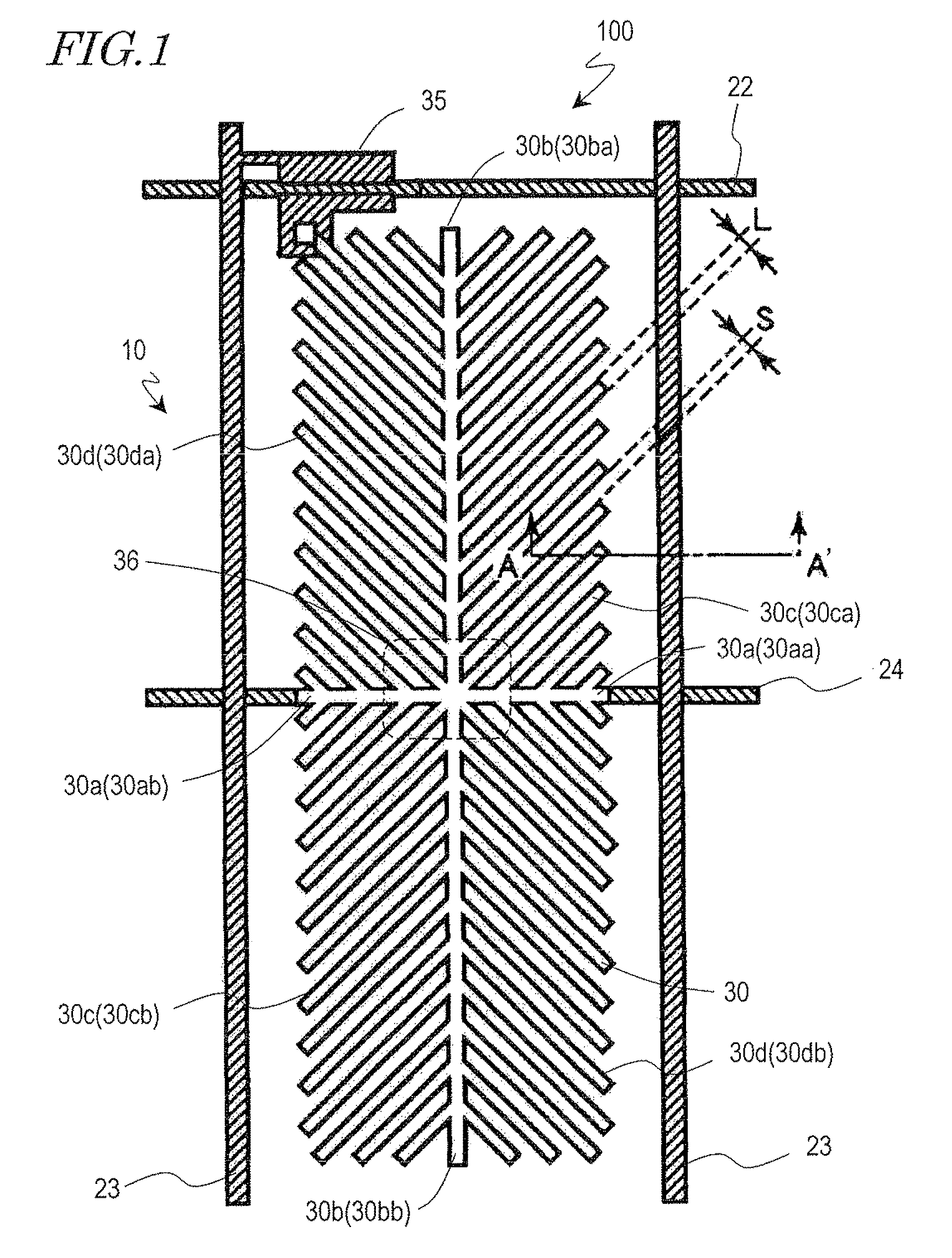

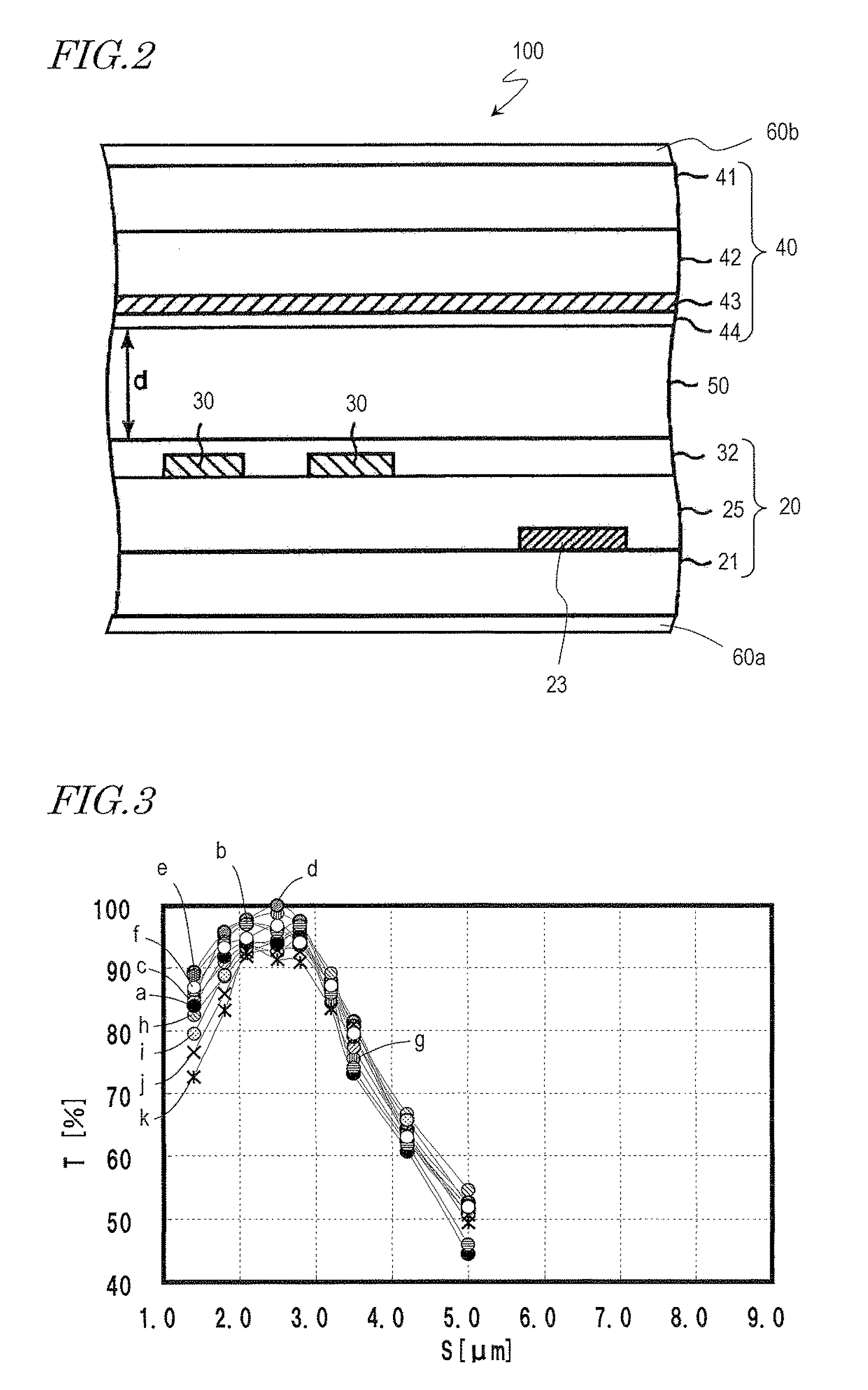

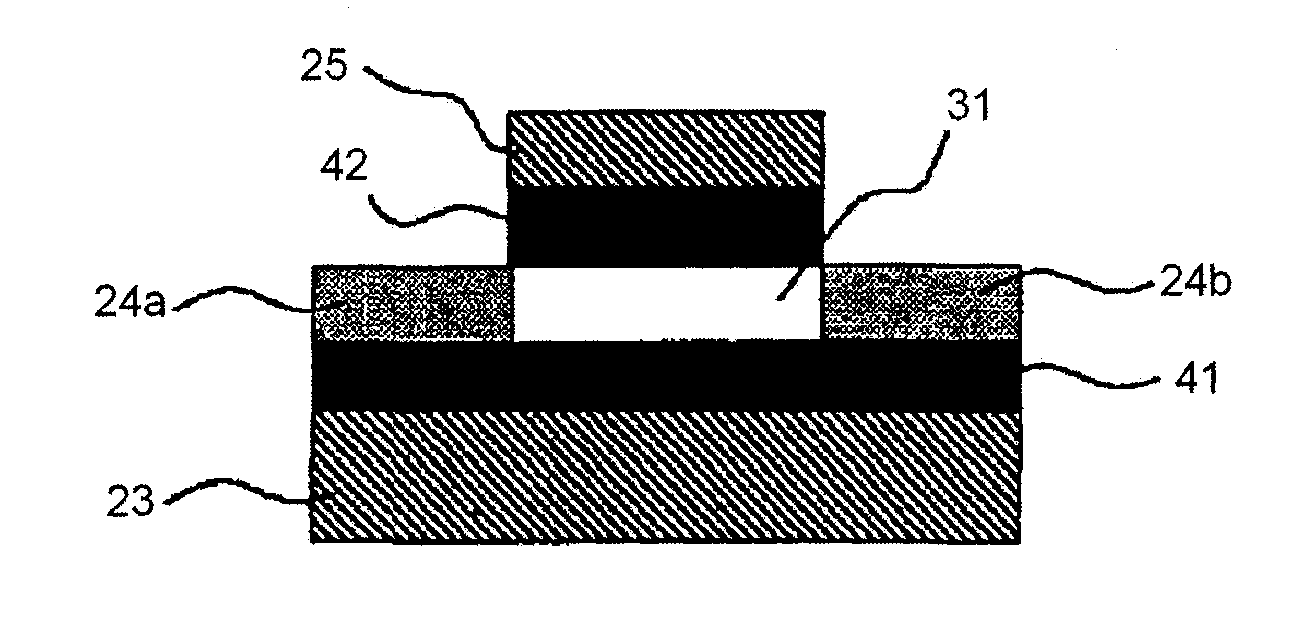

Liquid crystal display device

ActiveUS20100253897A1High quality displayAbnormal alignmentNon-linear opticsVertical alignmentEngineering

There is provided a liquid crystal display device of high picture quality with high brightness and small display unevenness.A vertical alignment type liquid crystal display device which has a plurality of pixels includes: a first electrode which includes, in each of the plurality of pixels, a plurality of first branch portions extending in a first direction and a plurality of second branch portions extending in a second direction that is different from the first direction; a second electrode disposed so as to oppose the first electrode; and a liquid crystal layer interposed between the first electrode and the second electrode, wherein a width of each of the plurality of first branch portions and the plurality of second branch portions is in a range not less than 1.4 μm and not more than 8.0 μm.

Owner:SHARP KK

Cell and semiconductor device

InactiveUS20070164317A1Suppress mutationConstant separationSolid-state devicesSemiconductor/solid-state device manufacturingImpurity diffusionSemiconductor

A cell includes a plurality of diffusion region pairs, each of the diffusion region pairs being formed by a first impurity diffusion region which is a constituent of a transistor and a second impurity diffusion region such that the first and second impurity diffusion regions are provided side-by-side in a gate length direction with a device isolation region interposed therebetween. In each of the diffusion region pairs, the first and second impurity diffusion regions have an equal length in the gate width direction and are provided at equal positions in the gate width direction, and a first isolation region portion, which is part of the device isolation region between the first and second impurity diffusion regions, has a constant separation length. In the diffusion region pairs, the first isolation region portions have an equal separation length.

Owner:SOCIONEXT INC

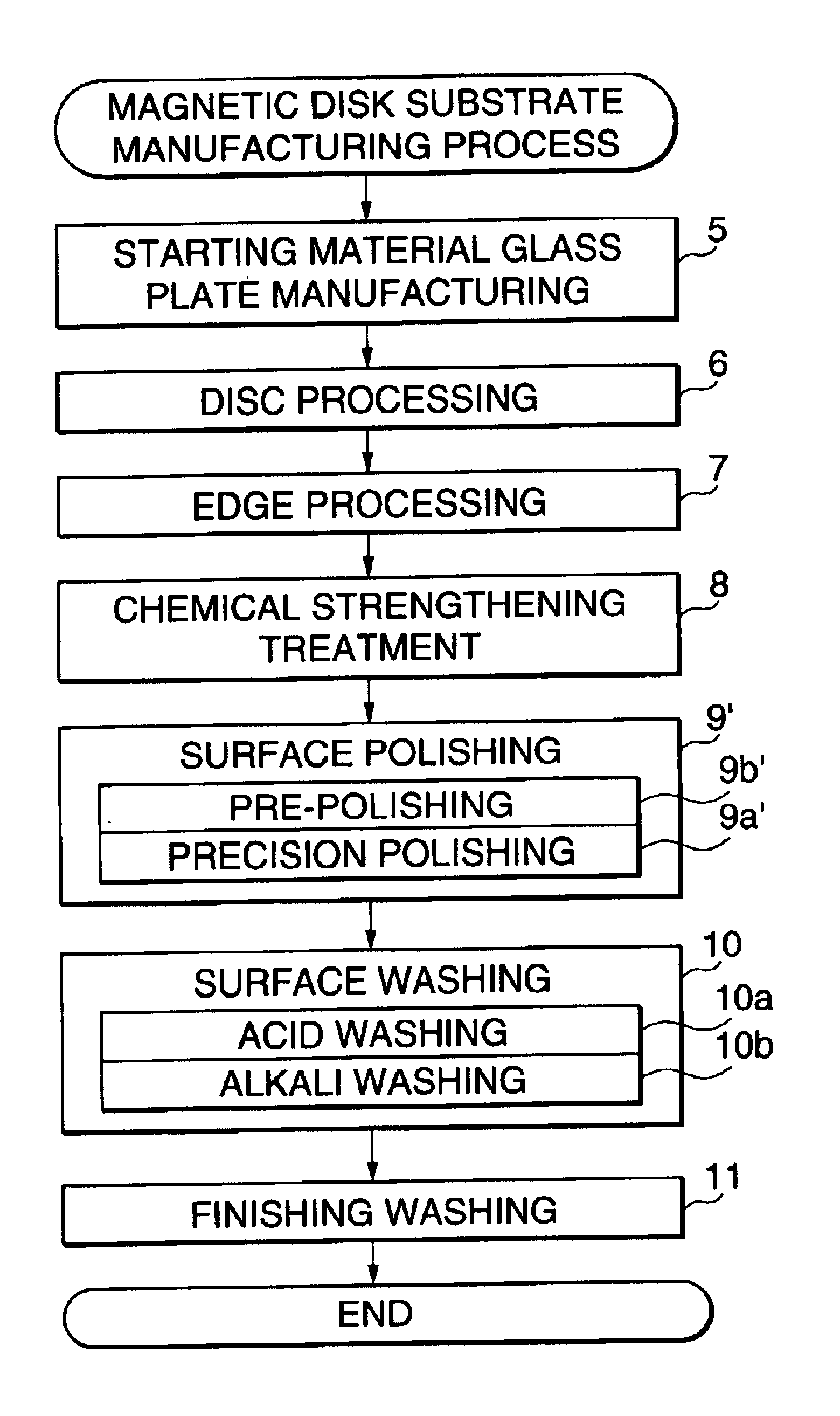

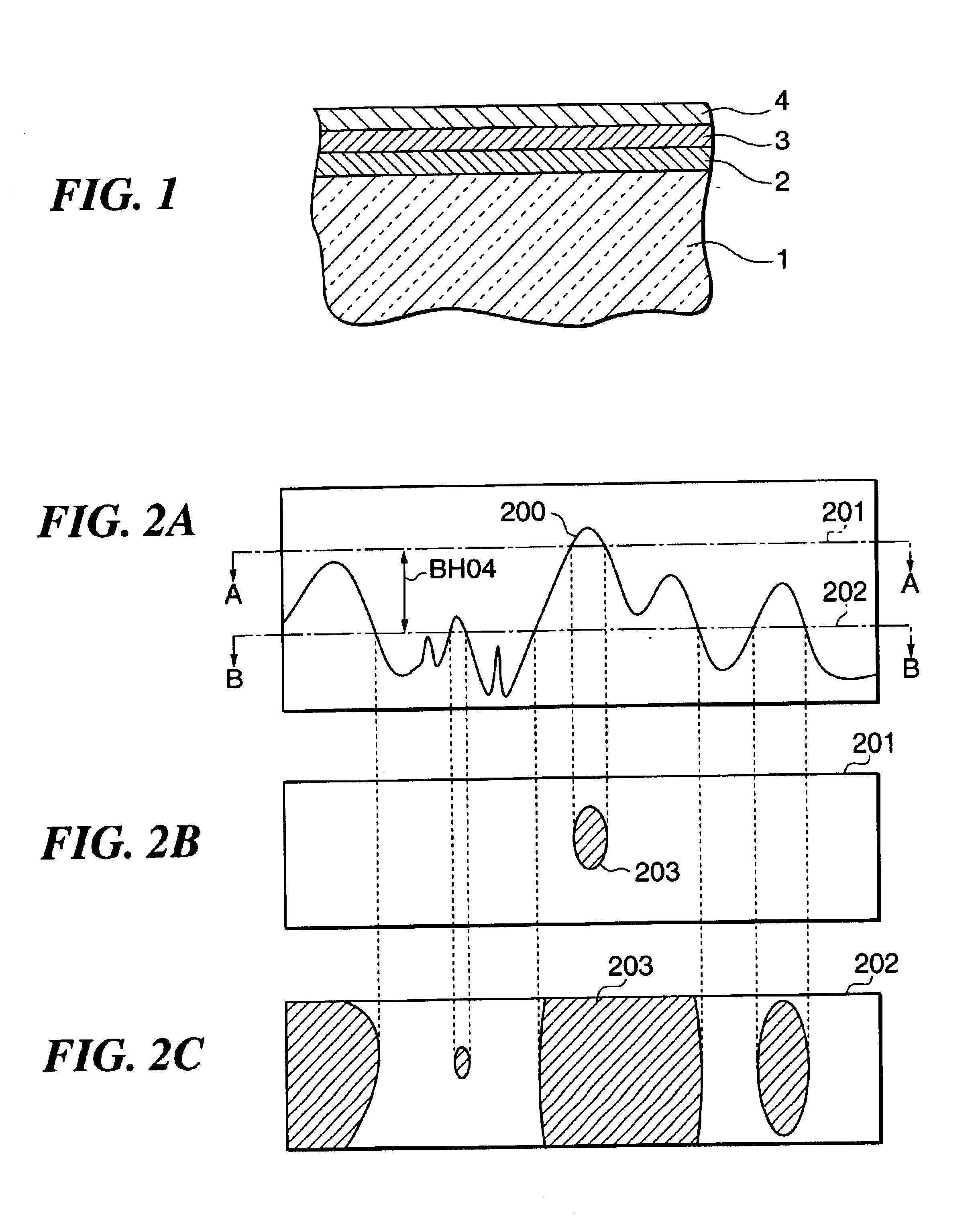

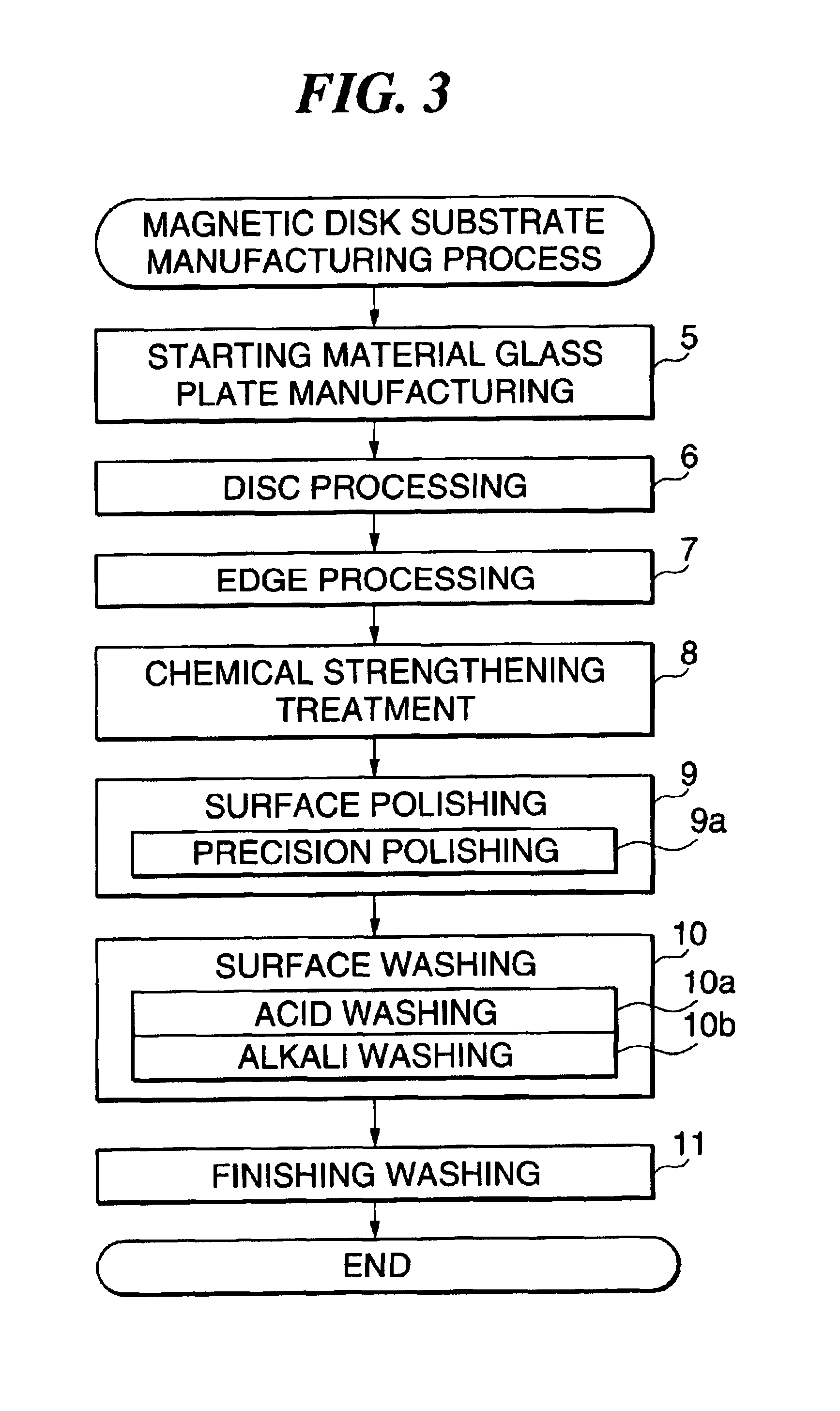

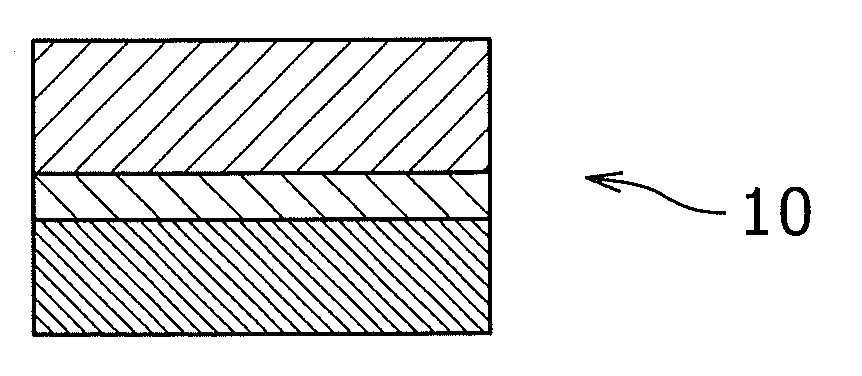

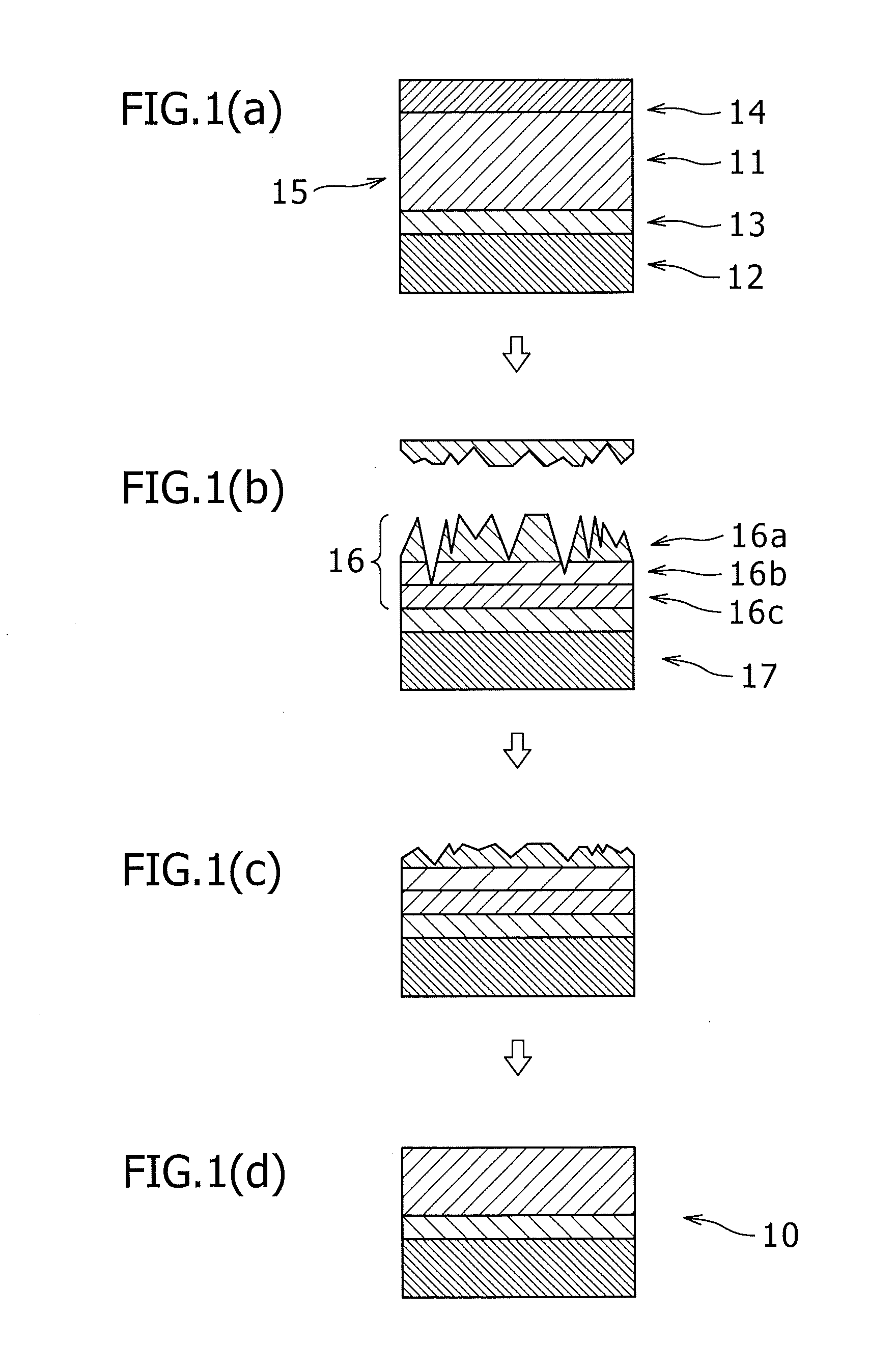

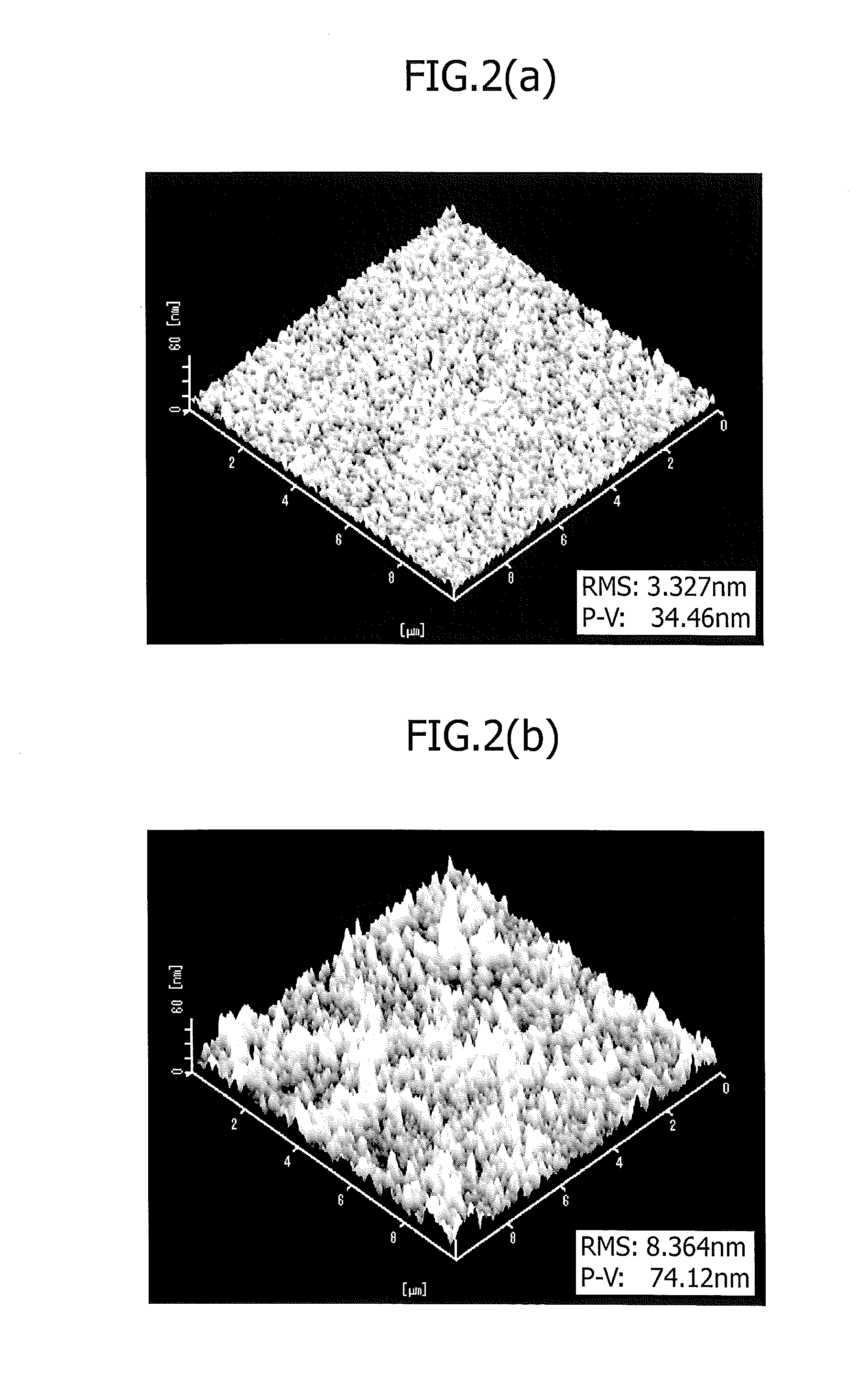

Substrate for information recording media and manufacturing method thereof, and information recording medium

InactiveUS7040953B2Variation can be suppressedSuppress mutationReconditioning/cleaning record carriersBase layers for recording layersMetallurgyGlass sheet

There are provided a substrate for information recording media and a manufacturing method thereof, according to which the projection height of minute undulations formed on the substrate surfaces can be made more uniform, and variation in the projection density can be suppressed. First, chemical strengthening treatment is carried out on a glass substrate that has been prepared by processing a sheet-shaped starting material glass plate into a predetermined shape. Then, precision polishing is carried out on the glass substrate that has been subjected to the chemical strengthening treatment, such that a polishing amount in a thickness direction of the glass substrate is within a predetermined range. Finally, surface washing is carried out on the glass substrate that has been subjected to said precision polishing.

Owner:HOYA CORP

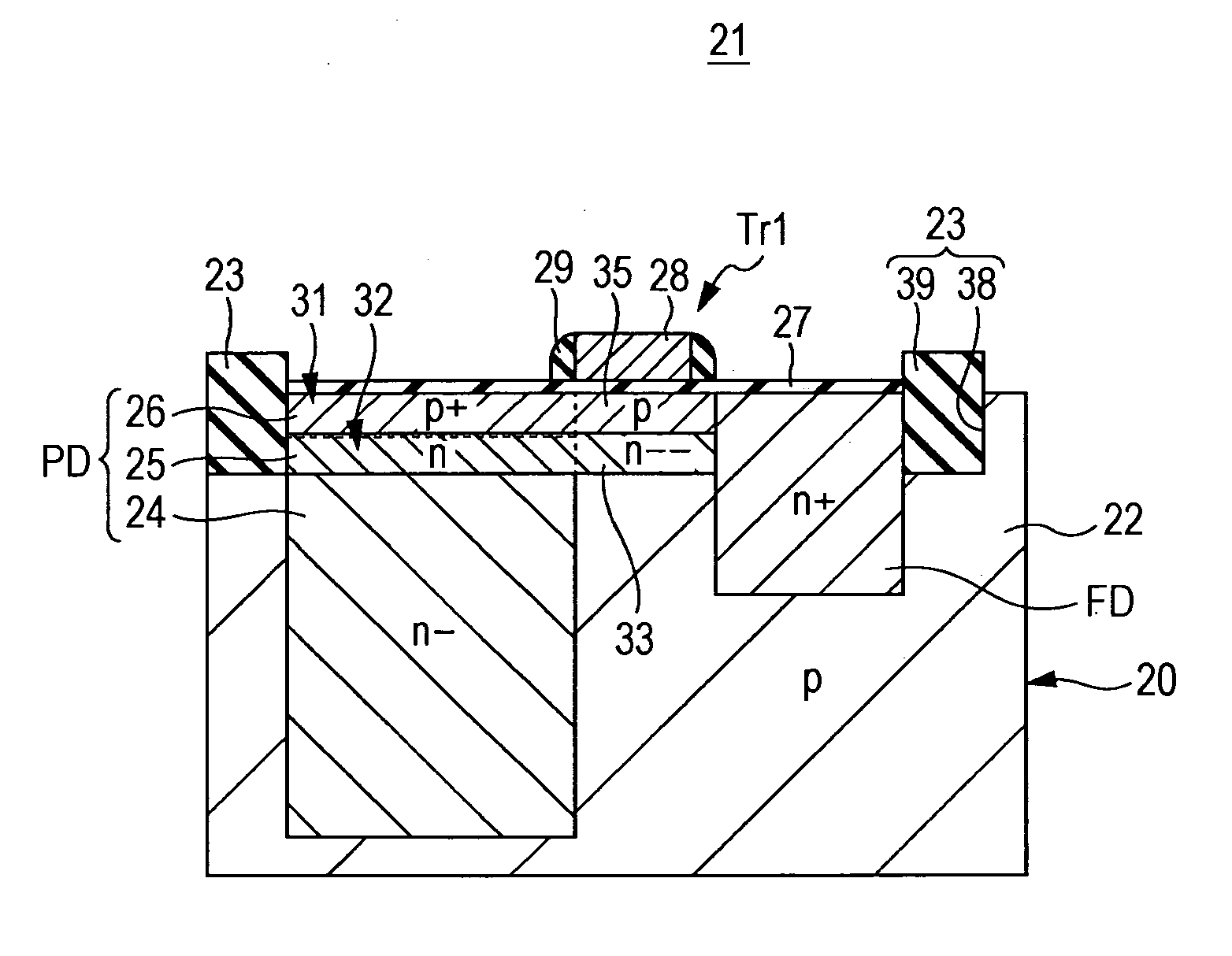

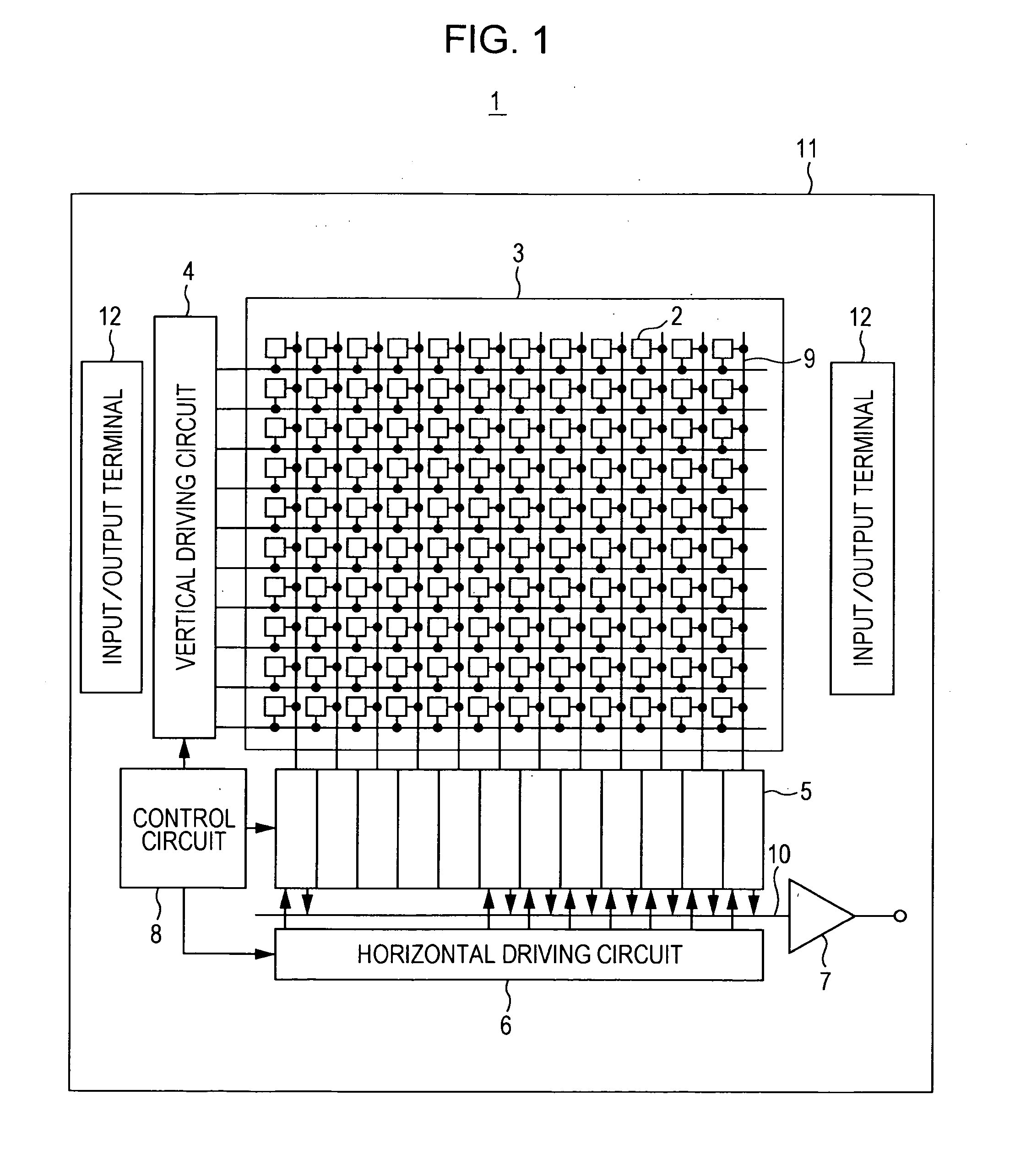

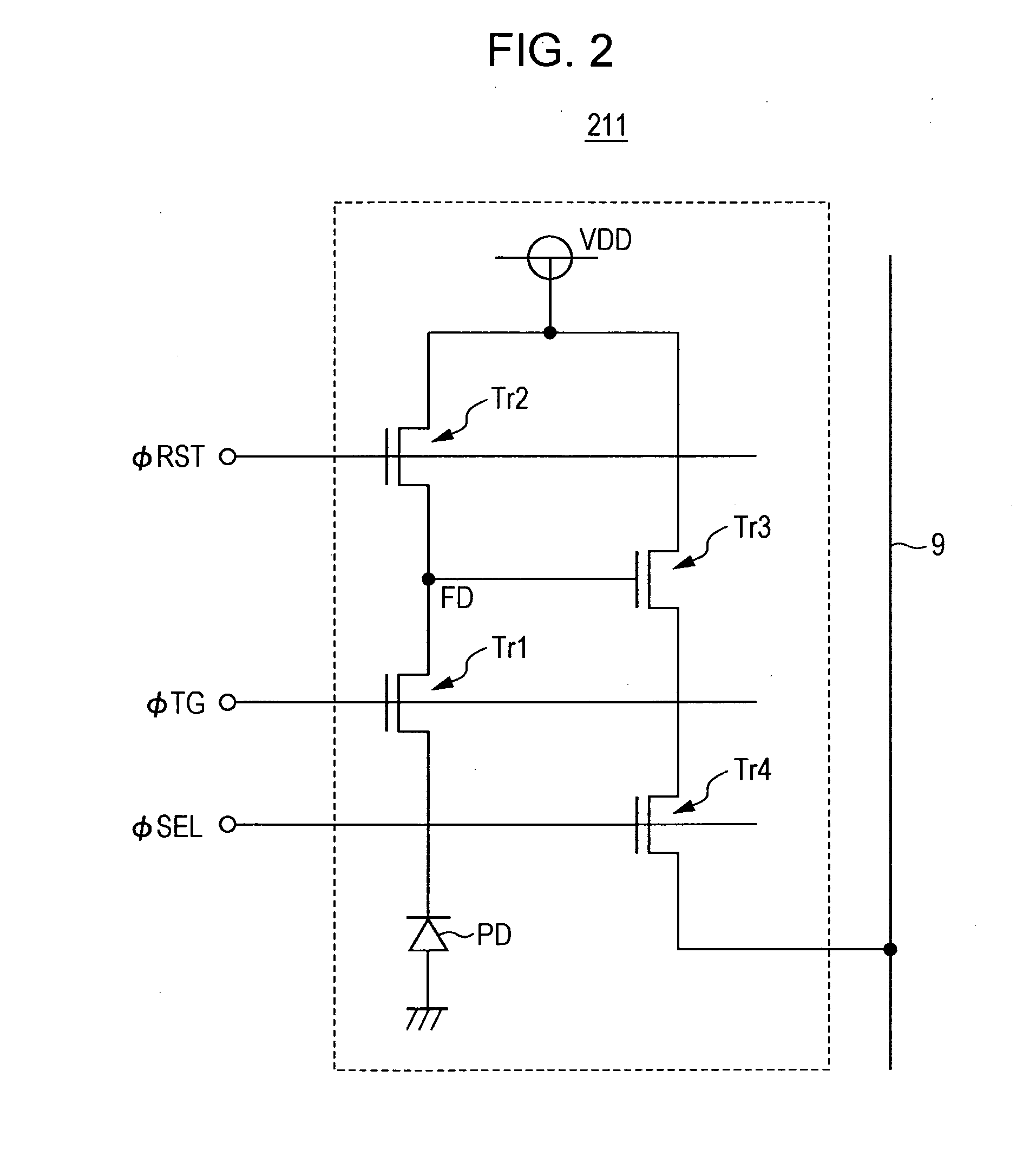

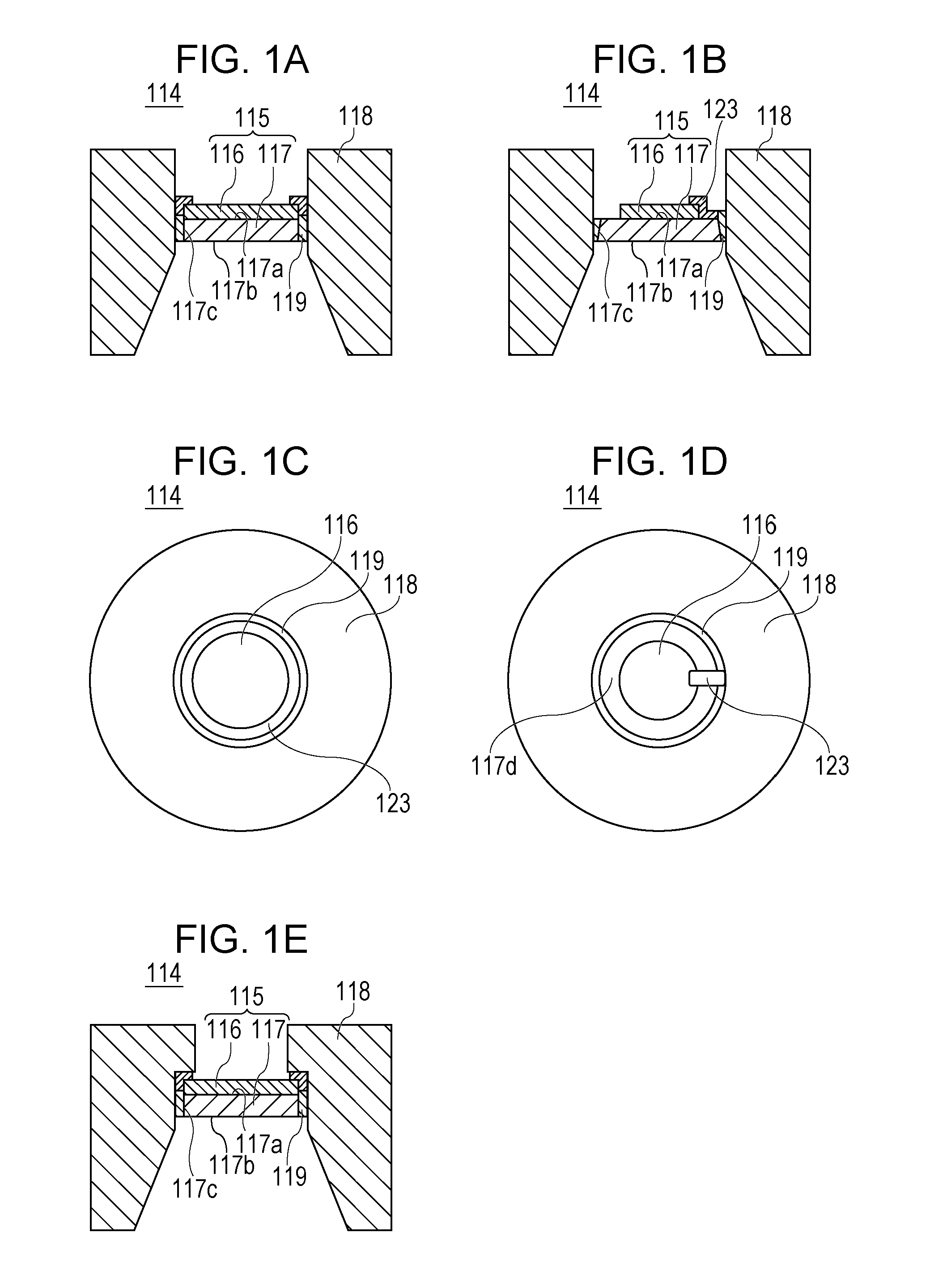

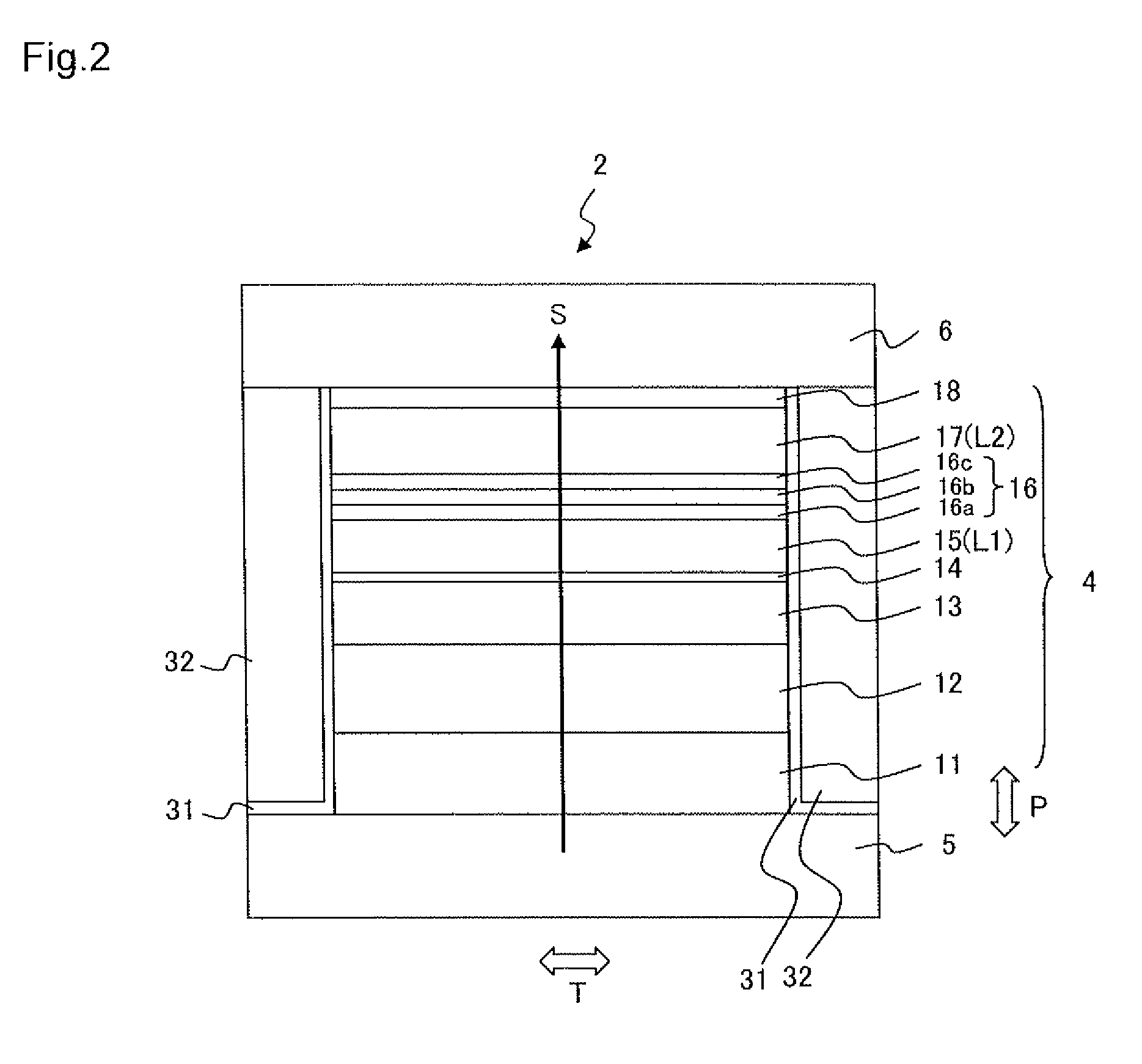

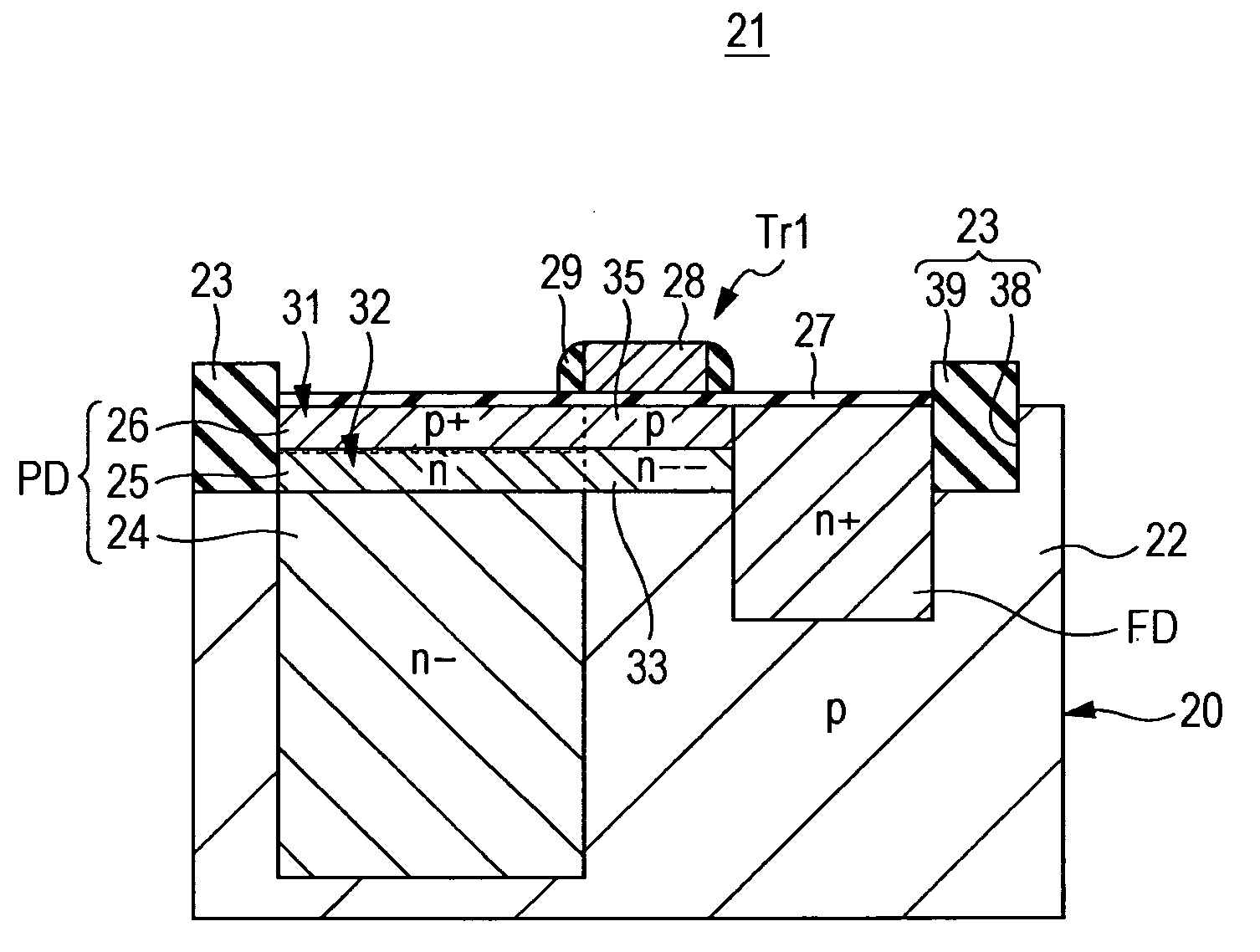

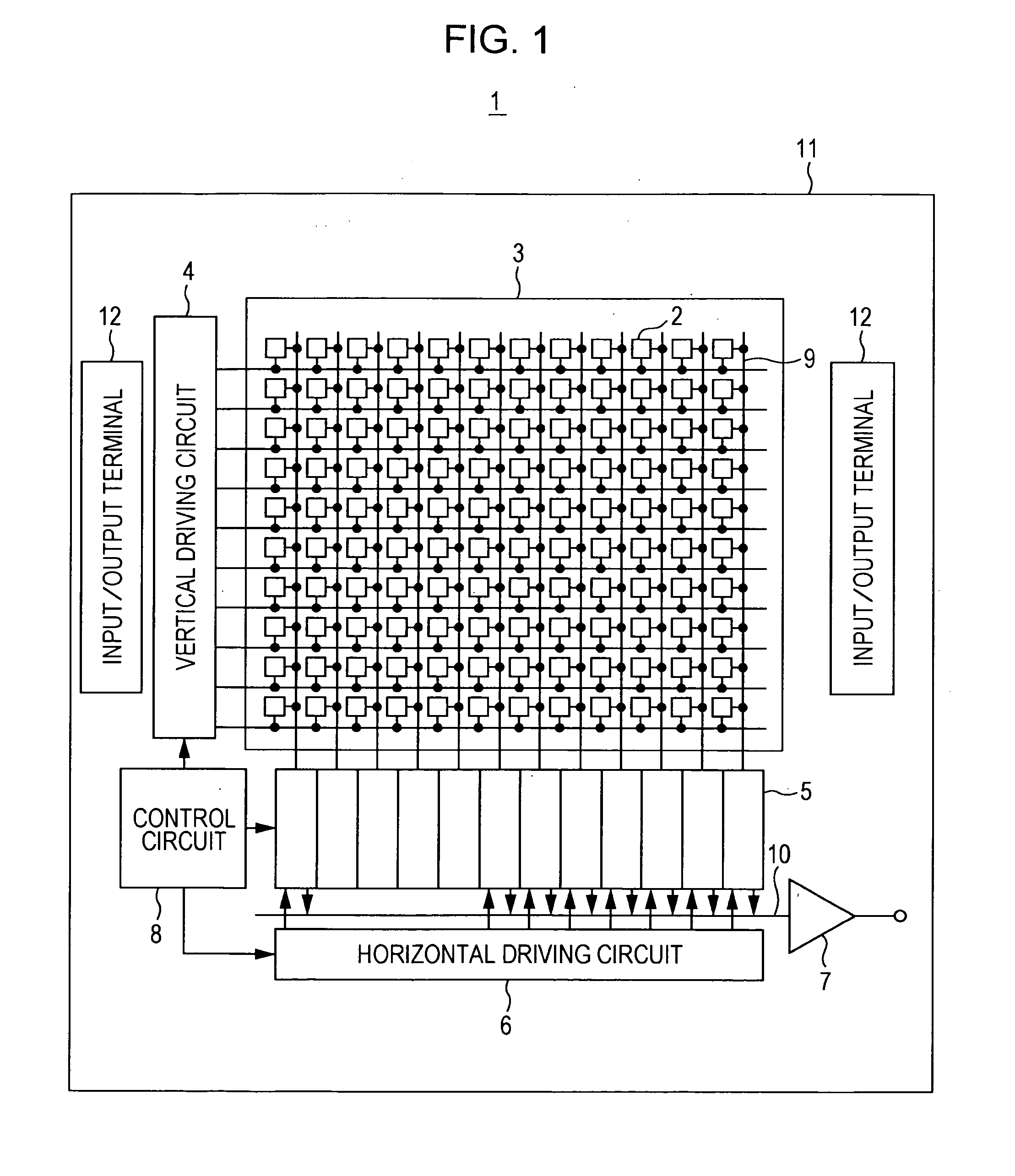

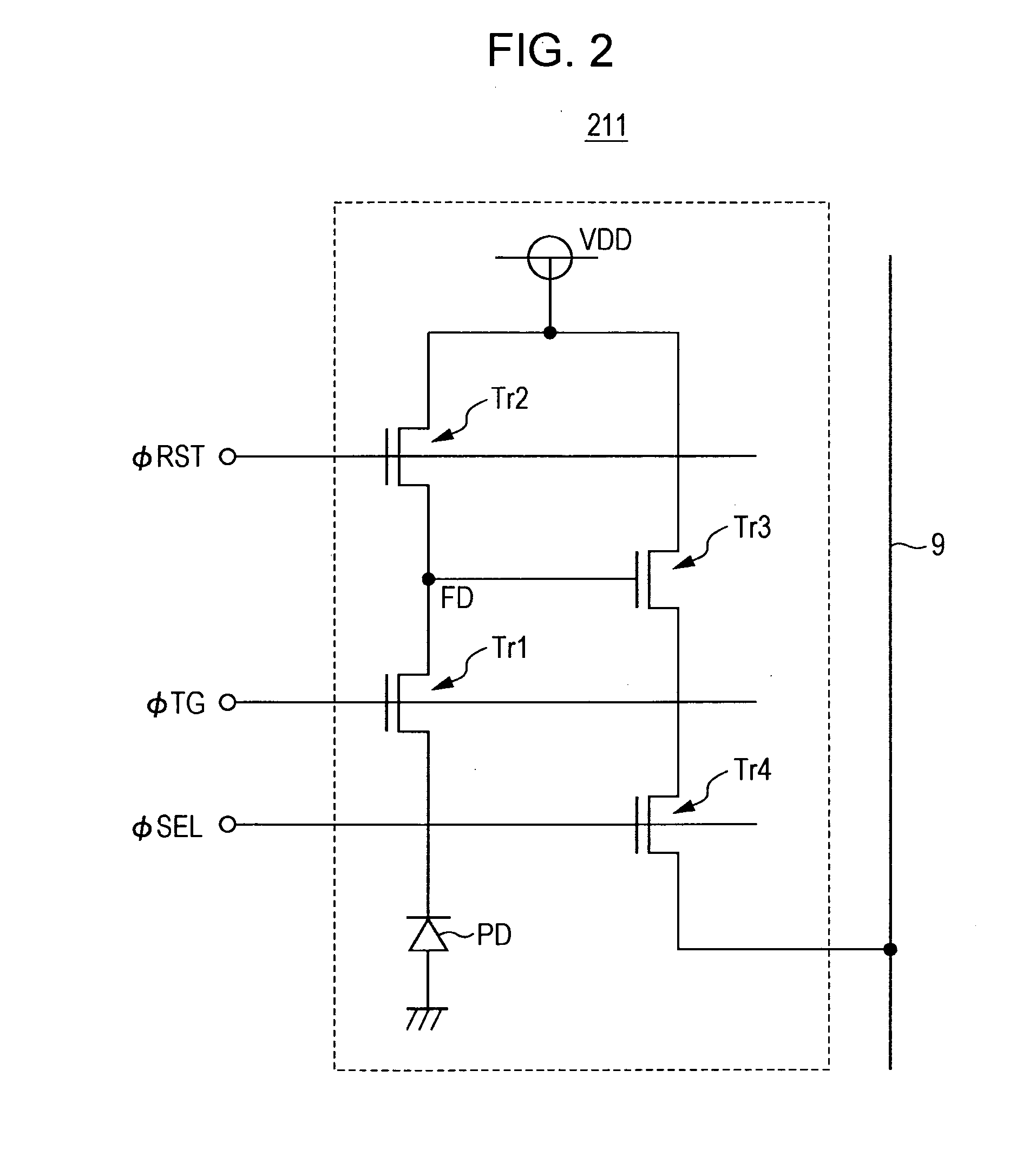

Solid-state imaging apparatus, method of manufacturing same, and electronic apparatus

ActiveUS20110180860A1Suppress mutationImprove pixel characteristicTransistorSolid-state devicesPhotoelectric conversionEngineering

A solid-state imaging apparatus includes a plurality of pixels each including a photoelectric conversion unit and pixel transistors, which are formed on a semiconductor substrate; a floating diffusion unit in the pixel; a first-conductivity-type ion implantation area for surface pinning, which is formed over the surface on the side of the photoelectric conversion unit and the surface of the semiconductor substrate; and a second-conductivity-type ion implantation area for forming an overflow path serving as an overflow path for the floating diffusion unit, the second-conductivity-type ion implantation area being formed below the entire area of the first-conductivity-type ion implantation area. An overflow barrier is formed using the second-conductivity-type ion implantation area. A charge storage area is formed using an area in which the second-conductivity-type semiconductor area and the second-conductivity-type ion implantation area superpose each other.

Owner:SONY SEMICON SOLUTIONS CORP

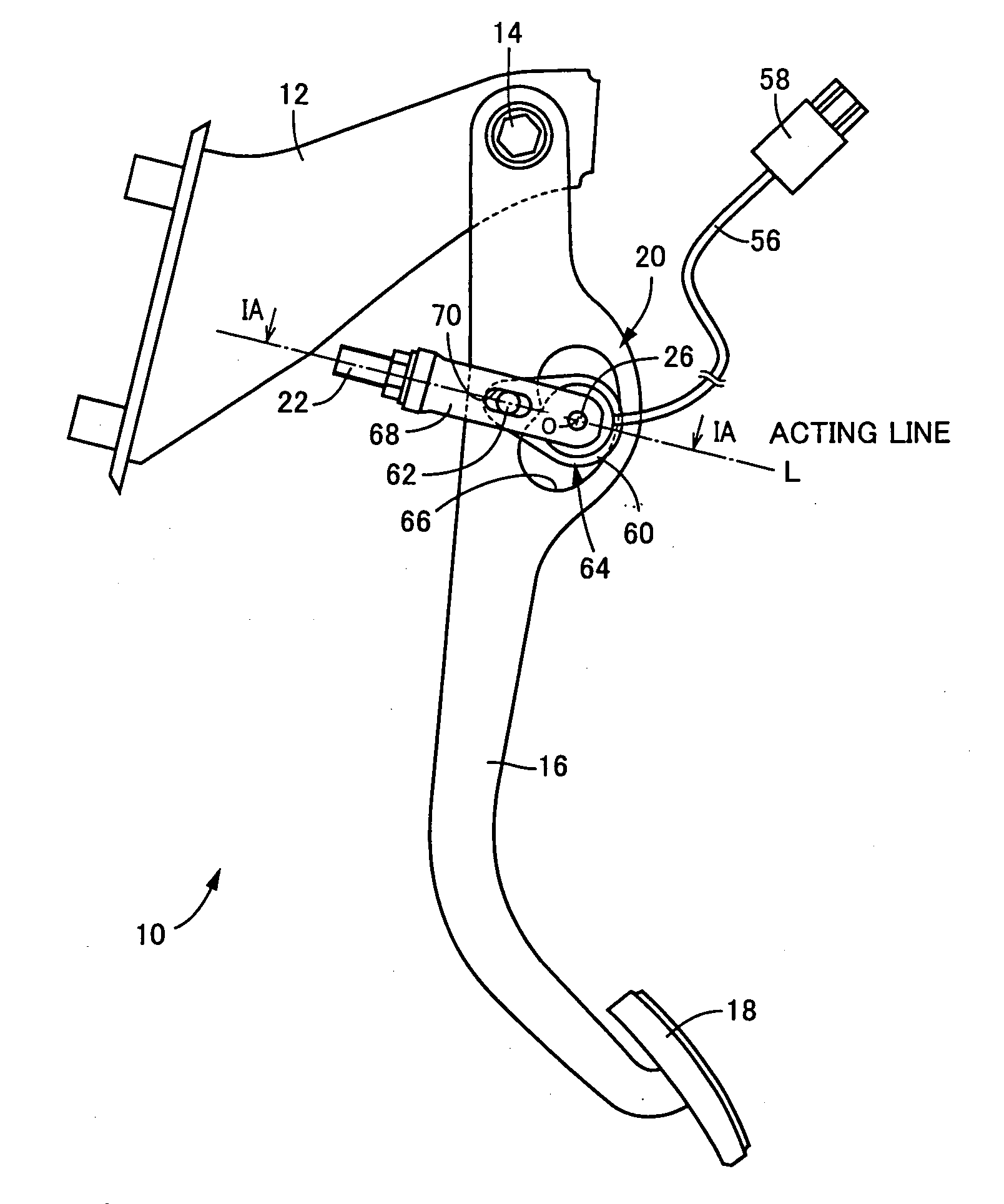

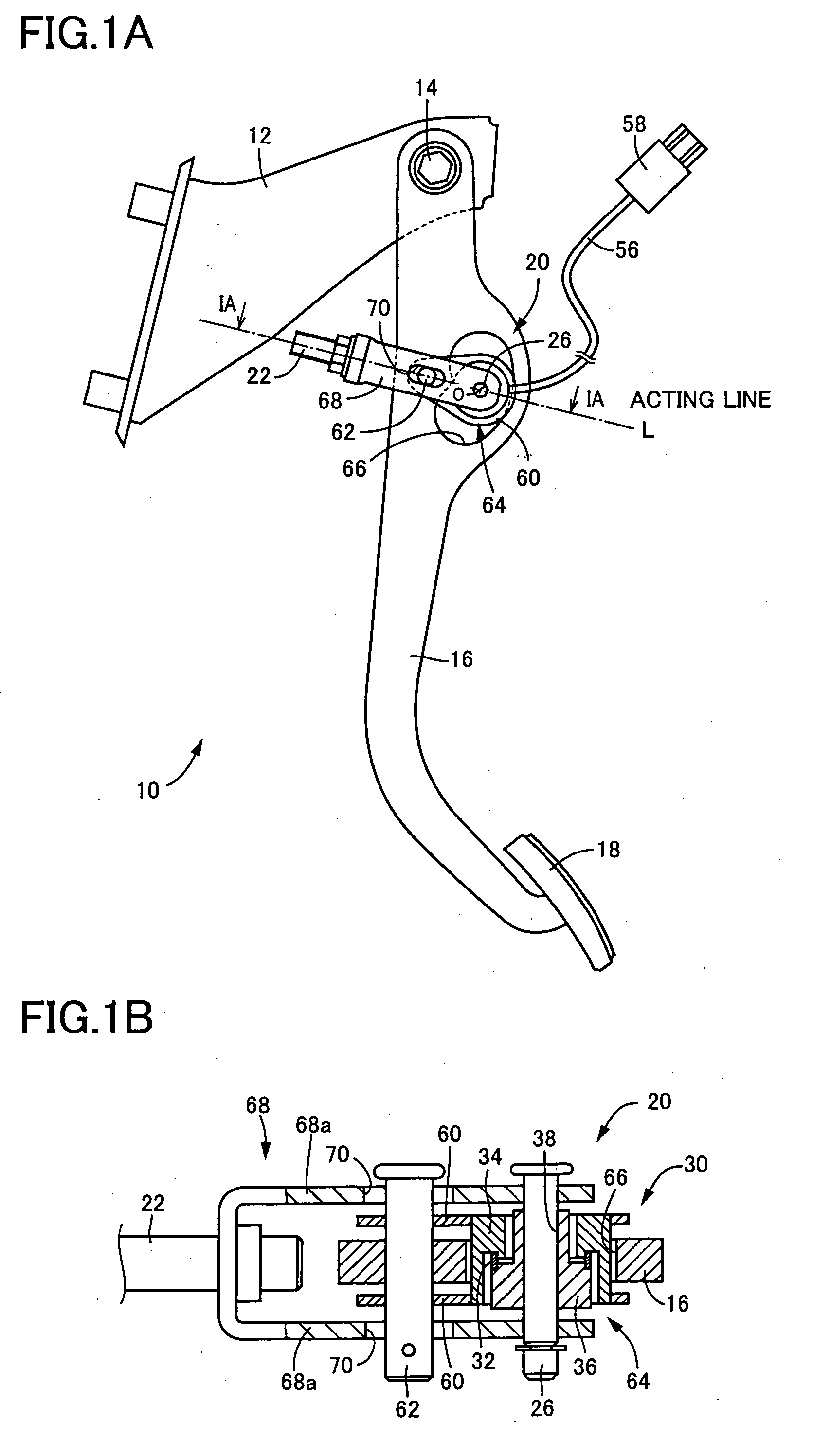

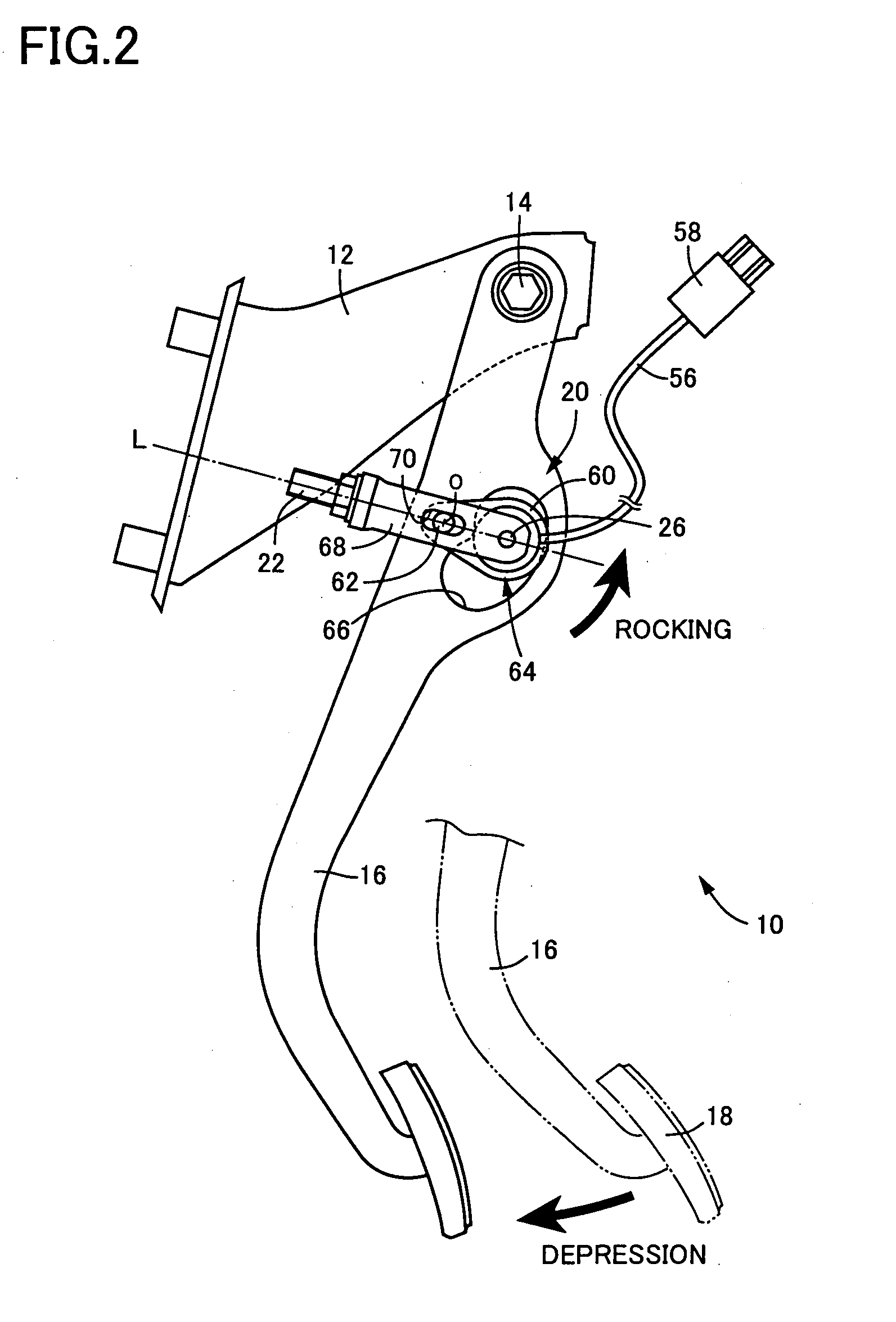

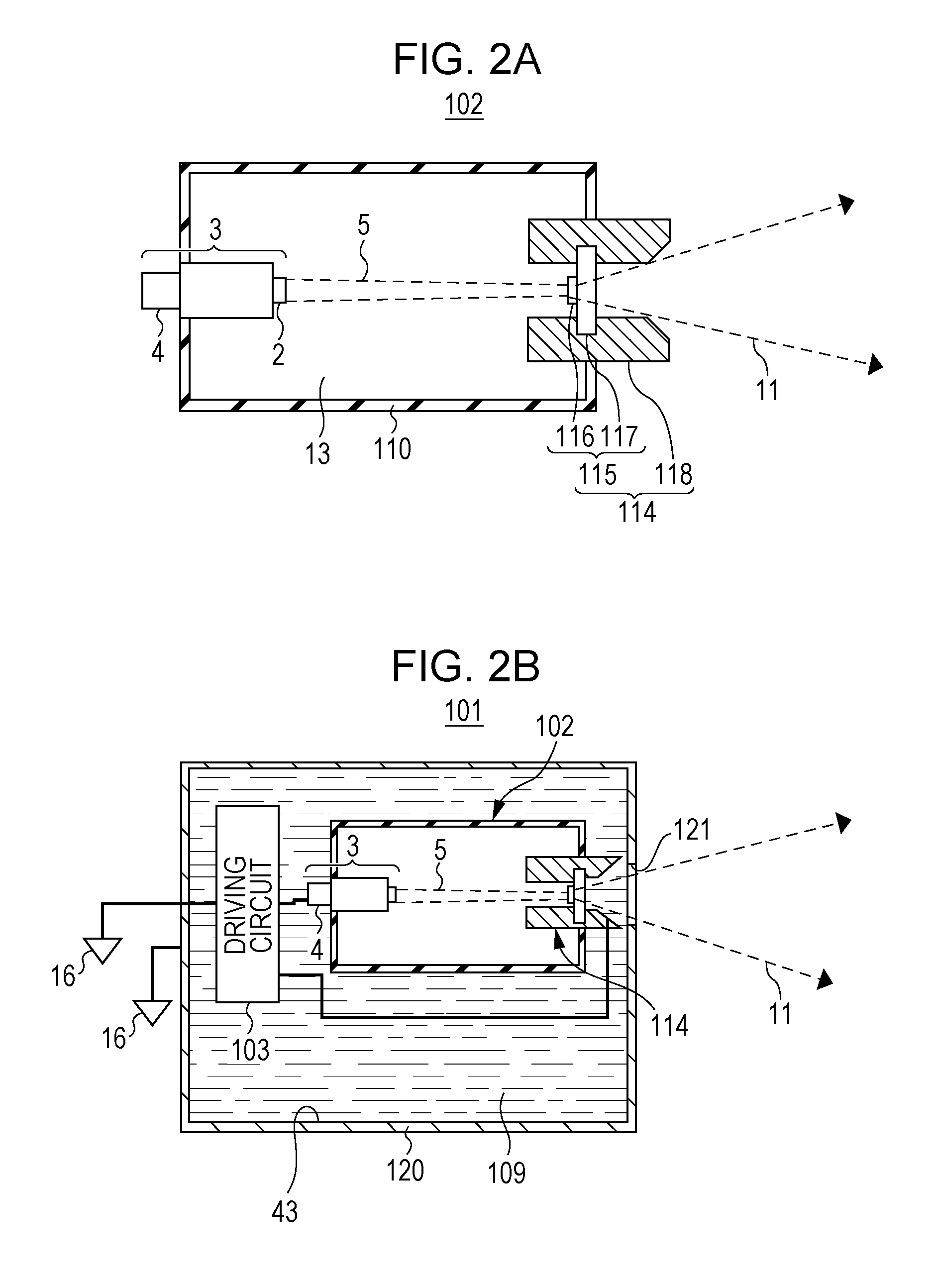

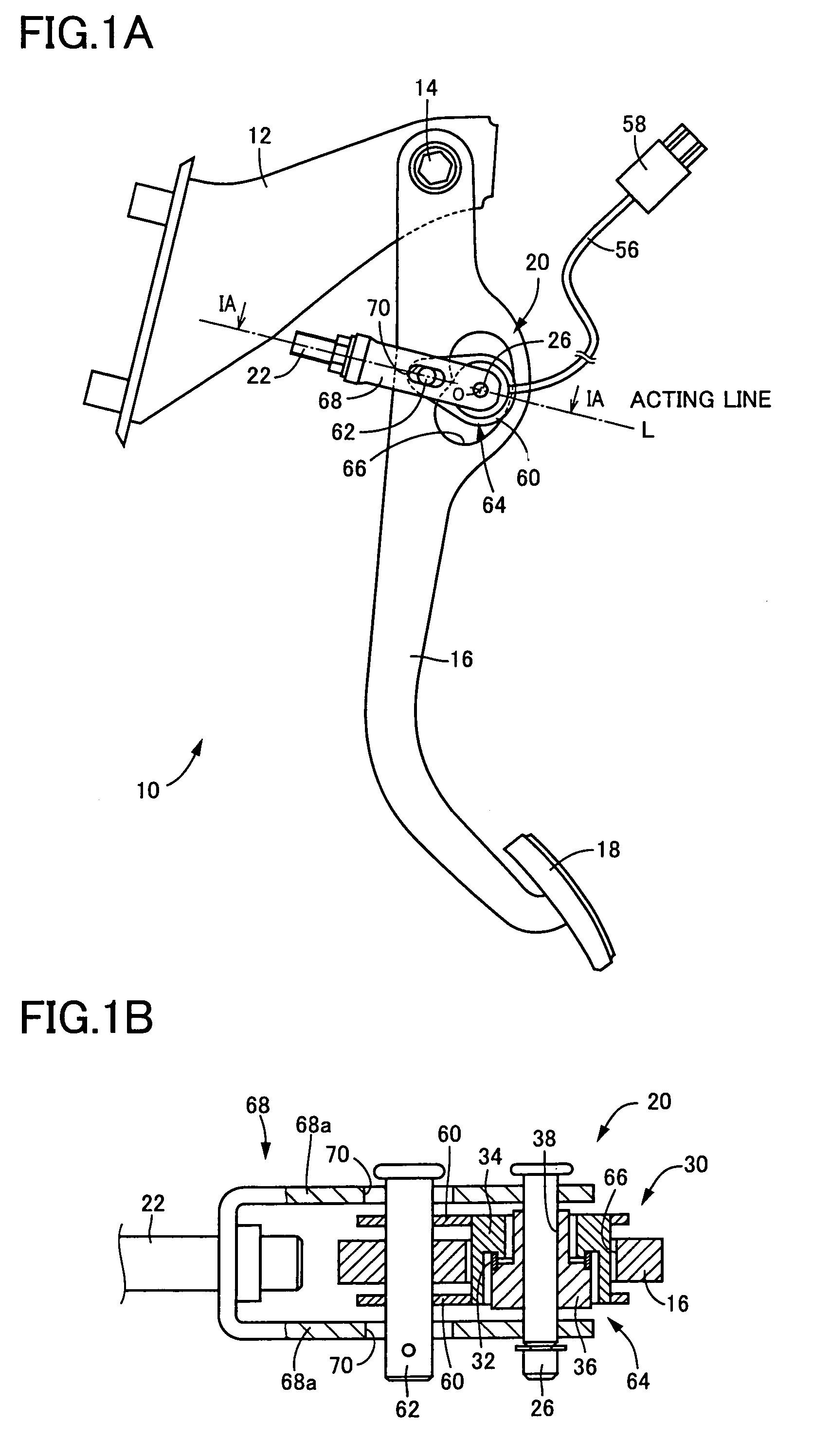

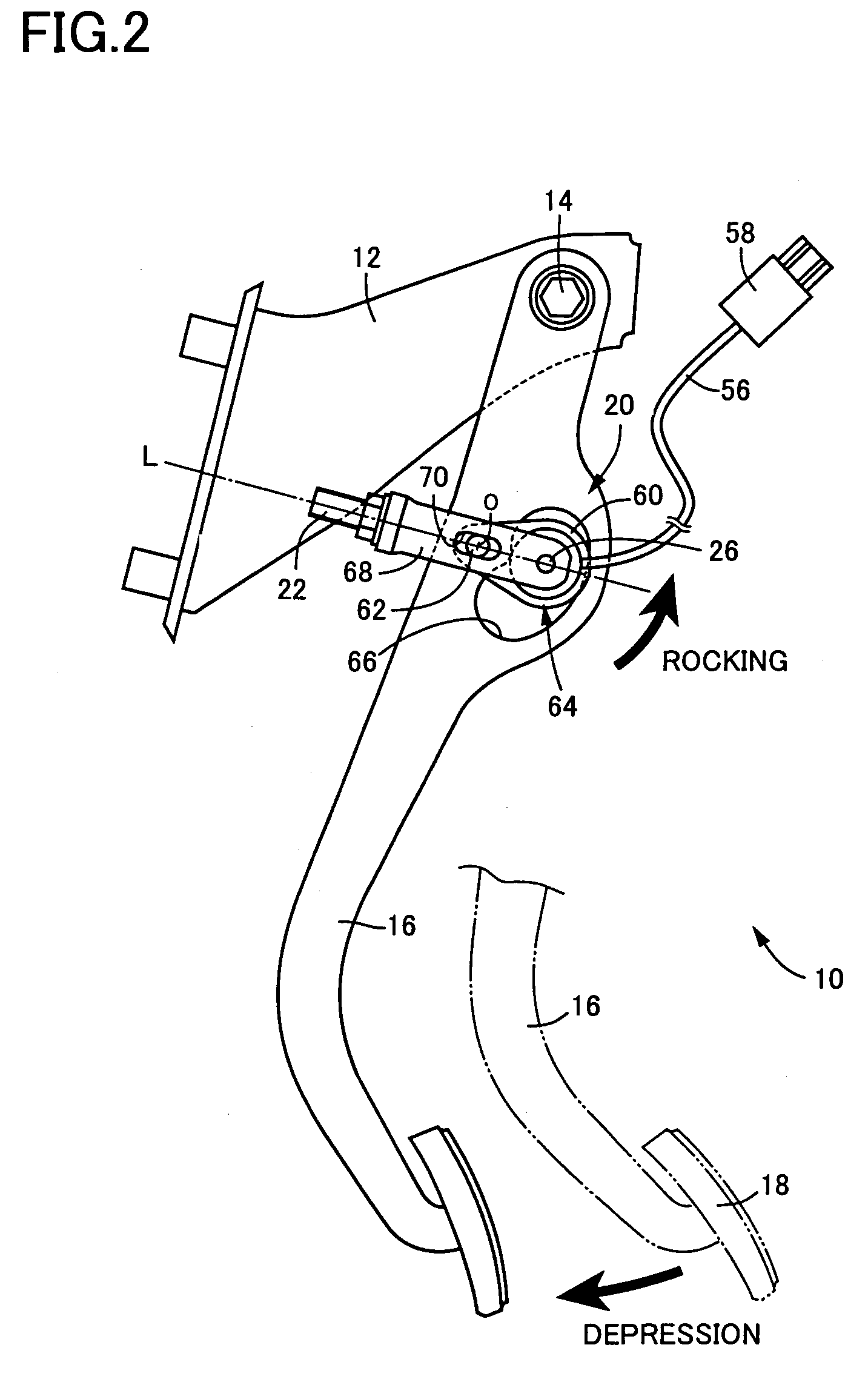

Load sensor-equipped operating apparatus

InactiveUS20080307920A1High accuracyEasy to detectControlling membersMechanical apparatusRelative displacementElectricity

Owner:TOYODA IRON WORKS CO LTD

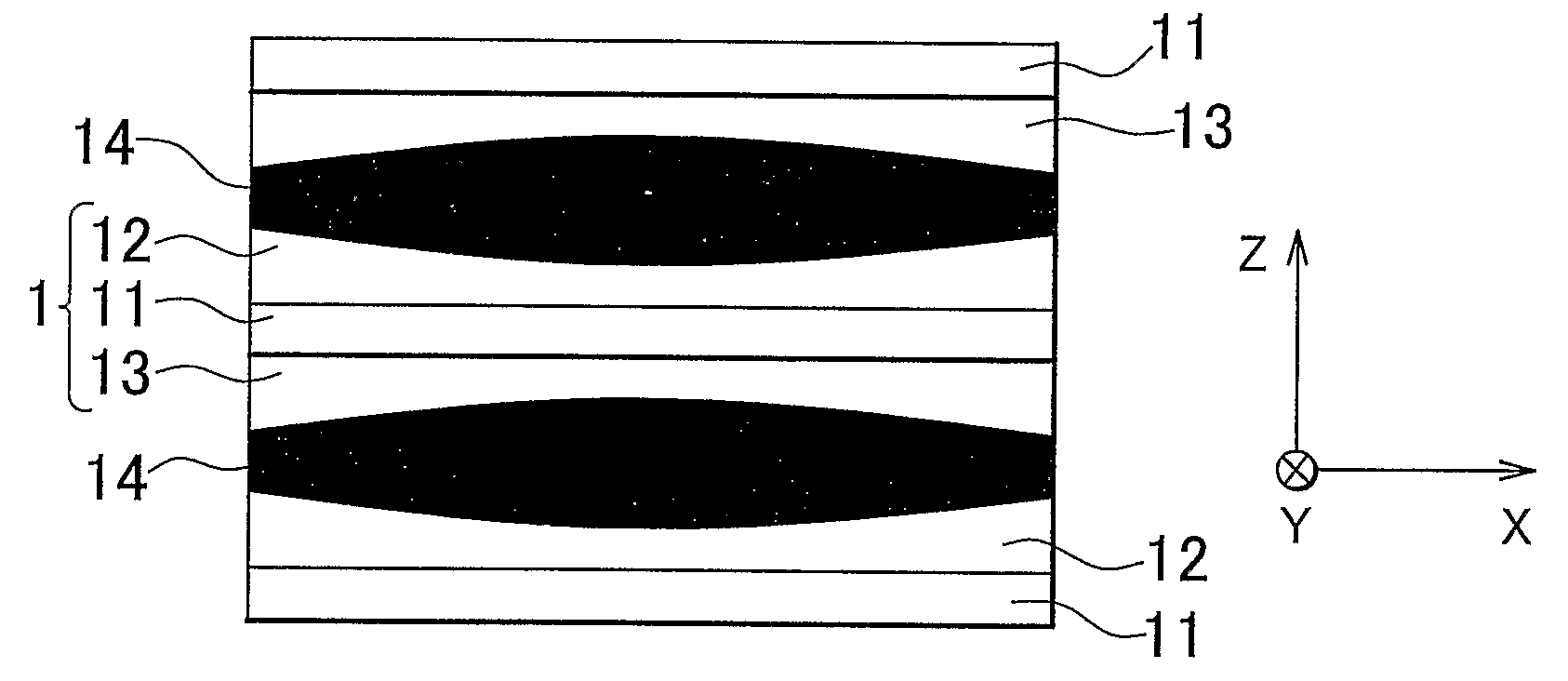

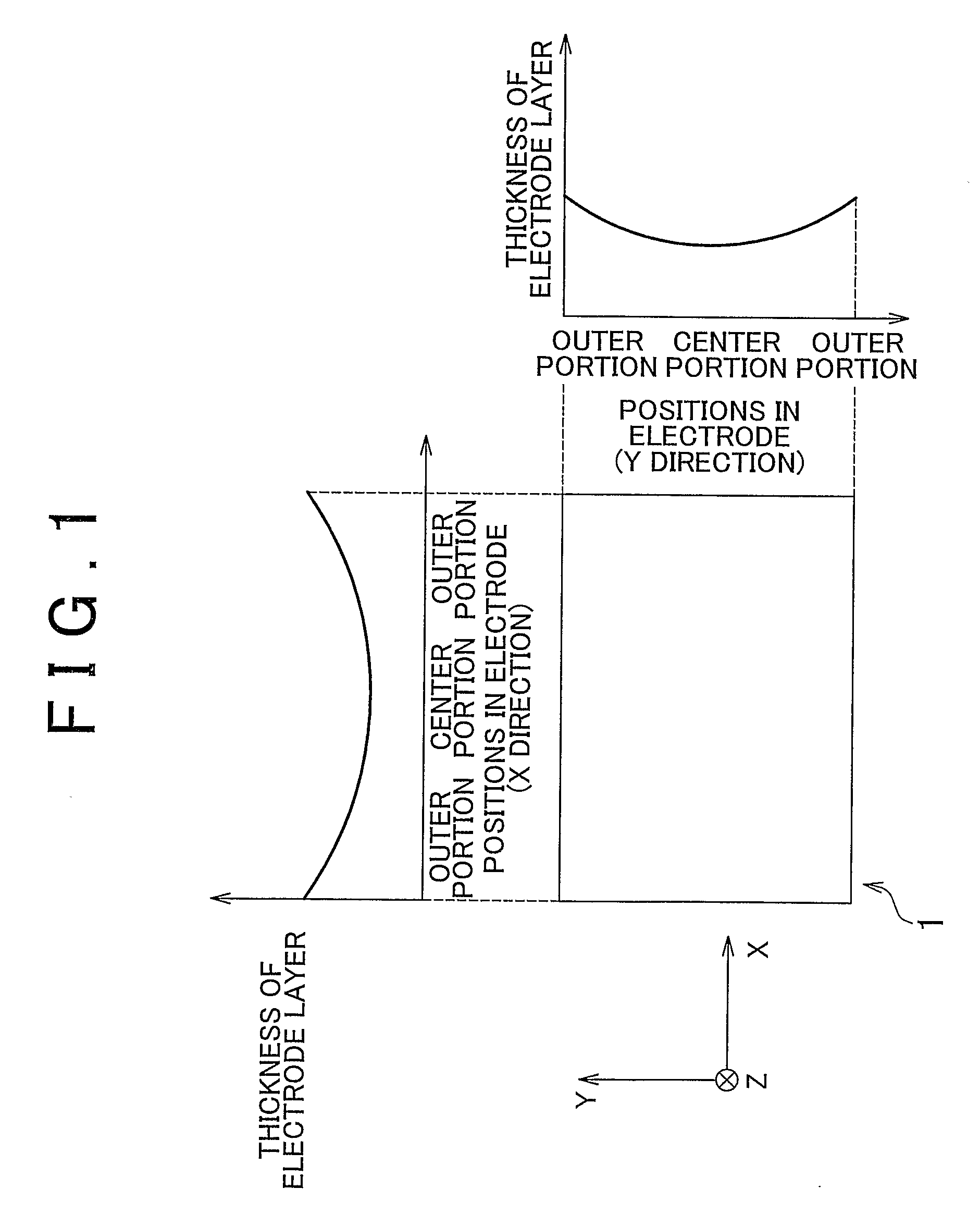

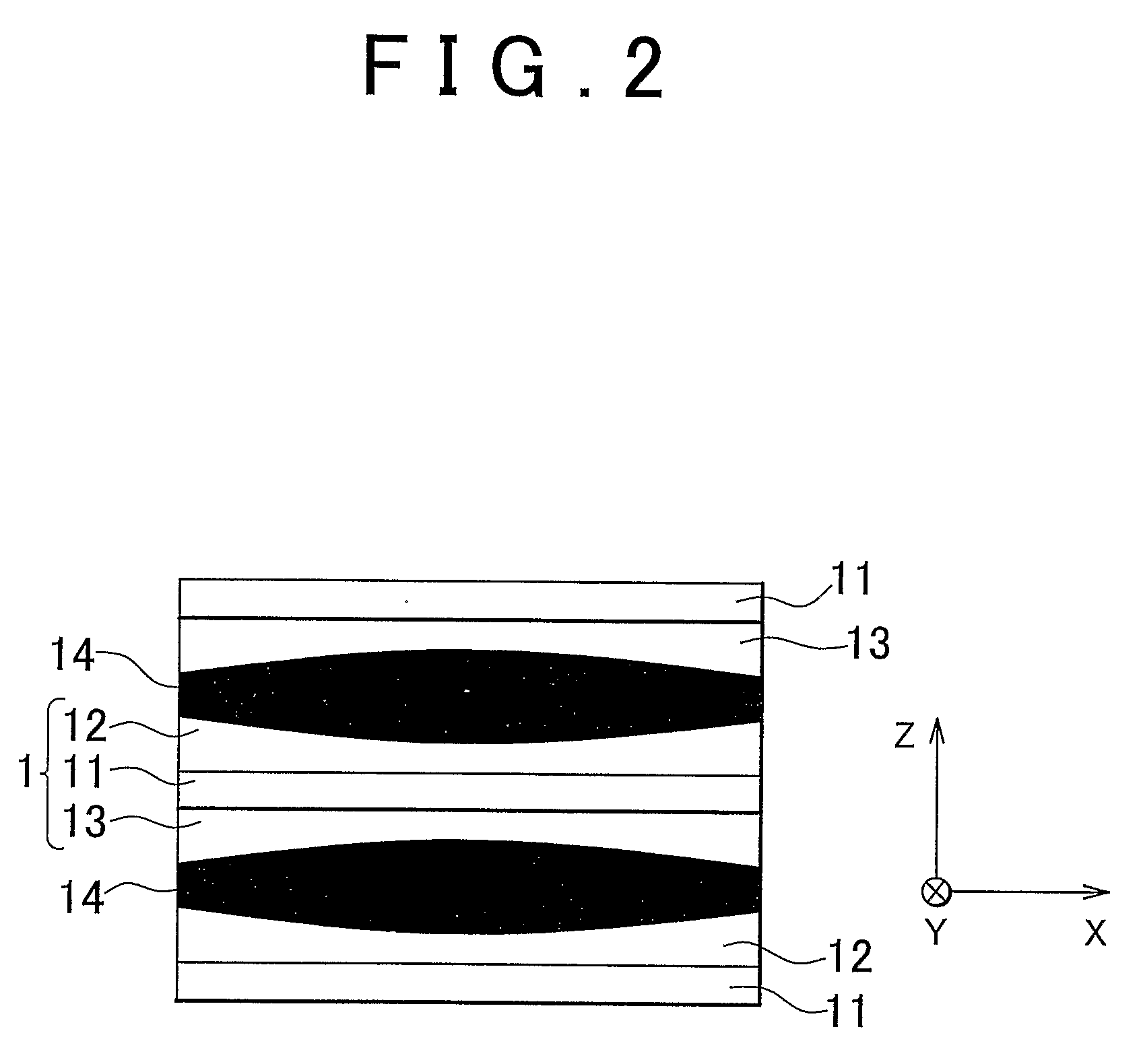

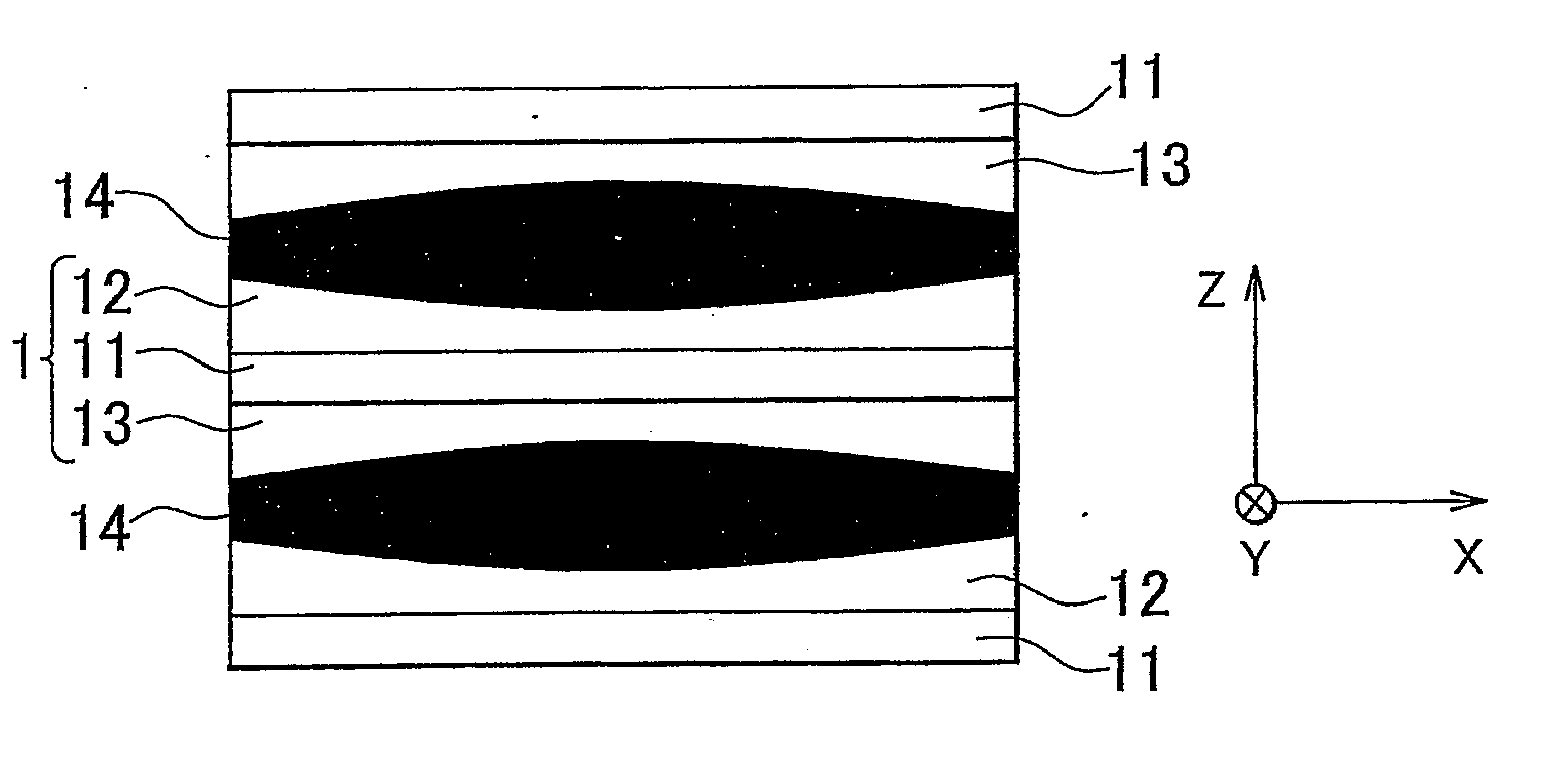

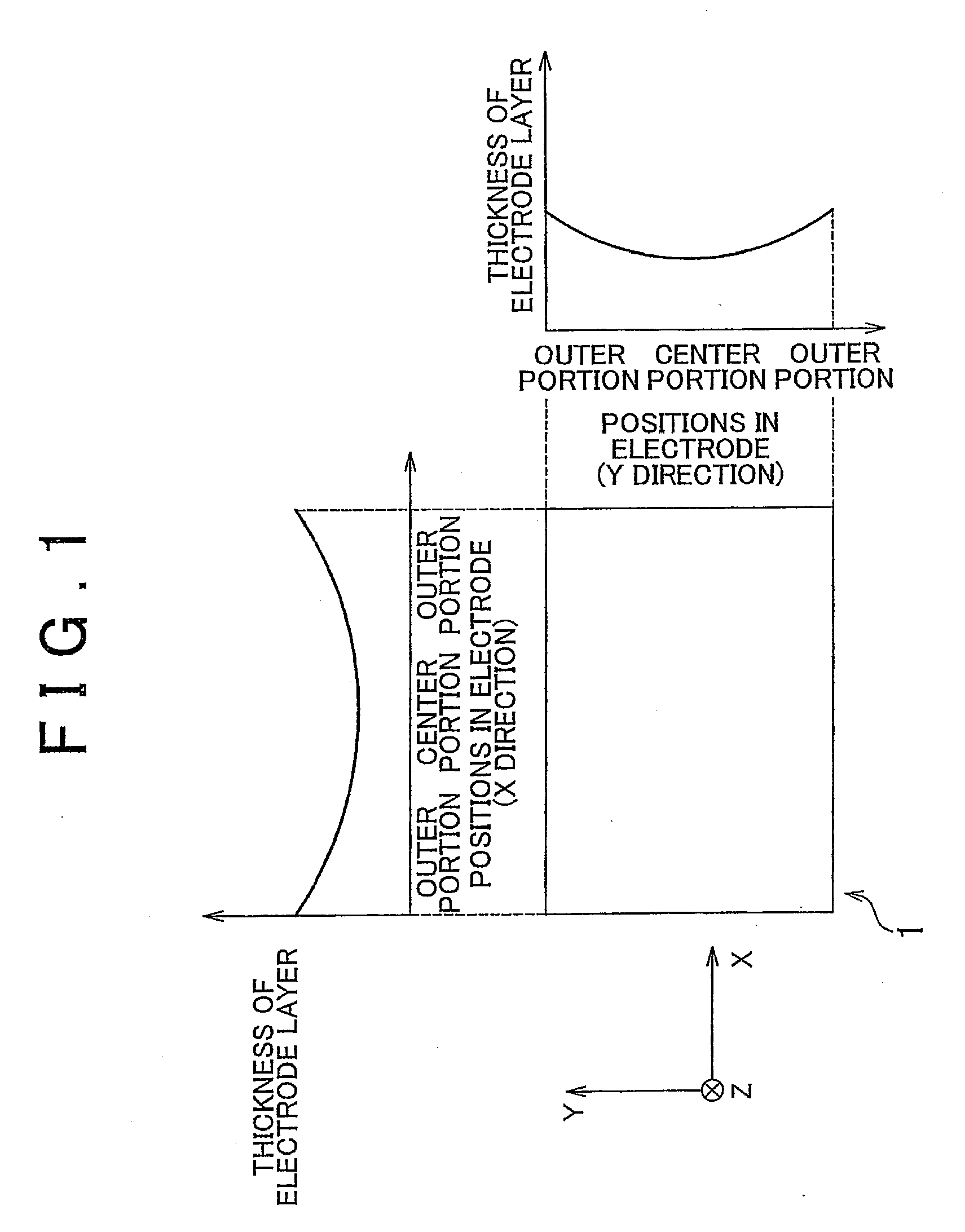

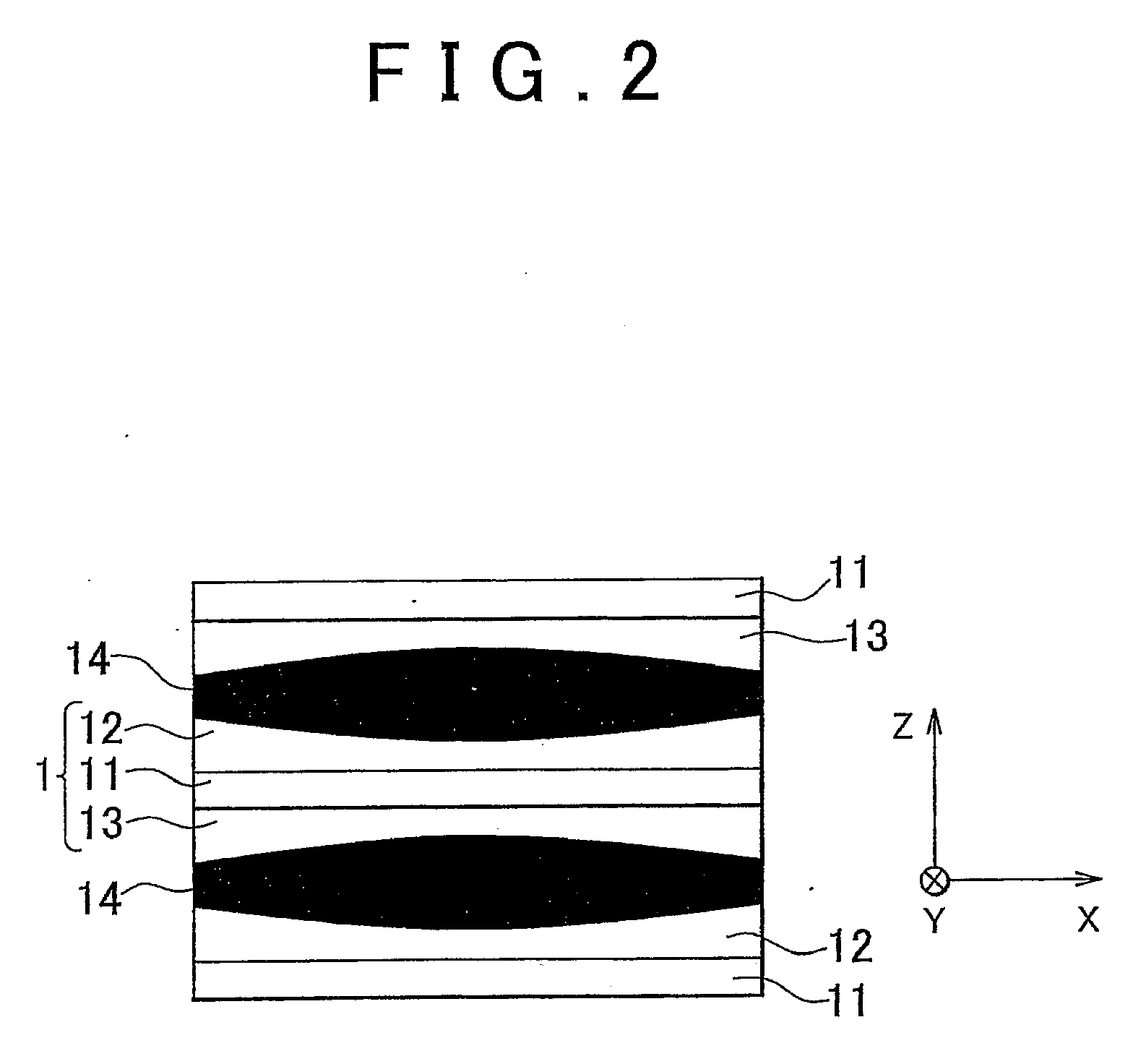

Electrode for electric storage device and electric storage device

ActiveUS20090191461A1Suppress mutationIncrease the areaElectrolytic capacitorsFinal product manufactureEngineeringThermal radiation

An electrode is used for an electric storage device that includes plural electrodes that are stacked such that an ion-conductive layer is disposed between each pair of the electrodes. Each of the plural electrodes includes a current collector, and an electrode layer, formed on the current collector, which contains an active material. The configuration of the electrode layer (for example, the amount of the active material) varies according to the position in the electrode layer such that a current density in a first region of the electrode, where heat radiation performance is lower than the heat radiation performance in a second region of the electrode, is lower than the current density in the second region of the electrode.

Owner:TOYOTA JIDOSHA KK

Transmission-type X-ray target and radiation generating tube including the same

ActiveUS9502204B2Avoid separationHigh reliability in electrical connectionX-ray tube electrodesX-ray apparatusX-rayDiamond substrate

A transmission-type X-ray target includes a flat plate-shaped diamond substrate having a first surface and a second surface facing the first surface and a target layer that is located on the first surface. A residual stress of the first surface is lower than a residual stress of the second surface.

Owner:CANON KK

Load sensor-equipped operating apparatus

InactiveUS7712371B2Easy to detectVariation is suppressedControlling membersMechanical apparatusElectricityEngineering

Owner:TOYODA IRON WORKS CO LTD

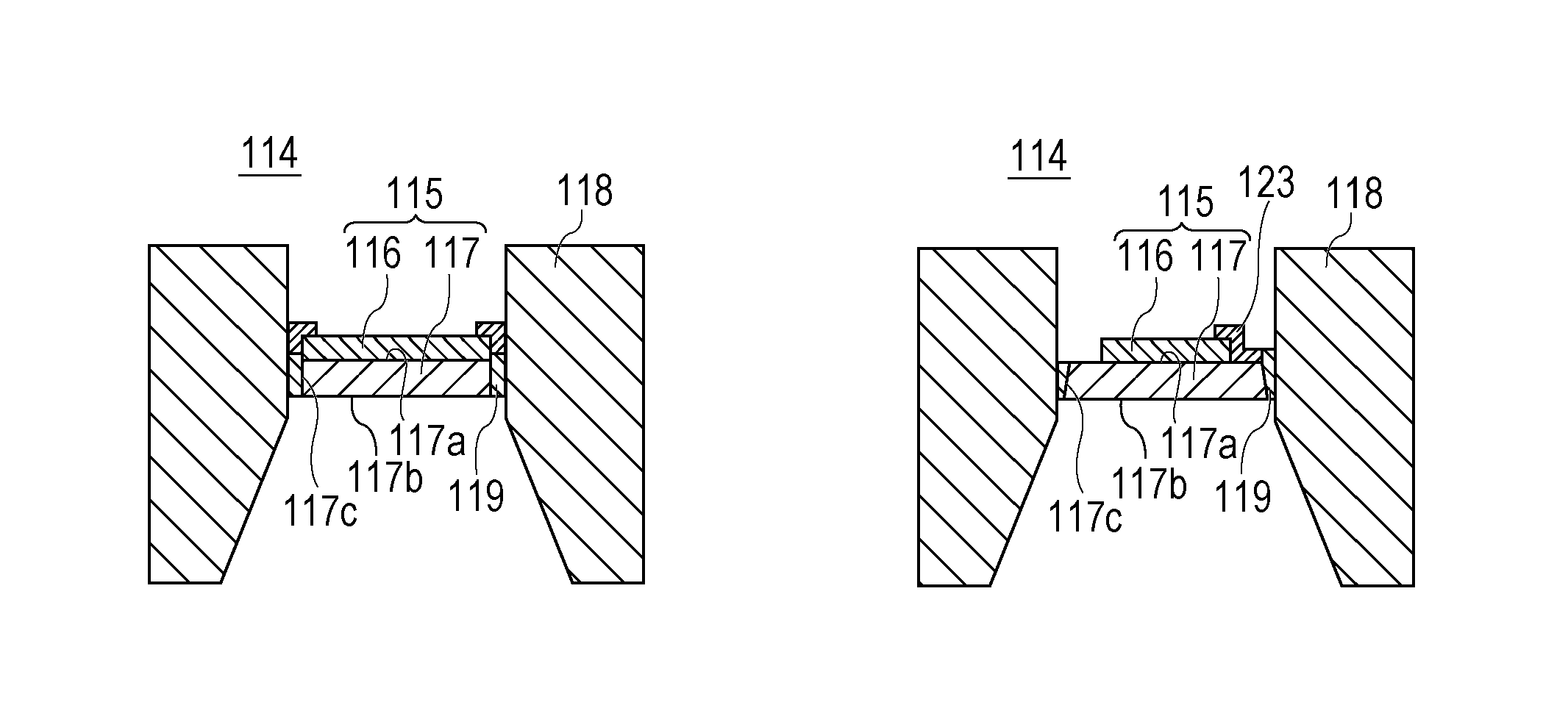

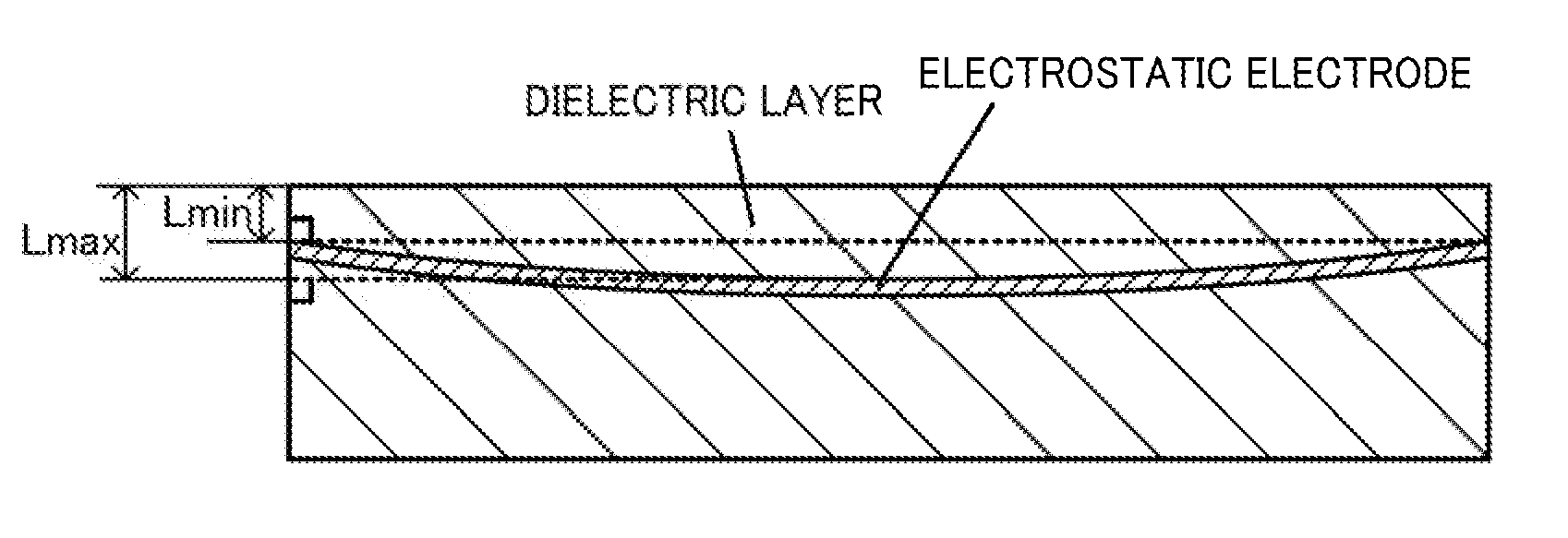

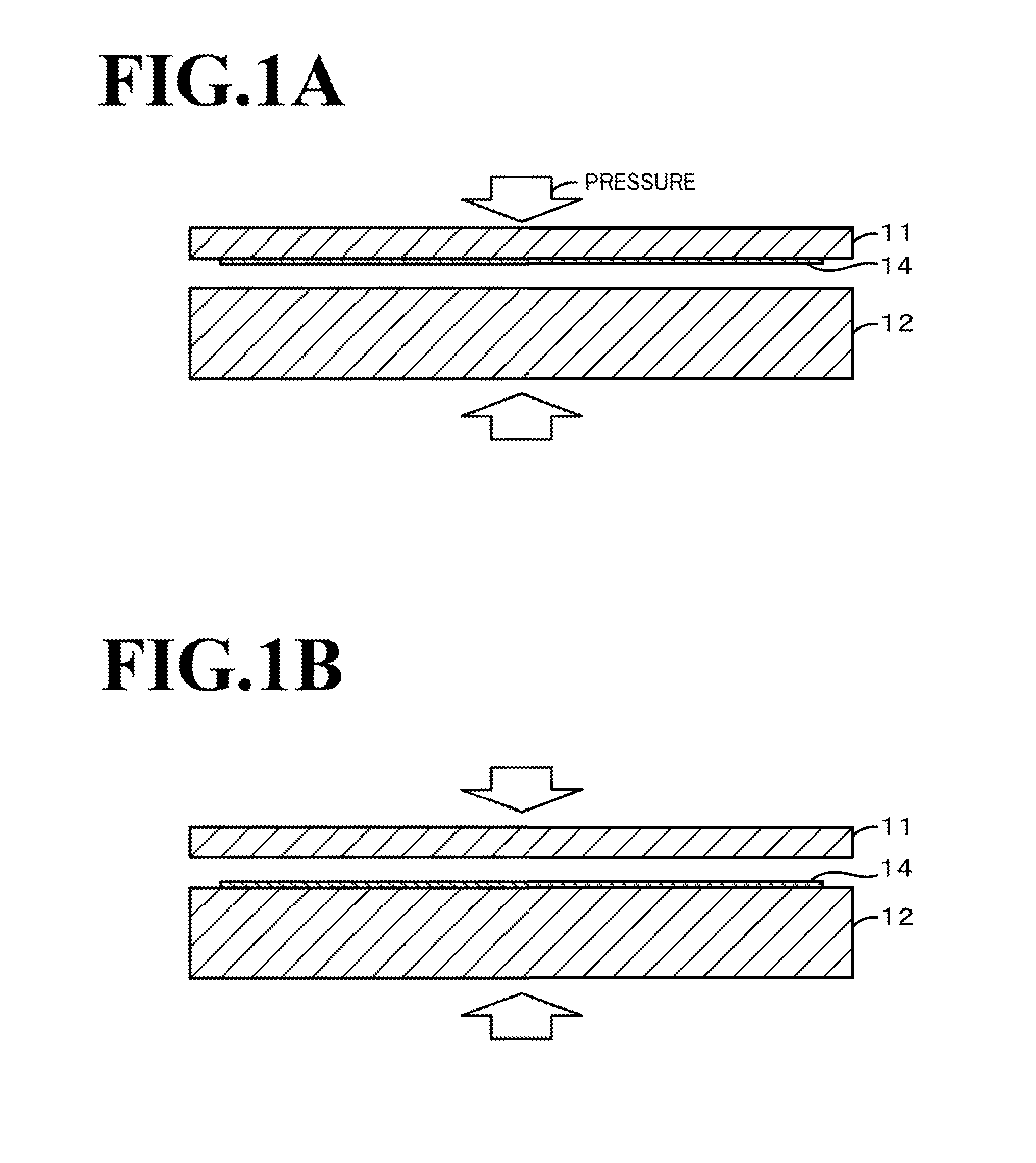

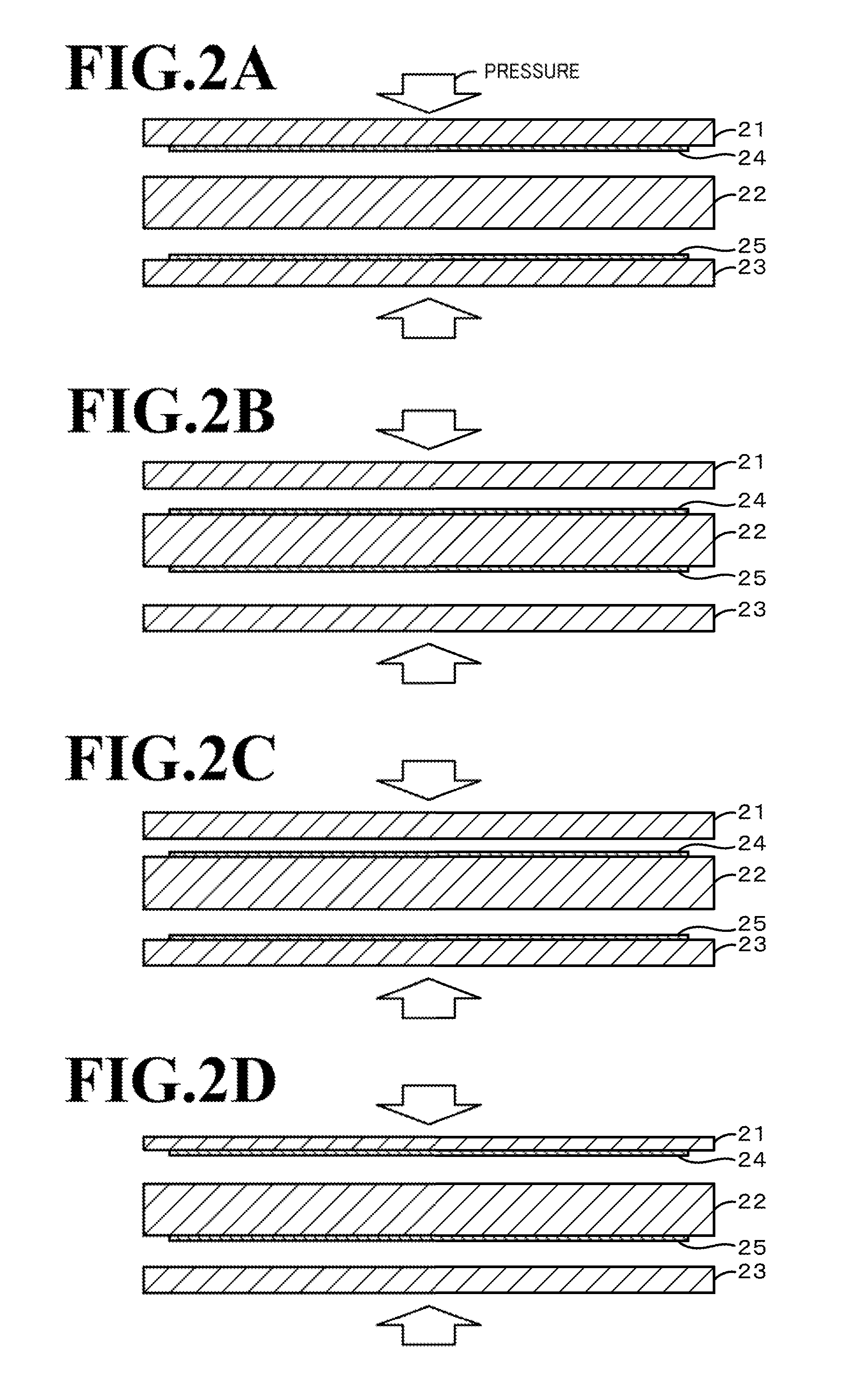

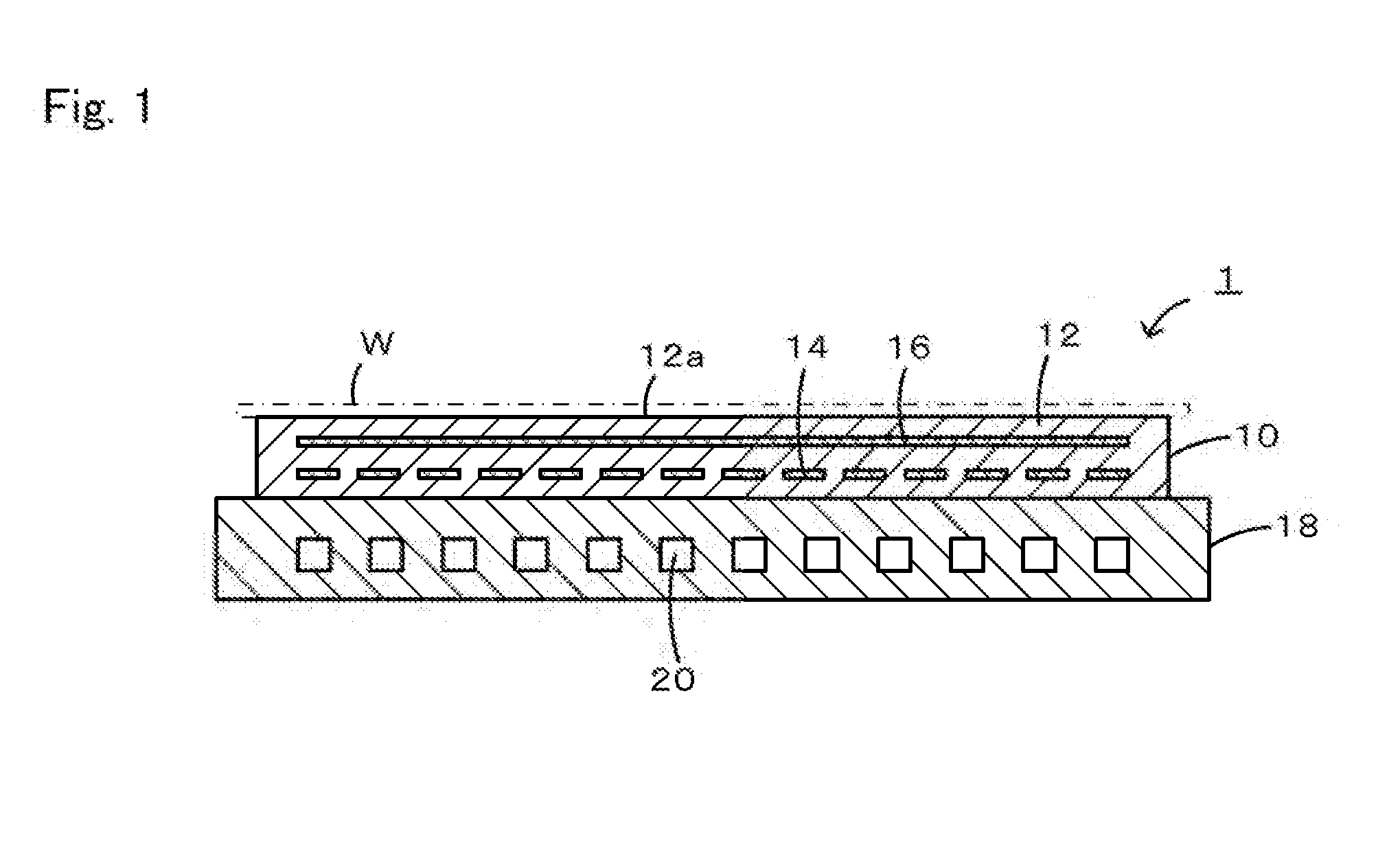

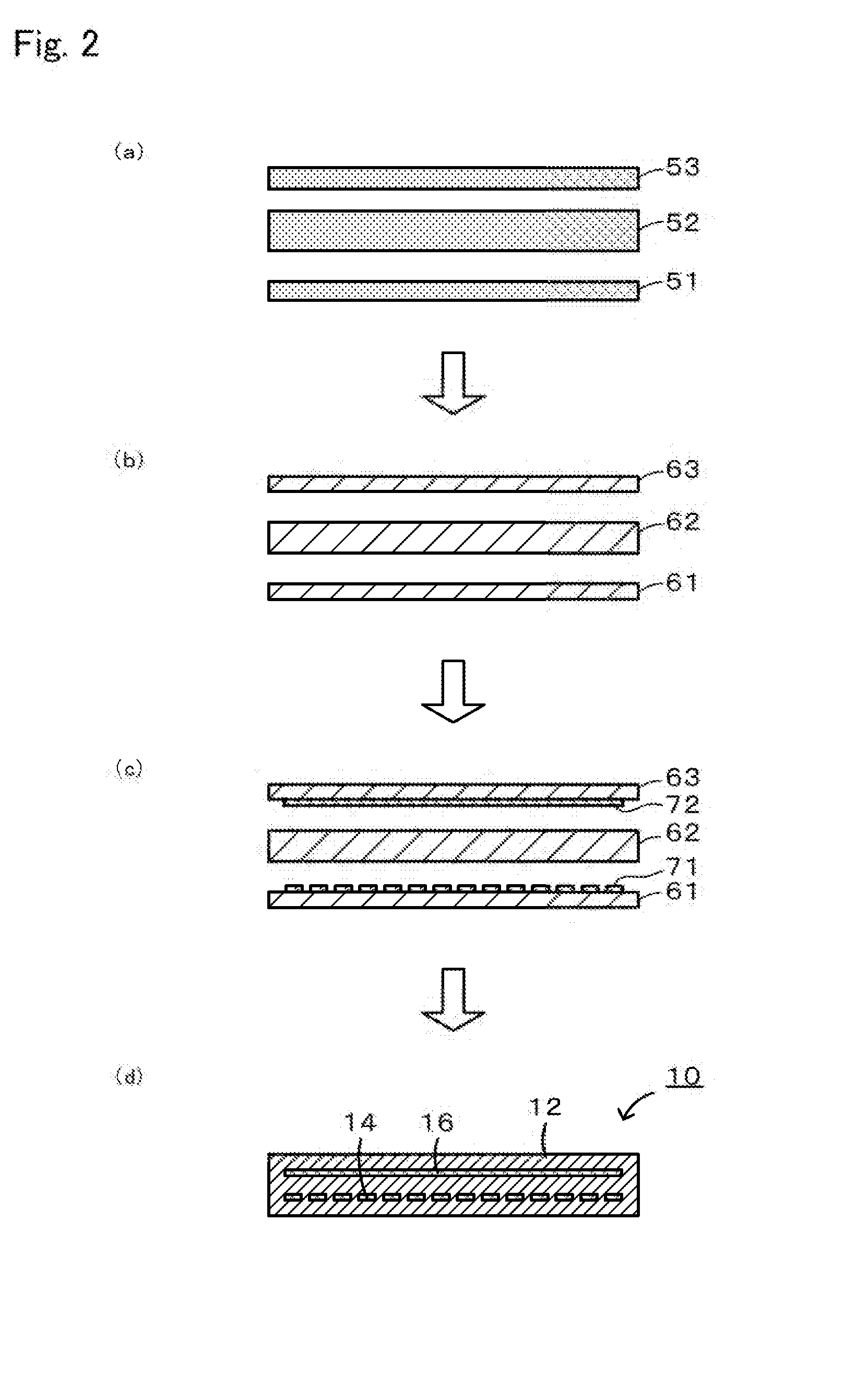

Method for producing electrostatic chuck and electrostatic chuck

ActiveUS20120248716A1Suppress generation of particleIncrease breakdown voltageSleeve/socket jointsSemiconductor/solid-state device manufacturingSolventHot press

A method for producing an electrostatic chuck includes the steps of (a) placing a ceramic slurry in a molding die, the ceramic slurry containing a ceramic powder, a solvent, a dispersing agent, and a gelling agent, gelatinizing the ceramic slurry in the molding die, and removing the molding die to obtain first and second ceramic molded bodies; (b) drying, debinding, and calcining the first and second molded bodies to obtain first and second ceramic calcined bodies; (c) printing an electrostatic electrode paste on a surface of one of the first and second ceramic calcined bodies to form an electrostatic electrode while assuming the first ceramic calcined body is to form a dielectric layer of an electrostatic chuck; and (d) superposing the first and second ceramic calcined bodies on each other to sandwich the electrostatic electrode and subjecting the first and second calcined bodies to hot-press firing.

Owner:NGK INSULATORS LTD

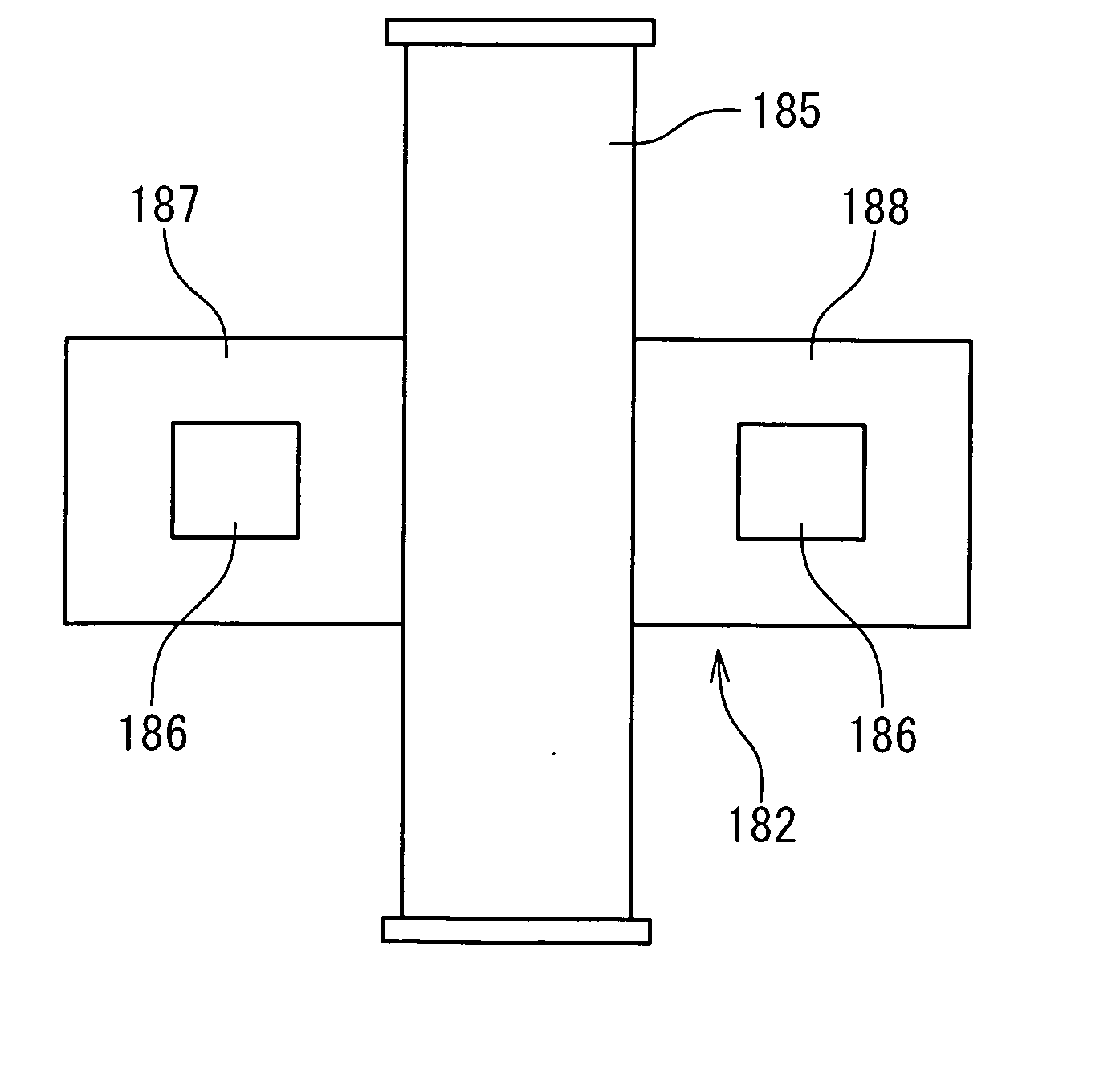

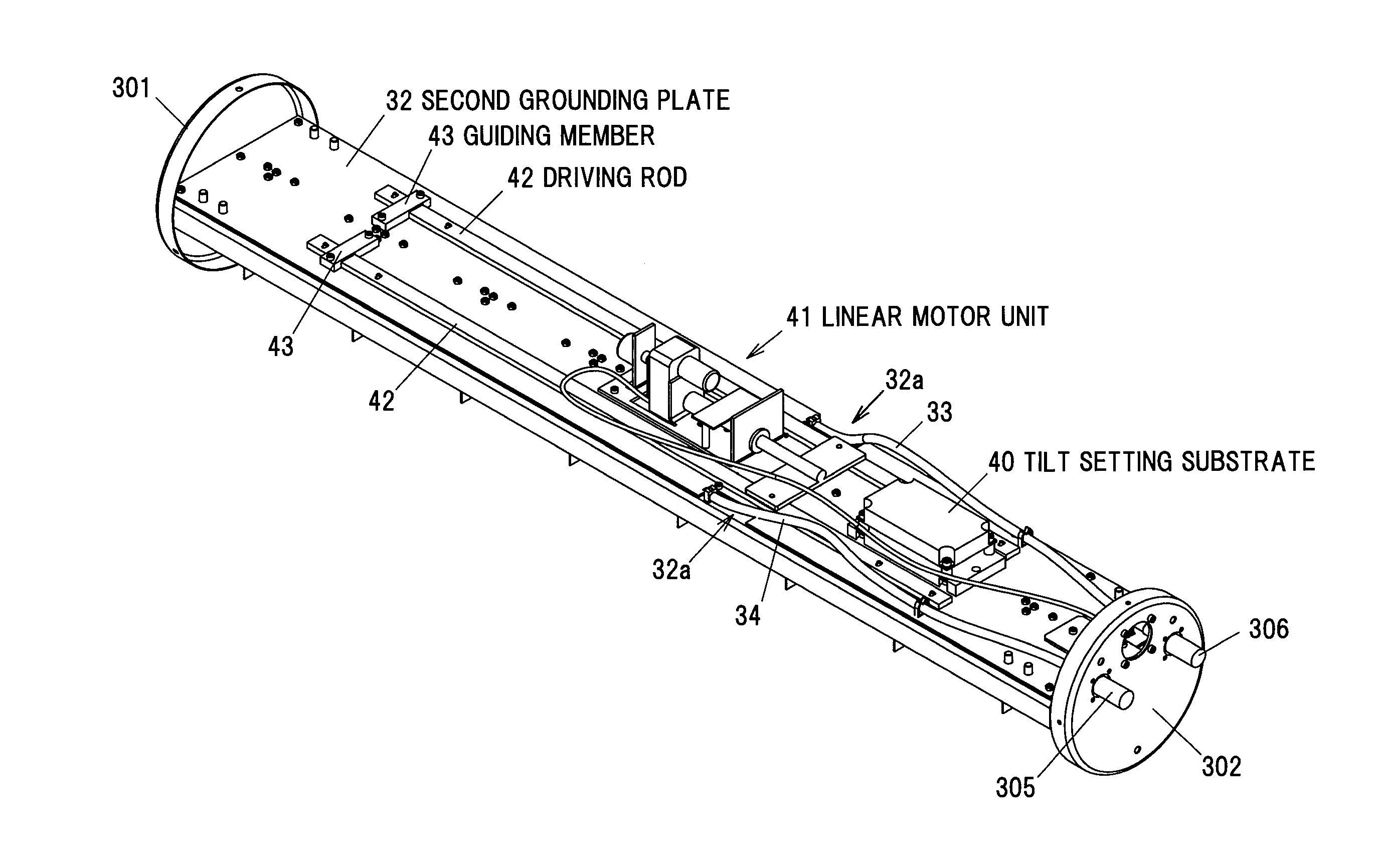

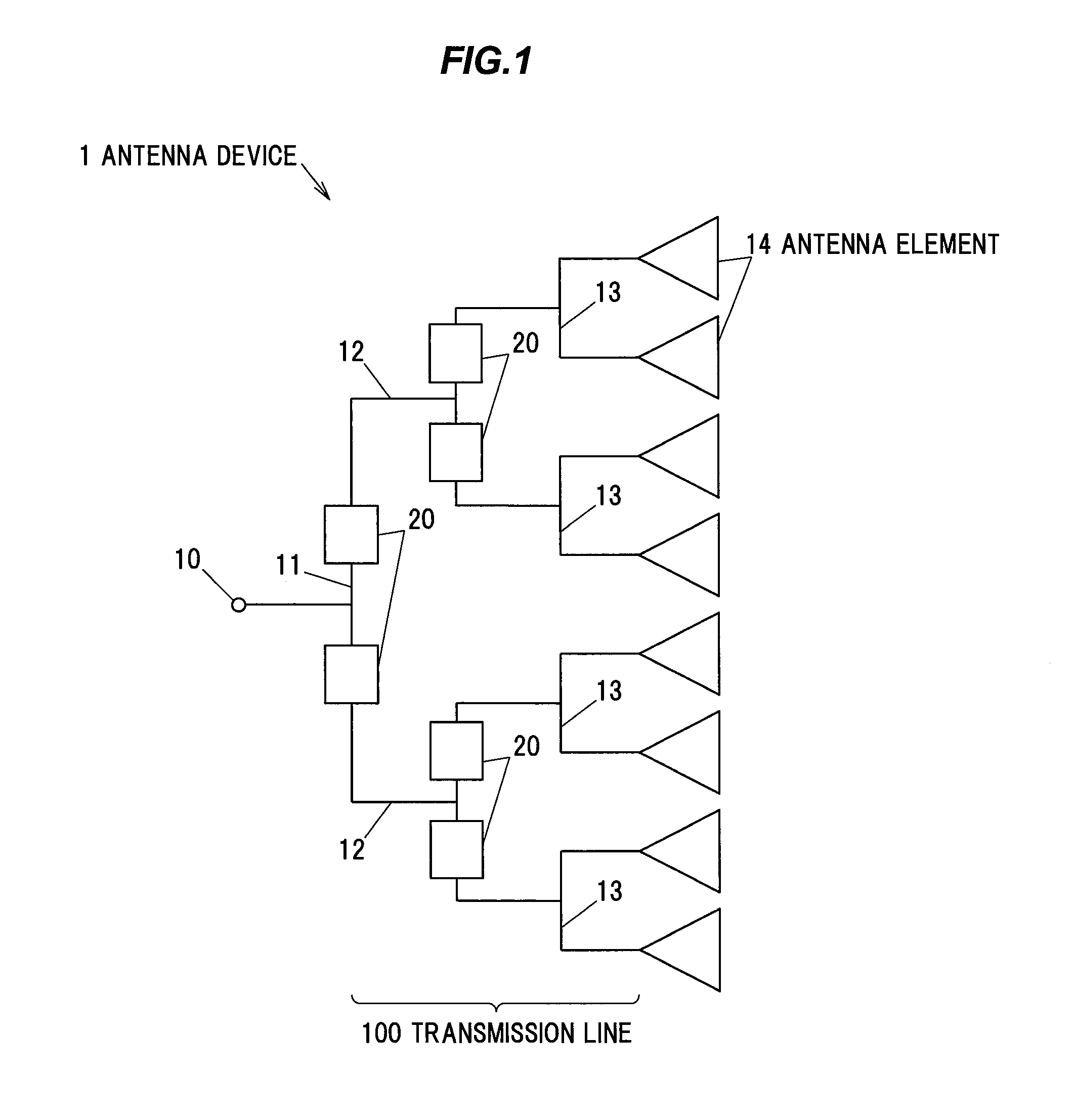

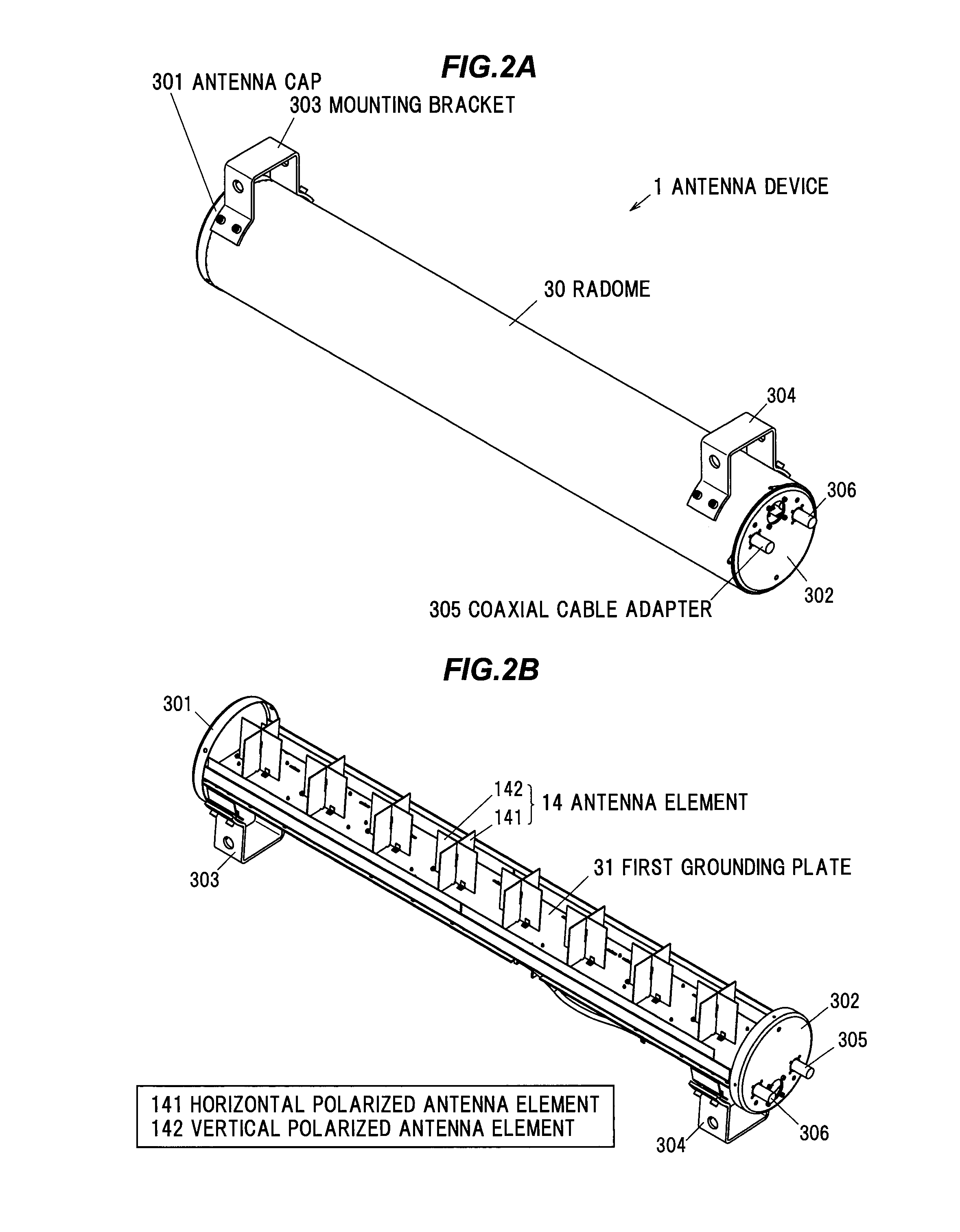

Phase shifter and antenna device having same

ActiveUS20160013532A1Variation is suppressedAdjust directivityDelay linesWaveguidesDielectricSignal lines

A phase shifter includes dielectric members including facing portions facing a signal line formed on a surface of a substrate and being made of a dielectric material, a supporting member configured to support the dielectric members and receive a moving force for moving the dielectric members in a direction which is parallel to the substrate and crosses the signal line, and a moving mechanism configured to apply the moving force to the supporting member. At least either the dielectric members or the supporting member is provided with a protrusion configured to keep a distance between the facing portions of the dielectric members and the signal line.

Owner:HITACHI METALS LTD

Electrode for electric storage device and electric storage device

ActiveUS20120196180A1Suppress mutationIncrease the areaFinal product manufactureActive material electrodesThermal radiationIon

An electrode is used for an electric storage device that includes plural electrodes that are stacked such that an ion-conductive layer is disposed between each pair of the electrodes. Each of the plural electrodes includes a current collector, and an electrode layer, formed on the current collector, which contains an active material. The configuration of the electrode layer (for example, the amount of the active material) varies according to the position in the electrode layer such that a current density in a first region of the electrode, where heat radiation performance is lower than the heat radiation performance in a second region of the electrode, is lower than the current density in the second region of the electrode.

Owner:TOYOTA JIDOSHA KK

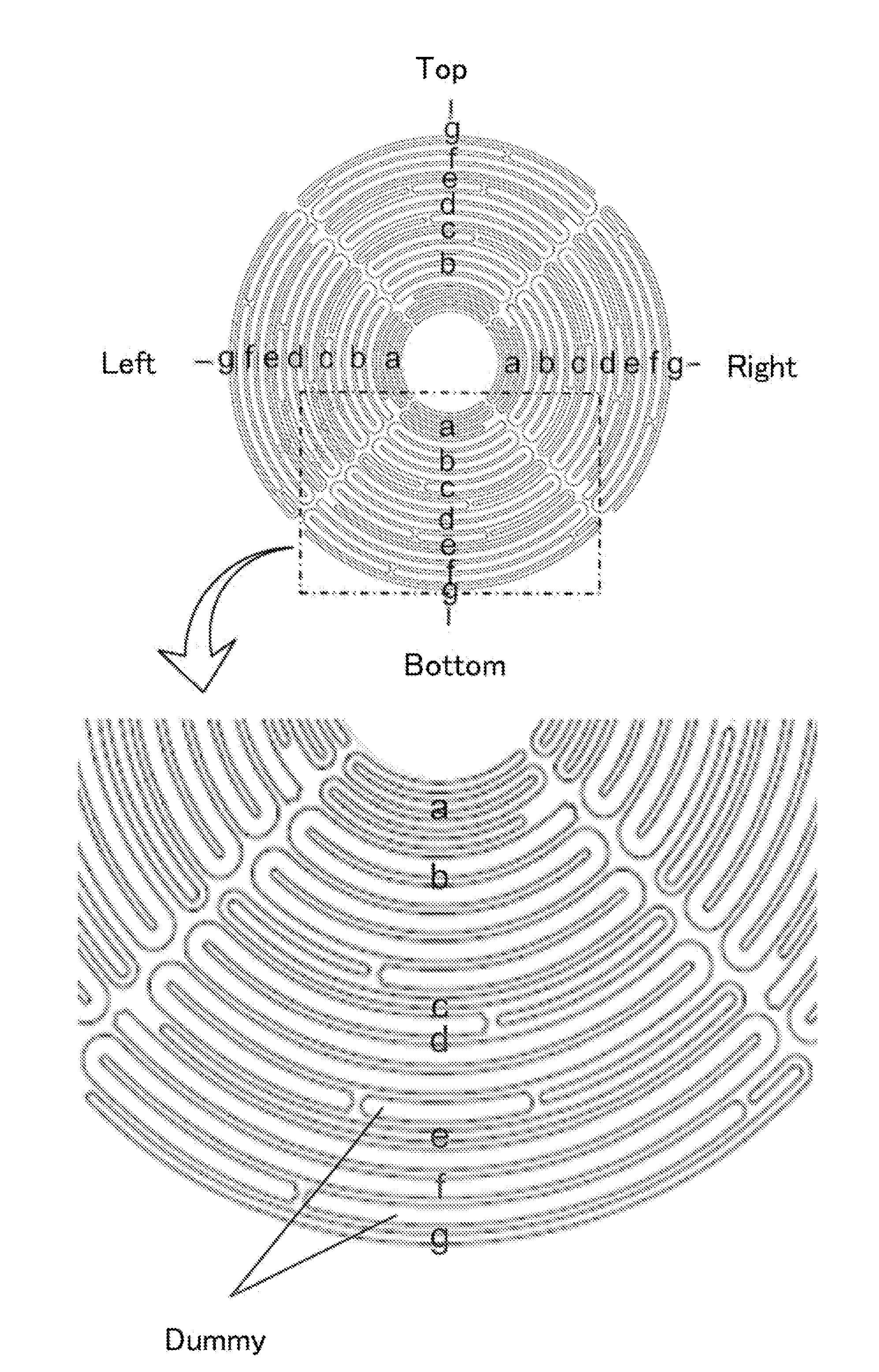

Ceramic heater and method for producing the same

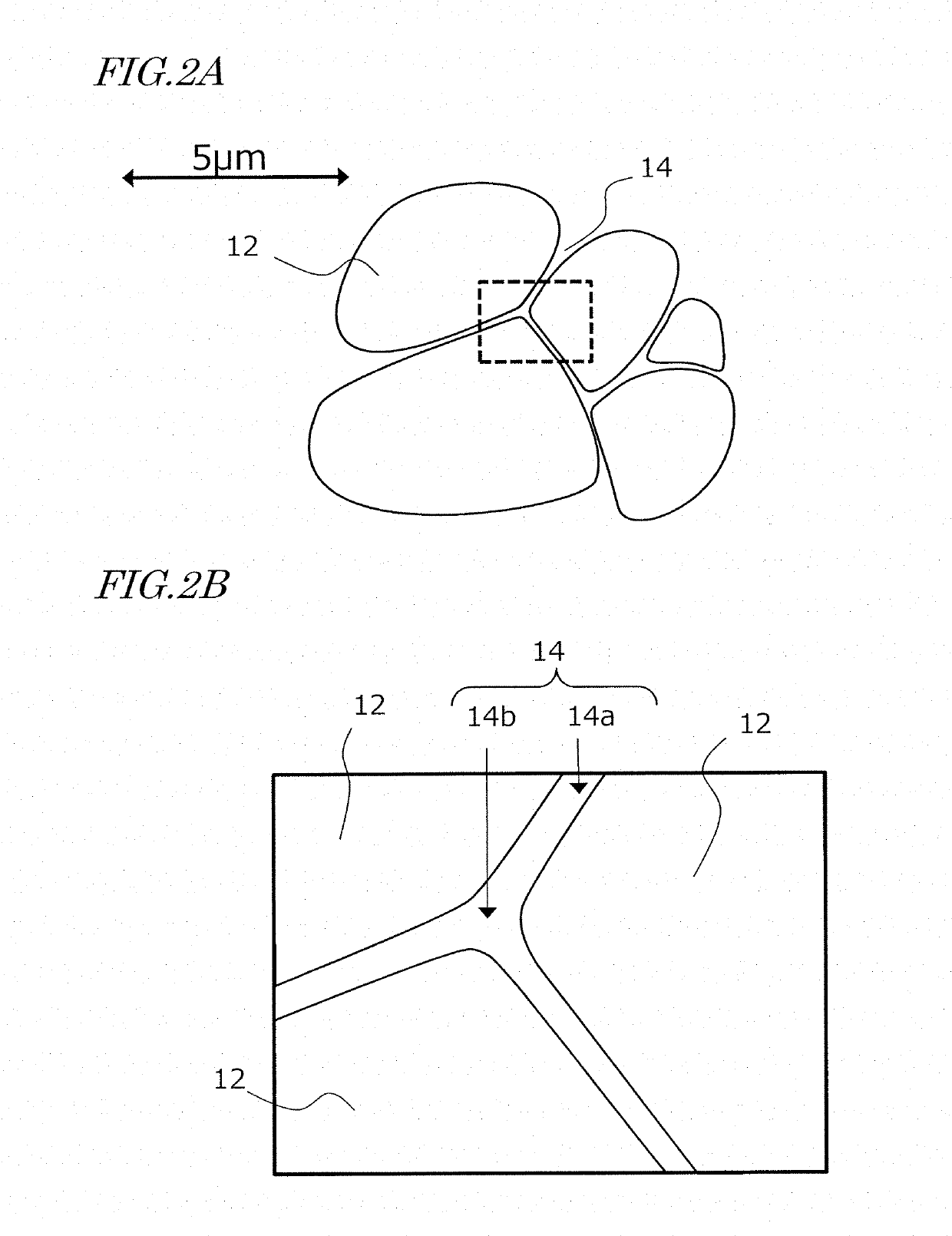

ActiveUS20140284320A1Suppress in-plane variationReversal phenomenon is suppressedOhmic-resistance electrodesSemiconductor/solid-state device manufacturingBrush strokeMetallurgy

An electrostatic chuck 10 includes a disc-shaped alumina ceramic base 12, and a heater electrode 14 and an electrostatic electrode 16 that are embedded in the alumina ceramic base 12. An upper surface of the alumina ceramic base 12 functions as a wafer-receiving surface 12a. The heater electrode 14 is formed in a pattern shape, for example, in the manner of a single brush stroke so as to be arranged over the entire surface of the alumina ceramic base 12. When a voltage is applied to the heater electrode 14, the heater electrode 14 generates heat, and heats a wafer W. This heater electrode 14 contains TiSi2 as a main component.

Owner:NGK INSULATORS LTD

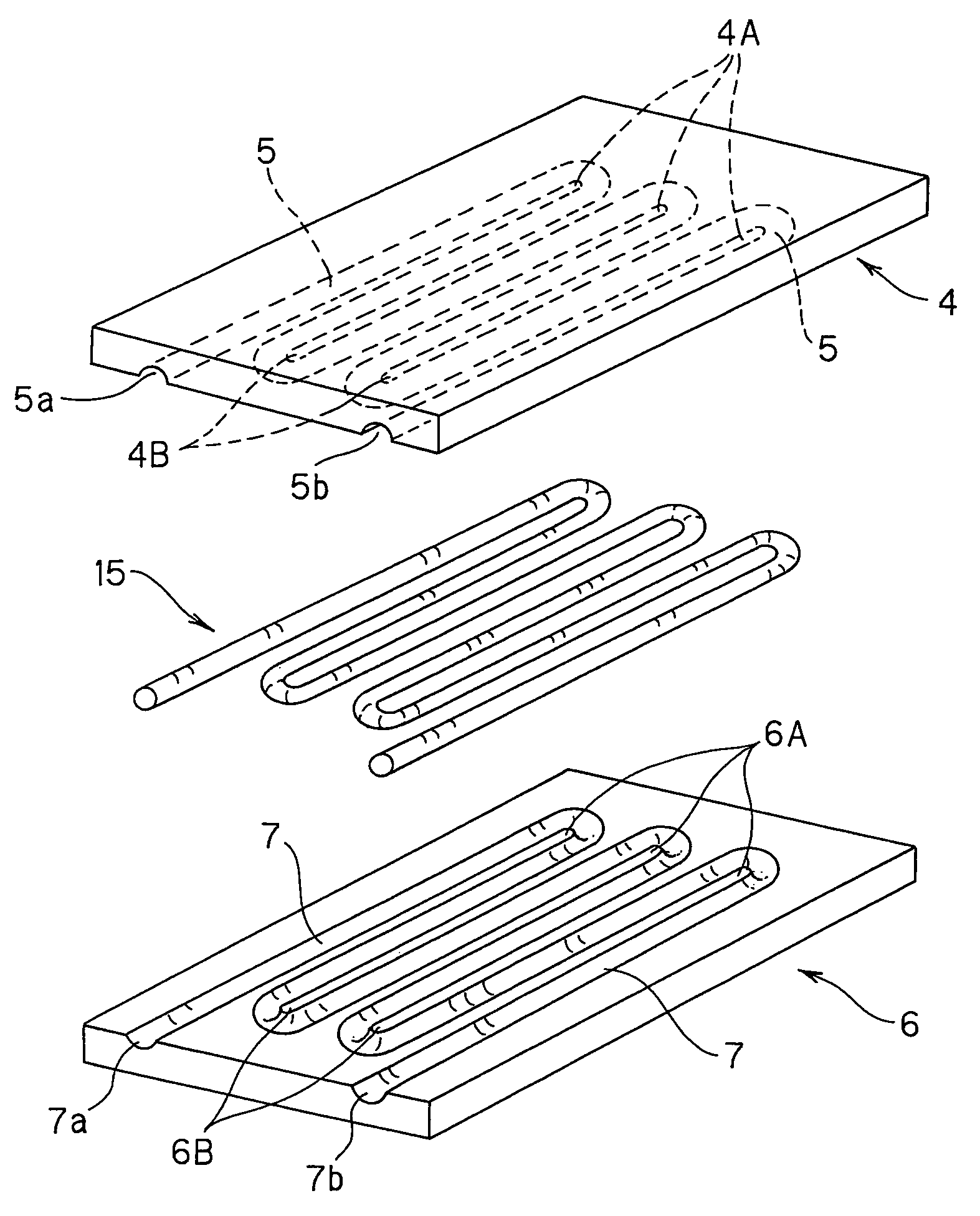

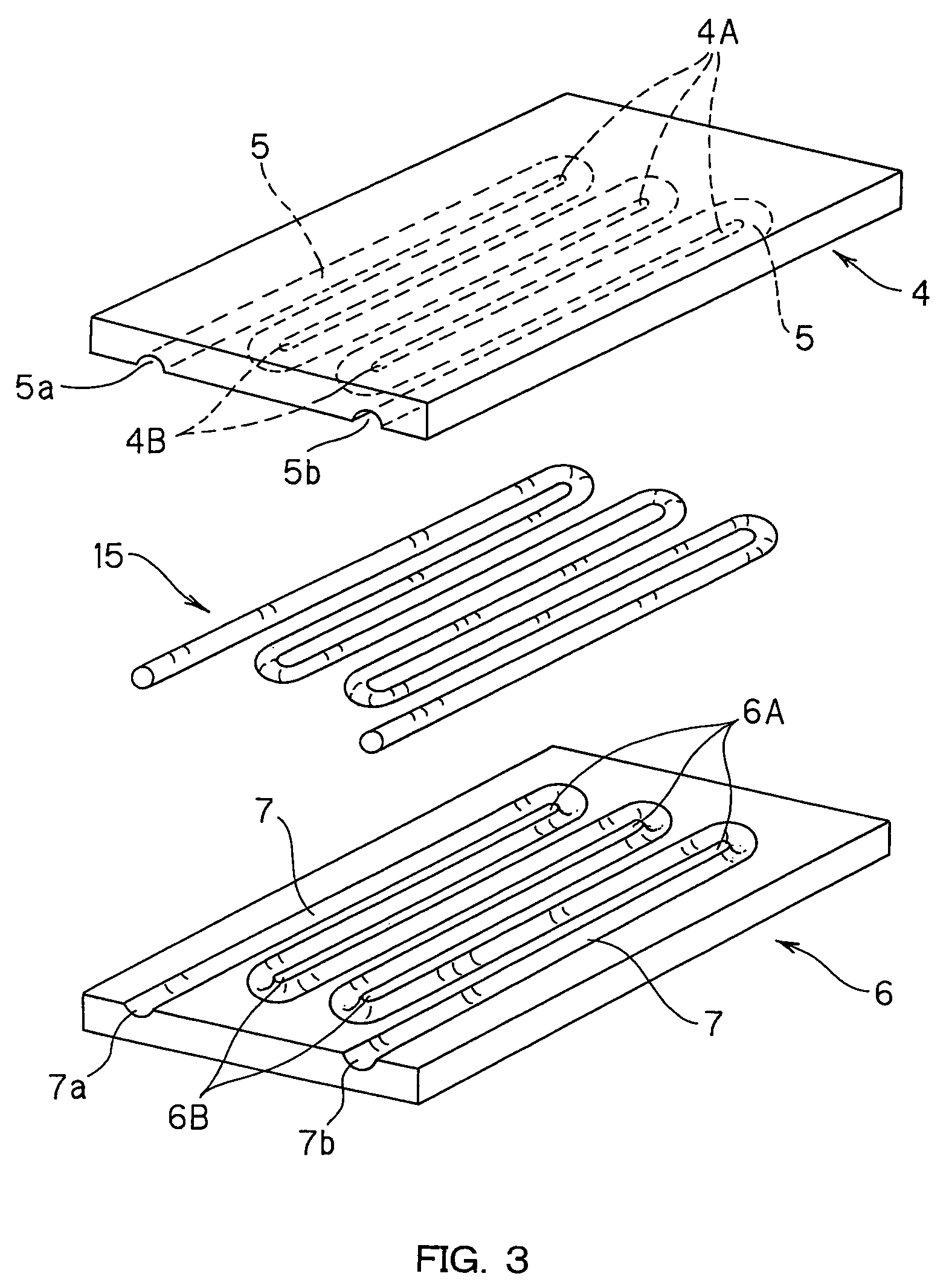

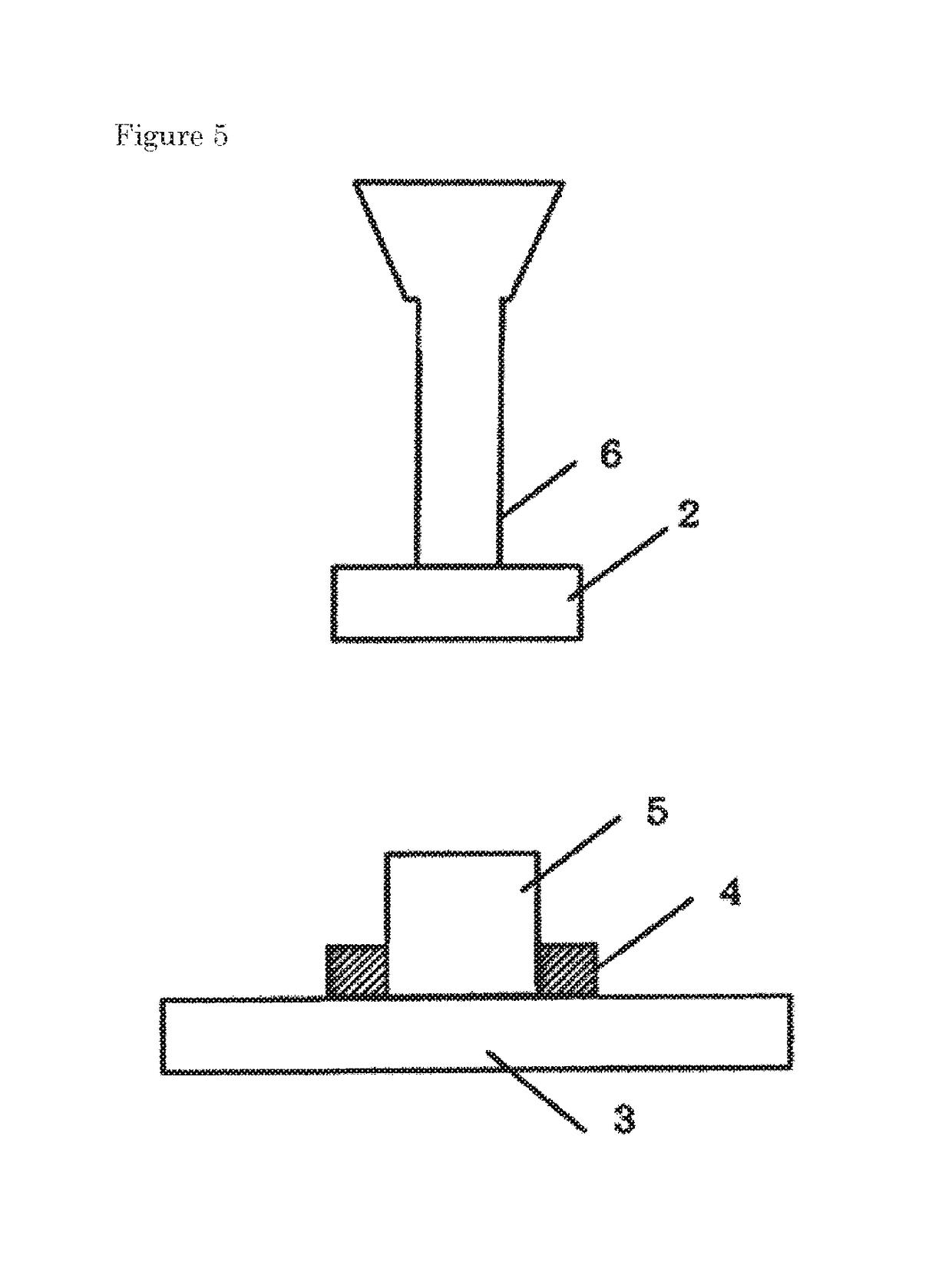

Micro-reactor and method of manufacturing the same

InactiveUS7857874B2Highly efficient catalytic reactionEasy to produceAnodisationChemical/physical/physico-chemical microreactorsMicroreactorMechanical engineering

A structure of a microreactor includes a joined body having a pair of substrates joined together, a flow path formed by a microchannel portion formed on a joining surface of at least one of the substrates, and a catalyst carrying member disposed in the flow path. In the production of such a microreactor, the catalyst carrying member is produced separately from formation of the joined body and the catalyst carrying member is disposed in the flow path at the time of forming the joined body.

Owner:DAI NIPPON PRINTING CO LTD +2

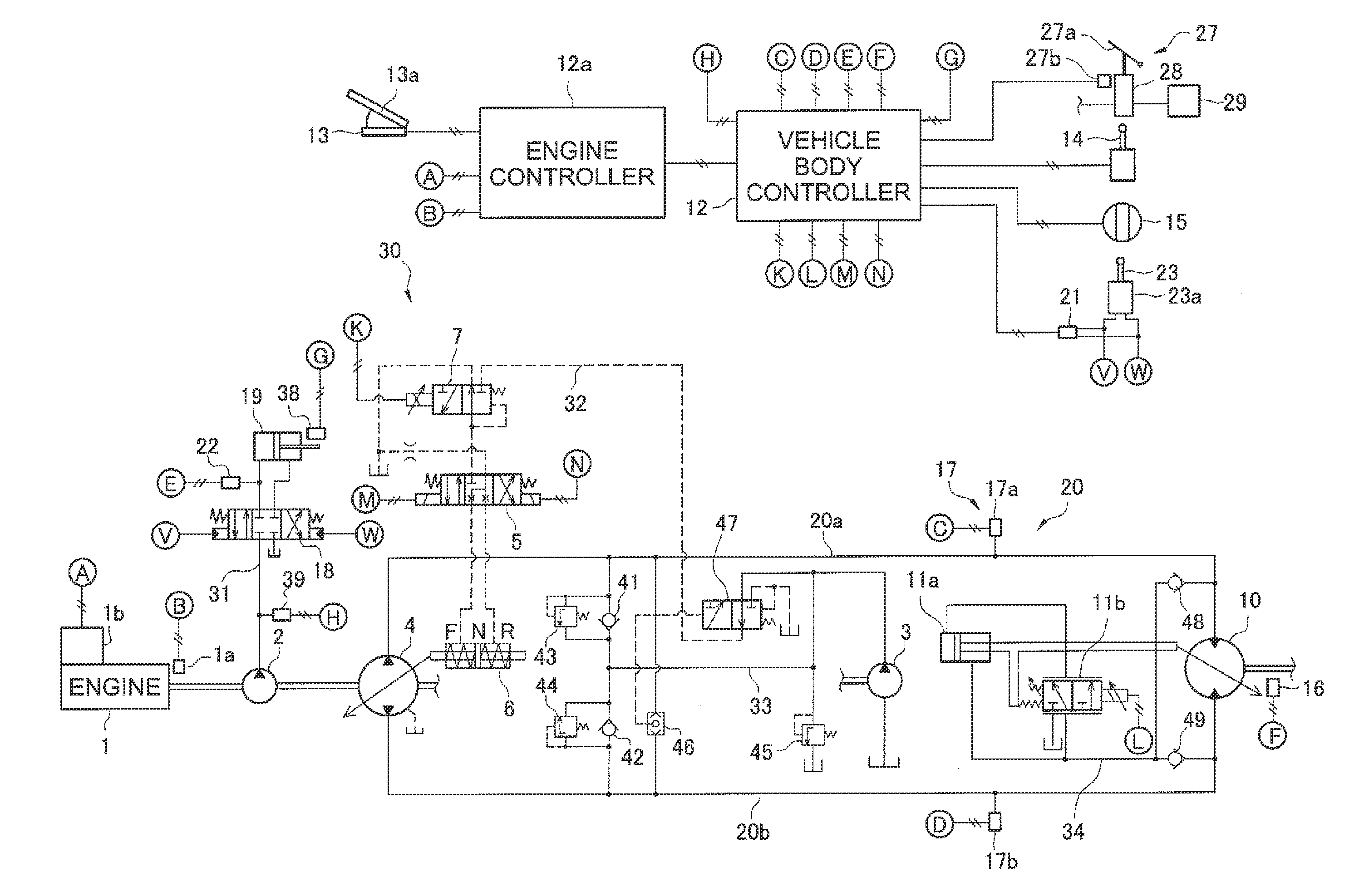

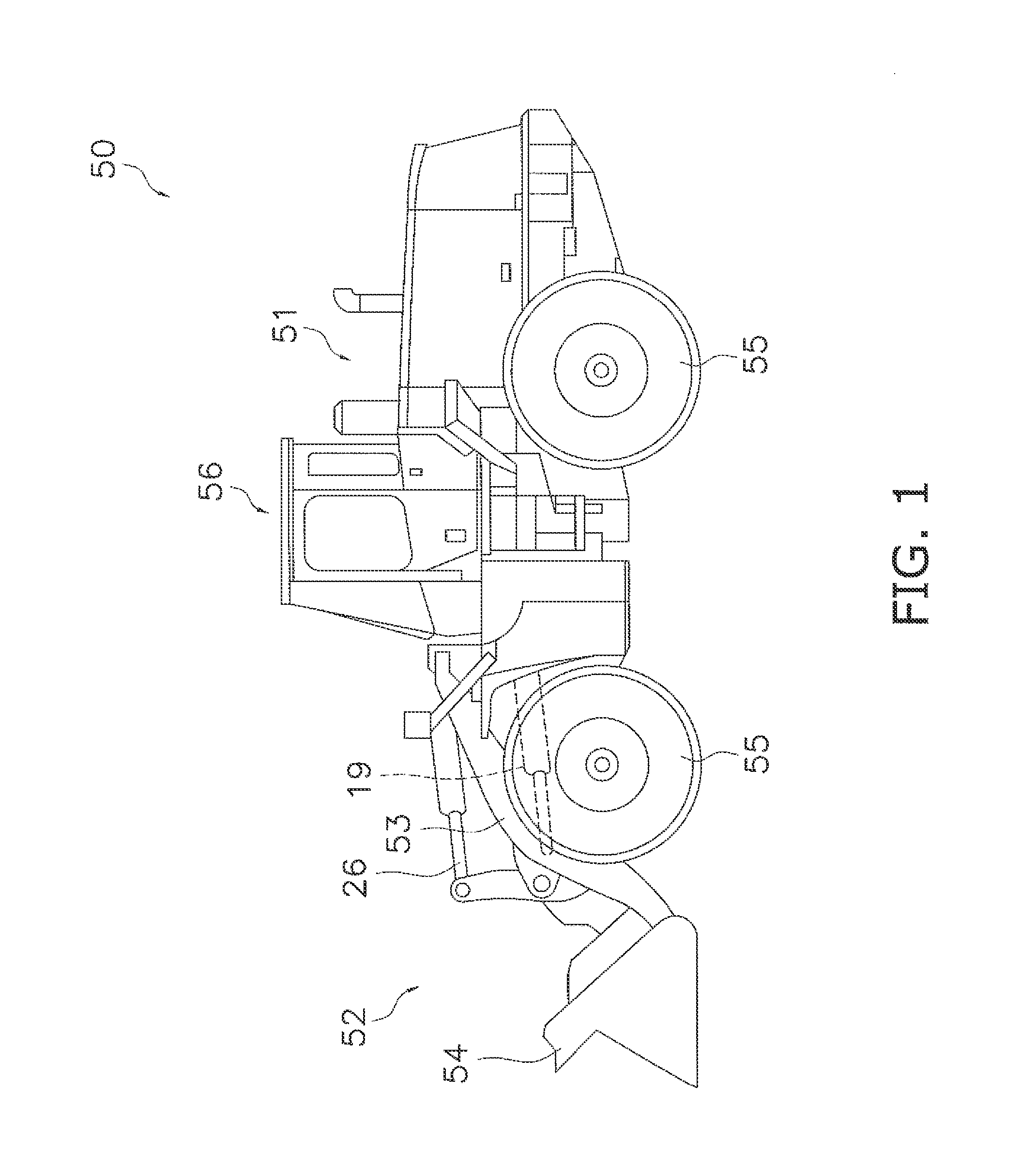

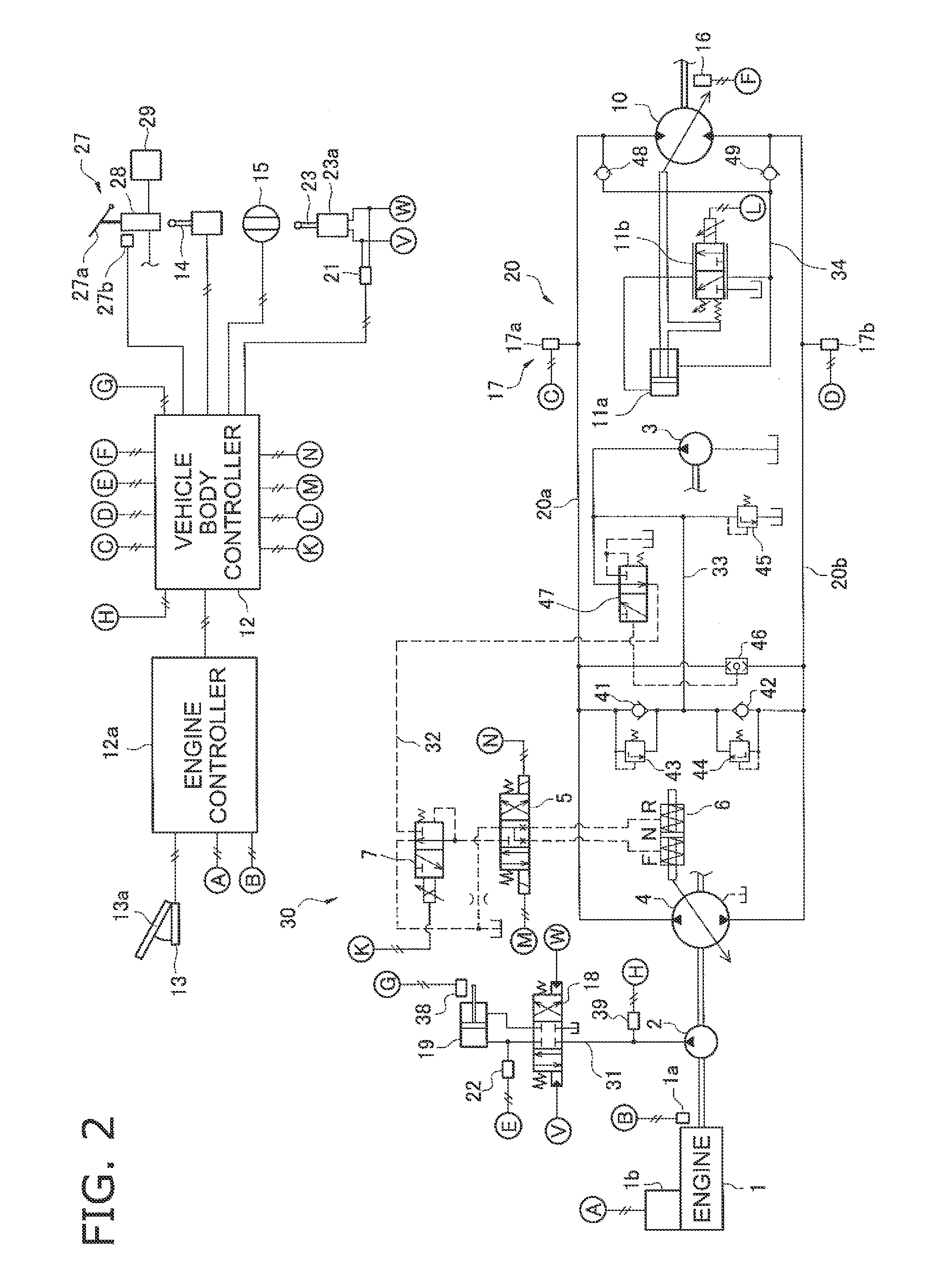

Work vehicle and method for controlling work vehicle

ActiveUS20130243556A1Reduced ease of operationFigther reducedAnalogue computers for trafficServomotor componentsHydraulic motorHydraulic pump

A work vehicle includes an engine, a throttle opening degree setting unit, first and second hydraulic pumps driven by the engine, a travel hydraulic motor driven by hydraulic fluid discharged from the first hydraulic pump, a work implement driven by hydraulic fluid discharged from the second hydraulic pump. A first control unit is configured to determine a work phase of the work implement and to set an upper limit for the throttle opening degree in accordance with the work phase. A second control unit is configured to control output of the engine based on the smaller of the throttle opening degree set by the throttle opening degree setting unit and the throttle opening degree set by the first control unit.

Owner:KOMATSU LTD

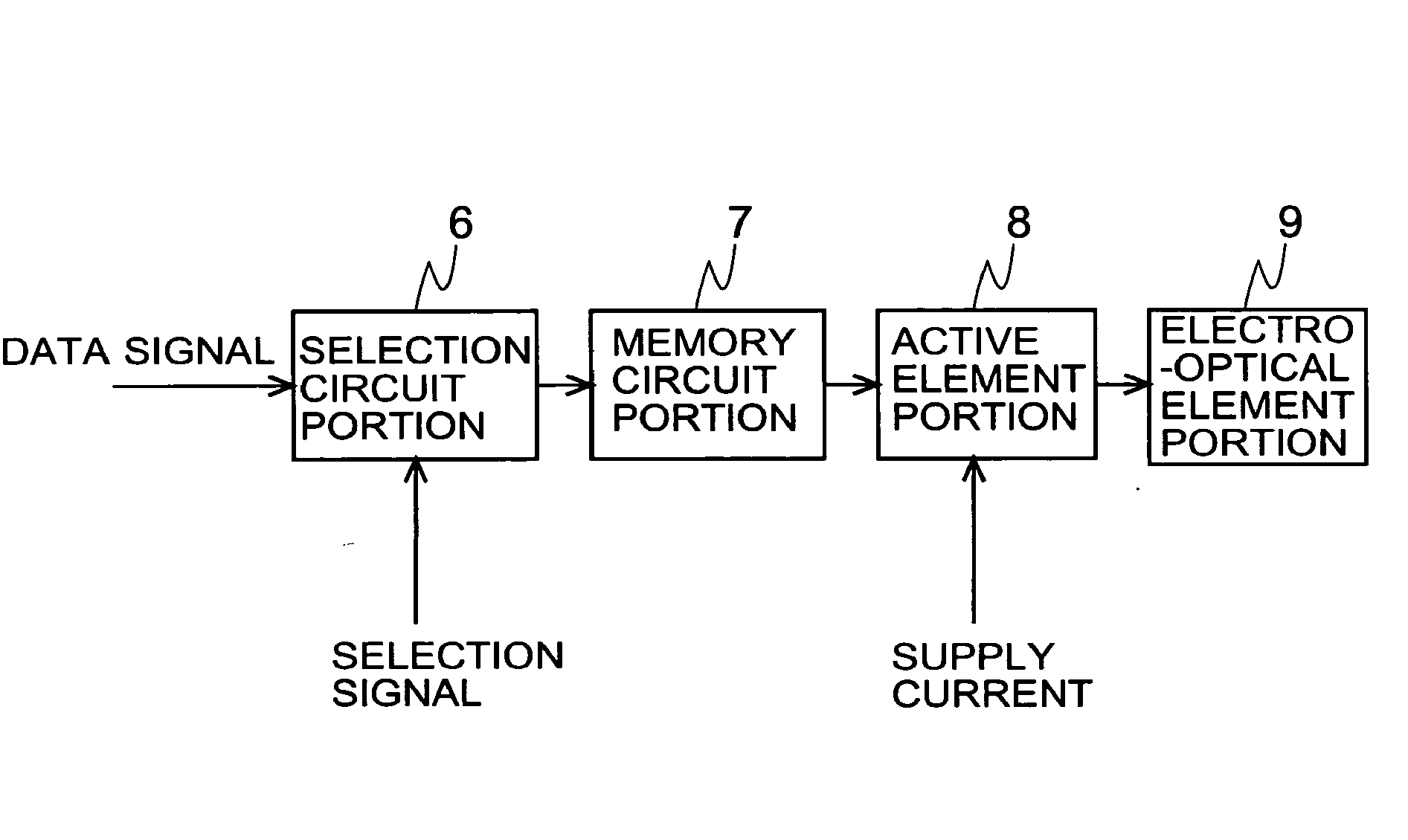

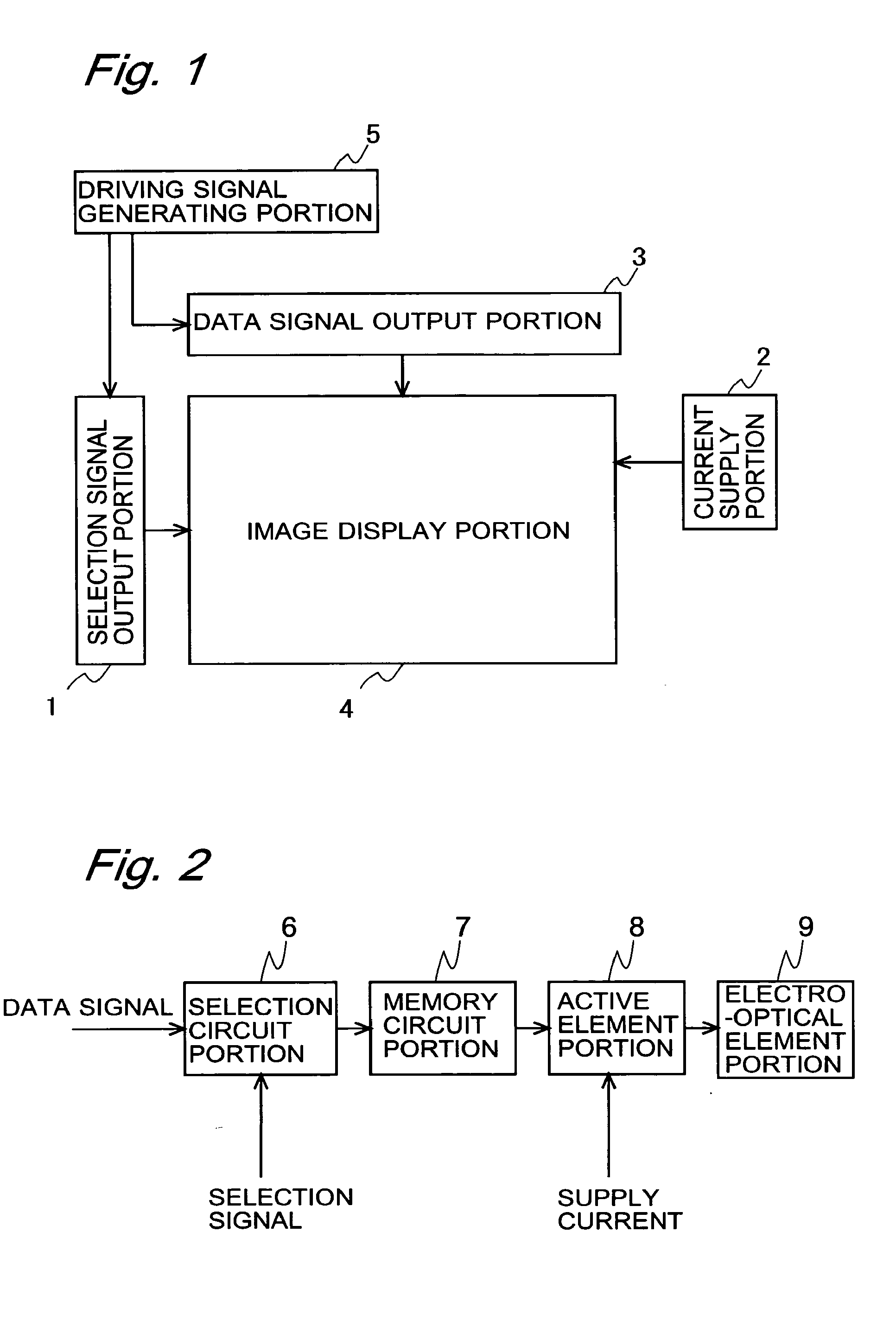

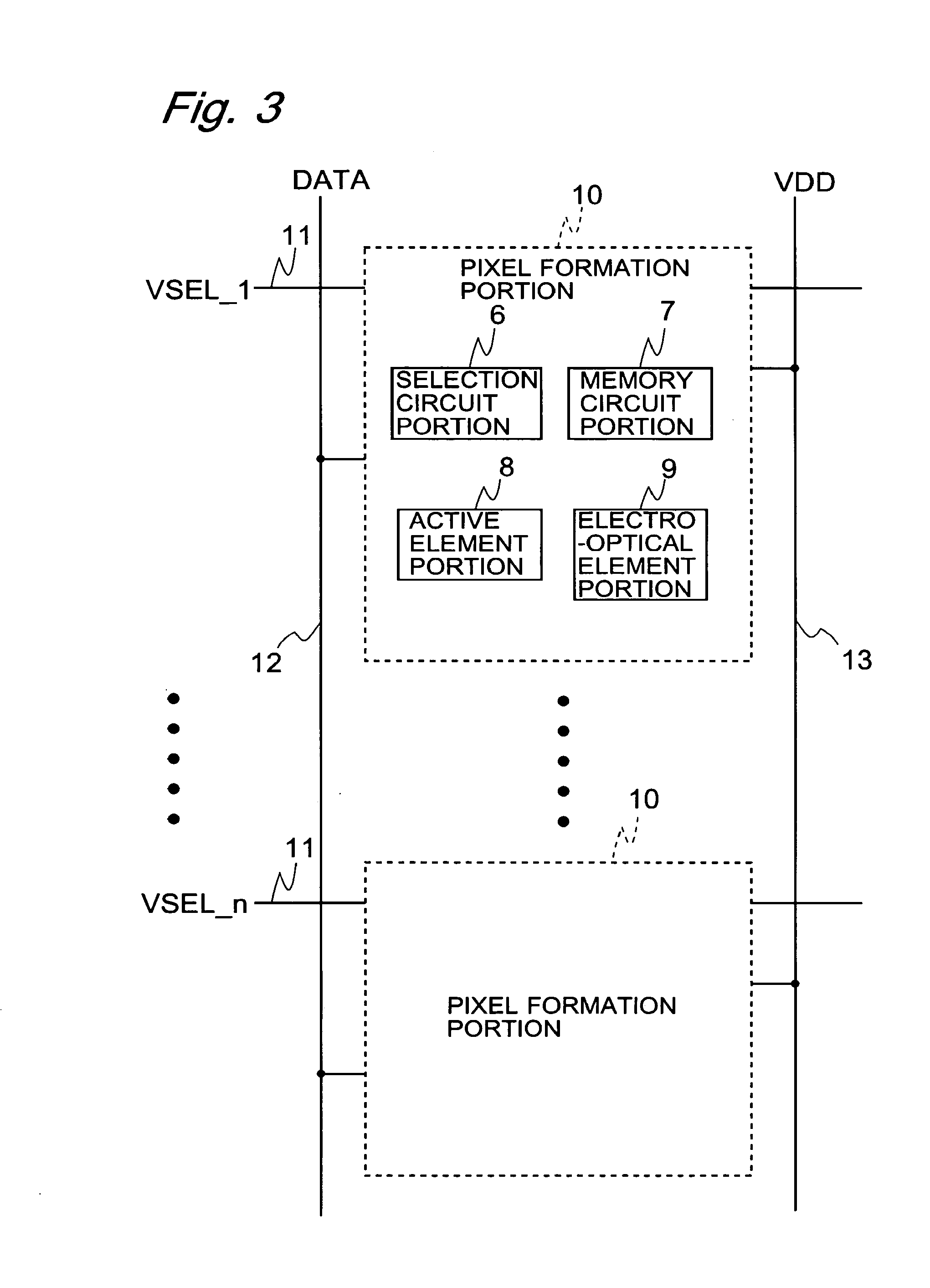

Display element and display device

ActiveUS20080150424A1Variation is suppressedIncrease the number ofDischarge tube luminescnet screensElectroluminescent light sourcesHigh numerical apertureData signal

A display element included in a display device is provided with a TFT circuit portion and a pixel aperture portion to which an organic EL element material is applied and which emits light in accordance with a current from the TFT circuit portion, as well as a scanning signal line electrode, a data signal line electrode and a power source line electrode. The resistance Re of the power source line electrode can be reduced, because the electrode width at a portion where the power source line electrode is in contact with the pixel aperture portion is larger than the electrode width at other portions. The resistance ratio Rx / Re between the electrode resistance Re and a combined resistance Rx of a current path from the power source line electrode through the pixel aperture portion is at least 105. Thus, a display element and a display device are realized, which have little luminance variation within the display screen, which have a high numerical aperture, a high light emission efficiency and a long lifetime.

Owner:SHARP KK

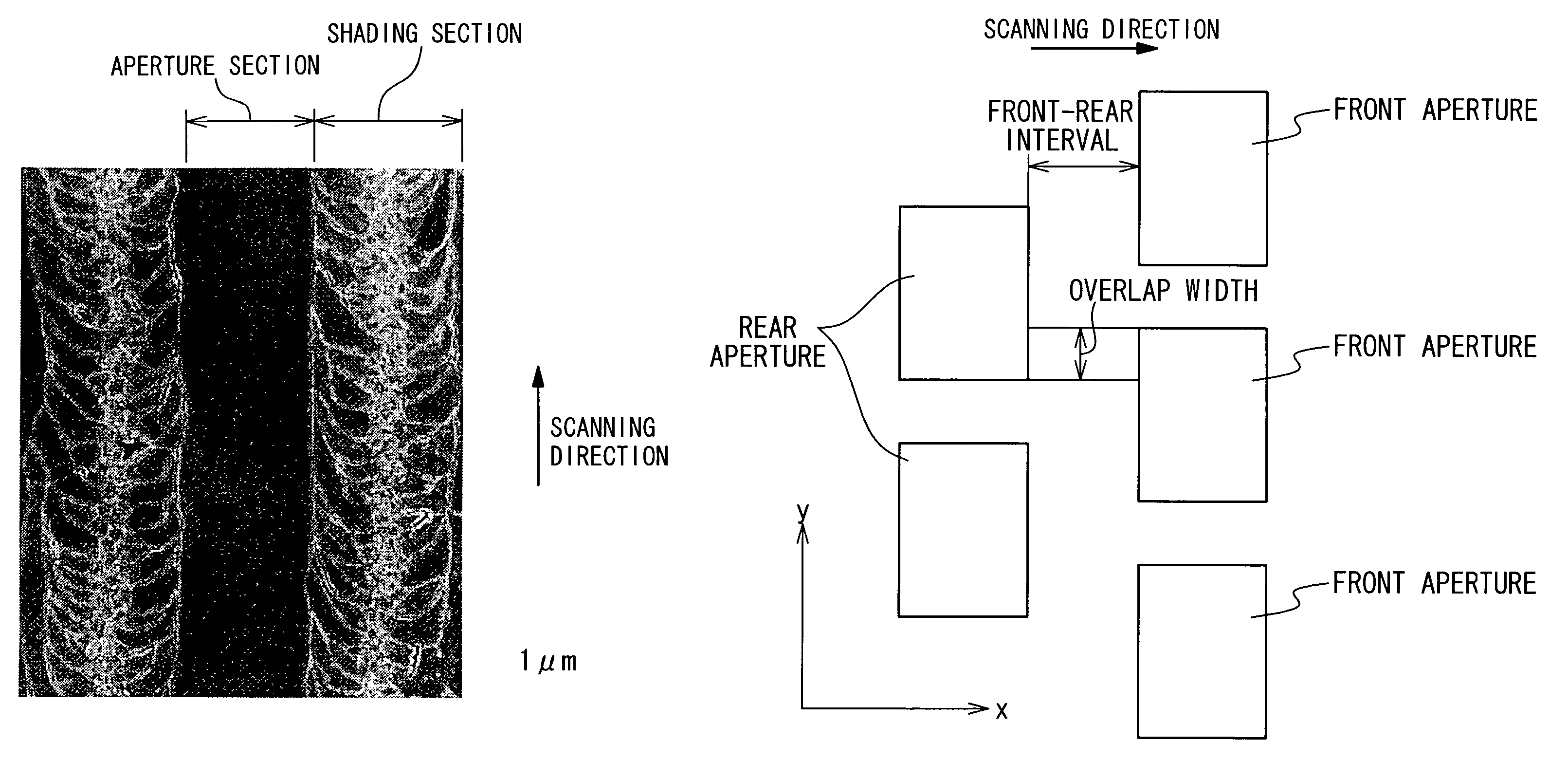

Method of and apparatus for manufacturing semiconductor thin film, and method of manufacturing thin film transistor

InactiveUS7354810B2Reduce in quantityImprove mobilityFrom gel stateTransistorOptoelectronicsSemiconductor

A method of manufacturing a semiconductor thin film includes (A) forming an amorphous semiconductor film on a substrate, (B) irradiating a beam to a surface of the amorphous semiconductor film such that a predetermined region of the amorphous semiconductor film is melted and solidified to form a crystallized semiconductor film, and (C) scanning the beam in a first direction. A second direction is a direction on the surface of the amorphous semiconductor film perpendicular to the first direction. A length along the second direction of a cross section of the beam is substantially equal to or less than two times a width along the second direction of the crystallized semiconductor film.

Owner:VISTA PEAK VENTURES LLC

Magneto-resistive effect element having spacer layer including gallium oxide layer with metal element

ActiveUS20120212860A1Big ratioWide bandgapNanomagnetismDisposition/mounting of recording headsMagnetoresistanceMagneto

Owner:TDK CORPARATION

Method for manufacturing soi wafer

ActiveUS20110003462A1Etch rate reductionVariation is suppressedSolid-state devicesSemiconductor/solid-state device manufacturingIn planeHydrogen

Provided is a method for manufacturing an SOI wafer, which is capable of: efficiently removing an ion-implanted defect layer existing in an ion implanted layer in the vicinity of a peeled surface peeled by an ion implantation peeling method; ensuring the in-plane uniformity of a substrate; and also achieving cost reduction and higher throughput. The method for manufacturing an SOI wafer includes at least the steps of: bonding a silicon wafer with or without an oxide film onto a handle wafer to prepare a bonded substrate, wherein the silicon wafer has an ion implanted layer formed by implanting hydrogen ions and / or rare gas ions into the silicon wafer; peeling the silicon wafer along the ion implanted layer, thereby transferring the silicon wafer onto the handle wafer to produce a post-peeling SOI wafer; immersing the post-peeling SOI wafer in an aqueous ammonia-hydrogen peroxide solution; and performing a heat treatment at a temperature of 900° C. or higher on the immersed post-peeling SOI wafer, and / or polishing a silicon film layer of the immersed post-peeling SOI wafer, through CMP polishing by 10 to 50 nm.

Owner:SHIN ETSU CHEM IND CO LTD

Magneto-resistive effect element having spacer layer including gallium oxide layer with metal element

A magneto-resistive effect (MR) element includes: first and second magnetic layers in which a relative angle formed by magnetization directions changes according to an external magnetic field; and a spacer layer positioned between the first magnetic layer and the second magnetic layer. The spacer layer includes a main spacer layer composed of gallium oxide as a primary component and containing at least one metal element selected from a group of magnesium, zinc, indium and aluminum.

Owner:TDK CORPARATION

Solid-state imaging apparatus, method of manufacturing same, and electronic apparatus

ActiveUS8809921B2Variation is suppressedImprove featuresTransistorSolid-state devicesEngineeringPhotoelectric conversion

A solid-state imaging apparatus includes a plurality of pixels each including a photoelectric conversion unit and pixel transistors, which are formed on a semiconductor substrate; a floating diffusion unit in the pixel; a first-conductivity-type ion implantation area for surface pinning, which is formed over the surface on the side of the photoelectric conversion unit and the surface of the semiconductor substrate; and a second-conductivity-type ion implantation area for forming an overflow path serving as an overflow path for the floating diffusion unit, the second-conductivity-type ion implantation area being formed below the entire area of the first-conductivity-type ion implantation area. An overflow barrier is formed using the second-conductivity-type ion implantation area. A charge storage area is formed using an area in which the second-conductivity-type semiconductor area and the second-conductivity-type ion implantation area superpose each other.

Owner:SONY SEMICON SOLUTIONS CORP

Liquid crystal display device

ActiveUS8421972B2Improve the display effectNo roughnessNon-linear opticsVertical alignmentEngineering

There is provided a liquid crystal display device of high picture quality with high brightness and small display unevenness.A vertical alignment type liquid crystal display device which has a plurality of pixels includes: a first electrode which includes, in each of the plurality of pixels, a plurality of first branch portions extending in a first direction and a plurality of second branch portions extending in a second direction that is different from the first direction; a second electrode disposed so as to oppose the first electrode; and a liquid crystal layer interposed between the first electrode and the second electrode, wherein a width of each of the plurality of first branch portions and the plurality of second branch portions is in a range not less than 1.4 μm and not more than 8.0 μm.

Owner:SHARP KK

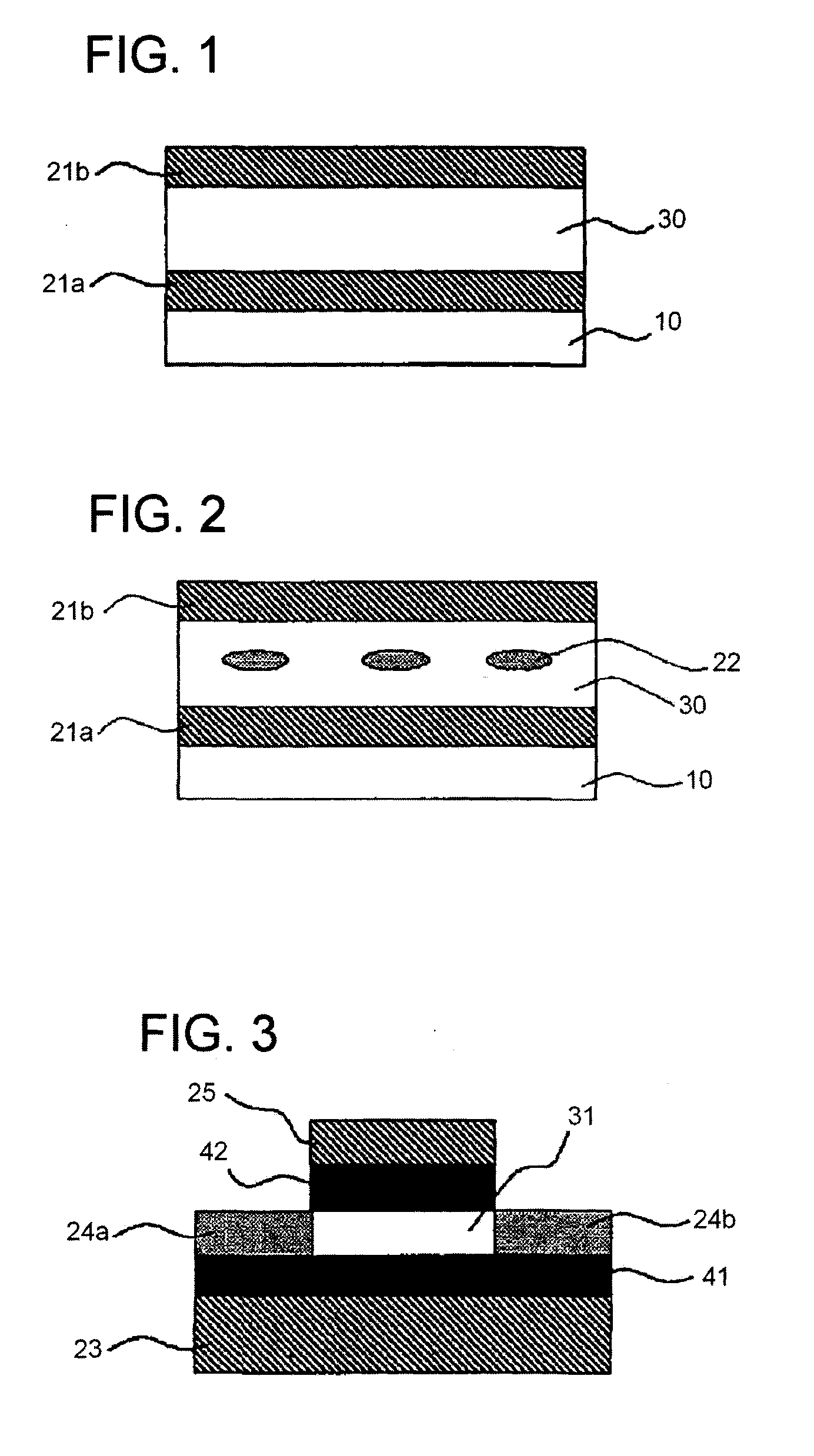

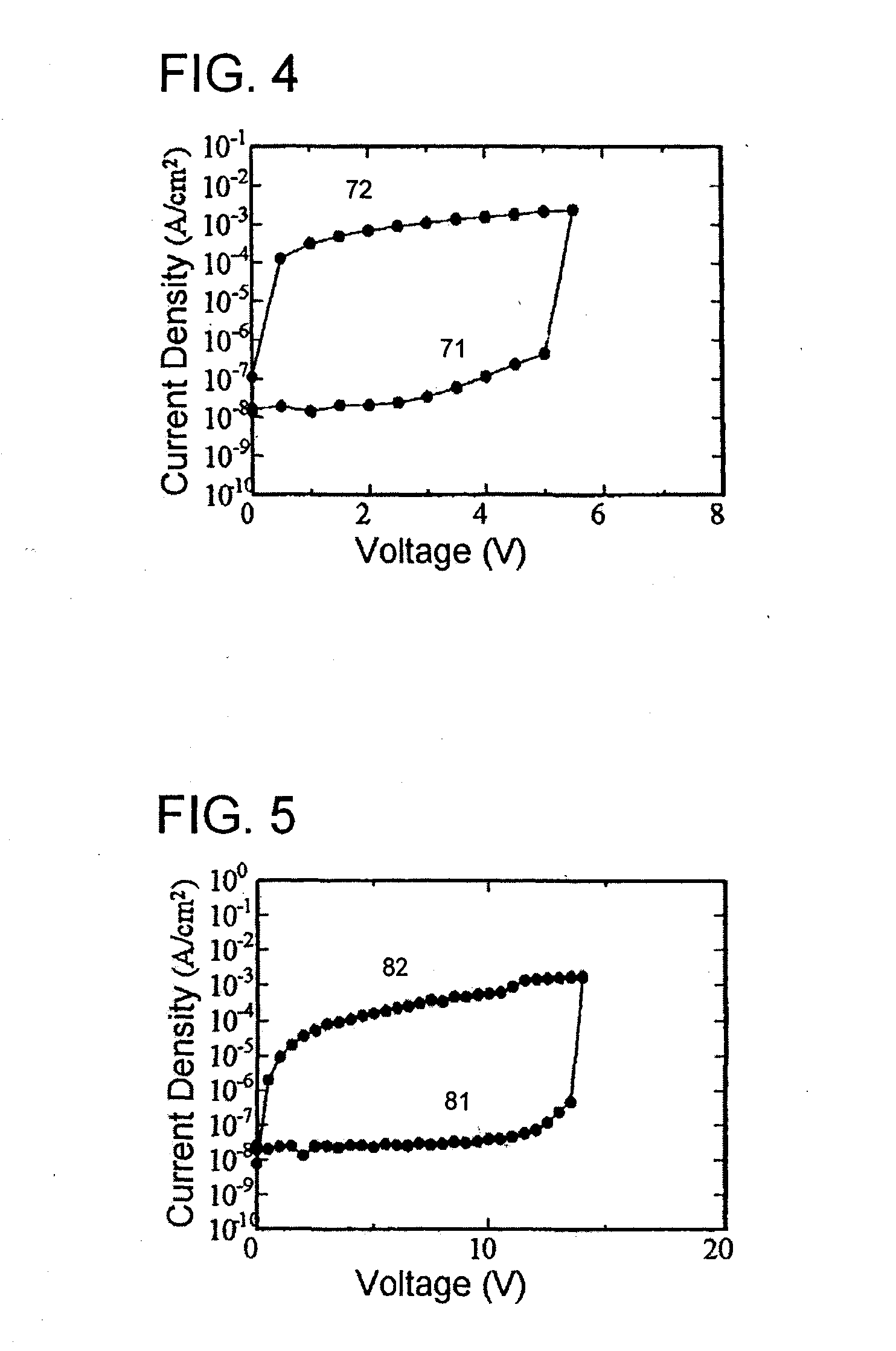

Switching device

InactiveUS20070108441A1Improve featuresUse of materialOrganic chemistryElectroluminescent light sourcesVoltmeterEngineering physics

A switching device is discloses that exhibits two stable resistance values to a voltage applied between electrodes. The switching device comprises thin films of a first electrode layer, an organic bistable material layer and a second electrode layer sequentially formed on a substrate, and the organic bistable material is a specified quinone compound.

Owner:SHARP KK

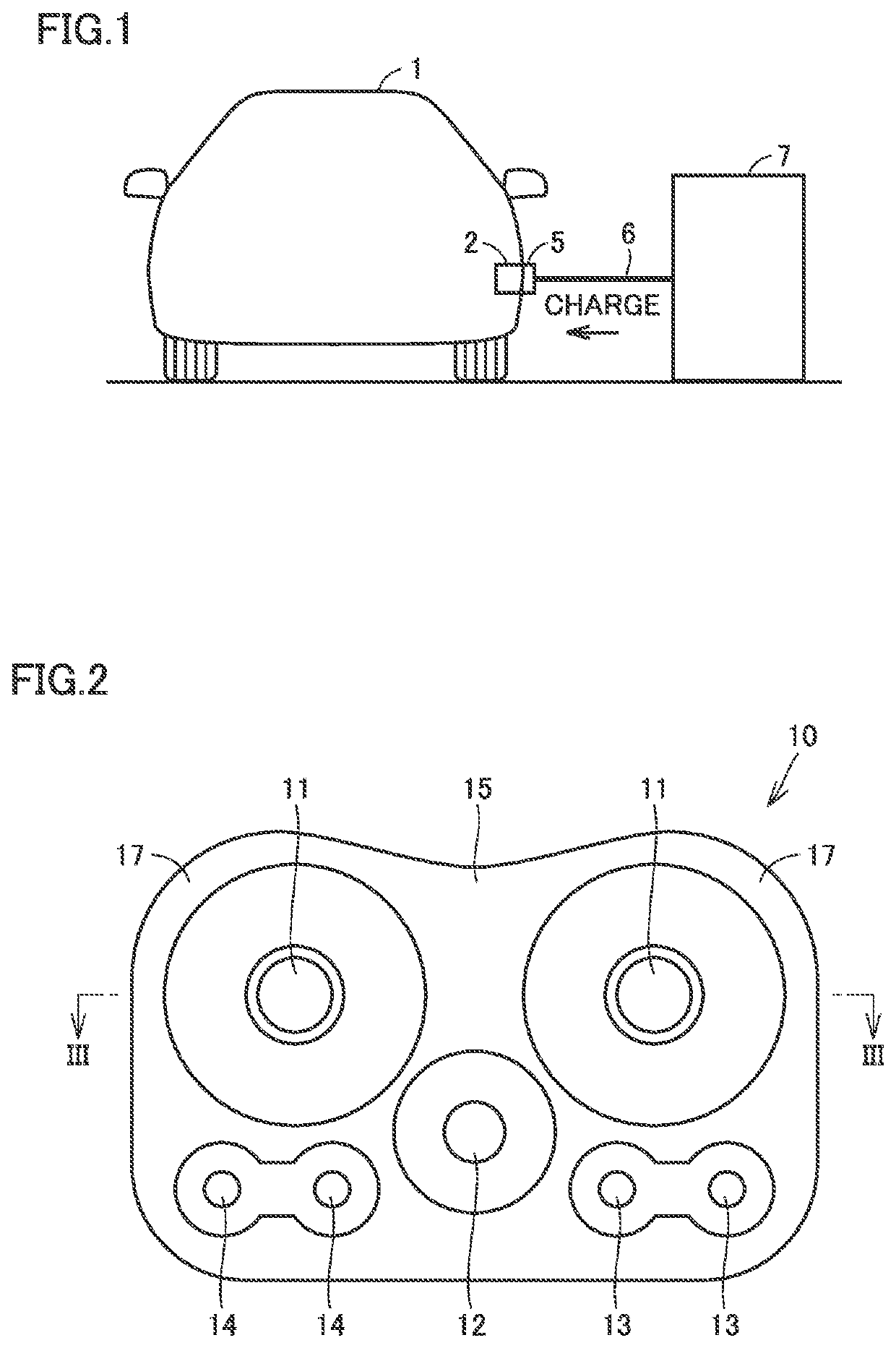

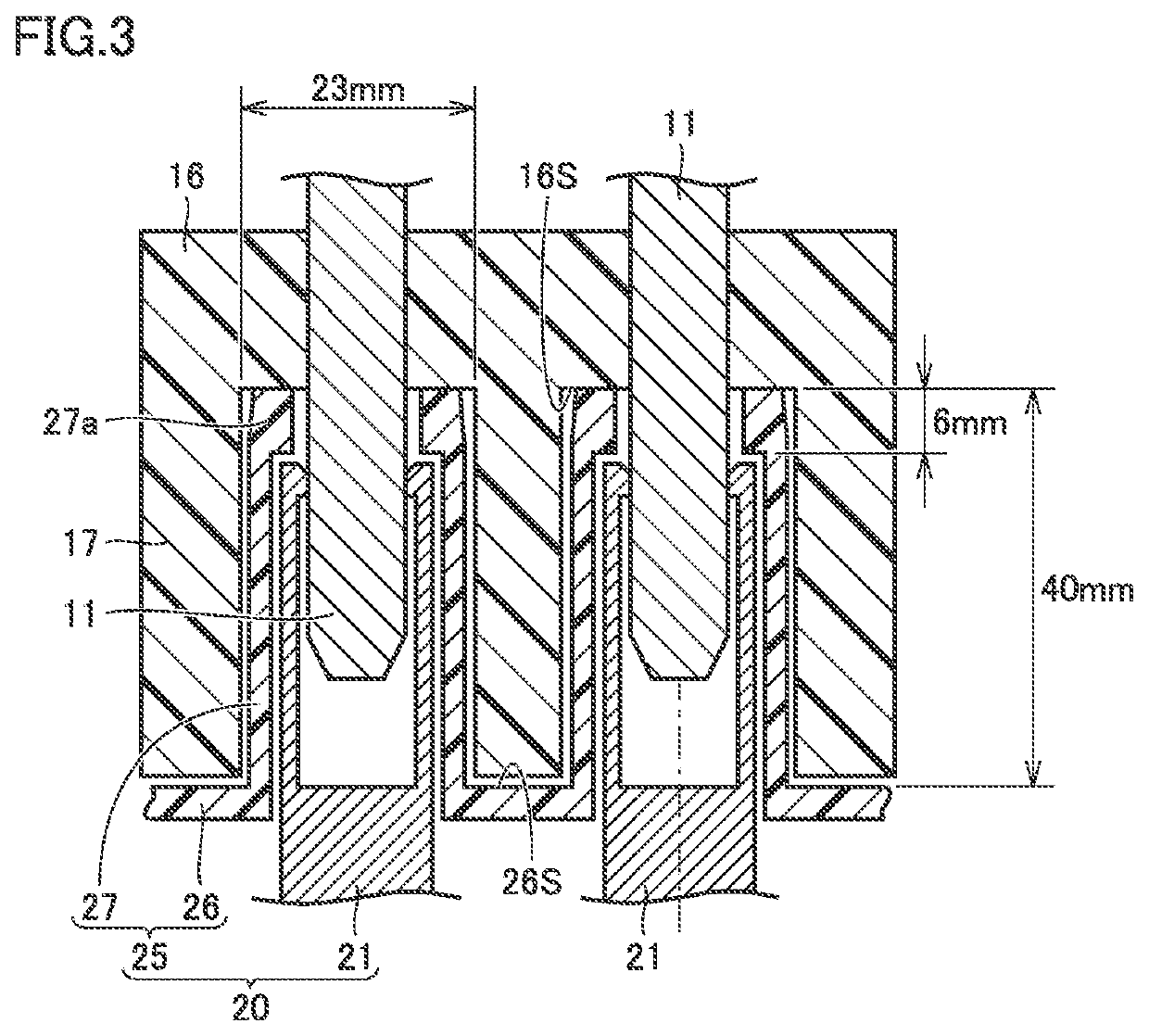

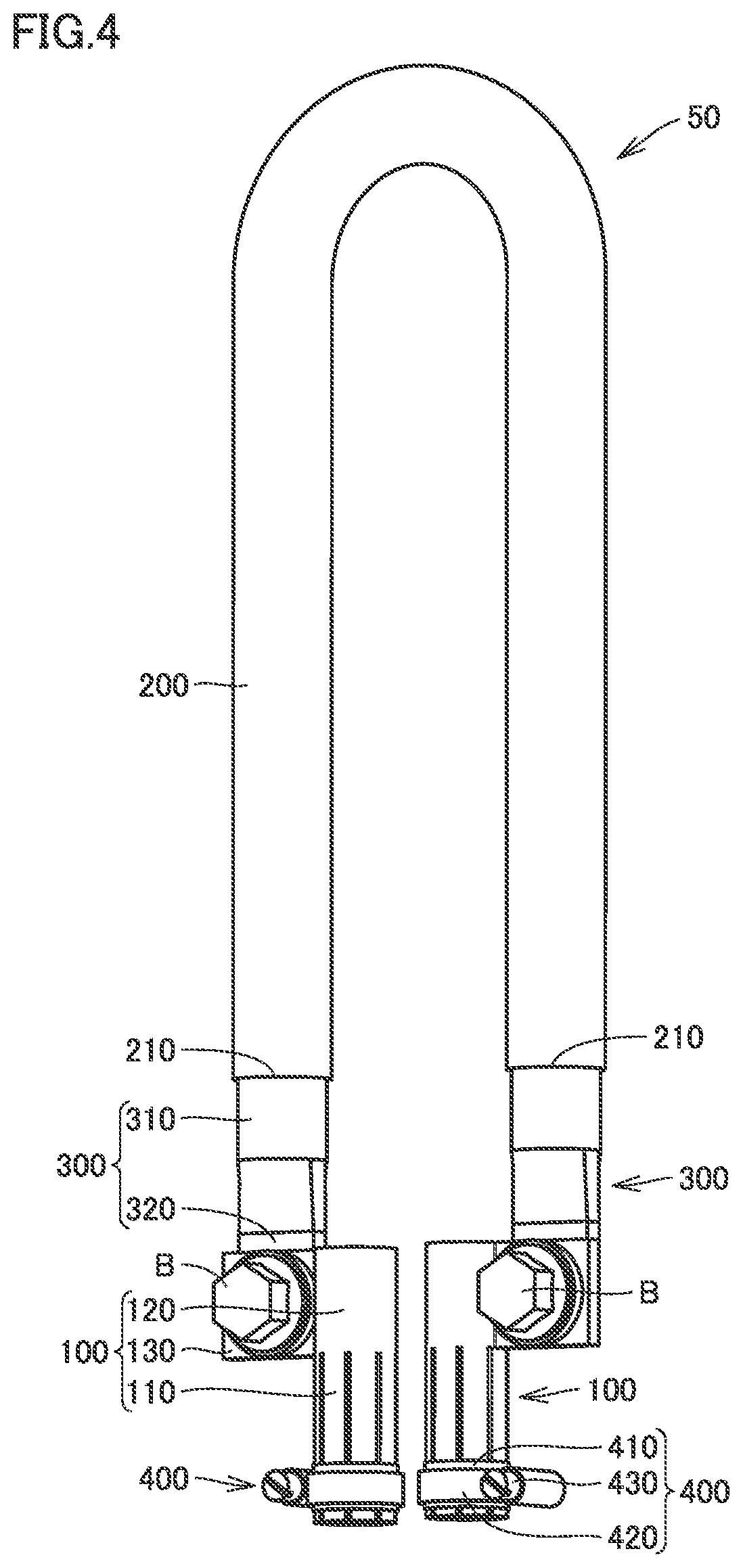

Evaluation method

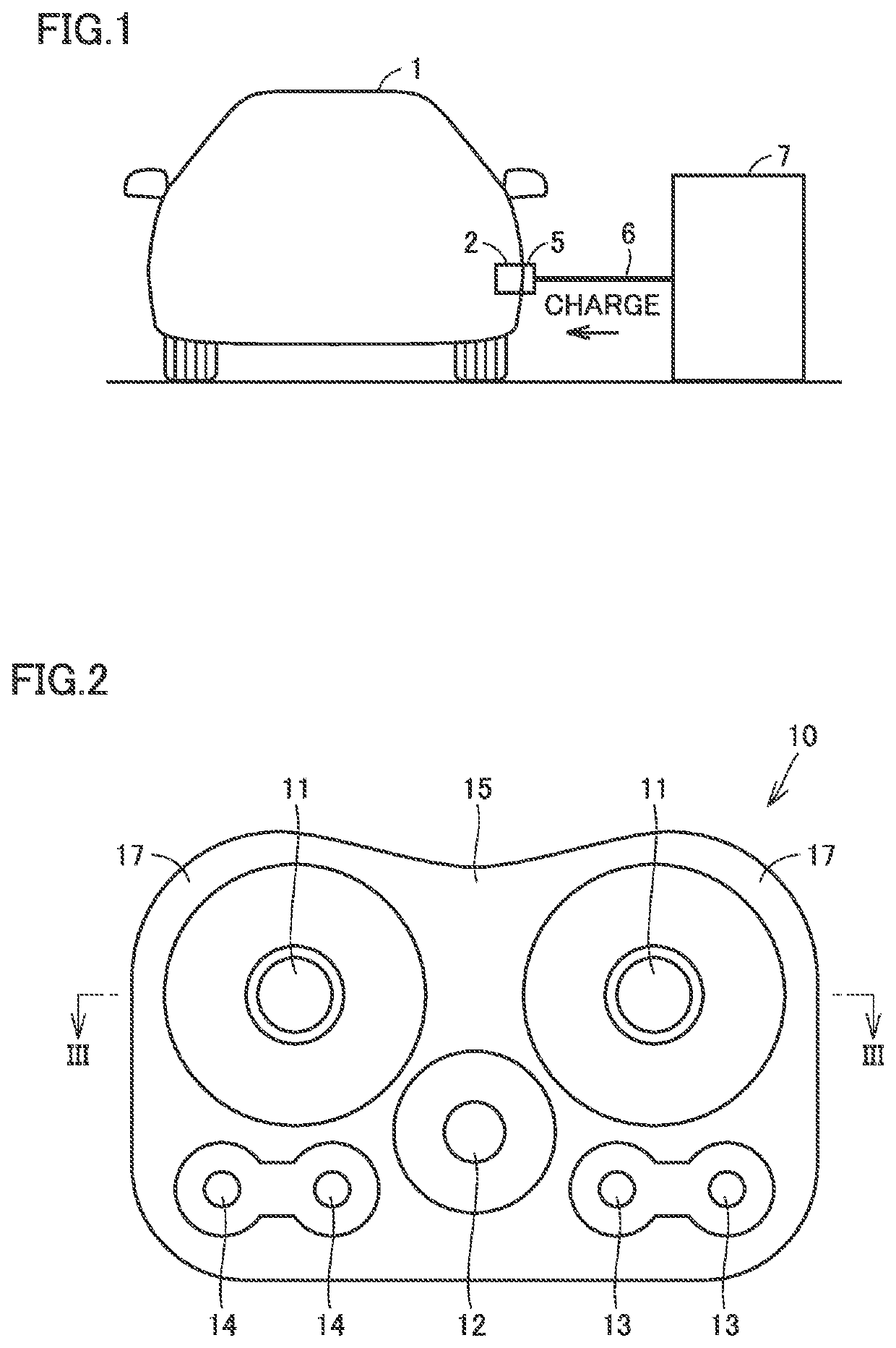

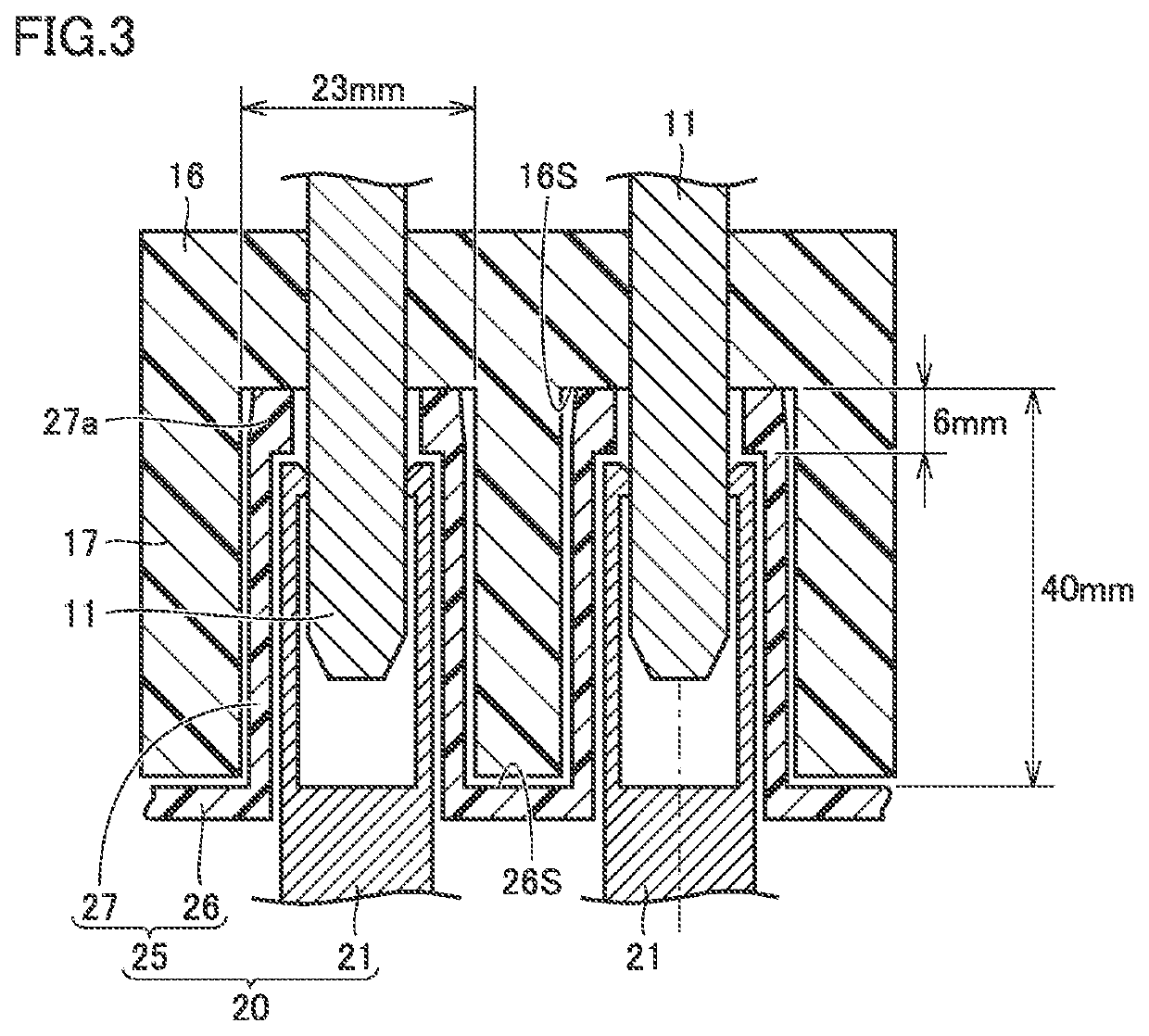

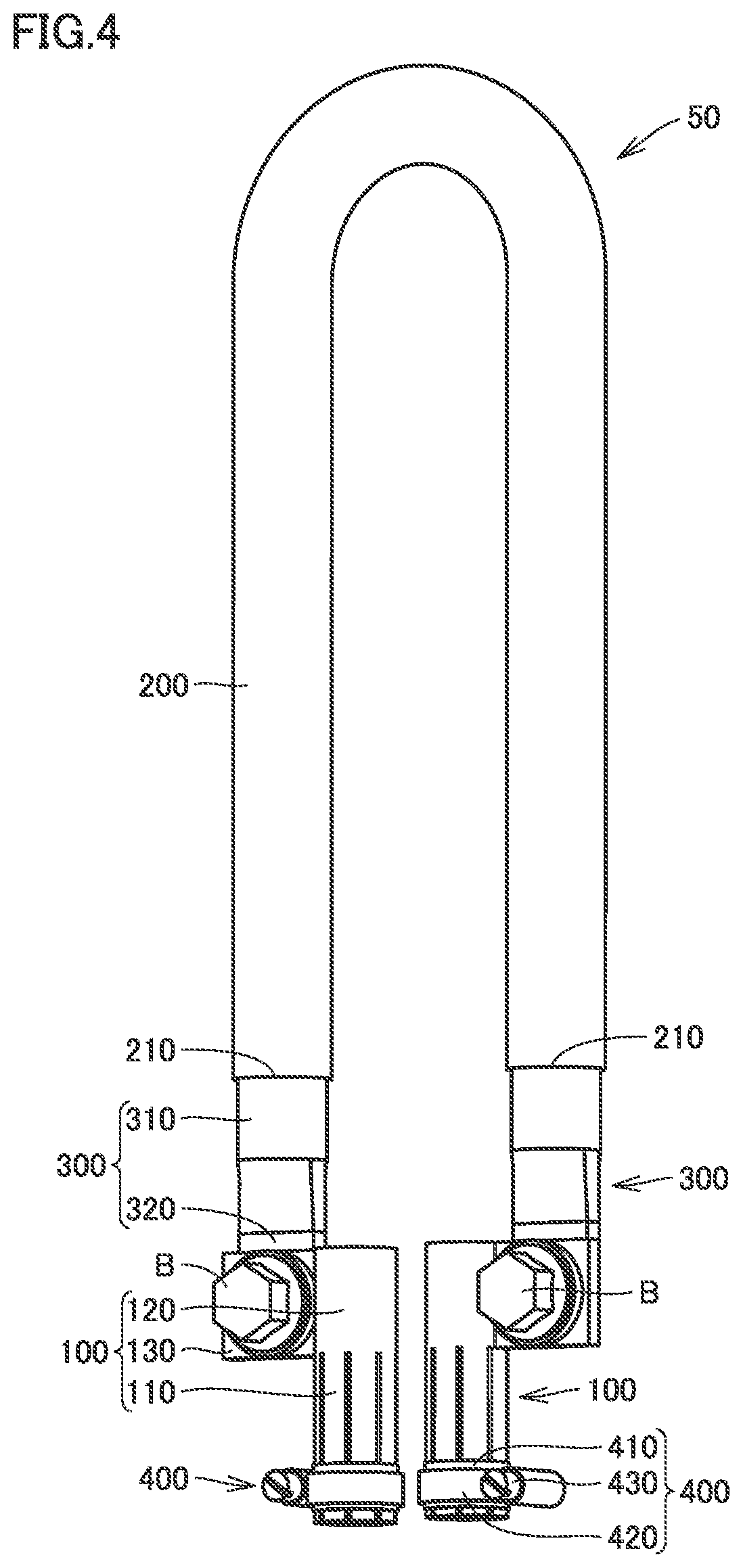

ActiveUS11402406B2Appropriately evaluatedVariation is suppressedData processing applicationsCharging stationsElectrical resistance and conductancePhysical medicine and rehabilitation

An evaluation method is a method for evaluating a charging connector in coolability by connecting an evaluation jig to the charging connector, the charging connector including a pair of male terminals coolable with a coolant, the evaluation jig including a pair of female terminals, the pair of female terminals being connected to the pair of male terminals in evaluating the charging connector in coolability. The method comprises: connecting the pair of female terminals to the pair of male terminals; adjusting a connection state between the male terminal and the female terminal such that contact resistance between the terminals is 0.06 mΩ or more and 0.15 mΩ or less; and after the adjusting, evaluating the coolability depending on whether the male and female terminals have a temperature of 90° C. or lower when a charging current of 400 A is supplied to the terminals for 30 minutes.

Owner:TOYOTA JIDOSHA KK

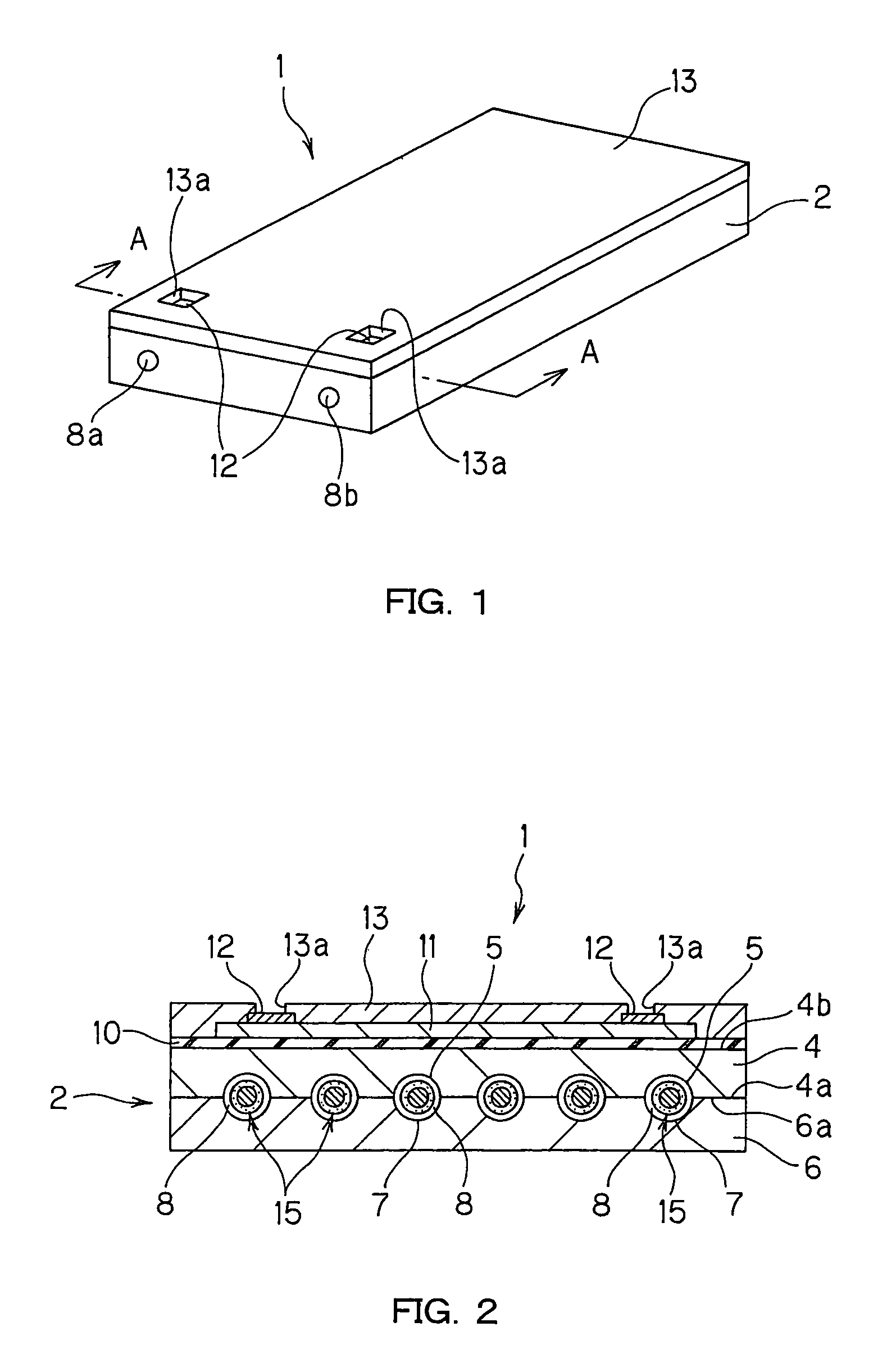

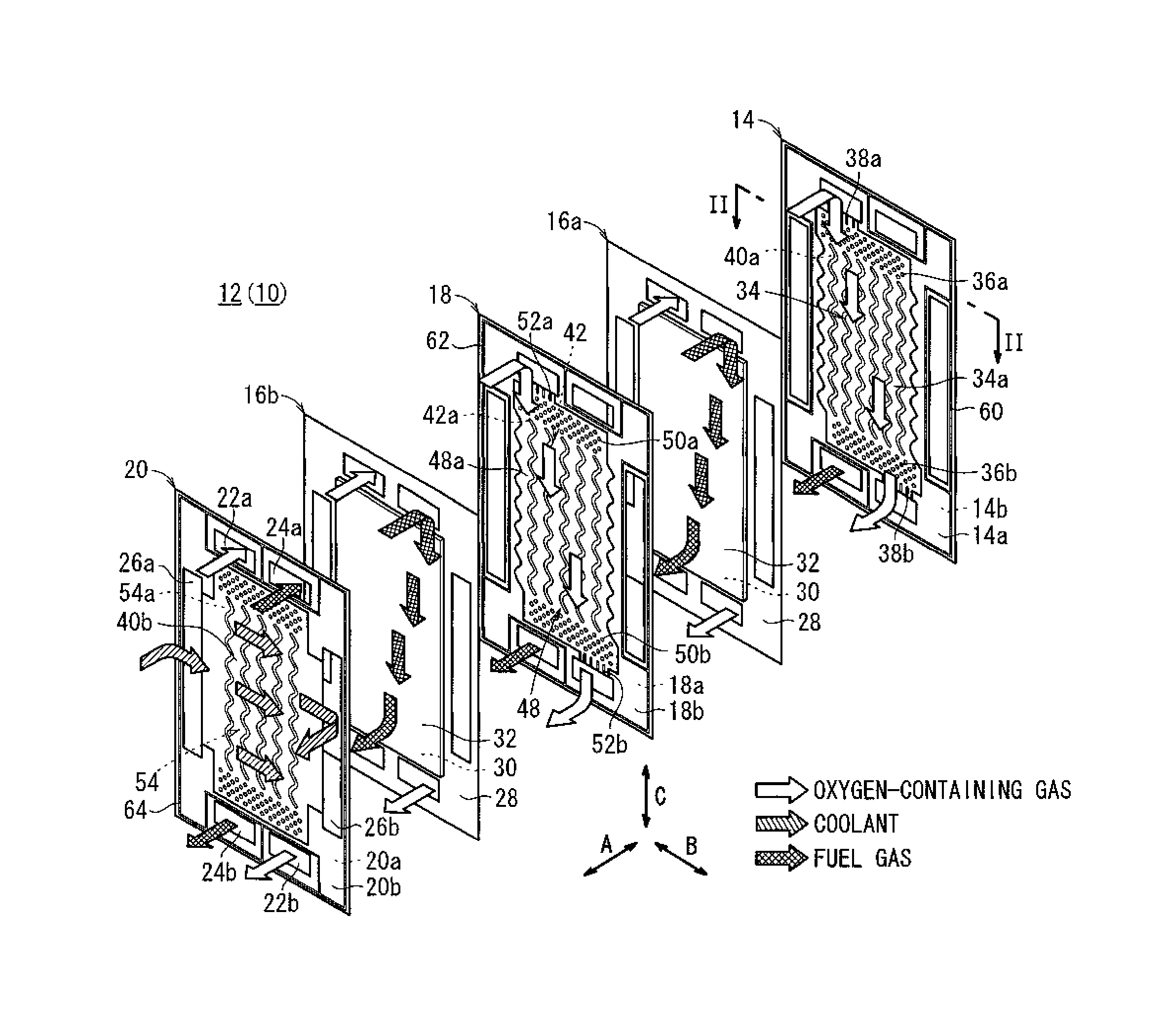

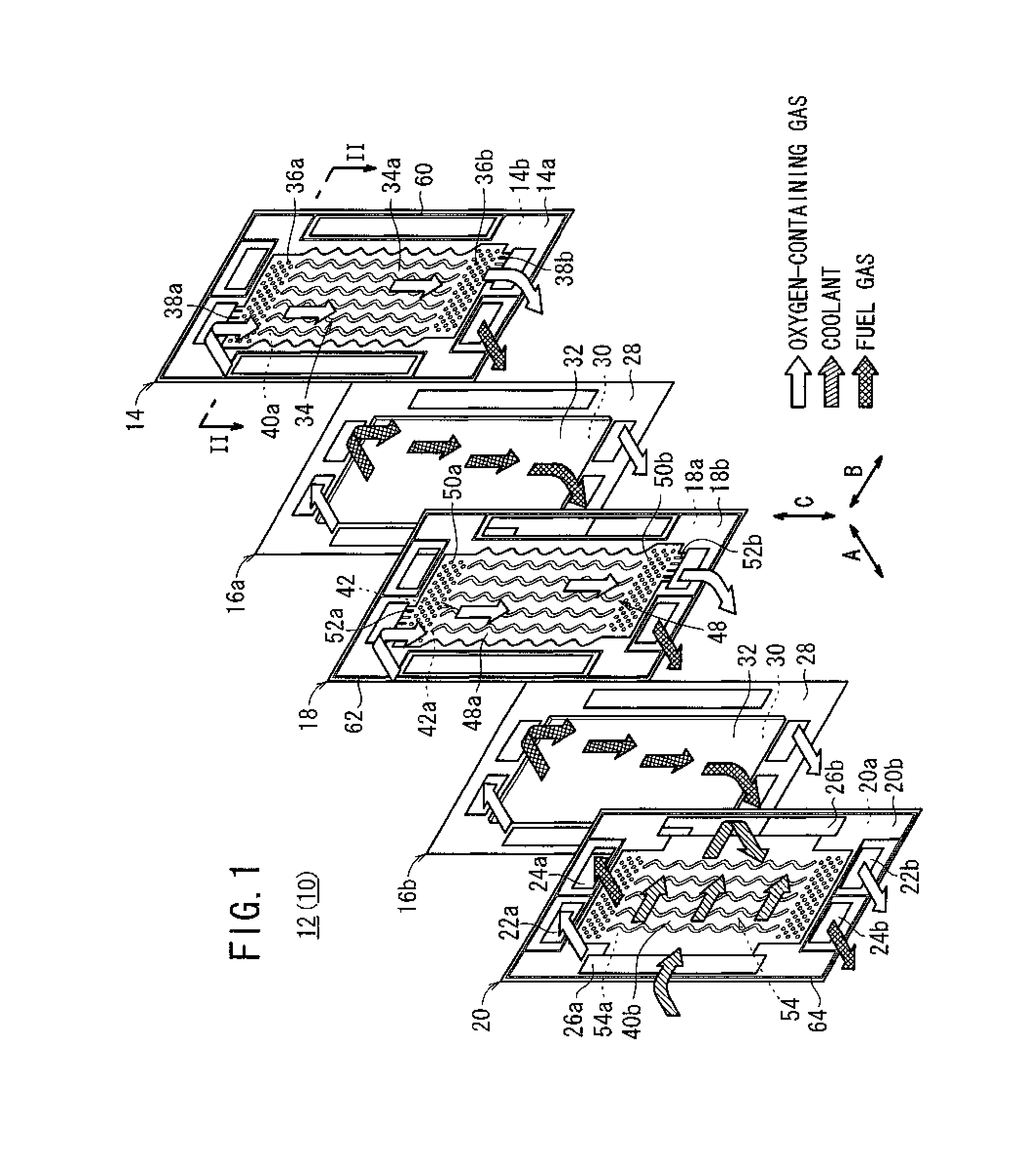

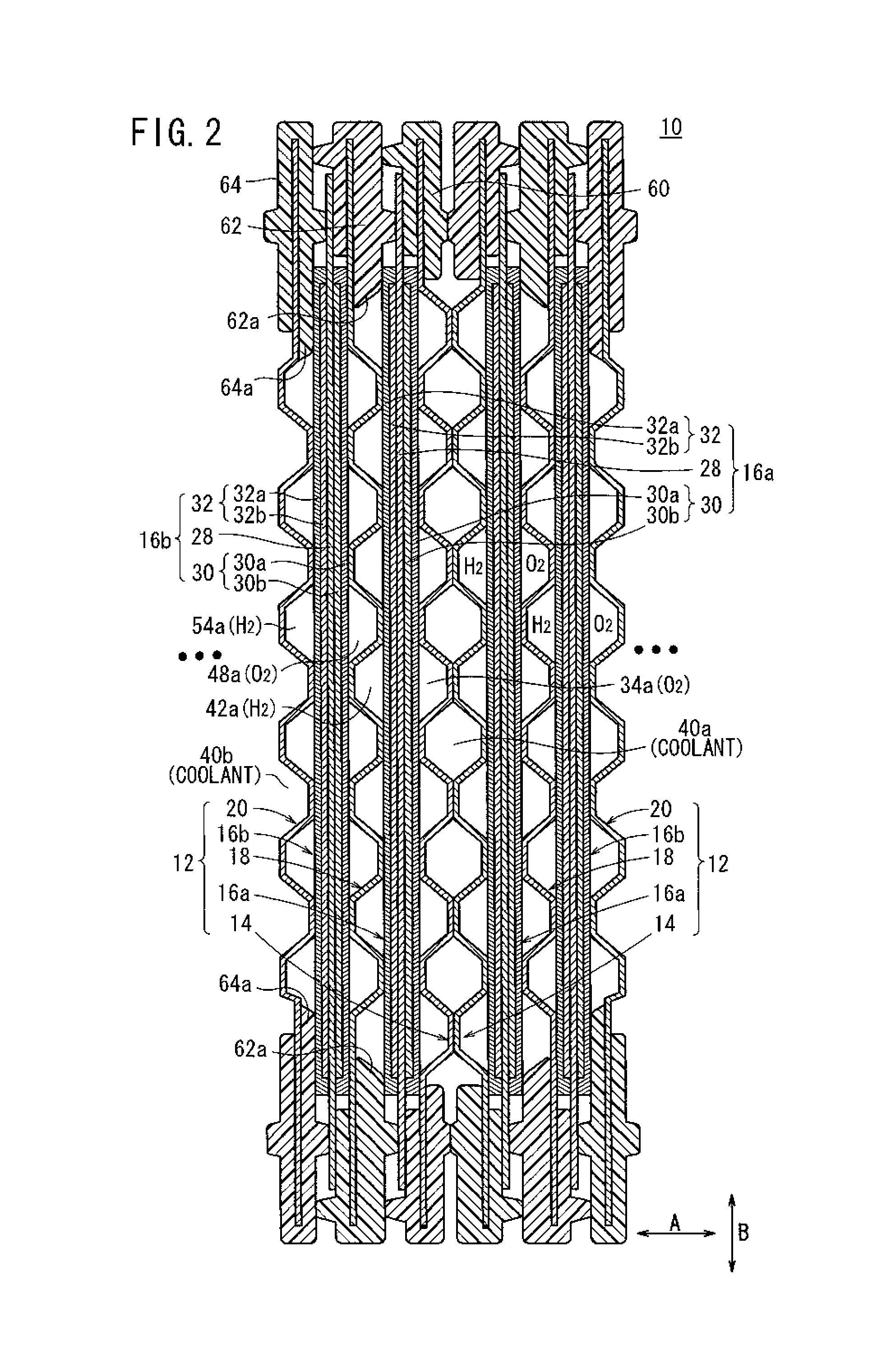

Fuel cell separators capable of suppressing variation in pressure loss

ActiveUS8802312B2Same power generation characteristicSimple structureElectrolyte moving arrangementsFuel cells groupingFuel cellsPhysical chemistry

A fuel cell according to the present invention includes a power generation unit. The power generation unit is formed by stacking a first metal separator, a first membrane electrode assembly, a second metal separator, a second membrane electrode assembly, and a third metal separator. The number of flow grooves in a first oxygen-containing gas flow field is different from the number of flow grooves in a second oxygen-containing gas flow field. The first oxygen-containing gas flow field and the second oxygen-containing gas flow field have the same length, and the flow grooves in the first oxygen-containing gas flow field and the flow grooves in the second oxygen-containing gas flow field have the same depth.

Owner:HONDA MOTOR CO LTD

Evaluation method

ActiveUS20210215739A1Appropriately evaluatedVariation is suppressedData processing applicationsCharging stationsElectrical resistance and conductancePhysical medicine and rehabilitation

An evaluation method is a method for evaluating a charging connector in coolability by connecting an evaluation jig to the charging connector, the charging connector including a pair of male terminals coolable with a coolant, the evaluation jig including a pair of female terminals, the pair of female terminals being connected to the pair of male terminals in evaluating the charging connector in coolability. The method comprises: connecting the pair of female terminals to the pair of male terminals; adjusting a connection state between the male terminal and the female terminal such that contact resistance between the terminals is 0.06 mΩ or more and 0.15 mΩ or less; and after the adjusting, evaluating the coolability depending on whether the male and female terminals have a temperature of 90° C. or lower when a charging current of 400 A is supplied to the terminals for 30 minutes.

Owner:TOYOTA JIDOSHA KK

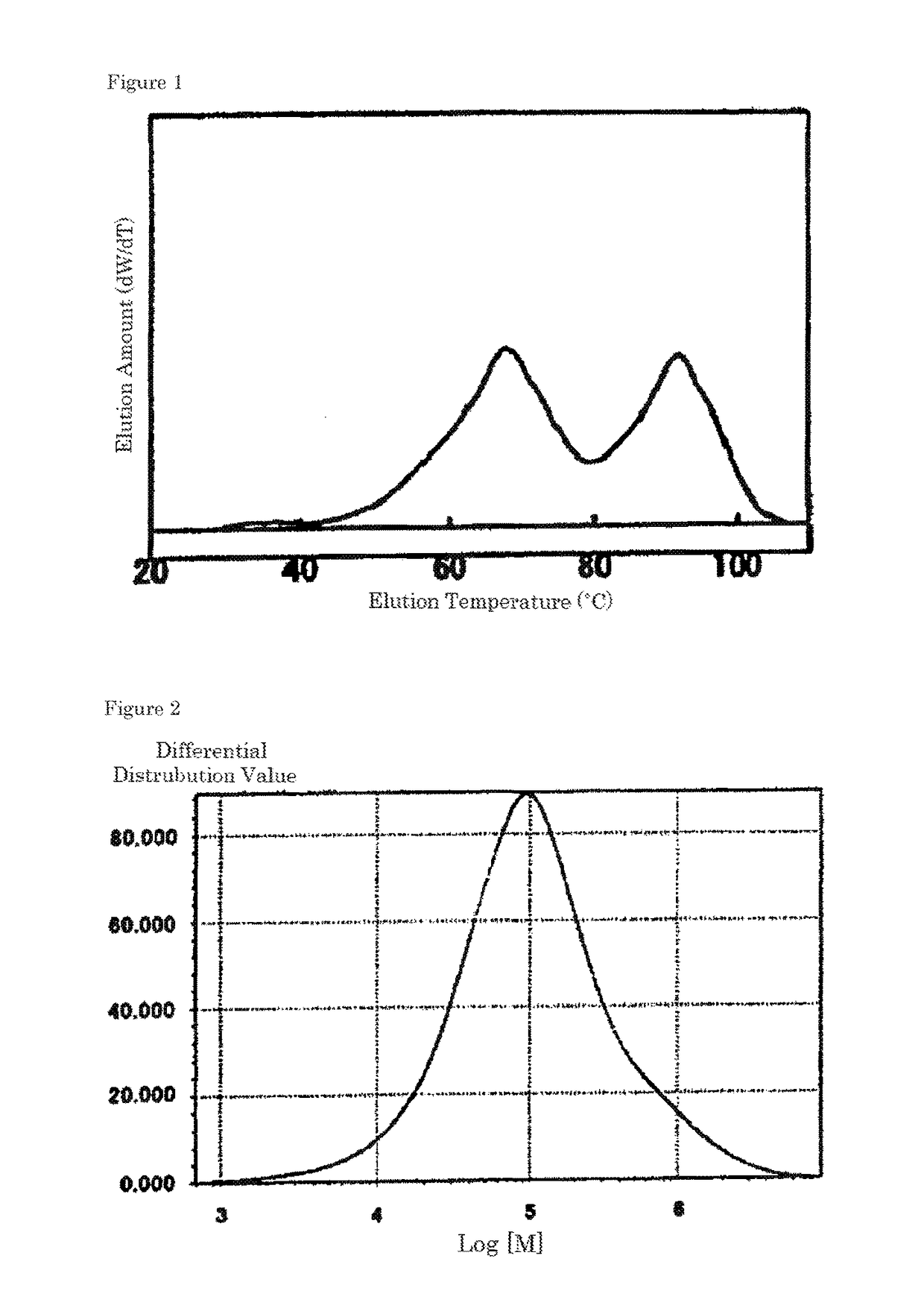

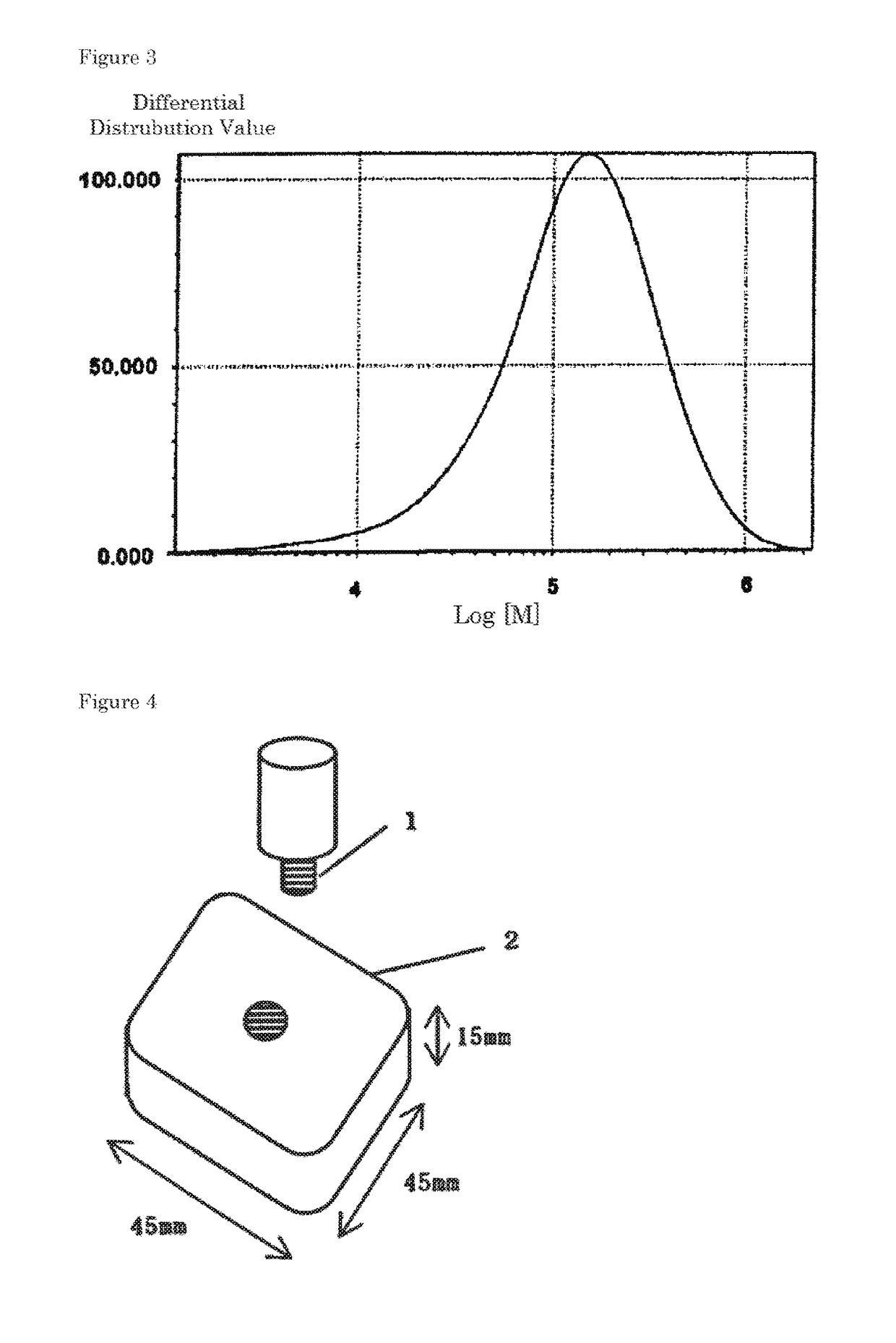

Composite resin particles, foamable particles, pre-foamed particles, and foam molded body

Composite resin particles including: a polyethylene-based resin and a polystyrene-based resin, wherein the polyethylene-based resin and the polystyrene-based resin are included in the ranges of 50 to 20% by mass and 50 to 80% by mass respectively, with respect to the total of these resins, the polyethylene-based resin is composed of: a first polyethylene-based resin having a medium density to a high density in the range of 925 to 965 kg / m3; and a second polyethylene-based resin which is linear and which has a lower density than the first polyethylene-based resin, and the first polyethylene-based resin and the second polyethylene-based resin are included in the ranges of 90 to 30% by mass and 10 to 70% by mass respectively, with respect to the total of these resins.

Owner:SEKISUI PLASTICS CO LTD

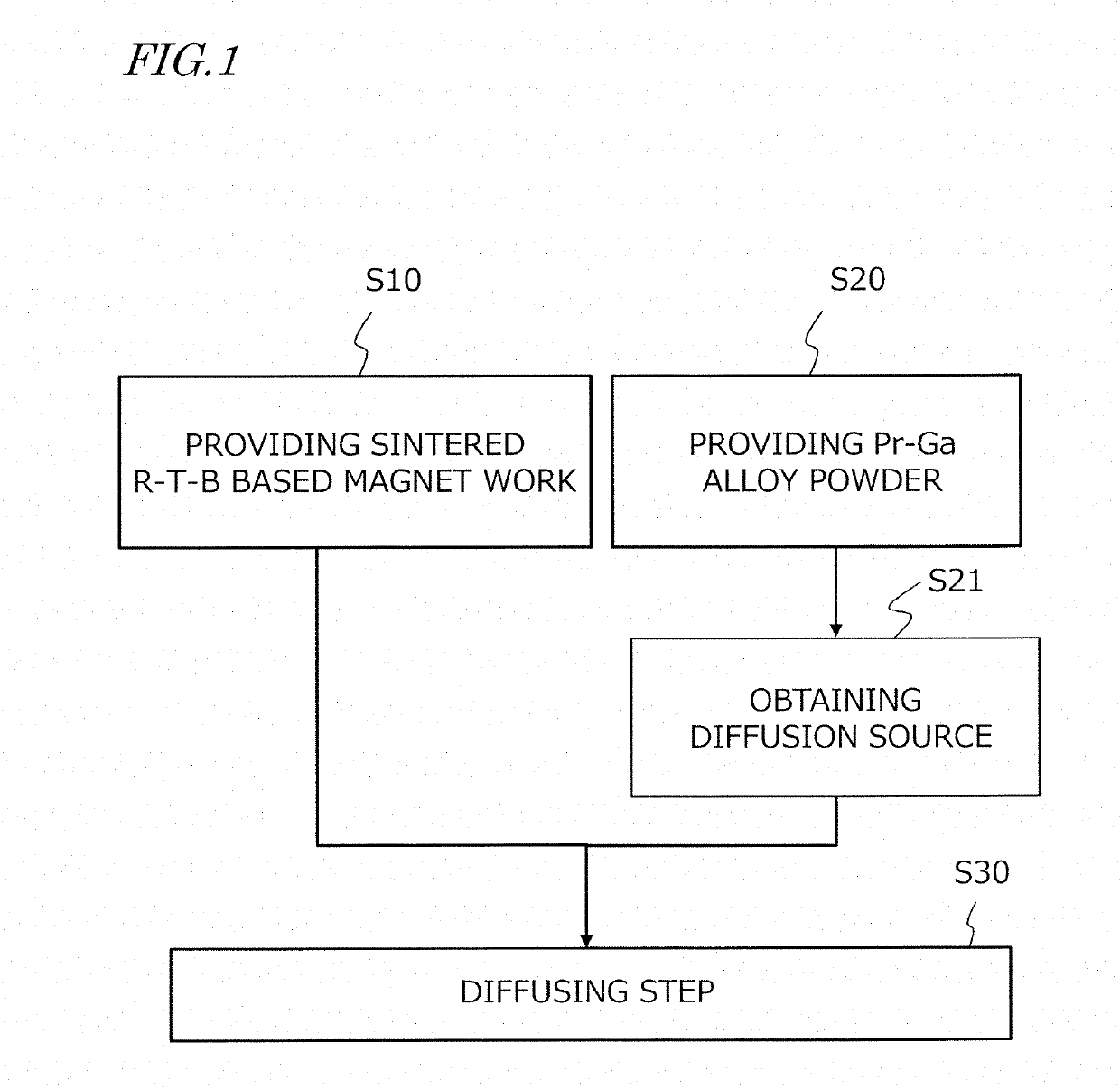

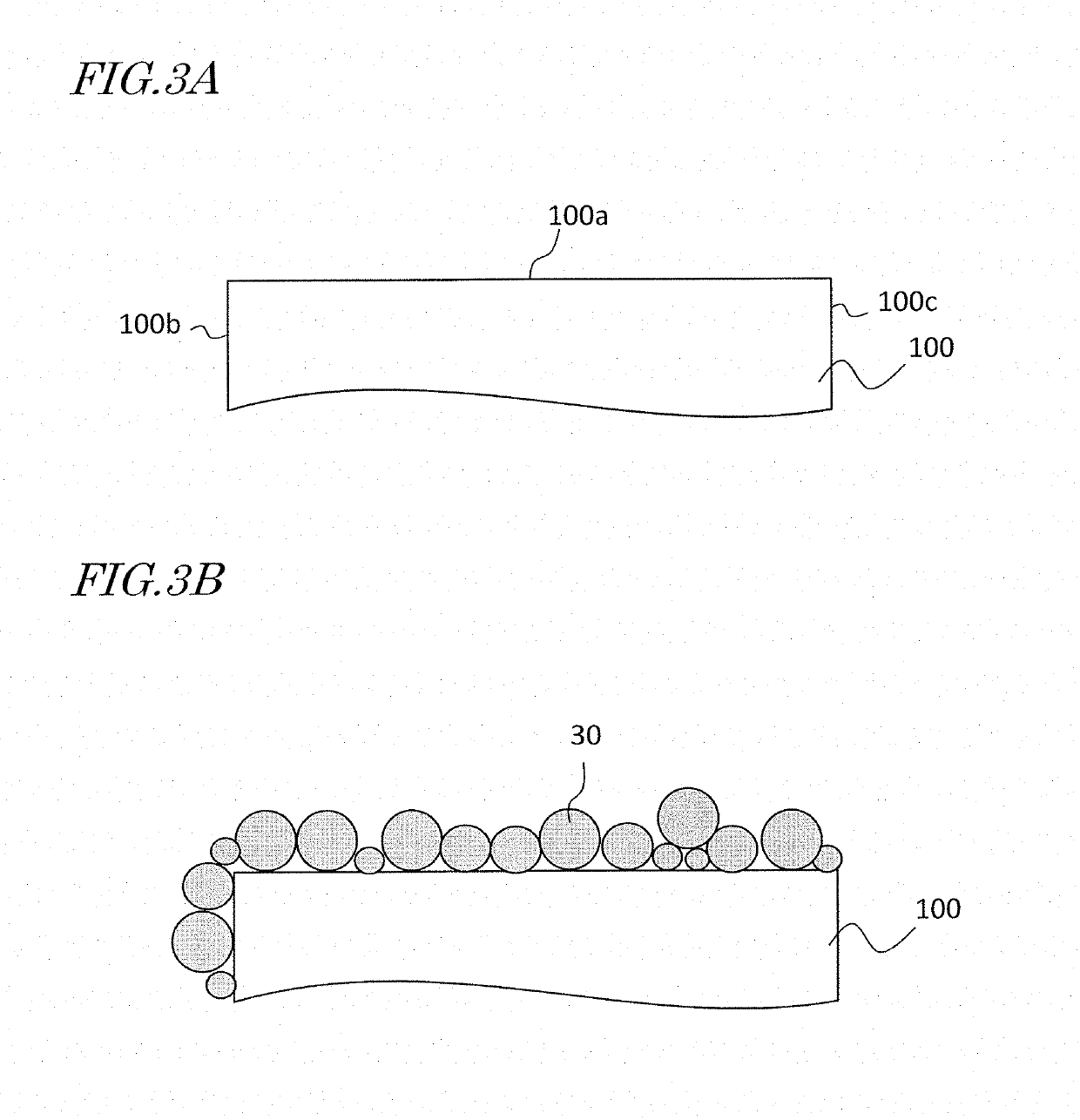

Method for producing sintered r-t-b based magnet and diffusion source

ActiveUS20190096550A1Reduce contentVariation is suppressedTransportation and packagingMetal-working apparatusAlloyHeat treated

A method for producing a sintered R-T-B based magnet includes the steps of: providing a sintered R-T-B based magnet work; providing a Pr—Ga alloy powder produced through atomization; subjecting the Pr—Ga alloy powder to a heat treatment at a temperature which is not lower than a temperature that is 250° C. below a melting point of the Pr—Ga alloy powder and which is not higher than the melting point, to obtain a diffusion source from the Pr—Ga alloy powder; and placing the sintered R-T-B based magnet work and the diffusion source in a process chamber, and heating the sintered R-T-B based magnet work and the diffusion source in a vacuum or an inert gas ambient, thereby allowing Pr and Ga to diffuse from the diffusion source into the interior of sintered R-T-B based magnet work.

Owner:HITACHI METALS LTD

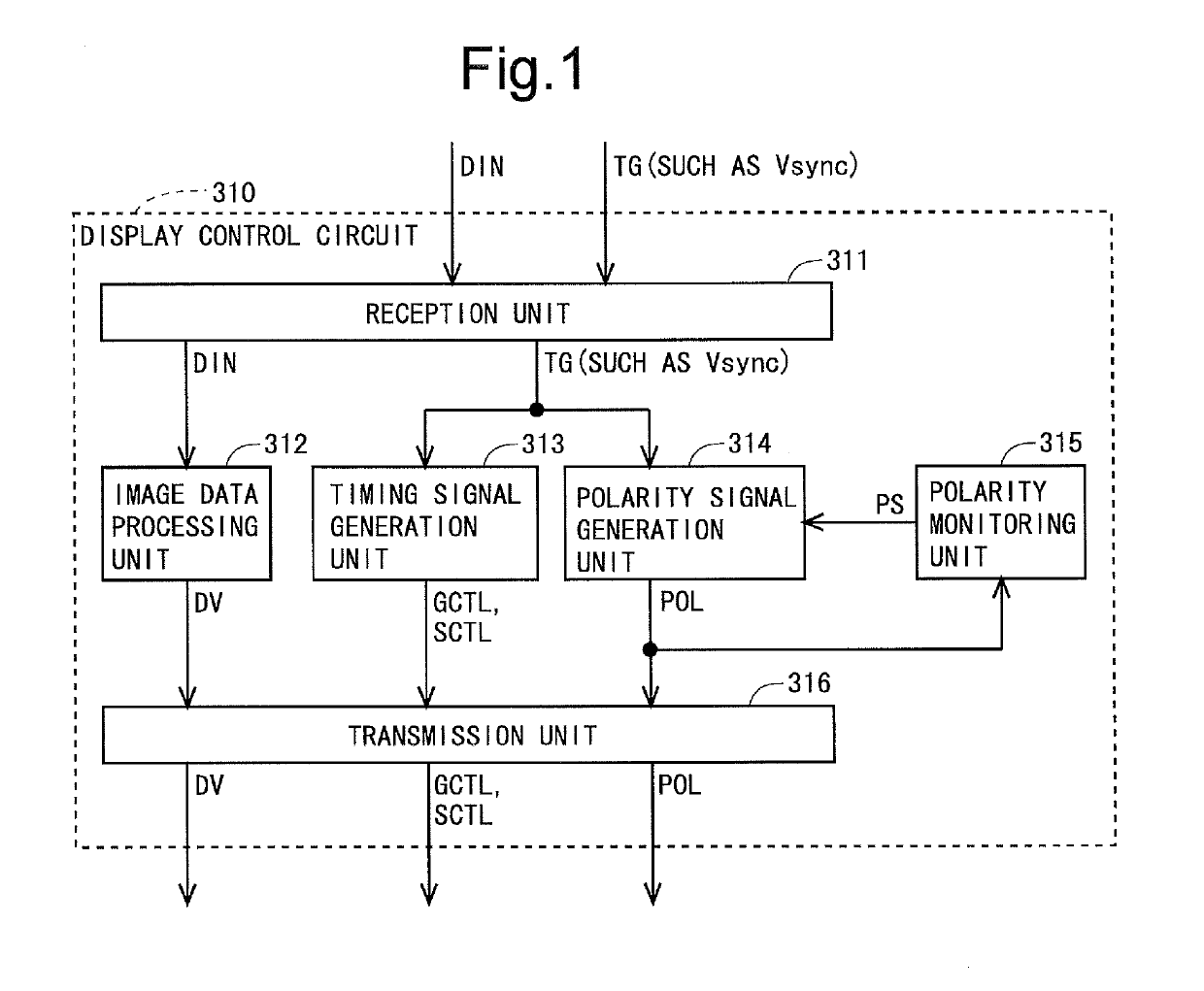

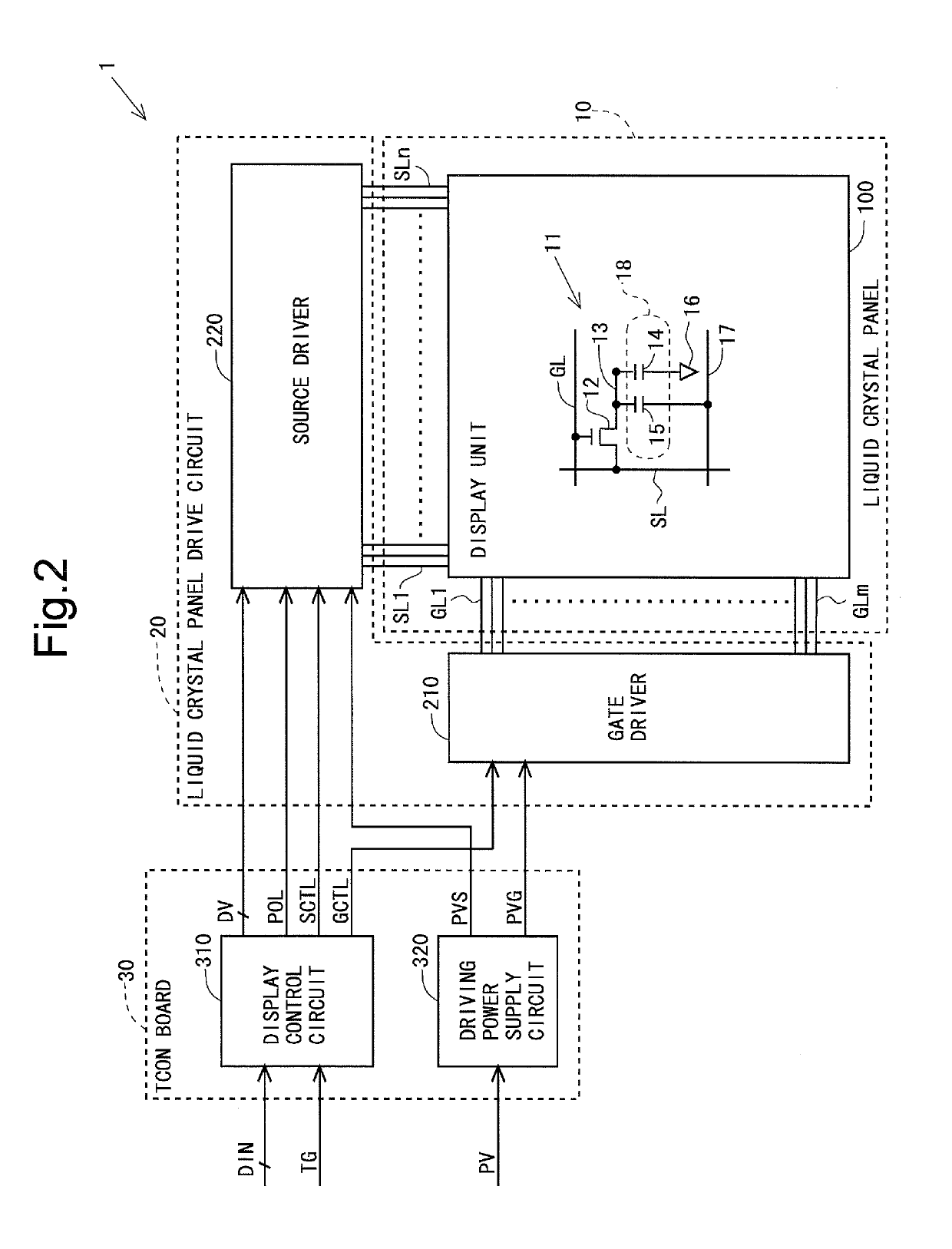

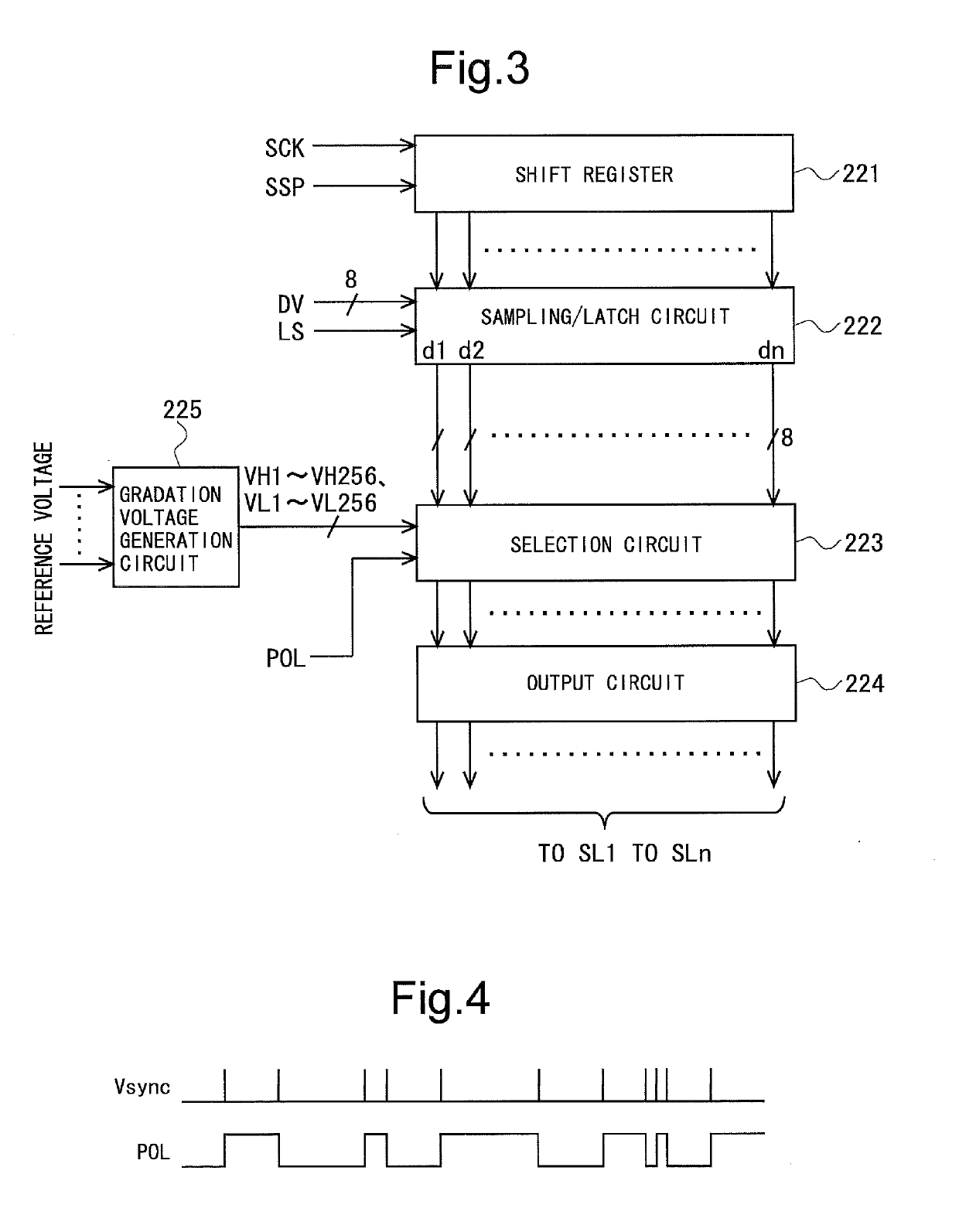

Liquid crystal display device and method of controlling the same

InactiveUS20190108804A1Polarity is suppressedVariation is suppressedStatic indicating devicesNon-linear opticsLiquid-crystal displayElectrical polarity

In a display control circuit (310) of a liquid crystal display device, there are provided: a polarity monitoring unit (315) configured to monitor a polarity signal (a signal for controlling a polarity of a liquid crystal application voltage) (POL) given to a liquid crystal panel drive circuit; and a polarity signal generation unit (314) configured to generate the polarity signal (POL) such that an increase in a polarity time difference (a difference between a length of a period during which a positive polarity voltage is applied to a liquid crystal and a length of a period during which a negative polarity voltage is applied to the liquid crystal) is suppressed on the basis of a polarity maintenance signal (PS) as a monitoring result produced by the polarity monitoring unit (315).

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com