Patents

Literature

395results about How to "Control position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

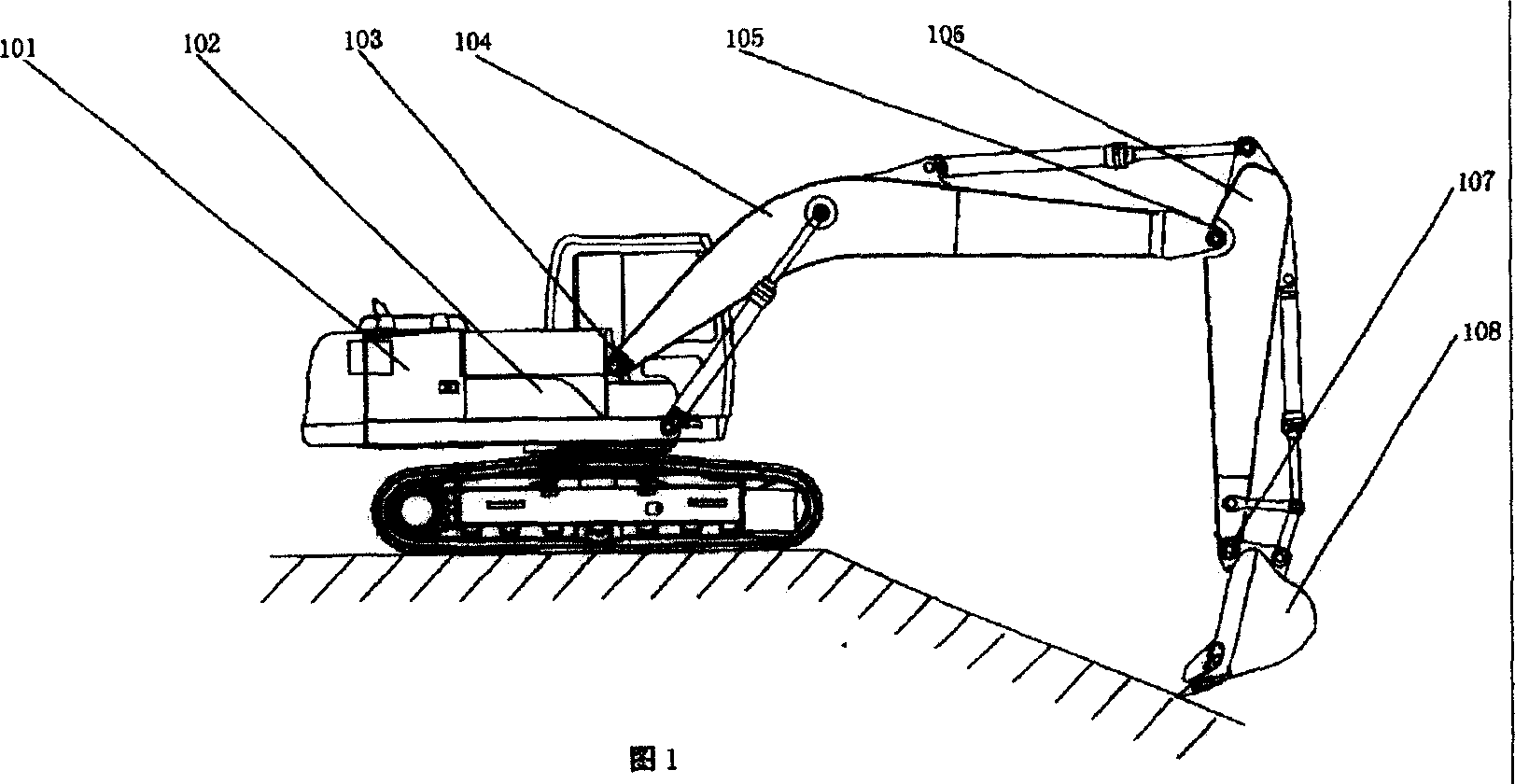

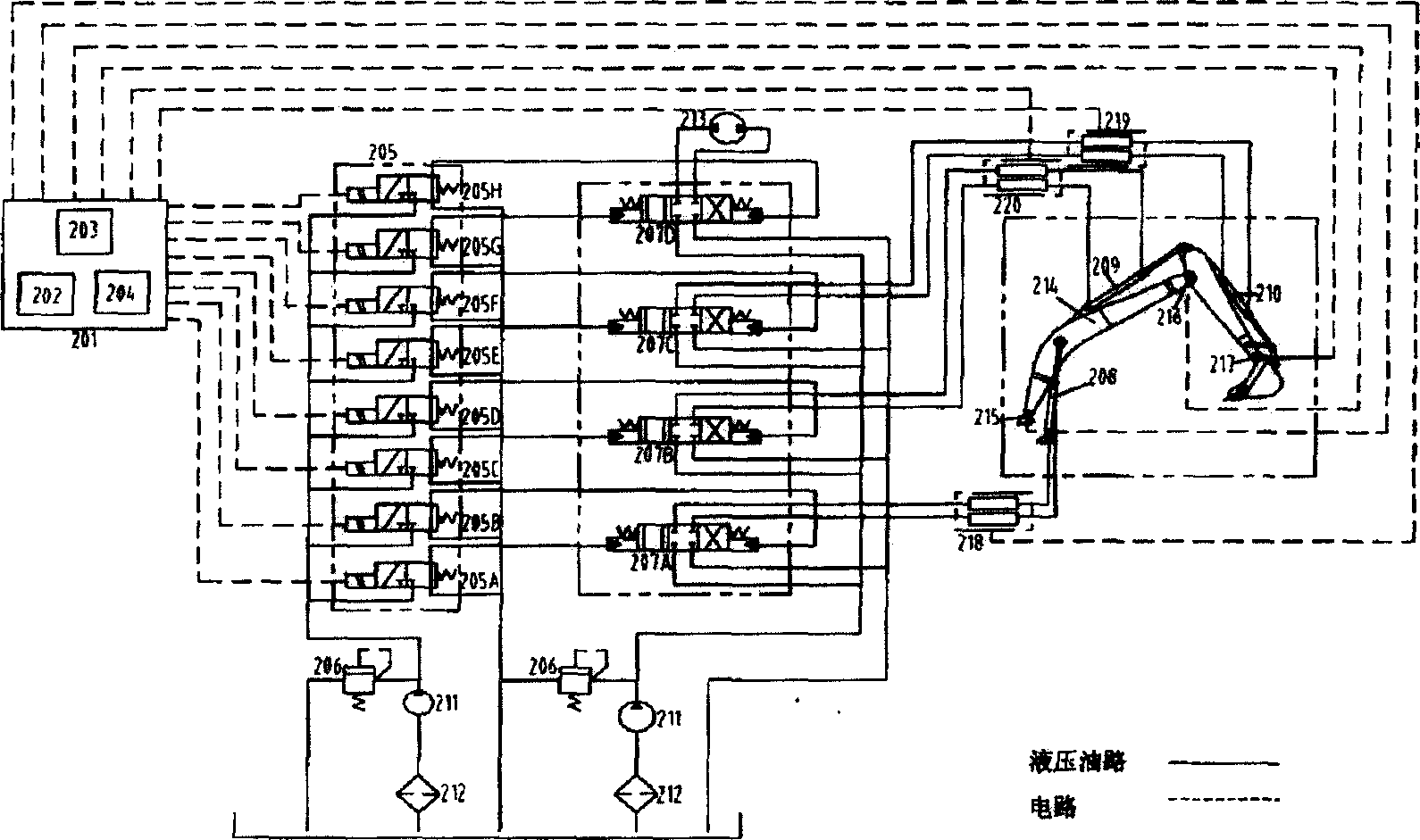

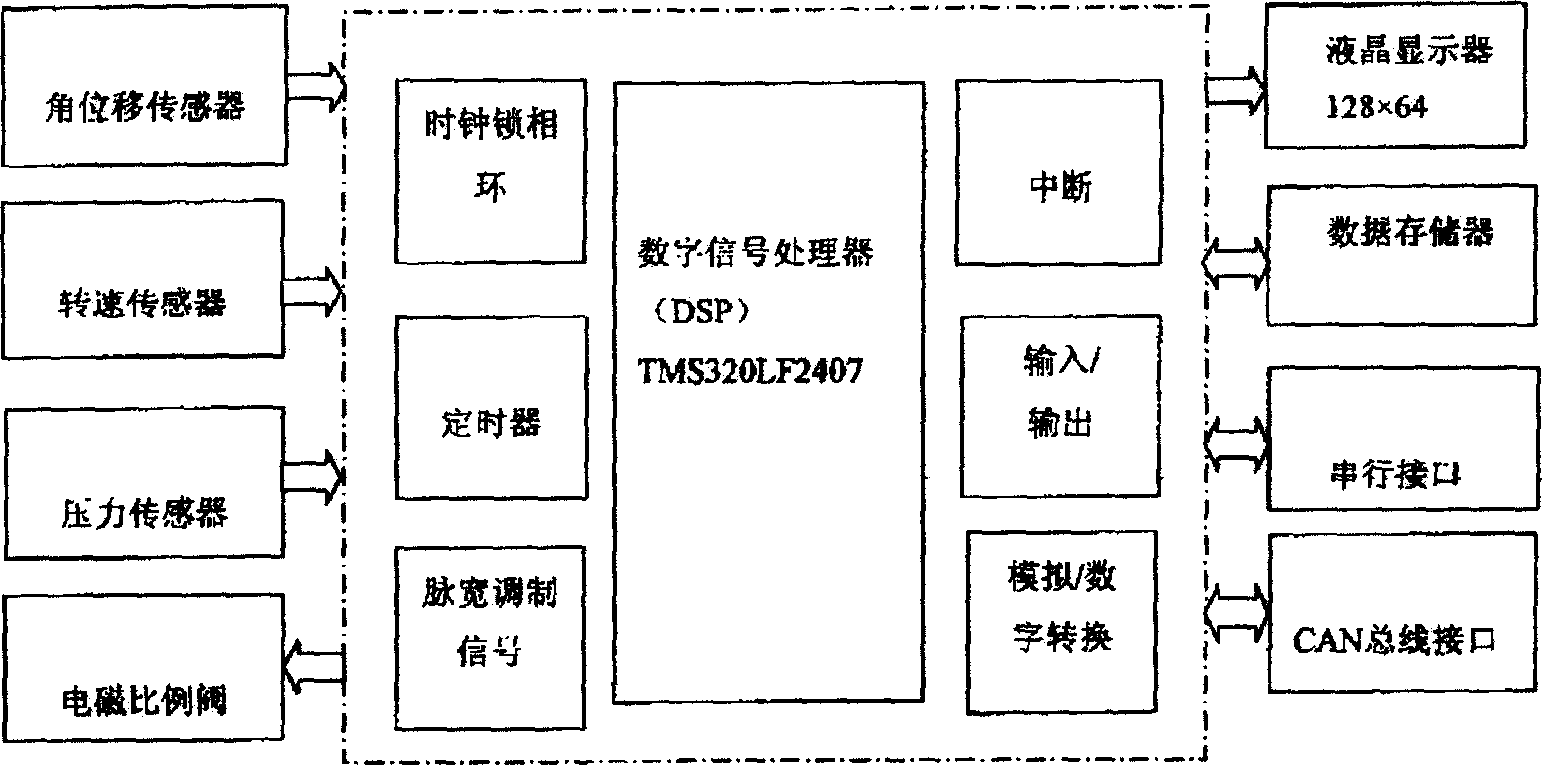

Path control system used for hydraulic digger operating device and its method

InactiveCN1651666ARealize automatic manipulationPrecise and stable positionSoil-shifting machines/dredgersPosition/direction controlHydraulic cylinderAutomatic control

The present invention relates to a track control system for hydraulic excavator working equipment and its method. Said system includes the following main components: DSP, moving arm angle detection mechanism, bucket arm angle detection mechanism, bucket angle detection mechanism, hydraulic cylinder, engine, working equipment and its driving cylinder and CAN bus. Said invention also provides the concrete steps of said control method. It can implement automatic control of hydraulic excavator working equipment, and can accurately and stably control the position and attitute of said hydraulic excavator working equipment so as to raise its working efficiency.

Owner:GUANGXI LIUGONG MASCH CO LTD

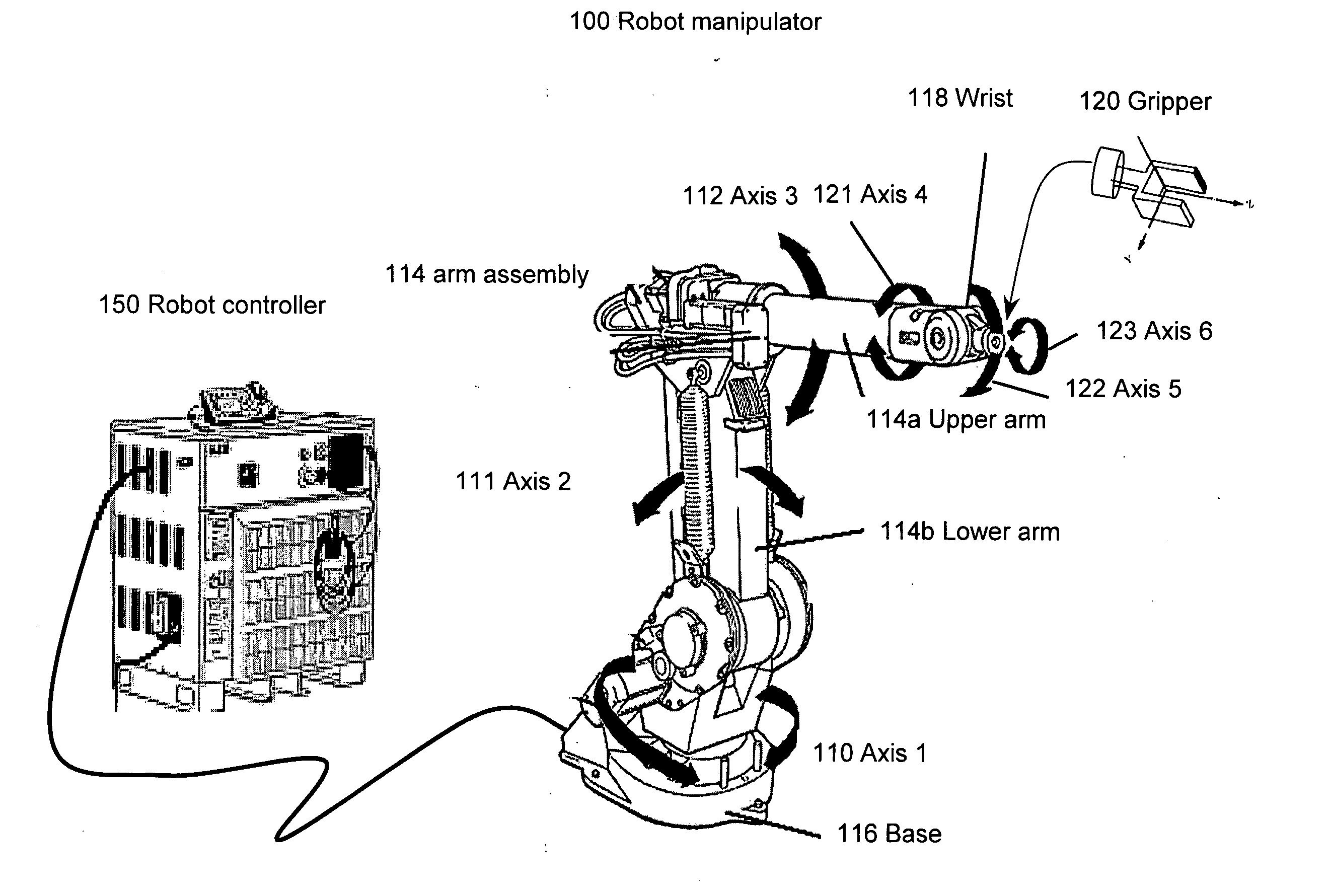

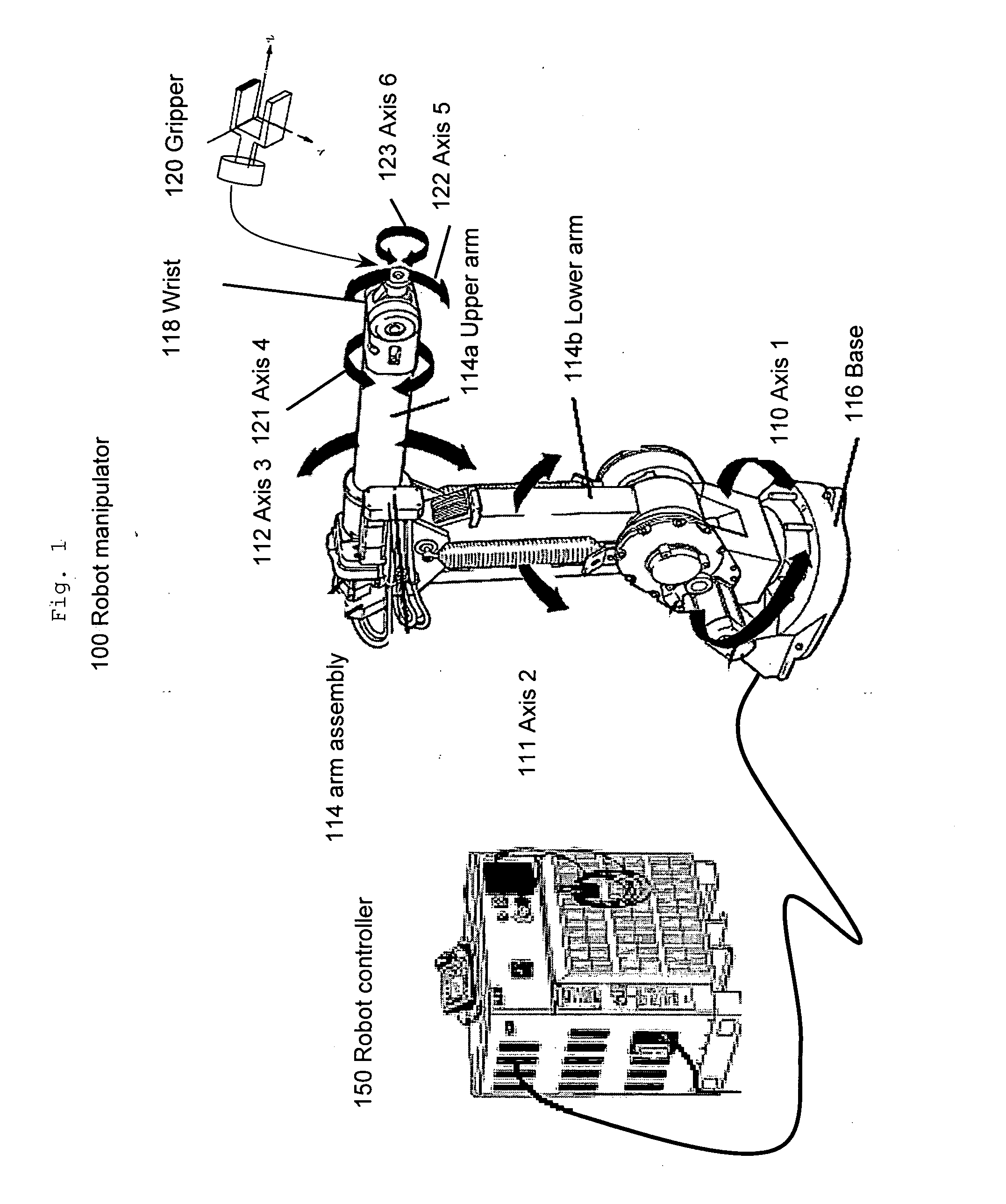

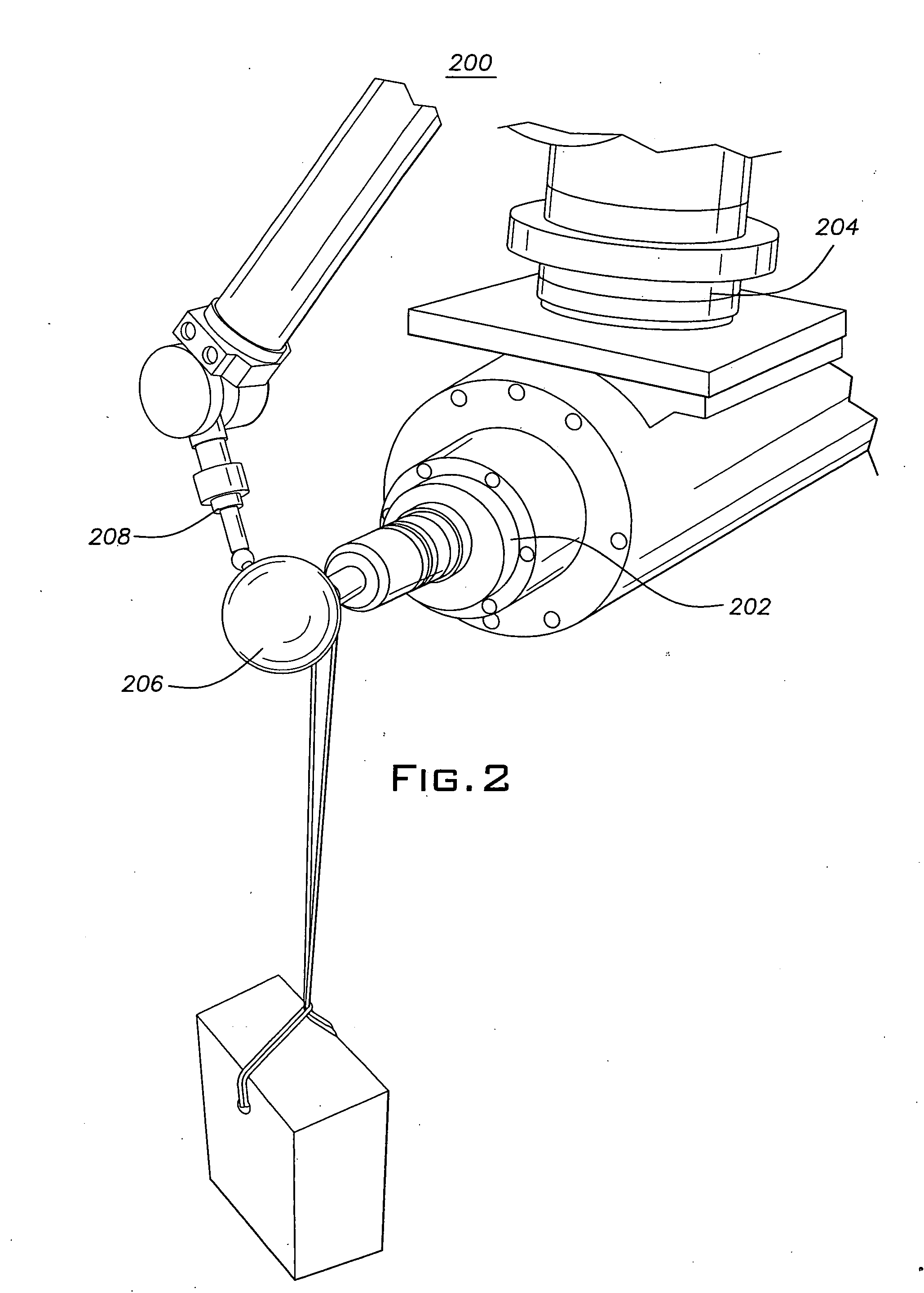

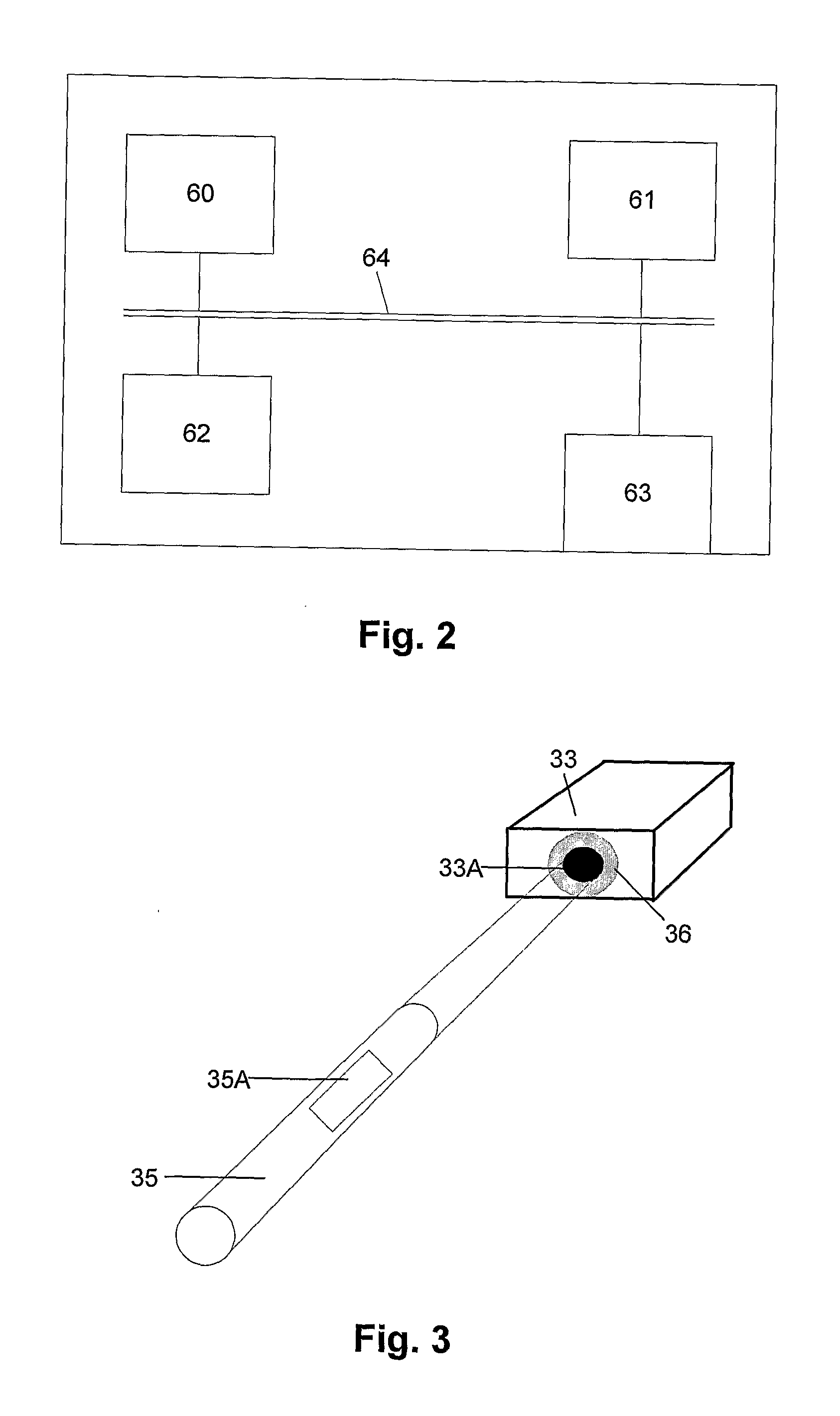

Robotic machining with a flexible manipulator

ActiveUS20060048364A1Control positionProgramme-controlled manipulatorAutomatic control devicesManipulatorEngineering

A robot machining with a flexible manipulator has an end effector which may either hold the tool to perform the machining or the work piece to be machined. A signal representative of a force applied by said tool to said work piece is used to control either the relative motion between the tool and the work piece to give a controlled material removal rate (CMRR) or the relative position between the tool or the work piece to provide deformation compensation or both CMRR and deformation compensation. A force sensor provides the signal for deformation compensation. For CMRR the signal may be obtained from either a force sensor or the current flowing in the motor of the robot's spindle. The force sensor can be mounted either on the robot or together with either the tool or work piece adjacent to the robot.

Owner:ABB RES LTD

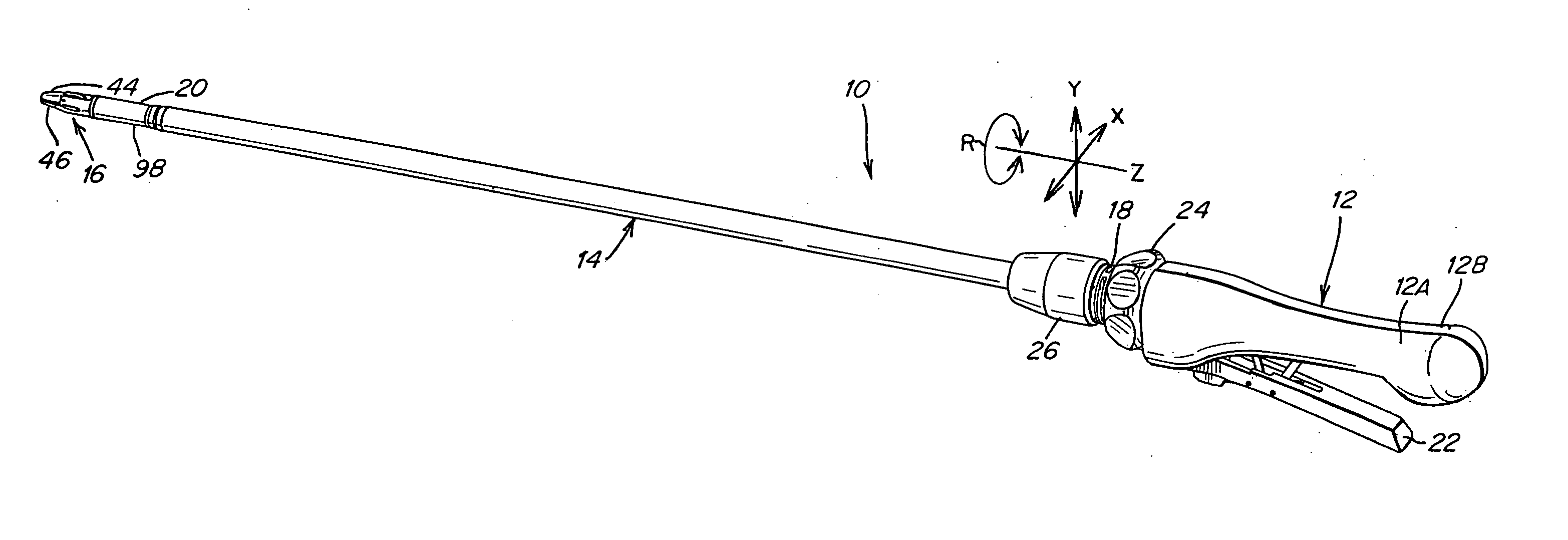

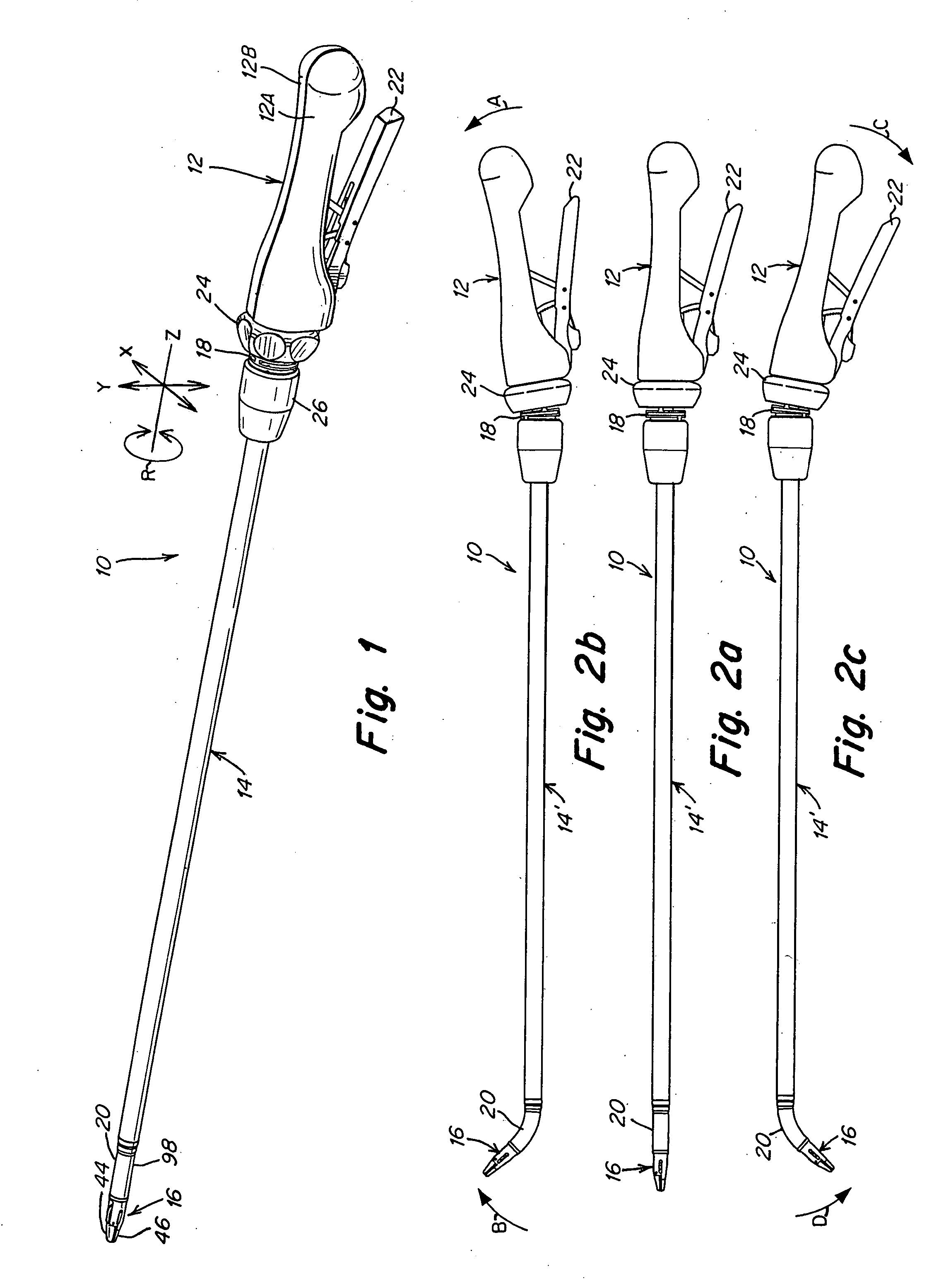

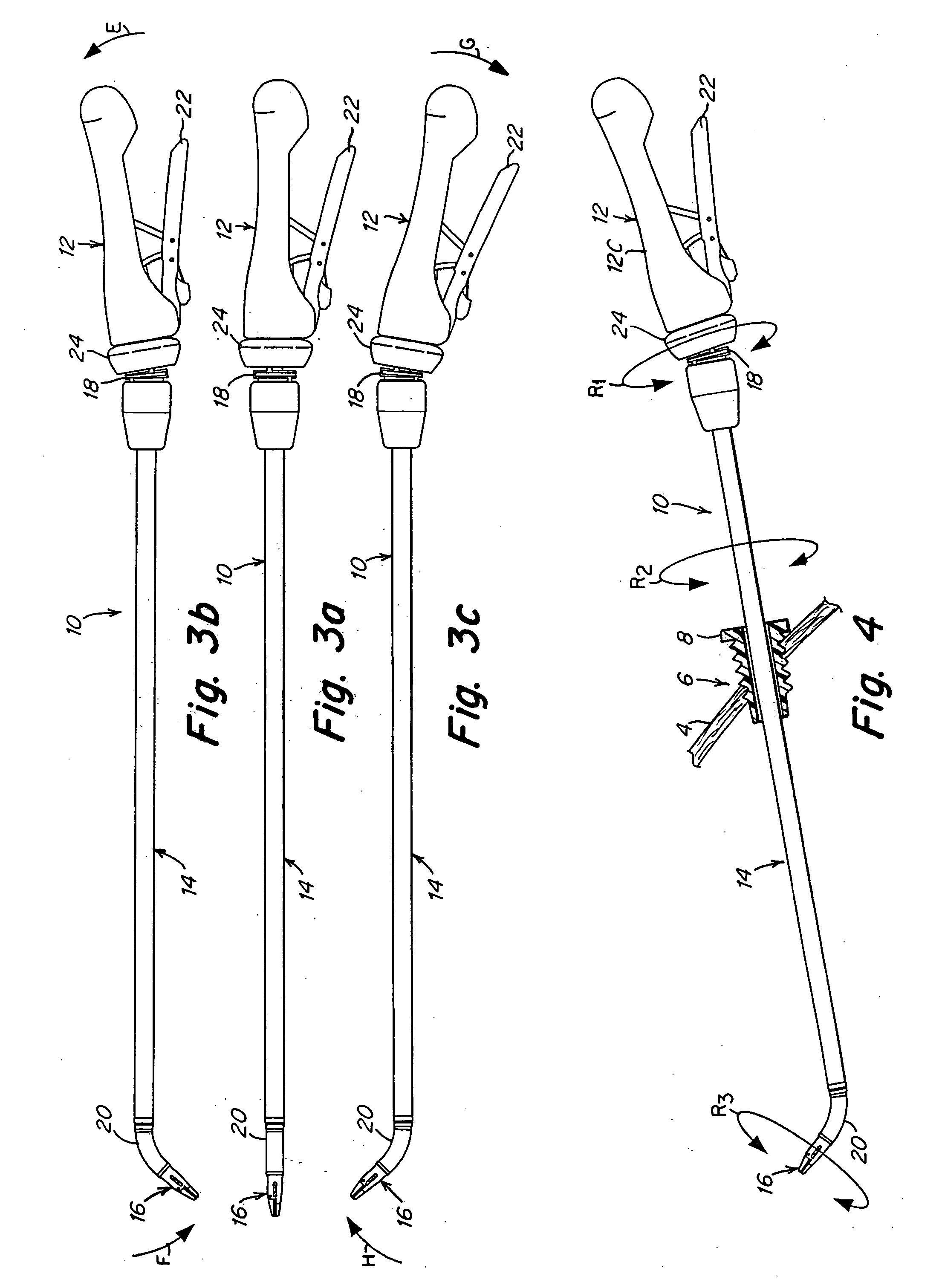

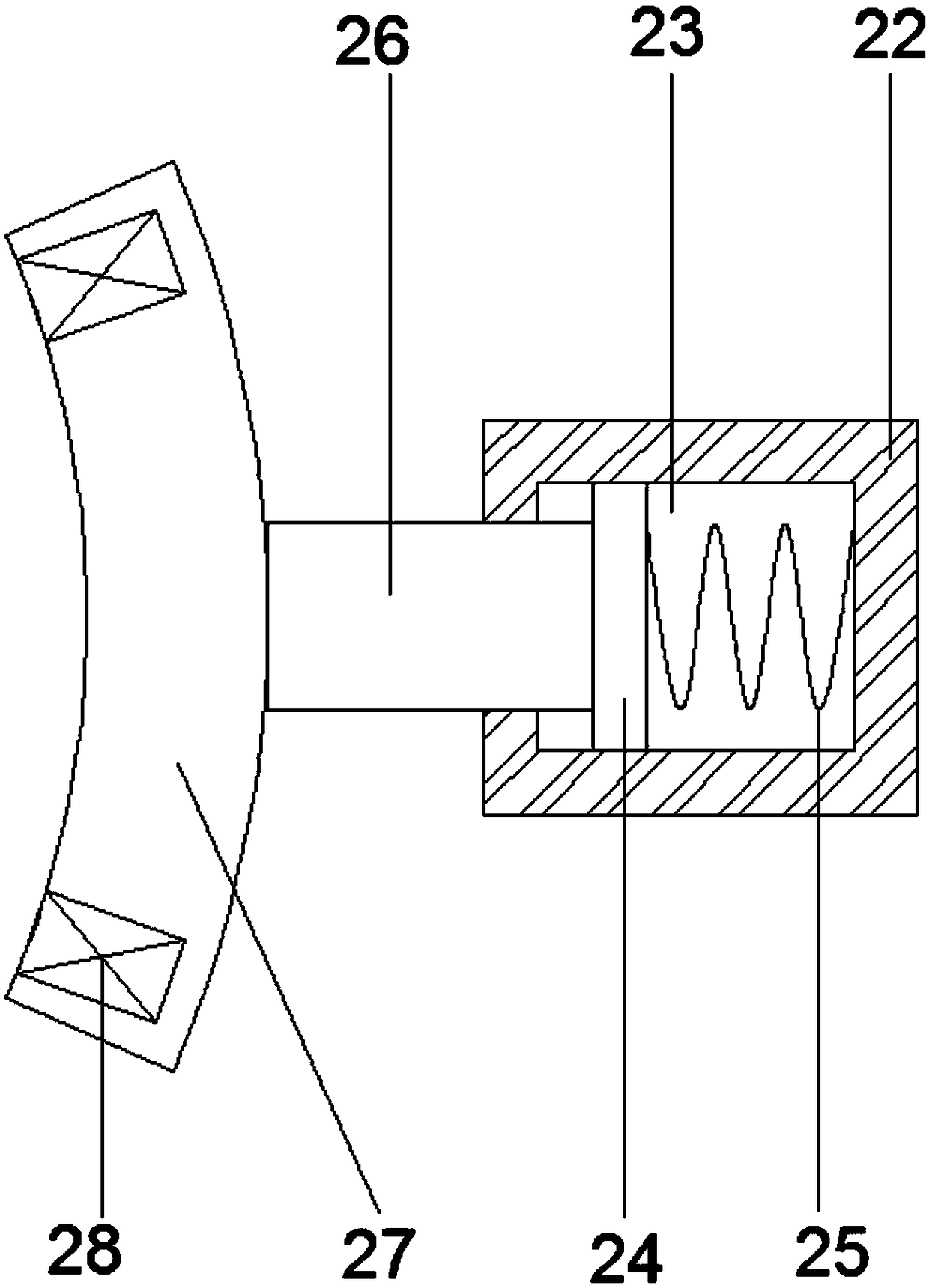

Surgical instrument

The surgical instrument includes a distal tool, a rigid or flexible elongated shaft that supports the distal tool, and a proximal handle or control member, where the tool and the handle are coupled to the respective distal and proximal ends of the elongated shaft via distal and proximal bendable motion members. Actuation means extends between said distal and proximal members whereby any deflection of said control handle with respect to said elongated instrument shaft causes a corresponding bending of said distal motion member for control of said working member. A manually rotatable member is arranged adjacent to the control handle for manually rotating the instrument shaft and working member relative to the control handle.

Owner:CAMBRIDGE ENDOSCOPIC DEVICES

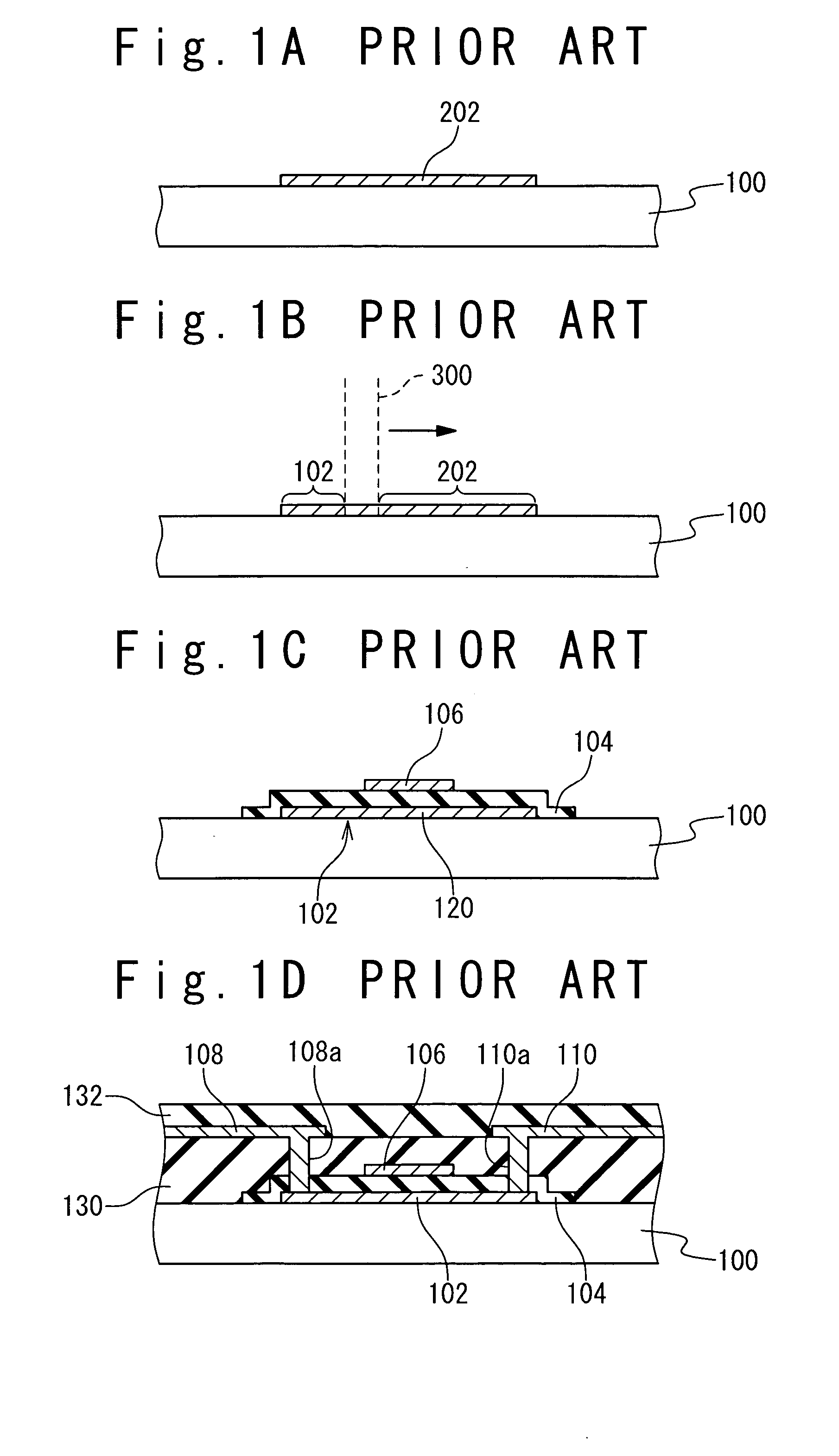

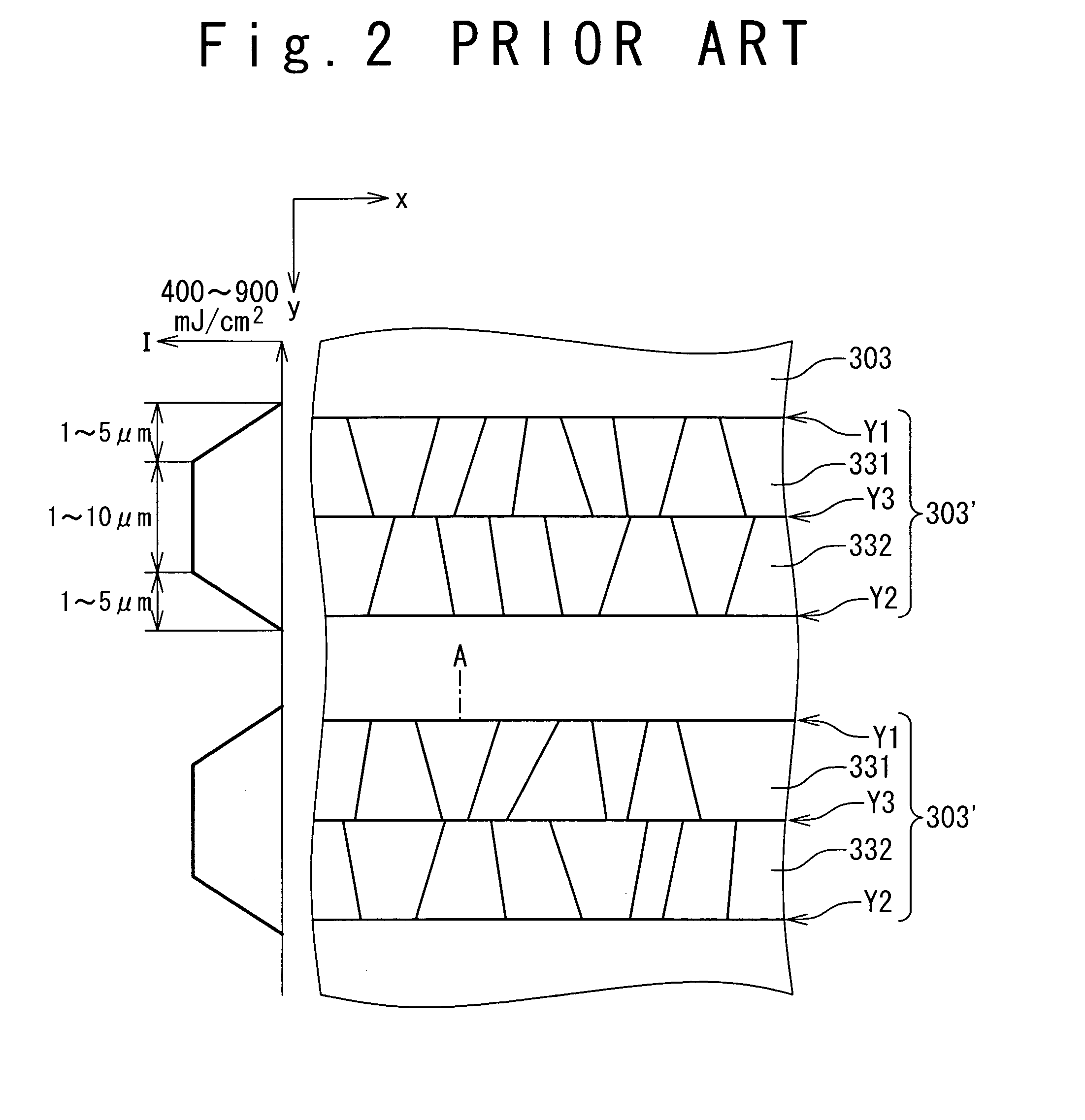

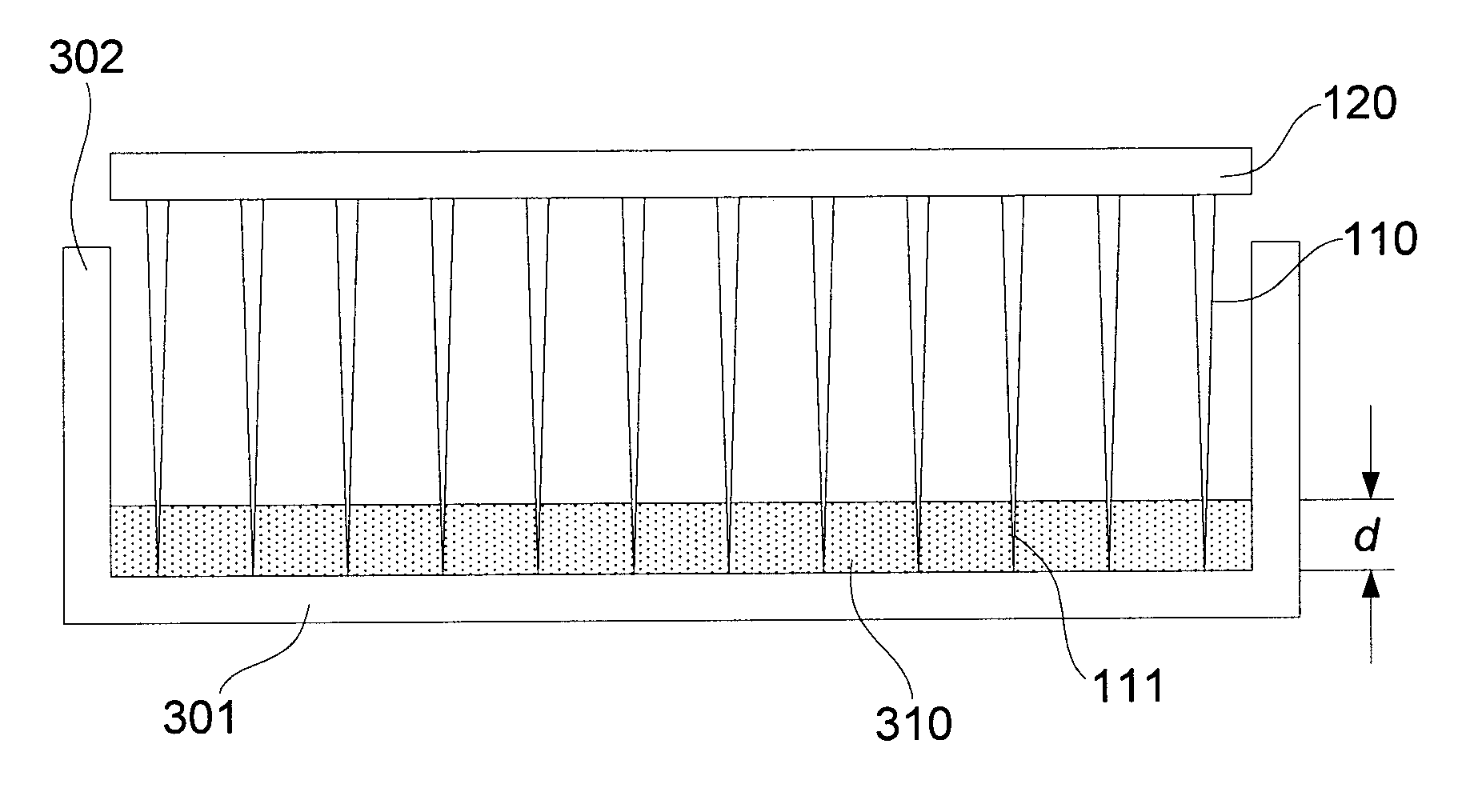

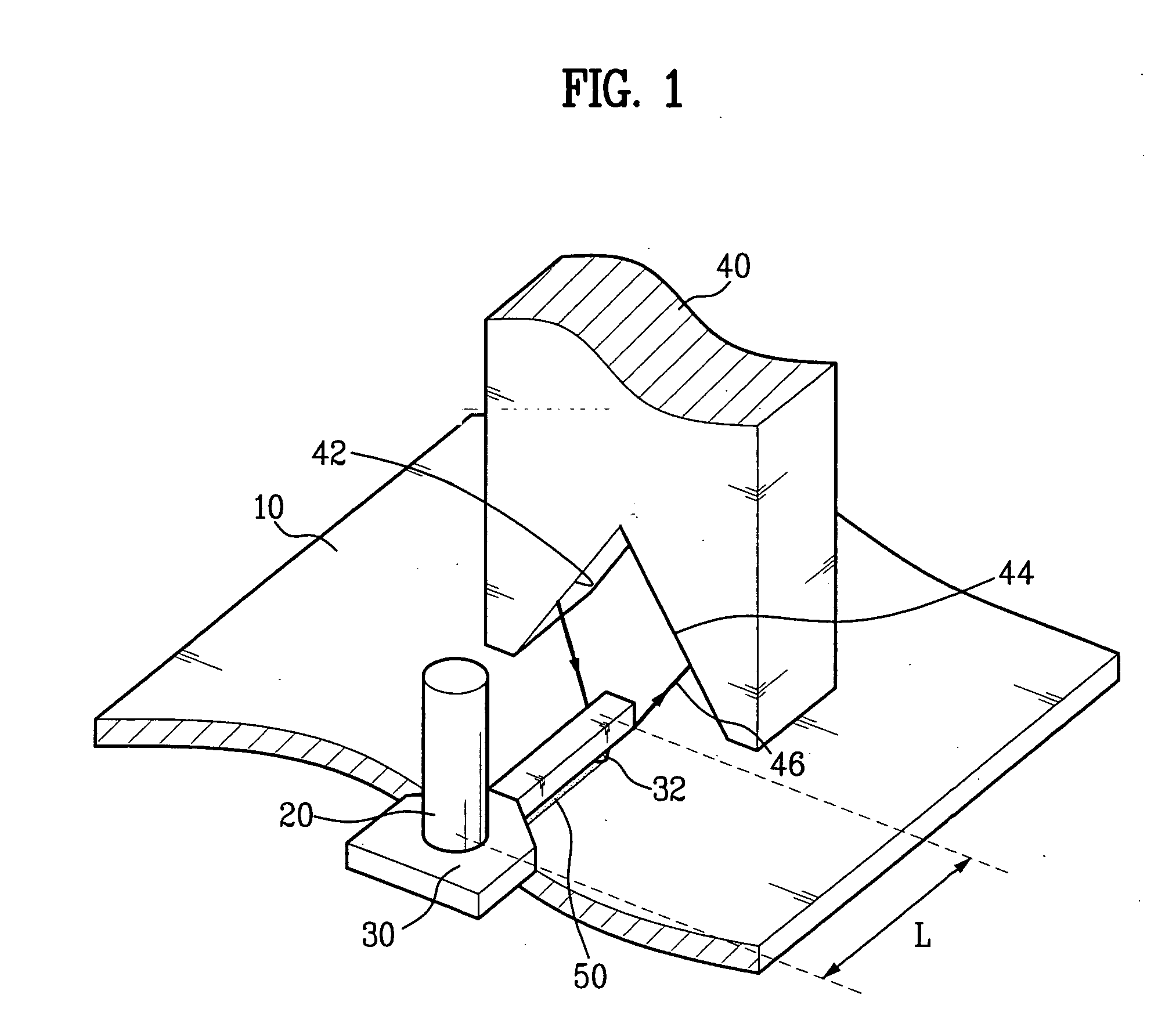

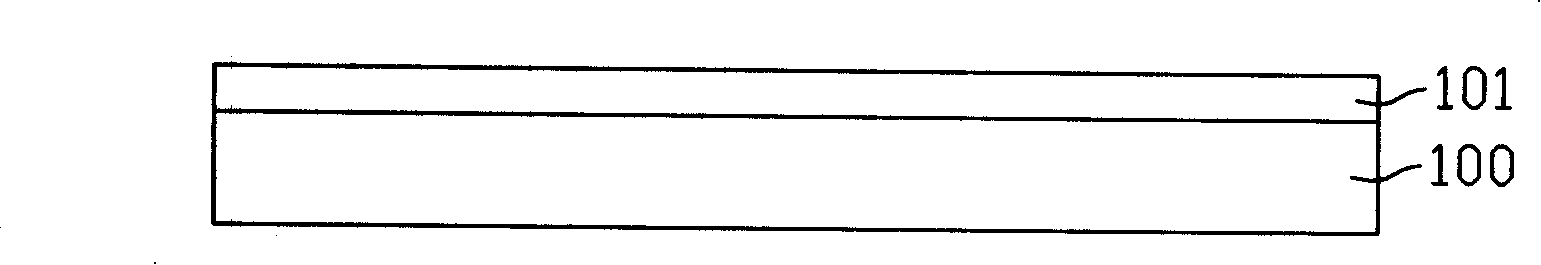

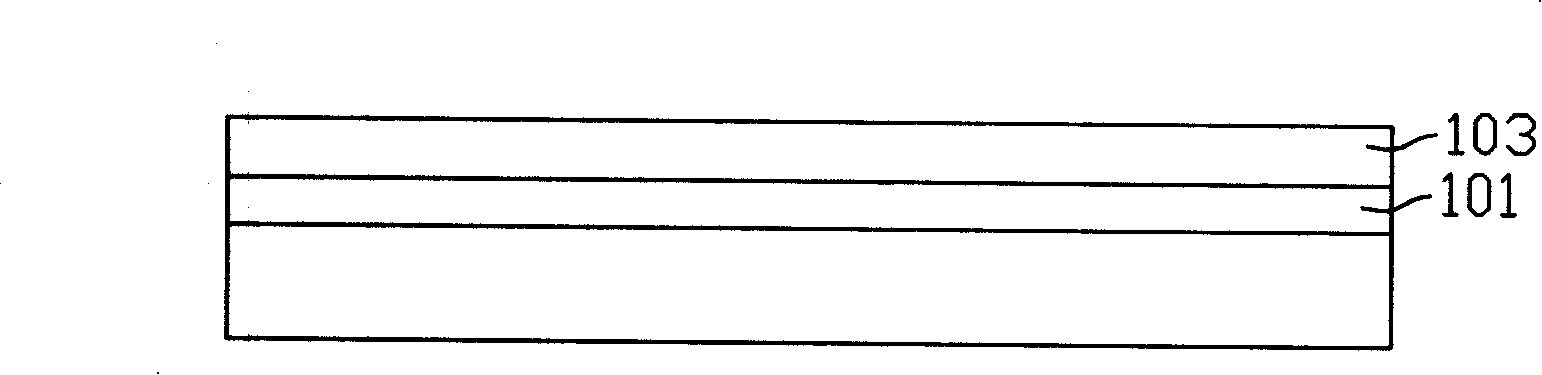

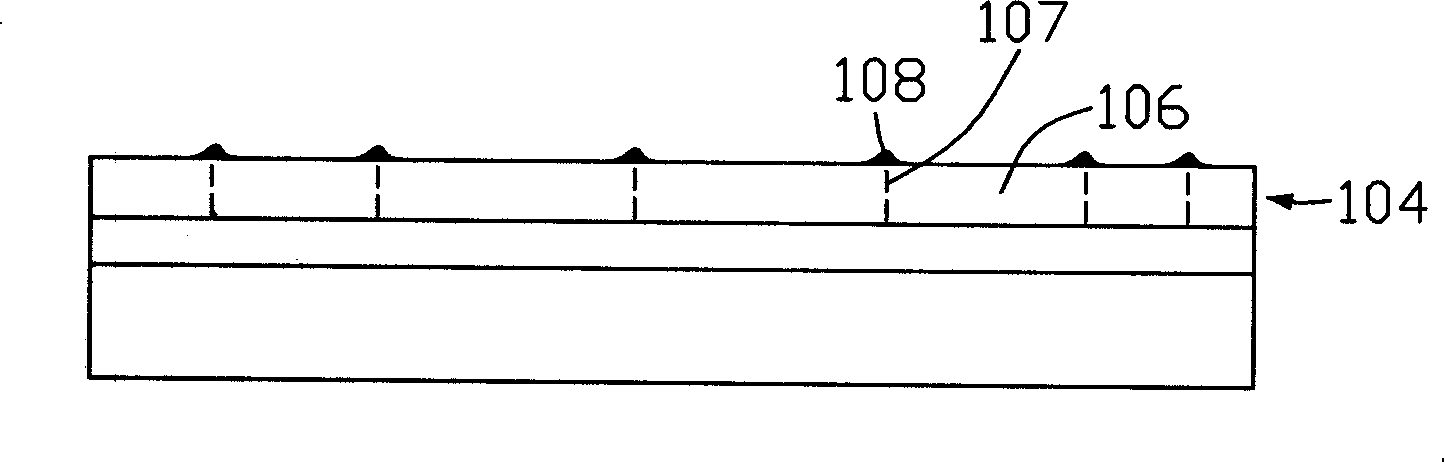

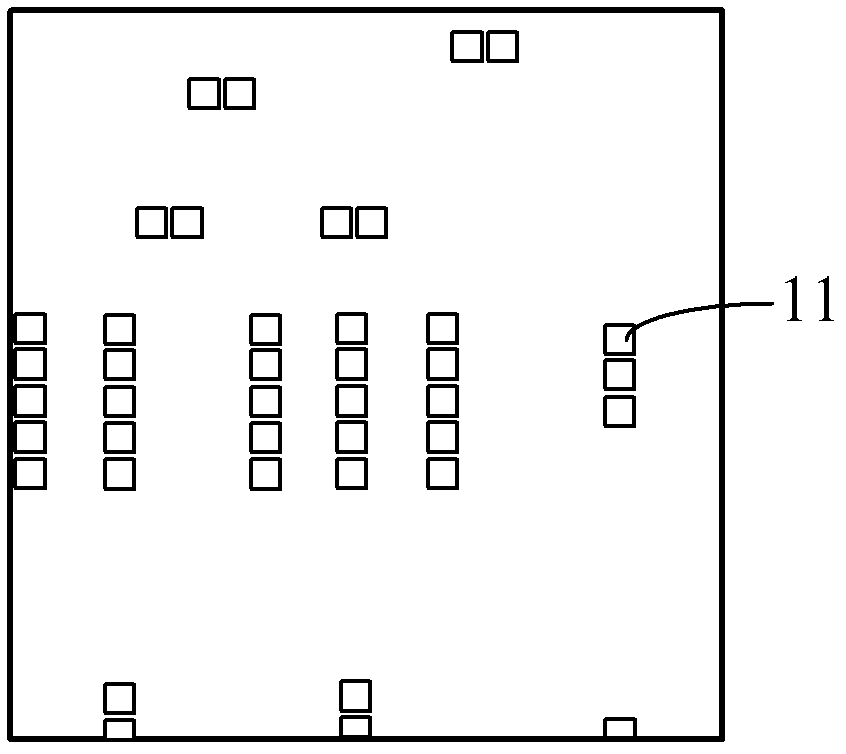

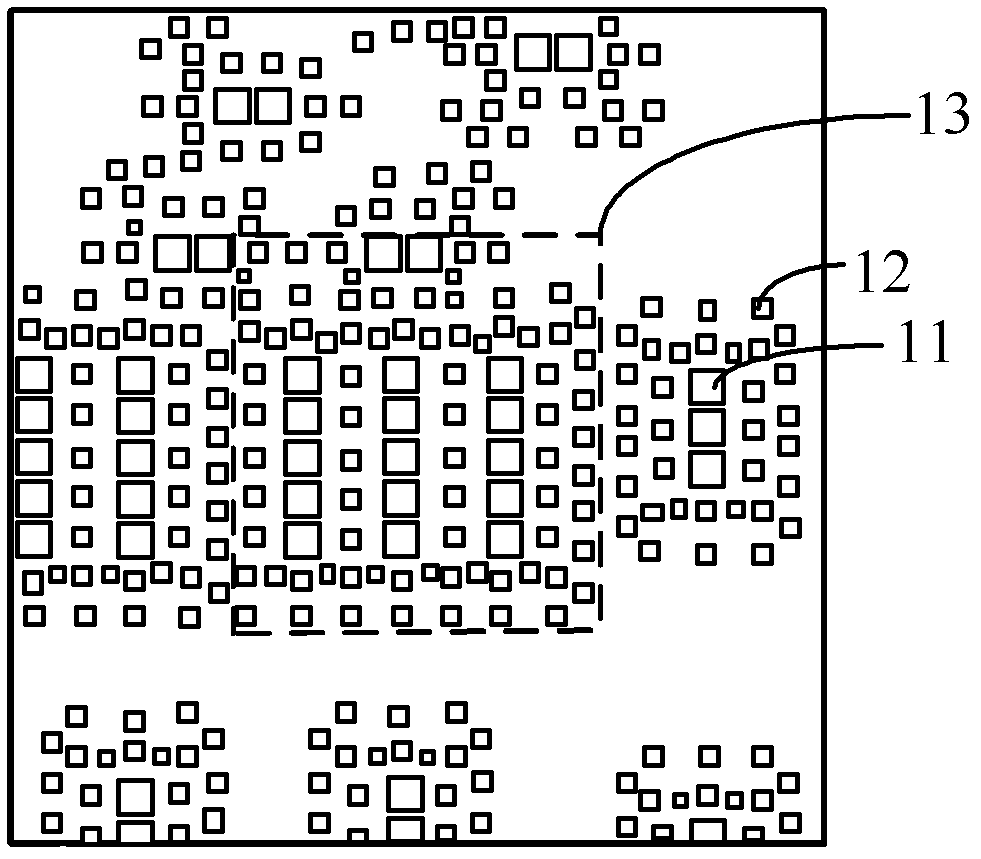

Method of and apparatus for manufacturing semiconductor thin film, and method of manufacturing thin film transistor

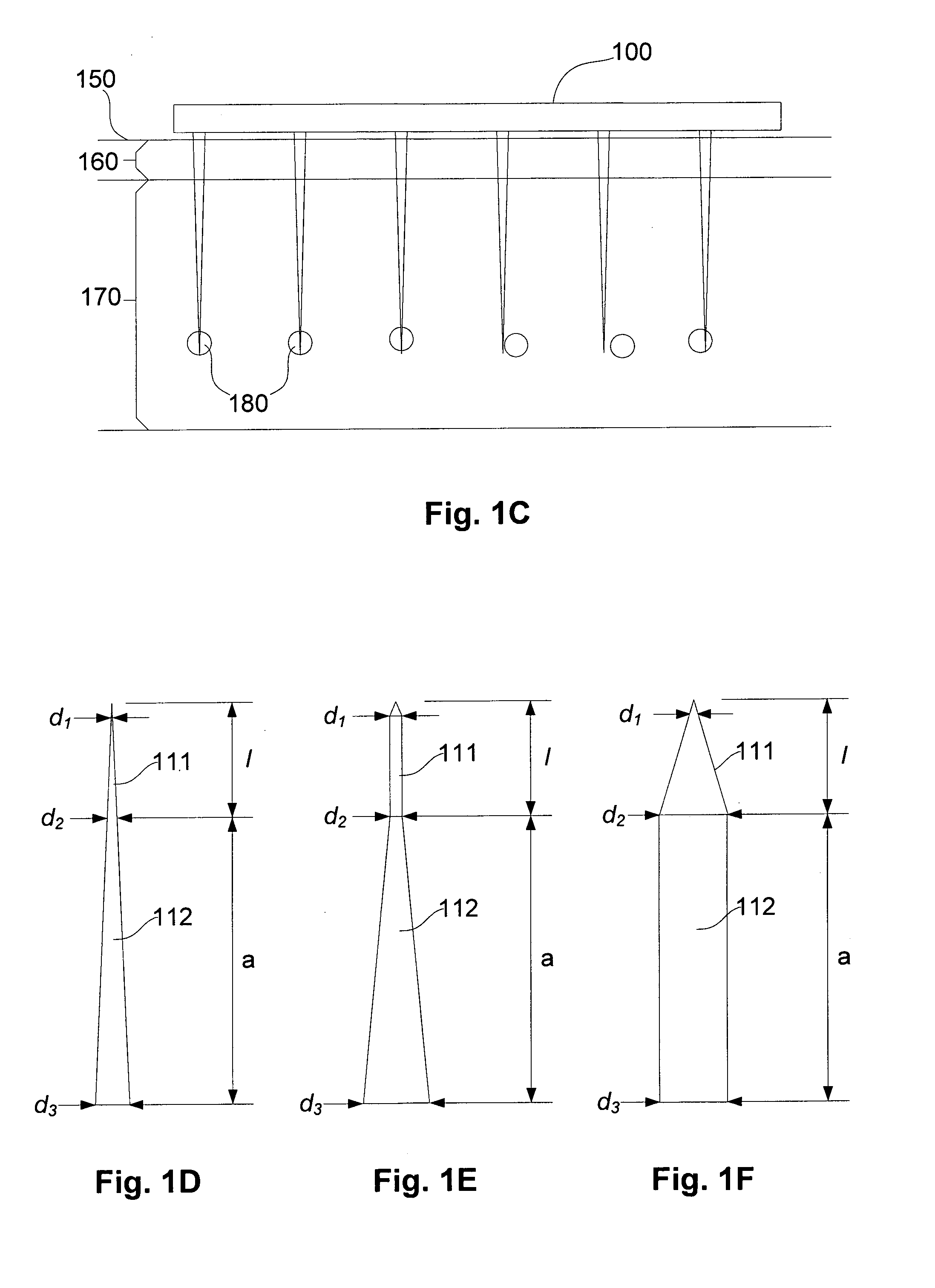

InactiveUS20050003591A1Reduce numberControl positionTransistorFrom gel stateAmorphous semiconductorsSemiconductor

A method of manufacturing a semiconductor thin film includes (A) forming an amorphous semiconductor film on a substrate, (B) irradiating a beam to a surface of the amorphous semiconductor film such that a predetermined region of the amorphous semiconductor film is melted and solidified to form a crystallized semiconductor film, and (C) scanning the beam in a first direction. A second direction is a direction on the surface of the amorphous semiconductor film perpendicular to the first direction. A length along the second direction of a cross section of the beam is substantially equal to or less than two times a width along the second direction of the crystallized semiconductor film.

Owner:VISTA PEAK VENTURES LLC

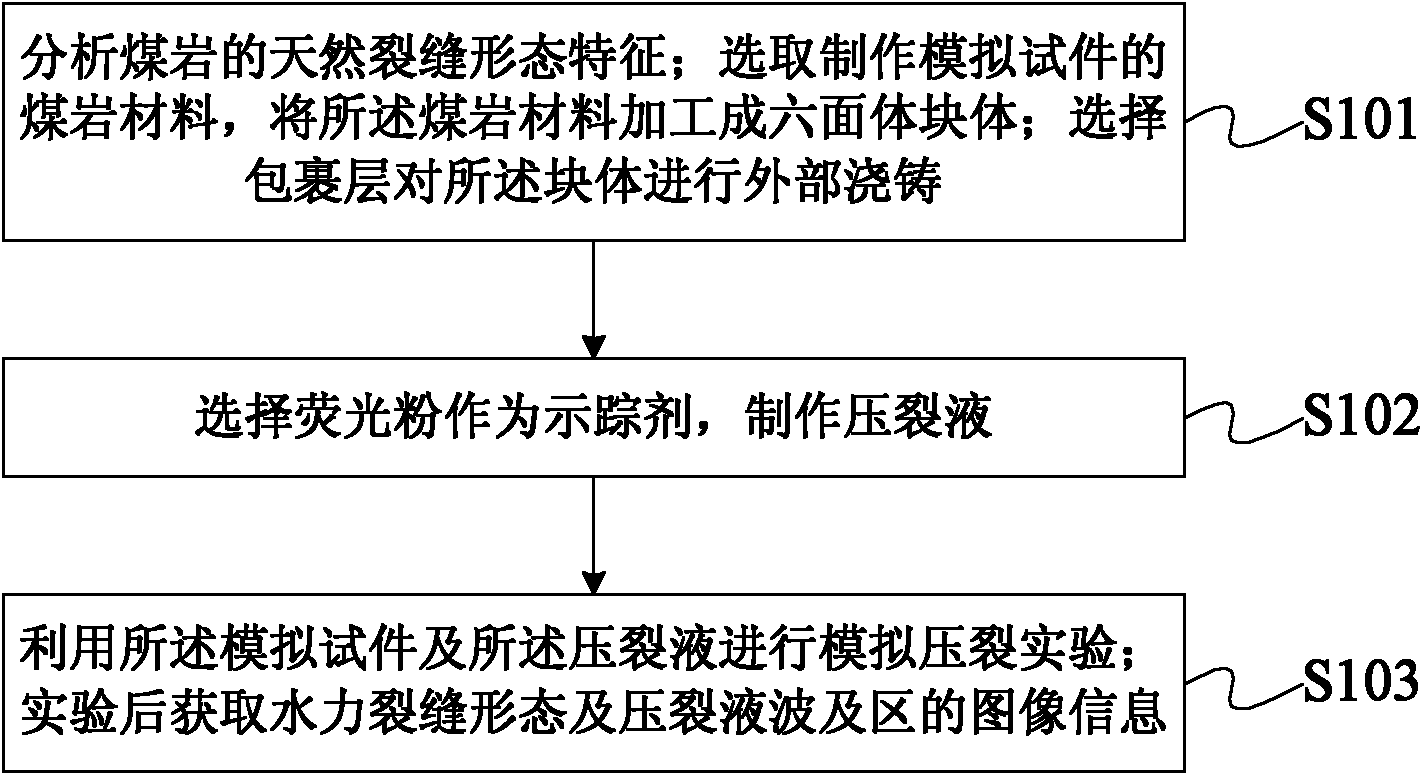

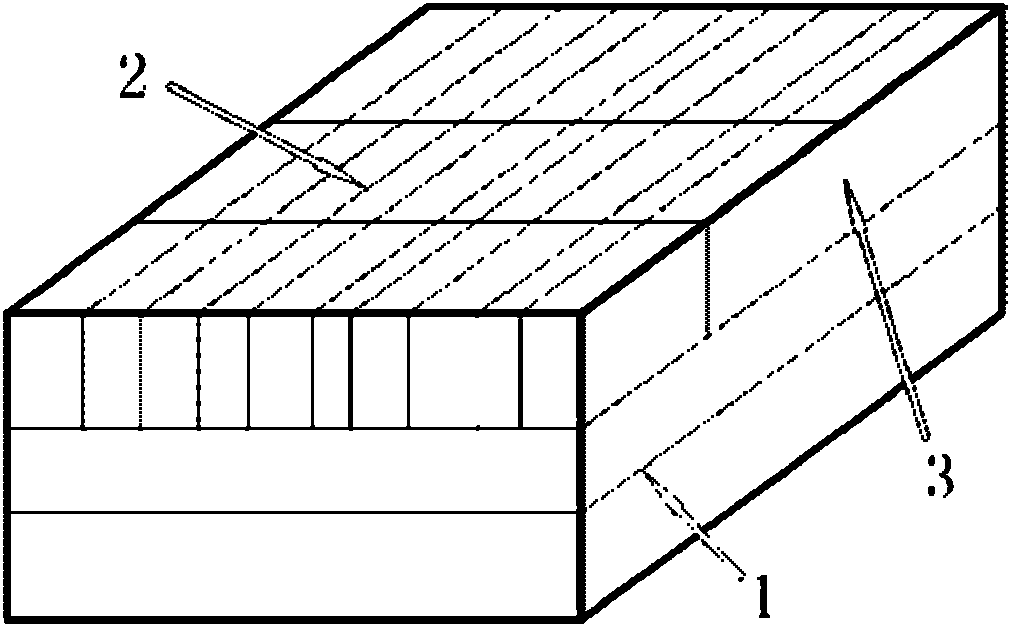

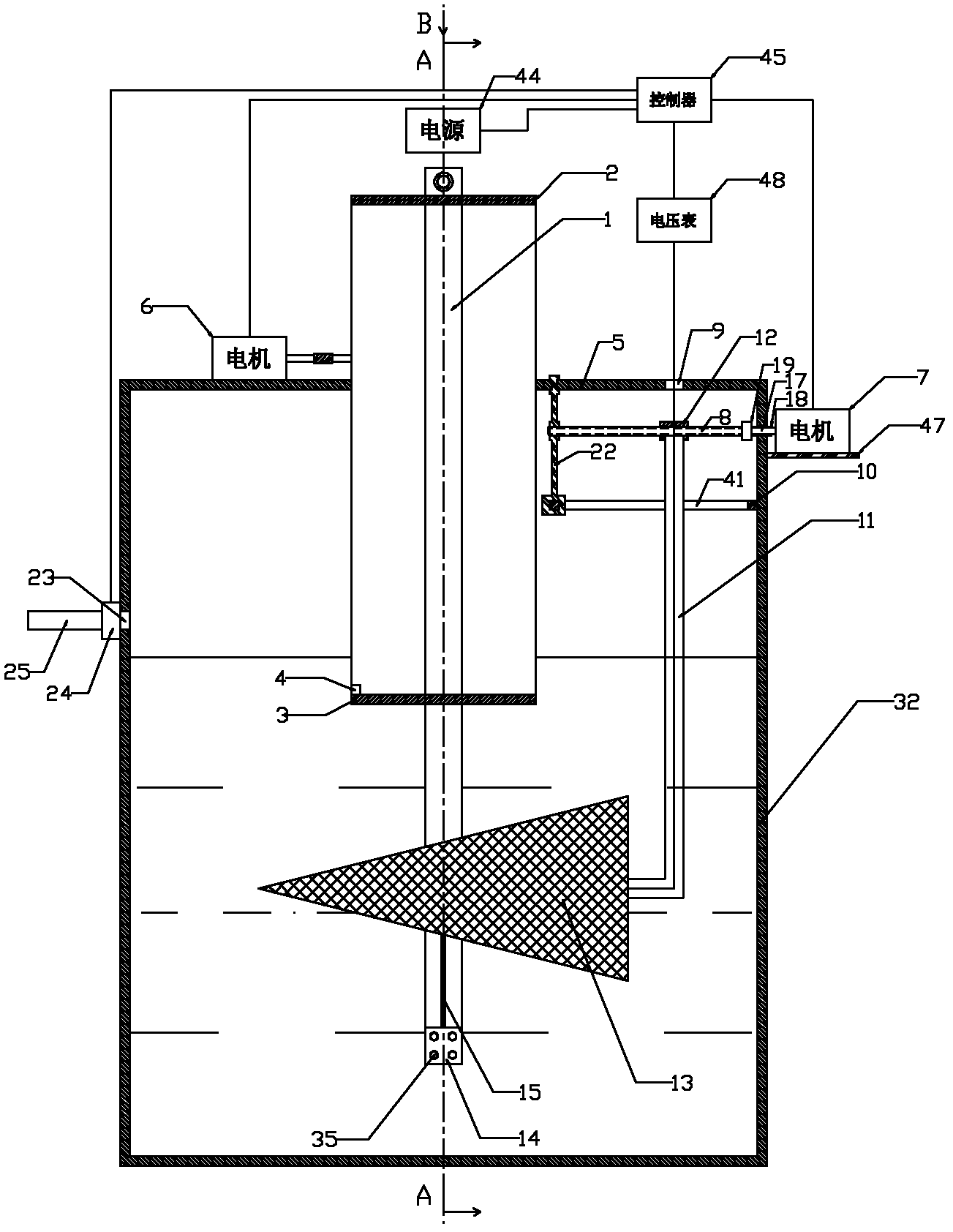

A coal seam hydraulic fracturing simulation experiment method

InactiveCN102279131AControl positionMaterial strength using tensile/compressive forcesMicro fractureFracturing fluid

The invention provides a simulation experiment method of coal seam hydraulic fracture, comprising the following steps of: (a) analyzing natural fracture shape characteristics of a coal rock in a stratum to be simulated, selecting a coal rock material for making a simulation specimen, processing the coal rock material into a hexahedral block according to the natural fracture shape characteristics,and selecting a coating layer carrying out external casting on the block to form the simulation specimen; (b) selecting fluorescent powder as a tracer, and then preparing fracturing fluid; and (c) performing a simulation fracturing experiment with the simulation specimen and the fracturing fluid and acquiring image information of a hydraulic fracture shape and a fracturing fluid swept region after the experiment. In terms of brittle and fragile coal rock with difficulty in processing, after the coating layer is cast by the method disclosed by the invention, the specimen has whole smooth and regular appearance, and the stratification and cutting positions of the coal rock can be well controlled. When the experiment result is acquired, the range of the hydraulic fracture can be clearly displayed by the fluorescent powder, and in particular the micro-fracture that cannot be viewed by the naked eyes can be displayed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

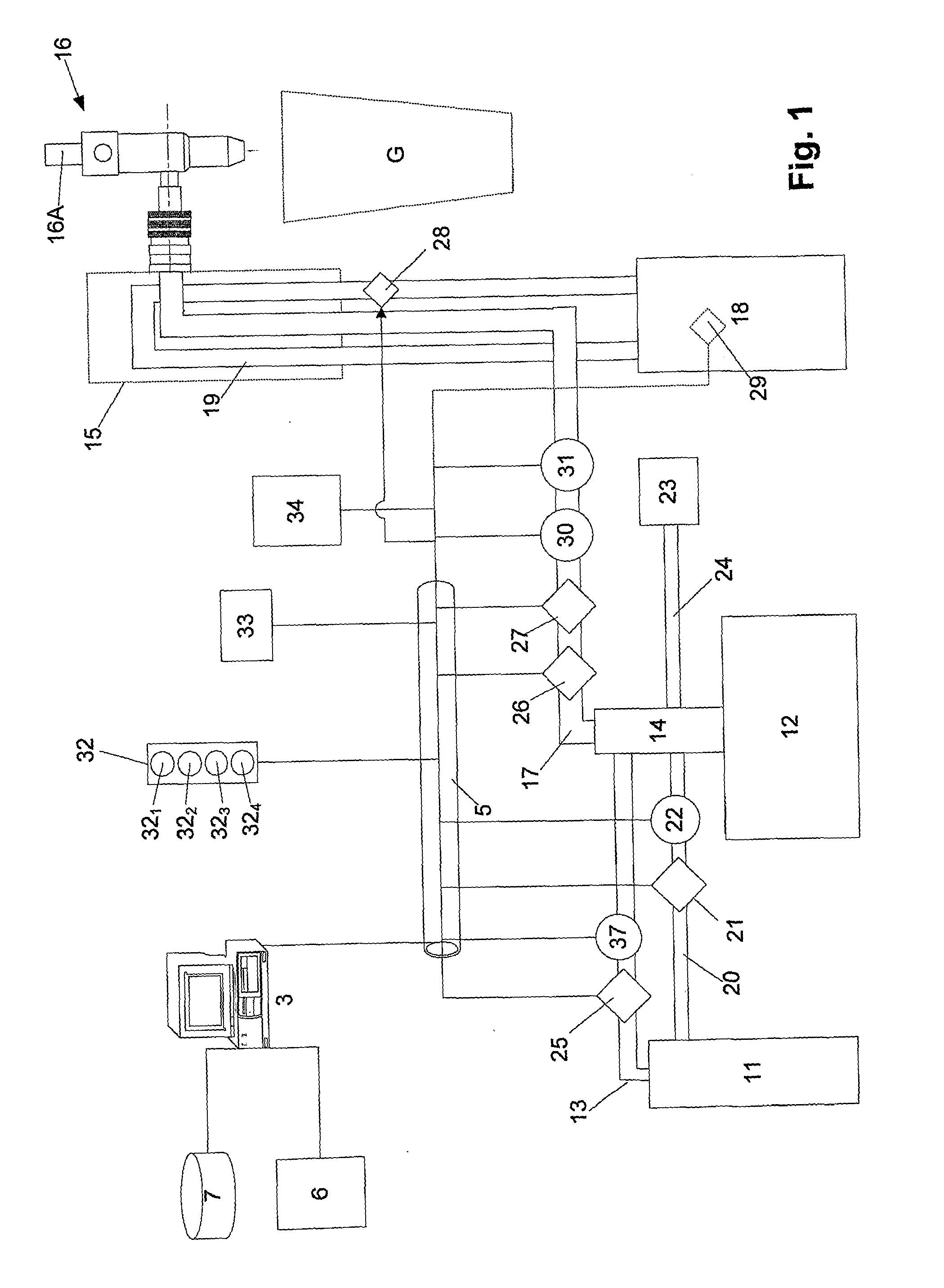

Dispensing Systems

InactiveUS20080189078A1Control positionOperating means/releasing devices for valvesFlow mixersProcess engineeringHandling system

Apparatus (15) for dispensing drinks formed from a number of drink components (12). A valve (16A) includes a housing having a number of inlets for coupling to respective drink component sources (12) and a number of outlets, each outlet being coupled to a respective inlet via a respective flow path (17). A number of flow controllers (30, 31) are provided, each flow controller (30, 31) being provided in a respective flow path (17) for controlling the supply of the respective drink component (12). In another embodiment a connector for coupling a keg to a line, the connector being adapted to couple to a cleaning solution supply is disclosed. In a further embodiment a method presenting content and apparatus for presenting content involving a processing system is disclosed.

Owner:BARILLIANT SYST

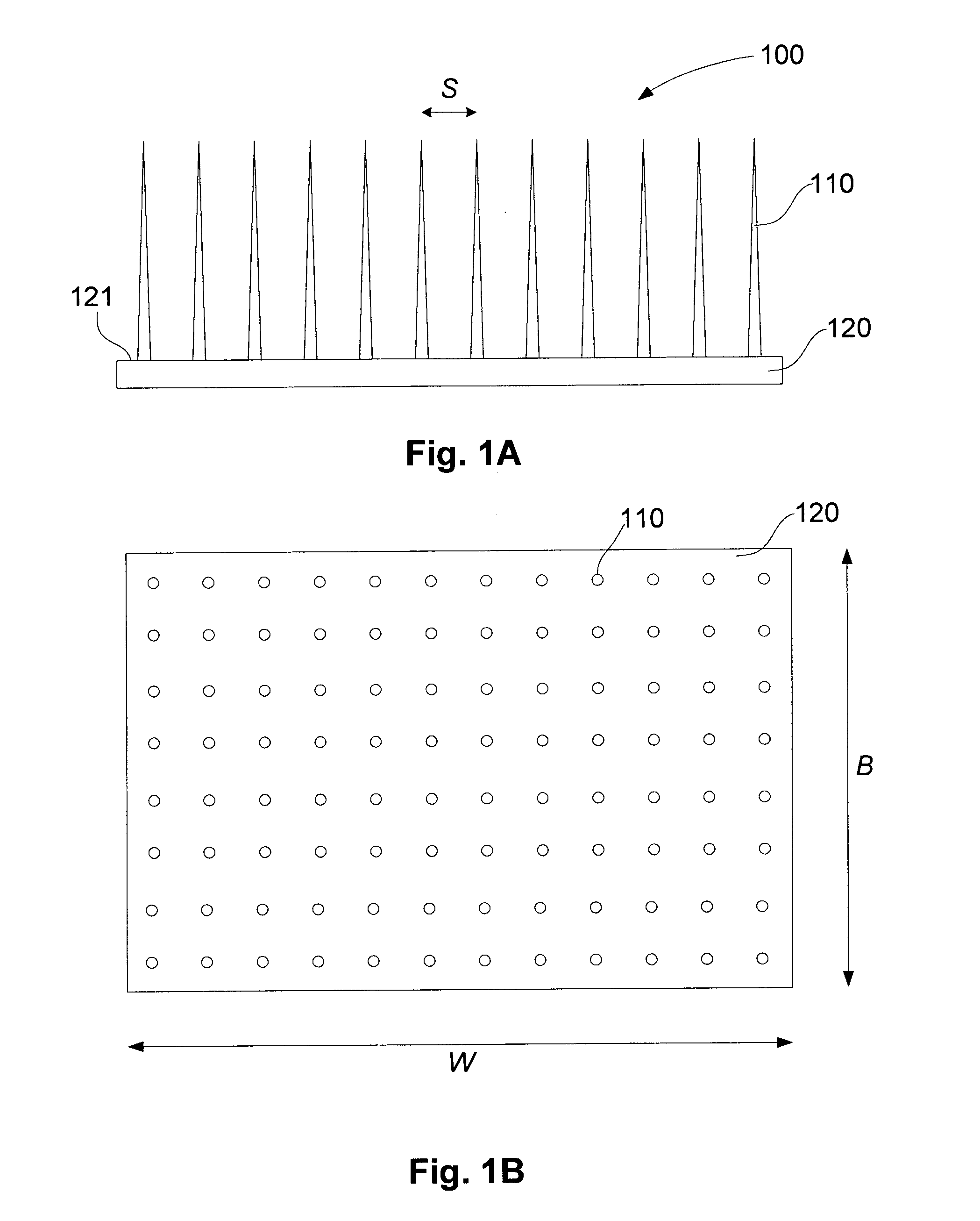

Method and associated apparatus for coating projections on a patch assembly

InactiveUS20110288484A1Control positionDegree of reductionElectrolysis componentsVolume/mass flow measurementCapillary actionViscosity

A method of coating projections on a patch, the method including, selecting a coating solution viscosity, the viscosity being selected to reduce the degree of capillary action between the patch and the coating solution and immersing at least part of tips of projections in a coating solution having the selected coating solution viscosity such that substantially only tips of the projections are coated.

Owner:THE UNIV OF QUEENSLAND

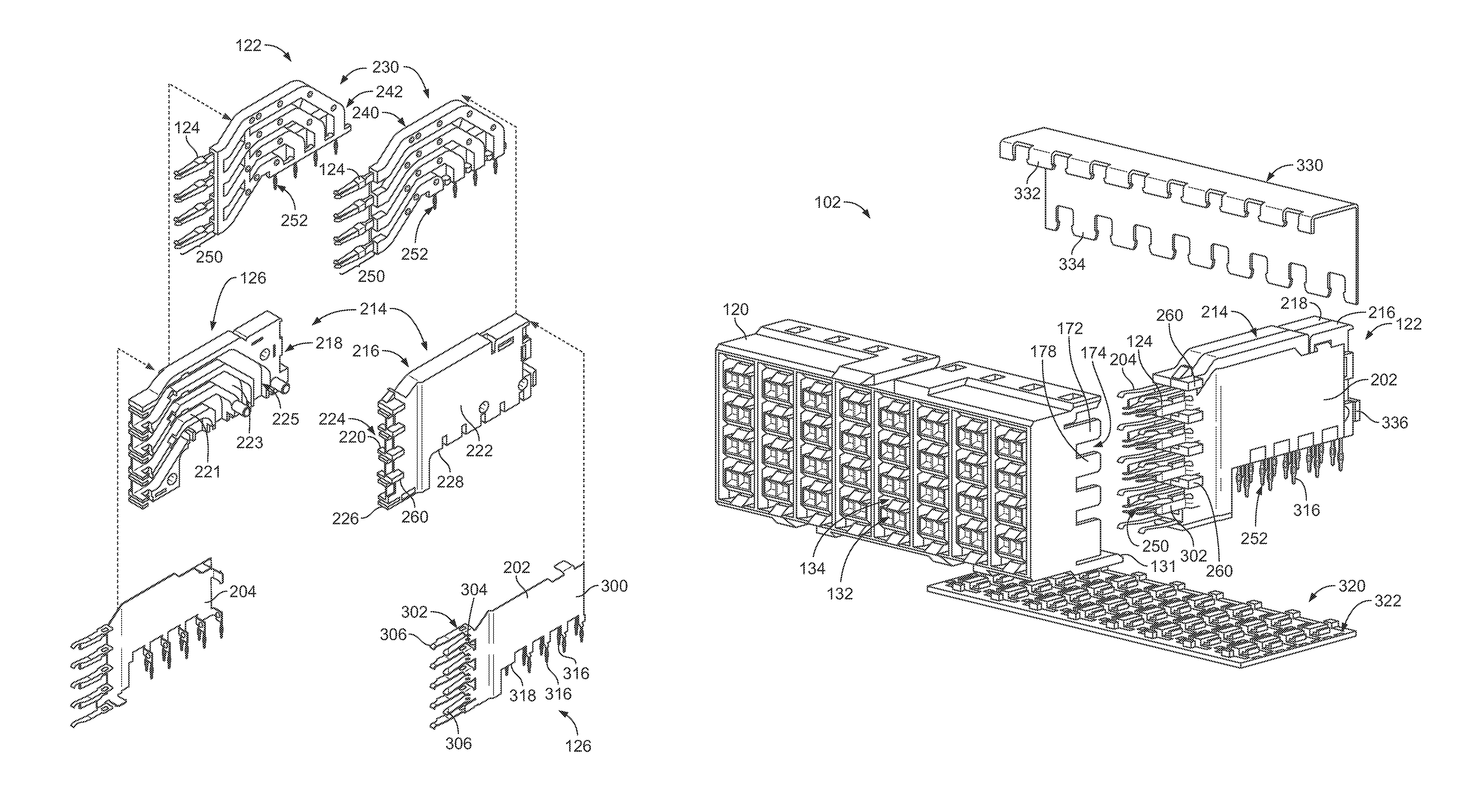

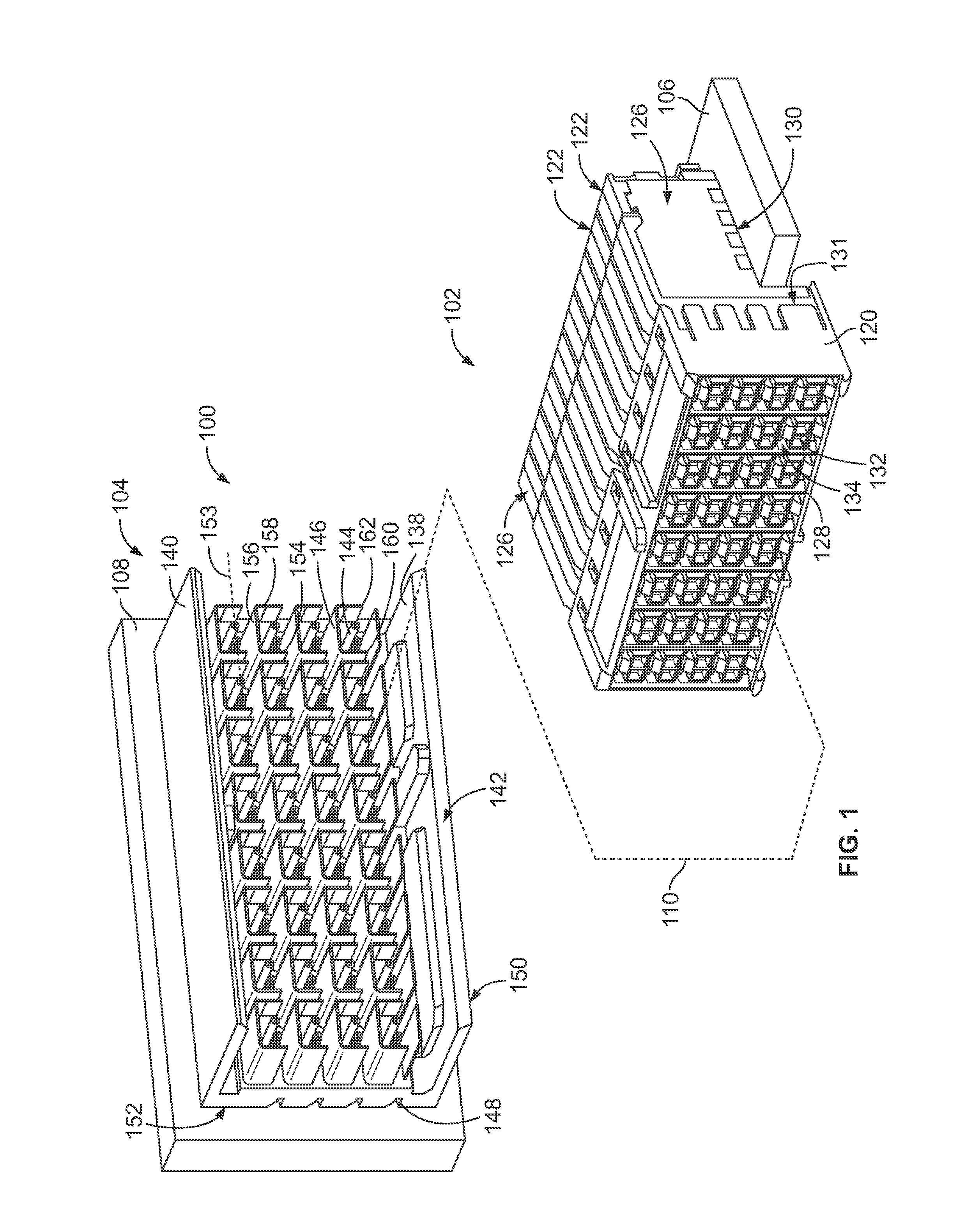

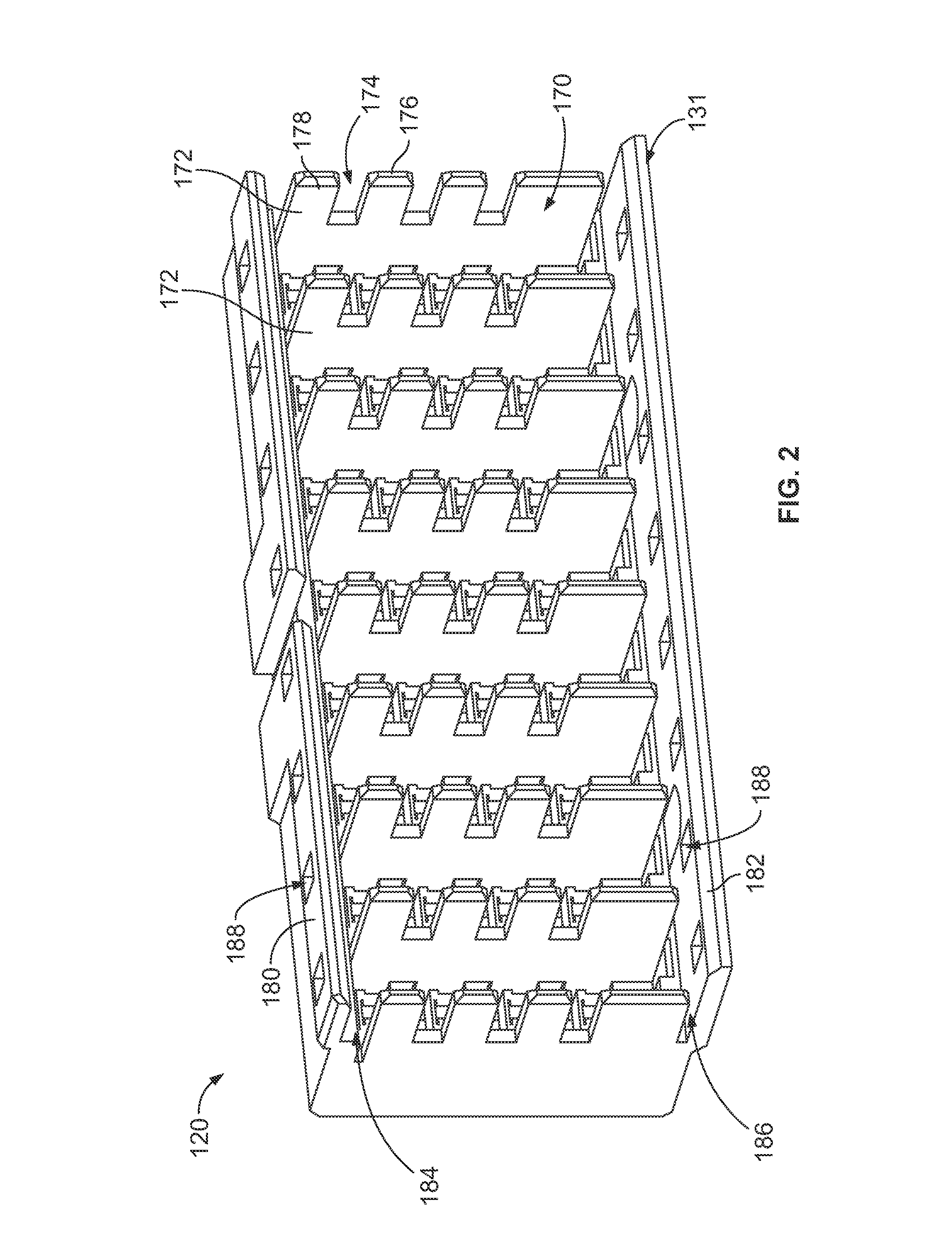

Receptacle assembly

ActiveUS8475209B1Control positionCoupling protective earth/shielding arrangementsEngineeringMechanical engineering

A receptacle assembly includes a front housing having a mating end and a loading end. The front housing has pockets at the loading end separated by separating walls having slots therethrough open at rears thereof. The front housing receives contact modules in corresponding pockets each having a holder holding a plurality of contacts between first and second side walls. The holders have embossments extending from the first side walls proximate to the fronts of the holders. The embossments are loaded into corresponding slots through the rears of the separating walls to control positions of the contact modules with respect to the front housing.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

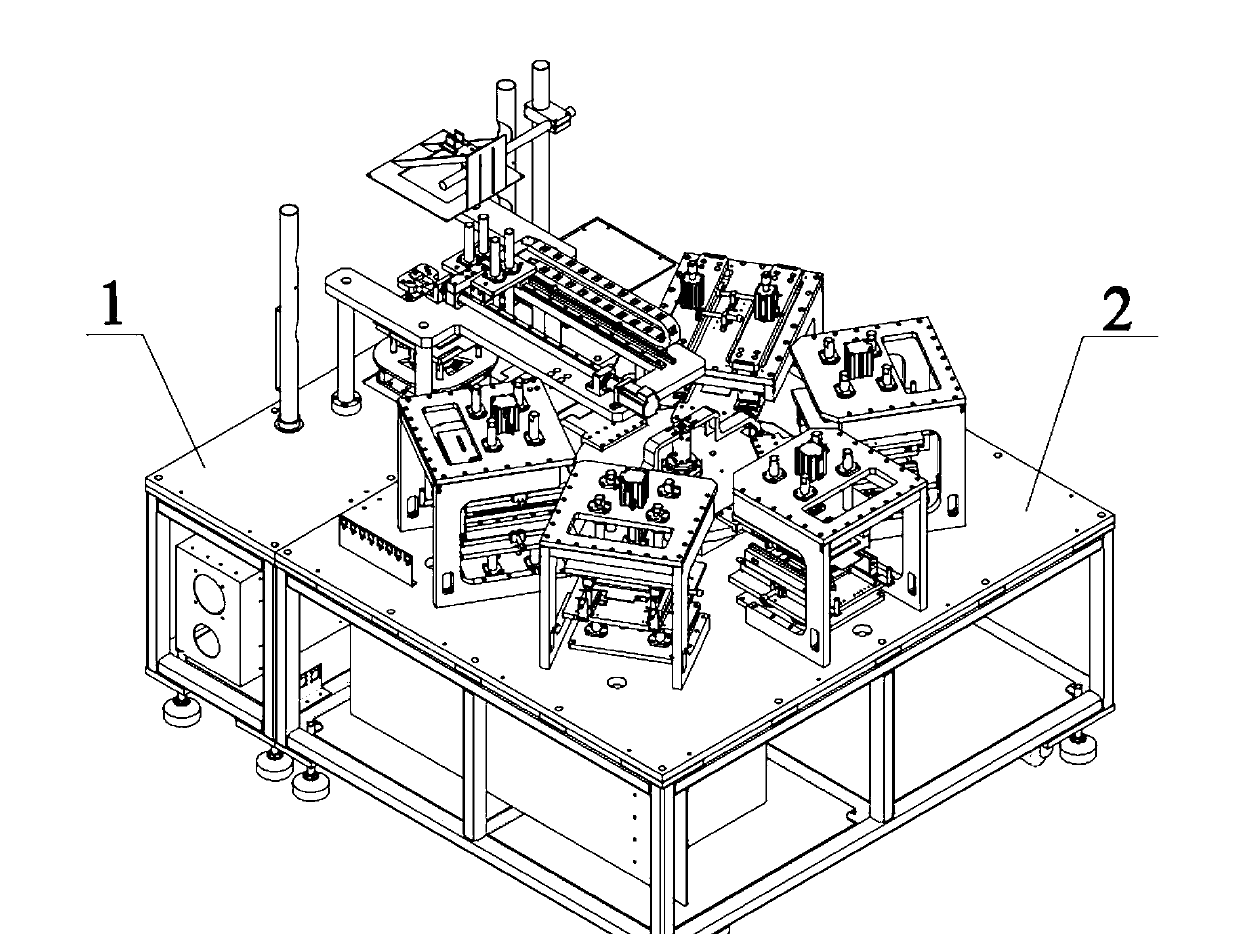

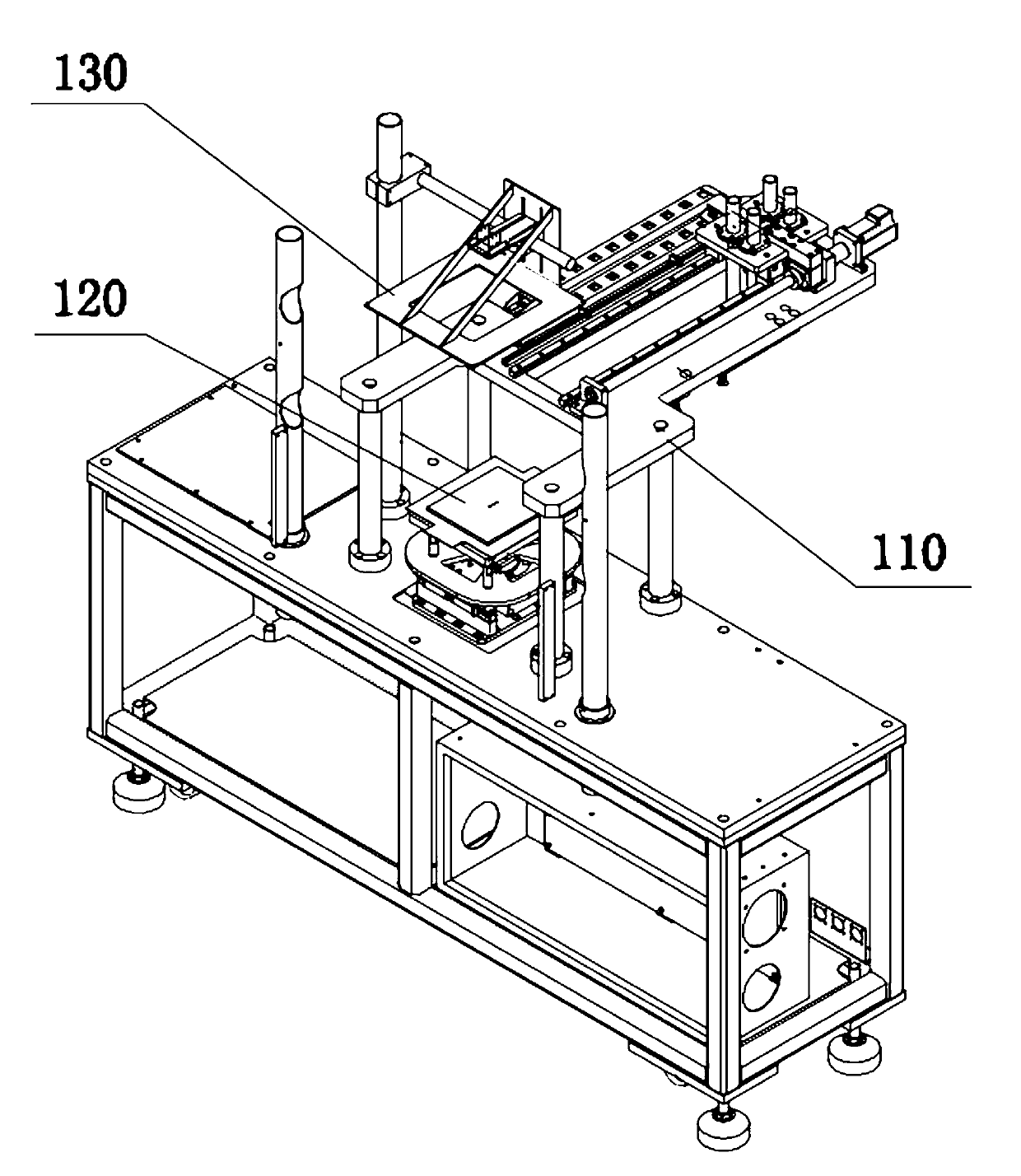

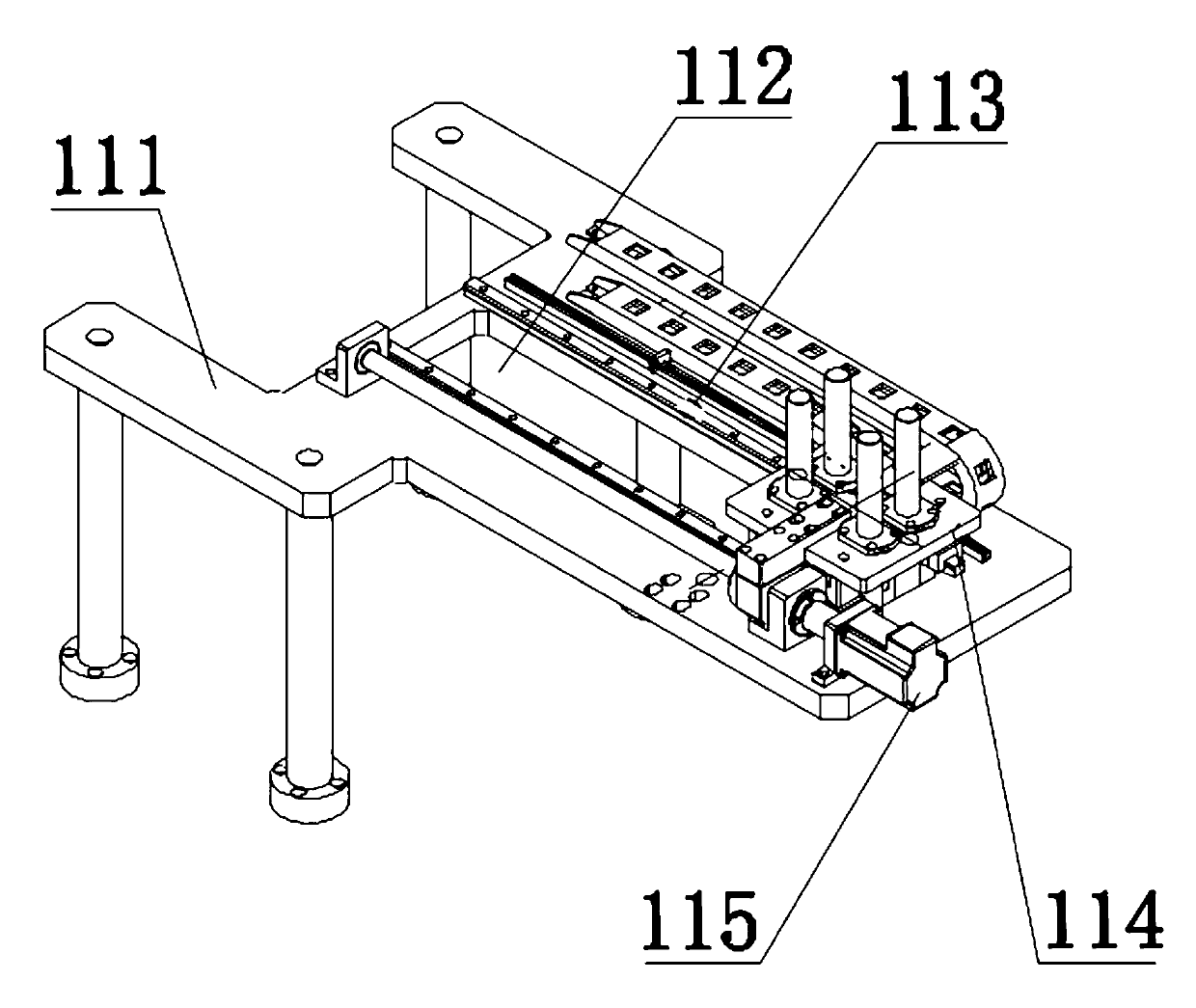

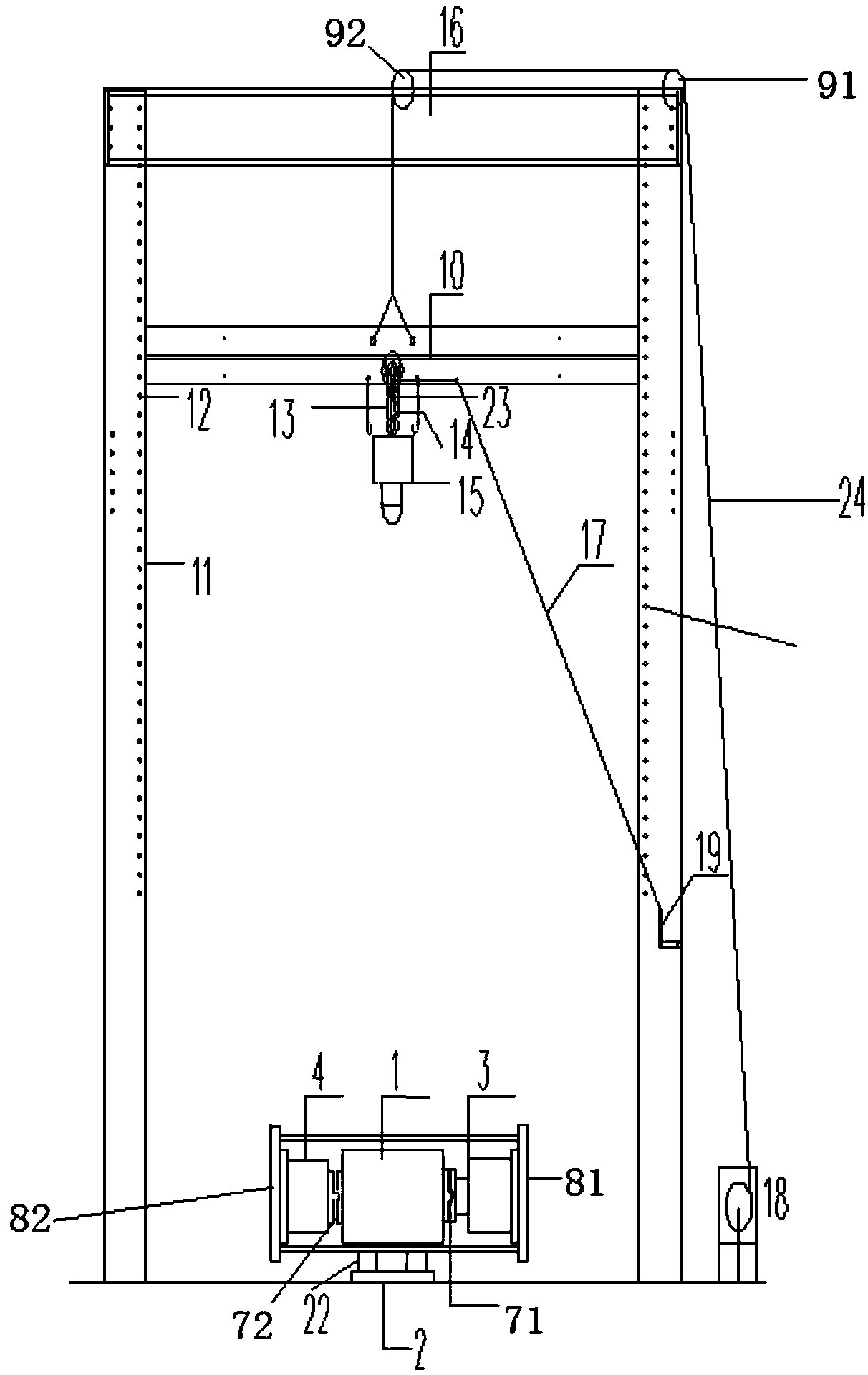

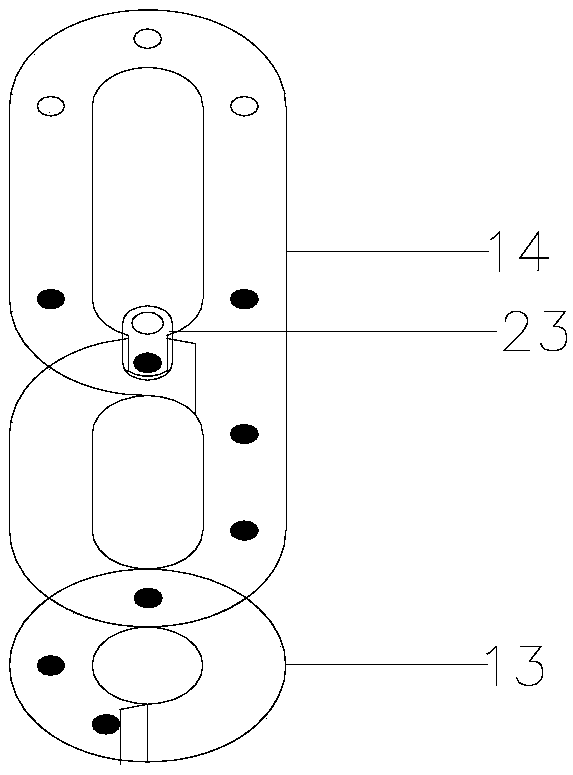

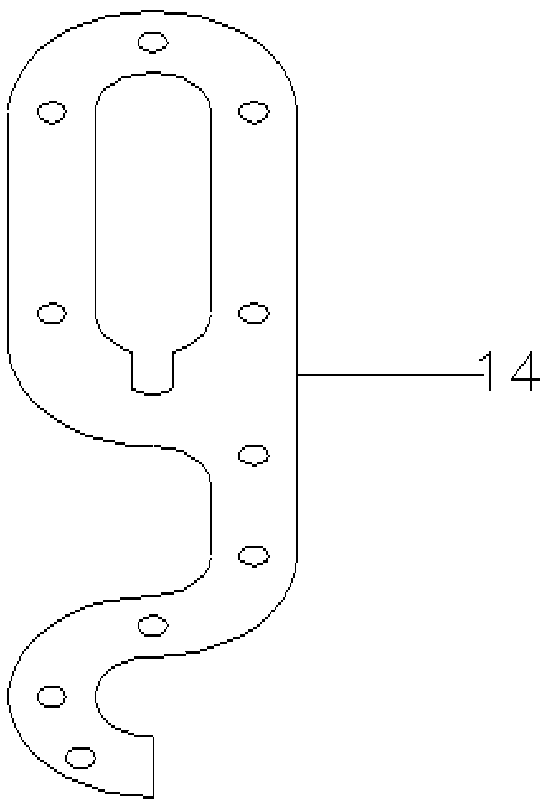

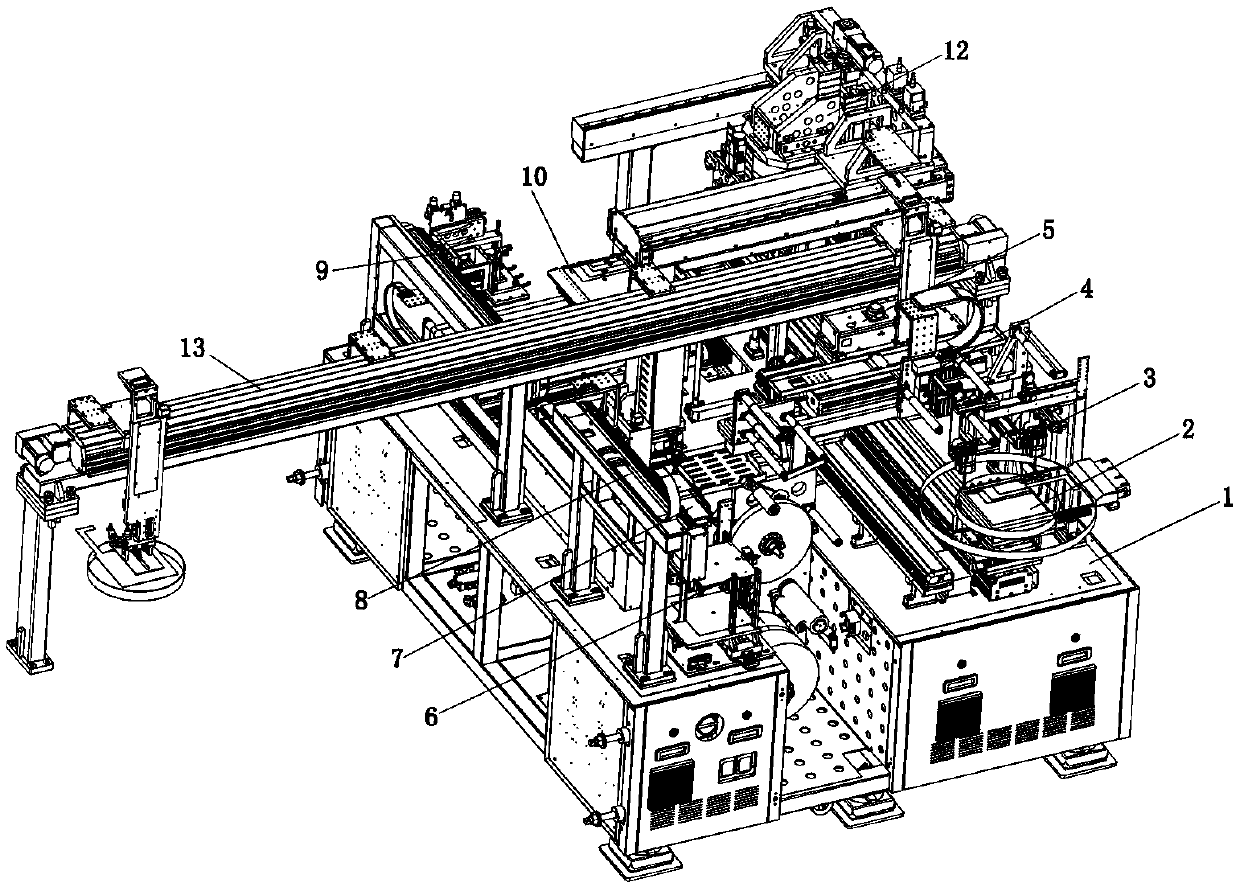

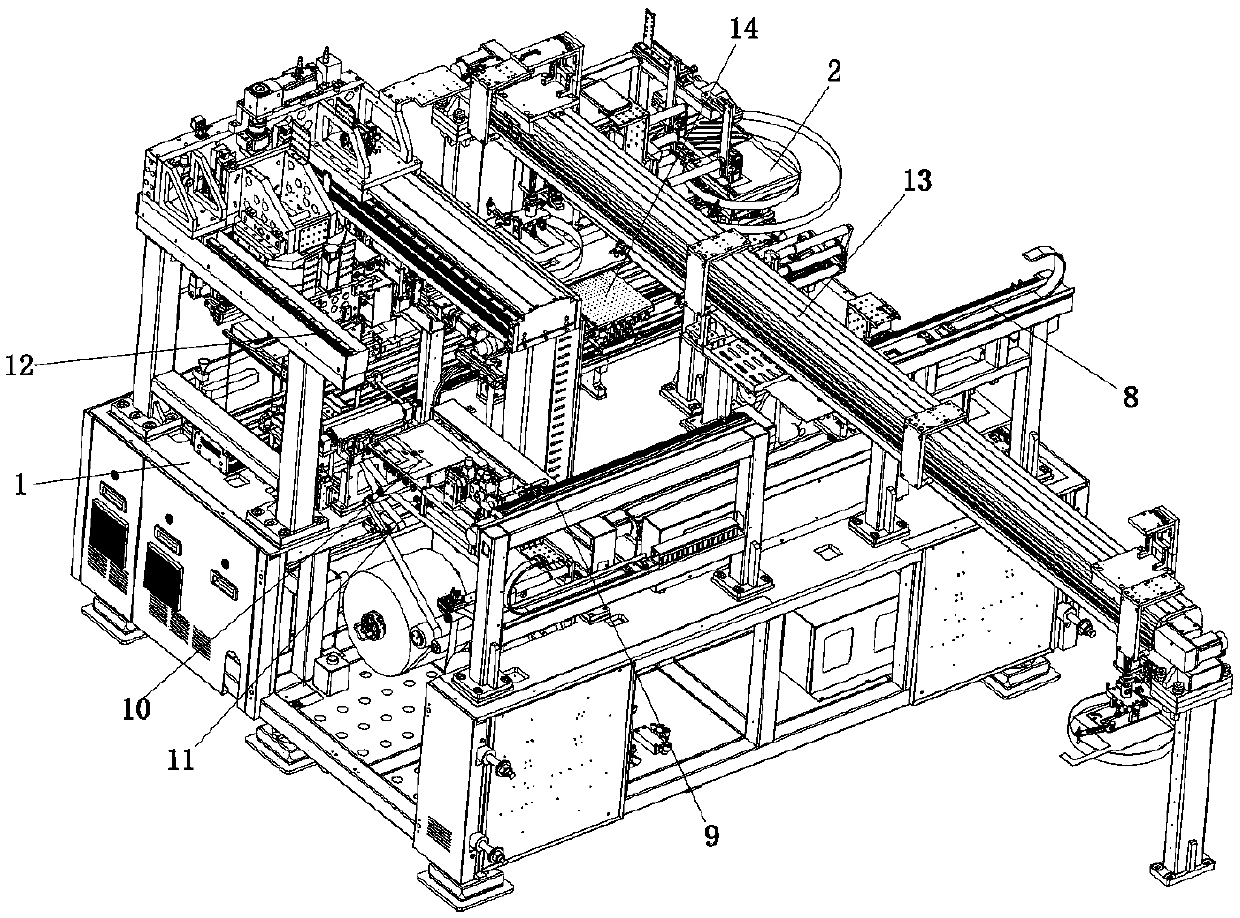

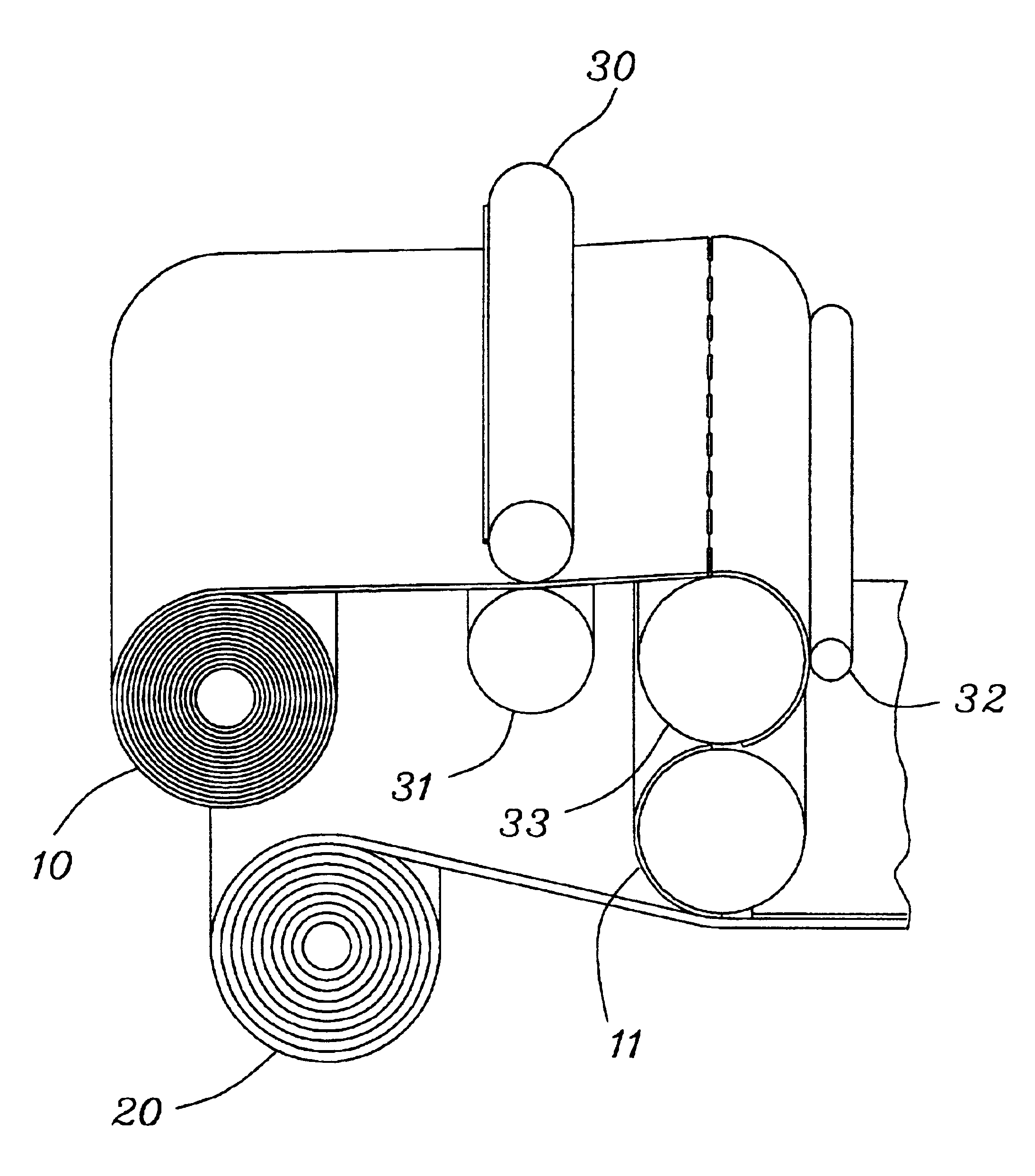

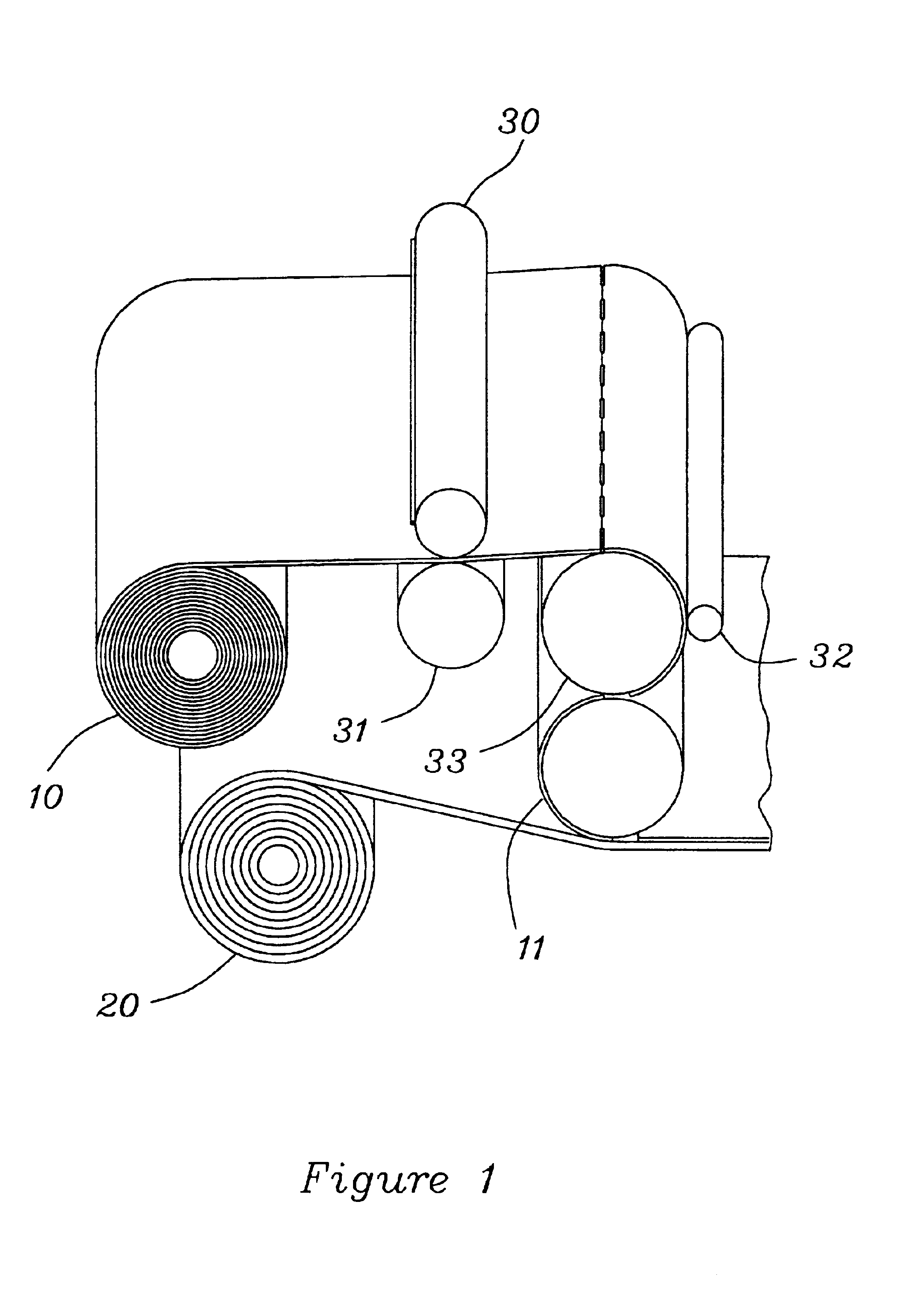

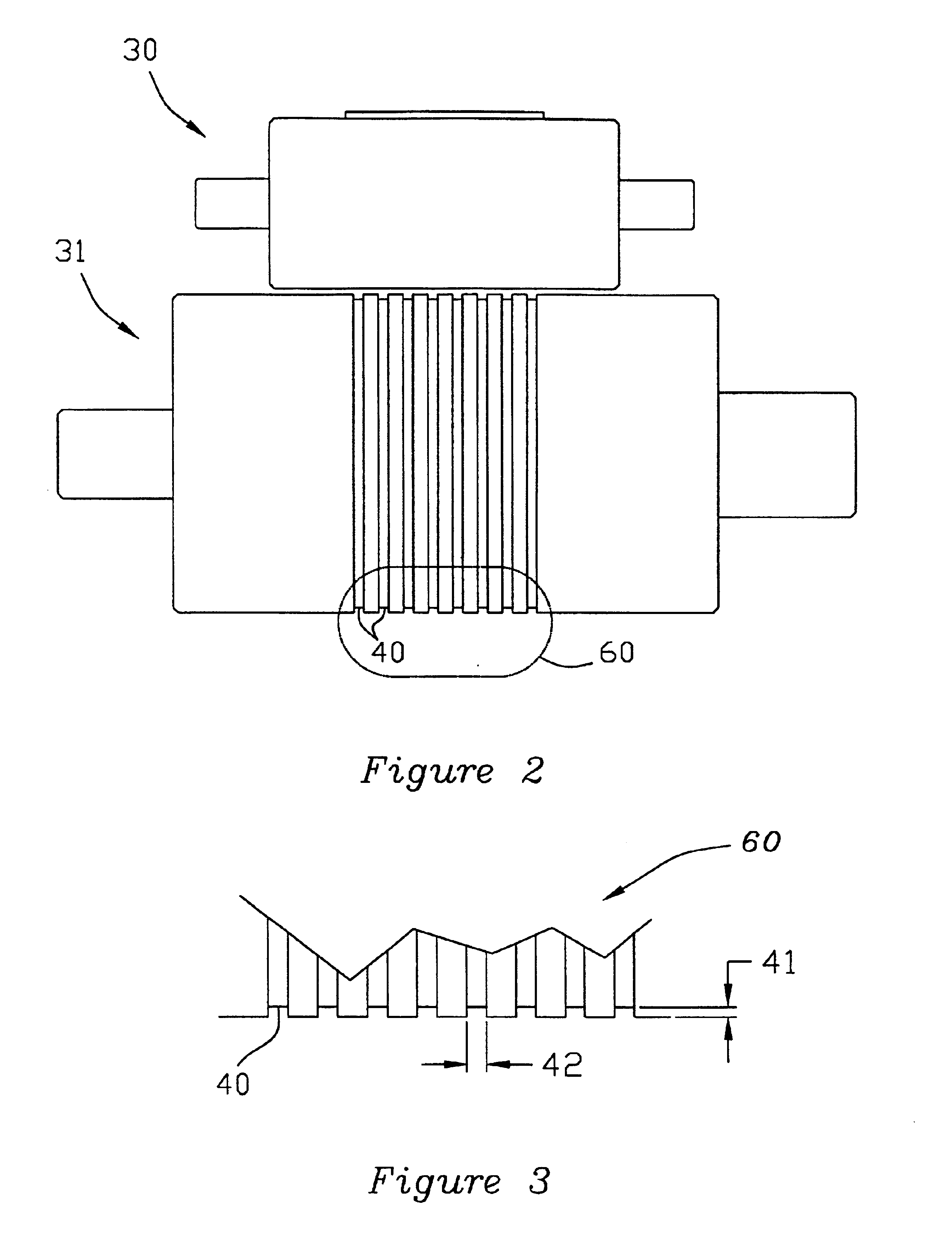

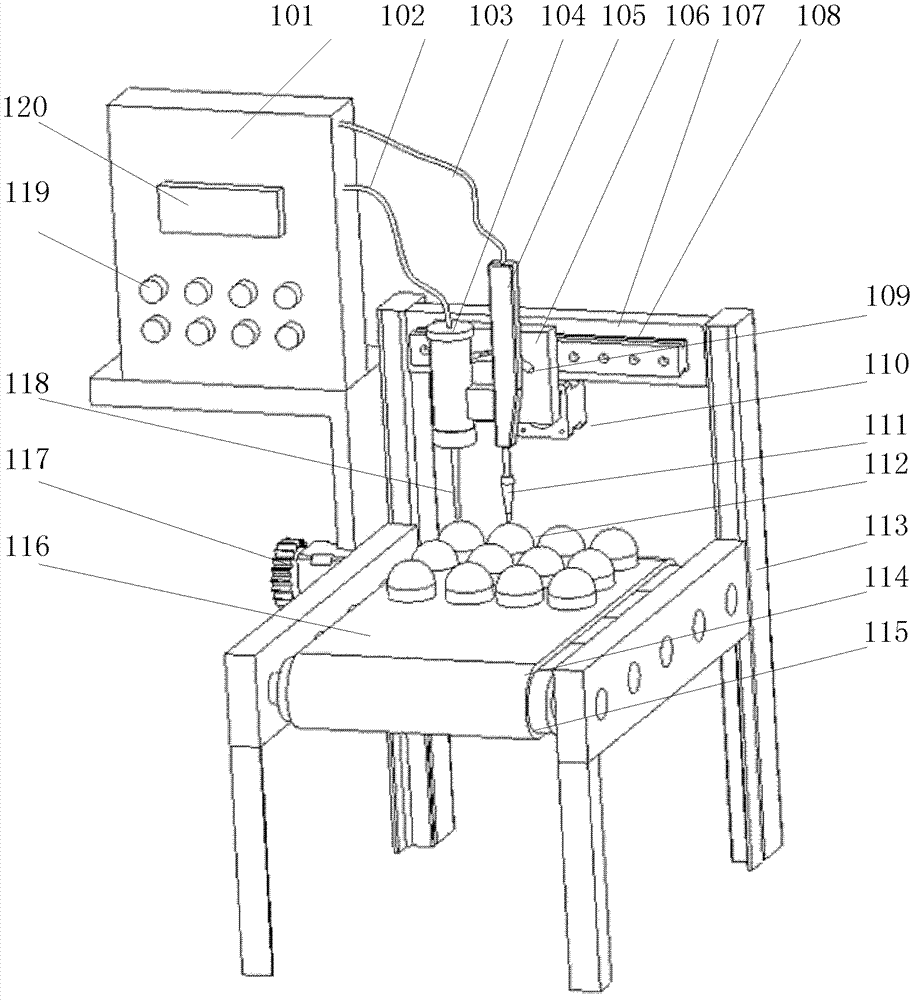

Battery core automatic forming device

ActiveCN103219539AControl positionImprove yieldFinal product manufactureSecondary cells manufactureElectrical batteryEngineering

The invention relates to the field of machinery manufacturing, and specifically relates to a forming device used in soft-package lithium battery automatic edge cutting, edge folding, and edge burning. The device comprises a loading and unloading device, and a plate loading, cutting, folding, and burning device. The loading and unloading device comprises a CCD visual positioning mechanism which is connected with an X, C axis correction mechanism. A turntable loading and unloading manipulator is arranged above the X, C axis correction mechanism. The plate loading, cutting, folding, and burning device comprises a turntable mechanism. The loading and unloading device, a double edge-cutting mechanism, a preheating mechanism, a 90 DEG C edge folding mechanism, a 150 DEG edge folding mechanism, and a 180 DEG edge trimming mechanism are sequentially arranged on the periphery of the turntable mechanism. With the device, battery packaging forming is sequentially completed. Therefore, edge cutting accuracy and high efficiency are ensured, soft package corner breakage during edge folding can be effectively prevented, and same high-precision edge folding effects on the two ends of the battery core can be maintained.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

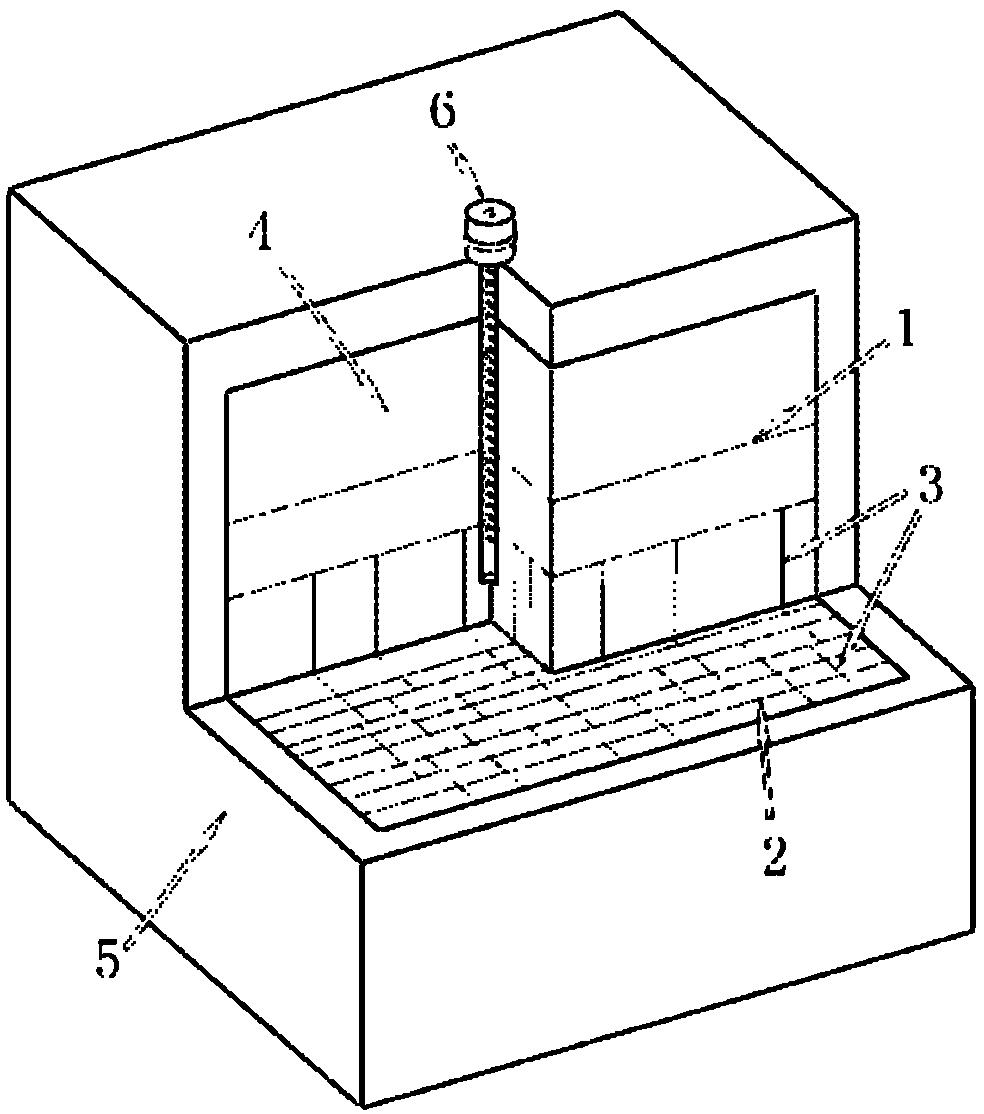

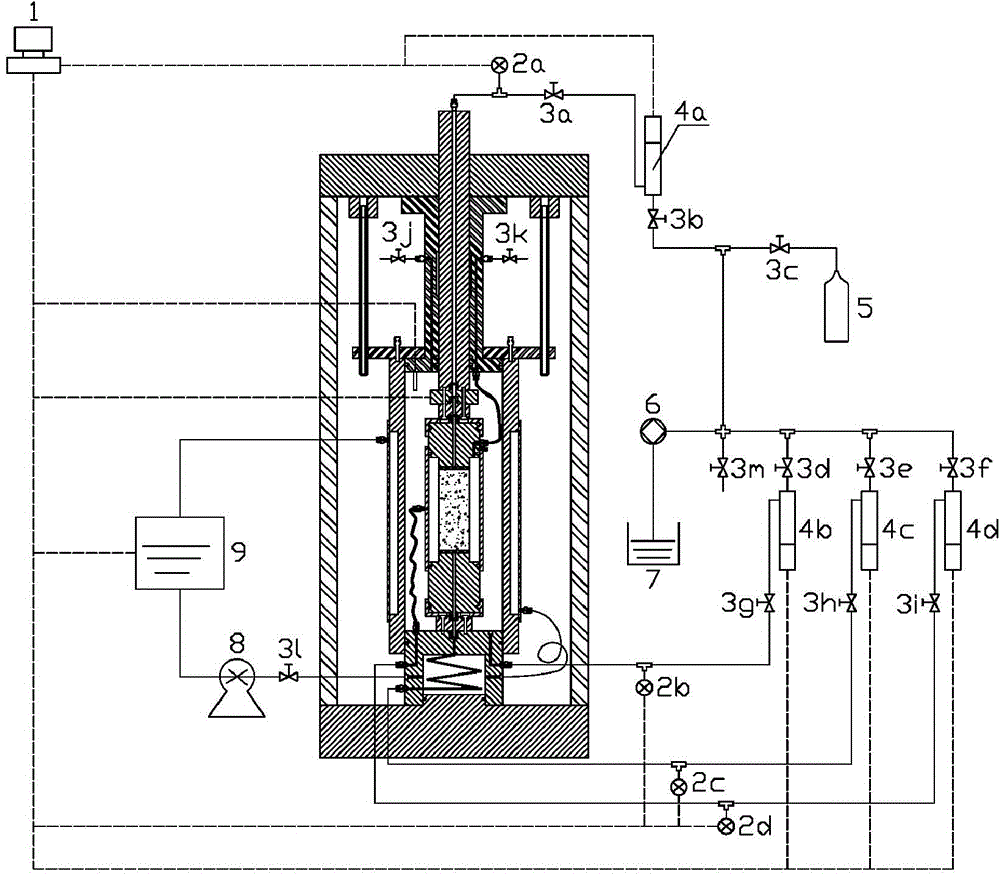

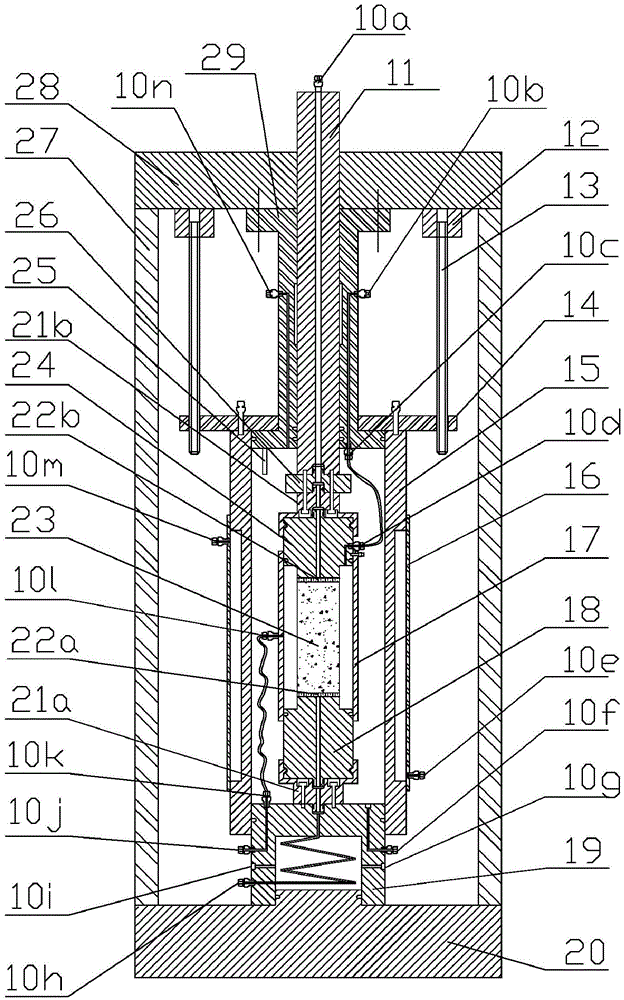

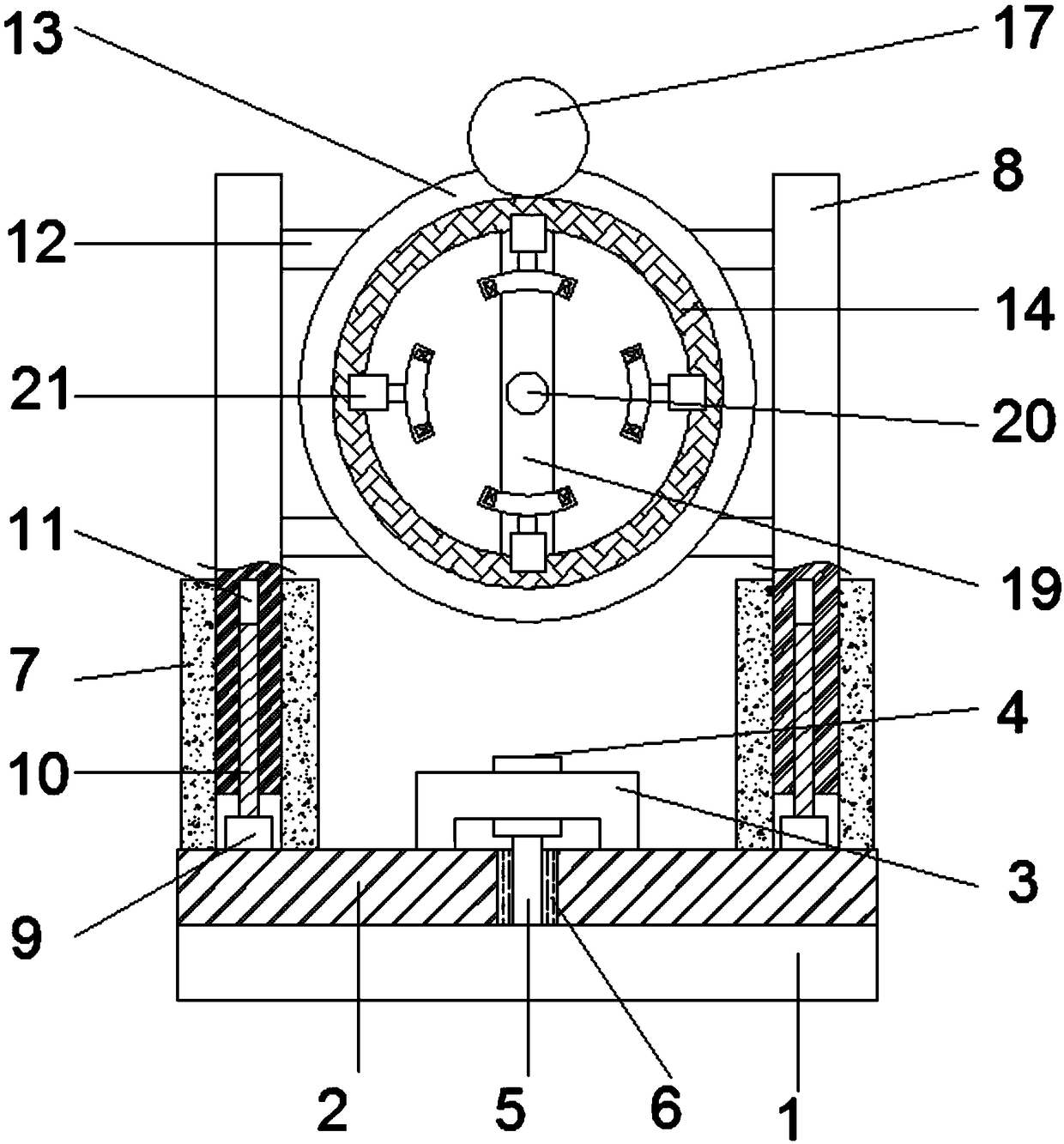

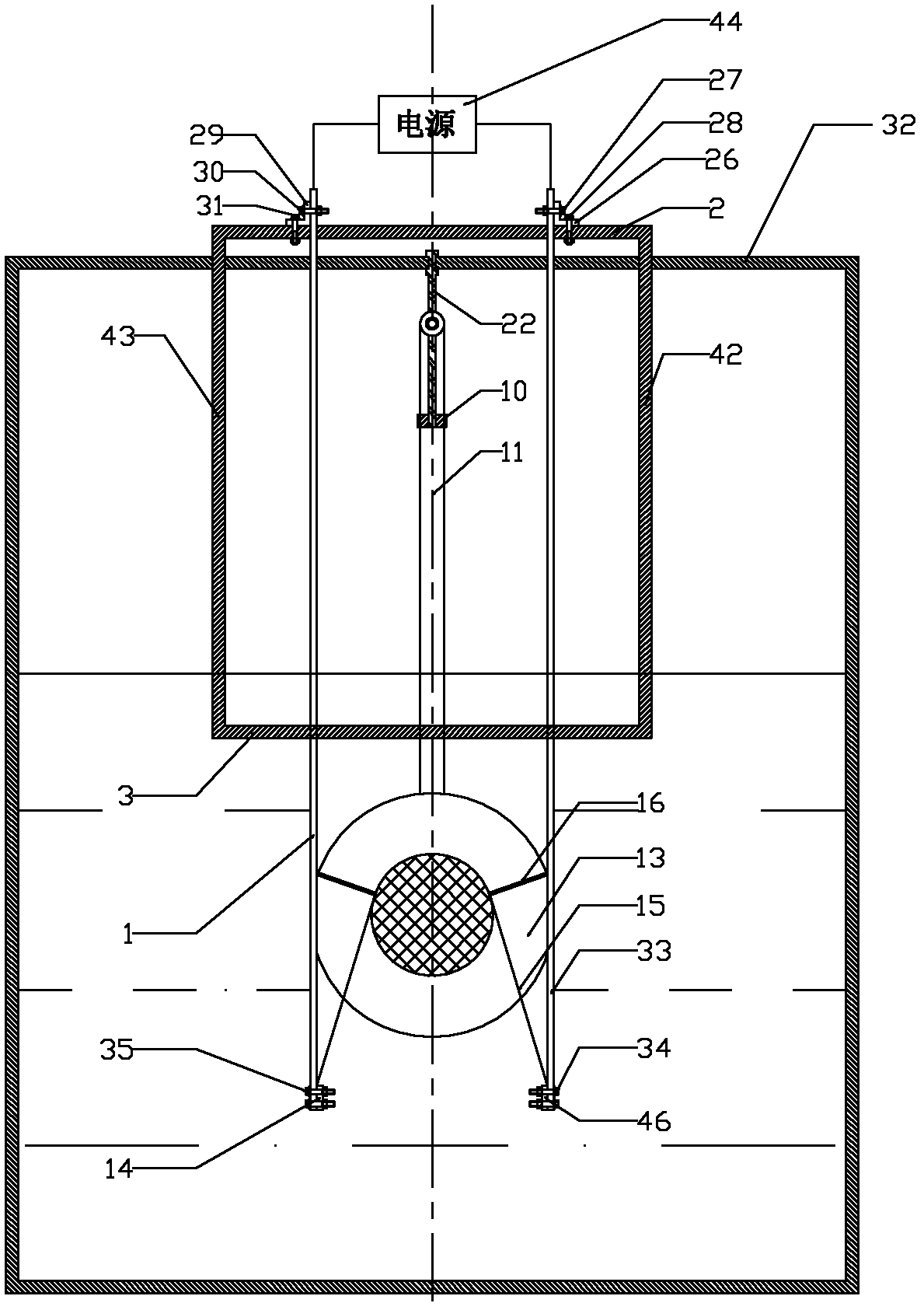

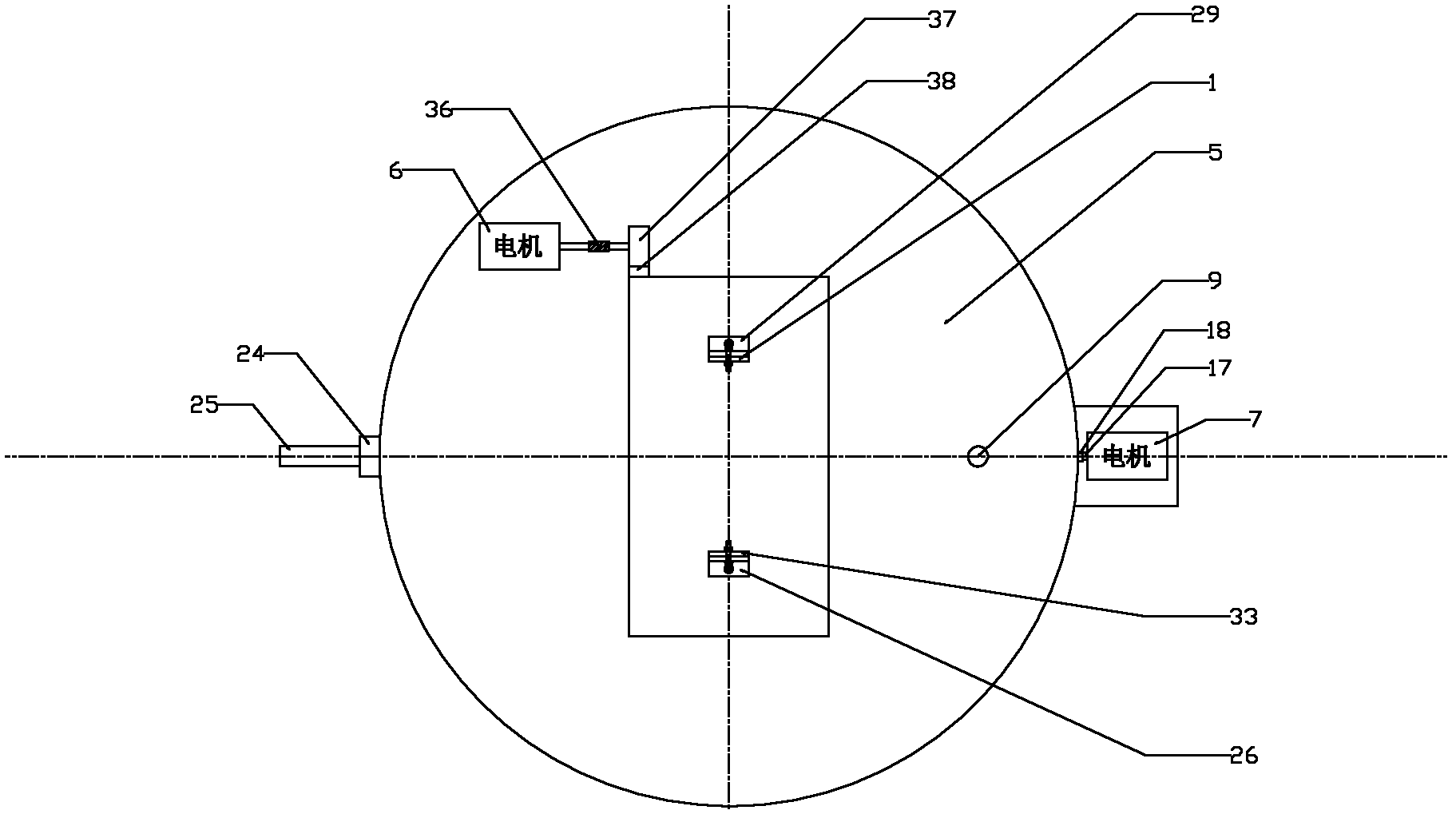

Natural gas hydrate sediment triaxial test device

ActiveCN104833582AApplicable volumetric measurementGain body changeMaterial strength using tensile/compressive forcesDecompositionData acquisition

The invention discloses a natural gas hydrate sediment triaxial test device, and belongs to the field of testing the mechanical properties of natural gas hydrate sediment. The device comprises a triaxial test device main machine, a temperature control system, a pore pressure control system, a confining pressure control system and a computer data acquisition and control system. The triaxial test device main machine, which is in a dual-pressure-chamber structure, can be used for accurately measuring volume change in the sediment in a natural gas hydrate decomposing process; a load sensor is arranged inside the pressure chamber and is capable of improving the precision of intensity data; a pre-cooling hollow cavity is formed inside a base to pre-cool pore gas and pore water which enter a sample, so as to relieve the decomposition of the natural gas hydrate in a saturated water process and to improve the precision of temperature control; in a sample installation process, a quick coupling is adopted for connection, so that the operation is convenient and rapid. The device can simulate the natural gas hydrate decomposing process under mining conditions, so as to achieve the high-precision temperature control, and accurate measurement of intensity and volume change; and the device has great significances for understanding the mechanical properties of the natural gas hydrate sediment and assessing the stability of a reservoir.

Owner:DALIAN UNIV OF TECH

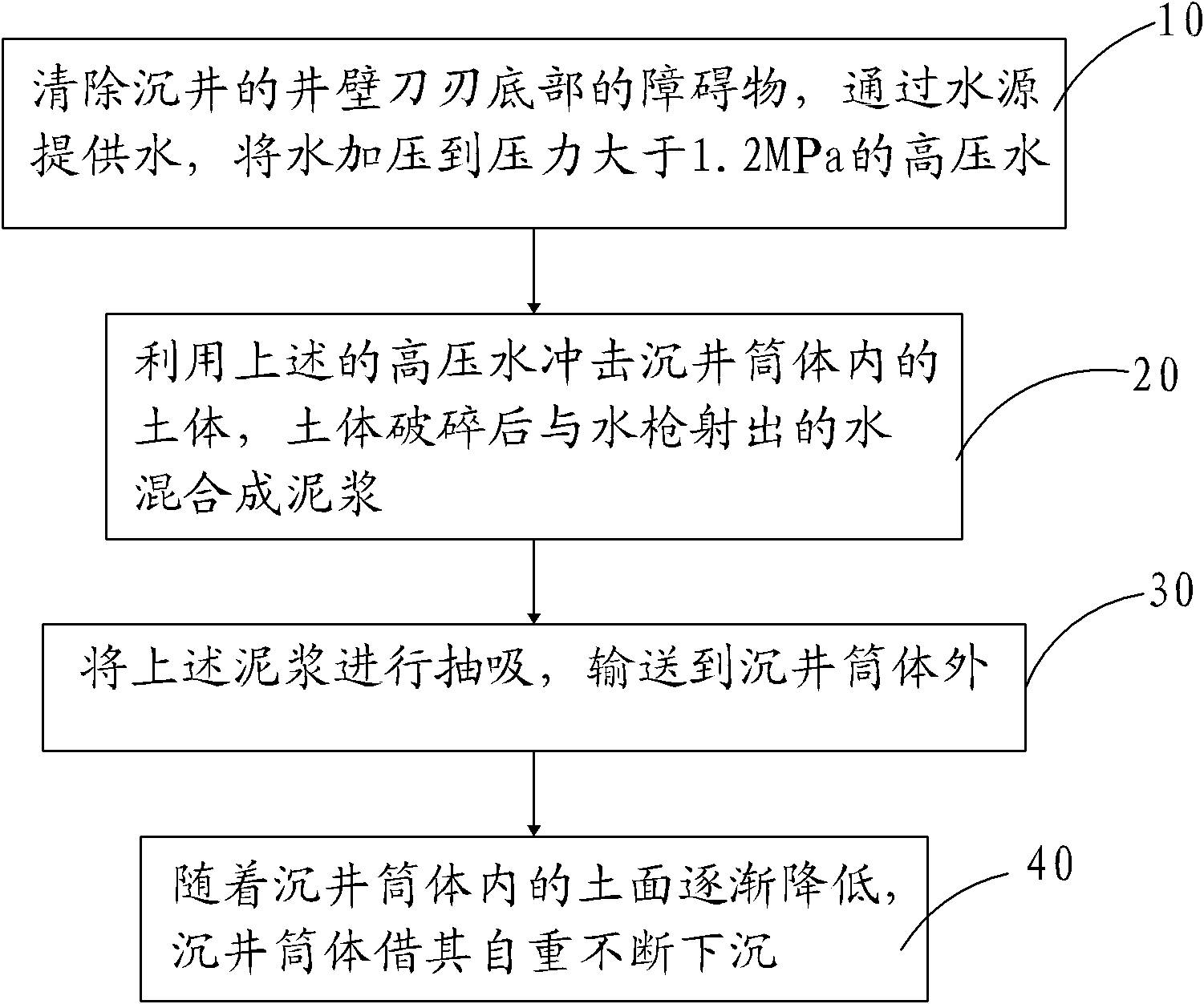

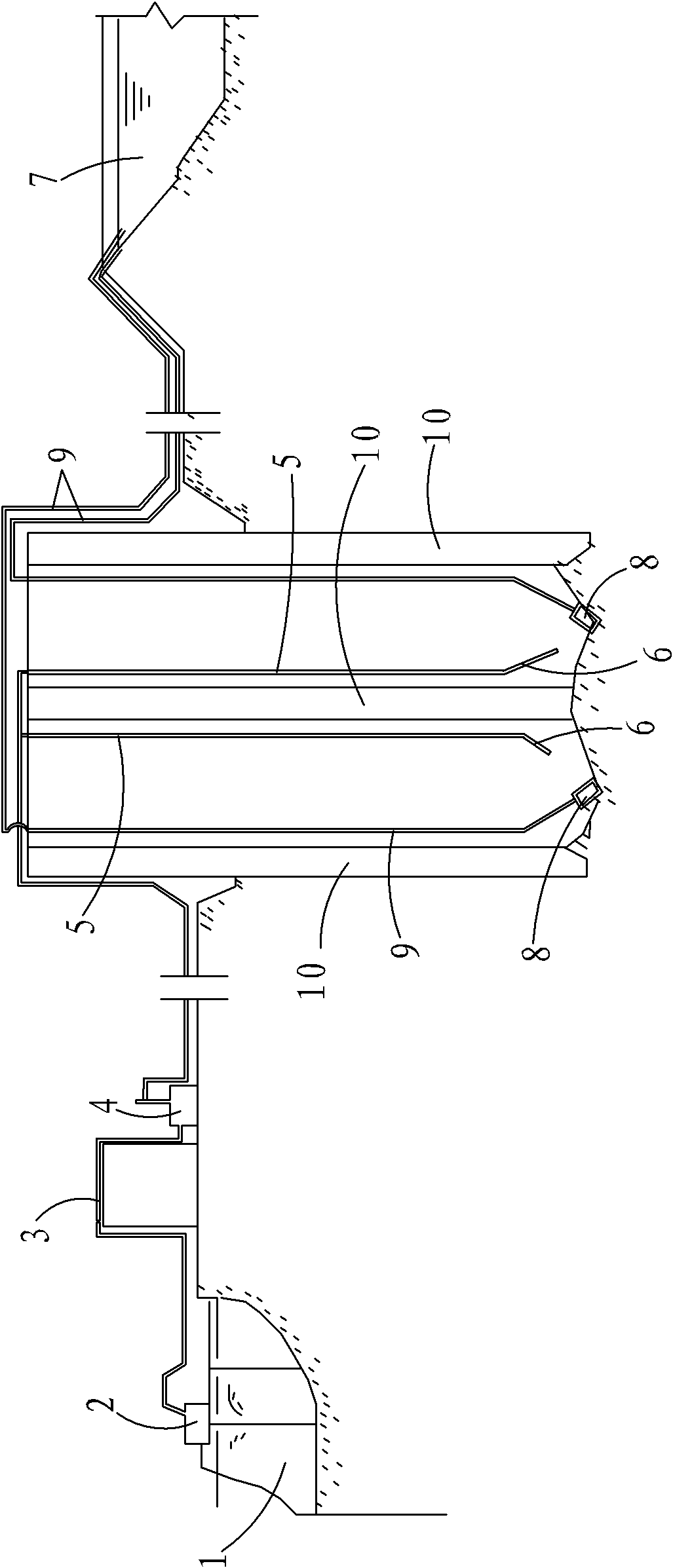

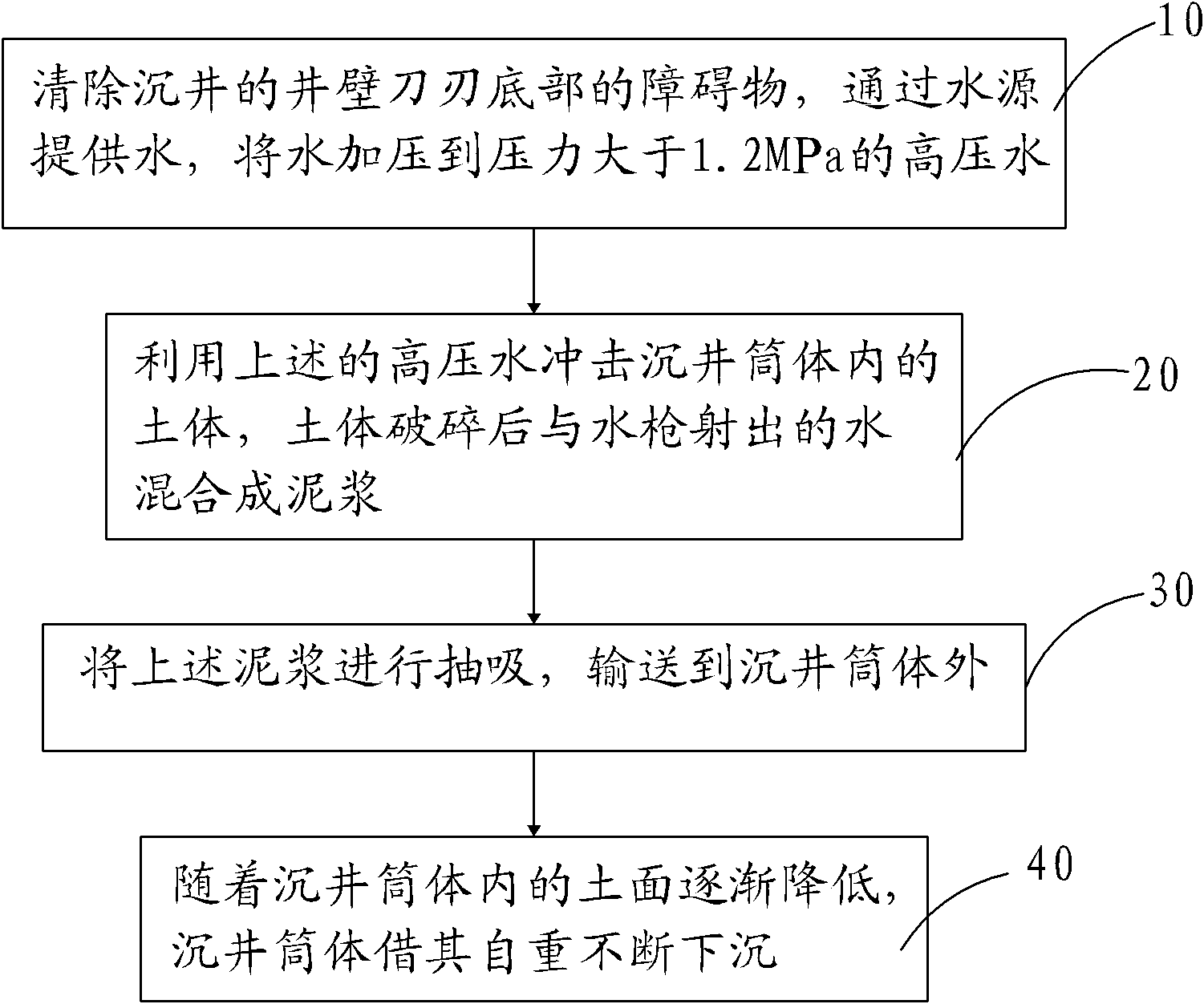

Open caisson construction method of reinforced concrete for soft soil layer

The invention provides an open caisson construction method of reinforced concrete for a soft soil layer. The open caisson construction method specifically comprises the followings steps: 10, barriers on the bottom of a wall blade of an open caisson are removed, water is supplied from a water source, and the water is pressurized to a pressure higher than 1.2 MPa; 20, the high-pressure water is utilized to impact soil mass in a tube body, and the broken soil mass and water sprayed from a water gun are mixed into slurry; 30, the slurry is pumped and delivered to the outside of the tube body of the open caisson; and 40, the tube body of the open caisson subsides gradually due to self gravity along with gradual reduction of soil surface in the tube body of the open caisson. The open caisson construction method disclosed by the invention can avoid over-digging of the bottom and the phenomena of sudden subsidence of the open caisson because hydraulic power is utilized to break oil, is easy to ensure the construction quality of the open caisson, can effectively control the soil breaking program and position, can enable the open caisson to subside steadily, is convenient for controlling the final subsiding elevation of the open caisson, and reduces the engineering cost.

Owner:FUJIAN UNIV OF TECH

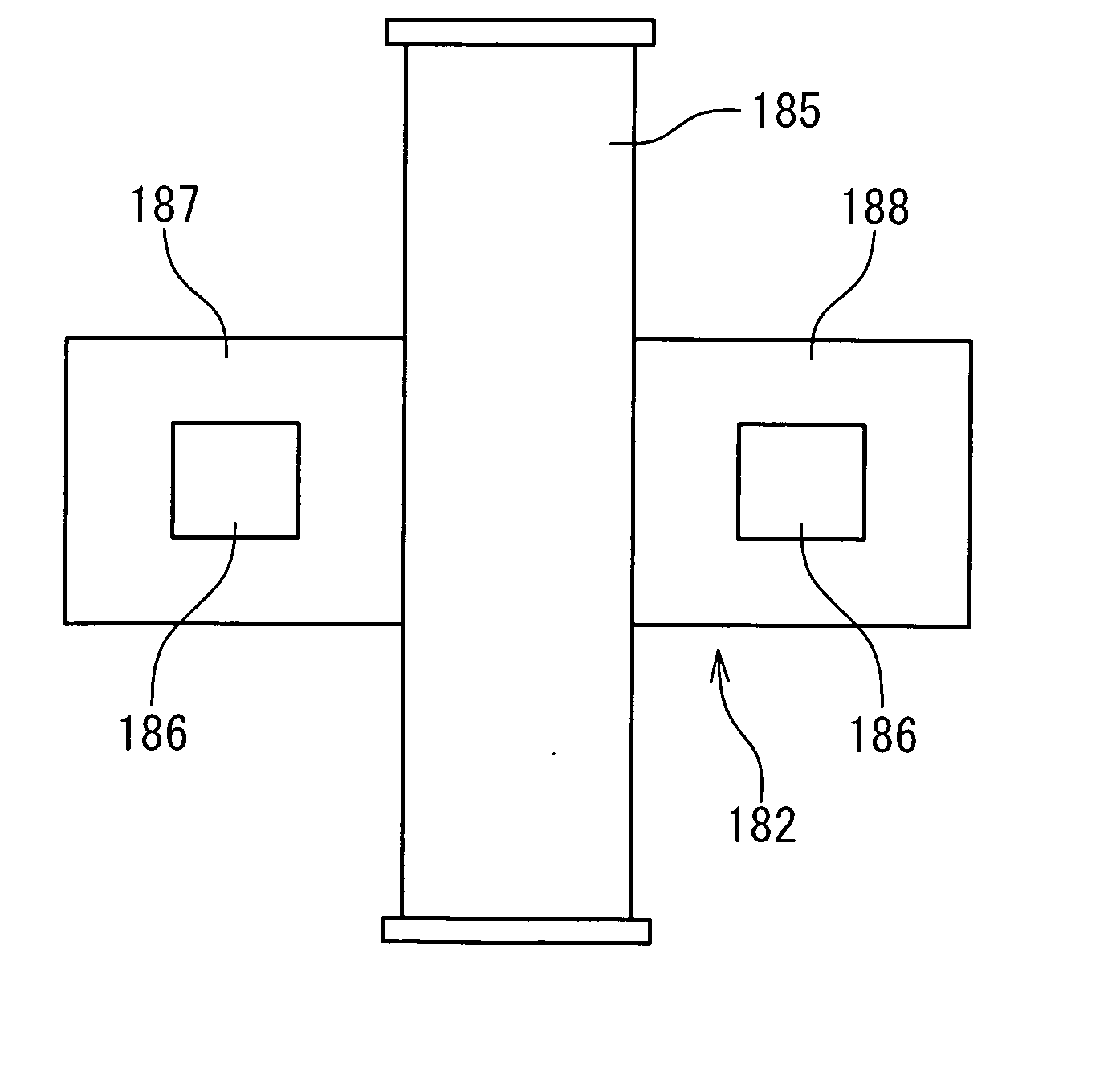

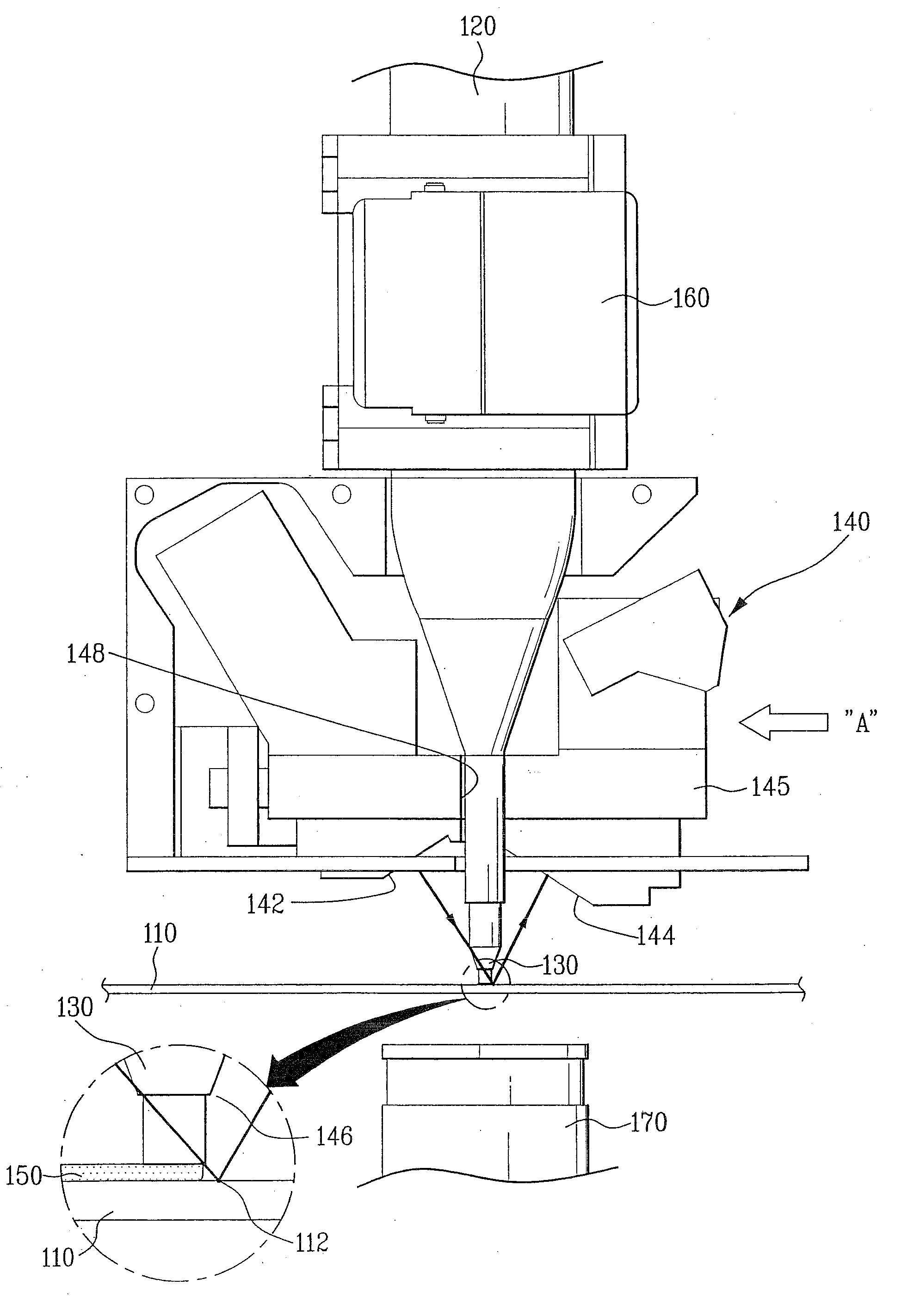

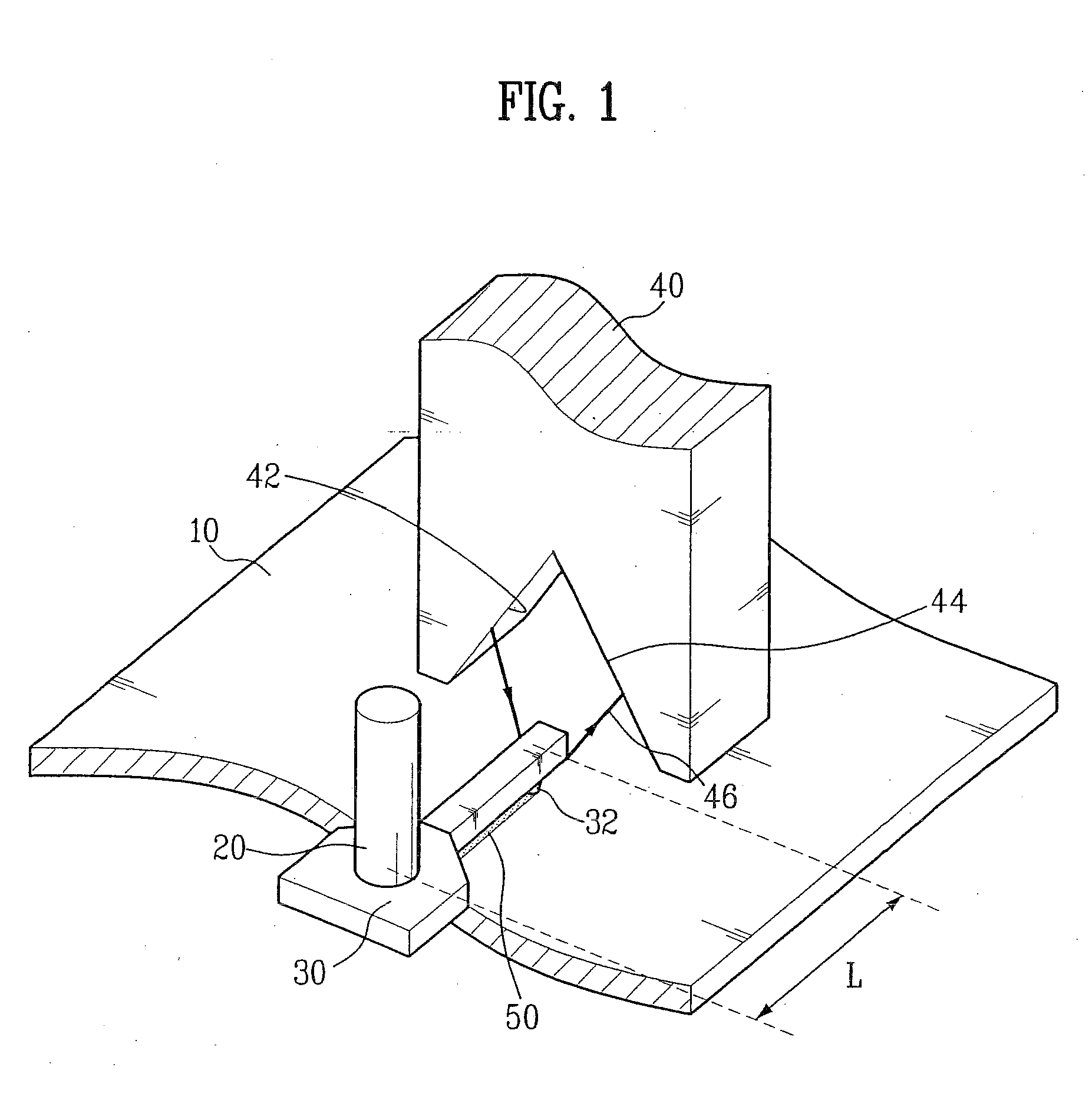

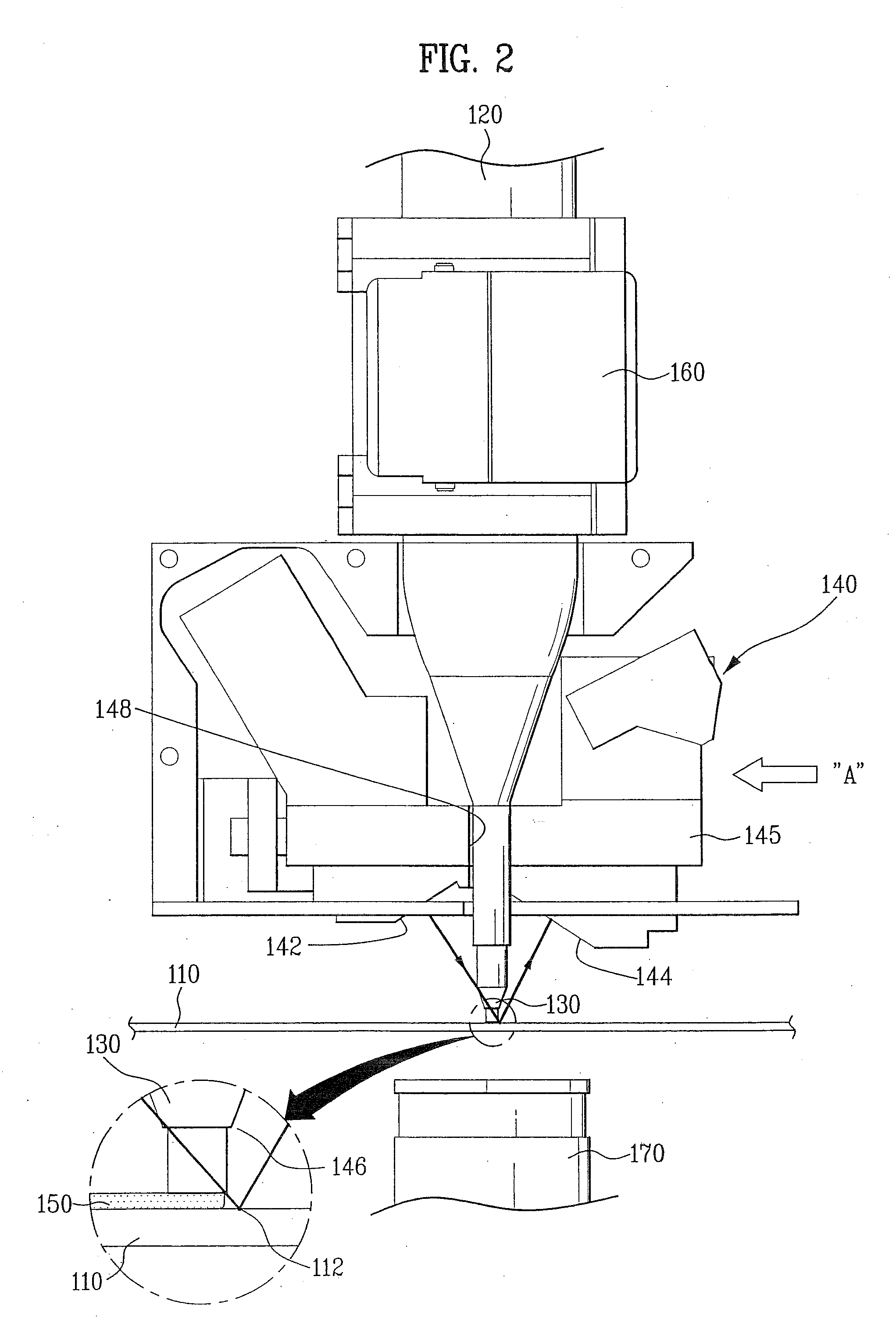

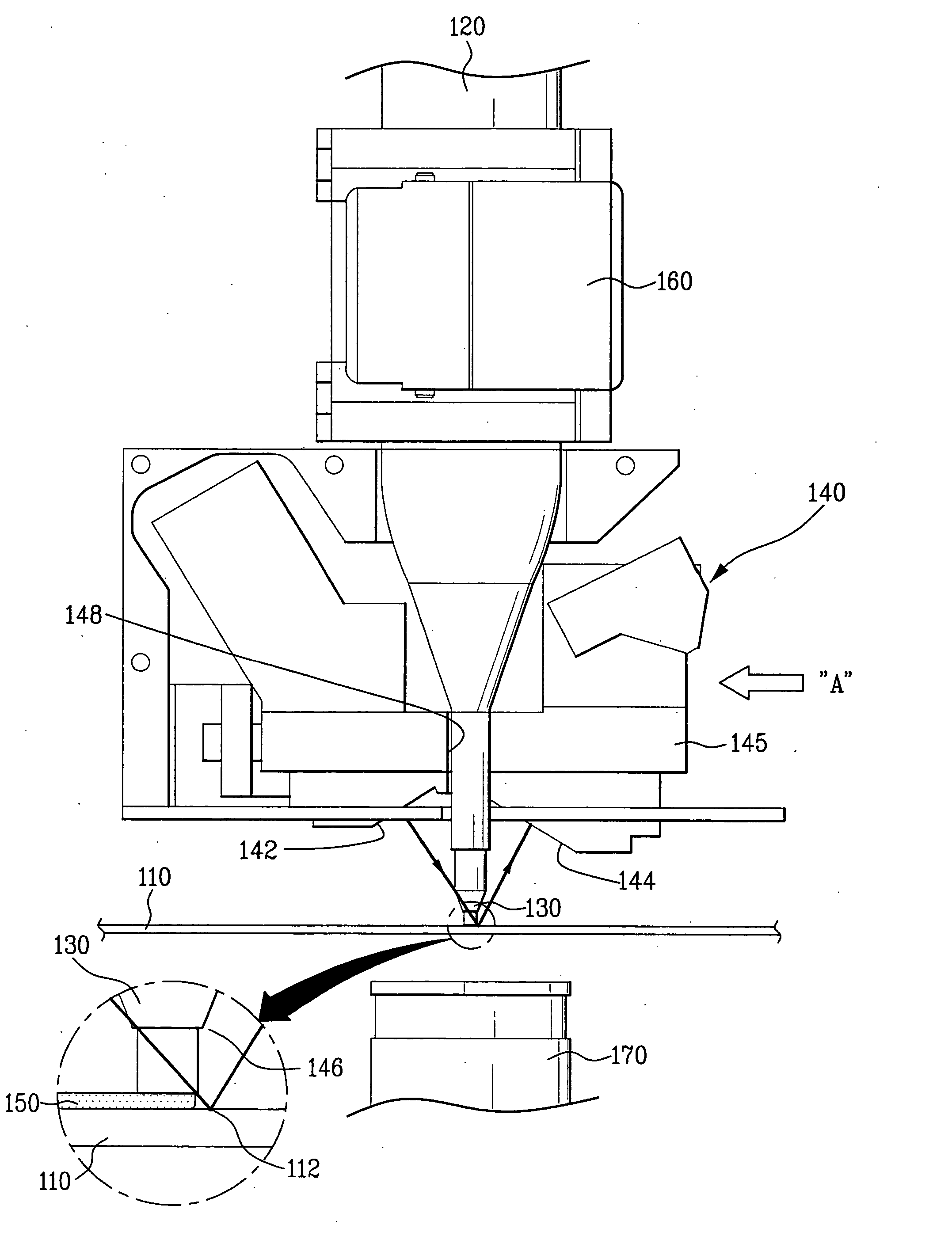

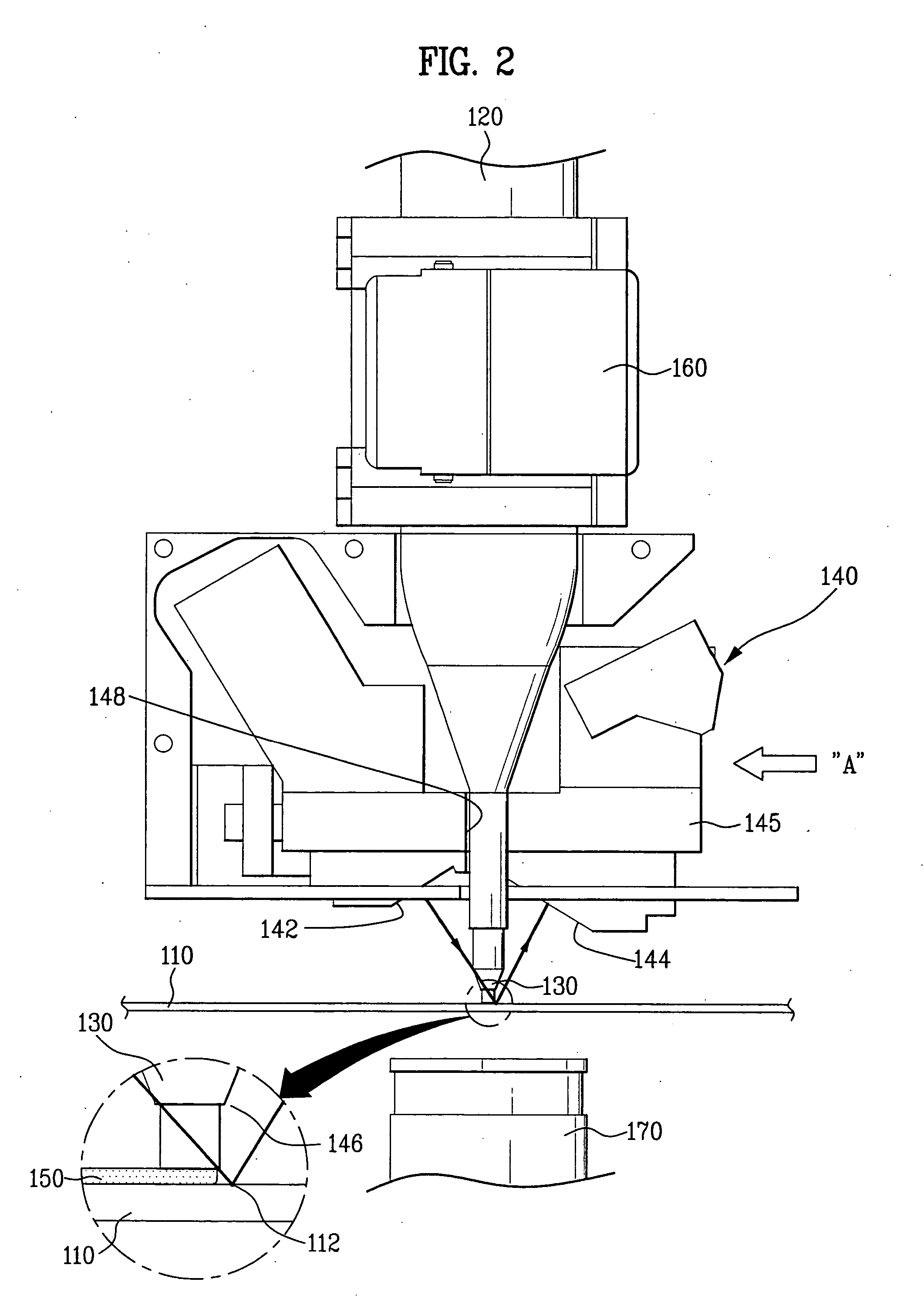

Sealant dispenser and control method thereof

InactiveUS20080210894A1Improve response speedControl amountOptical rangefindersLarge containersRelative motionDistance sensors

Disclosed is a sealant dispenser for more precisely dispensing a sealant onto a substrate, and a control method thereof. The sealant dispenser includes a stage on which a substrate is mounted; a nozzle for dispensing a sealant while making a relative motion with the substrate; a syringe coupled to the nozzle, for storing the sealant; and a distance sensor installed on both sides of a lower portion of the syringe, for measuring a vertical distance between a principal plane of the substrate and an outlet of the nozzle. According to the principles of the present invention, because the nozzle and the syringe have substantially the same central axis, the response speed of the sealant to be dispensed is increased and the start point and the end point of paste pattern are more precisely dispensed. Also, by minimizing the distance between the nozzle and a measuring point provided by the distance sensor, it becomes possible to dispense the sealant at higher precision.

Owner:TOP ENG CO LTD

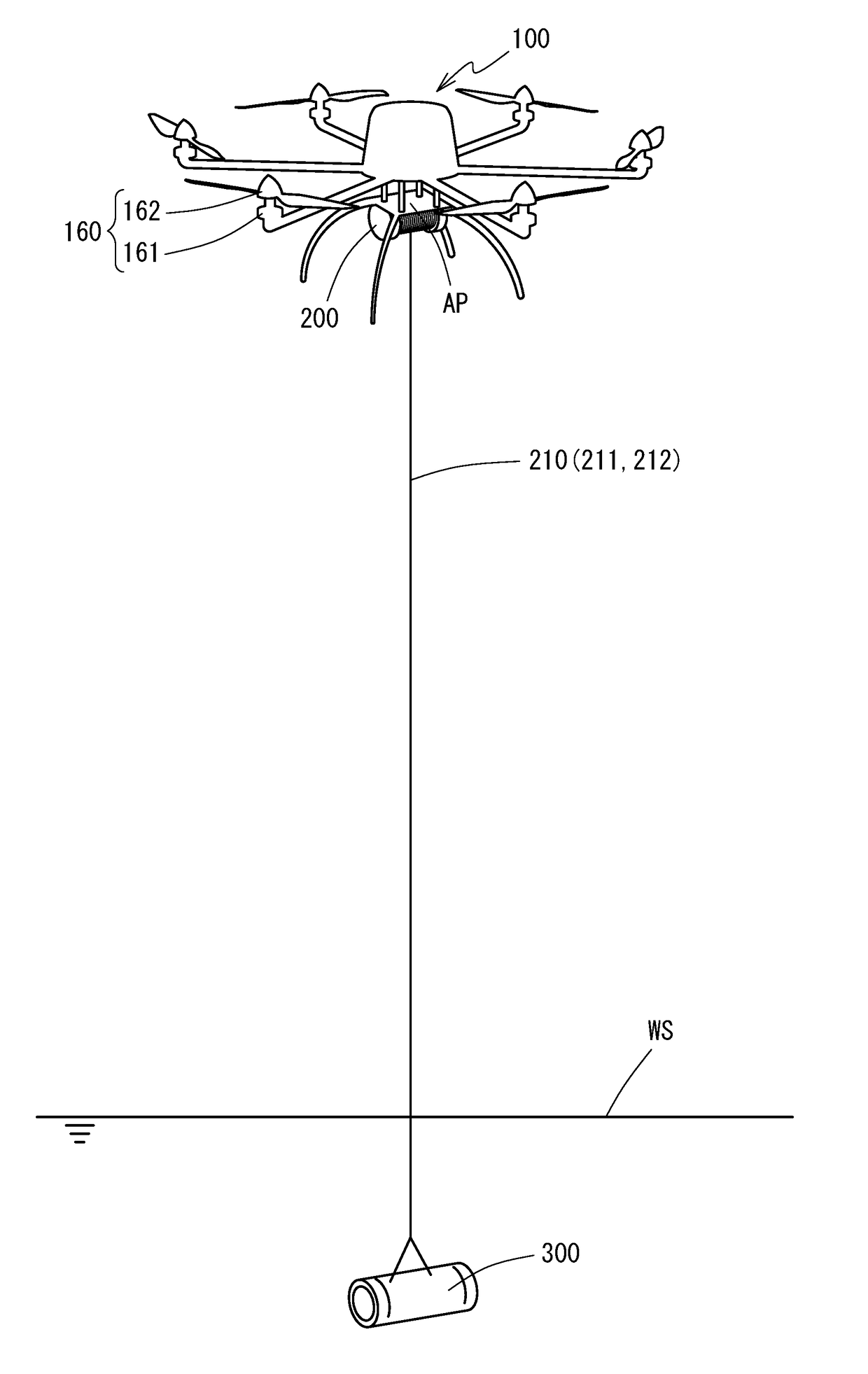

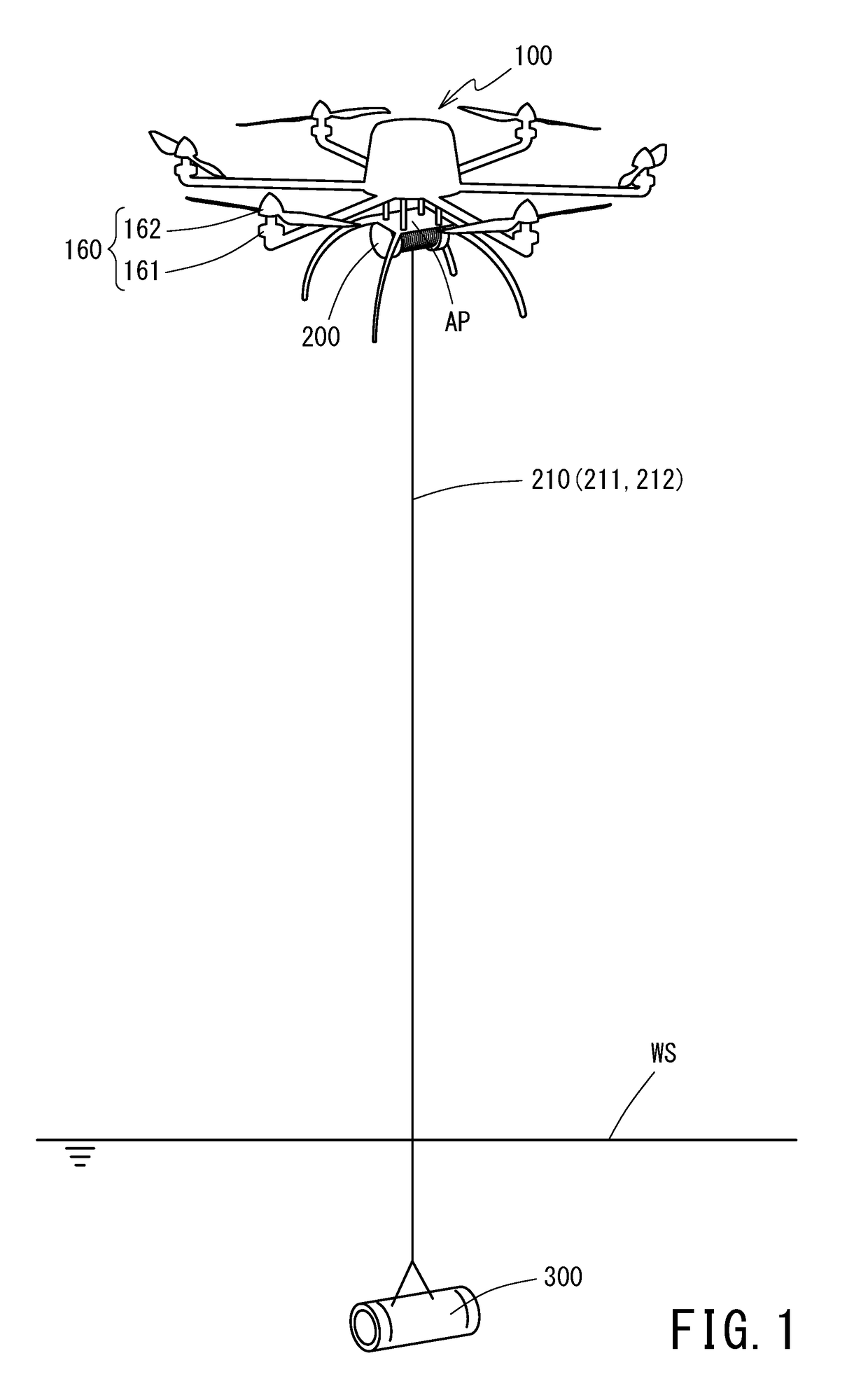

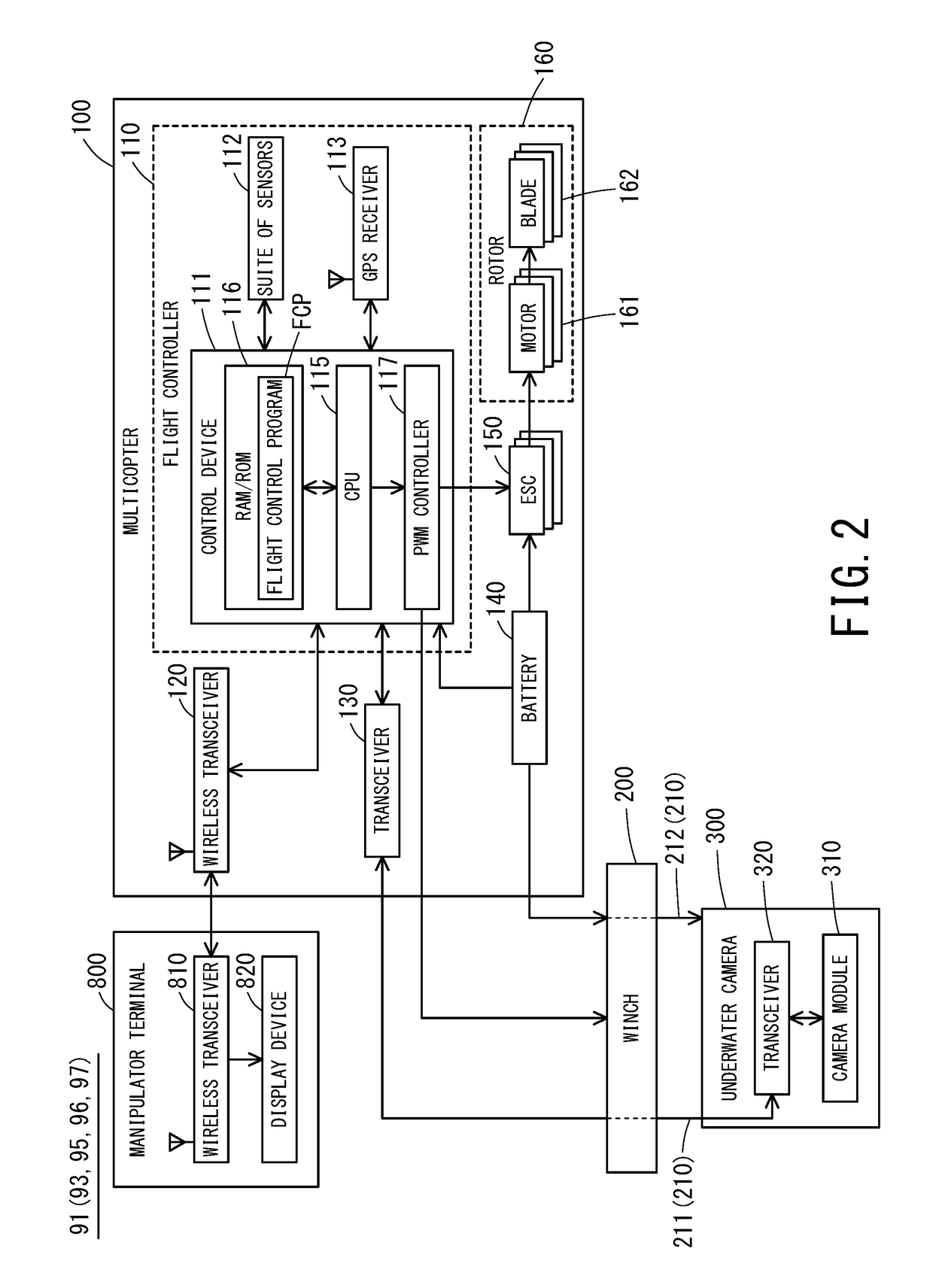

Underwater image capturing apparatus

ActiveUS20180284575A1Flexible and convenient controlControl directionAircraft componentsUnmanned aerial vehiclesWinding machineMarine engineering

To make it possible to control an image capturing position and its direction in water easily and flexibly through the use of a miniature unmanned aerial vehicle equipped with a plurality of rotors. This is solved by an underwater image capturing apparatus including a miniature unmanned aerial vehicle equipped with a plurality of rotors, a winding machine capable of delivering and winding a string-like member, and an underwater camera capable of capturing images in water, wherein the winding machine is fixed to the miniature unmanned aerial vehicle and the string-like member is connected to the underwater camera.

Owner:PRODRONE CO LTD

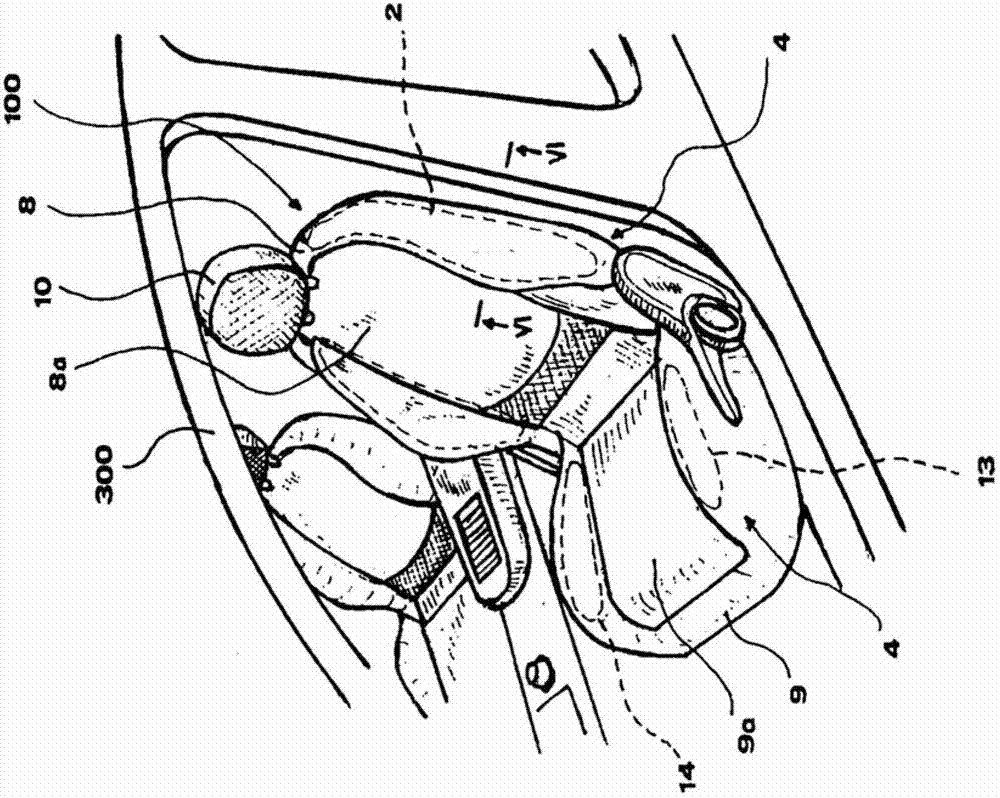

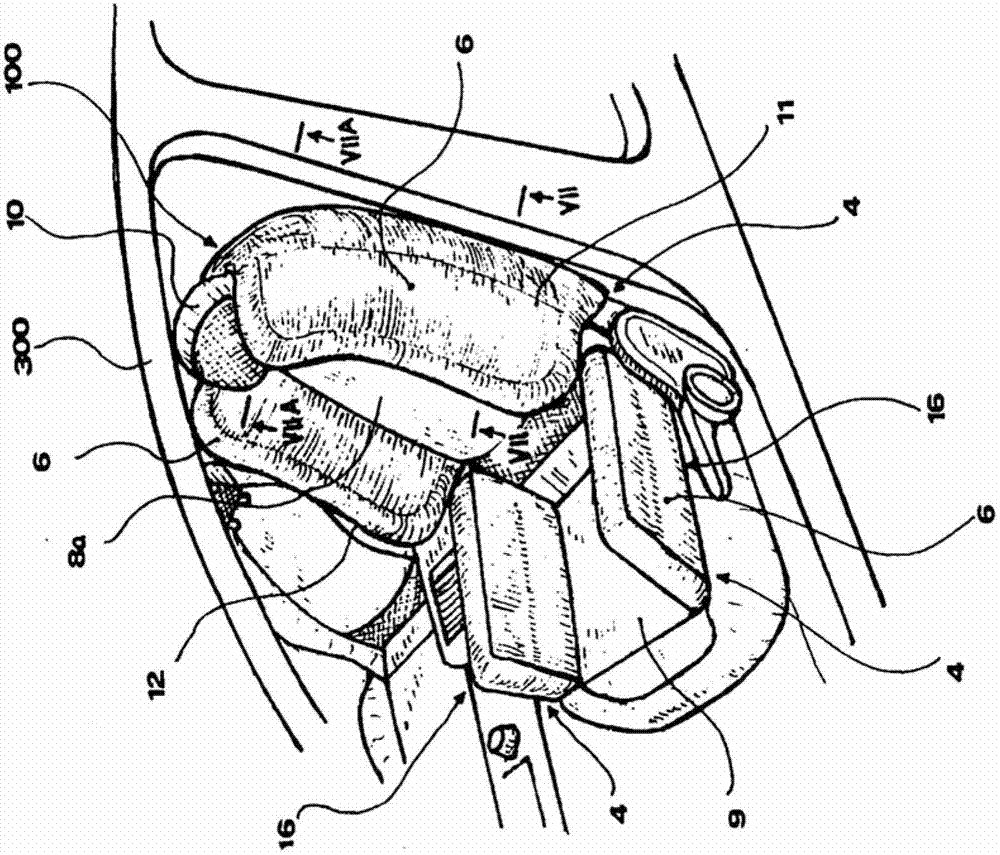

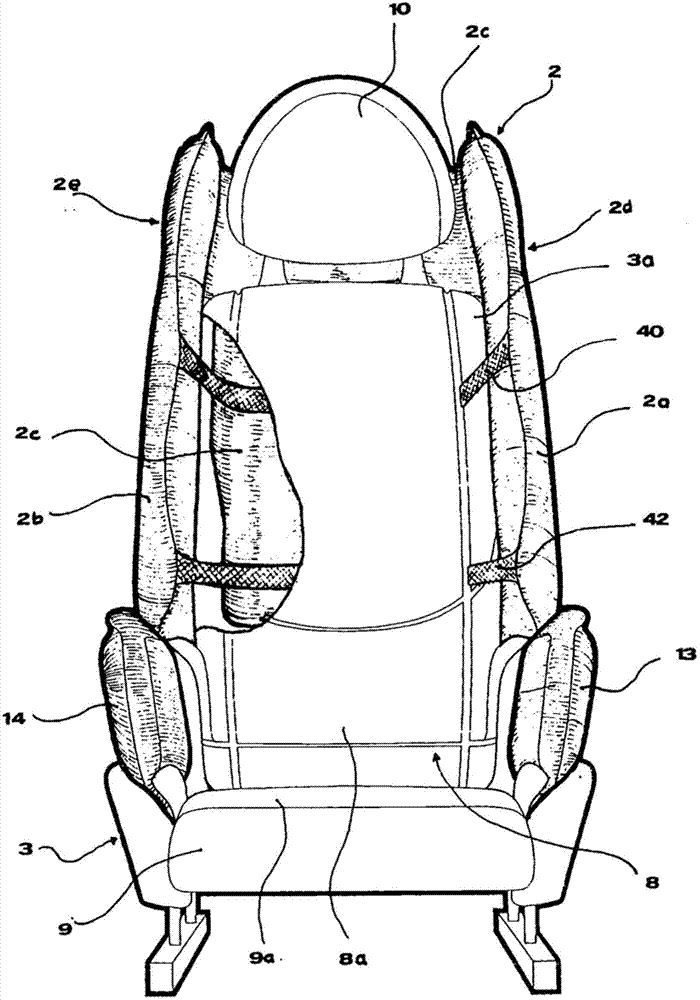

A covering assembly for a seat and seat adapted for protecting a user

ActiveCN102822015APrevent exitAvoid sharpVehicle seatsPedestrian/occupant safety arrangementBraced frameEngineering

A covering assembly for a seat, including a cover adapted to cover a support frame of the seat and an inflatable member adapted to assume a resting deflated condition and an active inflated condition is described. The inflatable member is located on a side of the cover intended to be faced towards the support frame. The cover is adapted to contain the inflatable member both in the deflated condition and in the inflated condition.

Owner:DAINESE

Impact test device

The invention discloses an impact test device. The impact test device comprises a protecting-limiting device, wherein the protecting-limiting device is arranged outside a test piece and comprises a protecting framework and a limiting device, the protecting framework is formed by welding steel rods, and the limiting device is fixed in the protecting framework; and the limiting device comprises a first memory metal, a second memory metal, a third memory metal and a fourth memory metal which are sequentially fixedly connected, electromagnets are arranged at joints among the four memory metals. The safety of a test operator can be protected by virtue of the protecting device, and the falling position of a drop hammer can be effectively controlled by virtue of the limiting device, so that the secondary or repeated impact caused by the drop hammer to the test piece is avoided, and the accuracy of the test is increased; and furthermore, by virtue of a specific rest function of the memory metals, the damage caused by the impact force of the drop hammer to the protecting device can be reduced, the uncertainty in the test can be reduced, and the test precision is increased.

Owner:CHANGAN UNIV

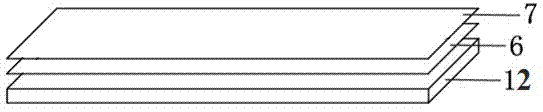

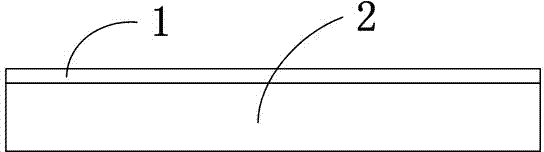

Aluminum substrate used for packaging LED (Light Emitting Diode)

InactiveCN102779922AHigh temperature resistantImprove adhesionSemiconductor devicesEpoxyAluminum substrate

The invention relates to an aluminum substrate used for packaging an LED (Light Emitting Diode). The aluminum substrate comprises a common aluminium plate and a mirror plane plate which are laminated under high temperature. Through holes used for mounting LEDs are evenly arranged on the common aluminium plate which comprises, from top to bottom, a line layer, an insulated layer and a substrate. The insulated layer is made of epoxy resin, and alumina, carborundum, silicon dioxide and aluminum nitride which are nanoscale additives; the average particle size of the nanoscale additives is 40nm; and the purity of the nanoscale additives is above 99%. By adopting the aluminum substrate, a single chip or a plurality of chips can be packaged without being notched or polished and the substrate can be in any shape. The aluminum substrate has a flexible structure in application, is simple and practical, good in heat dissipation, simplified in process and high in light emitting efficiency.

Owner:HANGZHOU DIANZI UNIV

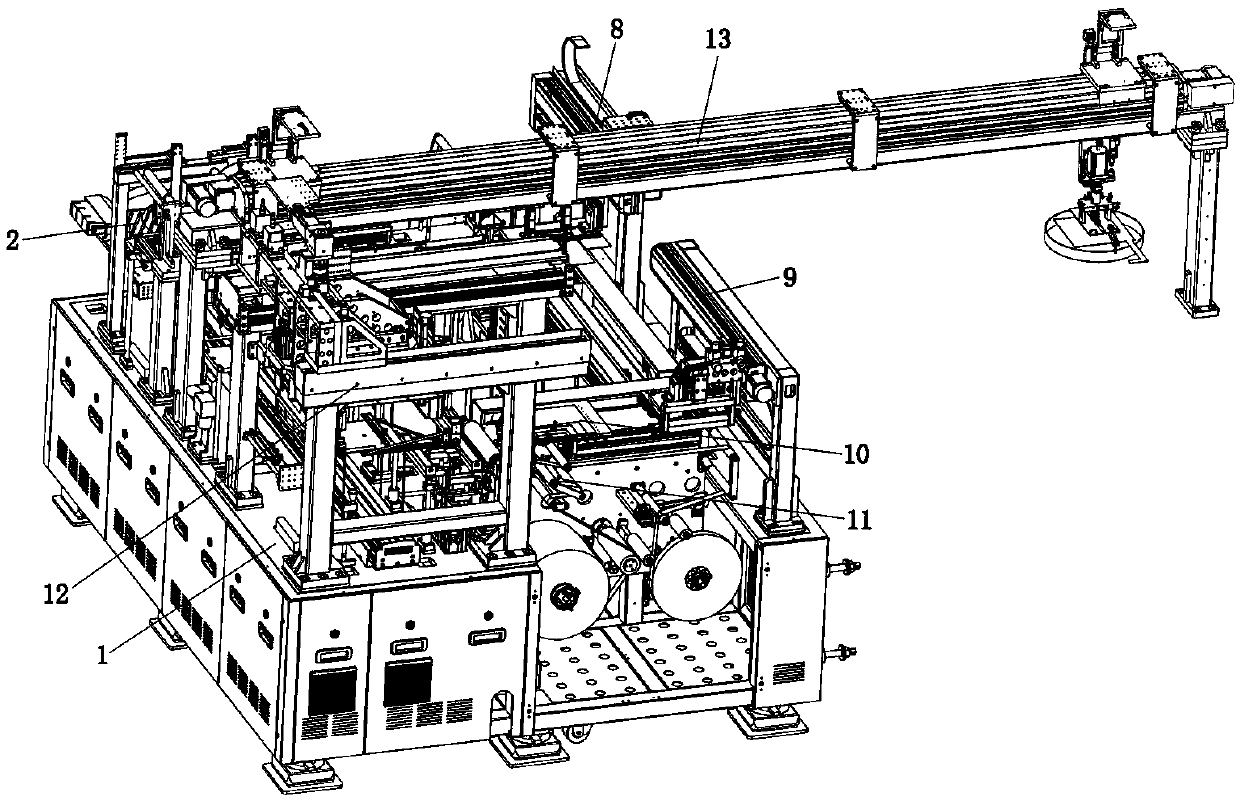

Automatic soft-to-soft flexible attaching machine and attaching process thereof

PendingCN109514969AControl tensionReduces fit bubblesLamination ancillary operationsLaminationArm movingEngineering

The invention discloses an automatic soft-to-soft flexible attaching machine and an attaching process thereof. The automatic soft-to-soft flexible attaching machine comprises an OLED adsorption and transfer platform, an OLED film tearing mechanism, a FILM feeding mechanism, a FILM transferring platform, a first carrying arm, a second carrying arm, a FILM tearing mechanism and an attaching mechanism. The OLED adsorption and transfer platform and the FILM transferring platform are horizontally arranged on a machine frame in the same direction at intervals, an OLED film is placed on the OLED adsorption and transfer platform, after initial positioning, the OLED film sequentially moves to the OLED film tearing mechanism and the attaching mechanism and the like to perform the film tearing action; and after a FILM is exported by the FILM feeding mechanism, the FILM is transported by the first carrying arm to the FILM transferring platform, the second carrying arm moves the FILM to the FILM tearing mechanism, the FILM tearing mechanism tears a film body at the bottom of the FILM, and the attaching mechanism attaches the FILM to the OLED film. The automatic soft-to-soft flexible attaching machine and the attaching process thereof solve the problems of bottom and surface film tearing of a flexible film, the adsorption stability during attaching and film tearing, the control over the angle change of the film or the film body during attaching and film tearing and the like.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

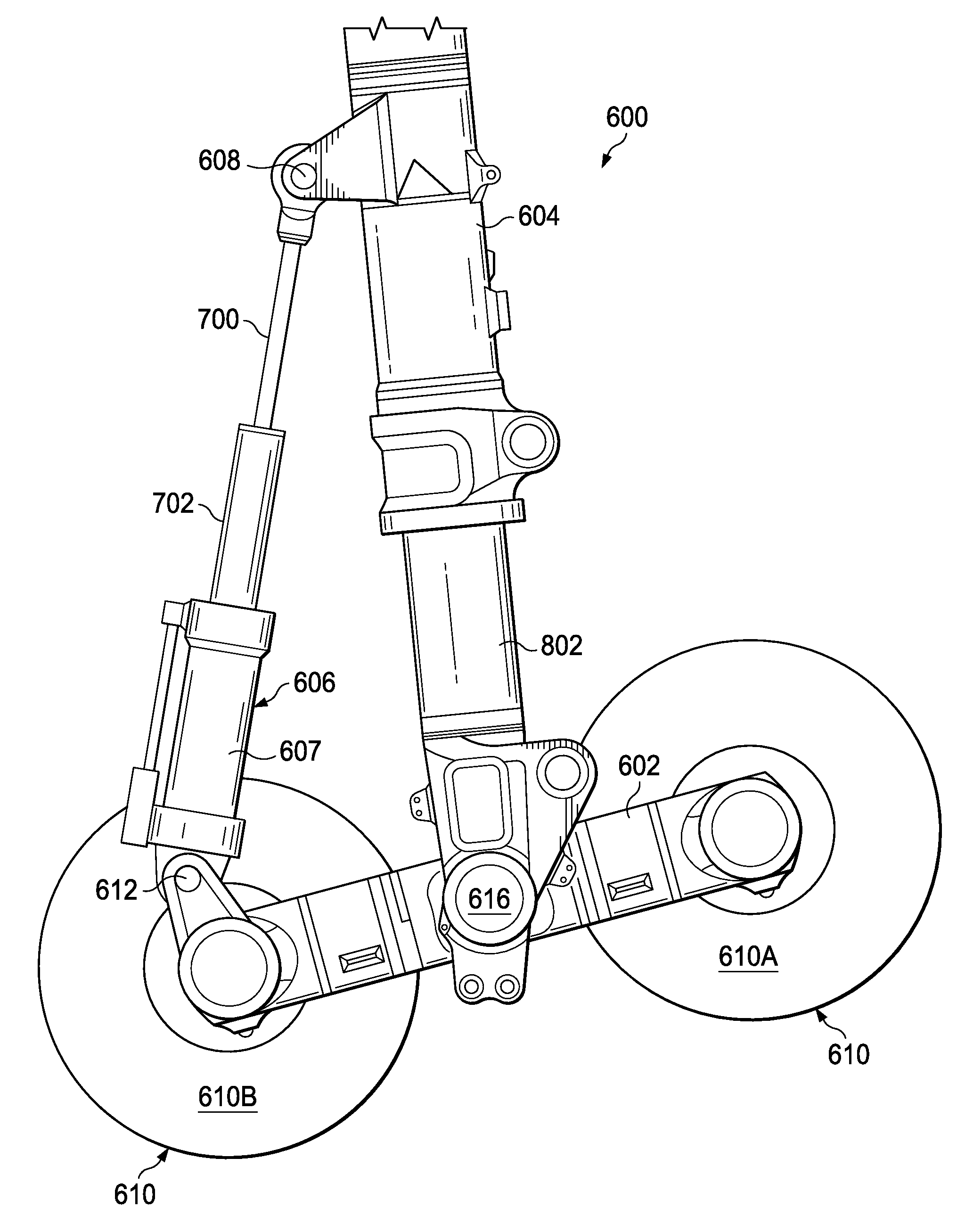

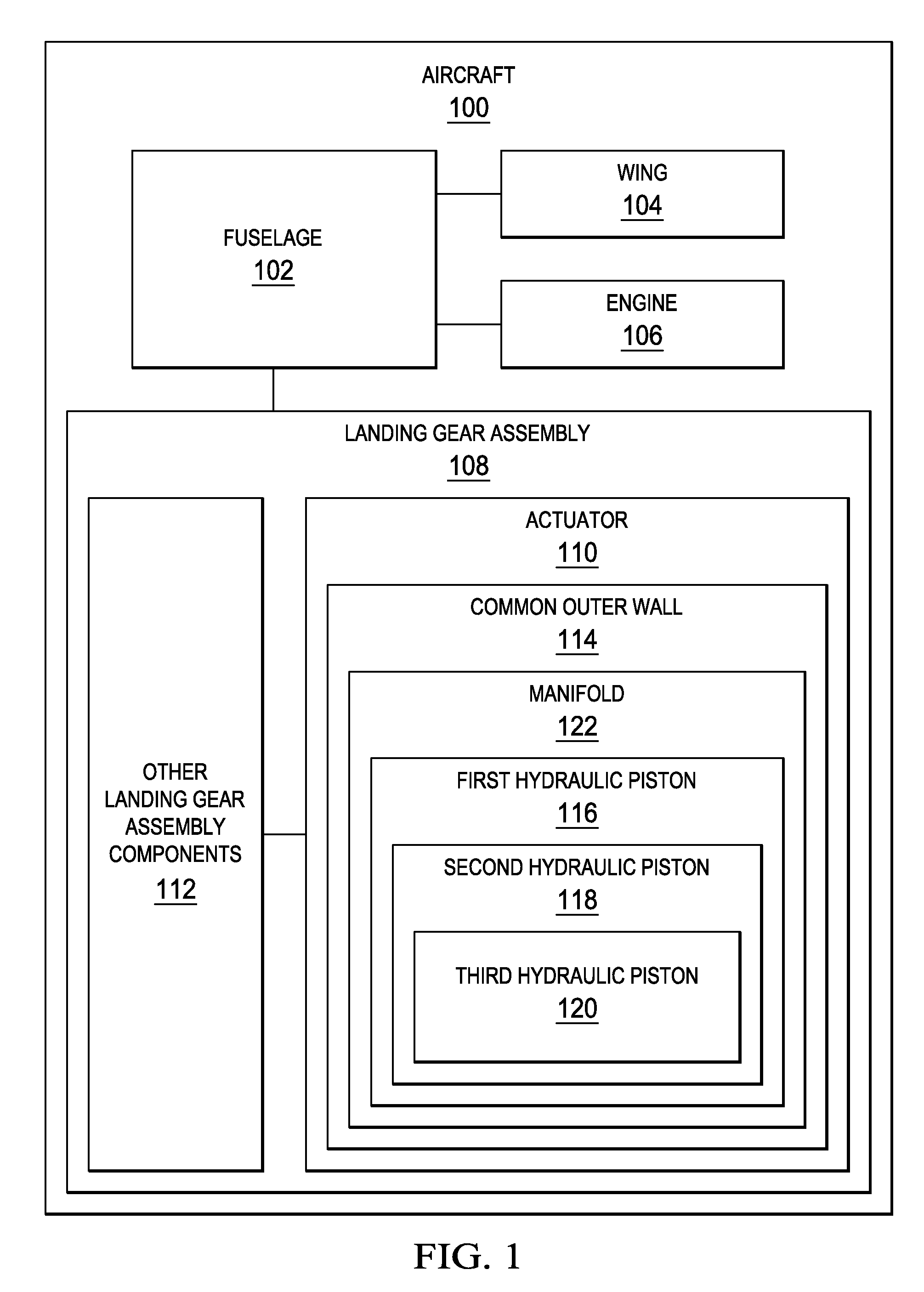

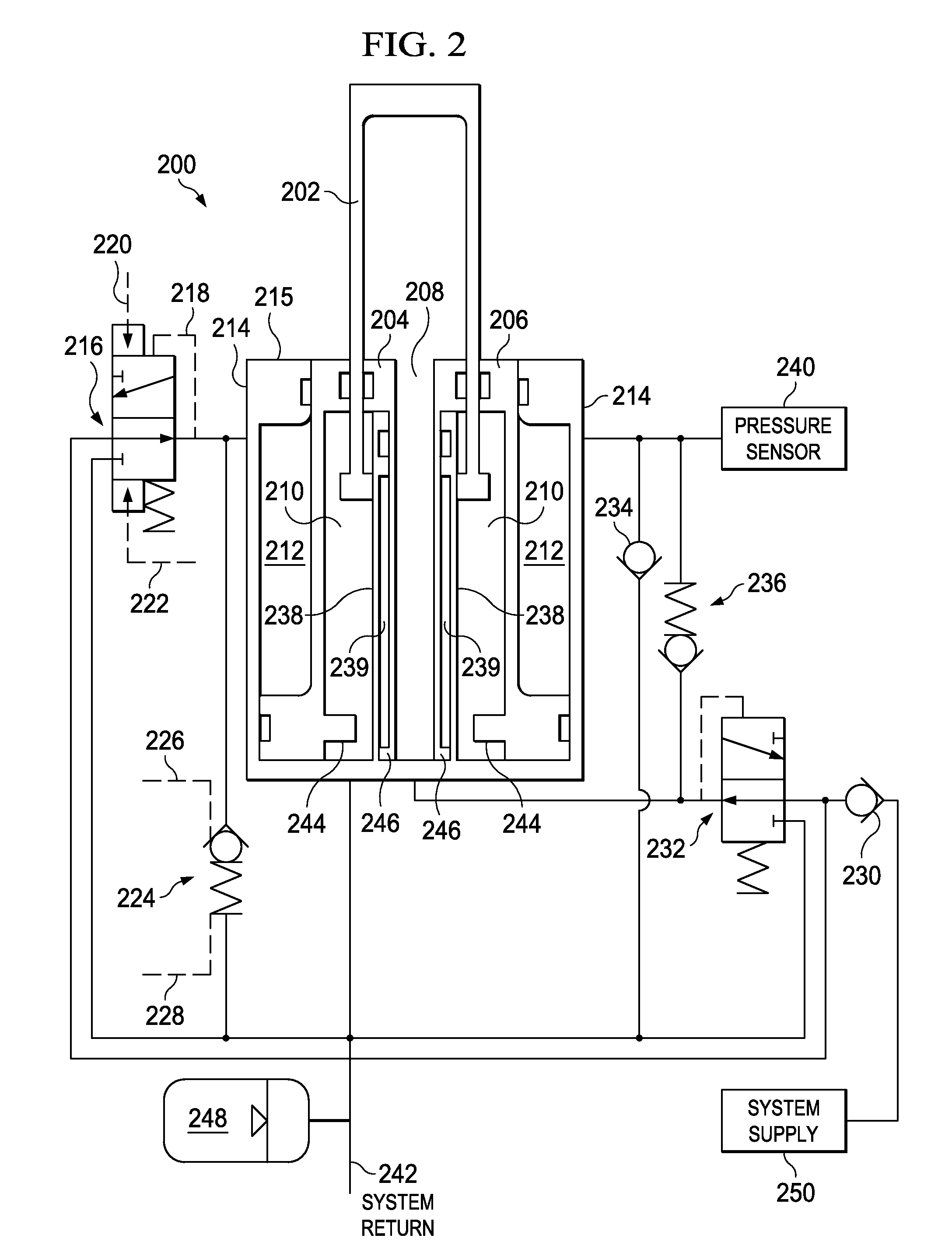

Hydraulic actuator for semi levered landing gear

A device including a first hydraulic piston, a second hydraulic piston disposed within the first hydraulic piston, and a third hydraulic piston disposed within both the first hydraulic piston and the second hydraulic piston. The first, second, and third hydraulic pistons are contained within a common outer wall. A manifold is connected to the first, second, and third hydraulic pistons. The manifold is disposed relative to the first, second, and third hydraulic pistons such that a fluid moving in the manifold can control positions of the first, second, and third hydraulic pistons.

Owner:THE BOEING CO

Sealant dispenser and control method thereof

ActiveUS20050269375A1Improve response speedControl amountLarge containersPretreated surfacesRelative motionSealant

Disclosed is a sealant dispenser for more precisely dispensing a sealant onto a substrate, and a control method thereof. The sealant dispenser includes a stage on which a substrate is mounted; a nozzle for dispensing a sealant while making a relative motion with the substrate; a syringe coupled to the nozzle, for storing the sealant; and a distance sensor installed on both sides of a lower portion of the syringe, for measuring a vertical distance between a principal plane of the substrate and an outlet of the nozzle. According to the principles of the present invention, because the nozzle and the syringe have substantially the same central axis, the response speed of the sealant to be dispensed is increased and the start point and the end point of paste pattern are more precisely dispensed. Also, by minimizing the distance between the nozzle and a measuring point provided by the distance sensor, it becomes possible to dispense the sealant at higher precision.

Owner:TOP ENG CO LTD

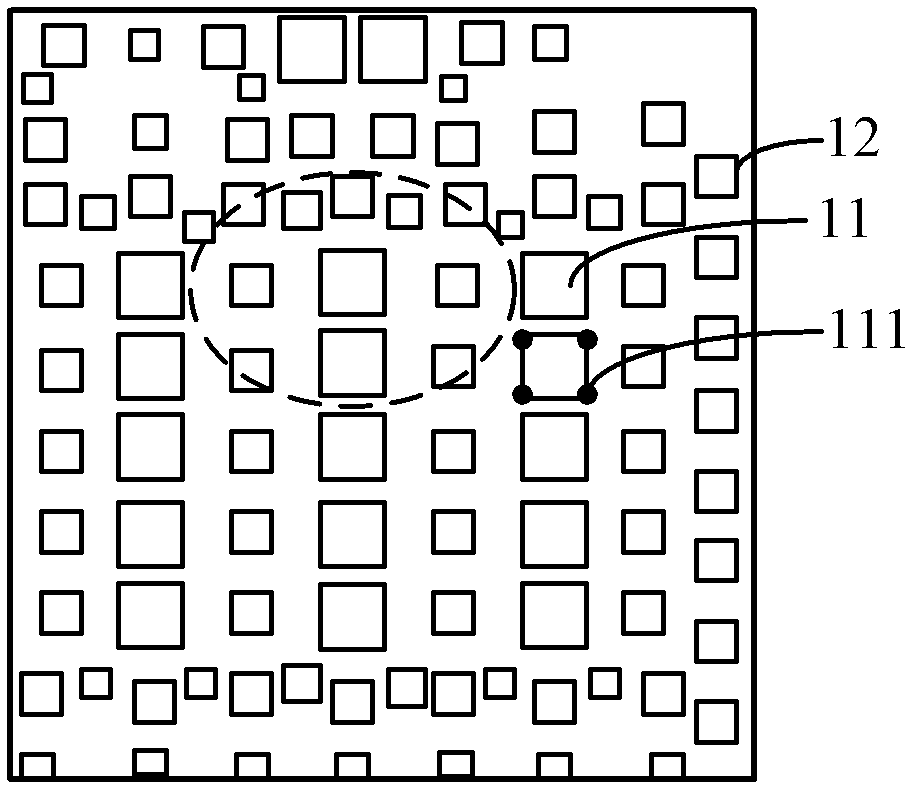

Pixel definition layer and preparation method and application thereof

InactiveCN107403823AHigh hardnessImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingRare-earth elementSilicon oxide

The invention relates to a pixel definition layer and a preparation method and an application thereof. The pixel definition layer comprises a first pixel definition layer and a second pixel definition layer stacked on the first pixel definition layer; the first pixel definition layer is prepared from at least one kind of the materials of unitary or multi-element metal oxide of non-rare-earth elements, unitary or multi-element metal nitride of non-rare-earth elements, unitary or multi-element metal sulfide of non-rare-earth elements, silicon carbide, silicon oxide, silicon nitride or silicon oxynitride; and the second pixel definition layer is prepared from at least one kind of rare earth oxide. By virtue of the pixel definition layer, the problem existing when PI is adopted as a bank layer can be avoided; and the pixel definition layer disclosed in the invention has the bank layer with a clear and definite hydrophilic and hydrophobic boundary line, so that it is ensured thin films with the same height and same uniformity can be obtained by ink of the same volume in different pixels.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

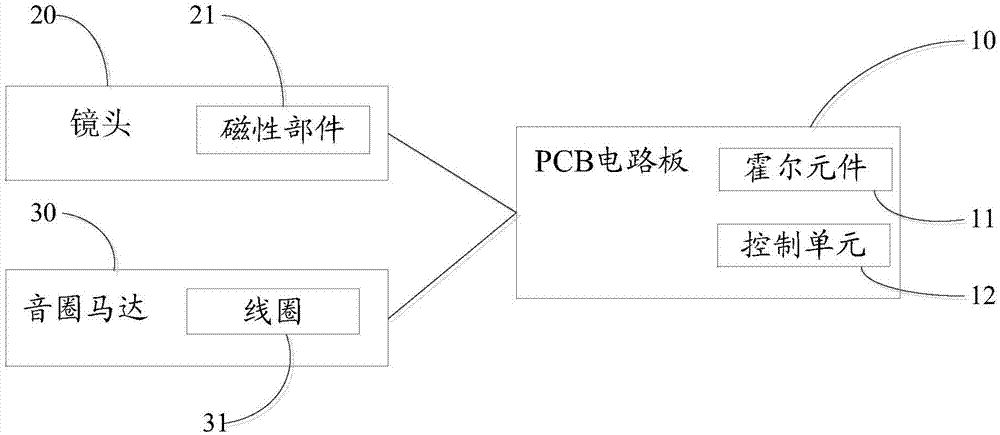

Camera module and electronic device

InactiveCN107197124AReduce manufacturing costSimple processing technologyTelevision system detailsColor television detailsDriving currentPower flow

The invention discloses a camera module, which comprises a PCB and a hall element arranged on the PCB, wherein the hall element is connected with a control unit arranged on the PCB and sensing current is outputted according to the sensed position of a magnetic part arranged on a lens; according to the sensing current, the control unit controls driving current outputted to the coil of a voice coil motor, and the position of the lens is controlled. Besides, the invention also discloses an electronic device. The electronic device comprises the above camera module. According to the camera module and the electronic device, through arranging the hall element on the PCB and being connected with the control unit, as the hall element is not arranged inside the voice coil motor independently, connection with the control unit through a lead is only needed, the voice coil motor processing process becomes simple, the yield improvement is improved, and the manufacturing cost of the camera module and the manufacturing cost of the electronic device are reduced.

Owner:TRULY OPTO ELECTRONICS

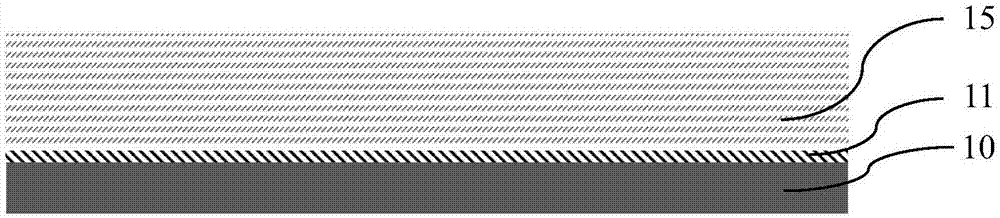

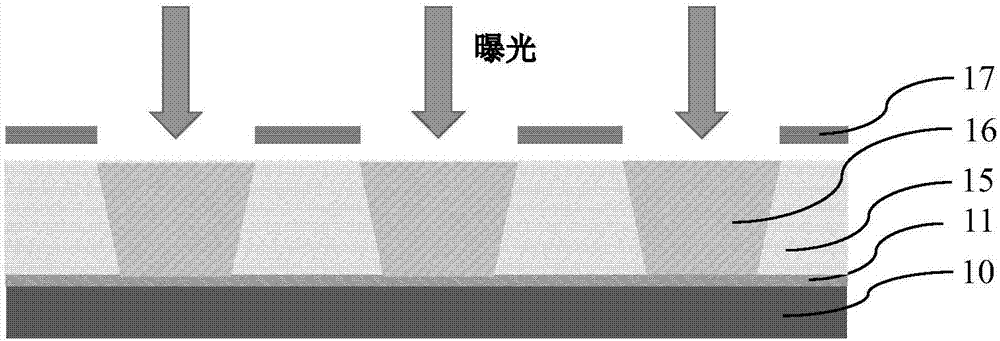

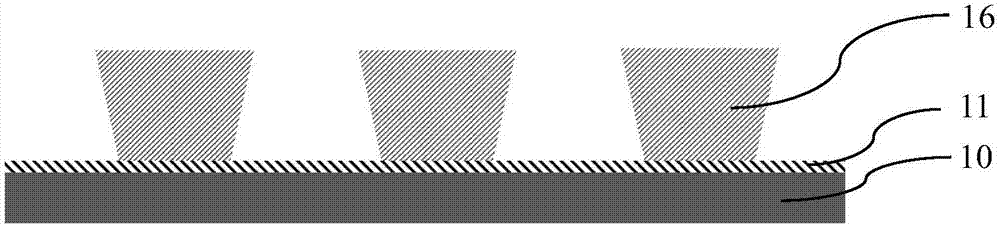

Making method for low-temperature multi-crystal silicon film

InactiveCN101236898ABig sizeUniform performanceSemiconductor/solid-state device manufacturingSeed crystalLow-temperature polycrystalline silicon

The invention provides a manufacturing method for a low temperature polycrystalline silicon thin film, which includes the following steps that: a substrate is provided, and a buffer layer is formed on the substrate; a first amorphous silicon thin film is deposited on the buffer layer; the first amorphous silicon thin film is etched by the lithography / etching process, and a plurality of scattered amorphous silicon particles are kept on the buffer layer; a second amorphous silicon thin film which covers the amorphous silicon particles is deposited on the buffer layer; a recrystallization process is applied to the second amorphous silicon thin film, which makes the second amorphous silicon thin film recrystallized by taking the plurality of amorphous silicon particles as crystal seeds after the second amorphous silicon thin film is melted, forming the polycrystalline silicon thin film.

Owner:INNOCOM TECH SHENZHEN +1

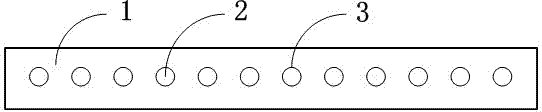

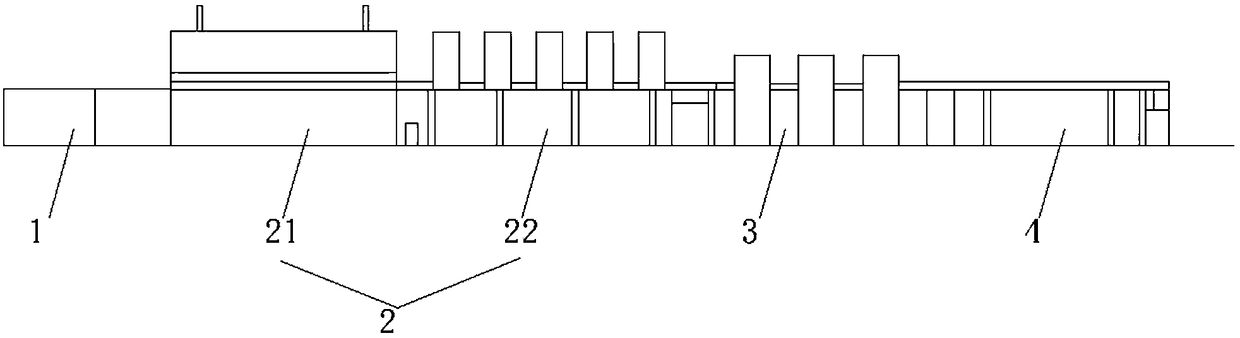

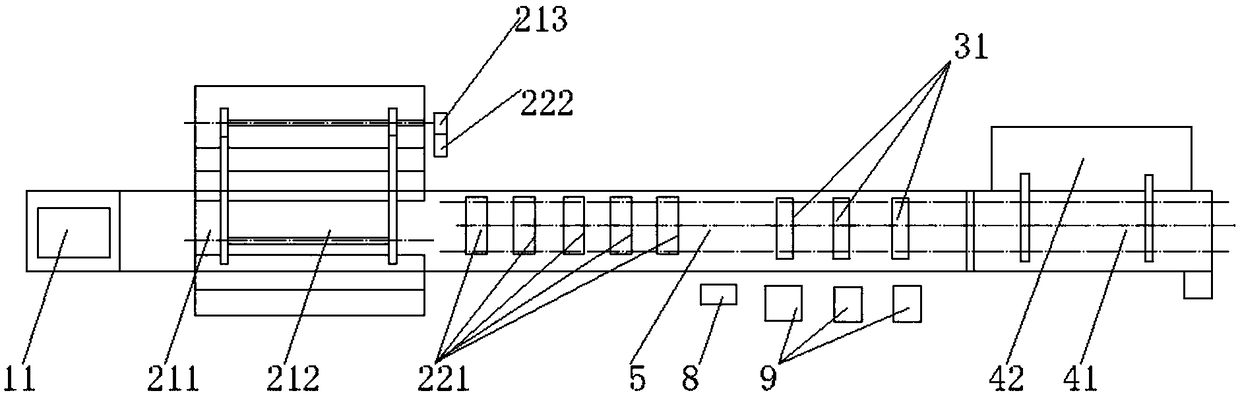

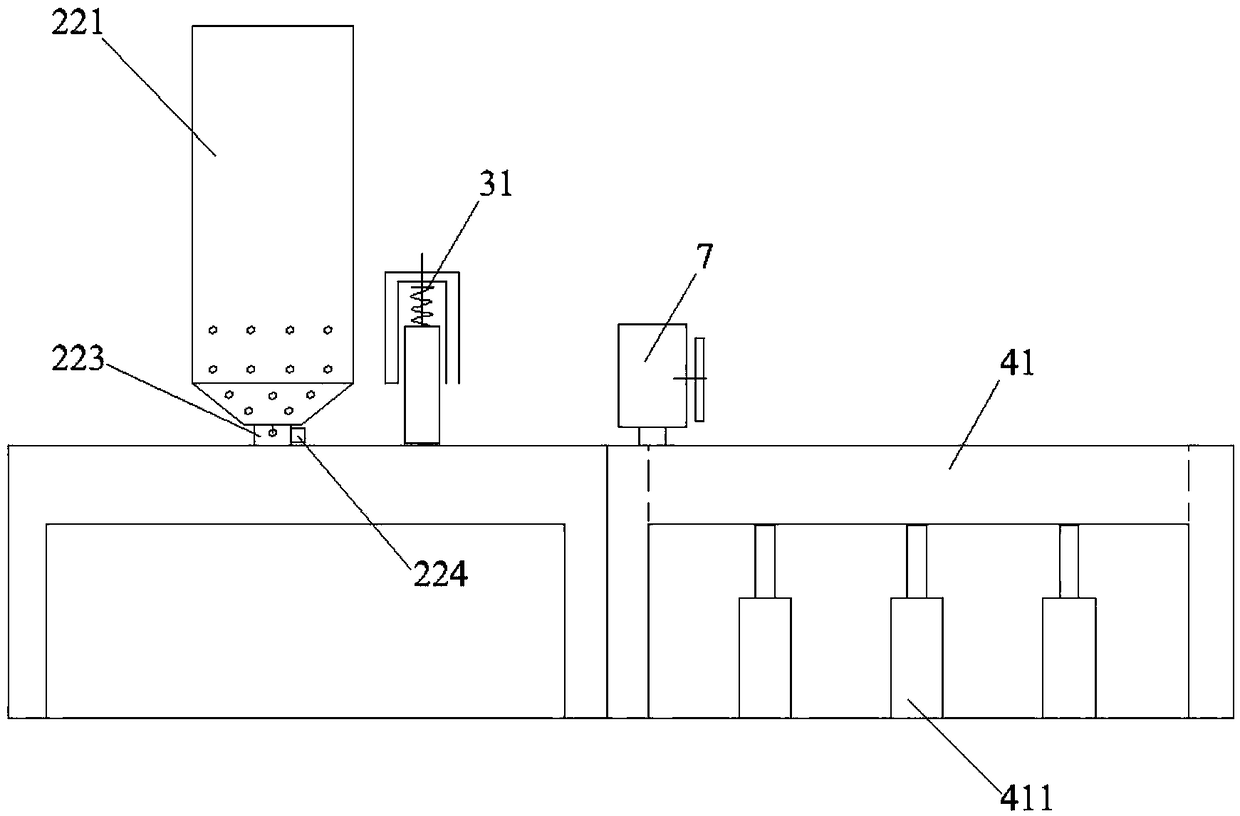

Automatic production line of rebar ladder

PendingCN108145295AControl timeControl positionOther manufacturing equipments/toolsResistance welding apparatusProduction lineEngineering

The invention discloses an automatic production line of a rebar ladder. The automatic production line comprises a straightening area, a rebar distributing area, a welding area and a finished product area which are sequentially arranged according to a production process, and materials are transported among the areas through a conveying line. The straightening area straightens long rebars through adrawing straightening machine and transports the long rebars to the rebar distributing area through the conveying line. The rebar distributing area comprises a long rebar distributing area for placingthe multiple long rebars in parallel in the transporting direction of the conveying line and a short rebar distributing area for placing multiple short rebars at intervals in the length direction ofthe long rebars. The welding area comprises a welding device for welding the long rebars and the short rebars conveyed from the rebar distributing areas to form the rebar ladder. The finished productarea comprises a turnover unloading mechanism for unloading the rebar ladder conveyed from the welding area and a finished product bin for storing the rebar ladder unloaded by the turnover unloading mechanism. The automatic production line of the rebar ladder is high in automation degree and good in stability, production efficiency and production capacity are effectively improved, the product quality is stable, and the finished product rate of products is increased.

Owner:内蒙古上海庙矿业有限责任公司

Fixing frame used for automotive brake disc processing

ActiveCN109227189AFixed firmlyConvenient processing workPositioning apparatusMetal-working holdersEngineeringBrake pad

The invention discloses a fixing frame used for automobile brake disc processing. The frame includes a fixed base, a first motor, a screw rod, a gear structure and a fixing component. The upper end ofthe fixed base is provided with a rotating base, and the middle of the upper end of the rotating base is provided with the first motor. The middle of the lower end of the first motor is connected with a first rotating shaft, and the lower end of the first rotating shaft runs through the rotating base, and the lower end of the first rotating shaft is connected with the fixed base. Fixed pipes aresymmetrically arranged on the left and right sides of the upper end of the rotating base, and the inner sides of the fixed pipes are slidably connected with the lower parts of lifting rods, and secondmotors are arranged on the bottoms in the fixed pipes. The center of a brake disc is located through a central fixing shaft, an electromagnet is electrified, a fixing block moves towards the side edge of the brake disc to attract the side edge of the brake disc, the side edge of the brake disc is then fixed, this design can allow the fixing frame used for automobile brake disc processing to fix various brake blocks different in size, and fixation is firm.

Owner:广德亚太汽车智能制动系统有限公司

Continuous method of providing individual sheets from a continuous web

A method for separating a supply of material into distinct sections of material, while controlling the position and orientation of these distinct sections during further manipulation in a continuous process is disclosed. The method includes forming a line of weakness comprising perforations and scores extending substantially from the first edge to the second edge and applying a force substantially parallel to the length of the web sufficient to separate an individual sheet from the web at the line of weakness.

Owner:MCNEIL PPC INC

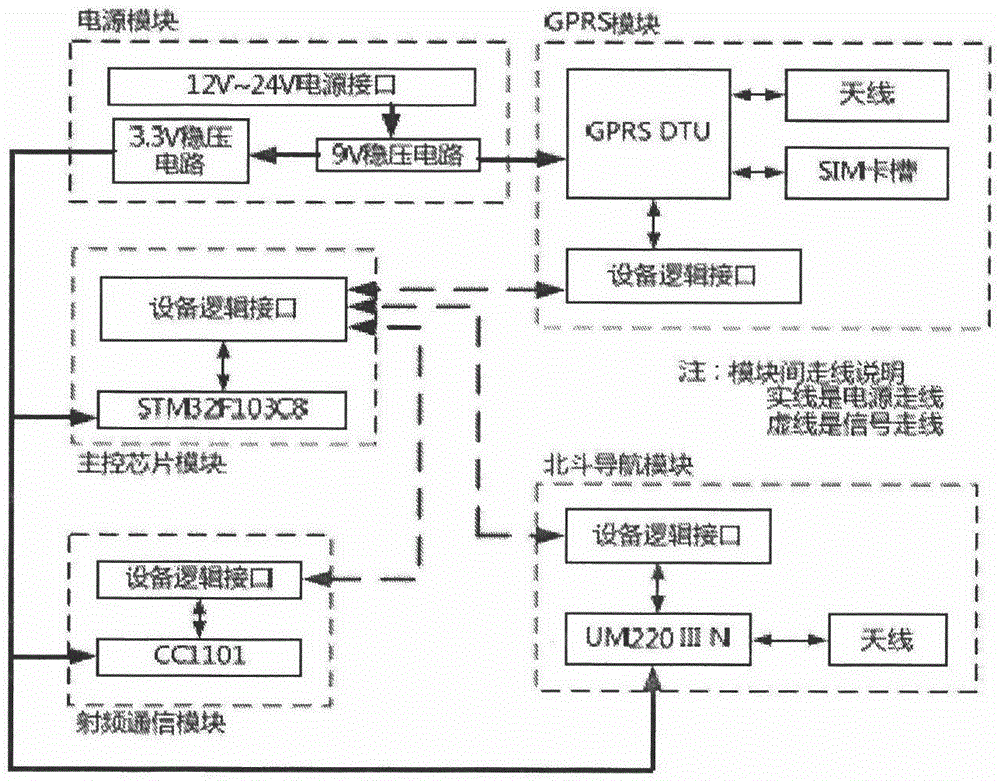

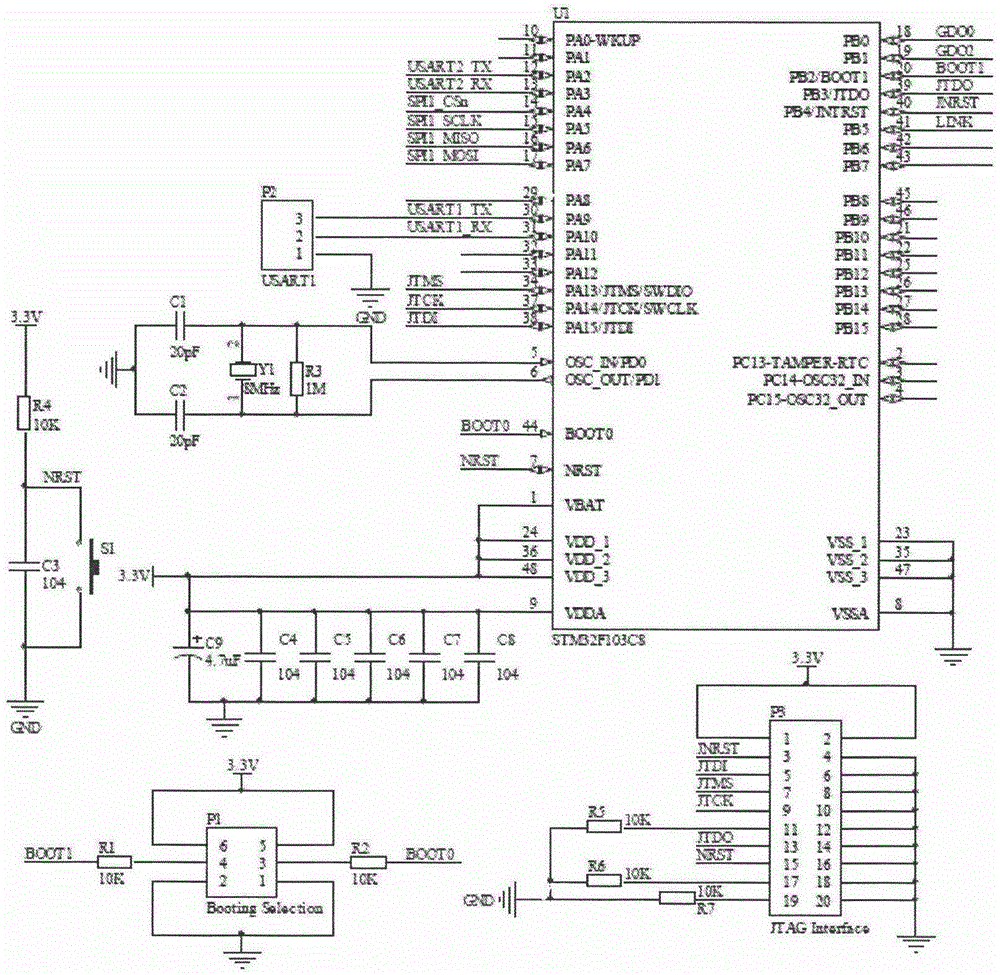

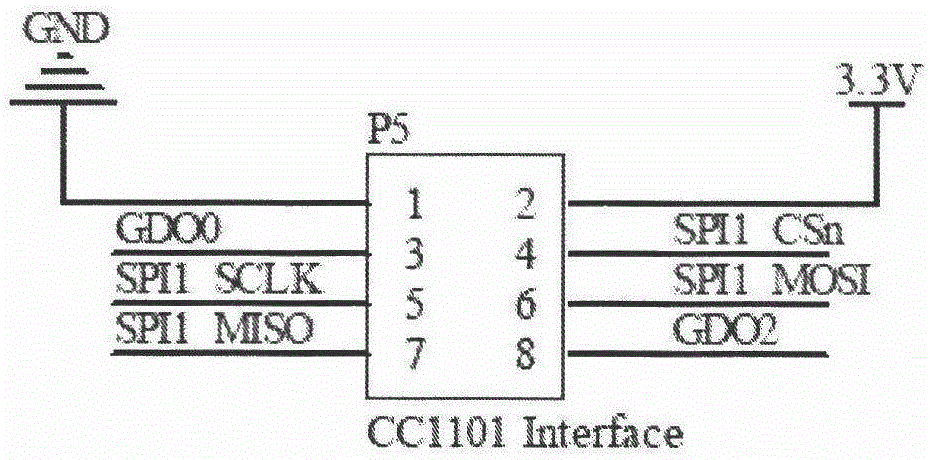

Beidou navigation-based refrigerator car intelligent monitoring cloud terminal device

InactiveCN105072585ALow costImprove securityWireless commuication servicesTransmissionSatelliteVoltage

The invention discloses a Beidou navigation-based refrigerator car intelligent monitoring cloud terminal device. The Beidou navigation-based refrigerator car intelligent monitoring cloud terminal device includes a main control module, a radio frequency communication module, a Beidou module, a GPRS module and a power source module, wherein the main control module is used for controlling the radio frequency communication module to receive monitoring node data of a refrigeration carriage and controlling the Beidou module to receive satellite signals, and performing positioning and speed control on a refrigerator car through data analysis and processing, the Beidou module is used for receiving the satellite signals, the GPRS module transmits data information processed by the main control module to a cloud platform, and the power source module provides matched voltage for the main control module, the Beidou module and the GPRS module respectively. The Beidou navigation-based refrigerator car intelligent monitoring cloud terminal device of the invention is a refrigerator car monitoring device integrated with wireless sensing network technologies, Beidou positioning technologies, radio frequency communication technologies and embedded technologies, and can monitor and control the position, operating speed and temperature of the carriage of the refrigerator car in real time, and can assist in reducing the transportation cost of the car and enhancing the safety of transportation.

Owner:扬州苏安物联传感科技有限公司

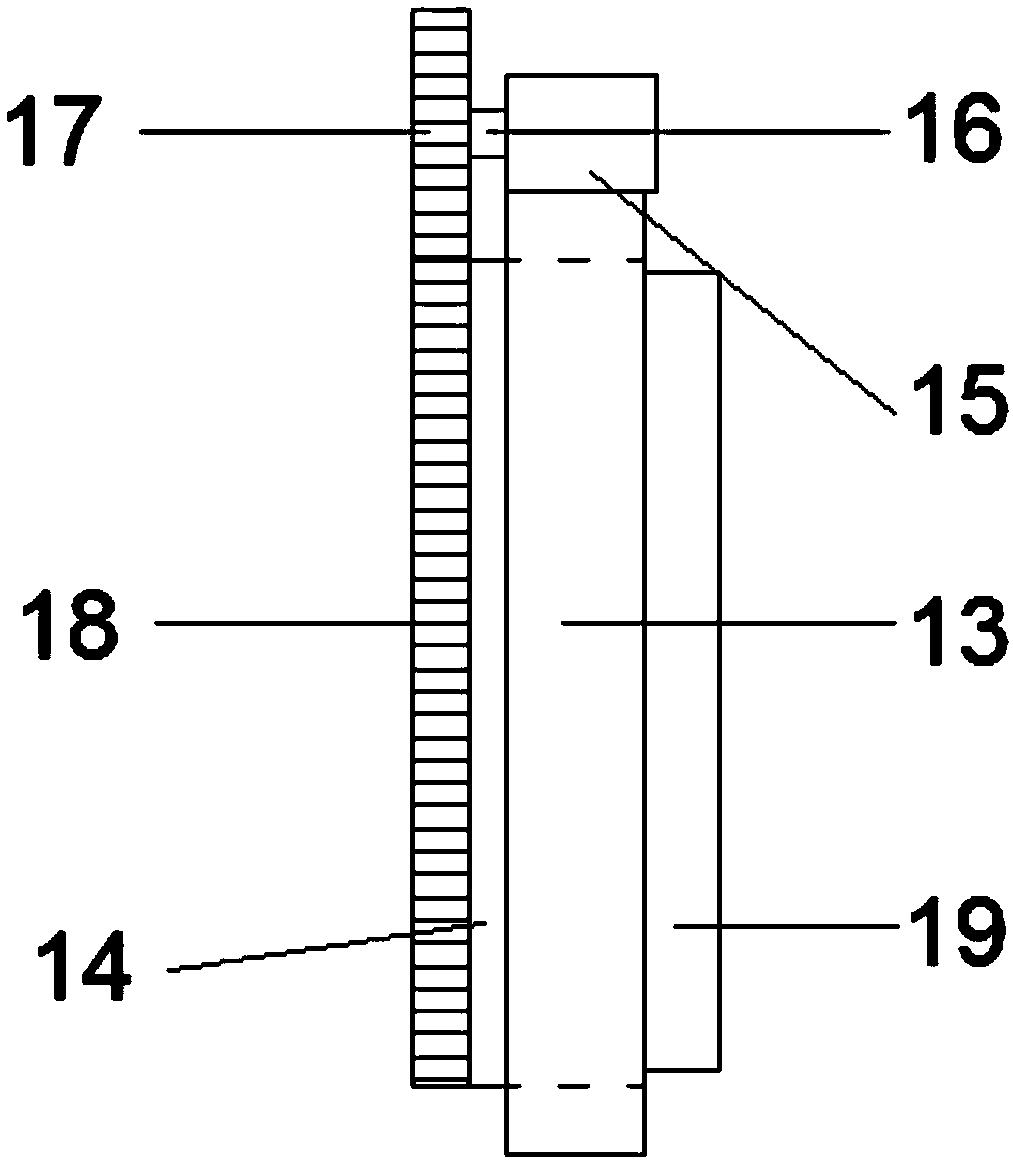

Bending characteristic measurement device for high-temperature superconducting tape

InactiveCN102520017AAllowable bending characteristicsHigh precisionMaterial analysis by electric/magnetic meansMeasurement deviceHigh temperature superconducting

The invention relates to a bending characteristic measurement device for a high-temperature superconducting tape. The bending characteristic measurement device comprises a high-temperature superconducting tape measurement current providing part, a high-temperature superconducting tap bending radius providing part, a high-temperature superconducting tape voltage measurement part, a liquid nitrogenvessel and a controller, wherein the controller is used for controlling operations of the high-temperature superconducting tape measurement current providing part, the high-temperature superconducting tape bending radius providing part and the high-temperature superconducting tape voltage measurement part so as to obtain the bending characteristic of the high-temperature superconducting tape. According to the measurement device, the high-temperature superconducting tape bending radius providing part comprises a stepless bending radius providing part, and a measured high-temperature superconducting tape is kept to be attached to the outer surface of the stepless bending radius providing part in a measuring process, so that a continuously changing bending radius in a preset bending radius range can be acquired to the measured high-temperature superconducting tape when the stepless bending radius providing part moves. According to the bending characteristic measurement device provided bythe invention, the bending characteristic of the high-temperature superconducting tape can be measured in high accuracy.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Layout graph correction method

ActiveCN103105726AControl feature sizeControl shapeOriginals for photomechanical treatmentGraphicsFeature Dimension

The invention discloses a layout graph correction method. The method comprises the following steps of: carrying out first segmentation on each side of a provided layout graph; carrying out first optical proximity correction on the segmented sides, which are subjected to the first segmentation, to obtain a layout middle graph, wherein a predetermined error exists between an actual graph simulated by the layout middle graph and a target graph; carrying out second segmentation on each side of the layout middle graph; and carrying out second optical proximity correction on the segmented sides, which are subjected to the second segmentation, to obtain a layout corrected graph. According to the technical scheme, the feature size, the shape and the position of the actually formed graph are easy to control.

Owner:SEMICON MFG INT (SHANGHAI) CORP

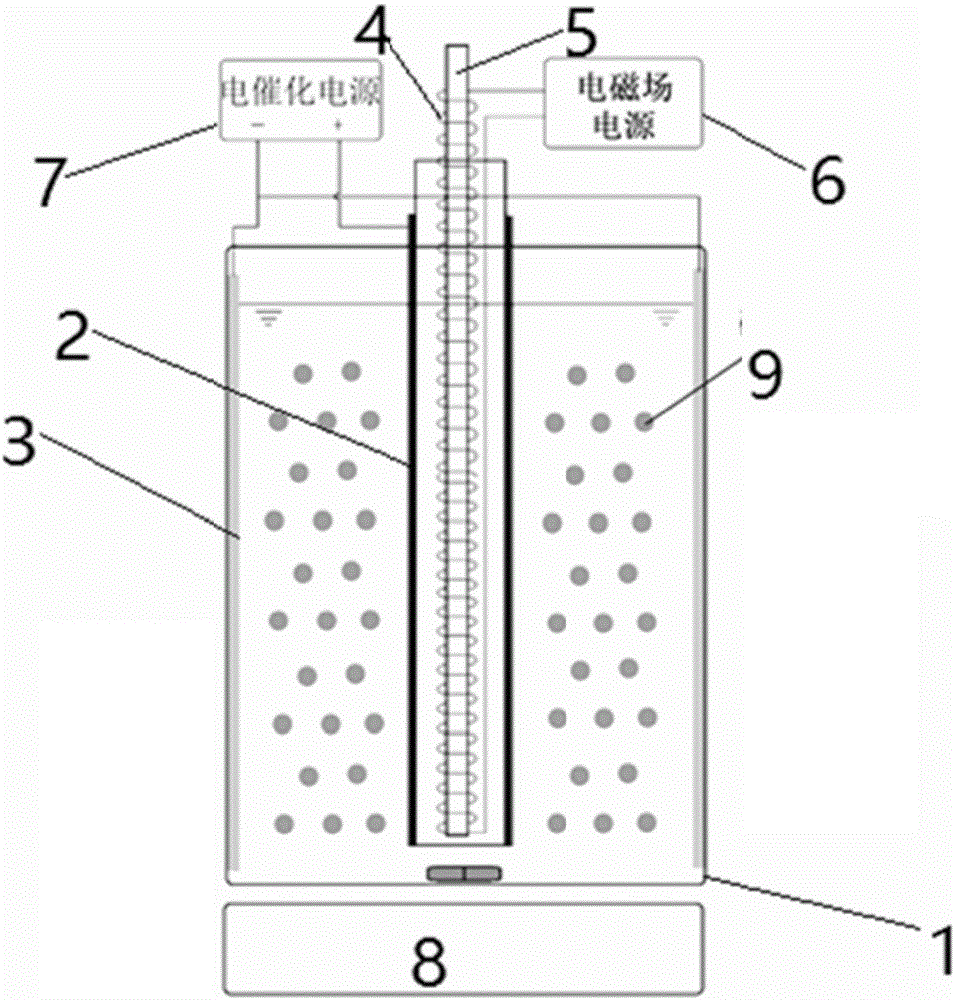

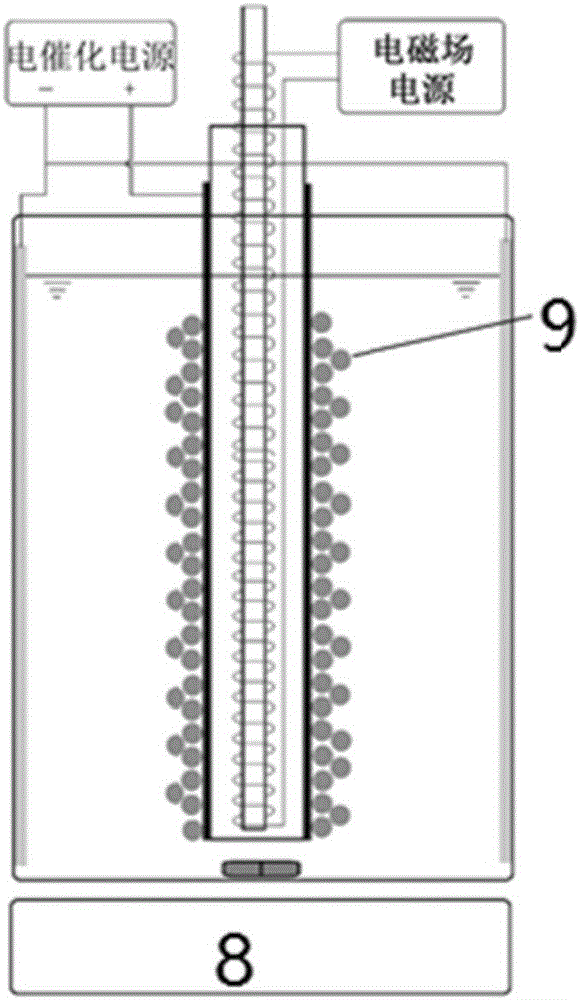

In-situ adsorption and electrocatalysis coupled organic wastewater treatment system and method

ActiveCN106430796AFacilitate desorptionPromote regenerationWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentElectrical conductorSorbent

The invention discloses an in-situ adsorption and electrocatalysis coupled organic wastewater treatment system, comprising an electrolytic cell, an electrocatalytic anode and an electrocatalytic cathode; the electrocatalytic anode is a hollow rod arranged in the center of the electrolytic cell, a wire wound conductor is placed in a cavity of the electrocatalytic anode, and two ends of the conductor are connected to an electromagnetic field power supply; the electrocatalytic anode and the electrocatalytic cathode are connected to a negative pole and positive pole of the electromagnetic field power supply; the electrocatalytic cathode is tubular in shape and arranged on the inner wall of the electrolytic cell and surrounds the electrocatalytic anode therein; a solution containing organic molecules to be treated is provided between the electrocatalytic anode and electrocatalytic cathode of the electrolytic cell, and the solution contains a plurality of magnetic adsorbent particles. By using the magnetic adsorbent particles with electromagnetic field control, the positions of the magnetic adsorbent particles in the solution can be controlled, mass transfer in electrocatalytic oxidation process is accelerated, the ability to enrich organics is improved, and the electrocatalytic degrading performance of the adsorbent is improved.

Owner:XI AN JIAOTONG UNIV

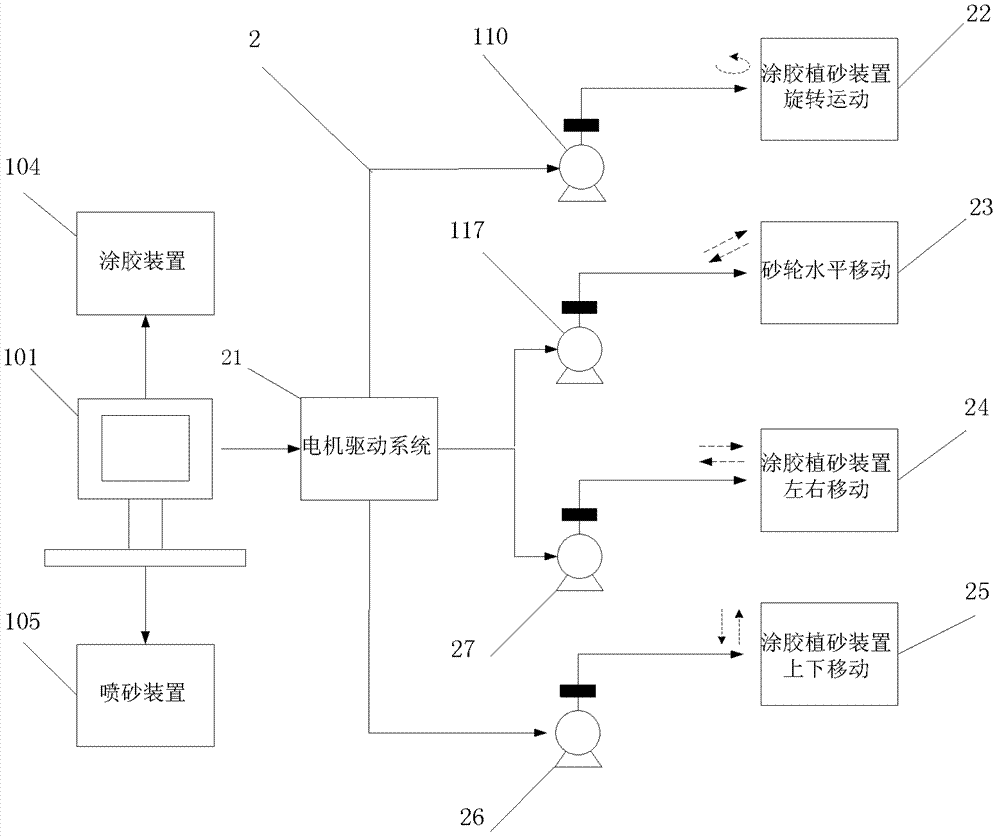

Device for manufacturing full-automatic soft fixed abrasive particle air pressure grinding wheel

The invention discloses a device for manufacturing a full-automatic soft fixed abrasive particle air pressure grinding wheel. The device comprises an abrasive particle solidifying platform for arranging an air pressure grinding wheel bracket and is supported by a four-corner bracket; rollers are arranged in the middle of the platform; the rollers form a rolling mechanism through an annular rubber belt, and the rolling mechanism is controlled by a servo motor to rotate; brackets are arranged on the left and right sides of the platform; guide rails are arranged on the inner sides of the brackets; a connecting rod is connected between the guide rails on two sides; the up-and-down movement of the connecting rod in the guide rails is driven by a second servo motor; a transverse guide rail is arranged on the connecting rod; a gluing device and an abrasive blasting device are both arranged on a semicircular guide rail of a connecting rack; a fourth servo motor drives the gluing device and the abrasive blasting device to move on the semicircular guide rail; the connecting rack is arranged on the transverse guide rail; a third servo motor drives the connecting rack to transversely move; the gluing device comprises a first solenoid valve and a hydraulic element; and the abrasive blasting device comprises a second solenoid valve and a pneumatic element.

Owner:浙江海宁经编产业园区开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com