Impact test device

A technology of impact test and limit device, which is used in measuring devices, instruments, scientific instruments, etc., can solve problems such as the influence of multiple impacts cannot be ignored, the impact results are not very accurate, and the lack of a drop weight limit device. The effect of reducing uncertainty, improving stability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

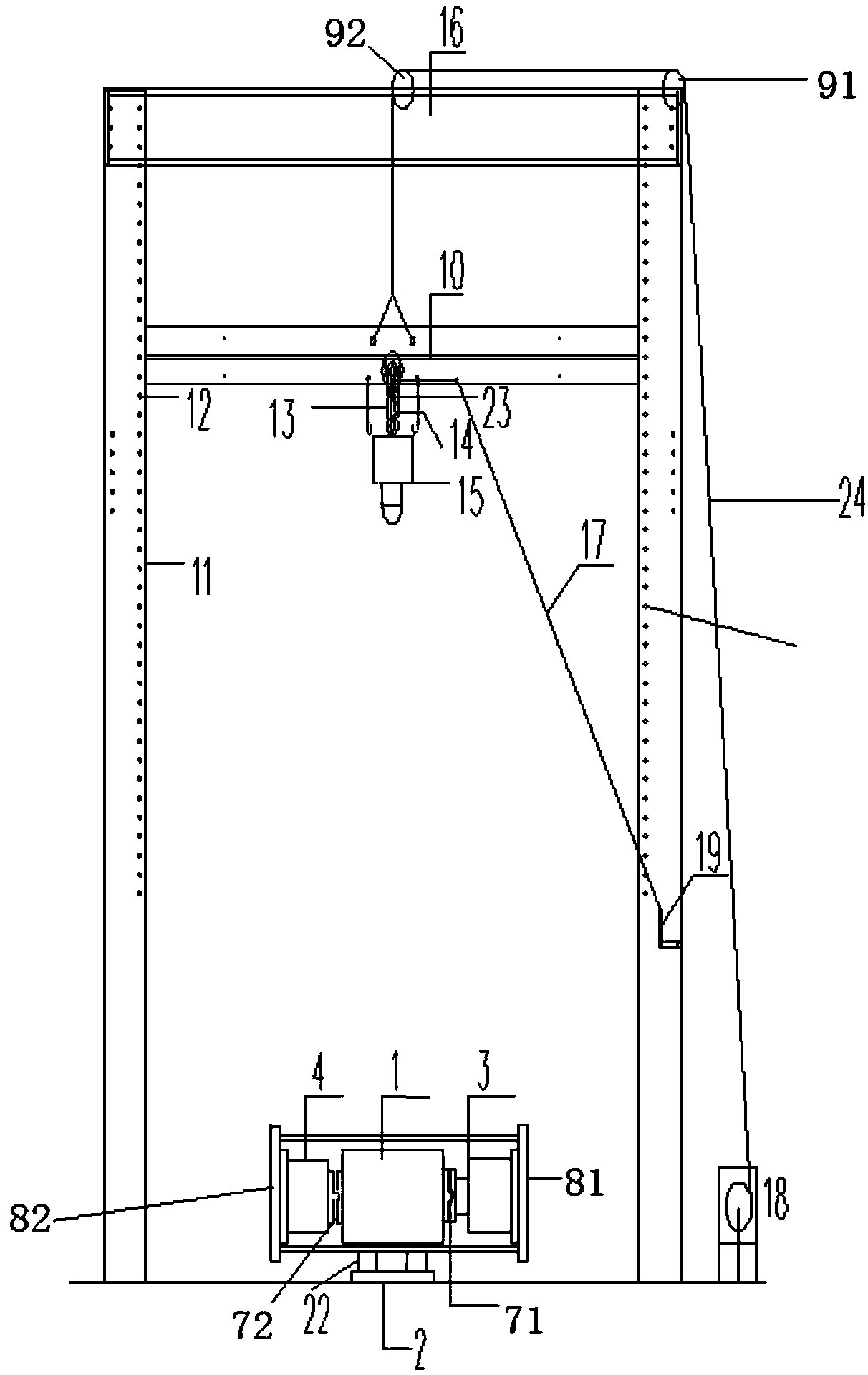

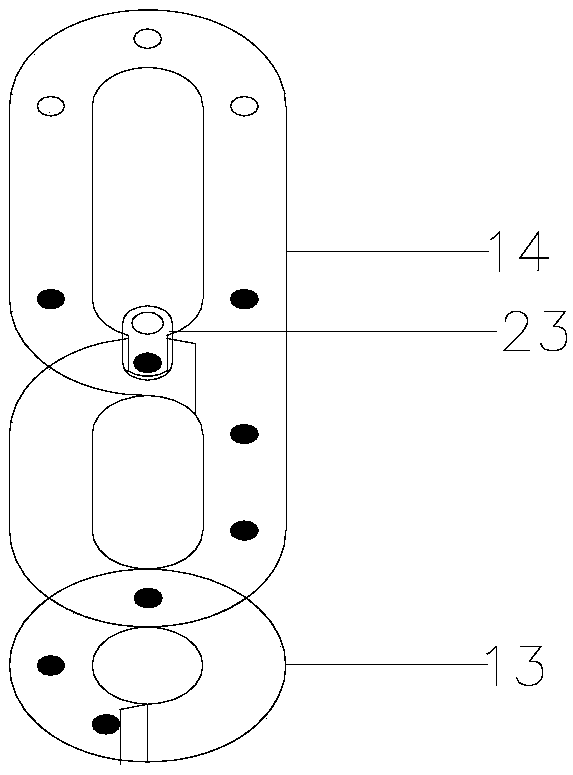

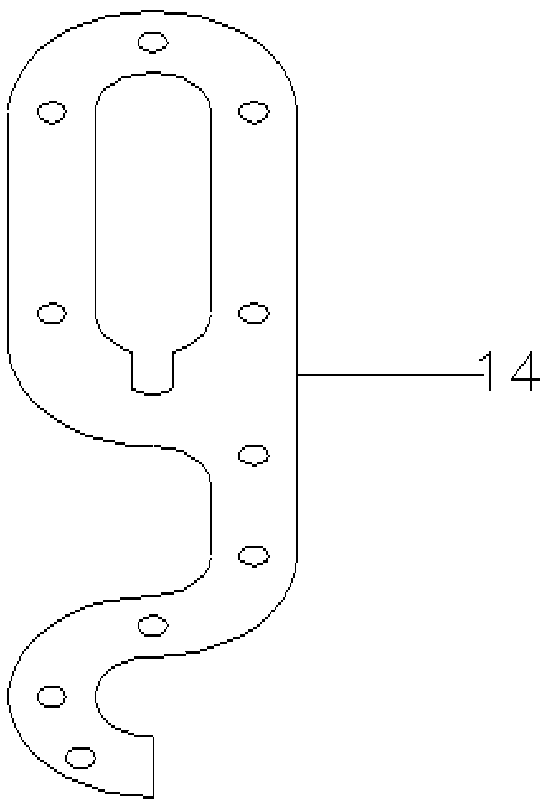

[0038] Follow the above technical solutions, refer to Figure 1 to Figure 10 , This embodiment provides an axial compression loading device and method for impact testing, which is used for research on impact loads under axial compression conditions.

[0039] refer to figure 1 , an impact test device includes a lifting device, a clamp control system, a pressurizing device, a base and a drop weight 15.

[0040] Wherein, the lifting device includes a column 11 , a movable beam 10 , a first shaft wheel 91 , a second shaft wheel 92 , a steel strand 24 , a winch 18 and a screw rod 12 .

[0041]Two columns 11 are arranged vertically, and fixed beams 16 are fixed on the tops of the two columns 11, and the columns 11 are I-shaped. The column 11 is evenly provided with some bolt holes 25 along the vertical direction. The two ends of the movable beam 10 are all fixed on the column 11 by the screw rod 12. The movable beam 10 can move up and down inside the column 11. The beam 10 is fix...

Embodiment 2

[0058] refer to Figure 10 , the difference between this embodiment and embodiment 1 is that a protective limit device 28 is provided outside the test piece, refer to Figure 11 , the protection limiter 28 comprises a rectangular protective frame and a limiter fixed in the frame by a steel bar welded cross-section. The upper part of the protective frame is welded by four cross bars 39 and steel columns 38. The left and right sides of the lower part of the protective frame are obliquely welded with intersecting steel rods 30 and steel columns 38 .

[0059] The lower part is fixed with an inclined steel rod 30 for improving the stability of the frame, and the steel rod at the lower part of the frame is inclined outwards to improve the stability of the whole frame.

[0060] refer to Figure 12 , the limiting device includes a first memory metal 31, a second memory metal 32, a third memory metal 33, a fourth memory metal 34 and an electromagnet 35, wherein the first memory metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com