Patents

Literature

46results about How to "Prevent secondary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

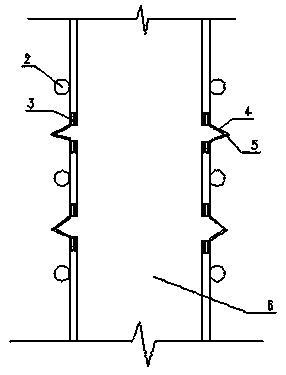

Impact test device

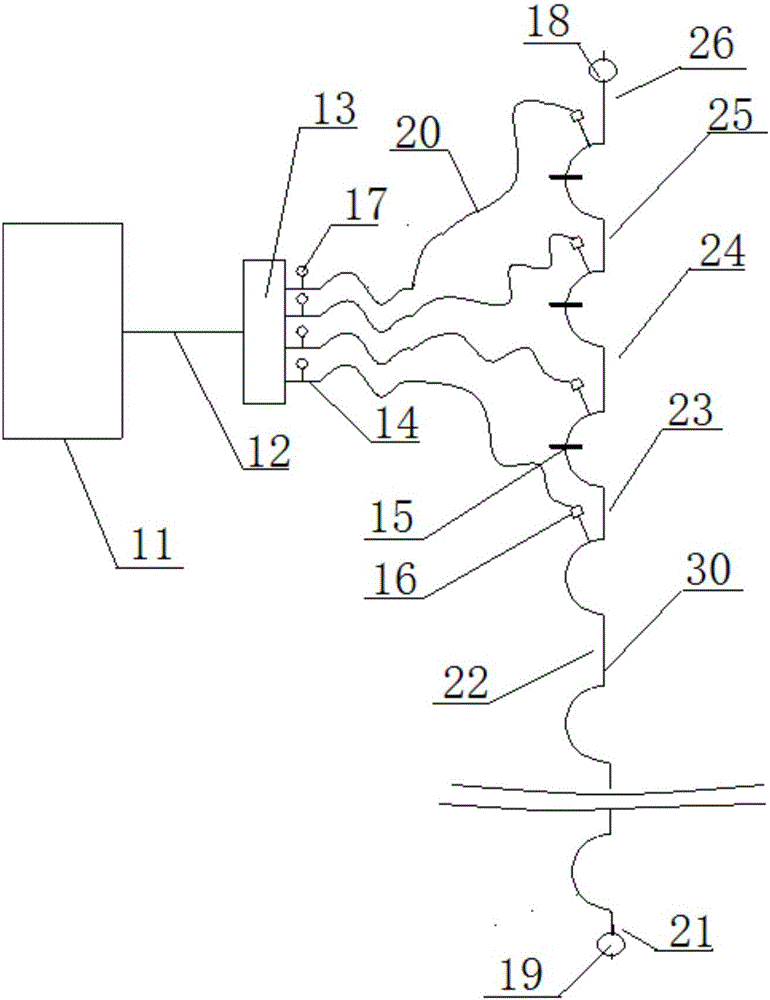

The invention discloses an impact test device. The impact test device comprises a protecting-limiting device, wherein the protecting-limiting device is arranged outside a test piece and comprises a protecting framework and a limiting device, the protecting framework is formed by welding steel rods, and the limiting device is fixed in the protecting framework; and the limiting device comprises a first memory metal, a second memory metal, a third memory metal and a fourth memory metal which are sequentially fixedly connected, electromagnets are arranged at joints among the four memory metals. The safety of a test operator can be protected by virtue of the protecting device, and the falling position of a drop hammer can be effectively controlled by virtue of the limiting device, so that the secondary or repeated impact caused by the drop hammer to the test piece is avoided, and the accuracy of the test is increased; and furthermore, by virtue of a specific rest function of the memory metals, the damage caused by the impact force of the drop hammer to the protecting device can be reduced, the uncertainty in the test can be reduced, and the test precision is increased.

Owner:CHANGAN UNIV

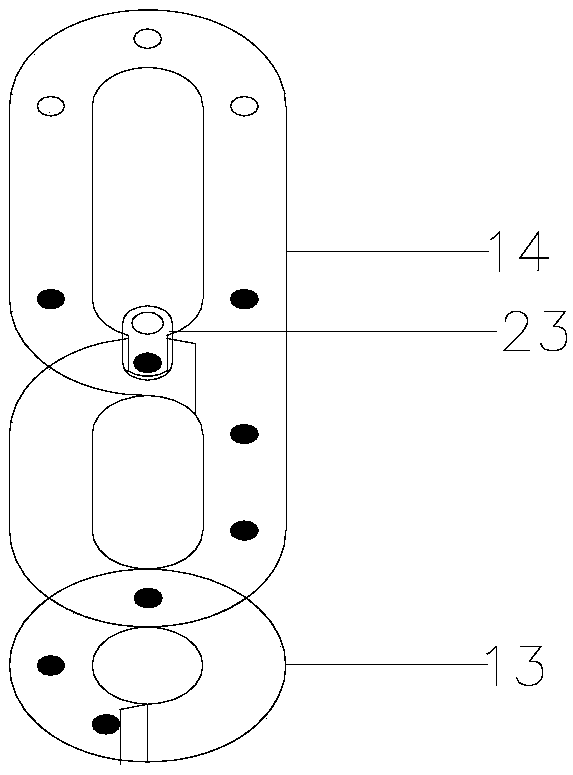

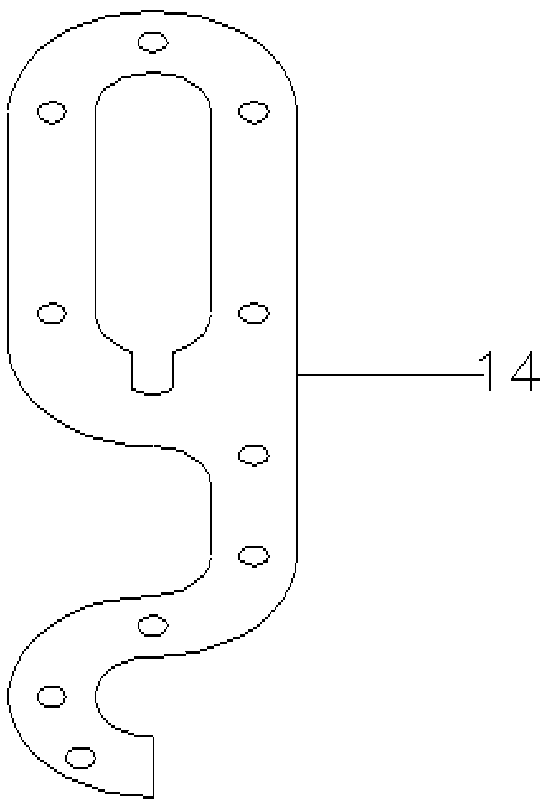

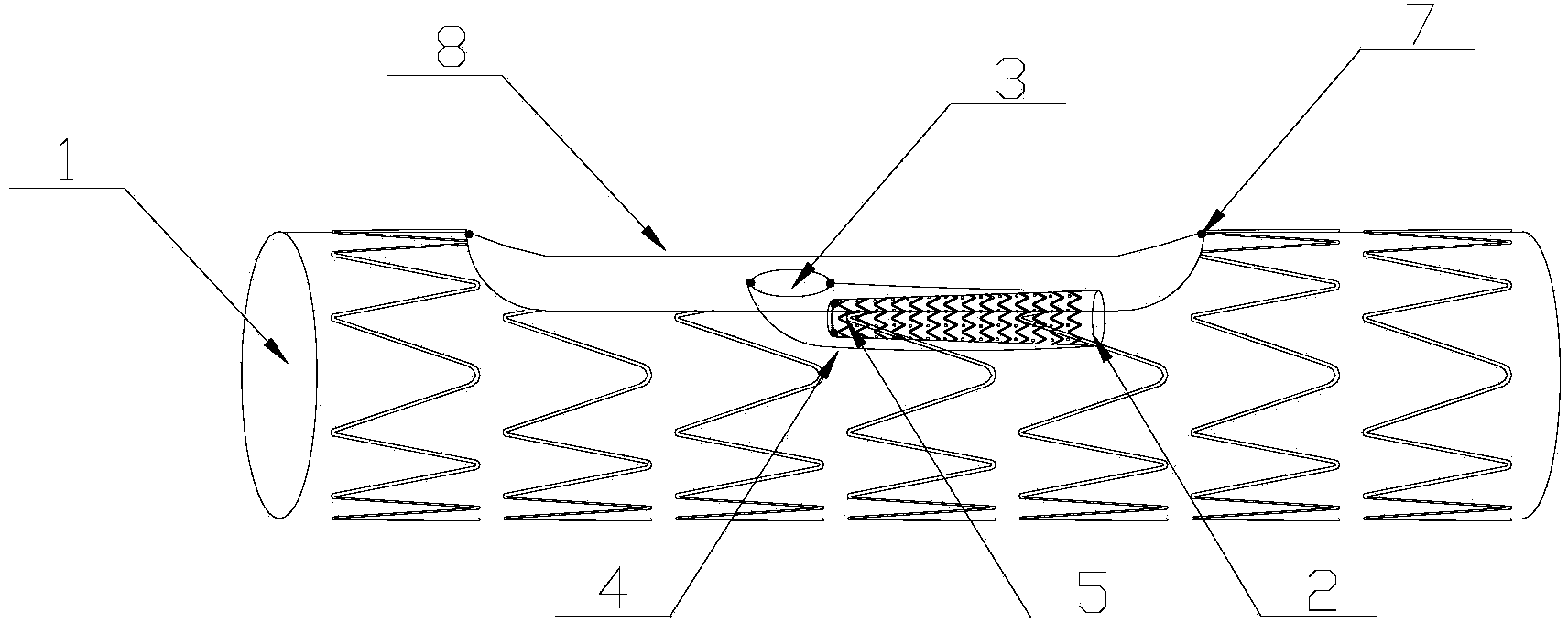

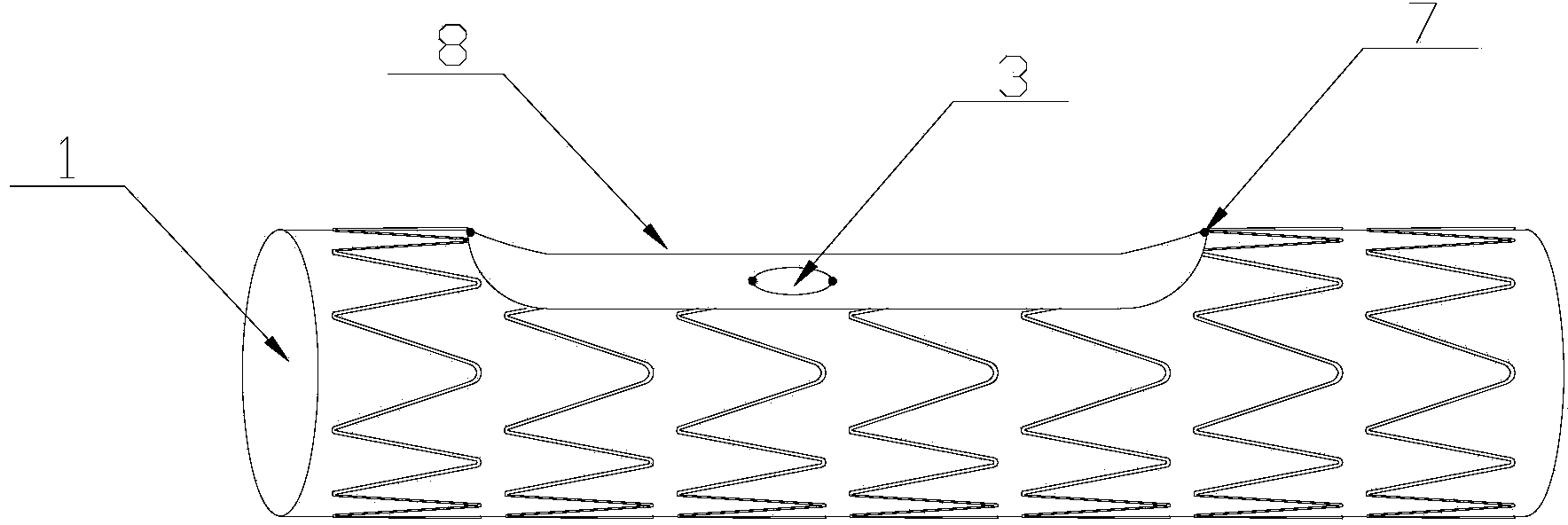

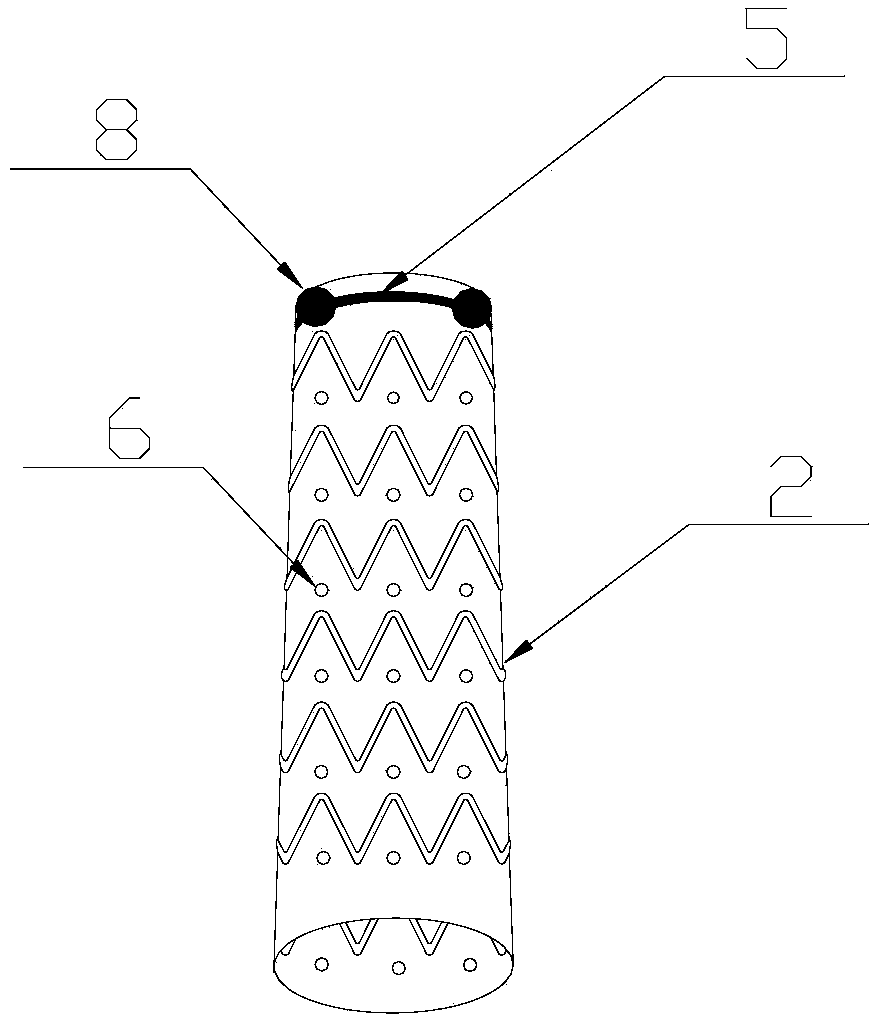

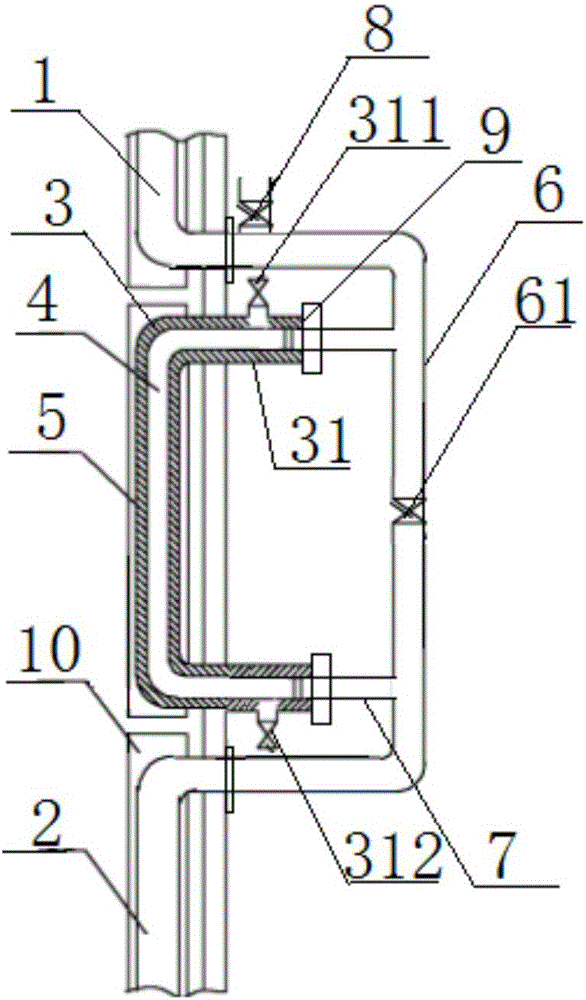

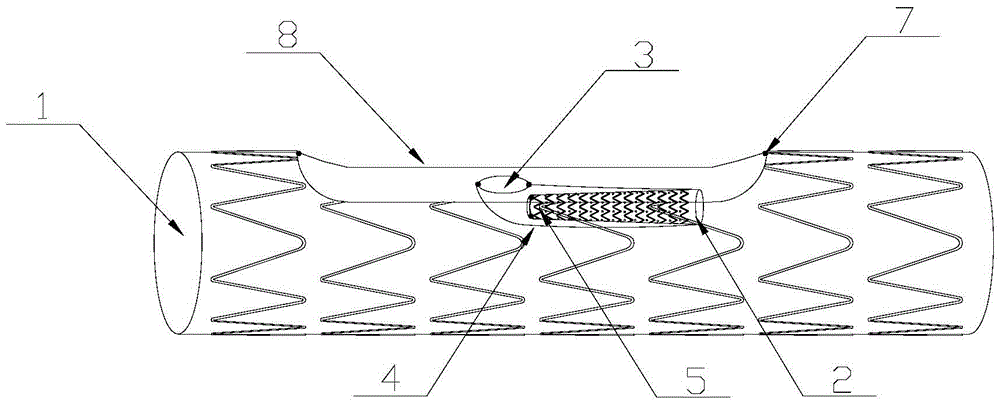

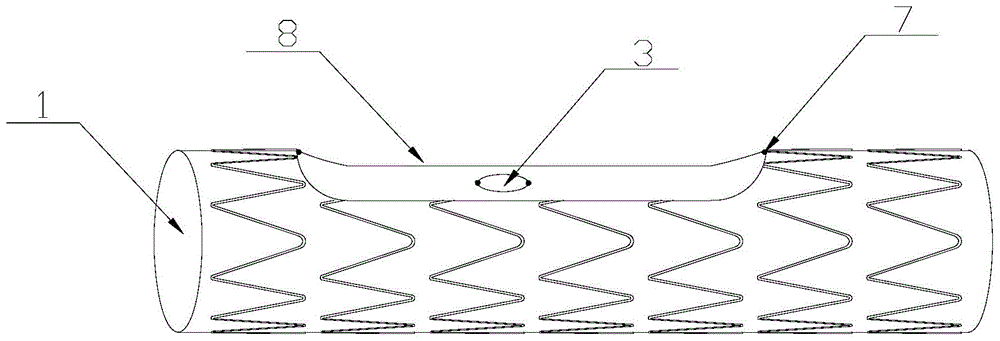

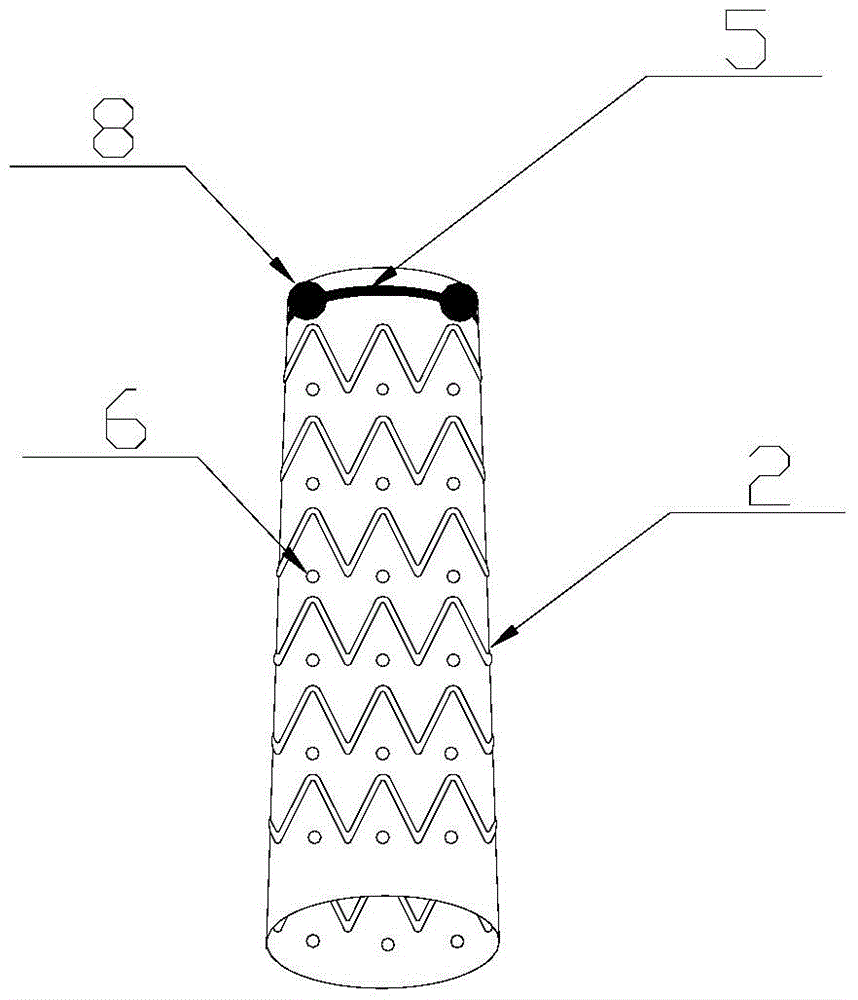

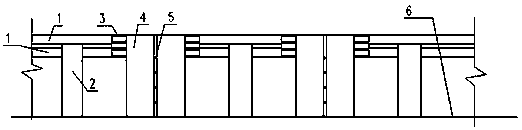

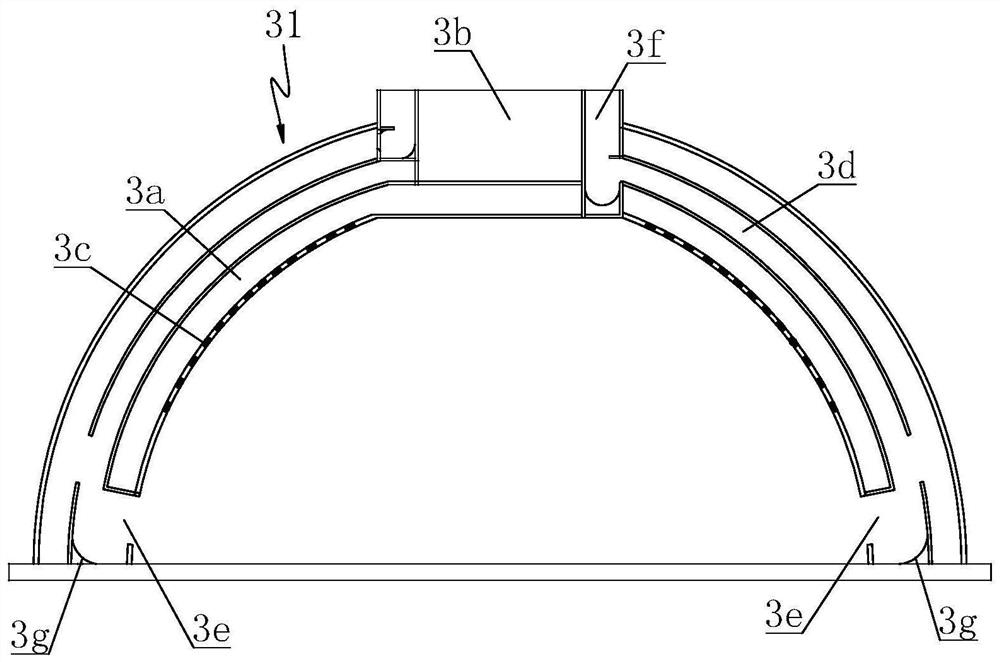

Stent graft

InactiveCN104367400AEffective positioningGuaranteed blood supplyStentsBlood vesselsVascular diseaseProximal point

The invention relates to the technical field of medical instruments, in particular to a stent graft used for treating peripheral arterial diseases and provided with a branch stent. The stent graft comprises a main stent and the branch stent, the main stent and the branch stent are each provided with a near end, a far end and an inner cavity arranged between the near end and the far end, an opening is formed in the main stent, the main stent and the branch stent are connected through a connector, the connector is provided with a bottom connected with the opening, a top capable of movably entering and exiting the opening and a connection inner cavity arranged between the bottom and the top, and the near end of the branch stent is connected with the top of the connector. The stent graft has the advantages that the stent graft is used for treating vascular diseases, is wide in adaptability, does not need to be customized, can be used for recovering multiple branch arteries when the peripheral arterial diseases are treated, prevents vascular stents from being implanted twice or many times and simplifies operation difficulty.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

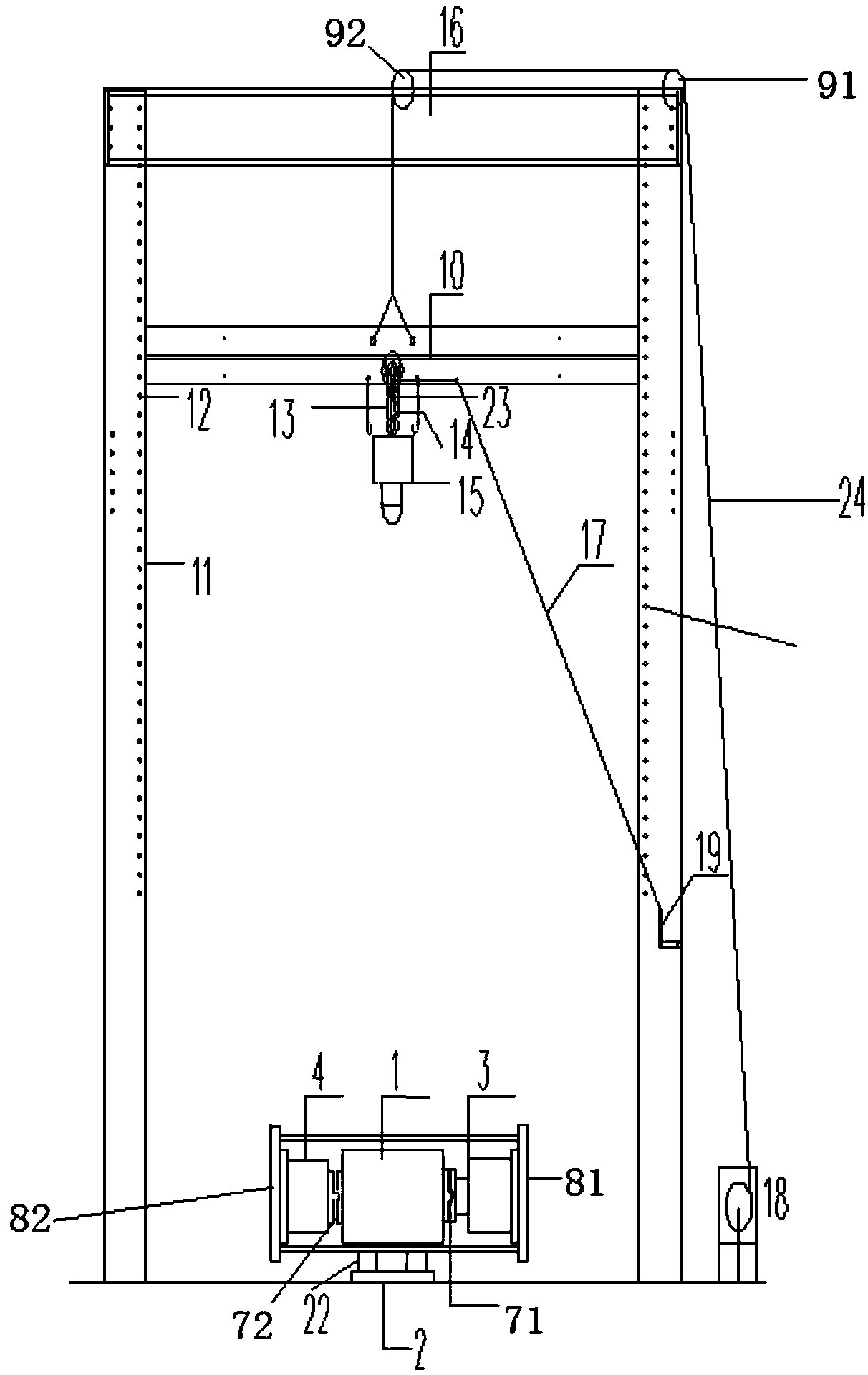

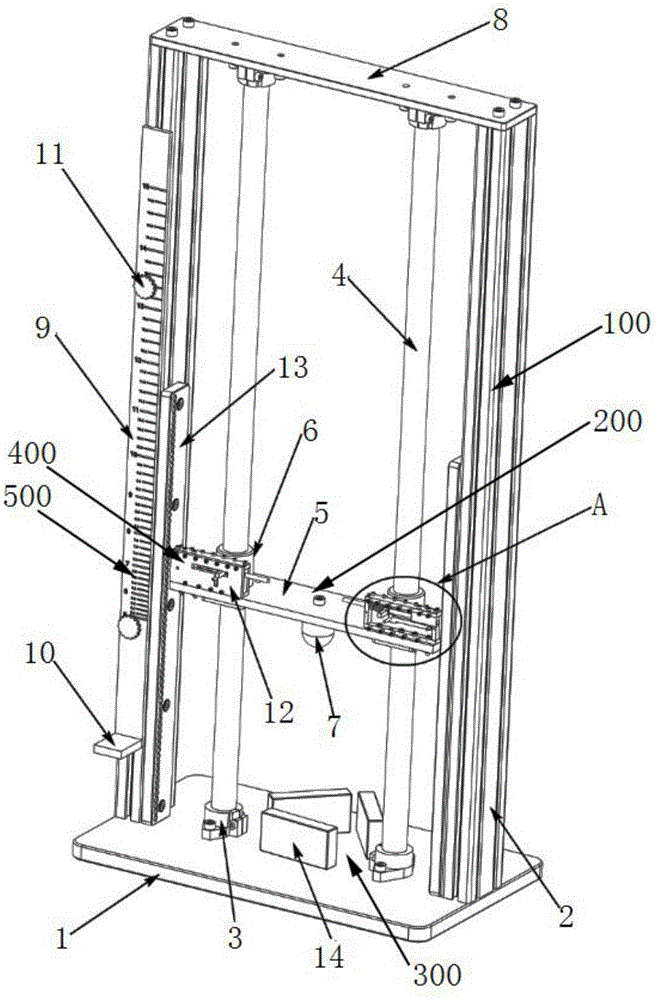

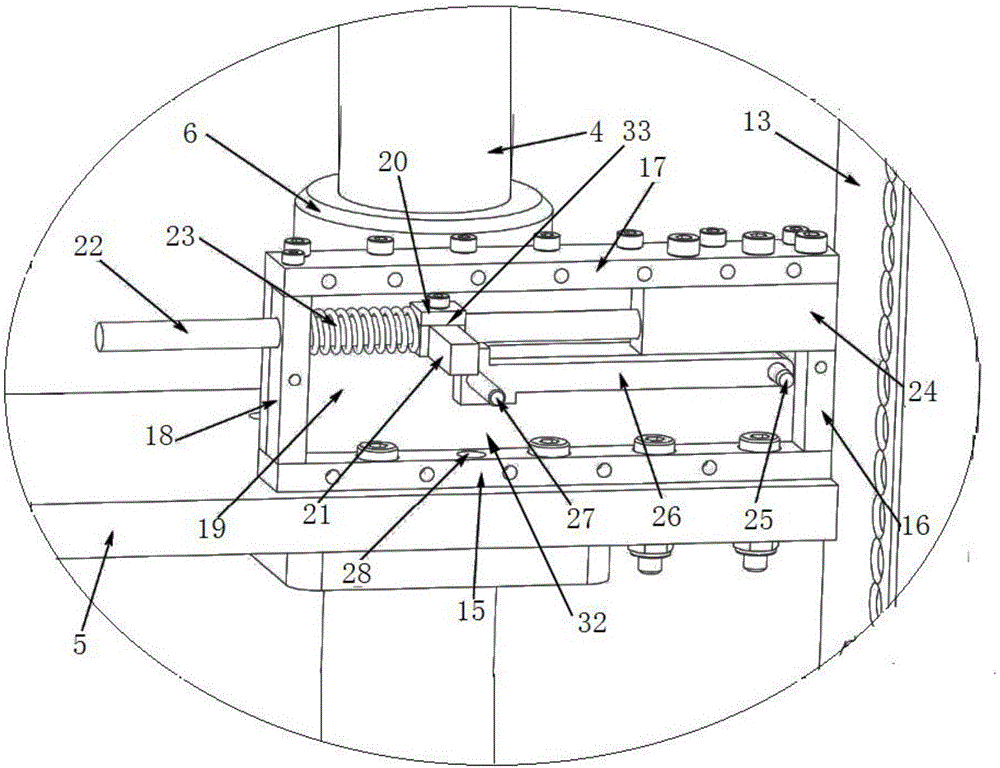

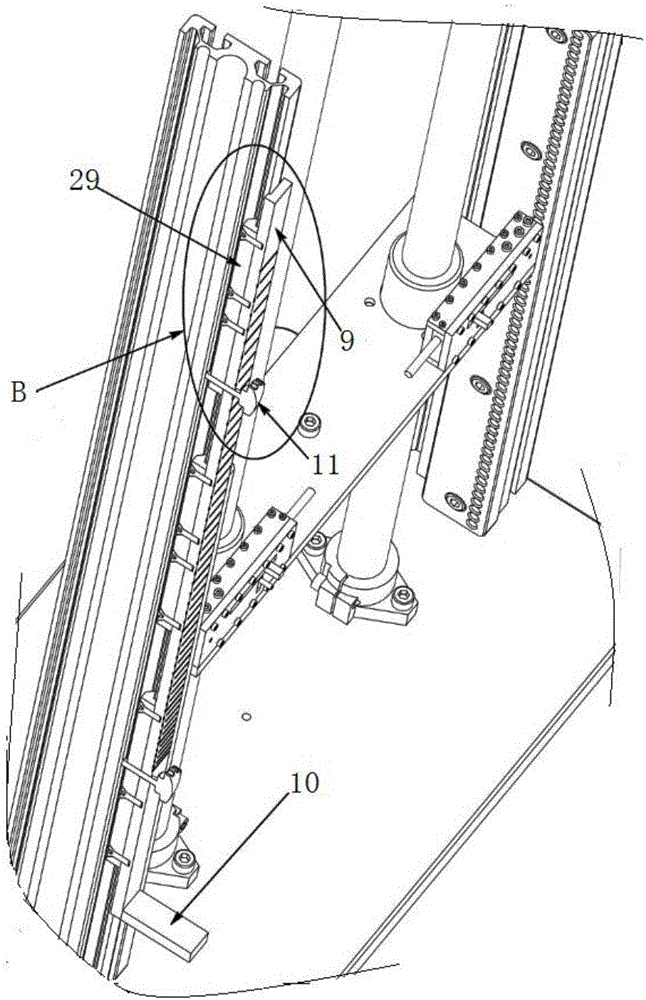

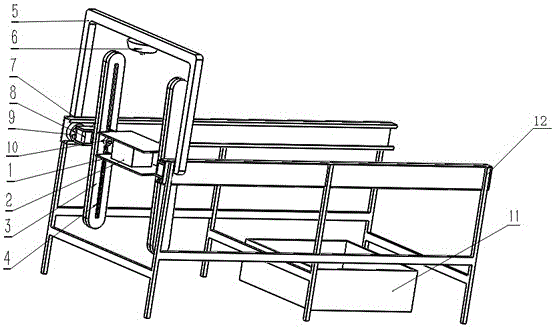

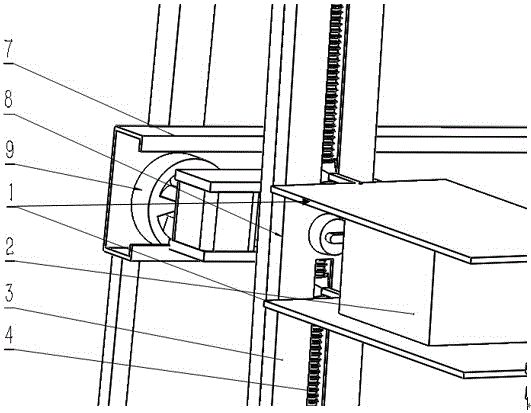

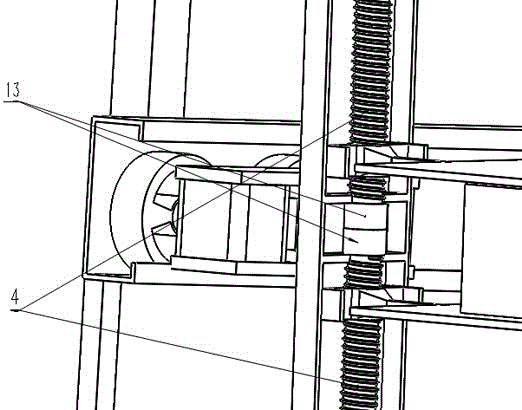

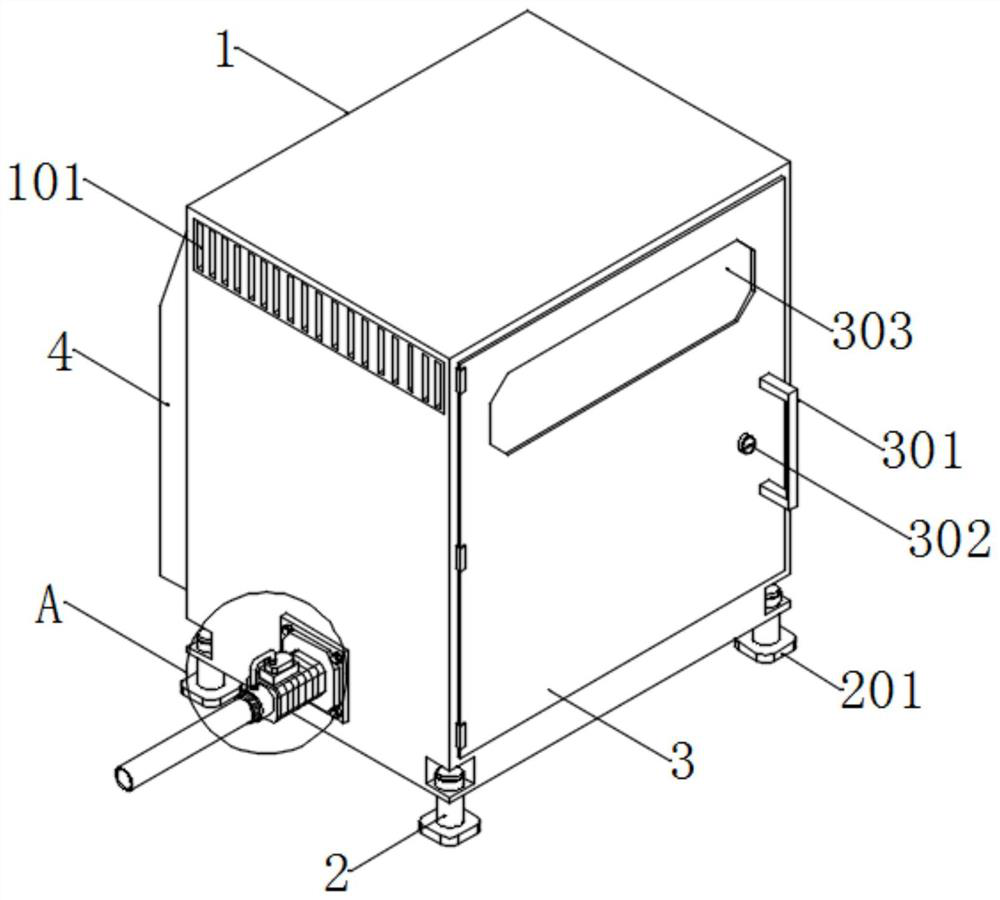

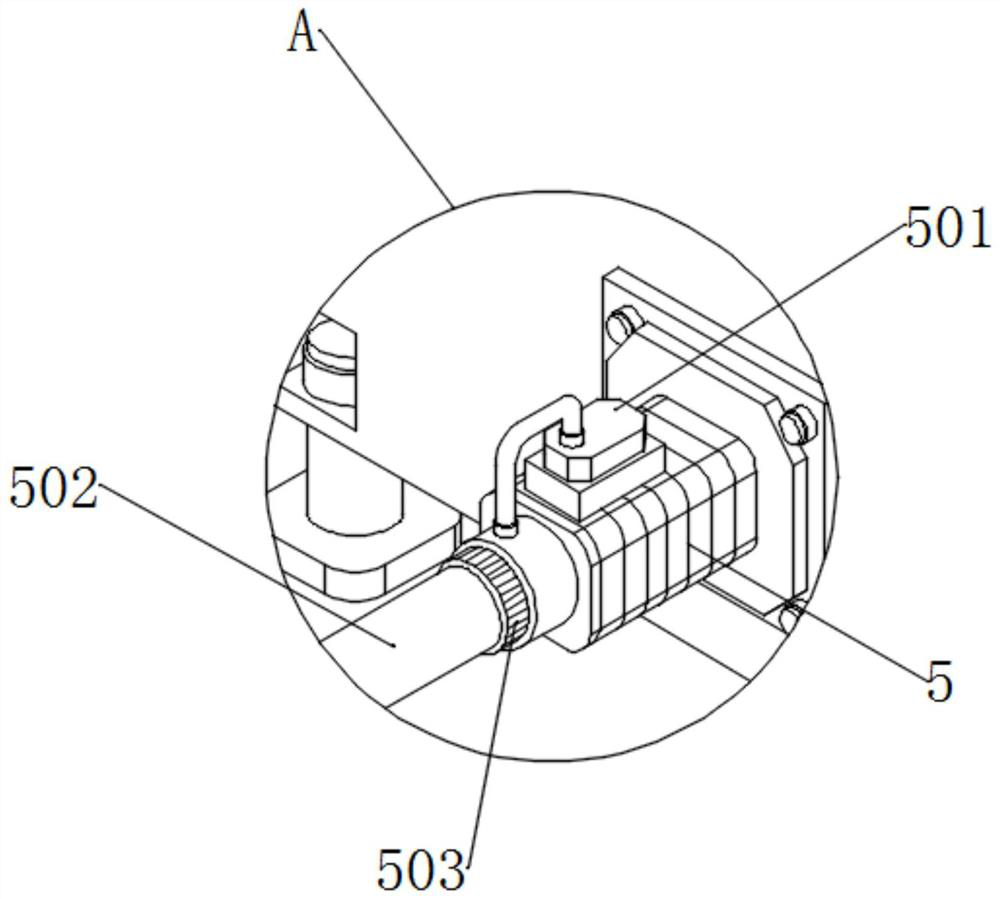

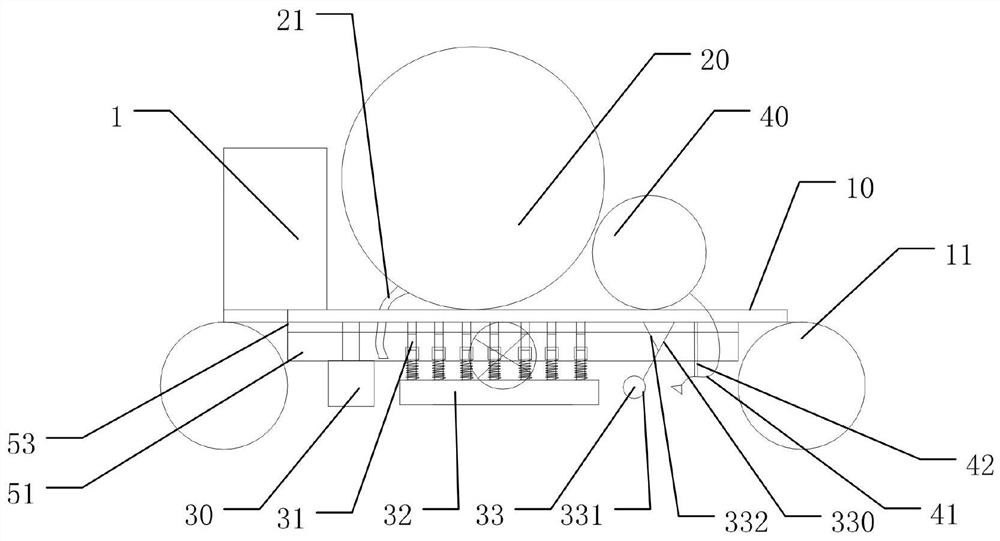

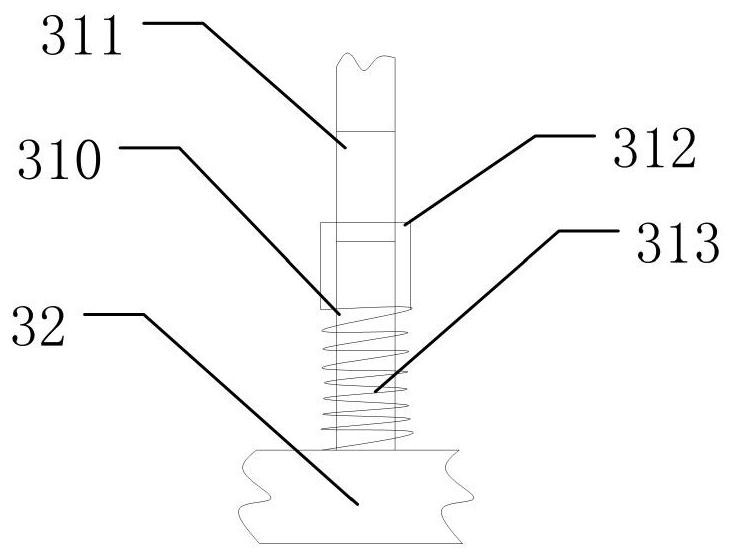

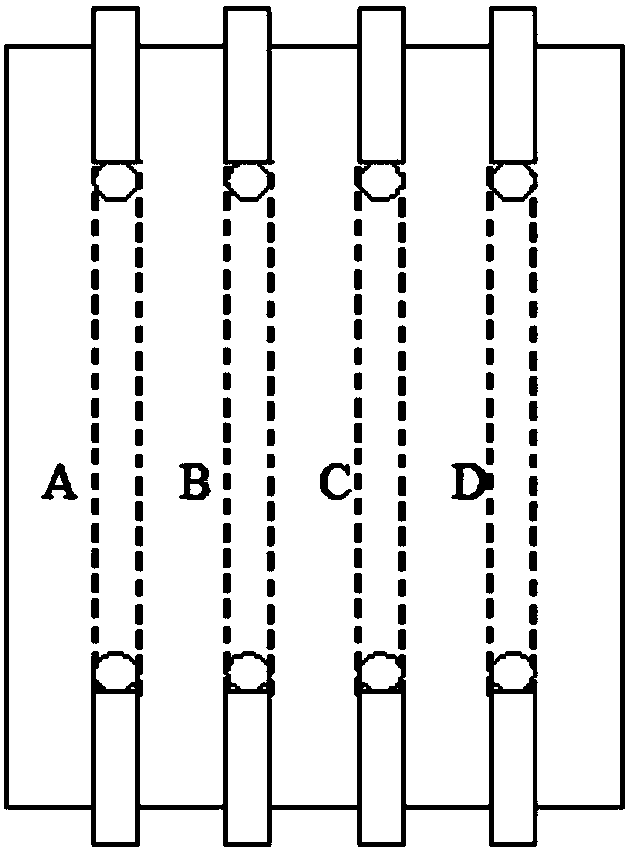

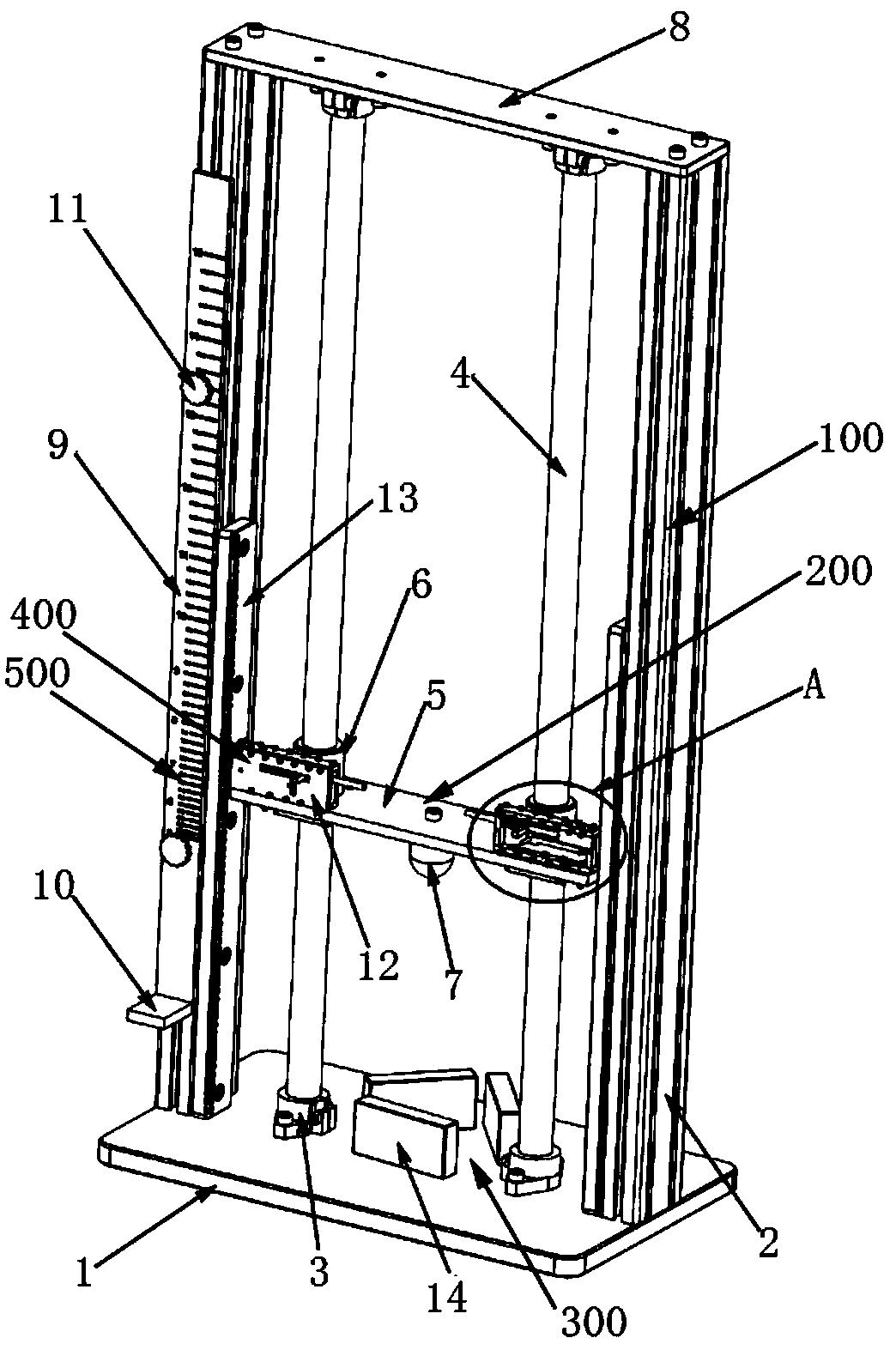

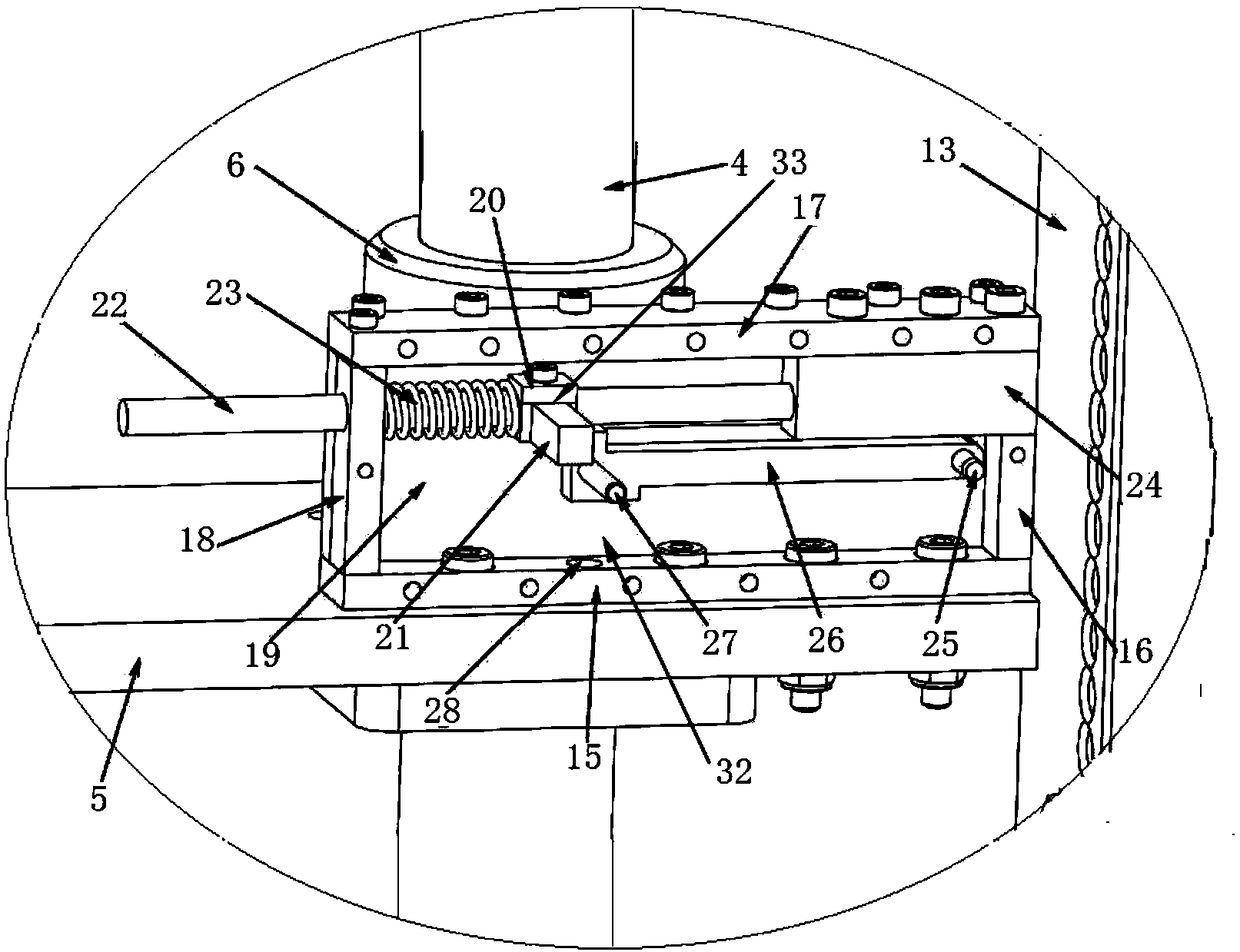

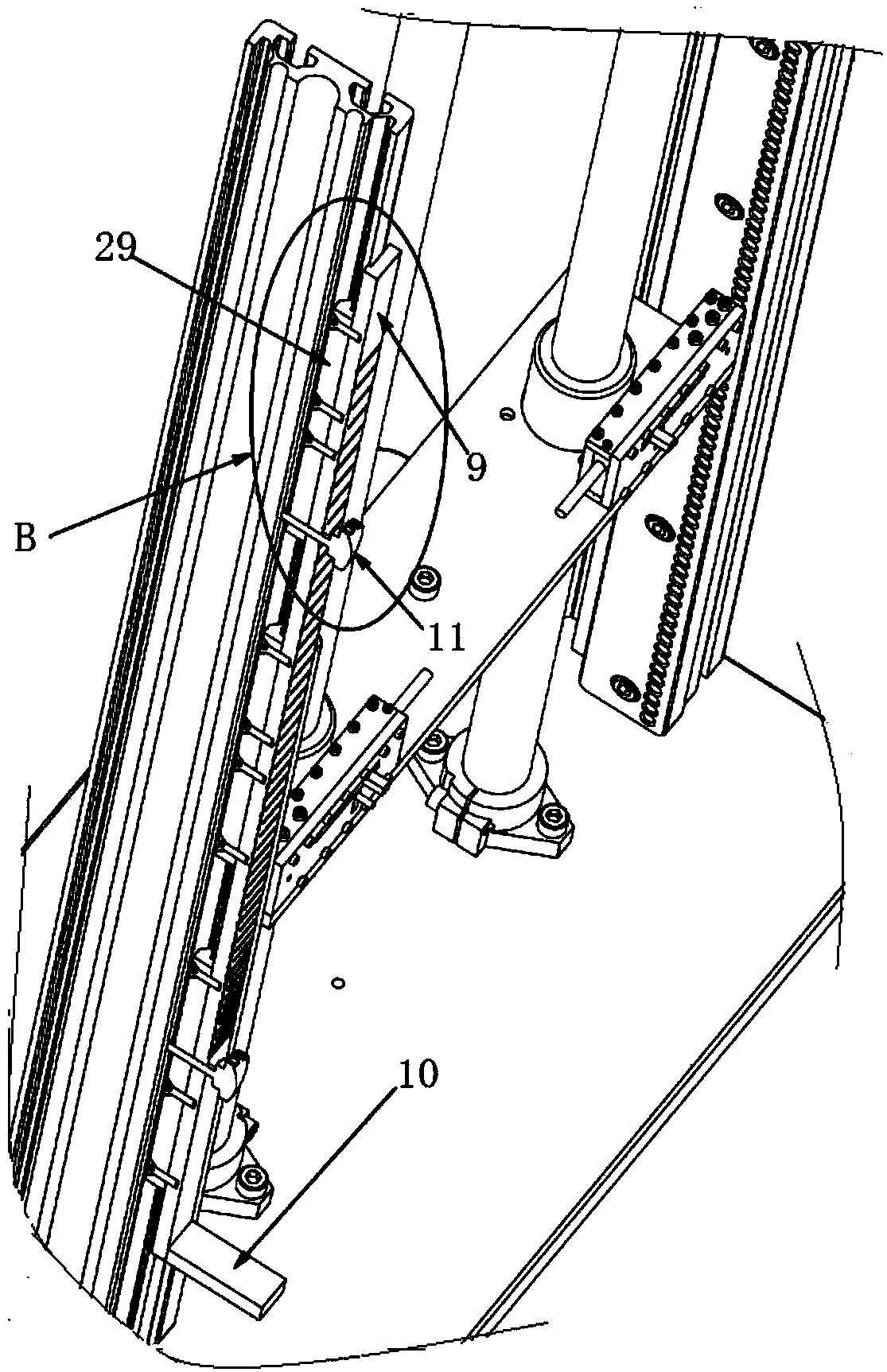

Vertical impact tester

ActiveCN105842088AGuaranteed accuracyPrevent repeated impactStrength propertiesComputer moduleModular design

The invention discloses a vertical impact tester which comprises a base frame module, an impact body module, a quick clamp module and at least one inertia triggering module .The base frame module forms a base framework of the vertical impact tester, and at least two guide shafts are longitudinally and vertically arranged in the base frame module .The impact body module comprises a movable carrier plate and a punch installed at the lower end of the movable carrier plate, and the movable carrier plate is connected with the guide shafts through linear bearings .The quick clamp module is installed on a bottom plate on the lower portion of the base frame module, opposite to the punch and used for holding an elastic workpiece to be subjected to impact testing .The inertia triggering modules are installed on the movable carrier plate .The impact body module impacts the elastic workpiece, rebounds and then triggers a locking action, and the impact body module is locked to the base frame module so as to prevent the impact body module from repeatedly colliding with the elastic workpiece .According to the technical scheme, modular design is adopted, the impacting action can be automatically locked after impact testing so as to prevent the elastic workpiece from being impacted twice or many times, and accuracy of testing is guaranteed.

Owner:THERMOS JIANGSU HOUSEWARES

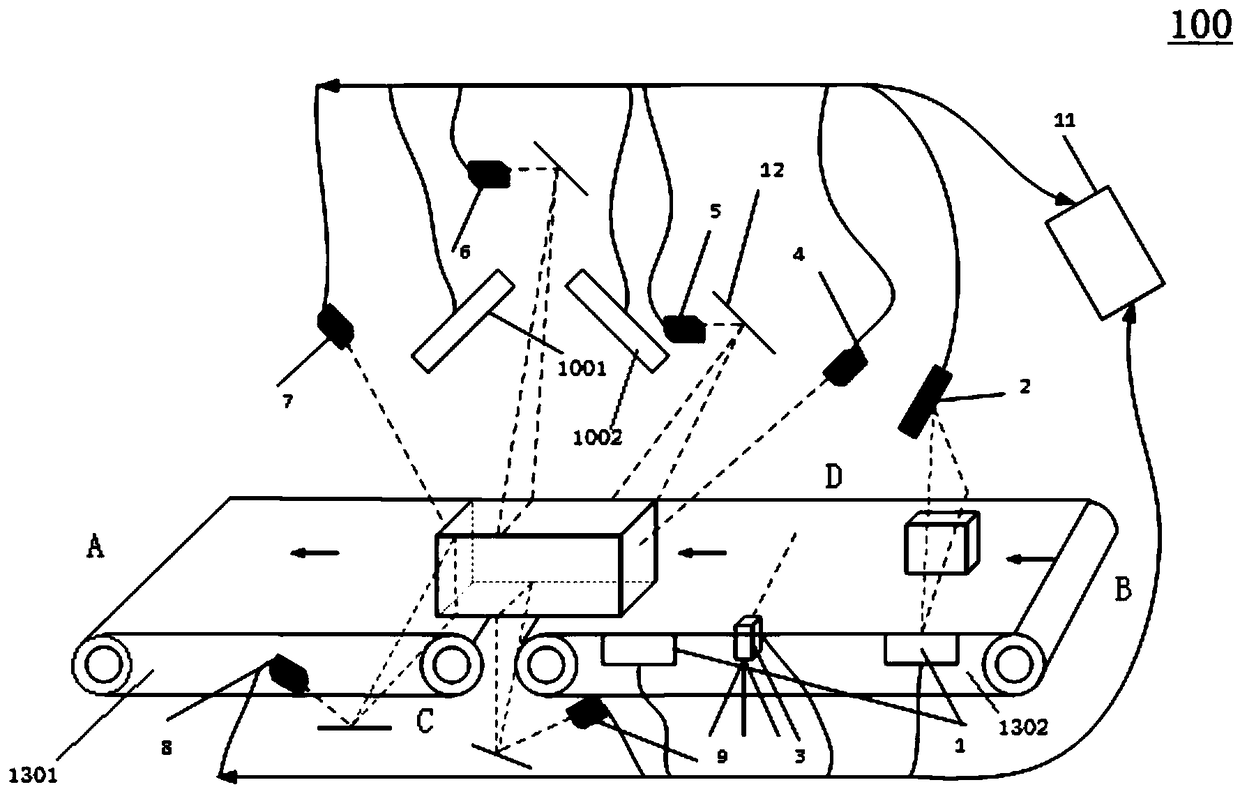

Barcode detecting device

PendingCN109063529APrevent secondaryAvoid missing codesSensing by electromagnetic radiationVertical planeBarcode

The invention discloses a bar code detecting device. The bar code detecting device comprises a multi-side camera module used for detecting the bar code on a package in all directions. The multi-side camera module comprises a plurality of linear array cameras and a plurality of area array cameras. A plurality of linear array cameras are angularly arranged on the vertical plane of the movement direction of the package, and a plurality of area array cameras are angularly arranged on the parallel plane of the movement direction of the package. By means of the above technical scheme of the invention, by arranging a plurality of line array cameras at an angle on a vertical plane of a movement direction of the package, and a plurality of area array cameras are arranged at an angle on the parallelplane of the movement direction of the package, so that the omni-directional code scanning can be completed in the package transportation process, the secondary code scanning is avoided or the code scanning is omitted, and the effect of high efficiency, convenience and manpower saving is achieved.

Owner:SF TECH +1

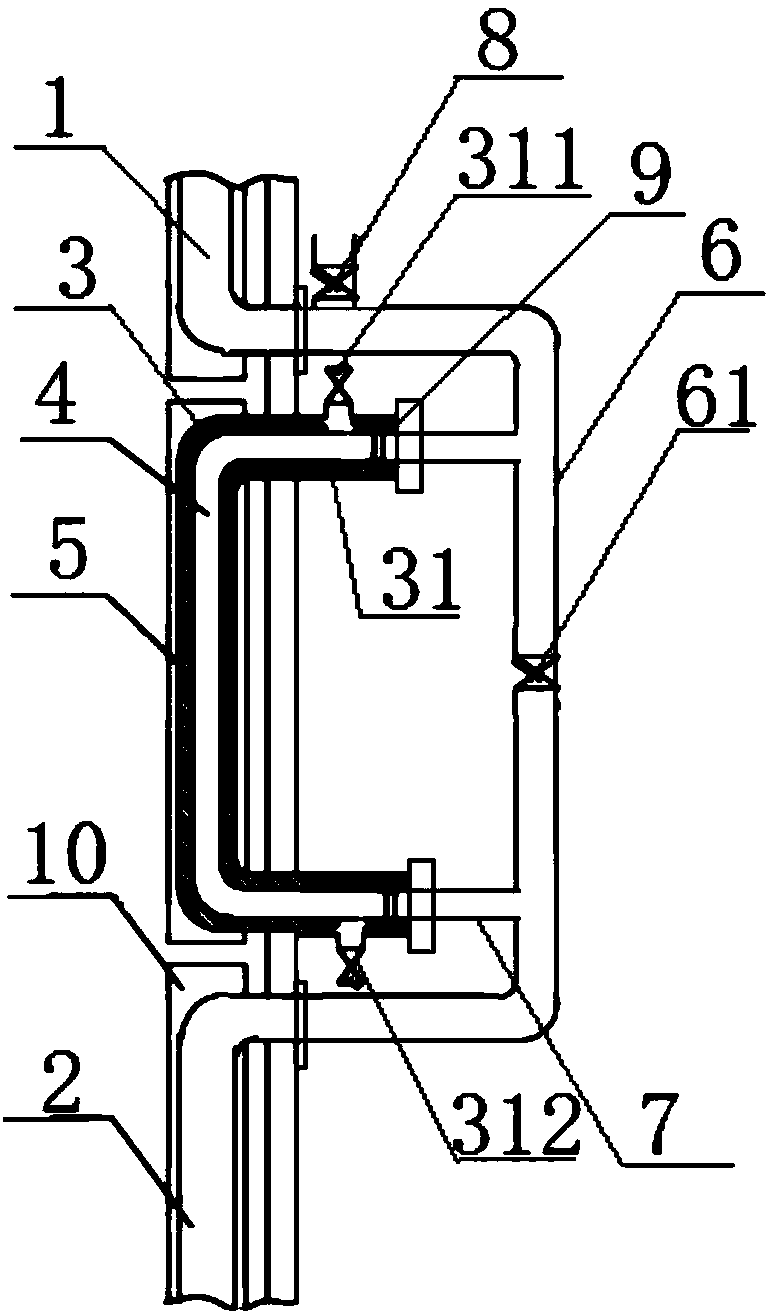

Blast furnace cooling-wall cooling water pipe repairing method and structure thereof and pressure leakage detection device

ActiveCN105969924AReduce resistancePrevent secondaryCooling devicesChecking devicesWater leakageWater source

The invention discloses a blast furnace cooling-wall cooling water pipe repairing method and a structure thereof and a pressure leakage detection device, belonging to the technical field of iron making blast furnace production. The repairing method disclosed by the invention comprises the steps of pressure leakage detection, disconnection of a damaged cooling water pipe, leakage point bypass, threading of the damaged cooling water pipe, silk threading of the damaged cooling water pipe, pipe threading of the damaged cooling water pipe, external connection of a water source, grouting and the like. The repairing structure of the blast furnace cooling-wall cooling water pipe disclosed by the invention comprises the damaged cooling water pipe, a cooling water-in end at the upper part of the damaged cooling water pipe and a cooling water-out end at the lower part, wherein the cooling water-in end and the cooling water-out end are folded outward and communicated through an external cooling pipe, and a metal hose penetrates inside; a gap formed between the metal hose and the damaged cooling water pipe is filled with a high-heat conduction grouting layer; and a bypass pipe is arranged at the upper part of the external cooling pipe. In the invention, the problems that the service life of the blast furnace cooling wall is influenced and the repairing cost is high due to the imbalance between the local cooling effect and peripheral cooling effect in water leakage repairing of the blast furnace cooling wall are effectively solved.

Owner:MAANSHAN IRON & STEEL CO LTD

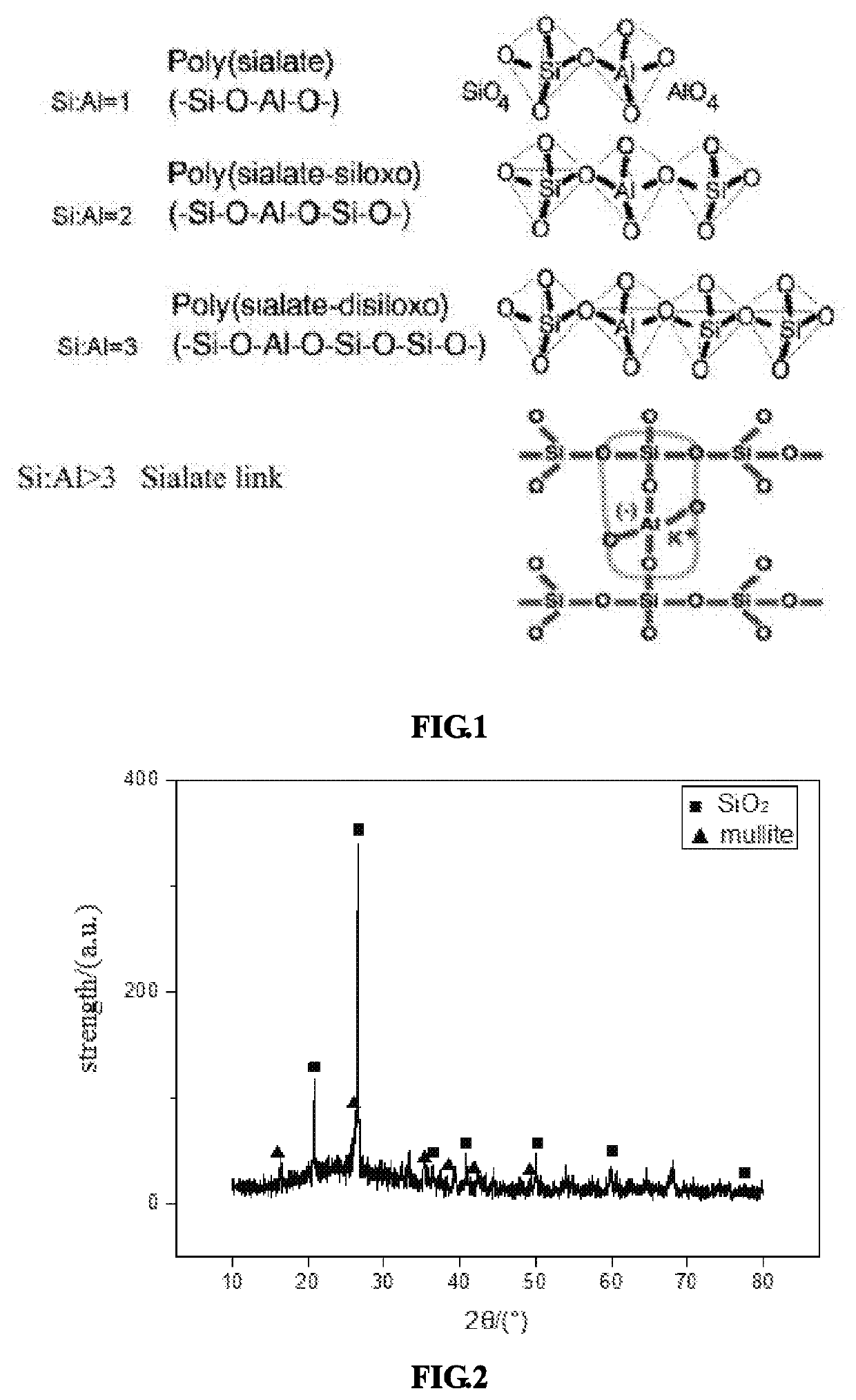

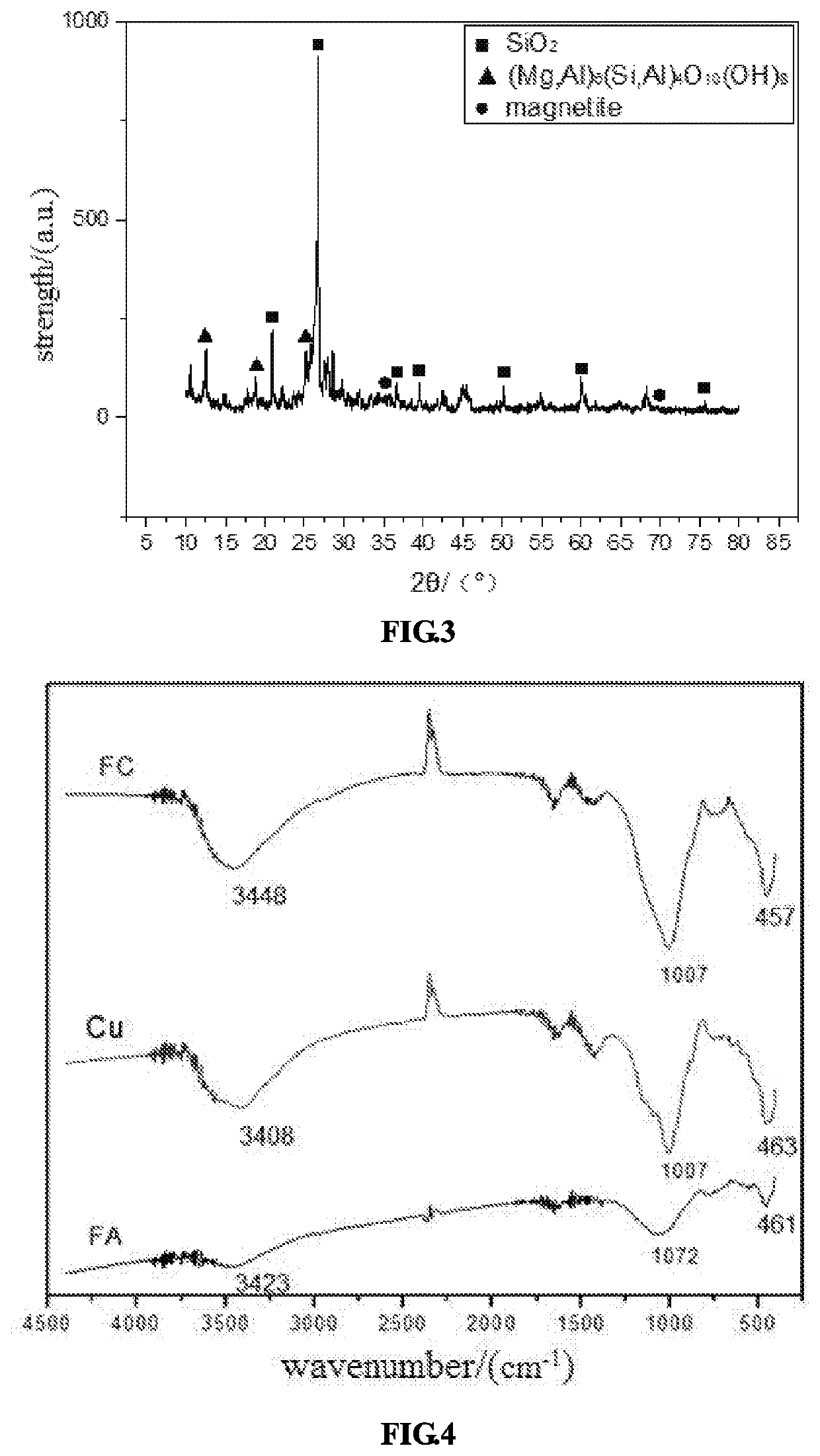

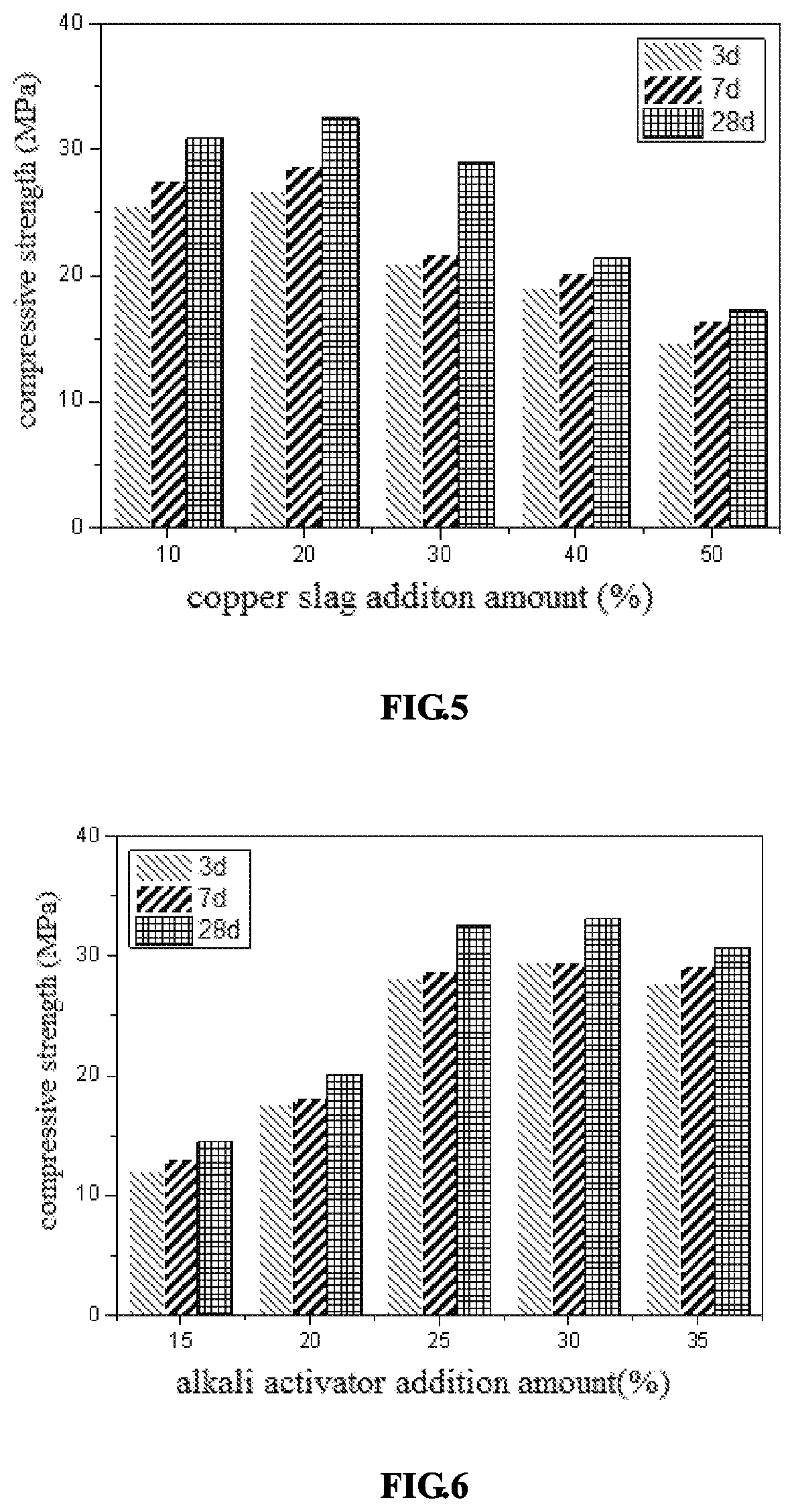

Copper slag-fly ash geopolymer, a preparation method thereof, and use thereof

InactiveUS20210188707A1Improve overall utilizationLow production costSolid waste managementCement productionGeopolymerAlkali activated

The present invention discloses a copper slag-fly ash geopolymer, a preparation method thereof, and use thereof, belongs to the technical field of geopolymer. The preparation method of copper-fly ash geopolymer provided by the application comprises the steps of: mixing the copper slag, fly ash and alkali activator solution, obtaining a slurry; proceeding polymerization to the slurry, obtaining a copper slag-fly ash geopolymer. The fly ash and copper slag are used as raw materials in the application, which greatly improve the utilization rate of the industrial waste residue. The advantages line in that no need for additional addition of inorganic reinforcing filler, low production cost, simple operation and competency for industrial production. Moreover, the copper slag-fly ash geopolymer has good compressive strength, and can solidify the heavy metal ions in copper slag at the same time, thus reducing the environmental pollution.

Owner:BEIFANG UNIV OF NATITIES

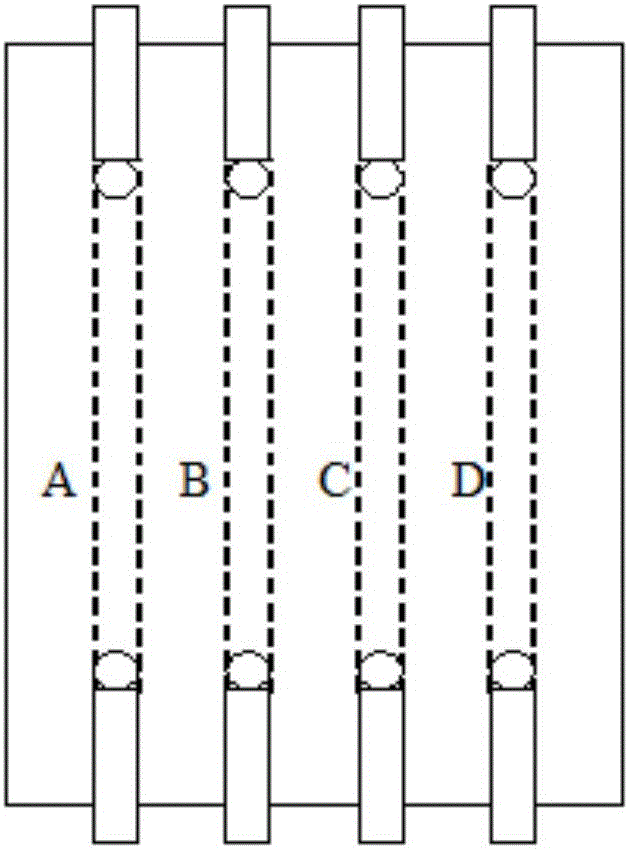

All-directional code scanning sorter

ActiveCN105728330ASimple structureReasonable designSortingSensing by electromagnetic radiationEngineeringMotor control

Owner:东台市智创精密制造产业园投资有限公司

Preparation method of hand-sticking-free kitchen paper and product thereof

ActiveCN109629340ASolve pollutionPrevent secondaryNon-fibrous pulp additionSpecial paperHand partsPaper towel

The invention discloses a preparation method of hand-sticking-free paper and a product thereof. The kitchen paper has a sheet-shaped structure and consists of an upper layer and a lower layer, whereinone layer is a surface with water absorption and oil absorption functions, and the other layer is a surface with water and oil prevention functions, the method comprises the processes of processing pulp, preforming size mixing, embossing and pressing, punching formed paper, rolling the paper, cutting the paper, sterilizing and packaging the paper. The hand pollution problem caused by the wettingof the kitchen paper by water or oil is solved, the secondary or multiple wiping caused by the wetting of the kitchen paper is avoided in the cleaning process, and the use experience is greatly optimized. A new process is not added, and the method has the advantages of simple production process, no environmental pollution, continuous large-scale industrial production and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

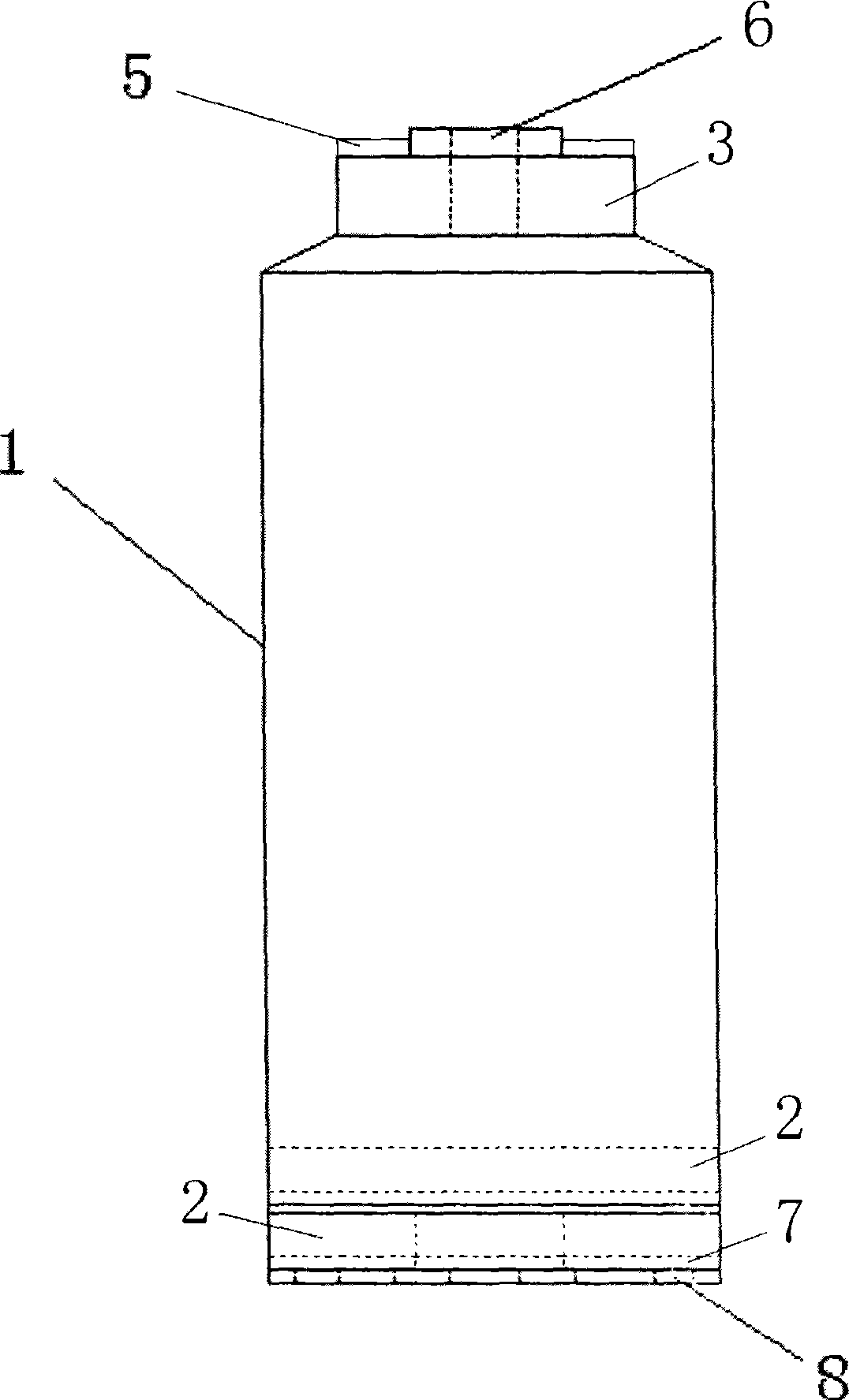

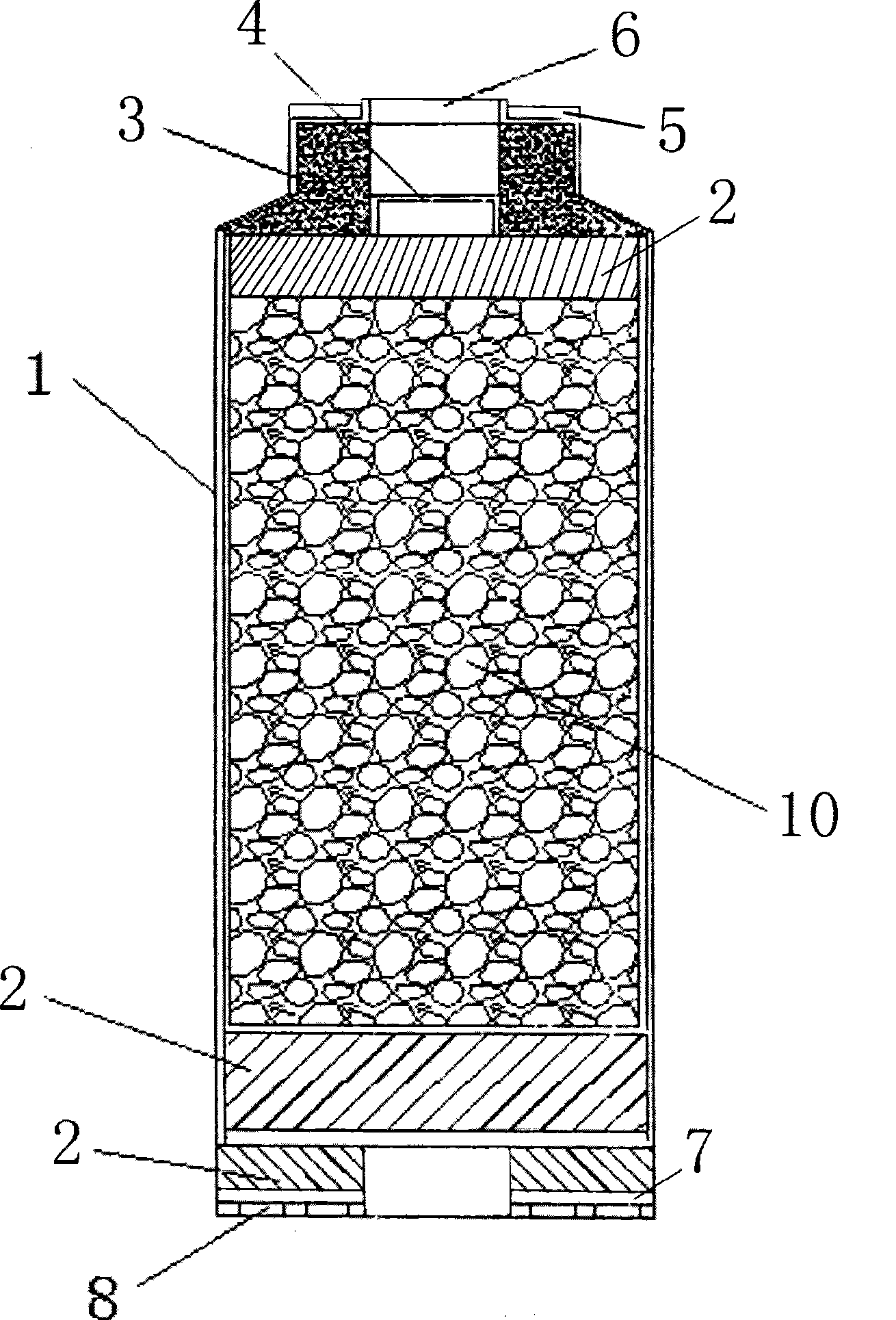

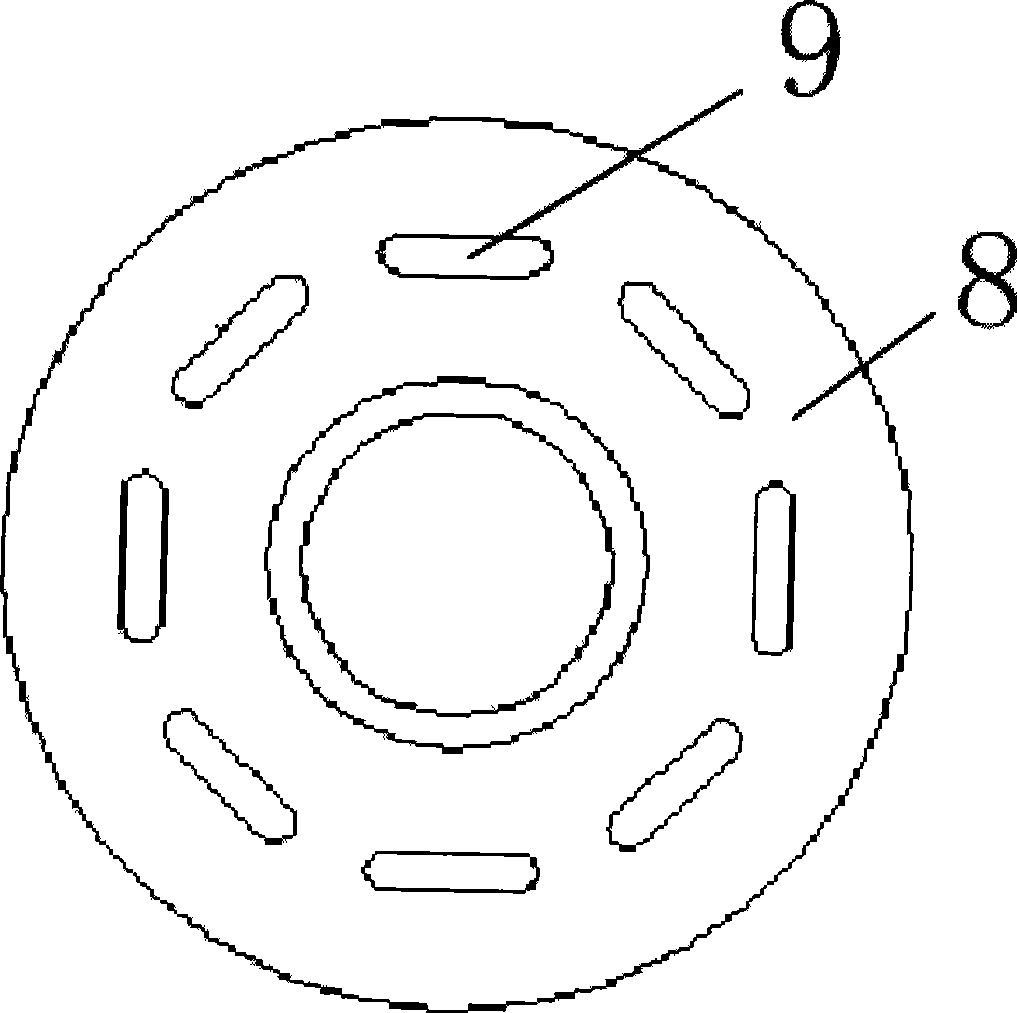

Filter element changeable filter material

InactiveCN101417186APrevent secondaryAvoid pollutionLoose filtering material filtersGravity filtersFiltrationFilter material

The invention provides a filter core with a replaceable filter material, comprising a cylindrical filter core shell used for storing the filter material and an end cover. The filter core is characterized in that the filter material is granular active carbon filter material; a water inlet at the bottom of the filter cylinder is provided with two layers of sponges used for filtration and a non-woven cloth protection layer; a round hole typed non-woven filter layer and a round water-retaining cap are embedded at a water outlet; an anti-leakage washer is arranged outside the water outlet of the filter cylinder; and the filter core structure can replace the filter material or mixes the filter material with other functional filter materials for use, and can be repeatedly used for many times. Therefore, the filter core reduces the cost, saves the energy resource, and avoids the problems of secondary pollution or multi-time pollution. The filter core with the replaceable filter material has wide applicable area and range, is economical and has large market potentials.

Owner:张金松

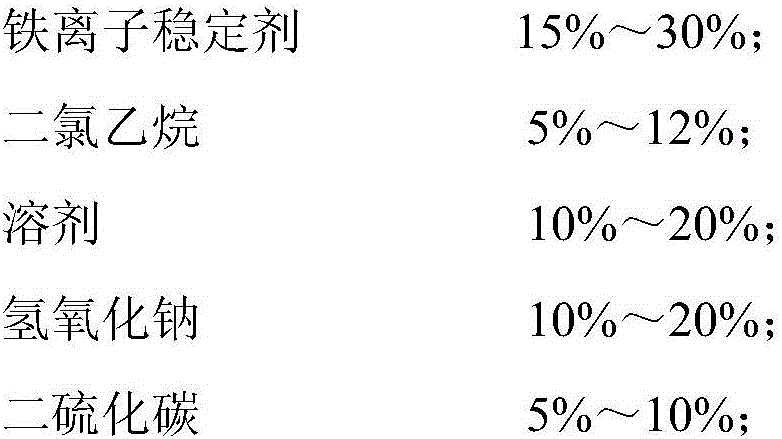

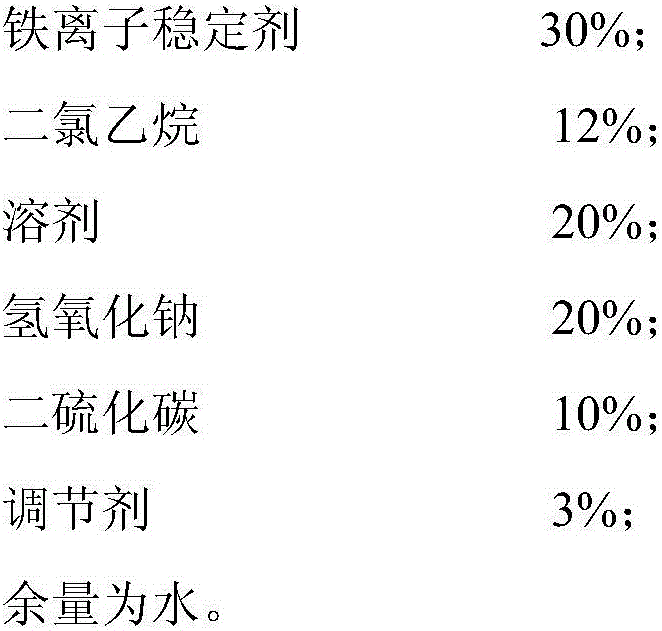

Chelating agent and preparation method and application thereof

InactiveCN106833581ALow priceWide variety of sourcesOrganic chemistryCleaning apparatusSolventSodium hydroxide

The invention provides a chelating agent and a preparation method and application thereof. According to the total amount of the prepared chelating agent as 100%, the chelating agent is prepared from the following raw materials in weight percentage: 15% to 30% of ferrous stabilizer, 5% to 12% of dichloroethane, 10% to 20% of solvent, 10% to 20% of sodium hydroxide, 5% to 10% of carbon disulfide, 1.5% to 4.5% of conditioning agent and the balance of water. The raw materials of the chelating agent disclosed by the invention have wide sources and low cost. The chelating agent disclosed by the invention has stable performance and long service life, can be stored and used for a long time and has good compatibility with acidized acid liquor systems.

Owner:PETROCHINA CO LTD

Water injection well long-acting augmented injection acid technology

InactiveCN108104782AStrong chelating abilityIncrease the amount of water injectedFluid removalHigh pressureLocal pressure

The invention provides a water injection well long-acting augmented injection acid technology. Through a mode of combining local pressure lifting with acidification, the problem of low pressure injection or no injection is solved, and purposes of comprehensive treatment and increasing the amount of injected water are achieved. The method does not need to take off a pipe string and flowback well washing is not required. II type chelating acid has strong chelating property, in the acid-rock reaction process, Ca<2+>, Mg<2+>, Fe<3+> and other metal ions can be chelated to avoid secondary or tertiary precipitation generation, the rust inhibition (less than 3.0g / (m<2>.h)) is low at the same time, and the pipe string in a wellbore cannot be corroded to bring downhole accident.

Owner:PETROCHINA CO LTD

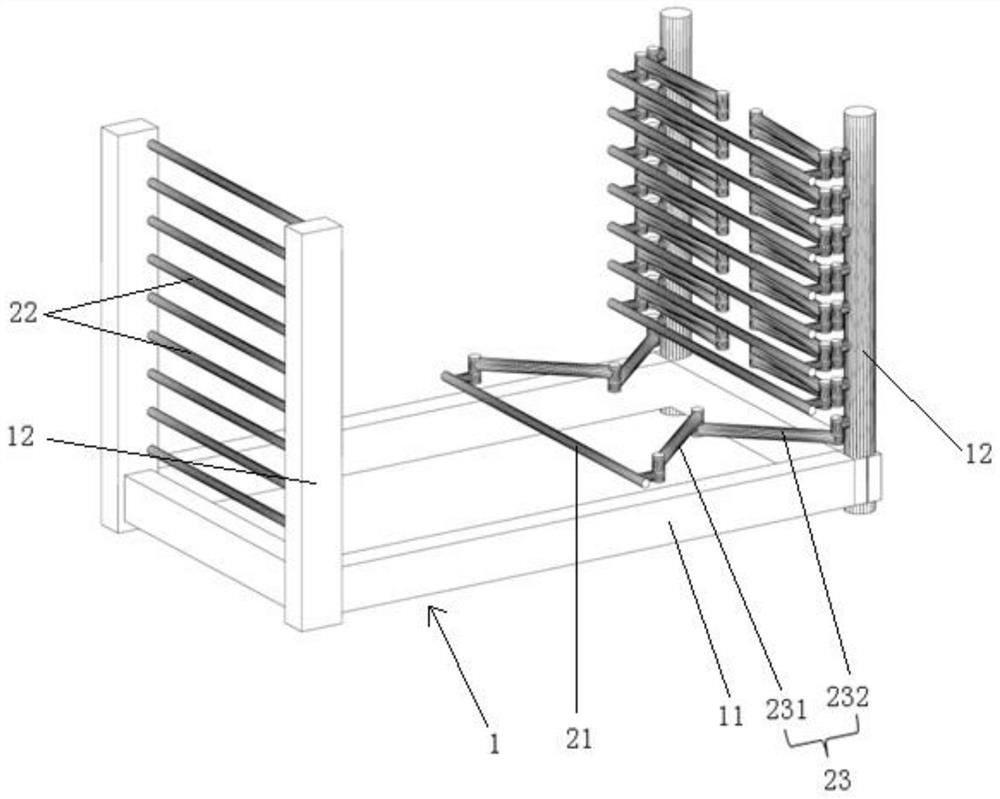

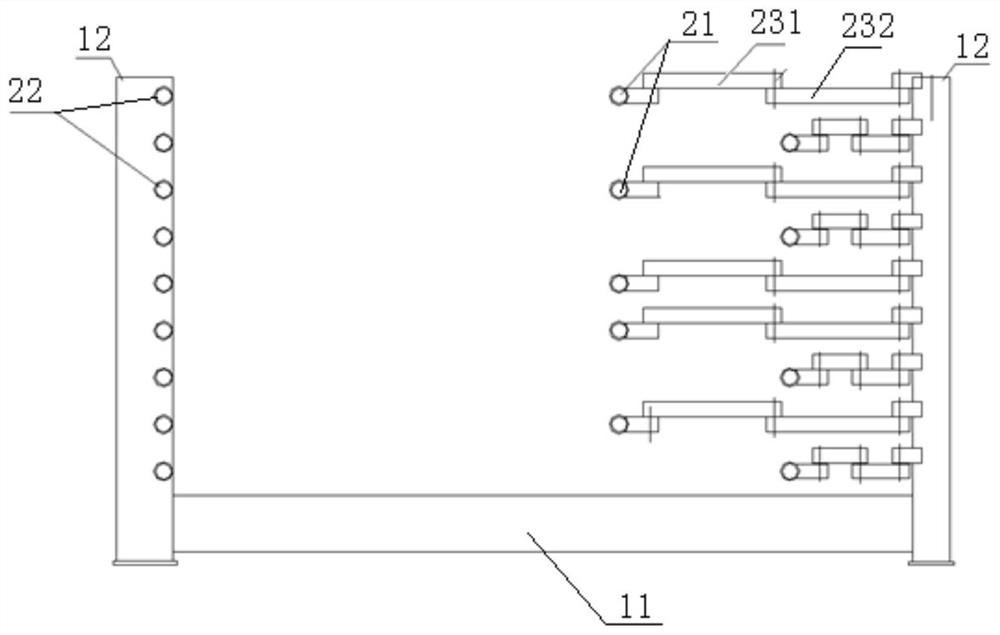

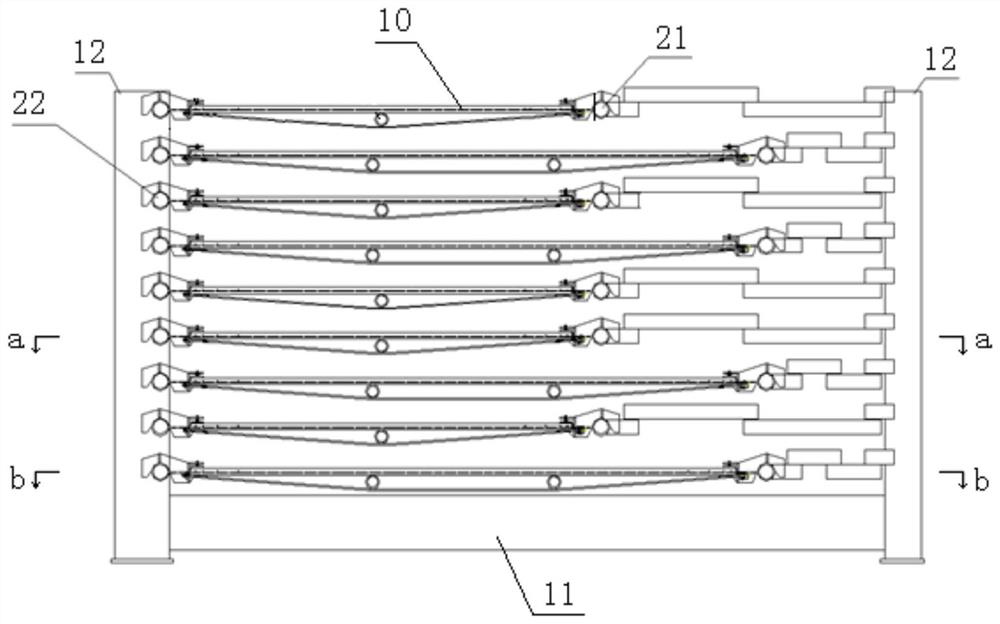

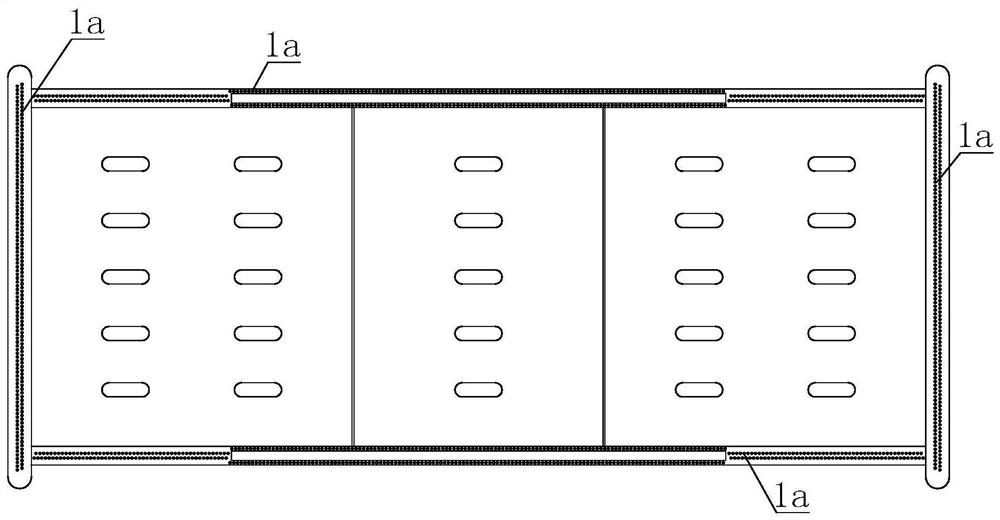

Prefabricated slab transportation frame

ActiveCN113443272AAchieve stackingSave storage spaceExternal framesArchitectural engineeringStructural engineering

The invention discloses a prefabricated slab transportation frame. The prefabricated slab transportation frame comprises a frame body and two opposite supporting rods arranged on the frame body, wherein one supporting rod is a movable supporting rod, the movable supporting rod telescopically moves relative to the other fixed supporting rod, and the distance between the two supporting rods is adjusted so as to adapt to supporting and fixing of prefabricated slabs of different sizes. At least two pairs of fixed supporting rods and movable supporting rods which are arranged in the vertical direction are arranged on the frame body. The movable supporting rod is connected with the frame body through a horizontal telescopic arm. By adjusting the distance between the movable supporting rod and the fixed supporting rod, supporting and fixing of the prefabricated slabs of different sizes can be adapted. Moreover, every two adjacent prefabricated slabs do not affect each other, damage to the prefabricated slabs in the transportation process is avoided, secondary or multiple times of transferring on a construction site can be avoided, the storage yard space of the prefabricated slabs on a construction site is saved, and the construction efficiency is improved.

Owner:ELITE ARCHITECTURAL CO LTD

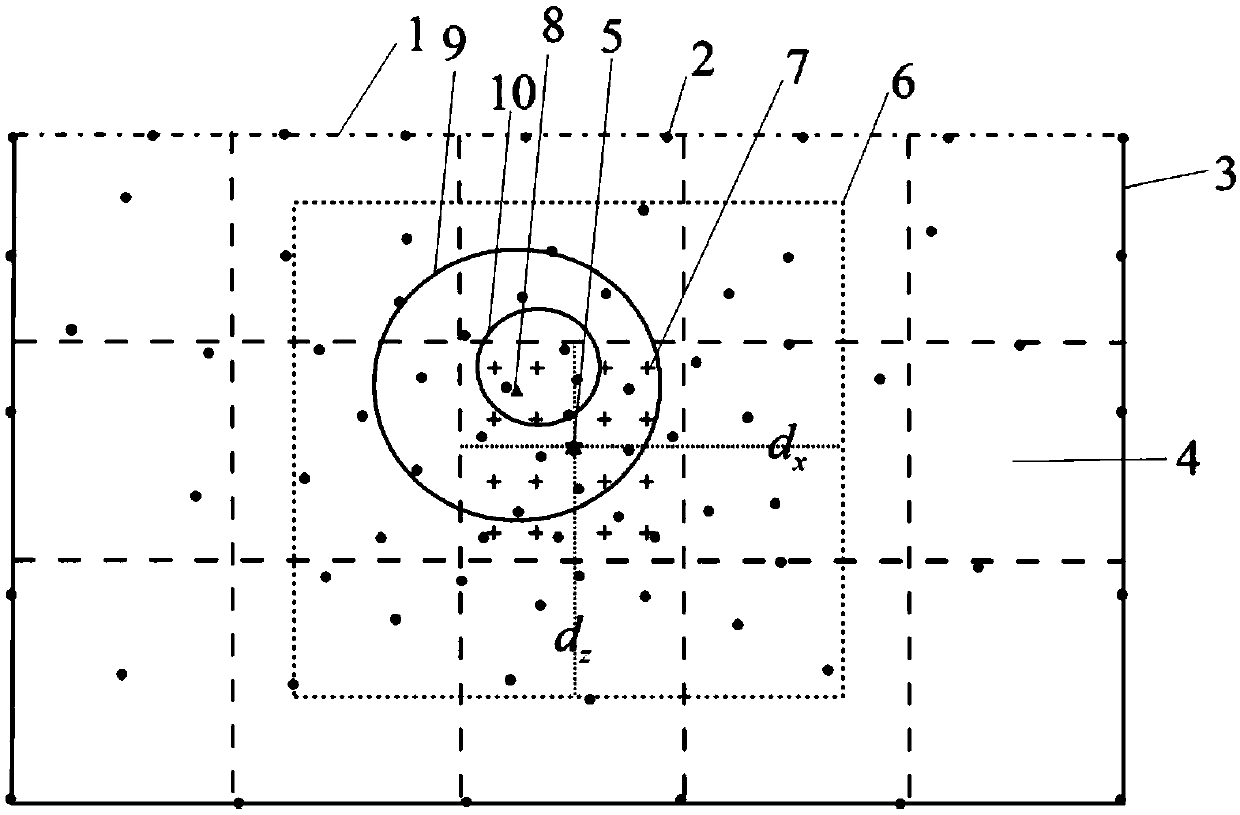

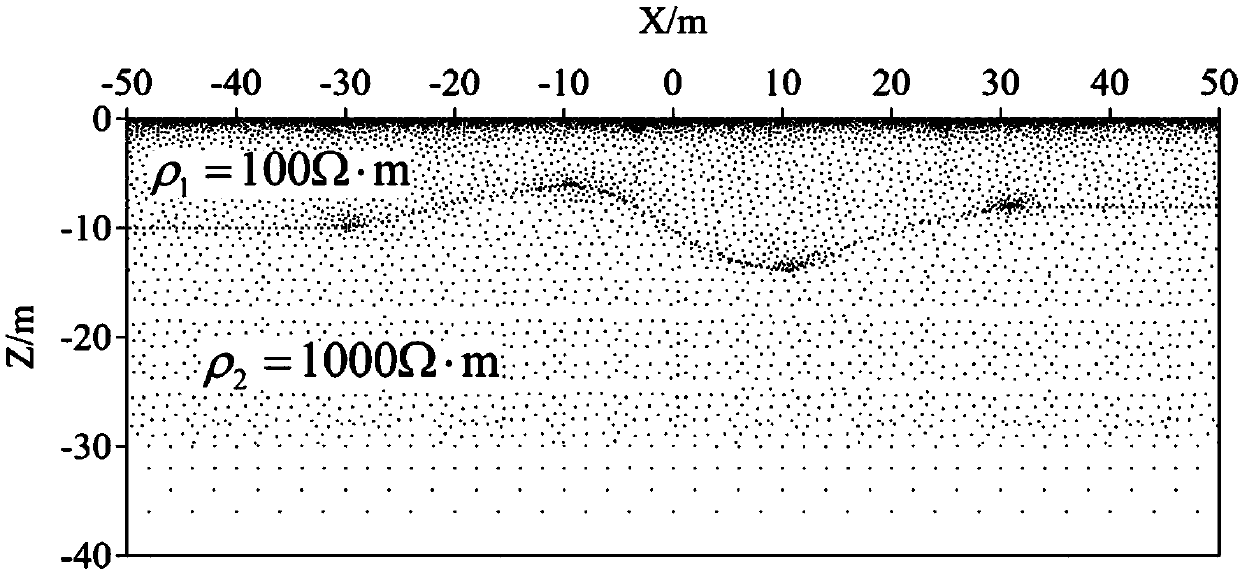

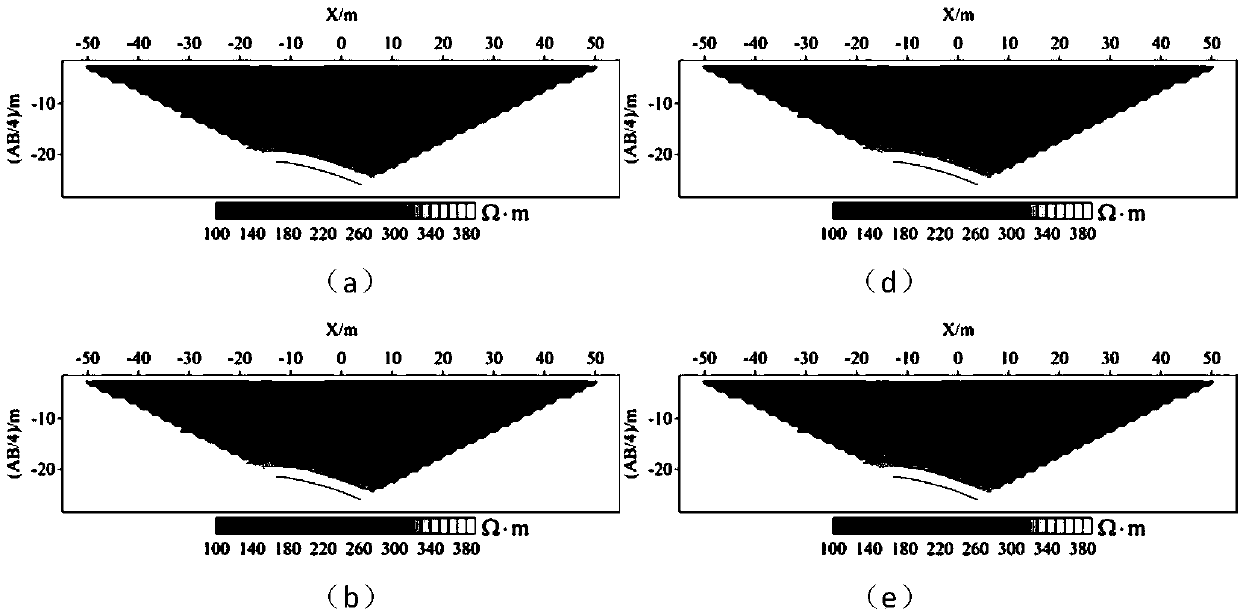

Support domain fast construction method of direct current resistivity element-free method simulation

ActiveCN108710156AShorten construction timeImprove forward calculation efficiencyElectric/magnetic detectionAcoustic wave reradiationNODALElectricity

The invention provides a support domain fast construction method of direct current resistivity element-free method simulation. The method includes the following steps: determining distribution information such as media, landforms and electrodes of a two-dimensional geoelectric model, establishing a calculating domain of a direct current resistivity element-free method, and utilizing an irregular node discrete geoelectric model; arranging and numbering all nodes from small to large according to the x coordinate of the nodes and the z coordinate to give initial support domain parameters; takingthe center point of a background unit as a center, constructing a first class local support domain according to the parameters, dividing the background unit into four sub-domains in the support domain, taking the center points of the sub-domains as centers, constructing second class support domains, and selecting Ng nodes which are close to a Gauss point as the support domain for each Gauss pointin the sub-domains; and performing element-free method calculation to obtain observation apparent resistivity parameters. The method can distribute discrete models based on any nodes so that the support domains can be rapidly constructed, and therefore, calculating efficiency of conventional direct current resistivity element-free method forward modeling can be enhanced.

Owner:HUNAN ZHILI ENG SCI & TECH

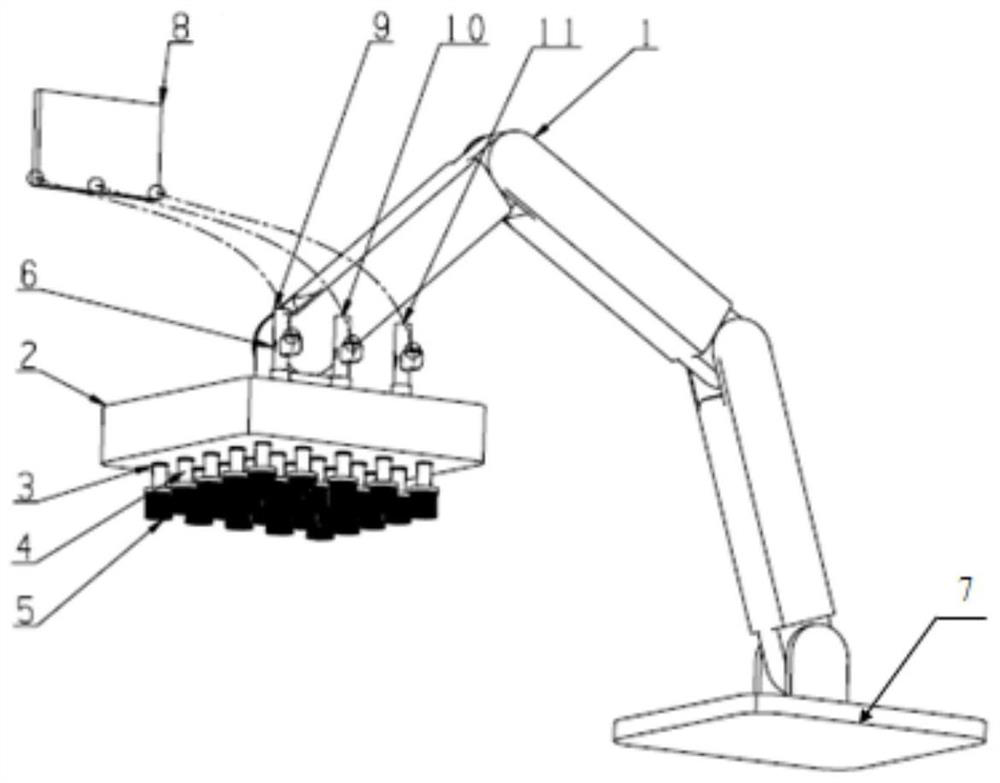

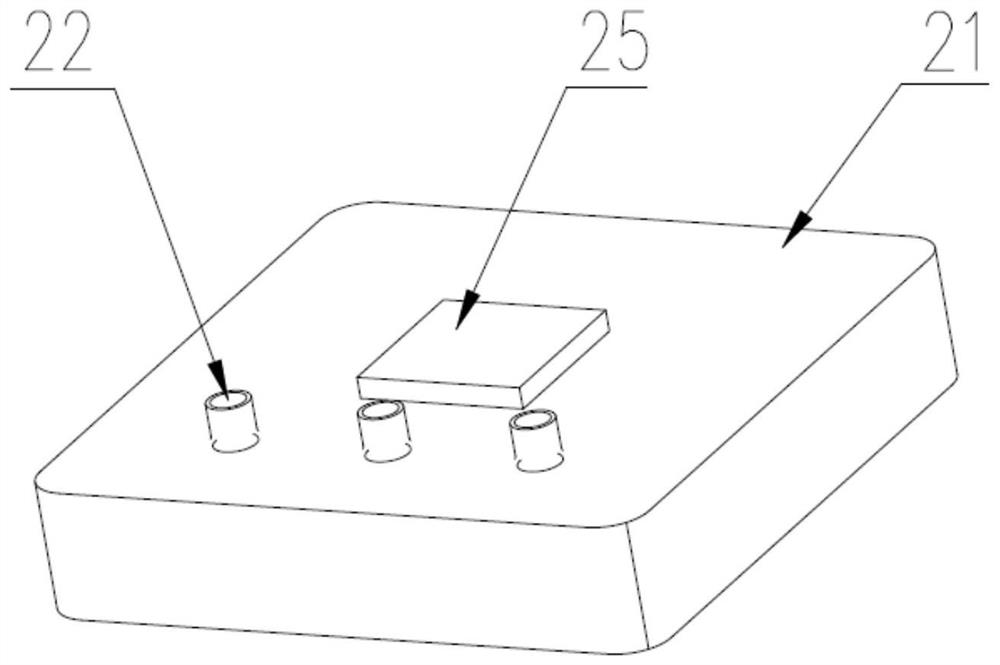

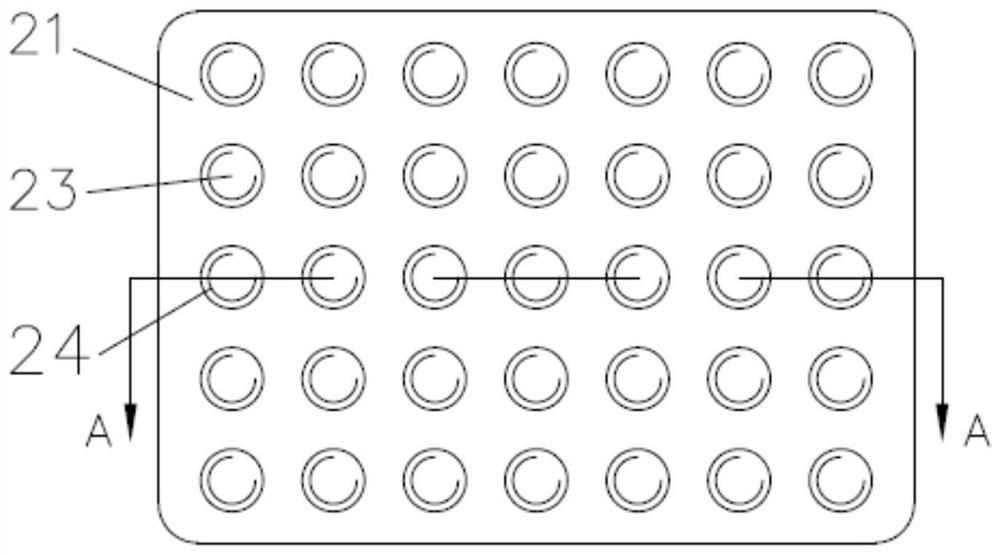

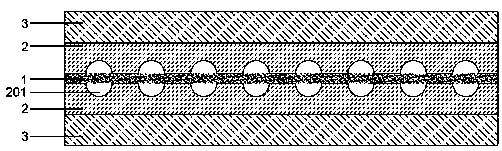

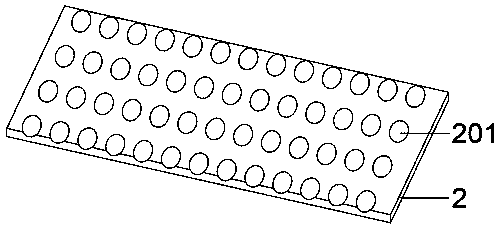

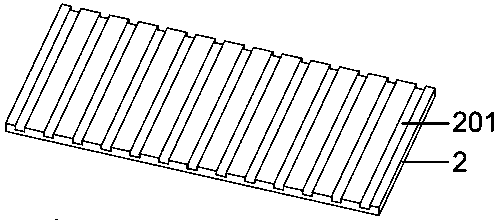

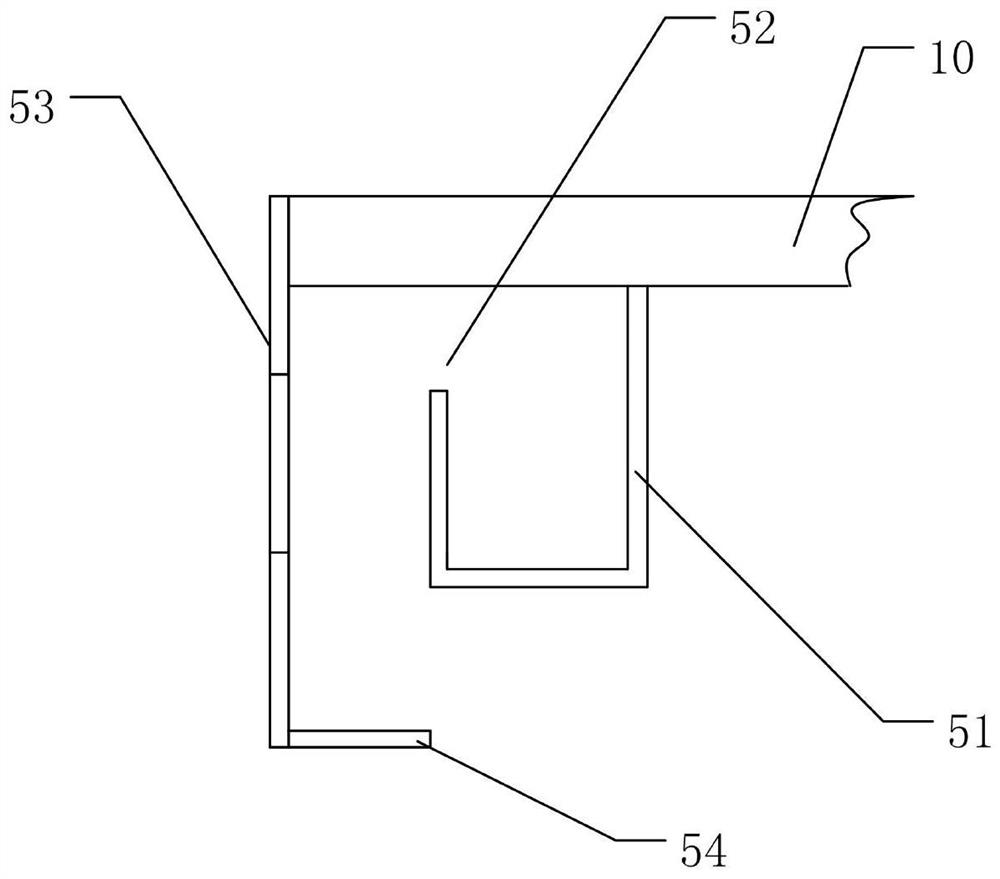

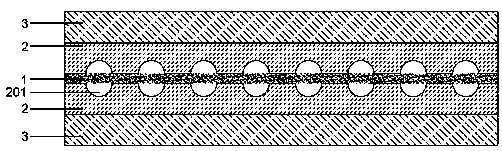

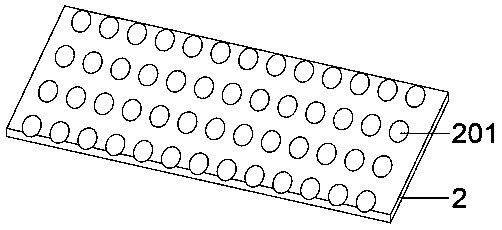

Integrated electroplating cleaning device

InactiveCN112481668AWell mixedGuaranteed cleanlinessDrying gas arrangementsCleaning using toolsAcid washingEngineering

The invention provides an integrated electroplating cleaning device. The integrated electroplating cleaning device comprises an electric mechanical arm (1), a pressure-resistant storage container (2),a spray head (4), a cleaning brush (5), a movable platform (7) and a controller (8), wherein the pressure-resistant storage container (2) comprises a container body (21), filling joints (22), discharge holes (23) and a mounting boss (25); the spray head (4) comprises a spray head shell (41), a sealing boss (42), a spraying channel (43), a brush mounting part (44) and a spraying hole (45); and thecleaning brush (5) comprises a cleaning brush disc (51), an arc-shaped guide plate (52) and brush heads (53). According to the device, acid pickling, cleaning, brushing, drying and combined compositewashing processes are effectively achieved; moreover, in the cleaning or drying process of the device, the brush heads always sweep the surface of a workpiece, so that dust is effectively prevented from being attached to the surface of the workpiece, the cleaning efficiency is high, and the effect is good; and the integrated electroplating cleaning device is widely suitable for cleaning treatmentof large-plane workpieces before electroplating.

Owner:龚兵

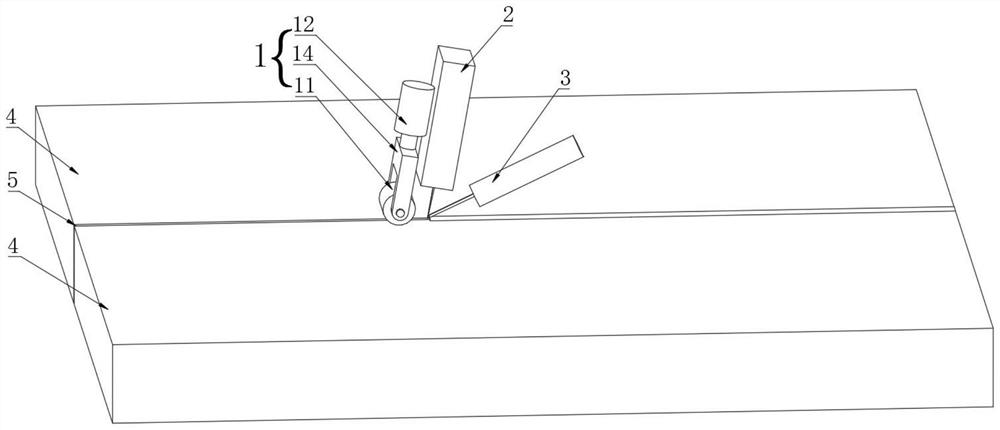

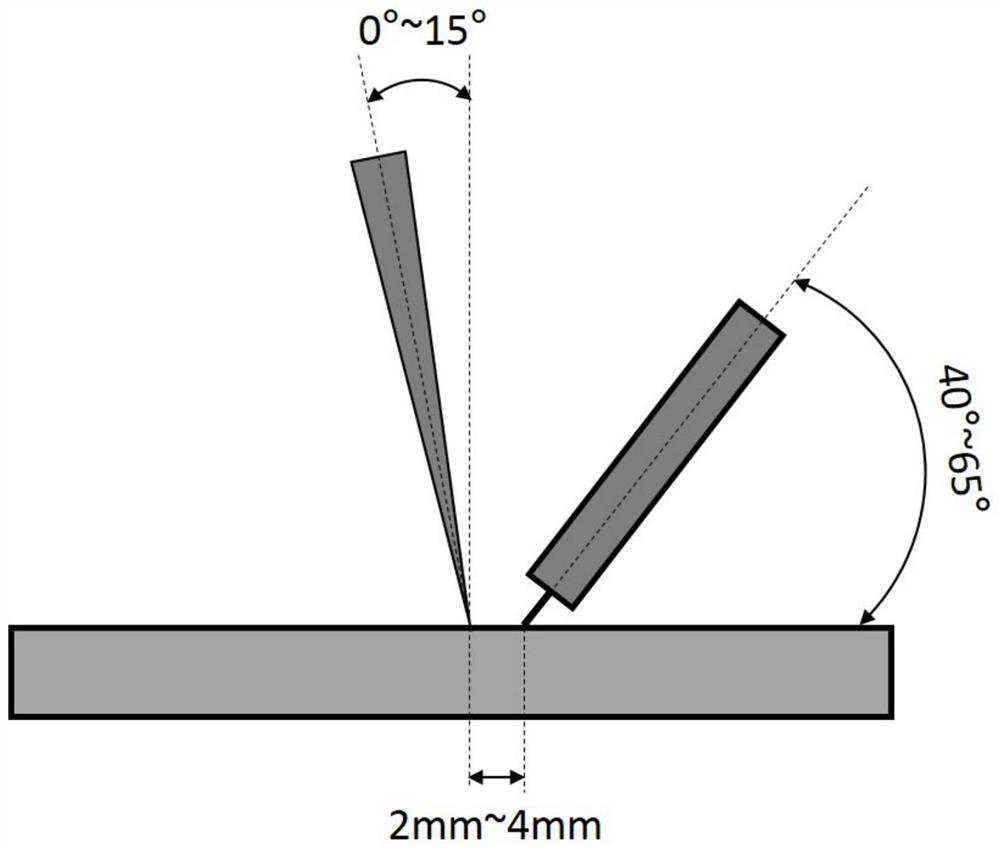

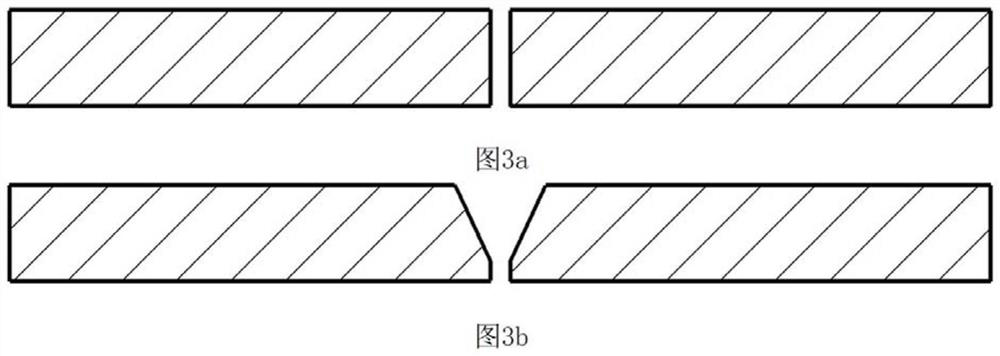

Welding system for aluminum alloy laser welding and surface treatment method

PendingCN113909678AReduce reflexesImprove welding qualityLaser beam welding apparatusSurface oxidationSurface roughness

The invention relates to the technical field of welding, in particular to a welding system for aluminum alloy laser welding. The welding system comprises a workbench, a surface machining device, a laser welding device and an electric arc welding device. A hard particle layer on a roller in the surface machining device is used for damaging a surface oxidation film of an aluminum alloy, so that the surface roughness of the aluminum alloy is improved, the reflection effect of the surface of the aluminum alloy on laser is effectively reduced, the welding process of the aluminum alloy is stabilized, and attractive and defect-free welding seams are obtained. Meanwhile, the invention further provides a surface treatment method of a to-be-welded part of the aluminum alloy by using the laser welding system, and a traditional surface treatment method used for laser or laser-arc welding hybrid welding of the aluminum alloy is changed, so that real-time treatment, namely surface treatment and the welding process of the surface of the be-welded part in the aluminum alloy welding process can be conducted synchronously, repeated treatment caused by the fact that the interval between surface pretreatment and the welding process is too long is avoided, the surface treatment method is simple and easy to operate, the welding pretreatment process is reduced, and the welding quality is improved.

Owner:HWI-NICHST WELDING & ENG INNOVATION CENT (QINGDAO) CO LTD

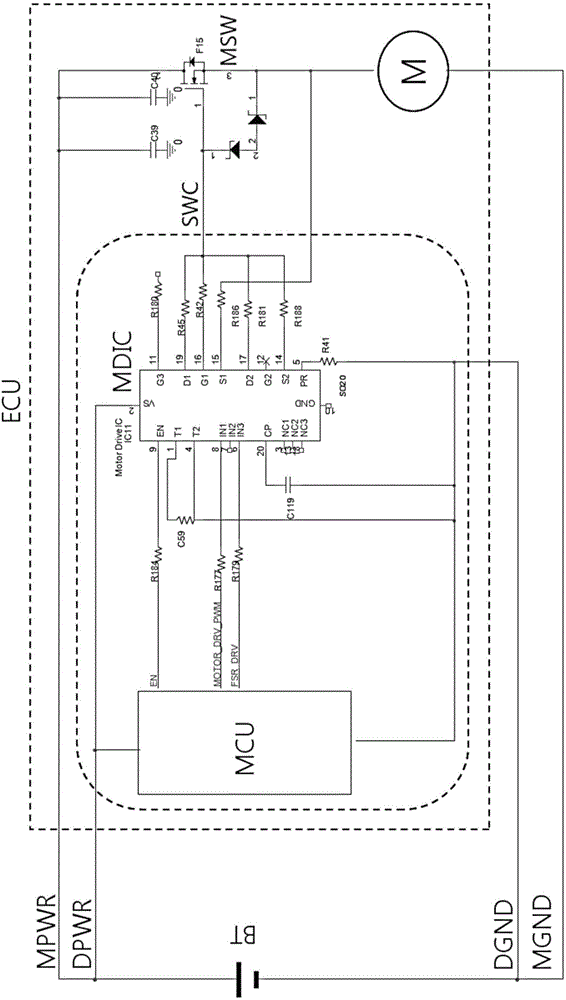

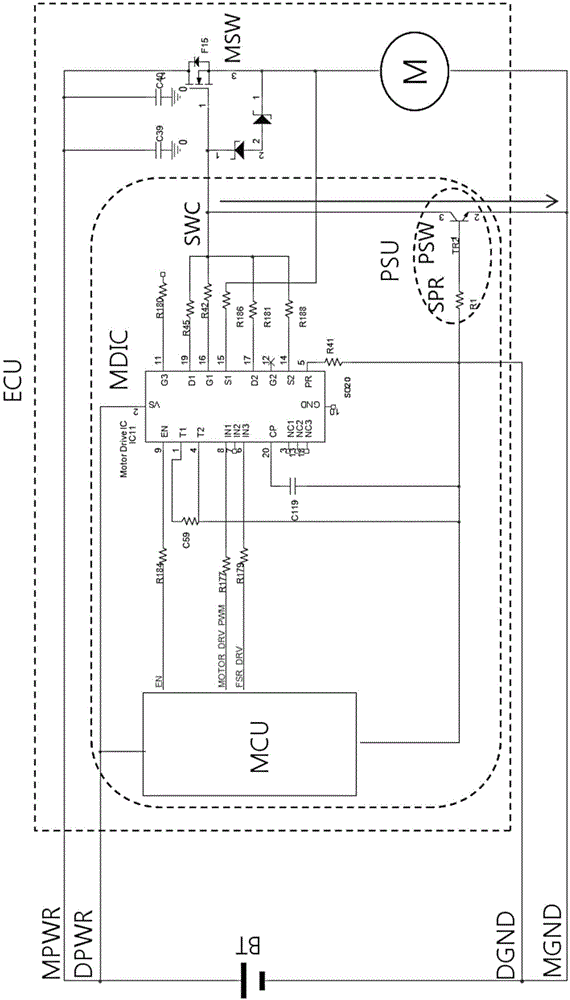

Vehicle motor drive circuit

ActiveCN104659745APrevent secondaryBoost signal levelDC motor speed/torque controlElectric motor controlDriver circuitMotor drive

Disclosed are a vehicle motor drive circuit and a driving method thereof. In the vehicle motor drive circuit according to the present invention, when the floating voltage is generated on the digital ground line due to a short circuit or a poor contact, the switch control signal is connected to the motor ground power supply to lower the signal level of the switch control signal in response to the voltage difference produced between the digital ground line and the motor ground line. Therefore, it is possible to prevent an erroneous operation of the motor switch or the motor. Accordingly, it is possible to prevent a damage of the motor or the motor switch and a secondary problem caused by unintentional operation of the motor.

Owner:HYUNDAI MOBIS CO LTD

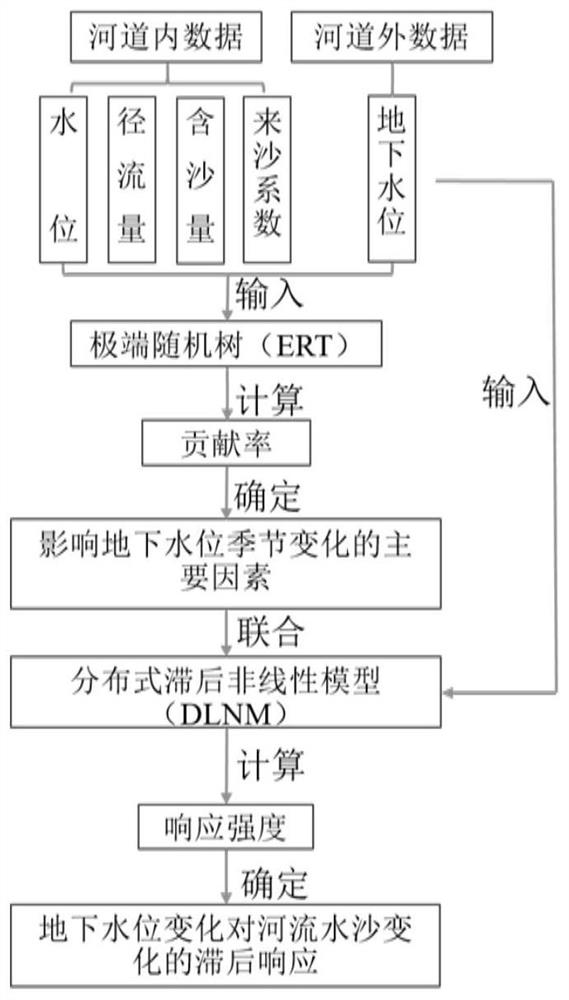

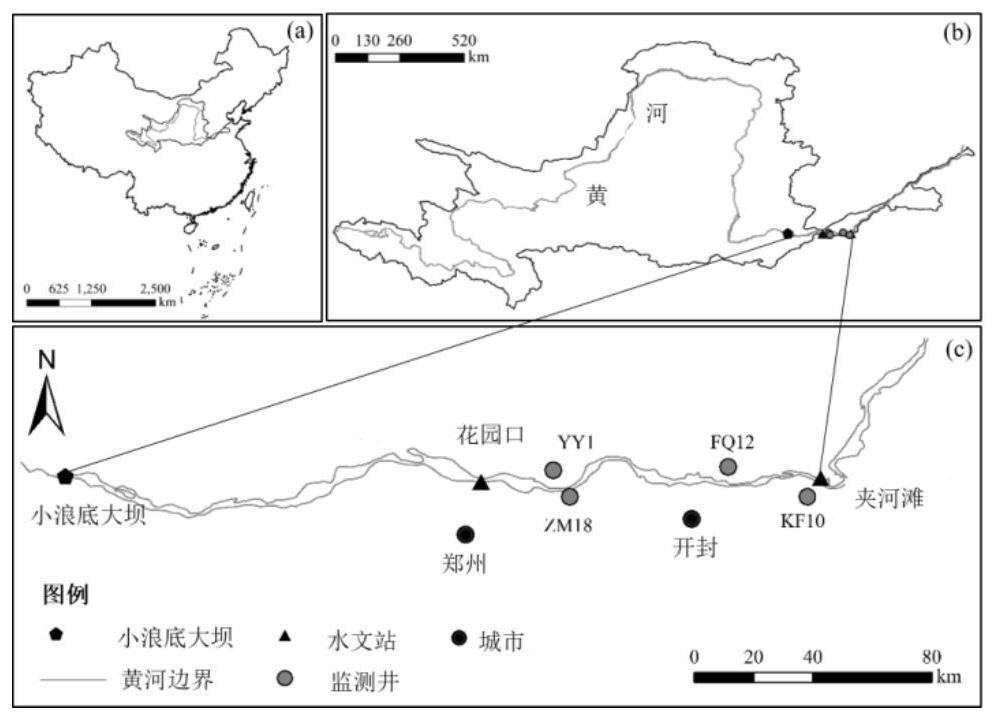

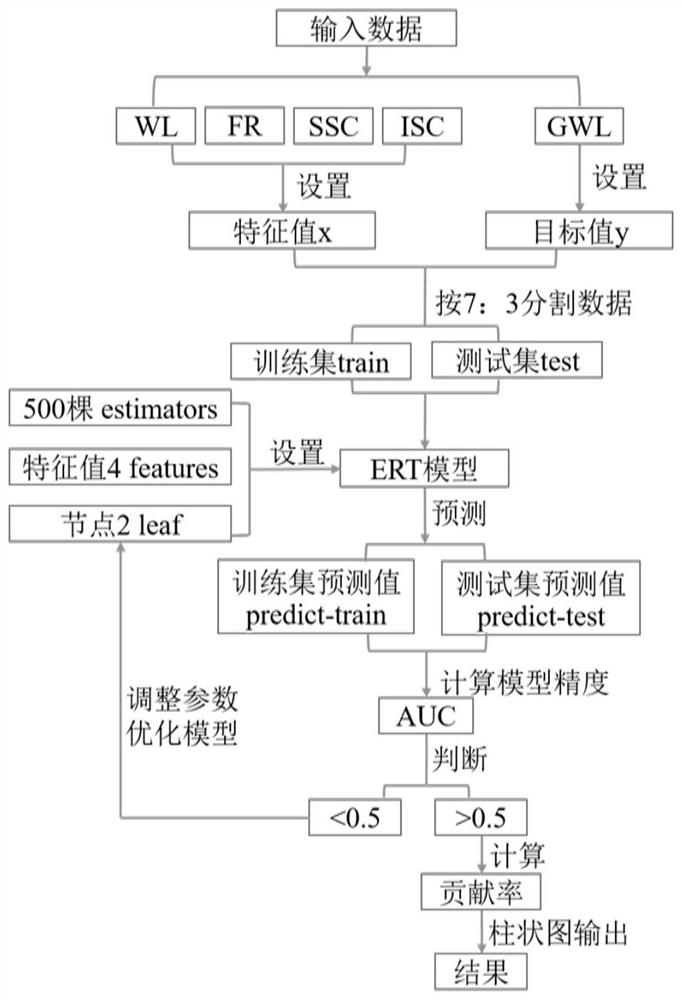

Method for determining lagging response time of mutual conversion of river water and underground water under influence of river water and sediment regulation

PendingCN114519308AEasy to operateShort timeGeneral water supply conservationDesign optimisation/simulationRiver routingEnvironmental engineering

The invention provides a method for determining lagging response time of mutual conversion of river water and underground water under the influence of river water and sediment regulation. The method comprises the following steps: 1, collecting and processing river and underground water data; 2, determining main water and sediment factors influencing the change of the underground water level outside the river channel based on an extreme random tree model; and 3, domesticating the original DNLM model, and analyzing by using the domesticated model to obtain the lag response time of the underground water level to the main water and sediment factors of the river. The method not only can quantify the lagging response time of the mutual conversion of the river water and the underground water, but also can improve the simulation efficiency, reduce the implementation cost and quickly process data.

Owner:HENAN UNIVERSITY

Multi-layer kitchen paper with composite gluing solution

ActiveCN110318298AControl percussionAvoid breedingWater-repelling agents additionReinforcing agents additionWater basedDecomposition

The invention relates to a kind of multi-layer kitchen paper with a composite gluing solution. The paper comprises upper-layer raw paper, a hollow layer, a gluing layer, a hollow layer and lower-layerraw paper. The upper-layer raw paper comprises an upper surface layer and a lower surface layer; the lower-layer raw paper comprises an upper surface layer and a lower surface layer. The gluing layeris the composite gluing solution which is prepared from an anion rosin gluing agent, a cation starch gluing agent, cation water-based polyurethane-acrylic ester, a gluing solution reinforcement agentand the balance water; the gluing solution reinforcement agent is a mixture including a pentafluoroethyl-substituted pyridine compound shown in the formula, polysorbate and carboxymethylcellulose; through the composite gluing solution, the face, with oil strains, water strains and other pollutants, of the kitchen paper can keep high oil and water absorption characteristics, transfer and wetting of the pollutants to the handheld face can also be completely separated, the capacity of pollutant storage of the kitchen paper is improved, and the kitchen paper also has a new heat insulation function and helps to inhibit bacterium breeding, delay decomposition and reduce pollution.

Owner:深圳市铭诚生活科技有限公司

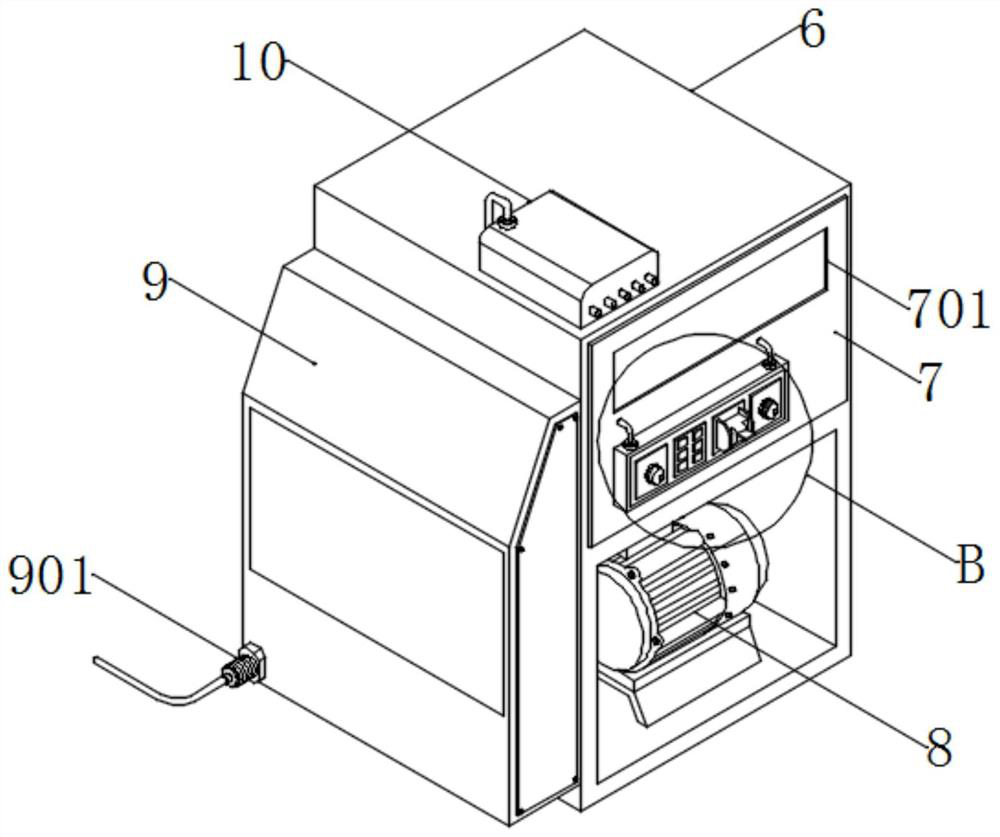

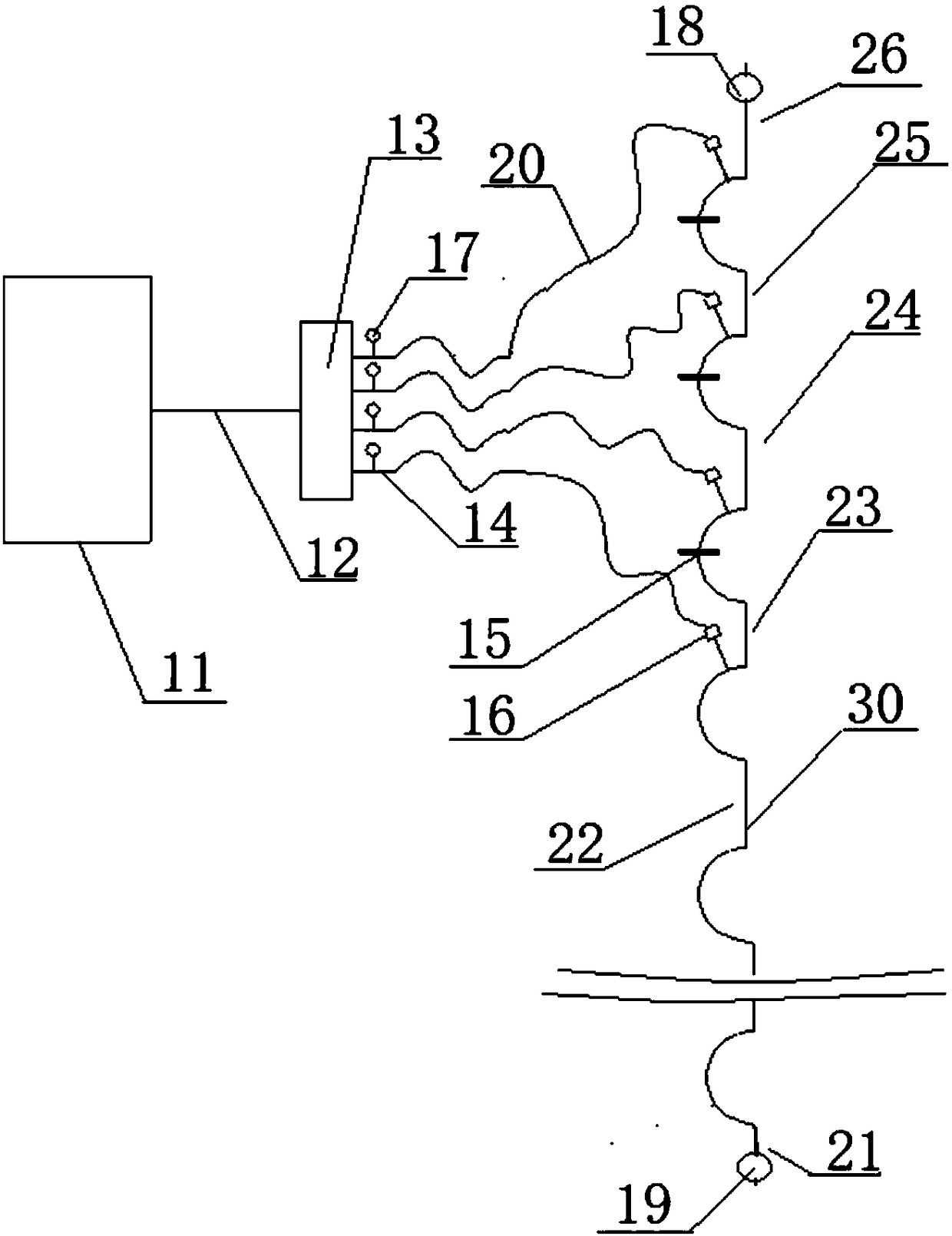

Air purification spraying device for printing and dyeing room and spraying control method of air purification spraying device

ActiveCN113350935AReduce impactPrevent drippingUsing liquid separation agentSpecific water treatment objectivesAir cleaningProcess engineering

The invention discloses an air purification spraying device for a printing and dyeing room, and belongs to the technical field of air purification. The device comprises a main body box and suction pumps arranged in the left side and the right side of the main body box and used for pumping a water source into the main body box for circulation and then discharging. The device overcomes the defects in the prior art, multiple sprayers can be installed at the upper end of a water pipe by screwing connectors into the water pipe one by one through sprayers, an adjusting ring, nozzles and the connectors, the spraying direction of the device is effectively increased, and after the adjusting ring moves up and down, the impact force generated when water flow collides with the adjusting ring can be adjusted; water flow can be extruded out of the nozzles at different injection speeds according to the magnitude of impact force to be sprayed, then the spraying range of the device is changed, and the device can conduct wide-range spraying or fixed-point spraying on part of areas with serious air quality according to the actual air conditions of different areas in the printing and dyeing room, resources are saved, and the working efficiency is improved.

Owner:桐乡市京都印染股份有限公司

Acidizing solution for dissolution of clay mineral and preparation method thereof

ActiveUS20210054261A1Reaction is slowEasy to disassembleFluid removalDrilling compositionClay mineralsPerfluoroacetic Acid

The invention provides an acidizing solution for dissolution of a clay mineral and a preparation method thereof. The acidizing solution comprises hydrochloric acid, fluoboric acid, acetic acid, trifluoroacetic acid, hydrogen peroxide, ammonium chloride, dimethylamino-methylbenzotriazole, alkyl ammonium chloride, and polymethylacrylic acid. The acidizing solution provided by the invention can effectively dissolve organic matter, such as clay minerals and cements, in a high-temperature oil-gas reservoir over 160° C., inhibit swelling and migration of clay particles in the presence of water in the acidizing process, avoid secondary deposition of the reservoir, and improve the permeability of the reservoir. The acidizing solution can be prepared and used on the field conveniently and is safe and reliable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

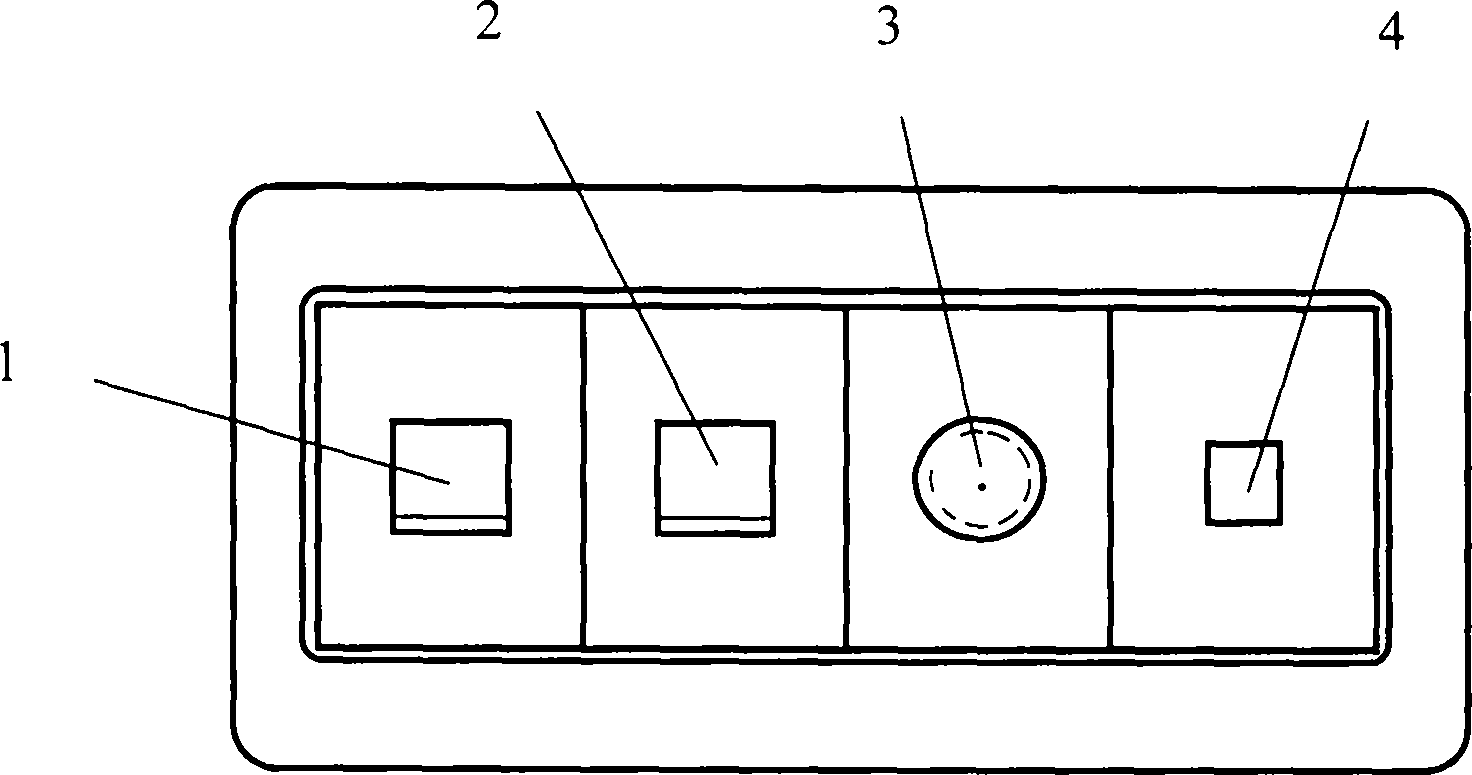

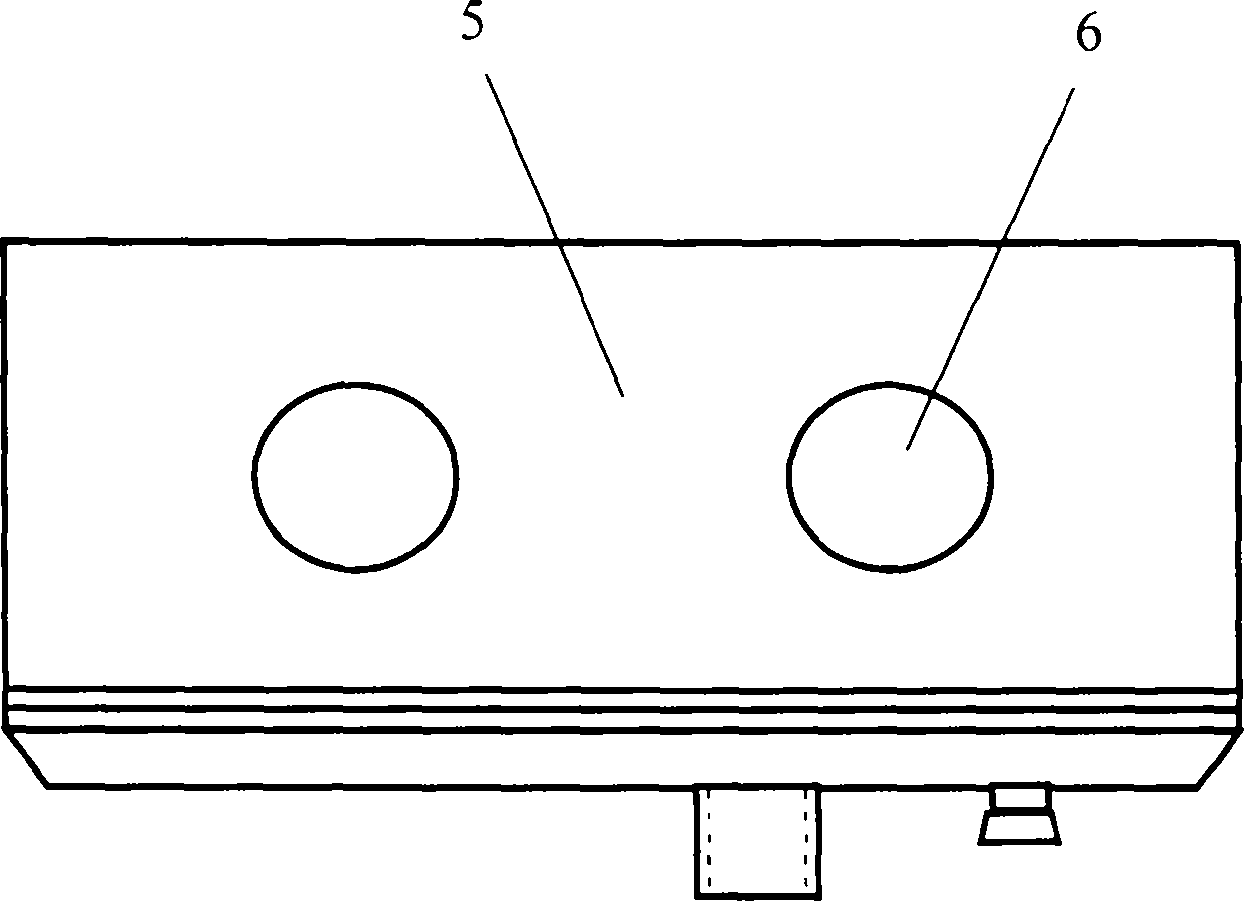

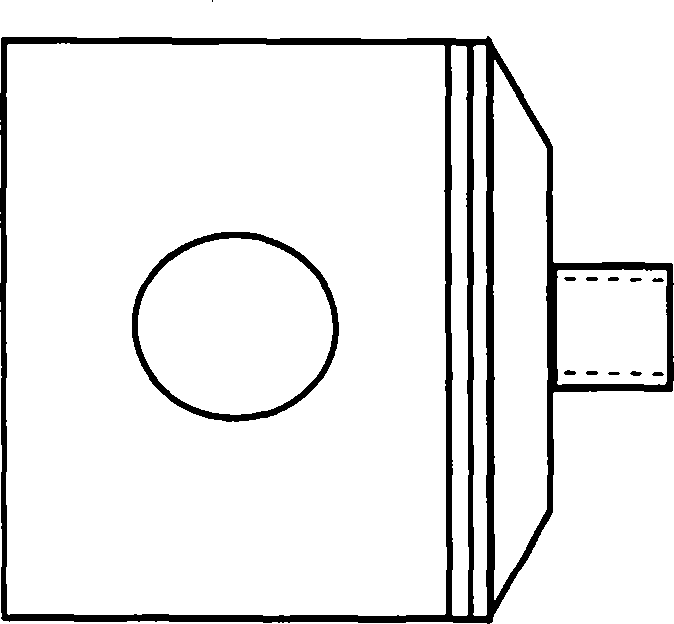

Multi-purpose terminal box

InactiveCN103427380AFirmly connectedPrevent secondaryElectrical apparatusEngineeringElectrical and Electronics engineering

Owner:刘彩声

Highway pavement tamping device

ActiveCN111676784AImprove rolling effectSave time for accurate positioningRoads maintainenceMoving partsDrill bit

The invention discloses a highway pavement tamping device, which includes a vehicle body that comprises a supporting plate and a moving part, and the moving part comprises rolling wheels arranged at the front bottom end and the rear bottom end of the supporting plate; a stirring mechanism is arranged on the supporting plate; a repairing device comprises a drill bit part, a tamping part and an auxiliary rolling part, which are arranged at the bottom end of the supporting plate; an auxiliary rolling part is arranged at the rear end of the tamping part in a rotatable and telescopic manner; a controller; a repairing positioning module which is used for positioning the drill bit relative to the to-be-repaired surface; a repairing shape determining module which is used for scanning and analyzingthe size and repairing depth of the to-be-repaired surface so as to generate a travel path of the drill bit; and the filling analysis module is used for receiving the size and the depth of the repaired area analyzed by the repairing confirmation module so as to generate the amount of the repairing material used for filling the repaired surface in the compacted state. The device integrates stirring, conveying and tamping, the repairing efficiency is high, and the compaction effect is good.

Owner:刘江桥

A kind of multi-layer kitchen paper containing composite sizing solution

ActiveCN110318298BControl percussionAvoid breedingWater-repelling agents additionReinforcing agents additionCellulosePolymer science

The invention relates to a kind of multi-layer kitchen paper with a composite gluing solution. The paper comprises upper-layer raw paper, a hollow layer, a gluing layer, a hollow layer and lower-layerraw paper. The upper-layer raw paper comprises an upper surface layer and a lower surface layer; the lower-layer raw paper comprises an upper surface layer and a lower surface layer. The gluing layeris the composite gluing solution which is prepared from an anion rosin gluing agent, a cation starch gluing agent, cation water-based polyurethane-acrylic ester, a gluing solution reinforcement agentand the balance water; the gluing solution reinforcement agent is a mixture including a pentafluoroethyl-substituted pyridine compound shown in the formula, polysorbate and carboxymethylcellulose; through the composite gluing solution, the face, with oil strains, water strains and other pollutants, of the kitchen paper can keep high oil and water absorption characteristics, transfer and wetting of the pollutants to the handheld face can also be completely separated, the capacity of pollutant storage of the kitchen paper is improved, and the kitchen paper also has a new heat insulation function and helps to inhibit bacterium breeding, delay decomposition and reduce pollution.

Owner:深圳市铭诚生活科技有限公司

a stent graft

InactiveCN104367400BEffective positioningGuaranteed blood supplyStentsBlood vesselsVascular diseaseStent grafting

The invention relates to the technical field of medical instruments, in particular to a stent graft used for treating peripheral arterial diseases and provided with a branch stent. The stent graft comprises a main stent and the branch stent, the main stent and the branch stent are each provided with a near end, a far end and an inner cavity arranged between the near end and the far end, an opening is formed in the main stent, the main stent and the branch stent are connected through a connector, the connector is provided with a bottom connected with the opening, a top capable of movably entering and exiting the opening and a connection inner cavity arranged between the bottom and the top, and the near end of the branch stent is connected with the top of the connector. The stent graft has the advantages that the stent graft is used for treating vascular diseases, is wide in adaptability, does not need to be customized, can be used for recovering multiple branch arteries when the peripheral arterial diseases are treated, prevents vascular stents from being implanted twice or many times and simplifies operation difficulty.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Acidizing solution for dissolution of clay mineral and preparation method thereof

ActiveUS10961441B2Easy to disassembleReaction is slowFluid removalDrilling compositionClay mineralsPerfluoroacetic Acid

The invention provides an acidizing solution for dissolution of a clay mineral and a preparation method thereof. The acidizing solution comprises hydrochloric acid, fluoboric acid, acetic acid, trifluoroacetic acid, hydrogen peroxide, ammonium chloride, dimethylamino-methylbenzotriazole, alkyl ammonium chloride, and polymethylacrylic acid. The acidizing solution provided by the invention can effectively dissolve organic matter, such as clay minerals and cements, in a high-temperature oil-gas reservoir over 160° C., inhibit swelling and migration of clay particles in the presence of water in the acidizing process, avoid secondary deposition of the reservoir, and improve the permeability of the reservoir. The acidizing solution can be prepared and used on the field conveniently and is safe and reliable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Highway safety guardrail

InactiveCN108677810APrevent secondaryReduce impactRoadway safety arrangementsEngineeringVehicle driving

The invention belongs to the technical field of highway facilities, and in particular relates to a highway safety guardrail. The highway safety guardrail comprises protective rails, protective columns, connecting bands, folding safety fences, connecting locks and a roadbed, wherein the protective columns are anchored to the roadbed; the protective rails are fixed to the upper ends of the protective columns; one end of each connecting band is connected to the corresponding protective rail and the other end of each connecting band is connected to the corresponding folding safety fence; and two safety fences of each folding safety fence are locked by the corresponding connecting lock. When a vehicle driving at high speed hits the highway safety guardrail, the high plasticity of the connectingbands can reduce a certain impact force, and the folding safety fences are completely unfolded and locked by the connecting locks so as to prevent the vehicle from going off the road. In the impact process, the deformation of the connecting bands and the unfolding of the folding safety fences have a cushioning effect on the vehicle and provide road space to form a temporary emergency lane so as to prevent second or more impact by following vehicles.

Owner:SHENYANG JIANZHU UNIVERSITY

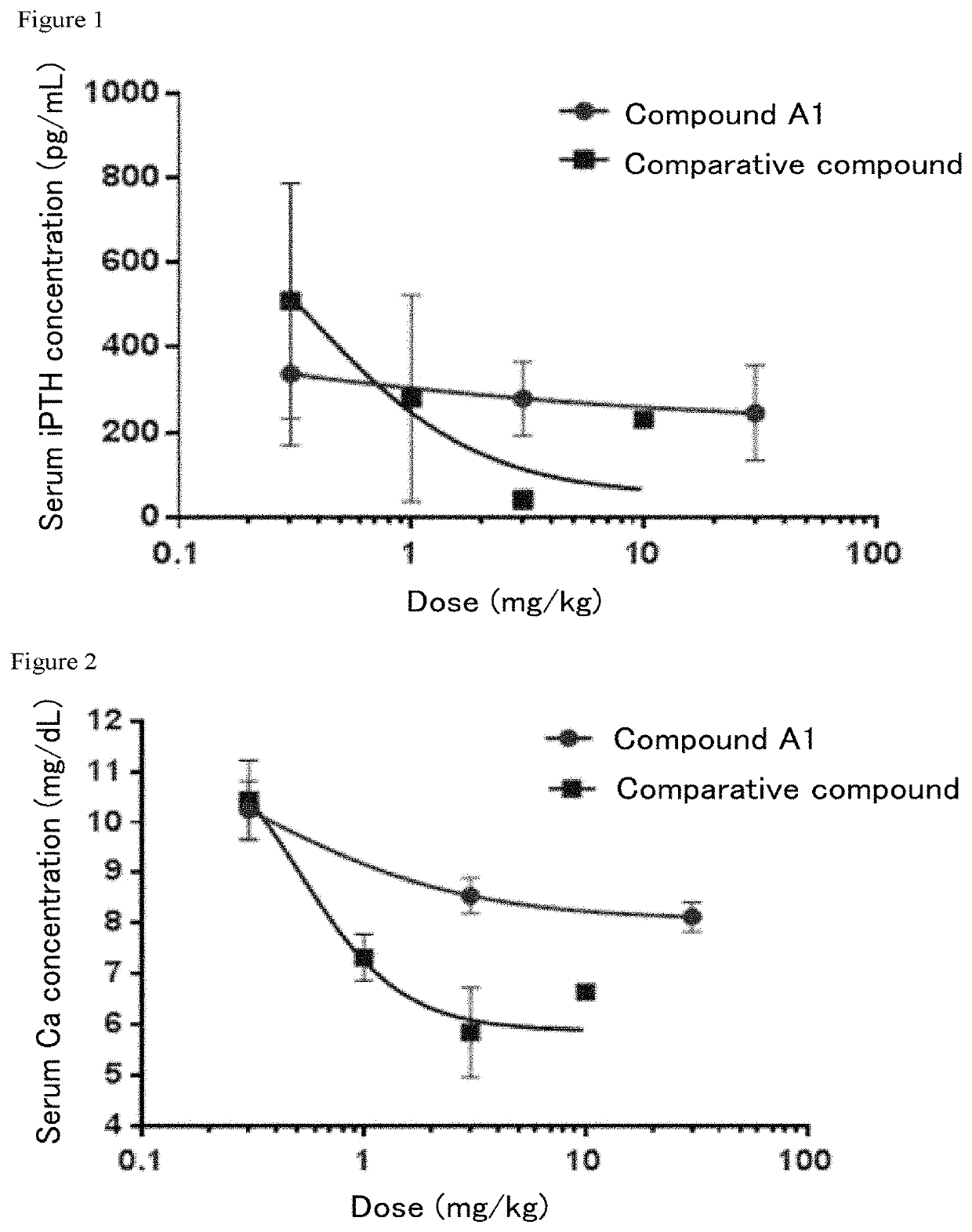

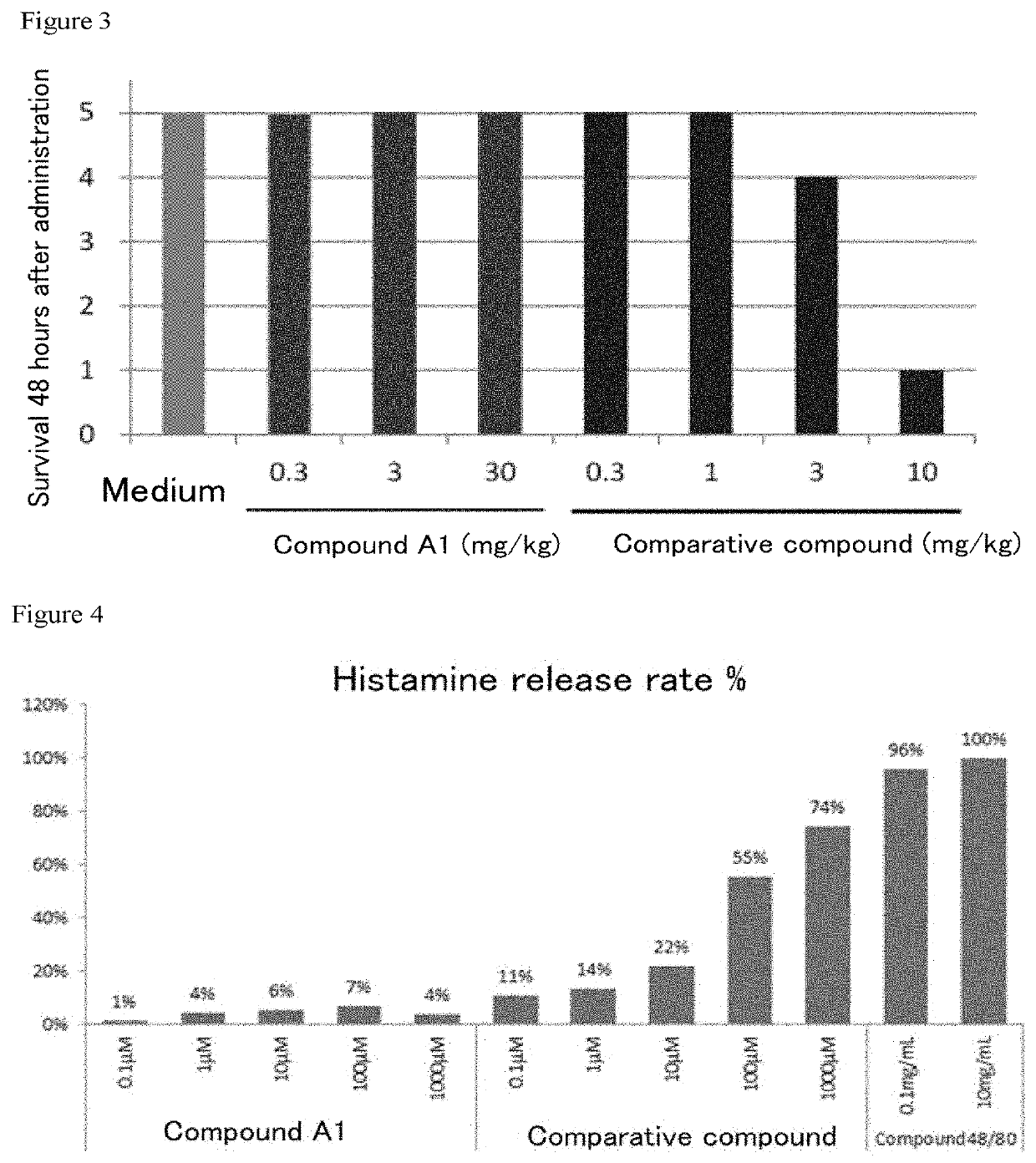

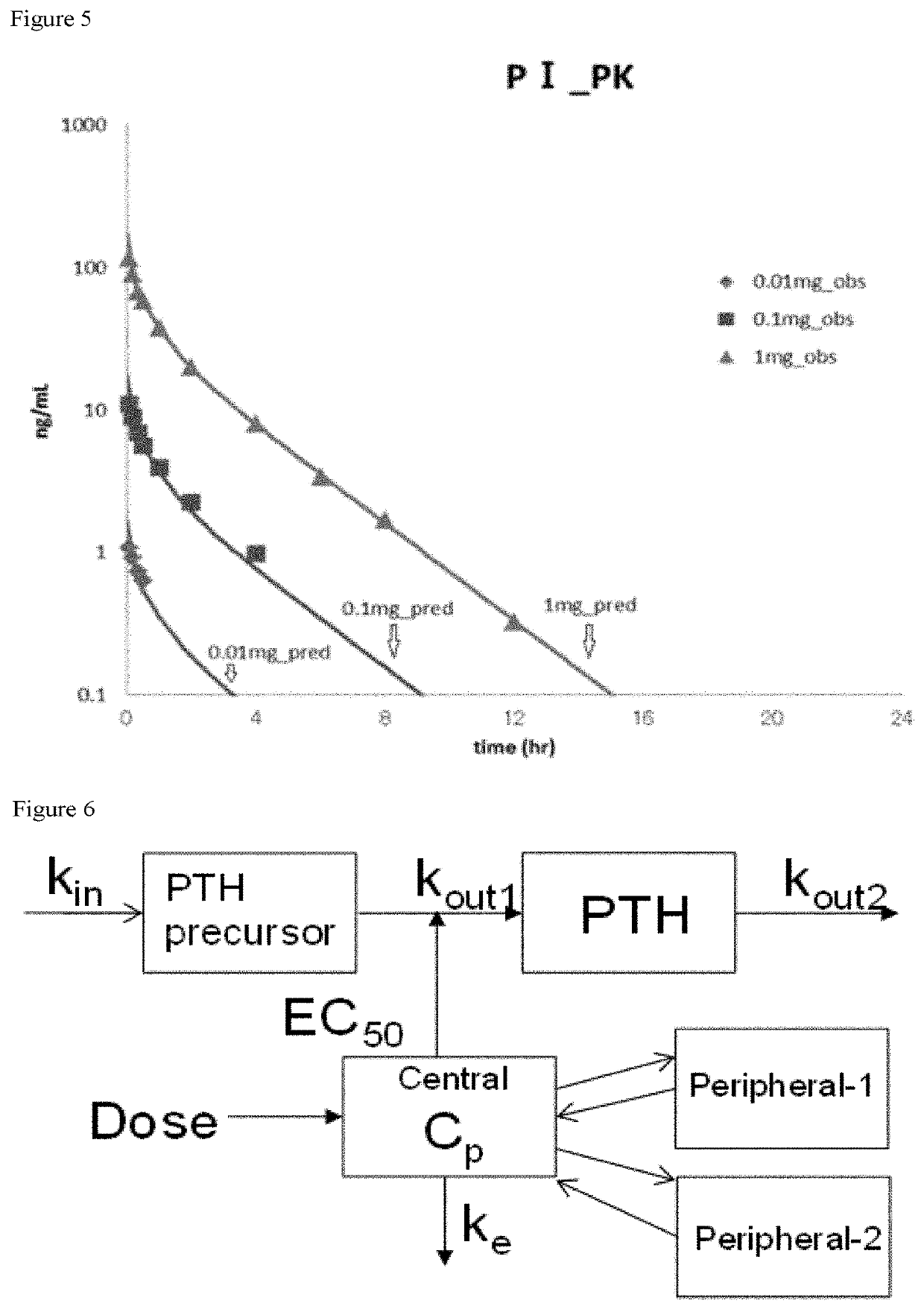

Medicinal composition for preventing or treating secondary hyperparathyroidism under maintenance dialysis

ActiveUS20200397731A1Eliminate side effectsEasy dosage managementOrganic active ingredientsPharmaceutical delivery mechanismPharmaceutical medicineDialysis

A medicinal composition for preventing or treating secondary hyperparathyroidism under maintenance dialysis, said medicinal composition comprising 3-{[(2S)-2-amino-2-carboxyethyl]carmaboylamino}-5-chloro-4-methylbenzenesulfonic acid or a pharmaceutically acceptable salt thereof, or a solvate of the same which is to be administered by a predefined route in a predefined dosage. According to the present invention, it is possible to provide a prophylactic or therapeutic agent for secondary hyperparathyroidism under maintenance dialysis, said agent showing reduced side effects or no significant accumulation. This medicinal agent allows easy administration management and has a high safety compared with conventional products.

Owner:EA PHARMA CO LTD

A method for repairing the cooling water pipe of the stave of a blast furnace, its structure, and a pressure leak detection device

ActiveCN105969924BReduce resistancePrevent secondaryCooling devicesChecking devicesWater leakageWater source

The invention discloses a blast furnace cooling-wall cooling water pipe repairing method and a structure thereof and a pressure leakage detection device, belonging to the technical field of iron making blast furnace production. The repairing method disclosed by the invention comprises the steps of pressure leakage detection, disconnection of a damaged cooling water pipe, leakage point bypass, threading of the damaged cooling water pipe, silk threading of the damaged cooling water pipe, pipe threading of the damaged cooling water pipe, external connection of a water source, grouting and the like. The repairing structure of the blast furnace cooling-wall cooling water pipe disclosed by the invention comprises the damaged cooling water pipe, a cooling water-in end at the upper part of the damaged cooling water pipe and a cooling water-out end at the lower part, wherein the cooling water-in end and the cooling water-out end are folded outward and communicated through an external cooling pipe, and a metal hose penetrates inside; a gap formed between the metal hose and the damaged cooling water pipe is filled with a high-heat conduction grouting layer; and a bypass pipe is arranged at the upper part of the external cooling pipe. In the invention, the problems that the service life of the blast furnace cooling wall is influenced and the repairing cost is high due to the imbalance between the local cooling effect and peripheral cooling effect in water leakage repairing of the blast furnace cooling wall are effectively solved.

Owner:MAANSHAN IRON & STEEL CO LTD

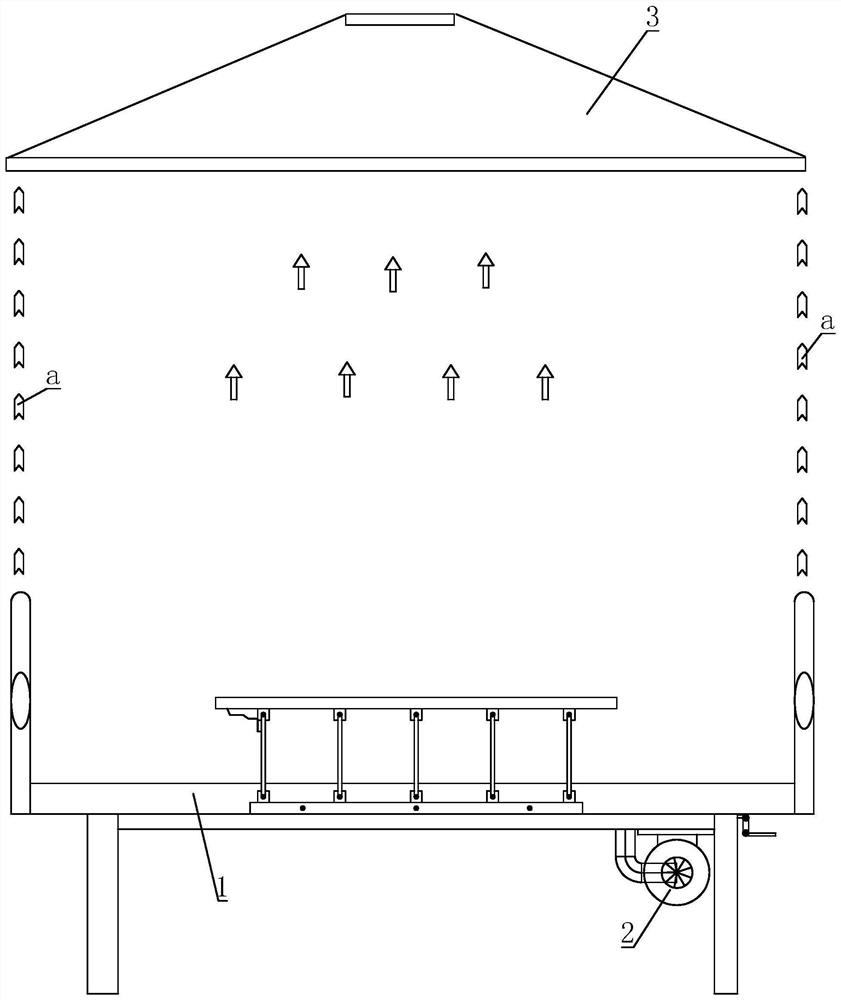

Air curtain type nursing bed and ambulance with same

InactiveCN112472445AFree from infectionReduce the risk of infectionNursing bedsAmbulance serviceNursing careEngineering

The invention discloses an air curtain type nursing bed and an ambulance with the same. A plurality of air outlet holes are distributed in the circumferential direction of a bed table of the nursing bed, an air supply device used for supplying air to the air outlet holes is installed on the nursing bed, a negative pressure air collecting device is arranged above the bed table and used for absorbing airflow from the air outlet holes, and the airflow forms an air curtain along the circumferential direction of the bed table. The ambulance comprises an air curtain type nursing bed, a movable framewith wheels is installed on the lower side of the bed table, sliding ways matched with the wheels are arranged in the ambulance, and the negative pressure air collecting device is installed on the top wall of the ambulance. The air curtain type nursing bed has the beneficial effects that the air curtain structure formed by airflow can guarantee communication between doctors and patients and can also play a role in physical isolation, so that medical staff are prevented from being infected.

Owner:CHONGQING JINQI TECH SHARES

A vertical impact testing machine

ActiveCN105842088BGuaranteed accuracyPrevent repeated impactStrength propertiesModular designMechanical engineering

The invention discloses a vertical impact tester which comprises a base frame module, an impact body module, a quick clamp module and at least one inertia triggering module .The base frame module forms a base framework of the vertical impact tester, and at least two guide shafts are longitudinally and vertically arranged in the base frame module .The impact body module comprises a movable carrier plate and a punch installed at the lower end of the movable carrier plate, and the movable carrier plate is connected with the guide shafts through linear bearings .The quick clamp module is installed on a bottom plate on the lower portion of the base frame module, opposite to the punch and used for holding an elastic workpiece to be subjected to impact testing .The inertia triggering modules are installed on the movable carrier plate .The impact body module impacts the elastic workpiece, rebounds and then triggers a locking action, and the impact body module is locked to the base frame module so as to prevent the impact body module from repeatedly colliding with the elastic workpiece .According to the technical scheme, modular design is adopted, the impacting action can be automatically locked after impact testing so as to prevent the elastic workpiece from being impacted twice or many times, and accuracy of testing is guaranteed.

Owner:THERMOS JIANGSU HOUSEWARES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com