Patents

Literature

271results about How to "Achieve stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

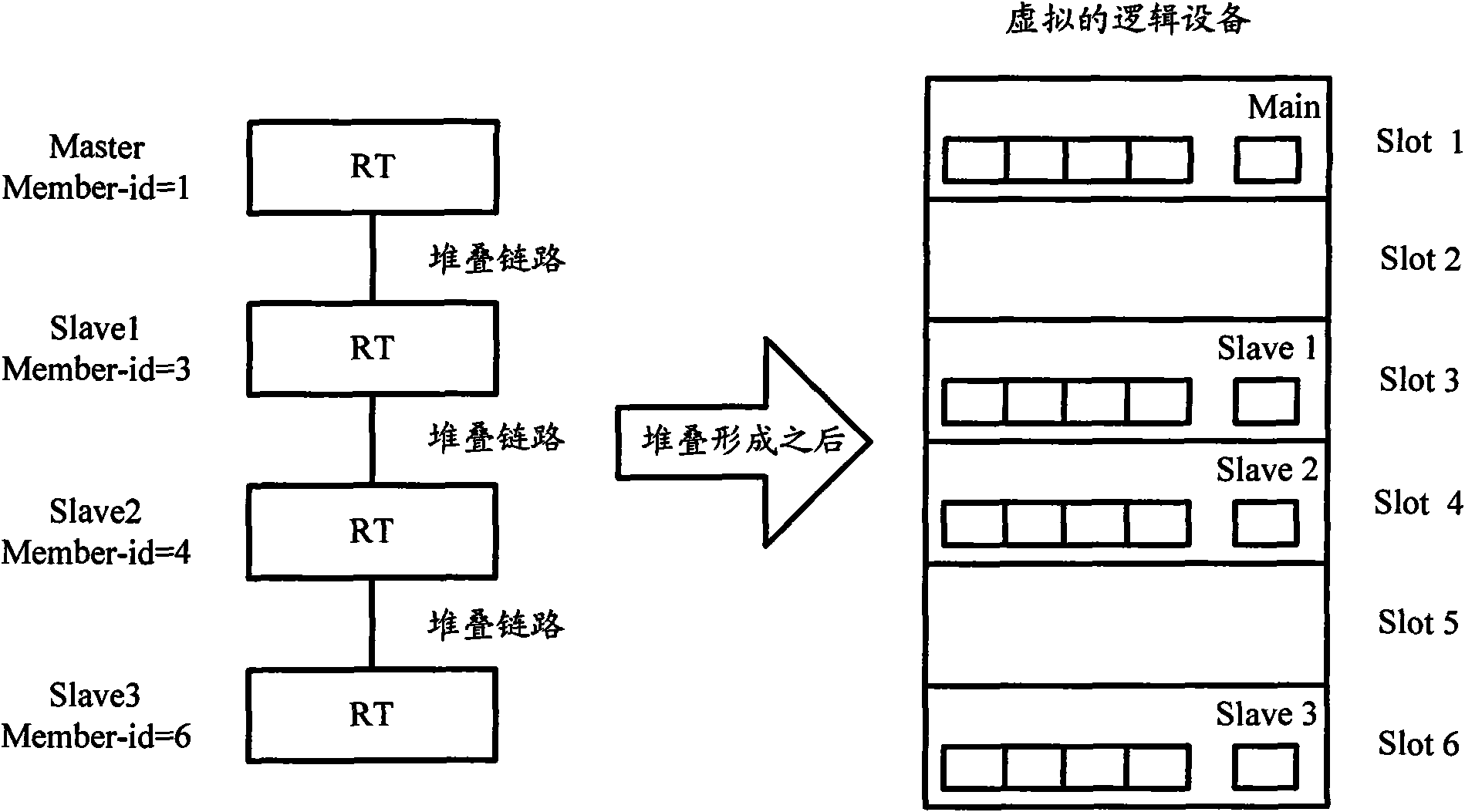

A method for stacking route switching device

InactiveCN101170483AIncrease flexibilityStrong scalabilityCircuit switching systemsSystem topologyComputer hardware

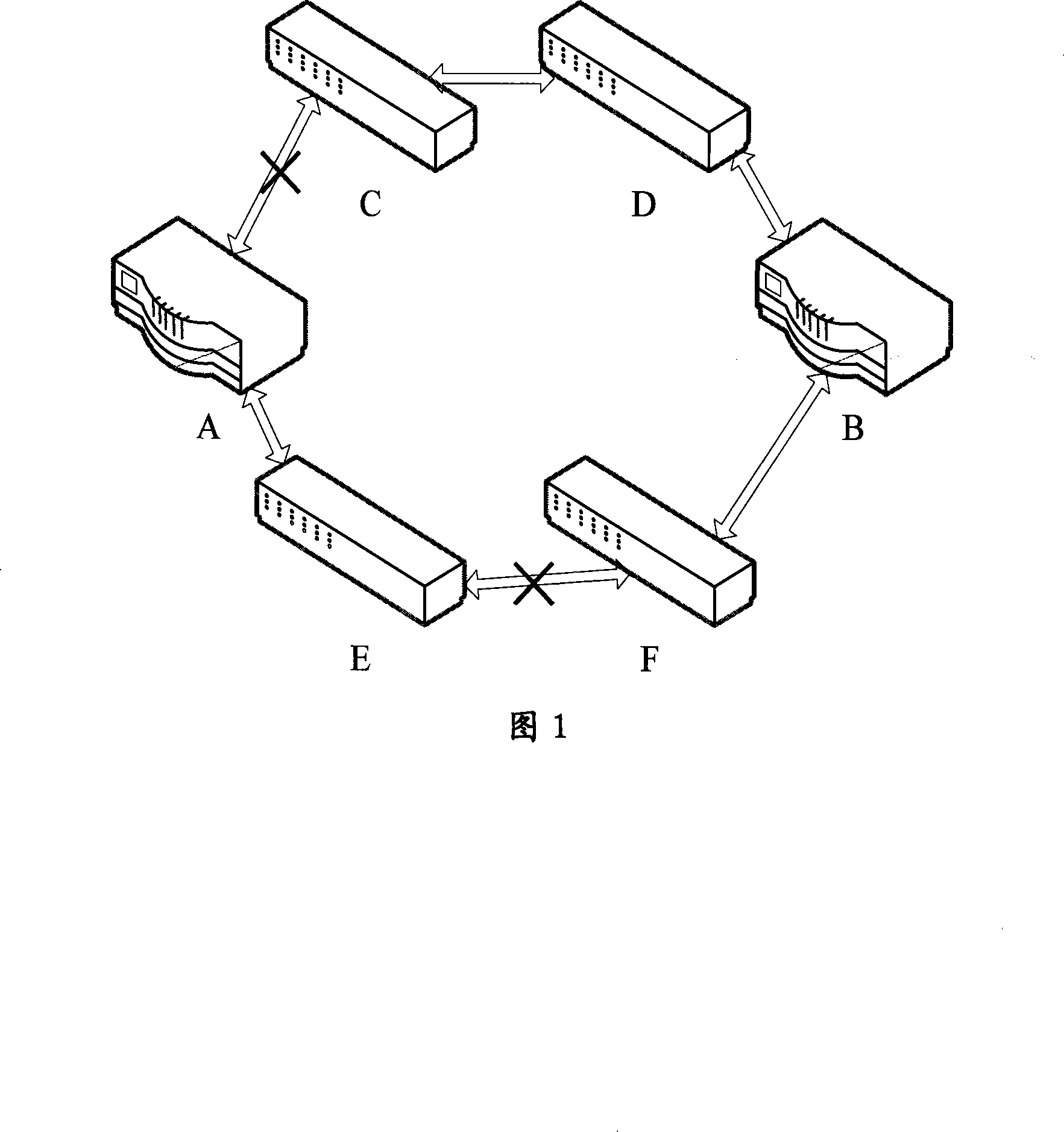

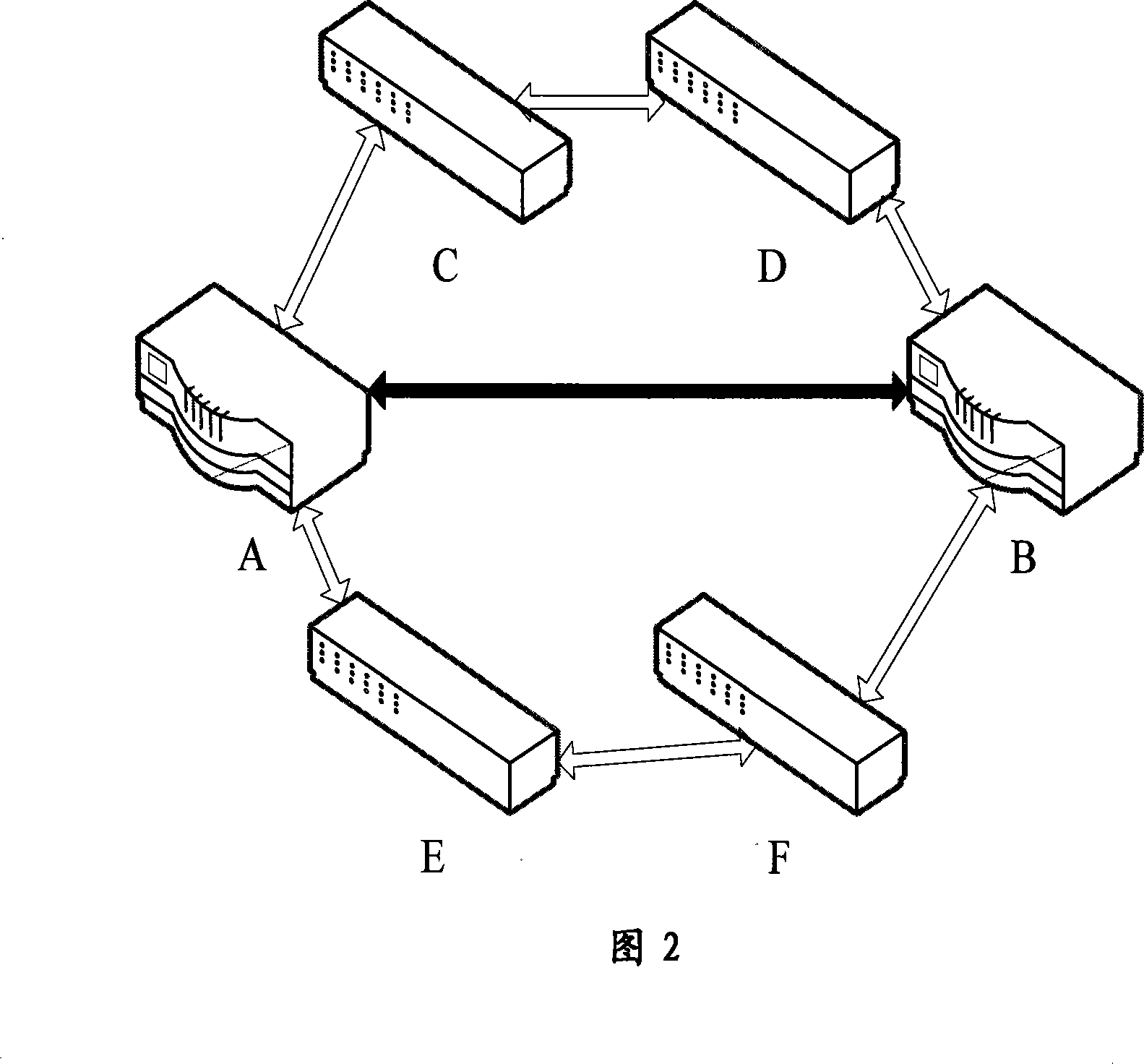

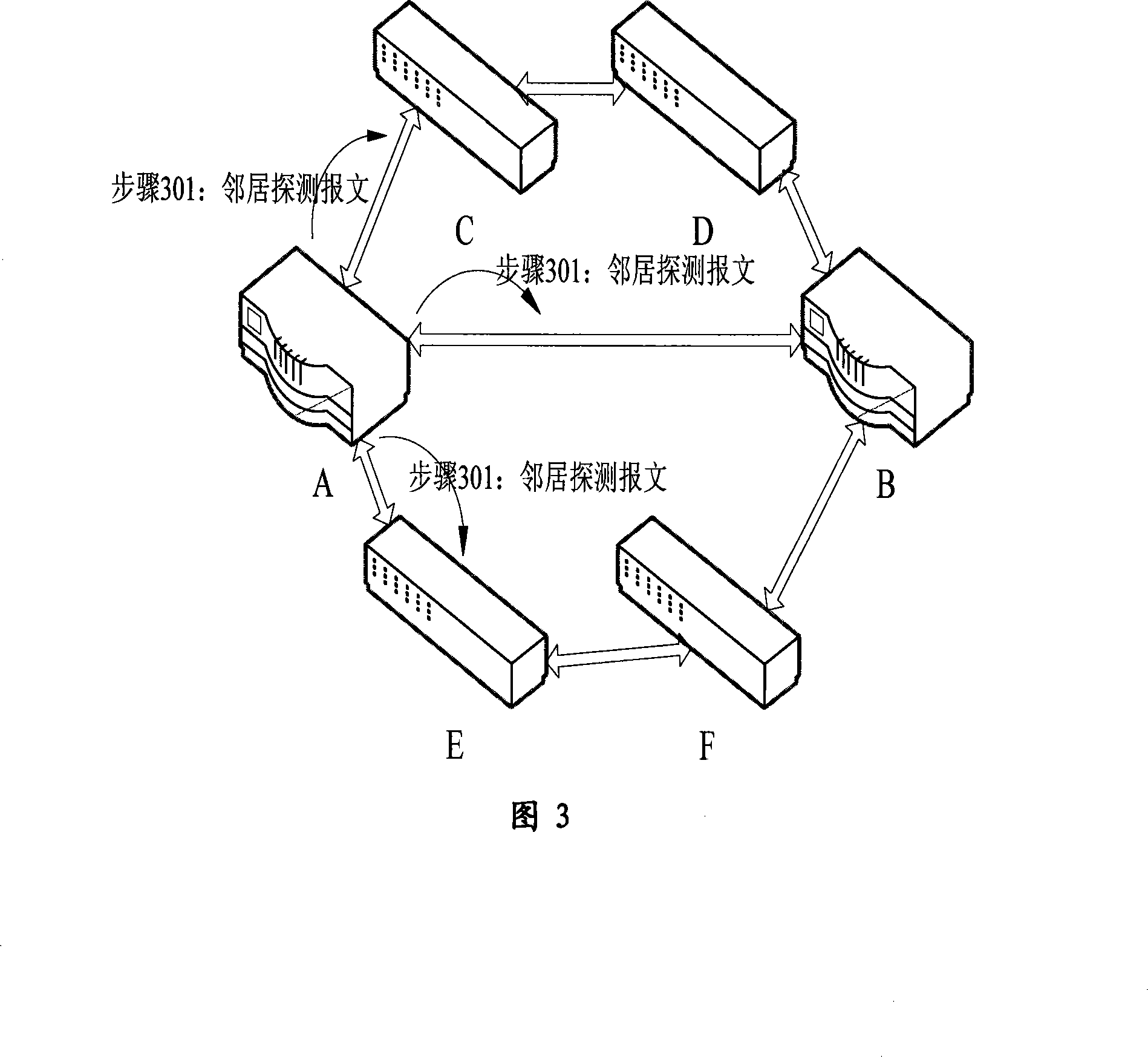

A method for stacking routing and switching devices is applied to a stacking system including at least two stacking devices, and can realize mixed stacking of routers and switches. After the stacking device is started, it sends and receives a neighbor detection message through the stacking interface, and the message contains at least the MAC address of the stacking device; and obtains the MAC address of the neighbor device after receiving the neighbor detection message sent by the neighbor device ; Then generate a stack topology information packet according to the stack interface information and the MAC address information of the neighbor device, and send it to the stack interface of the neighbor device; Other stacking interfaces other than the stacking interface flood the packet; all stacking devices select the master device according to the stacking topology information packets generated and received by themselves, and obtain the topology mapping table of the entire topology system. The topology mapping table is the stacking interface information Mapping table with stack device MAC address information.

Owner:ZTE CORP

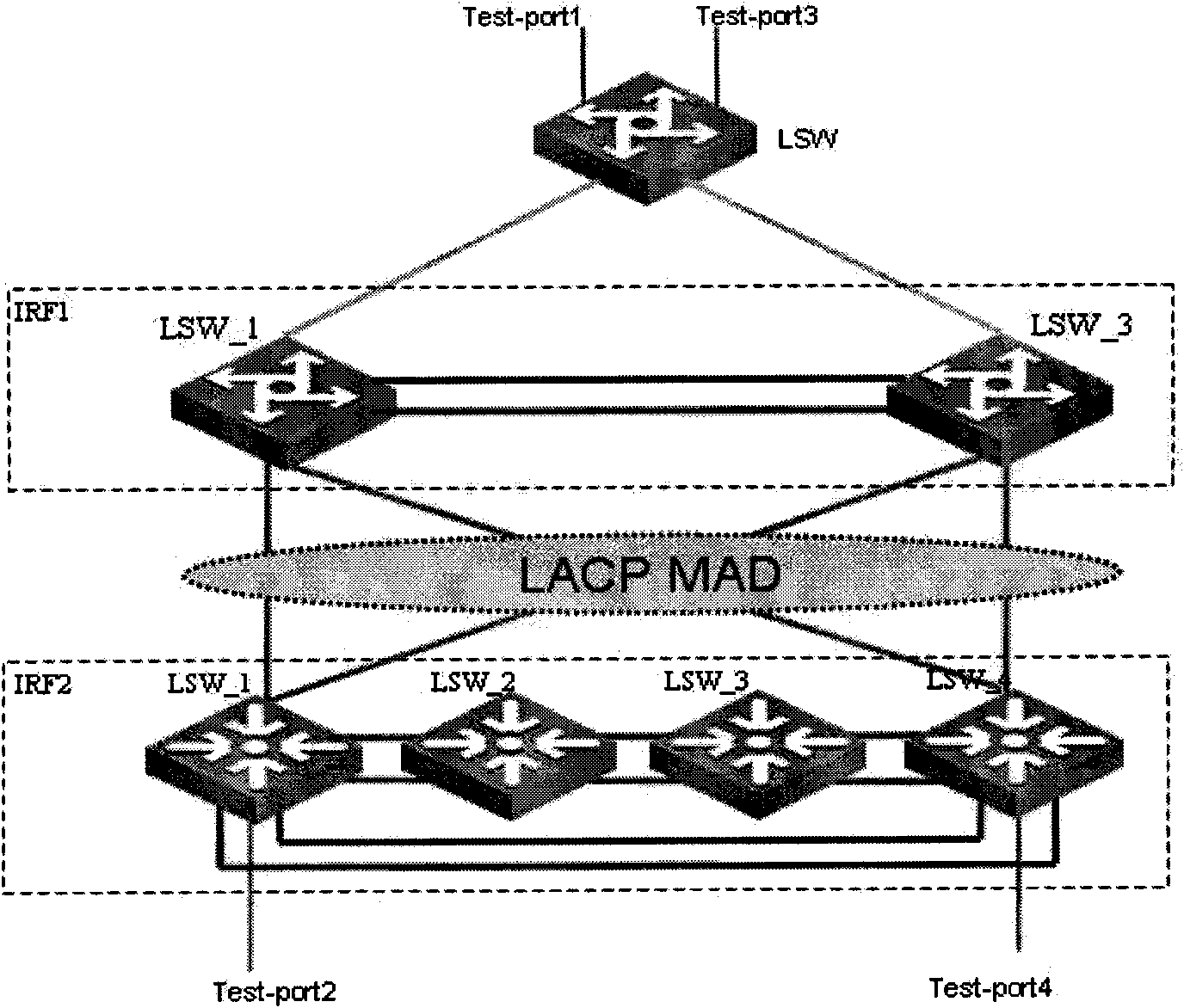

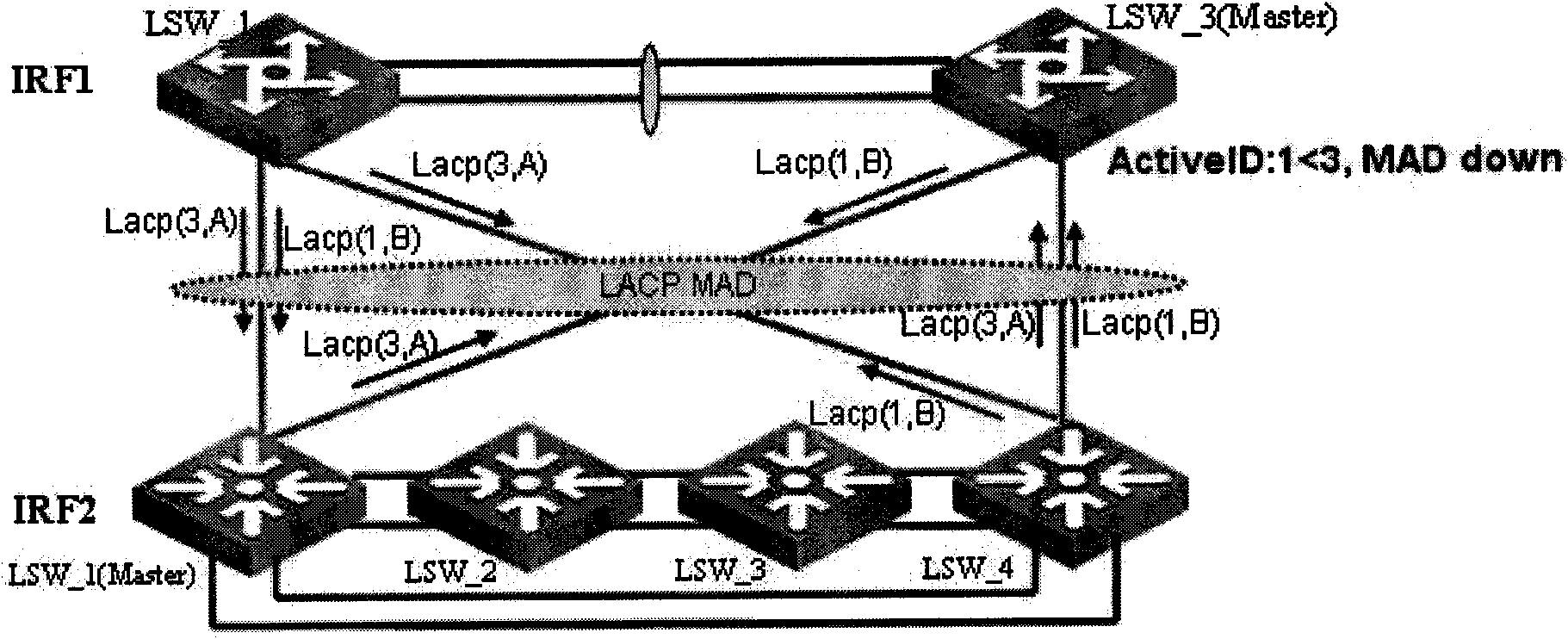

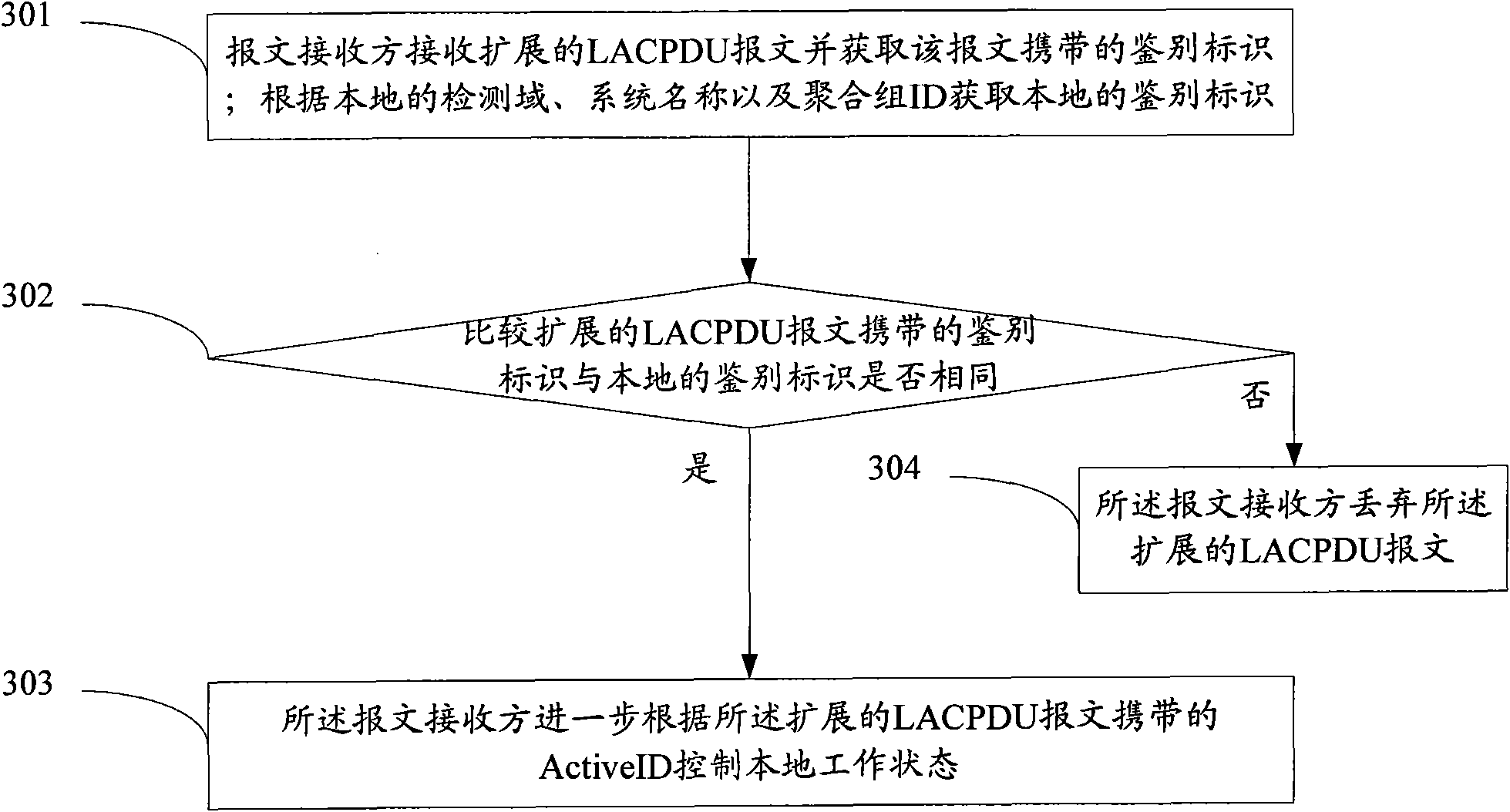

LACP MAD detection method and device thereof

The invention discloses an LACP MAD detection method. The method comprises the following steps: a message recipient obtains identity authentication carried by an expanded LACPDU message received, andobtains local identity authentication according to a local detection domain, a system name and an aggregation group ID; the message recipient compares whether the identity authentication carried by the expanded LACPDU message is the same as the local identity authentication; the message recipient further controls local working state according to Active ID carried by the expanded LACPDU message incase the comparison result is the same, and discards the expanded LACPDU message in case the comparison result is different. The method helps realize bidirectional stack LACP MAD detection by carryingthe identity authentication for distinguishing different stack systems in the expanded LACPDU message.

Owner:NEW H3C TECH CO LTD

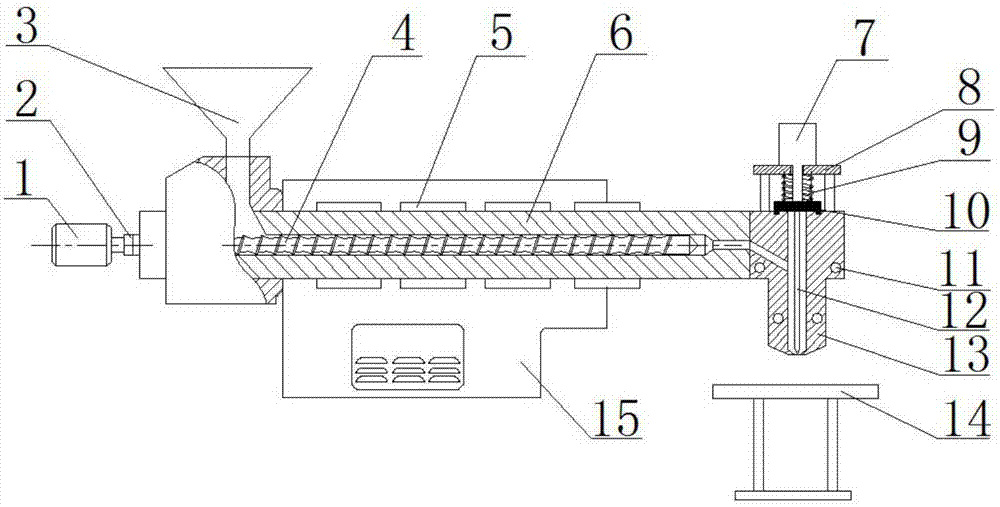

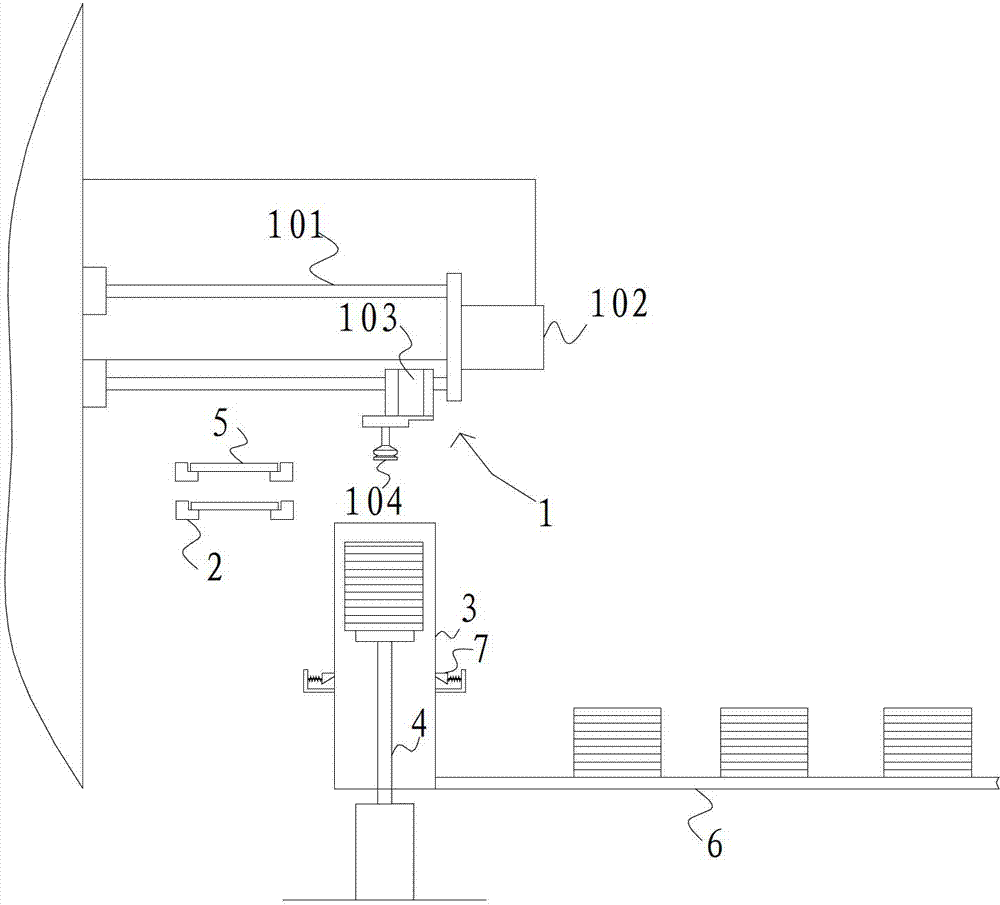

3D (three dimensional) printing equipment for preparing thermoplastic elastomer product

InactiveCN104842561AAddressing Stiffness RequirementsAchieve stackingAdditive manufacturing apparatusElastomerHot runner

The invention discloses 3D (three dimensional) printing equipment for preparing a thermoplastic elastomer product, which mainly consists of a material melting and conveying unit, a material squeezing unit, a three-dimensional coordinate platform and a rack; in the material squeezing unit, a valve body is full of melted and plasticized materials through a hot runner; the opening and closing of the nozzle of the valve body is controlled by a valve needle; the valve needle is fixed onto a thermal insulator which has certain elastic deformation capability and thermal insulation capability; corresponding force is applied to the upper side of the thermal insulator by using a spring and an electromagnet, so as to enable pressure generated by the melted materials in the valve body to be balanced with the applied force, so that the valve needle can seal the nozzle, and when the electromagnet is controlled to intermittently move up and down according to certain rules by a controller, the valve needle also moves up and down correspondingly due to the fact that the balance of the force is broken, so that the nozzle is continuously opened and closed to form micro droplets; micro droplets are cooled and formed on the three-dimensional platform, and the product is finally printed. According to the equipment disclosed by the invention, different materials of micro droplets or fuses can be sprayed according to different time sequences, and the product, which is made from a soft and hard composite material and has multifunctional gradients, can be printed.

Owner:BEIJING UNIV OF CHEM TECH

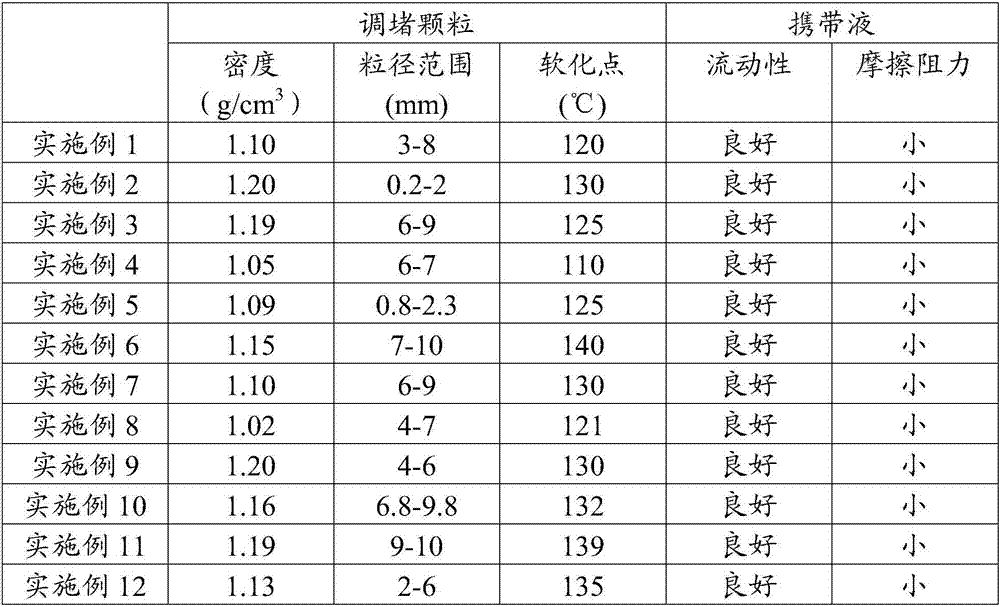

Flow channel regulation agent for fractured-vuggy oil reservoir and preparation method thereof

InactiveCN107474807AReduce frictional resistanceDensity controllableDrilling compositionWater flowOil production

The invention relates to a flow channel regulation agent for a fractured-vuggy oil reservoir. The flow channel regulation agent is prepared from a carrying solution and plugging regulation particles, wherein the carrying solution is prepared from a polymer and water at the ratio of (0 to 3) : (97 to 100); the plugging regulation particles are of an viscoelastic particle mixture, and are prepared from a high molecular polymer, calcium carbonate and bentonite at the ratio of (95 to 100) : (0 to 5) : (0 to 5); the ratio of the carrying solution to the plugging regulation particles is (10 to 100) : (0 to 90). The flow channel regulation agent for the fractured-vuggy oil reservoir, provided by the invention, is suitable for high-temperature and high-mineralization-degree flow channels of a reservoir stratum, and can realize layer-by-layer plugging from a water injection well to a preferred water flow channel of an oil production well, and the layer-by-layer plugging is a key point for realizing the implementation of the flow channel regulation agent for the fractured-vuggy oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP

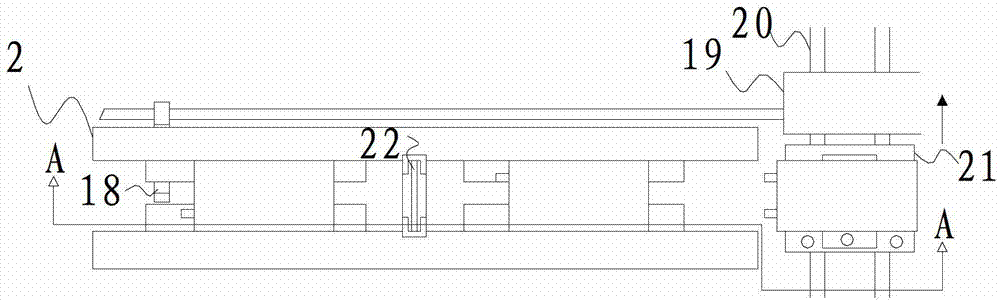

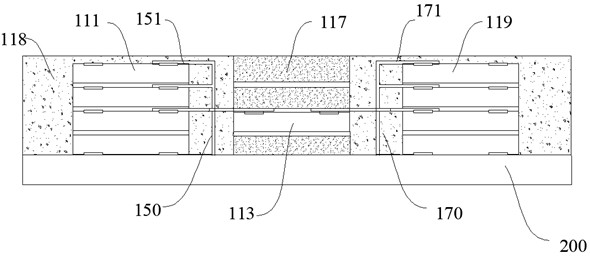

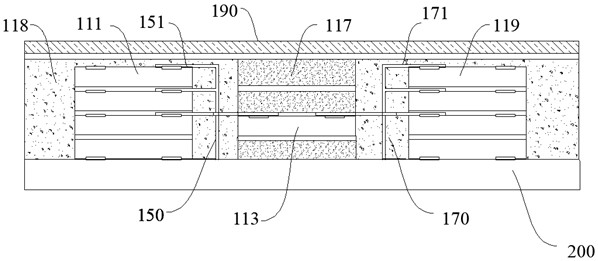

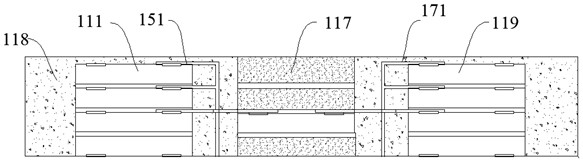

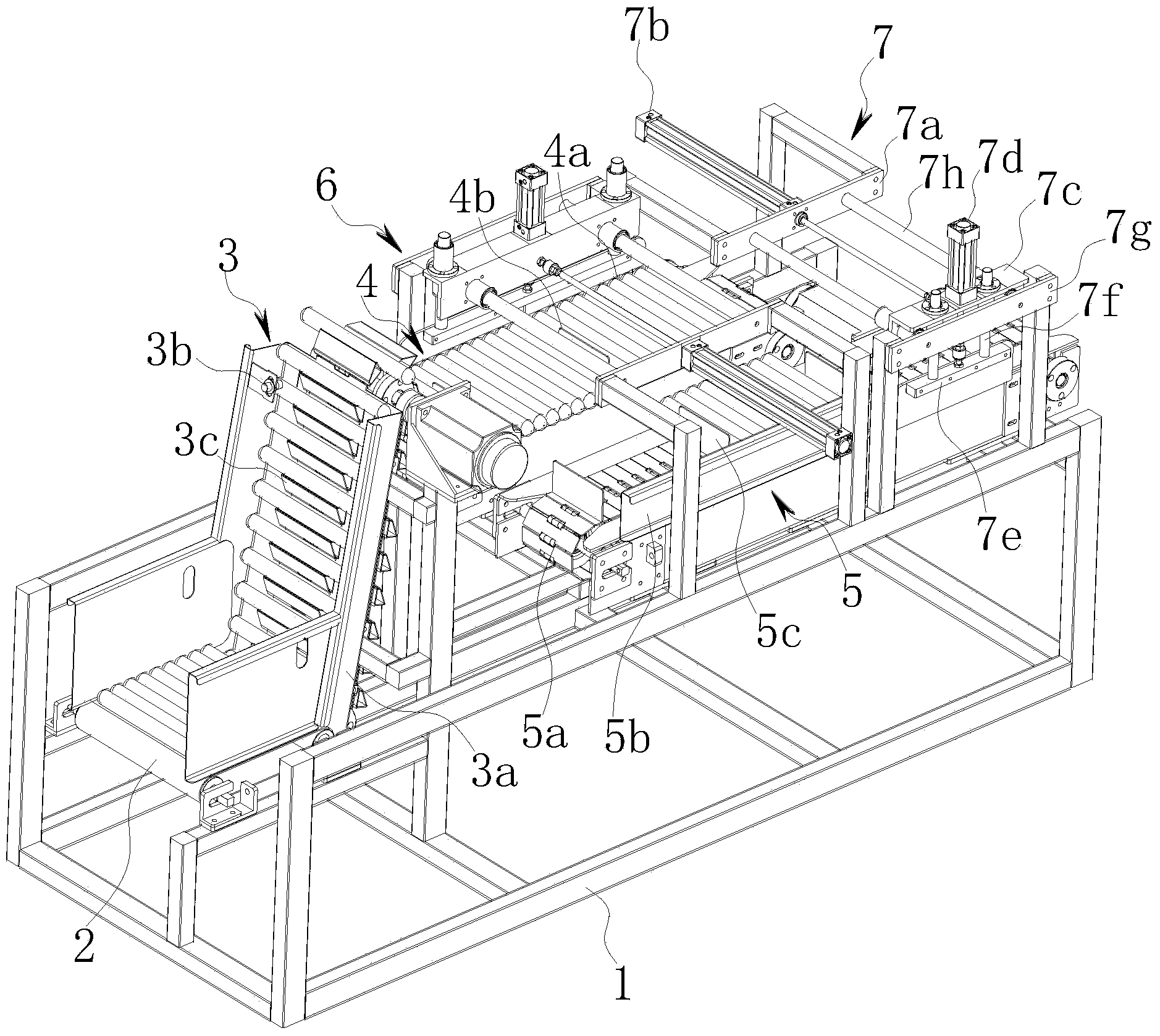

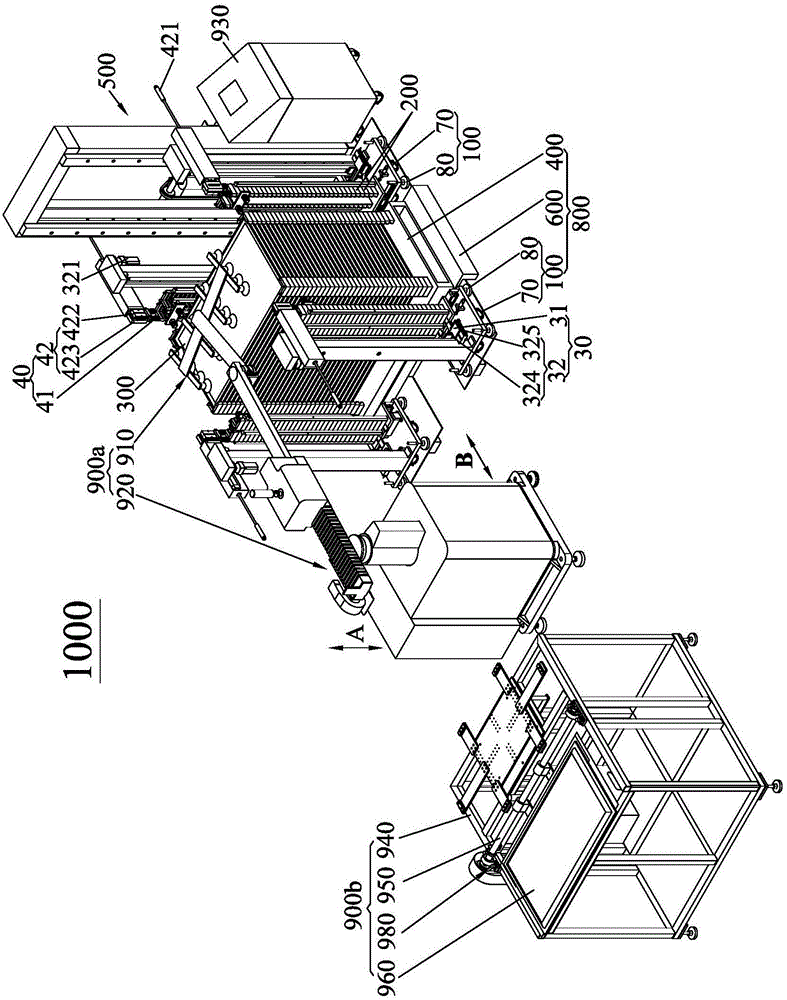

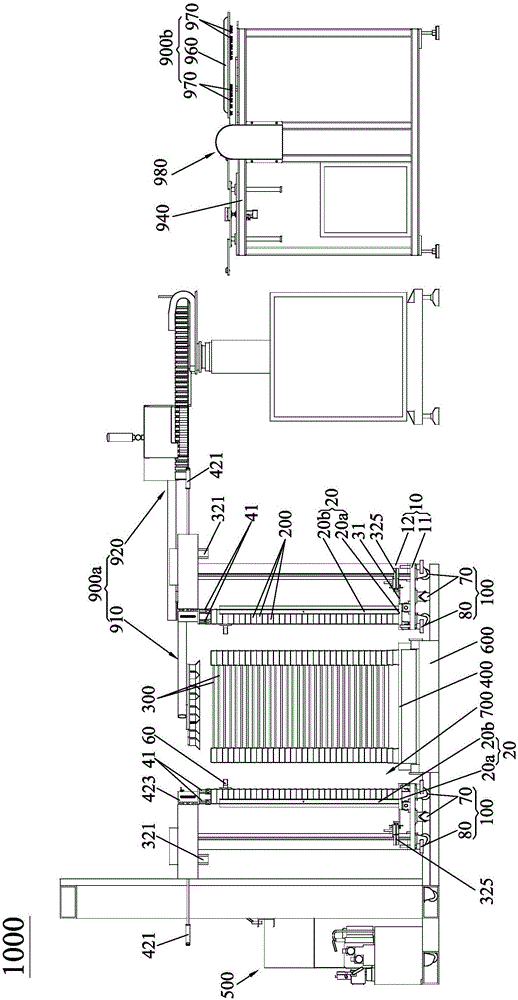

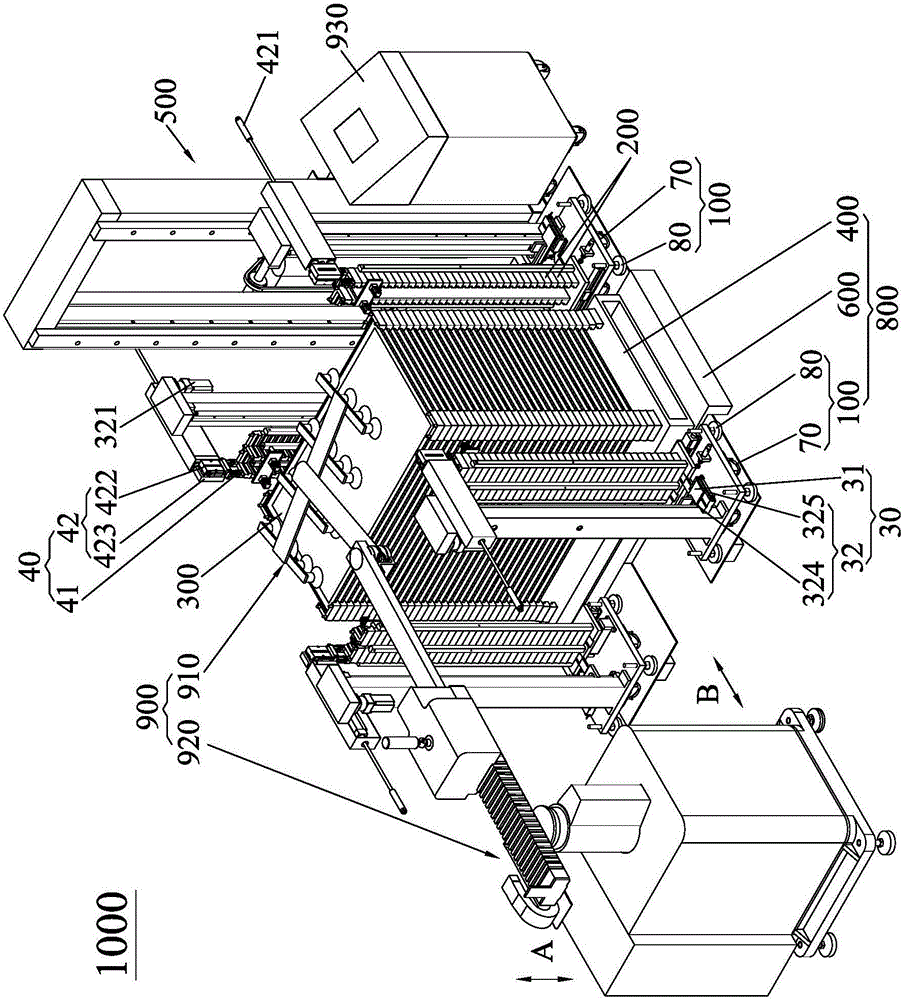

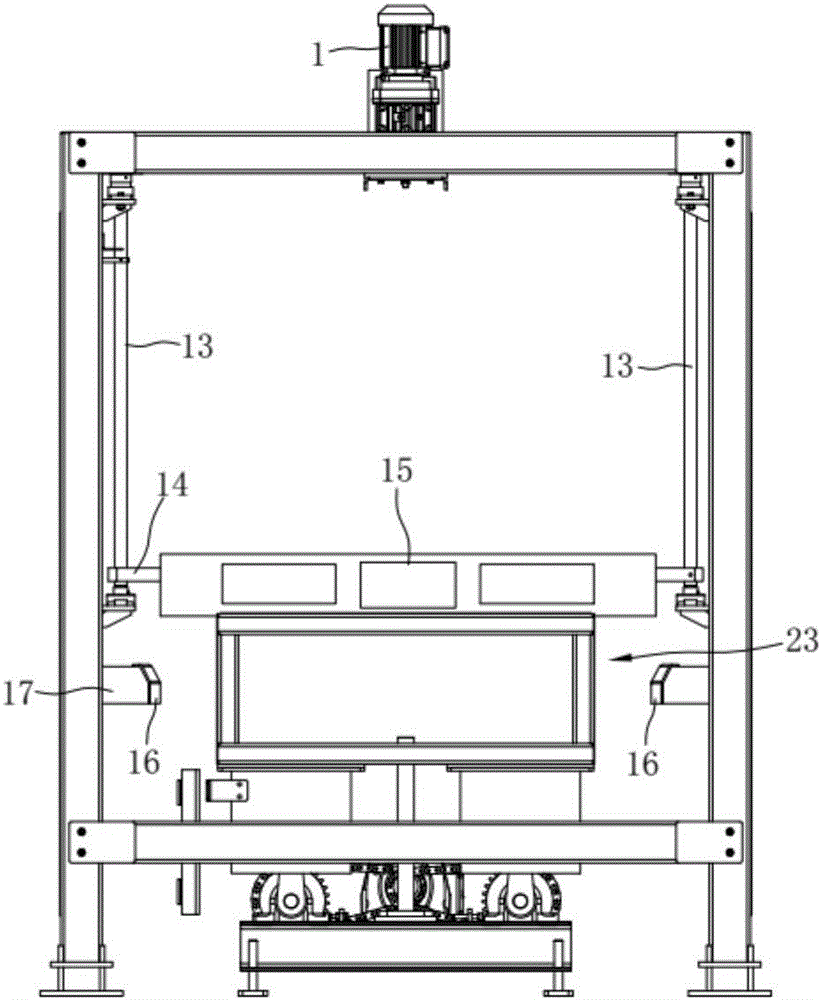

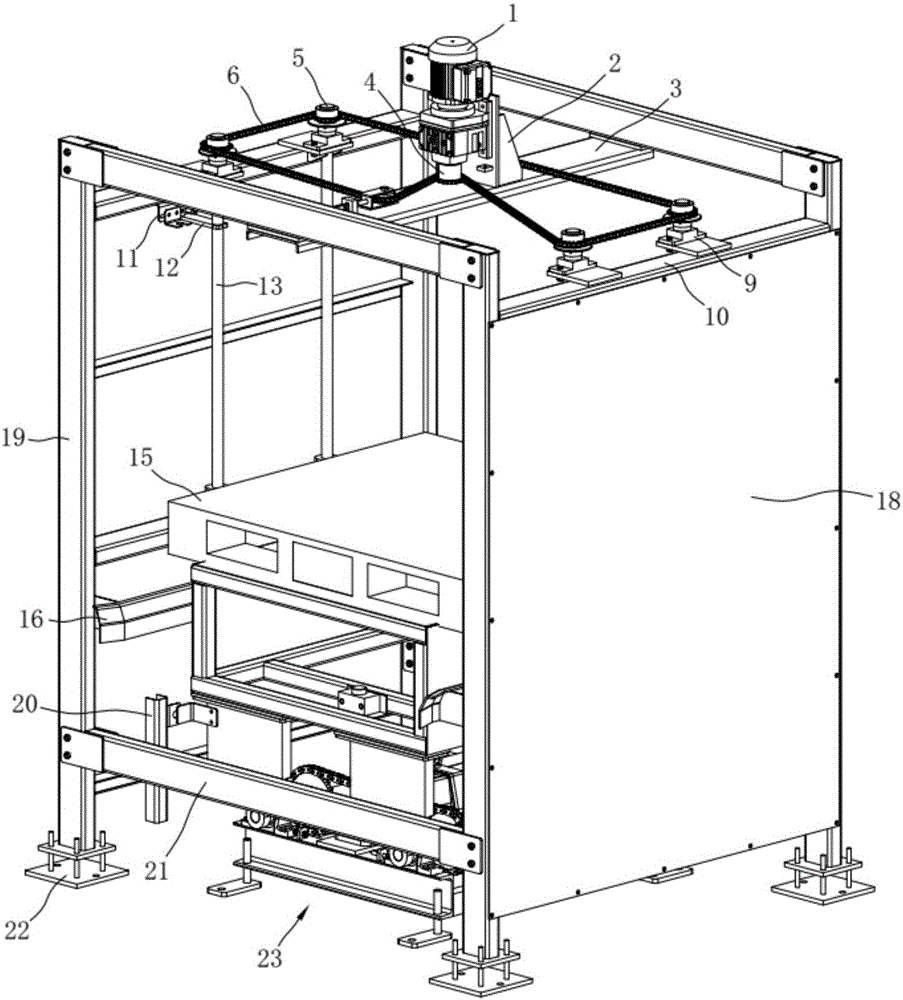

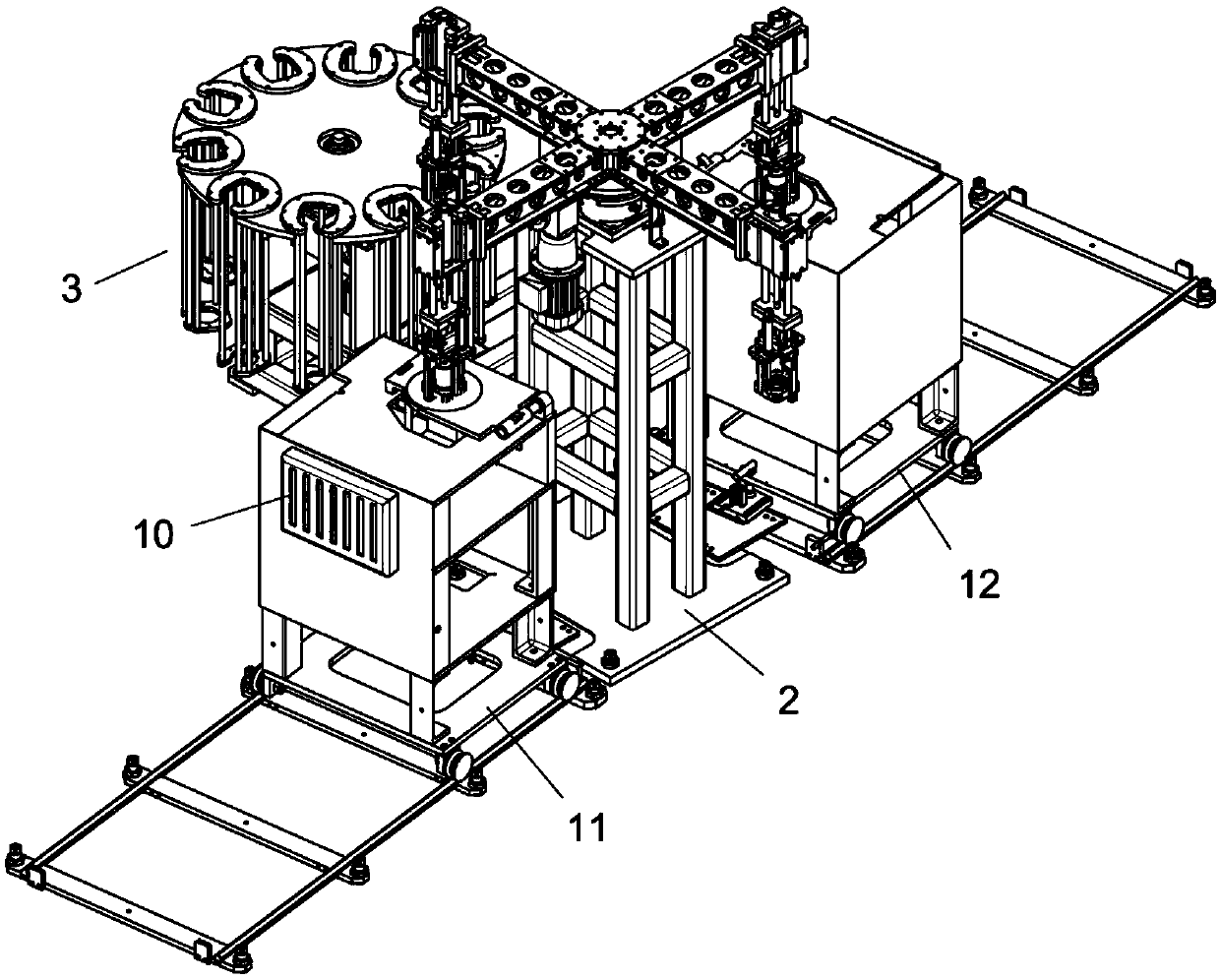

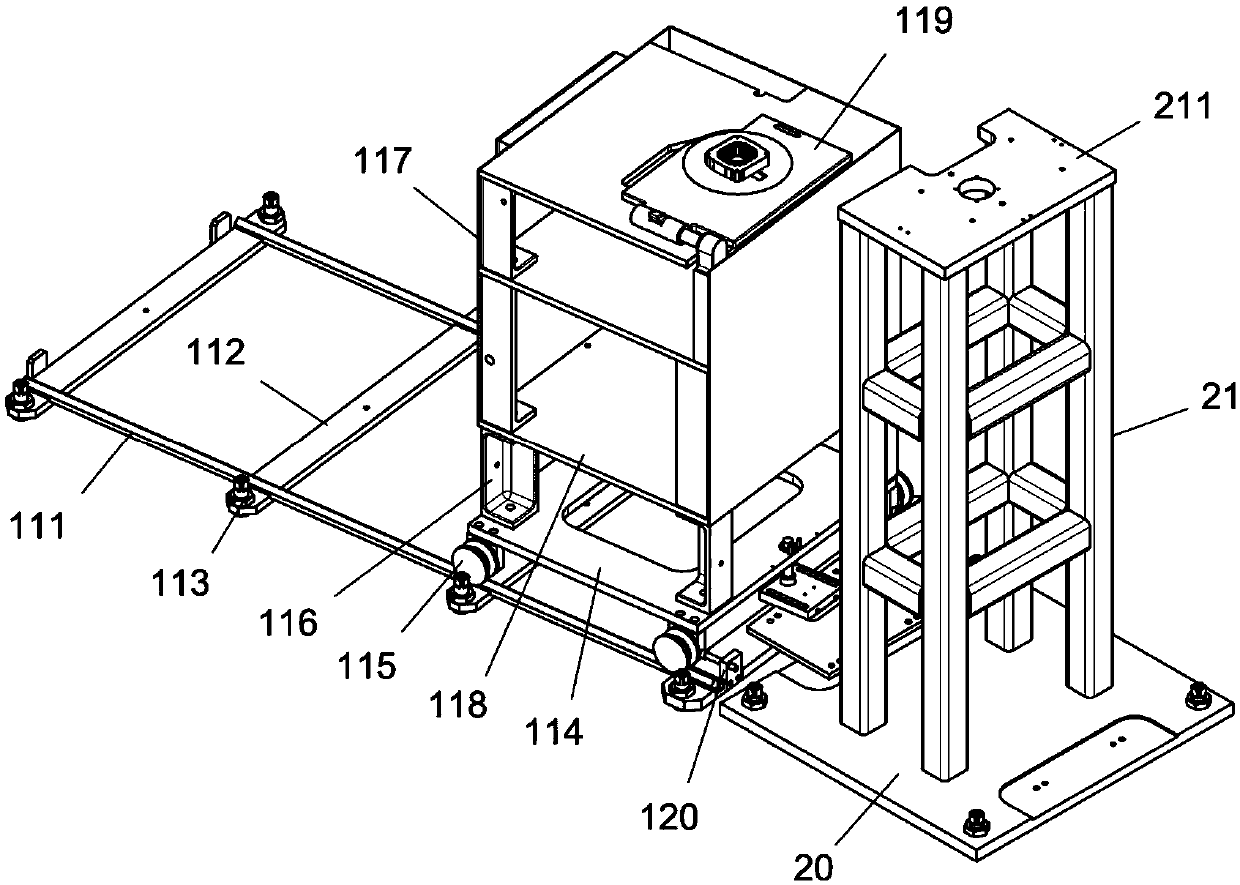

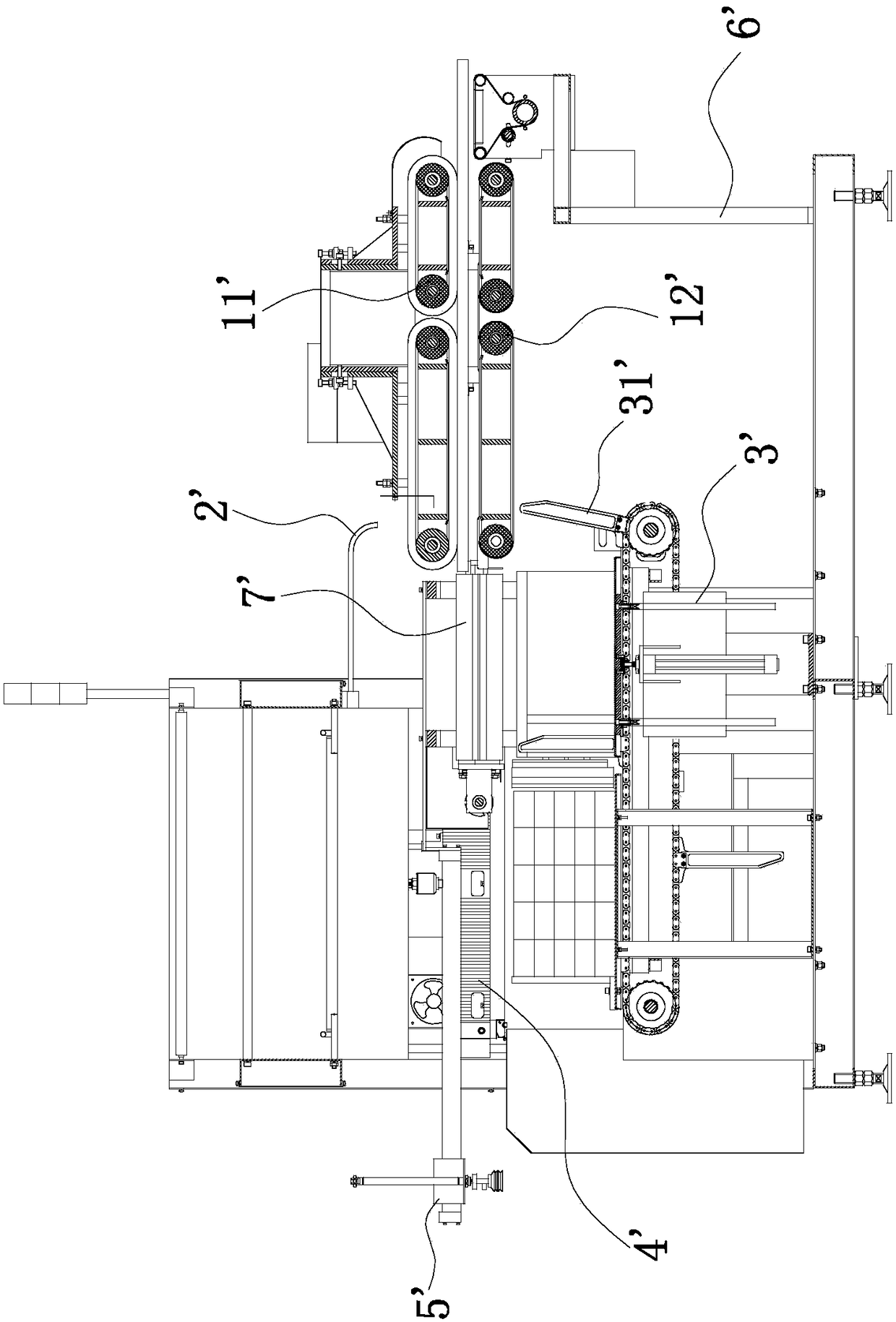

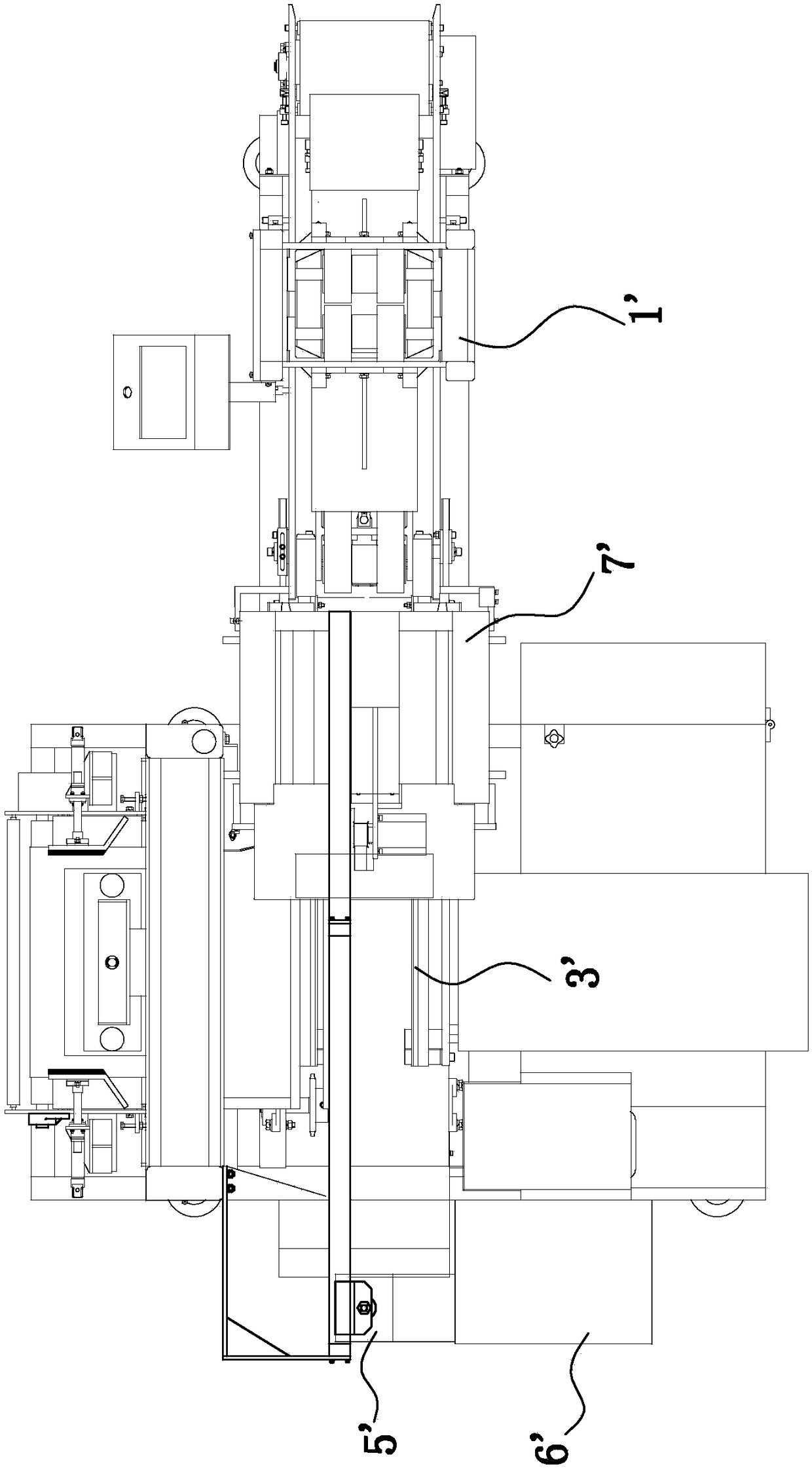

Automatic stacking machine for pole plates

ActiveCN103401027ARealize automatic assemblyAchieve transshipmentFinal product manufactureSecondary cells manufactureStack machineEngineering

The invention discloses an automatic stacking machine for pole plates. The automatic stacking machine comprises a pole plate supplying mechanism, a division plate supplying mechanism and a pole plate stacking mechanism, wherein the pole plate supplying mechanism comprises two pole plate conveying belts, two pole plate storage frames and pole plate top rods arranged under the corresponding pole plate storage frames; the division plate supplying mechanism comprises two raw material rolls, a first guide cylinder used for bearing division plates, a pair of division plate pull rolls, a division plate cutting-off mechanism, a second guide cylinder used for bearing the division plates and a division plate bracket, and a gap through which the pole plates can pass is formed between the division plate bracket and an outlet of the second guide cylinder; the pole plate stacking mechanism comprises two guide rails, two transferring arms, a conveying chain, a plurality of pole plate transferring boxes and a pole plate push hook; a channel through which the division plate can pass is formed in the guide rail positioned at the lower part; the pole plate transferring boxes are fixedly arranged on the conveying chain; the pole plate push hook is used for transferring the pole plates from the two guide rails onto the pole plate transferring boxes. The automatic stacking machine for the pole plates realizes the automatic supply of the positive and negative pole plates and the division plates, the automatic stacking of the positive and negative pole plates and the automatic assembly and transfer of pole groups.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Wood tray manufacture method

InactiveCN101417452AThe nailing position is uniform and beautifulImprove the stabilityWood working apparatusProduction lineUltimate tensile strength

The invention relates to a manufacturing method of wood trays, including the following steps of: forming front components of wood trays; turning over the front components of the wood trays; forming back components of the wood trays at back sides of the front components of the wood trays to produce the wood trays; postprocessing procedures; lining up and stacking the wood trays into a block; and exporting and carrying the whole block of wood trays stacked well into a warehouse. Compared with the prior art, the invention has the advantages that only 4 to 6 operators are needed in the whole production line, which equals the production efficiency of 20 operators with manual operation; the amount of labor can be saved by 70 percent and the production efficiency can be increased by more than 5 times; the labor intensity of workers can be reduced; the wood trays are lined up in order and can be staggered positively and negatively to save space; and single-deck trays can save space by more than 40 percent, site and space can be saved, and all processing equipment can be installed on the production line.

Owner:吴继荣

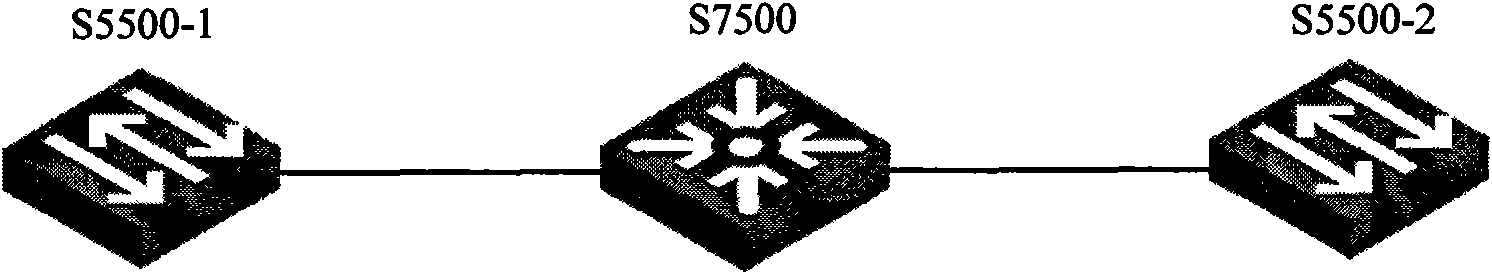

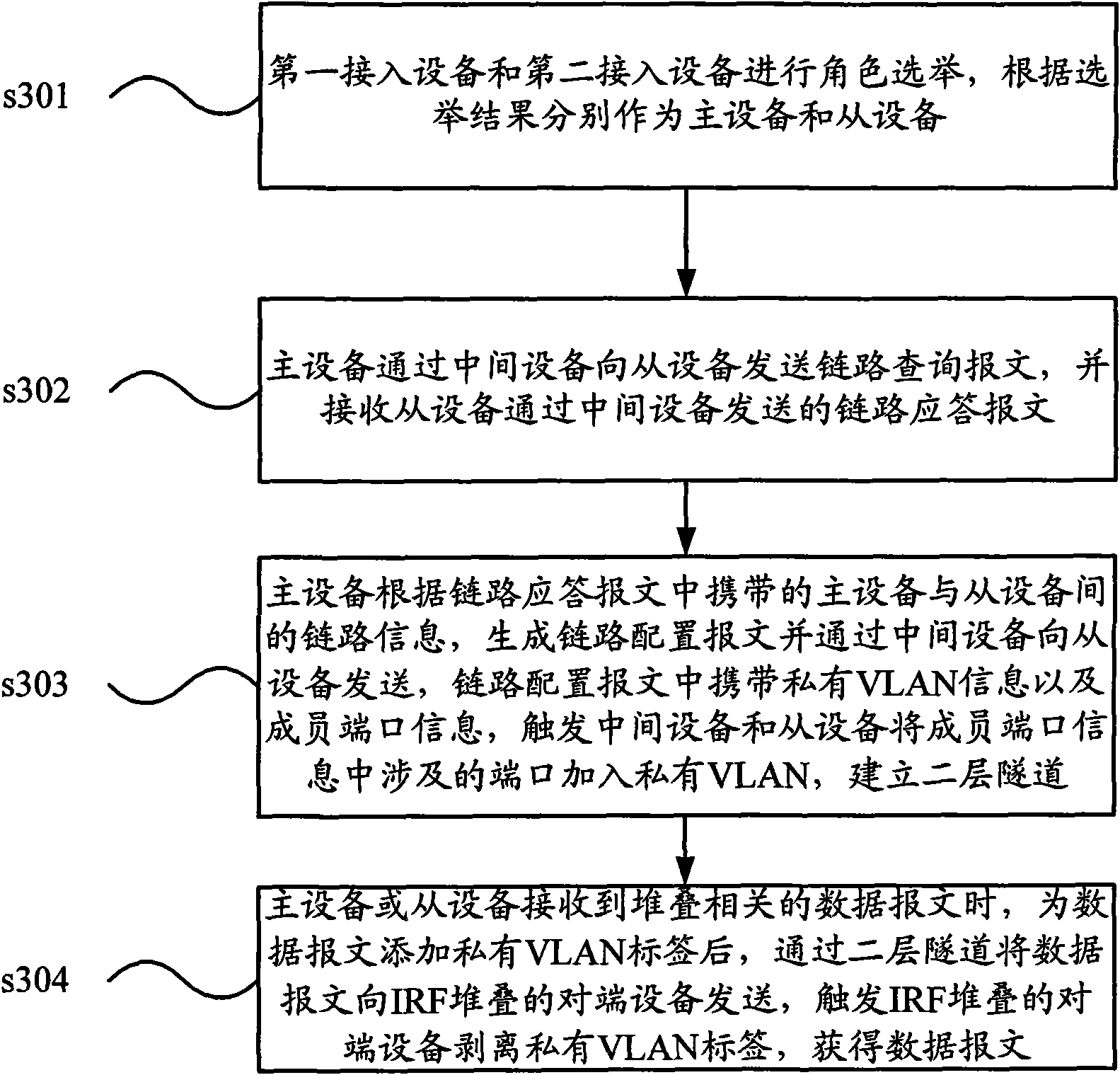

Implementation method of remote IRF stacking and equipment thereof

The invention discloses an implementation method of remote IRF stacking and stacking equipment. The method is applied to first access equipment and second access equipment which need to establish IRF stacking, and the first access equipment is connected with the second access equipment by intermediate equipment. The method comprises the following steps: performing role election among access equipment crossing networks, and transmitting link information; sending a link configuration message to the access equipment of master equipment according to the election result to trigger the intermediate equipment and slave equipment among the access equipment to add a member port to a private VLAN; and establishing a layer-two tunnel, and performing data message interaction by virtue of the layer-two tunnel to realize the IRF stacking crossing networks among the access equipment.

Owner:NEW H3C TECH CO LTD

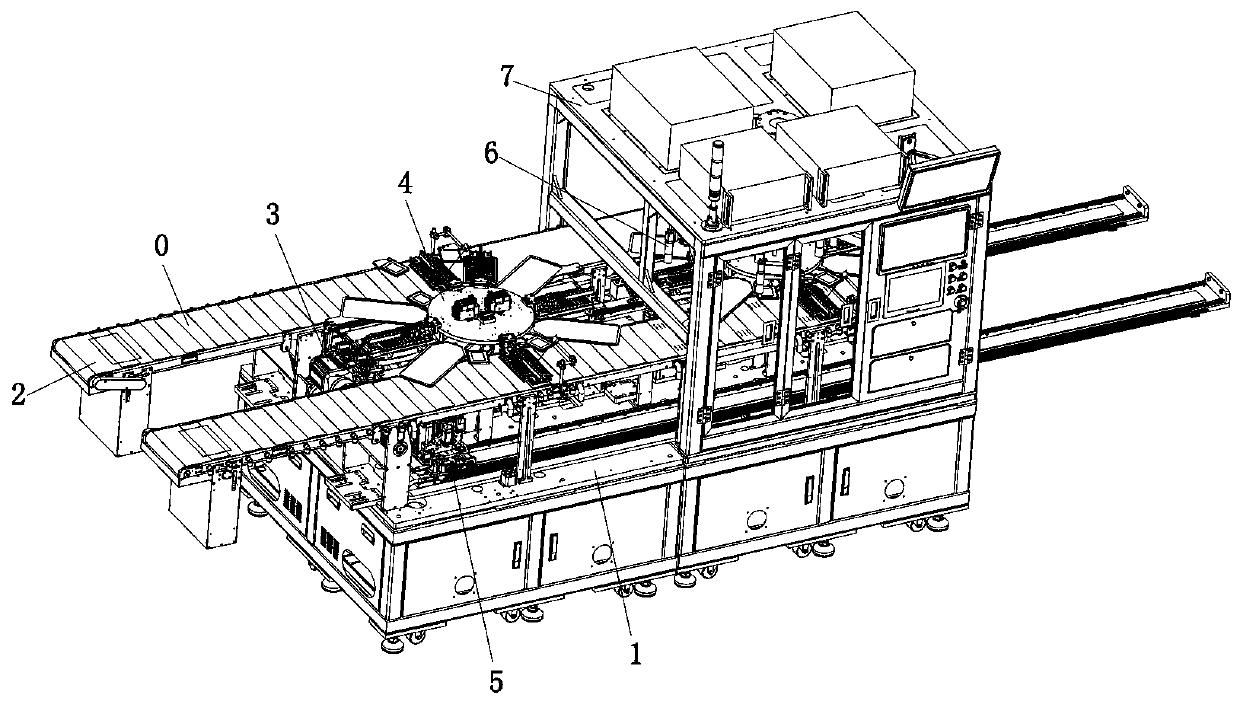

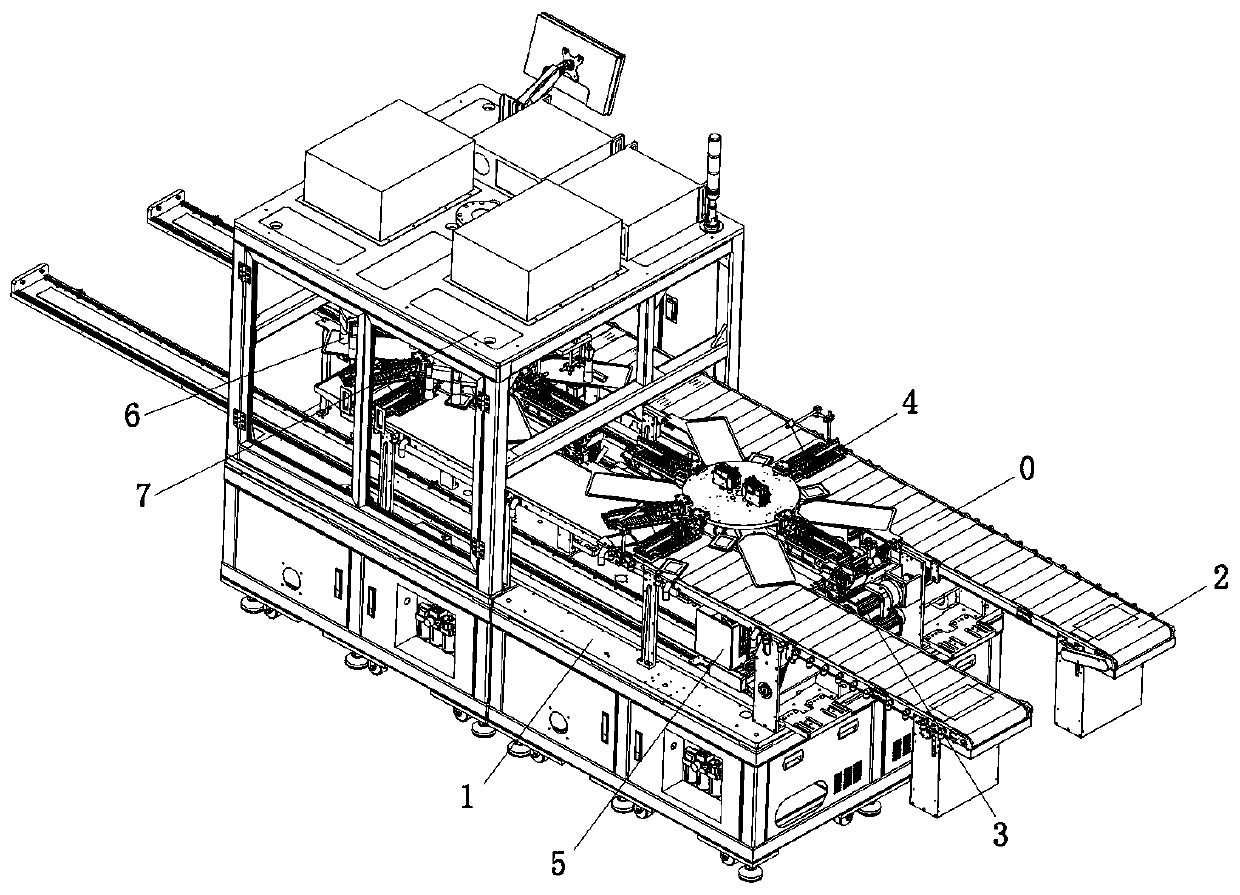

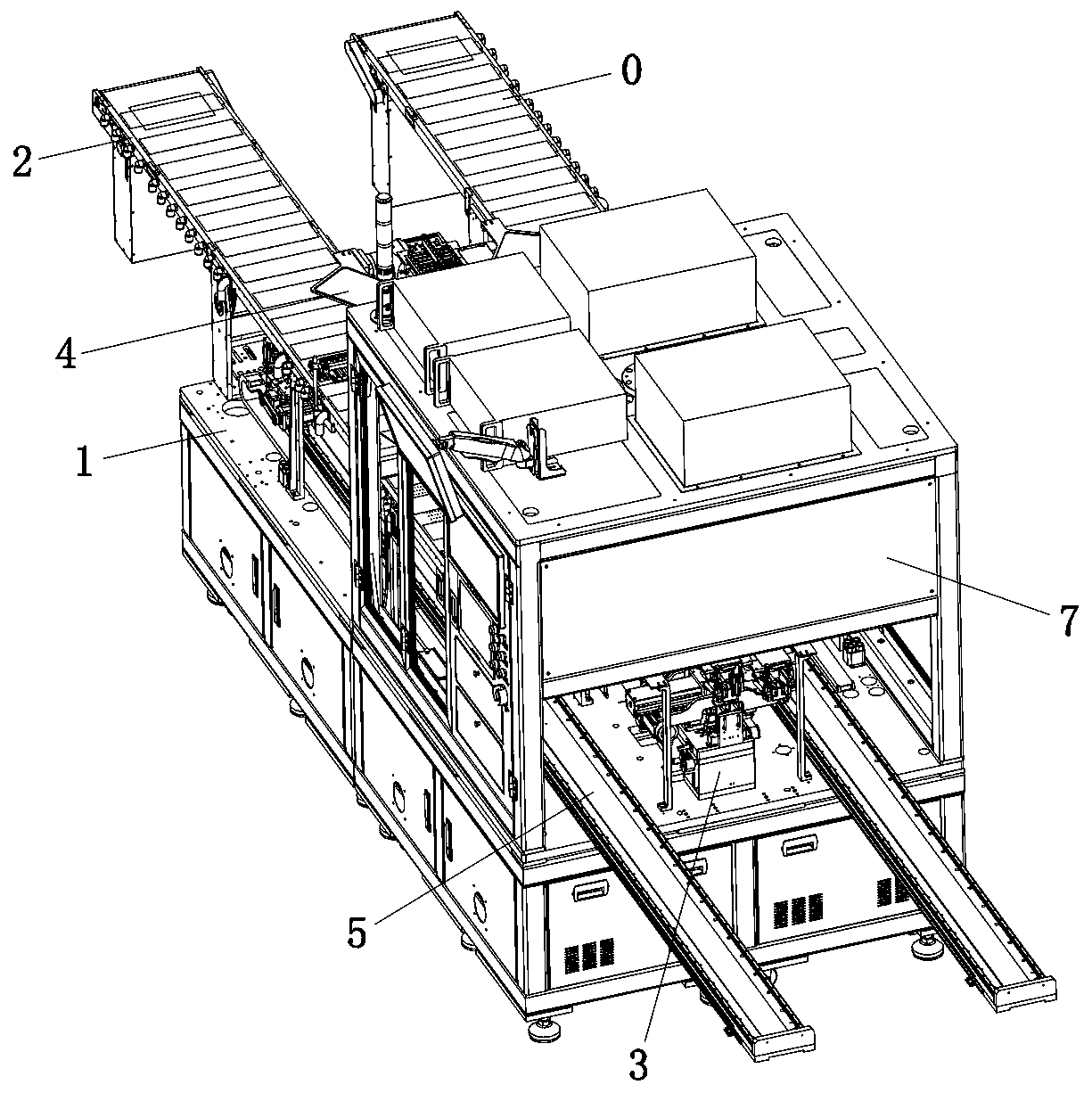

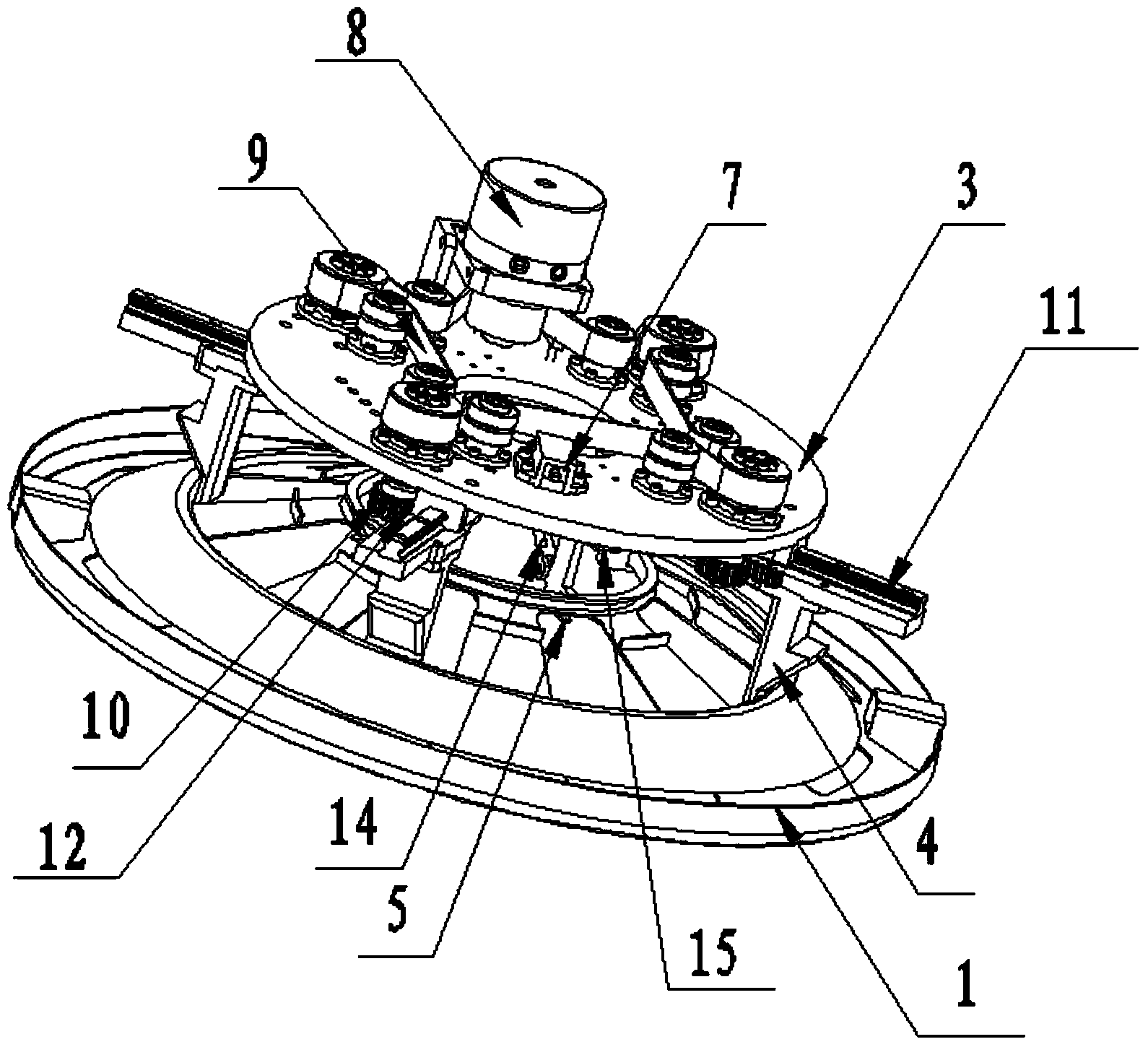

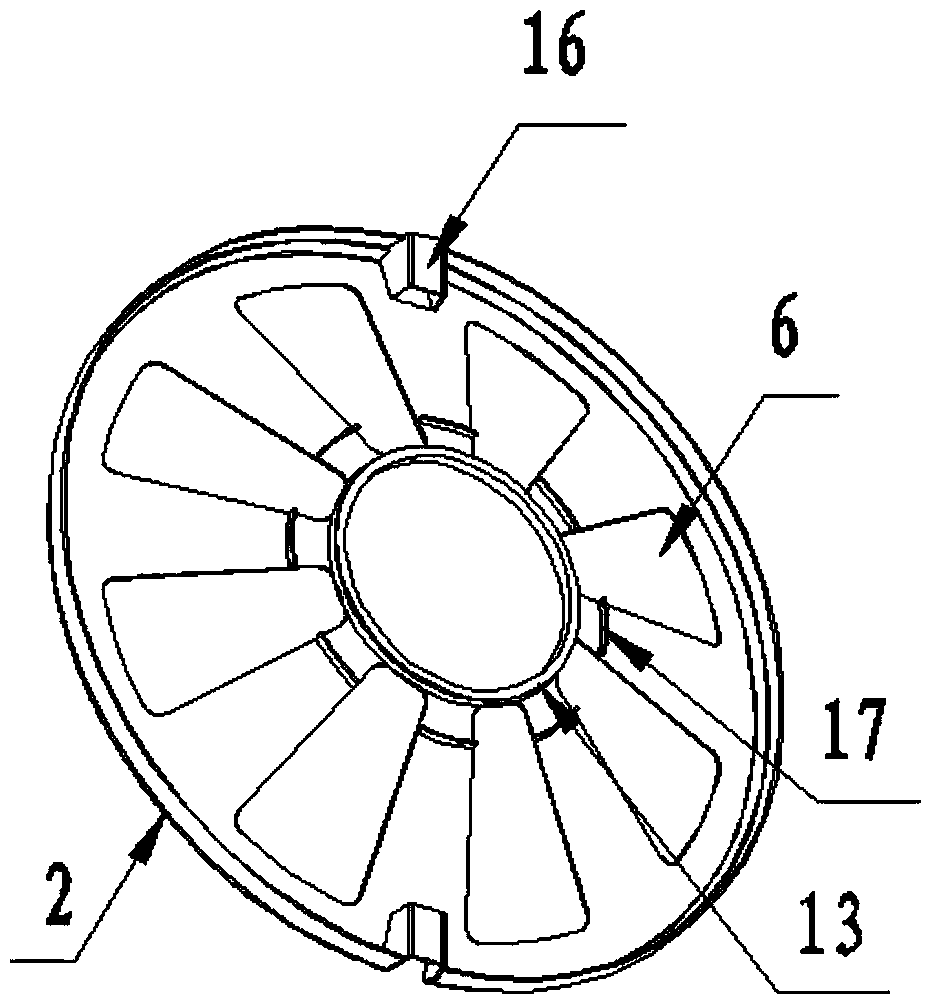

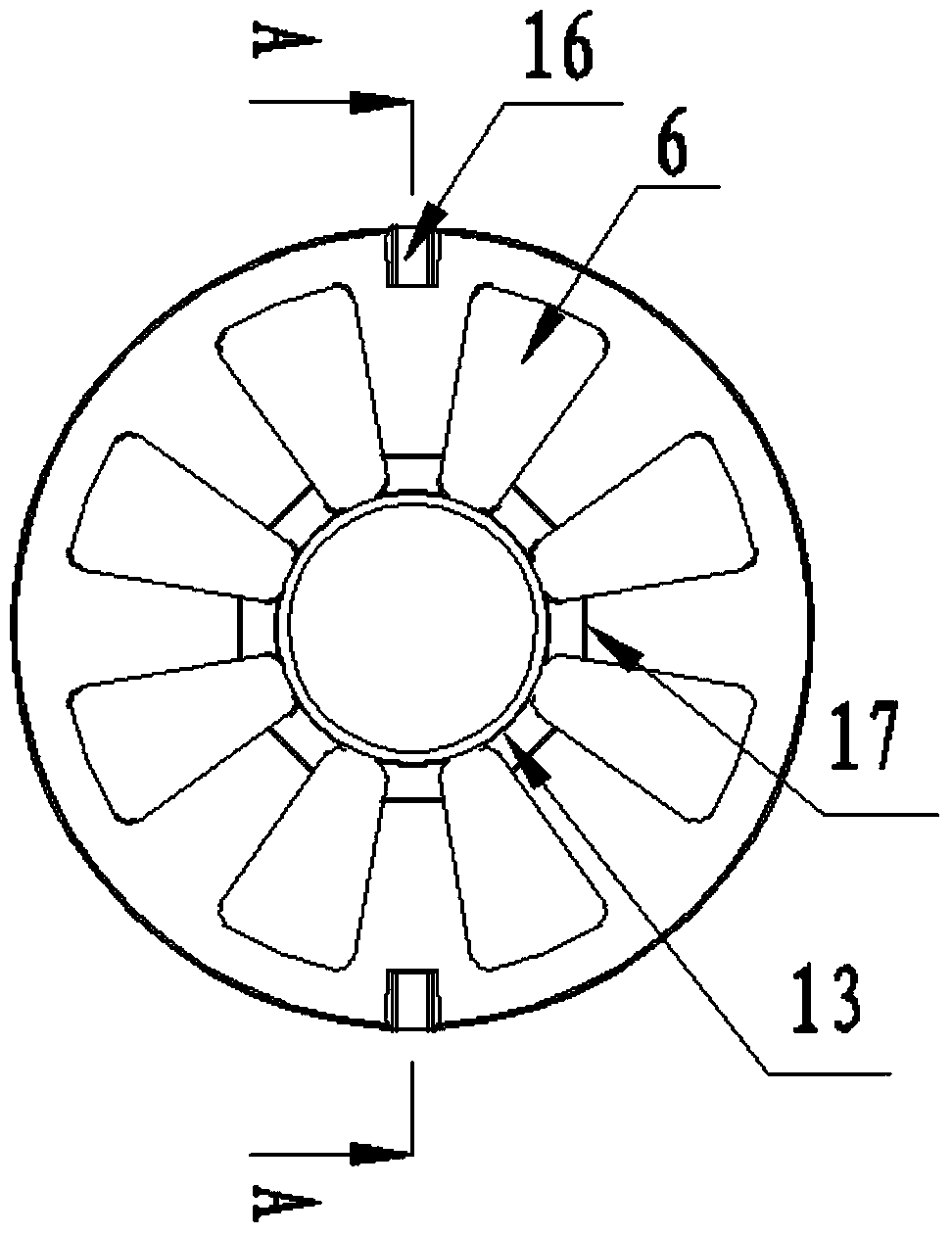

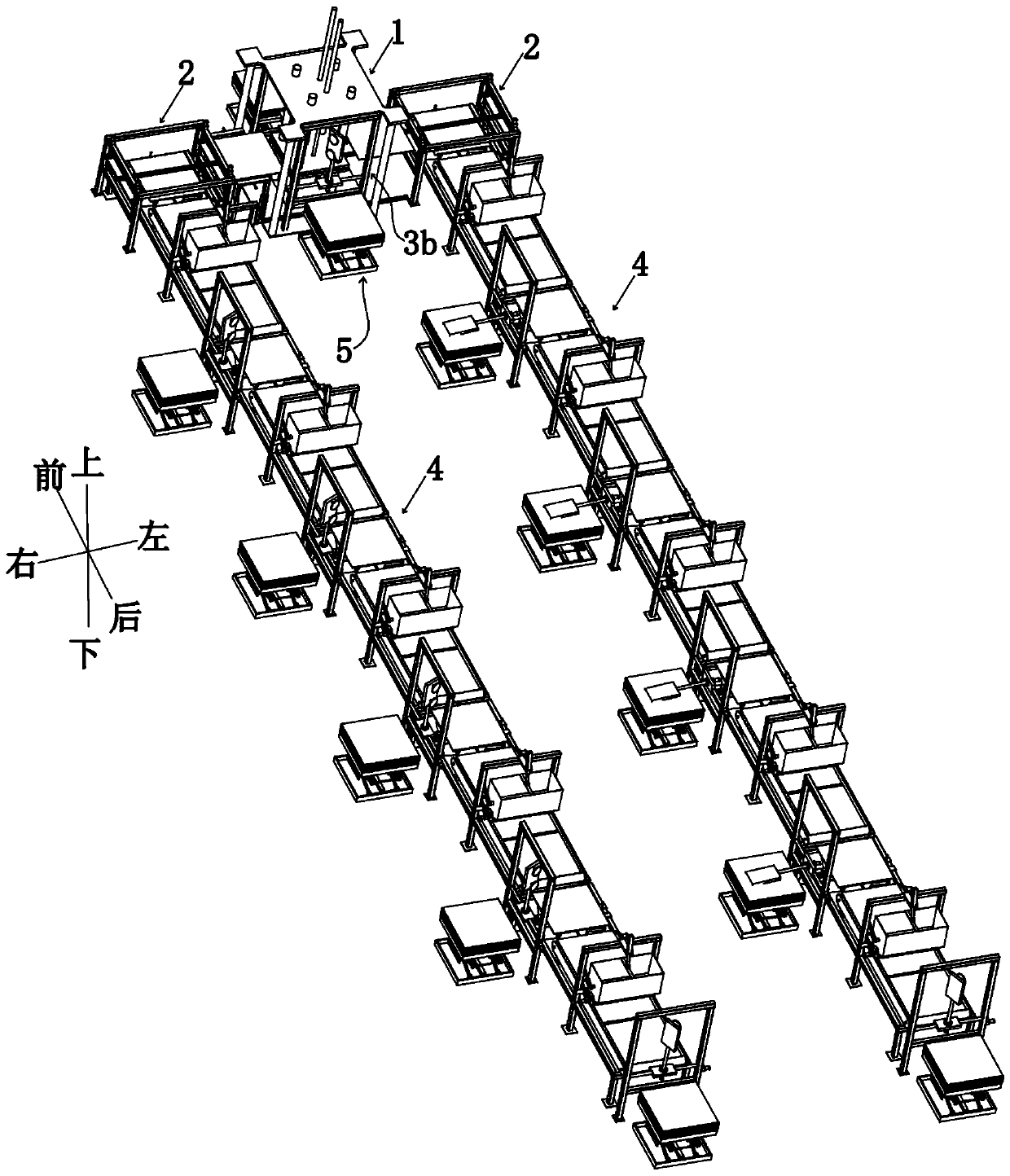

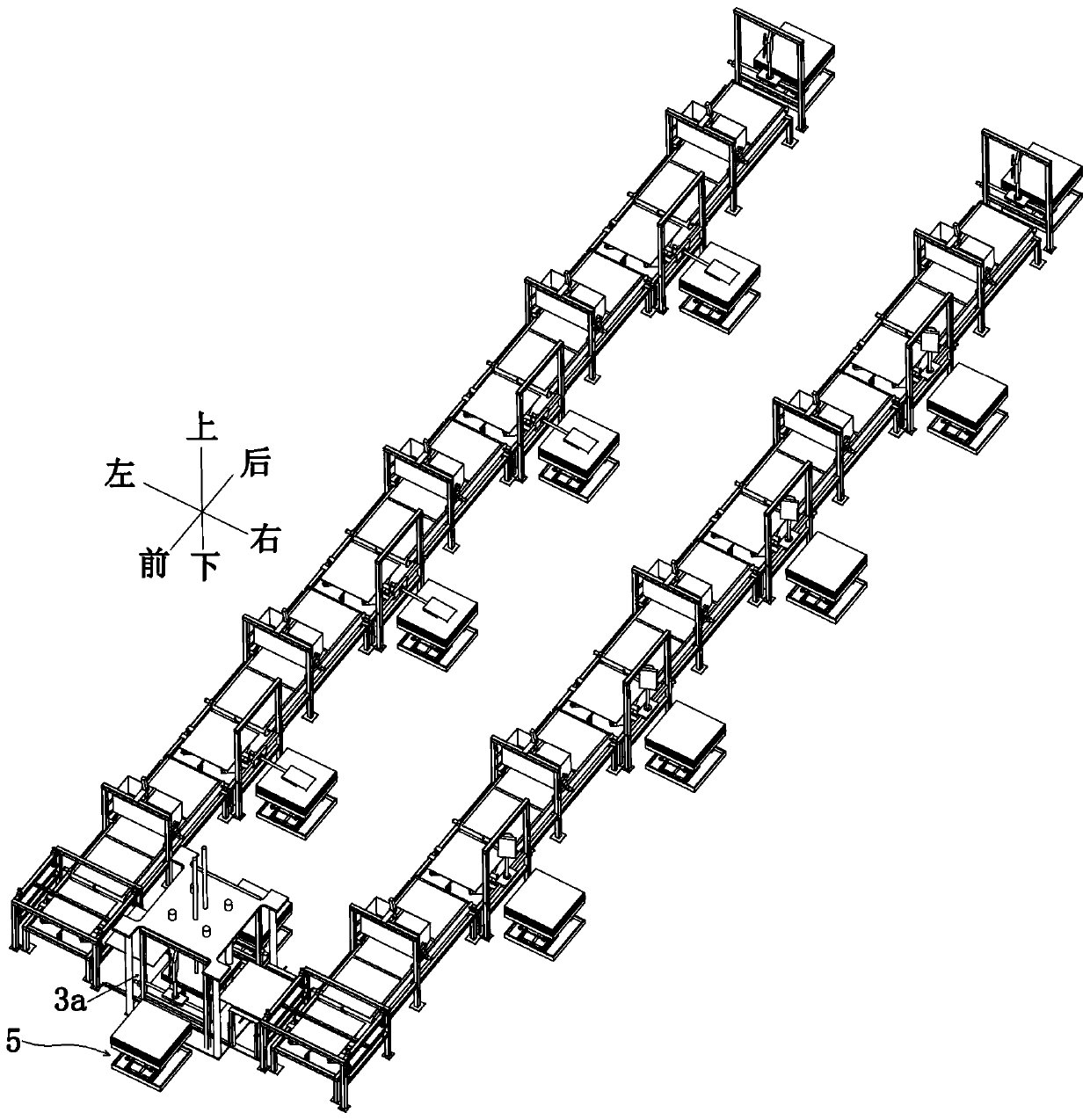

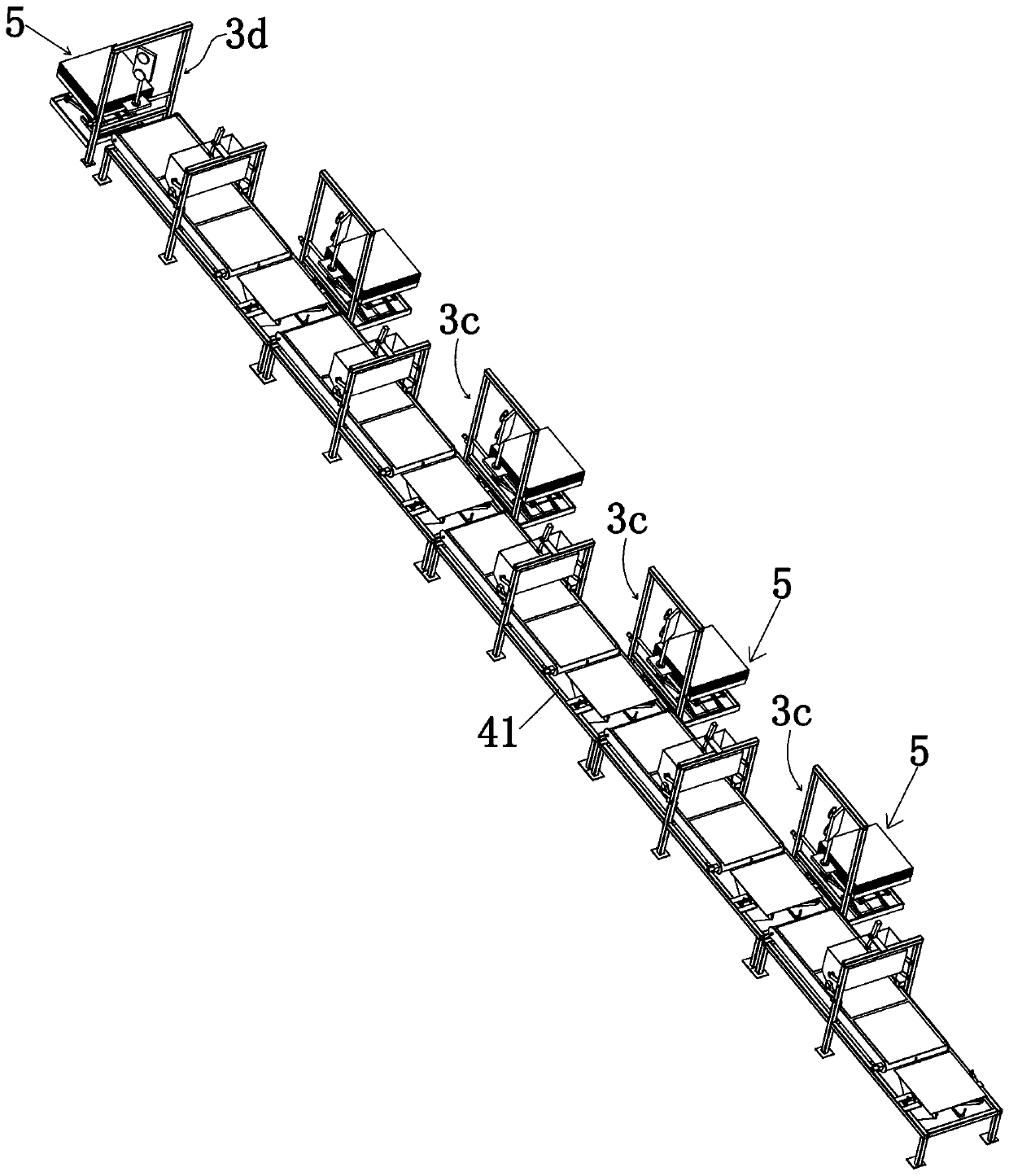

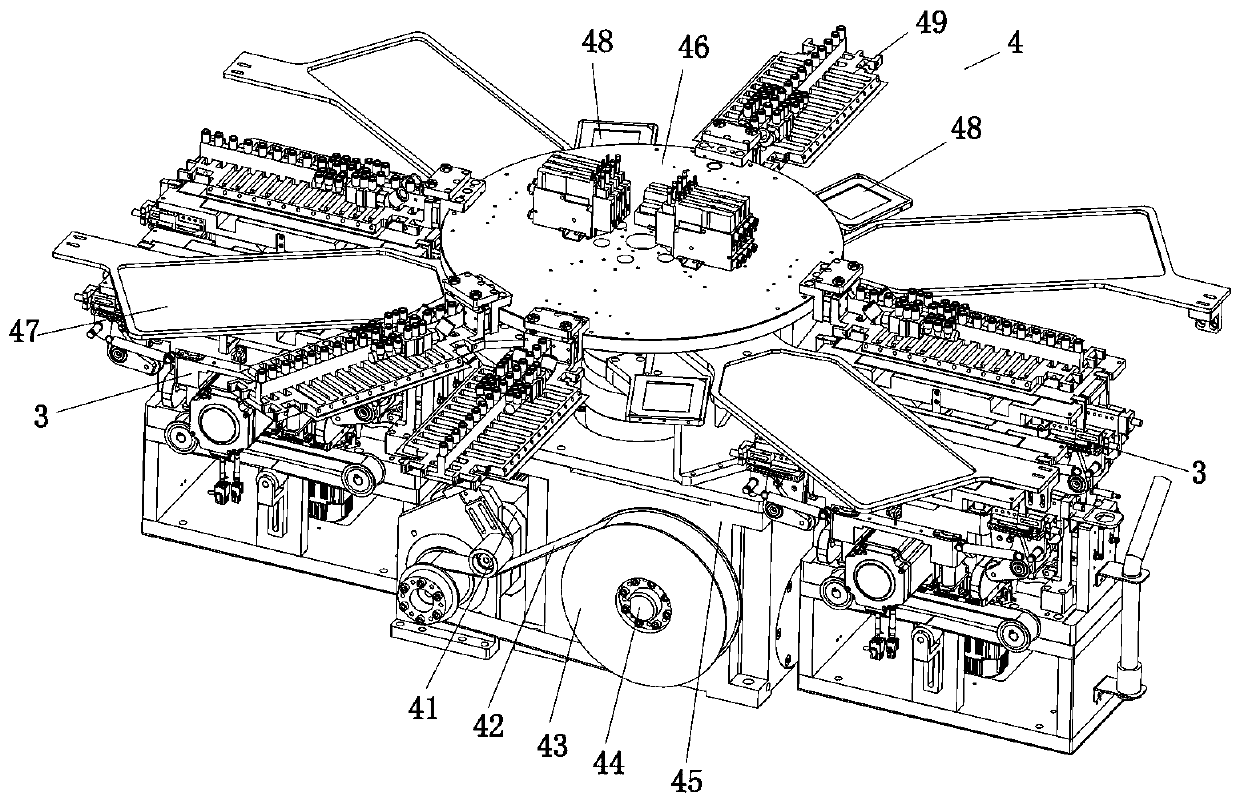

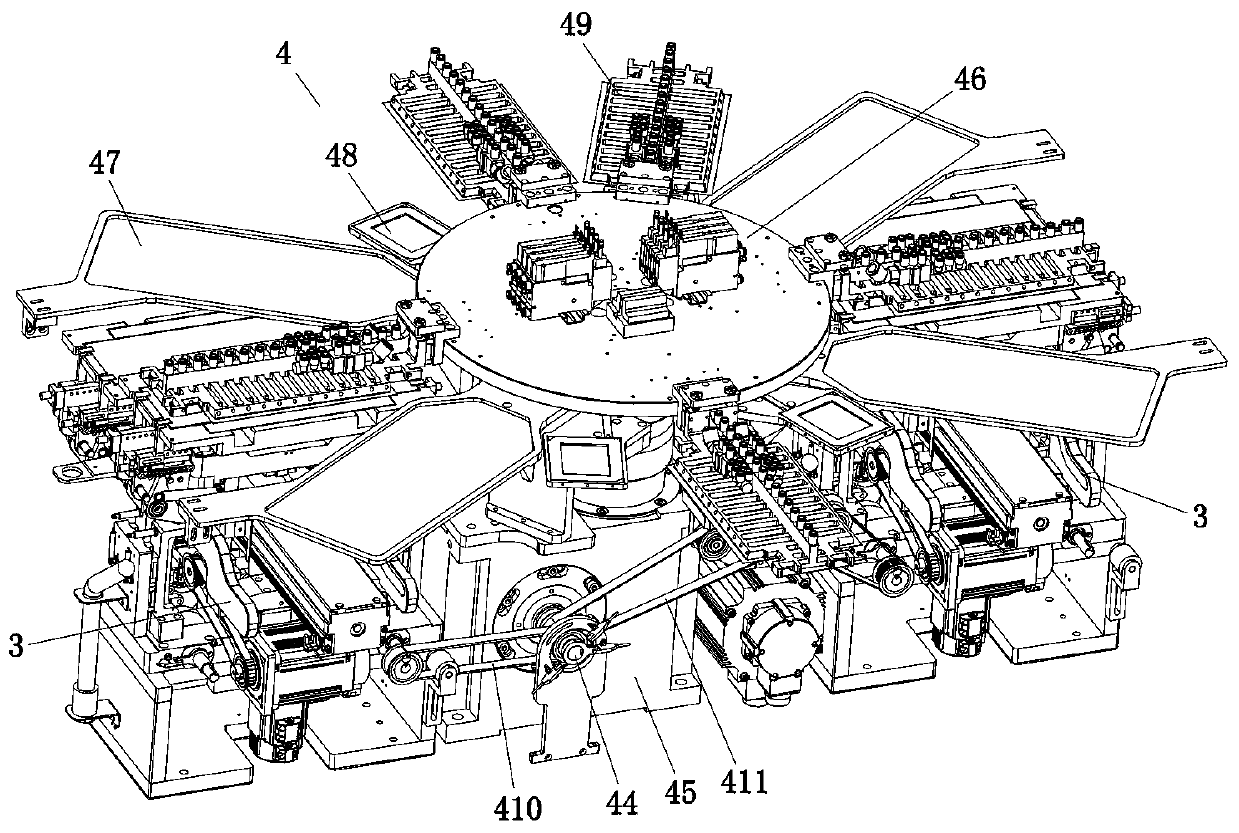

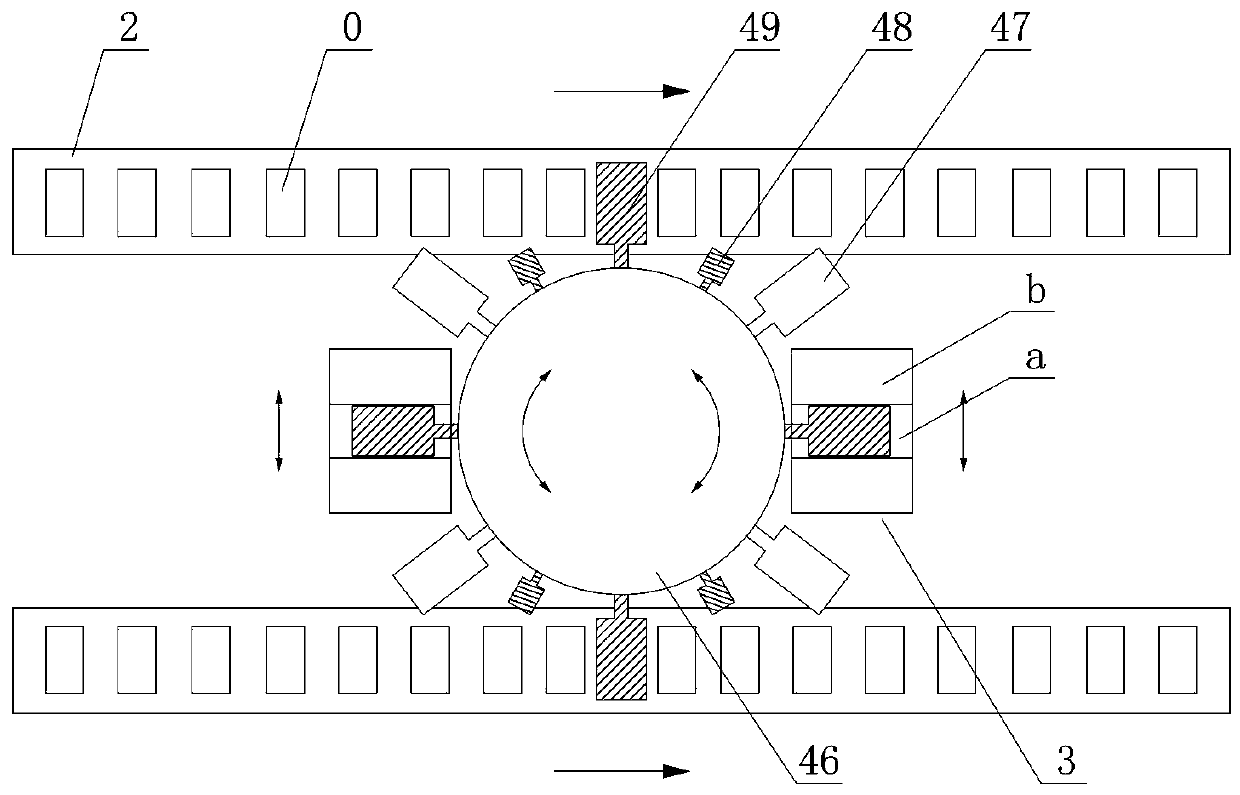

Turret type automatic lamination production line and lamination process thereof

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

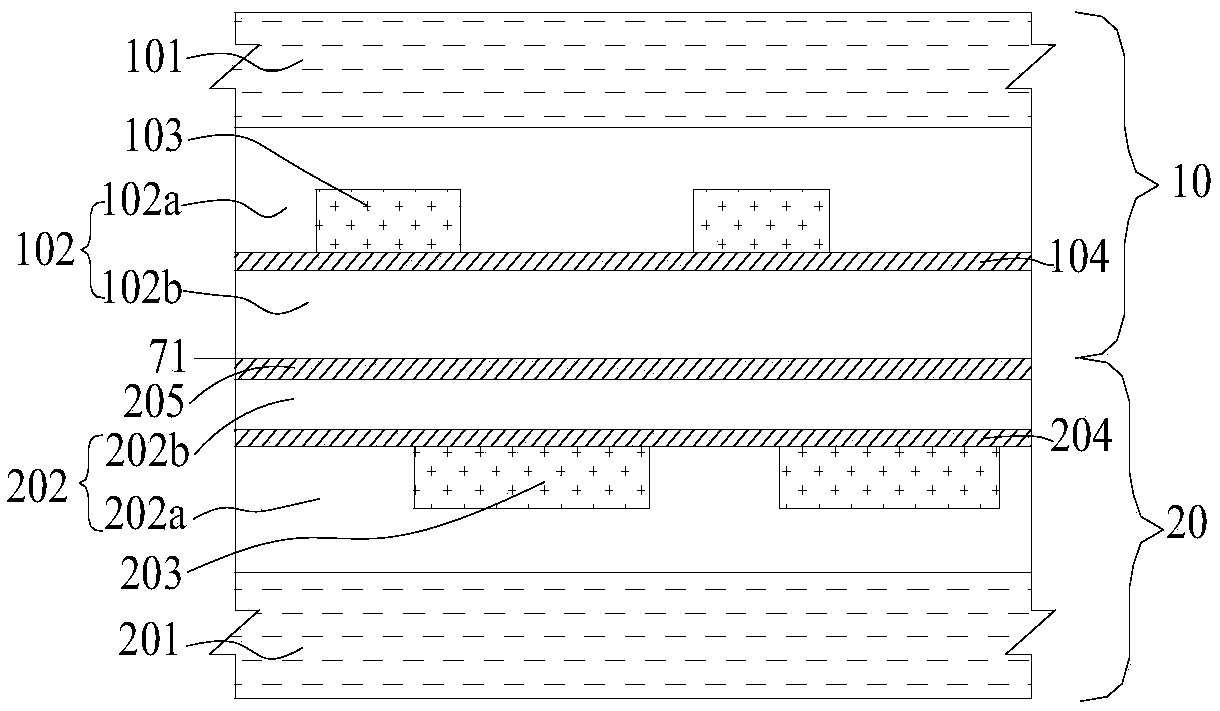

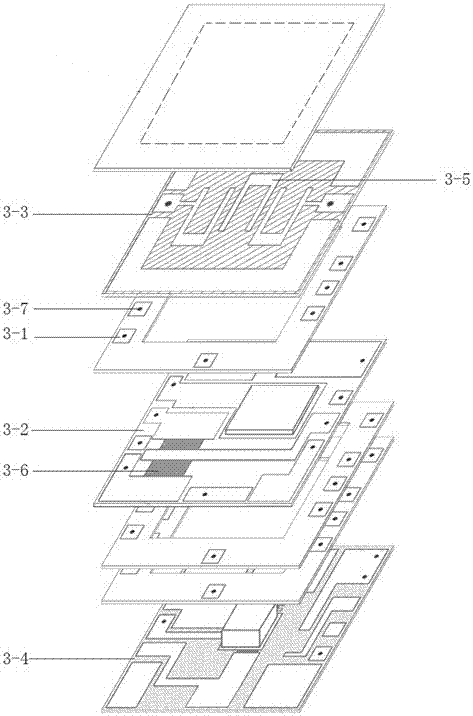

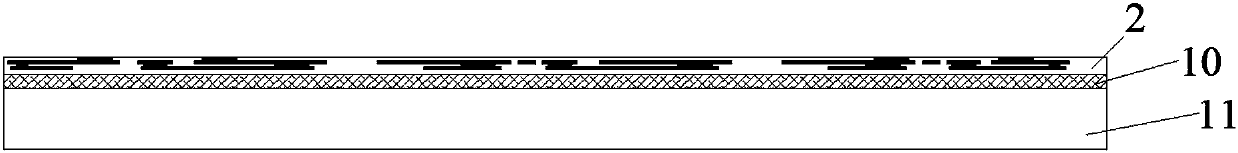

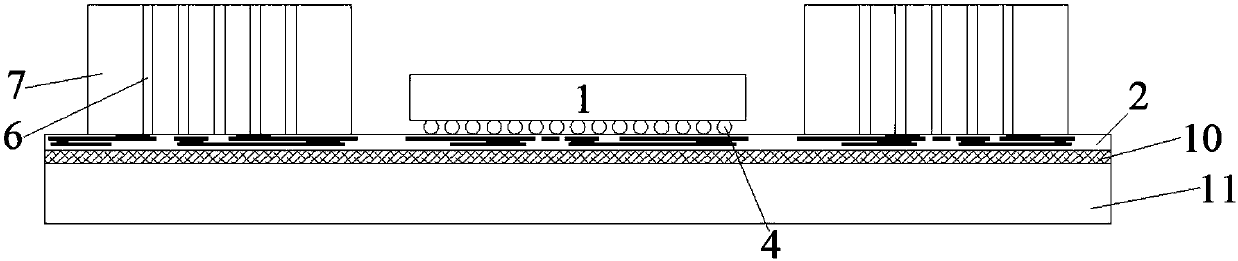

Chip packaging structure and preparation method of chip packaging structure

ActiveCN112820726AAchieve stackingImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingDielectric layer

The embodiment of the invention provides a chip packaging structure and a preparation method of the chip packaging structure, and relates to the technical field of chip packaging, and the chip packaging structure comprises a dielectric layer and a chip packaging module arranged on the dielectric layer. The chip packaging module comprises a plurality of first storage chips, a logic chip, at least one first heat dissipation block, at least one second heat dissipation block and a plastic packaging layer. The first storage chips are arranged on a dielectric layer in a stacked mode, the first heat dissipation blocks are arranged on the dielectric layer, the logic chip is arranged on the first heat dissipation blocks, the second heat dissipation blocks are arranged on the logic chip, and extend to the surface of the plastic packaging layer. Compared with the prior art, by arranging the first heat dissipation block and the second heat dissipation block, the good heat dissipation effect of the logic chip can be guaranteed, meanwhile, through the stacking structure of the first storage chip, stacking of multiple chips is achieved, the stacking number is increased, and meanwhile the good heat dissipation effect is guaranteed.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

Automatic steel ring grabbing system

ActiveCN104259835ASimple structureIngenious designVehicle componentsMetal working apparatusEngineeringSurface layer

The invention discloses an automatic steel ring grabbing system. Placing space which is for placing a steel ring in a positioning mode is formed in one side of a steel ring tray; the edge on one side of the steel ring tray forms into a surrounding of external spigot; the edge on the other side of the steel ring tray forms into an internal contraction step structure; the external spigot on one side of the steel ring tray can sleeve the external side of the internal contraction step structure of the adjacent steel ring tray to be superposed; a steel ring gripper and a tray gripper can be respectively positioned on a positioning disc side which is towards the steel ring direction; the steel ring gripper can grab and loosen the steel ring; the tray gripper can grab and loosen the tray; a first driving device and a second driving device respectively drive the steel ring gripper and the tray gripper to act; a position sensing device can sense the surface layer superposed steel ring and transmit to a controller to control a conveying mechanism to convey a steel ring grabbing mechanism to a grabbing position which is corresponding to the surface layer steel ring tray and control the first driving mechanism and the second mechanism to act. The automatic steel ring grabbing system achieves automatic ring assembling, saves manpower, improves the production efficiency and reduces production costs.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

Automatic explosive cartridge medium-package packaging machine

The invention discloses an automatic explosive cartridge medium-package packaging machine, and belongs to the technical field of emulsion explosive packaging equipment. According to the technical scheme, the automatic explosive cartridge medium-package packaging machine comprises a rack, wherein a feeding belt device, a stacking chain plate device and a first horizontal conveying device which are sequentially connected to one another are arranged on the rack; a second horizontal conveying device and a first pushing mechanism are arranged on a side of the first horizontal conveying device; a second pushing mechanism is arranged on the rack and on a side of the second horizontal conveying device; a third horizontal conveying device and a fourth horizontal conveying device are sequentially arranged on the rack and on the side of the second horizontal conveying device; a film forming sleeve is sleeved on the periphery of the third horizontal conveying device; a film supplying device is arranged on the rack and on a side of the film forming sleeve; a longitudinal film sealing device is arranged on a side of the fourth horizontal conveying device; and a transverse sealing and film cutting device is arranged at a discharging end of the fourth horizontal conveying device. The automatic explosive cartridge medium-package packaging machine is compact in structure, high in work efficiency and easy to maintain, and is used for automatically packaging explosive cartridges.

Owner:广东振声智能装备有限公司 +2

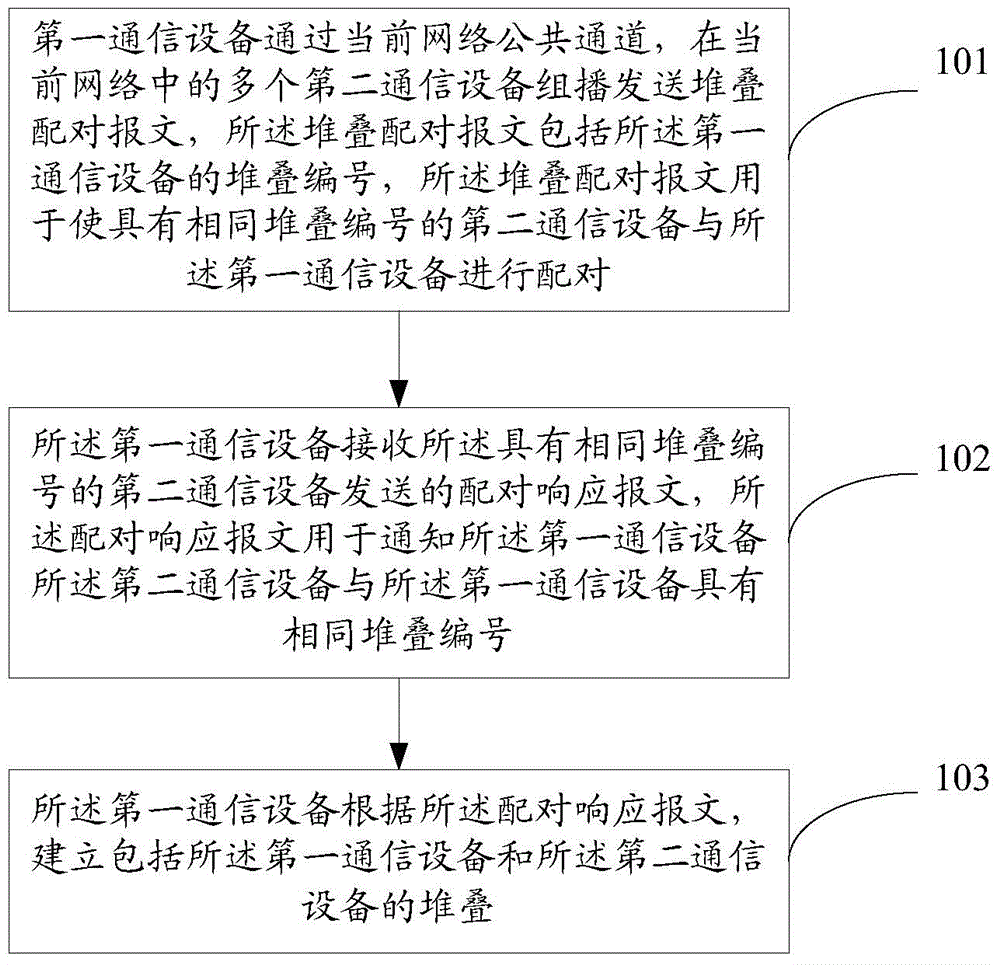

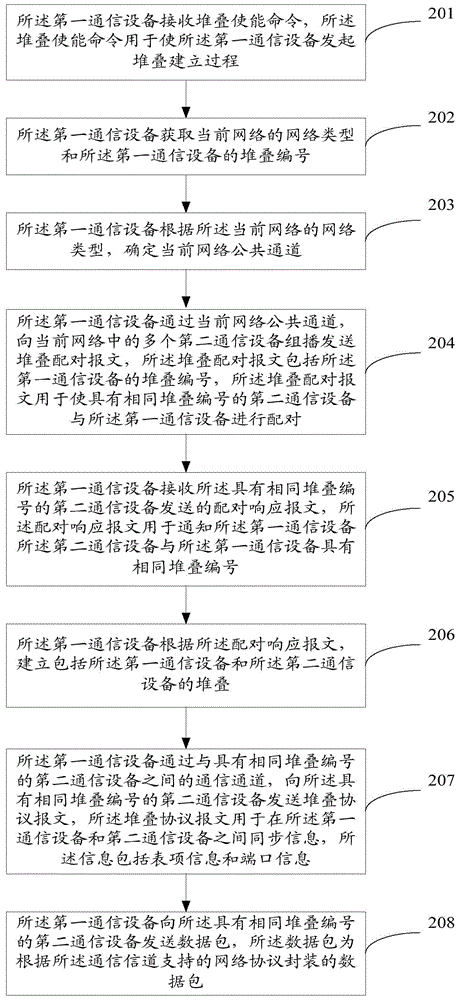

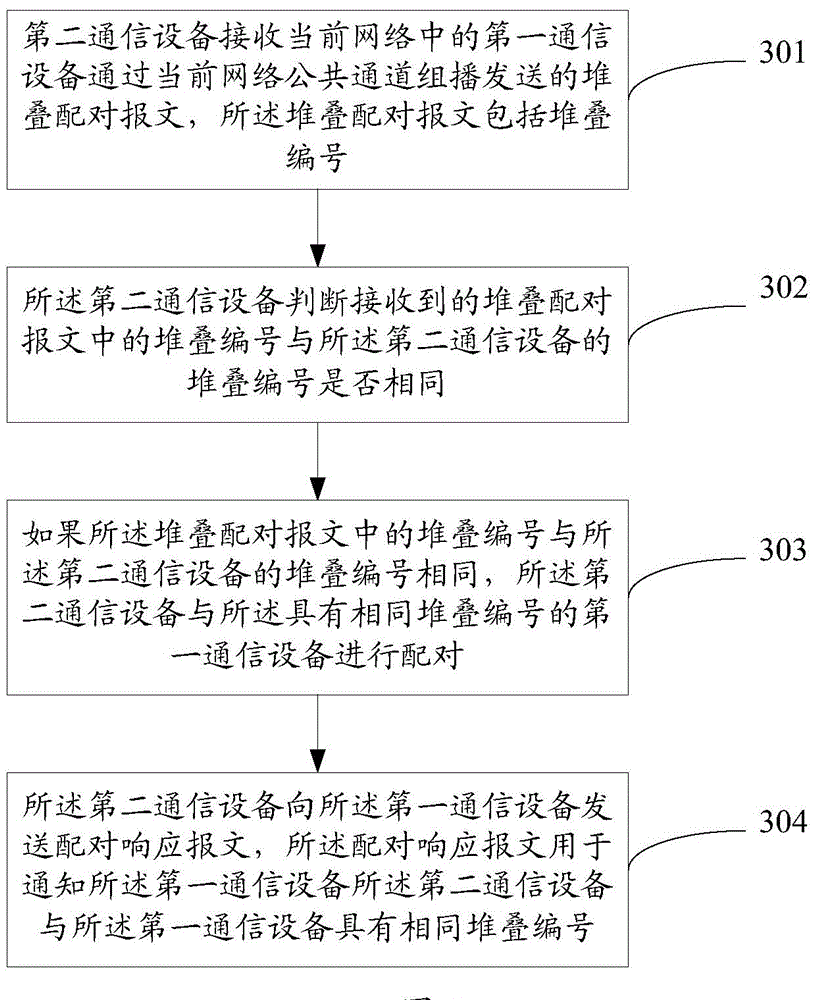

Stack establishing method and communication equipment

The invention discloses a stack establishing method and communication equipment, and belongs to the communication field. The stack establishing method comprises the following steps: first communication equipment sends a stack pairing message to second communication equipment in an existing network through an existing network public channel; the first communication equipment receives the pairing response message sent by the second communication equipment, wherein the repairing response message is used for noticing the first communication equipment that the second communication equipment and the first communication equipment have a same stack serial number; according to the pairing response message, the first communication equipment establishes stacks comprising the first communication equipment and the second communication equipment. According to the stack establishing method disclosed by the invention, by an existing network public channel, the communication equipment is paired and the stacks between the paired communication equipment are established, so that the communication equipment which needs stack establishing is free of interferences of a physical position and a network, and thus, the physical-region-crossing or network-crossing stack between the network equipment is realized.

Owner:HUAWEI TECH CO LTD

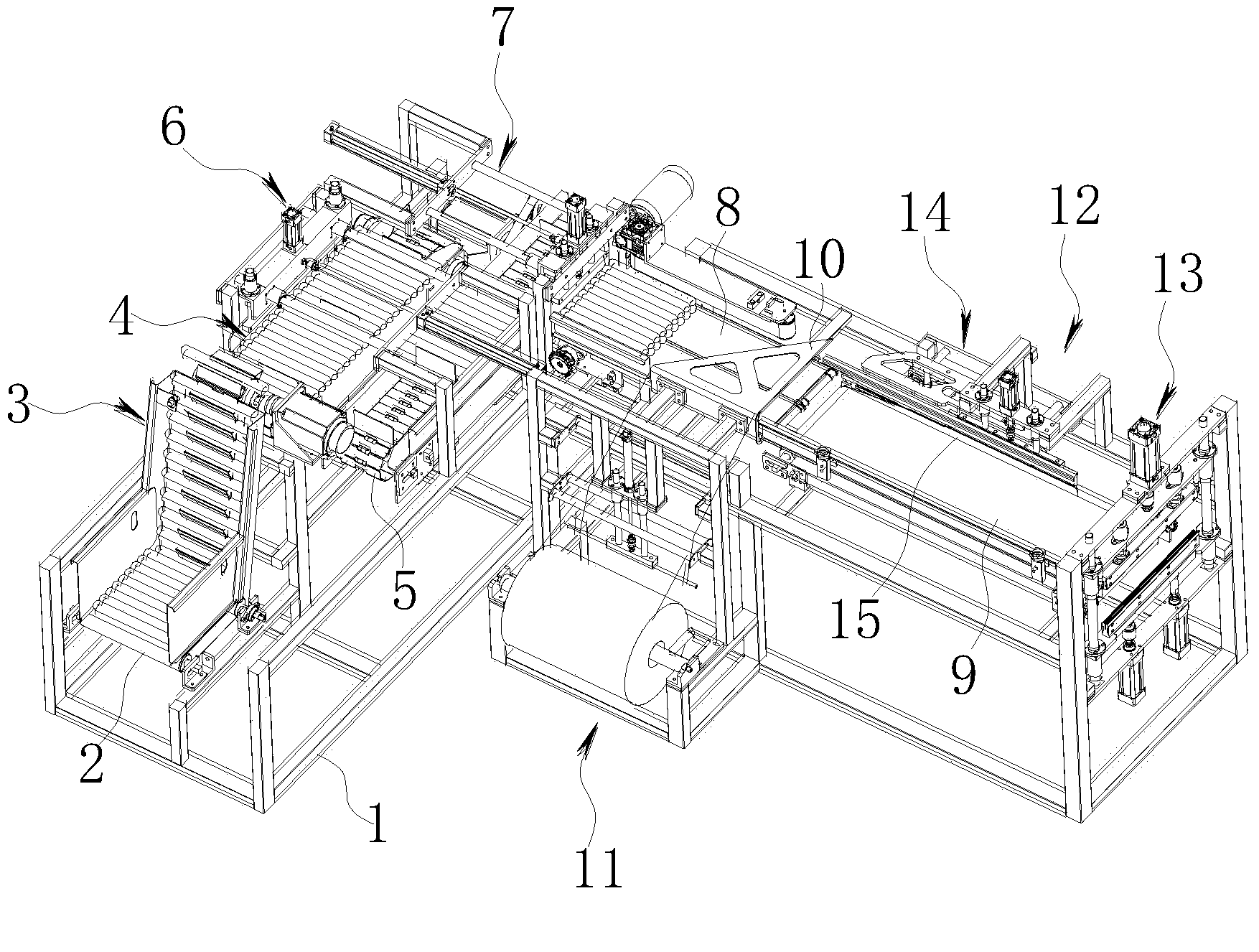

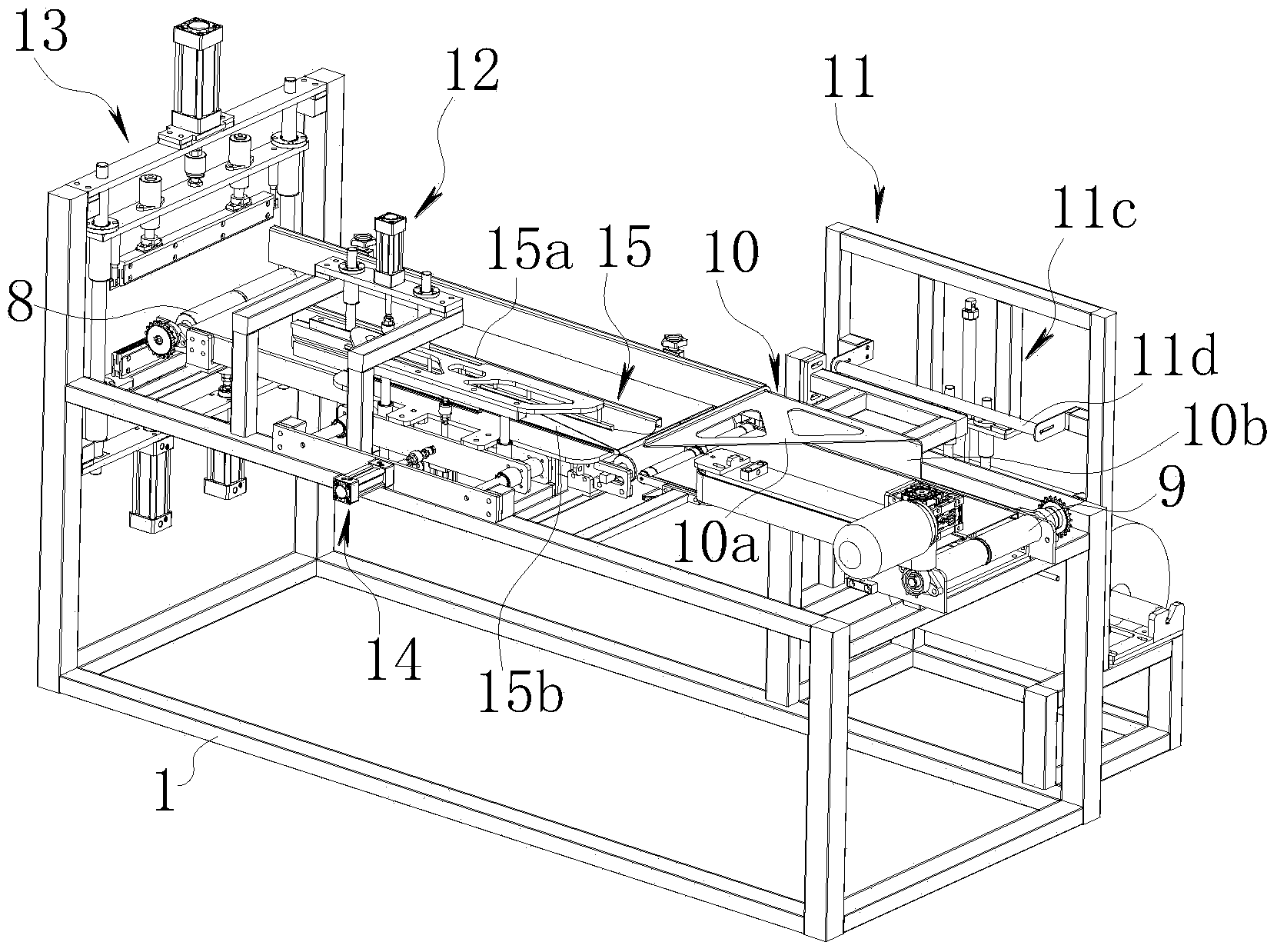

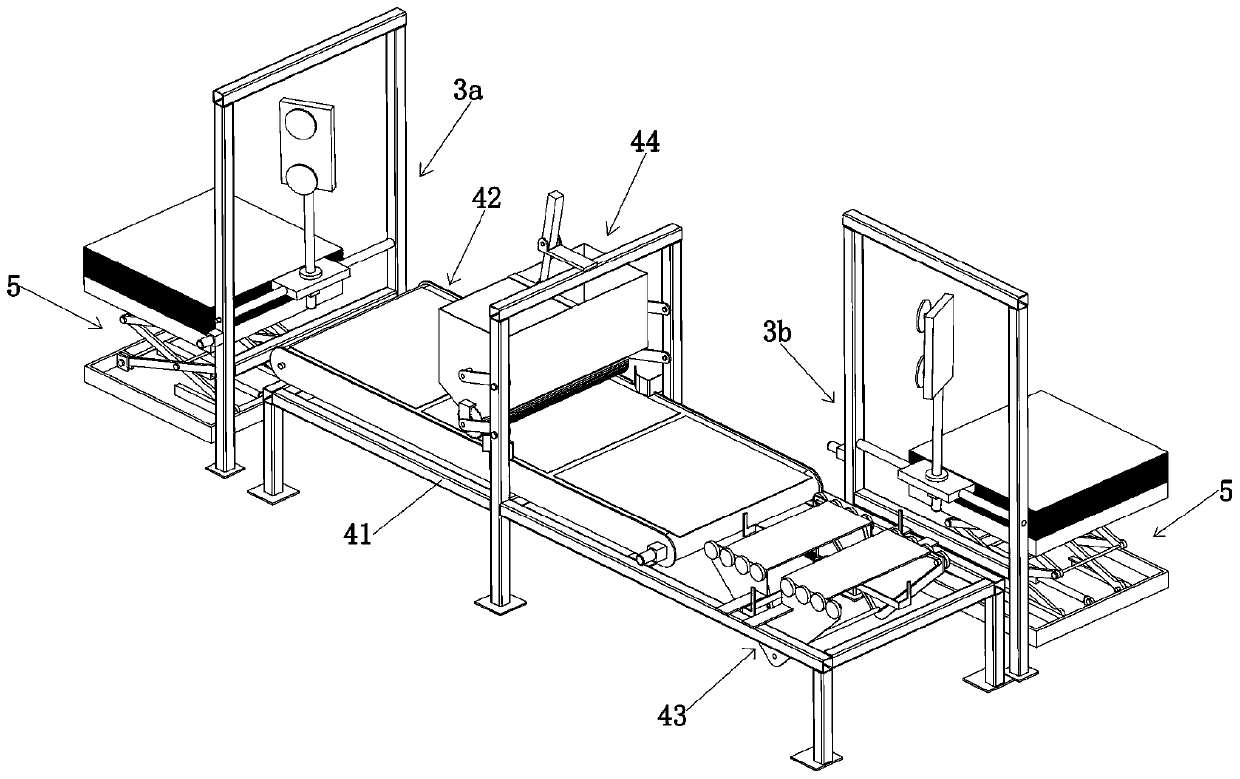

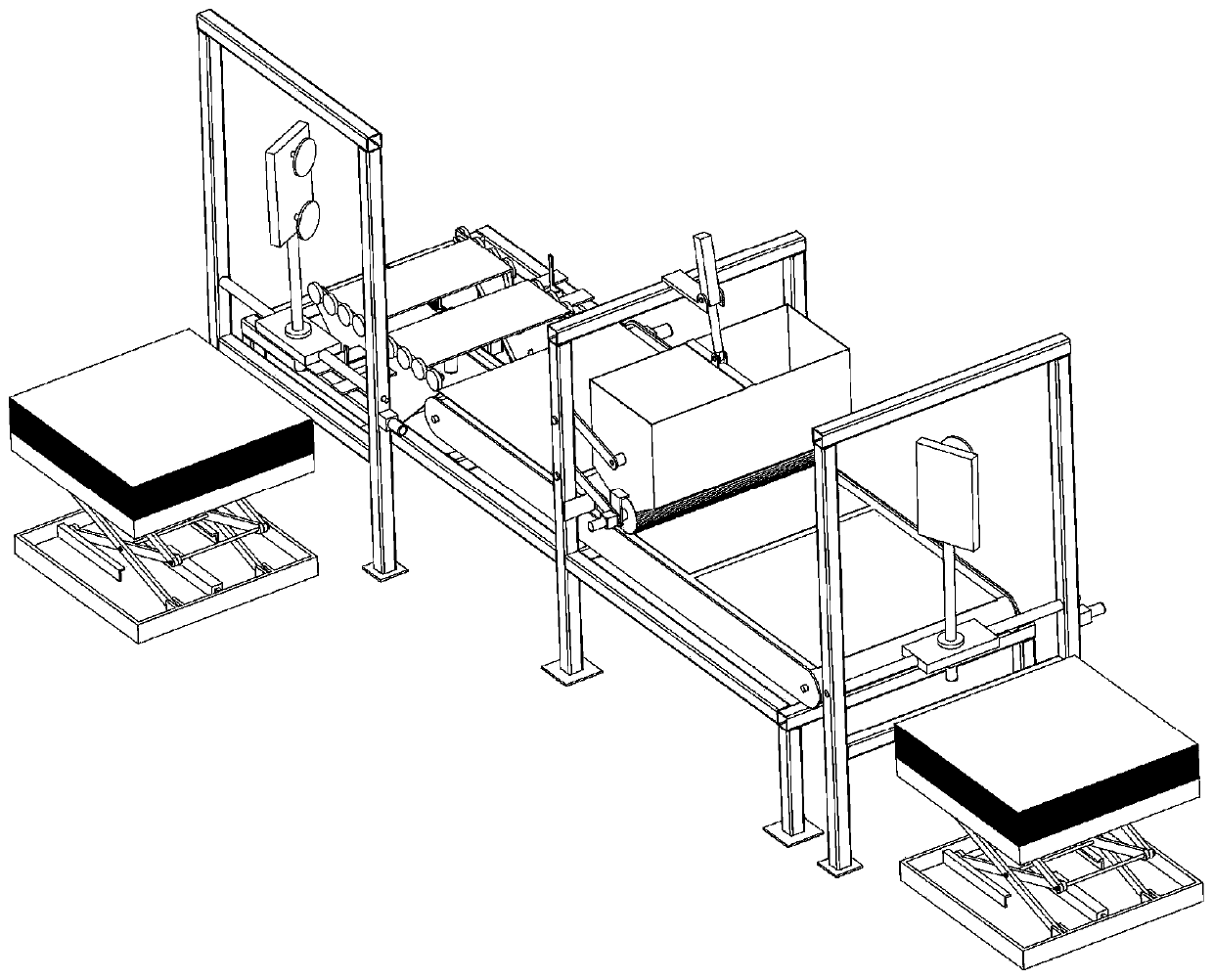

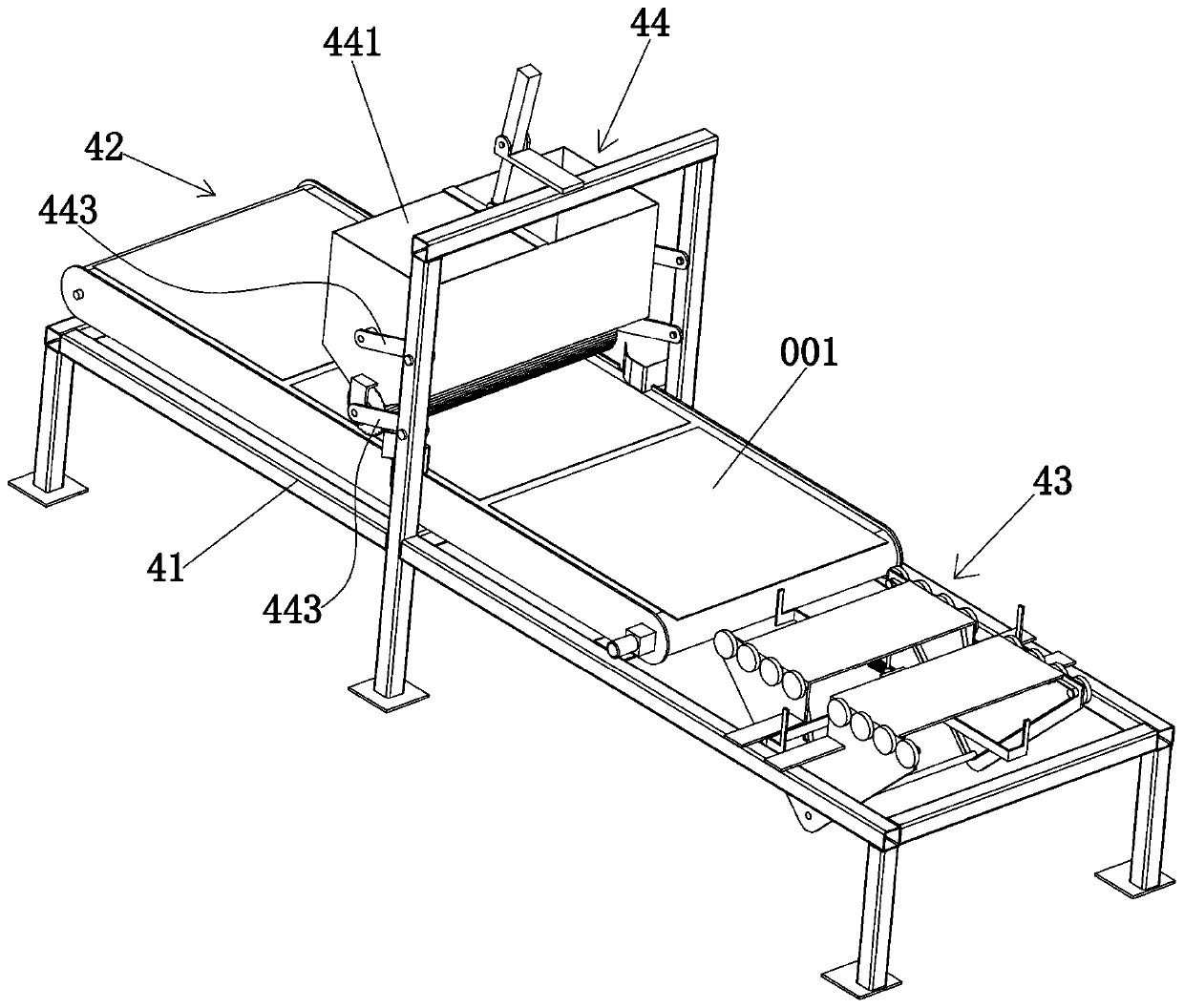

Composite wood board automatic processing device and composite wood board processing process

InactiveCN111391044ARealize automatic feeding processAchieve stackingPlywood pressesVeneer pressesAdhesive glueWood plank

The invention discloses a composite wood board automatic processing device and a composite wood board processing process. The automatic processing device comprises a pressing machine assembly, gluingmold board carrying assemblies which are arranged on the left and the right sides of the pressing machine assembly, a first board feeding assembly which is arranged on the front side of the pressing machine assembly, and a board discharging assembly which is arranged on the rear side of the pressing machine assembly. The automatic processing device further comprises two board stacking assemblies which are arranged on the two gluing mold board carrying assemblies respectively; the board stacking assemblies are for applying glue to the upper surface of a plurality of thin boards and stacking thethin boards to form a stacked board to be pressed and for delivering the stacked board to be pressed to the gluing mold board carrying assemblies; the first board feeding assembly is for placing a thin board on the upward side of the stacked board to be pressed; and the pressing machine assembly is for receiving the stacked boards to be pressed delivered by the gluing mold board carrying assemblies and pressing the stacked boards with a thin board arranged on the upward side to form a composite wood board. The composite wood board automatic processing device can realize automatic processing and manufacturing of a composite wood board and can greatly save the input of manpower.

Owner:佛山信卓派思机械科技有限公司

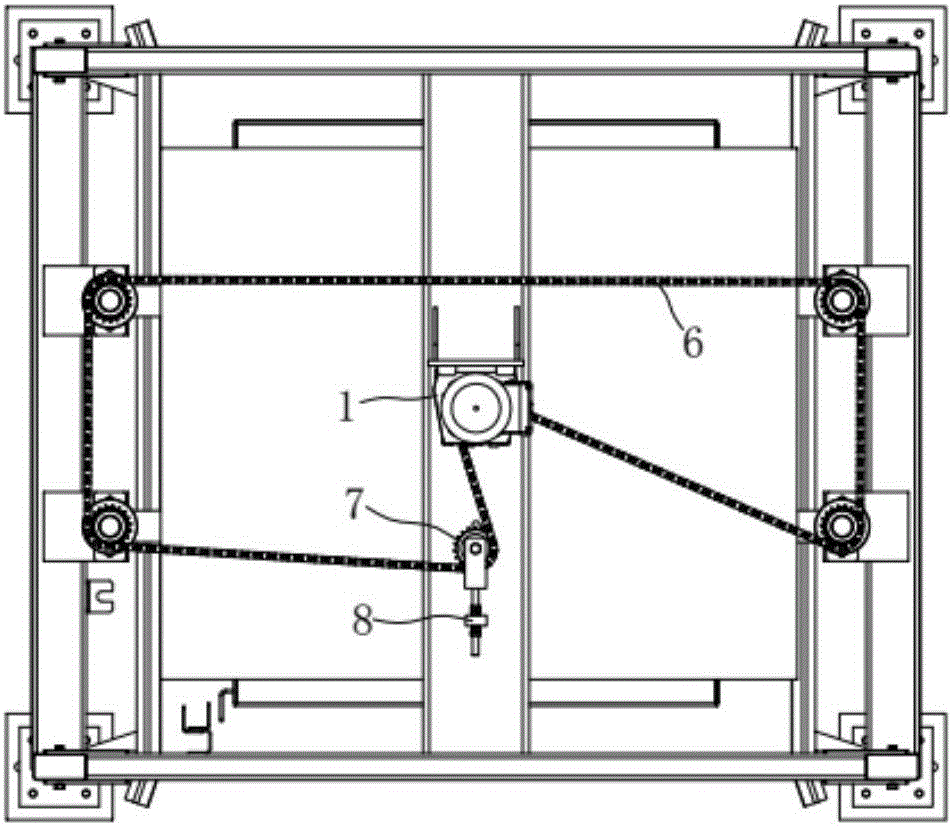

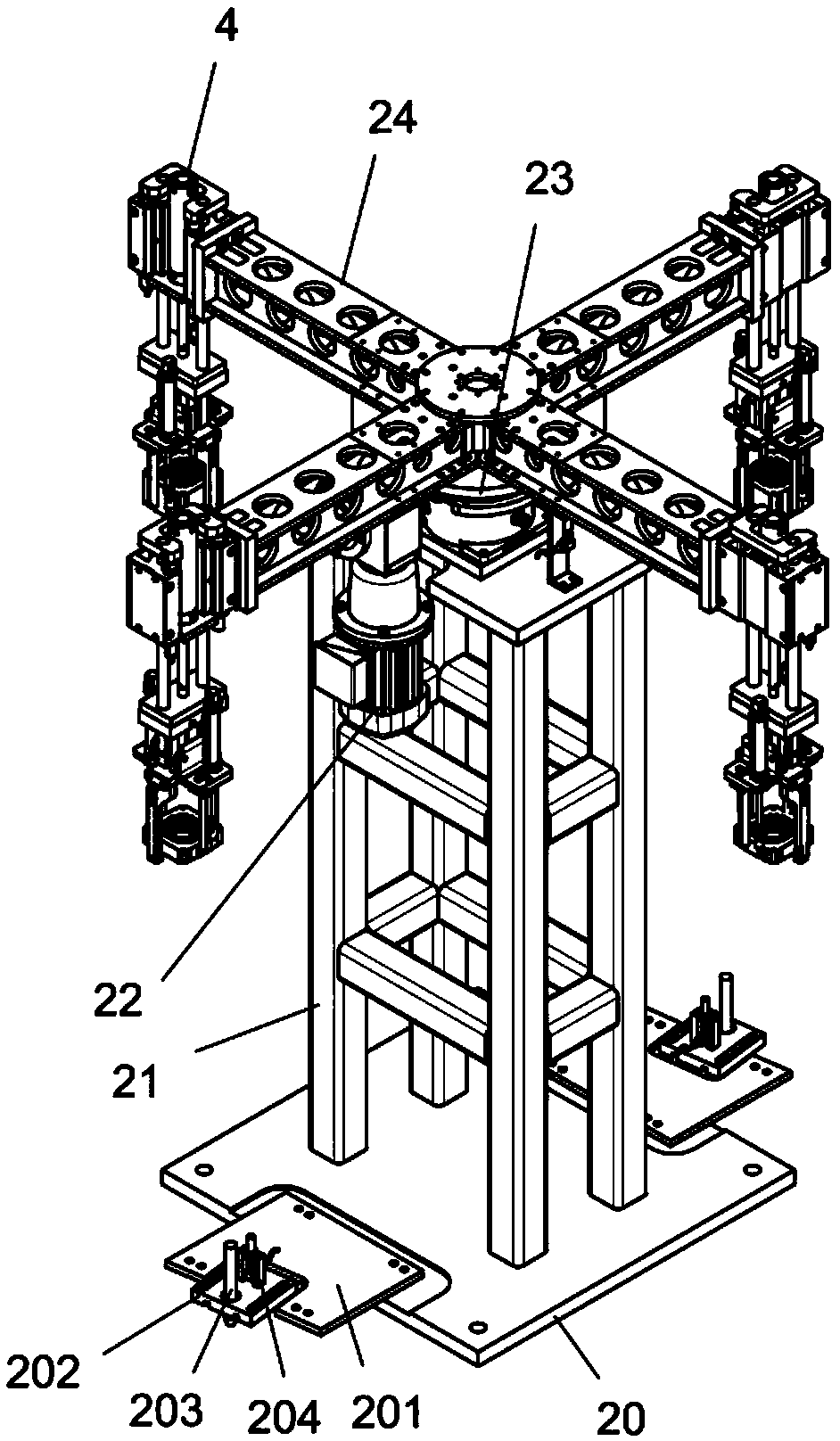

Automatic stacking system for television backboards

ActiveCN105966918AFully automatedReduce the burden onCharge manipulationConveyor partsEngineeringManipulator

The invention provides an automatic stacking system for television backboards. The automatic stacking system comprises turning equipment, a mechanical arm and television backboard stacking equipment. The television backboard stacking equipment comprises a forklift rack, protection corner stacking, taking and delivering devices and lifting devices. The protection corner stacking, taking and delivering devices are arranged on the periphery of the forklift rack. Each protection corner stacking, taking and delivering device comprises a rack body, a stacking frame, a supporting mechanism and a taking and delivering mechanism. Each rack body comprises a base and a vertical rack. Each stacking frame is arranged in the corresponding base and provided with a stacking cavity. Protection corners are stacked in each stacking cavity. Each supporting mechanism comprises a supporting piece and a power assembly used for driving the supporting piece to move upwards to support the protection corners in the corresponding stacking cavity. Each power assembly is arranged on the corresponding vertical rack. Each supporting piece corresponds to the corresponding stacking cavity. Each taking and delivering mechanism is assembled on the corresponding vertical rack and located above the corresponding supporting piece. Each taking and delivering mechanism comprises a taking-out piece and a driving assembly used for driving the taking-out piece so that the protection corners can be transferred towards the forklift rack. Each lifting device is located between every two adjacent protection corner stacking, taking and delivering devices. The turning equipment is used for turning the television backboards. The mechanical arm is used for transferring the turned television backboards to the position of the television backboard stacking equipment, and thus automatic stacking of the television backboards is achieved.

Owner:DONGGUAN SANNIAN INTELLIGENT TECH CO LTD

Pallet stacking and separating mechanism

The utility model relates to a pallet stacking and separating mechanism. The pallet stacking and separating mechanism comprises a shifting fork rotating shaft and a stacking jacking mechanism which are arranged up and below. A pallet shifting fork is arranged on the shifting fork rotating shaft. In pallet stacking operation, a pallet is jacked to the position of a shifting fork by the stacking jacking mechanism, the rotating shaft of the shifting fork rotates, the palletshifting fork is inserted in a trench at the bottom of the pallet to support the pallet, the stacking jacking mechanism moves in circles to jack the pallet, so as to stack the pallet one by one. The pallet separating principle is opposed to the pallet separating mechanism. According to the pallet stacking and separating mechanism, the stacking and separating of pallet can be achieved on the same device, the work efficiency is improved, the stacking effect and the separating effect are enhanced, and the storage and withdrawal of a goods shelf are facilitated.

Owner:BOZHON PRECISION IND TECH CO LTD

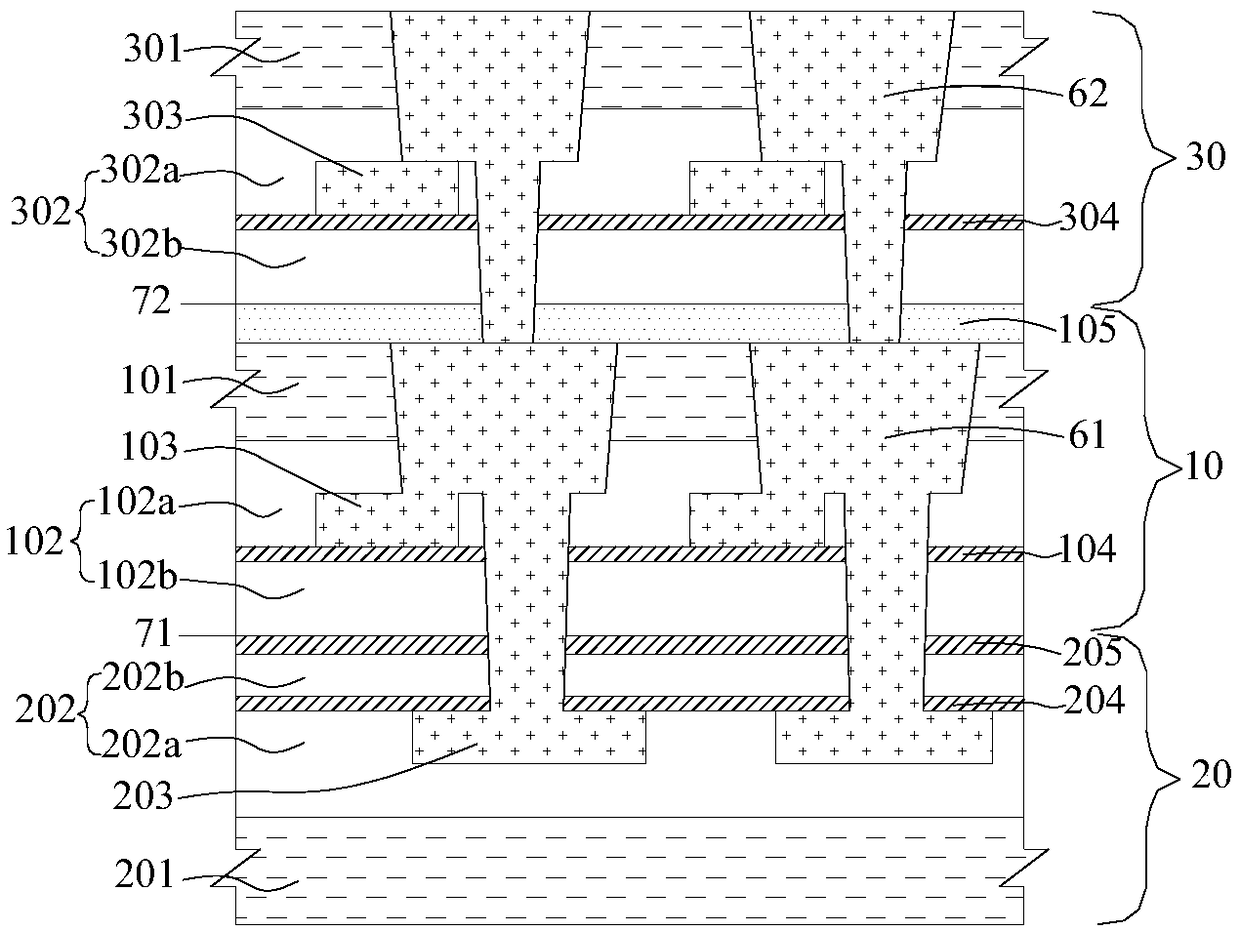

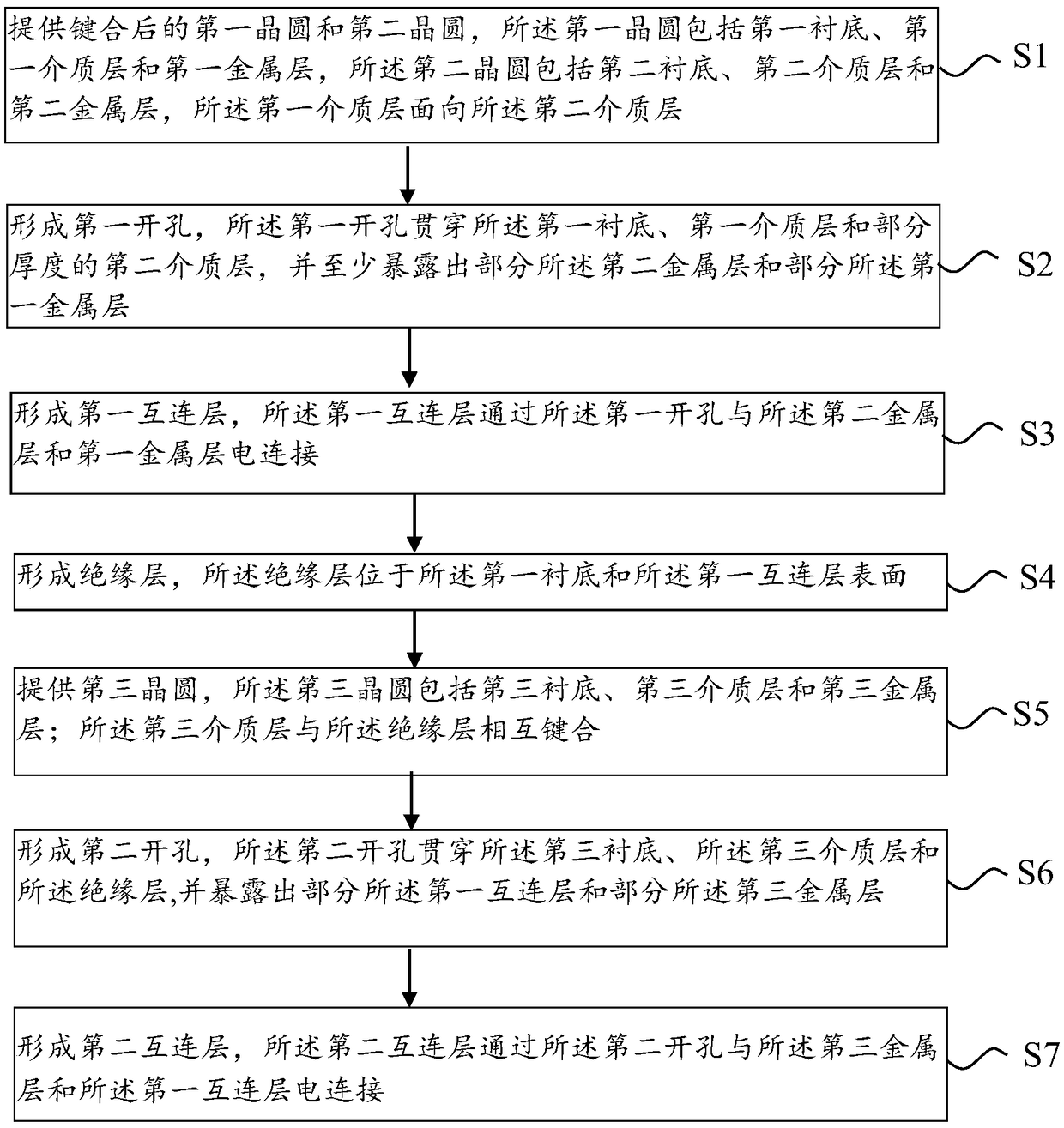

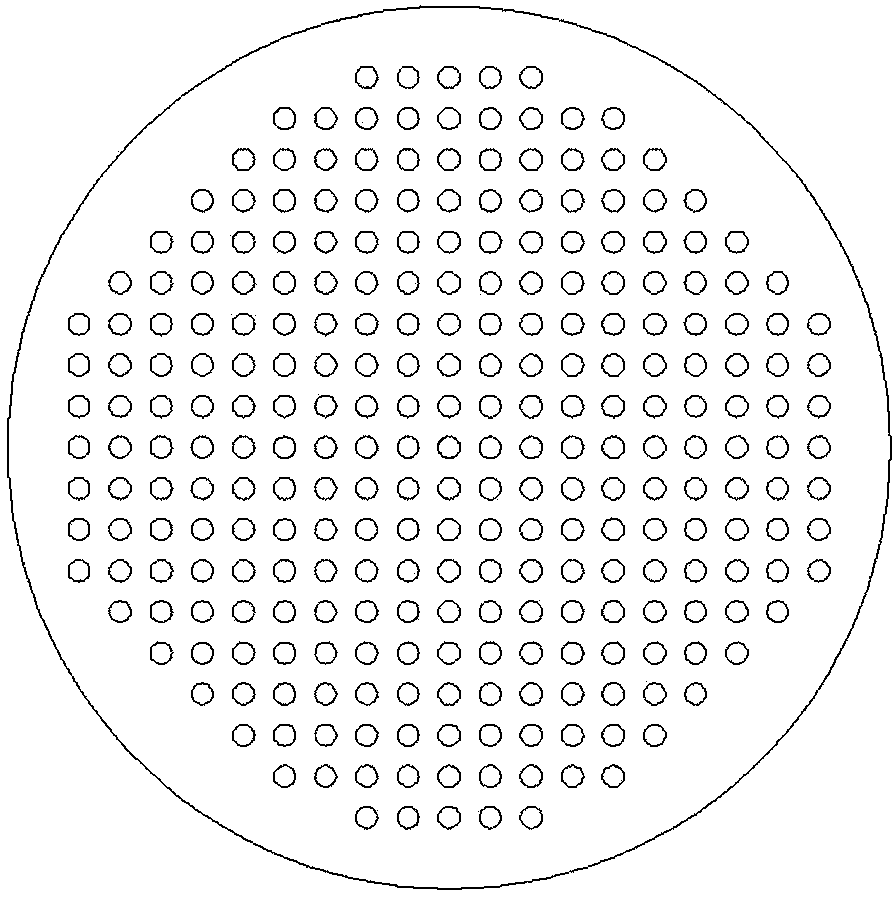

Multi-wafer stack structure and forming method thereof

ActiveCN109166840AAchieve stackingReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesWafer stackingInterconnection

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Container

InactiveCN102689751AGuaranteed stability and securityNo damageLarge containersEngineeringMechanical engineering

The invention provides a container used to be arranged in a stacking area that possesses multiple first corner fittings and second corner fittings. The container at least comprises: a tank and multiple positioning buffers, first corner fittings correspondingly connected to various first corner fittings which are respectively arranged on the corner fittings of the tank, wherein sidewall of the tank outside the first corner fitting respectively possesses a cavity. The multiple positioning buffers are arranged inside the cavities. The multiple positioning buffer comprises a buffer unit and a second corner fitting, and an center distance between the first corner fitting and the second corner fitting is equal to a standard center distance between the first corner fitting and the second corner fitting in the stacking area. The buffer unit stretches out of the tank to contact the second corner fitting under the drawing of the second corner fitting in a state of tank hanging in the air, and the buffer unit retracts into the cavity with a constant speed by compression of tank gravity to play a role of tank buffer at the time when the second bottom corner fitting is combined with the corner fitting in the stacking area, thereby nonoccurrence of cargo damage in the tank in loading and unloading operations is guarantied.

Owner:NIPPON EXPRESS CO LTD +1

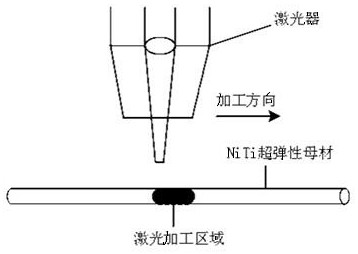

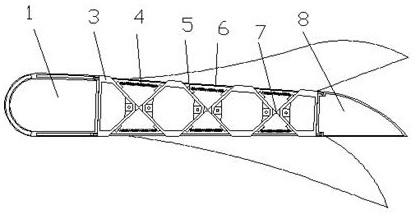

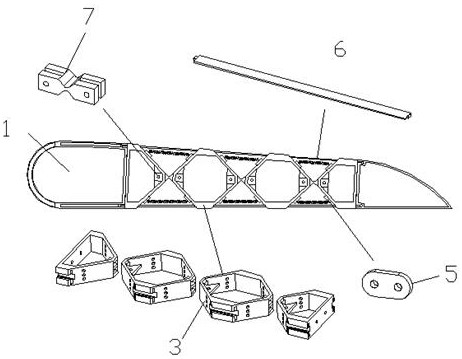

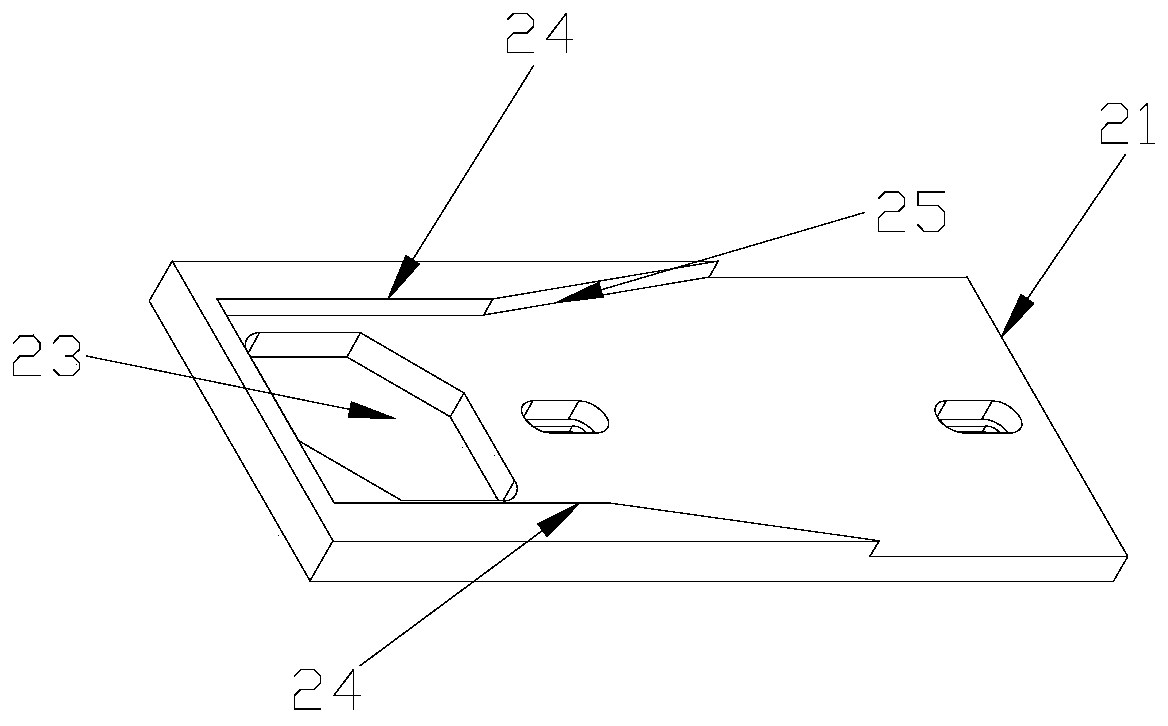

Flexible wing structure based on shape memory alloy and manufacturing method thereof

PendingCN111717368AReduce weightLight in massAdditive manufacturing apparatusFurnace typesShape-memory alloyStructural engineering

The invention relates to a flexible wing structure based on shape memory alloy and a manufacturing method of the flexible wing structure, which belong to the field of aircraft parts. The flexible wingstructure comprises a shaping frame and a plurality of independent bending mechanisms, and the bending mechanisms are parallel in the wing arm direction and are fixedly connected with the shaping frame; each bending mechanism comprises a memory alloy piece, a flexible hinge, an elastic skin, a swing tail and a plurality of rigid connecting pieces connected with one another; the swinging tail is connected with the shaping frame through a rigid connecting piece; each rigid connecting piece is provided with a conical connecting part; the conical tip end of each connecting part is connected withthe adjacent rigid connecting piece through a flexible hinge; the upper side and the lower side of each flexible hinge are each provided with a memory alloy piece; each memory alloy piece is connectedwith the adjacent rigid connecting piece; and each memory alloy piece can control the bending mechanism to swing up and down when powered on or powered off. The problems that an existing wing structure is not easy to control, fatigue life of a wing part structure is short due to control structure defects, and efficiency is low are solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

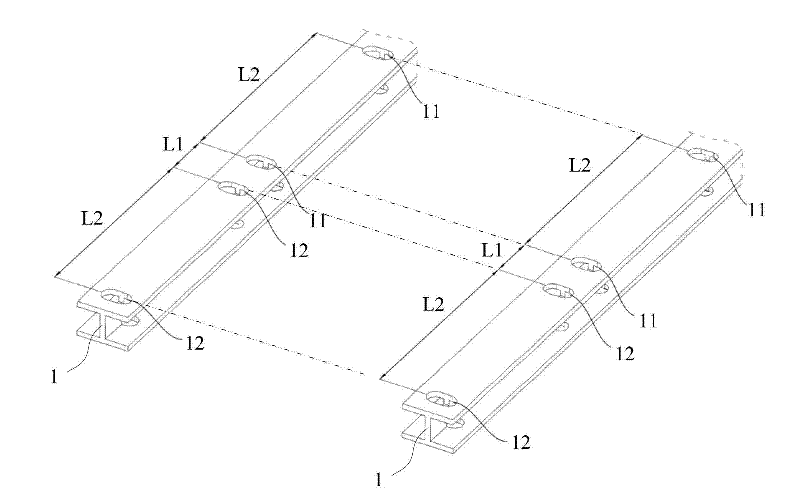

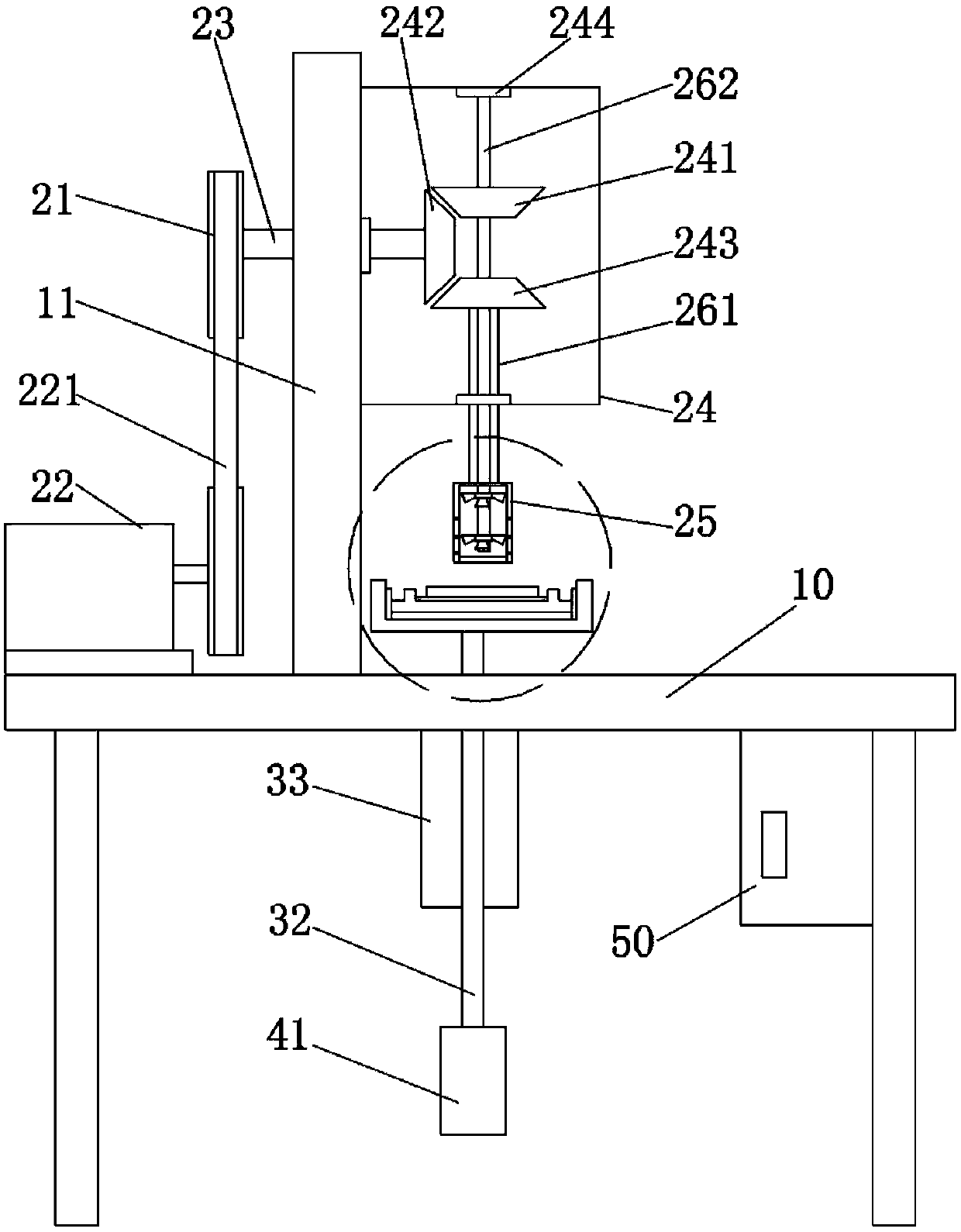

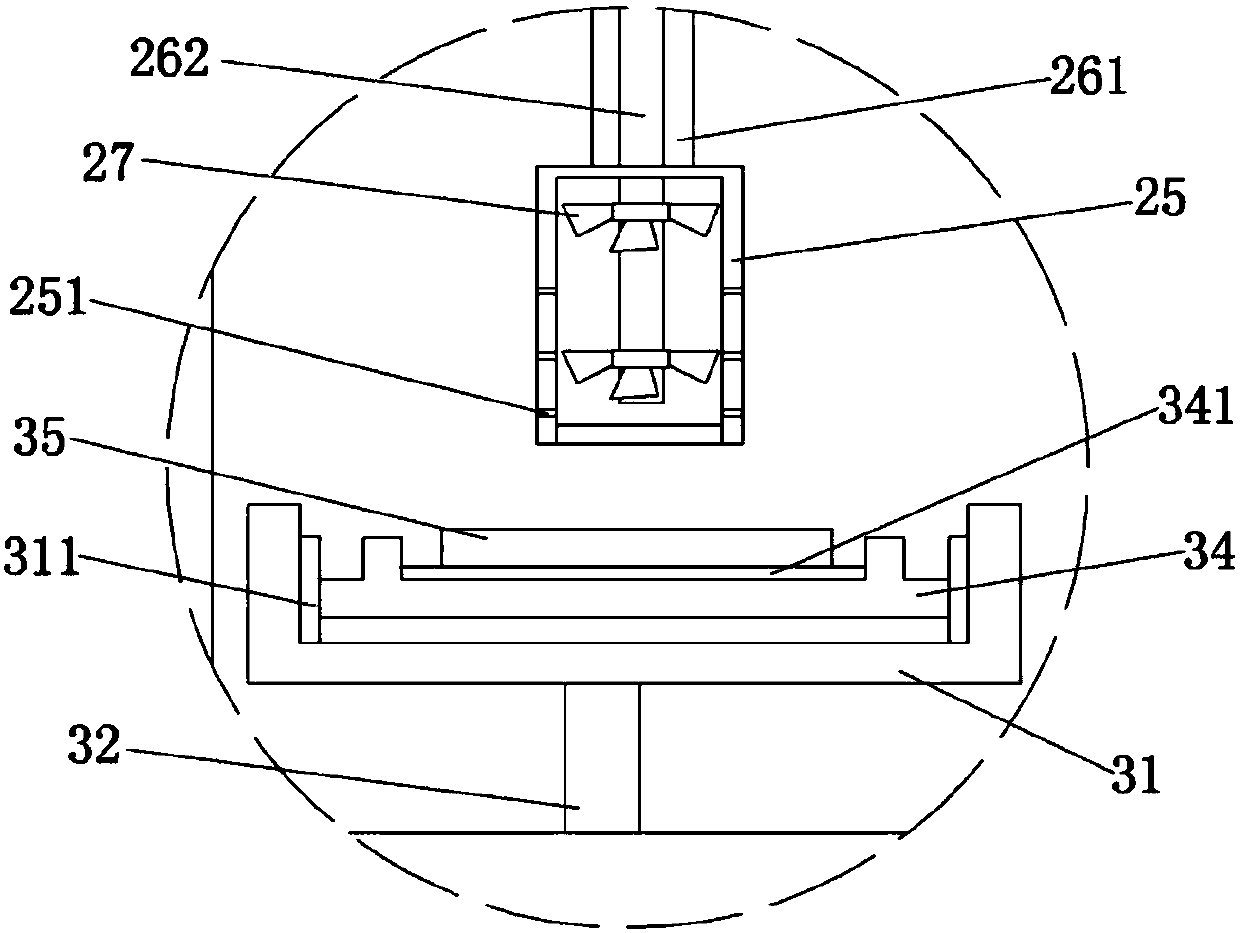

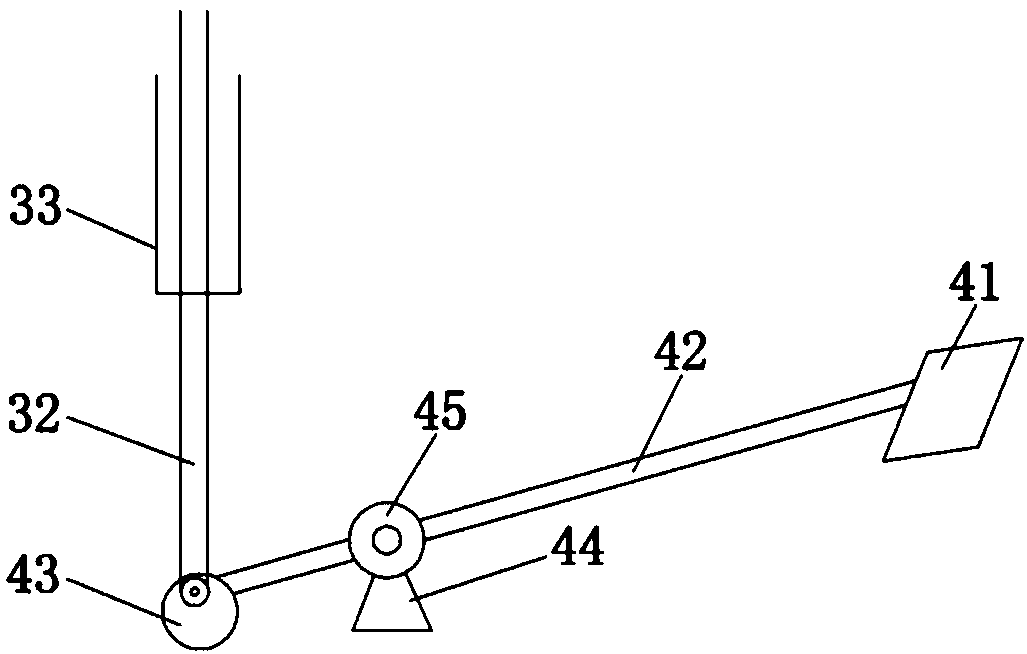

Workpiece conveying, stacking and storing device

ActiveCN109592429AAchieve stackingImplement storageStacking articlesDe-stacking articlesManipulatorEngineering

The invention discloses a workpiece conveying, stacking and storing device comprising a workpiece conveying unit, a gasket conveying unit, a rotational lifting unit and a rotational storage frame. Therotational lifting unit is fixedly installed on the operation ground. The workpiece conveying unit and the gasket conveying unit are arranged on the front side and the back side of the rotational lifting unit. The rotational storage frame is arranged beside the rotational lifting unit and fixedly installed on the operation ground. According to the workpiece conveying, stacking and storing device,the workpiece conveying unit and the gasket conveying unit which are located on the front side and the back side of the rotational lifting unit feed workpieces and gaskets correspondingly, multiple mechanical arms of the rotational lifting unit grab the workpieces and the gaskets correspondingly and alternately place the workpieces and the gaskets in the rotational storage frame, and then stacking and storing of the workpieces are achieved; and since material loading racks can be detached from the rotational storage frame, fetching and placing are convenient, and the flexibility is improved.

Owner:LUAN XIANGCHUAN TECH CO LTD

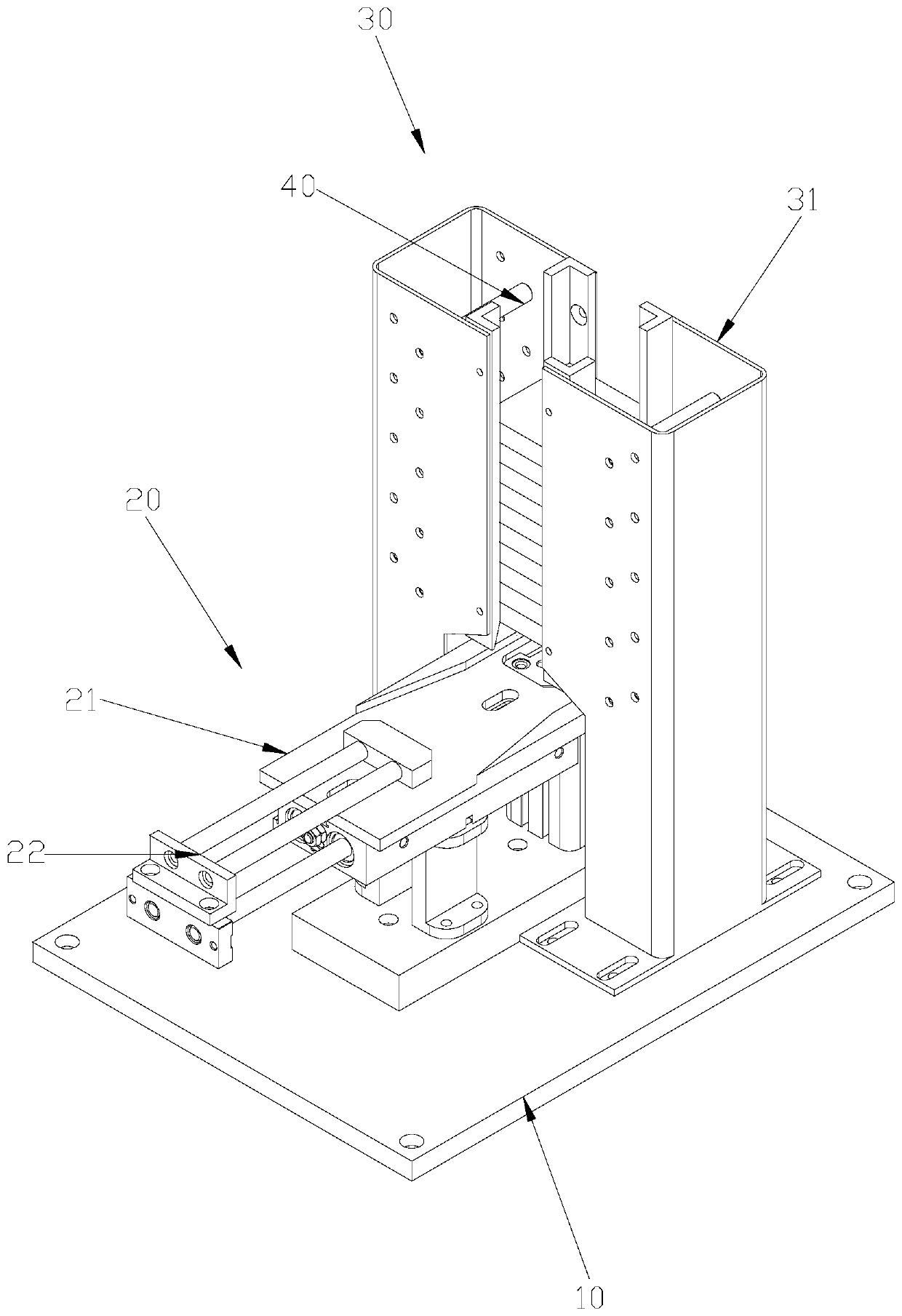

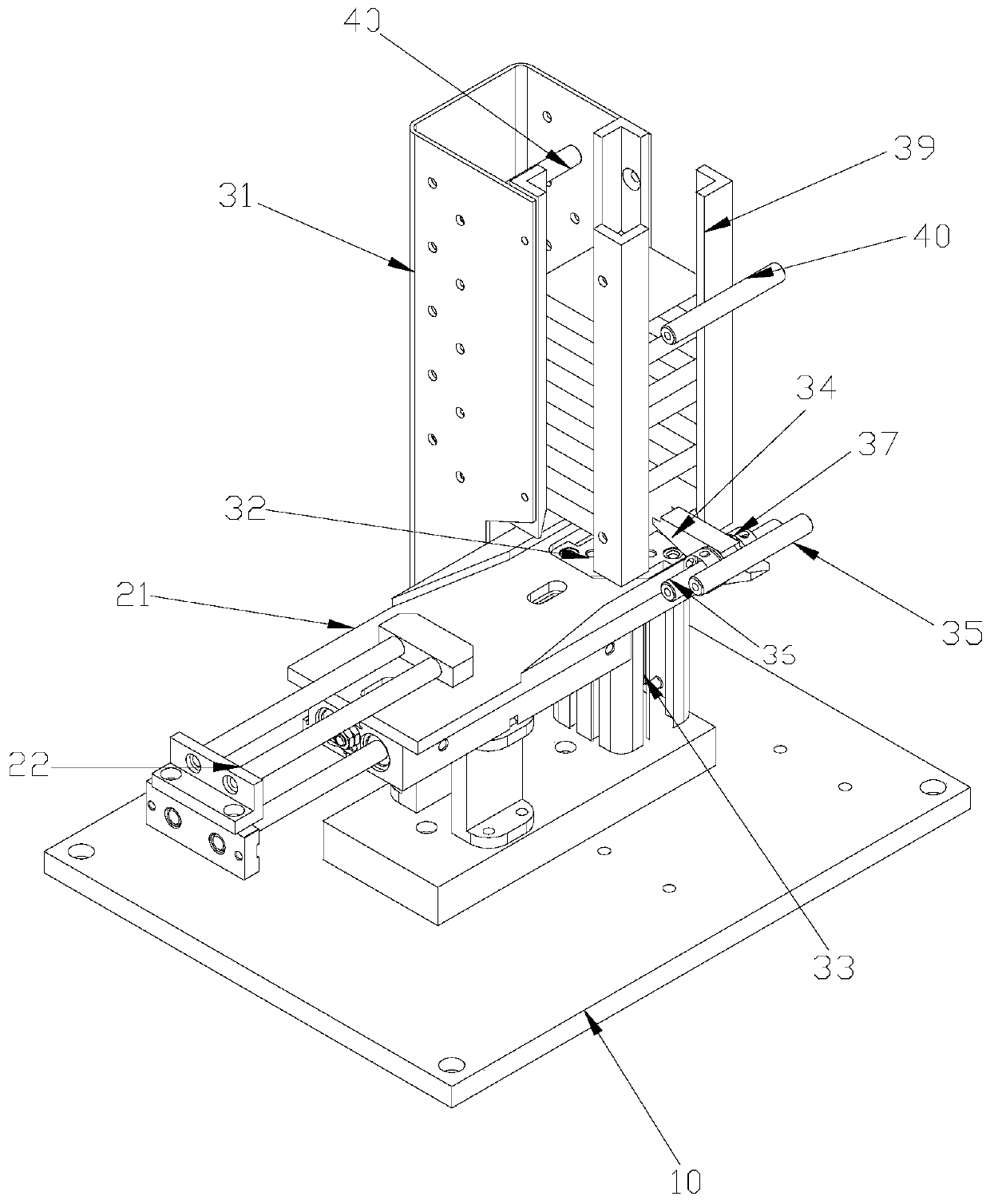

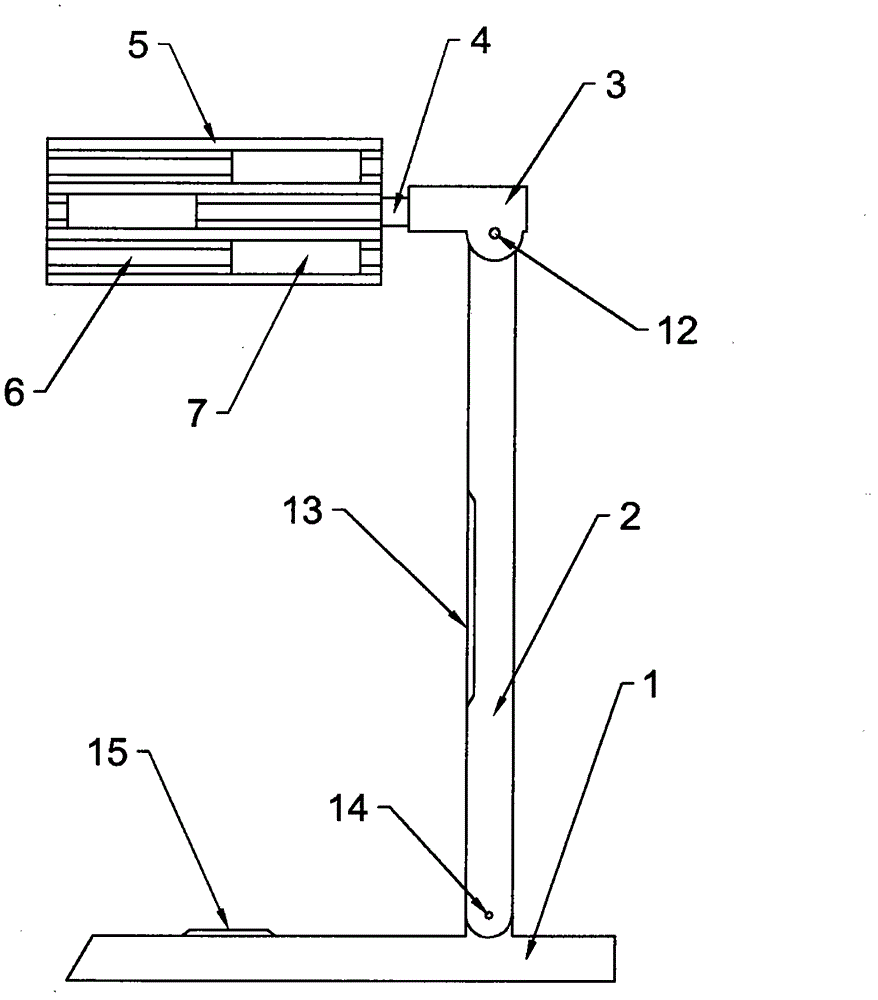

Vertical stacking and feeding device

PendingCN110467004AAchieve stackingAchieve automatic handlingStacking articlesMechanical engineeringEngineering

The invention relates to the technical field of storage, and discloses a vertical stacking and conveying device. The vertical stacking and conveying device comprises a supporting base, a conveying mechanism and a storage mechanism, wherein the conveying mechanism and the storage mechanism are arranged on the supporting base; the conveying mechanism is configured to horizontally push materials intothe storage mechanism; the storage mechanism comprises a shell, a material jacking assembly and a material supporting assembly, wherein the material jacking assembly is arranged at the bottom of theshell, and a material supporting assembly is arranged in the shell; the shell is provided with a space for containing the materials; the material jacking assembly can jack the materials pushed by theconveying mechanism; and the material supporting assembly can support and lift the materials to enter the shell. The vertical stacking and conveying device has the advantages that the materials are pushed to move horizontally by utilizing the conveying mechanism, so that the materials are automatically and horizontally moved into the shell, then the materials are vertically moved in the shell through the material jacking assembly and are supported one by one under the action of the material supporting assembly, so that the materials are stacked in the vertical direction, and therefore the purposes of automatic carrying and vertical warehousing and stacking of the materials are achieved.

Owner:武汉天之逸科技有限公司

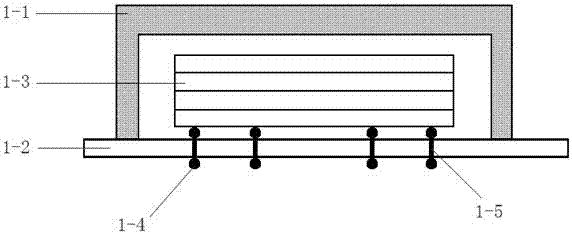

Three-dimensional stack structure of thin-film ceramic circuit

ActiveCN107275317AAchieve stackingReduce floor areaSemiconductor/solid-state device detailsSolid-state devicesBroadbandProduct integration

The invention provides a three-dimensional stack structure of a thin-film ceramic circuit. Between two adjacent thin-film ceramic substrates, through ball mounting welding or prefabricated pad welding, stacking of more than three thin-film ceramic circuit substrates is realized. Solid metal through holes are used for realizing electric connection of a random layer. The structure comprises a local electromagnetic self-shielding structure of a chip and / or a passive component. The local electromagnetic self-shielding structure comprises an upper metal layer, a lower metal layer and side surface solid metal through holes. The three-dimensional stack structure can realize stacking of the thin-film ceramic circuit so that an active chip, an RF structure, a high-power structure, a broadband switching structure and the like are integrally integrated in a three-dimensional direction, thereby reducing plan area of a function core by more than 70%, effectively improving product integration level, synchronously realizing hermetic sealing and electromagnetic self-shielding, and improving product adaptability. The three-dimensional stack structure can replace 60-70% of similar products and has advantages of saving cost by more than 60% and improving production efficiency by more than 40%.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

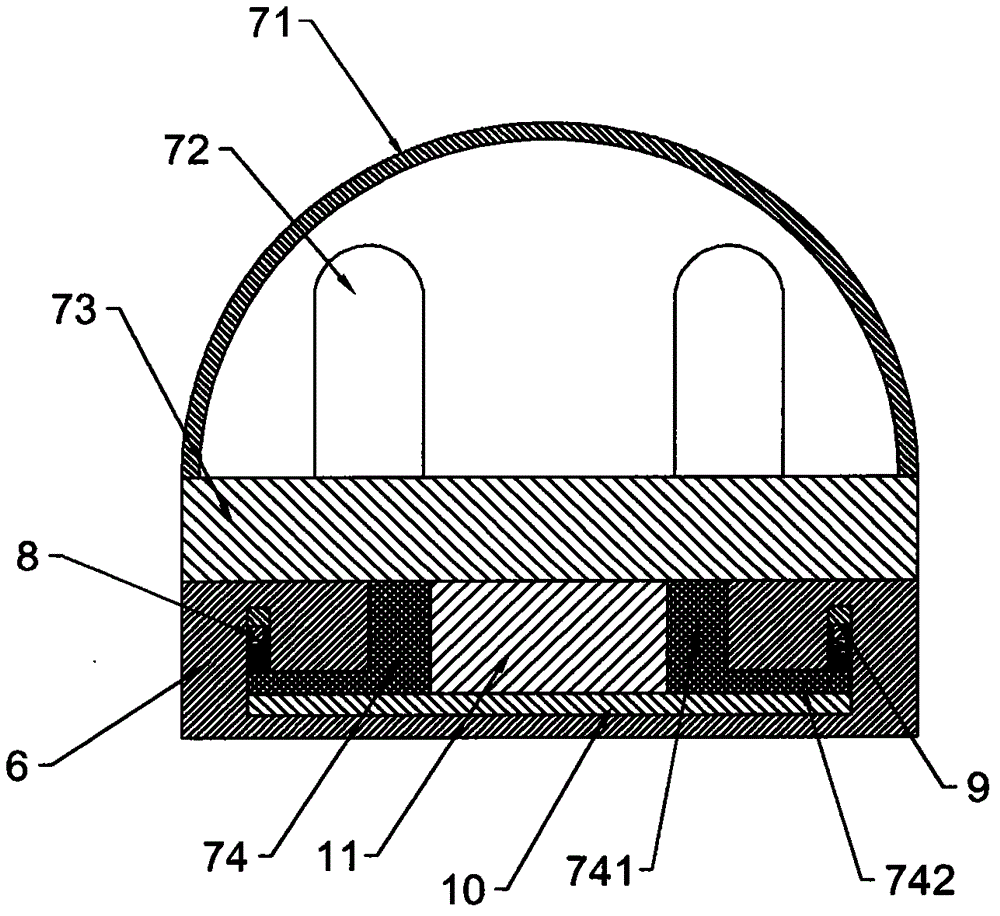

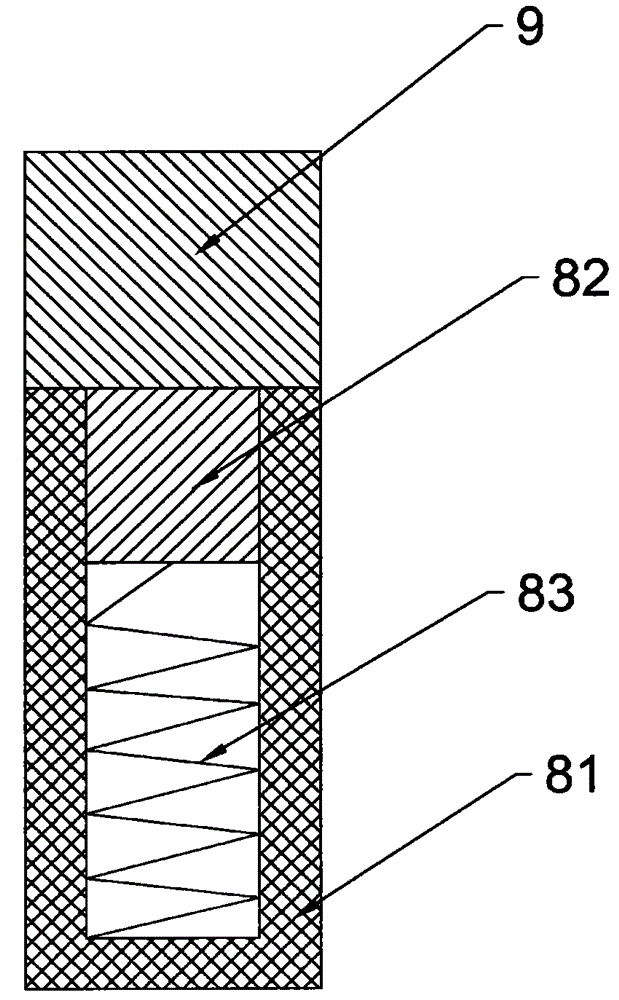

Touch clock LED table lamp

InactiveCN104989991ARealize the stacking of light intensityAchieve stackingLighting support devicesPoint-like light sourceElectricityControl manner

The invention discloses a touch clock LED table lamp. The touch clock LED table lamp comprises a lamp base. The lamp base is connected with a lamp pole through a lamp base rotating shaft. The lamp pole is connected with a lamp shell support through a lamp pole rotating shaft. The lamp shell support is connected with a lamp shell through a support rotating shaft. A slide groove is vertically formed in the side face of the lamp shell and connected with light-emitting assemblies in a sliding mode. A power supply connection block is arranged in the slide groove. The light-emitting assemblies are electrically connected with the power supply connection block through connection assemblies fixed to the light-emitting assemblies. A touch panel is arranged on the lamp base and is provided with a touch switch and a touch brightness regulation button. A clock control and display panel where clock functions are integrated is arranged on the lamp pole. Stacking of illumination intensities of three light sources is achieved, regulation is convenient, the service life of the LED lamp is prolonged, the heat dissipation effect is improved, and the use safety is improved. The touch clock LED table lamp has the beneficial effects that the structure is simple, the touch control mode is achieved, the clock functions are integrated, and light rays of a lampshade can be adjusted at multiple angles.

Owner:施婷婷

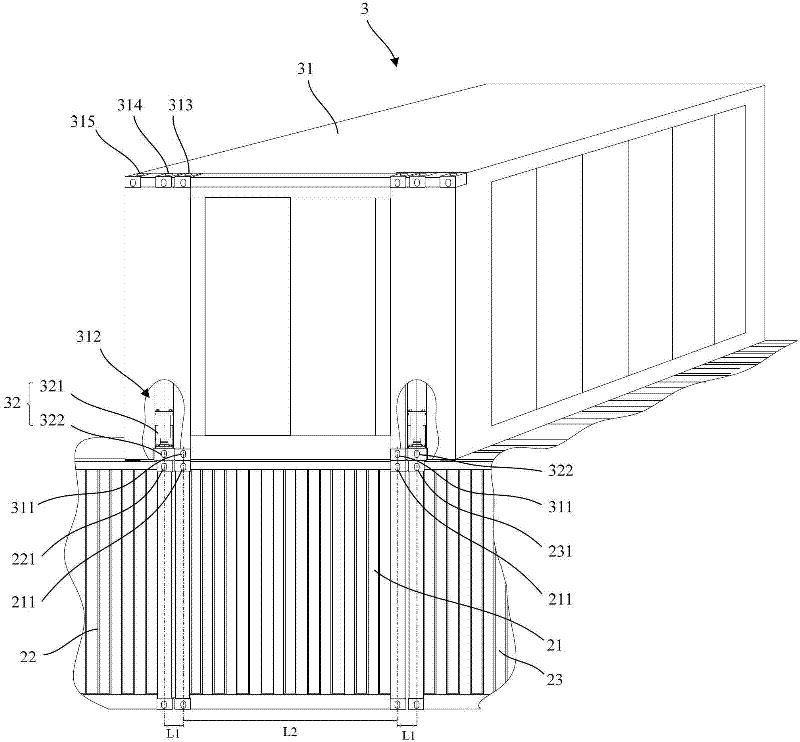

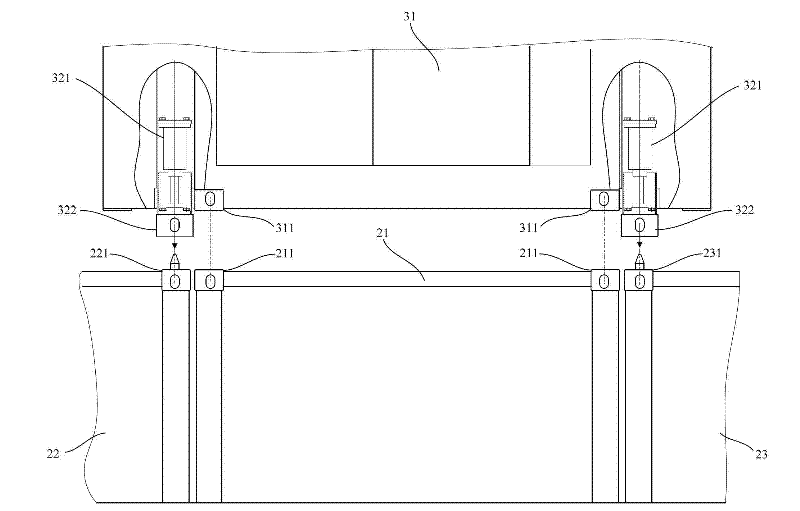

Double-platform circulating sectional type turret lamination device and lamination process thereof

PendingCN110661023AUninterrupted compressionImprove lamination efficiencyAssembling battery machinesFinal product manufactureEngineeringStructural engineering

The invention discloses a double-platform circulating sectional type turret lamination device and a lamination process thereof. The double-platform circulating sectional type turret lamination devicecomprises a turret mechanism and lamination mechanisms; the turret mechanism is arranged between two feeding vacuum pull bodies; positions where vacuum suction plates connected to the turret mechanismare perpendicular to the feeding vacuum pull bodies, are lamination initial positions; two lamination mechanisms are provided and are symmetrically arranged on two sides of the turret mechanism in atransverse direction respectively; two lamination spaces are respectively formed on two sides of the central line of the turret mechanism extending along the longitudinal direction of the turret mechanism; and the corresponding rotation angles of the two lamination spaces are 180 degrees respectively; each lamination mechanism is in linkage with the turret mechanism through one transmission assembly; and when the turret mechanism rotates to perform lamination, two groups of pole sheet pressing assemblies alternately press laminated pole sheets uninterruptedly. With the double-platform circulating sectional type turret lamination device and the lamination process thereof adopted, sequential alternate lamination on the double lamination mechanisms is simultaneously realized in the same rotation period; and therefore, lamination efficiency is improved, the uninterrupted lamination of the platforms is realized, the uninterrupted compression of the pole sheets is realized, and the displacement of the pole sheets is avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

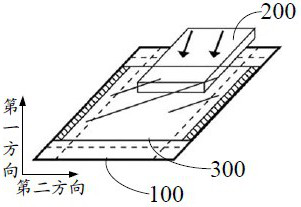

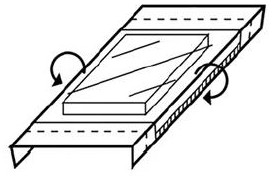

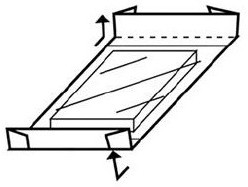

Automatic board gluing and stacking machine and working method thereof

InactiveCN111546440ARealize automatic feeding processAchieve stackingLiquid surface applicatorsWood veneer joiningAdhesive glueEngineering

The invention discloses an automatic board gluing and stacking machine and a working method thereof. The automatic board gluing and stacking machine comprises a first frame, and a first conveying assembly and a second conveying assembly which are used for conveying thin boards are sequentially arranged on the first frame in the length direction of the first frame; the first frame is provided witha gluing assembly at the first conveying assembly, and the gluing assembly is used for smearing glue on the upper surfaces of the thin boards on the first conveying assembly; a first plate feeding assembly is arranged at one end of the first frame and used for placing the thin boards on the first conveying assembly; and a second plate feeding assembly is arranged on the side face of the first frame, and a positioning assembly is arranged below the second conveying assembly. According to the automatic board gluing and stacking machine, automatic feeding, gluing and stacking of the thin boards can be achieved, the thin boards coated with the glue can be positioned and aligned, and manpower input is greatly saved.

Owner:佛山信卓派思机械科技有限公司

Film covering device and film covering method

ActiveCN114229076AReduce movement speedAchieve stackingWrappingWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to the technical field of packaging, and discloses a film covering device and a film covering method.The film covering device comprises a rack, a film adsorption roller, a bearing body conveying unit and a slow stop assembly; when the film adsorption roller rotates to a first state and the bearing body is located at a first station, the film adsorption roller moves in the direction close to the bearing body conveying unit, so that the front end of the cut film is bonded with the front end of the bearing body; when the film adsorption roller rotates to a second state and the bearing body is located at a second station, the film adsorption roller moves in the direction close to the bearing body conveying unit, so that the rear end of the cut film is bonded with the rear end of the bearing body; the slow stop assembly can reduce the moving speed of the bearing body or enable the bearing body to stop moving after the front end of the cut film is bonded with the front end of the bearing body and before the rear end of the cut film is bonded with the rear end of the bearing body. According to the film covering device and the film covering method, the problem that the lengthening length of the film is greatly limited is solved.

Owner:ZHEJIANG DAHUA TECH CO LTD

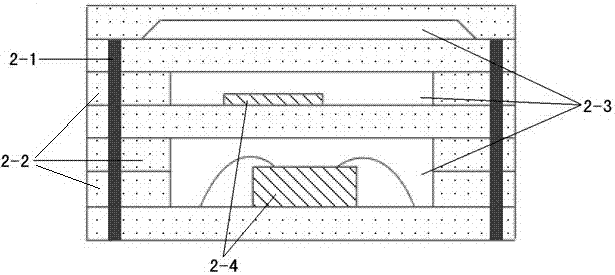

FC chip system stacked fan-out package structure and preparation method thereof

InactiveCN107634049AAchieve stackingSimplify interconnectionSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical connection

The invention relates to a FC chip system stacked fan-out package structure and a preparation method thereof. The package structure comprises a stacked package body formed by two FC chips. The back surfaces of the two FC chips in the stacked package body are abutted against each other. An upper rewiring layer is arranged above the stacked package body; a lower rewiring layer is arranged under thestacked package body; and corresponding chip bumps of the two FC chips in the stacked package body are electrically connected with the upper rewiring layer and the lower rewiring layer. The outer sides of the stacked package body are provided with symmetrically-distributed vertical interconnection transfer boards respectively; and through required electrical connection between through-hole connectors in the vertical interconnection transfer boards and the upper rewiring layer and the lower rewiring layer, required signal interconnection and / or signal leading-out end transfer between the two FCchips in the stacked package body is realized. The package structure is compact in structure, can effectively realize stacked package of the FC chips, can simplify process and improve packaging efficiency, and is safe and reliable.

Owner:58TH RES INST OF CETC

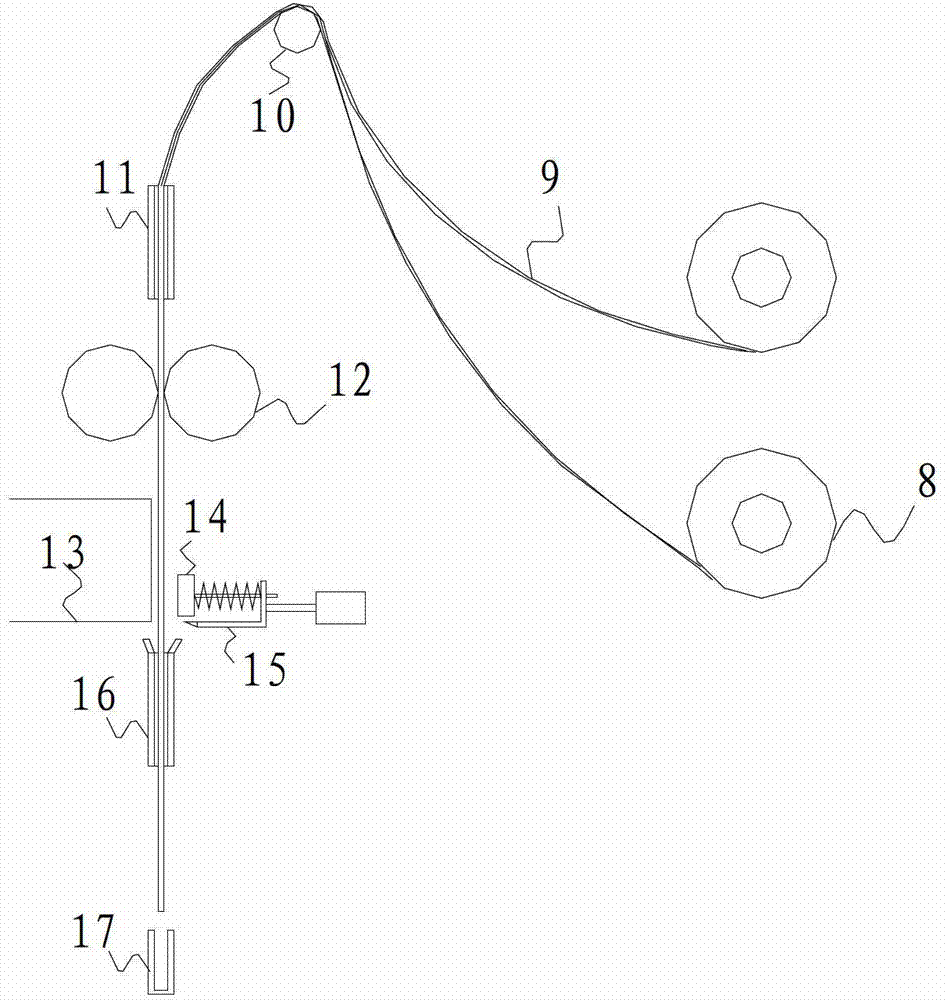

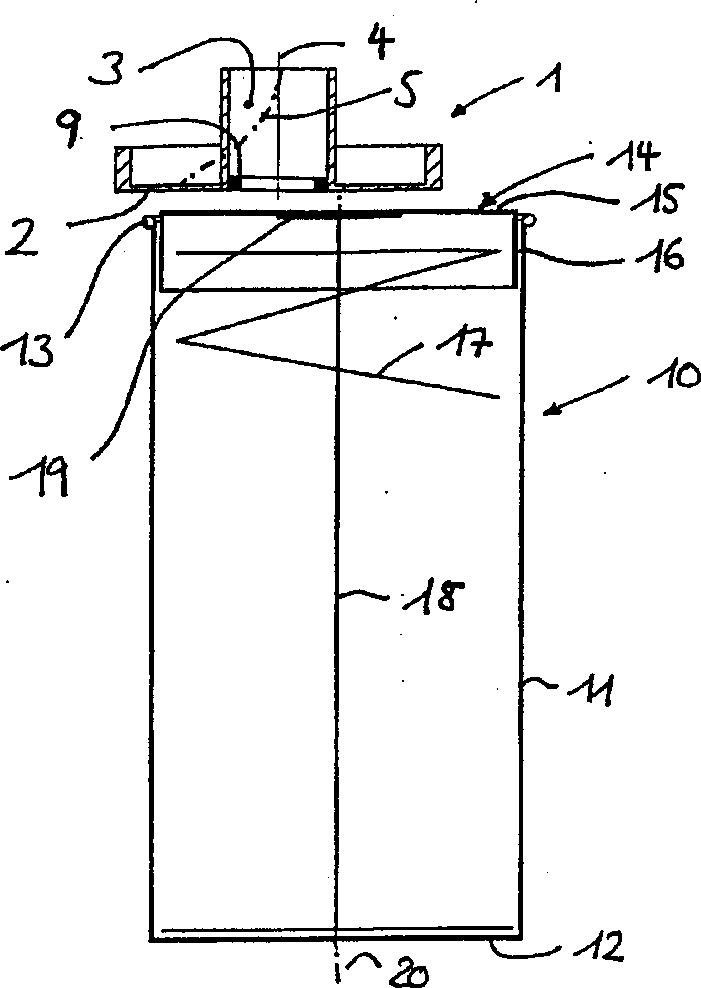

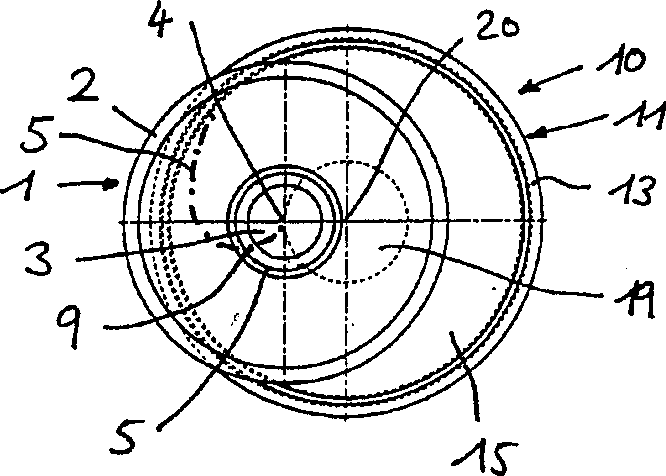

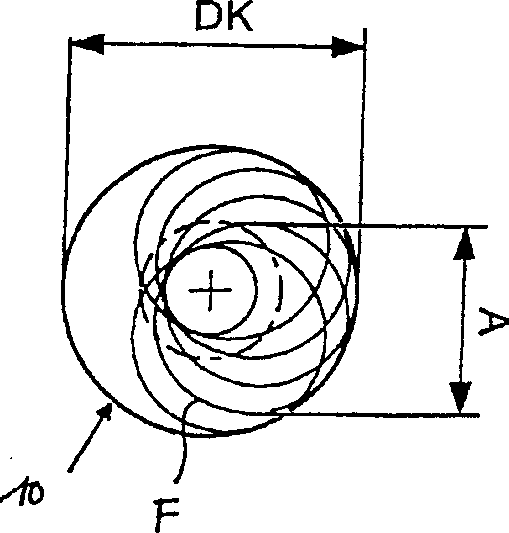

Method and apparatus for adjusting height of bobbin base-plate for spinning

InactiveCN1350075AGood frictional contactEliminate fatigueFilament handlingTextiles and paperFiberBobbin

A process for the level adjustment of the can plate 14 of a spinning can 10, 100 is proposed which is in a filling position at the output of a textile machine to be filled with fiber sliver F, whereby the can plate 14 is moved before the start of the filling process by a first moving device 17 from a lower can plate position into a higher can plate position and is moved into the lower can plate position during the filling of the spinning can 10, 100. The process according to the invention is characterized in that the can plate 14 is moved before the start or during the starting phase of the filling process by a second moving device 9, 109 from the higher can plate position into an upper filling position as the spinning can 10, 100 is in filling position. Furthermore a suitable apparatus is presented.

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

Multistage stacking packaging method for cigarettes

Owner:QUANZHOU KESHENG PACKAGING MACHINERY

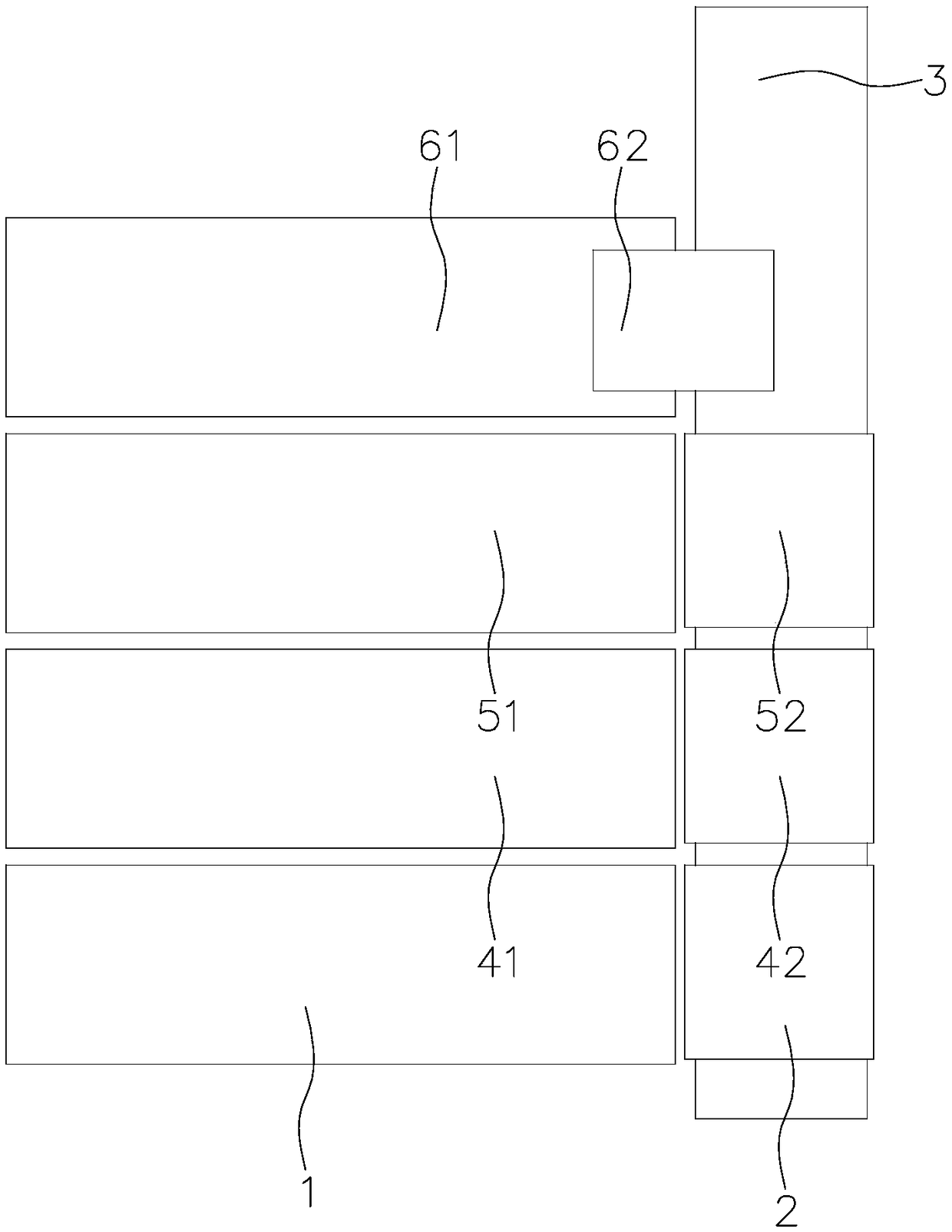

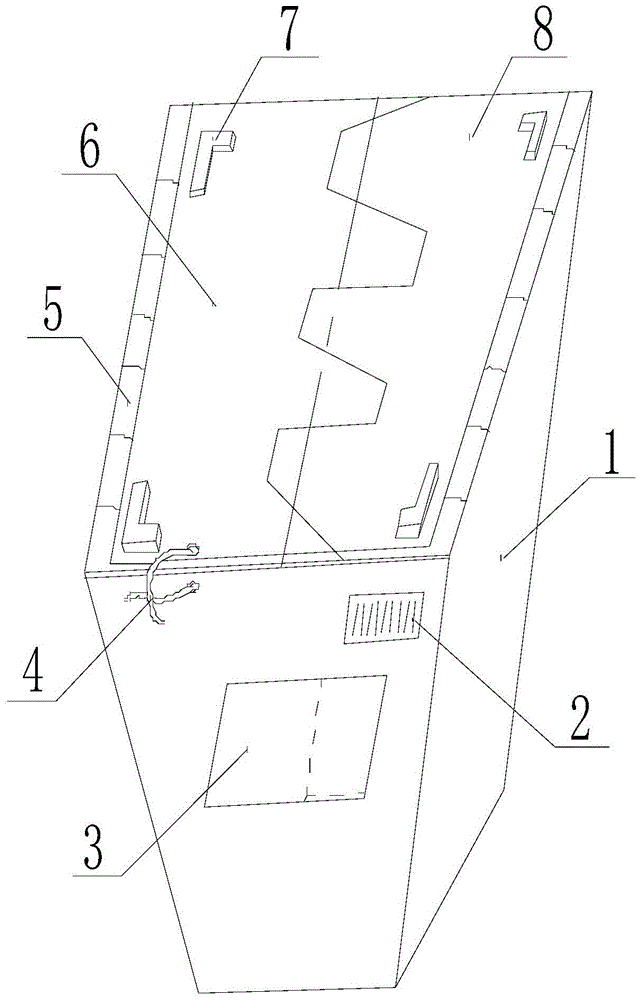

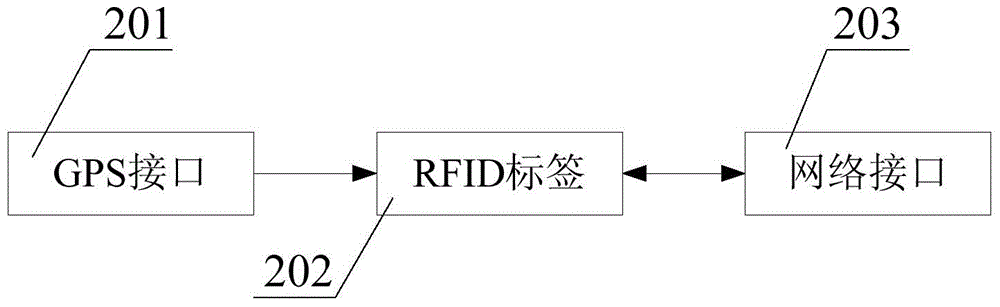

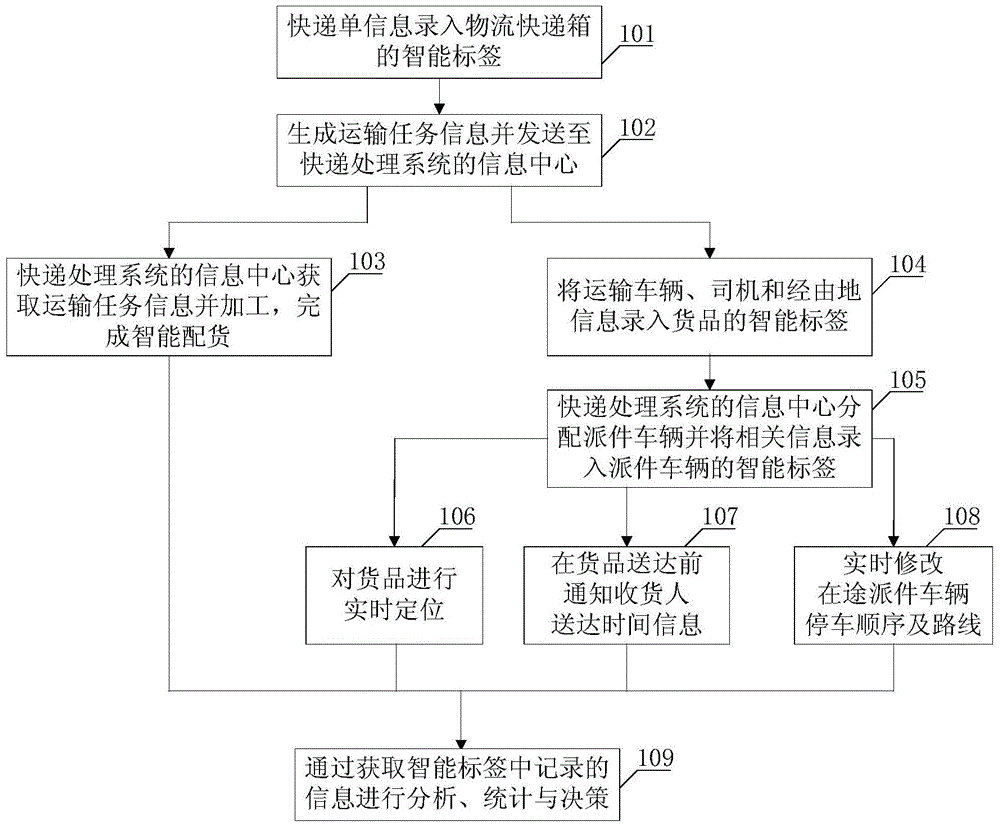

Intelligent logistics express box and intelligent real-time data exchange logistics method

ActiveCN105059669AEnsure safetyAchieve stackingContainer/bottle contructionLogisticsLogistics managementReal-time data

The invention discloses an intelligent logistics express box. The intelligent logistics express box comprises a main body, wherein a slot is formed at a transparent window part in the main body, and an intelligent label and a box sealing pull ring are mounted on the front, close to box covers, of the main body. The logistics express box adopts a trapezoidal structure, so that empty boxes can be stacked and occupy small space. Bosses are arranged on the box covers so as to fix the bottoms of the stacked boxes. The disposable box sealing pull ring ensures the safety of the logistics express box, and the serrated box covers have better air tightness and can be repeatedly utilized. The invention further discloses an intelligent real-time data exchange logistics method. Due to the arrangement of the intelligent label, users can grasp the moving direction of the logistics express box at any moment, and data is exchanged in real time by using an information center of an express processing system based on the Internet in combination with the intelligent logistics box. Goods can be supervised and tracked in real time, and dispatchers can also be supervised in real time. A dispatching scheme is intelligently provided for the dispatchers, the management is more convenient, and the efficiency of the whole logistics process is improved.

Owner:江苏麦艾信息科技有限公司

Metal fitting polishing device and polishing method

InactiveCN107671689ACompact structureRealize security protectionPolishing machinesGrinding drivesImpellerEngineering

The invention discloses a metal fitting polishing device and a polishing method. The polishing device comprises a worktable, a polishing mechanism and a positioning mechanism; the polishing mechanismcomprises a driving wheel; the driving wheel is in engaged transmission with an upper bevel gear and a lower bevel gear; a rotating inner shaft is inserted in a rotating outer shaft, and is coaxiallyarranged with the rotating outer shaft; a polishing cylinder is fixedly connected with the bottom of the rotating outer shaft; the internal of the polishing cylinder is a cavity, and multiple exhaustholes are formed in the side wall of the polishing cylinder; at least one air blowing impeller is mounted on the rotating inner shaft in the polishing cylinder in the length direction of the rotatinginner shaft; the positioning mechanism comprises a jacking rod; the jacking rod is lifted through a jacking pedal; the bottom of a positioning base is fixedly connected with the top of the jacking rod; and a table plate for placing fittings is arranged in the positioning base. The polishing device can effectively polish the fittings, effectively prevents accumulation of dust in the machining process, greatly improves the fitting polishing quality, and improves the use safety.

Owner:嘉兴创诺精密五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com