Workpiece conveying, stacking and storing device

A workpiece and conveying unit technology, applied in the field of conveying and stacking devices for workpieces, can solve the problems of workpiece collapse, reduced performance and service life, damage to the surface of the workpiece, etc., and achieves the effect of convenient pick and place and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

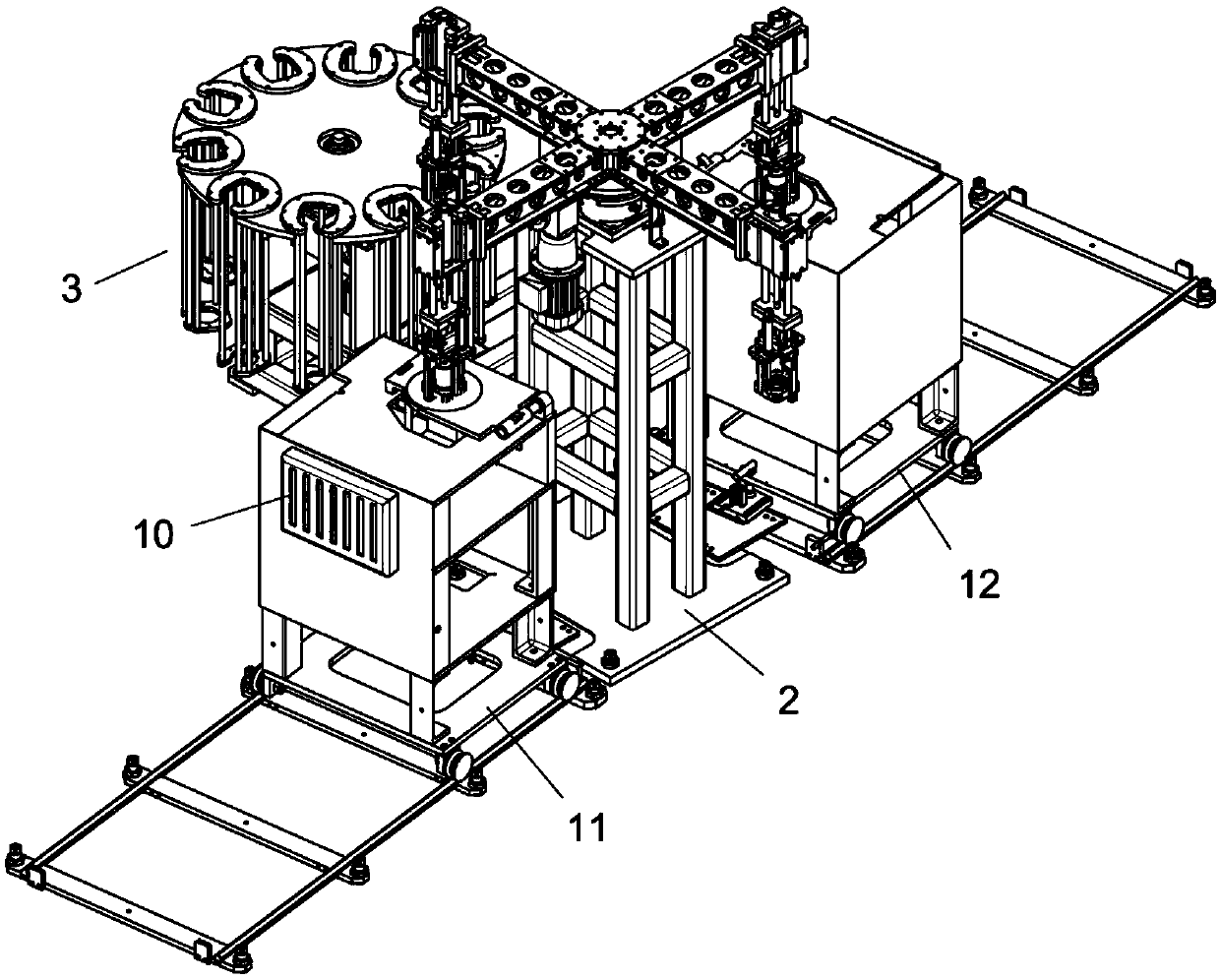

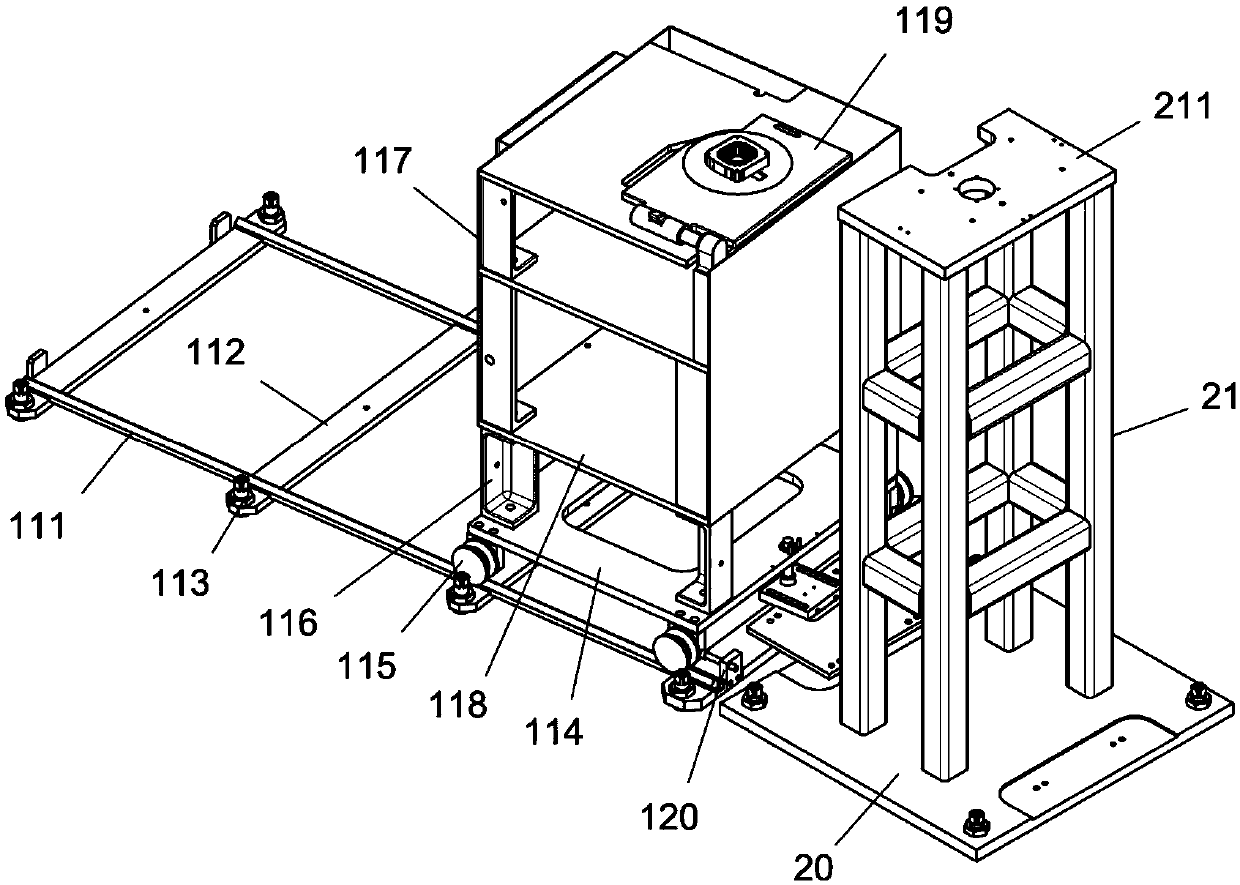

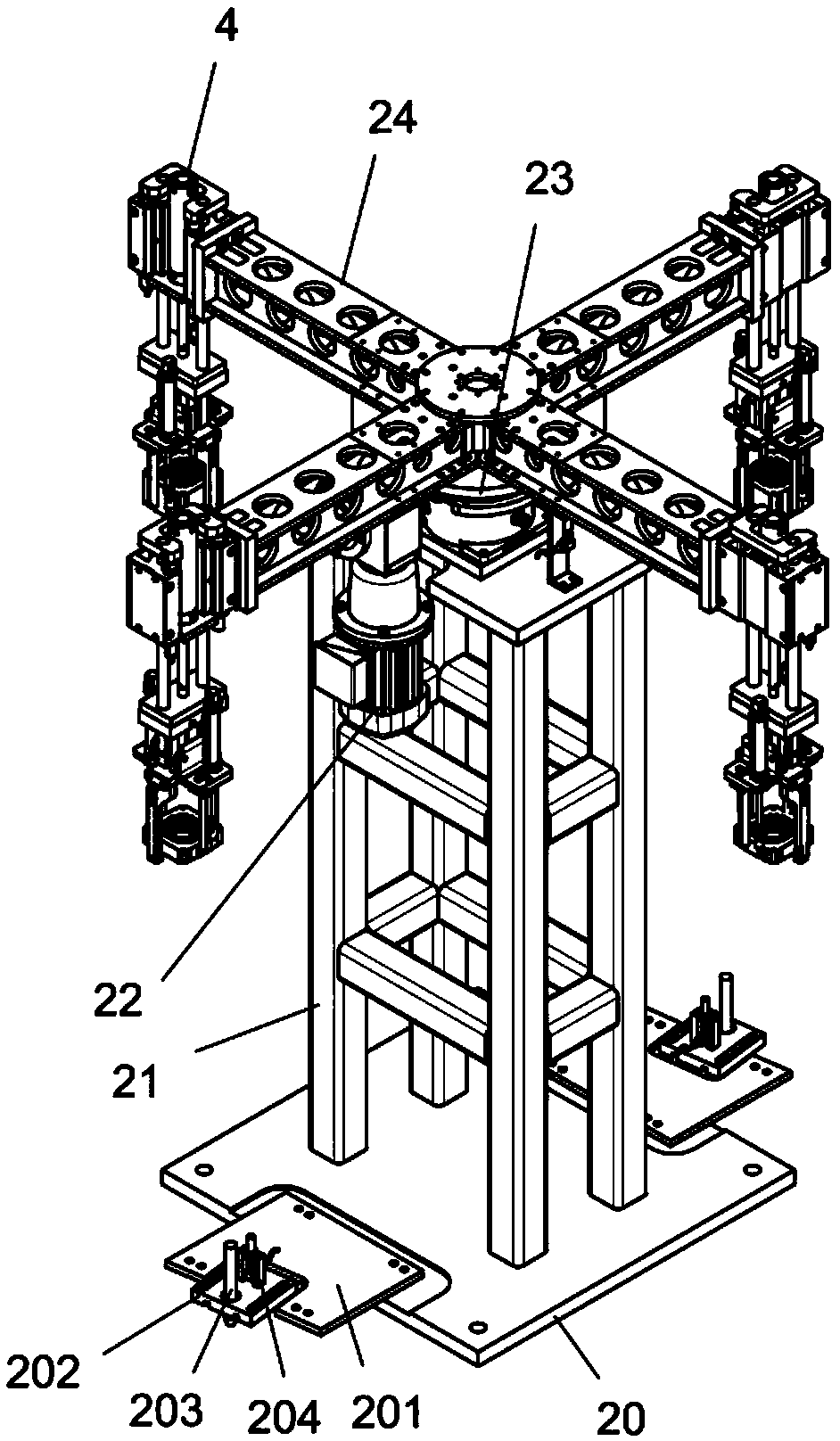

[0022] like Figure 1-7 As shown, a conveying and stacking device for workpieces includes a workpiece conveying unit 11, a gasket conveying unit 12, a rotating hoisting unit 2 and a rotating storage rack 3, wherein the rotating hoisting unit 2 is fixedly installed on the working ground, and the workpieces are conveyed The unit 11 and the gasket conveying unit 12 are respectively arranged on the front and rear sides of the rotary hoisting unit 2, the rotary storage rack 3 is arranged on the side of the rotary hoisting unit 2, and the rotary storage rack 3 is also fixedly installed on the working ground; the rotary hoisting unit 2 Including the lifting lower fixing plate 20 fixed on the working ground, the lifting operation frame 21 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com