Method and apparatus for adjusting height of bobbin base-plate for spinning

A technology of height adjustment and can, applied in transportation and packaging, textile and papermaking, thin material handling, etc., can solve problems such as reduced productivity of textile machines, and achieve the effects of improved quality, high productivity, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

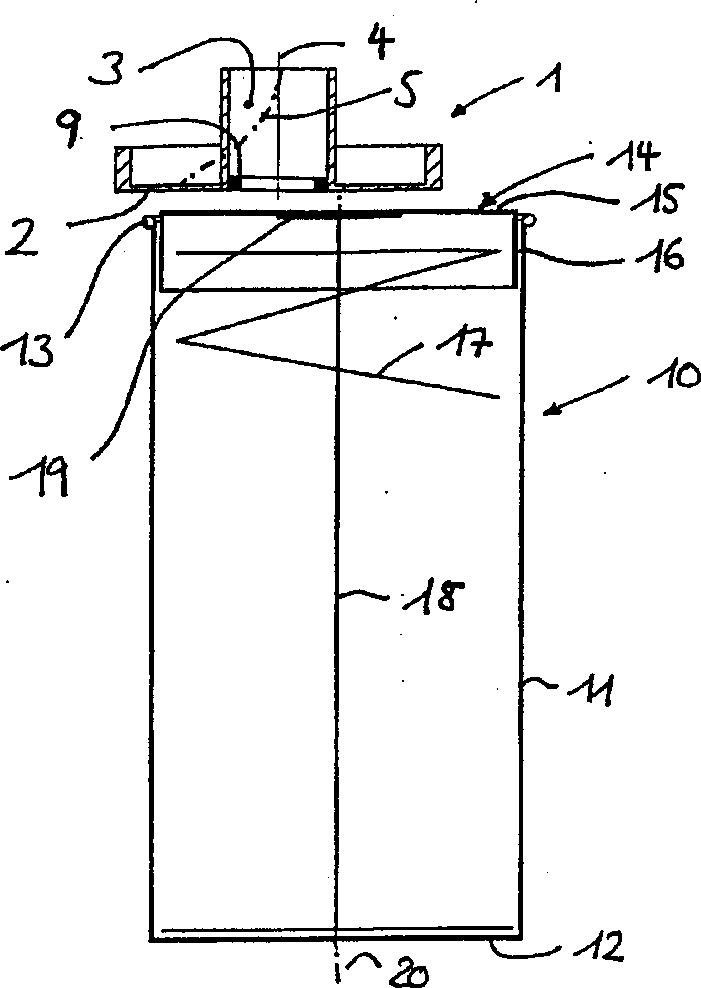

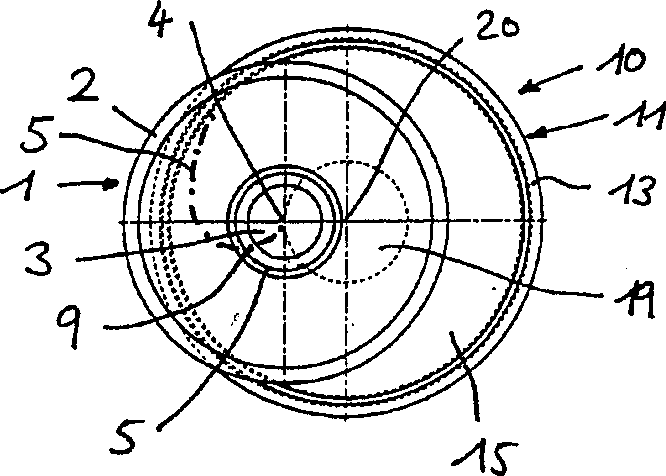

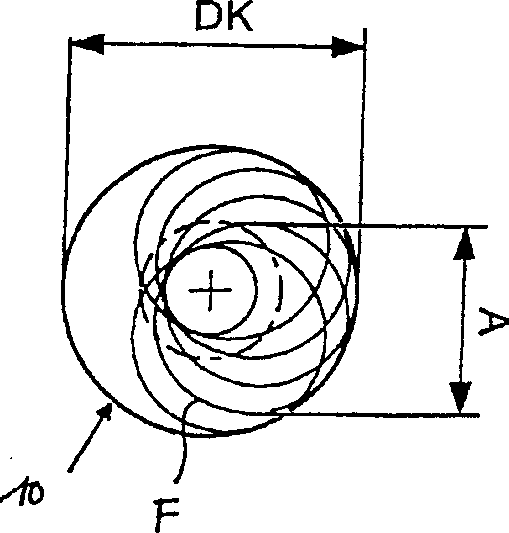

[0043] figure 1 , 2 as well as Figure 4 , 5 The outlet of the textile drafting unit and in particular the turntable 1 , the spinning package 10 or 100 to be filled located below the turntable 1 and in the filling position is schematically shown. In front of the turntable 1 at least one feed rod is drawn in the drafting unit to form a fiber sliver F of as uniform a diameter as possible and fed into the spinning package 10 , 100 by means of the turntable 1 . Commonly used spinning cylinders 10 , 100 have a circular cross section (so-called round cans) or an approximately rectangular cross section (so-called square cans). When a spinning tube 10 , 100 is filled with drawn fiber sliver, it leaves its filling position, while a subsequent spinning tube 10 , 100 is located under the turntable 1 .

[0044] In order to ensure as efficient and consistent filling of the spinning bobbins 10, 100 as possible, the turntable 1 has an open, generally circular cavity extending from a cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com