Double-platform circulating sectional type turret lamination device and lamination process thereof

A lamination device and a segmented technology, which are applied in the double-platform circulating segmented turret lamination device and the lamination process field, can solve the problem of time-consuming lamination taking and feeding, limited quantity, inability to adapt and match the poles. Film export speed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing:

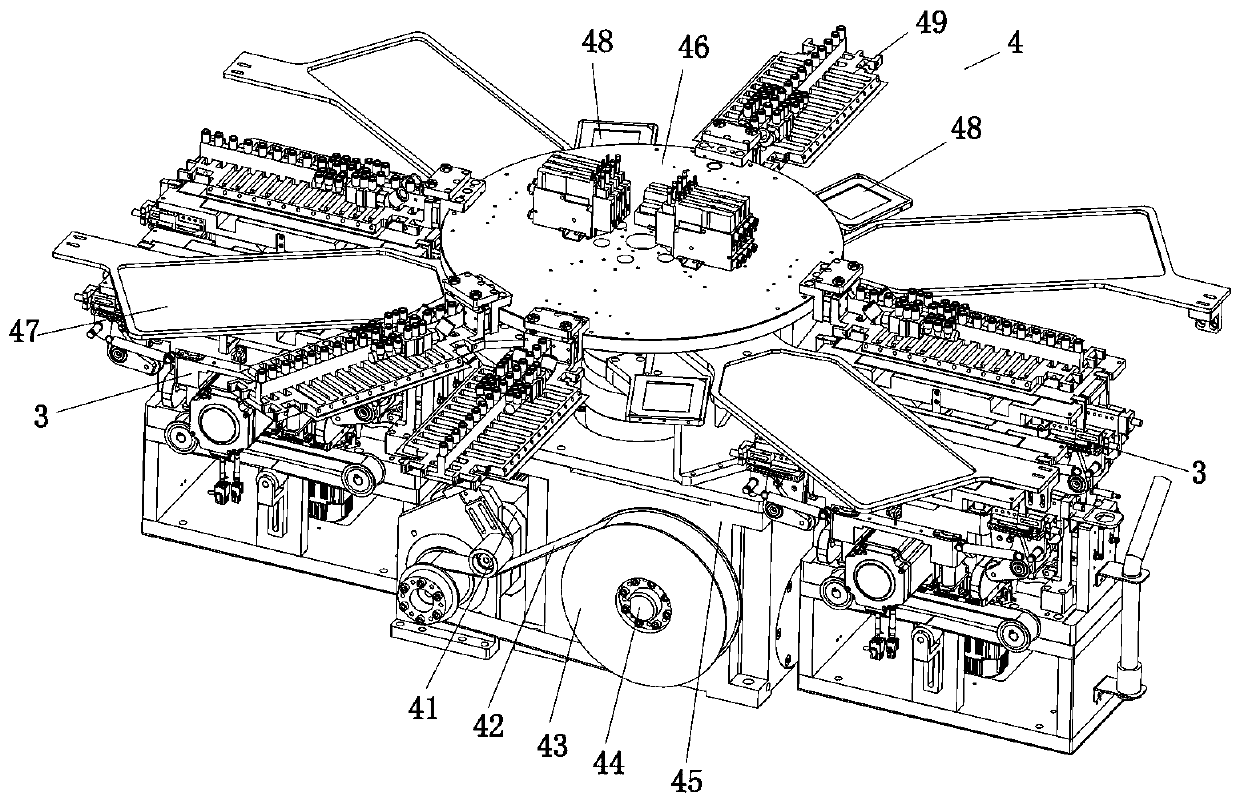

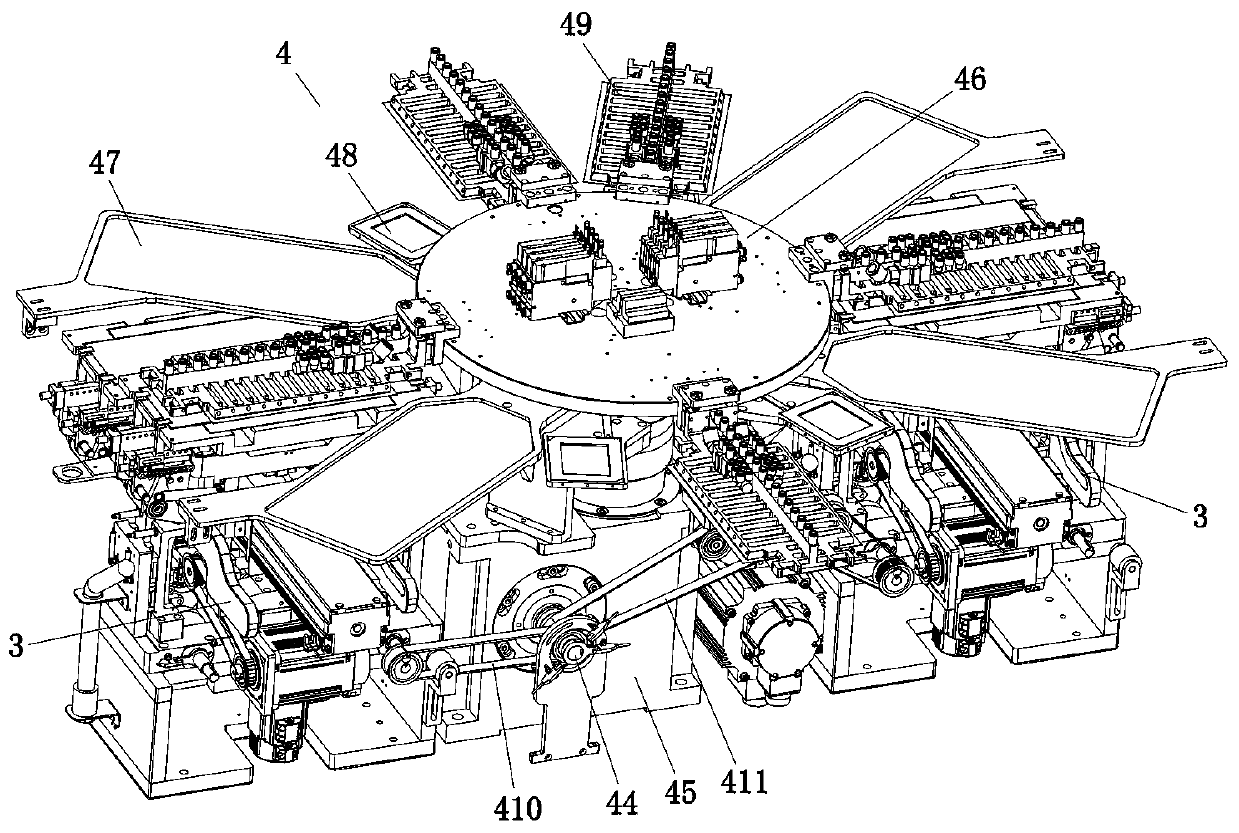

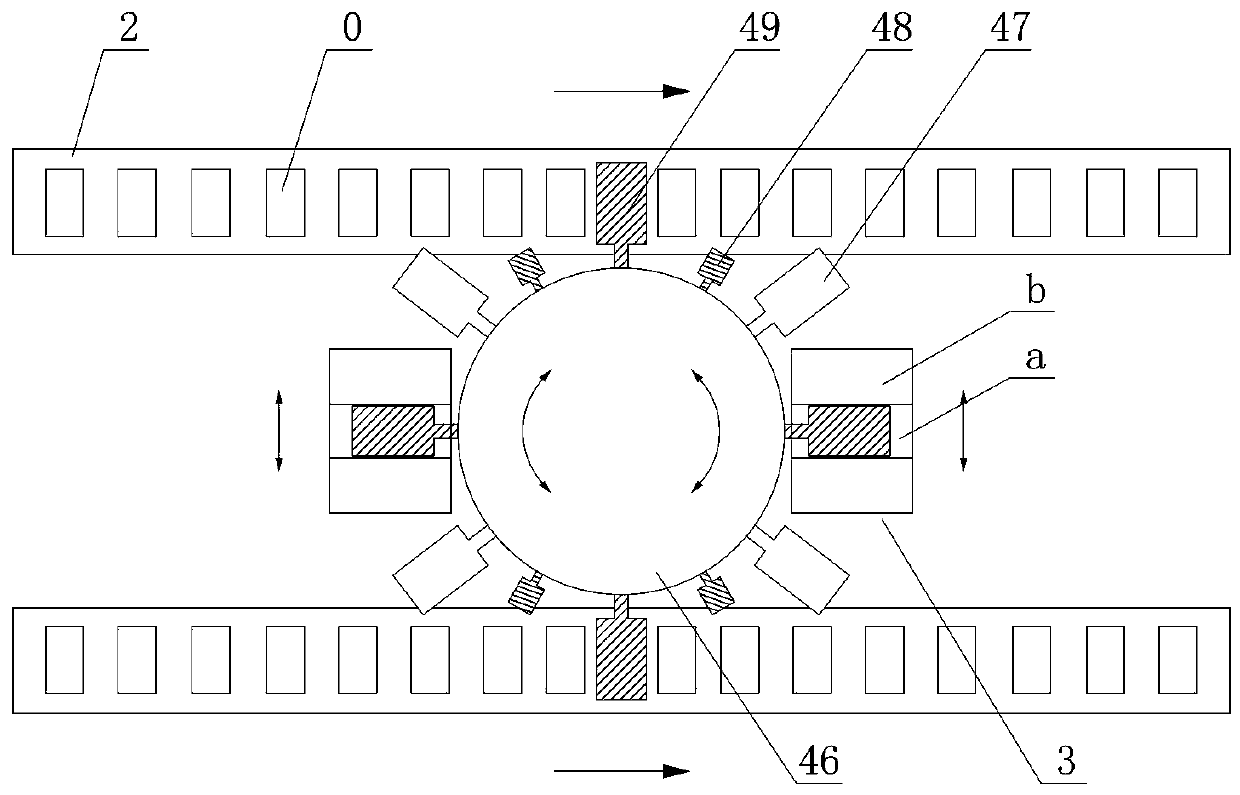

[0064] Such as Figure 1 to Figure 22 As shown, the technical scheme adopted by the present invention is as follows: a double-platform circulating segmented turret stacking device, including a turret mechanism 4 and a stacking mechanism 3, wherein the turret mechanism 4 is arranged on two feeding vacuum pulling bodies 2, the two feeding pull bodies 2 extend linearly along the transverse direction, and are symmetrically arranged on both sides of the turret mechanism 4 along the longitudinal direction; the two symmetrically arranged vacuum suction plates connected to the turret mechanism 4 are perpendicular to the two feeding The position of the vacuum pulling body 2 is the initial position of the lamination; the above-mentioned lamination mechanism 3 includes two, and the lamination mechanism 3 is symmetrically arranged on both sides of the turret mechanism 3 along the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com