Rotary stacking equipment and stacking method

A technology of lamination and equipment, applied in the field of rotating lamination equipment and lamination, can solve the problems of speed-up space restriction, slow lamination speed, etc., and achieve the effect of improving lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

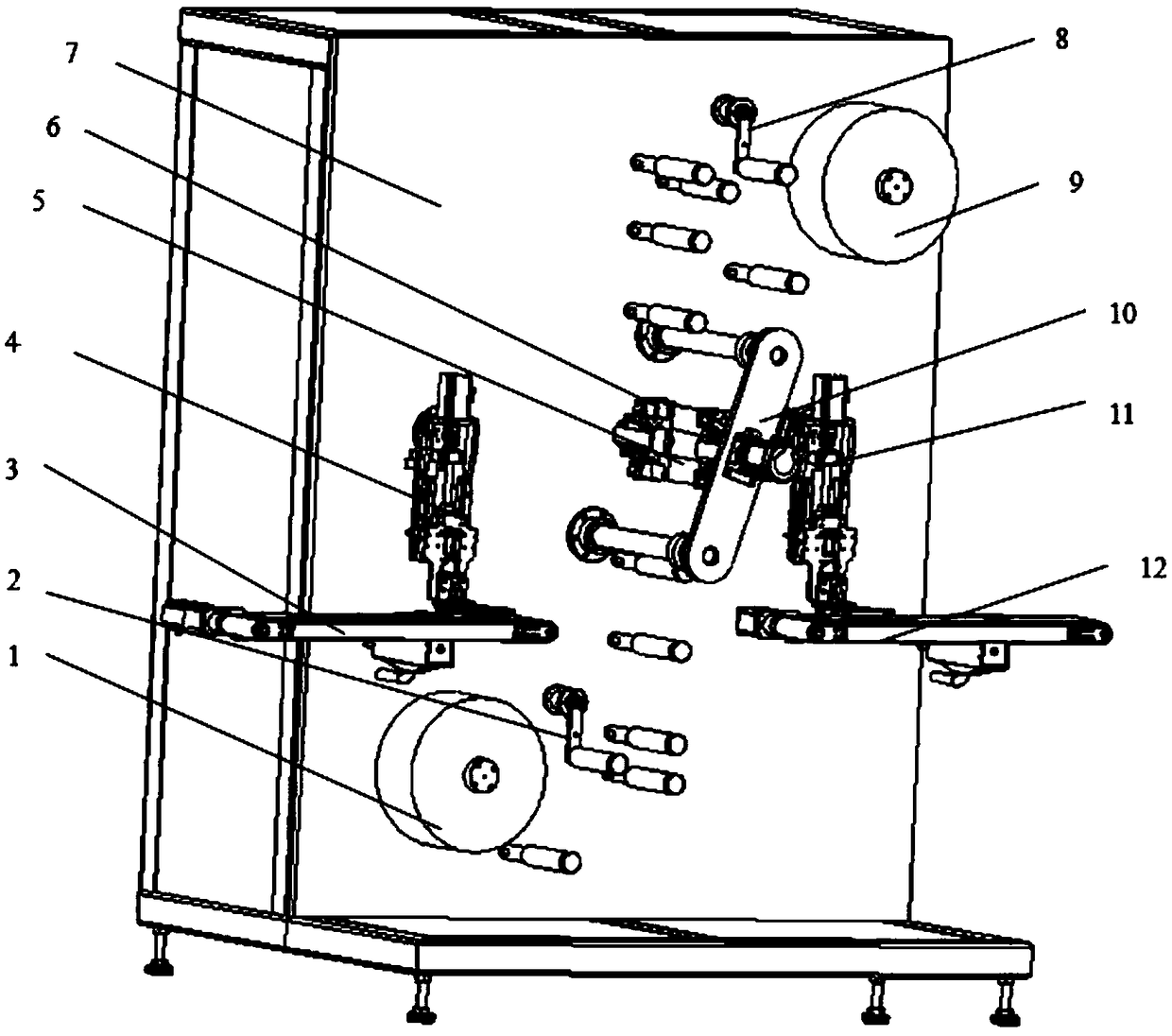

[0033] In one embodiment of the present invention, as Figure 1-3 As shown, a rotary lamination equipment is provided, and the equipment includes: a substrate 7; a first diaphragm unwinding and deviation correction mechanism 1, a first tension control mechanism 2, a negative pole piece conveyor belt 3, a negative pole lamination manipulator 4, a rotating lamination Sheet stage 5, lamination clamping mechanism 6; second diaphragm unwinding and deviation correction mechanism 9, second tension control mechanism 8, positive electrode sheet conveyor belt 12, positive electrode lamination manipulator 11, and support 10 in front of the lamination stage.

[0034] The first diaphragm unwinding and deviation correcting mechanism 1 and the second diaphragm unwinding and deviation correcting mechanism 9 place the diaphragm roll at the same time, and correct the position of the diaphragm to ensure that the position of the diaphragm relative to the substrate is constant. The reason why the ...

Embodiment 2

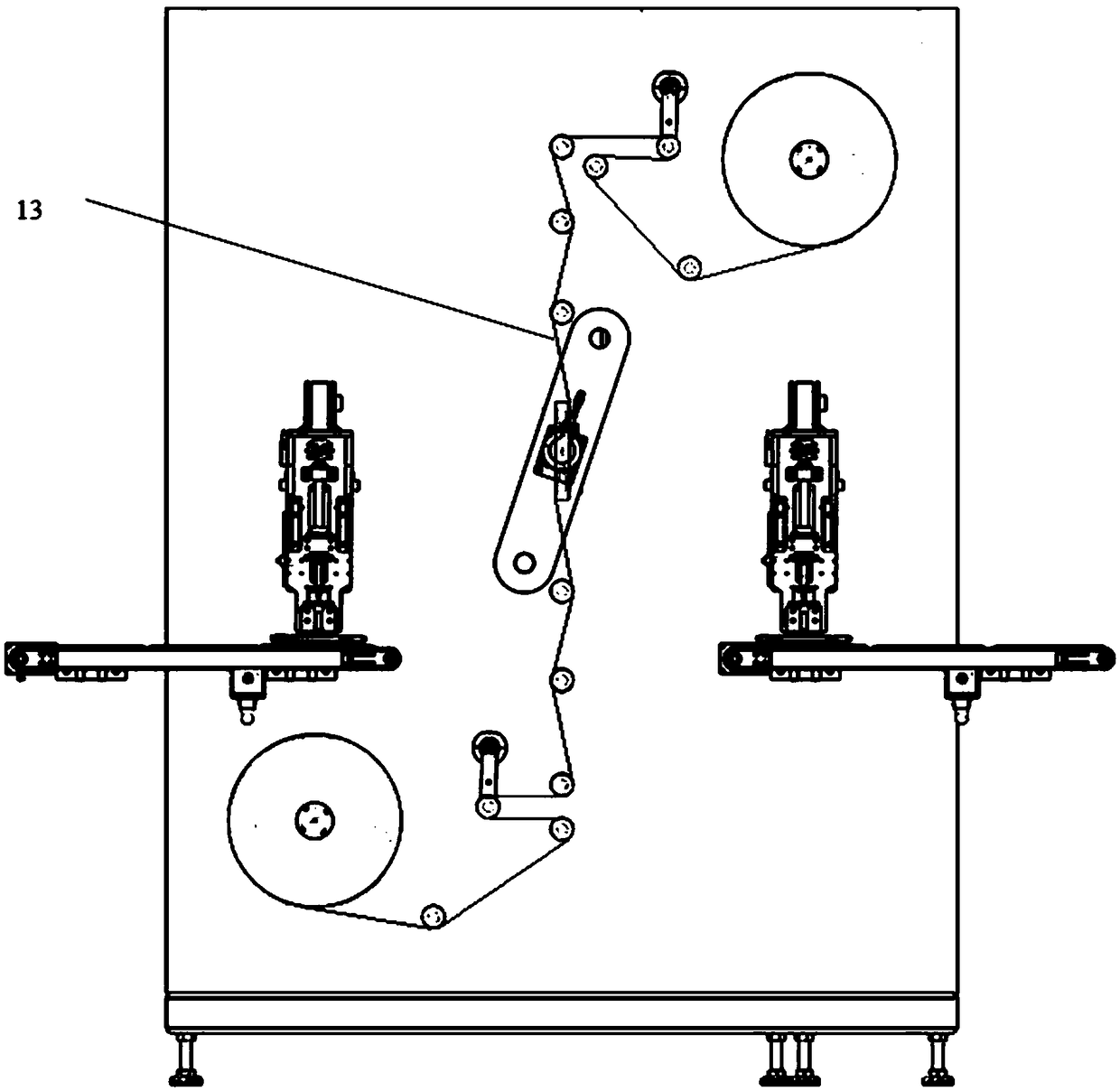

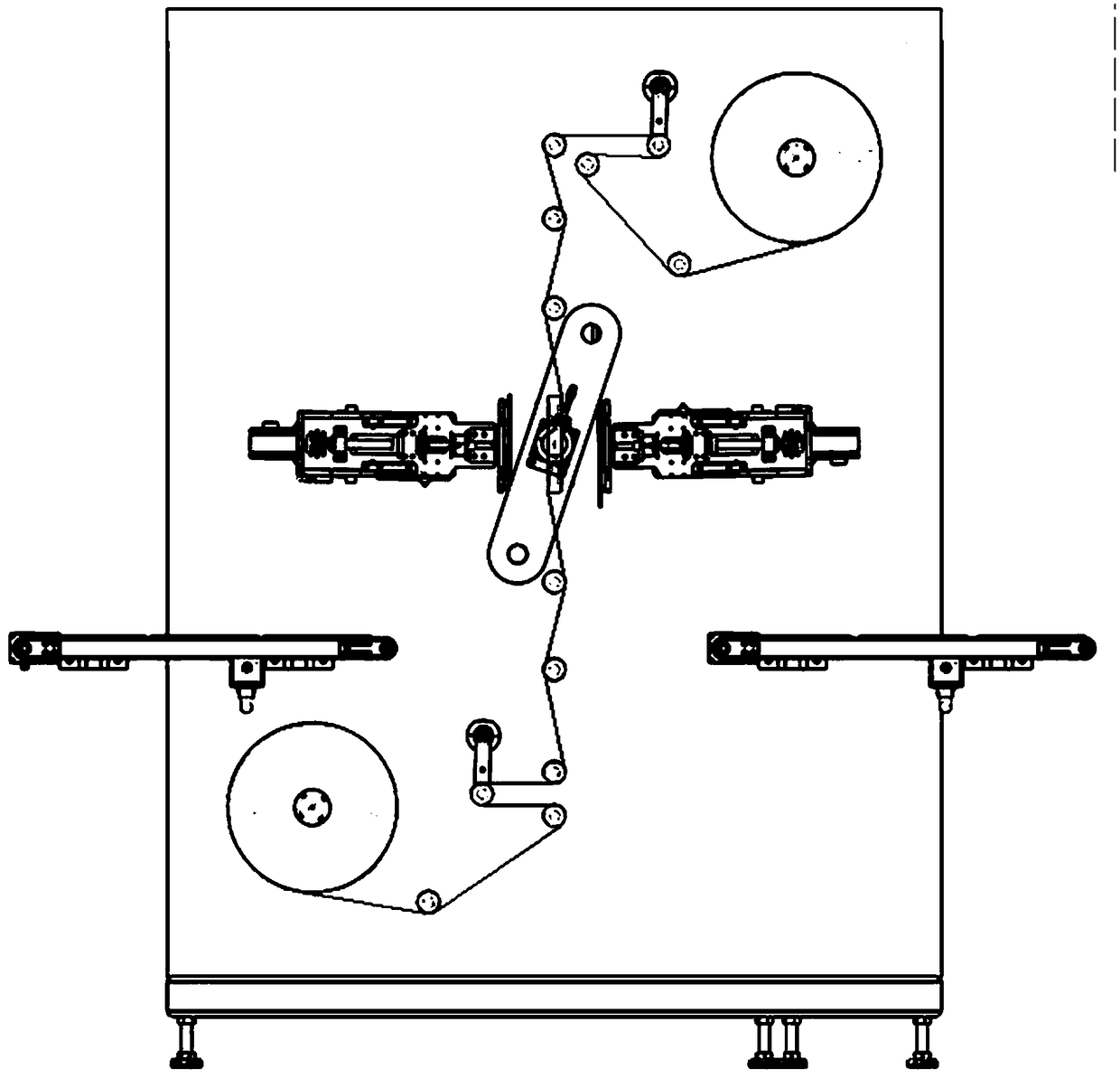

[0039] In an alternative embodiment, such as figure 2 , 3 As shown, the first diaphragm unwinding and correcting mechanism 1 and the second diaphragm unwinding and correcting mechanism 9 place the first diaphragm roll and the second diaphragm roll respectively, and the two diaphragm rolls are joined together to form the diaphragm 13 in working condition.

[0040] Such as Figure 4-9 As shown, the rotating lamination table performs a series of reciprocating lamination movements to realize the lamination action. Such as Figure 4 As shown, the pole piece conveyor belt 3 is used to transport the negative pole piece to the bottom of the negative pole stack manipulator 4; the positive pole piece conveyor belt 12 is used to transport the positive pole piece to the bottom of the positive pole stack manipulator 11; the negative pole stack manipulator 4 sucks The negative electrode sheet is transferred to the rotating lamination table 5; the positive electrode sheet is picked up by...

Embodiment 3

[0049] In an optional embodiment, the negative stack manipulator 4 sucks the negative pole piece and transfers the negative pole piece to the rotating stacking table 5; the positive pole stacking manipulator 11 picks up the positive pole piece and transfers the positive pole piece to the rotating stacking table 5 . The positive / negative lamination manipulator retracts after picking up the sheet on the belt, then rotates to the lamination position, then stretches forward, stacks the pole piece to the lamination table; then shrinks backward, rotates to the lamination position, stretches out to take the sheet.

[0050] Such as Figure 10 As shown, both positive and negative stacked manipulators have a telescopic function and are driven by a servo motor drive 1001 . And the retractable mechanism formed by the servo motor 1001, the ball screw 1002 and the slide rail 1003.

[0051] Specifically, such as Figure 10 As shown, the positive / negative stack manipulator has an inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com