Mulching film applicator

A mulch mulching machine and mulching machine technology, applied to plant protection covers, etc., can solve problems such as simple structure, ineffective production efficiency, complicated operation, etc., and achieve the effect of reducing labor intensity and improving film mulching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0024] The present invention is shown in the figure,

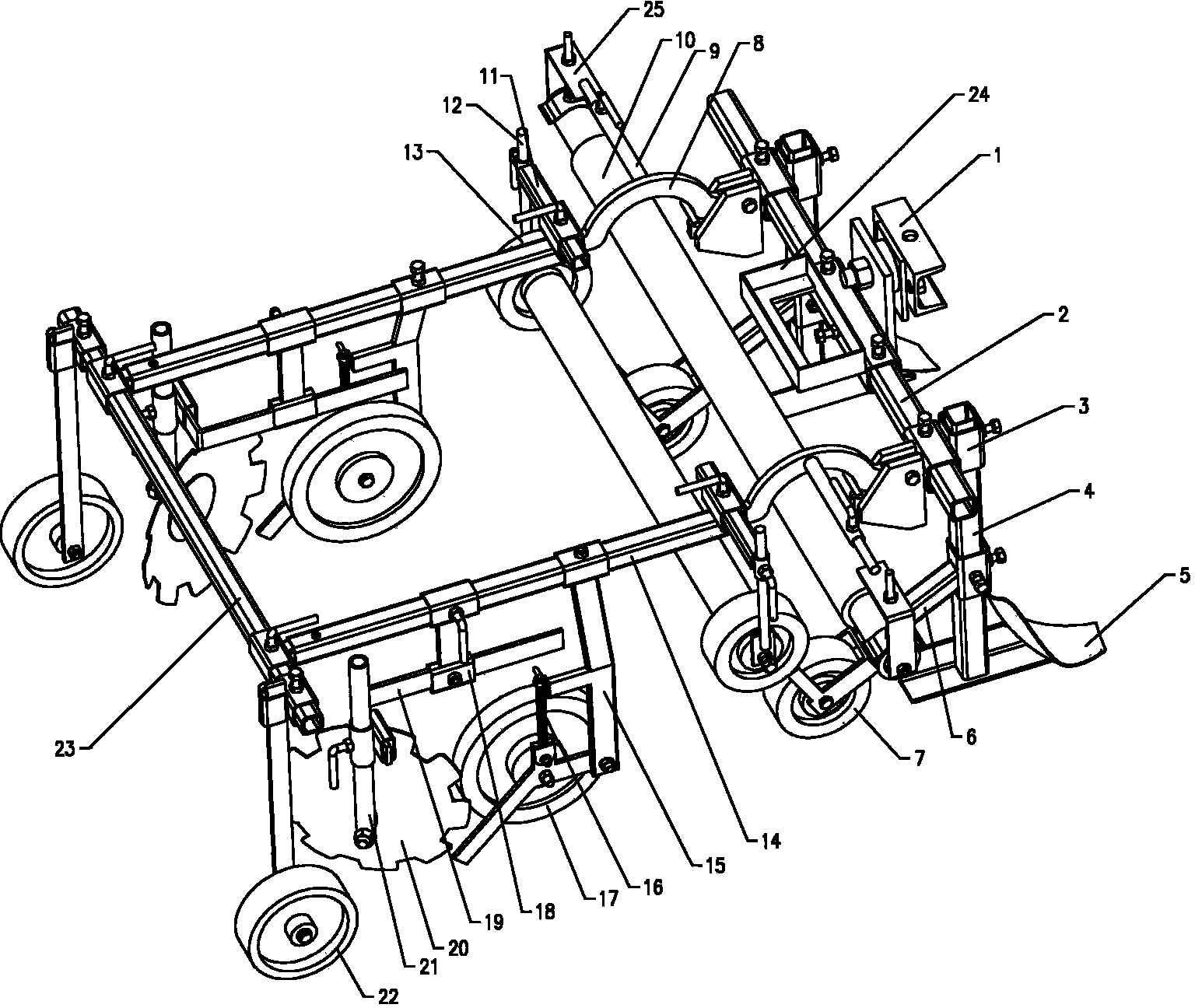

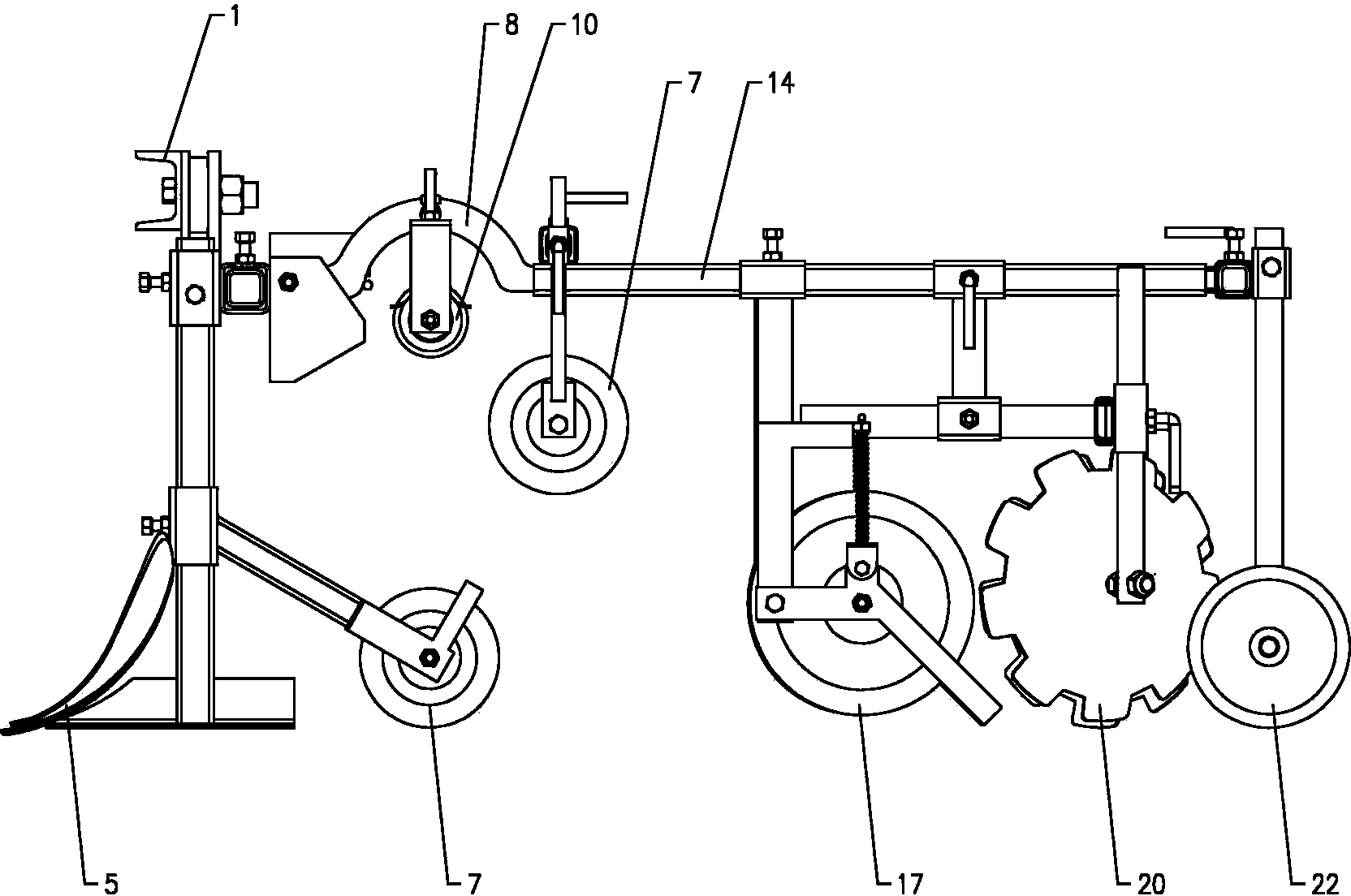

[0025] A plastic film laminating machine includes a furrow plow and a plastic film release roller. It is characterized in that it also includes a rocker arm connector 1 connected to the traction of the power system and a film-coated assembly;

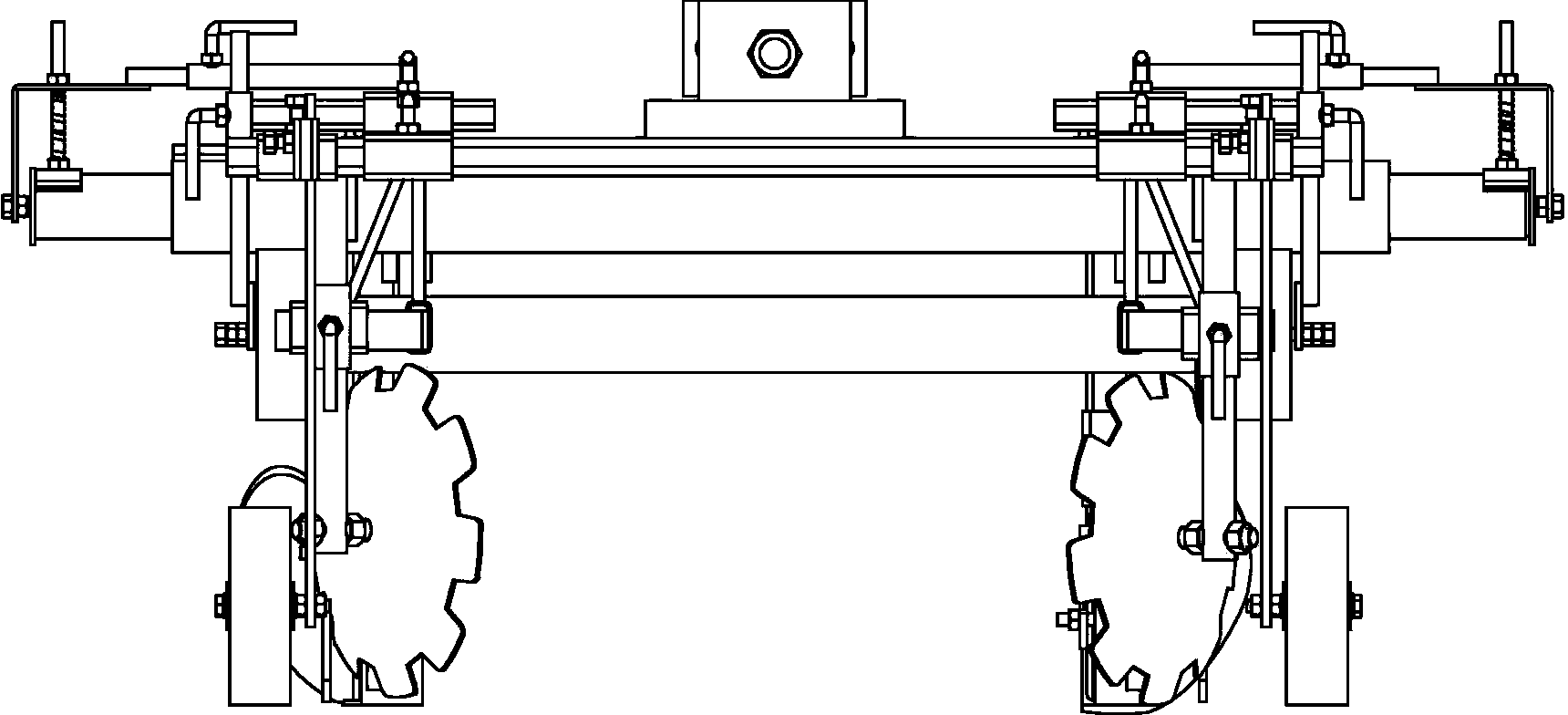

[0026] The film covering assembly includes a pair of film release roller assemblies, a film pressing shaft roller assembly, a film rolling wheel set, and a soil rolling plate wheel set;

[0027] A bracket 3 is arranged behind the rocker arm connector 1, and support wheels (7, 22) are arranged at the front and back of the bracket 3;

[0028] The furrowing plow 5 is arranged in front of the front supporting wheel, the front part of the left and right crossbeams of the bracket 2 is an arc-shaped rod structure 8, the highest part of the arc-shaped rod is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com