Patents

Literature

398results about How to "Improve lamination efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

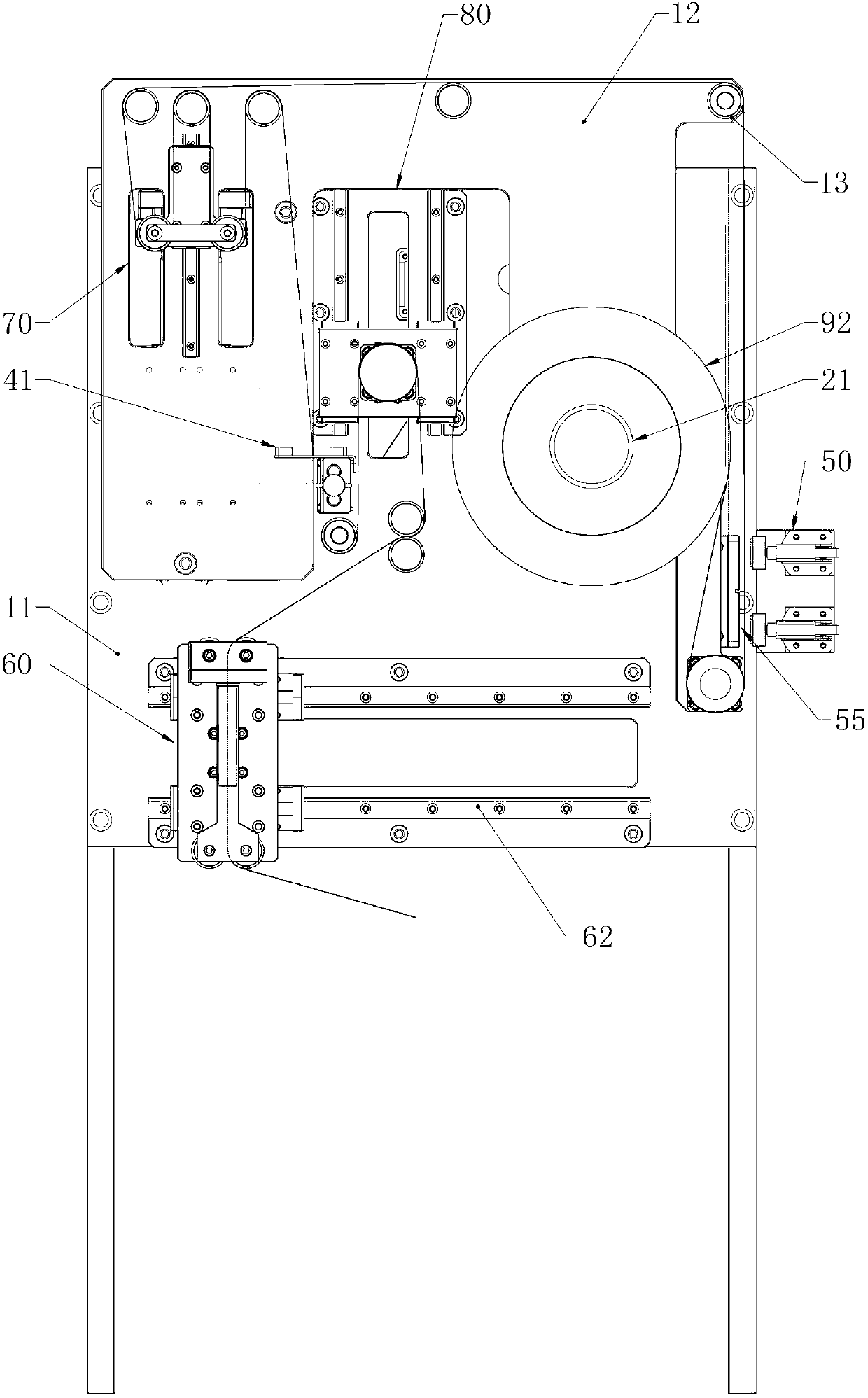

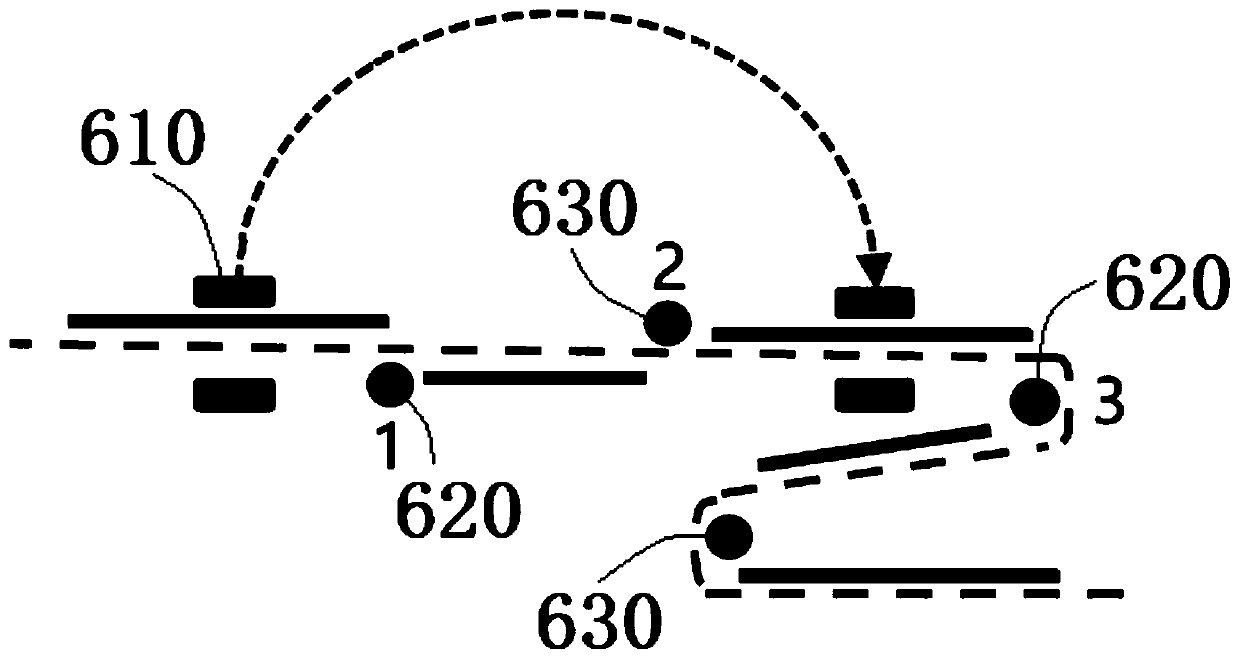

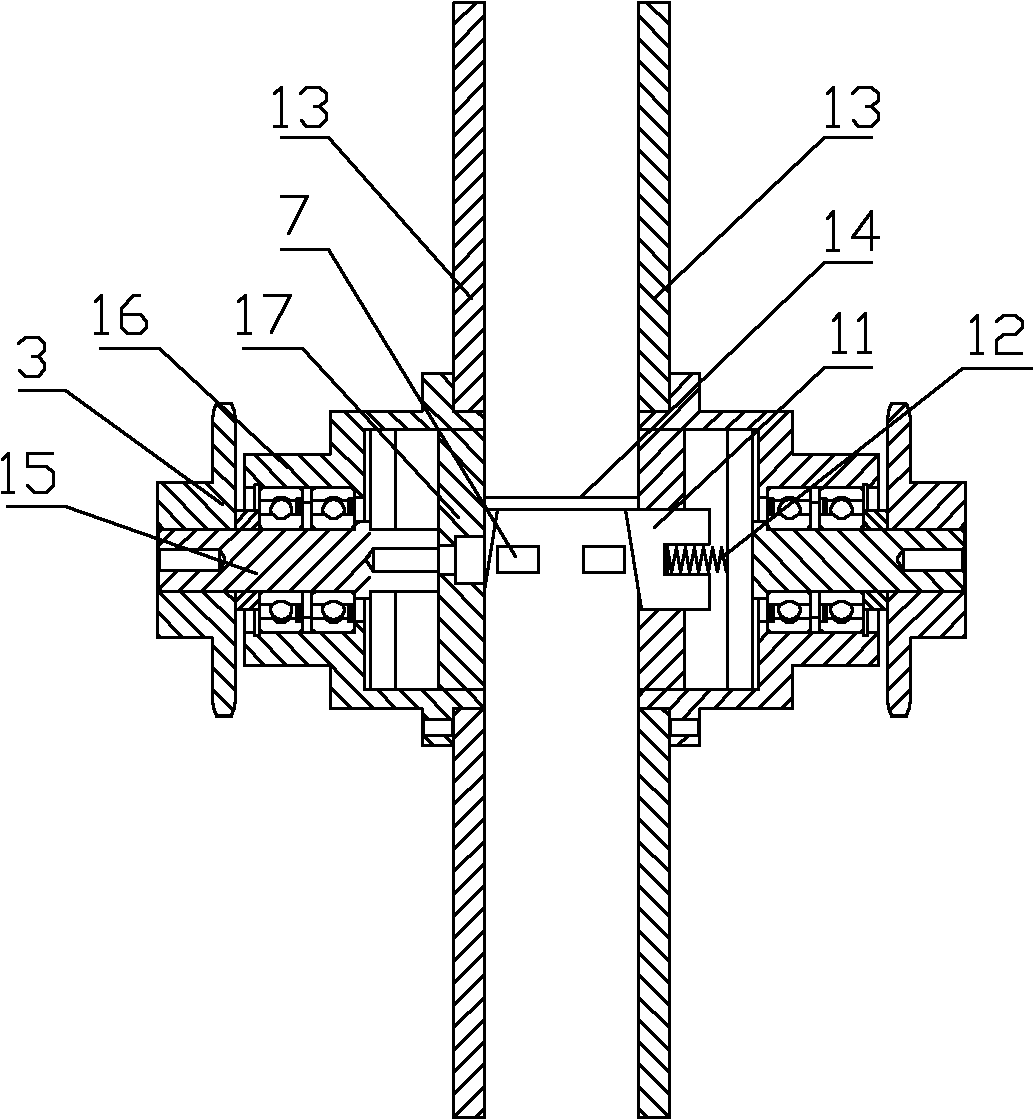

Winding laminating machine and laminating method thereof

InactiveCN102751538AImprove lamination efficiencyQuality improvementFinal product manufactureSecondary cellsPole pieceMechanical engineering

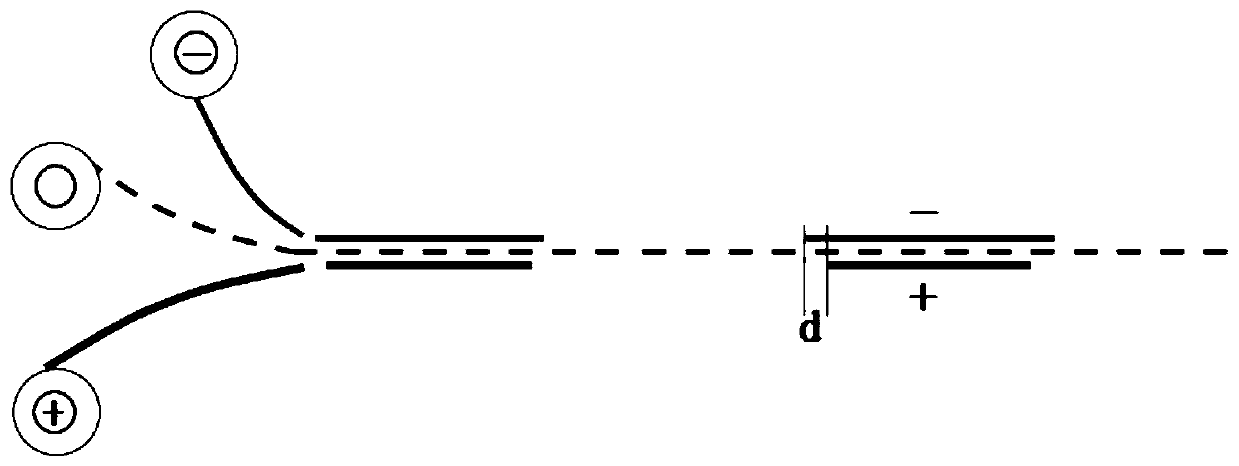

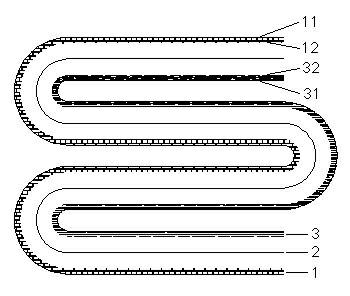

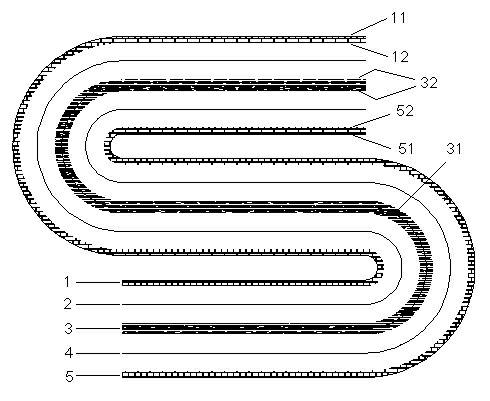

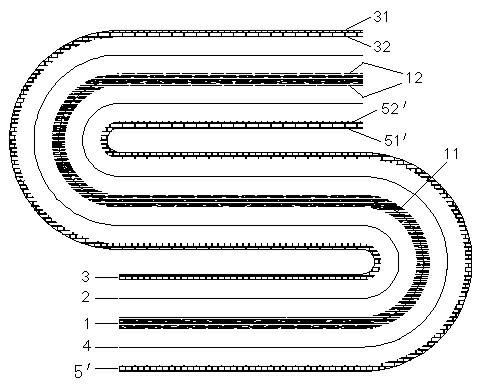

The embodiment of the invention discloses a winding laminating machine and a laminating method of the winding laminating machine. The winding laminating machine comprises a winding device and a controller, wherein the winding device comprises a clamp for clamping articles to be wound, and a rotating mechanism for driving the clamp to periodically and intermittently rotate a preset angle, so that a diaphragm is further wound outside the articles to be wound; the controller is connected with and controls a diaphragm supply device, a pole piece supply device, a winding device and a laminating device to be mutually matched to laminate and wind; two suits of laminating devices are arranged and symmetrically arranged at two sides of a winding station of the winding device, and a pole piece is respectively laminated to the diaphragm from two sides to form the articles to be wound at the same time. According to the winding laminating machine and the laminating method of the winding laminating machine disclosed by the embodiment of the invention, with the technical means of adopting the laminating devices which are symmetrically arranged at two sides of the winding device and laminate on the diaphragm from two sides at the same time after the winding device drives the diaphragm to wind at the preset angle each time, the technical effect of finishing laminating in the winding process of the diaphragm is achieved, the laminating efficiency is high and the quality is good.

Owner:SHENZHEN B&K TECH

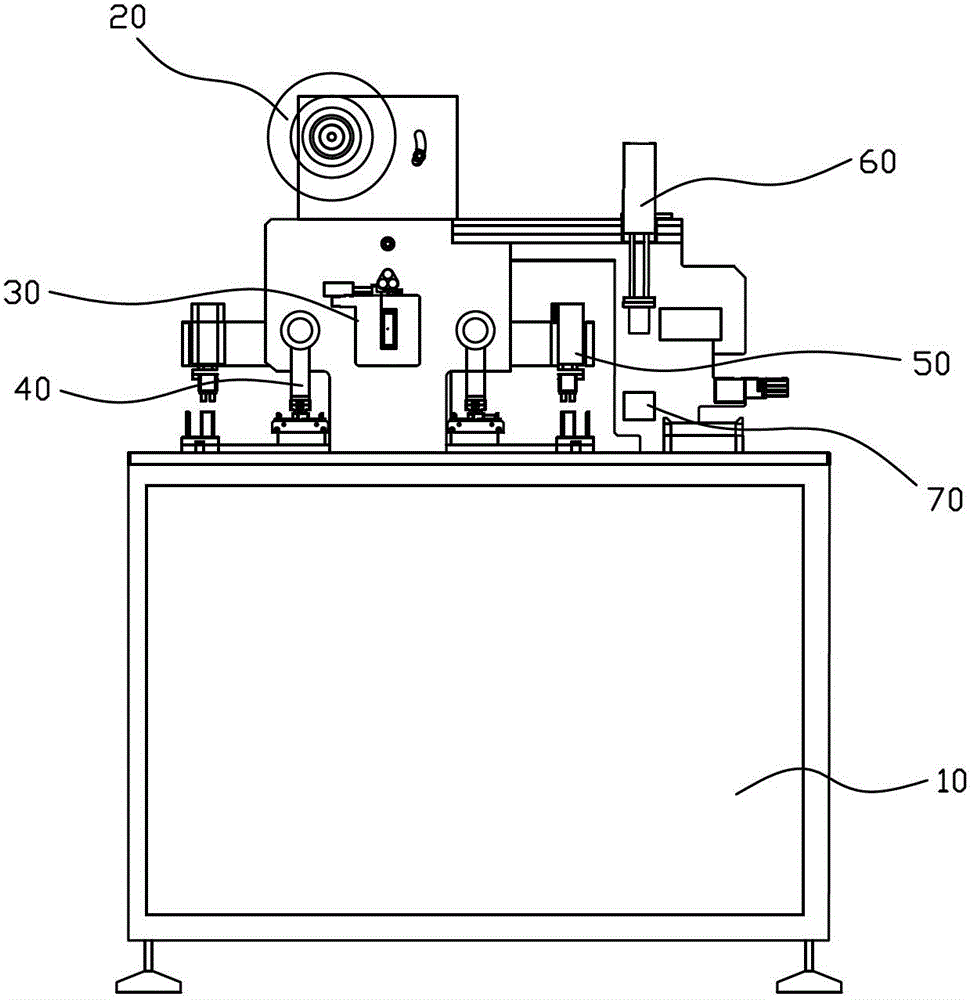

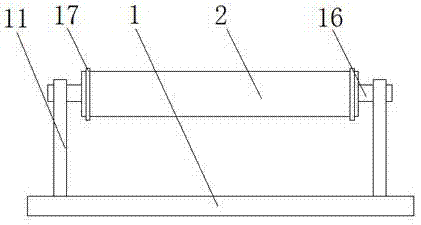

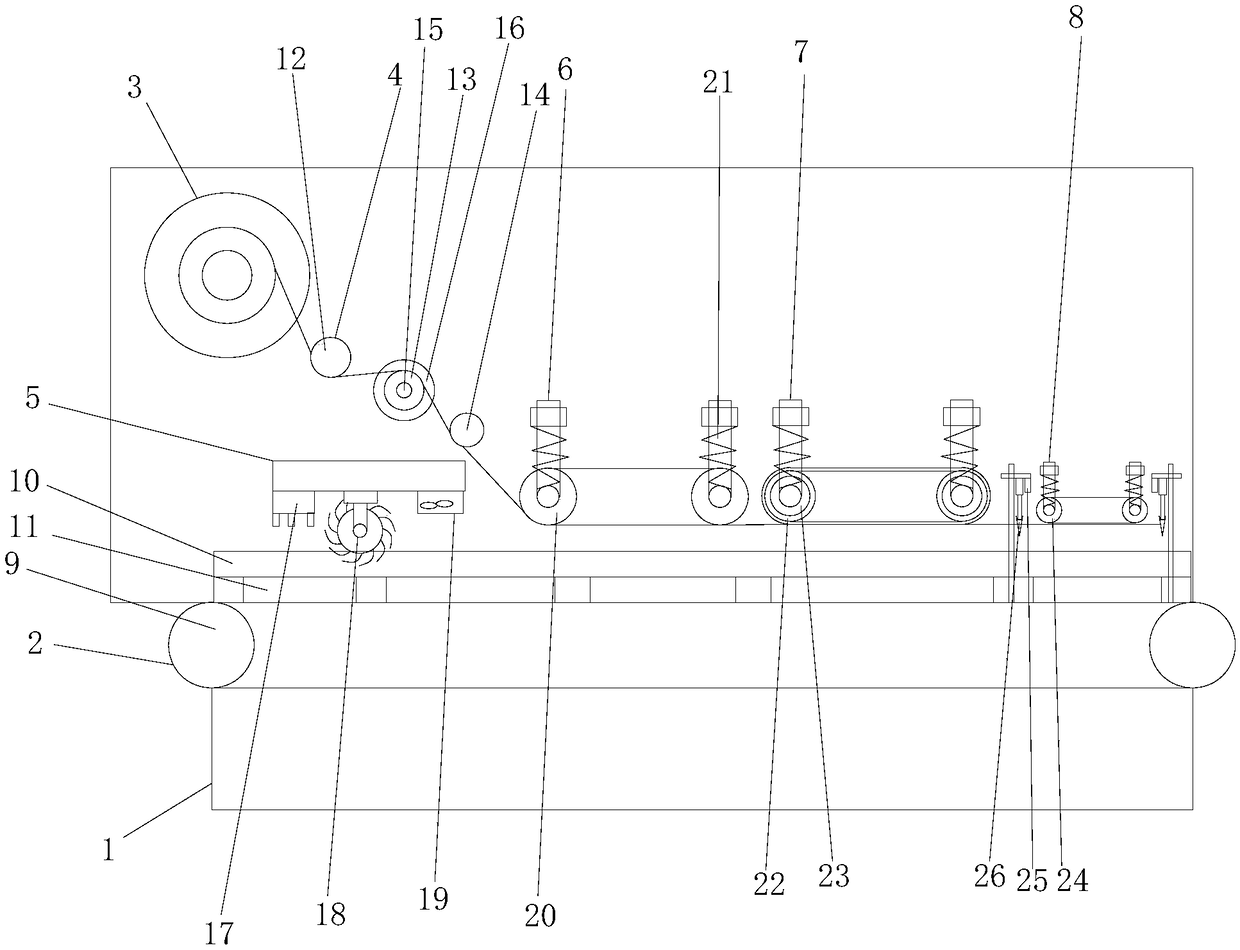

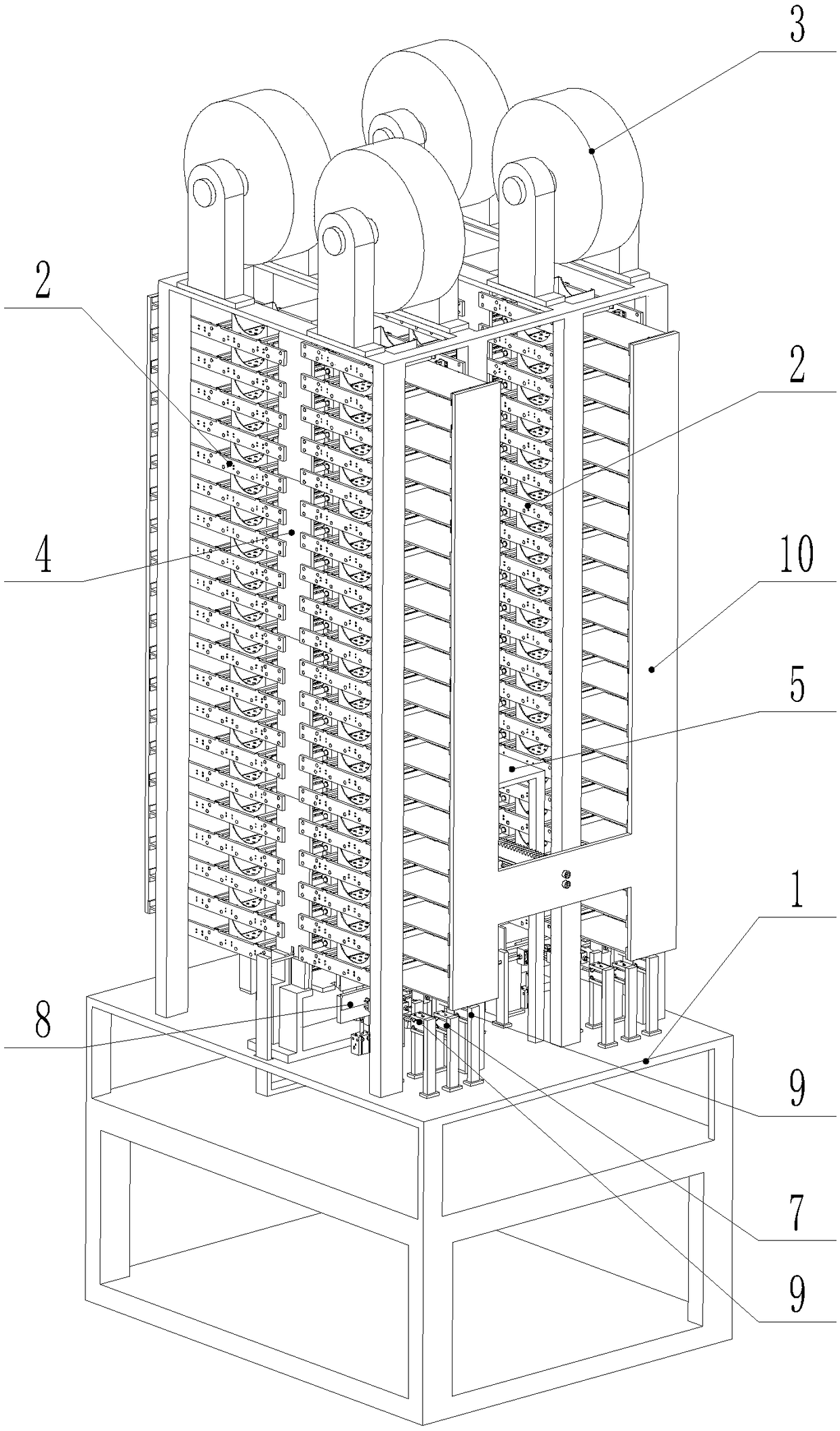

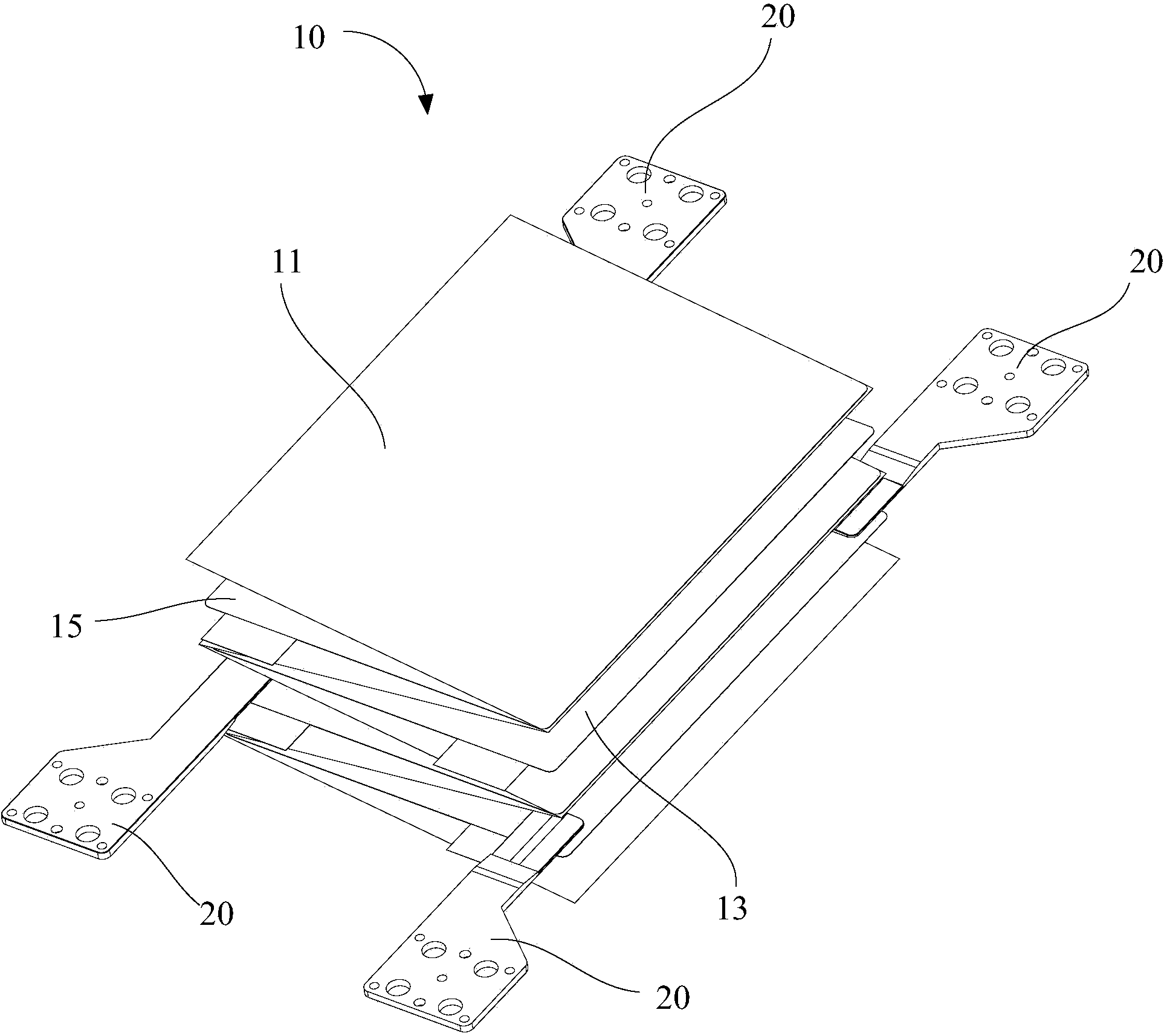

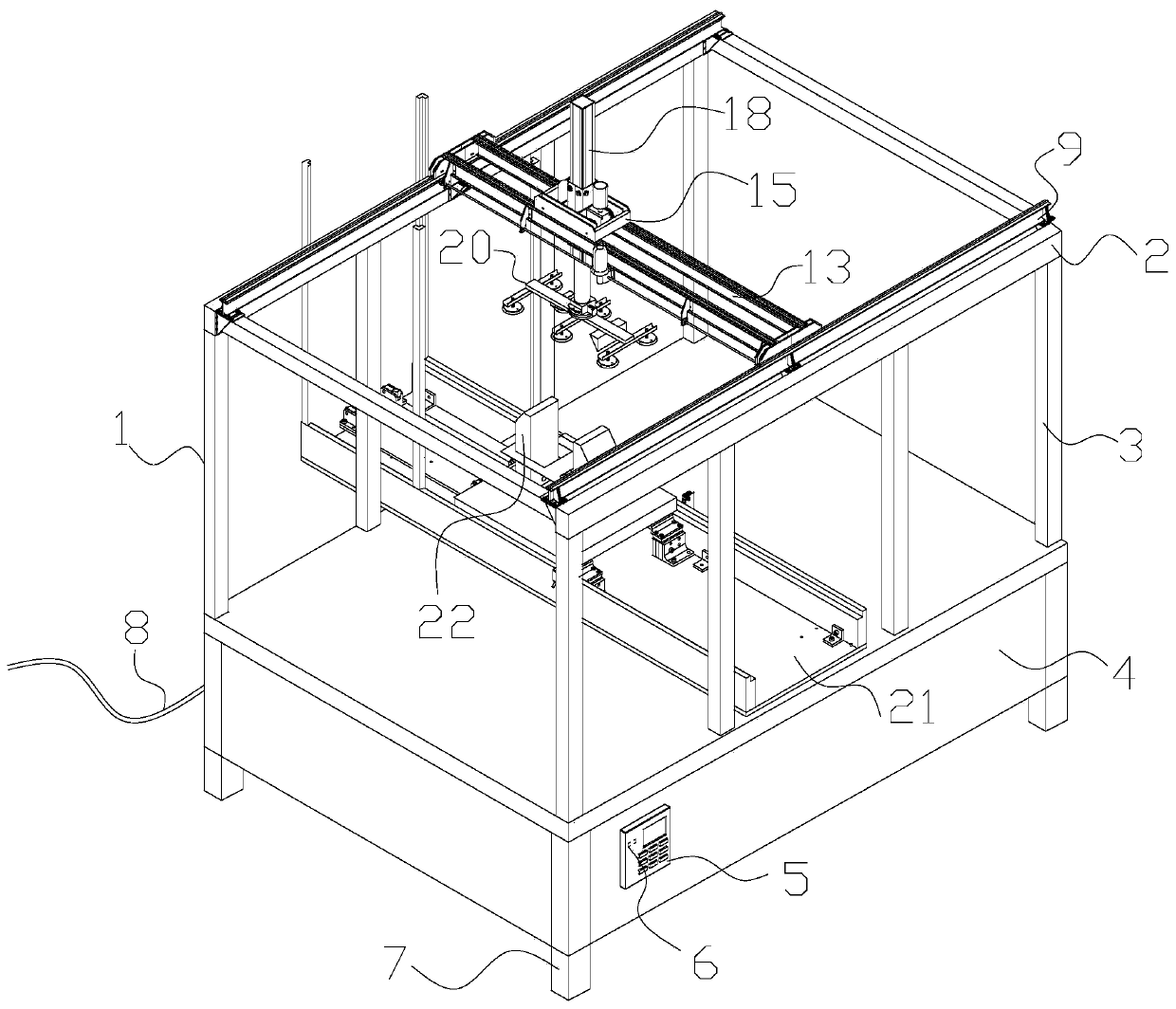

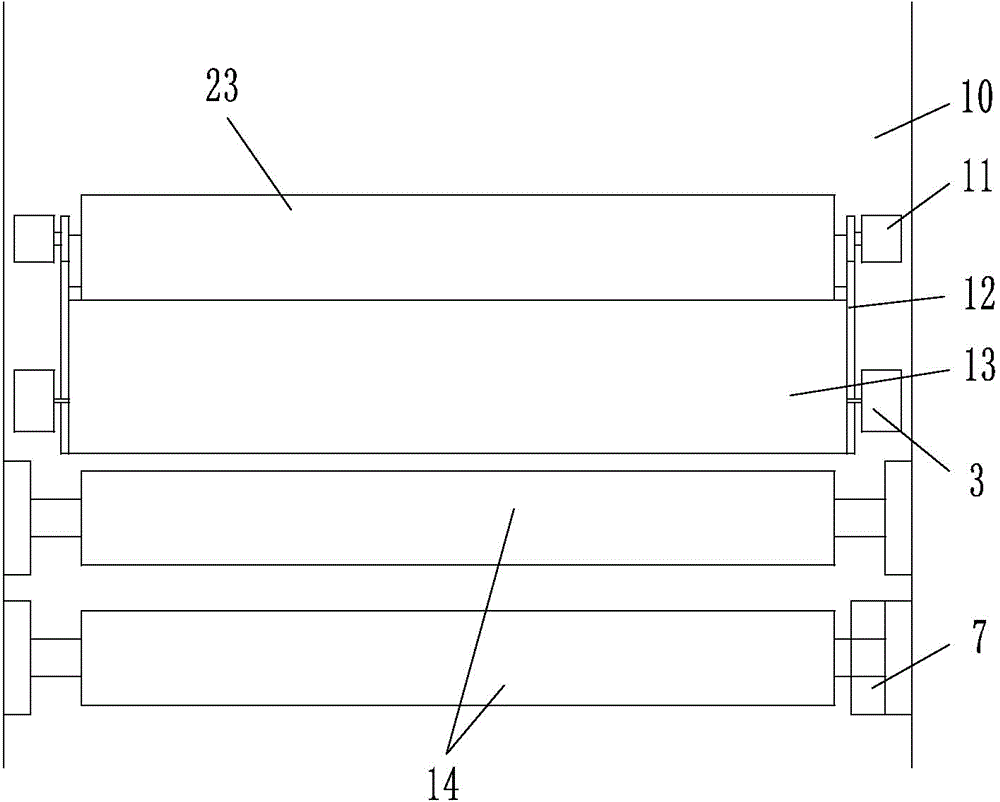

Constant tension diaphragm discharging device

ActiveCN102992073AAchieve constant tension controlQuality improvementWebs handlingEngineeringPosition sensor

The invention provides a constant tension diaphragm discharging device for a lamination stacking machine. The discharging device comprises an unreeling mechanism which is installed with a reeled diaphragm, a diaphragm laminating mechanism for folding and putting a diaphragm, a collecting and discharging connecting rod mechanism which is linked with the diaphragm laminating mechanism and keeps the diaphragm buffer length and a tension control mechanism which provides the diaphragm discharging tension. The tension control mechanism comprises a diaphragm fixing roll for guiding the diaphragm, a diaphragm floating roll for regulating the diaphragm buffer length, a sliding guide rail for installing the floating roll, a tension controller which pushes the floating roll to slide so as to change the buffer length and a position sensor for detecting the position information of the floating roll. The diaphragm laminating mechanism comprises a sliding roller group which drives the diaphragm to be discharged and a horizontal sliding rail for installing the sliding roller group. The collecting and discharging connecting rod mechanism comprises a collecting and discharging roller which is controlled by the diaphragm laminating mechanism, a vertical sliding rail for installing the collecting and discharging roller and a collecting and discharging connecting rod which connects the collecting and discharging roller with the sliding roller group. The discharging device has the advantages that the collecting and discharging connecting rod is matched with the tension control mechanism, so that the constant tension control of the diaphragm is realized.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

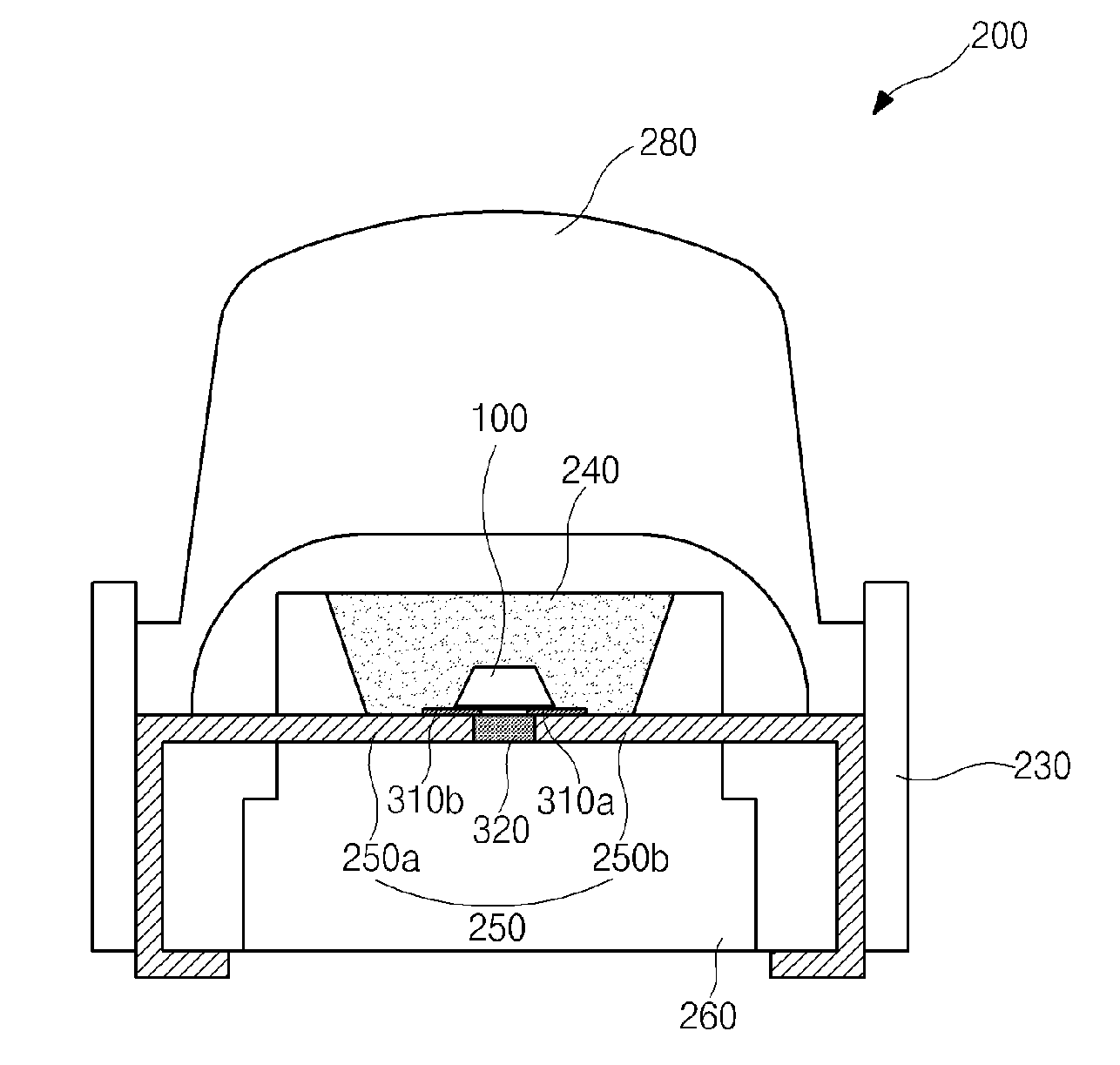

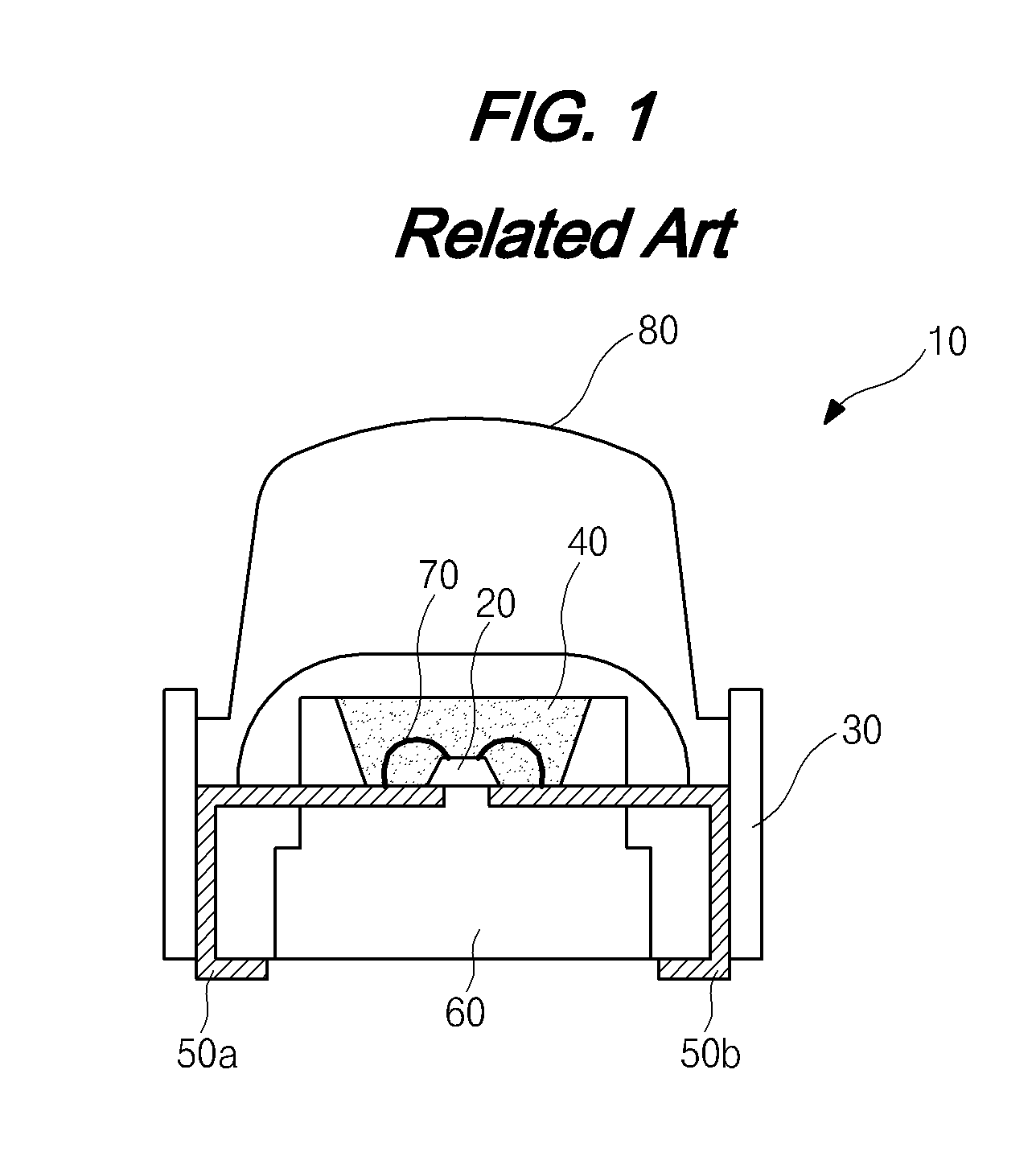

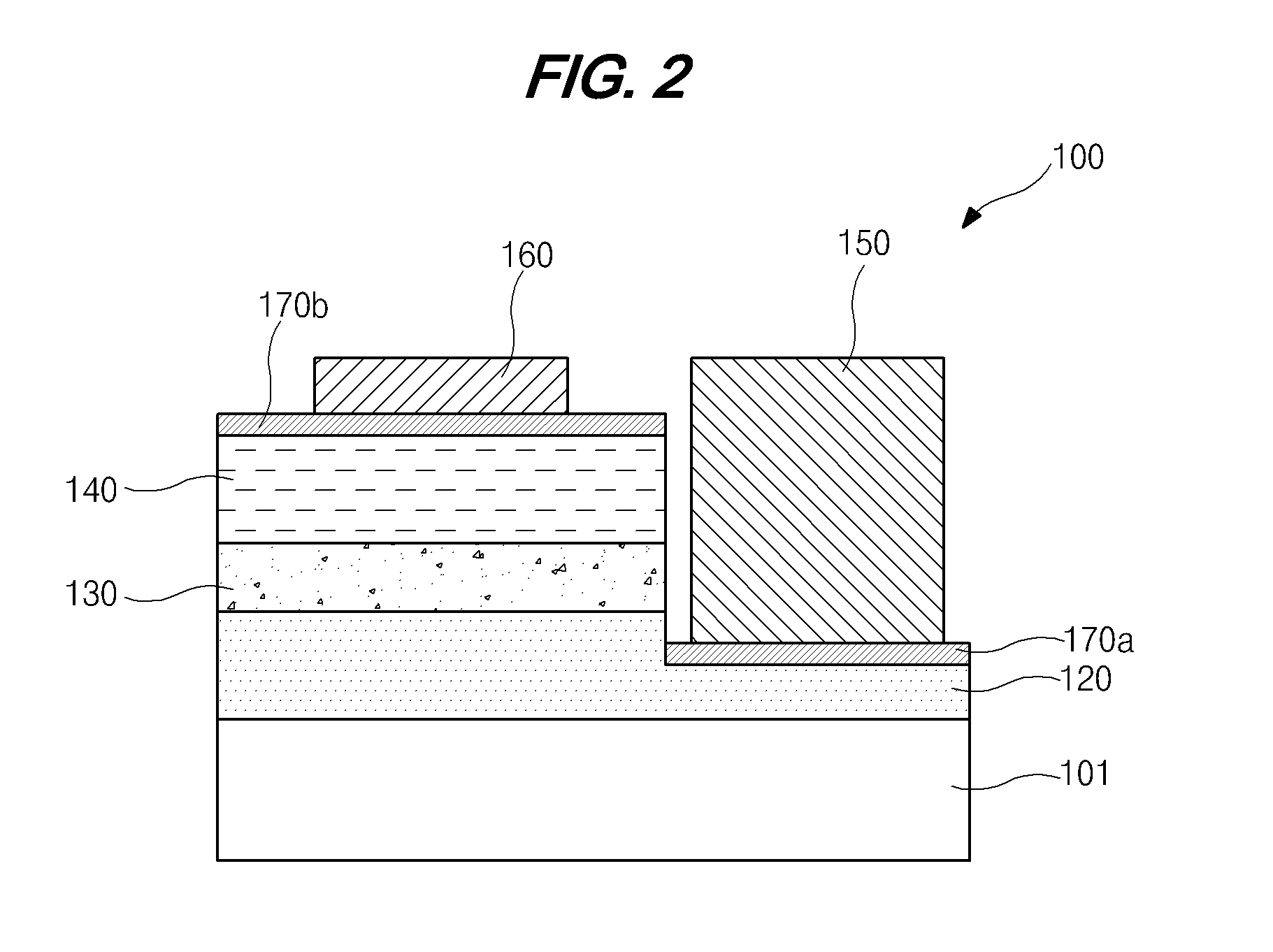

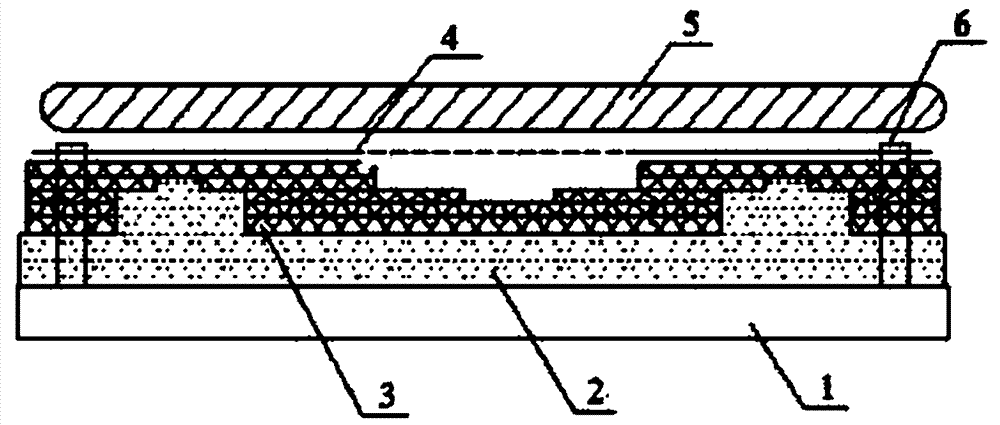

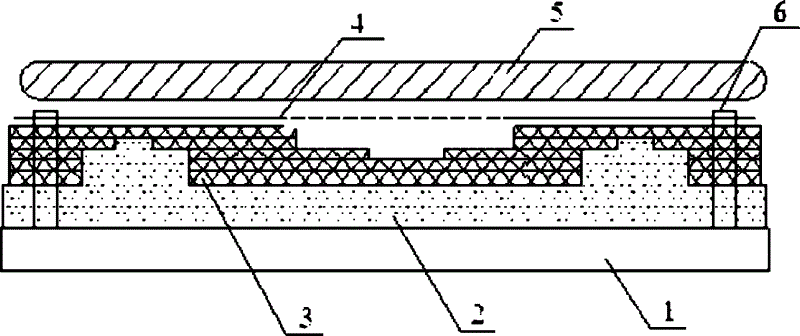

Light emitting diode package and method of fabricating the same

ActiveUS20110147779A1Improve lamination efficiencyAvoid problemsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLead frame

A light emitting diode (LED) package and a method of manufacturing a LED package is provided. The LED package includes a case having first and second lead frames disposed through the case; an LED chip disposed on the case, the LED chip having first and second electrodes directly connected to the first and second lead frames through a eutectic bond, respectively; and a lens disposed over the case covering the LED chip.

Owner:LG DISPLAY CO LTD

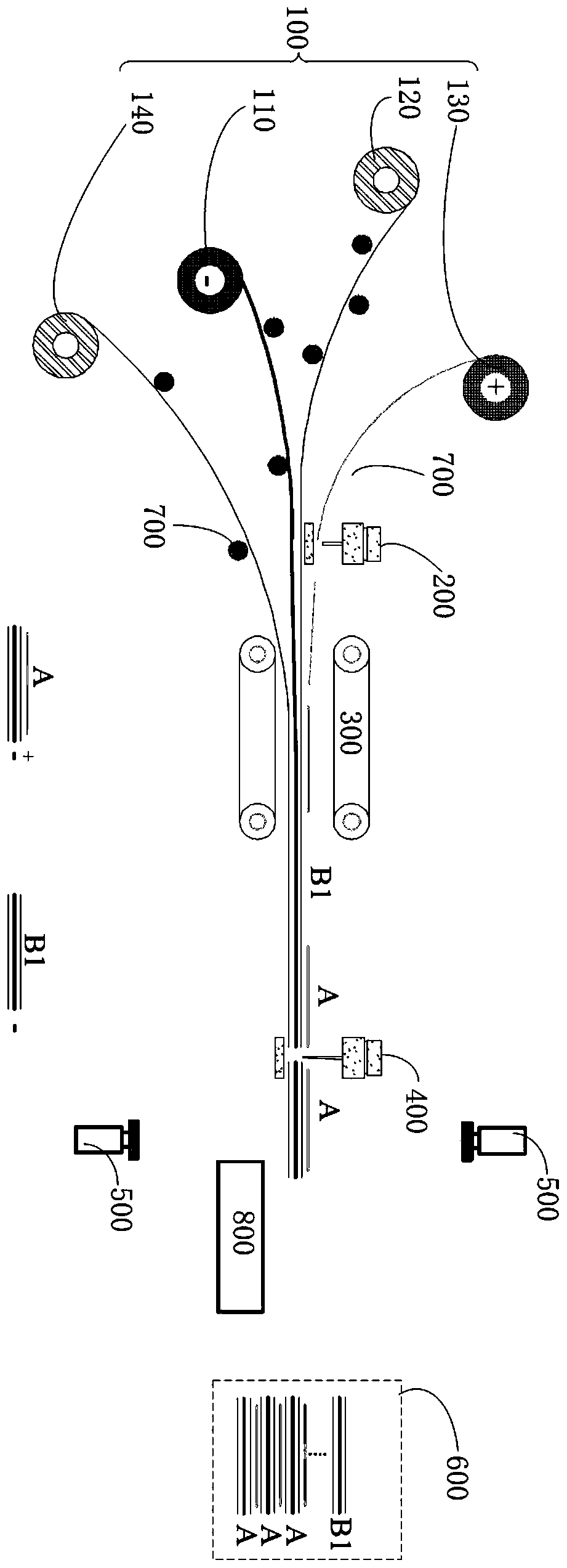

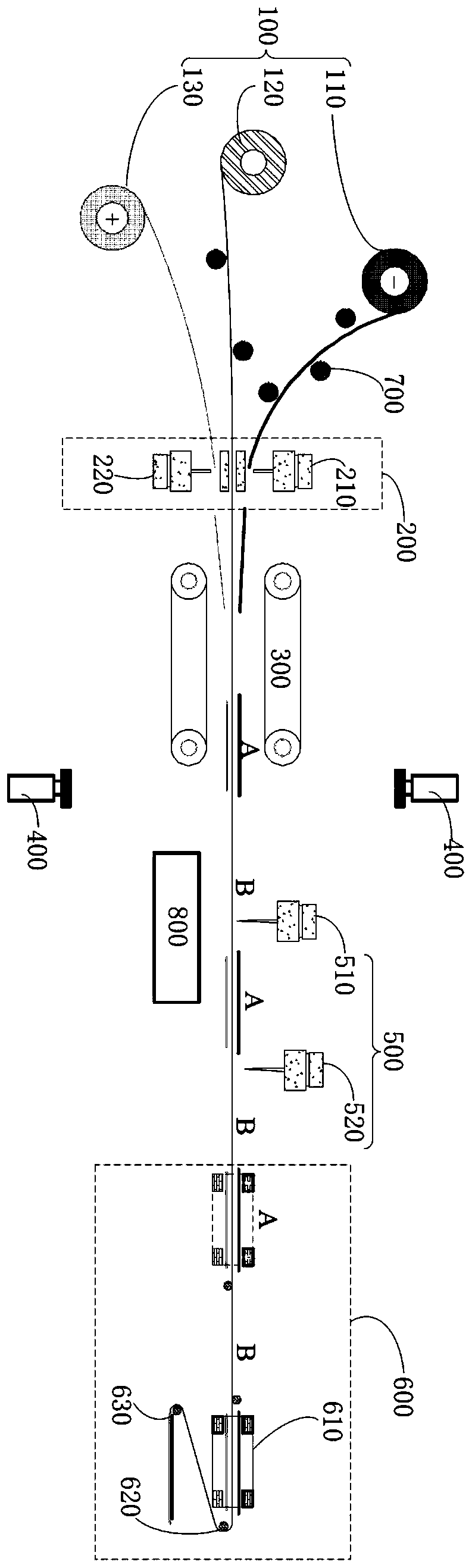

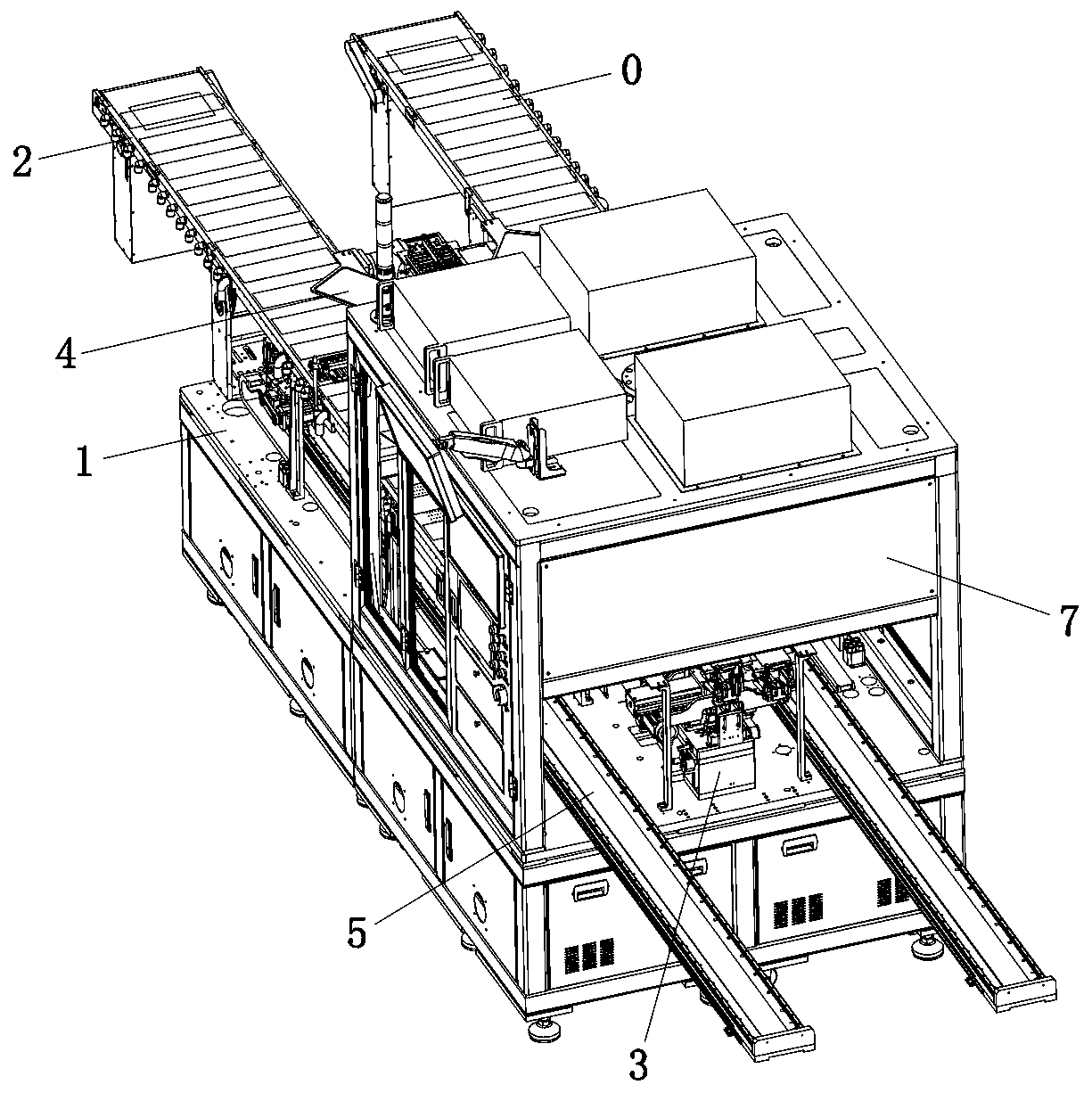

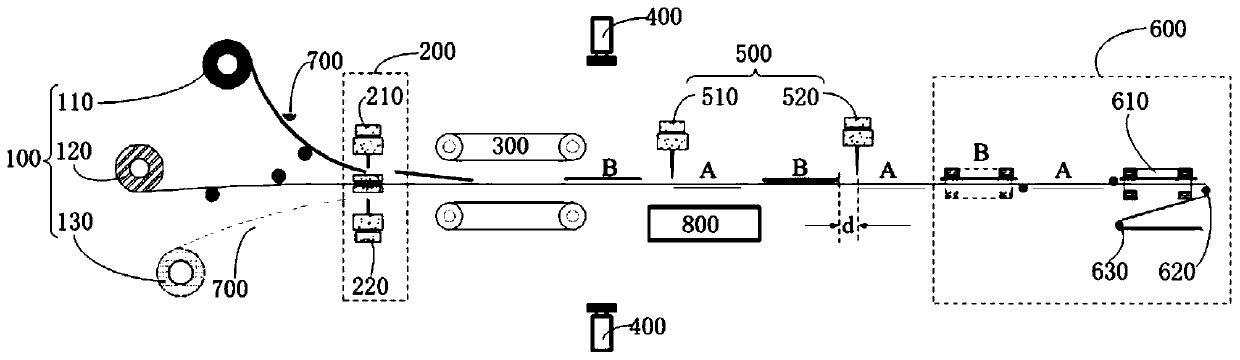

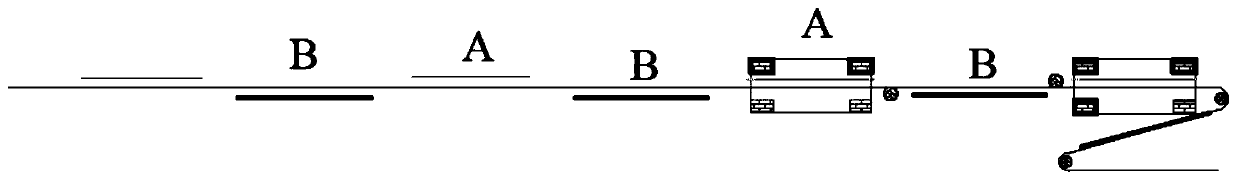

Die cutting lamination system and method

PendingCN110391449AEasy alignmentEasy to cutAssembling battery machinesFinal product manufactureOccupancy rateFailure rate

The invention provides a die cutting lamination system and method. The system comprises an unwinding mechanism, an anode cutting mechanism, a preheating rolling device, a cutting mechanism, a detection device and a lamination device, wherein the anode cutting mechanism is matched with the anode unwinding mechanism and cuts an anode sheet to obtain a lamination of the anode sheet relative to at least one of a first diaphragm, a second diaphragm and a cathode sheet in interval distribution; the rolling device enables at least two of the first diaphragm, the second diaphragm, the cathode sheet and the anode sheet to be adhered to each other; the lamination is cut by the cutting mechanism to obtain a core lamination unit and a cathode lamination unit, or obtain the core lamination unit, the cathode lamination unit and a diaphragm lamination unit; the detection device detects whether the lamination unit has defects or not; the lamination device is used for laminating the lamination units. The system has the advantages of the relatively simple structure, the high lamination speed, the low failure rate, the small horizontal lamination space occupancy rate, the convenient lamination cutting and the high cutting precision, and the negative influence of the diaphragm on the performances such as internal resistance and specific capacity of the battery is small.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

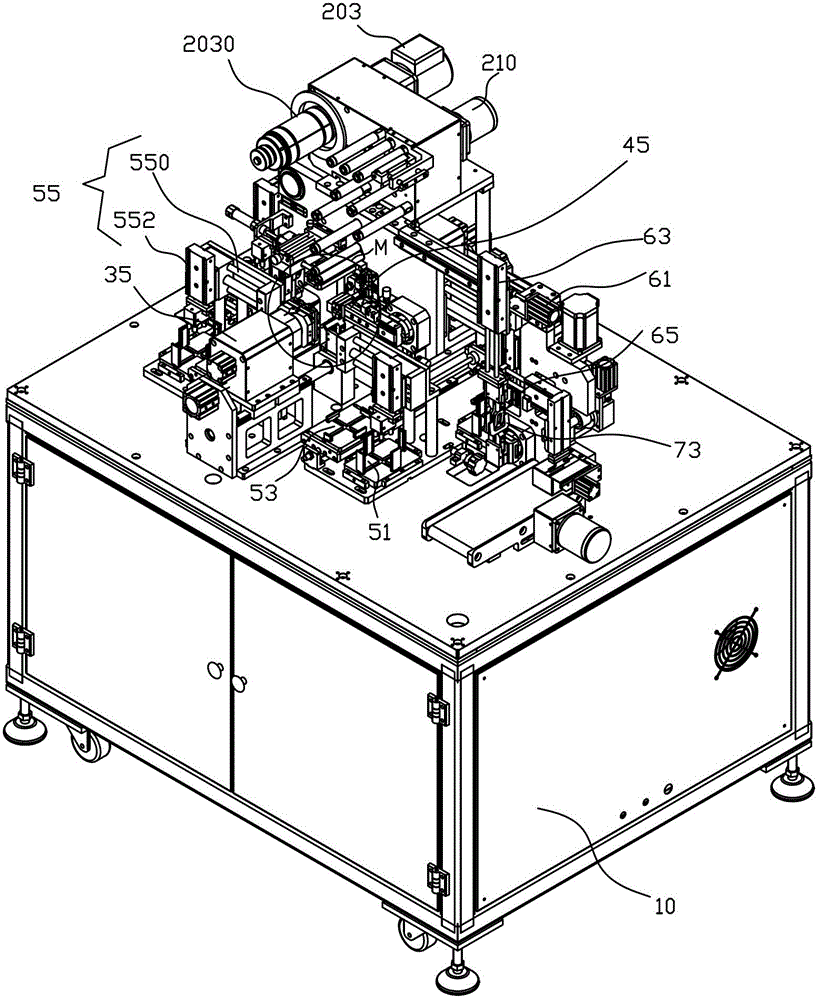

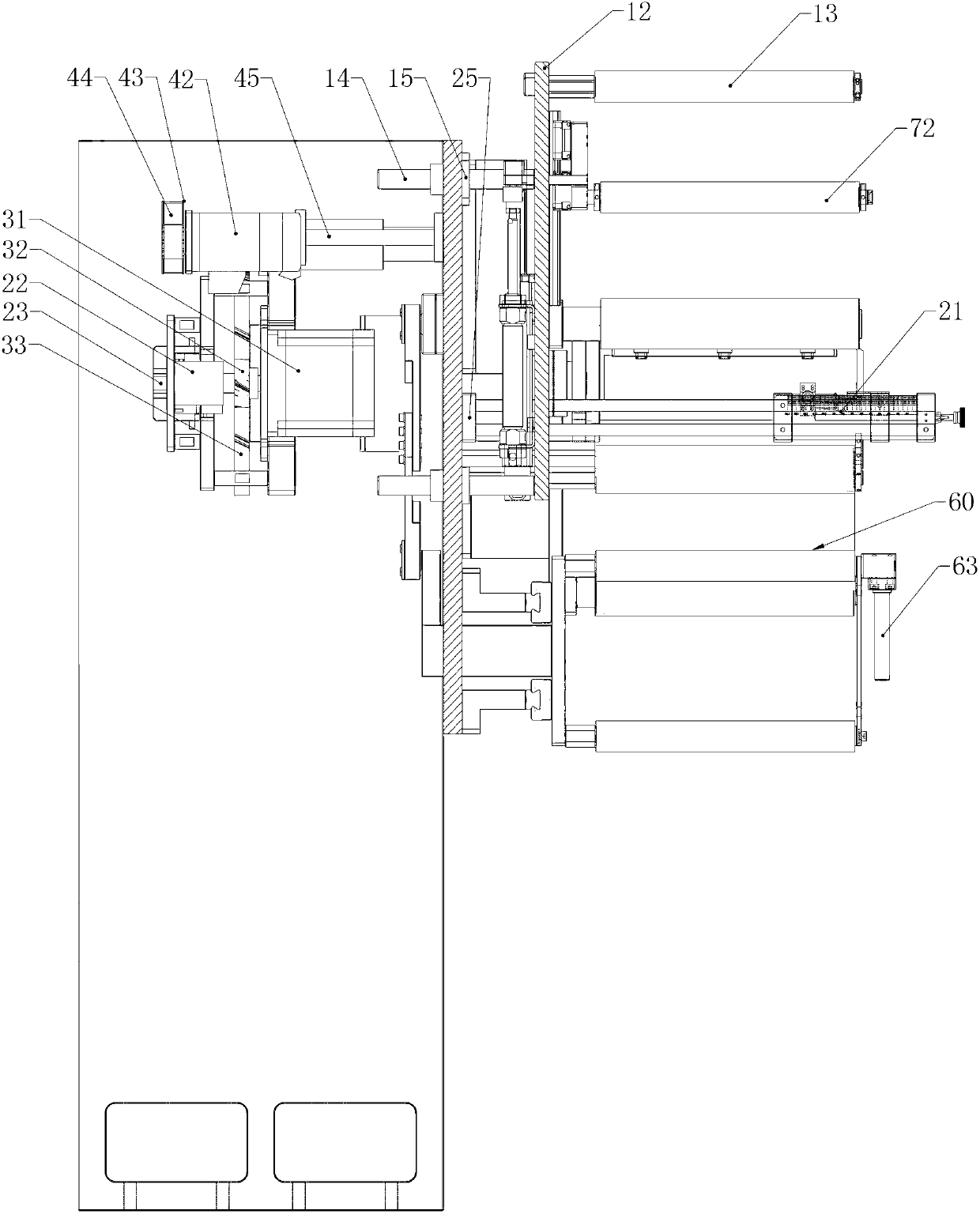

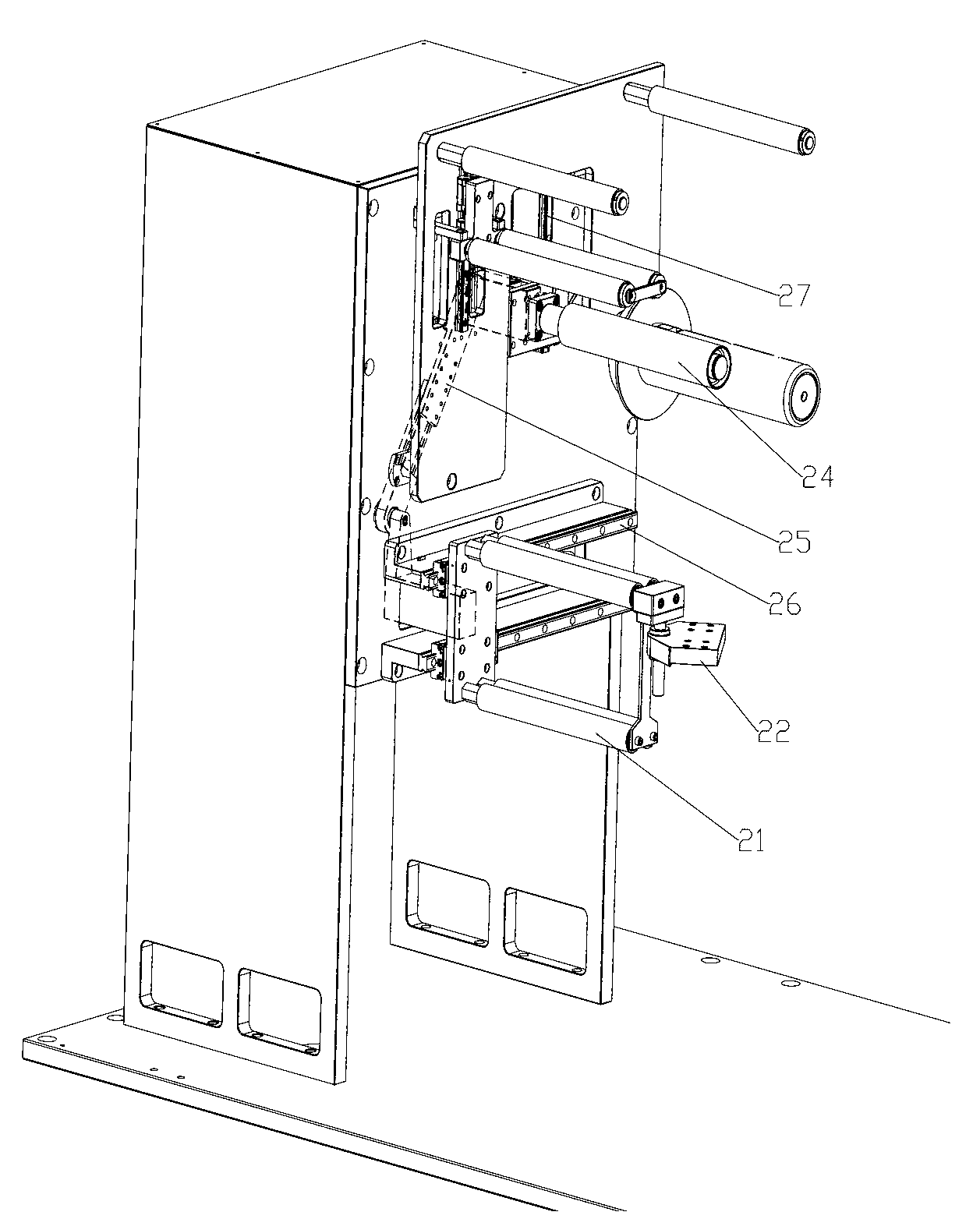

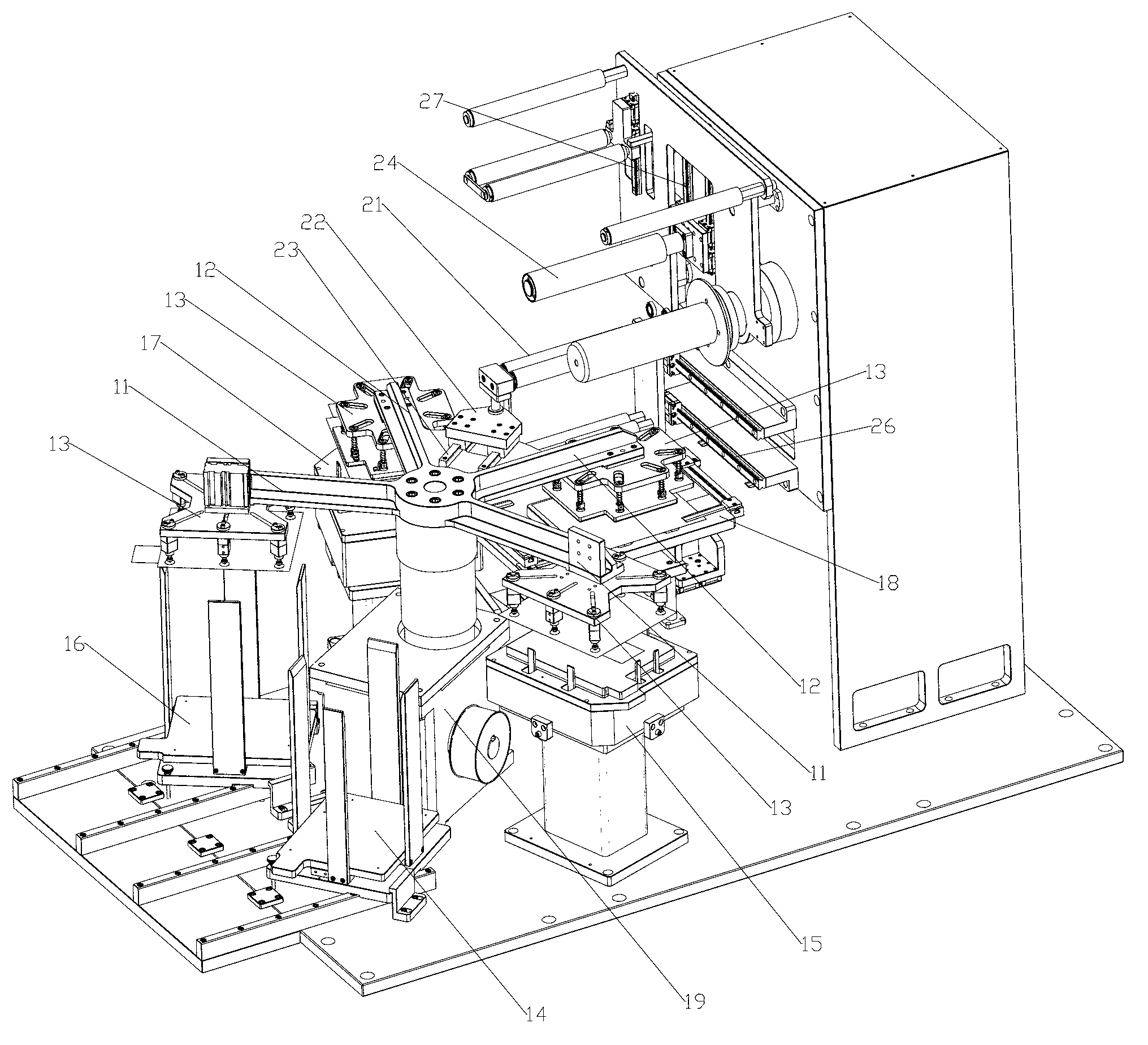

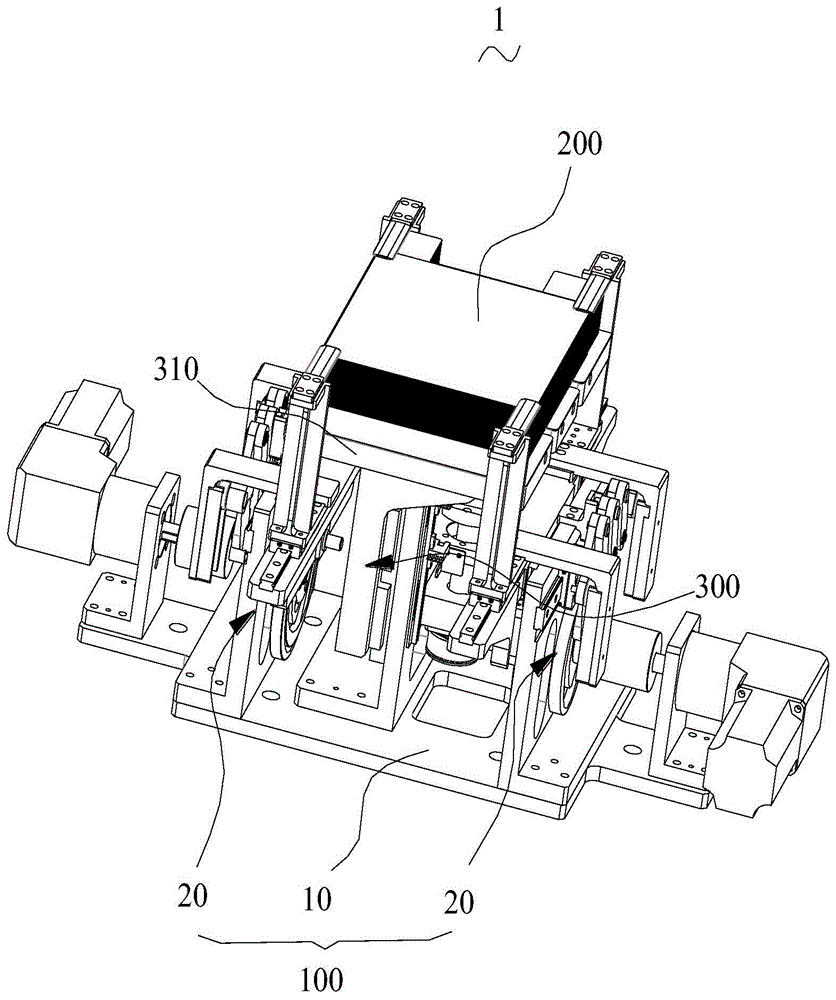

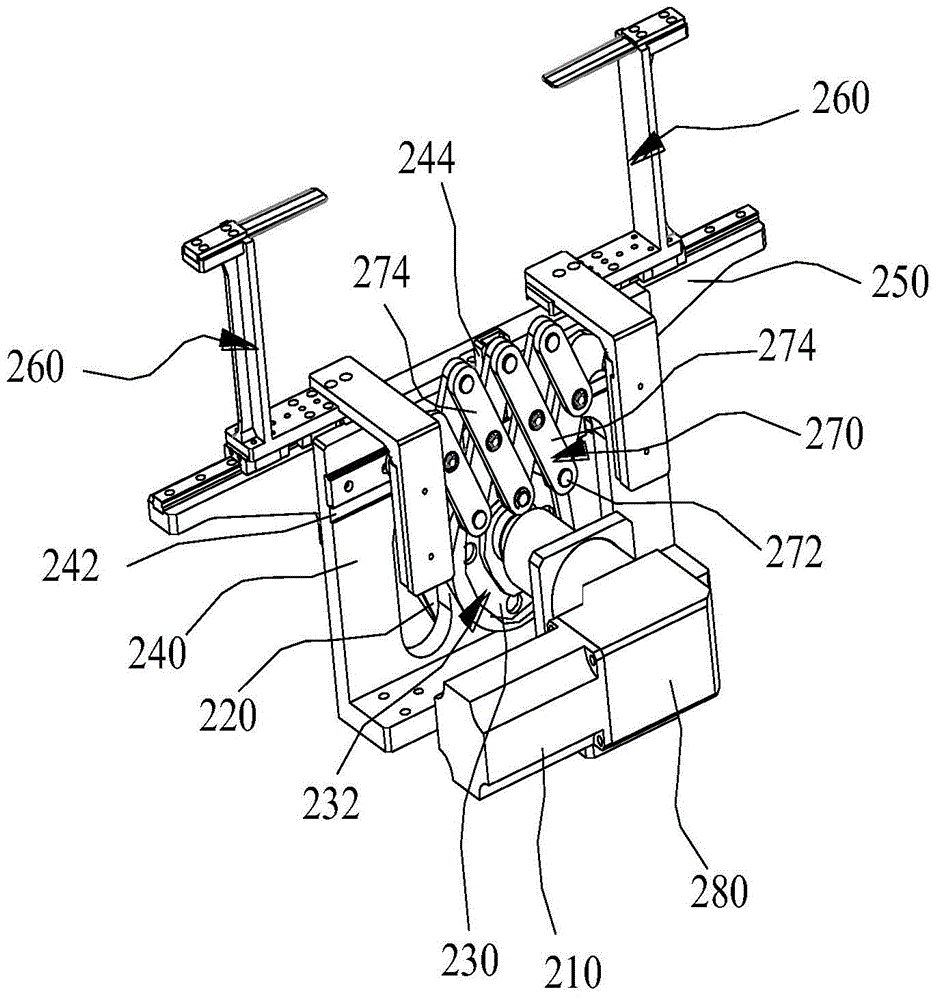

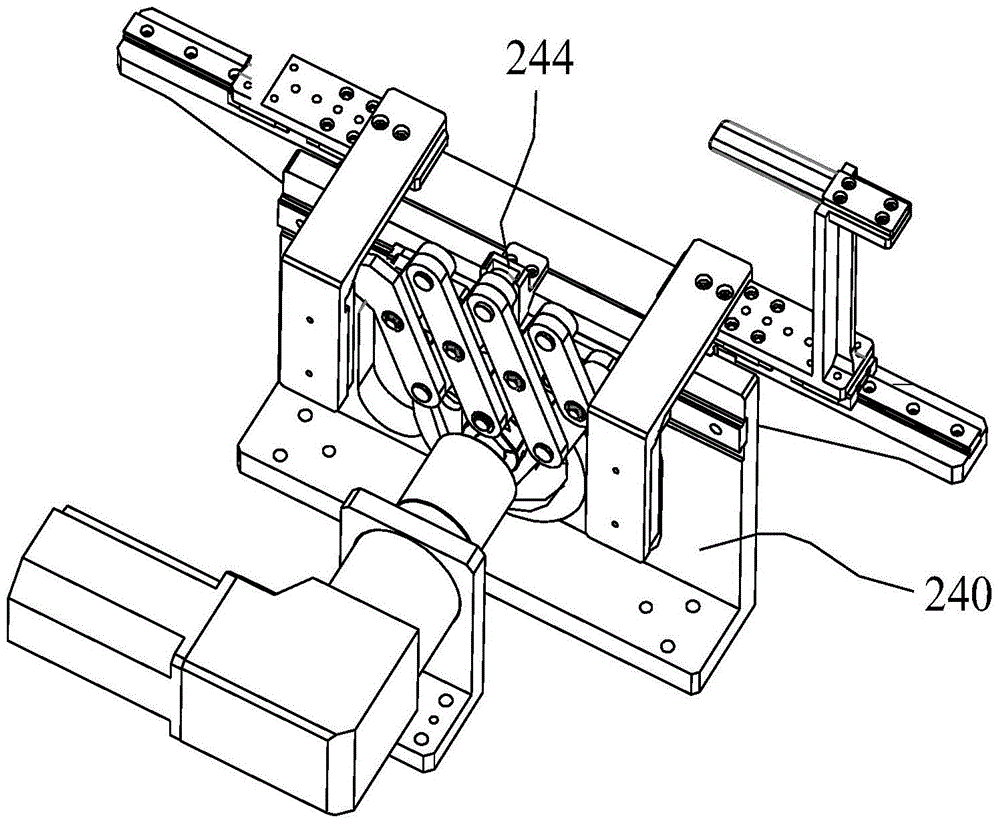

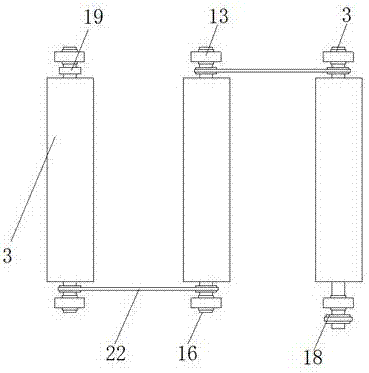

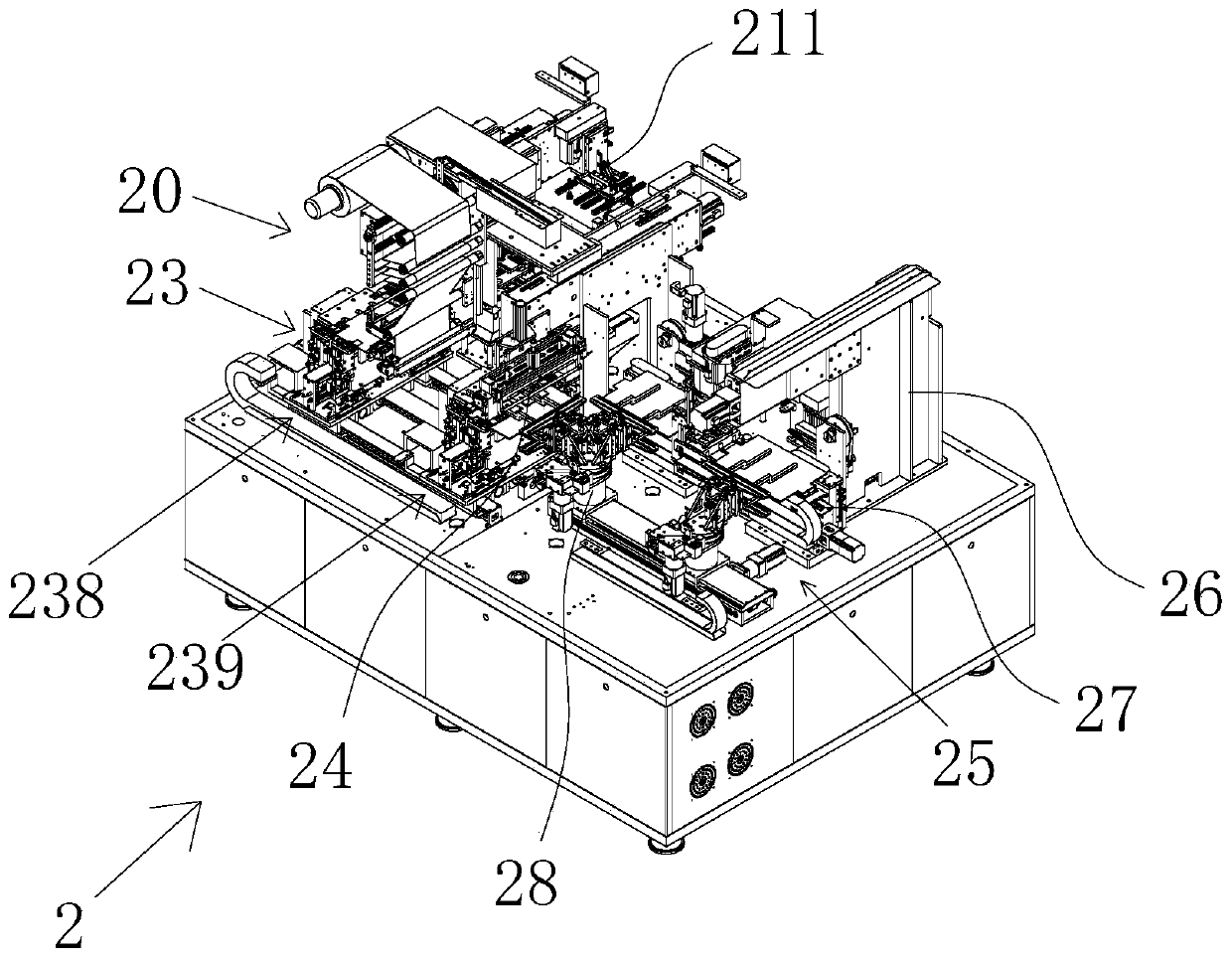

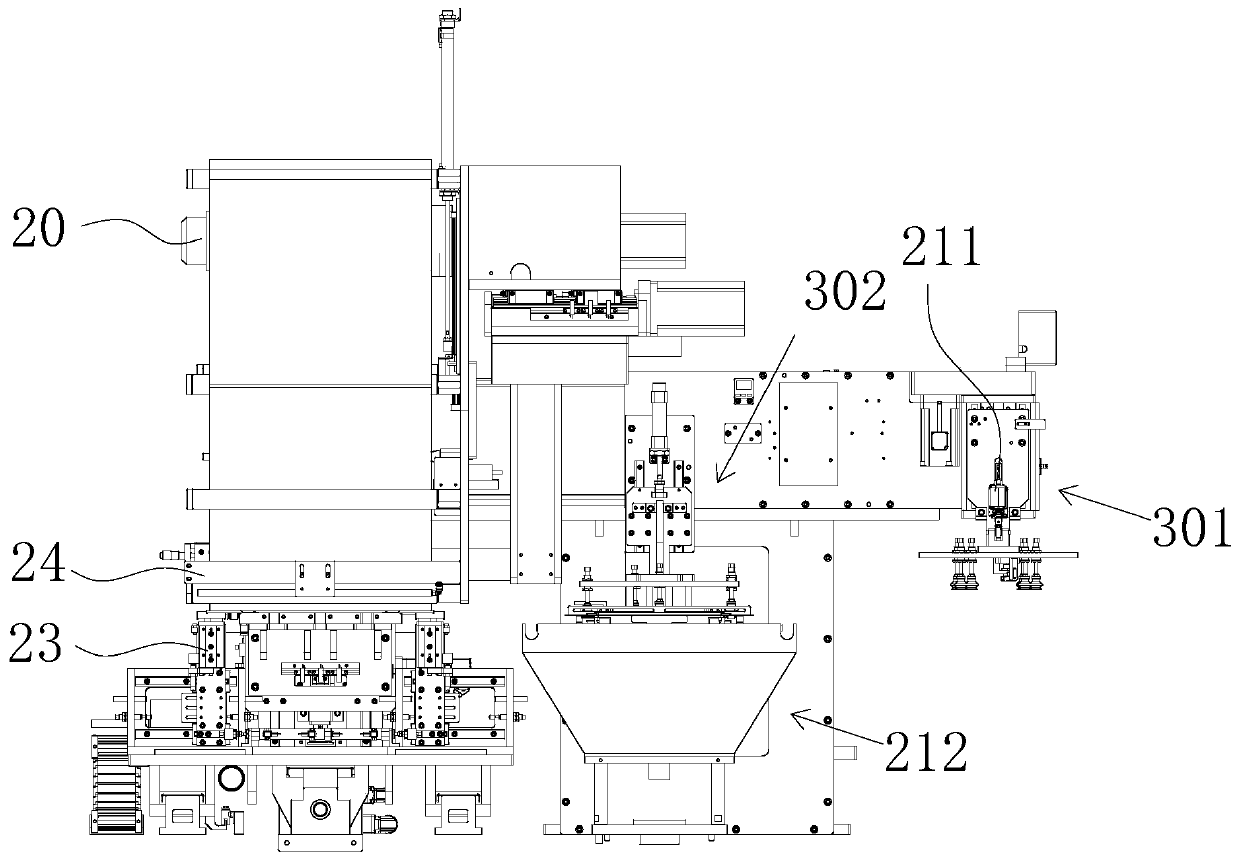

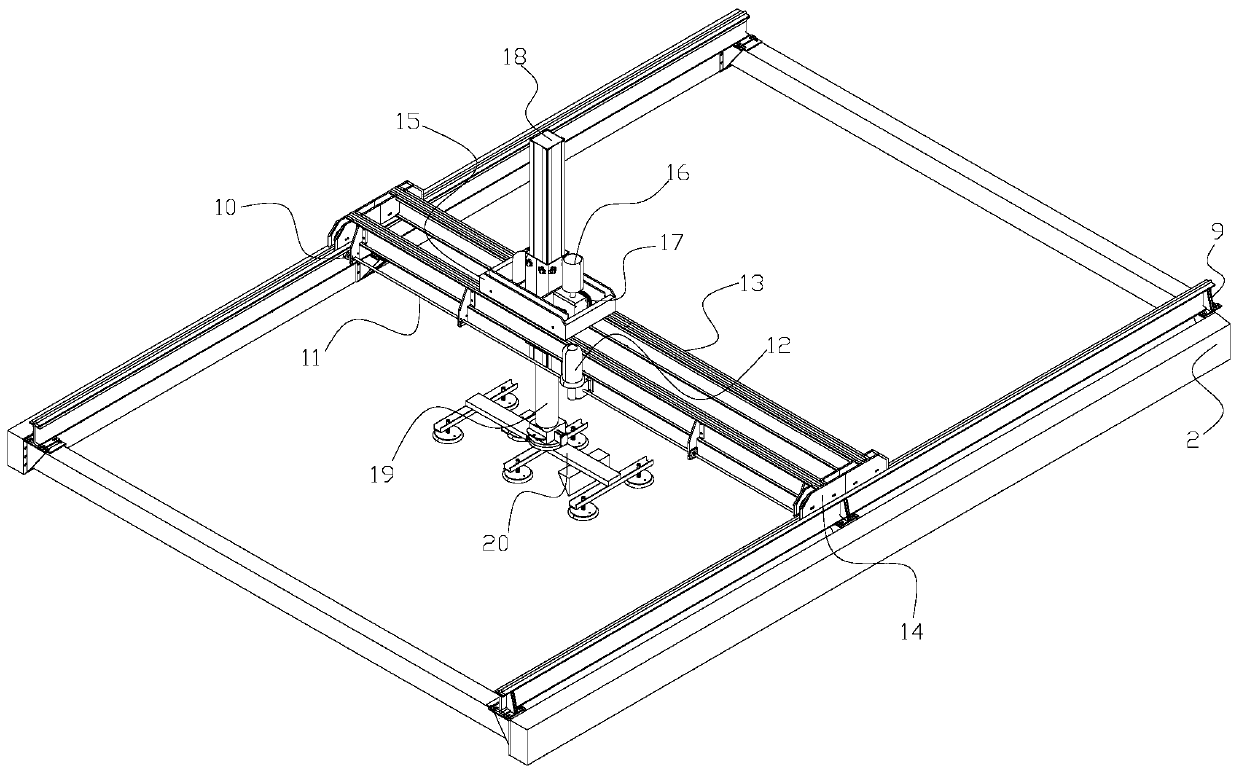

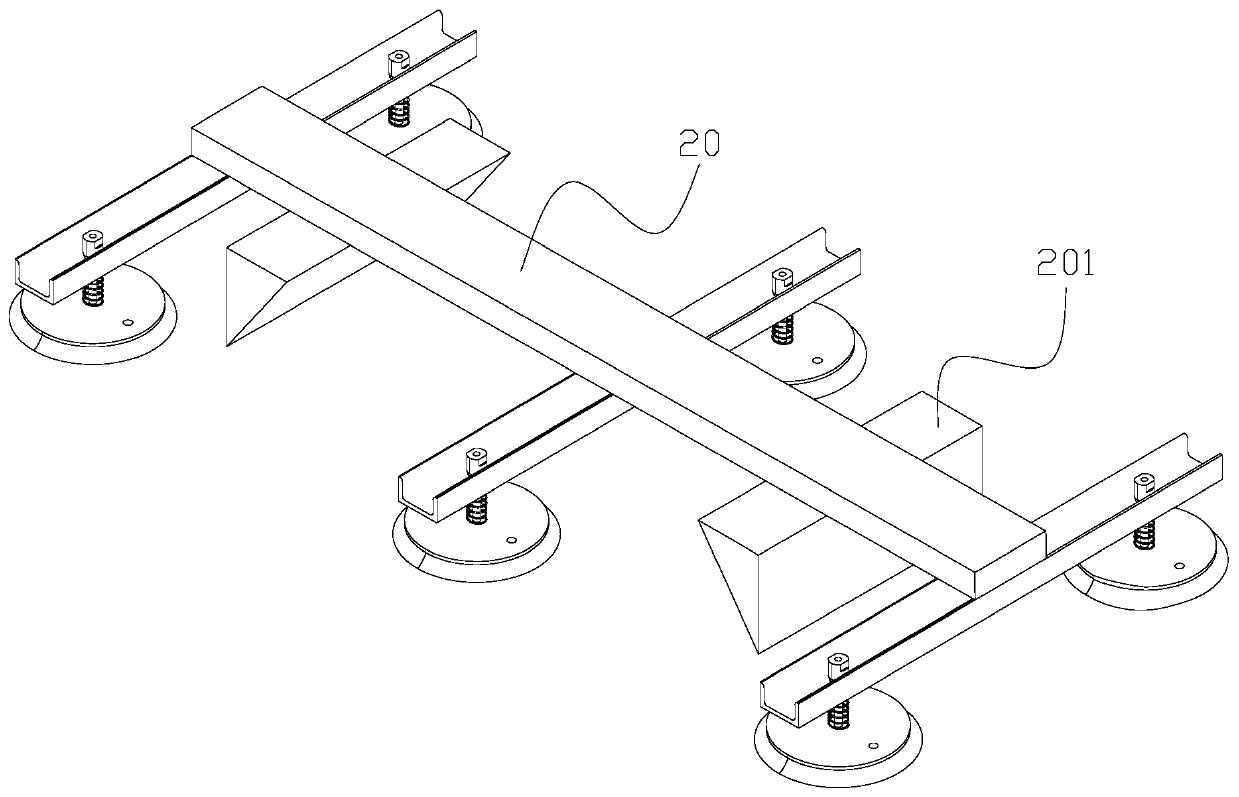

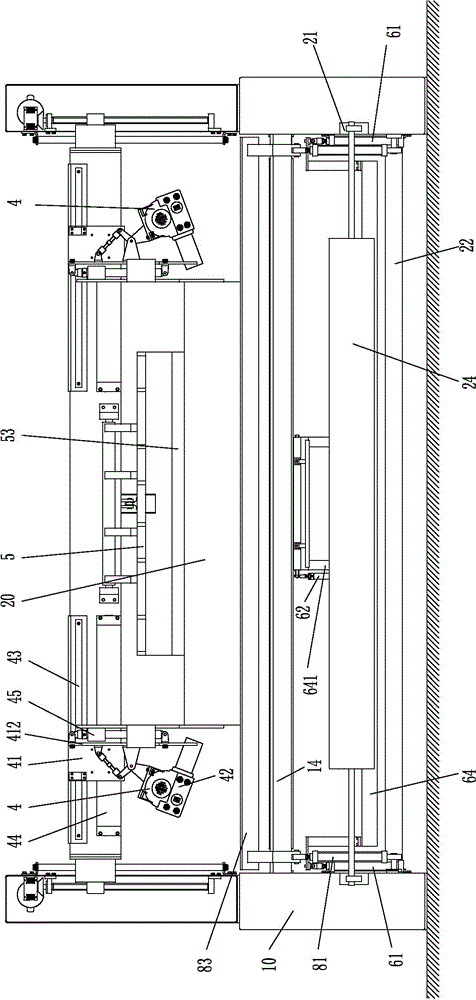

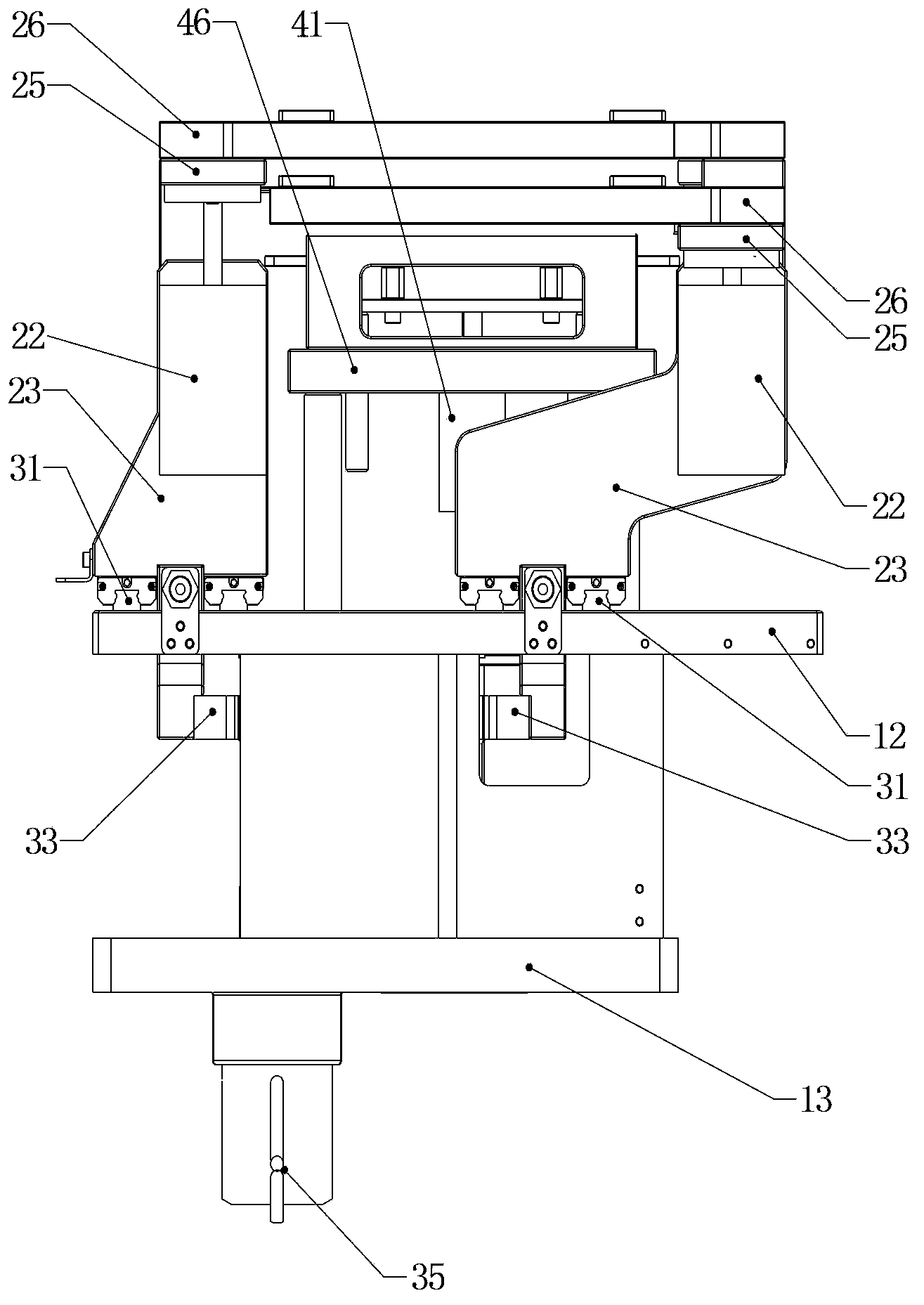

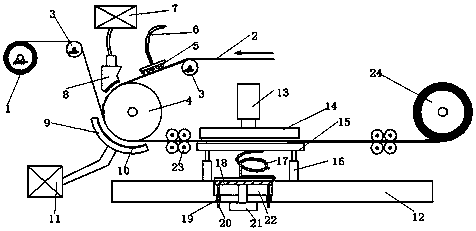

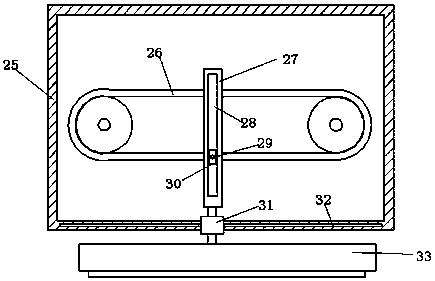

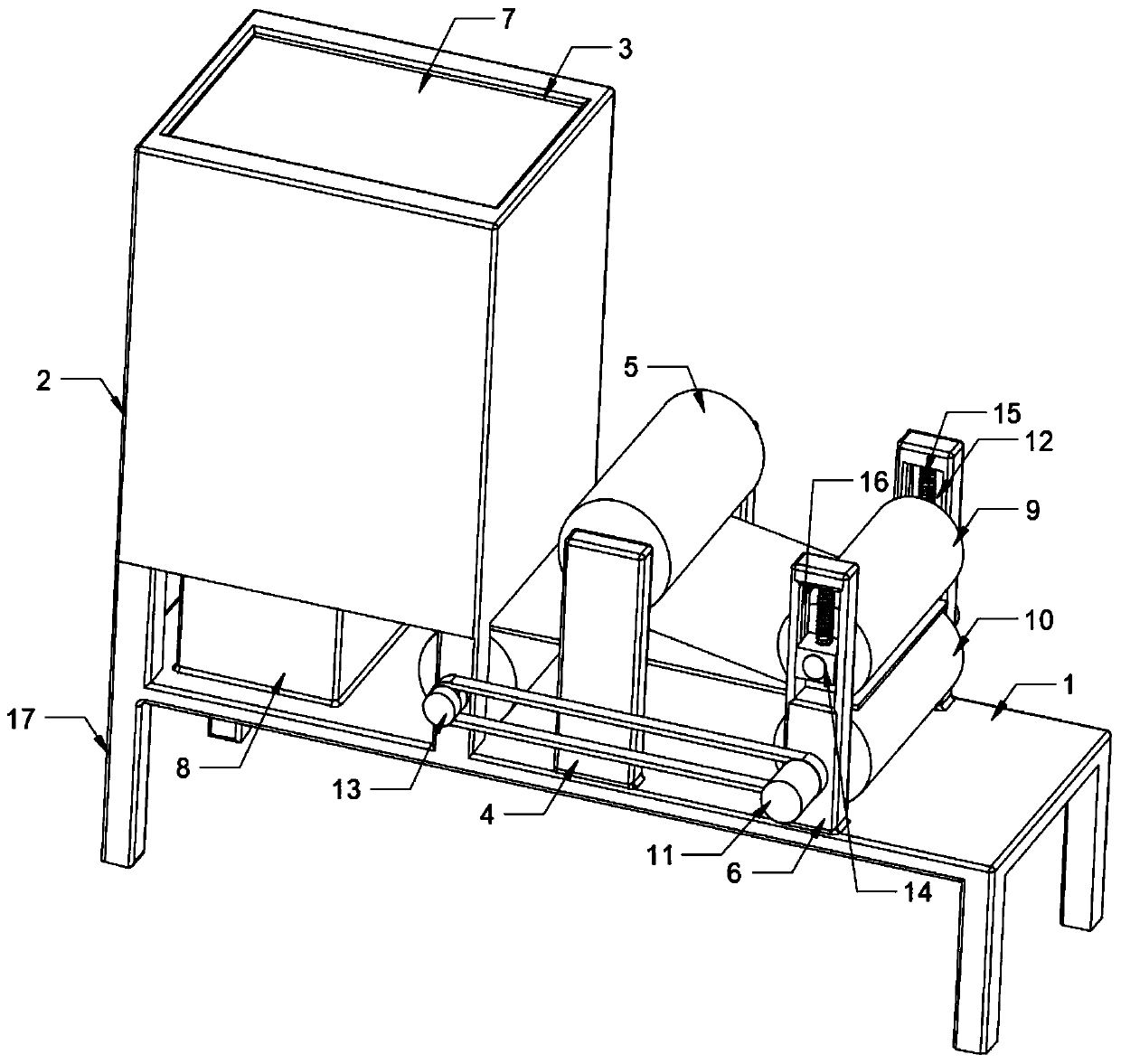

Laminating machine capable of driving film discharging by rotary loading

ActiveCN102709583ARealize reclaimingImprove lamination efficiencyFinal product manufactureSecondary cells manufactureSmall footprintEngineering

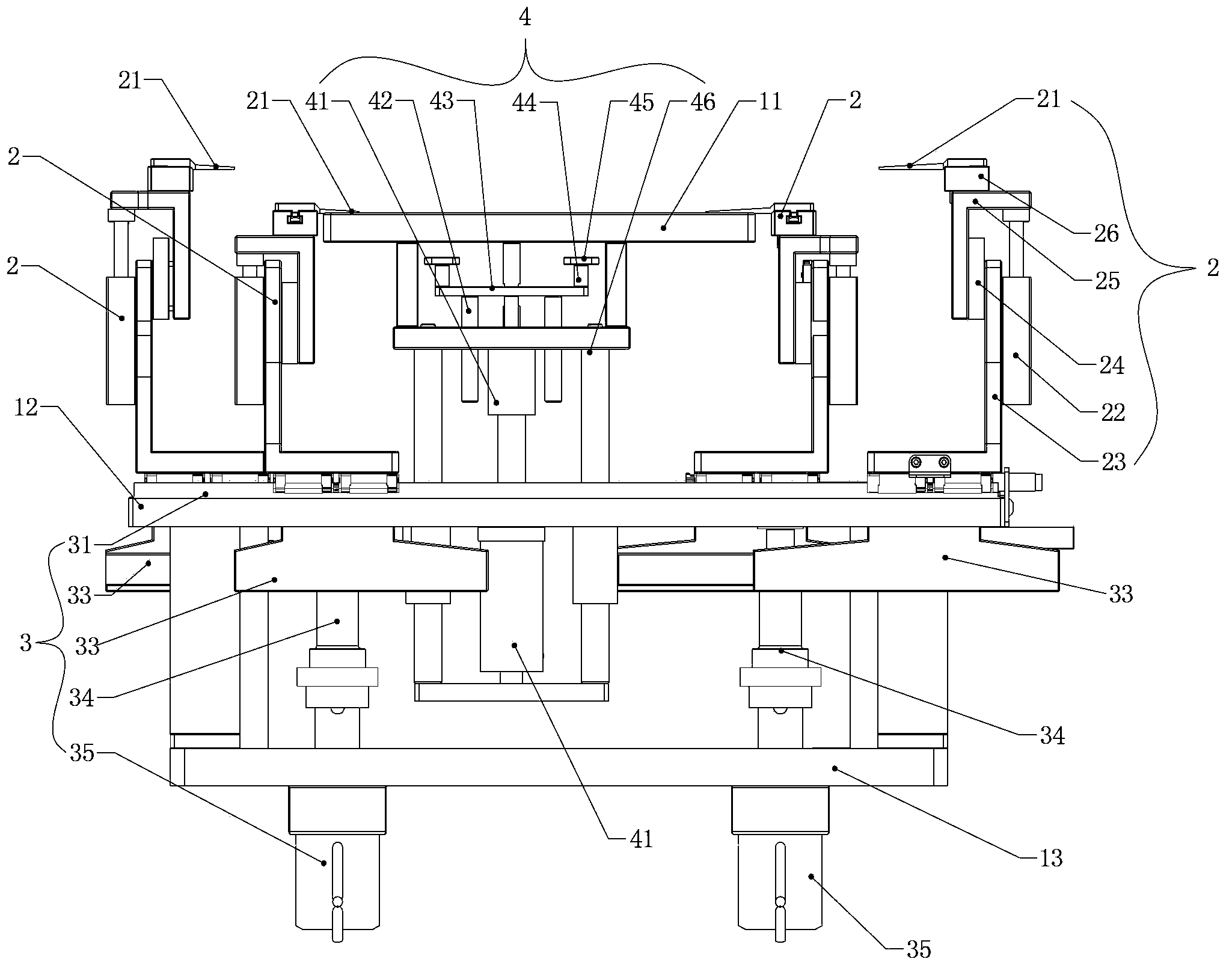

The invention relates to a laminating machine capable of driving film discharging by rotary loading. The laminating machine comprises a rotary loading mechanism, a positive pole piece trough, a positive pole piece calibration console, a negative pole piece trough, a negative pole piece calibration console, a lamination table and a film discharging mechanism, wherein the rotary loading mechanism is used for transferring pole pieces, and a big turntable which rotates in a reciprocating manner and is provided with four feeding arms is arranged at the upper part of the rotary loading mechanism; the positive pole piece trough, the positive pole piece calibration console, the negative pole piece trough, the negative pole piece calibration console and the lamination table are distributed along the periphery of the rotary loading mechanism; and the film discharging mechanism is arranged above the lamination table and driven by the big turntable which rotates in a reciprocating manner. When the big turntable rotates in a reciprocating manner, the two front feeding arms are used for respectively transferring positive pole pieces in the positive pole piece trough and negative pole pieces in the negative pole piece trough into the positive pole piece calibration console and the negative pole piece calibration console to be positioned; and the two rear feeding arms are used for respectively transferring the positioned positive pole pieces in the positive pole piece calibration console and the positioned negative pole pieces in the negative pole piece calibration console onto the lamination table and enabling the positive pole pieces and the negative pole pieces to be sequentially and alternately laminated with repeated Z-shaped films intermittently discharged by the film discharging mechanism. The laminating machine disclosed by the invention is simple in mechanisms for loading, transferring and laminating the positive pole pieces and the negative pole pieces in the circumferential direction, small in motion inertia, more stable in operation, small in occupied area and low in manufacturing cost.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

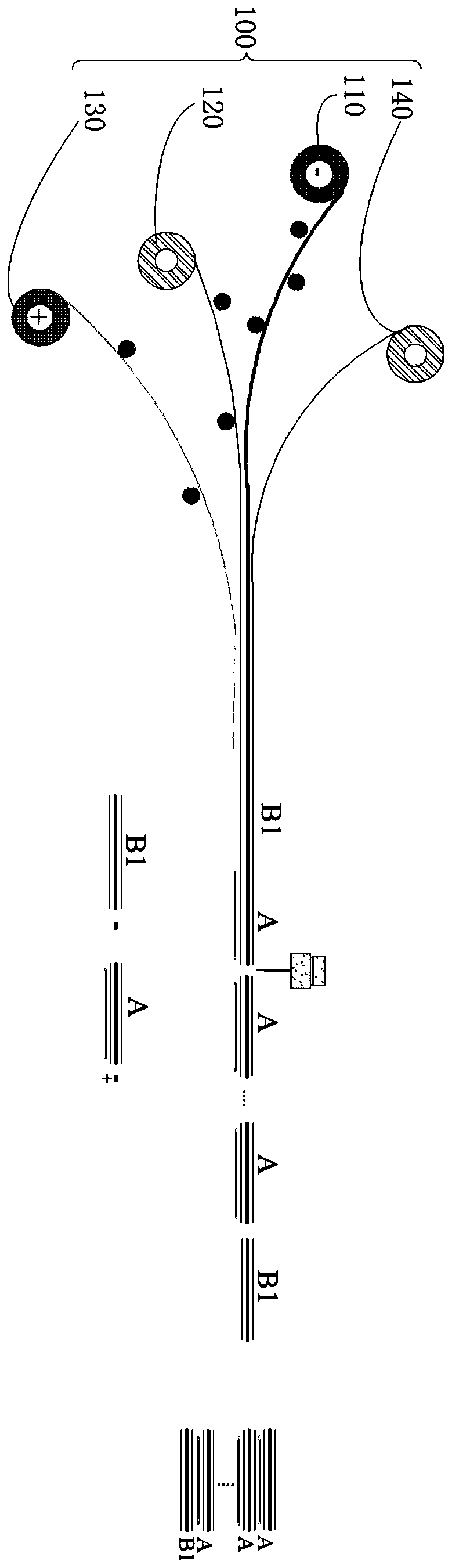

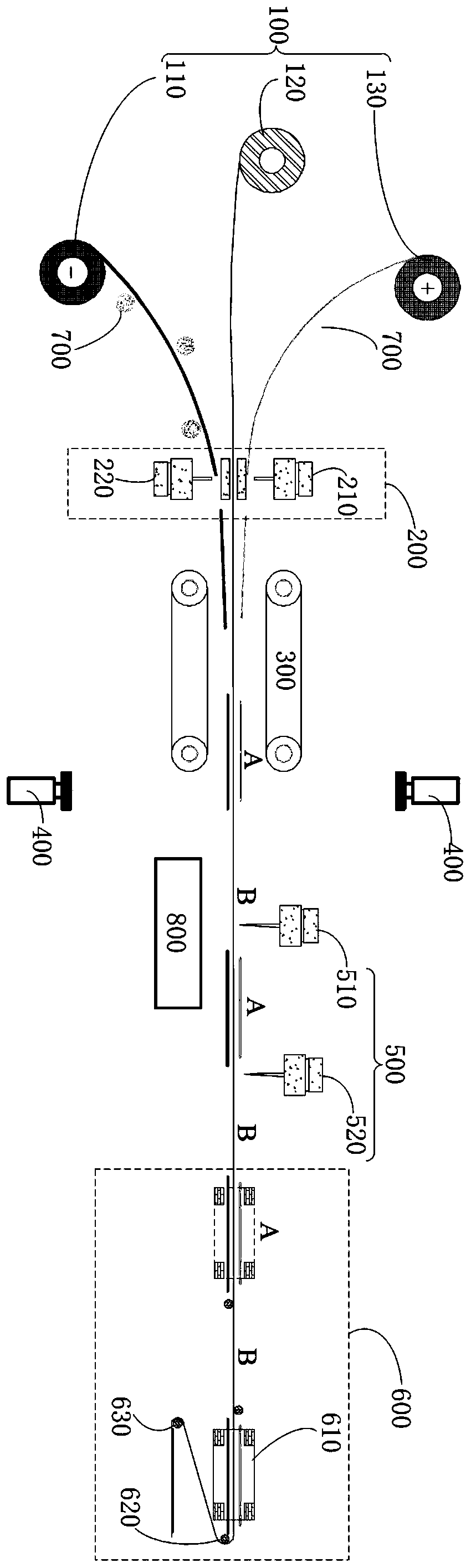

Die-cutting lamination system and method

ActiveCN110380128AEasy alignmentReduce in quantityElectrode rolling/calenderingAssembling battery machinesFailure ratePole piece

The invention provides a die-cutting lamination system and method. The system comprises an unwinding mechanism, a pole roll cutting mechanism, a preheating rolling device, a detection device, a diaphragm cutting mechanism and a lamination device, and is characterized in that a negative pole cutting mechanism is matched with a negative pole unwinding mechanism and cuts a negative pole piece, a positive pole cutting mechanism is matched with a positive pole unwinding mechanism and cuts a positive pole piece, and the lamination of the negative pole piece and the positive pole piece on the upper and lower sides of a diaphragm is obtained; the preheating rolling device enables the positive pole piece and the negative pole piece of the lamination to be adhered to the diaphragm; the detection device detects whether the lamination has a defect or not; a first diaphragm cutting mechanism cuts and discharges defective lamination units in pairs, a second diaphragm cutting mechanism carries out diaphragm cutting on the last qualified lamination unit based on the number of layers of the lamination; and the lamination device enables the positive and negative pole lamination units and diaphragm lamination units to be alternately laminated. The system has the advantages of relatively simple structure, high lamination speed, low failure rate, small number of diaphragm cutting times of the system and low risk of exposing pole pieces by diaphragm folds.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

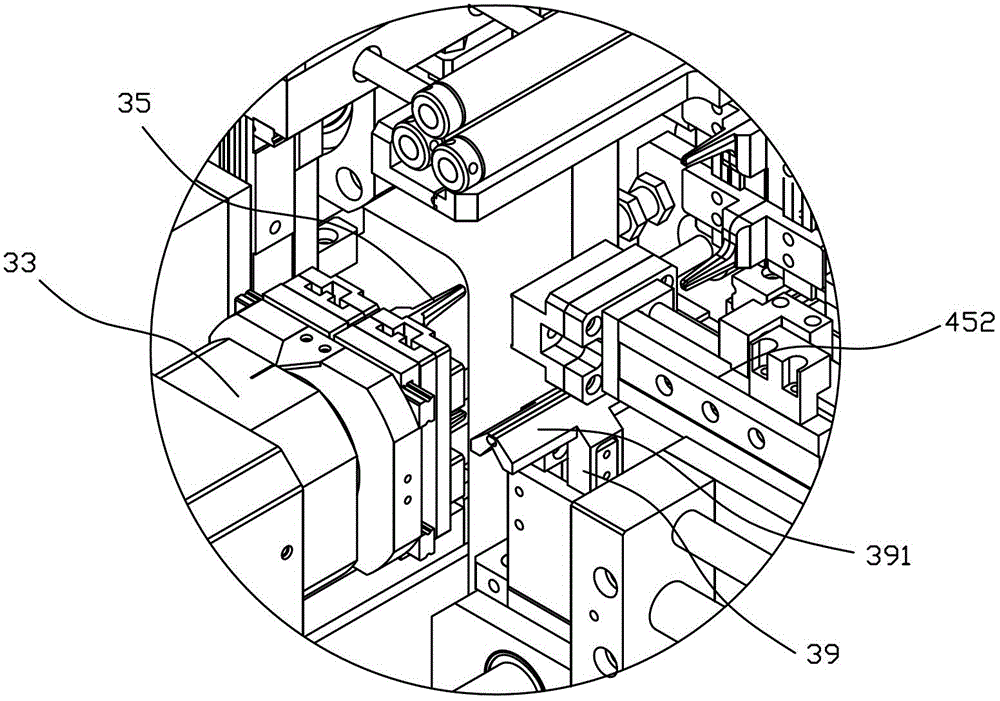

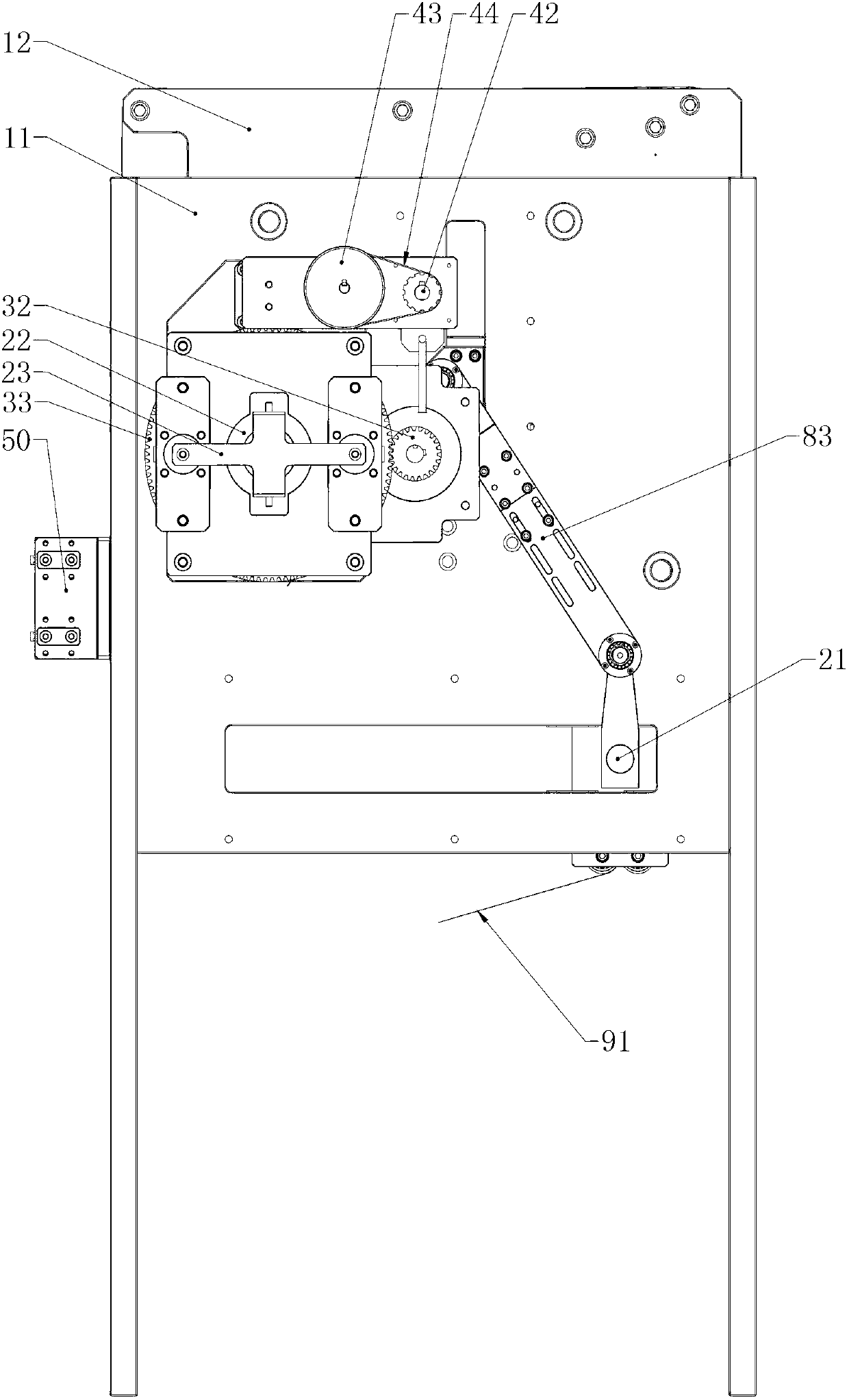

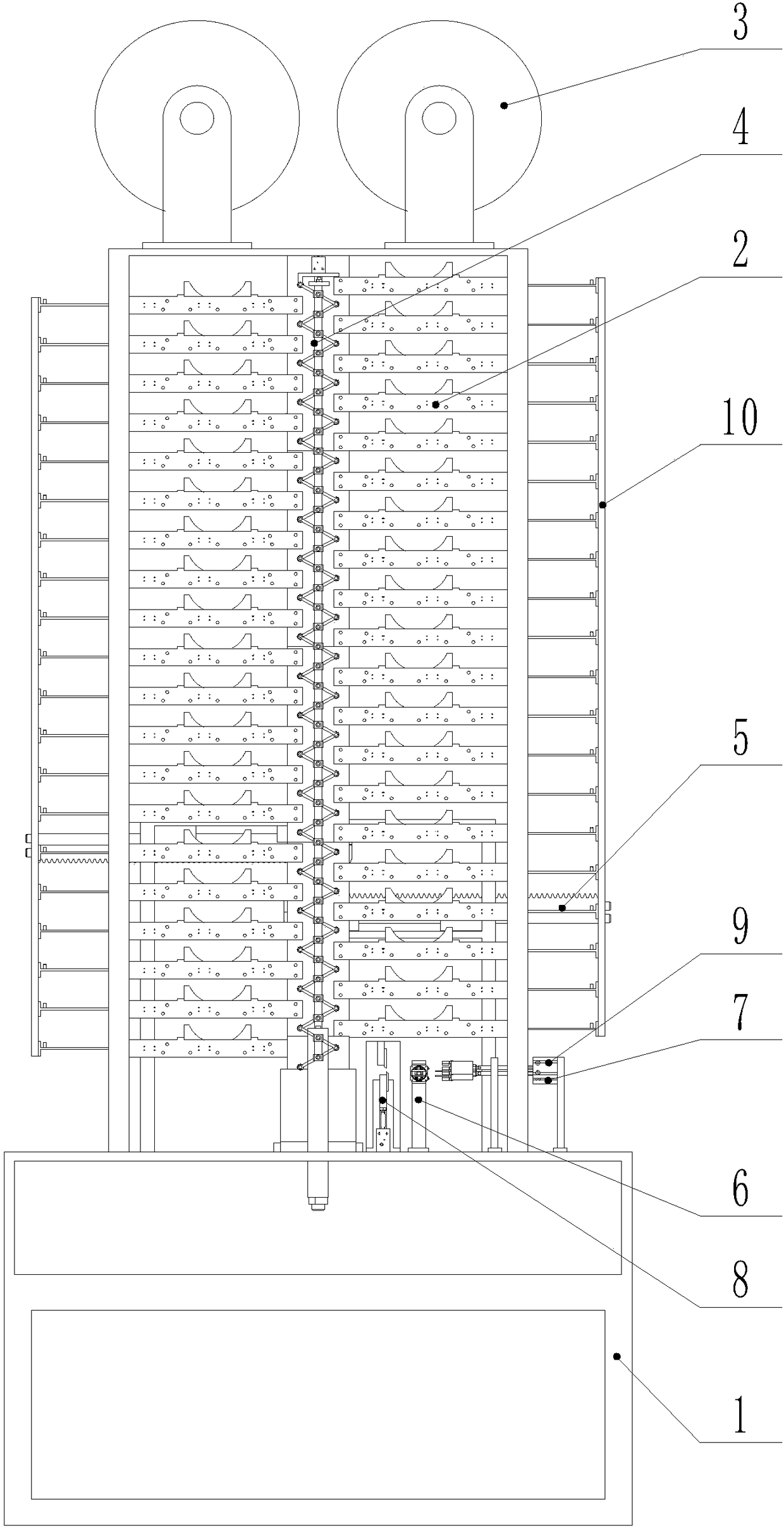

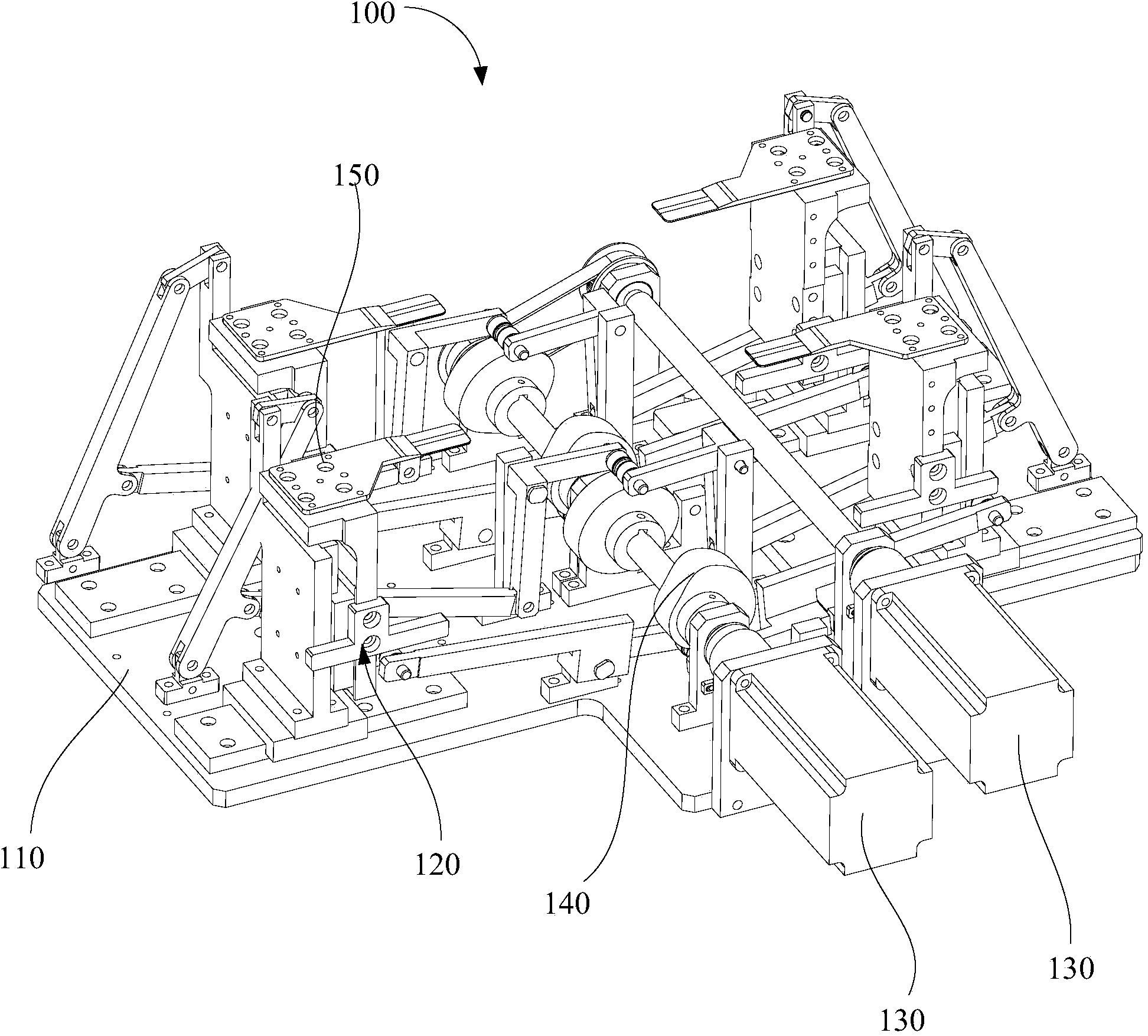

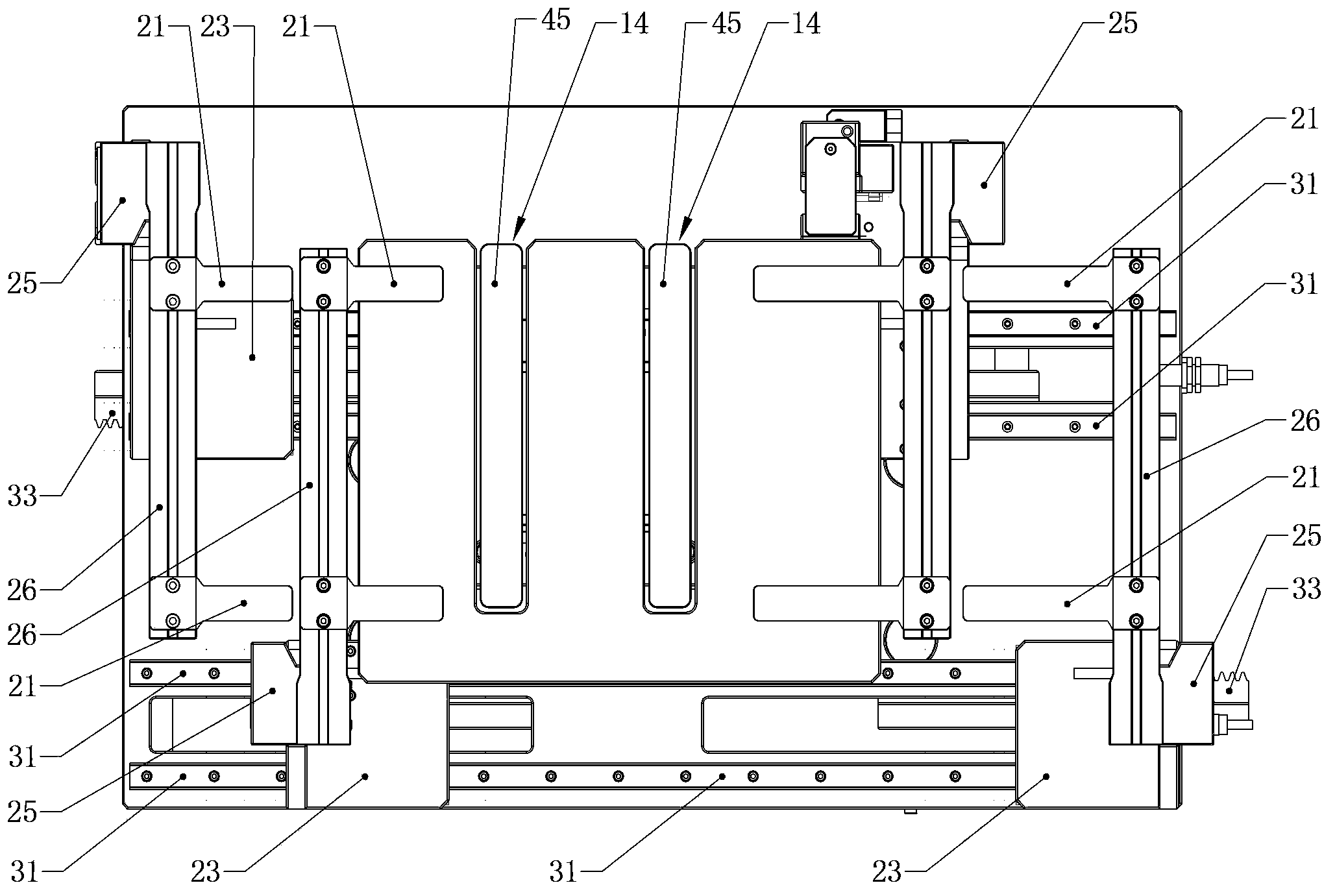

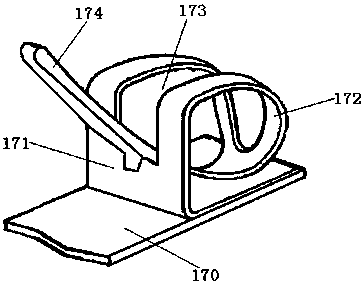

Laminating table device and laminating machine comprising same

ActiveCN104103855AImprove lamination efficiencyAssembling battery machinesFinal product manufactureMotor driveCam

The invention discloses a laminating table device. The device comprises a bearing plate, and pressing pin movable mechanisms fixedly arranged on the bearing plate, wherein each pressing pin movable mechanism comprises a first motor, a first cam, a second cam, a fixing base, a lifting plate, two pressing pin components and a stretching component; during the operation of the laminating table device, as the first motor drives the first cam and the second cam to rotate, the first cam drives the lifting plate to lift, and the lifting plate drives the two pressing pin components to lift, at the same time, the second cam drives a flexible component to open, and the flexible component drives the two pressing pin components to open relatively; when the first cam drives the lifting plate to descend, the lifting plate drives the two pressing pin components to descend, and at the same time, the second cam drives the flexible component to fold, and the flexible component drives the two pressing pin components to move towards each other. According to the laminating table device, through using one first motor only, the opening-closing and the lifting motions of the pressing pin components are controlled at the same time, the laminating efficiency is improved greatly, and moreover, the invention further provides a laminating machine comprising the laminating table device.

Owner:GEESUN AUTOMATION TECH

Laminating device with double laminating tables and laminating method thereof

PendingCN110416592ARealize rotation switchingShorten the blanking timeAssembling battery machinesFinal product manufactureEngineeringElectrical and Electronics engineering

The invention discloses a laminating device with double laminating tables and a laminating method thereof and relates to the technical field of battery production equipment. The laminating device comprises positive electrode sheet feeding mechanisms, negative electrode sheet feeding mechanisms, diaphragm unwinding mechanisms and double-laminating-table mechanisms. The positive electrode sheet feeding mechanisms and the negative electrode sheet feeding mechanisms are disposed on left and right sides of the double-laminating-table mechanisms to provide positive and negative electrode sheets to the double-laminating-table mechanisms. The diaphragm unwinding mechanisms are above the double-laminating-table mechanisms and are used for providing diaphragms clamped between the positive and negative electrode sheets to the two double-laminating-table mechanisms. The double-laminating-table mechanisms comprise rotating shafts, rotating arms, central rotating shafts, first laminating tables andsecond laminating tables. The device has the advantages that the device can achieve uninterrupted lamination operation, the blanking time is greatly saved, and the working efficiency of the device isimproved.

Owner:SHENZHEN GREENSUN TECH CO LTD

Laminating device used for identifying labels and operation method of laminating device

The invention discloses a laminating device used for identifying labels. The laminating device comprises a control console, a guide roller, bushings, transmission rollers, a motor, a top plate, an adjusting plate and a press roller and is characterized in that the operating console is arranged on a support, a bearing plate is arranged on the support, limit slots are arranged in vertical plates, the guide roller is arranged between fixing plates through a connecting shaft, the bushings are arranged in the corresponding limit slots, the connecting shafts are arranged at two ends of the transmission rollers, the motor is arranged on the bearing plate, the top plate is arranged on uprights, an air cylinder is arranged on the top plate, the adjusting plate is arranged on a piston rod, a positioning plate is arranged on the adjusting plate, and the press roller is arranged between positioning plates through the connecting shafts. The guide roller is arranged between the fixing plates, partition plates are arranged on the guide roller and can prevent a thin film skewing on the guide roller, and laminating quality in identifying the labels is improved.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

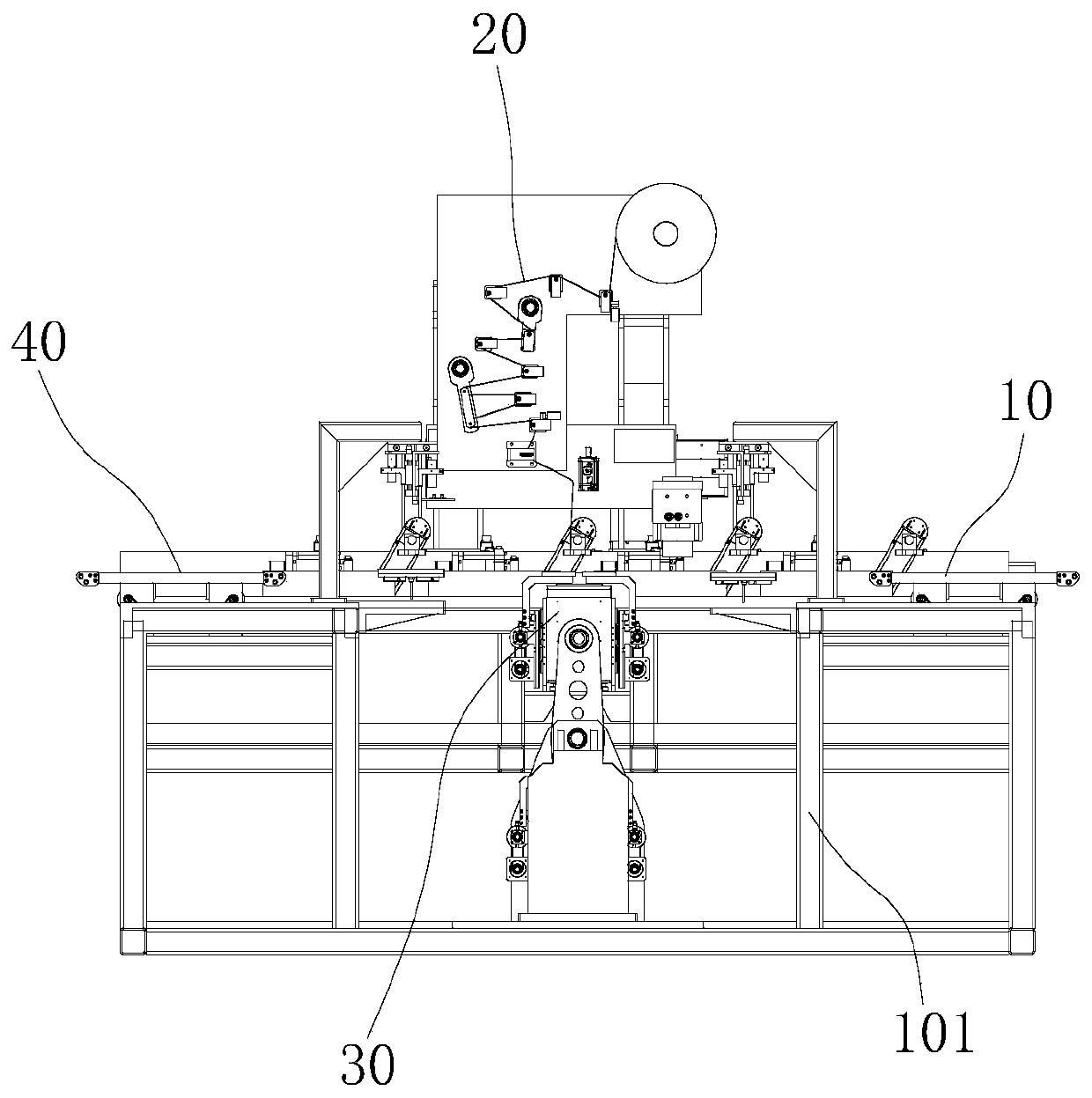

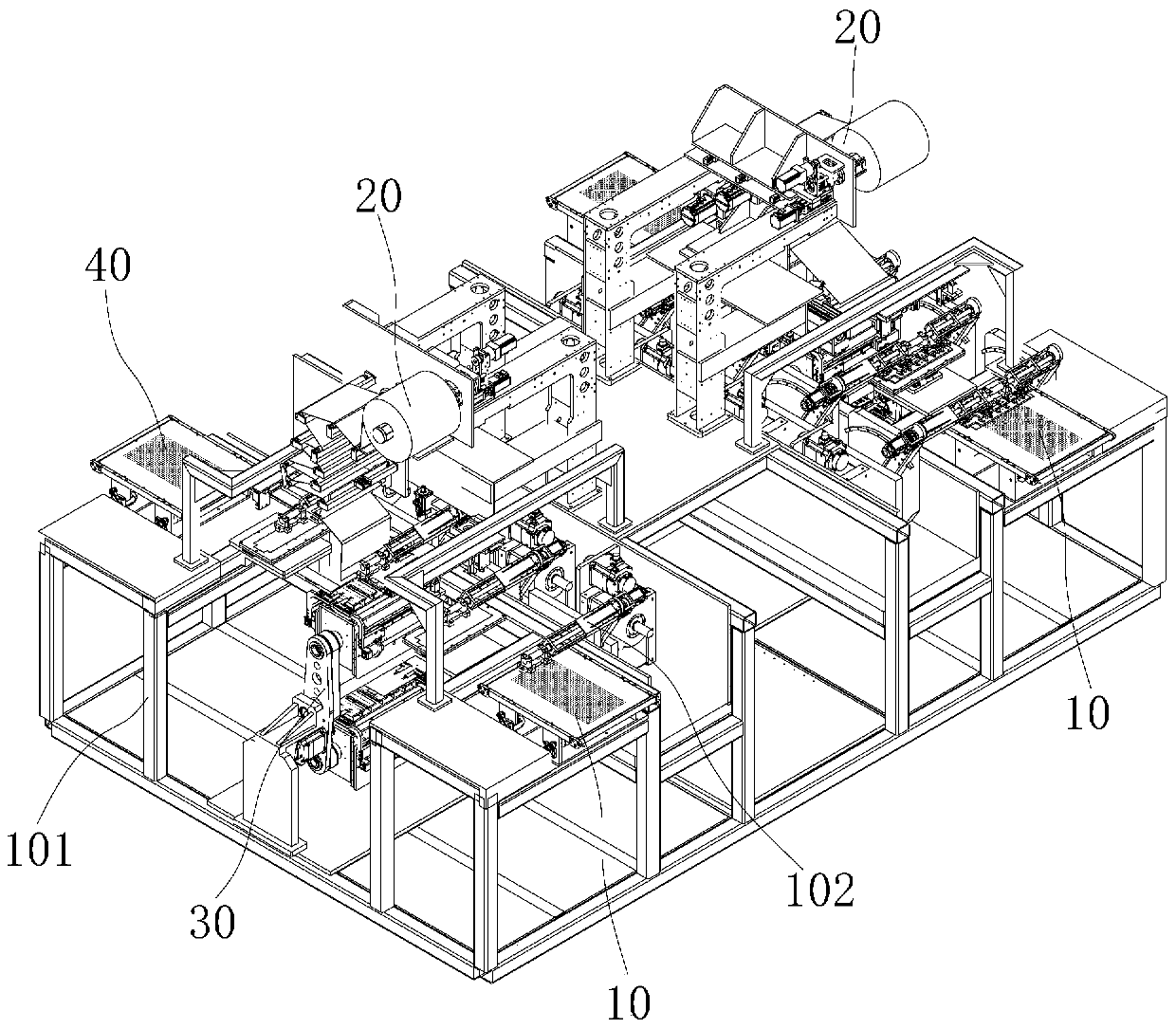

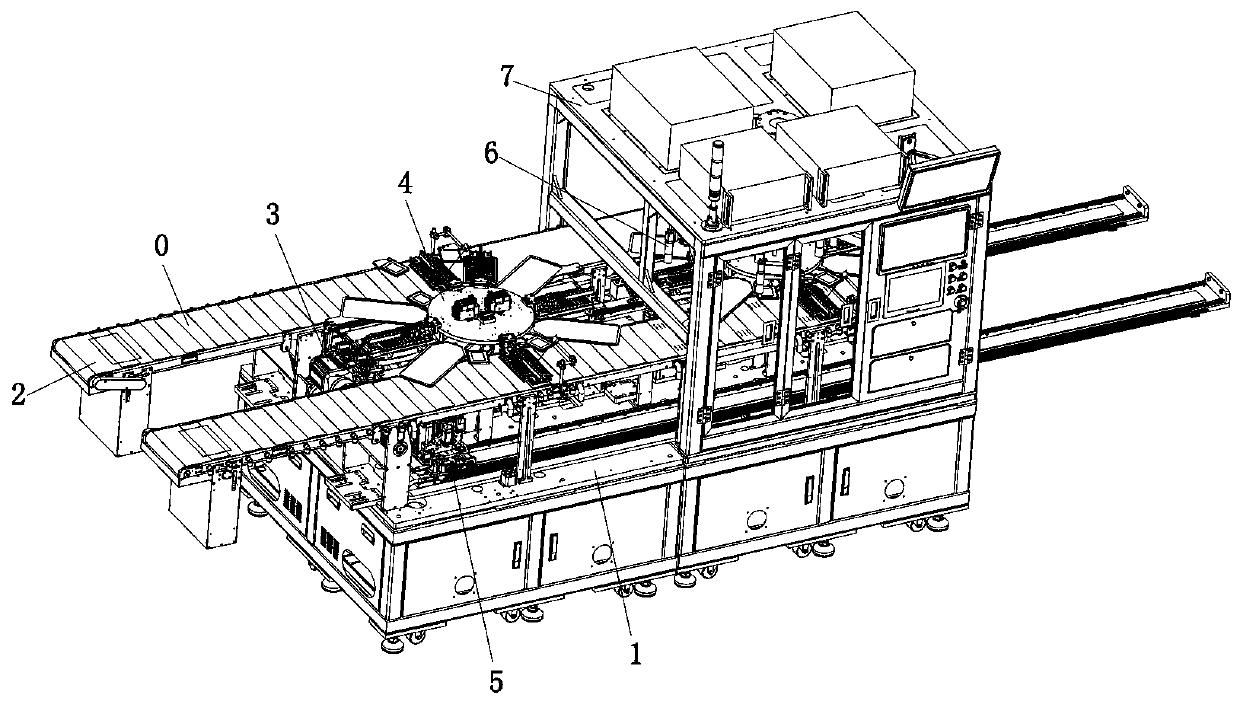

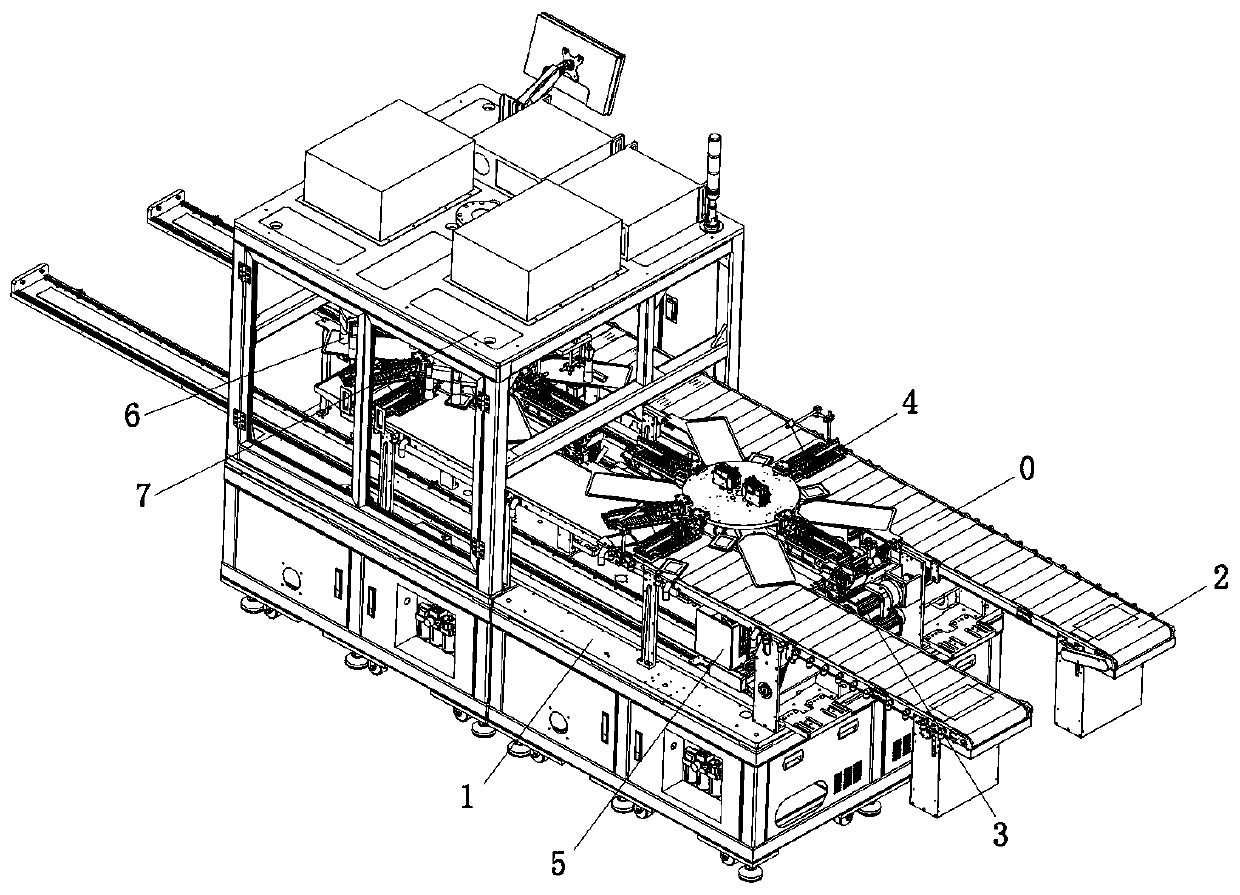

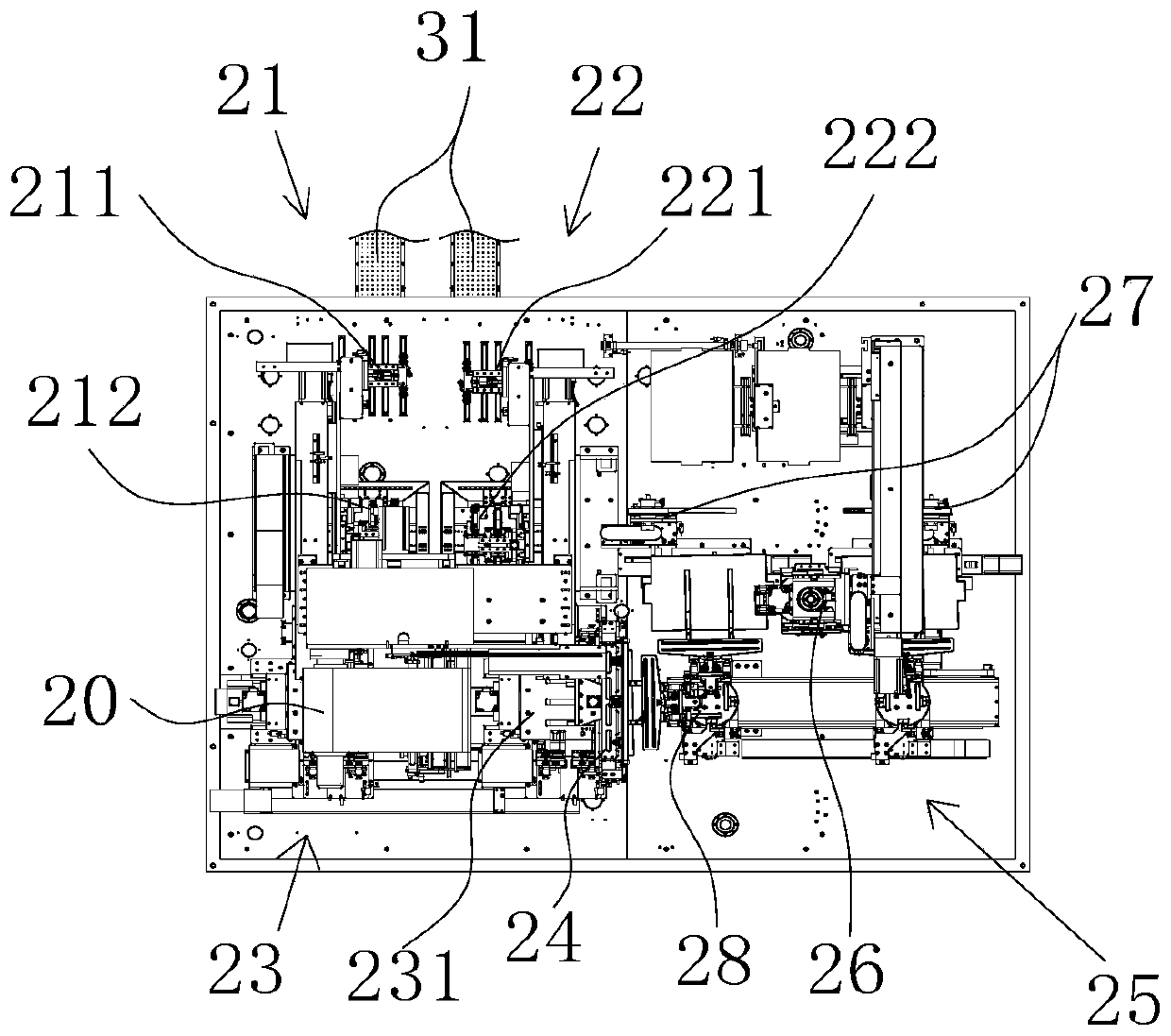

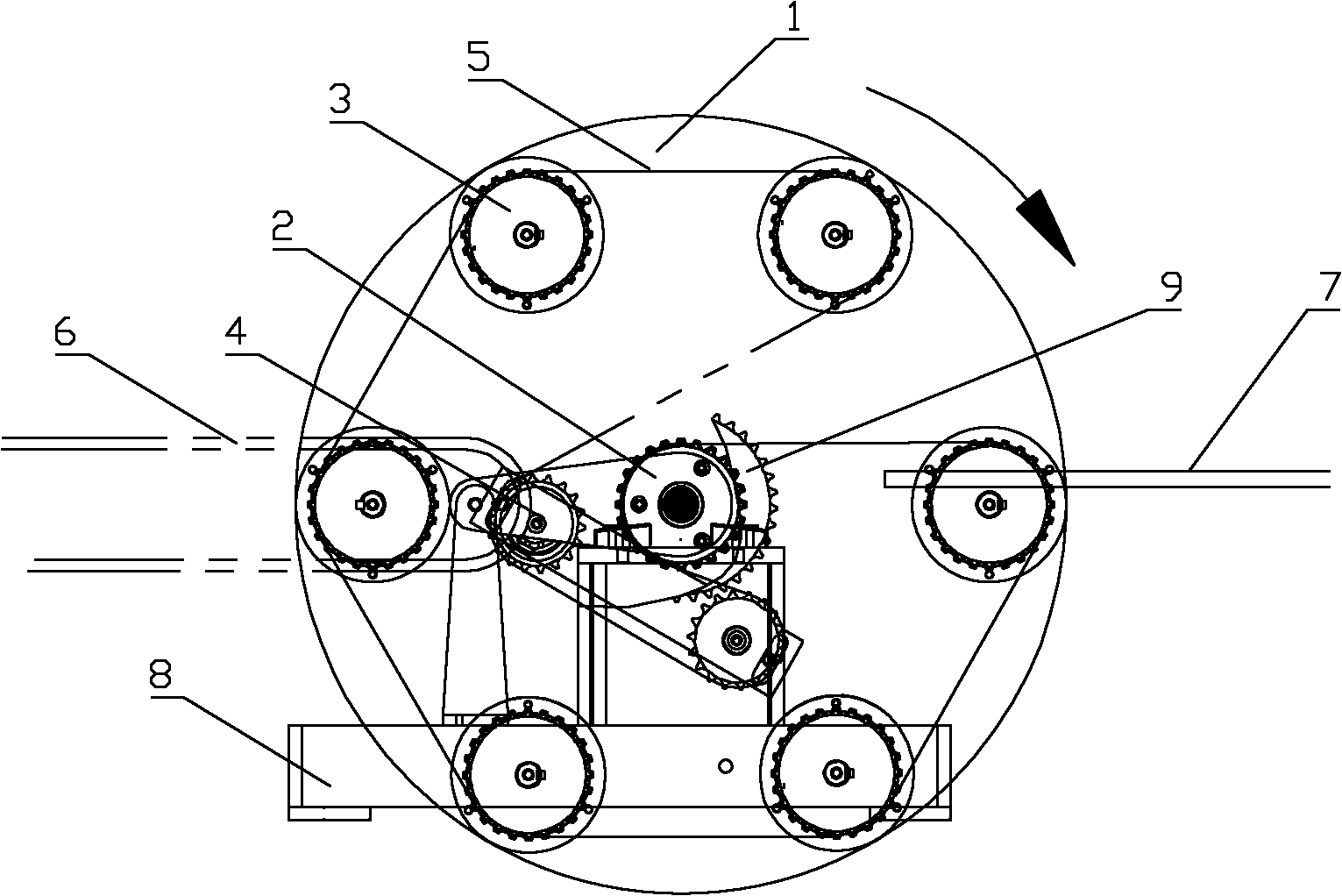

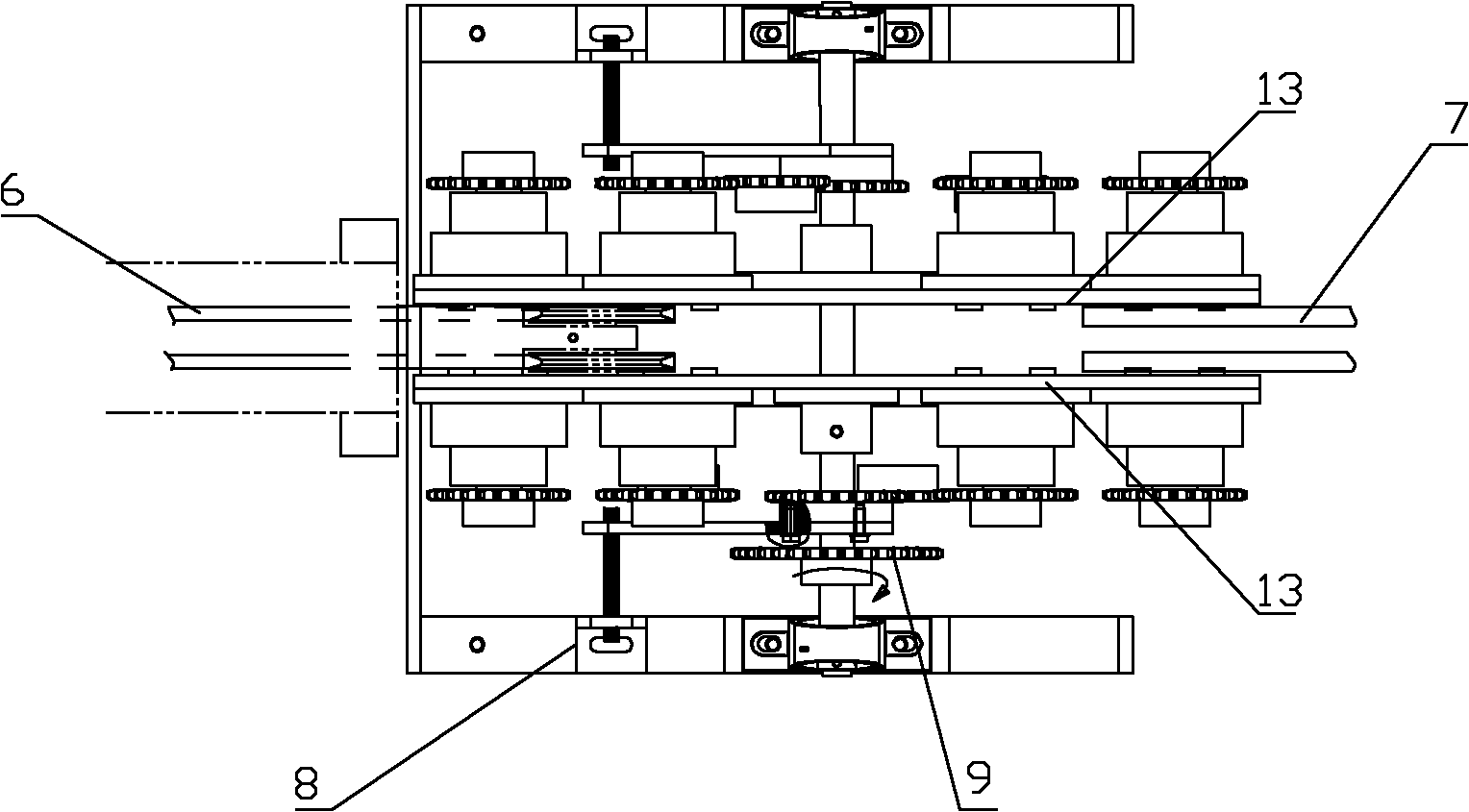

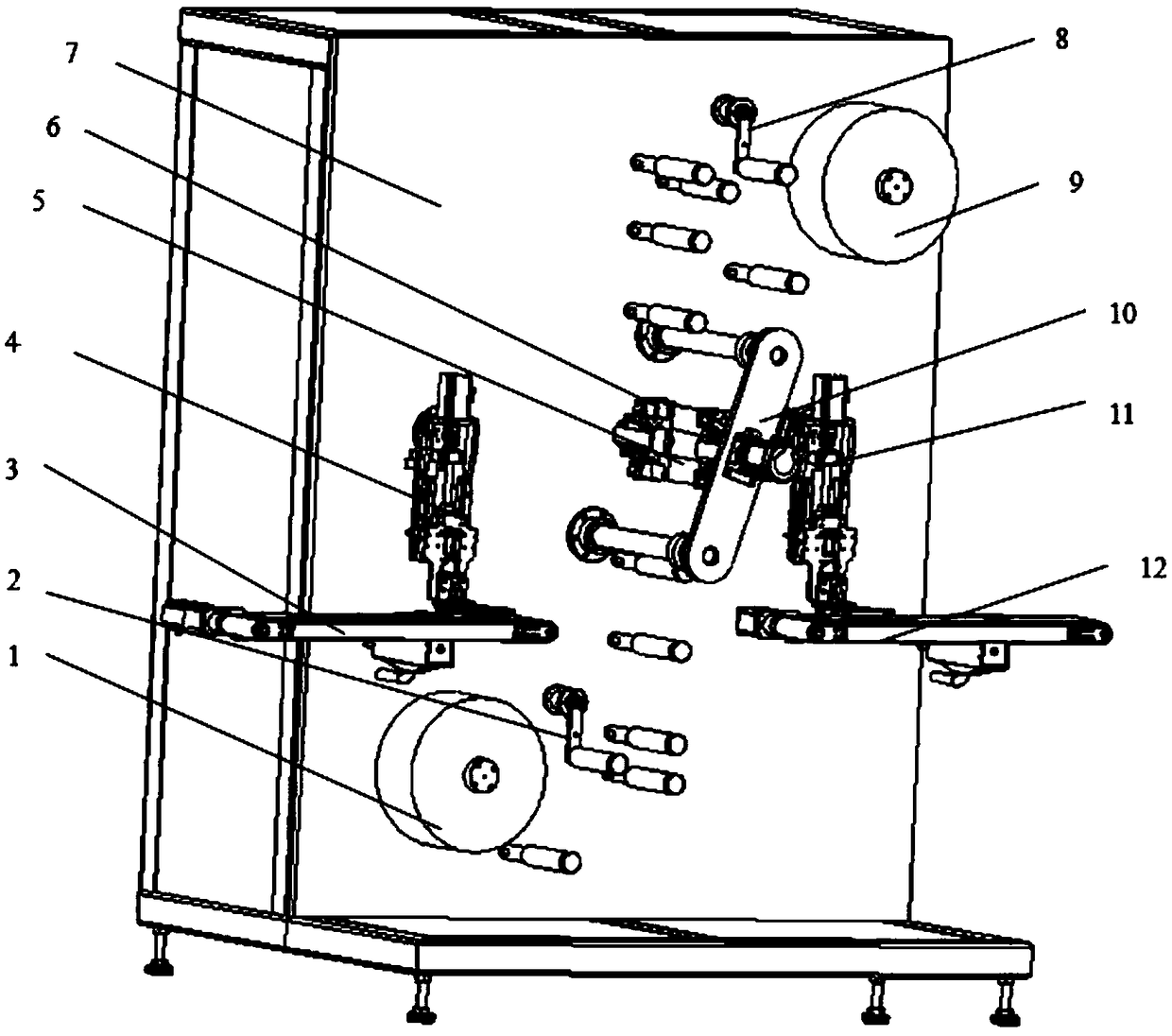

Turret type automatic lamination production line and lamination process thereof

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Electrical appliance panel laminating device

PendingCN108910140AAchieve non-foamingImprove lamination efficiencyPackagingEngineeringElectrical equipment

The invention discloses an electrical appliance panel laminating device comprising a working table. The top of the working table is provided with a guide conveying mechanism, and a film unwinding mechanism is arranged above the left side of the guide conveying mechanism; a film flattening mechanism is arranged below the right side of the film unwinding mechanism, and a panel cleaning mechanism isarranged below the film flattening mechanism; and the right side of the panel cleaning mechanism is provided with a film laminating mechanism of which the right side is provided with a lamination leveling mechanism, and the right side of the lamination leveling mechanism is provided with a locating trimming mechanism. According to the electrical appliance panel laminating device, a film can be flat attached to the surface of an electrical appliance panel, and the effects of no bubbles, wrinkles or floating are achieved; the whole process is automatic, and the laminating efficiency is high; andthe improvement of the production efficiency is benefited.

Owner:浙江龙泰电器科技有限公司

Laminating device and integrated die laminating device

PendingCN110492181AQuality improvementReduce defective rateFinal product manufactureSecondary cellsUltimate tensile strengthMechanical engineering

The invention discloses a laminating device. The laminating device comprises a diaphragm conveying mechanism for discharging and conveying rolled diaphragms; a positive electrode feeding mechanism which is used for continuously conveying single positive electrode plates; a negative electrode feeding mechanism which is used for continuously conveying single negative electrode plates; a laminating mechanism which reciprocates between the positive electrode feeding mechanism and the negative electrode feeding mechanism and receives the diaphragms, the positive electrode plates and the negative electrode plates, so that the diaphragms are pressed on the laminating mechanism and then move along with the laminating mechanism to form a Z-shaped diaphragm, wherein the positive electrode plates andthe negative electrode plates are alternately laminated on the Z-shaped diaphragm to form a Z-shaped laminated sheet; a diaphragm cutting mechanism which is used for cutting off the diaphragm supplyof the diaphragm conveying mechanism to the laminating mechanism after the laminating mechanism finishes laminating; and a rubberizing mechanism which is used for rubberizing the Z-shaped laminated sheet to form a battery cell. The defects of low speed and high labor intensity of manual feeding are overcome, the production cost is reduced, the lamination efficiency is improved, and modern automatic production integrated with die cutting and lamination is realized.

Owner:哈工大机器人(中山)无人装备与人工智能研究院

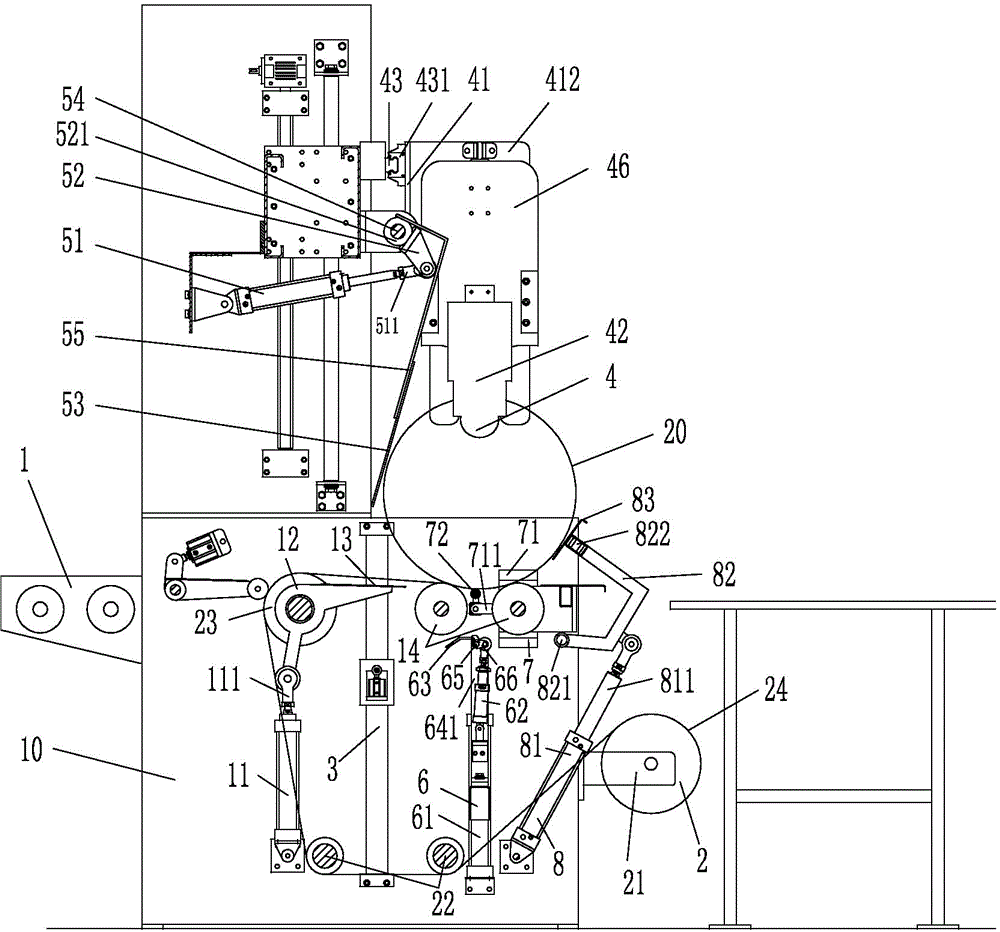

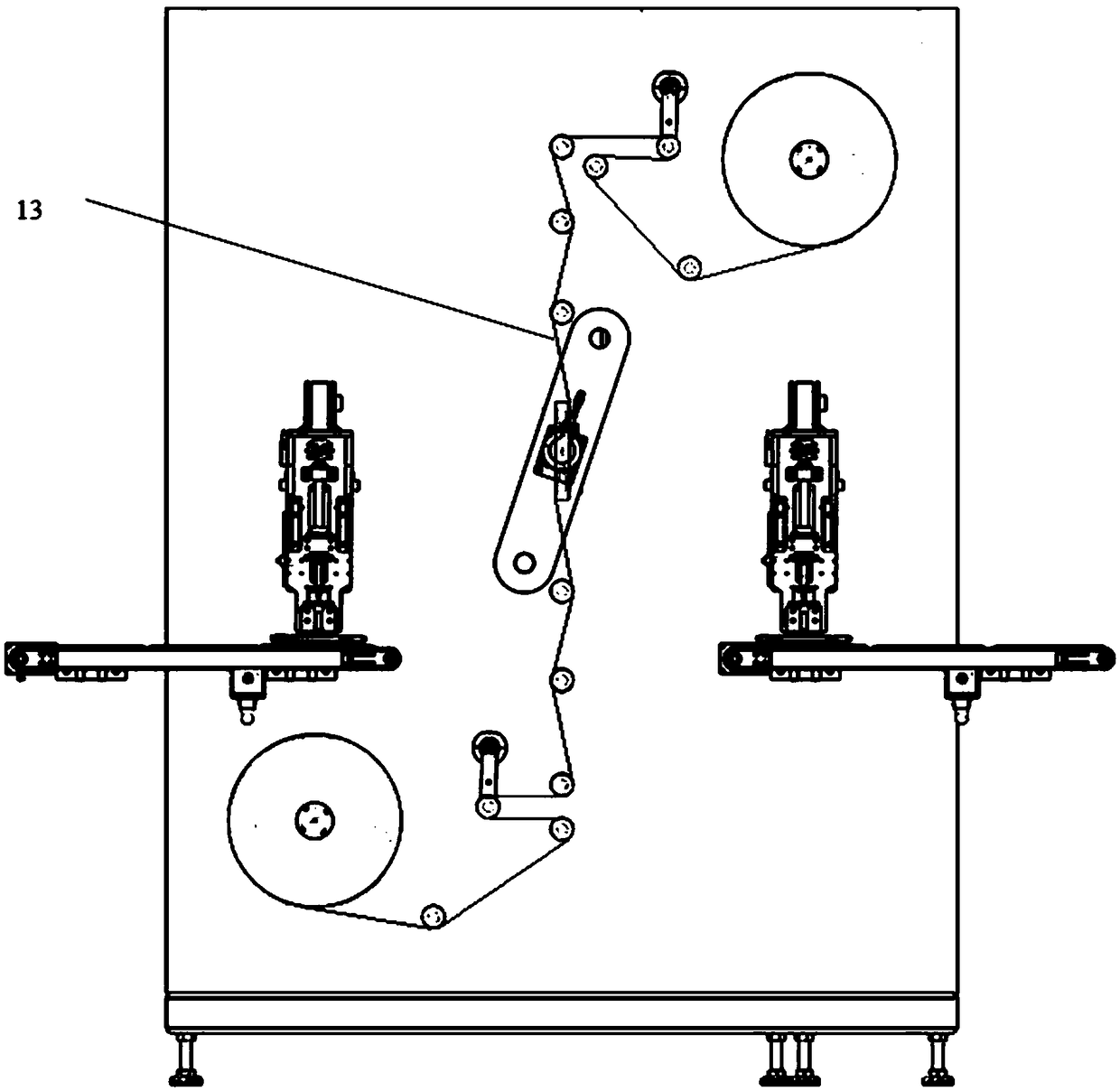

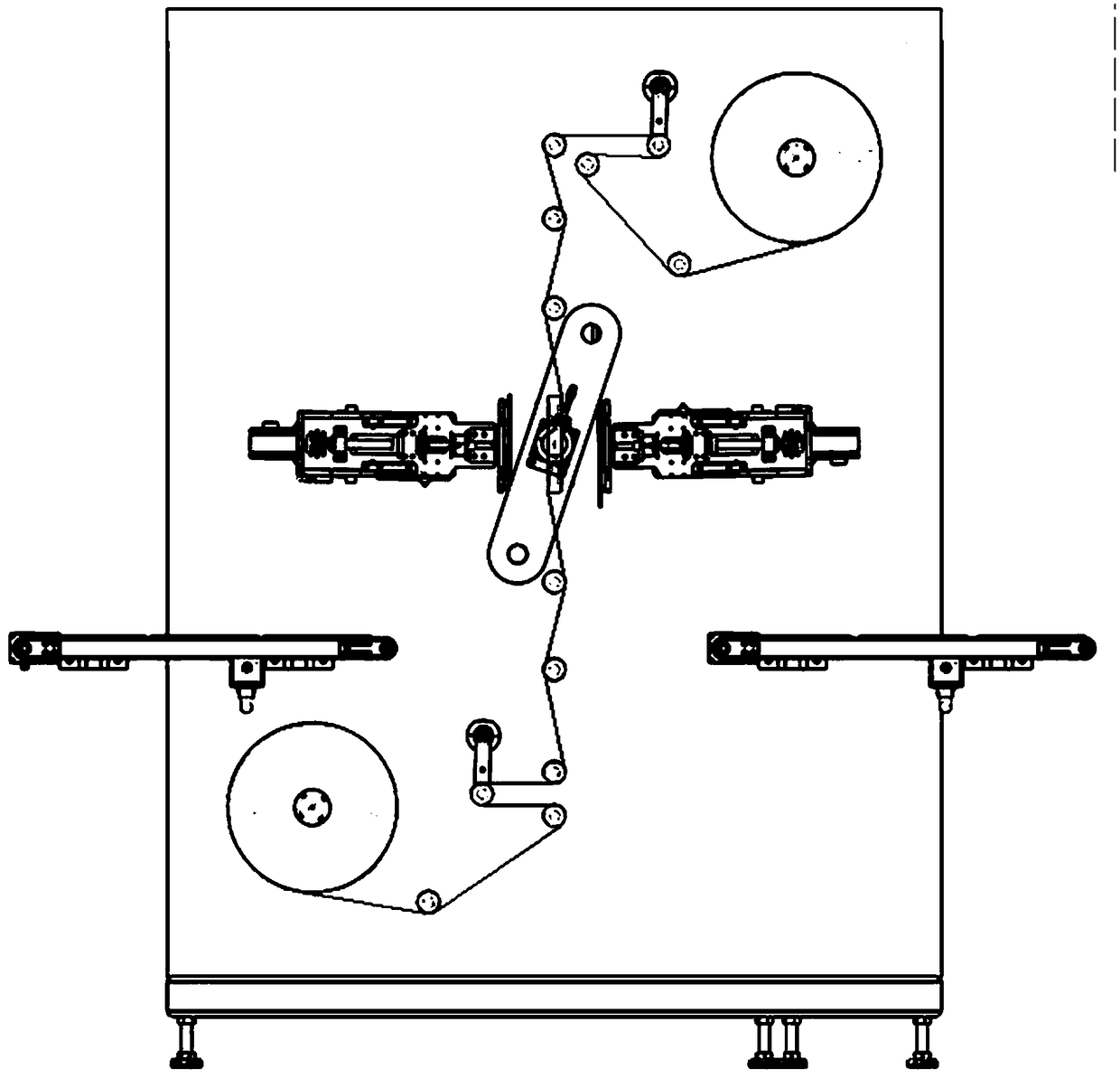

Primary formation lamination machine of battery cell of lithium battery

PendingCN108306055ARealize one-time lamination formingImprove lamination efficiencyFinal product manufactureSecondary cellsEngineeringMechanical engineering

The invention discloses a primary formation lamination machine of a battery cell of a lithium battery. The primary formation lamination machine comprises a rack, a separator unwinding mechanism, a separator winding mechanism, a battery cell clamping mechanism, a separator clamping mechanism, a connection plate, a pole plate transmission mechanism, a lamination mechanism, a transmission mechanism and a separator cutting mechanism, wherein the lamination mechanism is used for performing primary lamination assembly on a positive pole plate, a negative pole plate and a separator, the pole plate transmission mechanism is used for transmitting the positive pole plate and the negative pole plate, the separator unwinding mechanism is used for placing the separator between the positive pole plate and the negative pole plate, the transmission mechanism is used for providing power for the pole plate transmission mechanism, the separator winding mechanism is used for performing separator coating on the battery cell formed by the lamination mechanism, the battery cell clamping mechanism is used for clamping the battery cell before and after separator coating, the separator cutting mechanism isused for cutting the separator after separator coating is completed, and the separator clamping mechanism is used for transmitting the separator to a clamp at the bottom of the lamination mechanism. By the lamination machine, primary lamination formation of the positive pole plate and the negative pole plate is achieved, and the lamination efficiency is greatly improved.

Owner:HEBEI UNIV OF TECH +1

Lamination equipment

InactiveCN109921099ASimple structureEasy to implementFinal product manufactureSecondary cellsPole pieceEngineering

The invention discloses lamination equipment. The lamination equipment comprises at least one conveyer line for conveying a plurality of first lamination units and a plurality of lamination stations on the conveyer lines, wherein each lamination station comprises a first manipulator, a first storage table for storing a plurality of second lamination units, and a second storage table for storing anode single-face pole pieces; and the first manipulator is used for capturing the anode single-face pole pieces from the second storage table, capturing a plurality of first lamination units from the conveyer line and stacking the first lamination units on the anode single-face pole pieces, capturing the second lamination units from the first storage table to the upward side of the uppermost firstlamination unit, and capturing the anode single-face pole pieces from the second storage table to the upward side of the second lamination units in sequence so as to form a laminated electric core. The lamination equipment is simple in structure and easy to realize, and is capable of remarkably improving the lamination efficiency; and the anode pole pieces of the produced laminated electric core are one layer more than the cathode pole pieces, so that the capacity of the finished laminated electric core is increased.

Owner:GEESUN AUTOMATION TECH

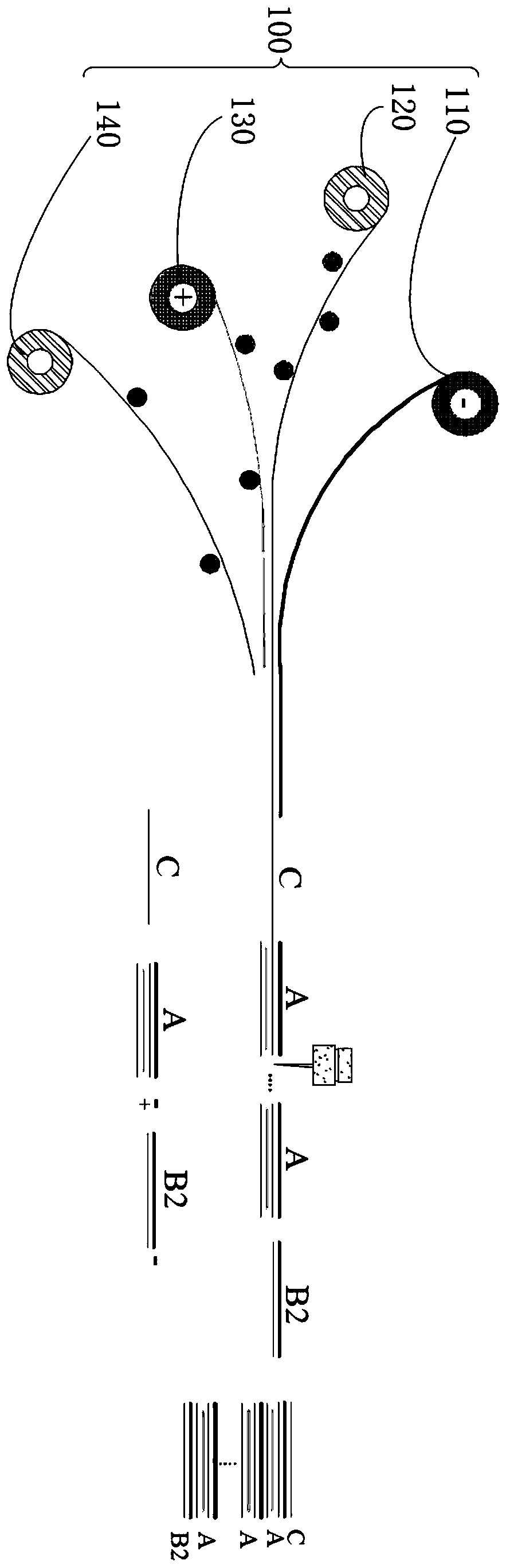

Die-cutting lamination system and method

ActiveCN110364766AEasy alignmentReduce in quantityAssembling battery machinesFinal product manufactureWrinkle skinFailure rate

The invention provides a die-cutting lamination system and method. The system comprises an unwinding mechanism, a pole roll cutting mechanism, preheating and rolling devices, detection devices, a diaphragm cutting mechanism and a laminating device. A negative pole cutting mechanism is matched with a negative pole unwinding mechanism and cuts a negative pole piece, and a positive pole cutting mechanism is matched with a positive pole unwinding mechanism and cuts a positive pole piece, so that a laminated layer in which the negative pole piece and the positive pole piece are alternately distributed on the upper side and the lower side of a diaphragm is obtained. The pre-heating rolling devices enable the positive pole piece and the negative pole piece of the laminated layer to be respectively adhered to the diaphragm. The detection device detects whether laminated sheets have defects or not. A first diaphragm cutting mechanism cuts and discharges defective laminated sheet units in pairs,and a second diaphragm cutting mechanism cuts diaphragms of the last qualified laminated sheet unit based on the number of laminated layers. The laminating device enables the positive pole laminatedsheet units and the negative pole laminated sheet units to be alternately laminated. The system is relatively simple in structure, high in lamination speed, low in failure rate, low in system diaphragm cutting frequency and low in risk of diaphragm wrinkles and outer leakage of the pole pieces.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

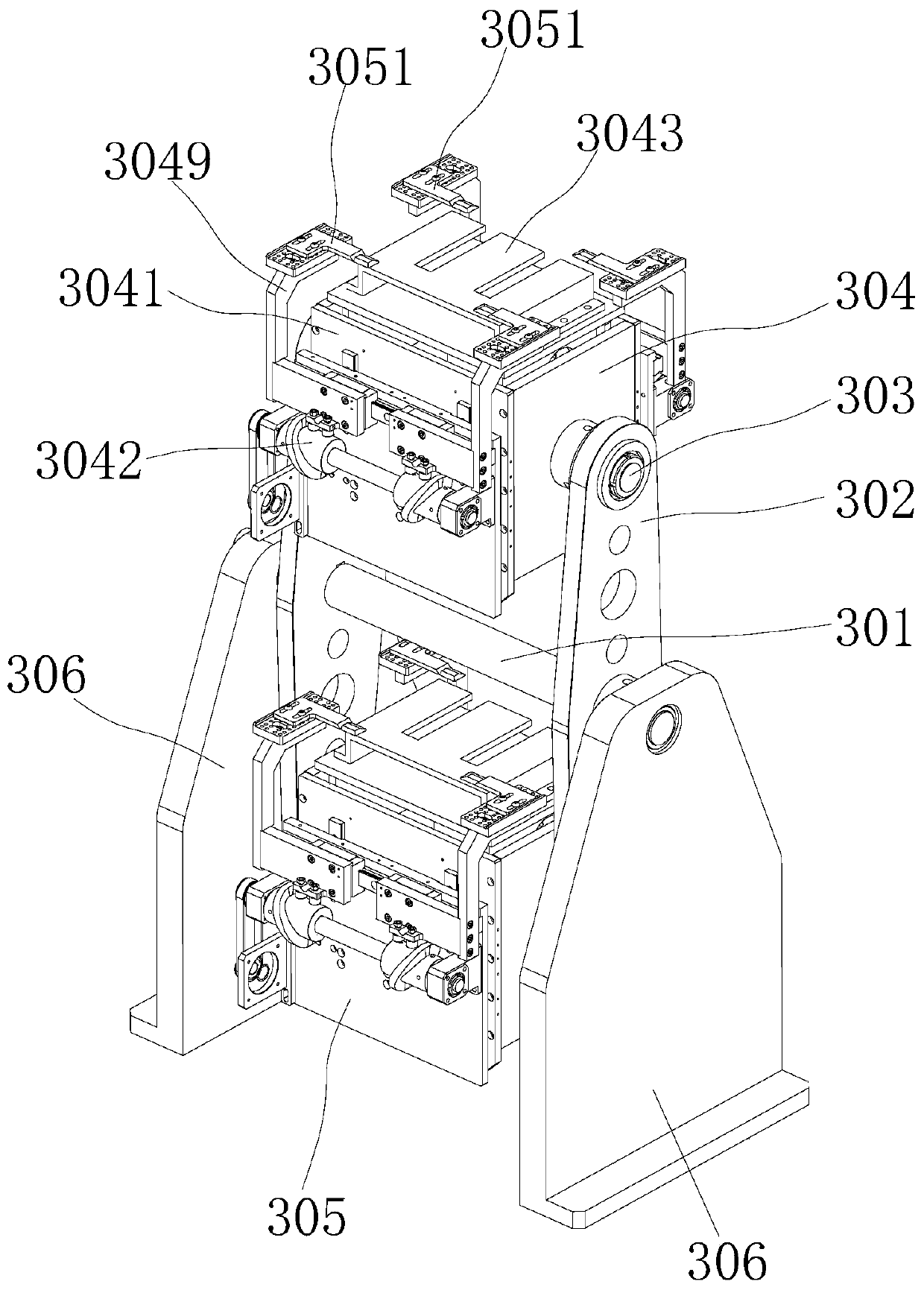

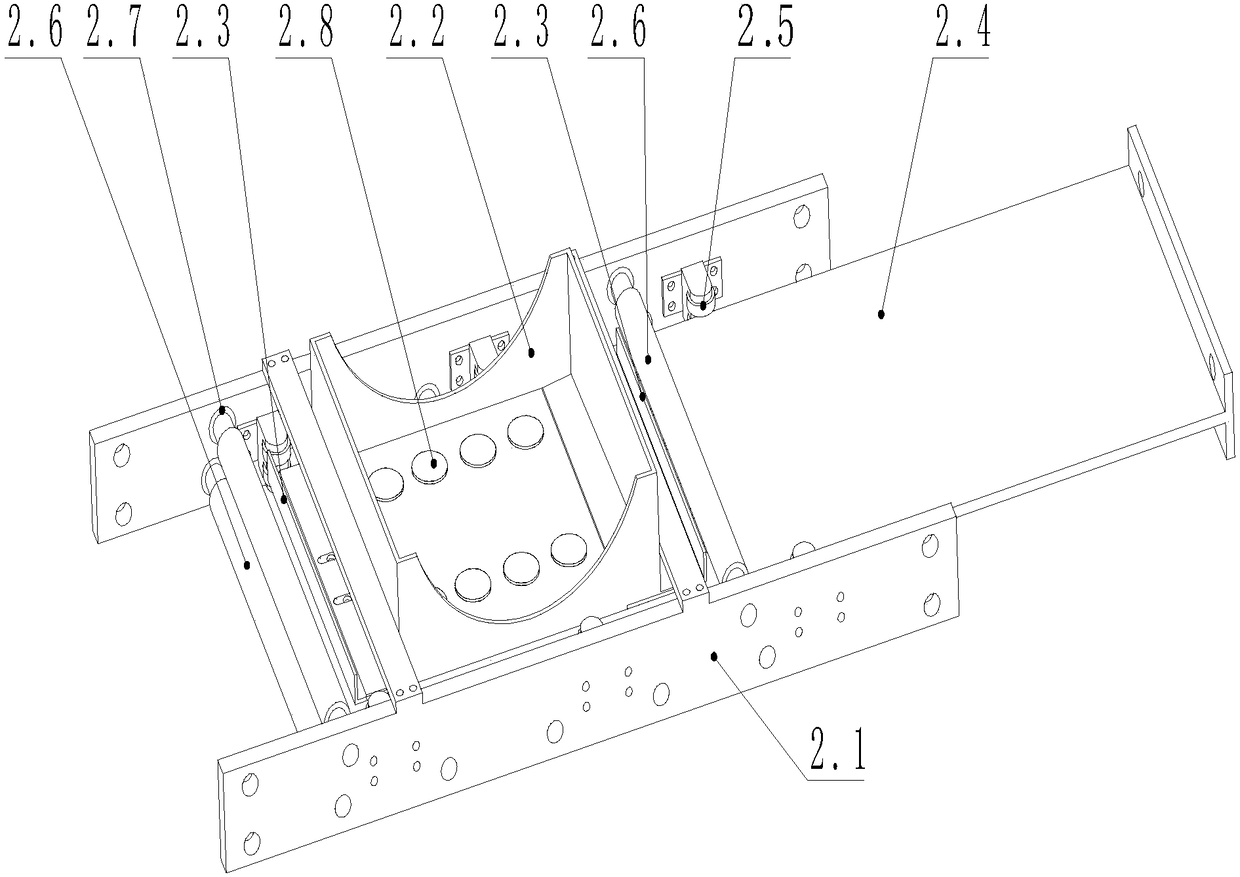

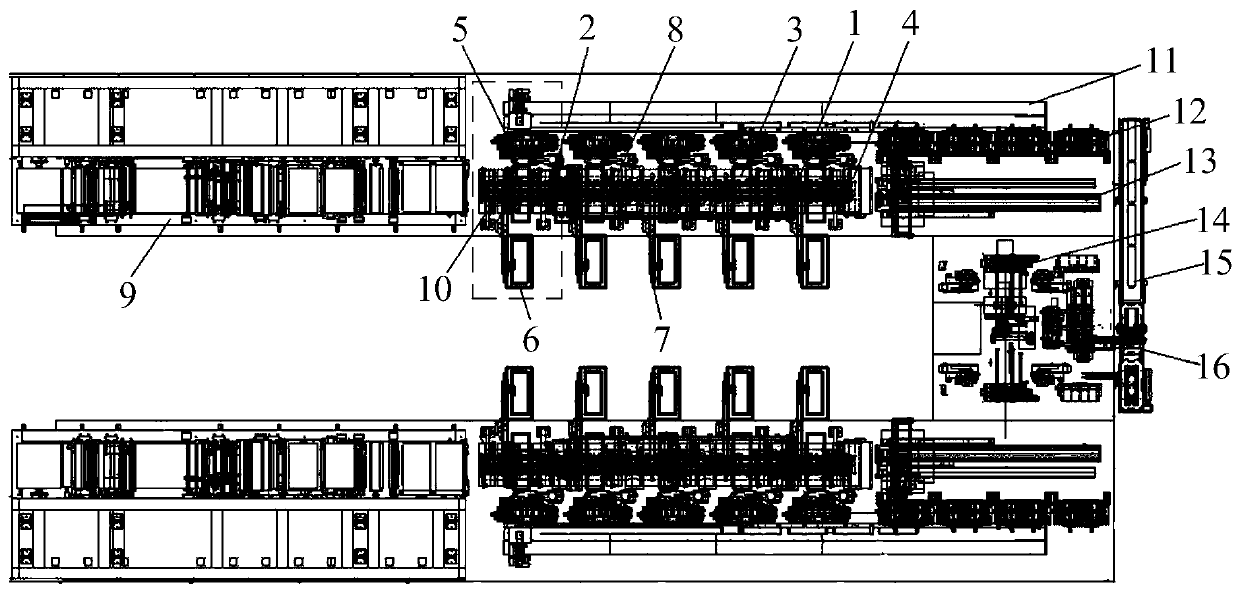

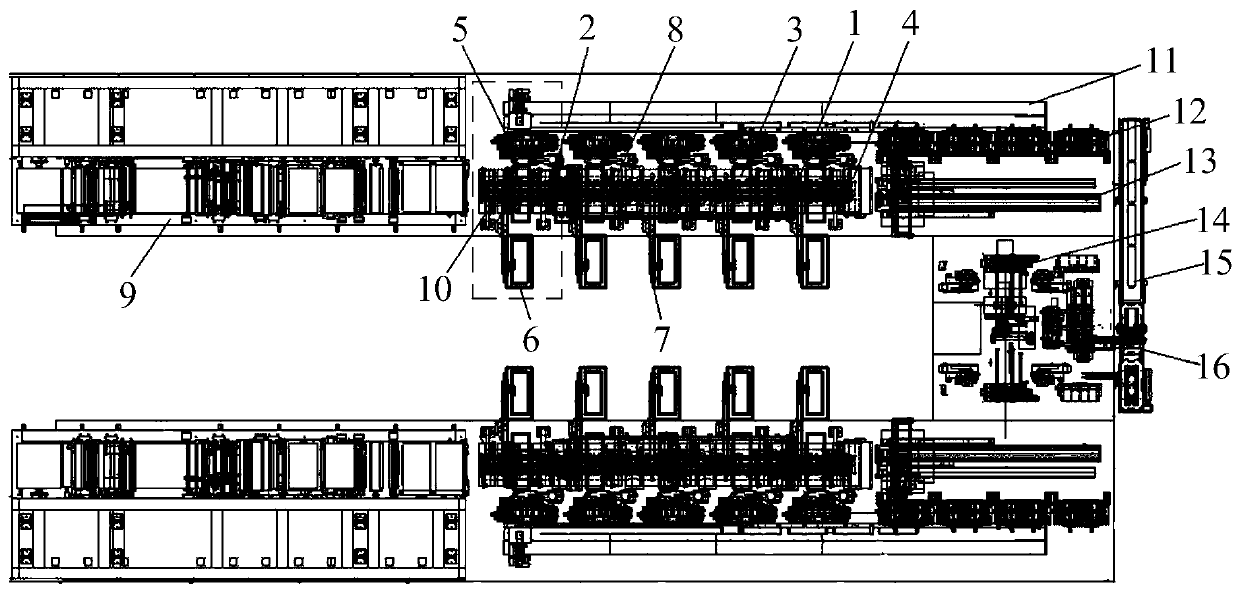

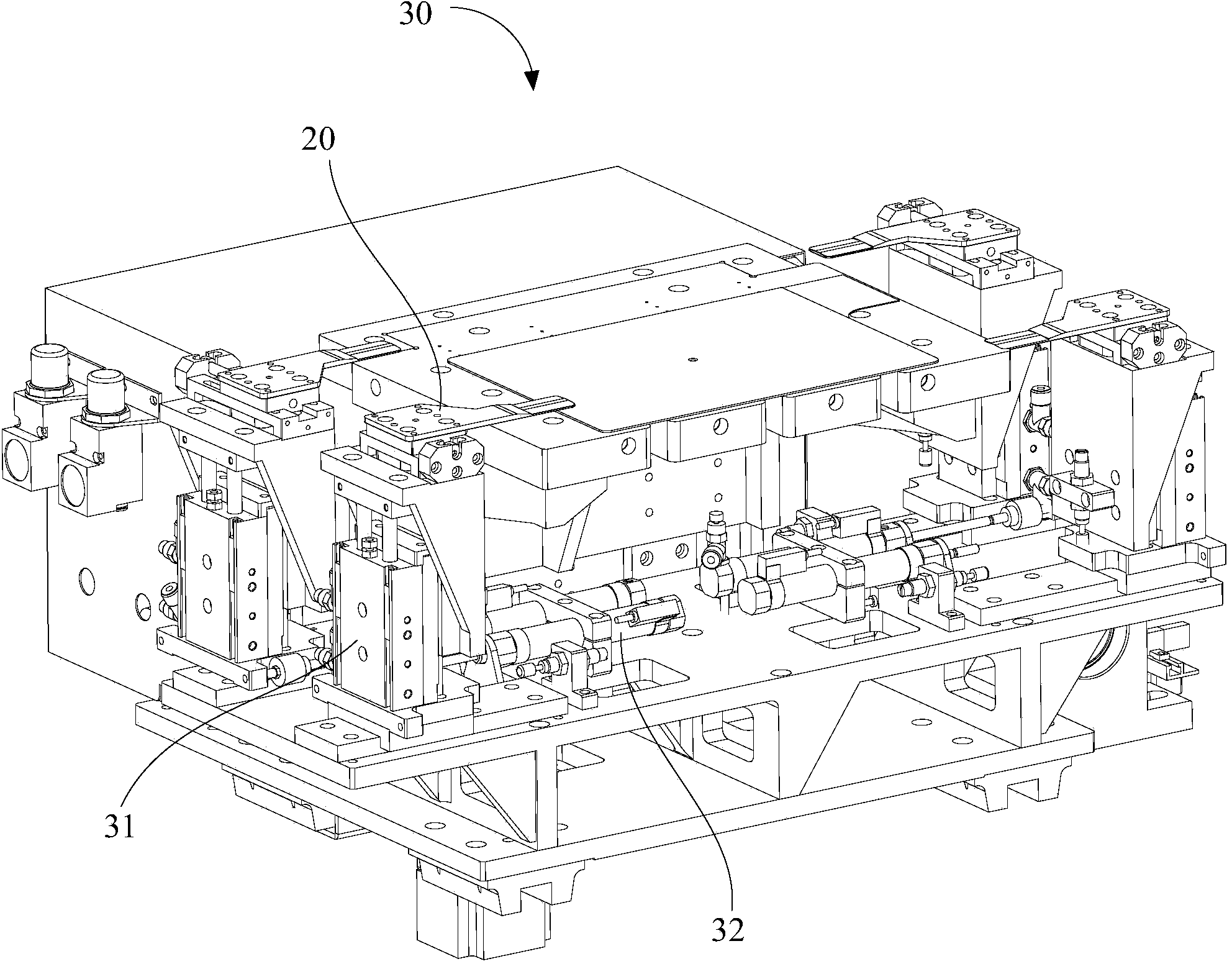

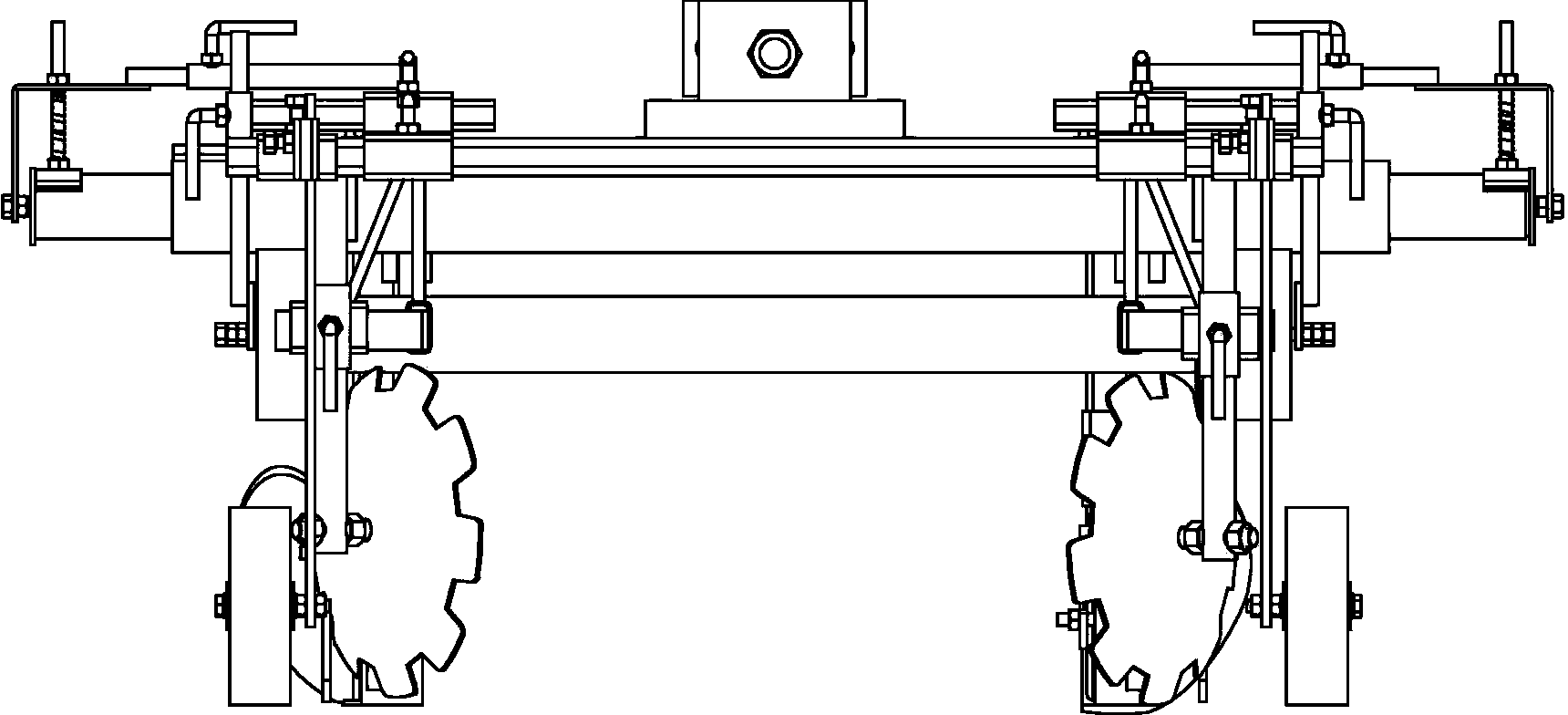

Lamination stacking machine of laminated type power battery and piece pressing mechanism thereof

ActiveCN103441298AImprove lamination efficiencyShorten the timeFinal product manufactureSecondary cells manufacturePower batteryDrive wheel

The invention provides a lamination stacking machine of a laminated power battery and a piece pressing mechanism thereof. The piece pressing mechanism comprises a bearing plate, a transmission unit mounted on the bearing plate, motors, first driving wheels which are sleeved fixedly on drive shafts of the motors, pressing pieces which are used for pressing pole pieces and membranes of the laminated power battery, wherein the transmission unit comprises a first sliding rail which is vertical to a plane in which the bearing plate is positioned, a first sliding block which is arranged on the first sliding rail and is capable of sliding along the first sliding rail, a lever assembly and a first restoration elastic member connected between a lever and the bearing plate, wherein the lever assembly which is arranged at the bearing plate comprises a first supporting seat fixedly arranged at the bearing plate and the lever; the central section of the lever is rotatably connected with the first supporting seat, the two ends of the lever are tilted up and down relative to the first supporting seat, and one end of the lever is used for pushing the first sliding block to slide. The piece pressing mechanism of the lamination stacking machine of the laminated power battery, provided by the invention, has higher efficiency.

Owner:HANS LASER TECH IND GRP CO LTD

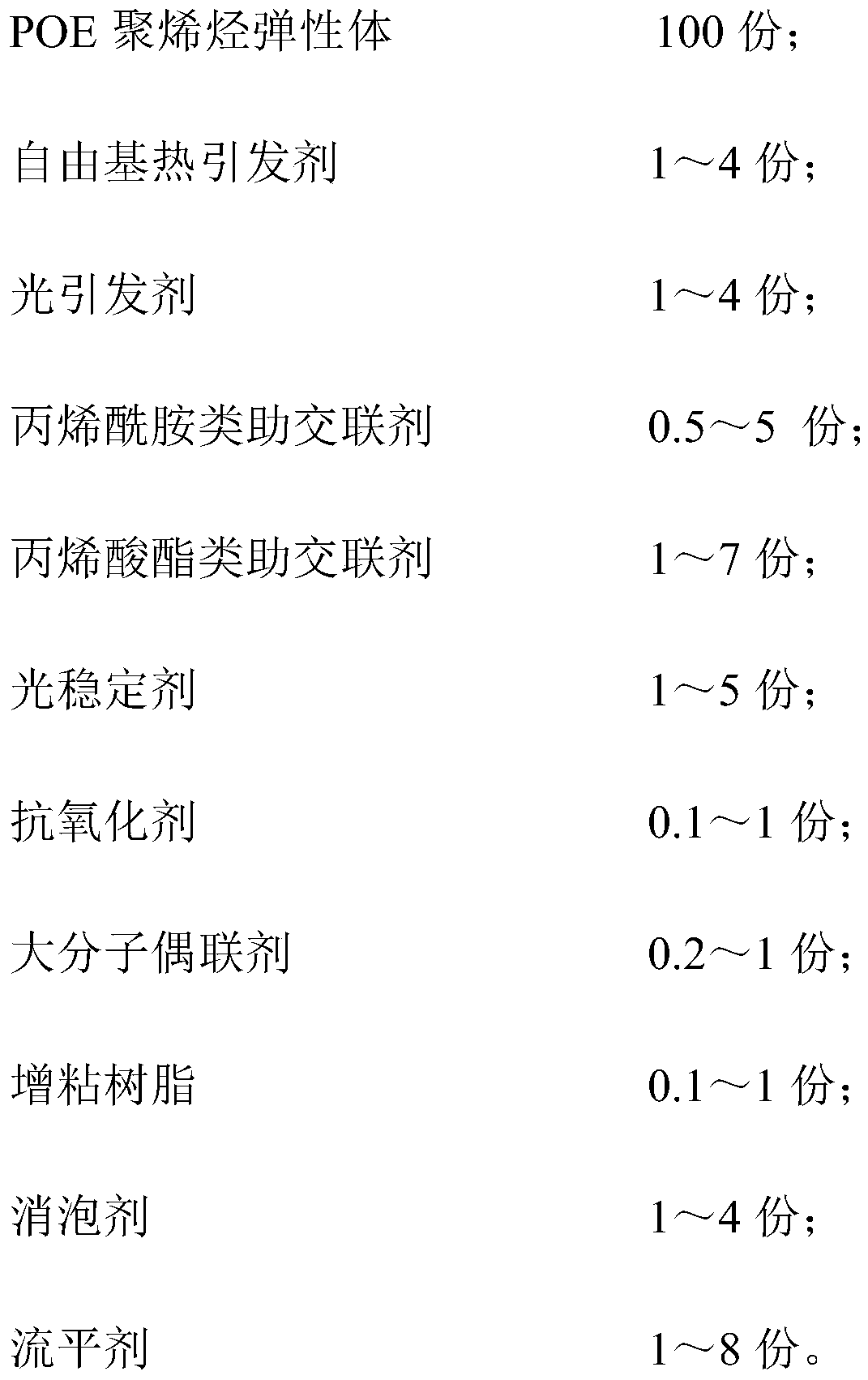

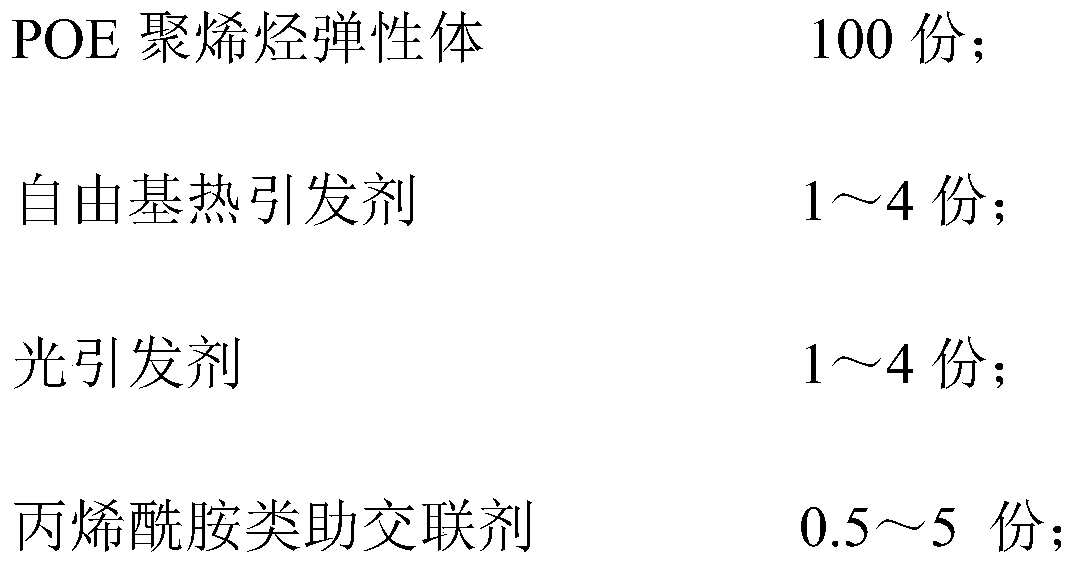

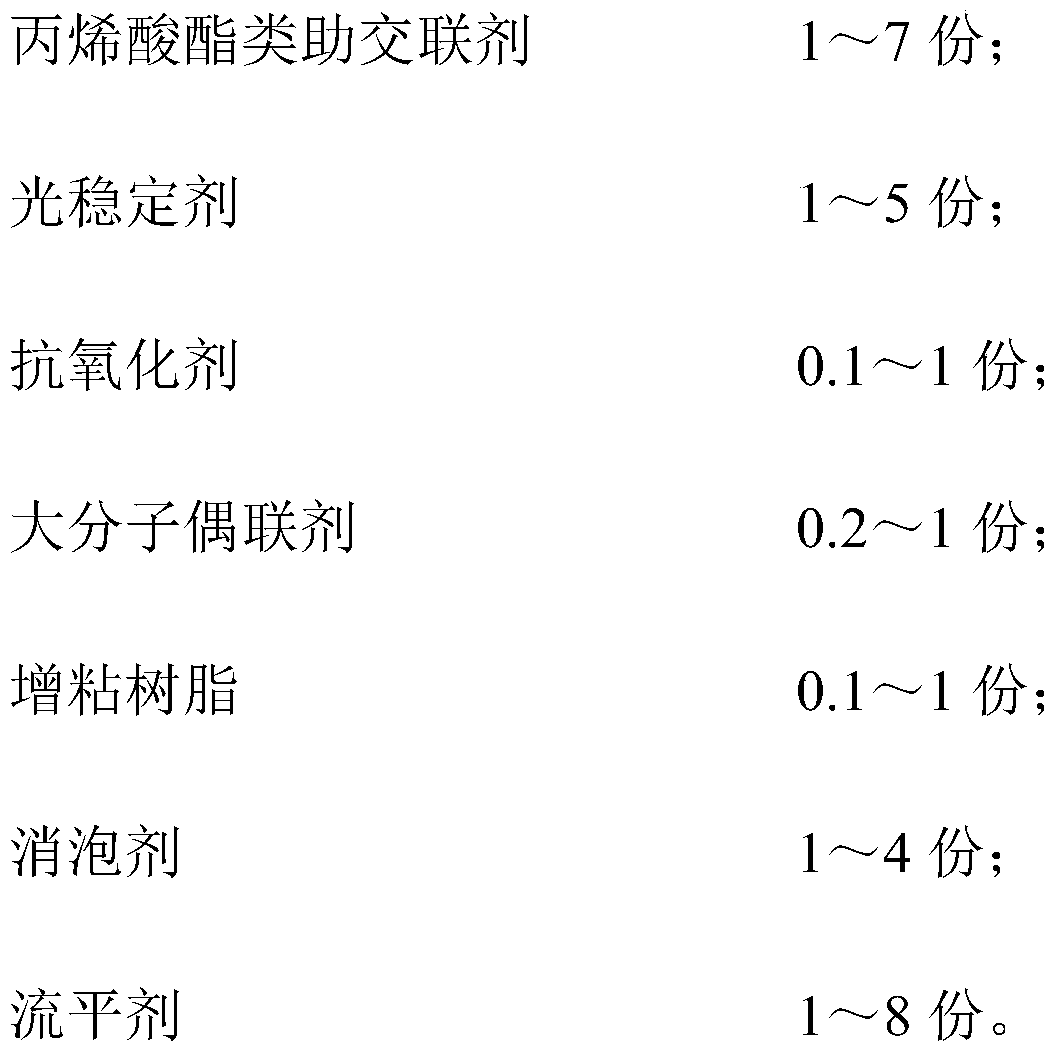

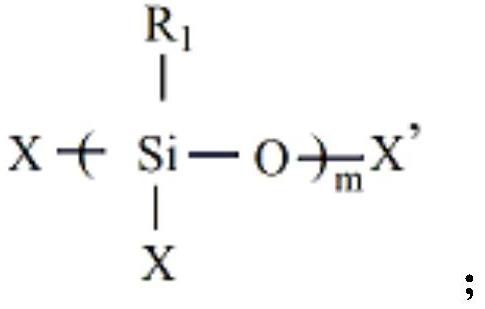

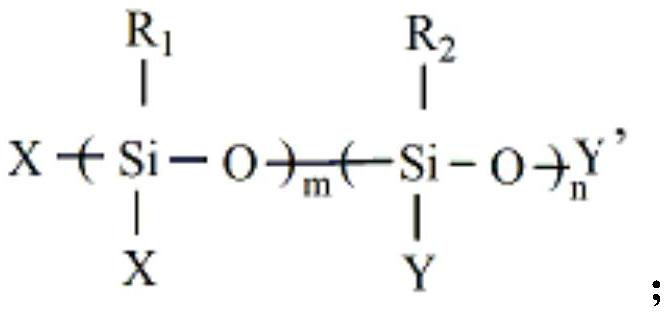

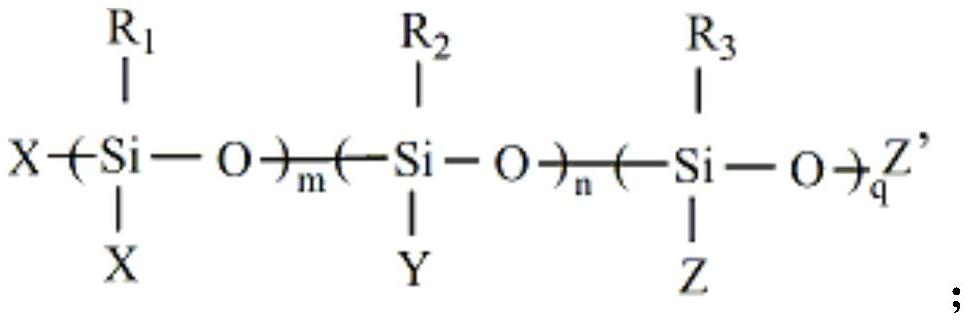

Photovoltaic photo-thermal dual-curing POE packaging adhesive film and preparation method thereof

ActiveCN111117498AImprove lamination efficiencyReduce energy consumptionFilm/foil adhesives without carriersPhotovoltaic energy generationBattery bankPolymer science

The invention discloses a photovoltaic photo-thermal dual-curing POE packaging adhesive film and a preparation method thereof. The packaging adhesive film comprises a POE polyolefin elastomer, a freeradical thermal initiator, a photoinitiator, an acrylamide assistant cross-linking agent, an acrylate assistant cross-linking agent, a light stabilizer, an antioxidant, a macromolecular coupling agent, tackifying resin, an antifoaming agent and a leveling agent. The packaging adhesive film can realize rapid low-temperature curing, has the advantages of high light transmittance, high adhesive strength, low shrinkage rate, low water permeability, no bubbles, high efficiency, low cost, easiness in reworking and the like after being laminated, and is suitable for an efficient battery assembly which is sensitive to temperature or has a high requirement for the packaging rate; compounding of POE with different melt indexes improves the fluidity, reduces the bubble rate and guarantees that glue overflowing and battery string spacing deviation do not occur; and the macromolecular coupling agent is added through a chemical grafting method, so that the long-term bonding reliability is improved.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

Transformer iron chip lamination mechanism, transformer iron chip lamination device and lamination machine

ActiveCN110364349AImprove lamination efficiencyStrong reliabilityInductances/transformers/magnets manufactureTransformerEngineering

The invention provides a transformer iron chip lamination mechanism, a transformer iron chip lamination device and a lamination machine, and relates to the technical field of automation equipment fortransformer production. The lamination accuracy of a common lamination machine is poor, and the efficiency is low; some lamination machines are additionally provided with devices for accurately positioning iron core sheets, and comprise a plurality of corresponding electric elements, so that the lamination machine has a complex structure, needs regular maintenance and is high in cost, the positioning devices need some time for positioning the iron chip sheets, the lamination efficiency is still not high, and a lot of electrical elements are used to reduce the whole reliability of the lamination machine. When sucking disc frame sucks the iron core sheets to be stacked downwards, a guide piece is matched with a clamping block group to enable the clamping block group to contract, the iron core sheets are easily placed among the clamping blocks, after the sucking disc frame is lifted, the clamping block group stretches under the action of the elastic piece to clamp the iron core sheets, the iron core sheets are fixed at the set positions, the lamination efficiency is high, the iron core sheets are not required to be accurately positioned, a mechanical structure is adopted, and the reliability of the device is high.

Owner:四川德华电气有限责任公司

Automatic stacking mechanism of flaker

InactiveCN102185151ASimple structureWork reliablyElectrode manufacturing processesFinal product manufactureTooth numberSprocket

The invention discloses an automatic stacking mechanism of a flaker. The automatic stacking mechanism comprises a turntable arranged on a support, wherein the turntable plane is vertical to the horizontal plane; the middle part of the turntable plane is provided with a static chain wheel which synchronously rotates with the turntable; the excircle of the turntable plane is uniformly and rotatablely connected with a plurality of synchronous chain wheels by taking the static chain wheel as a center; the tooth number of the static chain wheel is equal to that of the synchronous chain wheels; thesynchronous chain wheels are connected with a supporting device for supporting a polar plate; the synchronous chain wheels and the static chain wheel are driven by chains; the left side of the turntable is provided with a conveyor for placing the polar plate onto the supporting device; and the right side of the turntable is provided with a discharging device for receiving the polar plate placed down by the supporting device. Because the automatic stacking mechanism is provided with the turntable, the turntable shaft is provided with the static chain wheel, and the turntable plane is provided with a chain system formed by the synchronous chain wheels and chains, the polar plate on the supporting device connected with the synchronous chain wheels is in a horizontal state, and then the inputpolar plates can be horizontally stacked in turn. The automatic stacking mechanism is simple in structure, reliable in working and high in stacking efficiency.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

Cloth roll package machine

ActiveCN104691807AImprove stabilityImprove lamination efficiencyWrapper twisting/gatheringWrapping with article rotationMechanical engineering

The invention discloses a cloth roll package machine. The cloth roll package machine comprises a rack, a cloth feeding mechanism, a laminating mechanism and a thin film cut-off mechanism, wherein hot air blowing mechanisms are symmetrically mounted on the parts, positioned on the two sides of the laminating mechanism, of the rack; the laminating mechanism comprises a thin film support, a film guiding roller set and a film winding roller, the thin film support and the film guiding roller set are mounted at the bottom of the rack, the film winding roller is mounted on the part, positioned above the film guiding roller set, of the rack, and a thin film roll is positioned on the thin film support; at least two cloth supporting rollers are mounted at the back end of the film winding roller set, the thin film cut-off mechanism is mounted between the film winding roller and the cloth supporting rollers in a lifting manner, a lifting ejector plate device is mounted between the two cloth supporting rollers and is used for ejecting a cloth roll, a reversible cloth roll sealing mechanism is mounted below a position of the cloth roll when the laminating mechanism works, and a reversible cloth roll locating mechanism is mounted at the back ends of the cloth supporting rollers.

Owner:FUJIAN JINJIANG JILONG MACHINE IND

Lithium ion battery and manufacturing method thereof

InactiveCN102110854AImprove securityReduce the probability of micro-short circuitFinal product manufactureElectrolyte accumulators manufacturePunchingEngineering

The invention discloses a lithium ion battery. The lithium ion battery comprises a battery cell, a shell and electrolyte, wherein the battery cell comprises a first positive plate, a first diaphragm and a first negative plate; and the first positive plate, the first diaphragm and the first negative plate are overlaid in turn and then are repeatedly folded to form continuous laminates. The invention also provides a manufacturing method of the lithium ion battery. The method comprises the following steps of: manufacturing the first positive plate and the first negative plate; overlaying the first positive plate, the first diaphragm and the first negative plate in turn, and repeatedly and continuously folding to manufacture the battery cell; and arranging the shell, injecting the electrolyte, and forming to manufacture the lithium ion battery. The laminates of the battery cell are formed by repeated folding, so that micro-short circuit probability caused by burrs on slice edges of the laminates is reduced, and the safety performance of the battery is improved. Punching and repeated addition of a plurality of fragments are saved, so lamination efficiency is greatly improved, and production cost is dramatically reduced.

Owner:SHENZHEN EPT BATTERY

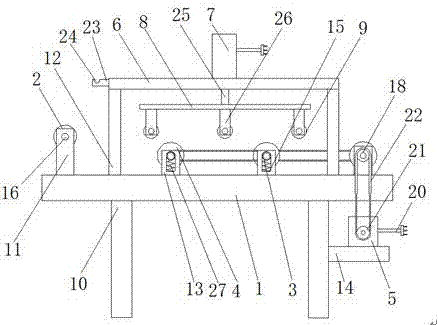

Alternately compressing lamination station device

InactiveCN103633341AShorten the timeImprove lamination efficiencyPrimary cell manufactureFinal product manufactureGear wheelPole piece

The invention provides an alternately compressing lamination station device. The alternately compressing lamination station device comprises four groups of pressing-claw mechanisms distributed at the two ends of a lamination station; every two groups of pressing-claw mechanisms act at one end of a panel of the lamination station alternately; each group of the pressing-claw mechanisms comprises two pressing claws used for compressing two corners of a pole piece, a pressing-claw cylinder which drives the pressing claws to move up and down, and a mobile seat which is used for installing pressing-claw cylinders and the pressing claws and is connected with the mobile mechanism. The device also comprises two sets of mobile mechanisms which respectively drive two groups of pressing-claw mechanisms to close to or leave away the lamination station alternately, wherein each mobile mechanism comprises a horizontal slide rail which is arranged below the panel of the lamination station and is used for installing the pressing-claw mechanisms, gear racks connected with the pressing-claw mechanisms, gear shafts which drive the gear racks to move horizontally, and servo motors which drive the gear shafts to rotate. The device also comprises position filling mechanisms used for filling grooves at clamp claw positions of the panel of the lamination station; and each position filling mechanism comprises a position filling board of which the area is close to that of the groove and a position filling cylinder which pushes the position filling plate. The alternately compressing lamination station device has the advantages that the two groups of pressing-claw mechanisms compress the pole piece alternately; the time is saved; and the lamination efficiency is high.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

Molding method of complicated two-side cavity structure with multilayer ceramics

ActiveCN102699986AHigh precisionNot easy to deform and damageCeramic shaping apparatusSilica gelUltimate tensile strength

The invention discloses a molding method of a complicated two-side cavity structure with multilayer ceramics. An elastic semi-fluid soft silicone pad is used as the filling mold of the upper-layer cavity structure, and the male die of a silicon rubber plug of the integral structure is used for filling the bottom-layer cavity structure, thus the molded cavity structure has high precision, is not easily deformed and can be used repeatedly. In addition, the molding method can be used for molding cavity structures with any shape, is easy to process and can guarantee the combination intensity and the gas tightness of the multilayer ceramics and improve the lamination efficiency and cleanability, thereby saving the molding cost.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Multifunctional packaging adhesive film and preparation method thereof

PendingCN111961422AImprove the attenuation effectExcellent anti-PID performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceOligomer

The invention provides a multifunctional packaging adhesive film and a preparation method thereof. The multifunctional packaging adhesive film comprises, by mass, 90 to 99% of a polymer and 1 to 10% of an auxiliary agent, and the auxiliary agent comprises a silane oligomer. The prepared multifunctional packaging adhesive film has excellent peeling force attenuation resistance and PID resistance, and can meet the requirements of packaging adhesive films with different functions.

Owner:CYBRID TECHNOLOGIES INC

Aerogel material surface laminating equipment

The invention discloses aerogel material surface laminating equipment. The aerogel material surface laminating equipment is simple in structure and convenient to use; during laminating pressing, a pressing force can be adjusted; meanwhile, the pressing force can be automatically adjusted so as to prevent an overlarge pressing force from exerting negative influence on the quality of an aerogel rollmaterial; meanwhile, during lamination, glue can be uniformly treated, the treatment speed is high, the movement is smooth and the vibration is small, so that the laminating quality can be improved and the aerogel laminating efficiency is enhanced; meanwhile, an elastic frame assembly is used for pressing, the pressing force is moderate, and compared with a spring design, the elastic frame assembly design has the advantages as follows: the service life is longer and the laminating quality is higher.

Owner:汉信天诚(江苏)科技有限公司

Polyester resin composition for laser direct structuring

ActiveUS10604649B2Improve the plating effectImprove mechanical propertiesLiquid/solution decomposition chemical coatingPolymer sciencePolyester resin

Provided is a polyester resin composition for laser direct structuring, which exhibits high platability and excellent mechanical properties. This polyester resin composition for laser direct structuring is characterized by containing a laser direct structuring additive (C) at a quantity of 1 to 20 parts by mass relative to a total of 100 parts by mass of a thermoplastic polyester resin (A) and a thermoplastic resin (B) having a water absorption rate of 0.15 mass % or more, as measured using the ISO 62A method.

Owner:MITSUBISHI ENG PLASTICS CORP

Rotary stacking equipment and stacking method

ActiveCN108899571AImprove lamination efficiencyPrimary cell manufactureAssembling battery machinesEngineeringManipulator

The invention relates to rotary stacking equipment and a stacking method. The equipment comprises a substrate, a first membrane unreeling and correcting mechanism, a second membrane unreeling and correcting mechanism, a first tension control mechanism, a second tension control mechanism, a cathode polar plate conveying belt, an anode polar plate conveying belt, a cathode stacking manipulator, an anode stacking manipulator, a rotary stacking table, a stacking table front support, a stacking clip mechanism, a membrane, a cathode plate and an anode plate, wherein the two sets of membrane unreeling correction mechanisms are used for unreeling the membrane at the same time; the two sets of tension control mechanisms are used for controlling the tension force of membrane movement; the two sets of conveying belts are used for conveying the cathode polar plate and the anode polar plate to below the stacking manipulators respectively; the two sets of stacking manipulators are used for respectively drawing the anode polar plate and the cathode polar plate and transferring the polar plates to the stacking table; the stacking clip mechanism is used for fastening the polar plates on the rotarystacking table; and the rotary stacking table rotates by 180 degrees when finishing each time of stacking.

Owner:SHENZHEN GREENSUN TECH CO LTD

Film laminating device for waterproof coiled material production

PendingCN111421943ARealize automatic deliveryImprove fitLaminationLamination apparatusEngineeringElectric control

The invention discloses a film laminating device for waterproof coiled material production. The film laminating machine comprises a supporting plate, a feeding box, a fixing frame, a film laminating shaft, a supporting frame, a pressing roller, a driving conveying roller, a servo motor and a driven conveying roller. A feeding box is fixedly mounted at one end of the top of a conveying supporting plate; a discharging groove in the vertical direction is formed in the top of the feeding box; according to the film laminating device for waterproof coiled material production, only a plurality of to-be-laminated waterproof coiled material bodies need to be stacked in the feeding box; the two ends of the waterproof coiled material at the bottommost feeding part are arranged on a supporting table and the driven conveying roller; an electric control mechanism is arranged to control a servo motor to work, so that the driving conveying roller and the driven conveying roller rotate; automatic conveying of materials can be achieved without manual alignment of the materials, and time and labor are saved; the pressing roller can press the laminated waterproof coiled materials through an arranged jacking spring, the laminating effect of a laminated film and the waterproof coiled materials is good, the film laminating quality is guaranteed, the subsequent pressing procedure is omitted, and the film laminating efficiency is improved.

Owner:山东正大防水材料股份有限公司

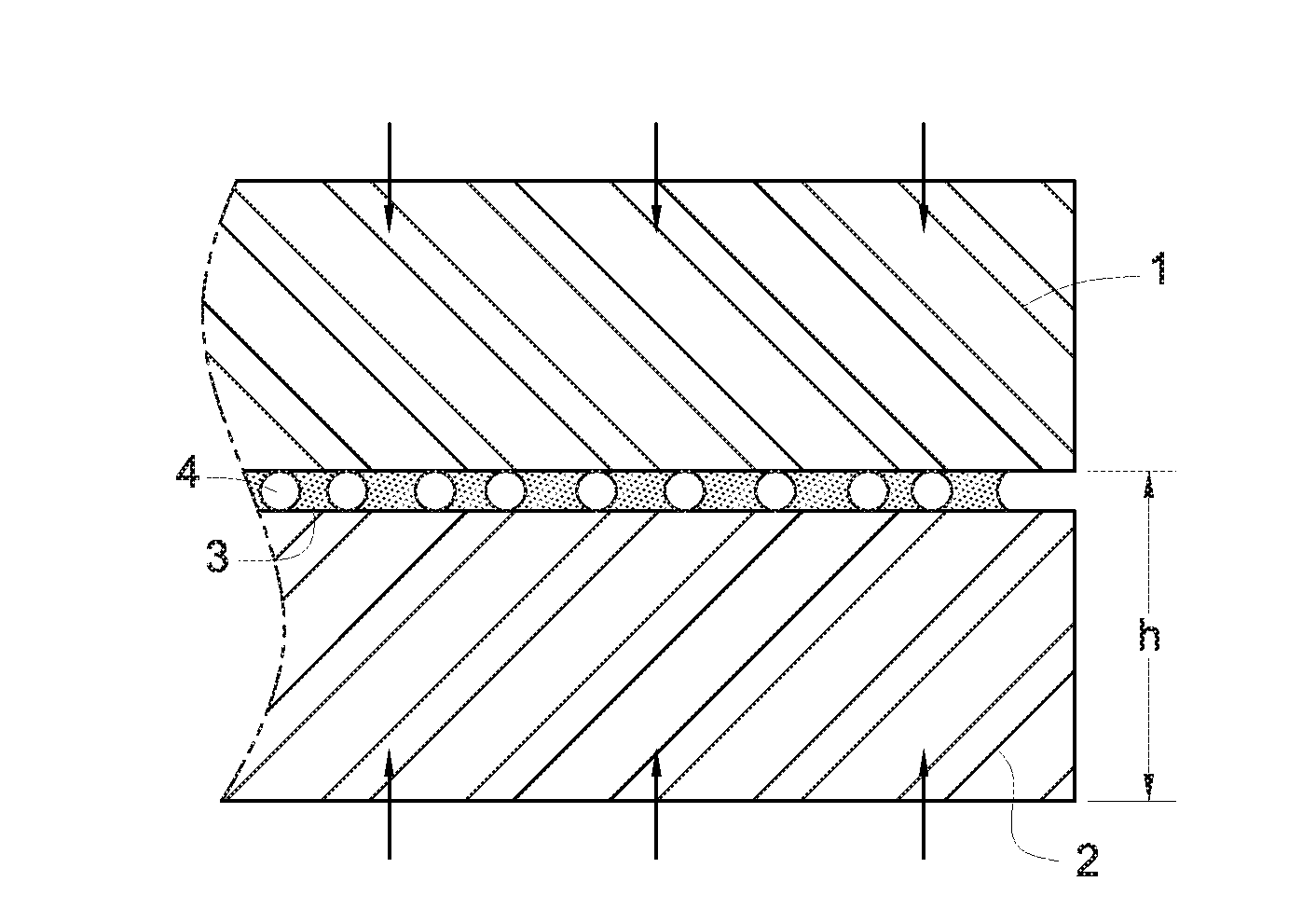

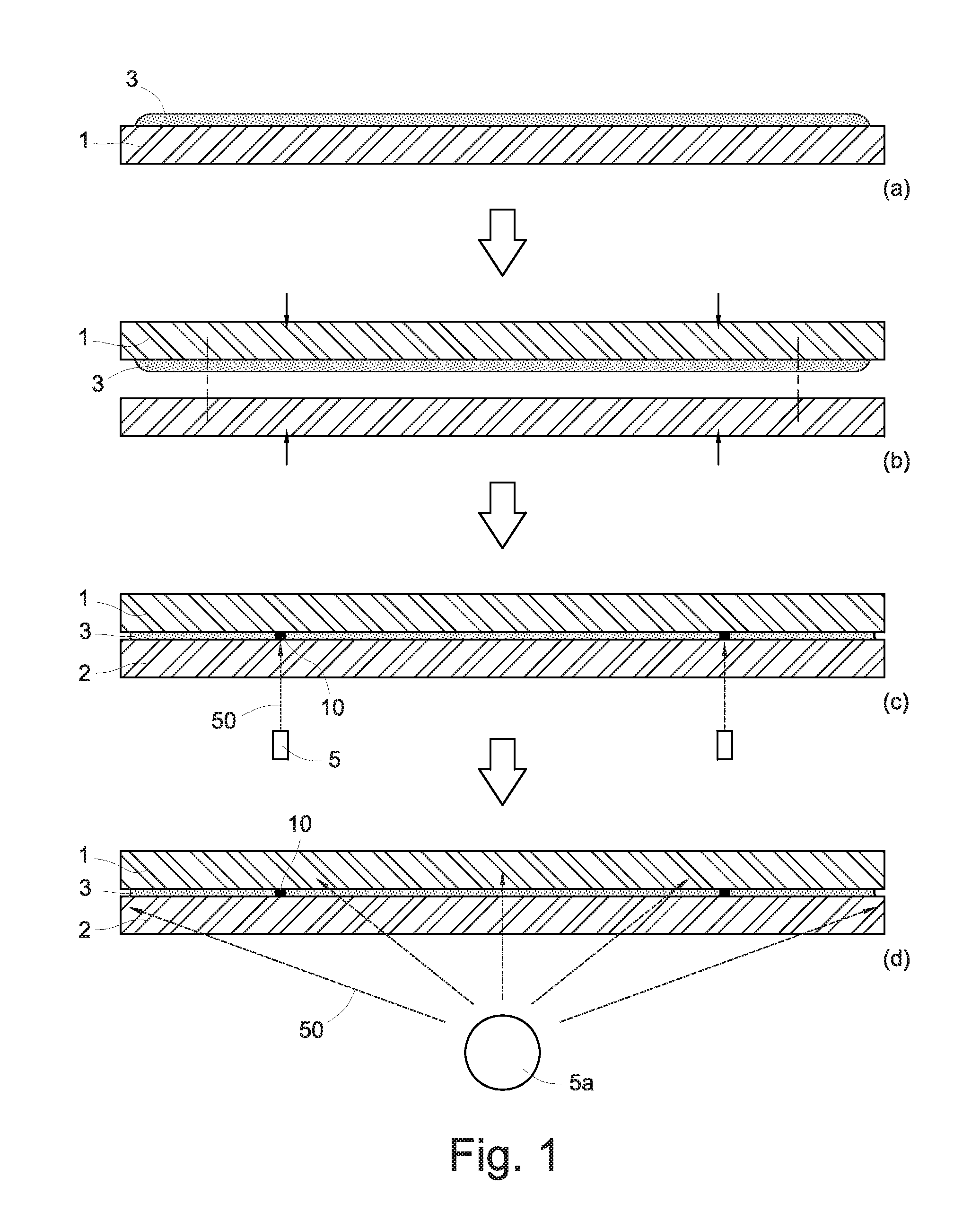

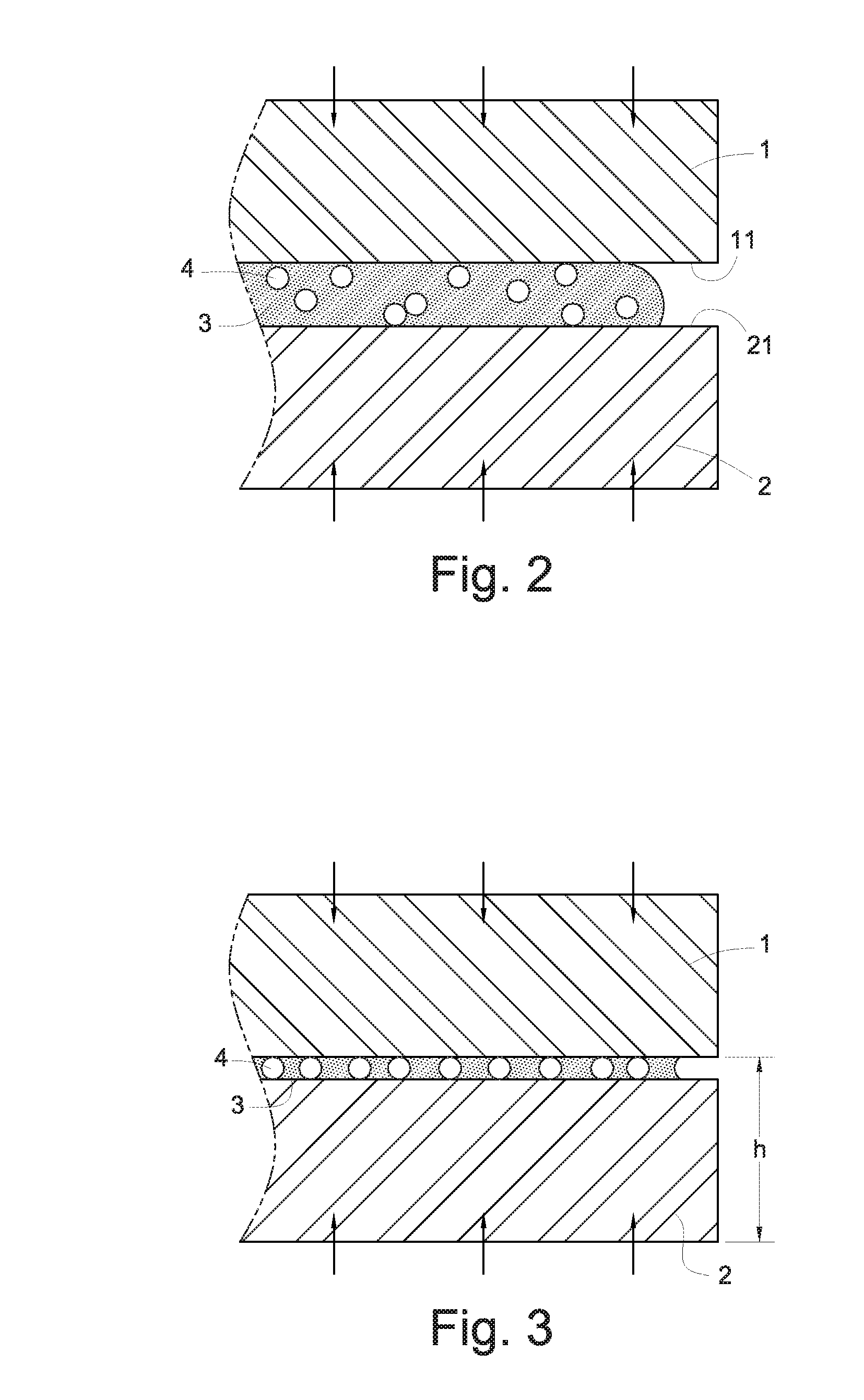

Optical curable resin composite for laminating optical substrates and method thereof

InactiveUS20130101827A1Avoid residual stressAvoid defectsAdhesive processesLamination ancillary operationsElastomerBead shape

In an optical curable resin (OCR) composite for laminating optical substrates and a method of using the OCR composite to laminating two optical substrates, the OCR composite is formed by projecting an ultraviolet light to cure a liquid adhesive containing a plurality of bead-shaped elastic particles, and the method includes the steps of coating the liquid adhesive onto a first optical substrate, stacking the first optical substrate to a second optical substrate, such that each particle is separated between the first and second optical substrates, and projecting the ultraviolet light onto the first and second optical substrate again to cure the liquid adhesive, so that the particles are separated to form a gap with equal heights between the first and second optical substrates to enhance the lamination efficiency and quality of the optical substrates.

Owner:CHEN CHIN YU

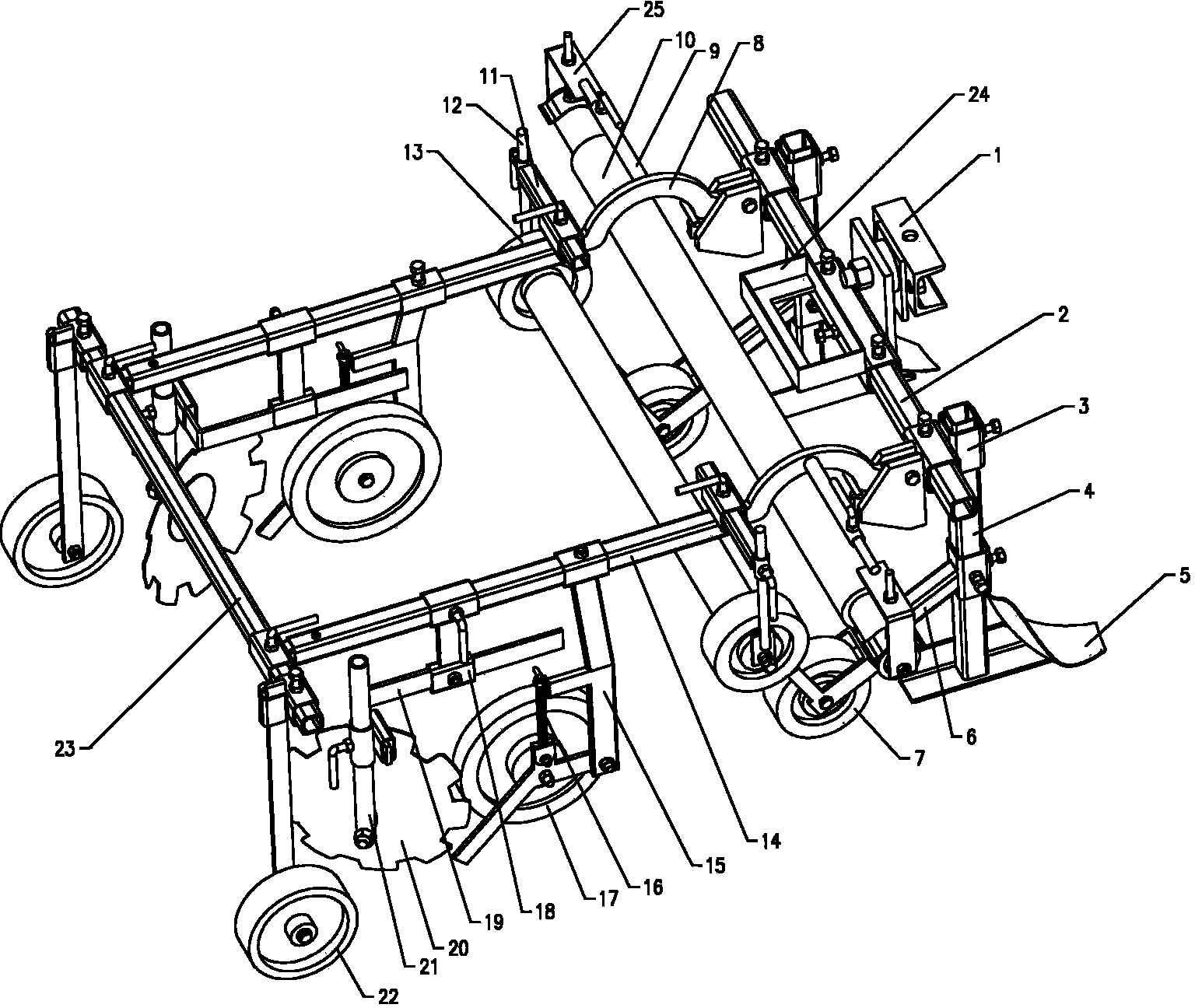

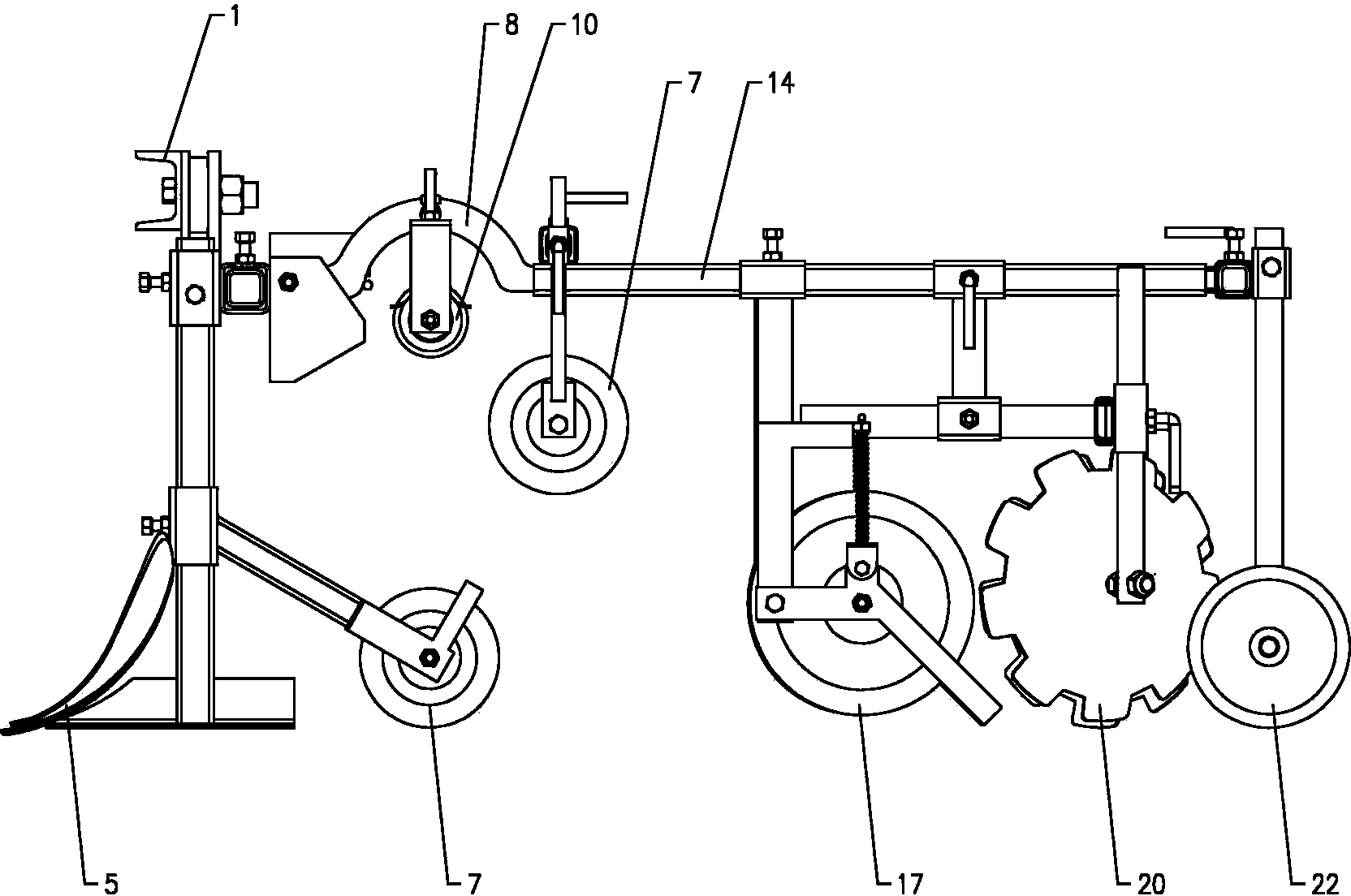

Mulching film applicator

ActiveCN103843635AImprove lamination efficiencyReduce labor intensityPlant protective coveringsPloughEngineering

The invention relates to a mulching film applicator, and in particular relates to a mulching film applicator which integrates a series of film application processes such as mulching film application and ditching and can quickly finish mulching film application. According to the technical scheme, the mulching film applicator comprises a ditching plough and a mulching film release roller, and is characterized by also comprising a rocker arm connector connected with a power system in a traction manner, and a mulching film application component. The mulching film applicator has the advantages that all mulching film application processes are integrated, so that the mulching film application efficiency is improved, and the labor intensity is alleviated.

Owner:青岛新能清源创新技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com