Electrical appliance panel laminating device

A laminating device and panel technology, which is applied in packaging and other fields, can solve the problems of difficult lamination, low efficiency, and difficult quality assurance, etc., and achieve the effect of high lamination efficiency and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

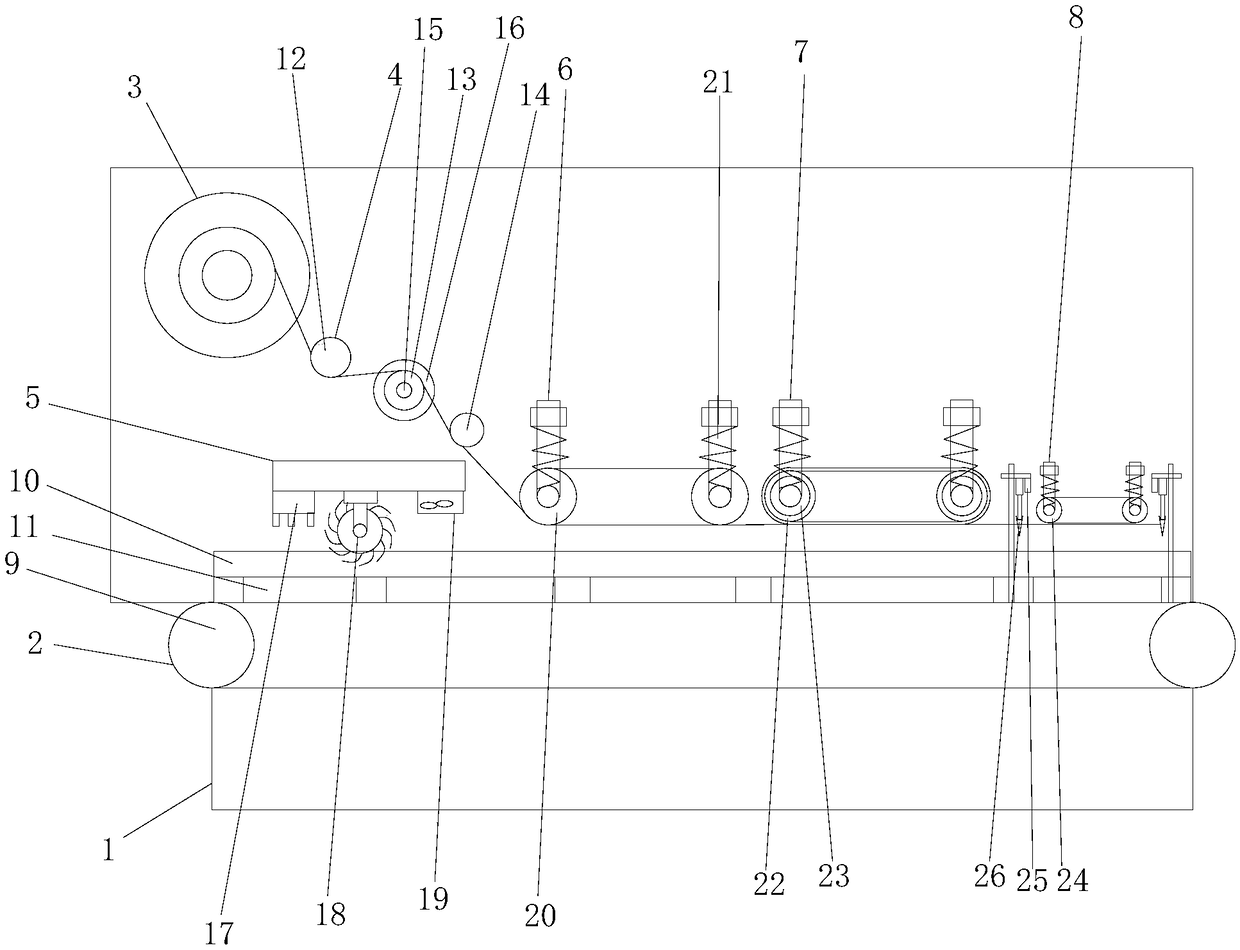

[0015] refer to figure 1 , an electrical panel coating device of the present invention, comprising a workbench 1, a guiding conveying mechanism 2 is arranged on the top of the workingbench 1, and a film unwinding mechanism 3 is arranged on the upper left side of the guiding conveying mechanism 2, so that The lower side of the film unwinding mechanism 3 is provided with a film stretching mechanism 4, and the lower side of the film stretching mechanism 4 is provided with a panel cleaning mechanism 5, and the right side of the panel cleaning mechanism 5 is provided with a film bonding mechanism. 6. A pressing and leveling mechanism 7 is provided on the right side of the laminating mechanism 6, and a positioning and trimming mechanism 8 is provided on the right side of the pressing and leveling mechanism 7. The conveyor belt 9 and the guide rails 10 arranged on the front and rear sides of the conveyor belt 9, the guide rails 10 are symmetrically arranged, the minimum distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com